Method for flower-editing, transposition and molding of electric machine bar line stick end

A forming method and strip wire technology are applied in the field of braided transposition forming at the end of a motor strip wire rod, which can solve the problems of inaccurate pressing of the R angle at the end, large scrap of wire rods, and irregular forming, etc. Improve efficiency, save production costs, and achieve consistent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

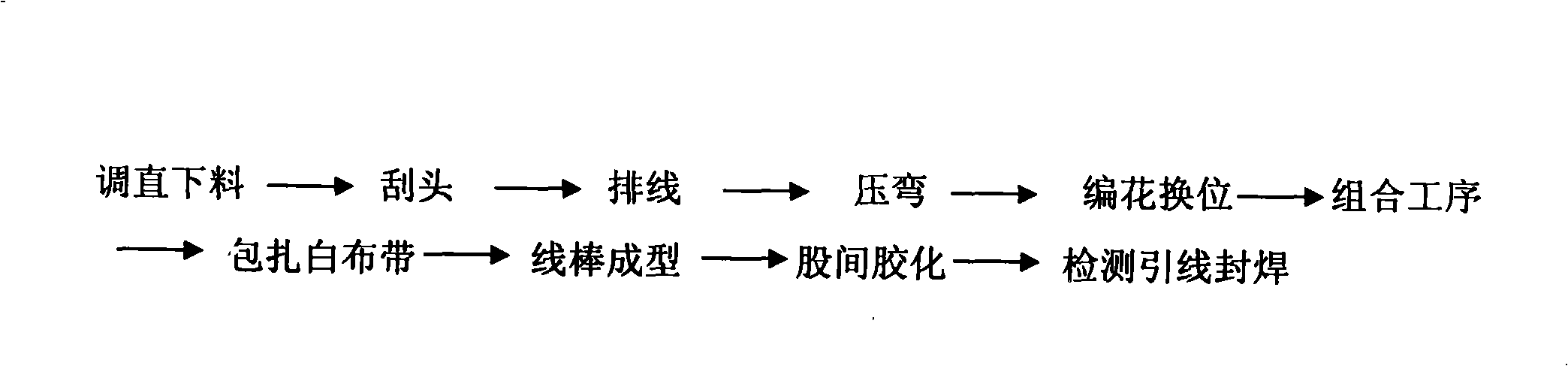

[0034] Reference attached figure 1 .

[0035] A method for knitting and transposition forming at the end of a motor strip bar includes the processes of wire arranging, bending, and forming. The knitting and transposition forming process at the end of the bar bar includes:

[0036] 1) Cable

[0037] (1) Separate the copper wires of the upper and lower bars and place the copper wires on the platform;

[0038] (2) Fix the cable board on the work surface, arrange the copper wires in sequence, and fix the arranged copper wires with the cable clamp;

[0039] 2) Press bending

[0040] The copper wire is bent in the upper and lower molds of the hydraulic press by hydraulic bending method; the bending tool considers the rebound amount of the copper wire and the bending size is appropriately considered on the basis of the design drawings. The processing depth is 0.3-0.5mm, and the knitting transposition pitch meets The drawing requires that the copper wire has no insulation damage.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com