A machining method for frame parts

A kind of mechanical processing and frame technology, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of unstable flatness and parallelism, inability to completely solve parts deformation, and tool marks on the surface of parts, etc., to achieve product quality The effect of stable quality, meeting the requirements of design drawings, and solving deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made.

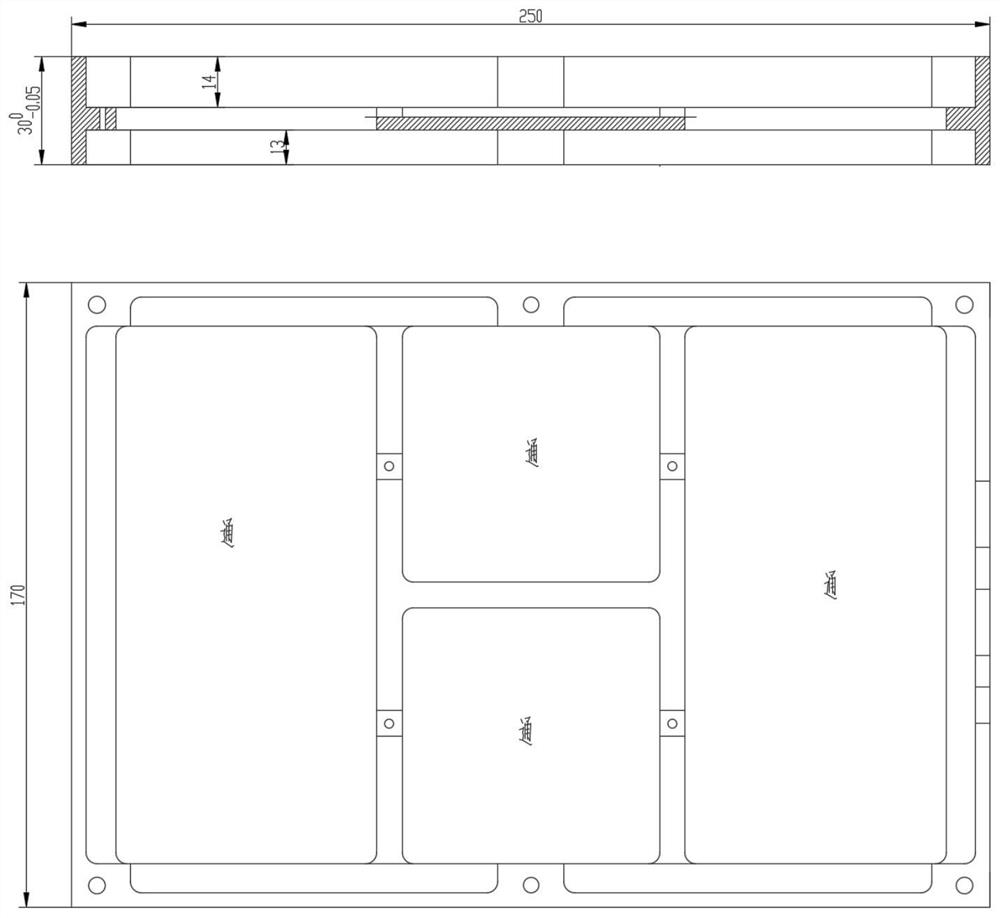

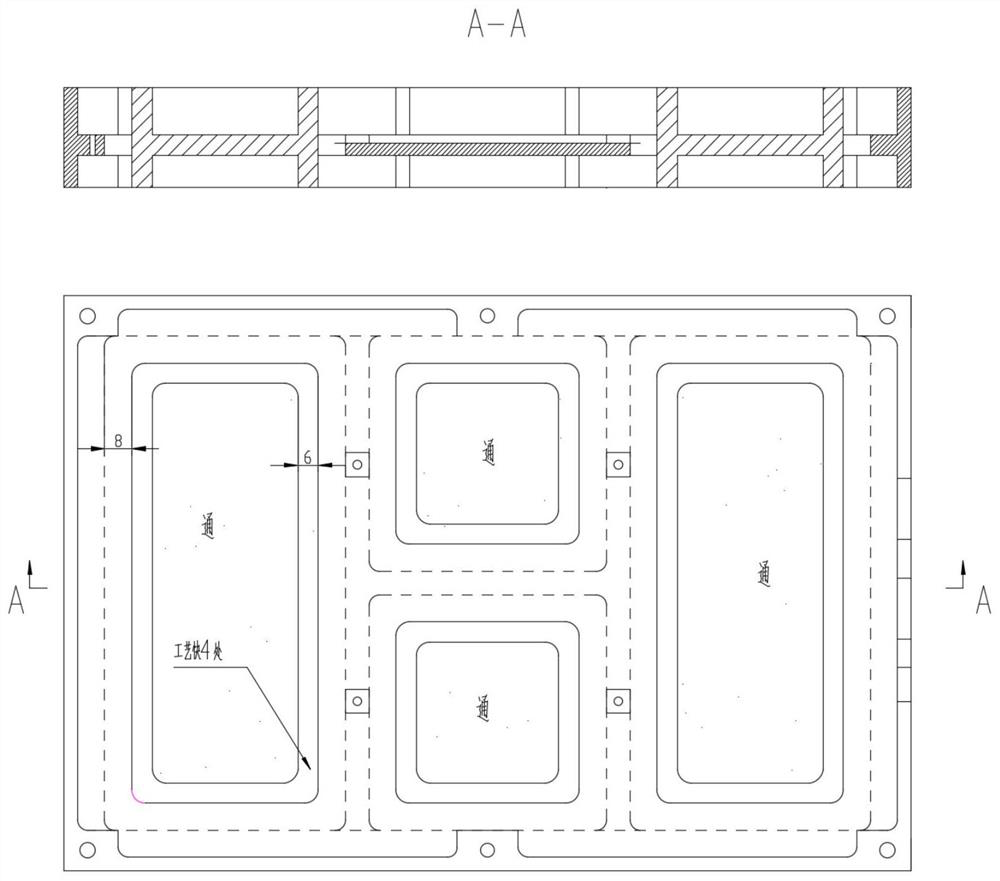

[0020] Such as Figure 1-2 As shown, the machining method of a kind of frame parts provided by the present invention, the processed frame parts size is as follows figure 1 , the schematic diagram of the process block is as follows figure 2 .

[0021] The main steps include: (1) Rough milling of the front and back of the part, according to the machining accuracy, a process block is reserved at the through cavity of the part, and a margin of 0.5mm is left on one side of the other processing places; (2) The front and back of the part are finely milled respectively. The front and back sides of the rough milling part are clamped in a vise.

[0022] The operation of retaining the process block is as follows: the surface of the process block and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com