Patents

Literature

30results about How to "Effective control of welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

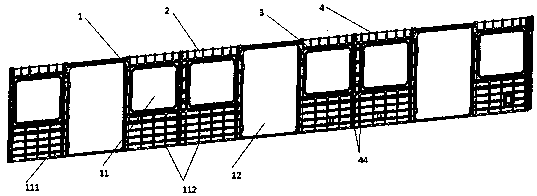

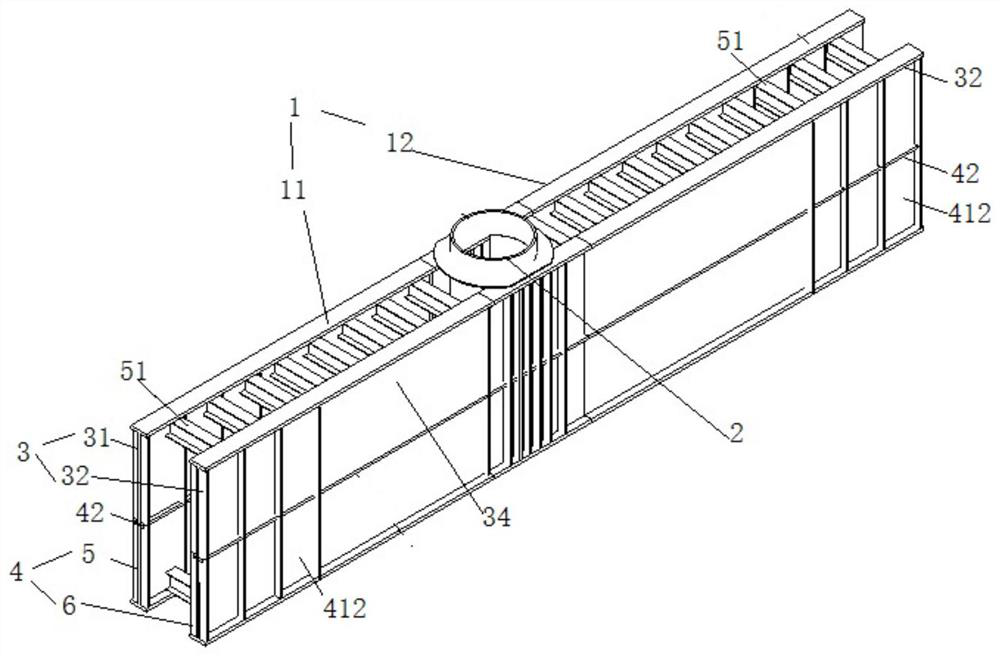

Novel stainless steel side wall structure and mounting method of novel stainless steel side wall

InactiveCN107901932AReduce welding processGuarantee the appearance qualityAxle-box lubricationRailway bodiesStructural engineeringEngineering

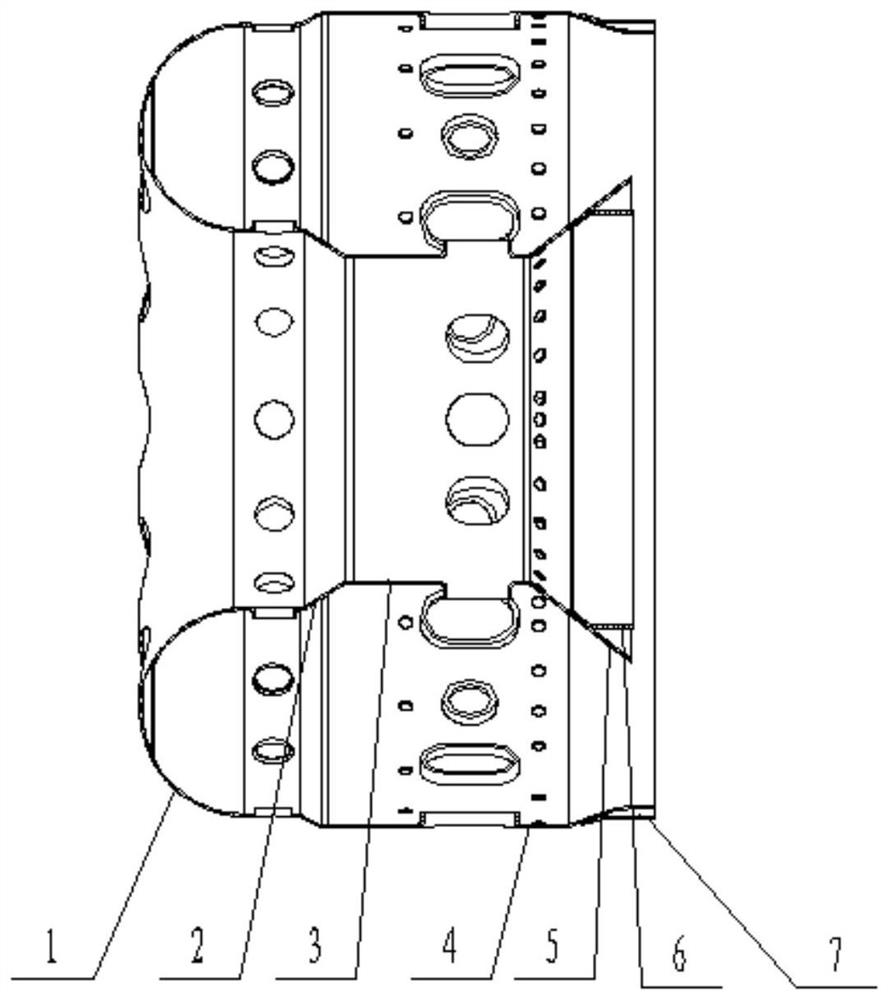

The invention provides a novel stainless steel side wall structure and a mounting method of a novel stainless steel side wall. The novel stainless steel side wall structure comprises a side wall skeleton. The side wall skeleton is formed by connecting a plurality of cross beams and a plurality of vertical columns in a mutually-crossing mode, and the cross beams and the vertical columns are fixed through mutual inserting; end vertical columns are arranged on the left and right sides of the side wall skeleton correspondingly; door vertical columns are arranged on the left and right sides of doorframes correspondingly; a window upper cross beam is arranged on the upper portion of each window frame, and a window lower cross beam is arranged on the lower portion of each window frame; a waist cross beam is arranged below each window lower cross beam; three lower cross beams are arranged below each waist cross beam; a window upper vertical column is connected to each window upper cross beam;skeleton connecting plates are welded inside the connecting positions of the window upper cross beams and the window upper vertical columns in the side wall skeleton; window lower vertical columns are connected among each window lower cross beam, the corresponding waist cross beam and the three corresponding lower cross beams; and skeleton connecting plates are welded inside the connecting positions of the window lower cross beams and the window lower vertical columns in the side wall skeleton. The cross beams and the vertical columns of the novel stainless steel side wall structure are fixedthrough mutual inserting connection, the deformation problem caused by welding of a skeleton is solved, the production cost is saved, and the assembly production efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

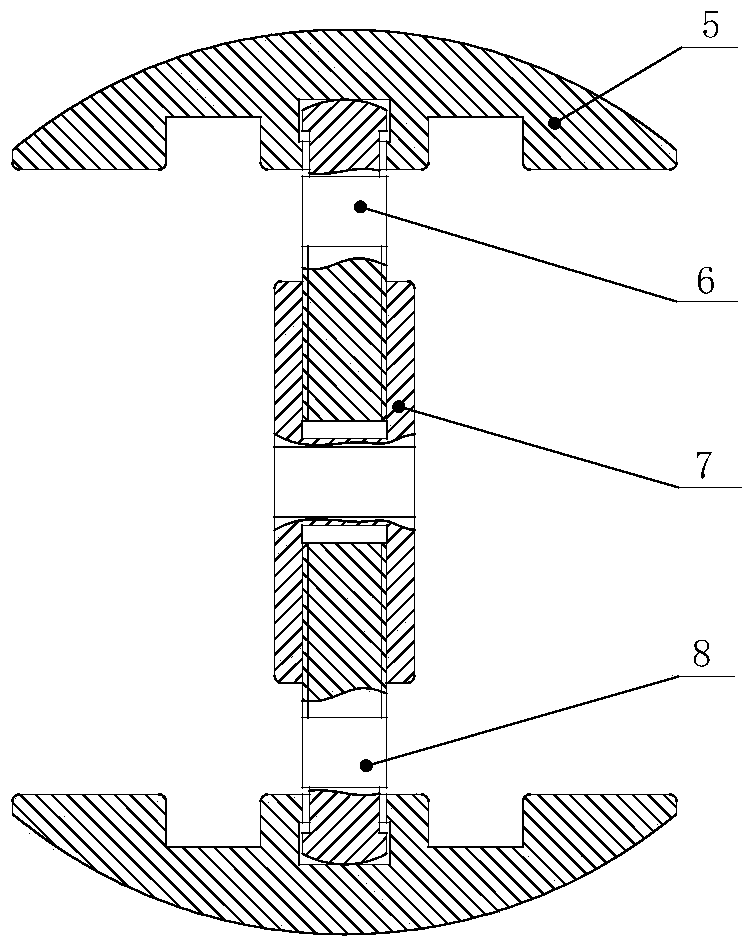

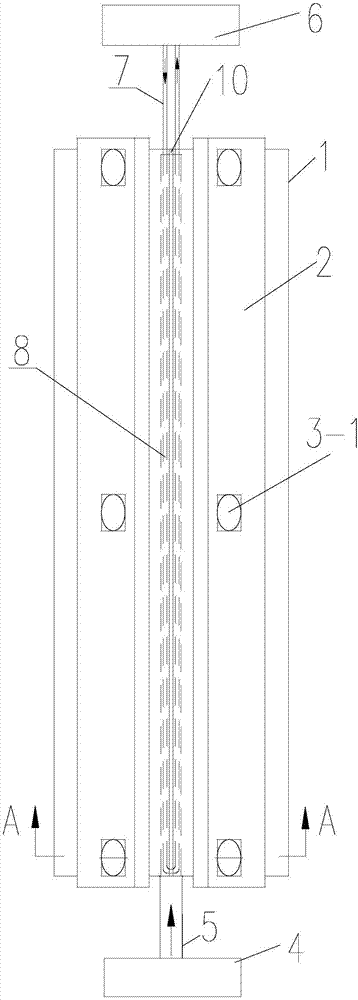

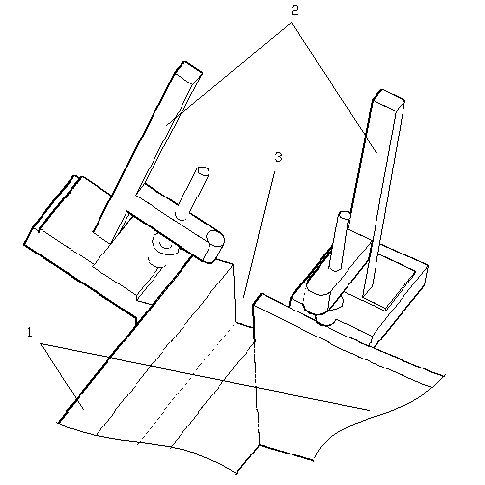

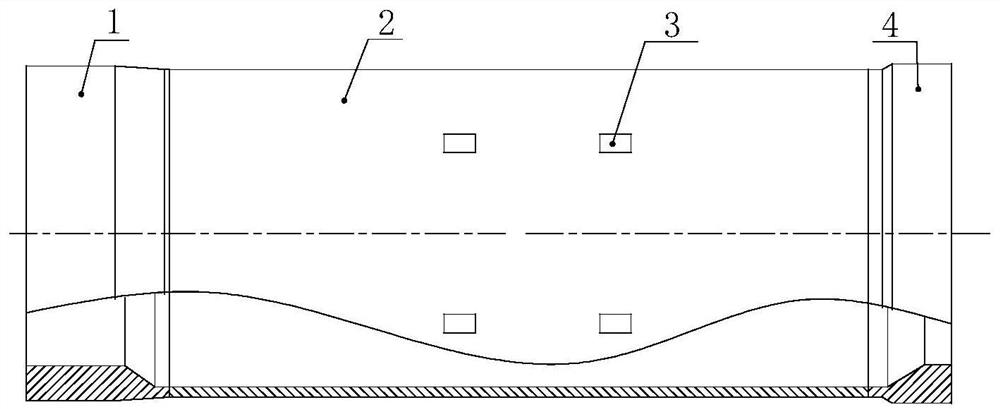

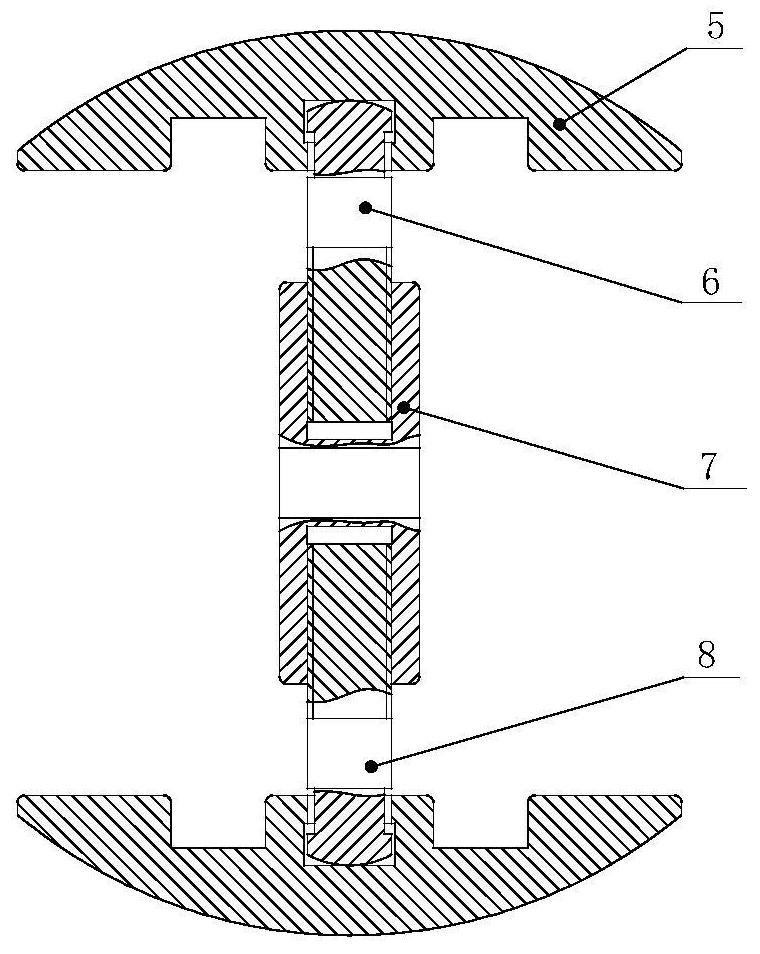

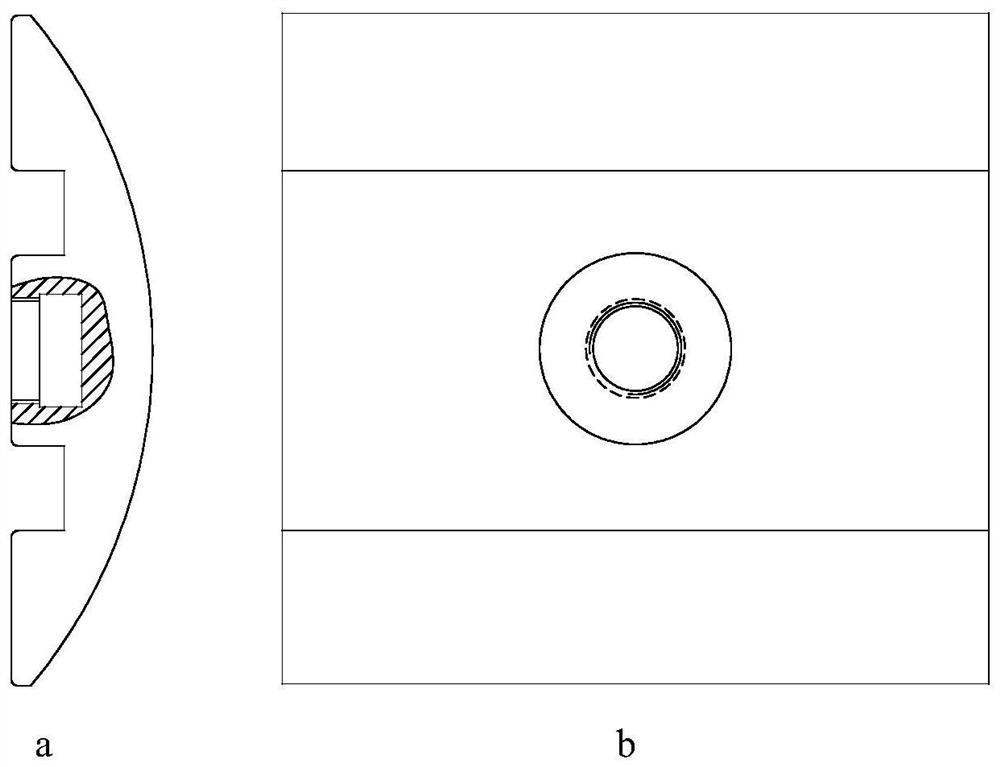

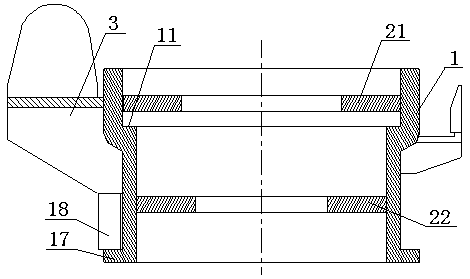

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

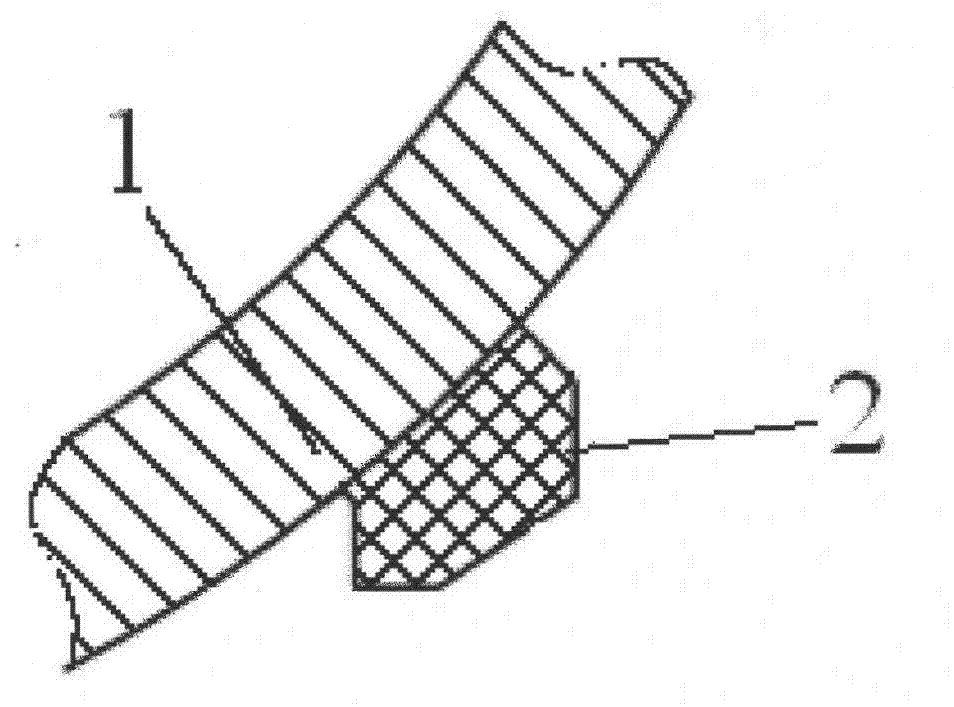

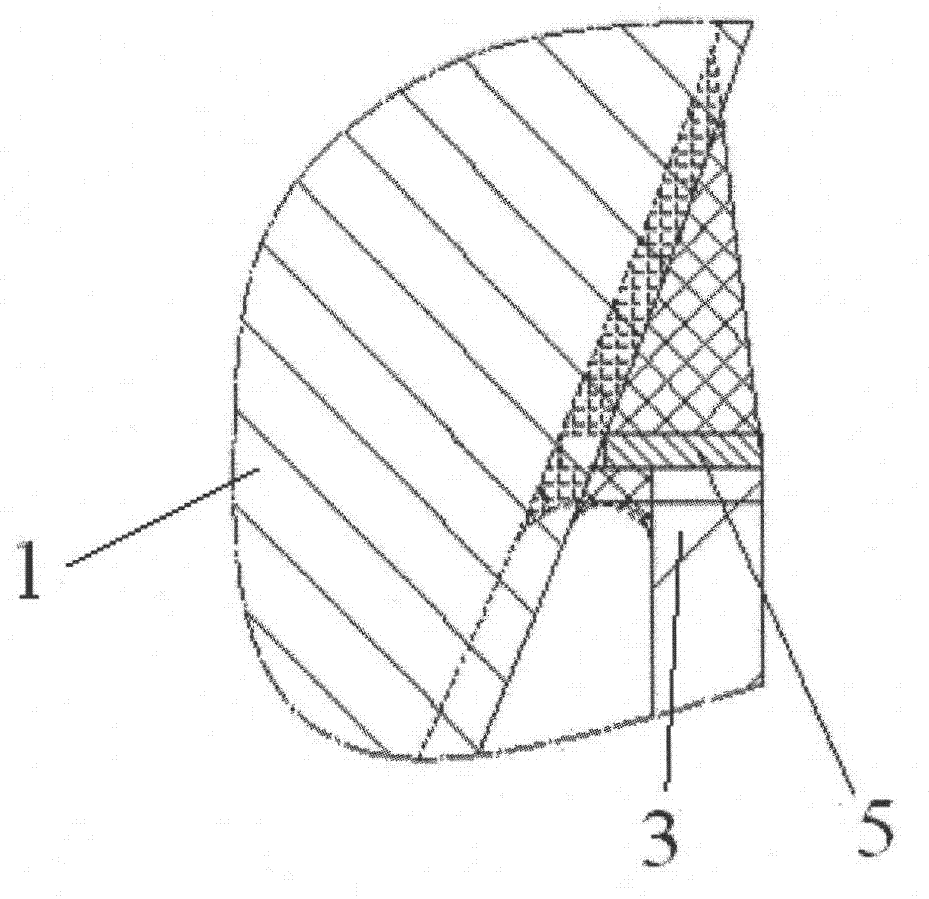

Method for controlling welding deformation between seal head and skirt transition section

ActiveCN103128459AReduce surfacing areaSave man hoursWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a method for controlling welding deformation between a seal head and a skirt transition section. The method includes welding a processing pad above a position, used for assembling the skirt transition section according to design, of the outer wall of the seal head; welding the skirt transition section at the bottom of the processing pad, and performing bead weld between the inner side surface of the skirt transition section and the seal head; removing the processing pad; and performing girth welding on the seal head and a barrel, and performing bead weld between the upper surface of the skirt transition section and the seal head. The method overcomes defects of the prior art; the welding deformation between the seal head and the skirt transition section can be effectively controlled; welding quality is guaranteed while welding materials are saved; and meanwhile, miss-match of welding joints can be guaranteed during assembling of the seal head and the barrel, and product quality is greatly improved.

Owner:SHANGHAI BOILER WORKS

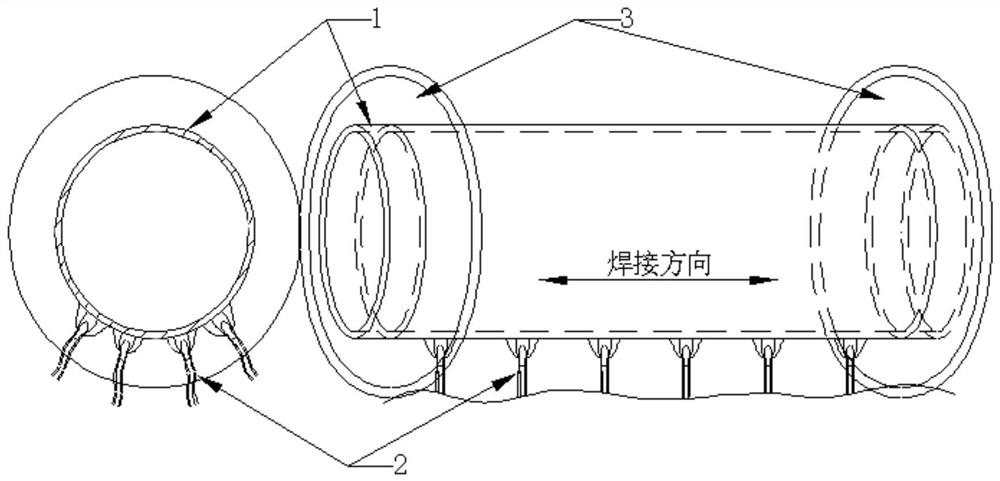

Control system and method for weld-forming of thin-walled pipe

ActiveCN107186342AIncrease stiffnessGuarantee the quality of back weld formationMetal working apparatusLaser beam welding apparatusControl systemPipe fitting

The invention discloses a control system and method for weld-forming of a thin-walled pipe. The control system comprises a welding tool used for weld-forming of the thin-walled pipe and a quality control device used for controlling the quality of longitudinal joints, welded by the welding tool, of the thin-walled pipe. The method comprises the following steps of 1, assembling the welding tool and the to-be-welded thin-walled pipe; 2, debugging the welding tool; 3, initializing the quality control device; 4, starting welding the to-be-welded thin-walled pipe; 5, acquiring real-time welding data of the thin-walled pipe; 6, judging whether the real-time welding data of the thin-walled pipe are abnormal or not; 7, judging whether the thin-walled pipe is defective or not; 8, judging whether the thin-walled pipe is deformed or not; and 9, carrying out stress relaxation on the thin-walled pipe. According to the control system and method for weld-forming the thin-walled pipe, the welding tool provides stable protective gas flow and double cooling measures for the to-be-welded thin-walled pipe, the welding quality of the to-be-welded thin-walled pipe is monitored in real time through the quality control device, so that the residual stress is eliminated, the fatigue life is prolonged, and the stress corrosion resistance is improved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

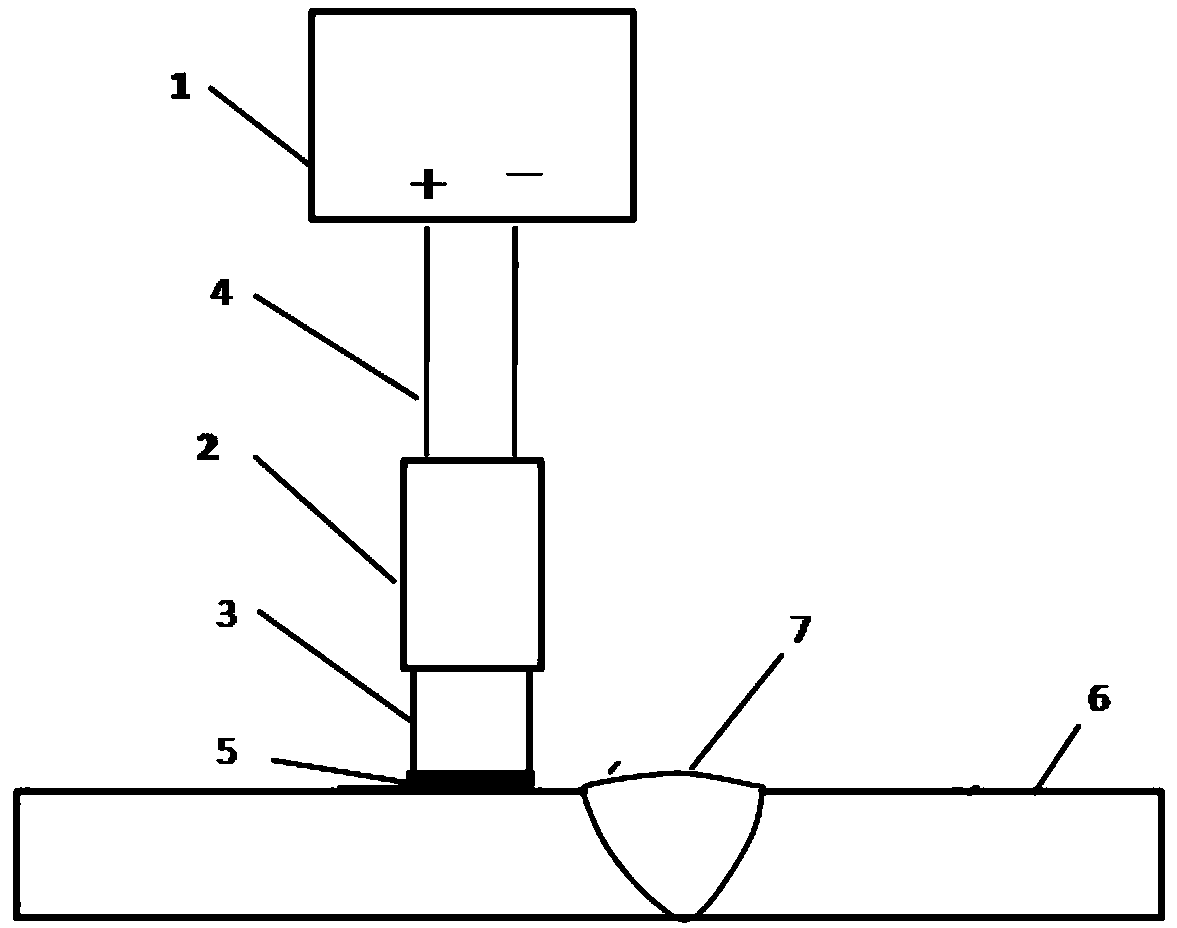

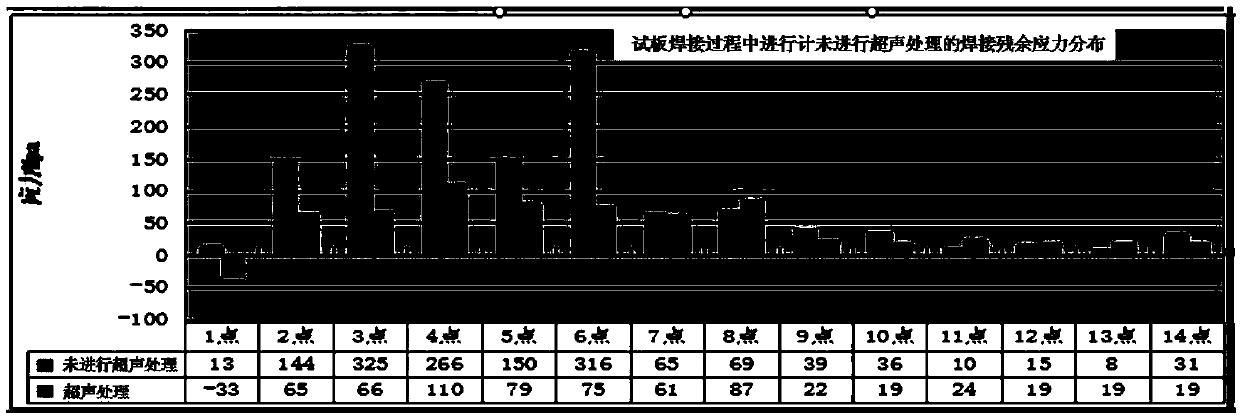

Welding deformation control method based on high-energy ultrasonic treatment

InactiveCN109570793ALower yield strengthFacilitated releaseWelding apparatusStress distributionStress concentration

The invention specifically relates to a welding deformation control method based on high-energy ultrasonic treatment. The welding deformation control method based on the high-energy ultrasonic treatment comprises the following steps that (1) an ultrasonic transducer is arranged at a appropriate position of a workpiece to be welded; (2) the ultrasonic transducer and an ultrasonic power supply are connected; (3) ultrasonic processing parameters are set; (4) the workpiece is welded; and (5) ultrasonic processing is conducted, specifically, a joint is still in a high temperature state after weldedmetal solidified, the ultrasonic power supply is started to drive the ultrasonic transducer, and ultrasonic energy is injected into the workpiece welded joint and a heat affected zone, and work is stopped until set processing time. According to the welding deformation control method based on high-energy ultrasonic treatment, the existing welding technology and process of the product is not changed, the equipment is simple, the technology is concise, the welding deformation can be effectively controlled by adjusting three parameters of an ultrasonic frequency, power and processing time, and meanwhile stress concentration can be eliminated and even stress distribution is lowered.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

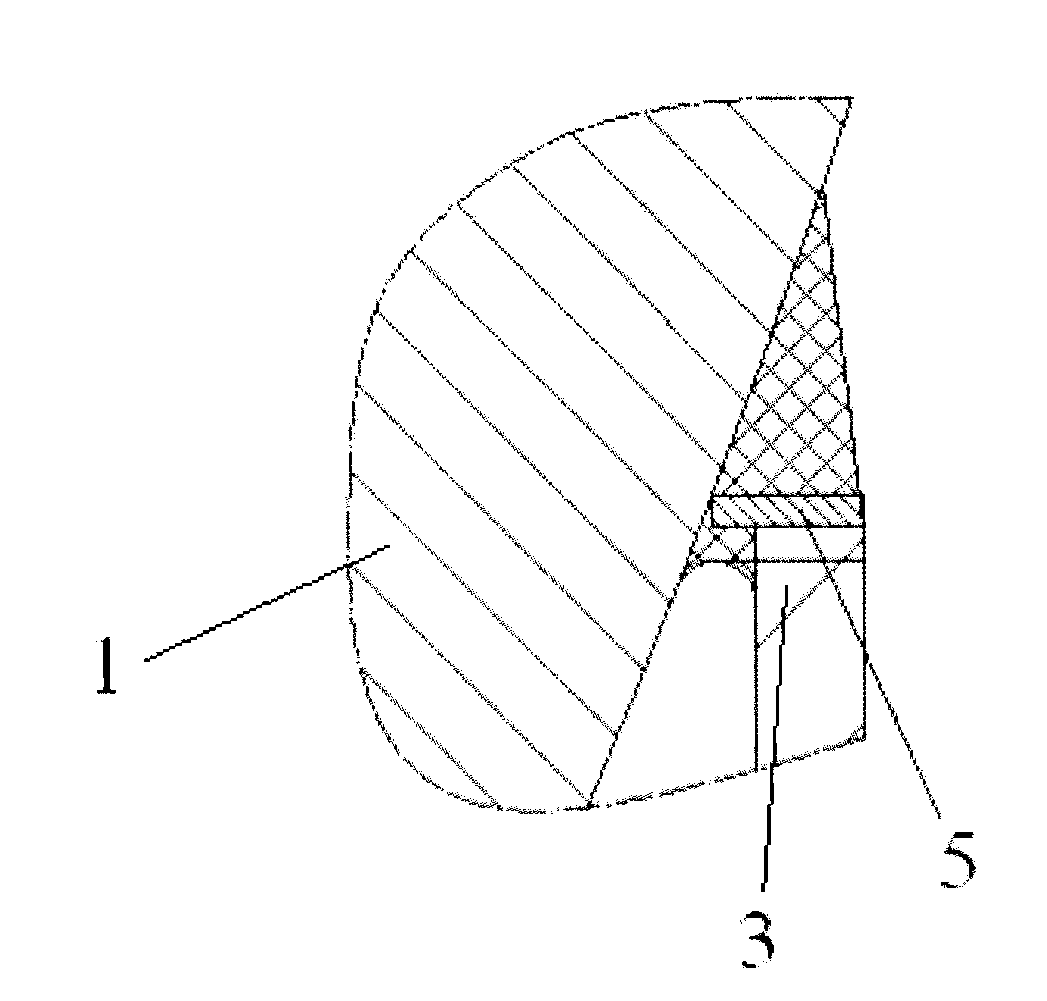

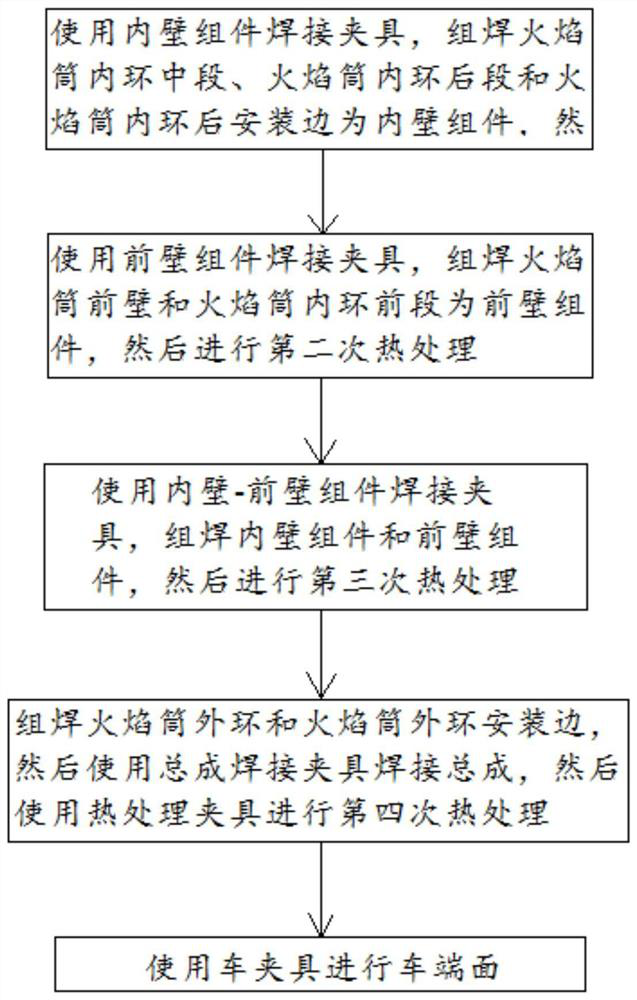

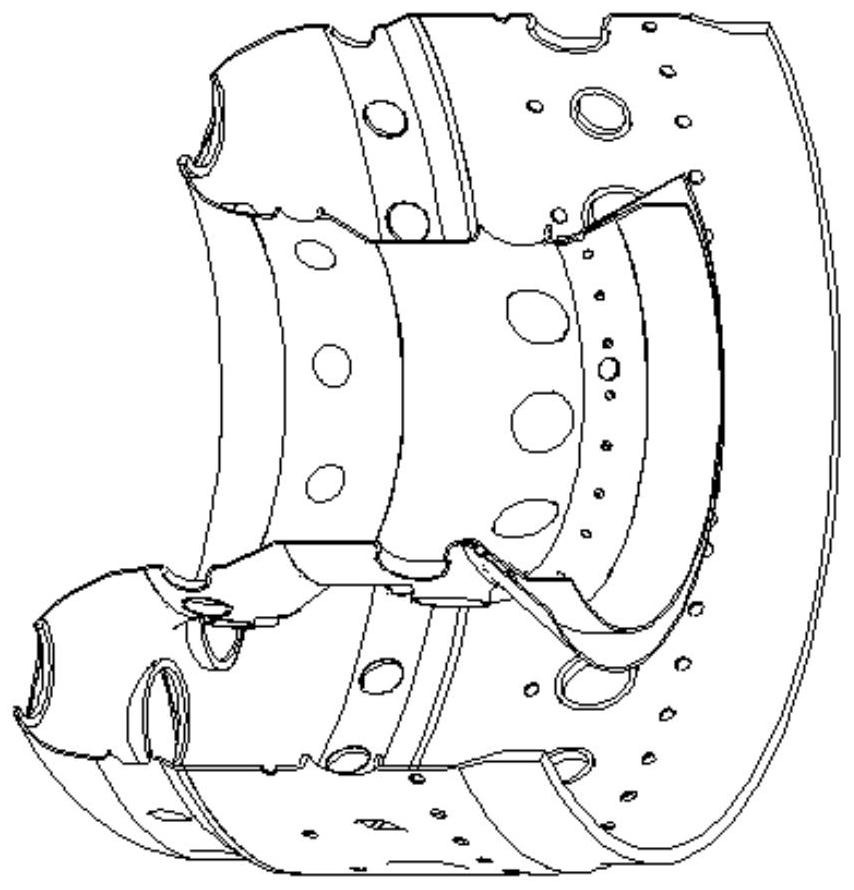

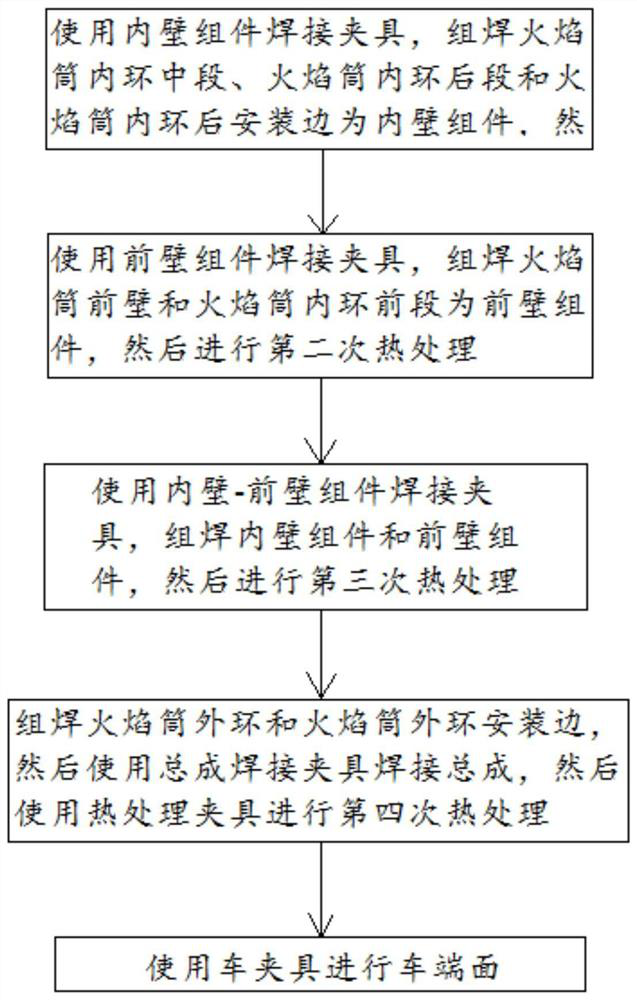

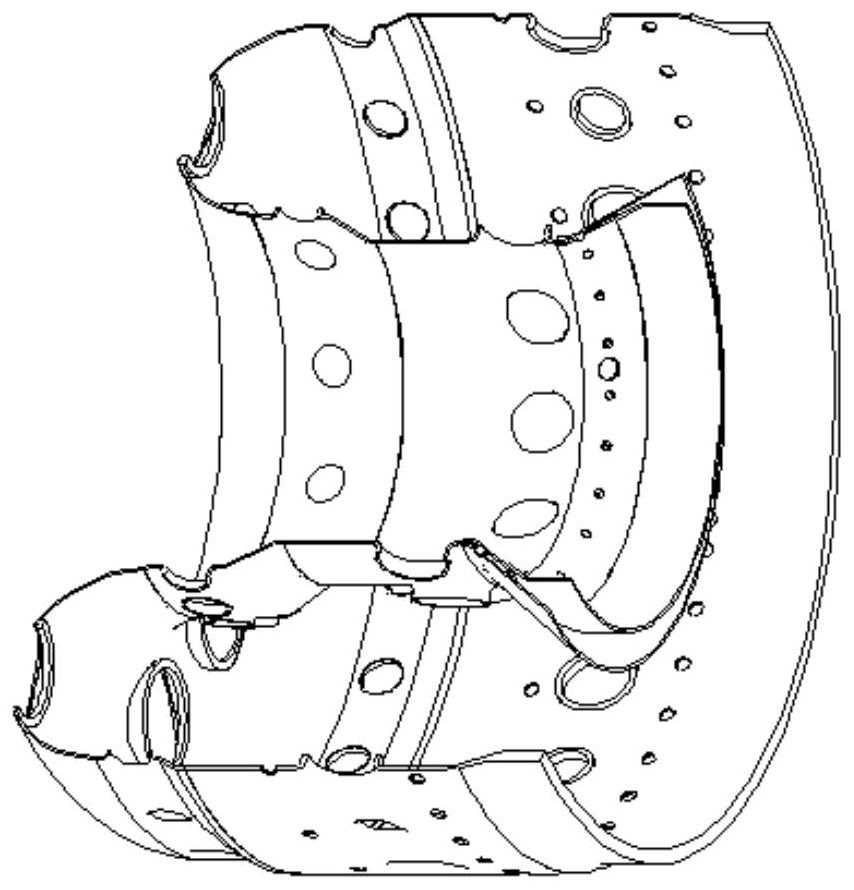

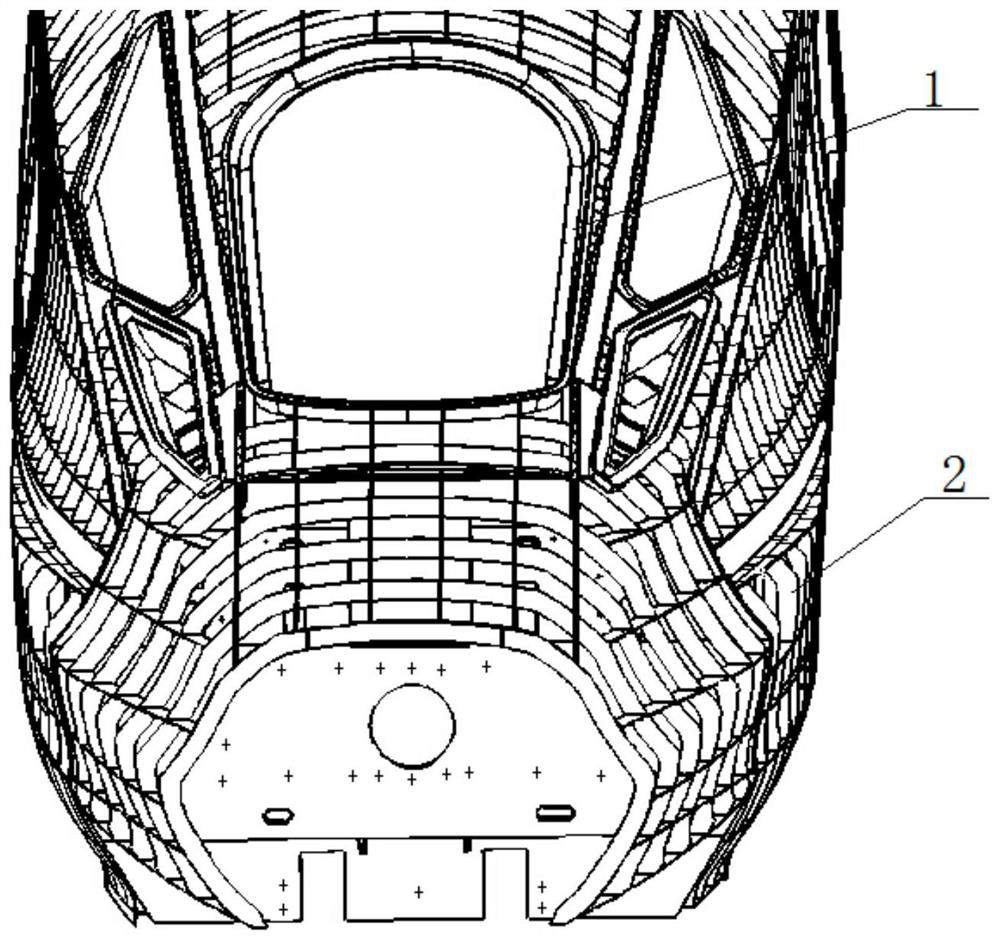

Assembling and welding machining method for semi-closed flame tube with deep U-shaped rotary section

The invention discloses an assembling and welding machining method for a semi-closed flame tube with a deep U-shaped rotary section, and belongs to the technical field of aero-engine machining. The method comprises the steps of firstly, assembling and welding a flame tube inner-ring middle segment, a flame tube inner-ring rear segment and a flame tube inner-ring rear mounting edge to form an innerwall component by using an inner wall component welding clamp, and then conducting first-time heat treatment; secondly, assembling and welding a flame tube front wall and a flame tube inner-ring front segment to form a front wall component by using a front wall component welding clamp, and then conducting second-time heat treatment; assembling and welding the inner wall component and the front wall component by using an inner wall and front wall assembly component welding clamp, and then conducting third-time heat treatment; assembling and welding a flame tube outer ring and a flame tube outer ring mounting edge again, then welding an assembly by using an assembly welding clamp, and then conducting fourth-time heat treatment by using a heat treatment clamp; and finally, lathing an end surface by using a lathing clamp. The method has the advantages of being small in machining difficulty, convenient to operate and reliable in quality.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

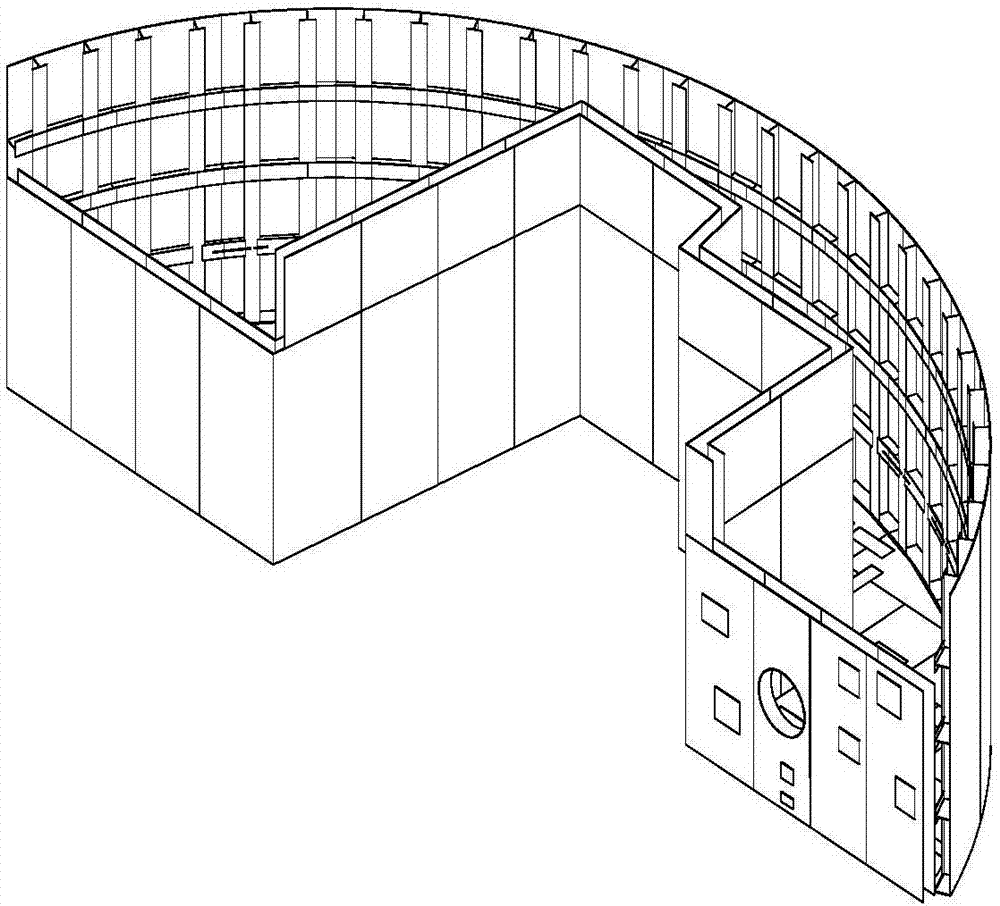

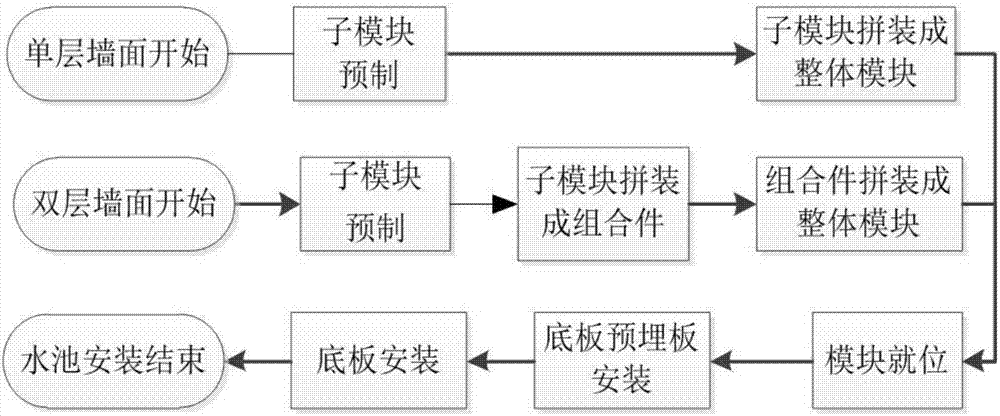

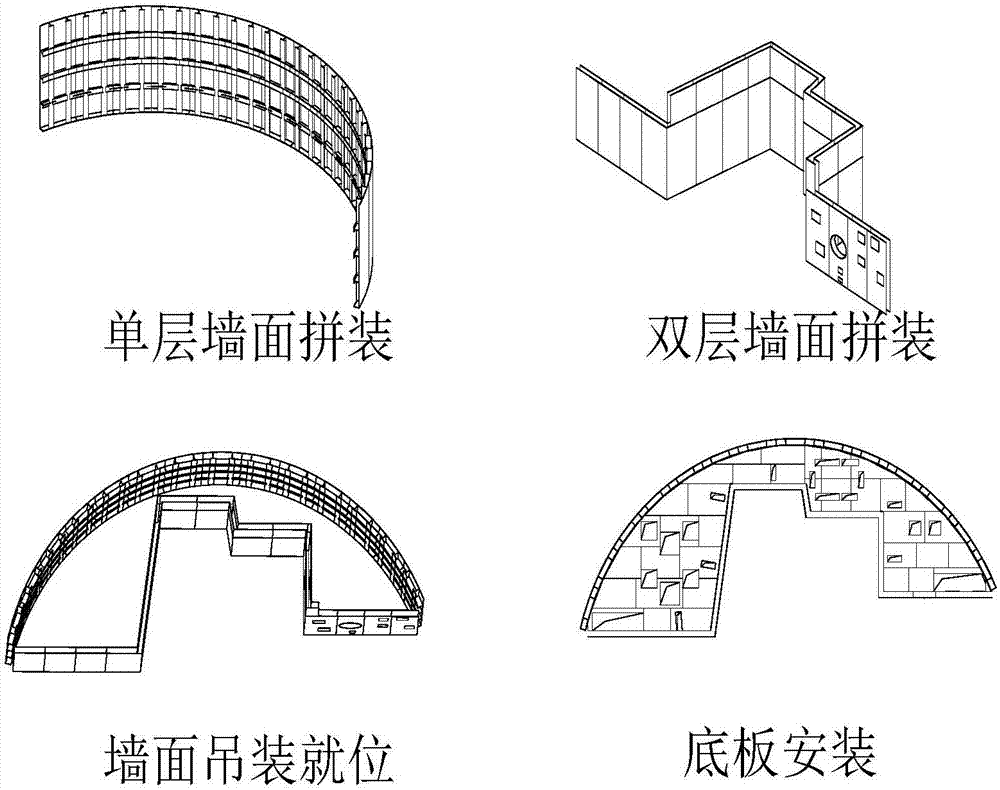

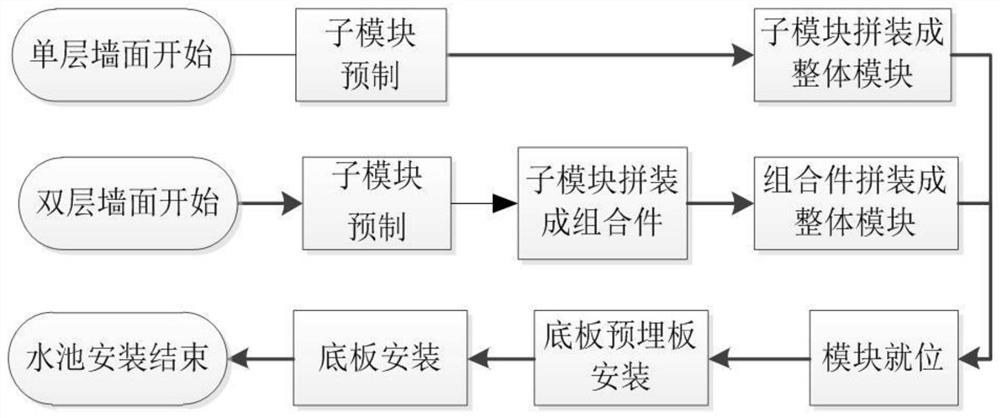

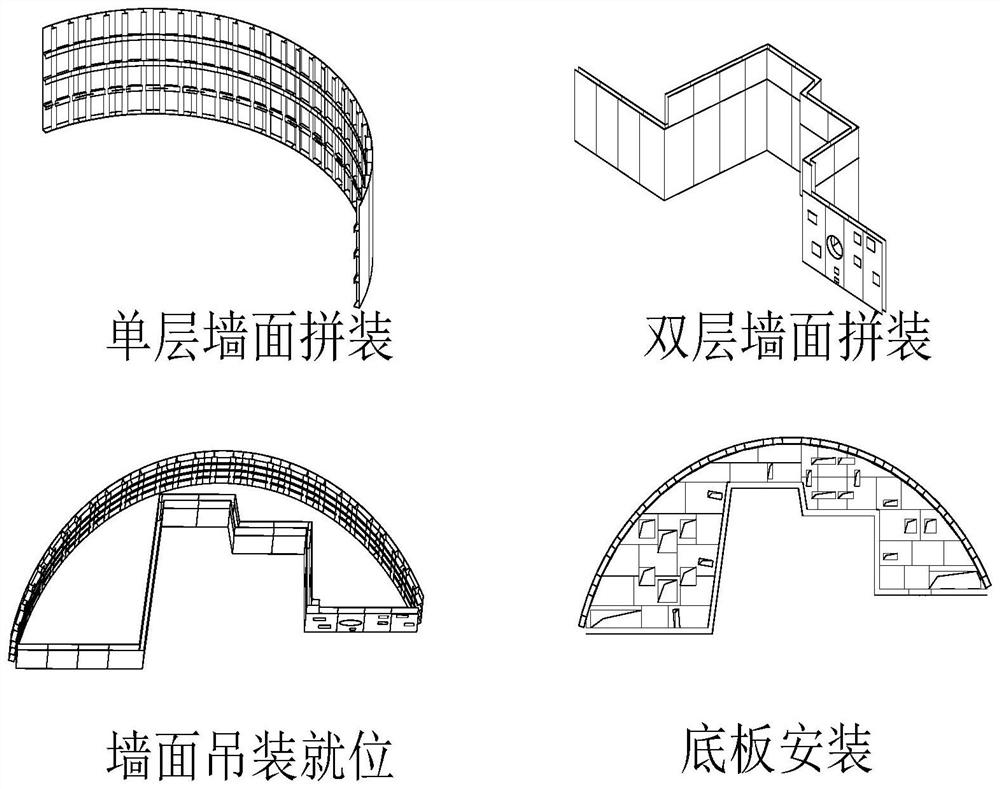

Surface-covered mounting method for dual-phase stainless steel water tank of nuclear power station and welding process

ActiveCN107511559AImprove construction efficiencyEffective control of welding deformationArc welding apparatusNuclear powerSemi automatic

The invention discloses a surface-covered mounting method for a dual-phase stainless steel water tank of a nuclear power station and a welding process, and belongs to the technical field of nuclear power station building. Wall surface covering adopts modularized manufacturing and mounting, and a reasonable wall surface-covered mounting sequence, so that mounting deformation of a surface-covered plate of the stainless steel water tank is reduced, and efficiency is improved; bottom plate surface-covering is performed after a wall surface is covered and is put in place, a bottom plate is fixed through rigidity of a pre-embedded plate, and a reasonable welding process sequence is adopted, so that effective control on bottom plate welding deformation can be realized; in a water tank mounting and welding process, an FCAW automatic or semi-automatic welding process greatly improves construction efficiency, and the construction period is shortened. The mounting method for the dual-phase stainless steel water tank of THE nuclear power station and the FCAW automatic or semi-automatic welding process are suitable for surface-covered mounting of a large dual-phase stainless steel water tank of the nuclear power station and a medium-thickness steel plate with a similar structure.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

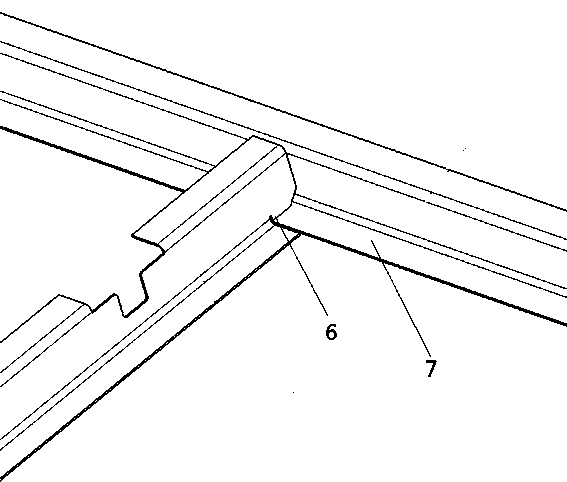

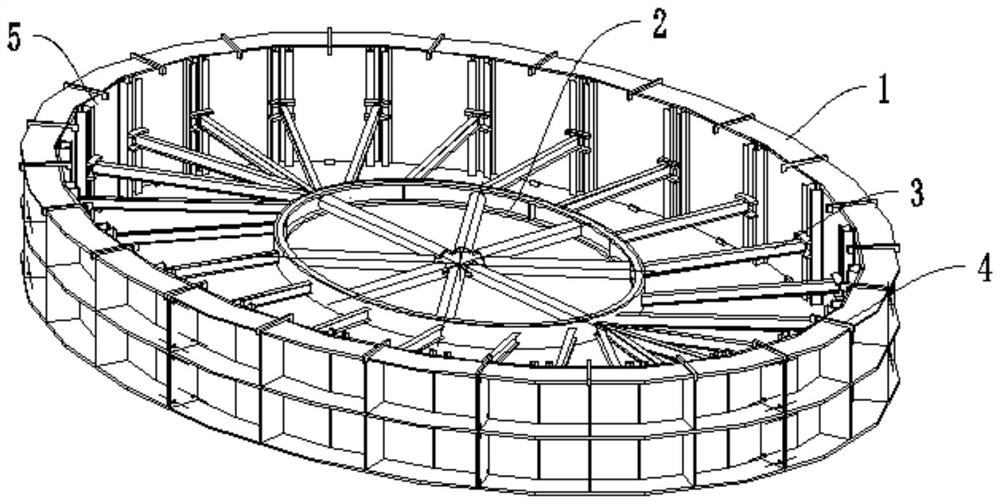

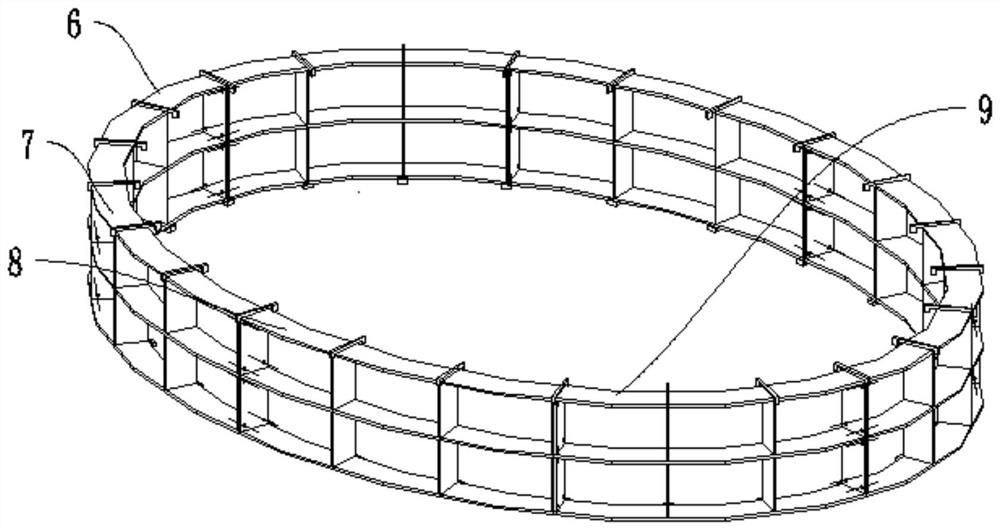

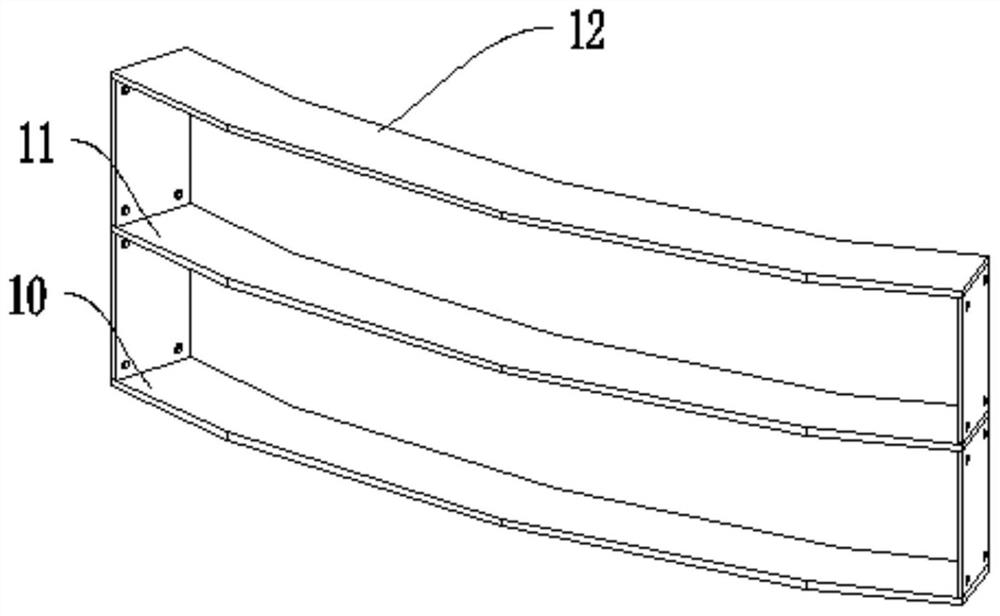

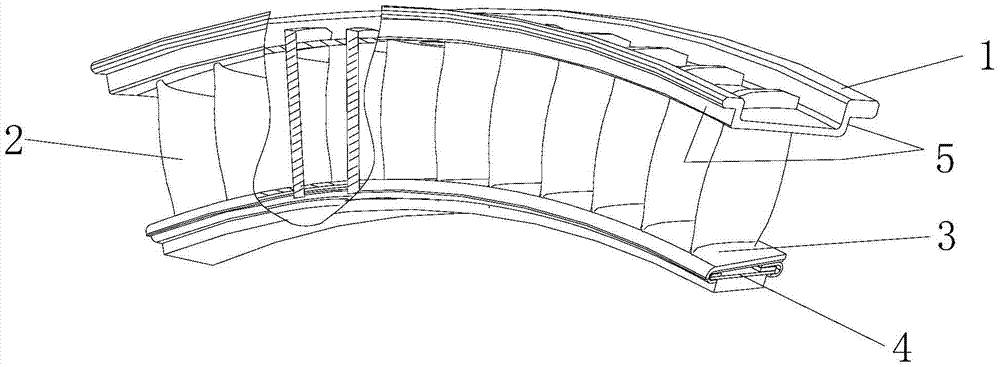

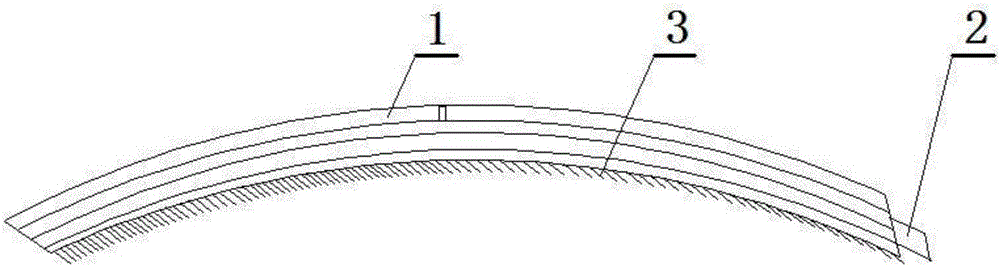

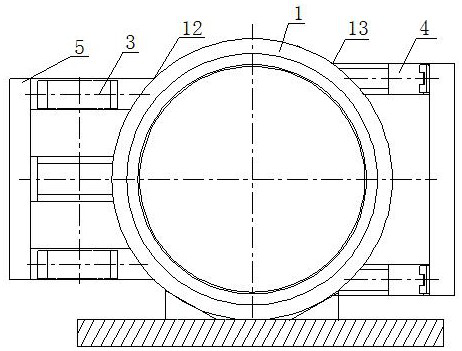

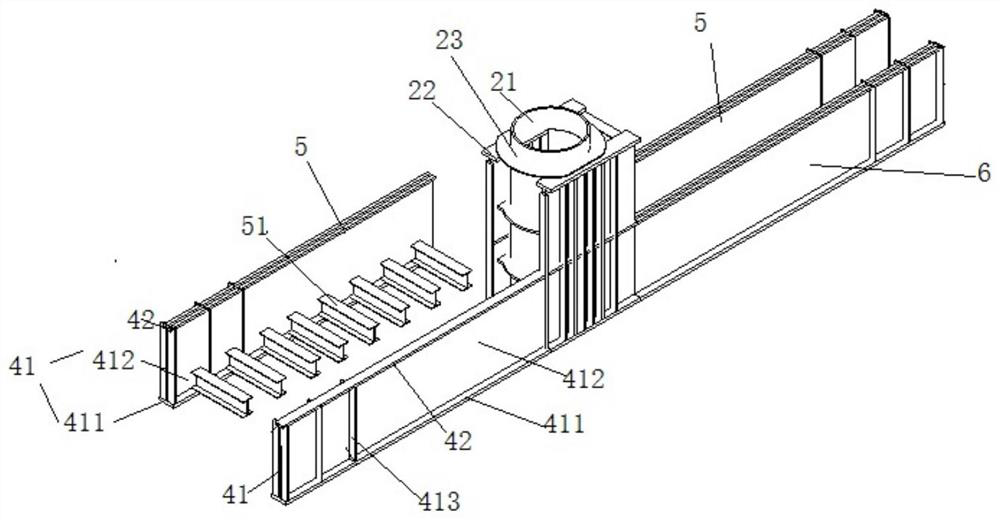

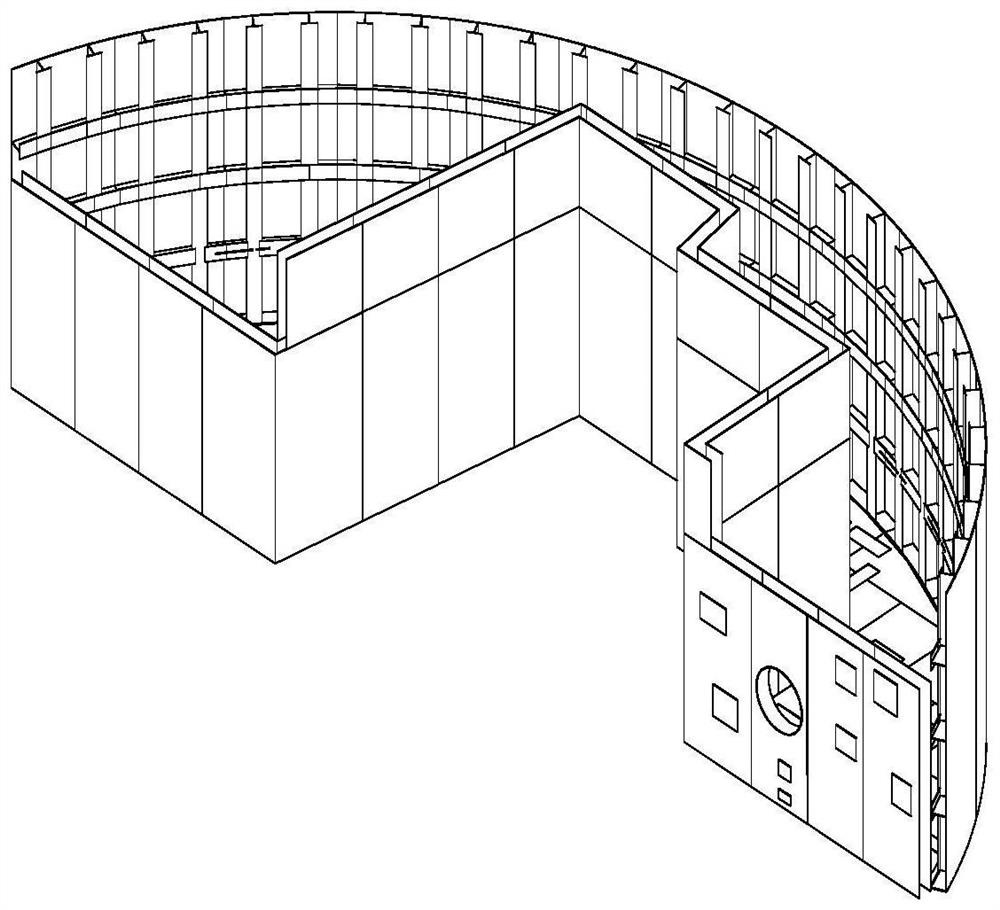

Tailor-welding device and tailor-welding method for inner-layer connecting ring of low-temperature wind tunnel

ActiveCN113664441AControl the dimensional accuracy of the inner surfaceAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesWeld seamWelding process

The invention provides a tailor-welding device and tailor-welding method for an inner-layer connecting ring of a low-temperature wind tunnel. An elliptical frame mold is of an elliptical-ring-shaped twenty-four-sided structure and is used for being connected to the outer circumferential wall of the elliptical-ring-shaped inner-layer connecting ring in a sleeving mode; an elliptical frame is of an elliptical-ring-shaped structure and is arranged at the central position in an inner cavity of the elliptical frame mold, the central point of the elliptical frame coincides with the central point of the elliptical frame mold, the long axis of the elliptical frame coincides with the long axis of the elliptical frame mold, and the short axis of the elliptical frame coincides with the short axis of the elliptical frame mold; one end of a rigid supporting assembly is welded to the outer circumferential wall of the elliptical frame, and the other end of the rigid supporting assembly abuts against two sides of each weld joint on the inner-layer connecting ring; and a fastening assembly is installed in the middle of each set of edges in the elliptical frame mold and used for fastening the inner-layer connecting ring. With the device and the method, the assembly precision of the inner-layer connecting ring is effectively improved, and the deformation in the welding process is controlled.

Owner:WUHAN YIYE STEEL STRUCTURE +1

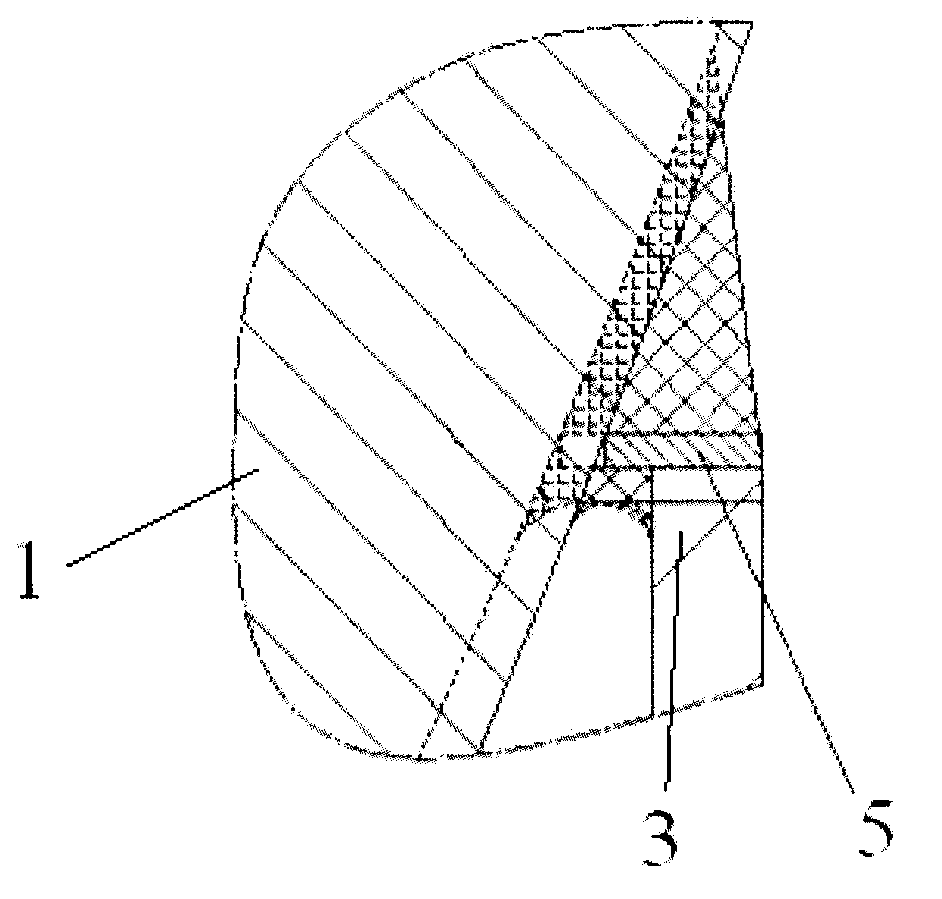

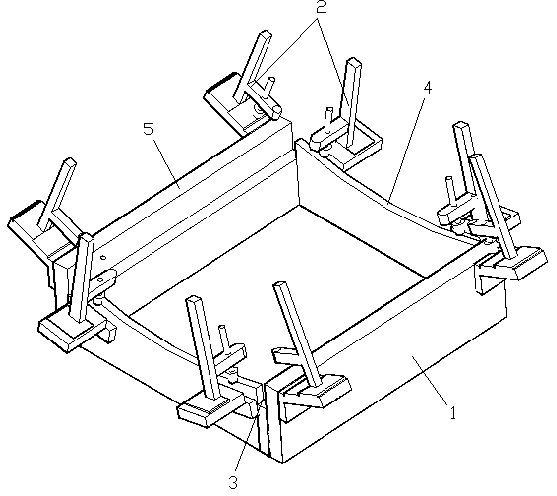

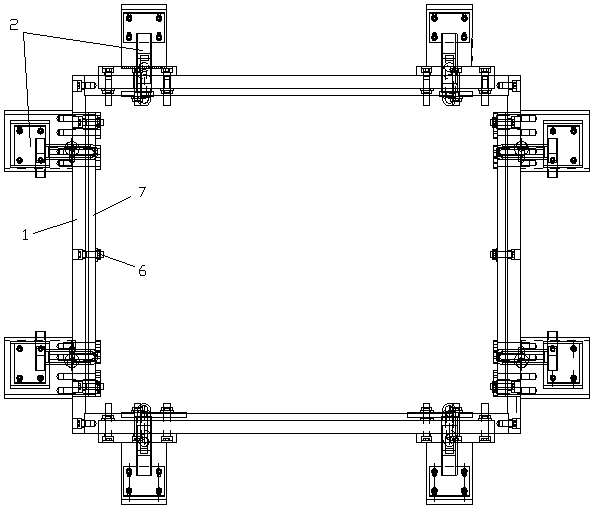

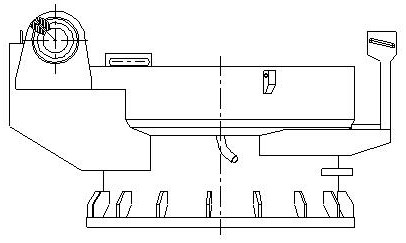

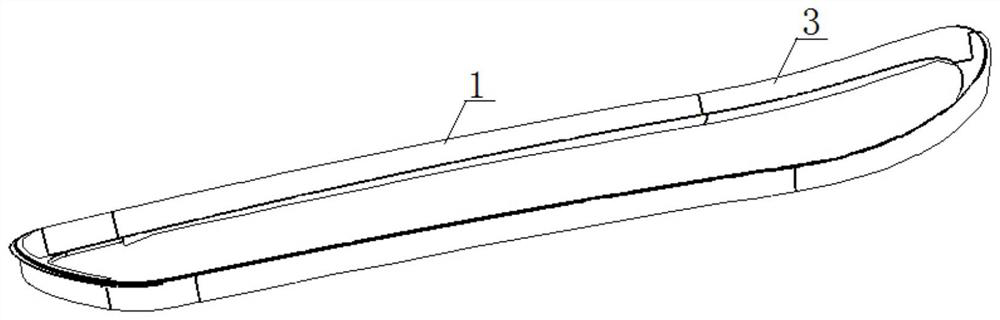

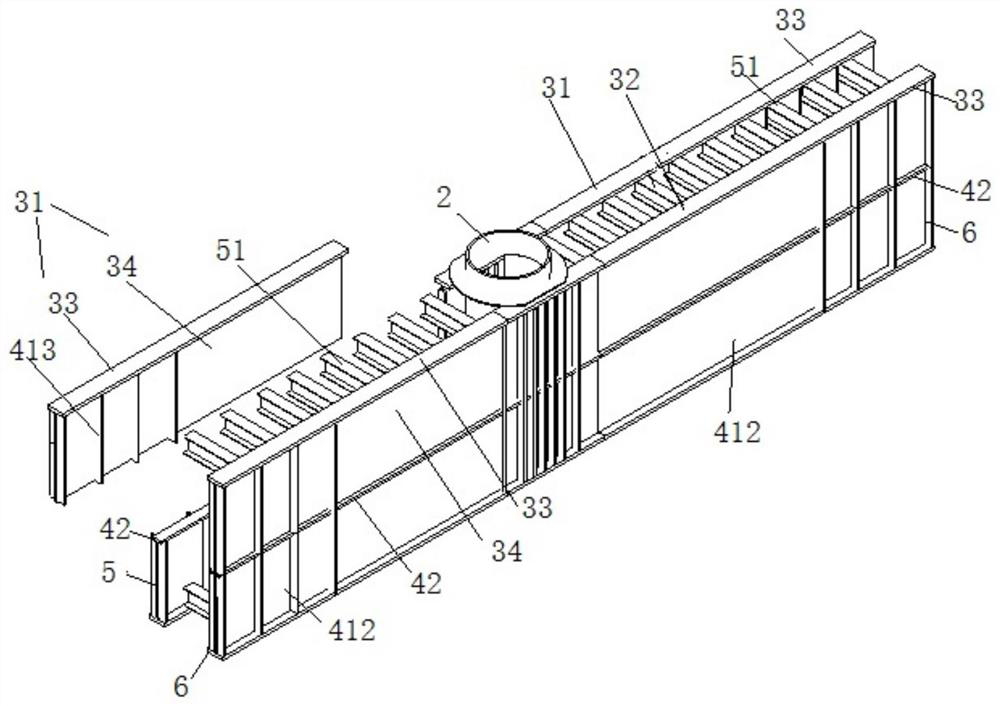

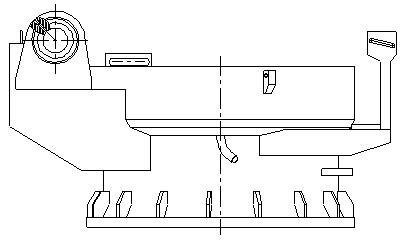

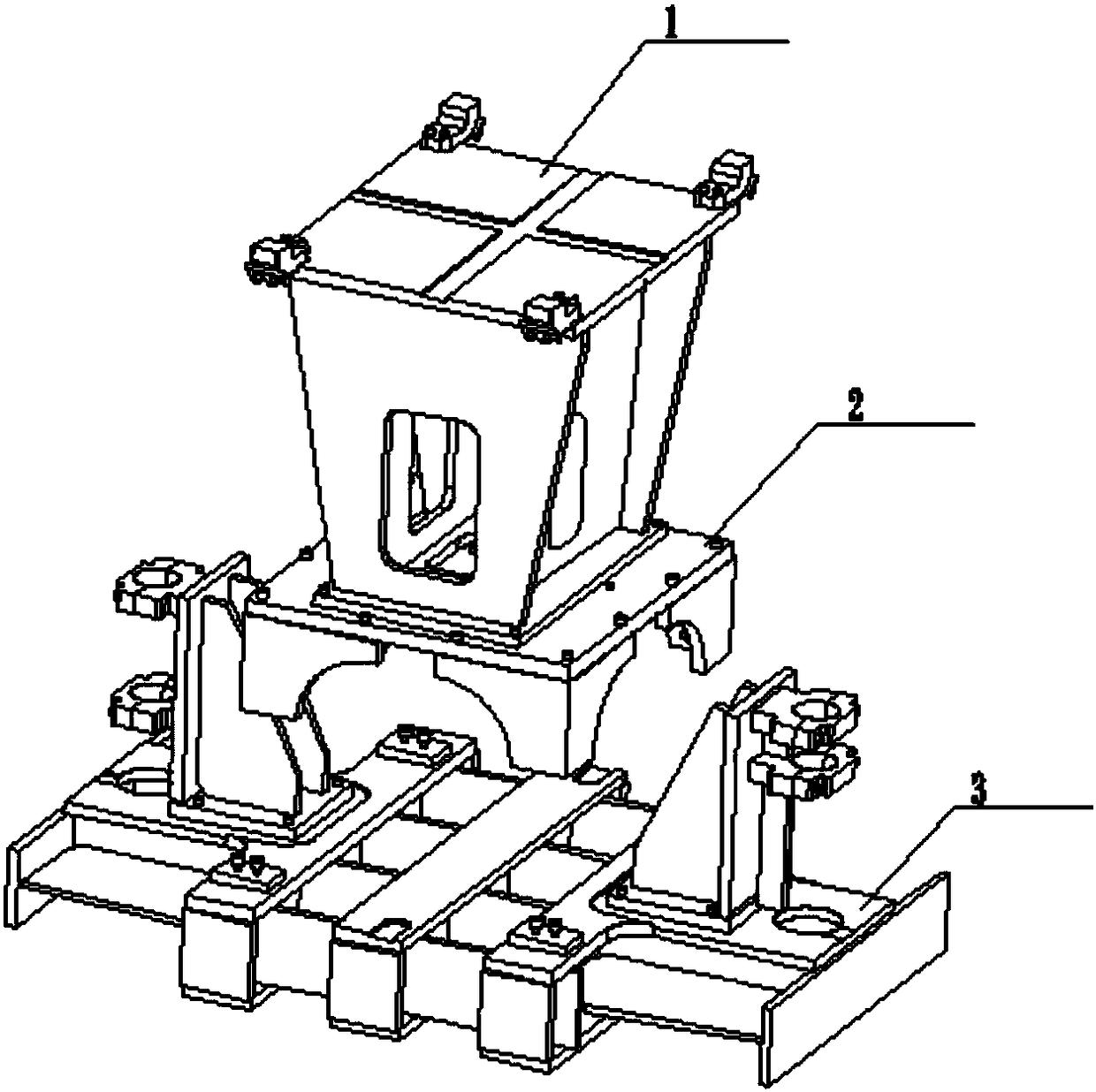

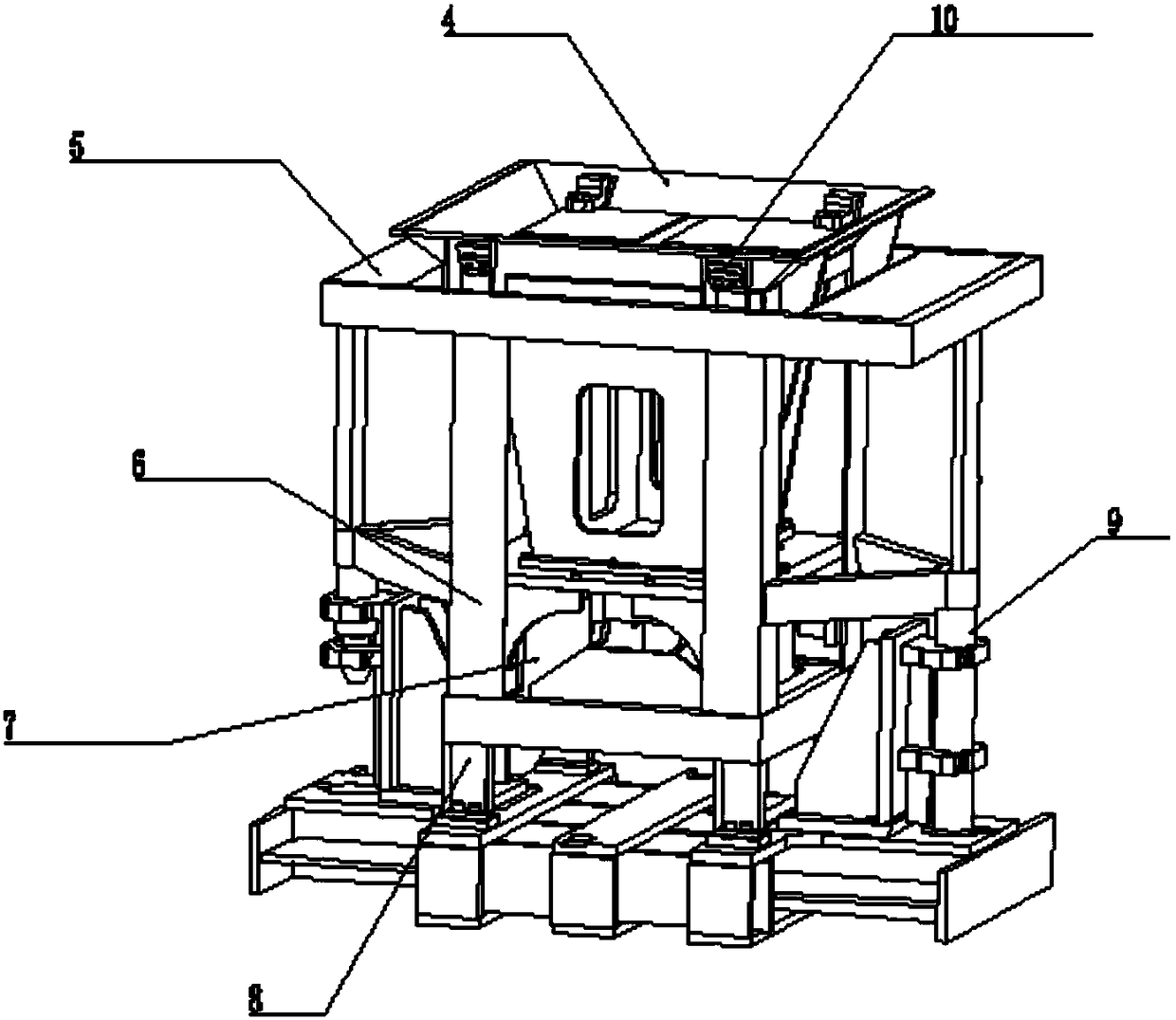

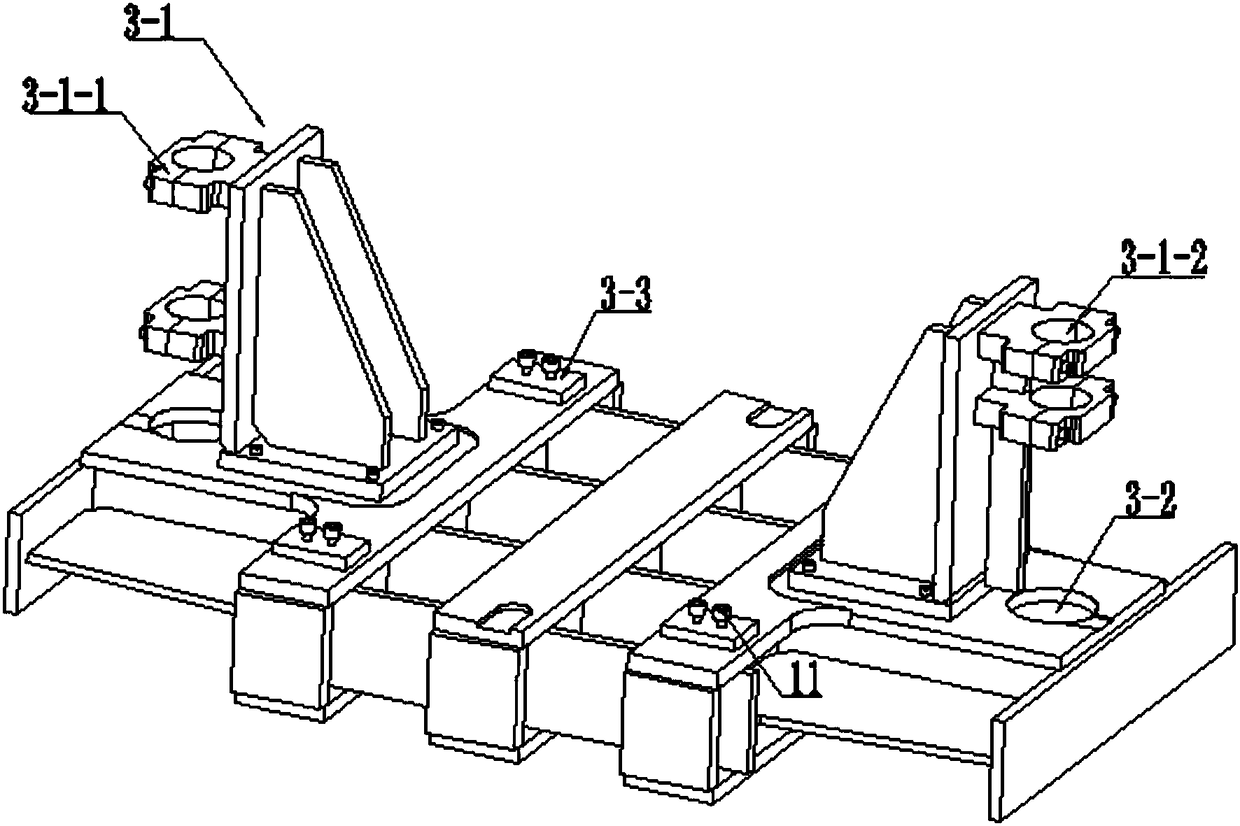

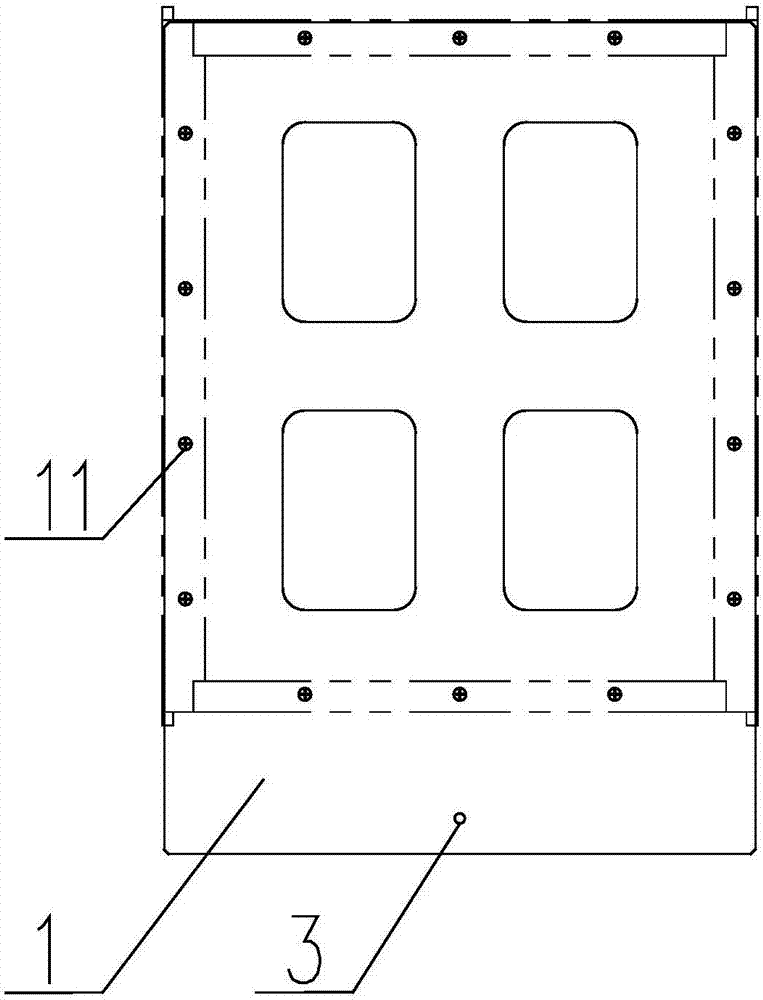

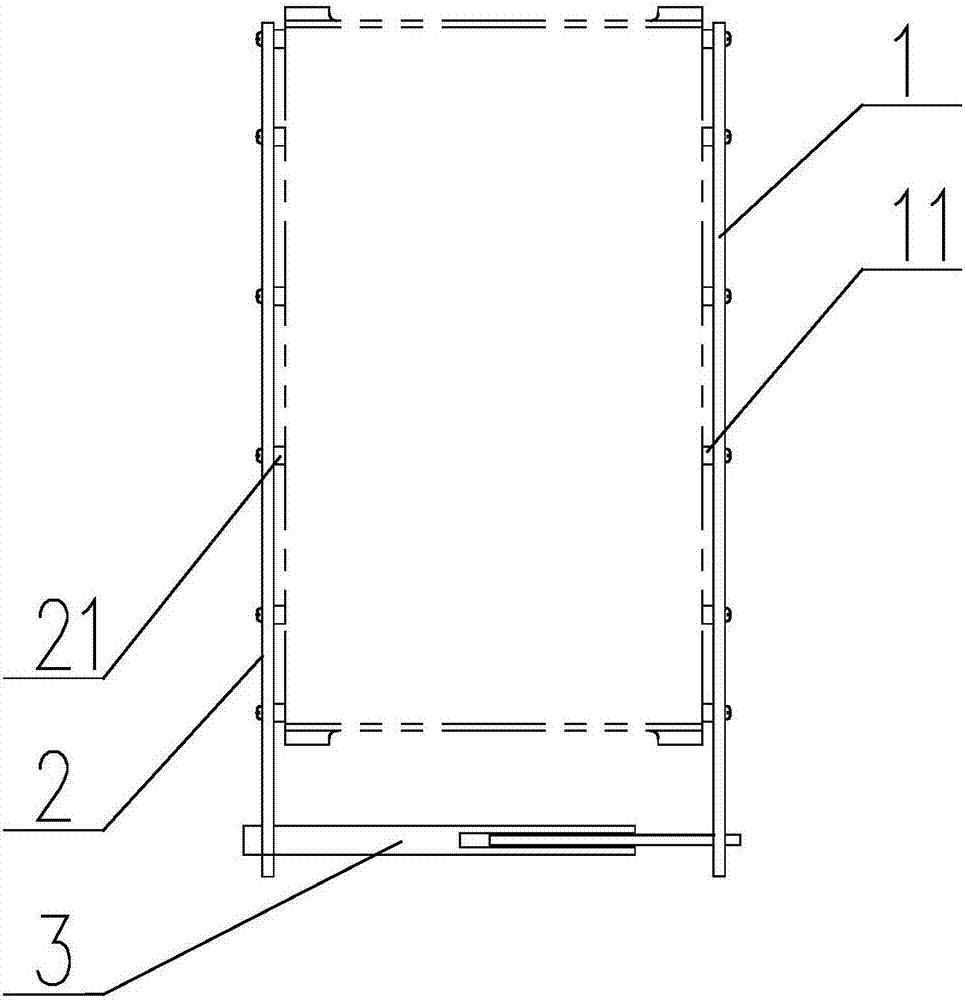

Tool for combined welding of skirt board frame of rail vehicle

ActiveCN102699608AEffective size controlEffective control of welding deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a tool for combined welding of a skirt board frame of a rail vehicle. The tool comprises a rectangular supporting frame for supporting and locating the skirt board frame, and chucks for fixing the skirt board, wherein windows for welding operation are arranged at the upper ends of four rectangular corners of the rectangular supporting frame, and the chucks are arranged on two outer sides of each rectangular corner. According to the tool for combined welding of the skirt board frame of the rail vehicle, a sideboard of each skirt board frame is located and supported through the rectangular supporting frame; the sideboard of each skirt board is tightly pressed on the rectangular supporting frame through the chucks; four rectangular corners of the rectangular supporting frame are provided with the windows for the welding operation, and an operator can conveniently carry out the welding operation. The sideboard of each skirt board frame is fixed on the rectangular supporting frame and then welded according to the size and position of the finished product of the skirt board frame, so that size deviation and welding deformation when the skirt board frame is welded can be effectively controlled through the tool and the welding quality can be ensured.

Owner:辽宁忠旺铝合金精深加工有限公司

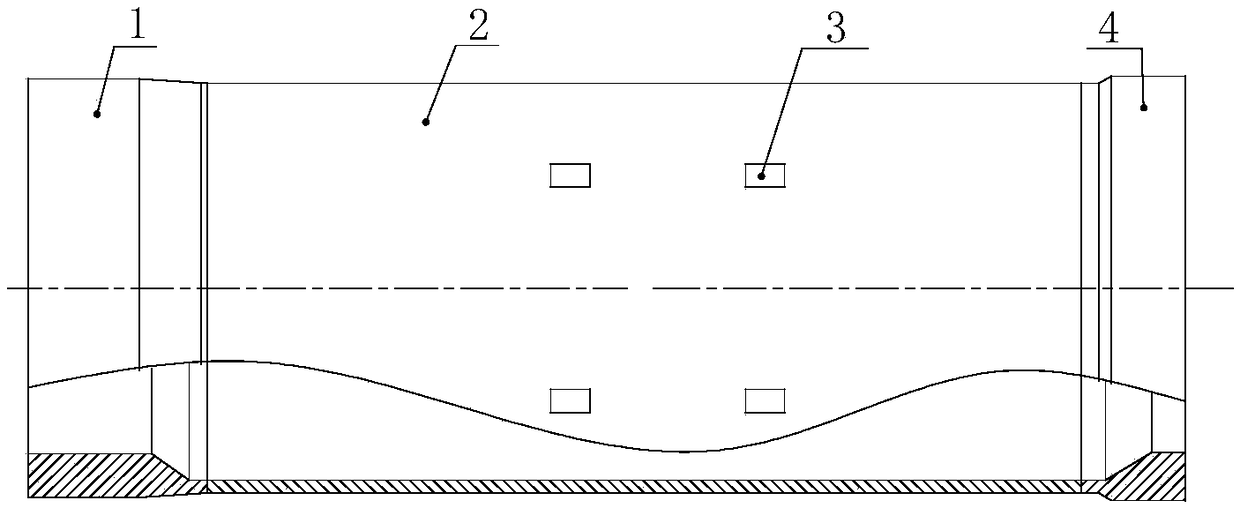

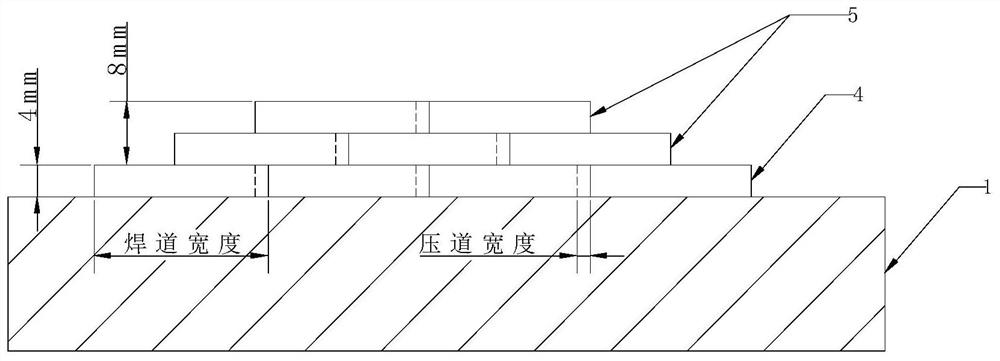

Large cladding nickel base surfacing process of barrel

InactiveCN111774692AImprove cladding efficiencyEffective control of welding deformationWelding accessoriesEngineeringStructural engineering

The invention discloses a large cladding nickel base surfacing process of a barrel. The large cladding nickel base surfacing process of the barrel specifically comprises the following steps that S1, outer tool tension bands are welded to the two ends of the barrel; S2, the inner surface of the barrel is cleaned; S3, a welding strip / welding agent combination of the EQNiCrMo-3 / NSAS3-50BS type is adopted for carrying out transition layer strip pole surfacing on the barrel; S4, the transition layer is subjected to heat treatment; S5, a welding strip / welding agent combination of the EQNiCrMo-4 / ES A-FB 2B type is adopted for carrying out corrosion-resisting layer strip pole surfacing on the barrel; and S6, 100% of permeation surface detection and 100% of ultrasonic qualification detection are carried out on the wear-resisting layer. Through the large cladding nickel base surfacing process of the barrel, welding deformation of container barrel surfacing can be effectively controlled, the quality of a bonding face between the basic layer and the surfacing layer of the barrel can be guaranteed, the requirements of mechanical property, chemical property and corrosion property detection can be met, and the requirements of product manufacturing and national standards can be met.

Owner:NANJING BAOSE

Welding method for panel assembly of low-frequency tester

InactiveCN106270961AEliminate internal stressEliminate work hardeningWelding/cutting auxillary devicesArc welding apparatusPower flowGasoline

The invention provides a welding method for a panel assembly of a low-frequency tester. The welding method comprises the following steps of 1, cleaning, wherein the panel assembly is cleaned with gasoline and then naturally aired; 2, thermal treatment, wherein the panel assembly is put into an oven at the temperature of 350-370 DEG C, heat preservation is carried out for 3 h, and the oven is cooled to the room temperature; 3, acid pickling, wherein the panel assembly is subjected to acid pickling with a spray acid pickling method; 4, welding, wherein the panel assembly is welded with the welding current being 80-90 A; 5, mark milling, wherein welding marks at the welding part of the panel assembly are primarily treated in a milling mode; 6, mark trimming and filing, wherein the welding marks at the welding part of the panel assembly are finely treated in a filing mode. According to the welding method, by improving the process, the internal stress generated in the assembly machining process can be effectively eliminated, machining hardening can be eliminated, hardness can be reduced, and plasticity can be improved, so that welding deformation is effectively controlled, the probability of welding cracks is reduced, and the welding percent of pass is improved and reaches 90% or above.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

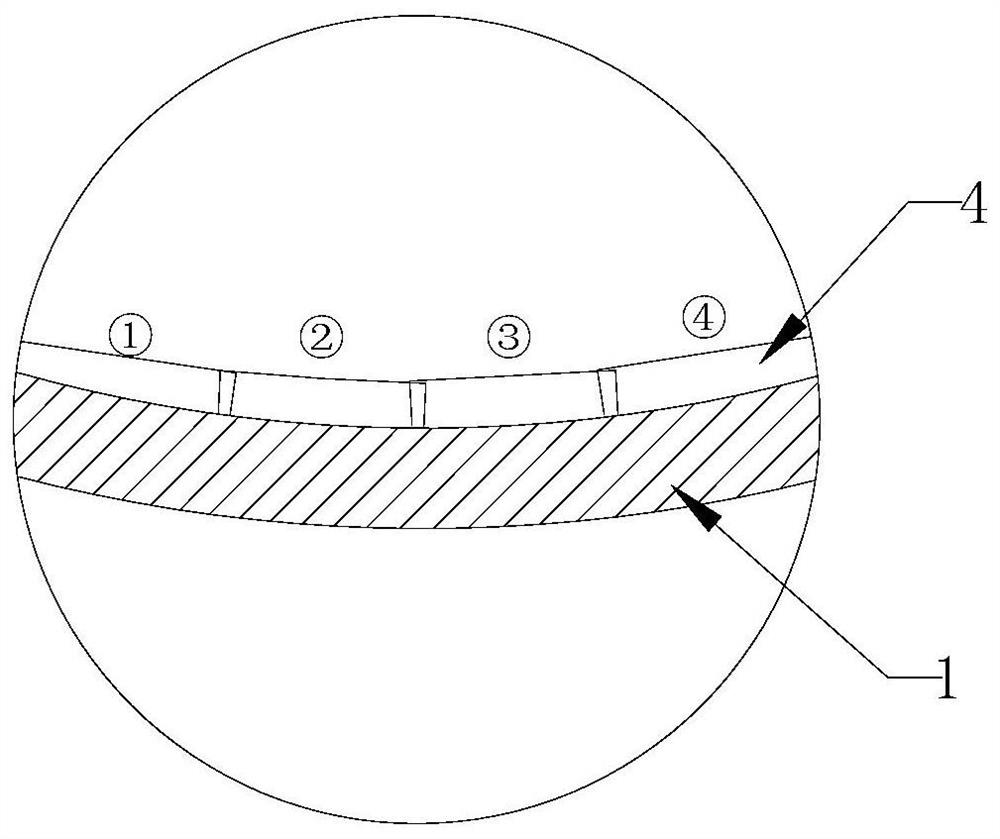

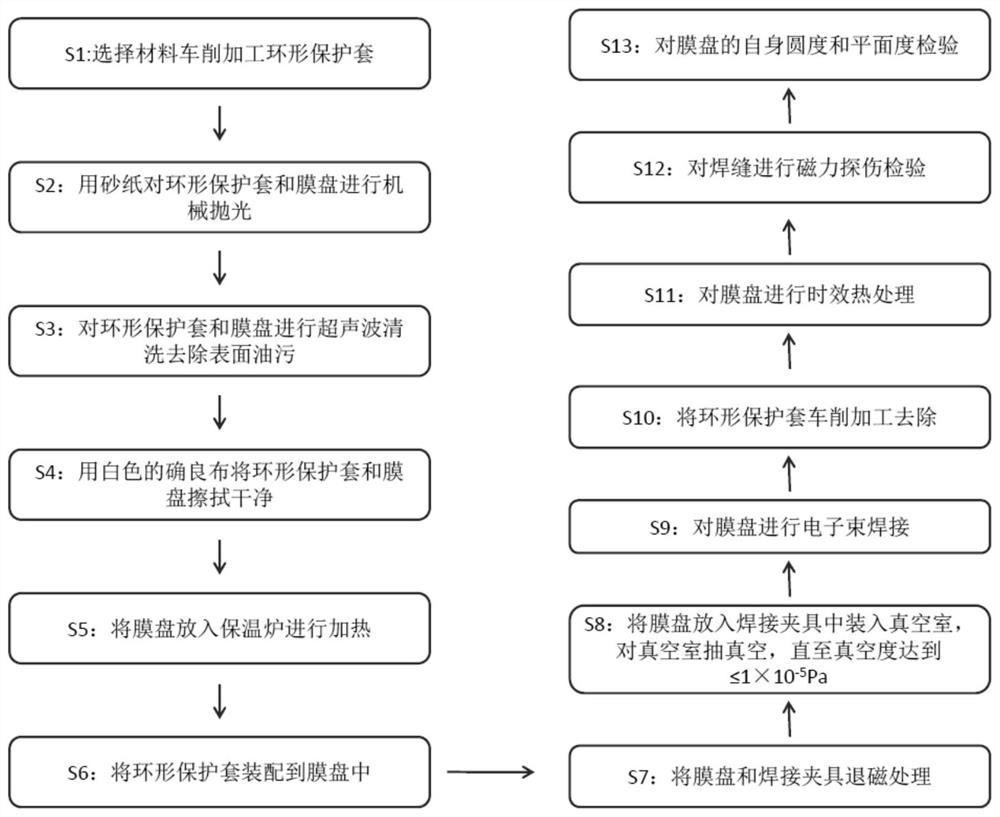

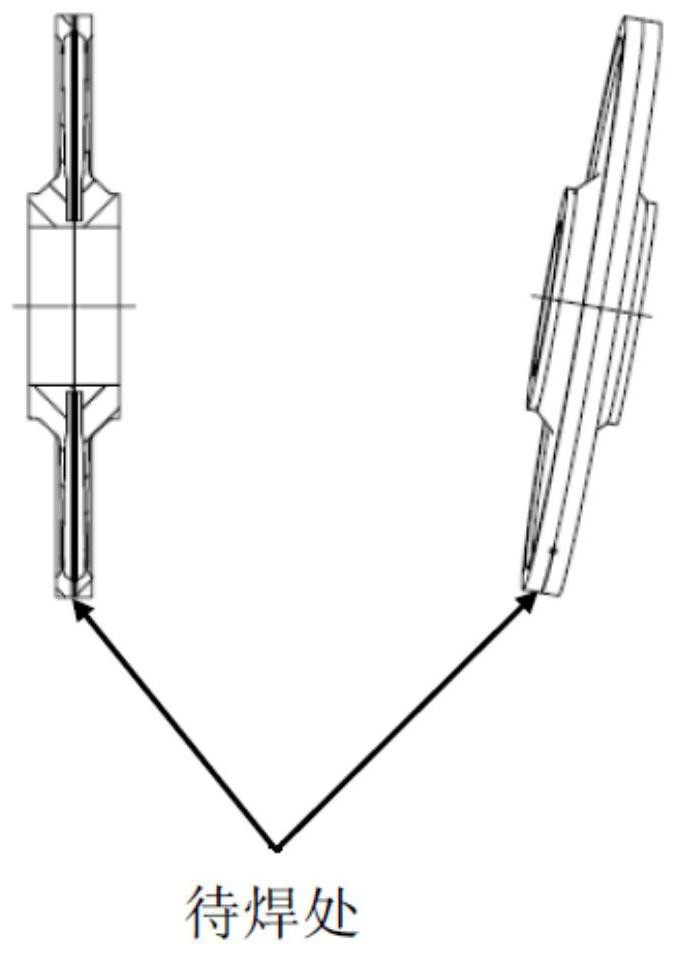

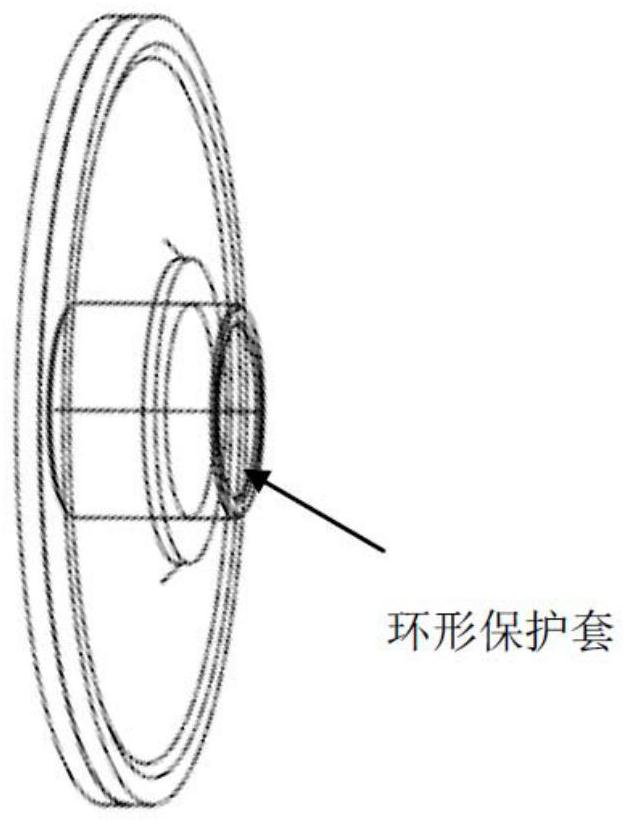

Electron beam welding method for lock-bottom-free film disc type part

ActiveCN112705831AGuarantee welding qualityControl welding deformationElectron beam welding apparatusElectron bunchesWelding deformation

The invention relates to the technical field of electron beam welding, in particular to an electron beam welding machining method for a lock-bottom-free film disc type part. An annular protective sleeve is added and electron beam welding process parameters are appropriate, so that the weld joint quality is guaranteed, welding deformation is effectively controlled, and good weld joints are obtained. By the adoption of the method, products are all qualified through flaw detection after welding, and a lock-bottom-free film disc meets the requirements that the roundness of the lock-bottom-free film disc is smaller than or equal to 0.1 mm and the parallelism of the lock-bottom-free film disc is smaller than or equal to 0.1 mm. The method is high in applicability and can be applied to various lock-bottom-free electron beam welding products.

Owner:HARBIN DONGAN ENGINE GRP

A deep U-shaped rotary cross-section semi-closed flame cylinder assembly welding processing method

ActiveCN112192157BEnough space for welding operationsGuarantee welding qualityEngineeringCylinder (engine)

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

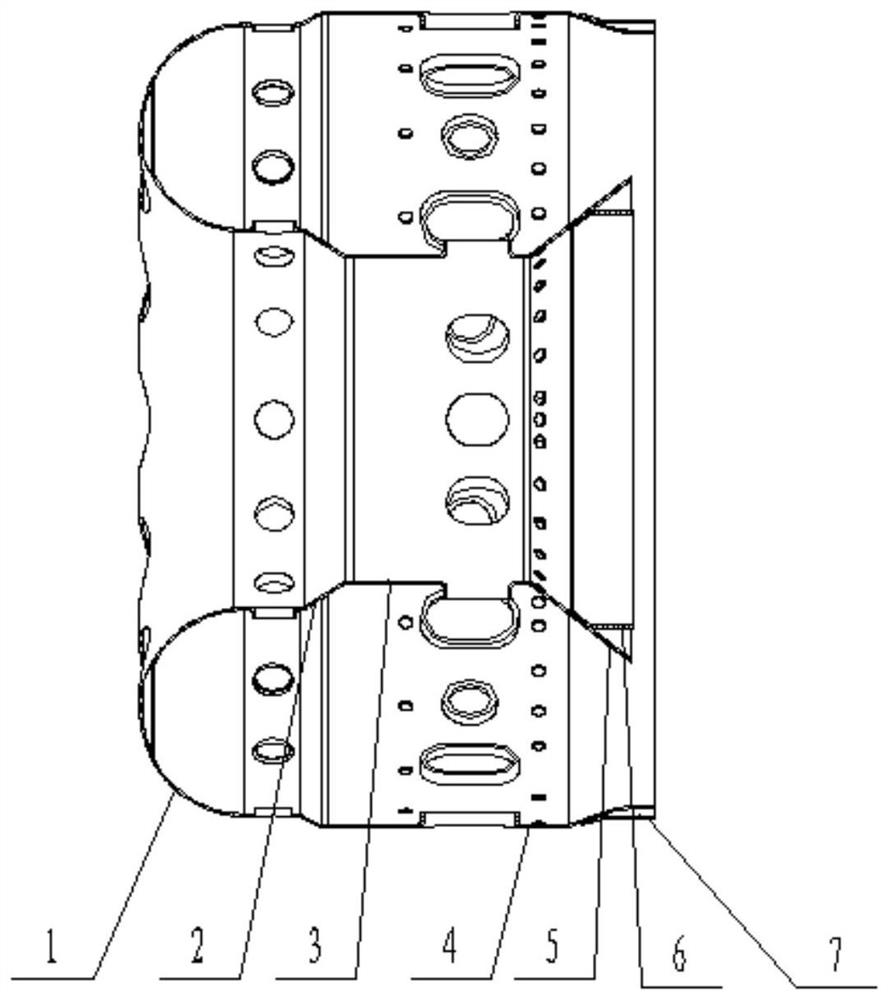

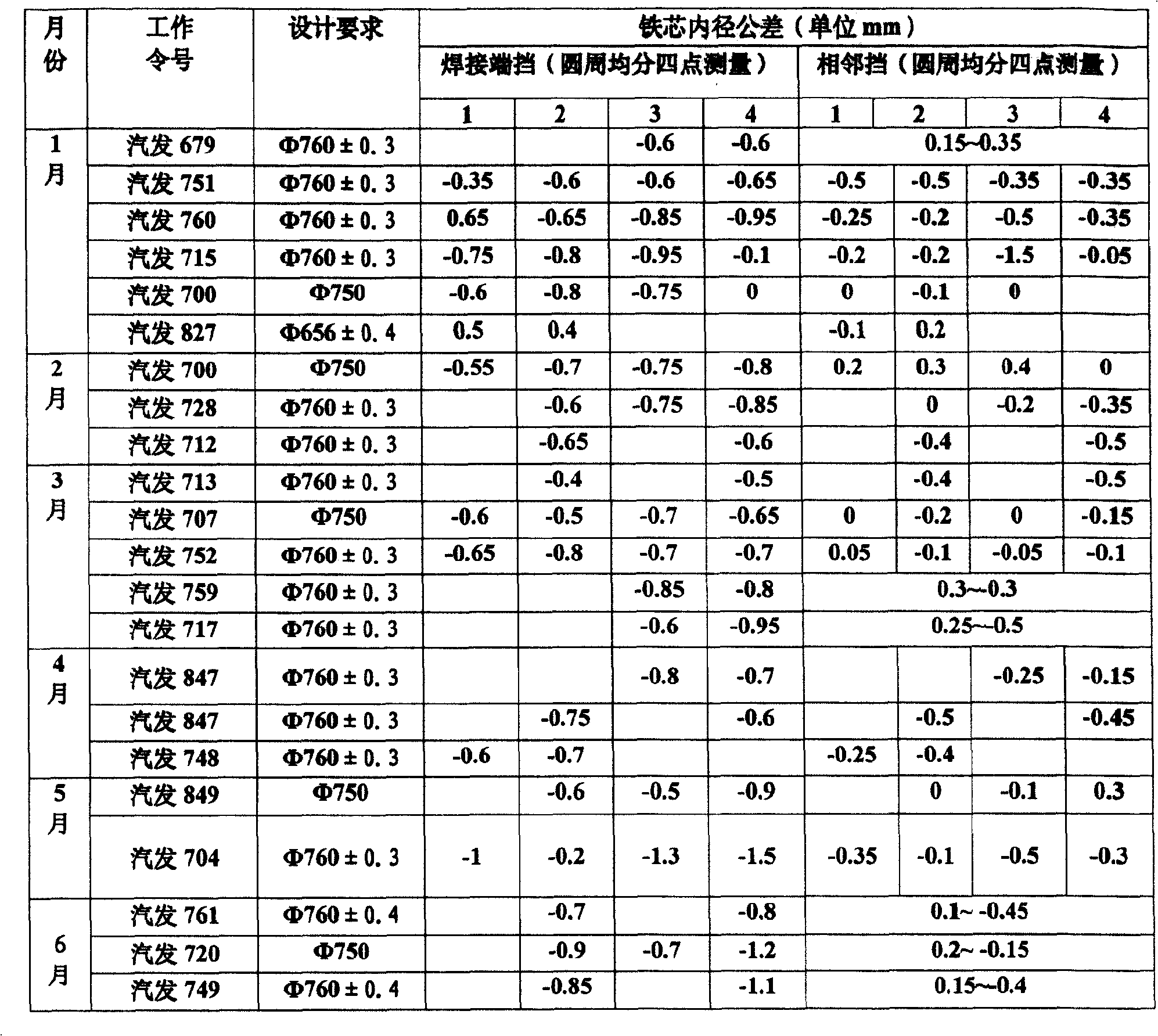

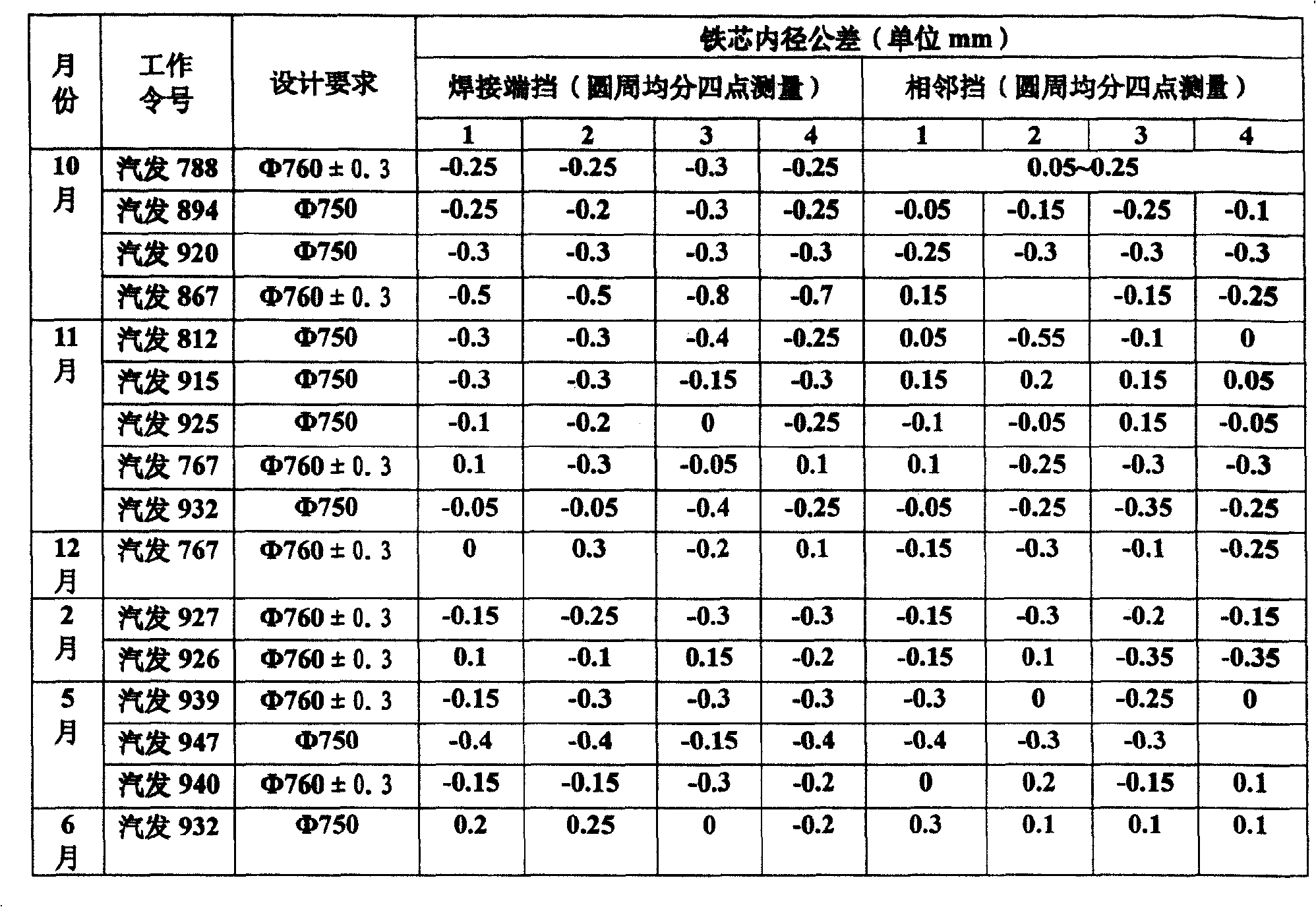

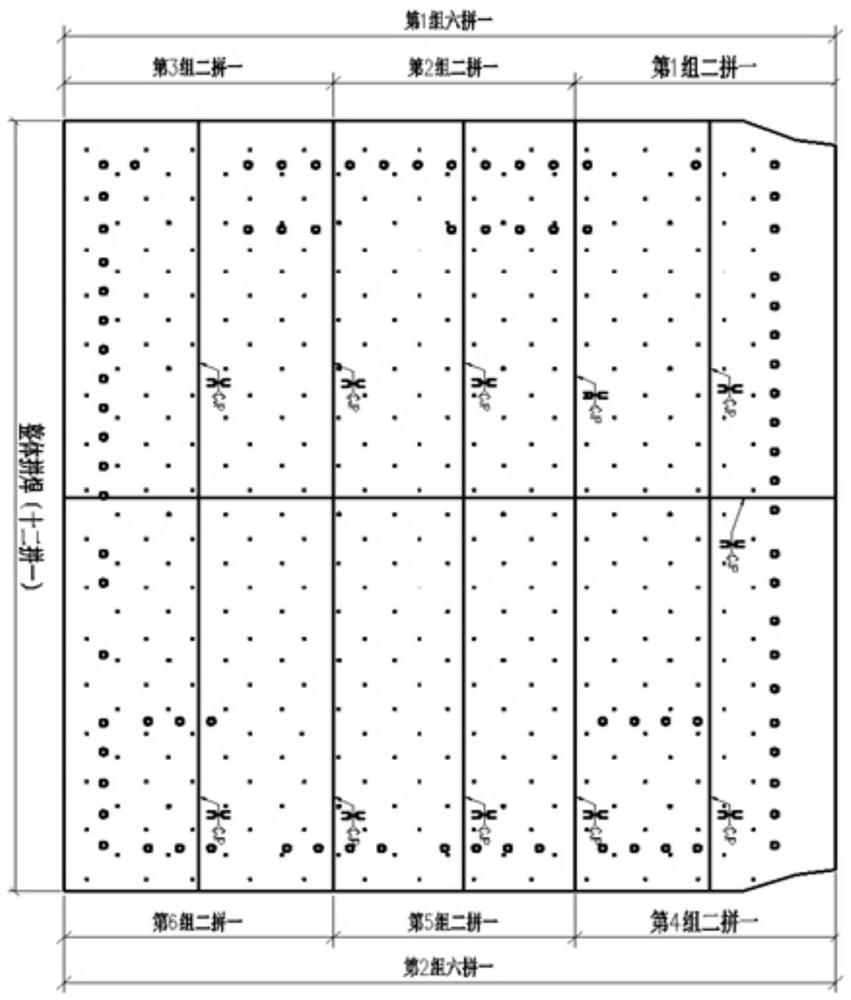

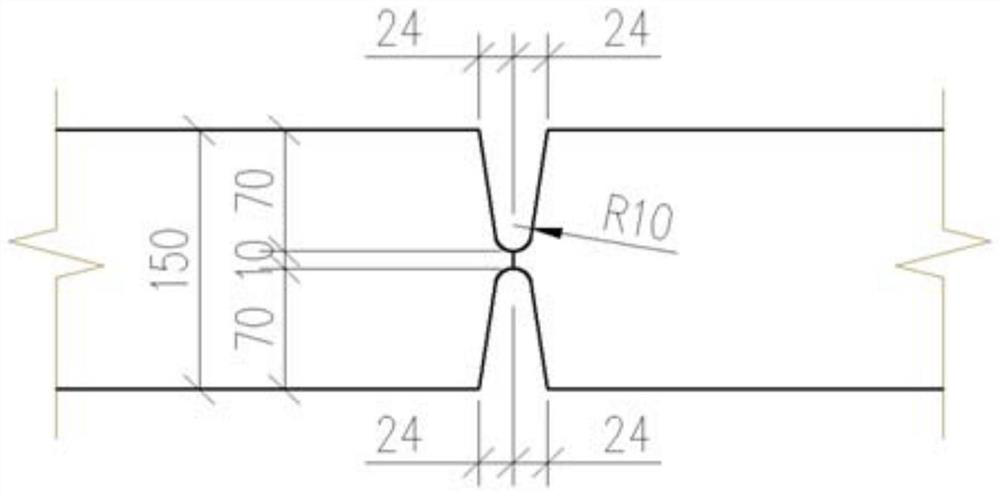

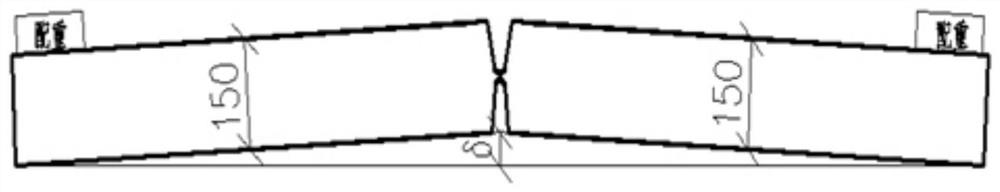

Steamer generator stator core welding deformation controlling means

InactiveCN100441356CEffective control of welding deformationEffective control of welding deformation controlArc welding apparatusWelding/cutting media/materialsTurbineWelding deformation

The invention relates to a stator iron core welding deformation control method of turbine generator. Wherein, it selects best welding technique, material and parameters, uses three-segment symmetry multilayer welding method, to control the welding deformation to confirm the stator iron core quality and confirm the safety of generator.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

A control method for welding deformation of large-size super-thick bridge steel tower pressure-bearing plate

ActiveCN110524129BEffective control of welding deformationControl welding deformationWelding apparatusButt weldingPre deformation

A method for controlling welding deformation of a large-size super-thick bridge steel tower pressure plate, comprising the following steps: (1) According to the principle of the shortest length of butt welds, the pressure plate is divided into five longitudinal welds and one transverse weld It is a splicing unit of 12 pieces; (2) Design the form of the weld groove as a double-sided symmetrical U-shaped groove, so that the amount of welding on both sides is basically equal, and the tendency of welding deformation to one side is reduced; (3) Reasonable design of the assembly sequence , and use the gas shielded welding bottoming and submerged arc automatic welding filling process welding to reduce the influence of welding on deformation; (4) use pre-deformation to set a reasonable welding pre-deformation before welding to reduce the influence of welding on deformation; (5) ) Flip along the direction of the weld seam when turning over during welding to prevent elastic-plastic deformation from enlarging the welding deformation. The invention greatly reduces the welding deformation of the thick plate and reduces the follow-up correction amount. The mechanical properties of the steel are ensured to the greatest extent. The construction efficiency is improved and the construction period is shortened.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

A retractable inner support tooling

ActiveCN109366052BGuaranteed roundnessImplement rigid constraintsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

A kind of compressor stator blade assembly replacement blade repair method

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

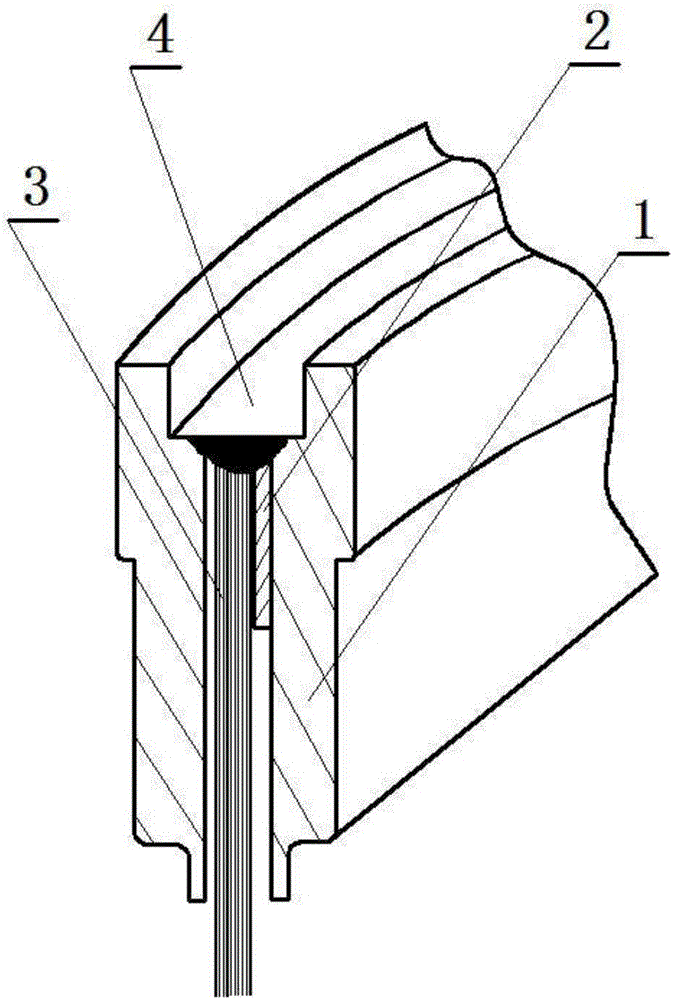

Novel industrial type gas turbine brush gas seal and manufacturing method thereof

InactiveCN106677835AHigh strengthAvoid assembly difficultiesLeakage preventionMachines/enginesEngineeringGas turbines

A novel industrial type gas turbine brush gas seal is formed in the manner that two symmetrical pressure bearing plates in upright ring shapes are welded at the top ends; brush wire bundles which are closely and evenly arranged are arranged in the middles of each pressure bearing plate body; a sunken cooling groove body is formed in the top end of each pressure bearing plate body; and a flow guiding piece is arranged on one side of the upper portion of the middle of each pressure bearing plate body. The novel industrial type gas turbine brush gas seal effectively reduces the production cost of manufacturers; and because the manner that the brush wire bundles, the pressure bearing plates and the flow guiding pieces are welded as a whole is adopted, the welding deformation of the brush gas seal caused when a welding part is too thin in the welding process is effectively controlled, and meanwhile, the overall strength of the brush gas seal is improved; cooling grooves formed in the pressure bearing plates guarantee the welding convenience, the problem that a sealing piece deforms and loses efficacy due to high temperature can be prevented, and therefore the service life of the sealing piece is prolonged; and meanwhile, the problem that secondary machining is needed because part assembling is difficult is avoided, and machining work procedures are reduced.

Owner:江苏透平电力技术有限公司

Method for controlling welding deformation between seal head and skirt transition section

ActiveCN103128459BReduce surfacing areaSave man hoursWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringWelding deformation

The invention provides a method for controlling welding deformation between a seal head and a skirt transition section. The method includes welding a processing pad above a position, used for assembling the skirt transition section according to design, of the outer wall of the seal head; welding the skirt transition section at the bottom of the processing pad, and performing bead weld between the inner side surface of the skirt transition section and the seal head; removing the processing pad; and performing girth welding on the seal head and a barrel, and performing bead weld between the upper surface of the skirt transition section and the seal head. The method overcomes defects of the prior art; the welding deformation between the seal head and the skirt transition section can be effectively controlled; welding quality is guaranteed while welding materials are saved; and meanwhile, miss-match of welding joints can be guaranteed during assembling of the seal head and the barrel, and product quality is greatly improved.

Owner:SHANGHAI BOILER WORKS

A method of manufacturing a high-strength silo fence structure

ActiveCN108857117BReduce welding distortionControl welding deformationWelding/soldering/cutting articlesWelding apparatusWelding deformationStructural component

Owner:WUHAN MARINE MACHINERY PLANT

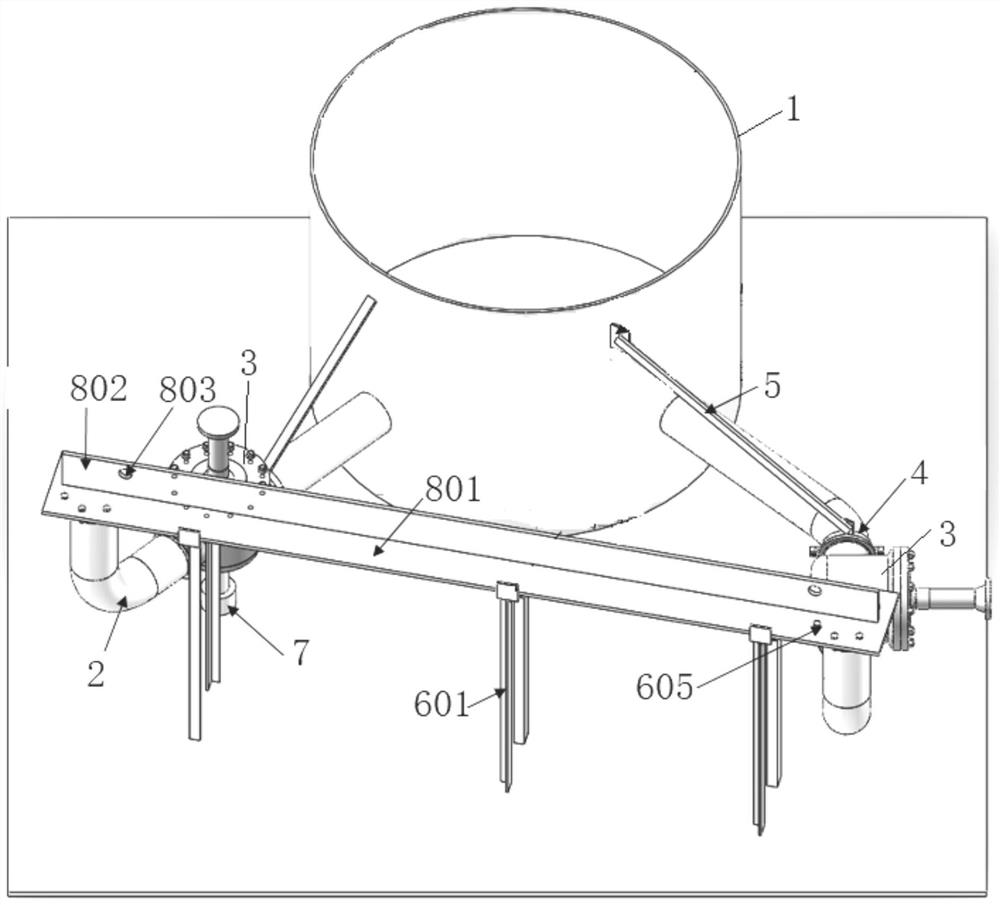

LNG (liquefied natural gas) ship gas dome safety valve pipe accessory assembling and positioning tool

ActiveCN113944875AAccurate and convenient positioningReduce the height and adjust the levelVessel mounting detailsVessel manufacturingMarine engineeringSafety valve

The utility model relates to an LNG ship gas dome safety valve pipe accessory assembling and positioning tool. The tool is characterized in that a safety valve pipe accessory comprises a first end and a second end, the first end of the safety valve pipe accessory is connected with a gas dome through a first flange, and the second end of the safety valve pipe accessory is connected with a ventilation mast pipe accessory of a liquid cargo tank through a second flange; and the positioning tool comprises a tool panel, wherein a first through hole matched with a bolt hole of the second flange is formed in the tool panel; and a supporting assembly used for supporting the tool panel. Through the simple and convenient design scheme and low manufacturing cost, a manufacturer can conveniently and effectively assemble, position and weld by using the tool, so that the assembling and positioning error is reduced, the welding deformation is reduced, the potential safety hazard is eliminated, and the product quality is improved.

Owner:SHANGHAI DONGDING STEEL STRUCTURE

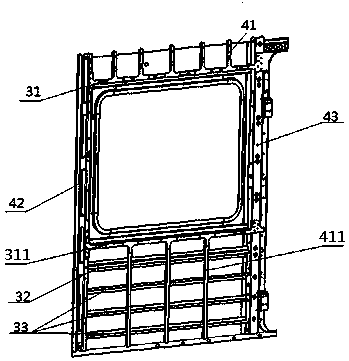

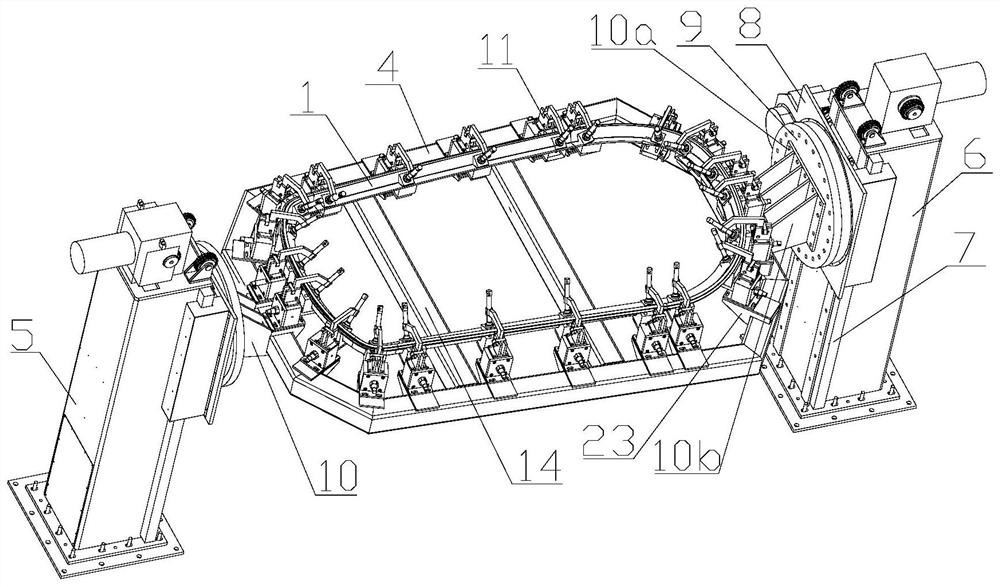

The welding device and process of the front window frame of the driver's cab and the welding process of the frame of the driver's cab

ActiveCN111230361BReduce contour distortionGuaranteed standard assemblyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a driver's cab front window frame welding device and process and a driver's cab frame welding process, including a welding platform on which the front window frame is placed, and several rigid restraint devices are arranged on the welding platform. The constraint device compresses and positions the front window frame, and sets the amount of anti-deformation for each constraint position of the front window frame through the rigid constraint device. The invention adopts a modular design concept and adjusts the amount of anti-deformation at different positions of the front window frame in a targeted manner before welding, so as to effectively control welding deformation, improve welding precision, and ensure the quality of finished products after welding. Improve work efficiency and save production cost.

Owner:CRRC QINGDAO SIFANG CO LTD

An ultra-large and ultra-wide double-combined I-shaped steel beam and its segmented installation method

Owner:JIANGSU HUNING STEEL MECHANISM

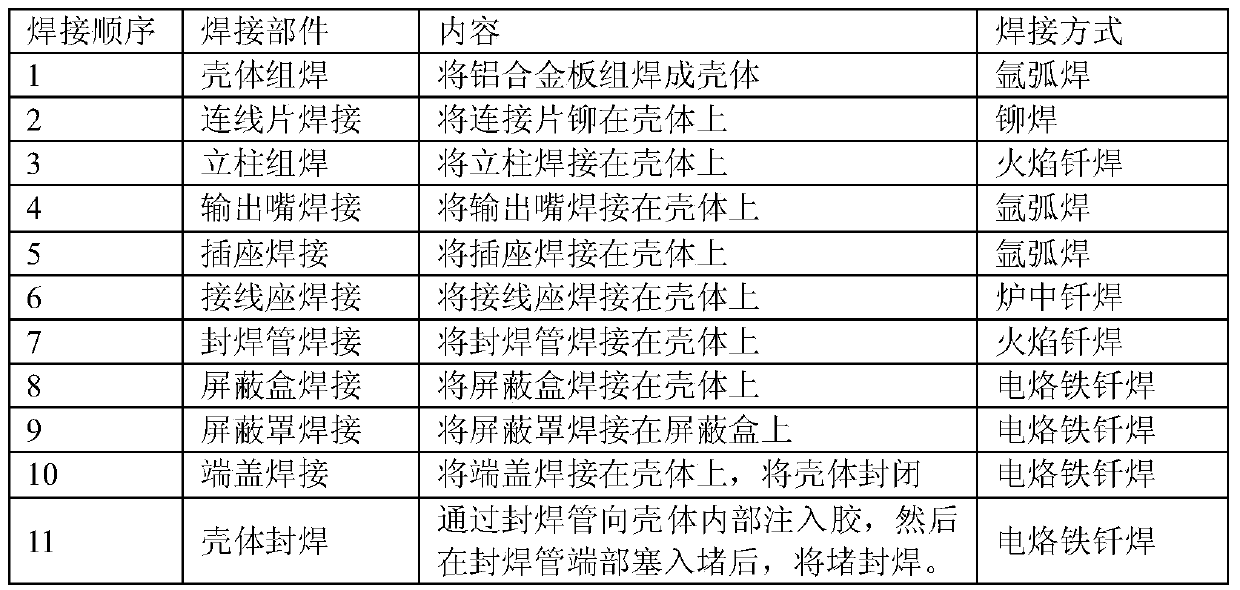

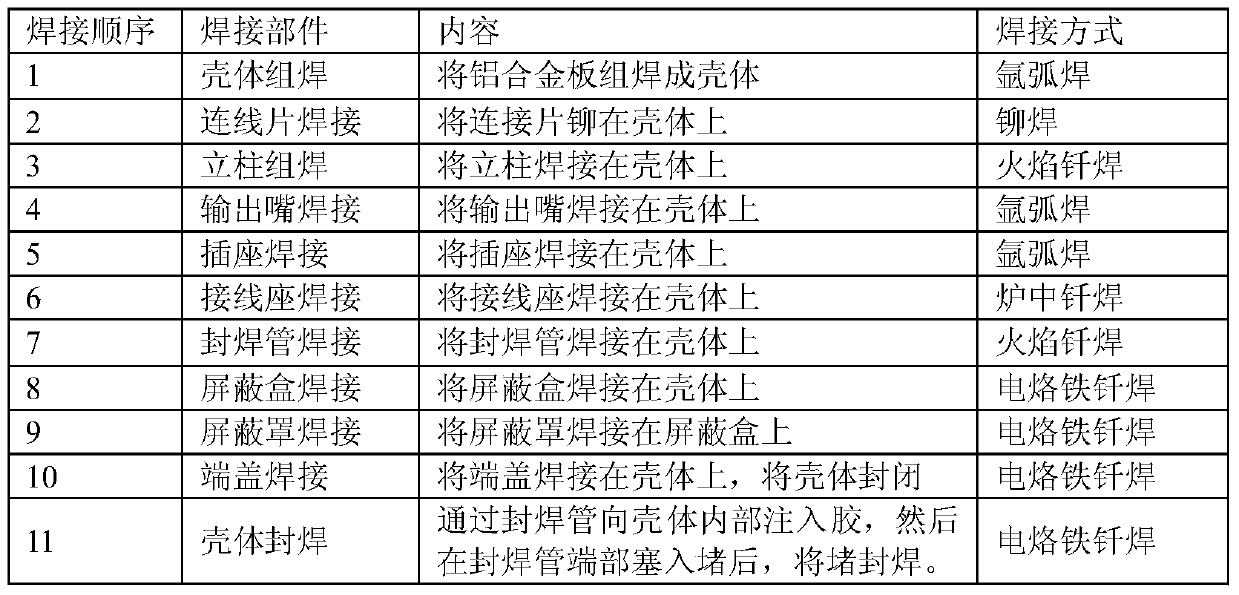

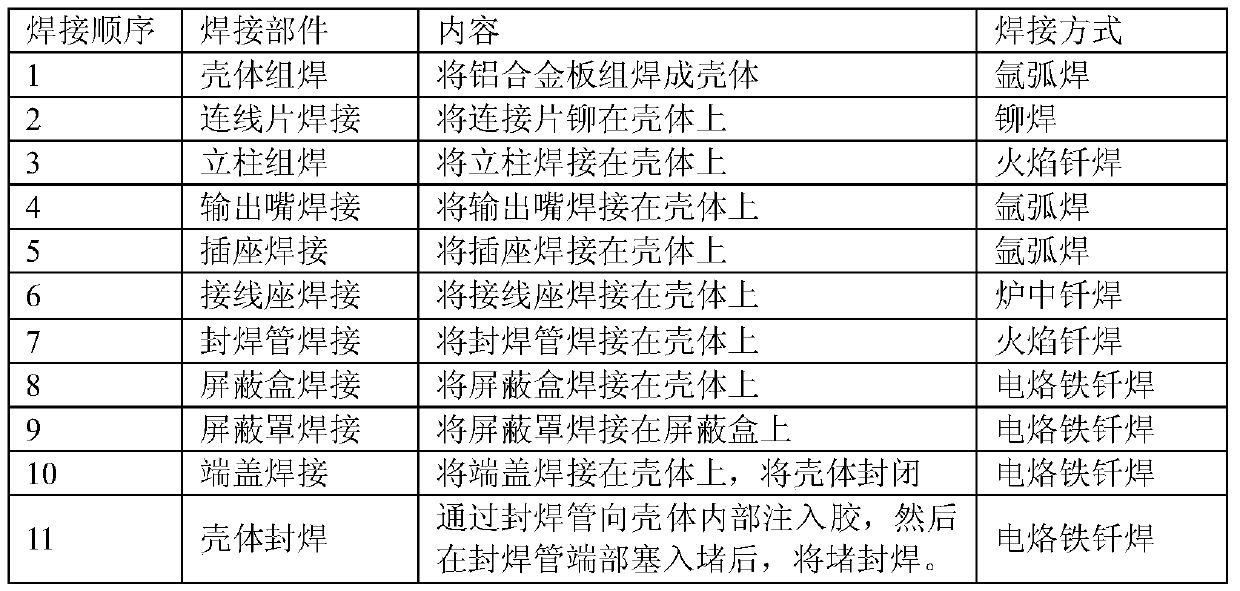

Welding method of aero-engine high-energy ignition device

InactiveCN103737137BAvoid generatingGuaranteed wettingSoldering apparatusLiquid/solution decomposition chemical coatingHigh energyIgnition coil

The invention relates to a welding method for a high-energy ignition device of an aero-engine. Chemical nickel-plating is conducted on the surface of an aluminium alloy part, wetting and combining of brazing filler metal and base metal are guaranteed, and it is guaranteed that welding can be conducted effectively. Multiple kinds of welding modes are combined, so that the difficult problems that operation space is small, and welding can not be conducted are solved, the shielding performance of the high-energy ignition device is guaranteed, welding deformation of aluminium alloy thin sheets is effectively controlled, operation can be conducted in narrow space conveniently, and it is guaranteed that a high-energy ignition coil is not burnt in the welding process. The difficult problem of aluminium tin soldering and brazing is well solved, and the special requirement for electromagnetic shielding of the high-energy ignition device can be met.

Owner:哈尔滨东安高精管轴制造有限公司

Manufacturing method of fence structural component of high-strength launching silo

ActiveCN108857117AReduce welding distortionSolve the narrow welding operation spaceWelding/soldering/cutting articlesWelding apparatusEngineeringStructural component

The invention discloses a manufacturing method of a fence structural component of a high-strength launching silo. The manufacturing method comprises the steps that firstly, a first anti-deformation supporting tool and a second anti-deformation supporting tool are welded along the inner wall of a barrel; then a buffer bracket is correspondingly assembled on one side of the barrel and a releasing-tensioning device mounting seat is correspondingly assembled on the other side of the barrel; channel steel tools are arranged on the outer sides of the buffer bracket and the releasing-tensioning device mounting seat; the buffer bracket and the releasing-tensioning device mounting seat and the barrel are welded; then a guide cylinder mounting seat, a bearing pedestal mounting seat plate, a buffer bracket web plate and various types of rib plates are sequentially welded and locked; subsequently, a cover-opened-in-place stop block is welded and a guide cylinder mounting panel is locked sequentially; and finally the first anti-deformation supporting tool and the second anti-deformation supporting tool are cut out and the inner circle of the barrel is subjected to overlay welding. Through the design, welding deformation of the fence structural component can be effectively controlled and the welding accessibility is ensured.

Owner:WUHAN MARINE MACHINERY PLANT

A cladding installation method and welding process of duplex stainless steel pool in nuclear power plant

ActiveCN107511559BImprove construction efficiencyEffective control of welding deformationArc welding apparatusNuclear powerStructural engineering

The invention discloses a surface-covered mounting method for a dual-phase stainless steel water tank of a nuclear power station and a welding process, and belongs to the technical field of nuclear power station building. Wall surface covering adopts modularized manufacturing and mounting, and a reasonable wall surface-covered mounting sequence, so that mounting deformation of a surface-covered plate of the stainless steel water tank is reduced, and efficiency is improved; bottom plate surface-covering is performed after a wall surface is covered and is put in place, a bottom plate is fixed through rigidity of a pre-embedded plate, and a reasonable welding process sequence is adopted, so that effective control on bottom plate welding deformation can be realized; in a water tank mounting and welding process, an FCAW automatic or semi-automatic welding process greatly improves construction efficiency, and the construction period is shortened. The mounting method for the dual-phase stainless steel water tank of THE nuclear power station and the FCAW automatic or semi-automatic welding process are suitable for surface-covered mounting of a large dual-phase stainless steel water tank of the nuclear power station and a medium-thickness steel plate with a similar structure.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

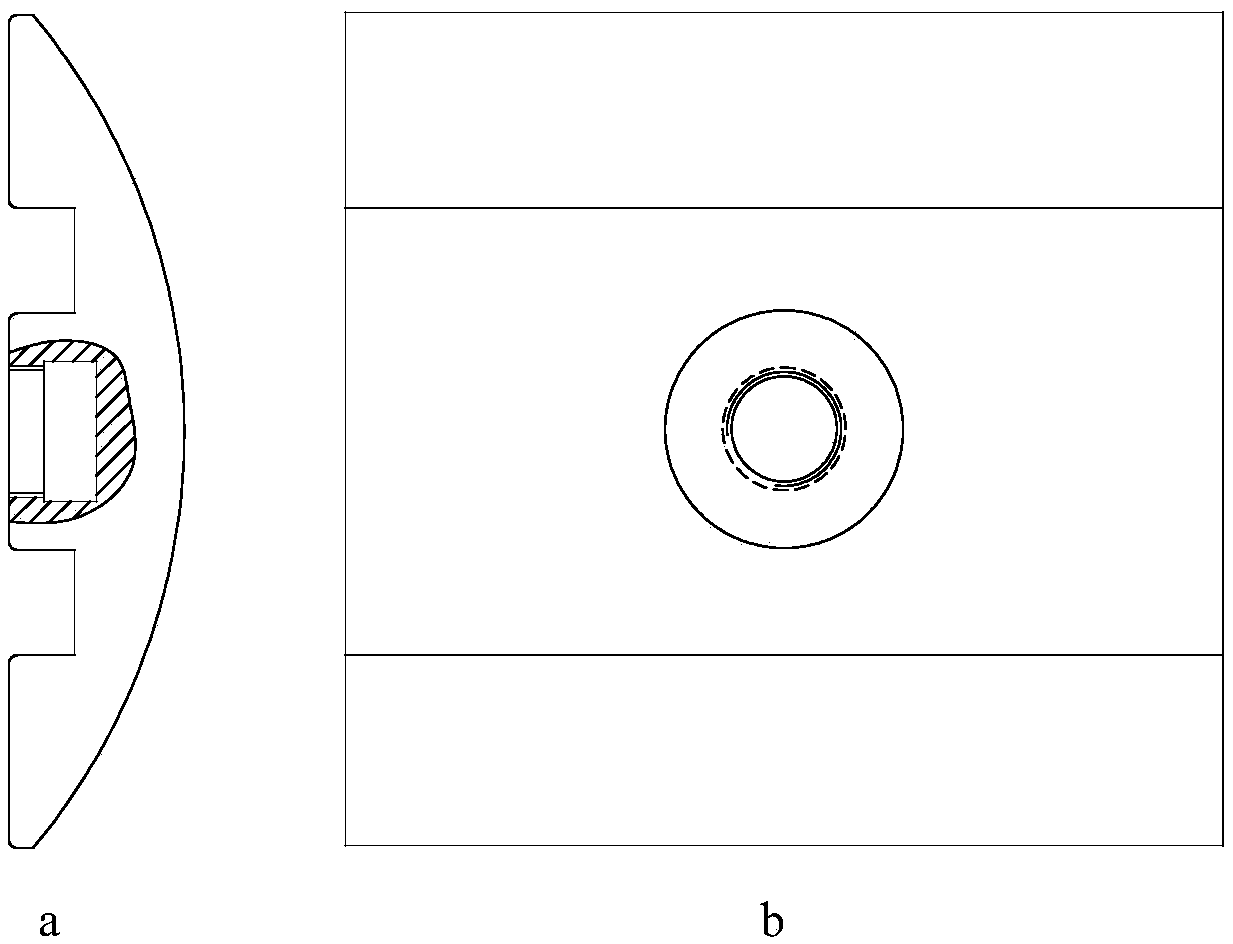

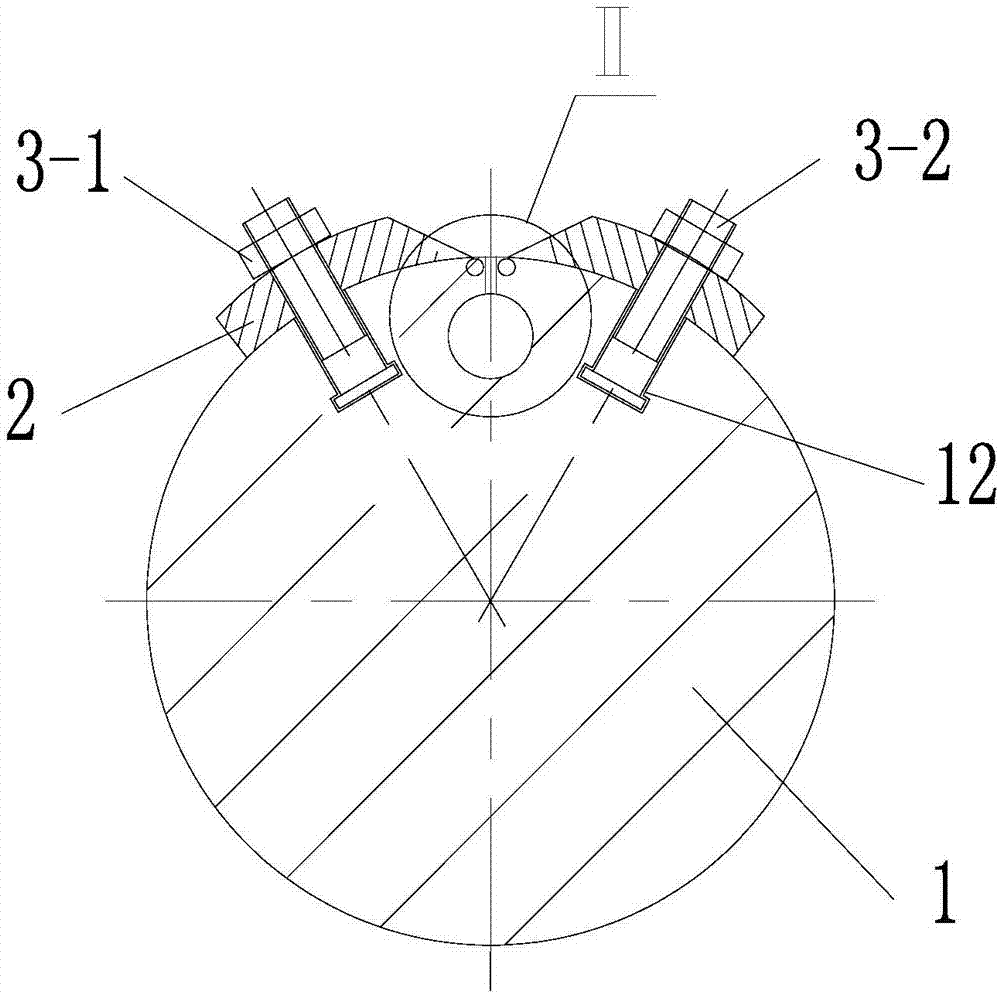

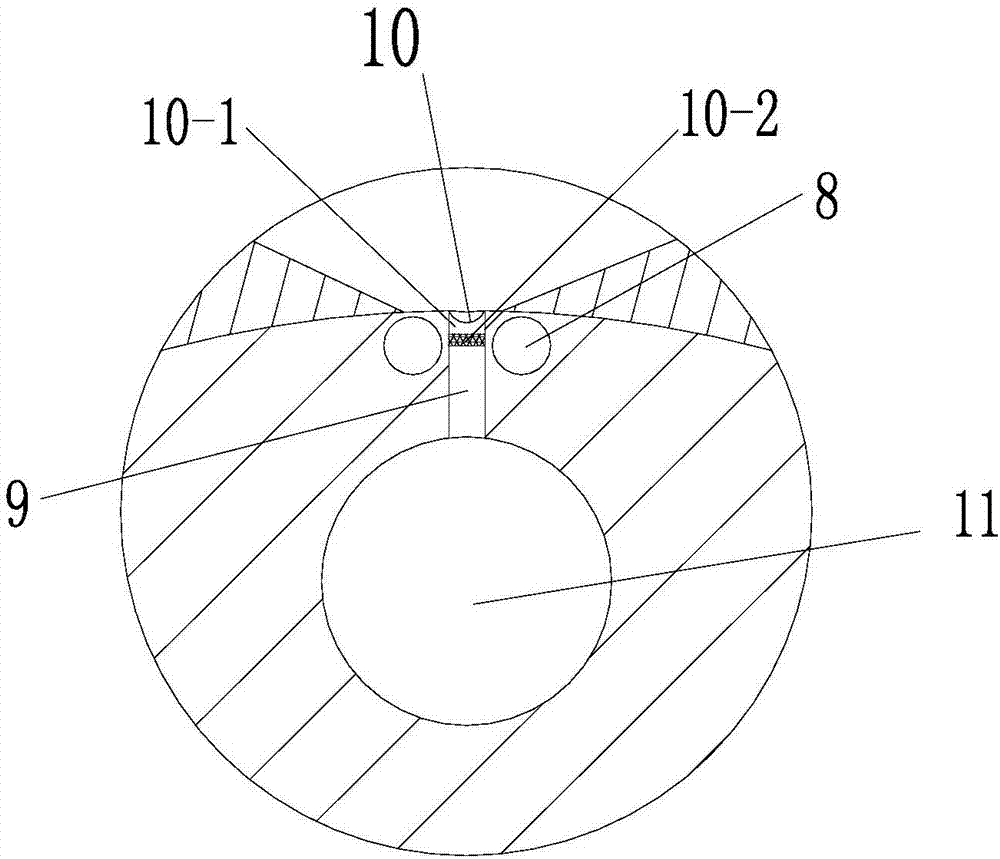

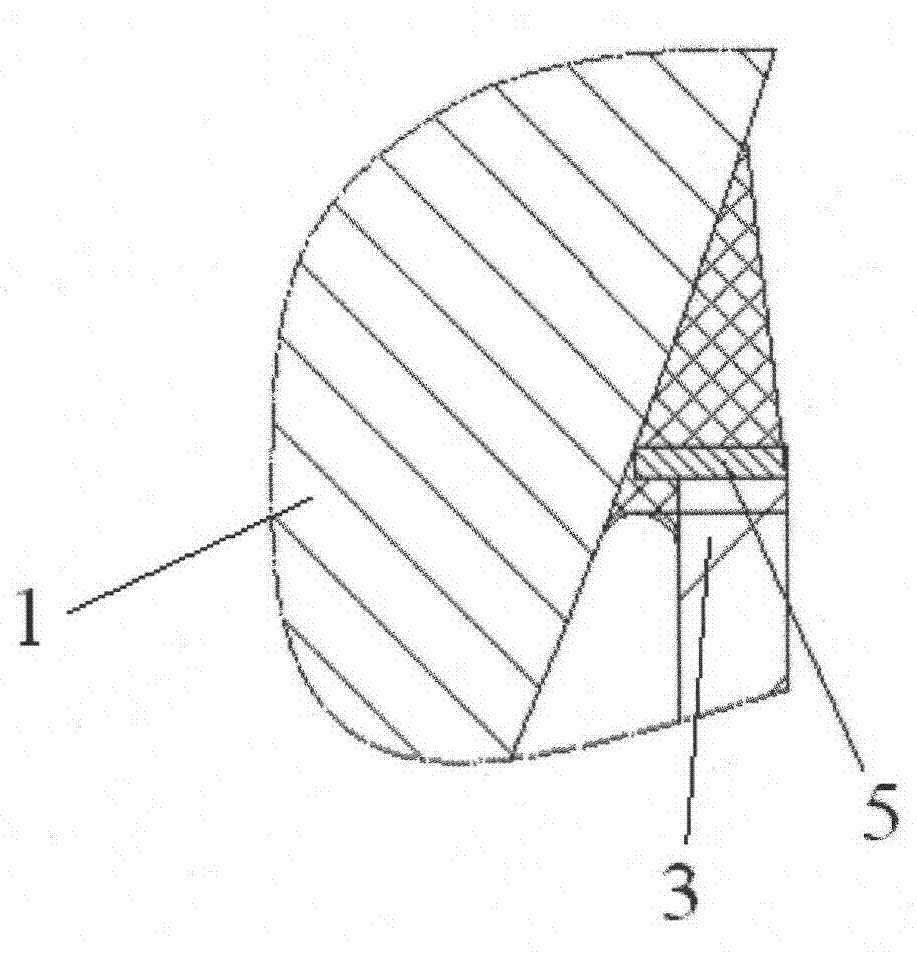

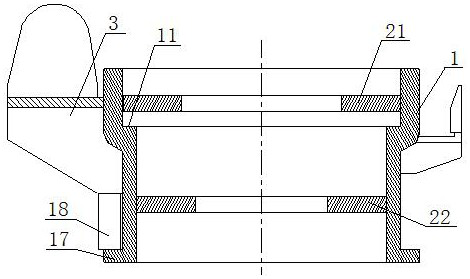

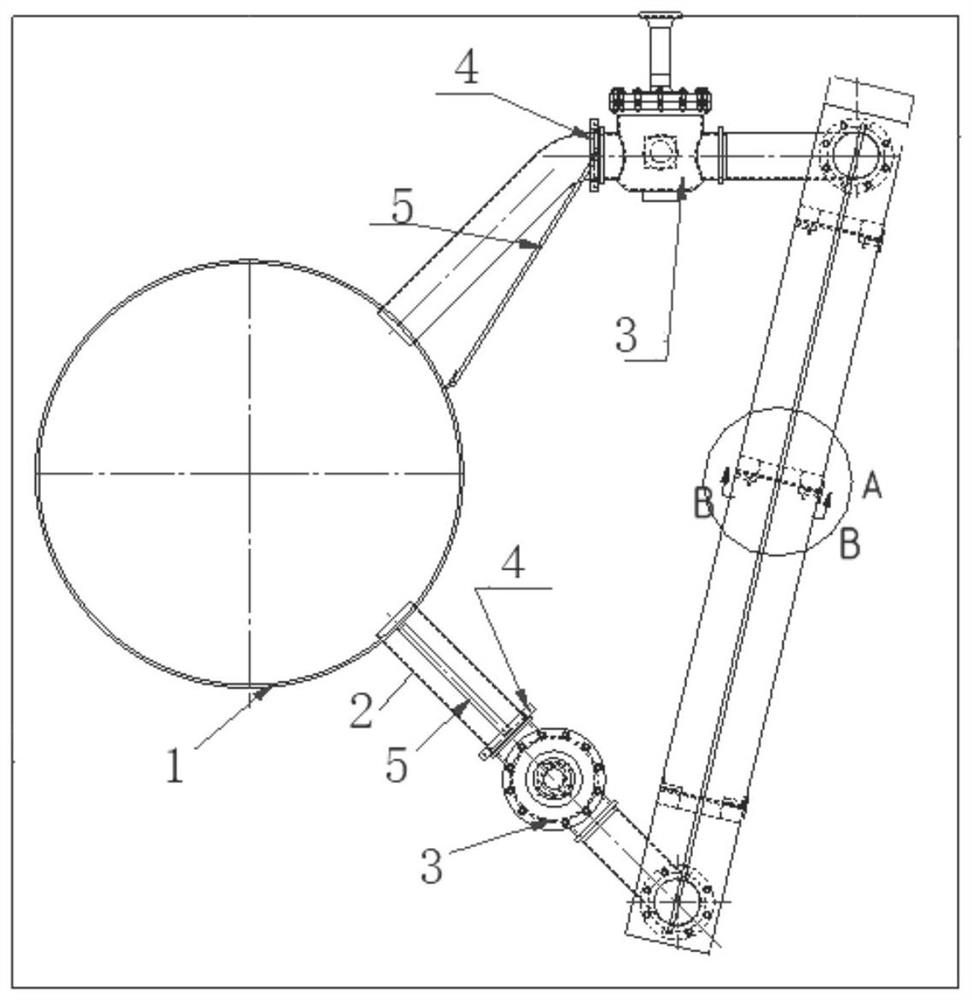

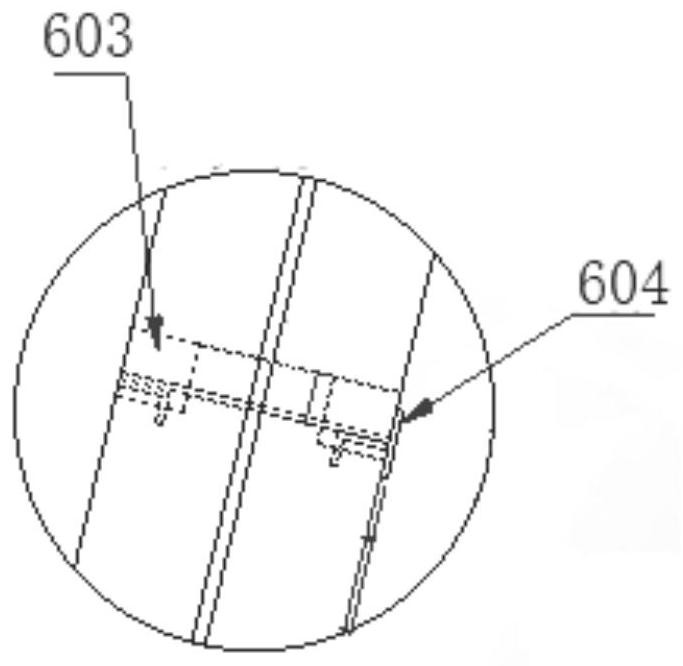

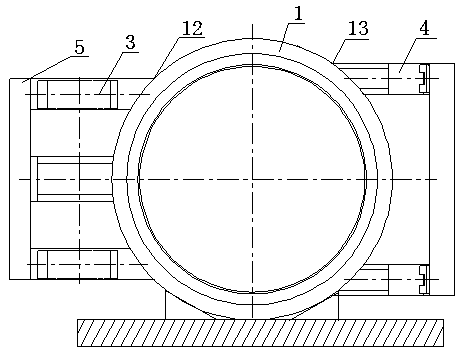

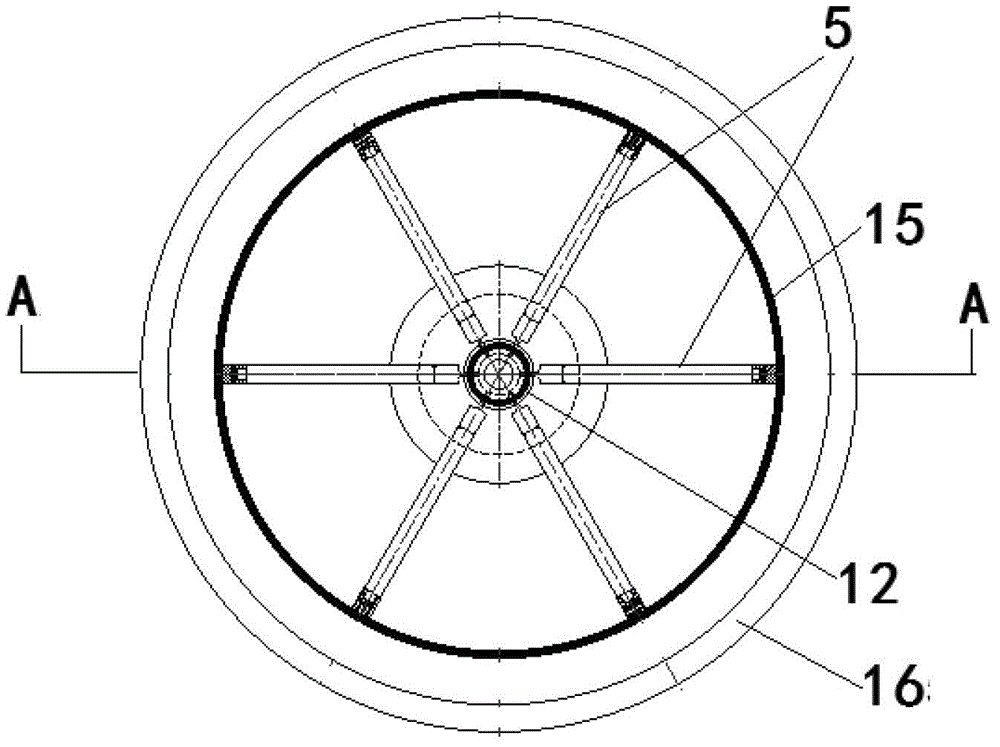

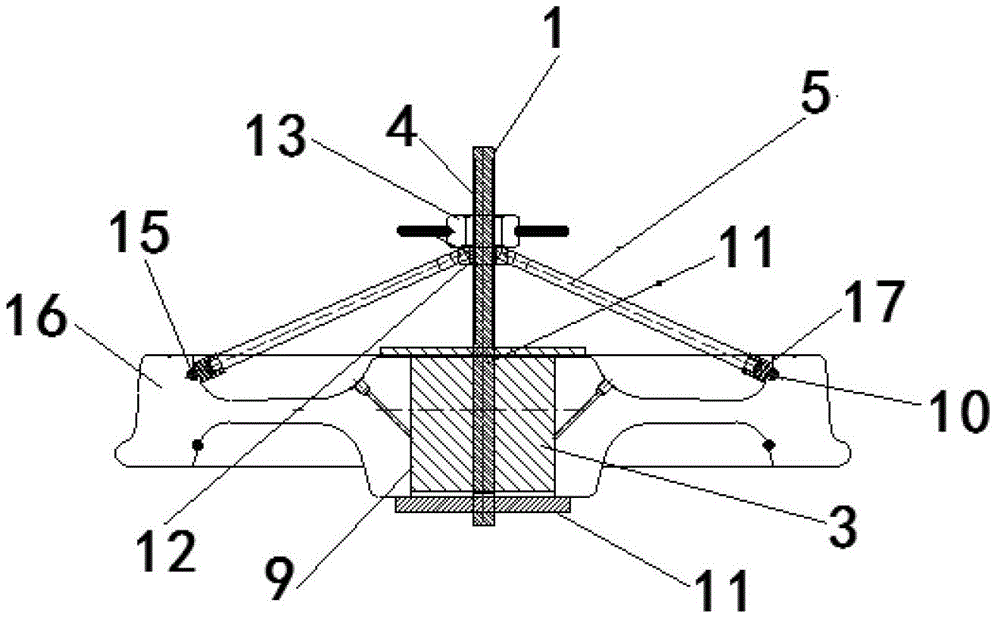

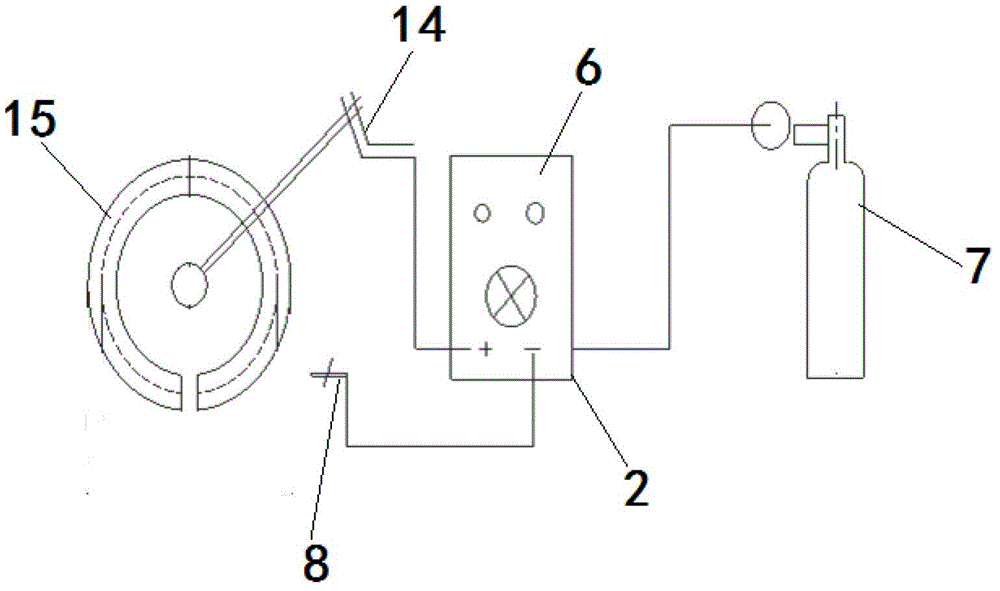

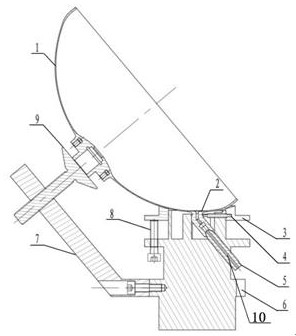

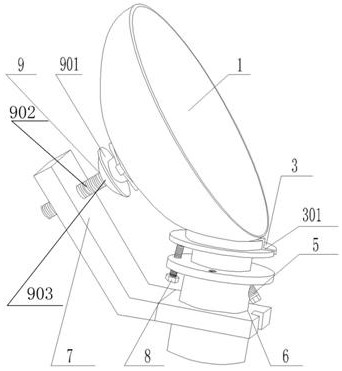

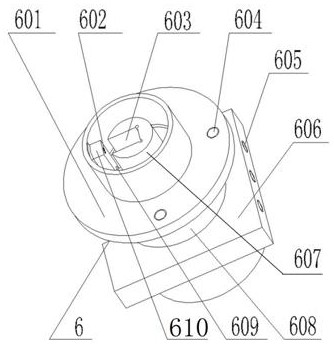

Welding device for wheel sound-absorbing ring

ActiveCN103357992BMeet the requirementsSimple structureWelding/cutting auxillary devicesArc welding apparatusUltrasound attenuationEngineering

The invention provides a welding device for a vehicle wheel sound attenuation ring, which can be applied in the technical field of vehicle wheel manufacturing and processing equipments. The welding device comprises a sound attenuation ring clamping tool (1) and a sound attenuation ring welding assembly (2), the sound attenuation ring clamping tool (1) comprises a pedestal (3), a screw rod (4) is movably connected with the pedestal (3), a plurality of support rods (5) are arranged on the screw rod (4), the pedestal (3) adopts a structure that can be clamped and mounted in the middle hole (9) of the vehicle wheel (16), when the pedestal (3) is clamped and mounted in the middle hole (9), the support rods are designed into a structure that can support a sound attenuation groove (10), the sound attenuation ring welding assembly (2) comprises a welding machine (6), the welding machine (6) is connected with a argon gas bomb (7), and a welding gun (8) is connected with the welding machine (6). The device provided by the invention has a simple structure, can accomplish the welding of a sound attenuation ring in the vehicle wheel sound attenuation groove conveniently and fast, and guarantees welding quality as well.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

An automatic spin welding device

ActiveCN113500274BAchieving tightnessAchieve positioningShielding gas supply/evacuation devicesShielding gasEngineering

The invention discloses an automatic rotary welding device, which comprises an automatic rotary bracket, a positioning device, a sealing device and a supporting device. The supporting device is set; the upper part of the automatic rotating bracket is provided with a welding cavity, and the nozzle is fixed in the welding cavity, and the positioning device is connected with the nozzle through the welding cavity; the top of the welding cavity is connected with the sealing device, and the shell that is welded with the nozzle is placed on the sealing device The contact position of the housing and the sealing device is sealed and connected by a seal; one end of the supporting device is connected to the lower part of the automatic rotating bracket, and the center of the bottom of the housing is located at the other end of the supporting device. The invention realizes the sealing of the welding cavity, ensures the filling of protective gas and the discharge of redundant air during the welding process, improves the quality of the weld seam, can effectively control the welding deformation, has simple operation, accurate welding positioning and high efficiency.

Owner:LIAONING METAL TECH

Assembly welding device, assembly welding method and Charismas tree guide frame

InactiveCN108526783AQuality assuranceFast Butt WeldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses an assembly welding device, an assembly welding method and a Charismas tree guide frame. The assembly welding device comprises three parts: a base part, a middle supporting assembly and a top supporting assembly, wherein the assembly welding device is of a split structure; the base part is separately arranged (is not connected with the middle supporting assembly and the topsupporting assembly); the top supporting assembly is fixedly connected to the upper part of the middle supporting assembly. After assembly welding of the Charismas tree guide frame is finished, the middle supporting assembly can be hoisted away from the top supporting assembly by simple detaching, and then the Charismas tree guide frame is hoisted away; the assembly welding process is convenientand quick, and complex detaching of a tooling is avoided, so that production cycle is shortened to a great degree and production efficiency is improved.

Owner:HIMILE MECHANICAL MFG

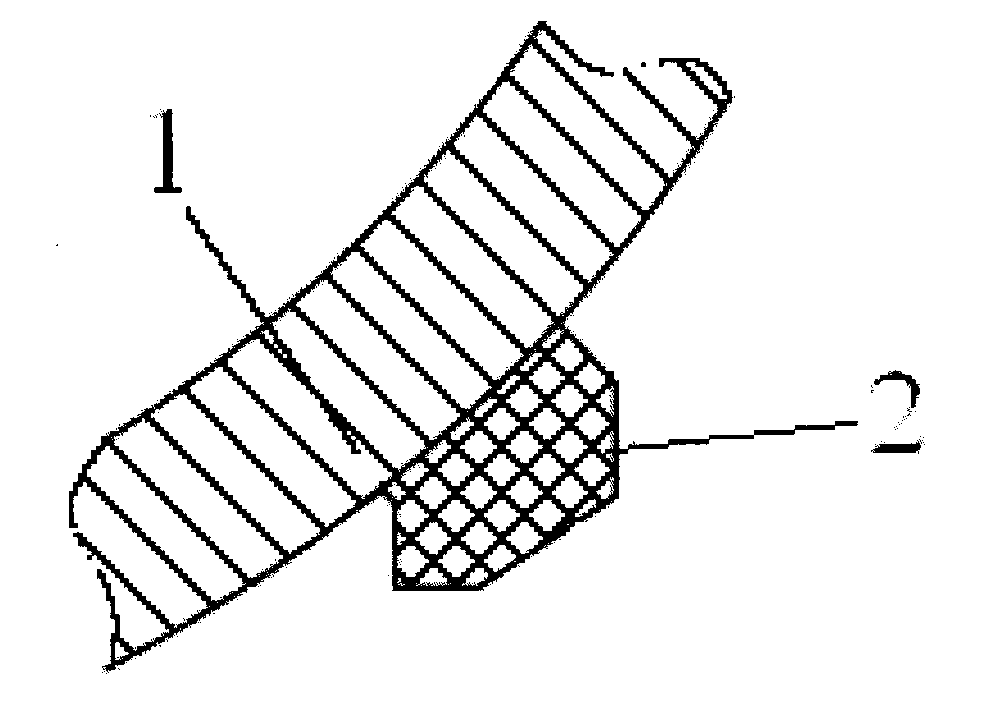

Welding tool for thin-wall case

PendingCN107498248ANot easy to shiftEffective control of welding deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding tool for a thin-wall case, relates to a welding device, in particular to the welding tool. The invention provides the welding tool for the thin-wall case, and the welding tool can effectively control welding deformation amount of the case, ensures welding precision of the case, is convenient to operate, and is high in efficiency. The welding tool comprises an upper clamping plate, a lower clamping plate, a plurality of upper clamping blocks and a plurality of lower clamping blocks, and further comprises a telescopic pole, wherein the upper clamping blocks are detachably connected on the end surface, which faces towards the lower clamping plate, of the upper clamping plate; the lower clamping blocks are detachably connected on the end surface, which faces towards the upper clamping plate, of the lower clamping plate; the upper clamping plate and the lower clamping plate are parallel and are oppositely arranged; one end of the telescopic pole is connected with the upper clamping plate; and the other end of the telescopic pole is connected with the lower clamping plate. The welding tool integrally has the advantages that welding deformation amount of the case is effectively controlled, welding precision of the case is guaranteed, and operation is convenient.

Owner:YANGZHOU HENGXING PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com