Roll forming method of large and medium high-temperature alloy solid disk forging

A high-temperature alloy and disc-shaped forging technology, which is applied in the field of rolling forming of forgings, can solve the problems of increasing production costs, over-burning and structure variation, and reducing productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

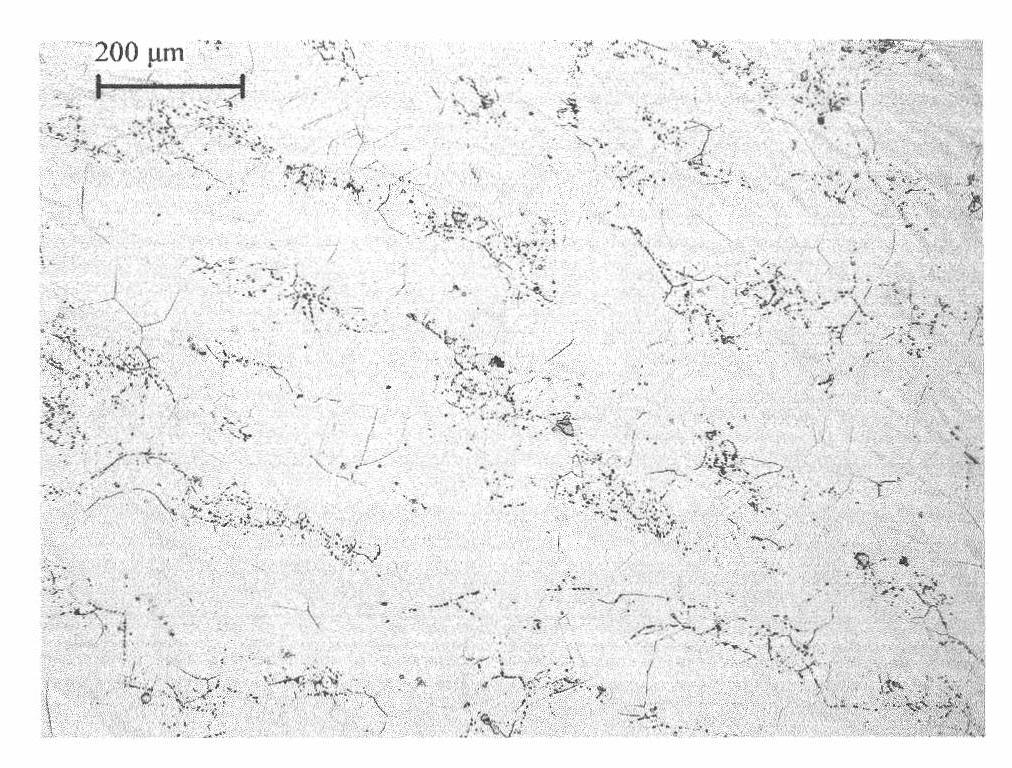

[0024] The superalloy material of GH2674 is taken as an example to illustrate the specific process steps of the present invention below:

[0025] Step 1: Heating the GH2674 high-temperature alloy bar blanked according to the specification to the deformation temperature of 1040°C to 1080°C, then upsetting and pressing to obtain a high-temperature alloy solid disc blank;

[0026] Step 2: heating the solid disk to the above-mentioned deformation temperature, loading it into a rolling machine and positioning it;

[0027] Step 3: Start the rolling machine, and manipulate the upper tapered roller to move axially at a speed of 1.6mm / s towards the solid disk, and the upper and lower tapered rollers of the rolling machine move along the direction of the solid disk. In the axial direction of the billet, the disk surface is rolled with a rolling force of 4000KN-4900KN and moved horizontally outward along the radial direction to realize the axial rolling of the billet; the solid billet is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com