Control system and method for weld-forming of thin-walled pipe

A welding forming and control system technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of inability to monitor and evaluate the welding process in real time, poor consistency of external welding position shape accuracy, and structural dimensions deviating from design technical requirements. , to achieve intelligent operation and quality control and science, good welding protection and deformation control effect, intelligent operation and comprehensive quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

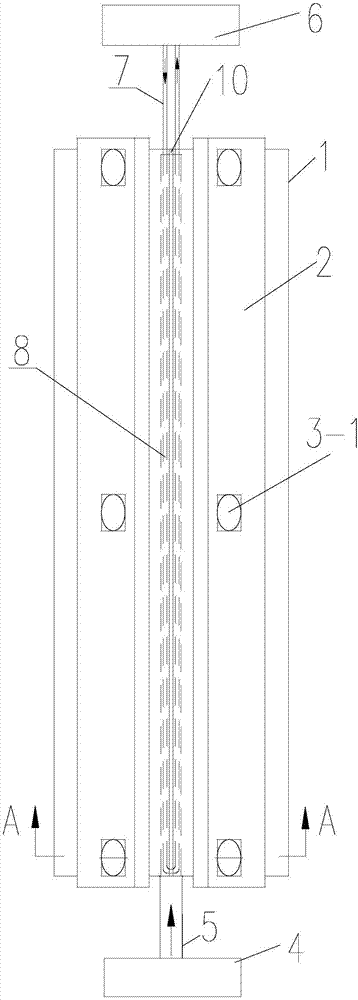

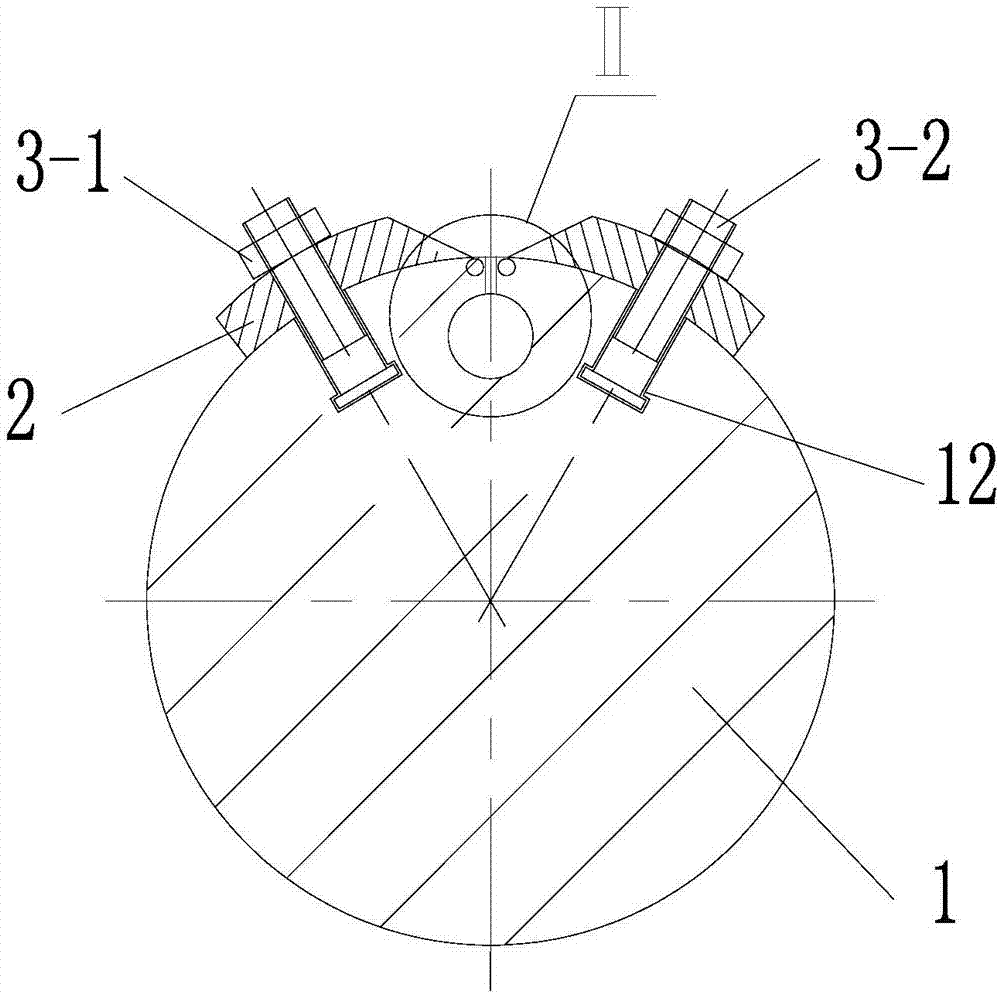

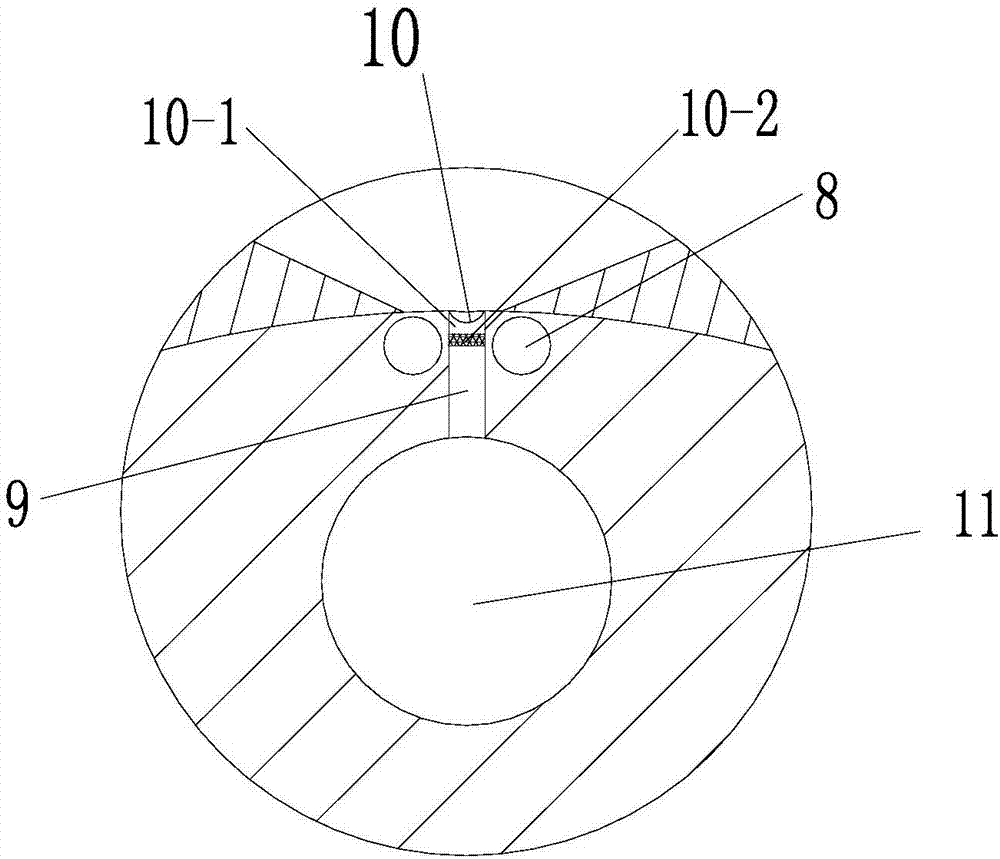

[0046] like Figure 1 to Figure 4 As shown, a thin-walled pipe fitting welding and forming control system according to the present invention includes a welding tool for welding and forming a thin-walled pipe fitting and a quality control device for controlling the quality of the longitudinal seam of the thin-walled pipe welded by the welding tool; The welding tool includes a cylinder 1 for supporting the thin-walled pipe to be welded, a clamping plate 2 for fixing the thin-walled pipe to be welded, an inert shielding gas source 4 for preventing the oxidation of the longitudinal seam of the thin-walled pipe to be welded, and a cooling aid for forming The cooling cycle mechanism 6, the axial surface of the cylinder 1 is provided with a U-shaped groove 10 parallel to the axis of the cylinder 1, and a blind hole connected to the inert protective gas source 4 is provided in the cylinder 1 near the U-shaped groove 10. The cavity body 11 and the U-shaped cooling medium flow cavity 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com