Patents

Literature

36results about How to "Meet the requirements of design drawings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

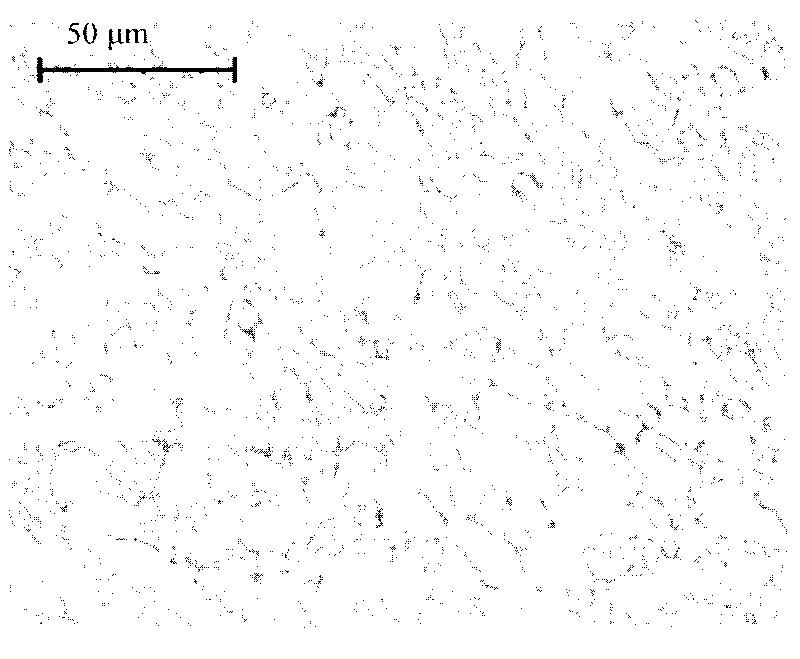

Method for restoring abrasion and deformation of spigot of thin-wall cartridge receiver

The invention relates to a method for restoring abrasion and deformation of a spigot of a thin-wall cartridge receiver. According to the technical scheme, the method for restoring the abrasion and the deformation of the spigot of the thin-wall cartridge receiver comprises the following steps: machining the abraded and deformed spigot of the thin-wall cartridge receiver, spraying a NiCrAl coating on the spigot and lathing the NiCrAl coating. According to the method for restoring the abrasion and the deformation of the spigot of the thin-wall cartridge receiver, the problem of restoring the failure of the spigot of the thin-wall cartridge receiver made from GH907 materials is solved, and meanwhile it is guaranteed that the cartridge receiver meets the requirements of design paper after being repaired. In this way, the service life of the cartridge receiver is prolonged so that the cartridge receiver can continue being used, and therefore production cost is saved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

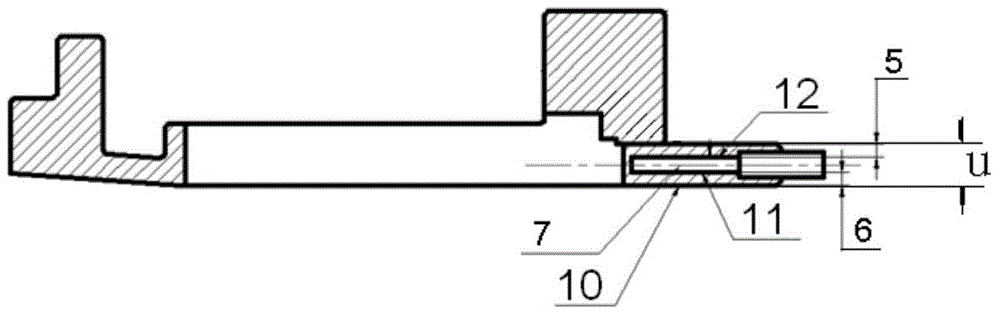

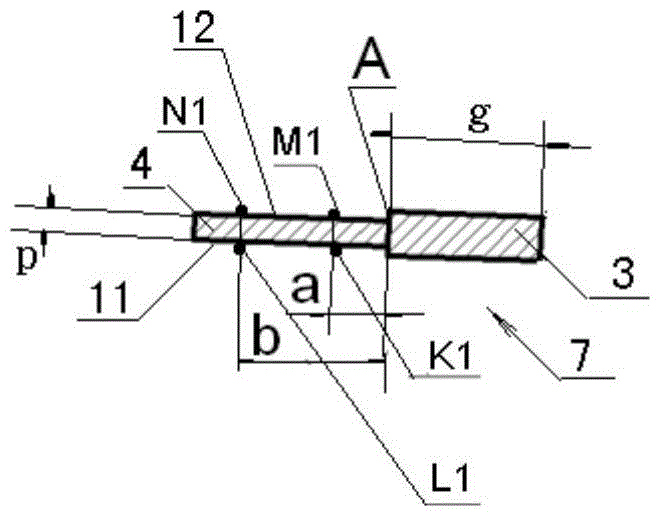

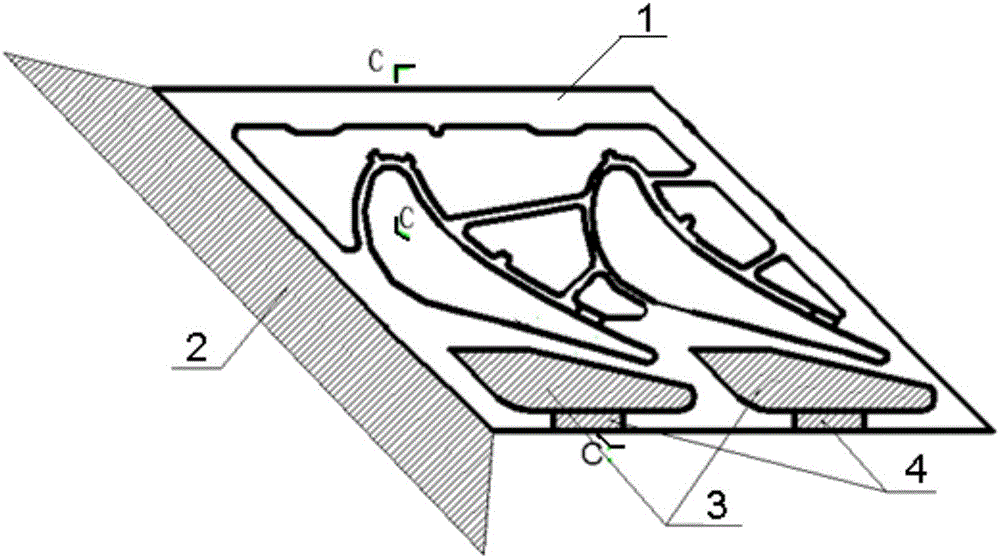

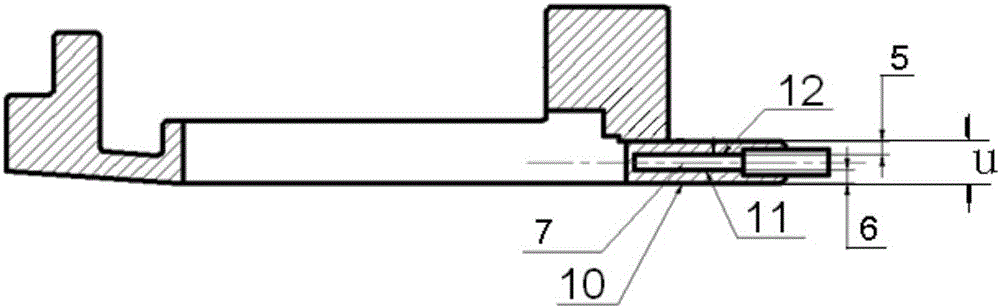

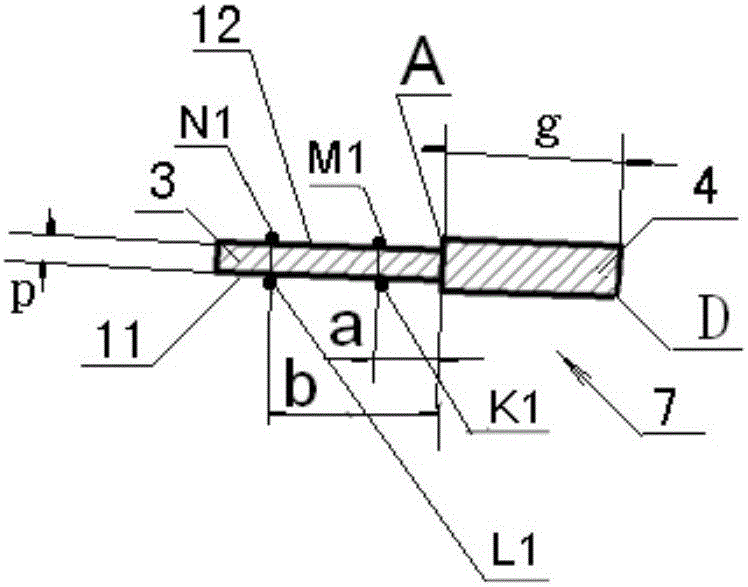

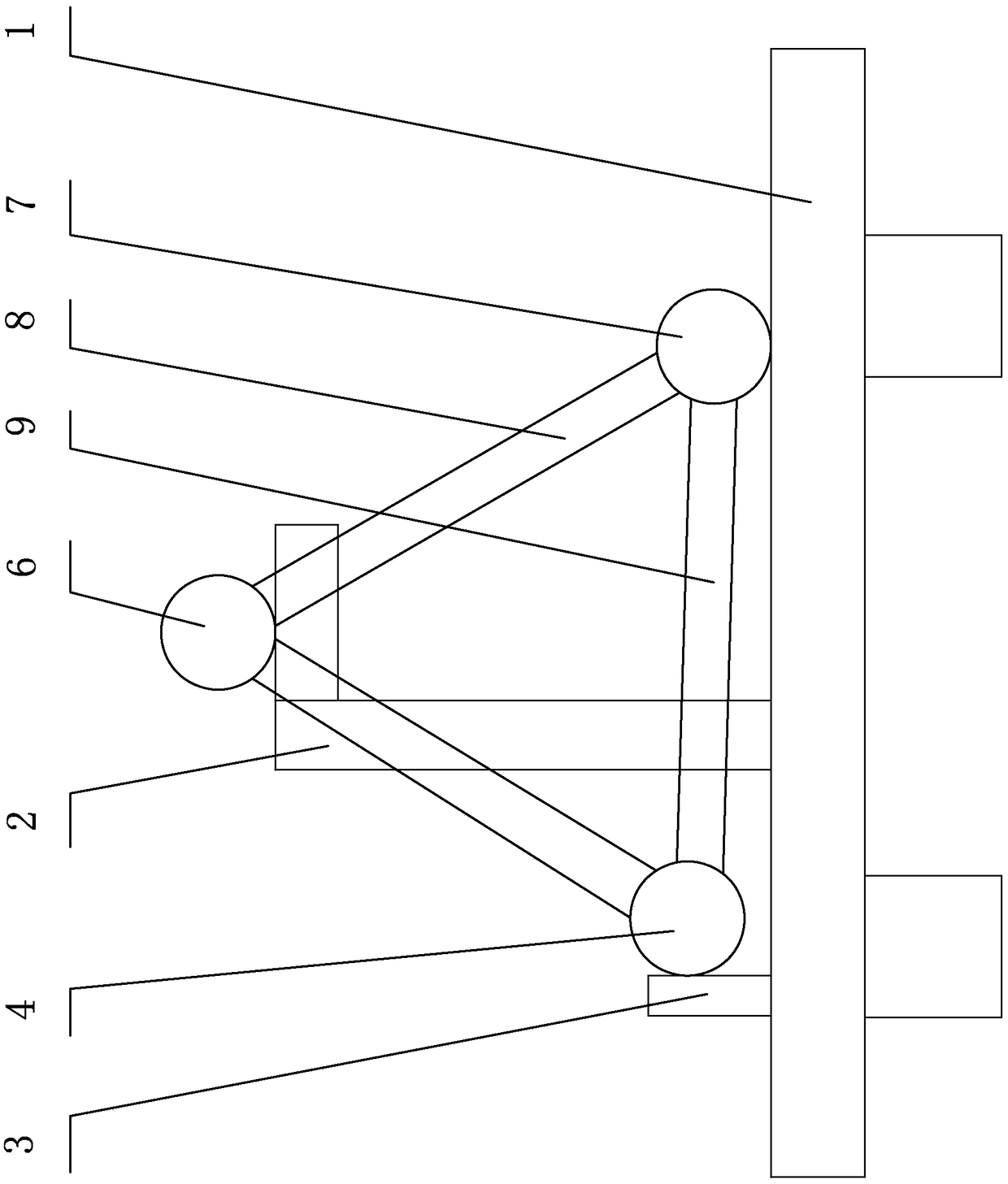

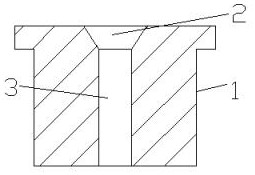

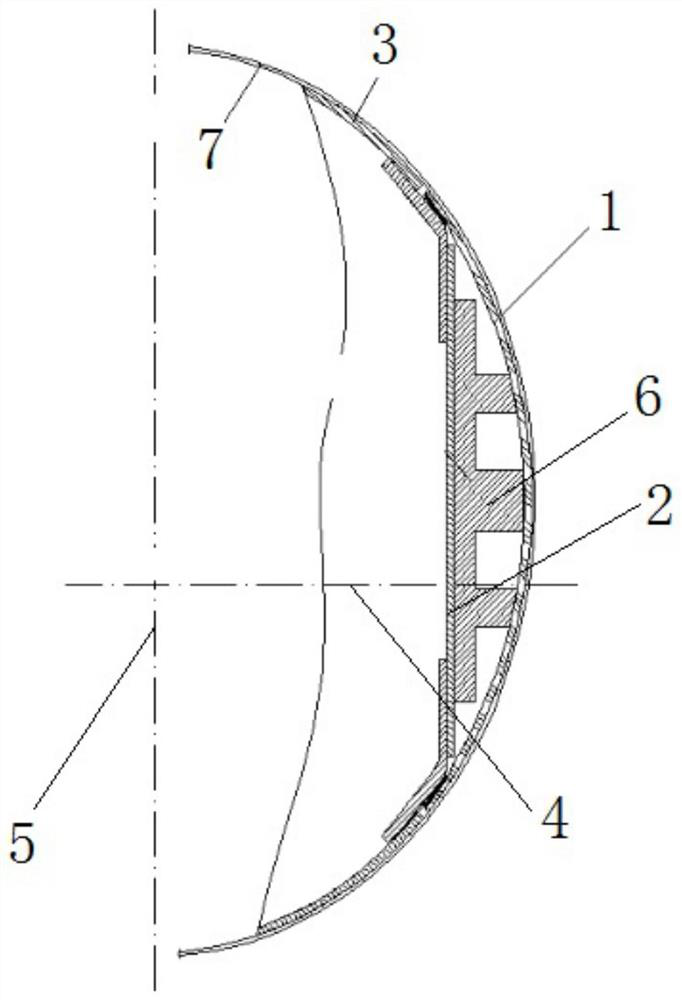

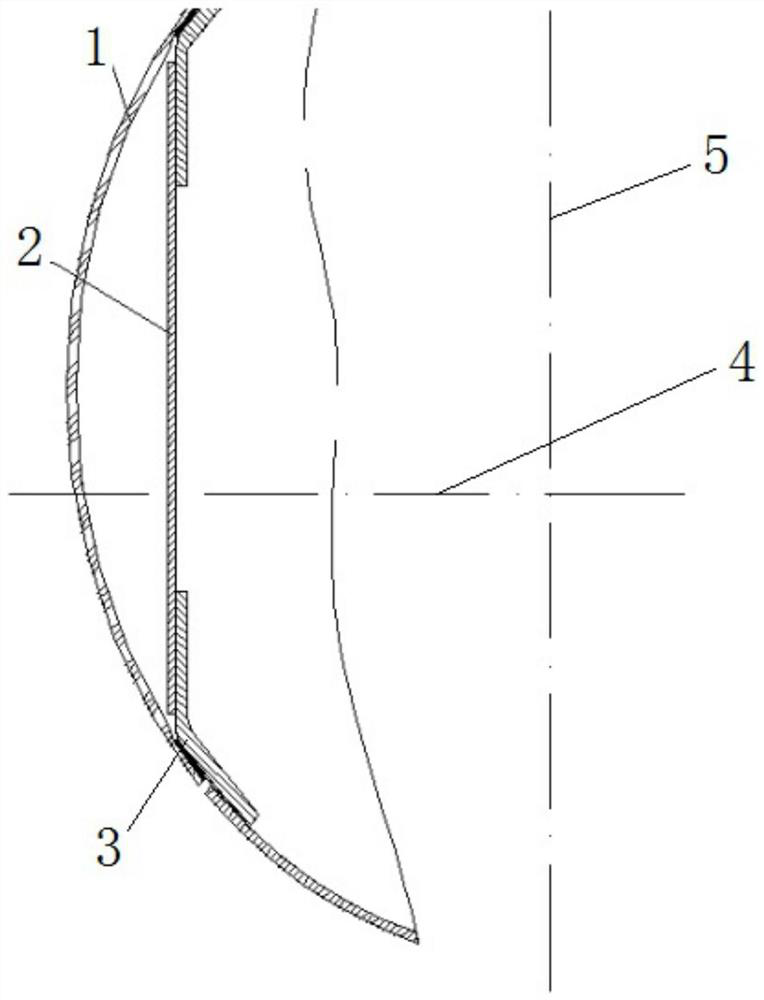

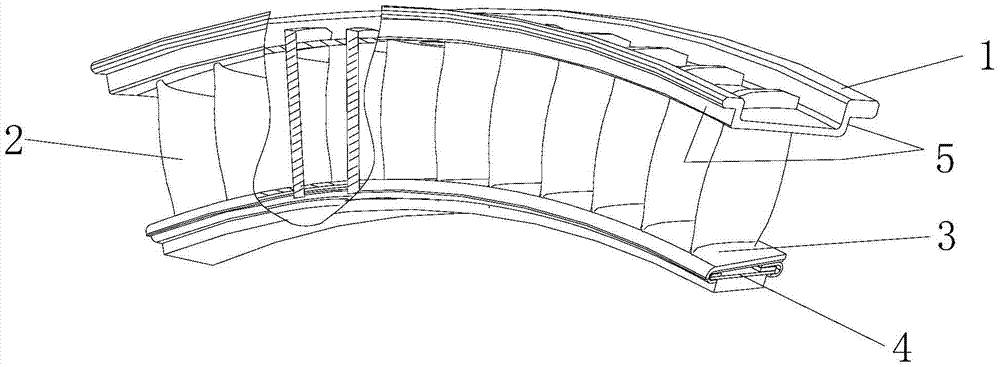

Method for controlling hollow guide blade upper edge plate cavity wall thickness

ActiveCN104923722AGuaranteed wall thickness uniformityMeet the requirements of design drawingsFoundry mouldsFoundry coresWaxInvestment casting

The invention belongs to the precise investment casting technology and relates to a method for controlling aero-engine hollow guide blade upper edge plate cavity wall thickness. The method is characterized in that the hollow guide blade upper edge plate wax pattern cavity wall thickness is changed to control casting cavity wall thickness, the front edge of the core body (3) of a ceramic core (7) is allowed to tilt towards a non-runner face, and the included angle alpha of the lower surface (11) of the core body (3) and the runner face (10) of a hollow guide blade upper edge plate wax pattern is allowed to range from 0 degree 30 minutes to 1 degree. By the method, hollow guide blade upper edge plate casting wall thickness evenness at hollow parts is guaranteed, design drawing requirements are satisfied, oversize and scrap are avoided, production yield is increased, and production cost is lowered.

Owner:AECC AVIATION POWER CO LTD

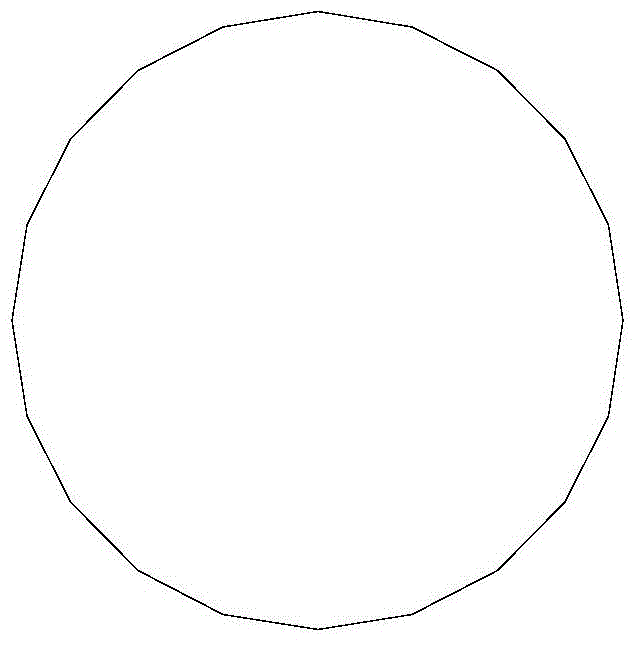

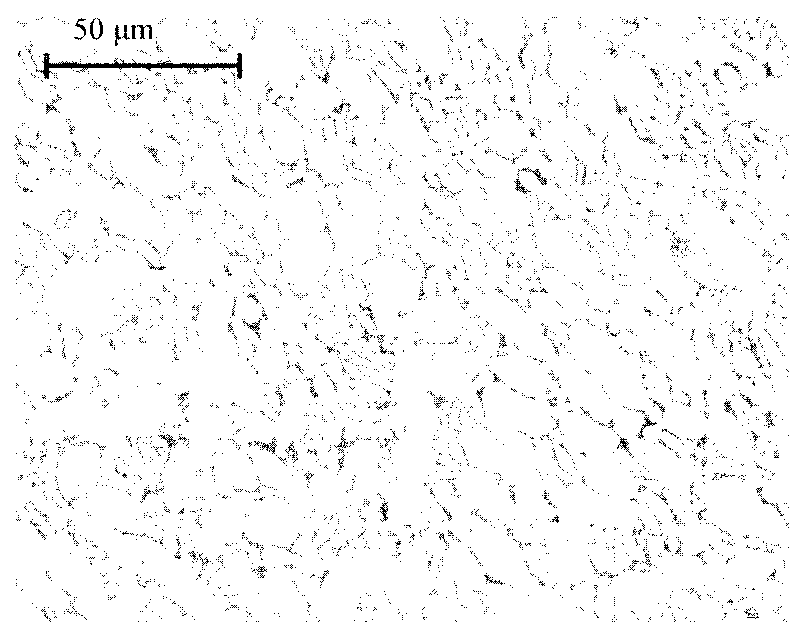

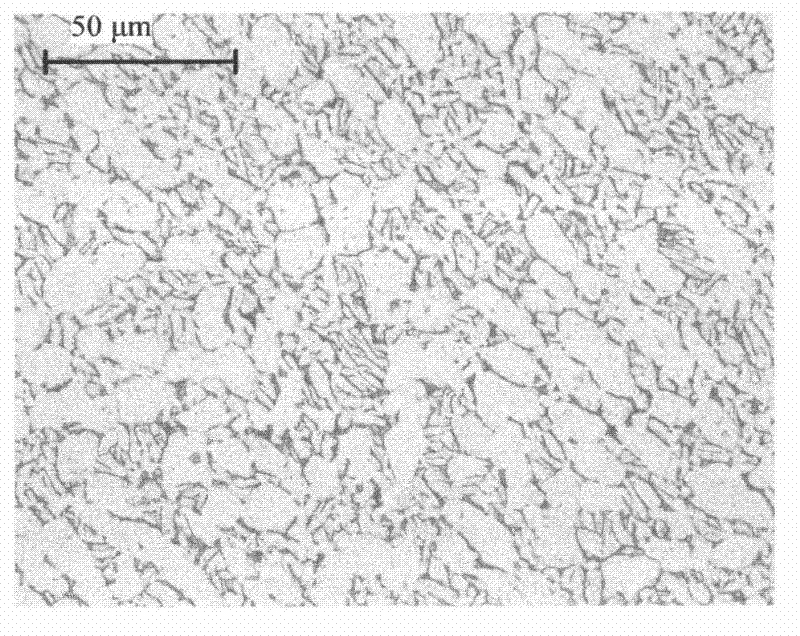

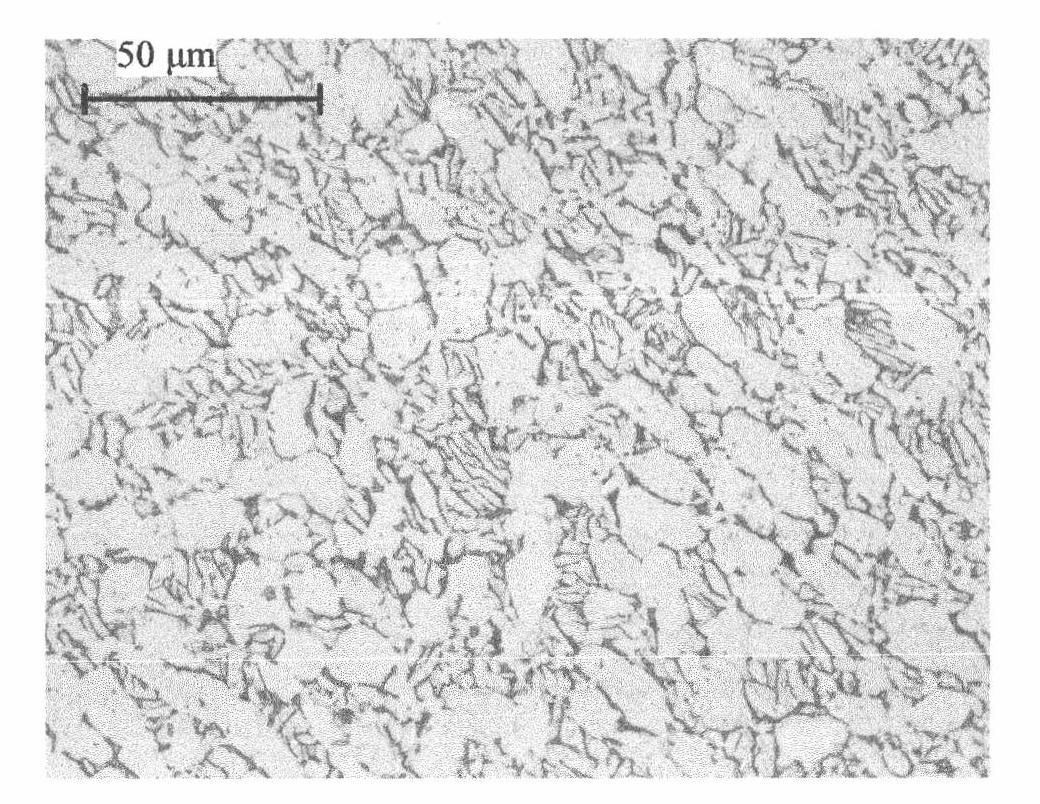

Rolling formation method of large and medium titanium alloy solid disc-shaped forge piece

InactiveCN101758151AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTitanium alloyForge

The invention discloses a rolling formation method of a large and medium titanium alloy solid disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a titanium alloy rod material into a solid disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s and axially rolling the hollow disc blank under an axial rolling force of 4000-4900KN at an axial feeding speed of 1.8mm / s to widen the hollow disc blank at a speed of 10-12mm / s; rolling the disc blank for 20-40s and axially rolling the hollow disc blank under an axial rolling force of 3000-3500KN at an axial feeding speed of 0.8mm / s to widen the hollow disc blank at a speed of 8-10mm / s; rolling the disc blank for 40-70s and axially rolling the solid disc blank under an axial rolling force of 2500-3000KN at an axial feeding speed of 0.5mm / s to widen the hollow disc blank at a speed of 5-8mm / s; and carrying out fire rolling to prepare the solid disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

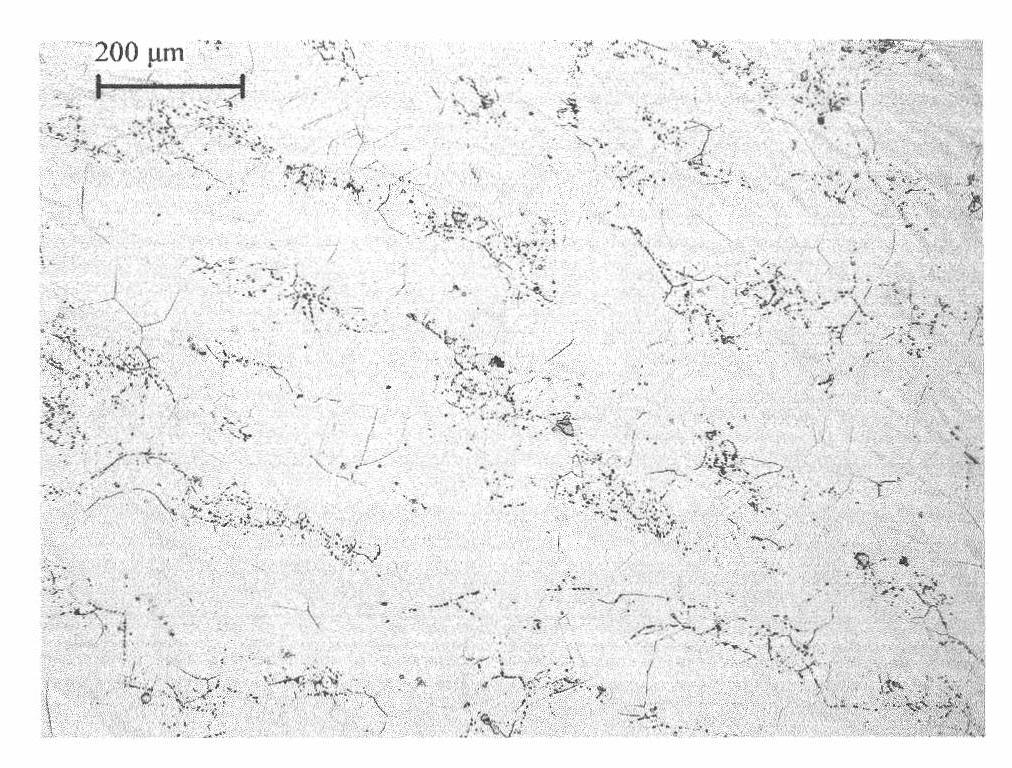

Rolling formation method of large and medium high-temperature alloy hollow disc-shaped forge piece

InactiveCN101758150AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesSuperalloyHollow core

The invention discloses a rolling formation method of a large and medium high-temperature alloy hollow disc-shaped forge piece, which comprises the following steps of: upsetting, compressing and punching a high-temperature alloy rod material into a hollow disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s to enable the disc blank to widen at a speed of 9-11mm / s under 4000-4900KN of an axial rolling force at an axial feeding speed of 1.6mm / s; rolling the disc blank for 20-40s to enable the disc blank to widen at a speed of 7-9mm / s under 3000-3500KN of an axial rolling force and 3000-4000KN of a radial rolling force at an axial feeding speed of 0.7mm / s; rolling the disc blank for 40-80s to enable the disc blank to widen at a speed of 4-7mm / s under an axial rolling force of 2500-3000KN and a radial rolling force of 2000-3000KN at an axial feeding speed of 0.5mm / s; and carrying out fire rolling to prepare the hollow disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

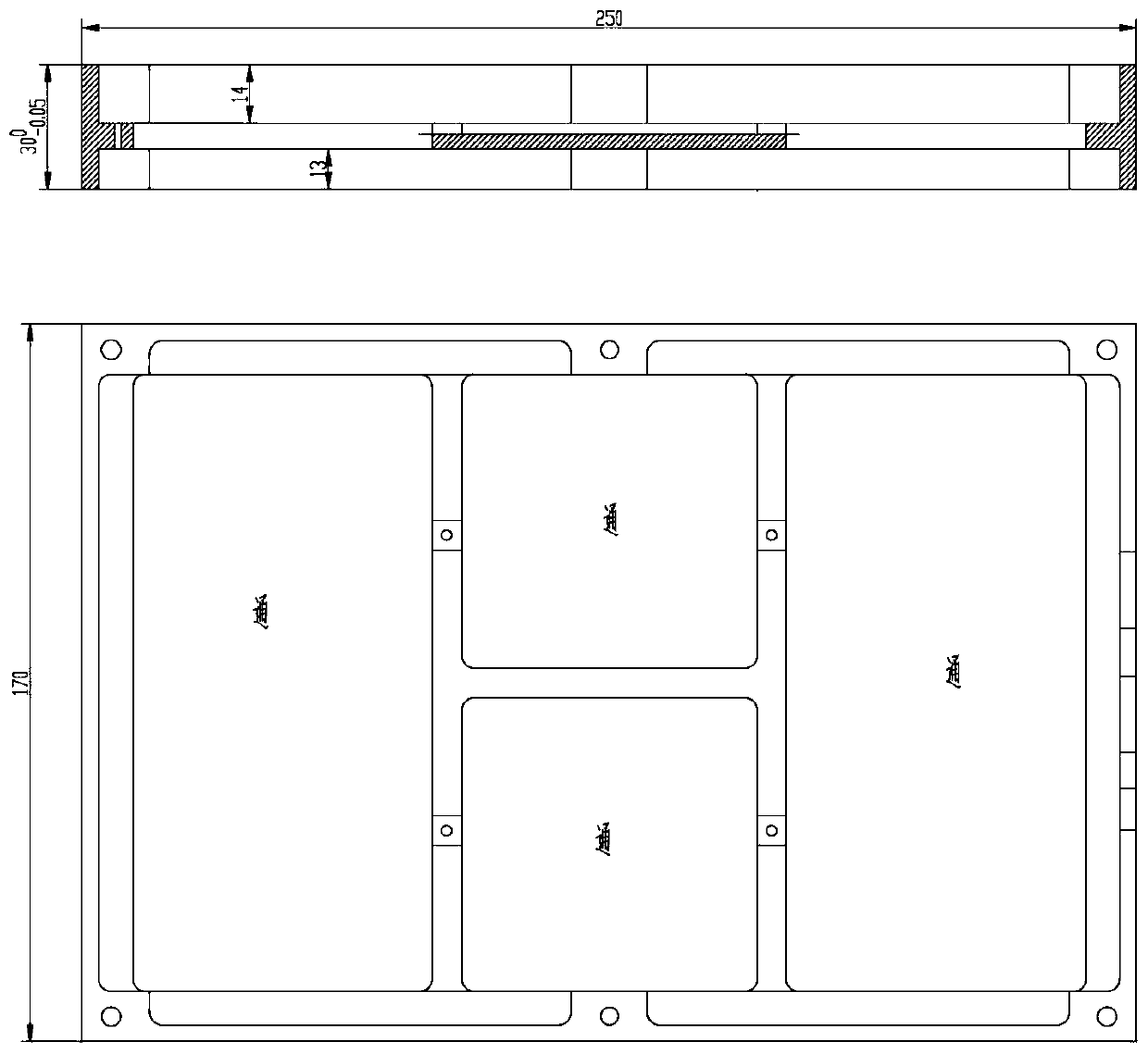

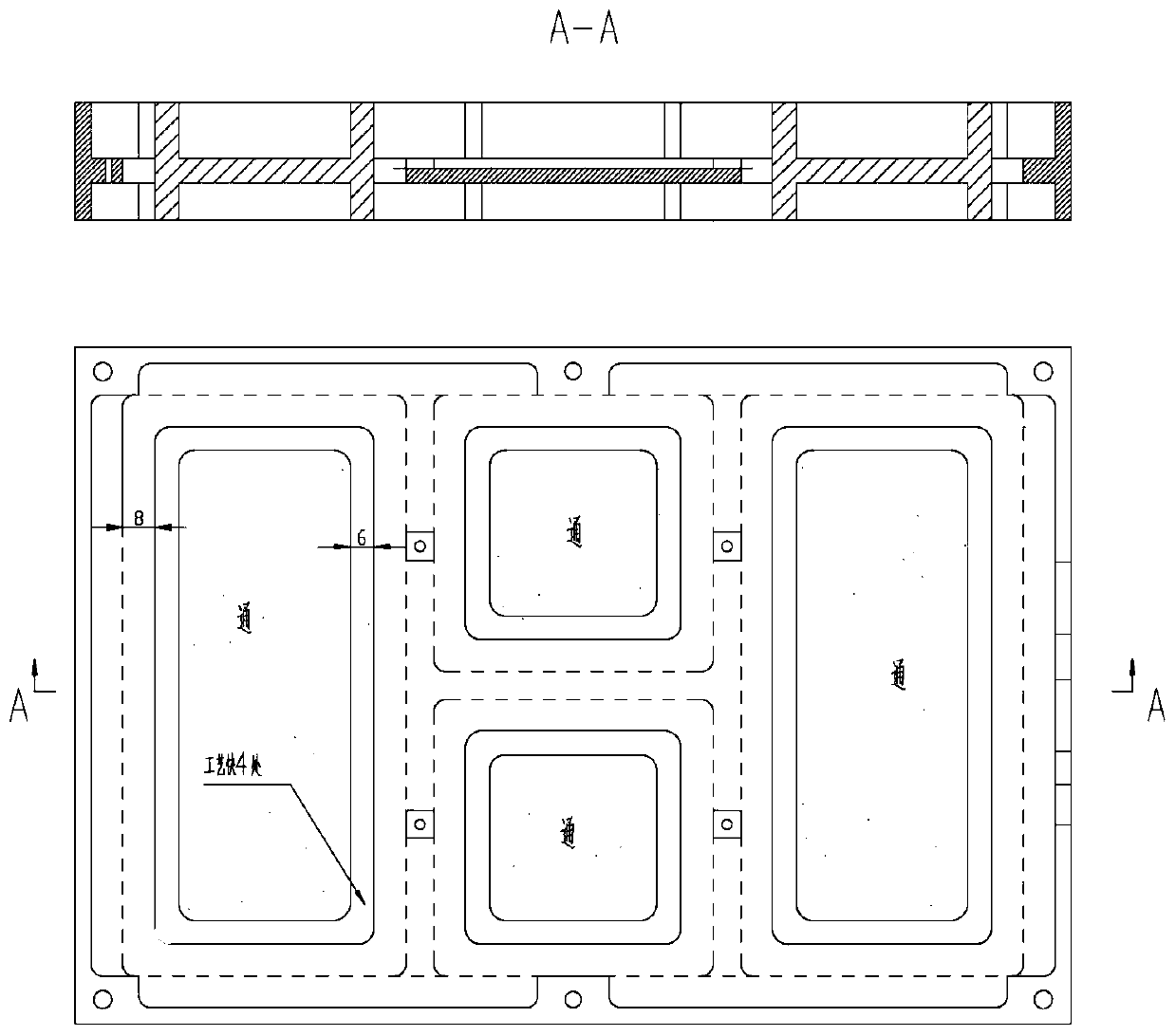

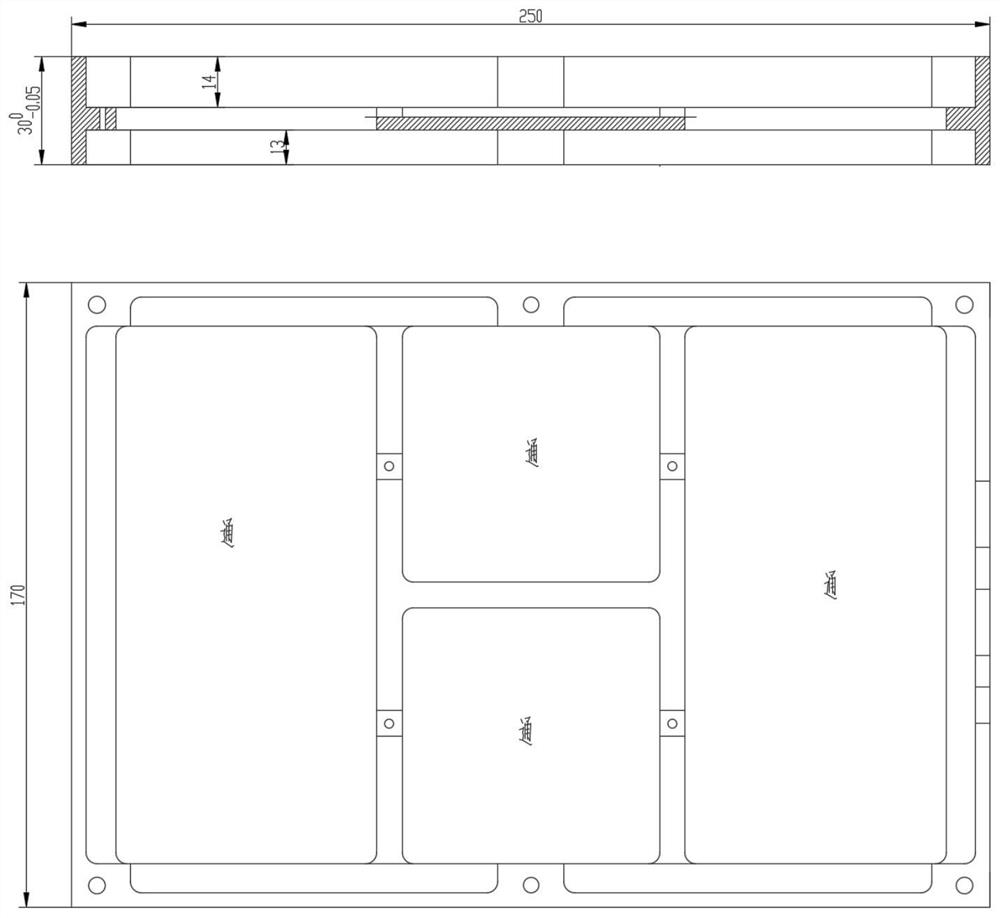

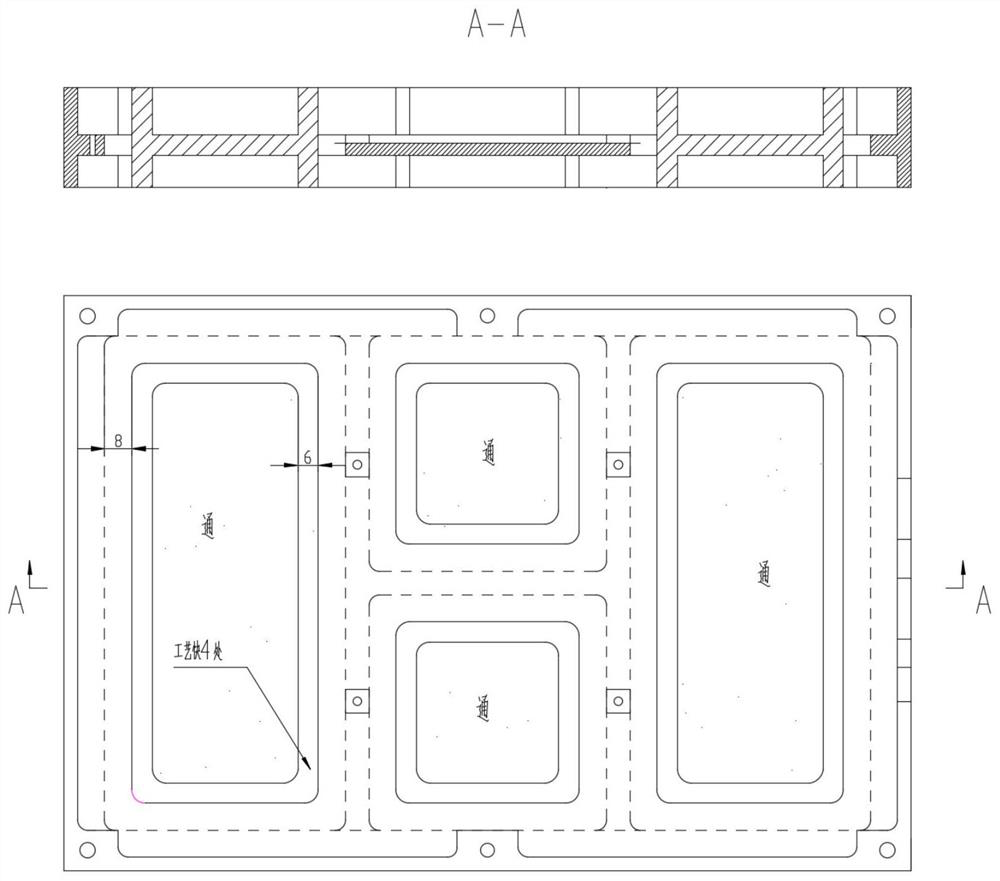

Machining method for frame parts

ActiveCN110102804AShorten the timeSolve the deformationMilling equipment detailsMachiningEngineering

The invention relates to the technical field of machining, in particular to a machining method for frame parts. The machining method comprises the following steps that the rough milling of the front and back surfaces of parts is performed, a process block at the part through cavity is reserved according to the machining precision, and a margin of 0.5 mm at the other machining positions is reserved; and the respective finish-milling of the front and back surfaces of the parts is performed. According to the method, by controlling machining allowance accurately, the parts are accurately and precisely milled; by reserving the process block, the deformation stress can be released during rough milling, the supporting effect can be achieved when inner depression and the surface of the frame are machined; and the product size is effectively guaranteed, the clamping is convenient, the pressure plate changing time is shortened, and the machining efficiency is improved. By adopting the machiningprocess method, the problem of deformation of frame parts is solved, the product quality is stable, the requirements of design drawings are met, and the product qualification rate and the machining efficiency are improved.

Owner:贵州航天风华精密设备有限公司

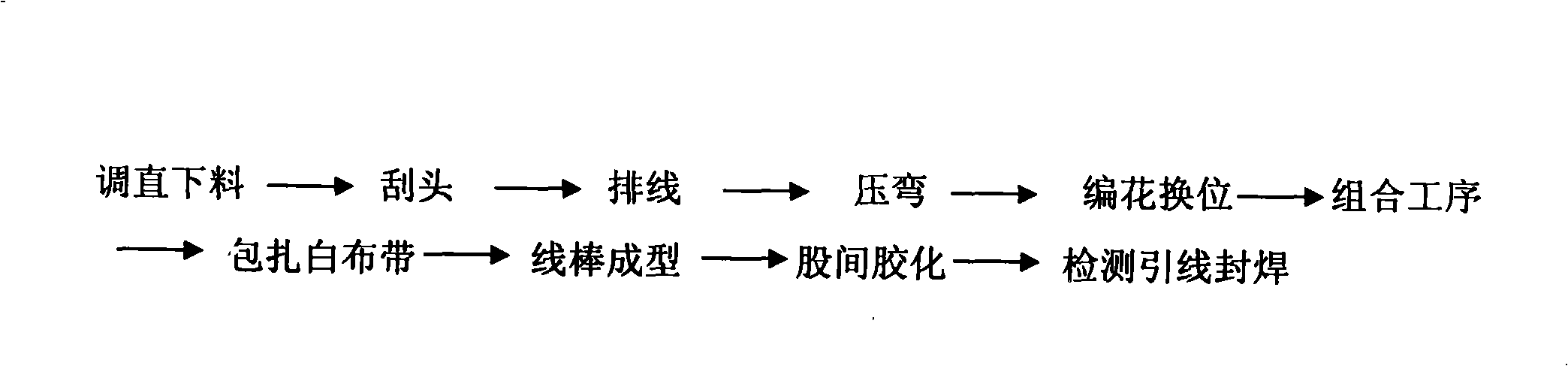

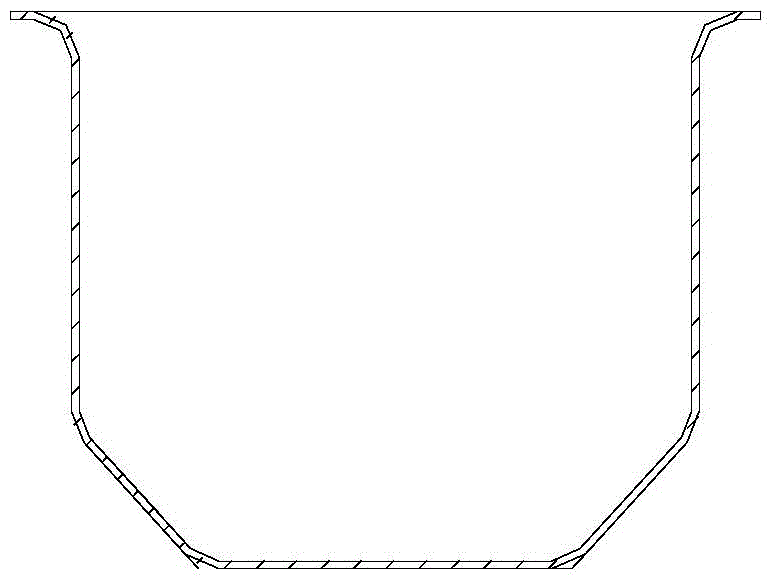

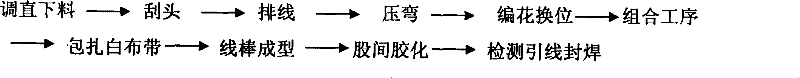

Method for flower-editing, transposition and molding of electric machine bar line stick end

InactiveCN101355278AConsistent shapeAvoid inter-share short circuit faultsManufacturing dynamo-electric machinesElectric machineCopper wire

The invention relates to a method for transposition forming of one end of a bar of a motor and belongs to the technical field of motors. The method comprises the following steps of 1. wire arrangement, in which (1) upper-layer bar copper wires and lower-layer bar copper wires are separately placed on a platform and (2) a wire arrangement board is fixed on the surface of a worktable and the arranged copper wires are fixed by a wire arrangement fixture; 2. pressure bending, in which a hydraulic pressure bending mode is adopted to bend the copper wires; 3 combining, in which the bent copper wires undergo transposition, gaskets and rows of the copper wires are insulated when the bar is combined, the middle pitch is processed to the preset standard, and the positions of transposition at both sides are beat out; 4. forming, in which the bar is placed into an upper forming die and a lower forming die, an iron core section part is beat out and is firmly fixed in a sizing die by the back of a wedge block, an end corner R is subject to simmer bending, then a leading wire R is subject to simmer bending, and the bar is beat out to be attached to the forming dies; and 5. colloidization among strands, in which the bar is placed into a colloidization model for colloidization molding to finish the transposition forming of one end of the bar. The method has the advantages of simple process, good bar effect, flat appearance, small gross weight of a motor, high efficiency and so on.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

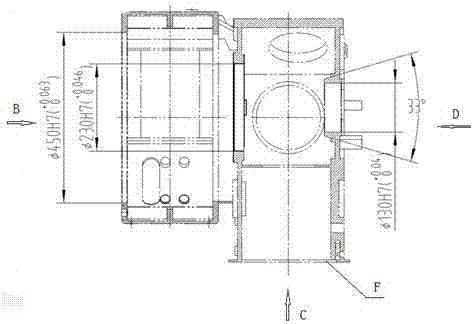

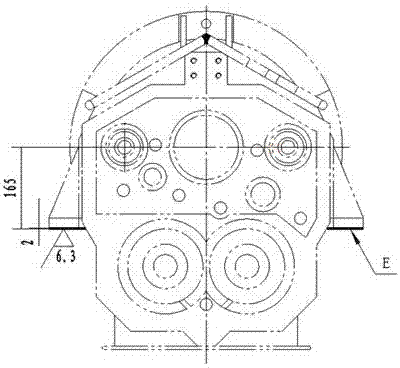

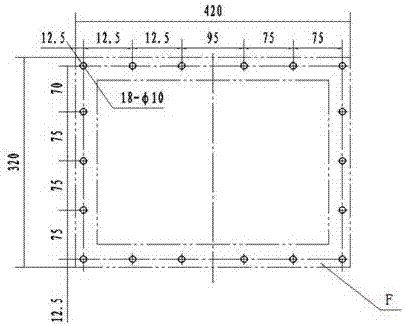

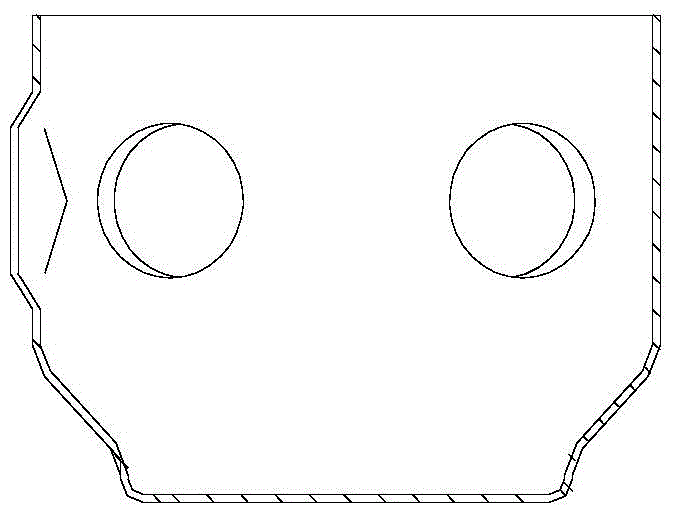

Anti-deformation machining technology for air compressor thin-wall machine body

InactiveCN107398574ASimple processing technologyAvoid deformationGas compressorMachining deformation

An anti-deformation processing technology for a thin-walled body of an air compressor. The anti-deformation processing technology for a thin-walled body of an air compressor is: designing special tooling to effectively avoid the phenomenon of benchmark shifting when processing special positions, The tooling can play a good role in positioning and supporting, and at the same time, the feed rate of each tool is strictly controlled to avoid machining deformation; the machining process of the fuselage is improved, and a new type of extended boring tool is selected. Move the worktable to complete one-time processing of the coaxial holes to ensure the processing accuracy of the coaxial holes of the fuselage; refine the processing technology, standard-definition the clamping method and processing size of the fuselage, improve the utilization rate of the process, effectively guide the operator to work, and reduce operations The phenomenon of processing errors and inability to process occurs; replace new equipment. The invention has technological innovation, strict technological requirements, control of the production process, and improves the processing accuracy of the thin-walled box parts of the air compressor fuselage, and is applied in the technical field of air compressors.

Owner:沈阳鼓风机集团申蓝机械有限公司

Rolling formation method of large and medium stainless steel hollow disc-shaped forge piece

InactiveCN101758153AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesForgeMaterials science

The invention discloses a rolling formation method of a large and medium stainless steel hollow disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a stainless steel rod material into a hollow disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s to enable the disc blank to widen at a speed of 10-15mm / s under 4000-4900KN of an axial rolling force at an axial feeding speed of 2mm / s; rolling the disc blank for 20-40s to enable the disc blank to widen at a speed of 8-12mm / s under 3000-3500KN of an axial rolling force and 3000-4000KN of a radial rolling force at an axial feeding speed of 1mm / s; rolling the disc blank for 40-60s to enable the disc blank to widen at a speed of 5-8mm / s under 2500-3000KN of an axial rolling force and 2000-3000KN of a radial rolling force at an axial feeding speed of 0.5mm / s; and carrying out fire rolling to prepare the hollow disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

Control Method of Wall Thickness of Upper Edge Plate of Hollow Guide Vane

ActiveCN104923722BGuaranteed wall thickness uniformityMeet the requirements of design drawingsFoundry mouldsFoundry coresWaxInvestment casting

The invention belongs to the precise investment casting technology and relates to a method for controlling aero-engine hollow guide blade upper edge plate cavity wall thickness. The method is characterized in that the hollow guide blade upper edge plate wax pattern cavity wall thickness is changed to control casting cavity wall thickness, the front edge of the core body (3) of a ceramic core (7) is allowed to tilt towards a non-runner face, and the included angle alpha of the lower surface (11) of the core body (3) and the runner face (10) of a hollow guide blade upper edge plate wax pattern is allowed to range from 0 degree 30 minutes to 1 degree. By the method, hollow guide blade upper edge plate casting wall thickness evenness at hollow parts is guaranteed, design drawing requirements are satisfied, oversize and scrap are avoided, production yield is increased, and production cost is lowered.

Owner:AECC AVIATION POWER CO LTD

0Cr17Ni4Cu4Nb multi-way pipe forming method and sidewall flanging die employed by same

ActiveCN104353735AReach manufacturing levelMeet the requirements of design drawingsShaping toolsEjection devicesBarrel ShapedFlanging

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Roll forming method of large and medium-size structural steel hollow disk-shaped forgings

InactiveCN101804439AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceDisc wheelsPunchingSteel bar

The invention discloses a roll forming method of large and medium-size structural steel hollow disk-shaped forgings, comprising the following steps of: firstly preparing structural steel bar stocks into hollow disk blanks through upsetting, profiling and punching, and then feeding the disk blanks into a rolling mill for rolling; broadening the disk blanks at the speed of 5-12 mm / s under the axial rolling force of 4500 kN-4900 kN within the rolling time of 60s and at the axial feeding speed of 1.5 mm / s; broadening the disk blanks at the speed of 3-10 mm / s under the axial rolling force of 3000 kN-3900 kN and the radial rolling force of 3500 kN-4000 kN within the rolling time of 60s-100s and at the axial feeding speed of 1.2 mm / s; and broadening the disk blanks at the speed of 2-6 mm / s under the axial rolling force of 200 kN-3000 kN and the radial rolling force of 2500 kN-3000 kN within the rolling time of 100-120s and at the axial feeding time of 0.8 mm / s, and then rolling the disk blanks into the hollow disk-shaped forgings under fire. The method is mainly used for rolling the disk-shaped forgings with excellent shapes, sizes, tissues and properties.

Owner:GUIZHOU ANDA AVIATION FORGING

Roll forming method of large and medium structural steel solid disk forging

InactiveCN101791669AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTime rangeSteel bar

The invention discloses a roll forming method of a large and medium structural steel solid disk forging, which comprises the following steps of: firstly upsetting structural steel bar materials, profiling into a solid disk blank; and rolling the disk blank in a rolling machine. When rolling within 60s, expanding the disk blank at a speed of 5-12mm / s under a 4500-4900KN axial rolling force with an axial feed speed of 1.5mm / s; when rolling in the time range of 60-100s, expanding the disk blank at a speed of 3-10mm / s under a 3000-3900KN axial rolling force with an axial feed speed of 1.2mm / s; and when rolling in the time range of 100-120s, expanding the disk blank at a speed of 2-6mm / s under a 2000-3000KN axial rolling force with an axial feed speed of 0.8mm / s, and finally rolling into the solid disk forging on one-grade fire. The method is mainly used for rolling the disk forging with excellent shape, dimension, organization and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

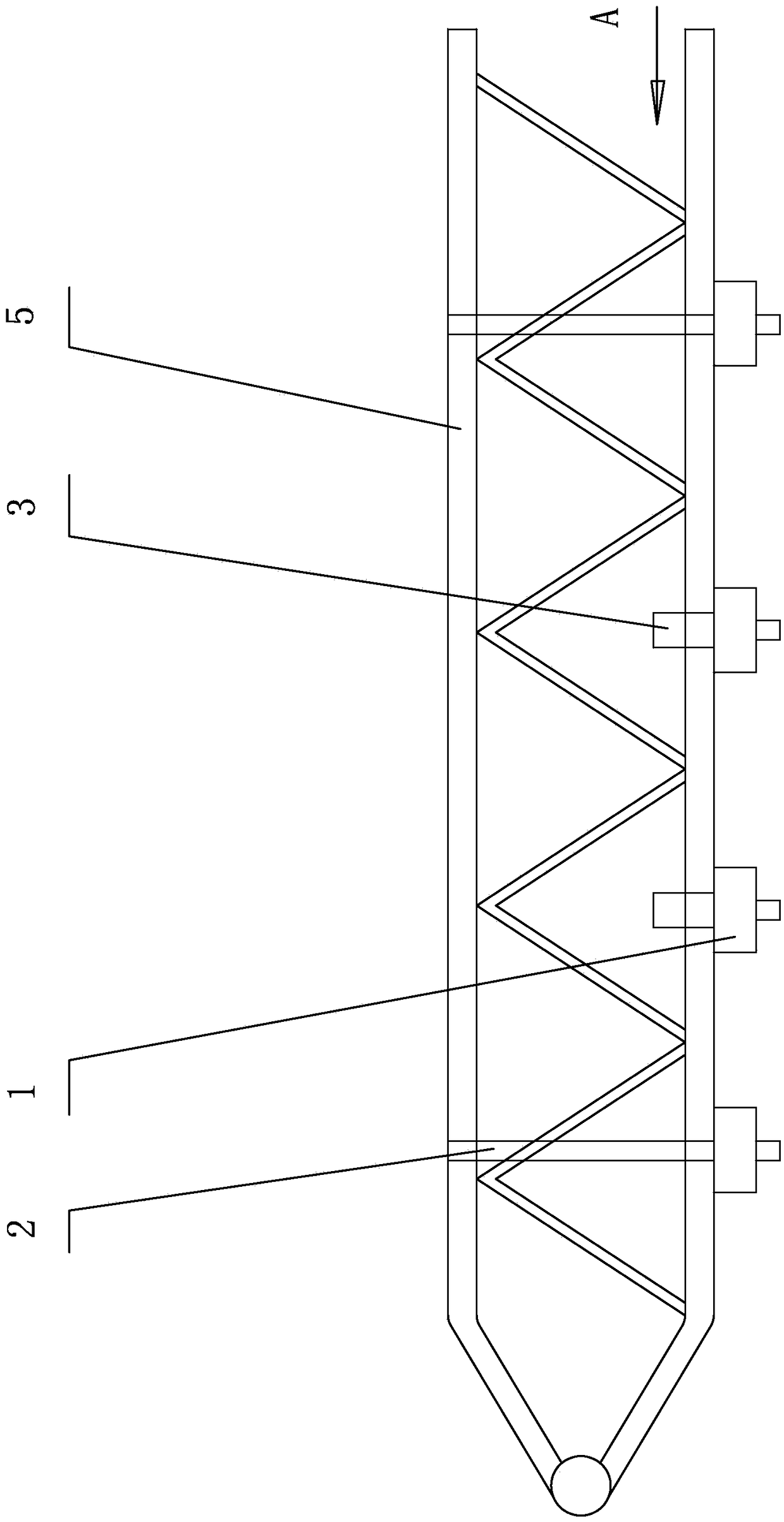

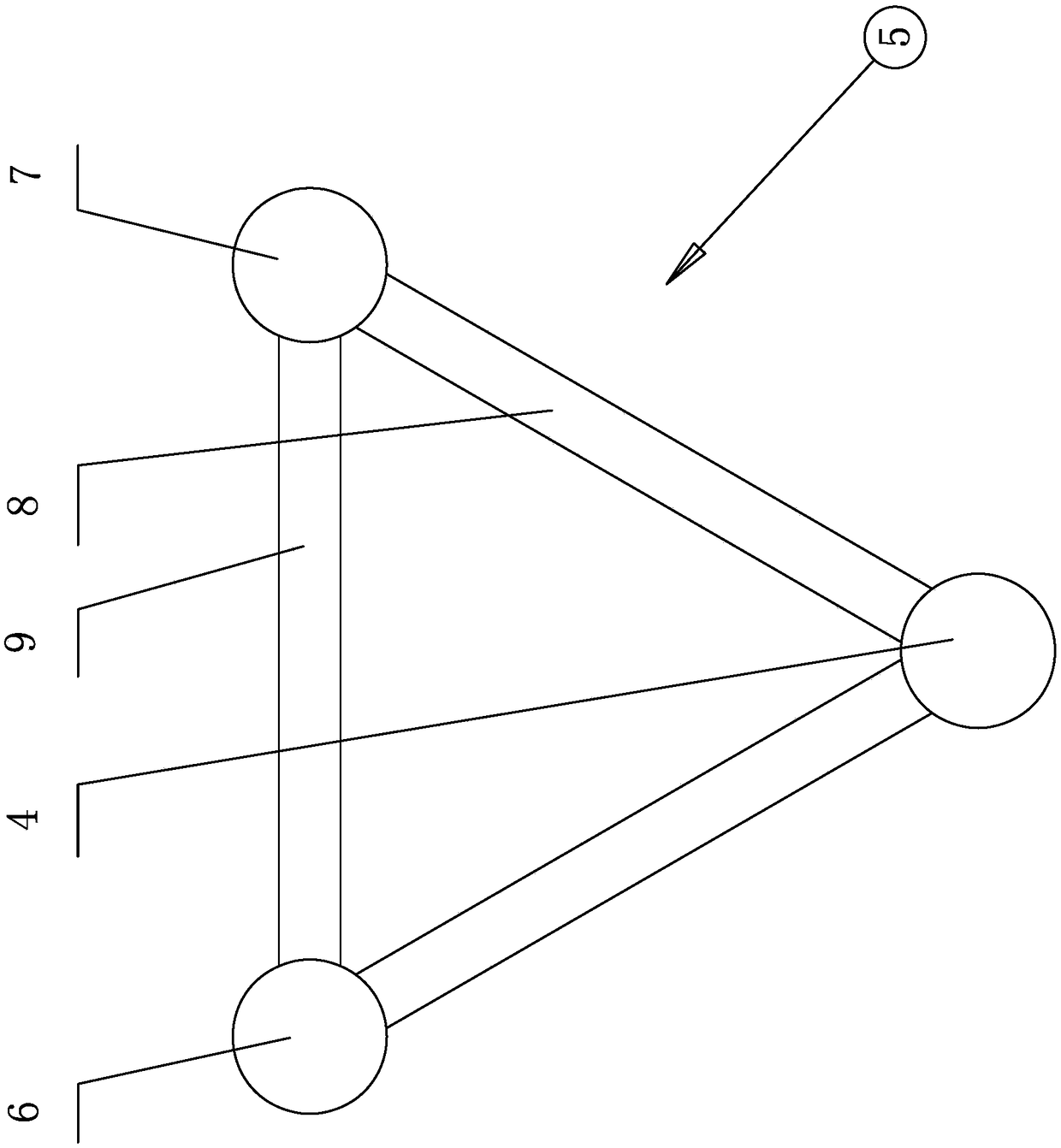

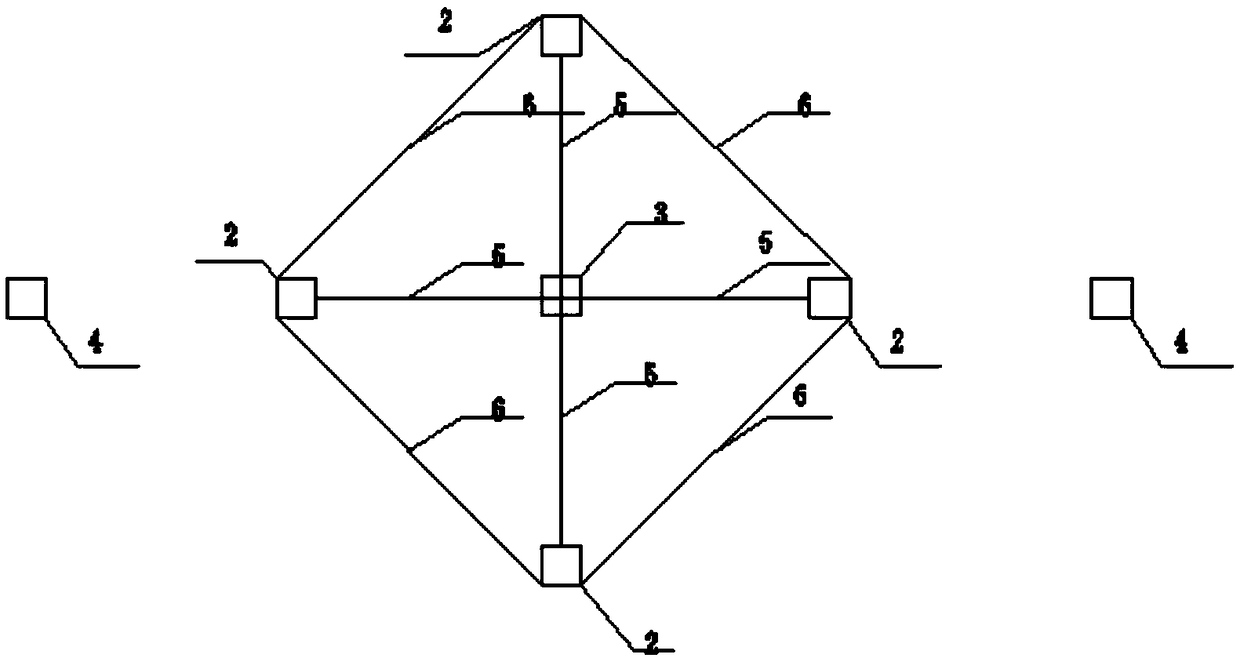

Lateral assembling method for large-span inverted triangular tube truss

InactiveCN109138449AMeet the requirements of design drawingsImprove assembly accuracyBuilding material handlingEngineeringSpandrel

The invention discloses a lateral assembling method for a large-span inverted triangular tube truss. The method comprises: step one, a plurality of assembling devices are arranged along an assemblingdirection, wherein all assembling devices include a plurality of assembling platforms that are spaced in a front-rear manner; step two, the front and rear assembling platforms are provided with trussupper tube support frames respectively and other saddle iron type assembling platforms are provided with truss lower tube fixation frames arranged at equal intervals at one side of the front and reartruss upper tube support frames; step three, all inverted triangular tube truss units are arranged at the corresponding assembling platforms laterally and are connected in an end-to-end manner; and one truss upper tube of each inverted triangular tube truss unit is supported at the front and rear truss upper tube support frames and the other truss upper tube is arranged at one corresponding assembling platform, wherein the truss lower tubes are higher than all assembling platforms and are fixed at all truss lower tube fixation frames; and step four, the aligned truss lower tubes and truss upper tubes are welded. Therefore, the construction quality and construction safety are ensured; the construction progress and the mounting precision are improved; and the construction cost is lowered.

Owner:FANGCHENGGANG ZHONGYI HEAVY IND

Rolling formation method of large and medium hollow titanium alloy disc-shaped forge piece

InactiveCN101758152AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTitanium alloyForge

The invention discloses a rolling formation method of a large and medium hollow titanium alloy disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a titanium alloy rod material into a hollow disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s and axially rolling the hollow disc blank under 4000-4900KN of an axial rolling force at an axial feeding speed of 1.6mm / s to widen the hollow disc blank at a speed of 10-12mm / s; rolling the disc blank for 20-40s and axially rolling the hollow disc blank under an axial rolling force of 3000-3500KN and a radial rolling force of 3000-4000KN at an axial feeding speed of 0.8mm / s to widen the hollow disc blank at a speed of 8-10mm / s; rolling the disc blank for 40-70s and axially rolling the hollow disc blank under an axial rolling force of2500-3000KN and a radial rolling force of 2000-3000KN at an axial feeding speed of 0.5mm / s to widen the hollow disc blank at a speed of 5-8mm / s; and carrying out fire rolling to prepare the hollow disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

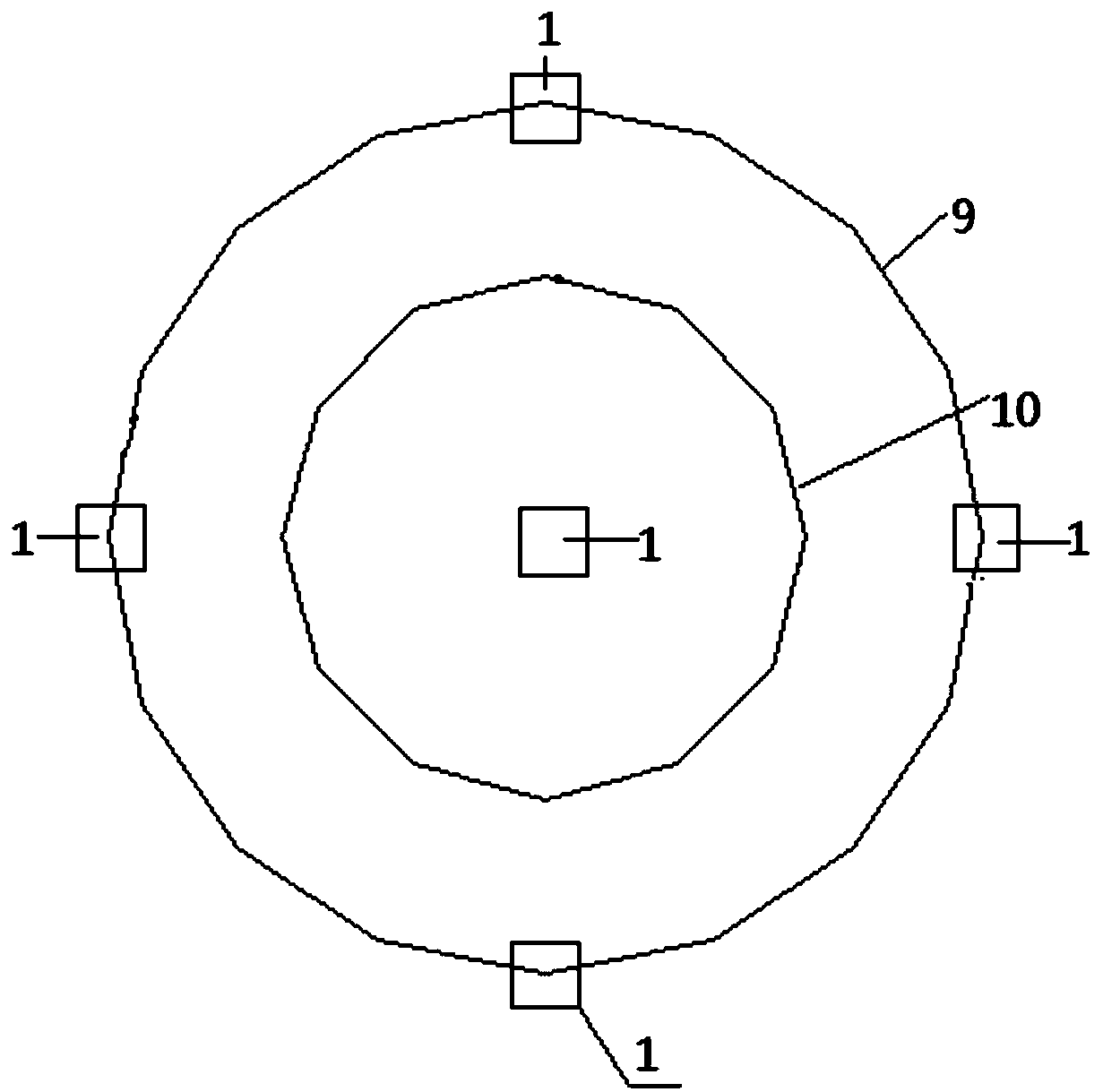

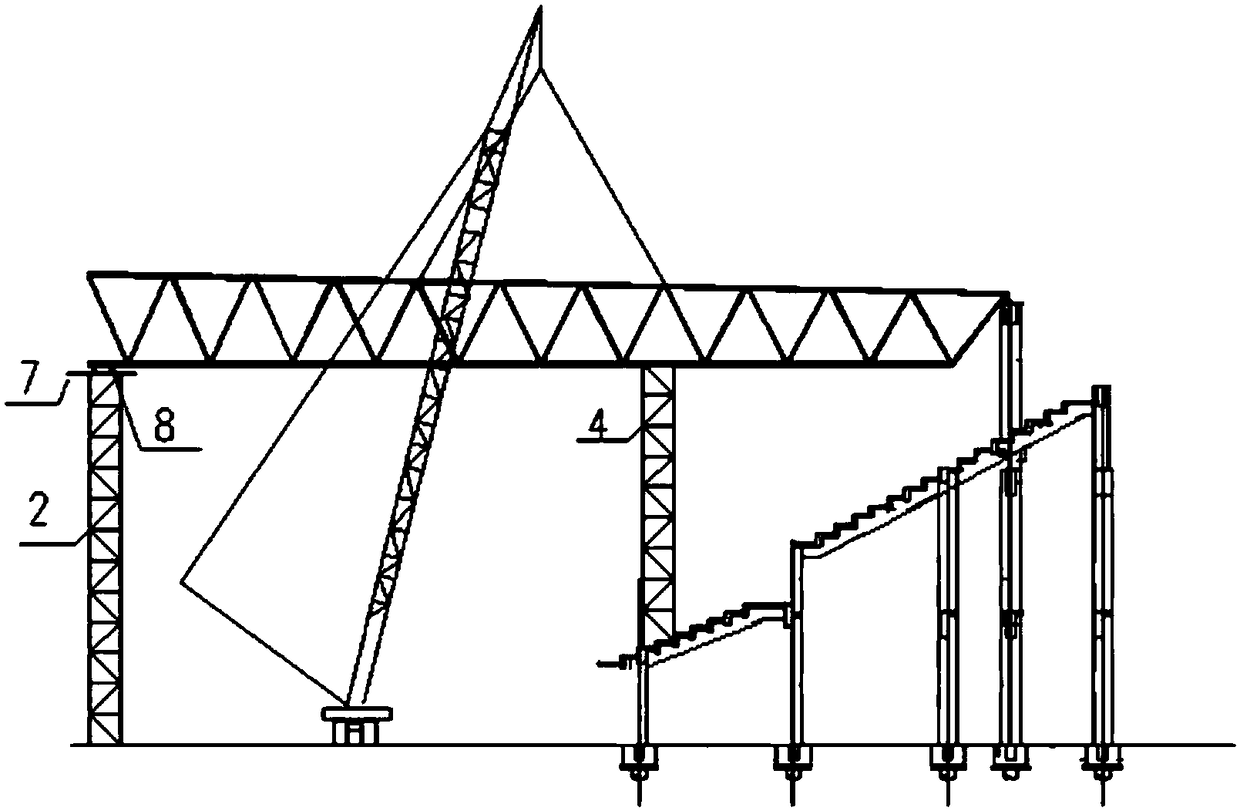

Installation method of large-diameter circular roof pipe truss

InactiveCN109057364AQuick installationImprove assembly efficiencyBuilding material handlingBuilding constructionWelding

The invention provides an installation method of a large-diameter circular roof pipe truss. The installation method comprises the following steps that step 1, construction fixing of a plurality of concrete foundations is carried out in the center of an installation site of the large-diameter circular roof pipe truss according to the design position; step 2, repetition measurement, labeling and recording of position coordinates and elevation are carried out on the concrete foundations; step 3, temporary supports are set up on site and fixed with the concrete foundations one to one respectively;step 4-5, hoisting and welding of an inner ring truss and outer ring truss of a center circle of a circular roof are carried out; step 6, trusses 12 are symmetrically arranged in sequence, and main truss welding is carried out; step 7, installation welding of secondary trusses, supporting rods and riding tracks is carried out; step 8, the pipe truss is integrally disassembled, and it is detectedwhether or not the deflection under the pipe truss meets the requirement; step 9, the temporary supports are disassembled, and site formation is recovered. The installation method of the large-diameter circular roof pipe truss has the advantages that the rapid installation of the large-diameter circular roof pipe truss is achieved, the splicing efficiency is improved, and the splicing quality is ensured.

Owner:CHINA FIRST METALLURGICAL GROUP +1

A processing method for flaring and forming stainless steel small-diameter thin-walled pipe fittings

The invention discloses a processing method for flaring and forming of stainless steel small-diameter thin-walled pipe fittings. It includes the following steps: a. Flatten the end face of the pipe fitting, and the cutting surface of the pipe fitting is at a right angle of 90°±0.2° to the axis of the pipe fitting to obtain product A; b. Perform solid melting treatment on the pipe fitting of product A to obtain product B; c. Remove product B The orifice of the pipe fitting and the burr in the hole, and the part of the pipe to be flared is cleaned to obtain product C; d. Use the tube clamp to clamp the pipe fitting of product C, and use the flared top cone to gradually expand the pipe fitting of product C to obtain Product D; e, carry out stress relief treatment on the pipe fittings of product D to obtain product E; f, carry out flat grinding on the pipe fittings of product E to obtain product F; g, put the pipes formed by the expansion of the pipe fittings of product F into the correction mold for correction Cone surface, finished product. The present invention has the diameter of the tube mouth, the taper of the flared surface, and the flatness of the tube mouth of the pipe fitting formed by flaring to a taper of 74°, which can meet the design requirements, and the qualified rate of the product is greatly improved.

Owner:GUIZHOU HONGLIN MACHINERY

Method for flower-editing, transposition and molding of electric machine bar line stick end

InactiveCN101355278BConsistent shapeAvoid inter-share short circuit faultsManufacturing dynamo-electric machinesElectric machineCopper wire

The invention relates to a method for transposition forming of one end of a bar of a motor and belongs to the technical field of motors. The method comprises the following steps of 1. wire arrangement, in which (1) upper-layer bar copper wires and lower-layer bar copper wires are separately placed on a platform and (2) a wire arrangement board is fixed on the surface of a worktable and the arranged copper wires are fixed by a wire arrangement fixture; 2. pressure bending, in which a hydraulic pressure bending mode is adopted to bend the copper wires; 3 combining, in which the bent copper wires undergo transposition, gaskets and rows of the copper wires are insulated when the bar is combined, the middle pitch is processed to the preset standard, and the positions of transposition at both sides are beat out; 4. forming, in which the bar is placed into an upper forming die and a lower forming die, an iron core section part is beat out and is firmly fixed in a sizing die by the back of a wedge block, an end corner R is subject to simmer bending, then a leading wire R is subject to simmer bending, and the bar is beat out to be attached to the forming dies; and 5. colloidization among strands, in which the bar is placed into a colloidization model for colloidization molding to finish the transposition forming of one end of the bar. The method has the advantages of simple process, good bar effect, flat appearance, small gross weight of a motor, high efficiency and so on.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

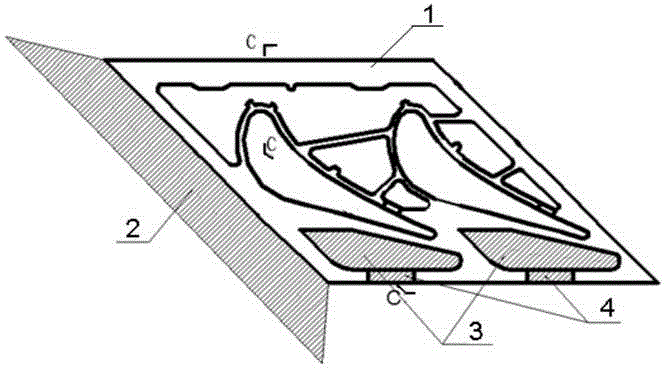

An installation method of an embedded conformal radome

ActiveCN109319090BManufacturing precision requirements are lowMeet the requirements of design drawingsRadiating element housingsAircraft assemblyAviationProcess equipment

The invention belongs to the technical field of aviation manufacturing, and relates to an installation method of a built-in conformal radome. The invention controls the manufacturing technical state of the radome and the mouth frame of the body, selects appropriate technological equipment, and plans a reasonable installation process flow. The method of process compensation reduces the requirements for the manufacturing accuracy of the radome and the body frame, and ensures that the installation of the embedded conformal radome meets the requirements of the design drawing.

Owner:SHAANXI AIRCRAFT CORPORATION

Rolling formation method of large and medium titanium alloy solid disc-shaped forge piece

InactiveCN101758151BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTitanium alloyForge

The invention discloses a rolling formation method of a large and medium titanium alloy solid disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a titanium alloy rod material into a solid disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s and axially rolling the hollow disc blank under an axial rolling force of 4000-4900KN at an axial feeding speed of 1.8mm / s to widen the hollow disc blank at a speed of 10-12mm / s; rolling the disc blank for 20-40s and axially rolling the hollow disc blank under an axial rolling force of 3000-3500KN at an axial feeding speed of 0.8mm / s to widen the hollow disc blank at a speed of 8-10mm / s; rolling the disc blank for 40-70s and axially rolling the solid disc blank under an axial rolling force of 2500-3000KN at an axial feeding speed of 0.5mm / s to widen the hollow disc blank at a speed of 5-8mm / s; and carrying out fire rolling to prepare the solid disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling forming method of large and medium scale stainless steel solid disk forgings

InactiveCN101712063AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesSteel barMaterials science

The invention discloses a rolling forming method of large and medium scale stainless steel solid disk forgings. Firstly stainless steel bar stock is upset and profiled to form a solid disk billet, and then the disk billet is loaded into an elongator to be rolled. During 20 s rolling, the disk billet is expanded at the speed of 10 to 15 mm / s under the condition that axial feeding speed is 2 mm / s and axial rolling force is 4000 to 4900 KN; during 20 to 40 s rolling, the disk billet is expanded at a speed of 8 to 12 mm / s under the condition that axial feeding speed is 1 mm / s and axial rolling force is 3000 to 3500 KN; and during 40 to 60 s rolling, the disk billet is expanded at a speed 5 to 8 mm / s under the condition that axial feeding speed is 0.5 mm / s and axial rolling force is 2500 to 3000 KN, and finally the solid disk forgings are rolled on one-grade fire. The method is mainly applied to the disk forgings with excellent rolling shapes, dimensions, tissues and properties.

Owner:GUIZHOU ANDA AVIATION FORGING

A kind of compressor stator blade assembly replacement blade repair method

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Rolling formation method of large and medium hollow titanium alloy disc-shaped forge piece

InactiveCN101758152BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTitanium alloyForge

The invention discloses a rolling formation method of a large and medium hollow titanium alloy disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a titanium alloy rod material into a hollow disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s and axially rolling the hollow disc blank under 4000-4900KN of an axial rolling force at an axial feeding speed of 1.6mm / s to widen the hollow disc blank at a speed of 10-12mm / s; rolling the disc blank for 20-40s and axially rolling the hollow disc blank underan axial rolling force of 3000-3500KN and a radial rolling force of 3000-4000KN at an axial feeding speed of 0.8mm / s to widen the hollow disc blank at a speed of 8-10mm / s; rolling the disc blank for 40-70s and axially rolling the hollow disc blank under an axial rolling force of2500-3000KN and a radial rolling force of 2000-3000KN at an axial feeding speed of 0.5mm / s to widen the hollow disc blank at a speed of 5-8mm / s; and carrying out fire rolling to prepare the hollow disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

Roll forming method of large and medium structural steel solid disk forging

InactiveCN101791669BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesTime rangeRoll forming

The invention discloses a roll forming method of a large and medium structural steel solid disk forging, which comprises the following steps of: firstly upsetting structural steel bar materials, profiling into a solid disk blank; and rolling the disk blank in a rolling machine. When rolling within 60s, expanding the disk blank at a speed of 5-12mm / s under a 4500-4900KN axial rolling force with anaxial feed speed of 1.5mm / s; when rolling in the time range of 60-100s, expanding the disk blank at a speed of 3-10mm / s under a 3000-3900KN axial rolling force with an axial feed speed of 1.2mm / s; and when rolling in the time range of 100-120s, expanding the disk blank at a speed of 2-6mm / s under a 2000-3000KN axial rolling force with an axial feed speed of 0.8mm / s, and finally rolling into the solid disk forging on one-grade fire. The method is mainly used for rolling the disk forging with excellent shape, dimension, organization and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

Roll forming method of large and medium-sized superalloy solid disc-shaped forgings

InactiveCN101791667BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceDisc wheelsRoll formingSuperalloy

The invention discloses a rolling forming method of a large and medium-sized high-temperature alloy solid disk-shaped forging. Firstly, the high-temperature alloy bar is upset and pressed into a solid disk blank, and then the disk blank is put into a rolling machine for rolling. Within 20s of rolling, the disk blank is widened at a speed of 9mm / s~11mm / s at an axial feed rate of 1.6mm / s and an axial rolling force of 4000~4900KN; within 20~40s of rolling, With an axial feed speed of 0.7mm / s and an axial rolling force of 3000-3500KN, the disk blank is widened at a speed of 7mm / s-9mm / s; The axial feed speed is 2500-3000KN under the axial rolling force of 2500-3000KN, so that the disk blank is widened at a speed of 4mm / s-7mm / s, and rolled into a solid disk-shaped forging. This method is mainly used for rolling disc-shaped forgings with excellent shape, size, structure and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling formation method of large and medium high-temperature alloy hollow disc-shaped forge piece

Owner:GUIZHOU ANDA AVIATION FORGING

Roll forming method of large and medium high-temperature alloy solid disk forging

InactiveCN101791667AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceDisc wheelsTime rangeRoll forming

The invention discloses a roll forming method of a large and medium high-temperature alloy solid disk forging, which comprises the following steps of: firstly upsetting high-temperature alloy bar materials, profiling into a solid disk blank; and rolling the disk blank in a rolling mill; when rolling within 20s, expanding the disk blank at a speed of 9-11mm / s under a 4000-4900KN axial rolling force with an axial feed speed of 1.6mm / s; when rolling in the time range of 20-40s, expanding the disk blank at a speed of 7-9mm / s under a 3000-3500KN axial rolling force with an axial feed speed of 0.7mm / s; and when rolling in the time range of 40-80s, expanding the disk blank at a speed of 4-7mm / s under a 2500-3000KN axial rolling force with an axial feed speed of 0.5mm / s; and finally rolling into the solid disk forging in one beating. The method is mainly used for rolling the disk forging with excellent shape, dimension, organization and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

A machining method for frame parts

ActiveCN110102804BShorten the timeSolve the deformationMilling equipment detailsMachiningDeformation Problem

The invention relates to the technical field of machining, in particular to a machining method for frame parts. The machining method comprises the following steps that the rough milling of the front and back surfaces of parts is performed, a process block at the part through cavity is reserved according to the machining precision, and a margin of 0.5 mm at the other machining positions is reserved; and the respective finish-milling of the front and back surfaces of the parts is performed. According to the method, by controlling machining allowance accurately, the parts are accurately and precisely milled; by reserving the process block, the deformation stress can be released during rough milling, the supporting effect can be achieved when inner depression and the surface of the frame are machined; and the product size is effectively guaranteed, the clamping is convenient, the pressure plate changing time is shortened, and the machining efficiency is improved. By adopting the machiningprocess method, the problem of deformation of frame parts is solved, the product quality is stable, the requirements of design drawings are met, and the product qualification rate and the machining efficiency are improved.

Owner:贵州航天风华精密设备有限公司

Roll forming method of large and medium aluminum alloy solid disk forging

InactiveCN101791668AReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceDisc wheelsTime rangeRoll forming

The invention discloses a roll forming method of a large and medium aluminum alloy solid disk forging, which comprises the following steps of: firstly upsetting aluminum alloy bar materials, profiling into a solid disk blank; and rolling the disk blank in a rolling machine; when rolling within 20s, expanding the disk blank at a speed of 9-12mm / s under a 4000-4900KN axial rolling force with an axial feed speed of 1.9mm / s; when rolling in the time range of 20-40s, expanding the disk blank at a speed of 8-10mm / s under a 3000-3500KN axial rolling force with an axial feed speed of 0.9mm / s; and when rolling within the time range of 40-70s, expanding the disk blank at a speed of 5-8mm / s under a 2500-3000KN axial rolling force with an axial feed speed of 0.5mm / s; and finally rolling into the solid disk forging one one-grade fire. The method is mainly used for rolling the disk forging with excellent shape, dimension, organization and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

Roll forming method of hollow disk forgings of large and medium-sized structural steel

InactiveCN101804439BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceDisc wheelsRoll formingMaterials science

The invention discloses a method for rolling and forming a hollow disk-shaped forging of large and medium-sized structural steel. Firstly, the structural steel bar is subjected to upsetting, pressing, and punching to form a hollow disk blank, and then the disk blank is put into a rolling machine for rolling. system. Within 60s of rolling, the disk blank is widened at a speed of 5mm / s~12mm / s with an axial feed rate of 1.5mm / s and an axial rolling force of 4500KN~4900KN; within 60s~100s of rolling, With an axial feed rate of 1.2mm / s, under an axial rolling force of 3000KN~3900KN and a radial rolling force of 3500KN~4000KN, the disk blank is widened at a speed of 3mm / s~10mm / s; rolling Within 100s ~ 120s, with the axial feed speed of 0.8mm / s, under the axial rolling force of 2000KN ~ 3000KN and the radial rolling force of 2500KN ~ 3000KN, the disk blank is fed at a speed of 2mm / s ~ 6mm / s Speed widening, one-fire rolling into a hollow disc forging. This method is mainly used for rolling disc-shaped forgings with excellent shape, size, structure and performance.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling formation method of large and medium stainless steel hollow disc-shaped forge piece

InactiveCN101758153BReduce rolling efficiencyReduce manufacturing costRoll force/gap control deviceFurnace typesForgeMaterials science

The invention discloses a rolling formation method of a large and medium stainless steel hollow disc-shaped forge piece , which comprises the following steps of: upsetting, compressing and punching a stainless steel rod material into a hollow disc blank; putting the disc blank into a rolling machine to roll; rolling the disc blank for 20s to enable the disc blank to widen at a speed of 10-15mm / s under 4000-4900KN of an axial rolling force at an axial feeding speed of 2mm / s; rolling the disc blank for 20-40s to enable the disc blank to widen at a speed of 8-12mm / s under 3000-3500KN of an axialrolling force and 3000-4000KN of a radial rolling force at an axial feeding speed of 1mm / s; rolling the disc blank for 40-60s to enable the disc blank to widen at a speed of 5-8mm / s under 2500-3000KNof an axial rolling force and 2000-3000KN of a radial rolling force at an axial feeding speed of 0.5mm / s; and carrying out fire rolling to prepare the hollow disc-shaped forge piece. The method is mainly used for rolling disc-shaped forge pieces with excellent shapes, sizes, textures and performances.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com