A kind of compressor stator blade assembly replacement blade repair method

A stator vane and repair method technology, which is applied in the field of aero-engine component repair, can solve the problems of large sealing plate locking, difficult removal, and oxide film in the hole, so as to control welding deformation, prevent deformation, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Faulty parts status:

[0031] The faulty parts are 4th to 6th stage stator vane assemblies of compressors, a total of 20 pieces. The blades are GH4169 alloy rolled parts, and the inner and outer rings are respectively GH600 alloy forgings or strips; the blades at both ends of the assembly and in the middle are damaged Or block defects, need to replace the blade repair, the number of replacement blades of the module is 2 or 3 pieces, and the faulty blades are not adjacent.

[0032] (2) Repair method, comprising the following steps:

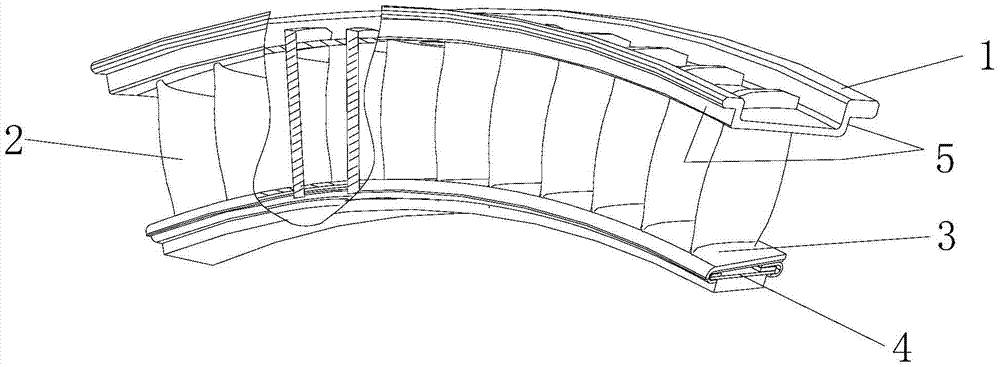

[0033] Step 1: Decompose and decompose the sealing board figure 1 The inner ring sealing plate shown specifically includes the following steps:

[0034] Step A: When the sealing plate with small locking degree is disassembled, place the assembly on the fixture, put the open end of the inner ring against the fixture, and clamp the inner and outer rings from both sides;

[0035] Step B: Press the sealing plate with a copper rod from the...

Embodiment 2

[0054] (1) Faulty parts status:

[0055] The faulty parts are 7th to 8th stage stator blade assemblies of compressors, a total of 15 pieces. The blades are GH4169 alloy rolled parts, and the inner and outer rings are respectively GH600 alloy forgings or strips; the blades at both ends of the assembly and in the middle are damaged Or block defects, need to replace the blade repair, the number of replacement blades of the module is 3 to 5 pieces, and there are 2 or 3 adjacent faulty blades.

[0056] (2) Repair method, comprising the following steps:

[0057] Step 1: Decompose and decompose the sealing board figure 1 The inner ring sealing plate shown specifically includes the following steps:

[0058] Step A: When the sealing plate with small locking degree is disassembled, place the assembly on the fixture, put the open end of the inner ring against the fixture, and clamp the inner and outer rings from both sides;

[0059] Step B: Press the sealing plate from the sealing end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com