Anti-deformation machining technology for air compressor thin-wall machine body

An air compressor and processing technology, which is applied in the field of anti-deformation processing technology of thin-walled air compressor body, can solve the problems of poor positioning accuracy, unqualified shape and position tolerance, deformation, etc., so as to improve the utilization rate and reduce the Processing, the effect of reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

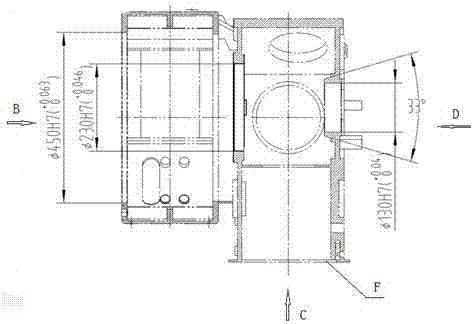

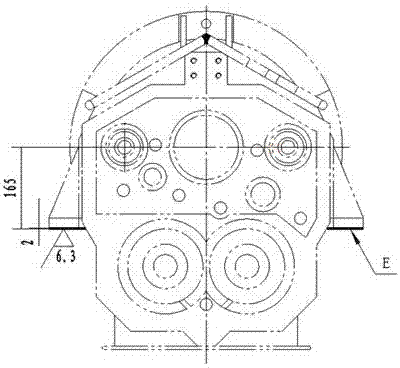

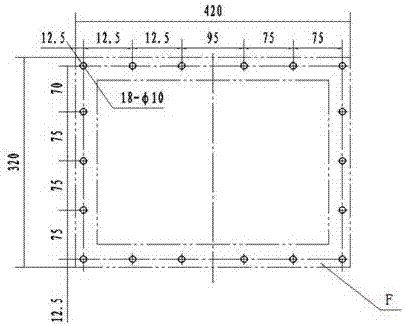

[0021] A new type of electric high-pressure air compressor body is processed by an anti-deformation processing technology of a thin-walled body of an air compressor:

[0022] (1) Design a special card alignment tool, because the body is a thin-walled part, and the box part and the cylinder part of the body are welded structures. In the process of processing certain sizes, it is not easy to install the card alignment. Deformation often occurs; according to the particularity of fuselage processing, a special aligning tooling for the fuselage is designed, and the use of this tooling can effectively avoid the phenomenon of reference movement when processing special positions, and the special aligning tooling can play a role in Good positioning and support, and at the same time strictly control the feed amount of each tool to avoid processing deformation;

[0023] (2) Improve the machining process of the fuselage. According to the coaxiality requirements of many parts of the fusela...

Embodiment 2

[0041] A small-displacement electric high-pressure air compressor body is processed by an anti-deformation processing technology for a thin-walled body of an air compressor:

[0042] (1) Design a special card alignment tool, because the body is a thin-walled part, and the box part and the cylinder part of the body are welded structures. In the process of processing certain sizes, it is not easy to install the card alignment. Deformation often occurs; according to the particularity of fuselage processing, a special aligning tooling for the fuselage is designed, and the use of this tooling can effectively avoid the phenomenon of reference movement when processing special positions, and the special aligning tooling can play a role in Good positioning and support, and at the same time strictly control the feed amount of each tool to avoid processing deformation;

[0043](2) Improve the machining process of the fuselage. According to the coaxiality requirements of many parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com