Patents

Literature

89 results about "Vise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

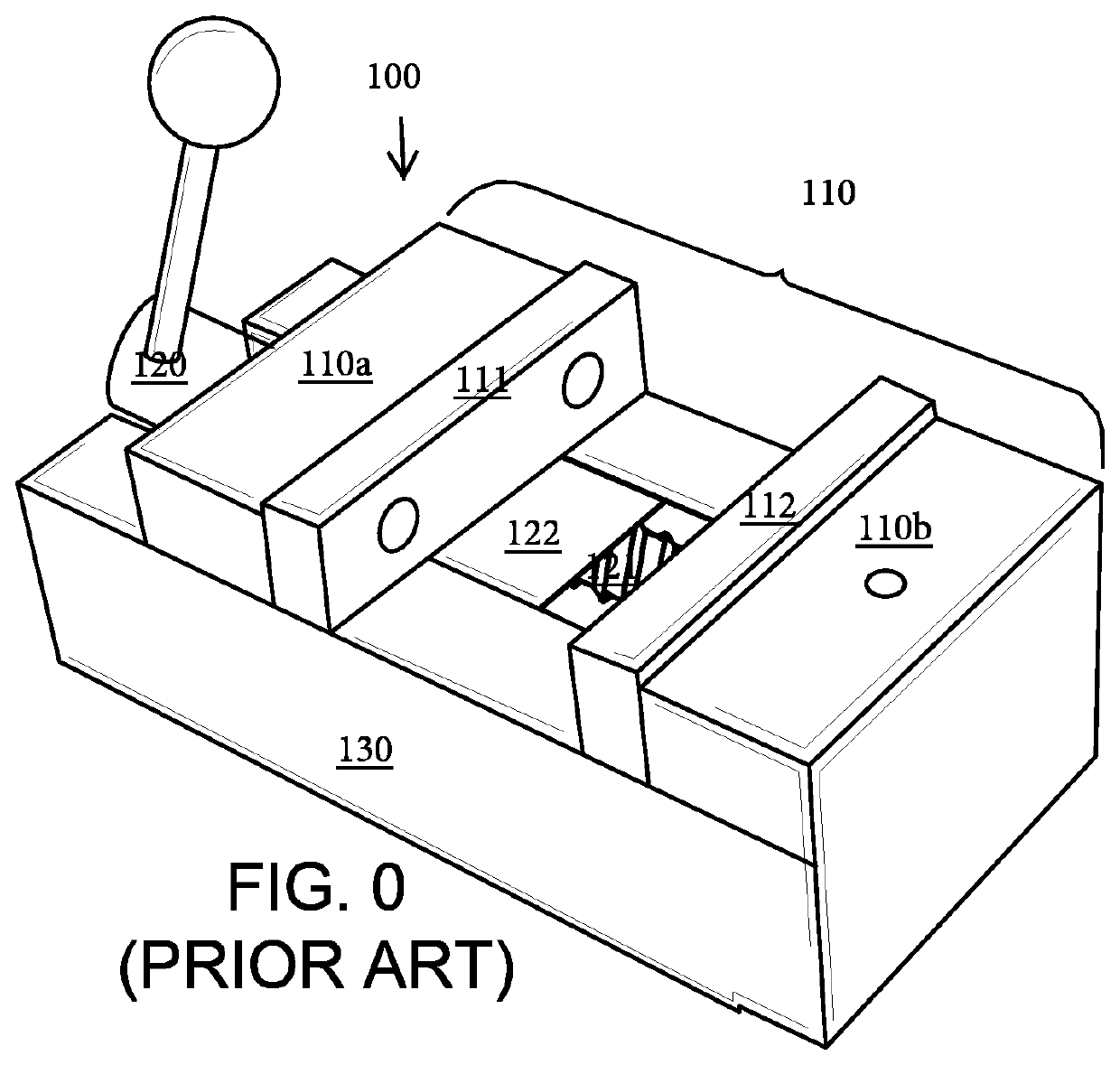

A vise (American English) or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

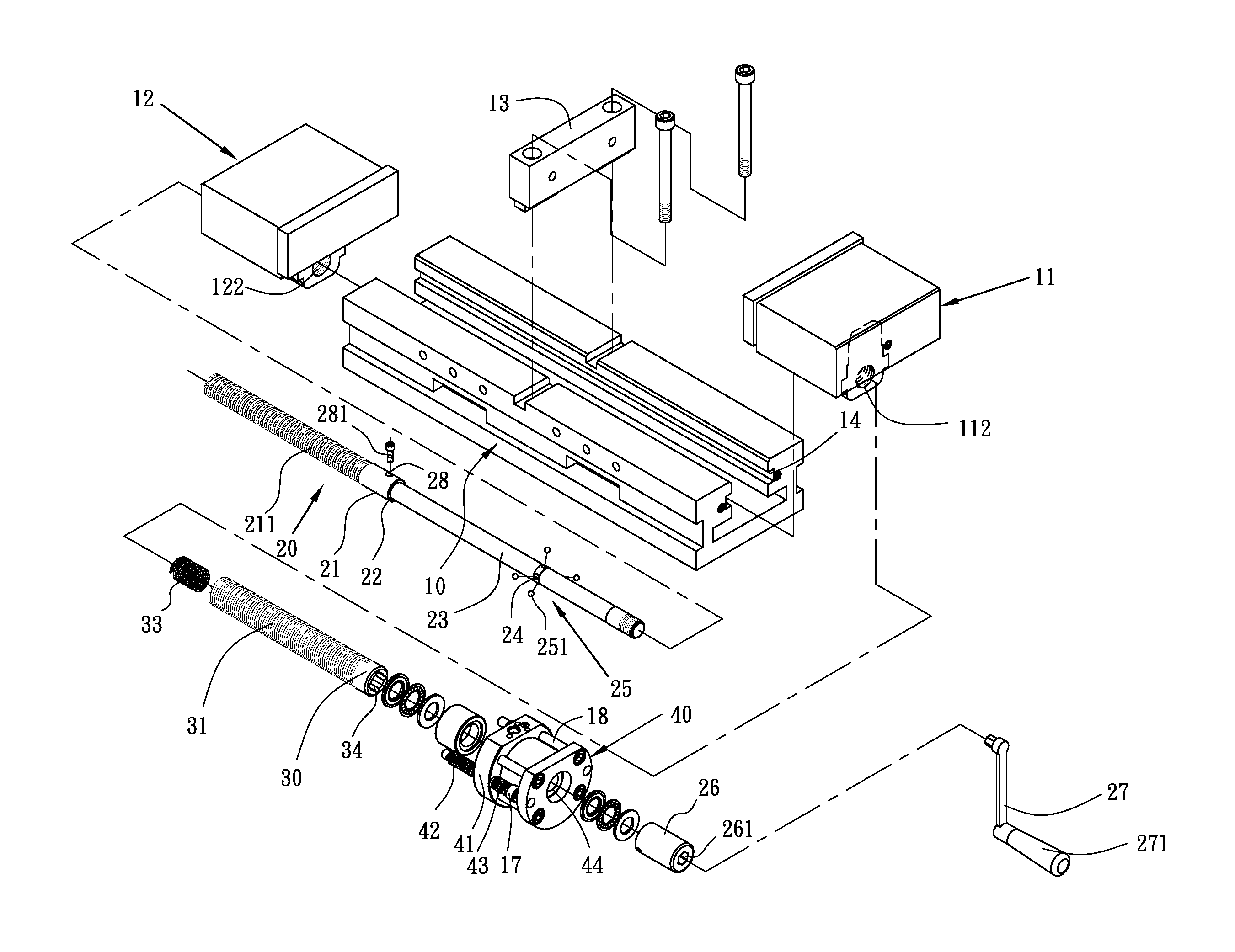

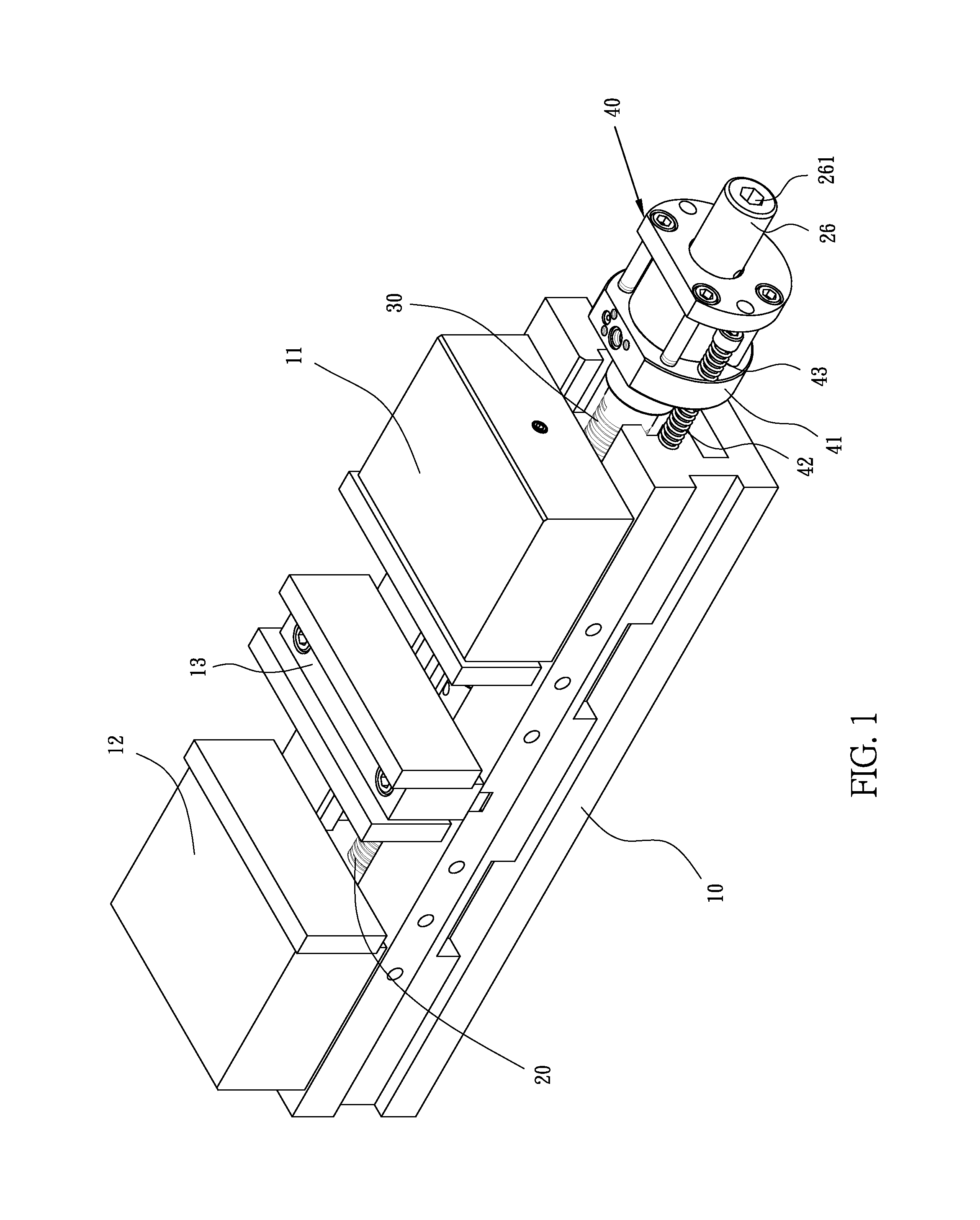

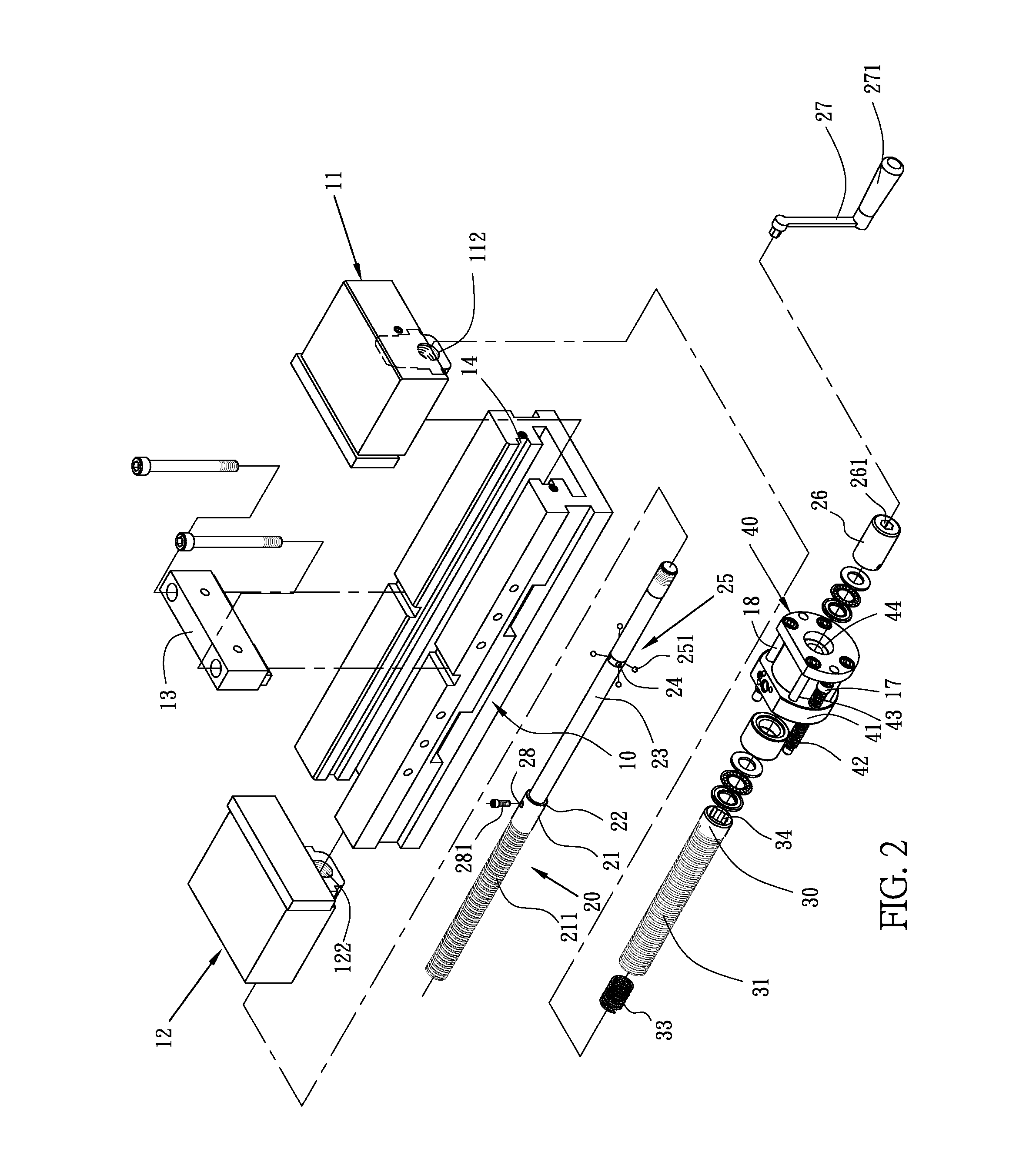

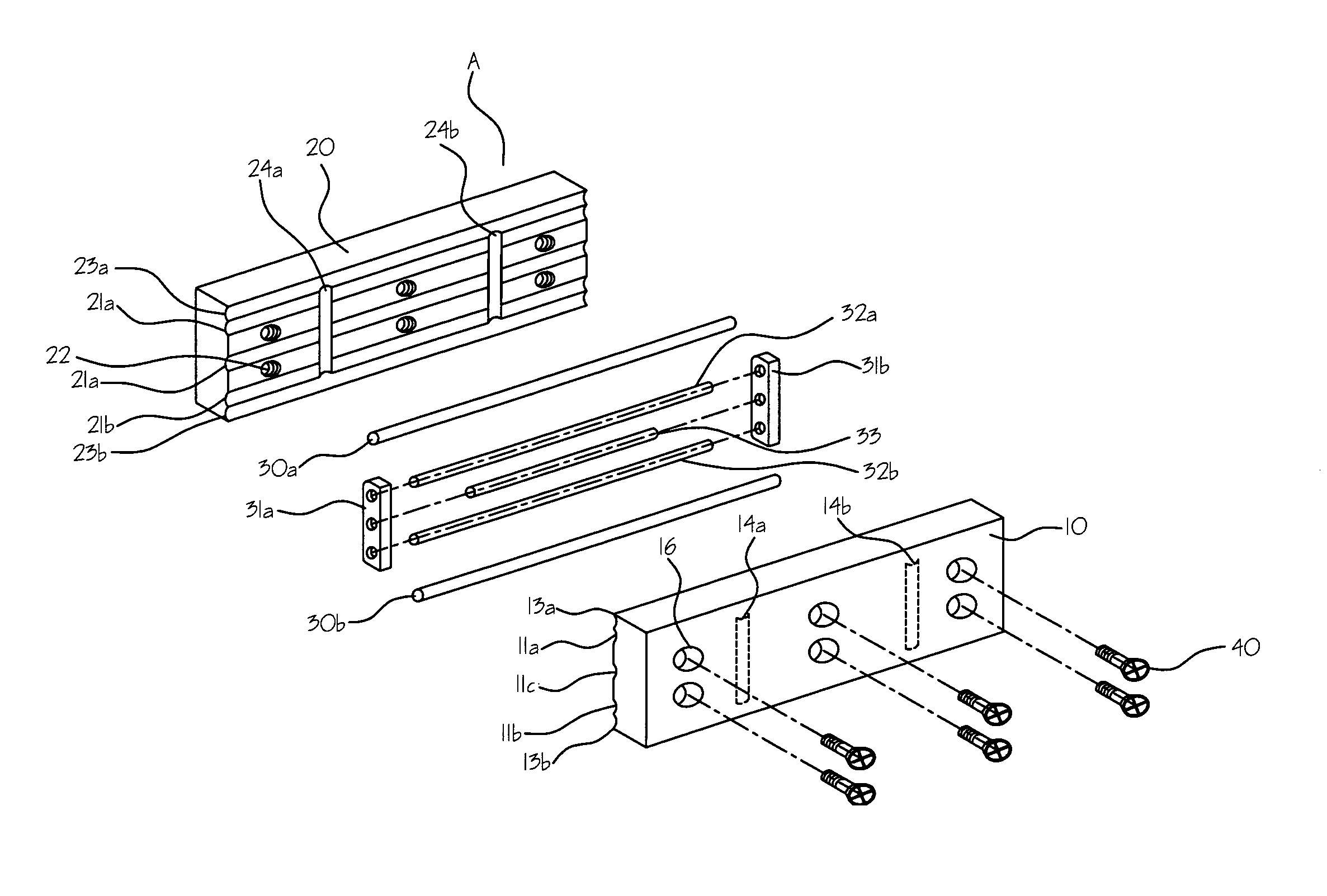

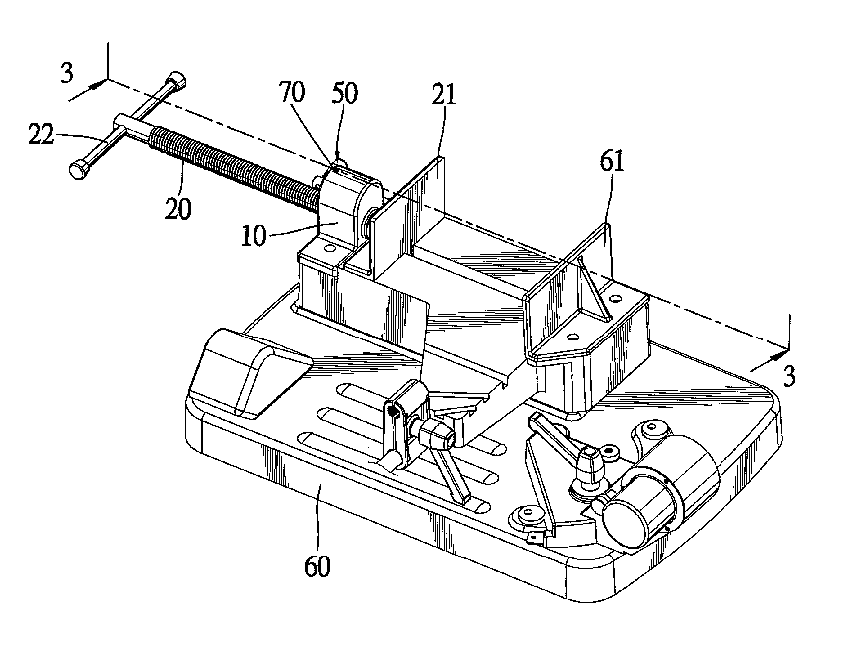

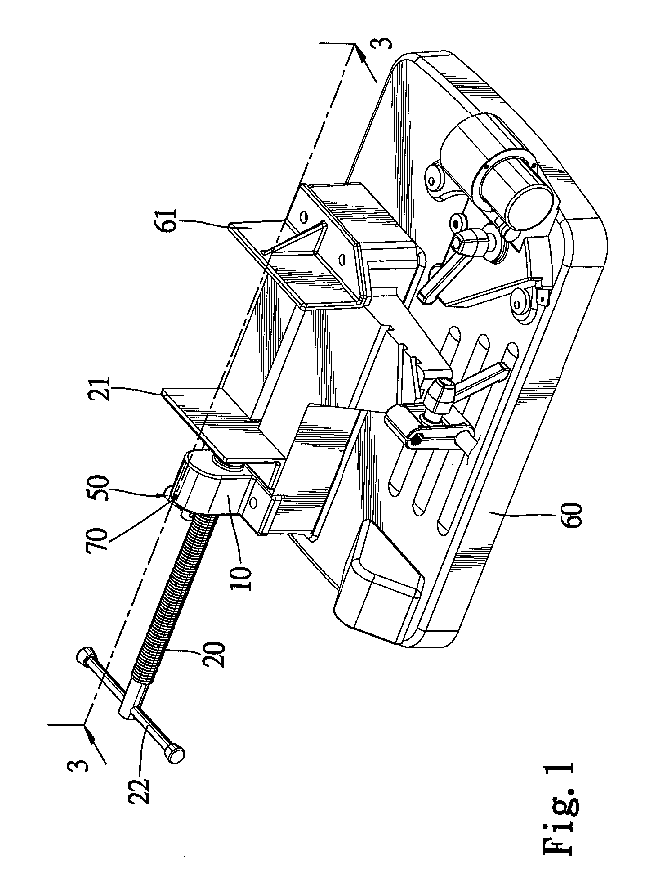

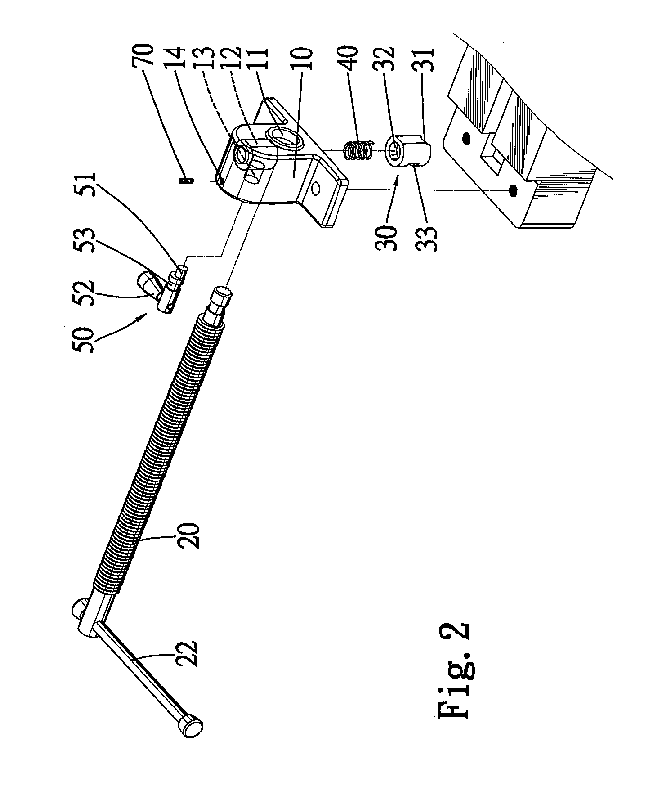

Double clamp vise

The vise includes a seat body having two movable jaws separately with two inner threads, a fixed jaw and a rail. A screwing rod has a rear portion and a front portion whose diameter is less than the rear portion. A first outer thread is formed on the rear portion. A step is formed between the front portion and the rear portion. A screwing tube telescopically and unrotatably sheathes the front portion of the screwing rod and has a second outer thread. The two movable jaws are separately engaged with the screwing tube and screwing rod by screwing the outer threads and the inner threads. A spiral direction of the first outer thread is contrary to the second outer thread. A main spring is nipped between the screwing rod and screwing tube. A crank is axially connected to the front portion of the screwing rod for rotating the screwing rod.

Owner:WANG WEN FENG

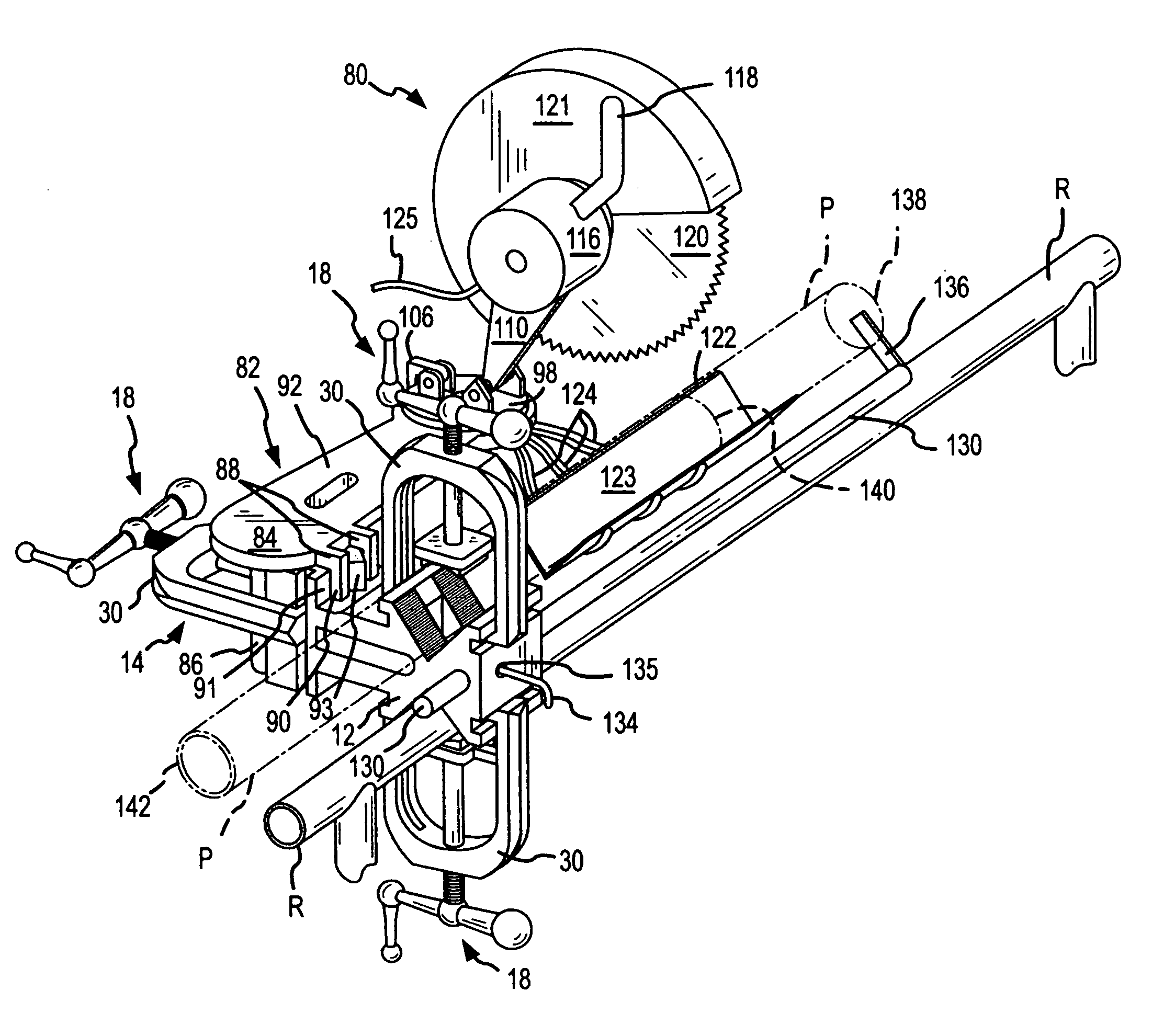

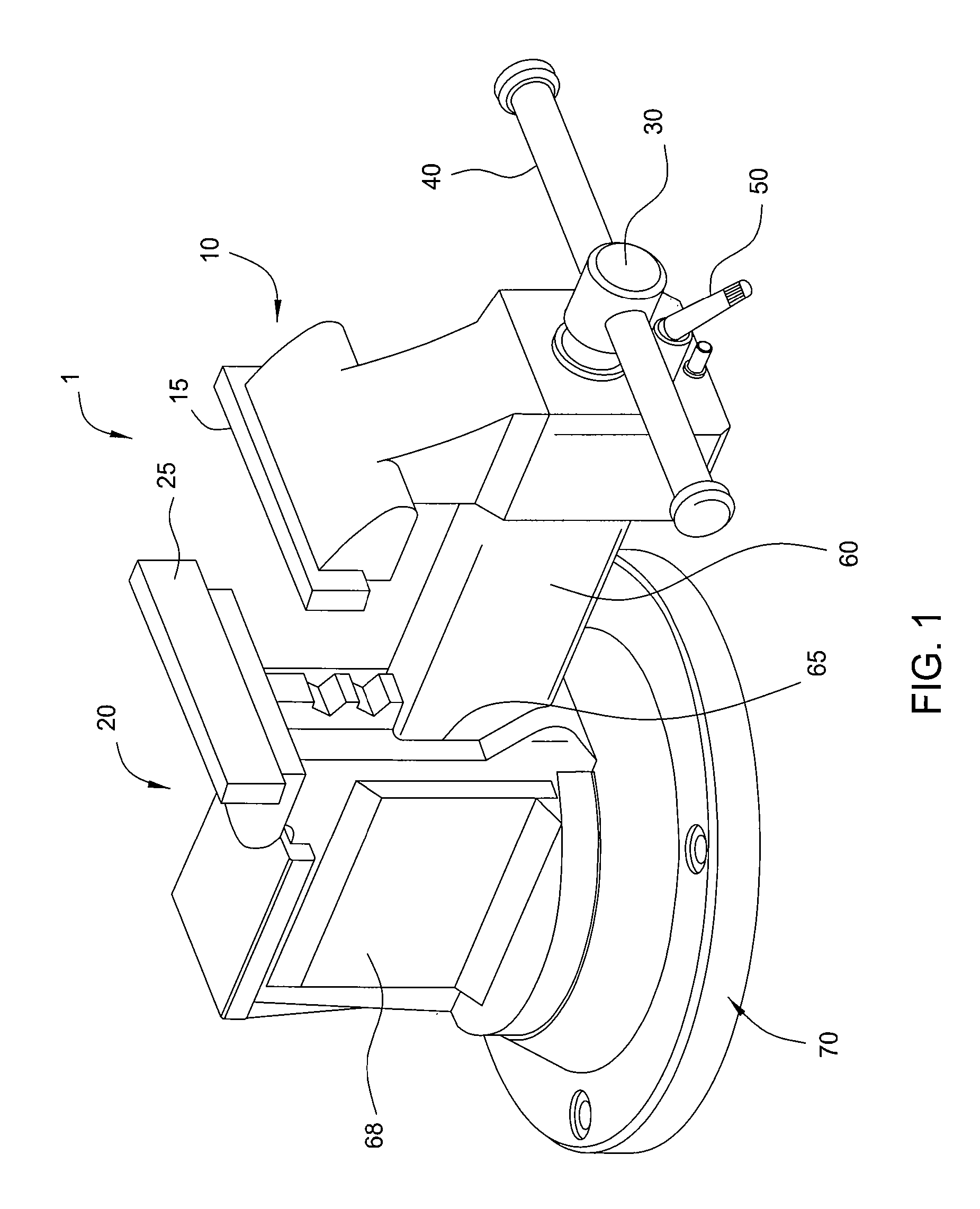

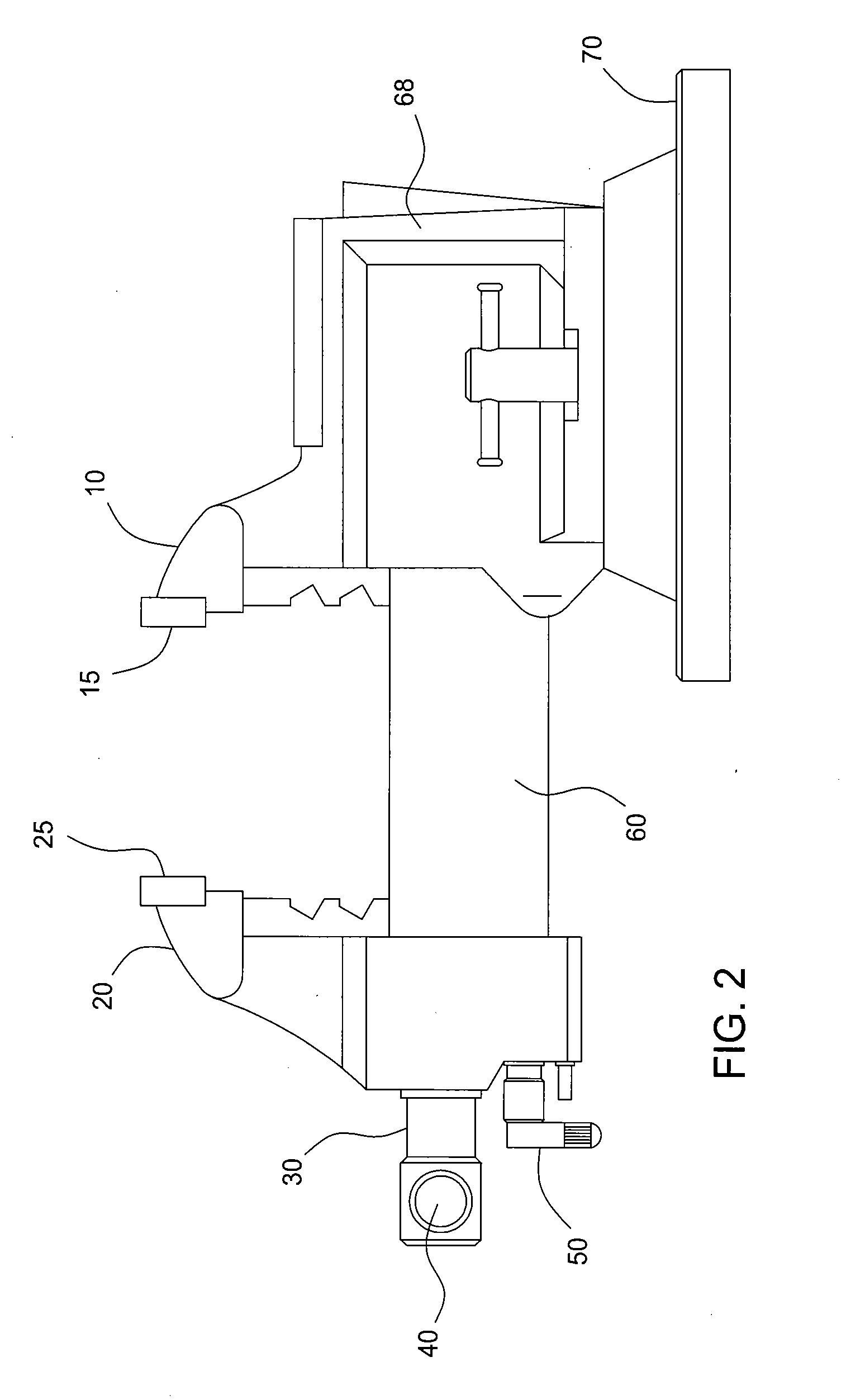

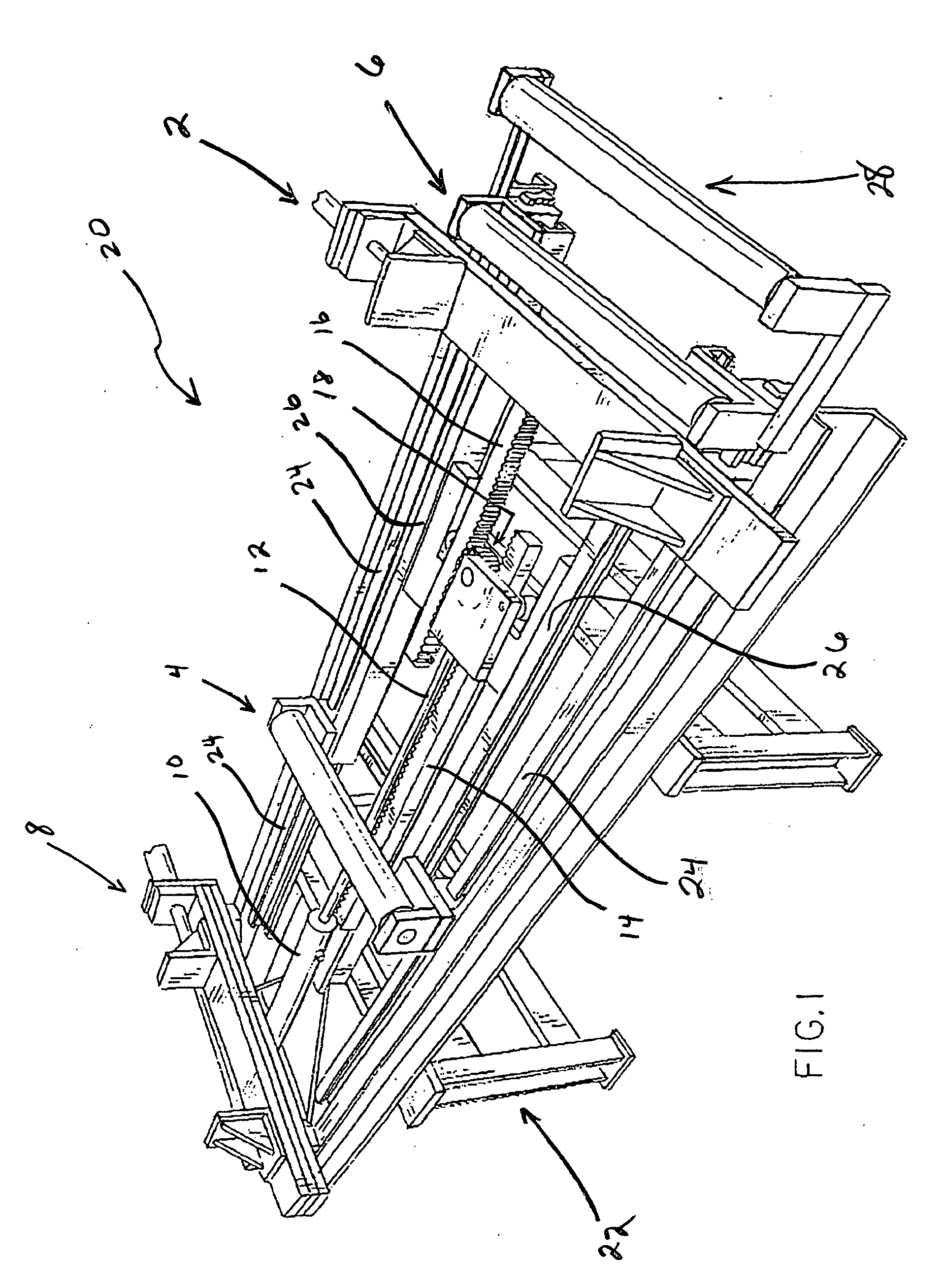

Portable vise and saw combination

A portable vise and saw combination includes a vise element having three attachment points. One attachment point is used to attach the vise to an existing support such as an existing horizontal rail, and another attachment point allows a saw to be mounted to the vise. A workpiece is mounted in the third attachment point. The saw is aligned with the workpiece so that the workpiece may be selectively cut at a desired length and angle. A measuring apparatus is also incorporated within the vise to allow an operator to set the saw to cut successive workpieces at the same lengths without having to remeasure each workpiece.

Owner:AMAESING TOOLS MFG

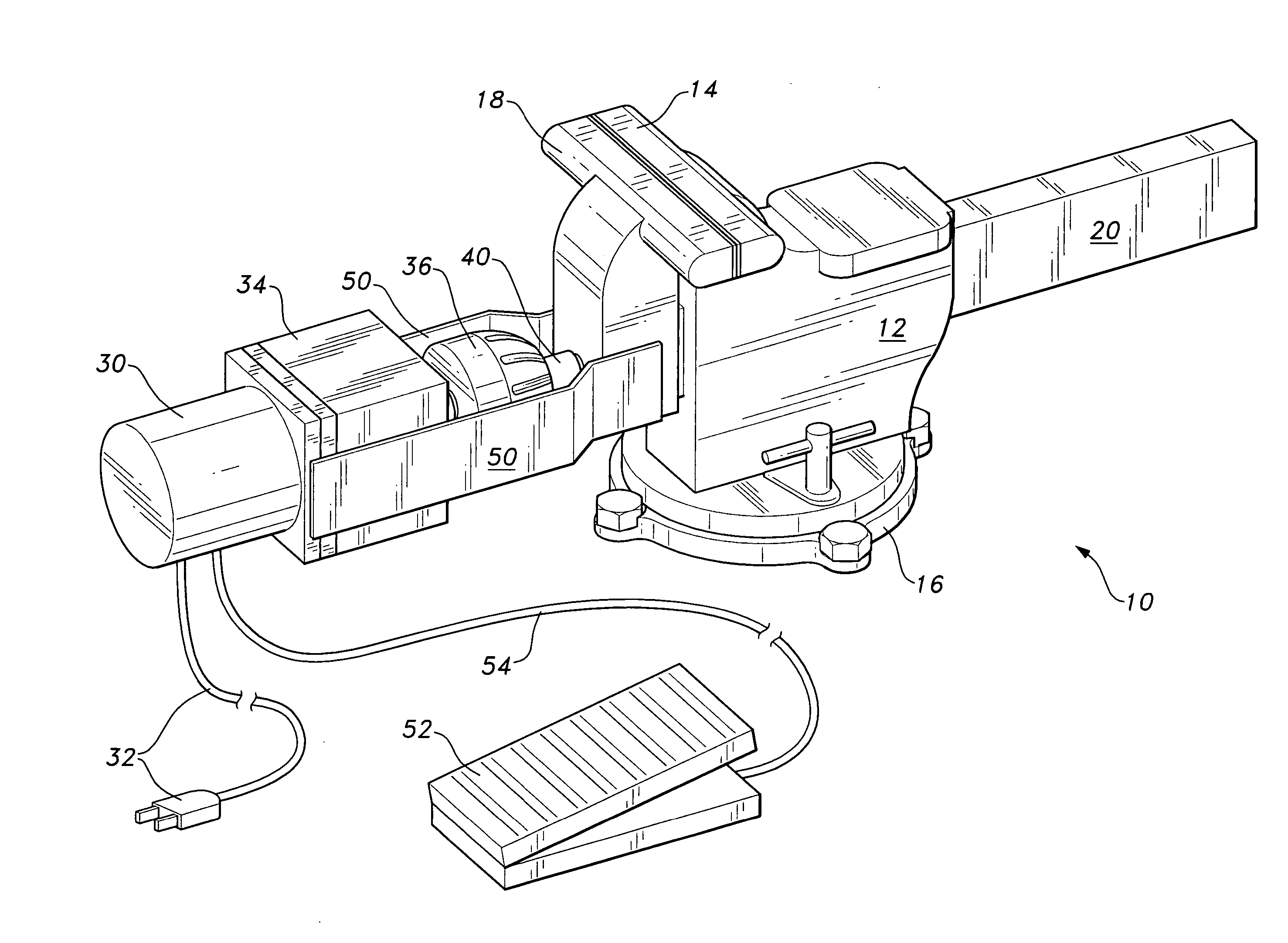

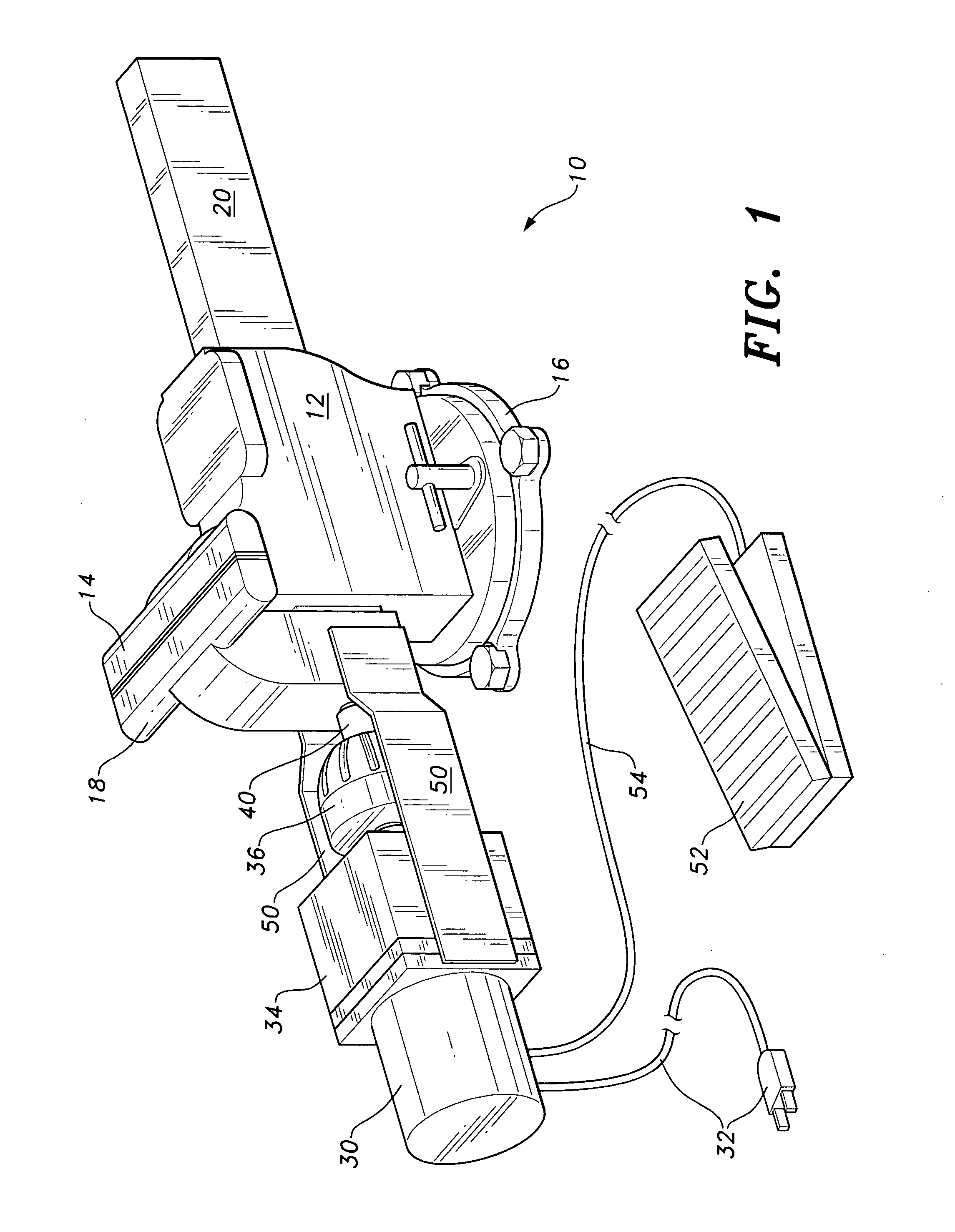

Power vise

The present invention comprises various embodiments of a power vise in which a supplementary power source is used to open and close the jaws. All embodiments may be actuated by a remote control, so the operator may have both hands free to hold the workpiece as it is placed in or removed from the vise. All embodiments may also include means for regulating the pressure developed between the jaws. A first embodiment is an electrically operated vise. The output shaft of an electric motor is connected to the advance screw of the vise to turn the screw and close or open the jaws. A second embodiment includes a hydraulic ram, with a first jaw affixed to the hydraulic cylinder and a second jaw affixed to the piston rod of the hydraulic device. Hydraulic pressure is used to retract and extend the piston rod, thereby closing and opening the jaws.

Owner:HOOPER RONALD L

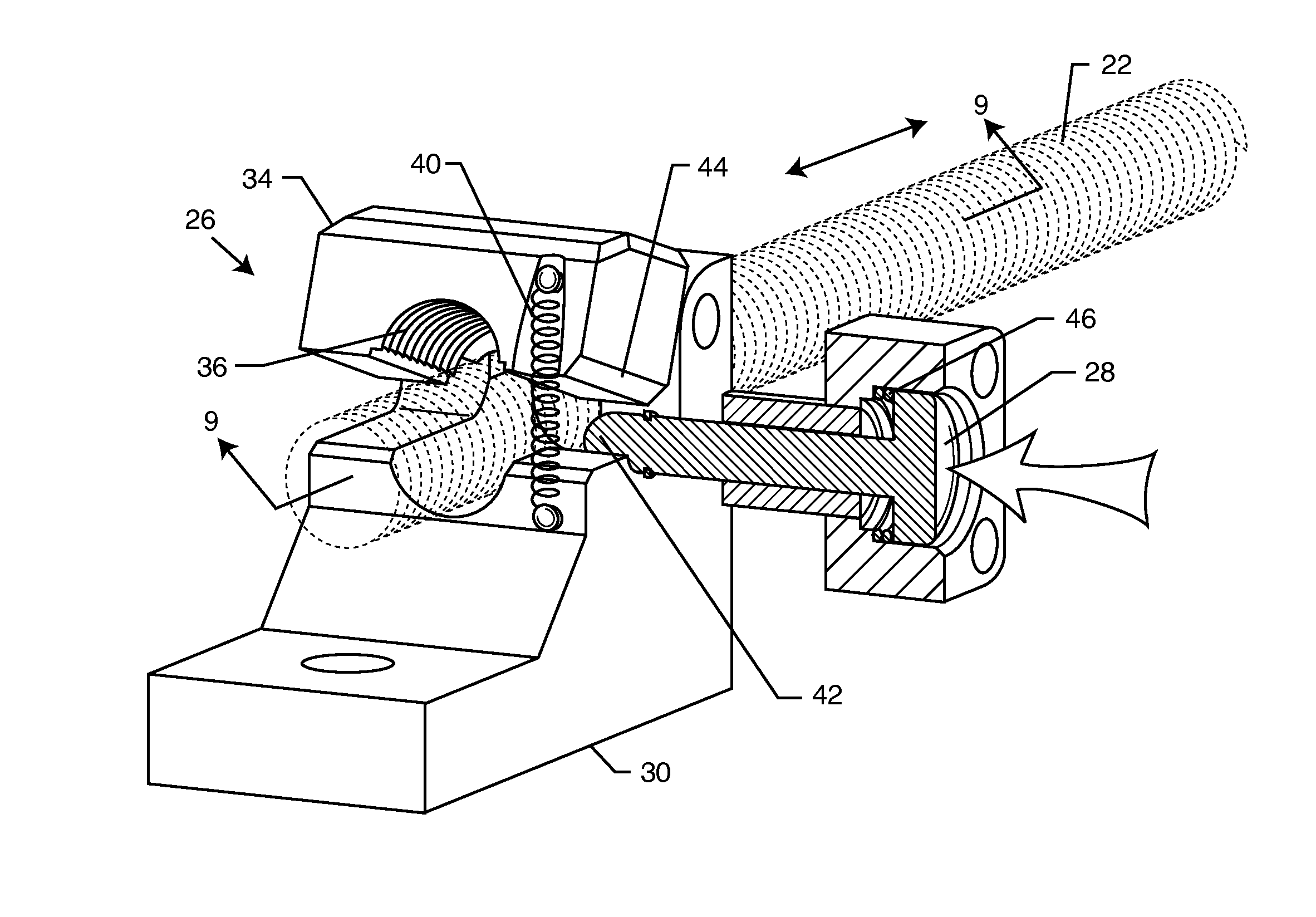

Brazed joint torque test apparatus and methods

InactiveUS20070068277A1Prevent rotationMeasurement of torque/twisting force while tighteningMeasurement arrangements for variableDrive shaftTest set

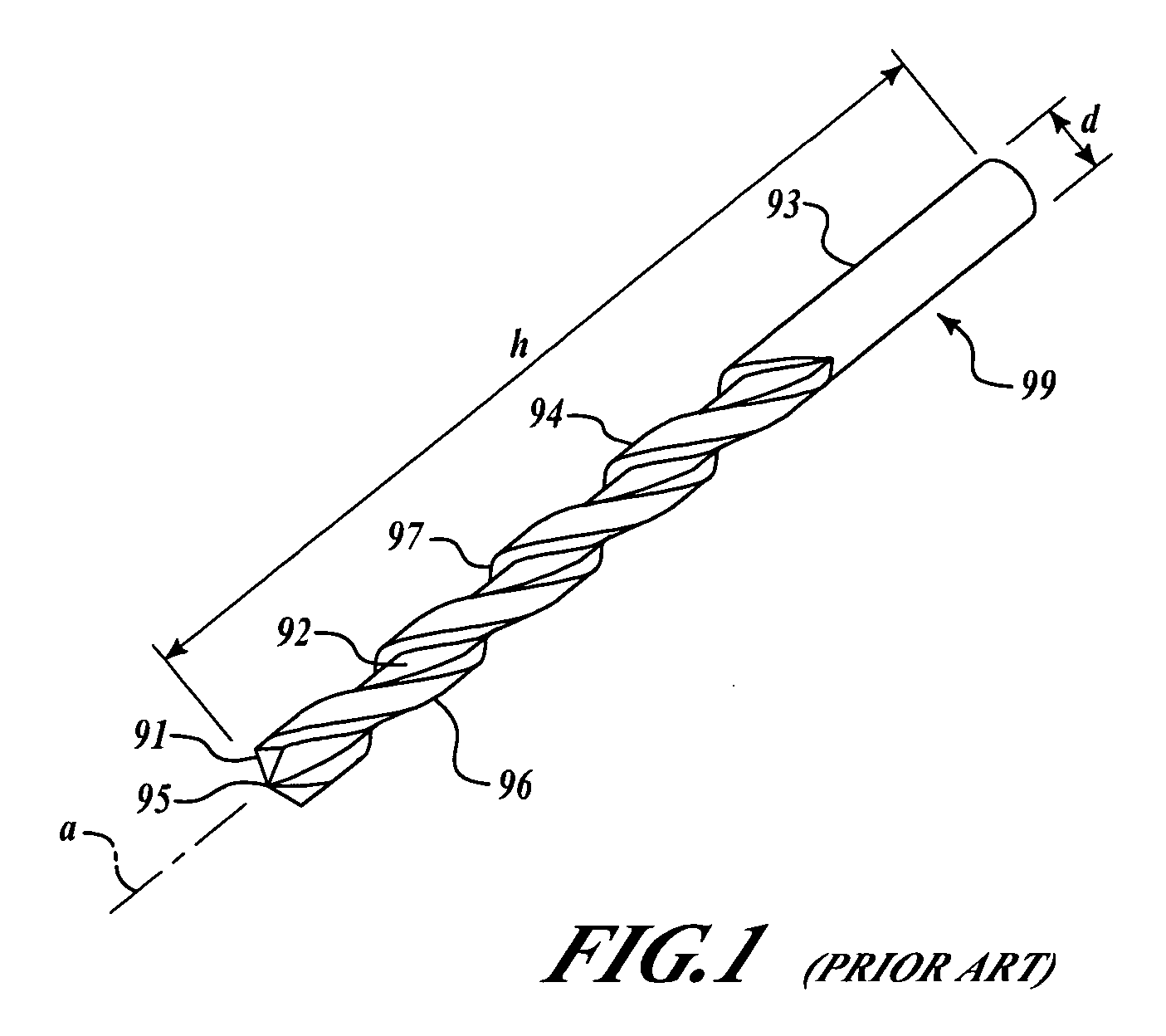

A method and device for testing a substantially cylindrical tool having an axis is performed by imparting a testing torque to the cylindrical tool. The tool is clamped in a vise. The tool has a driven end including a shank and a working end in opposed relation along the axis. The vise is configured to clamp the tool to prevent rotation of the tool about the axis. The shank is clamped in a chuck. The chuck has a adapter defining a void configured to engagingly receive a socket drive shaft. A torque wrench having a lever arm and a socket driver shaft is engaged by insertion of the socket drive shaft into the void. A torque is imparted to the cylindrical tool about its axis by suitably imparting a force on the lever arm. The quantum of torque imparted is measured based upon operation of the torque wrench.

Owner:THE BOEING CO

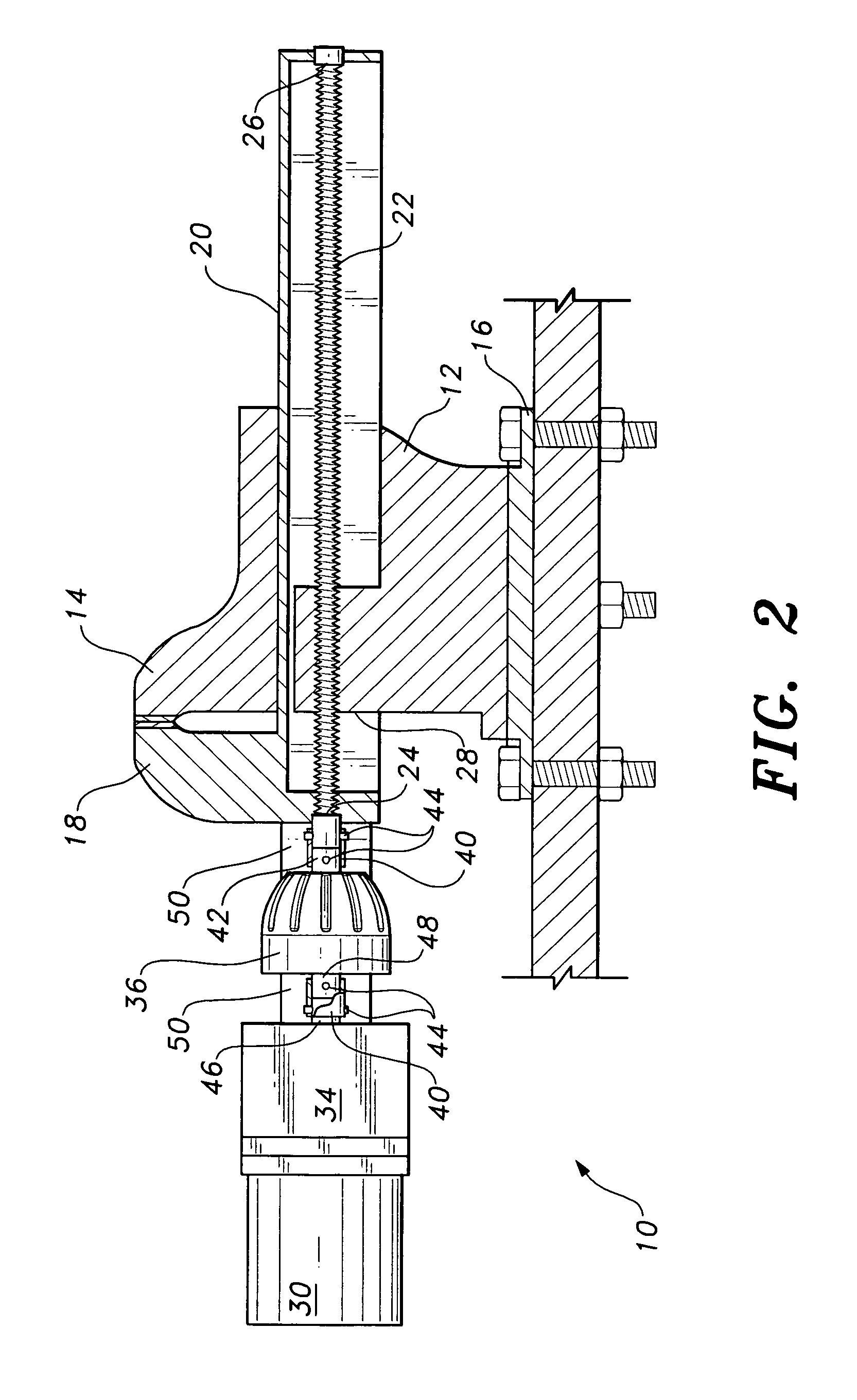

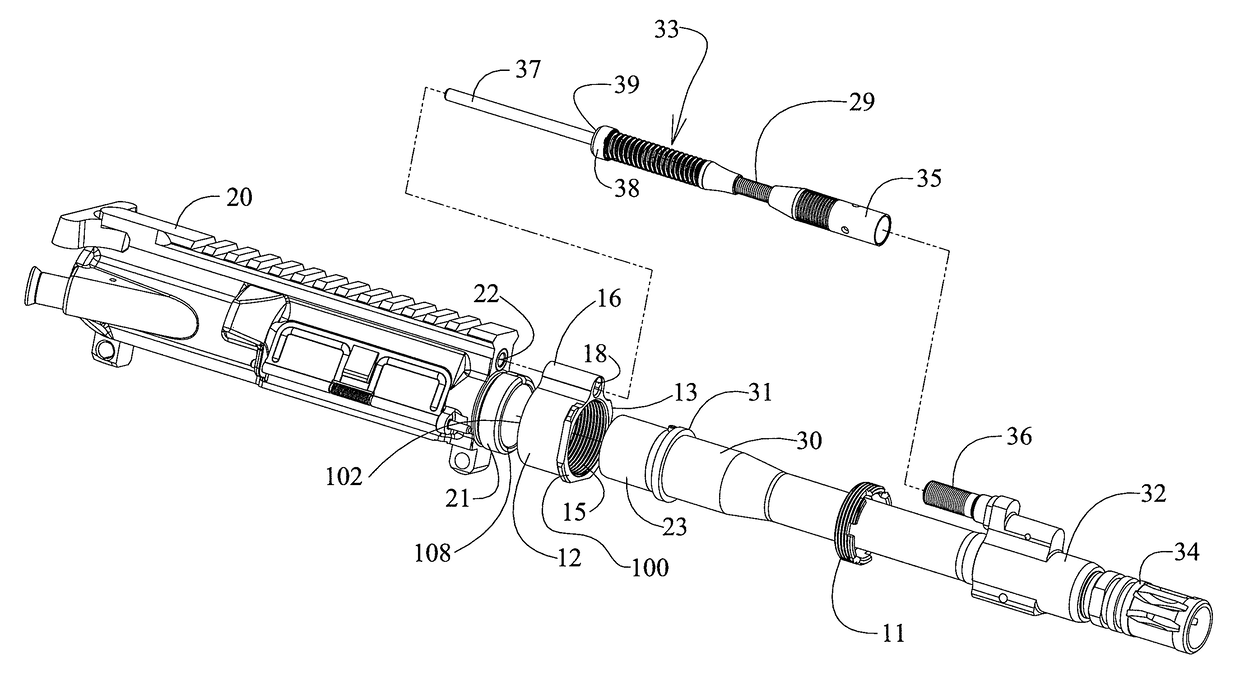

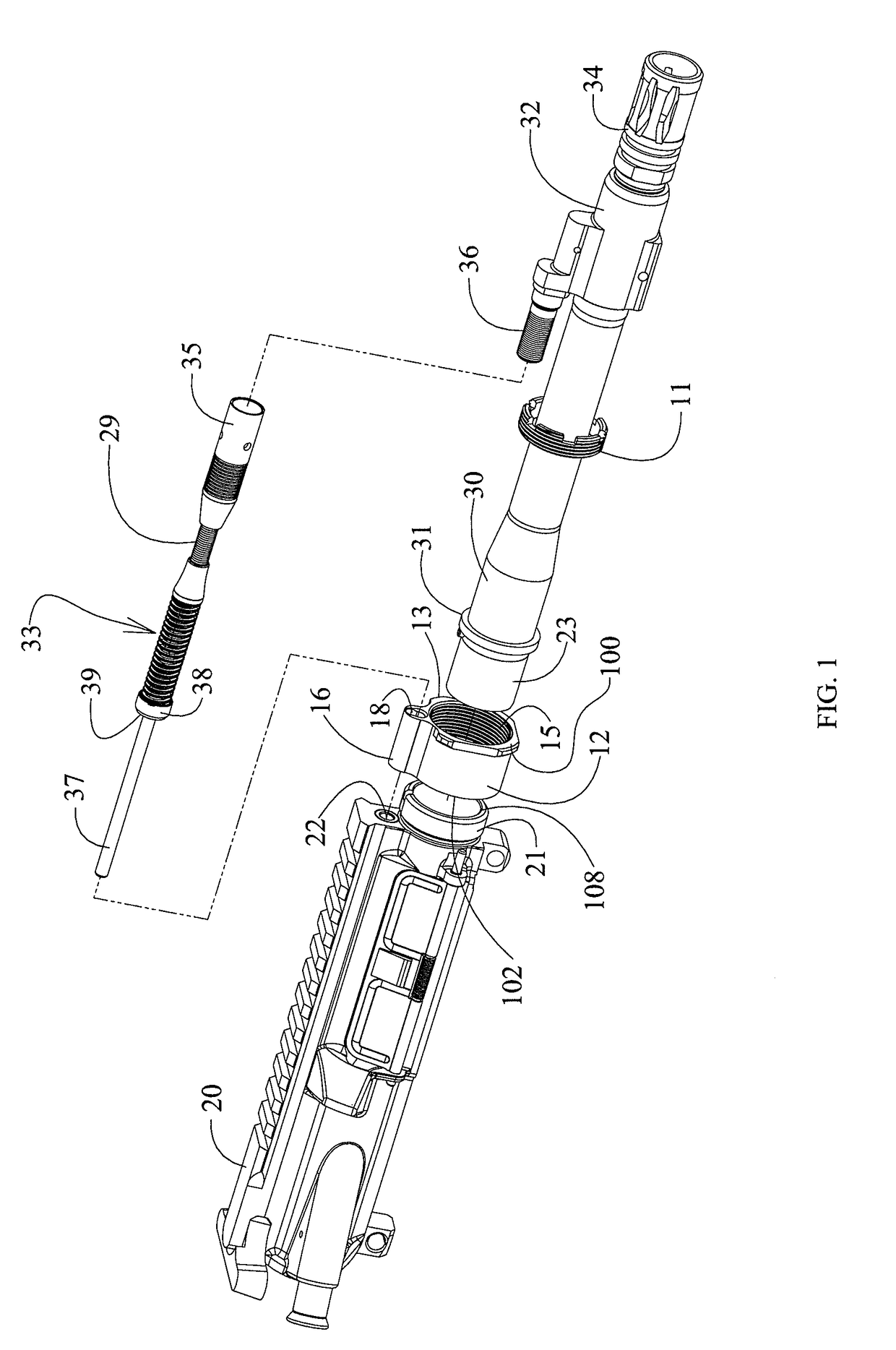

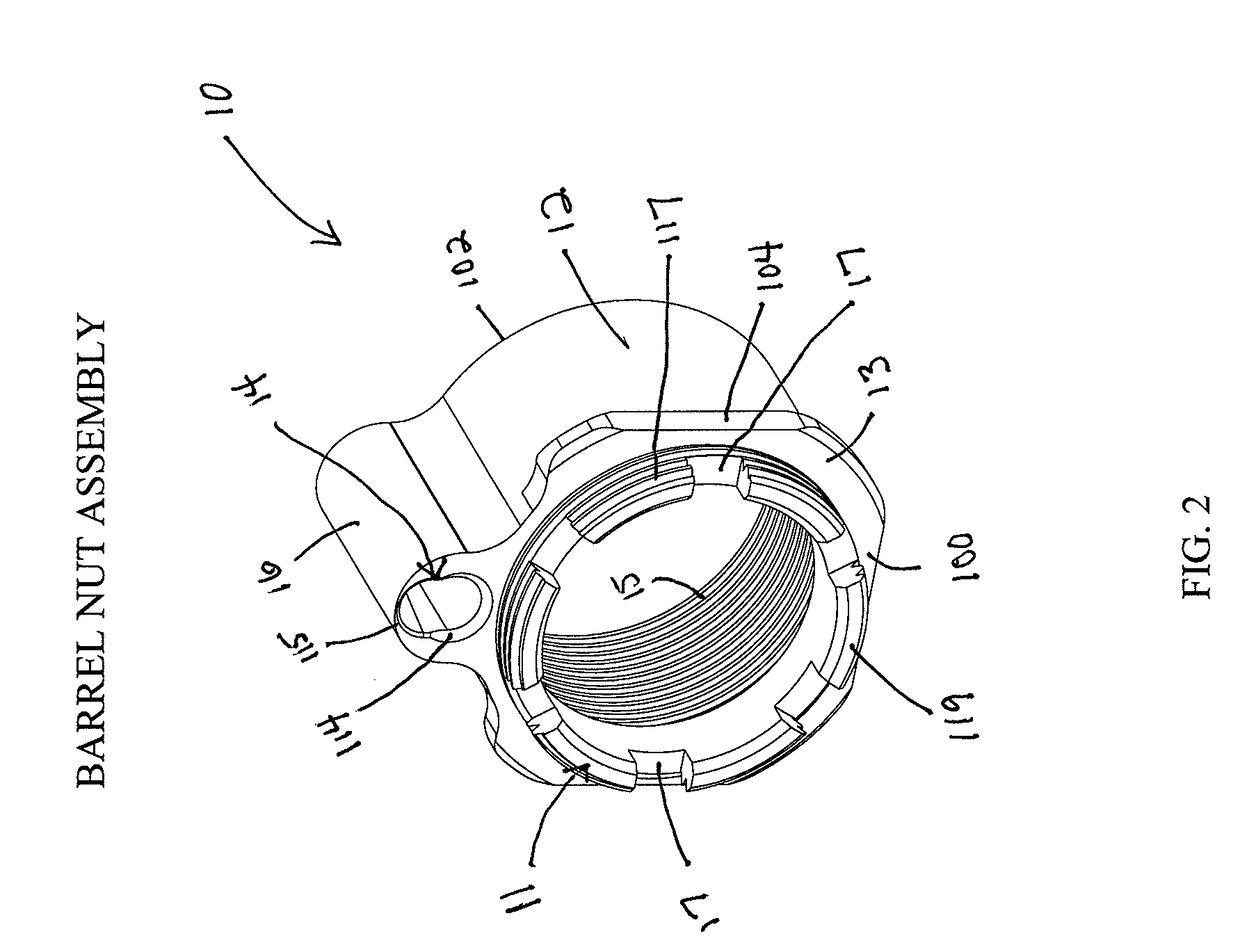

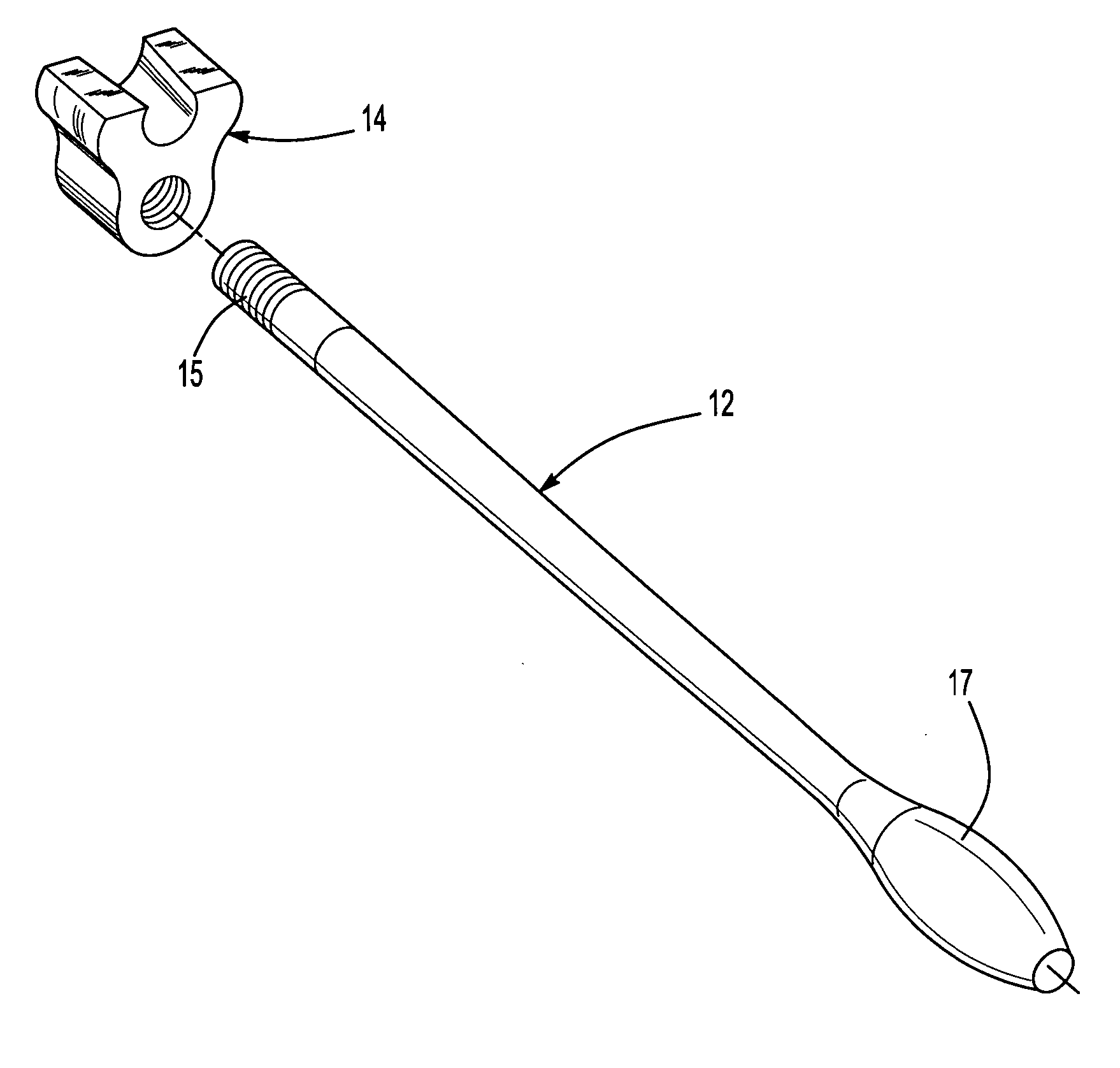

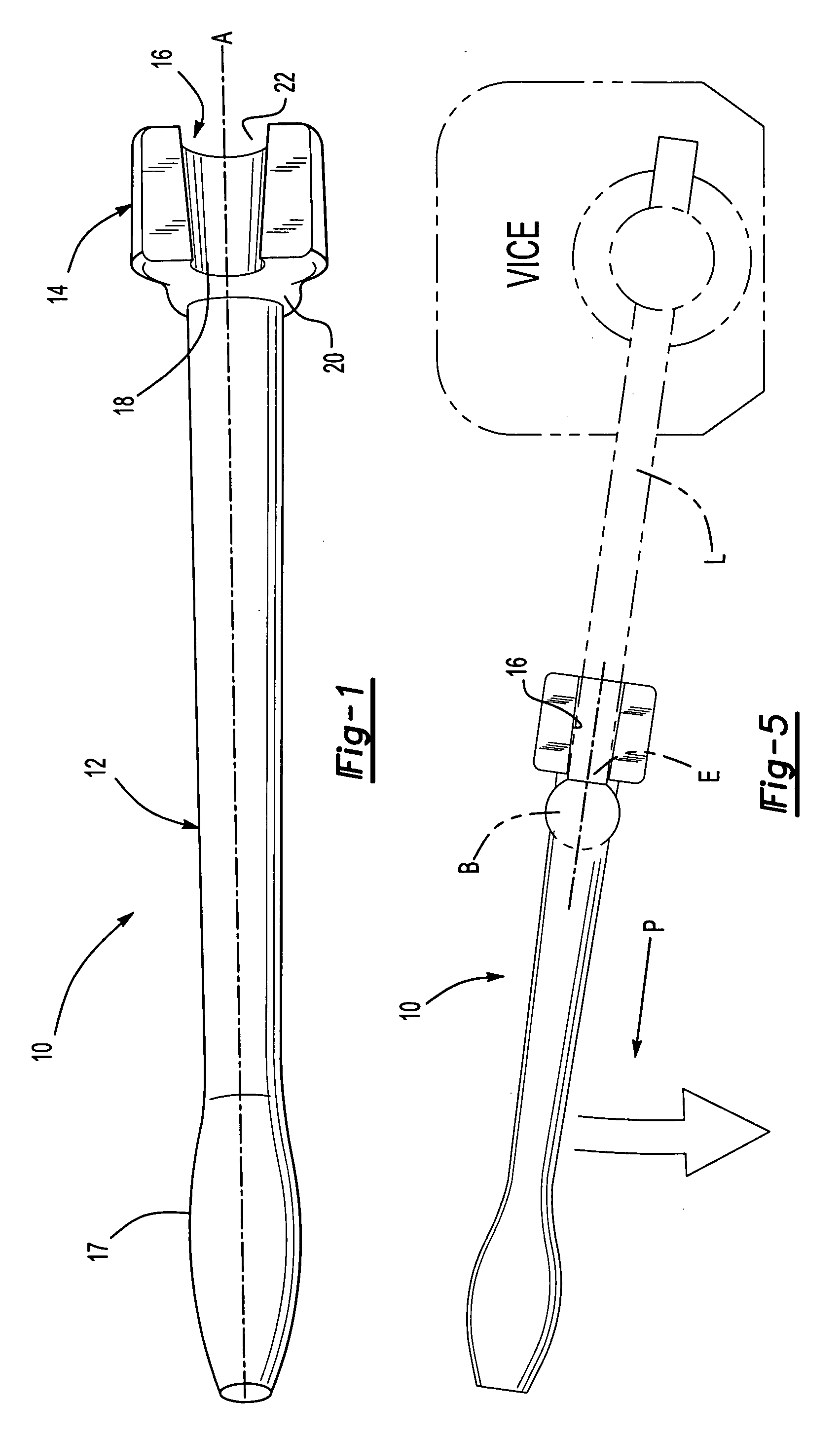

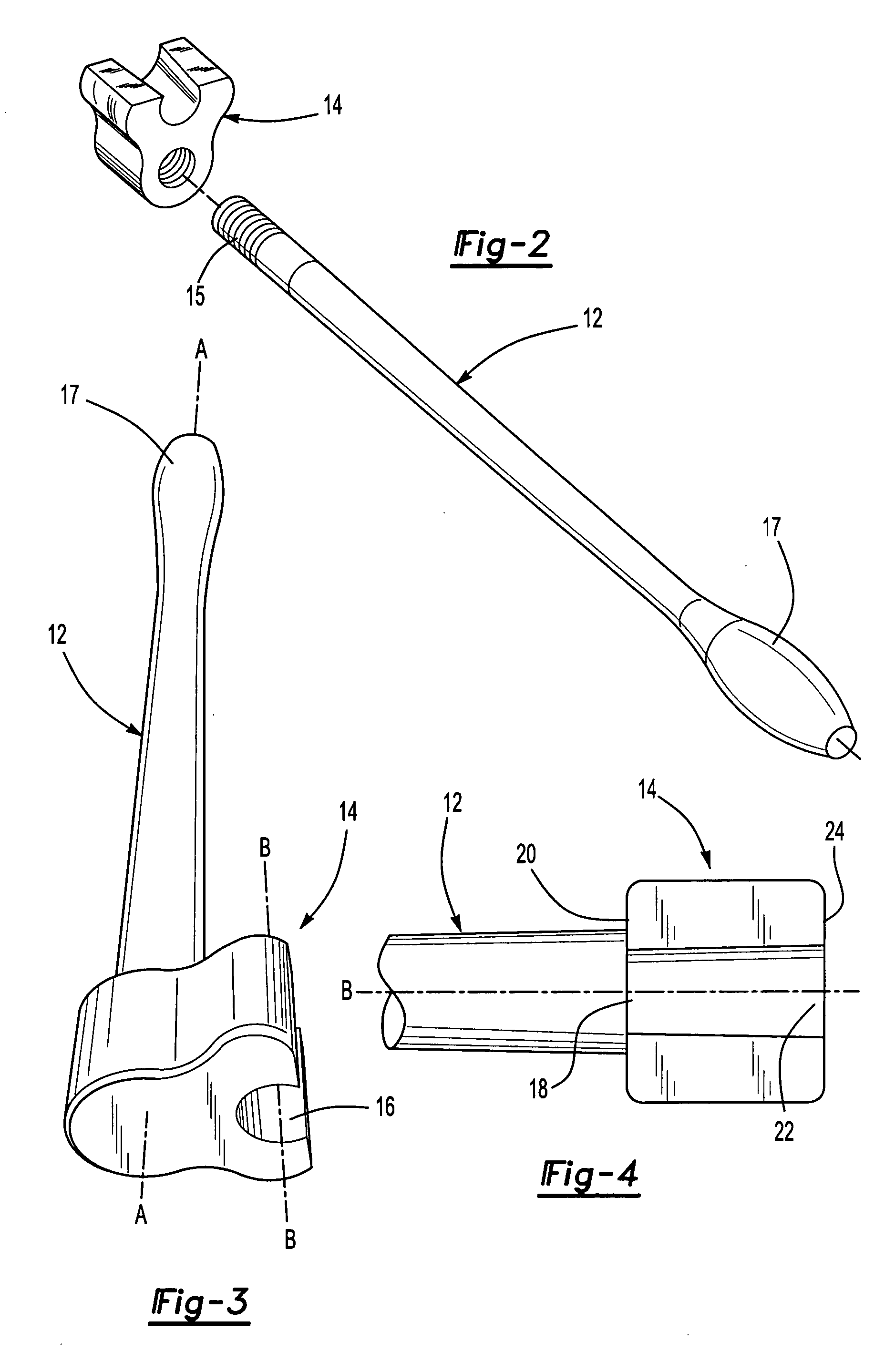

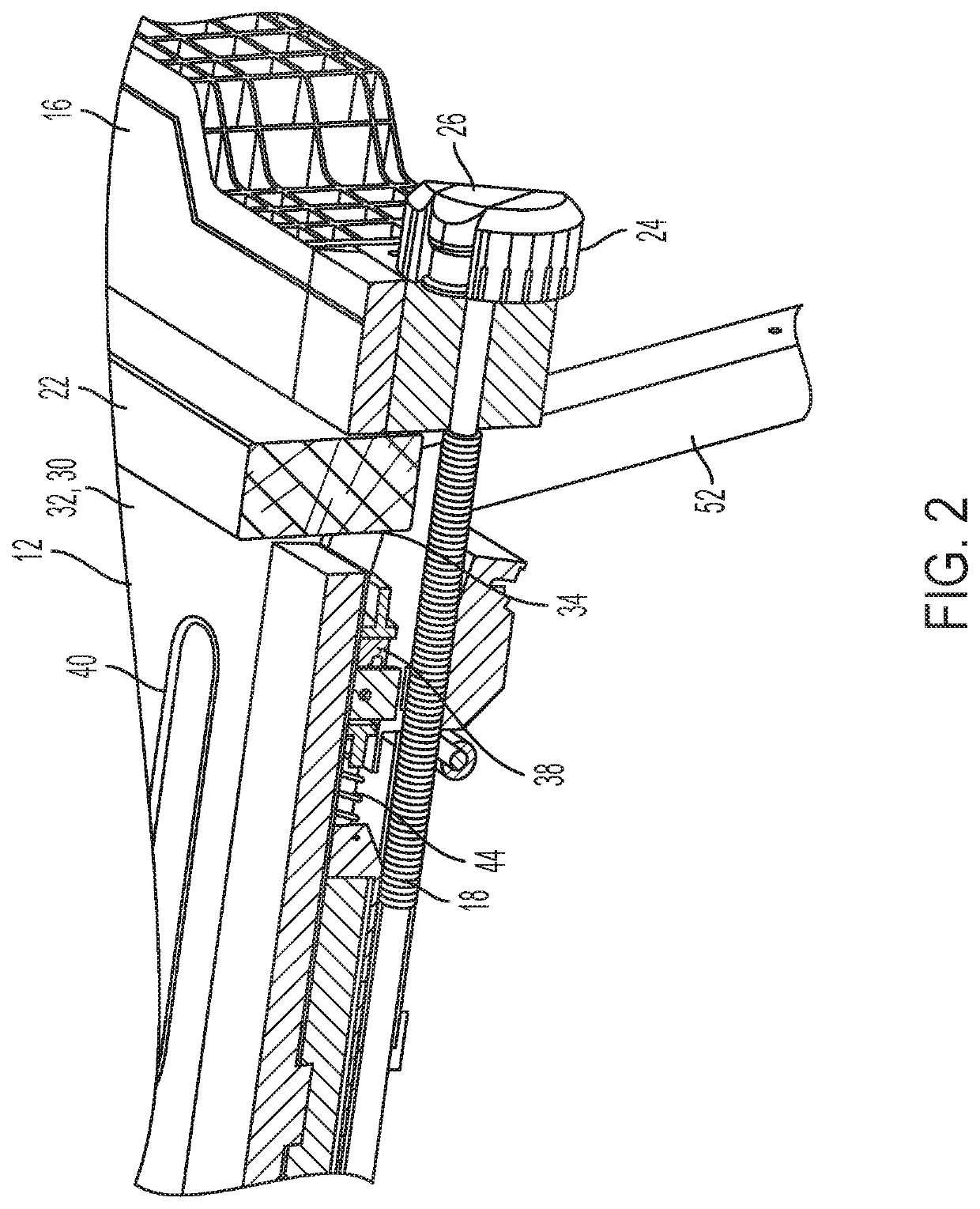

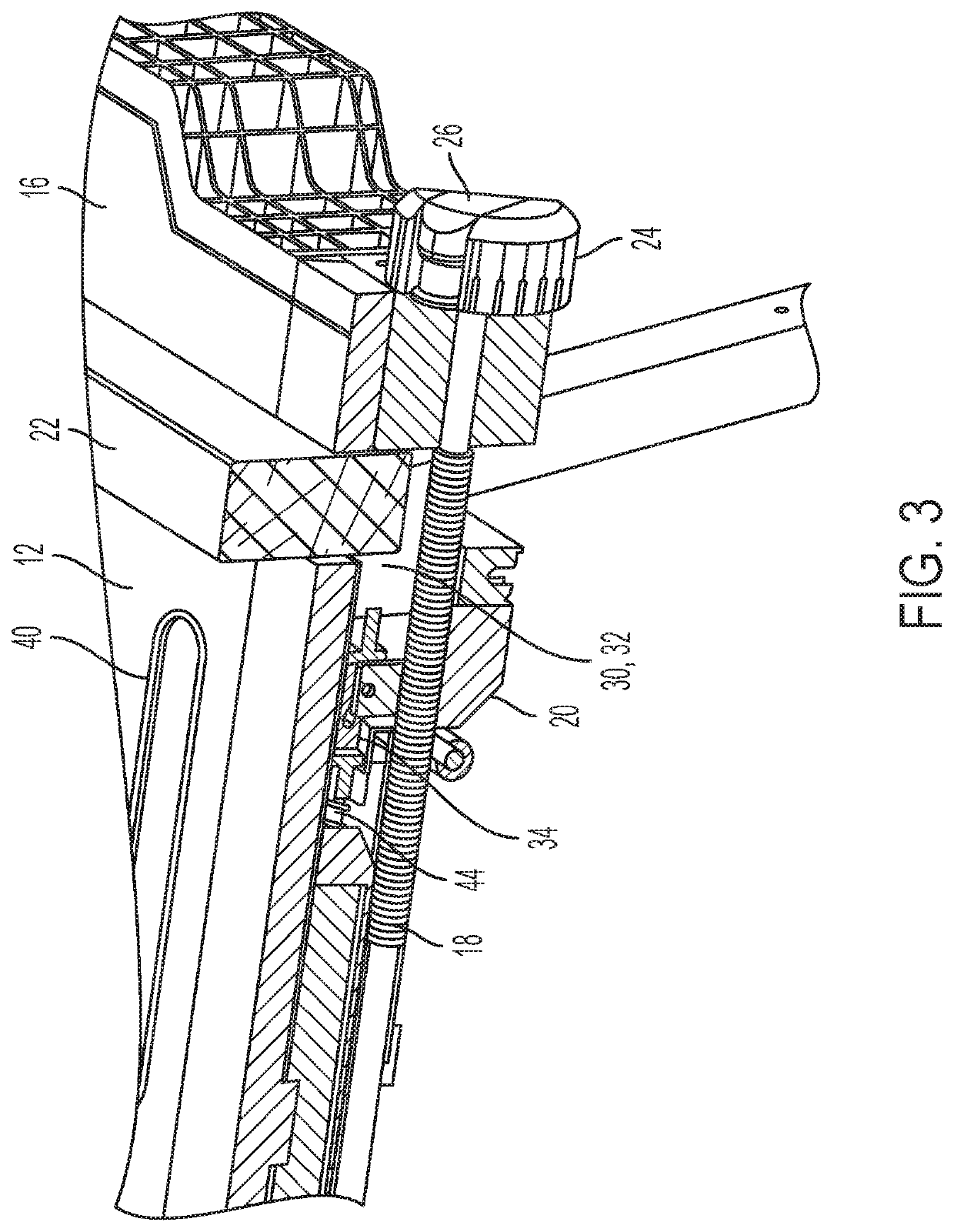

Barrel nut assembly and method to attach a barrel to a firearm using such assembly

A barrel nut assembly for use on a variety of firearms is provided. The assembly is made up of a barrel nut, generally cylindrical in shape with a threaded central bore, and an externally threaded locknut which is used in conjunction with the barrel nut to secure a barrel to a firearm upper receiver. The barrel nut has an integral bushing on its exterior constructed to support either the gas tube or piston of the host firearm's operating system. The barrel nut is configured so that it may be independently and non-rotationally held within a vice or other fixture during installation of the barrel and while the locknut is tightened to a preset torque to hold the barrel in place. The barrel nut assembly affords the user a method and apparatus that aligns a central bore in the bushing with the opening in the upper receiver that receives an operating system component of the firearm while the barrel nut is independent of the torque applied to the locknut to properly secure the barrel to the upper receiver.

Owner:LWRC INTERNATIONAL

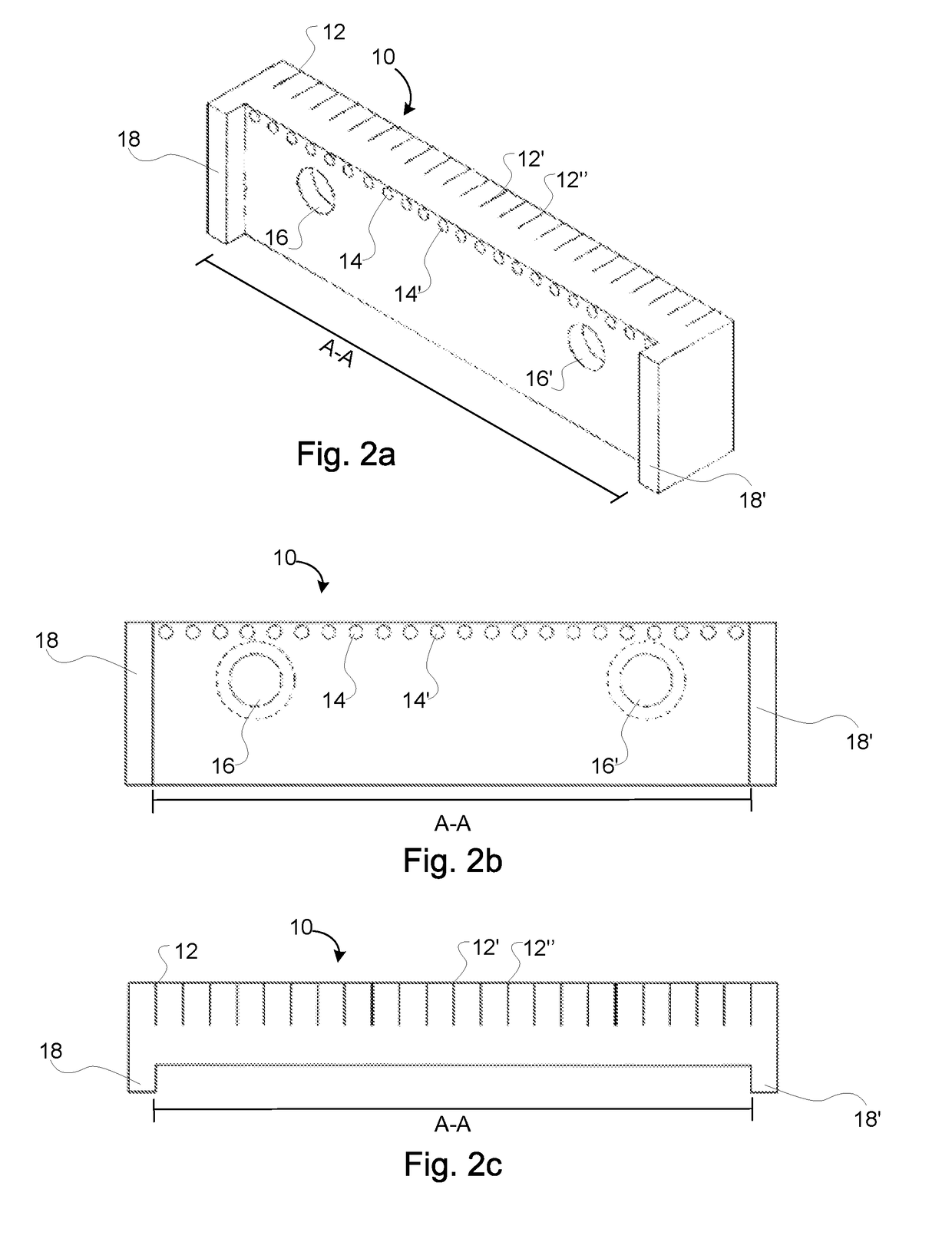

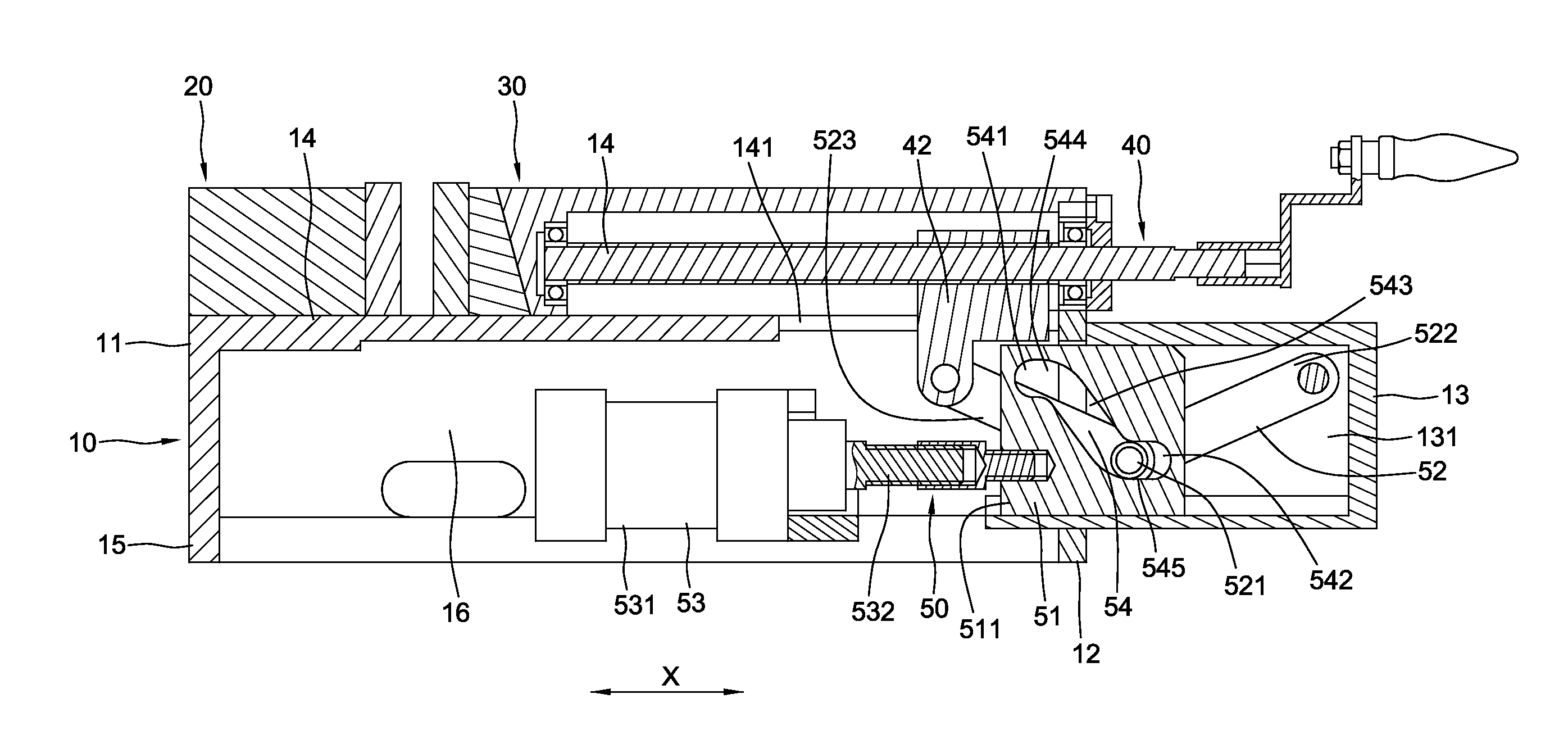

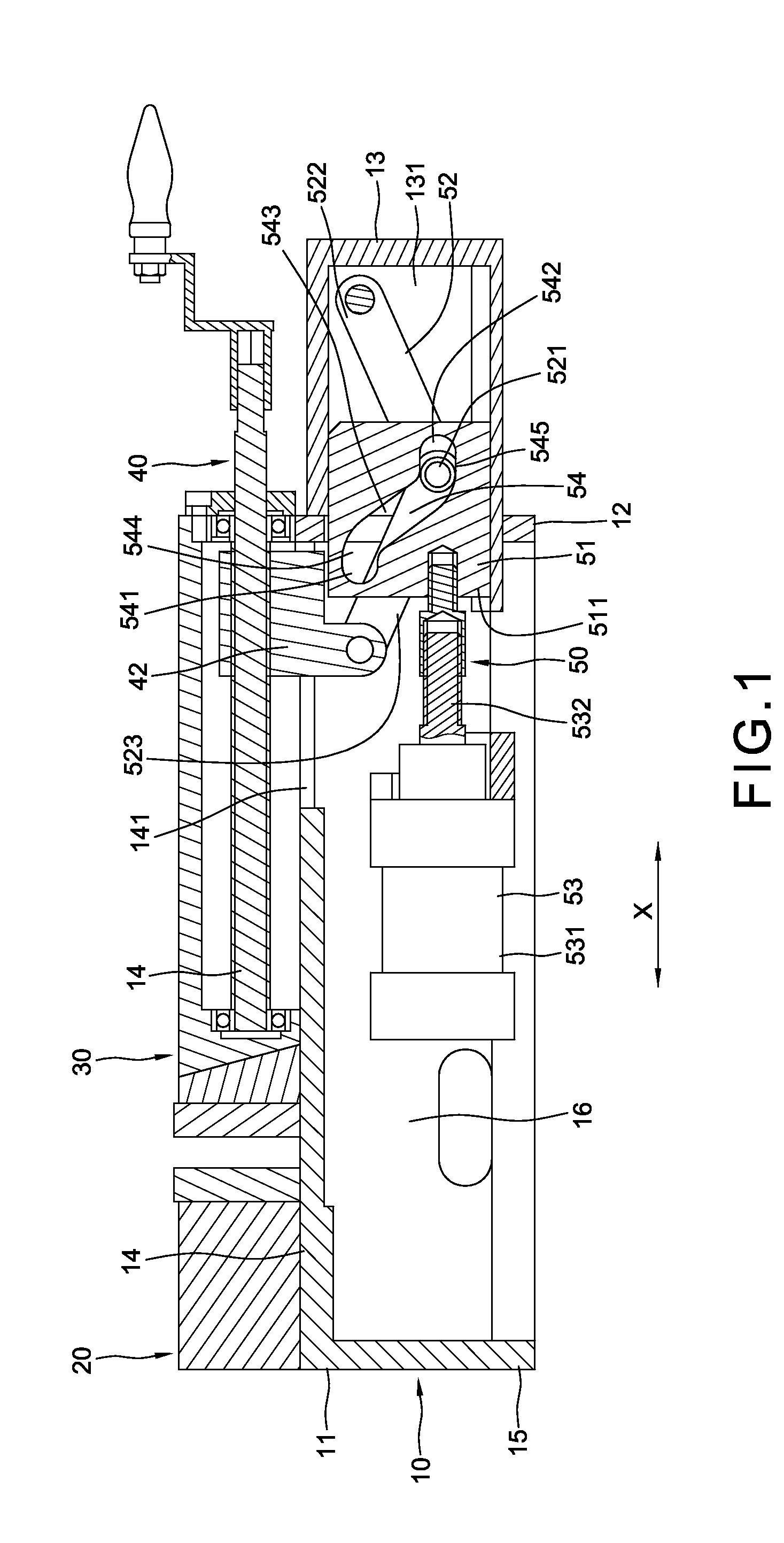

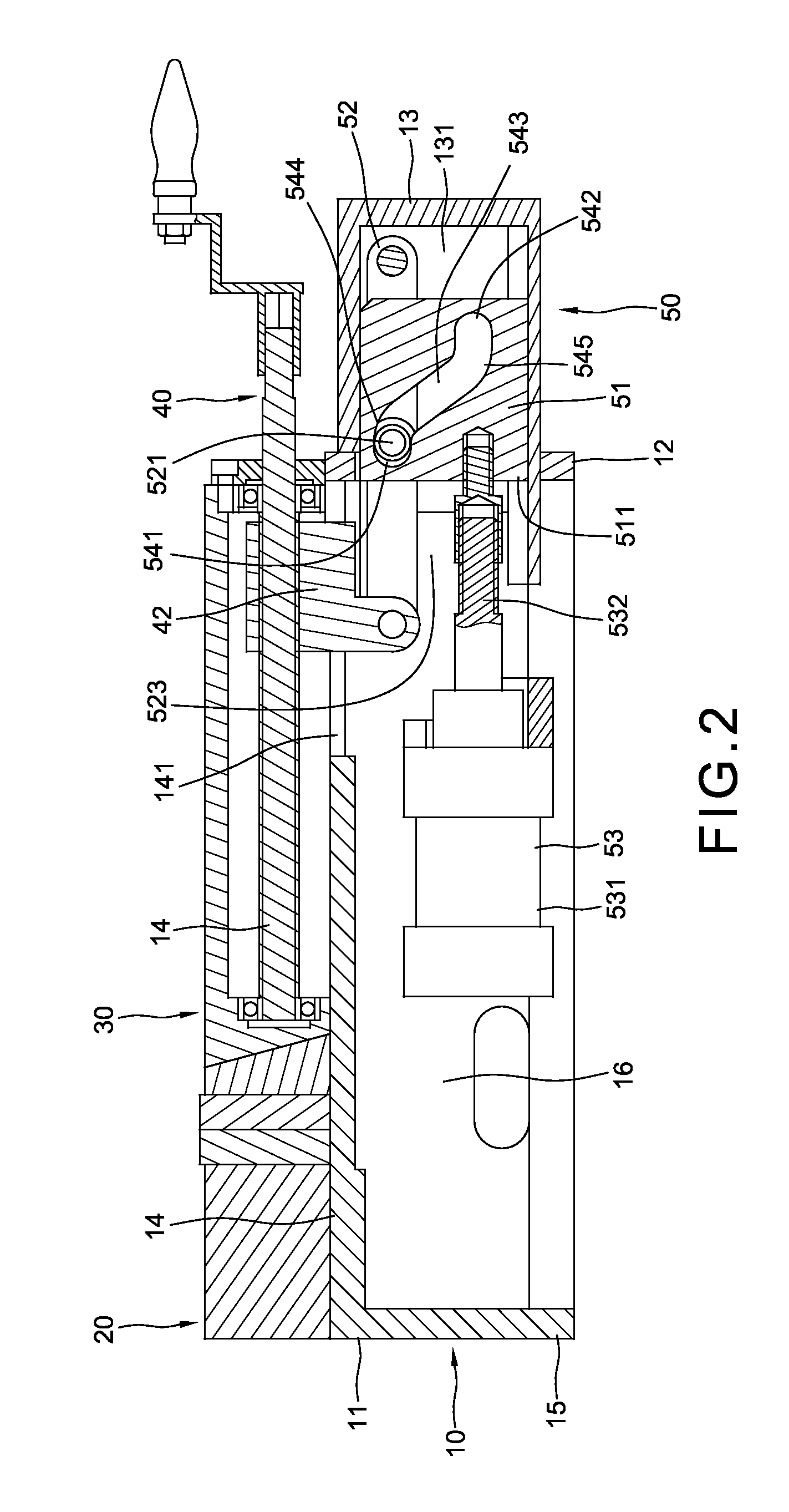

Bending machine die provided with a vise for clamping an elongated workpiece to be bent

A vise for clamping an elongated workpiece to be bent on a die of a bending machine includes a movable jaw, provided with a clamping portion approachable to and removable from the circumferential groove of the die. The movable jaw has a pivoting end and a retaining end opposite to the pivoting end. The pivoting end is rigidly connected to a spindle rotatable about an axis (X) at right-angles to the rotation axis (Y) of the die, so that the clamping portion of the movable jaw is displaced by an operating device from an opened position, far from the elongated workpiece to be bent, to a closed position in which the clamping portion mates with the elongated workpiece. A retaining device is able to grip the retaining end of the movable jaw and to maintain the movable jaw in its closed position.

Owner:CML INTERNAT SPA

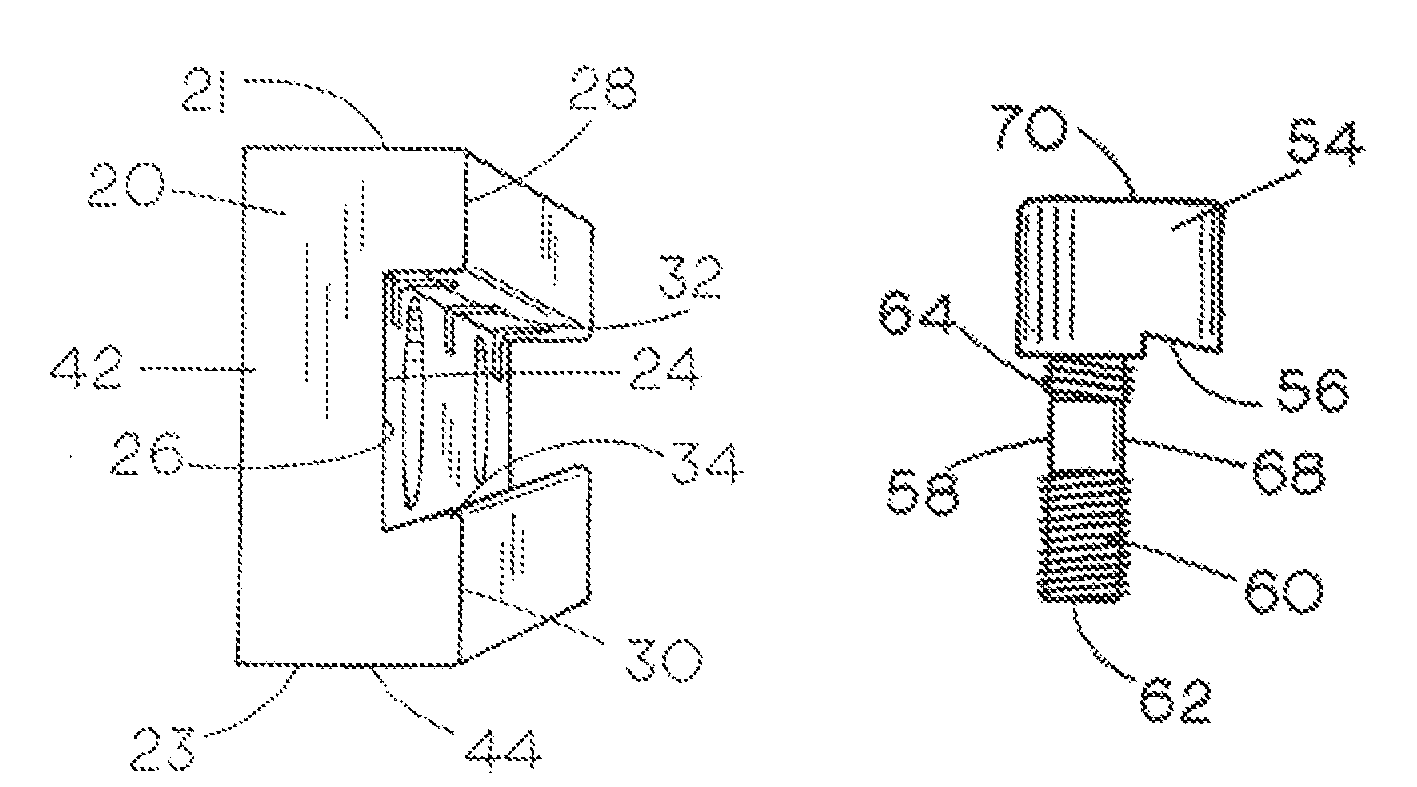

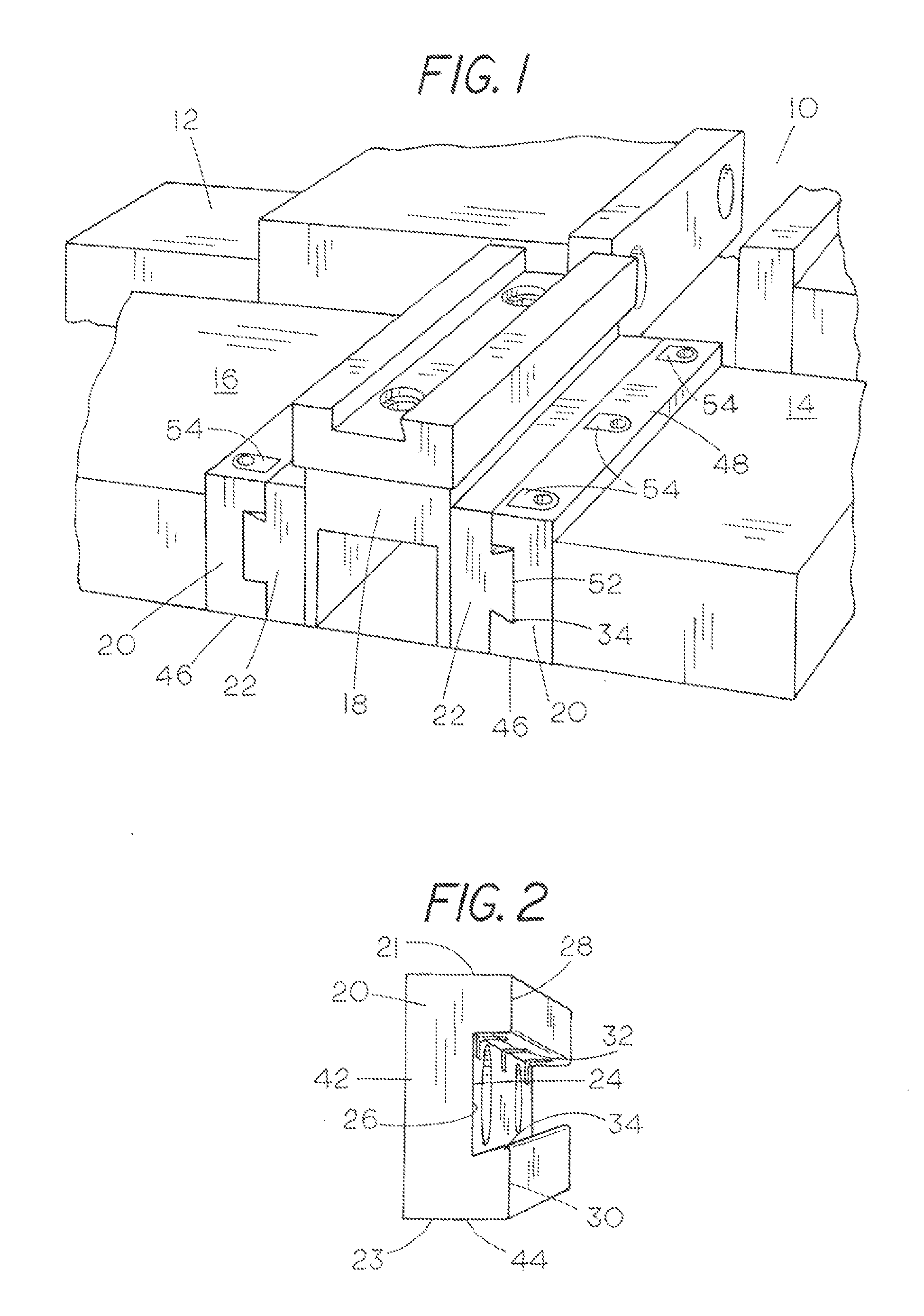

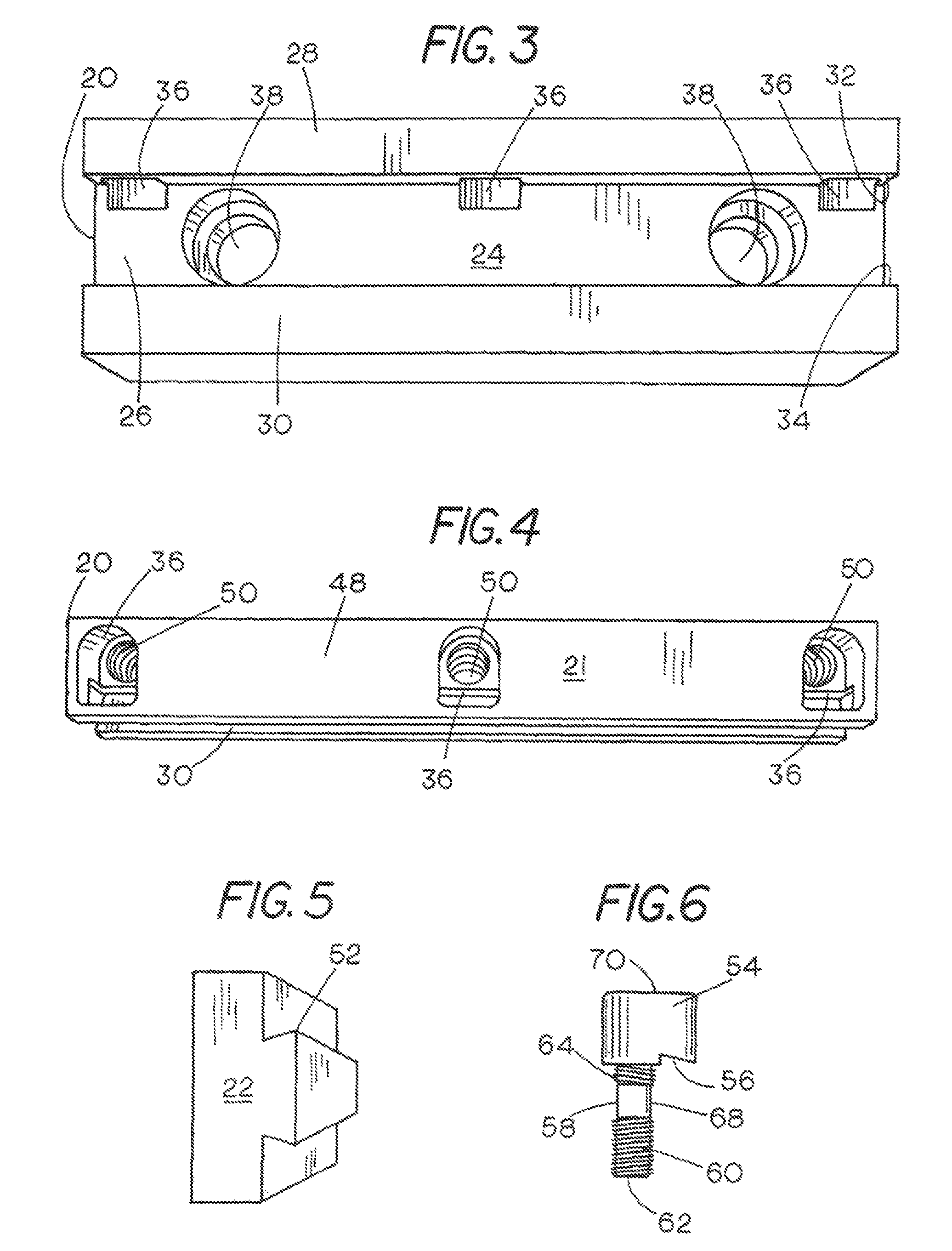

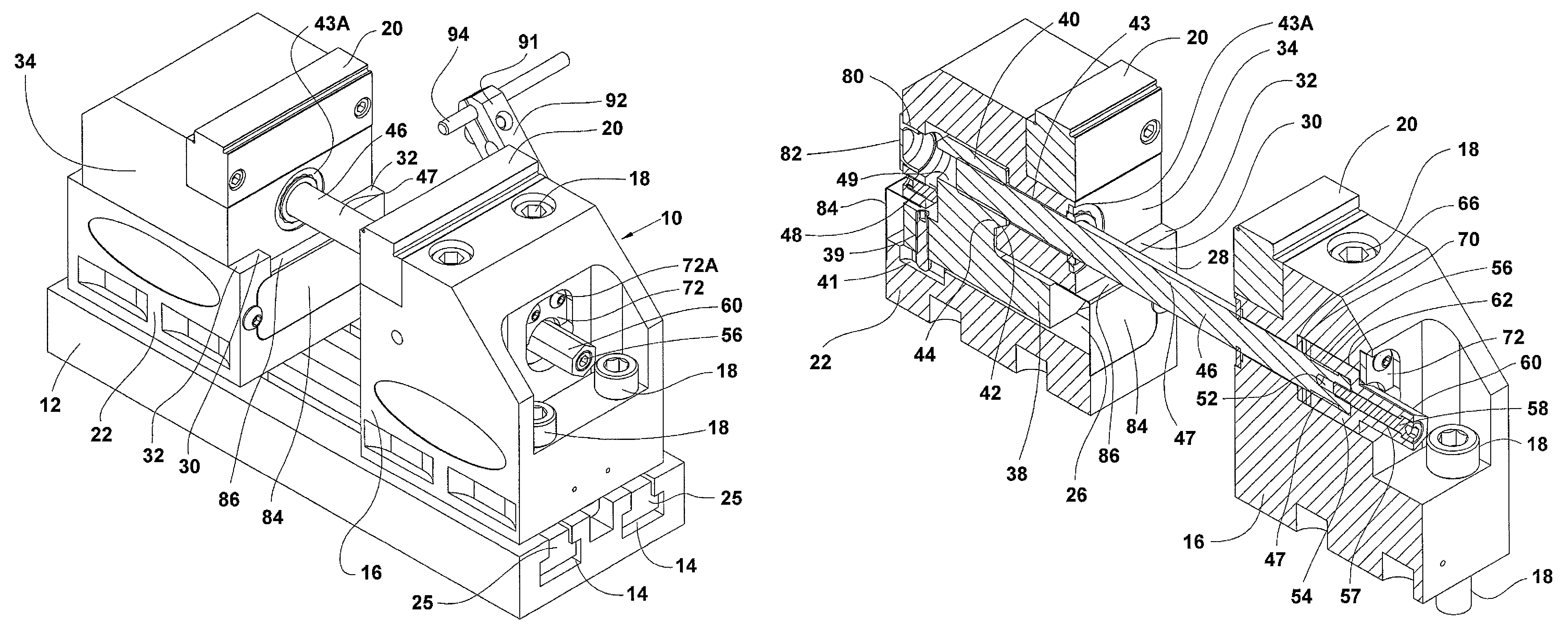

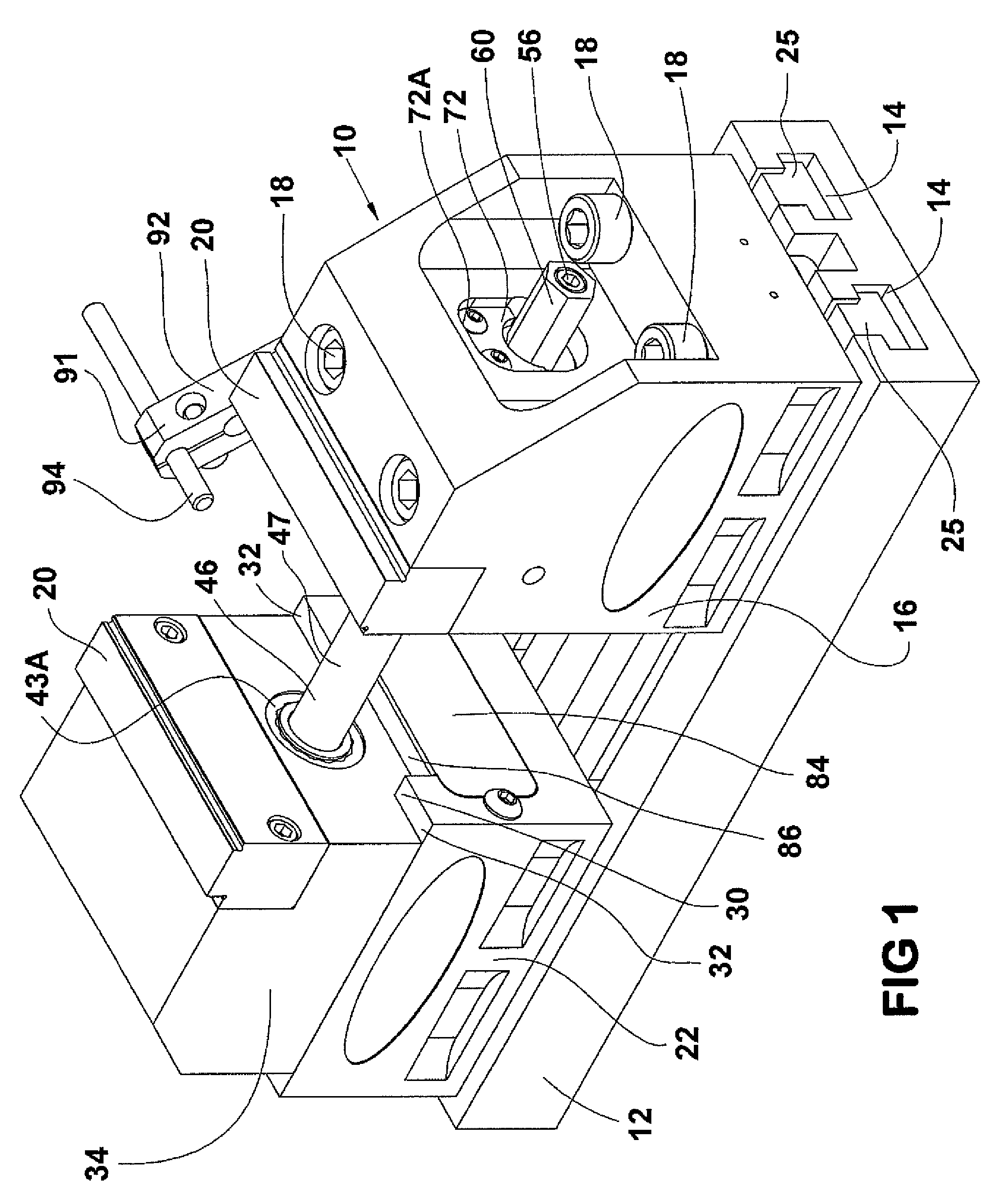

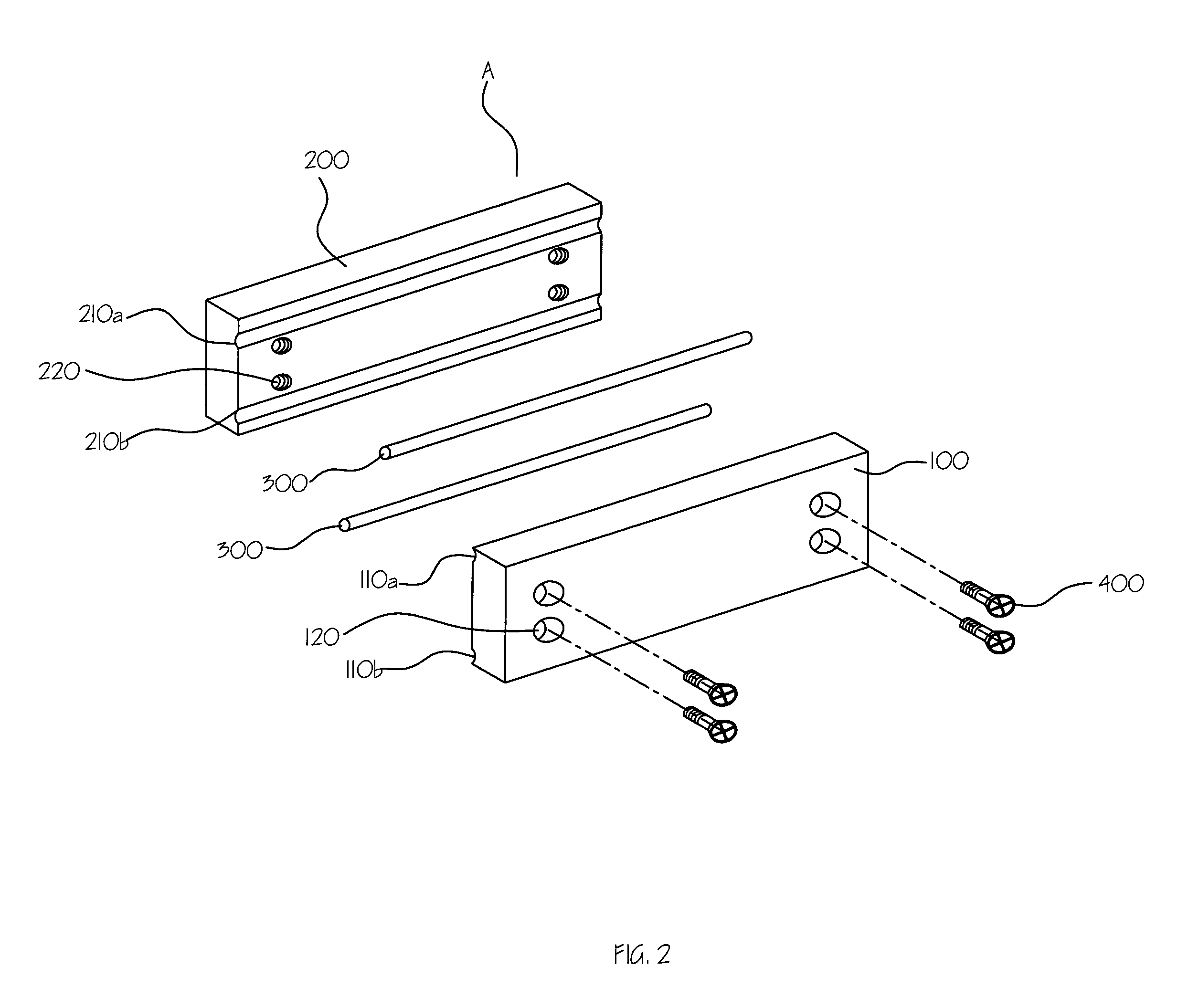

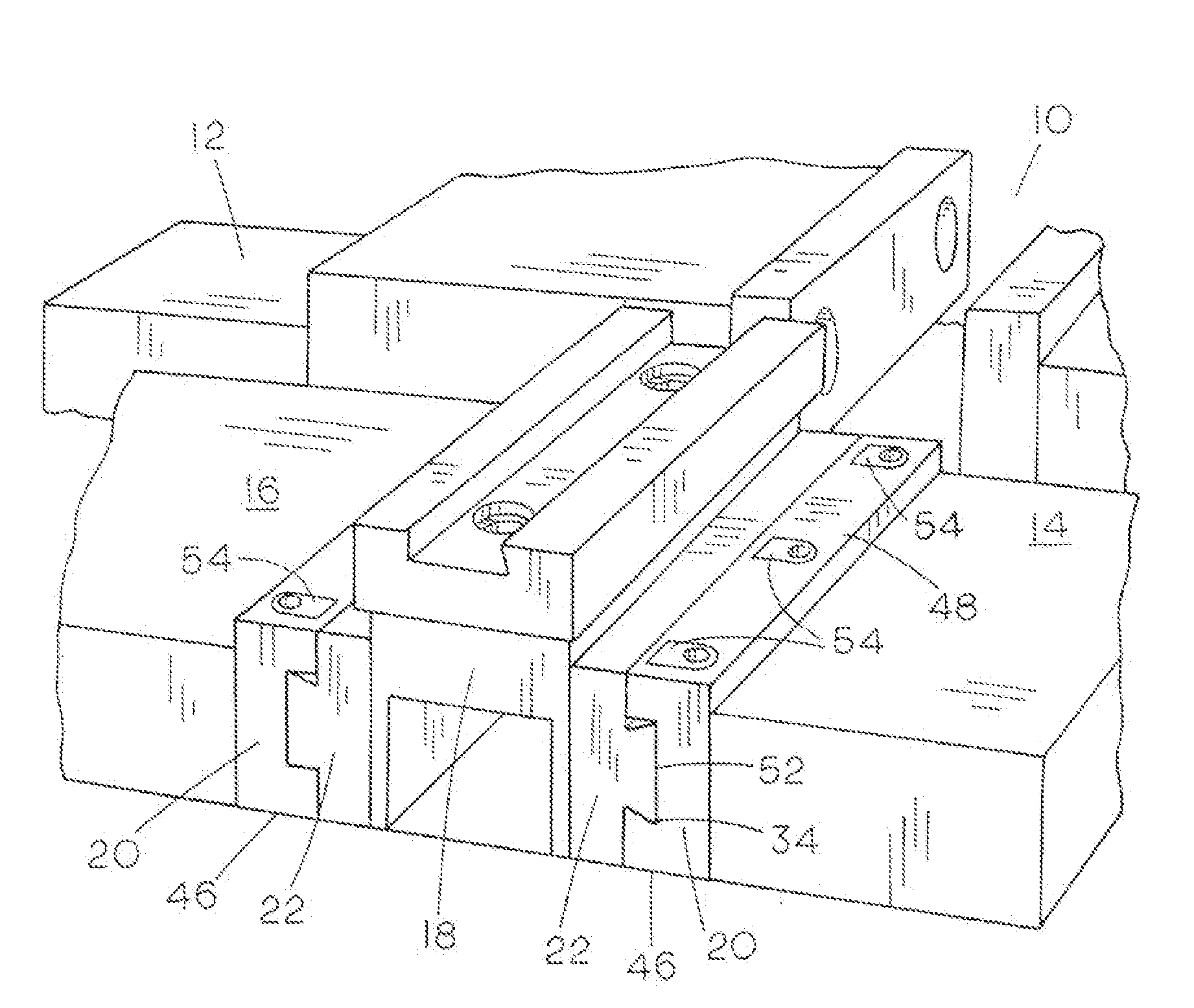

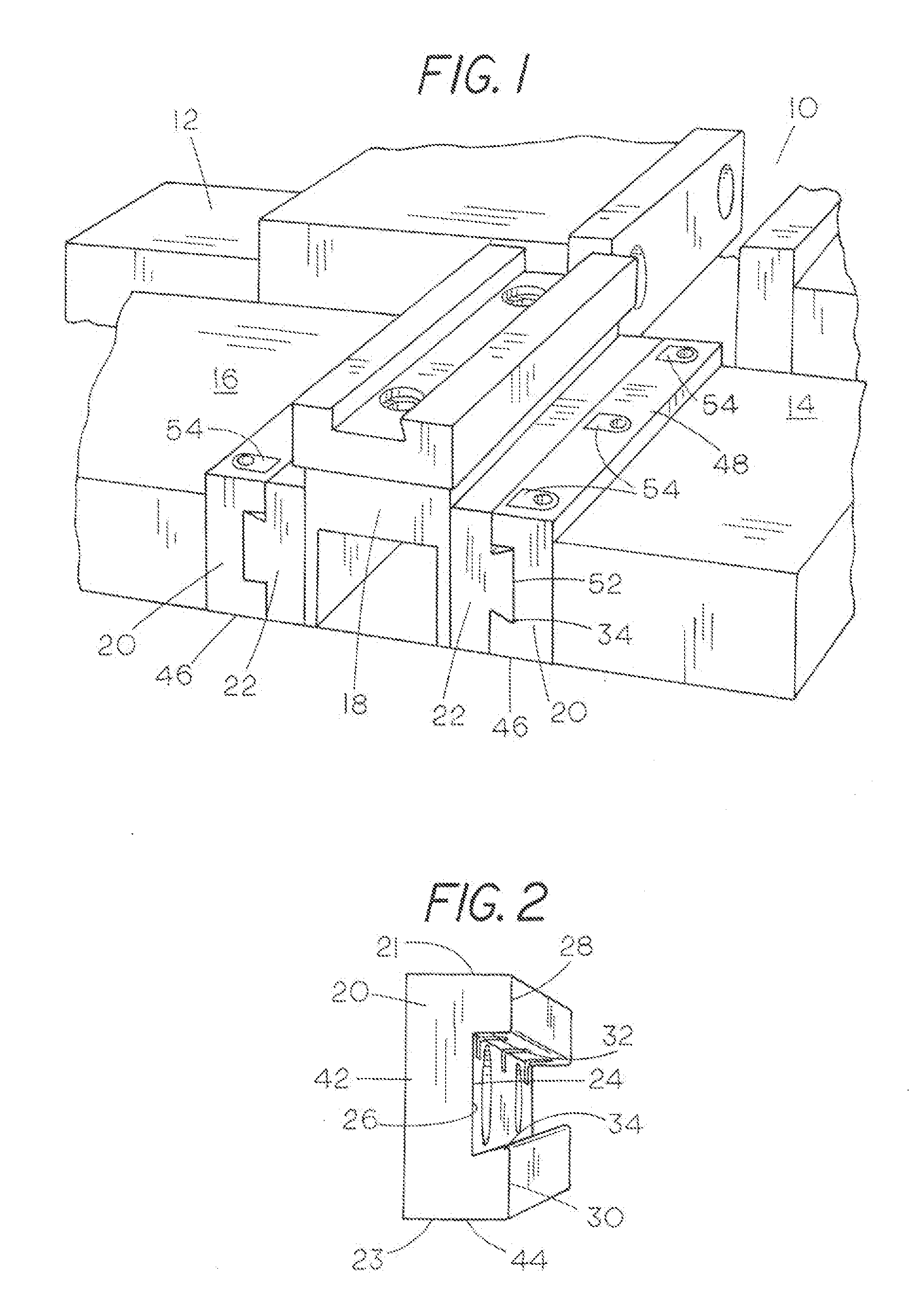

Quick change vise jaw system

A master jaw assembly used in a vise including a locking jaw, a detachable jaw and a clamping device disposed in the locking jaw, securely clamping the detachable jaw to the locking jaw. The locking jaw has a groove extending along an inner surface of the locking jaw defined by a first and second edge. The second edge is tapered inward and downward toward the base. The detachable jaw has a dovetail protrusion along one side surface thereof. The clamping device includes a plurality of specially-shaped clamp-nuts having a downwardly tapered edge, said clamp-nuts designed to receive one end of a double-ended threaded stud. The detachable jaw becomes fixed to the locking jaw by inserting the protrusion into the groove and torquing the studs to tighten the clamp-nuts downward against the protrusion such that the protrusion is clamped between the taper of the second edge and the clamp-nuts.

Owner:BELLATEX INDS

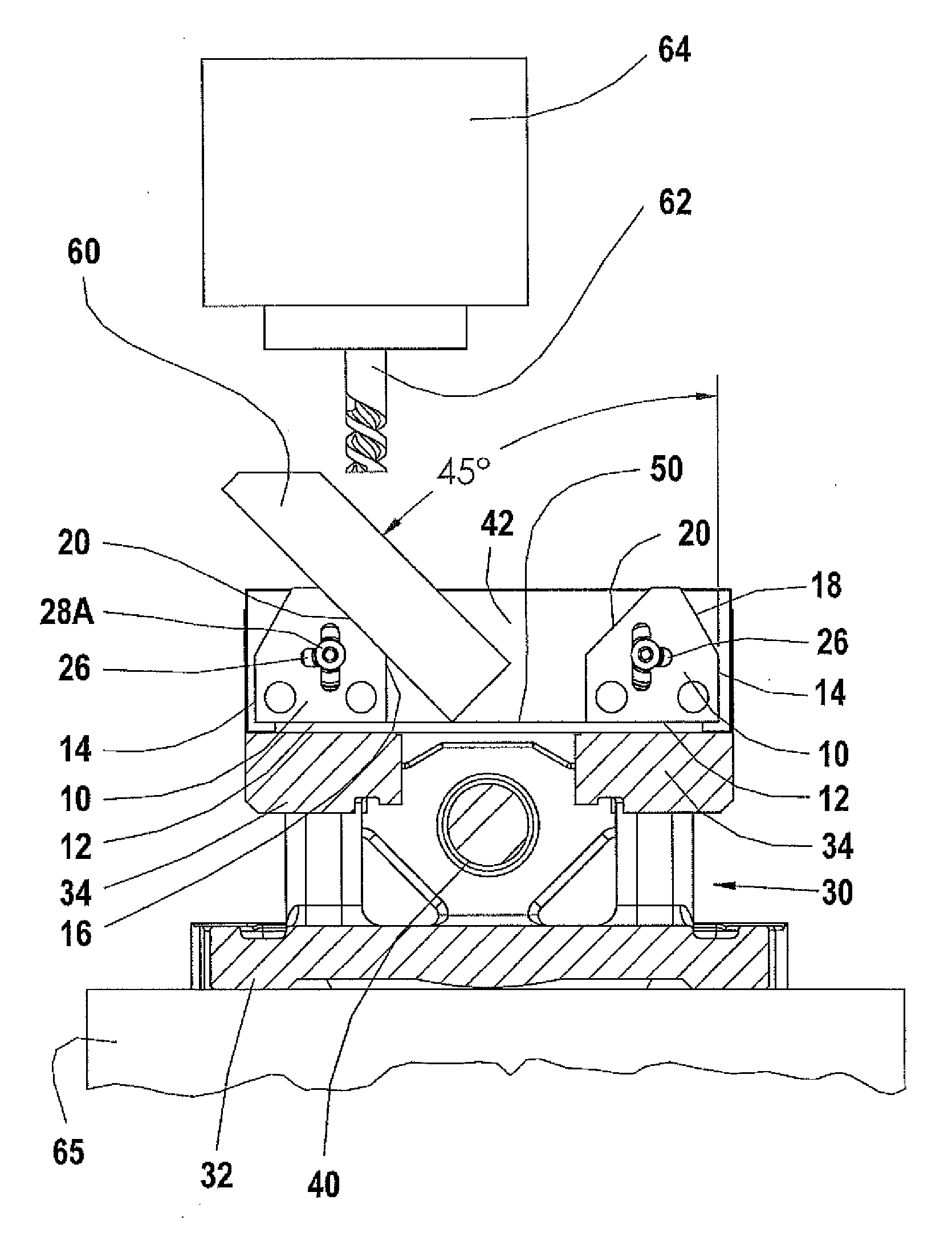

Machine vise parallel with angled edges

InactiveUS20130087963A1Great amount of timeLow profile designPositioning apparatusVicesViseHypotenuse

A work orienting plate or angled vise parallel for use with a machine vise and which angled plate has first, second and third reference edges with the second and third reference edges being spaced apart side edges that are perpendicular to the first edge. Angled work piece support edges join the second and third reference edges, respectively. The angled work piece support edges are at different angles from one another so that a work piece can be supported on any one of the edges relative to a reference surface of a vise on which the work orienting plate is mounted to position the work piece at selected angles for machining angled surfaces.

Owner:KURT MANUFACTURING COMPANY INC

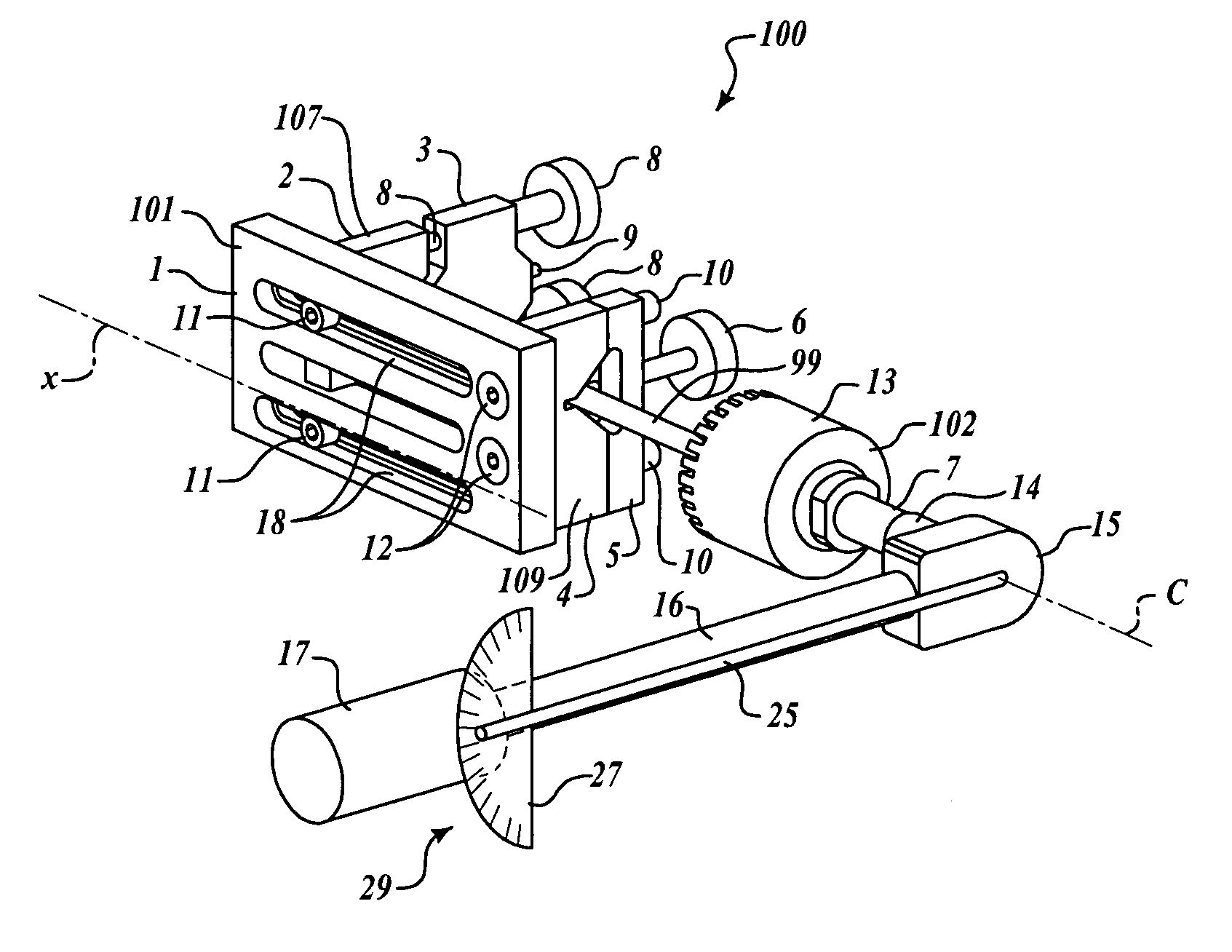

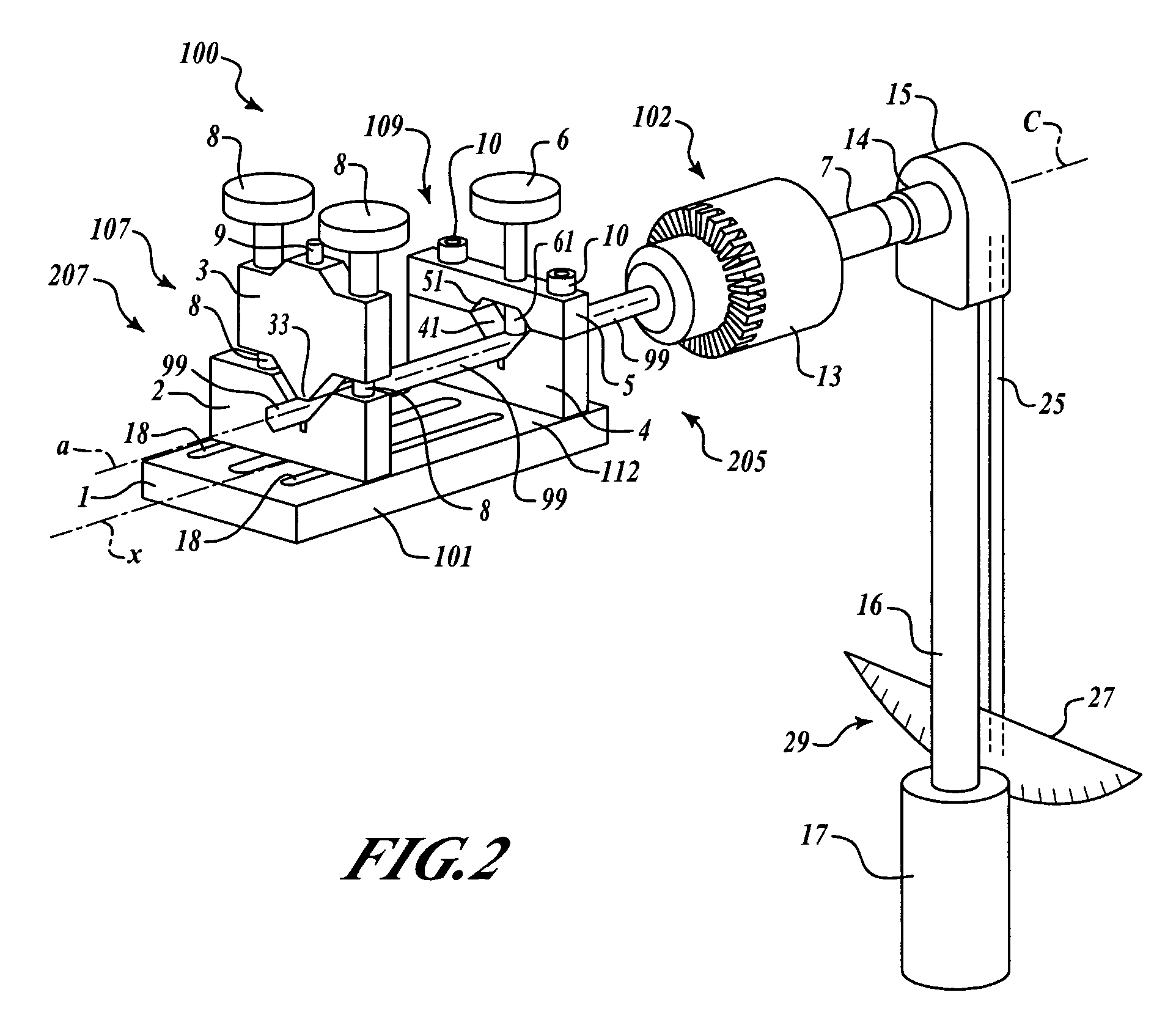

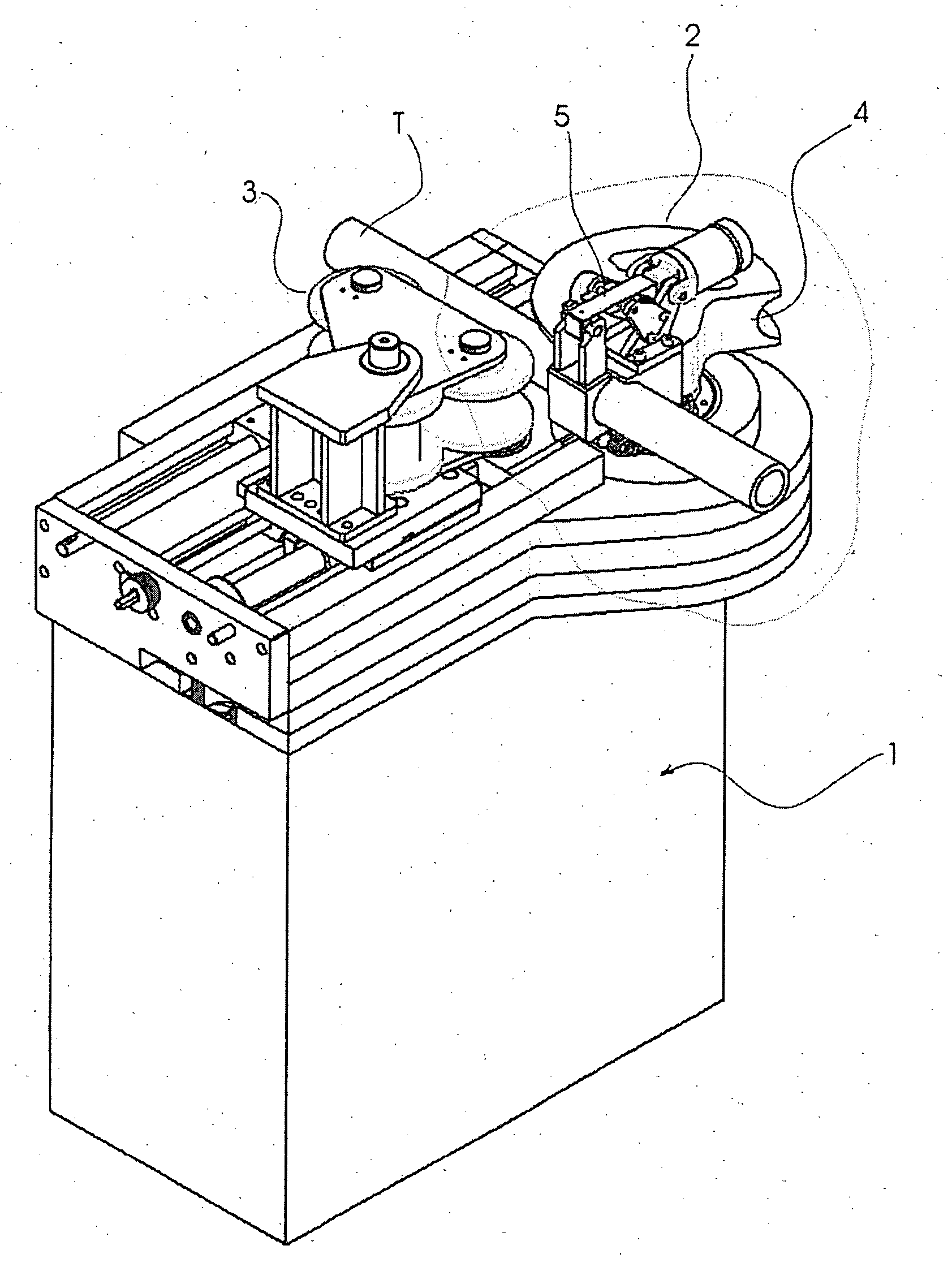

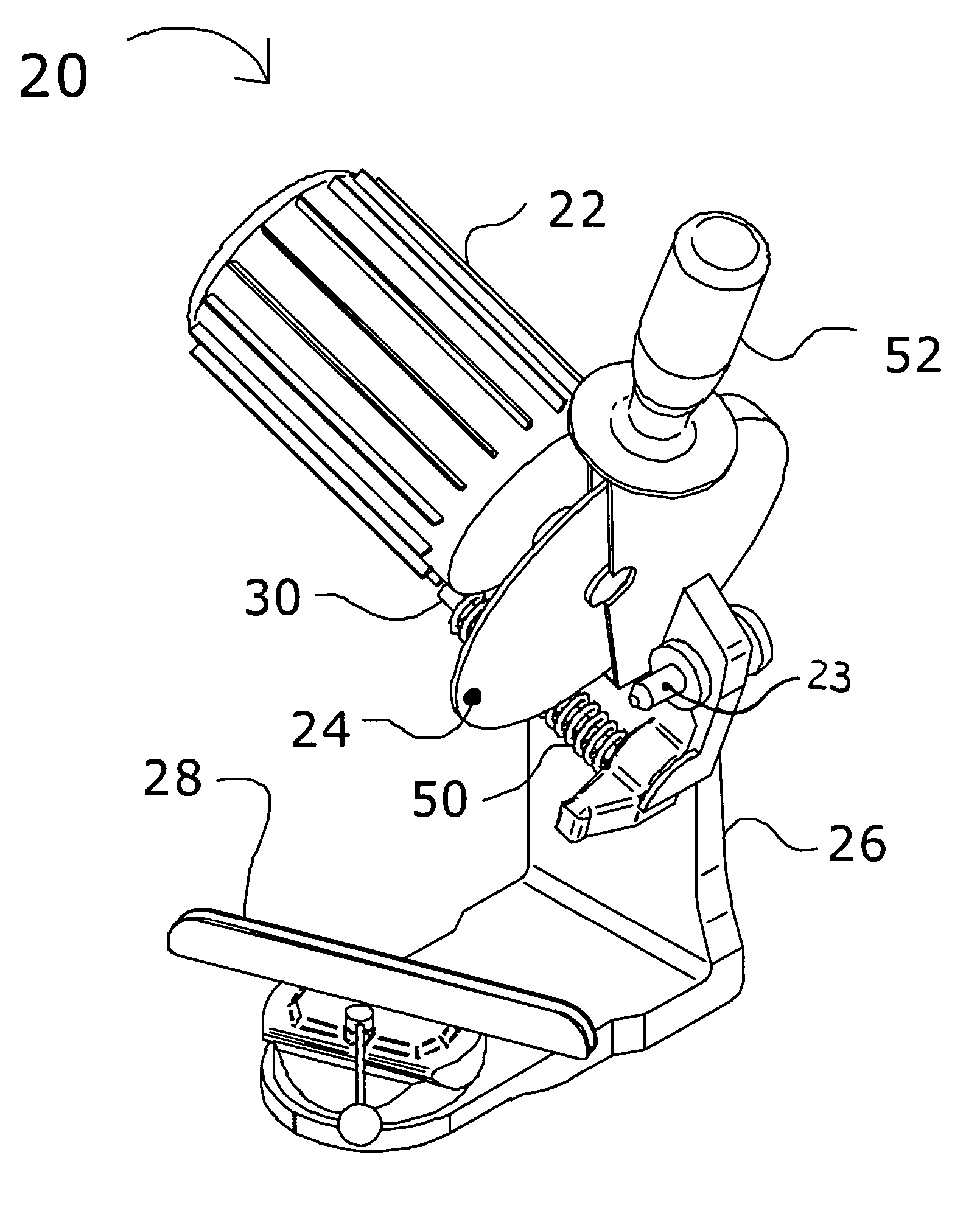

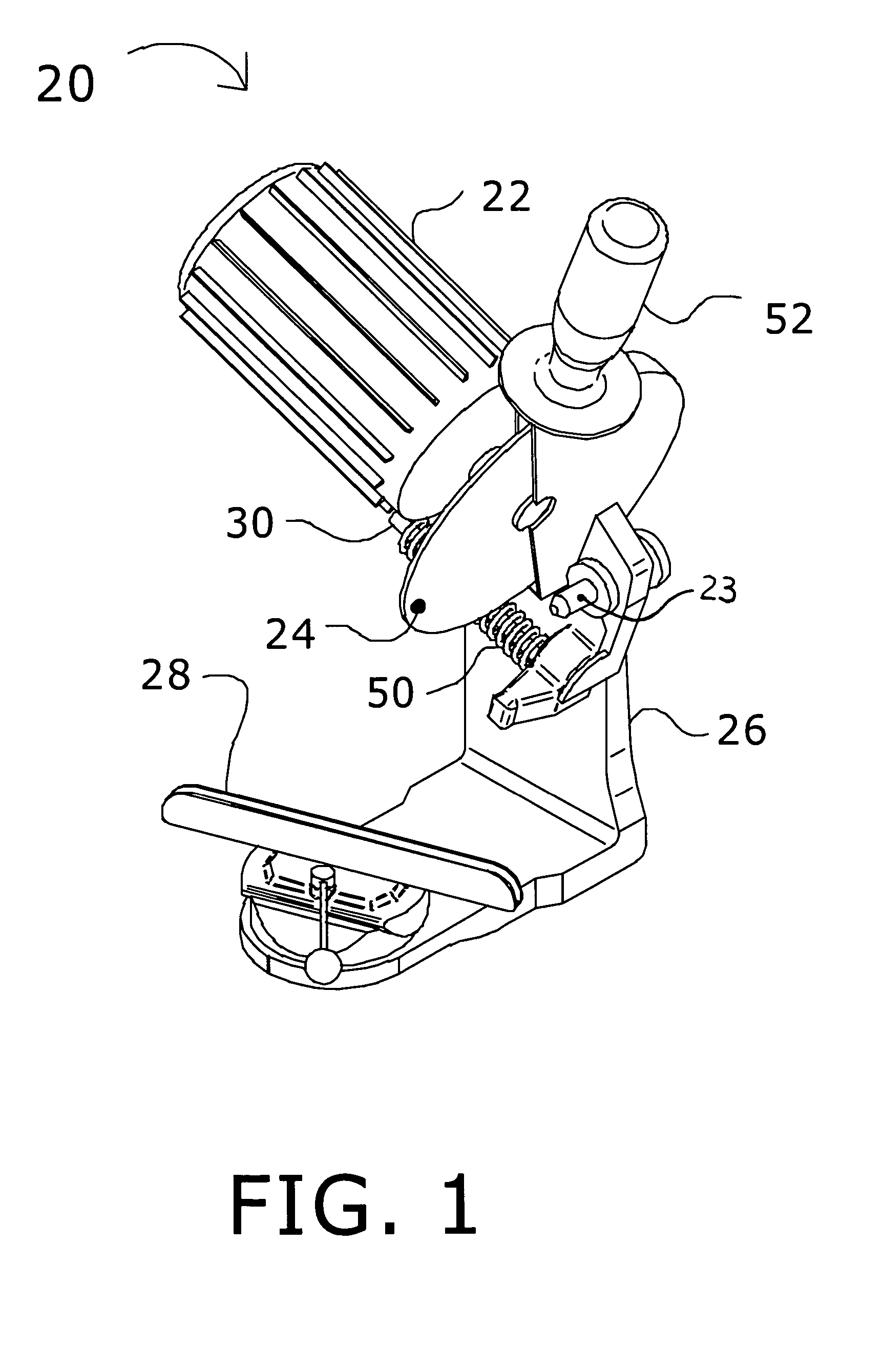

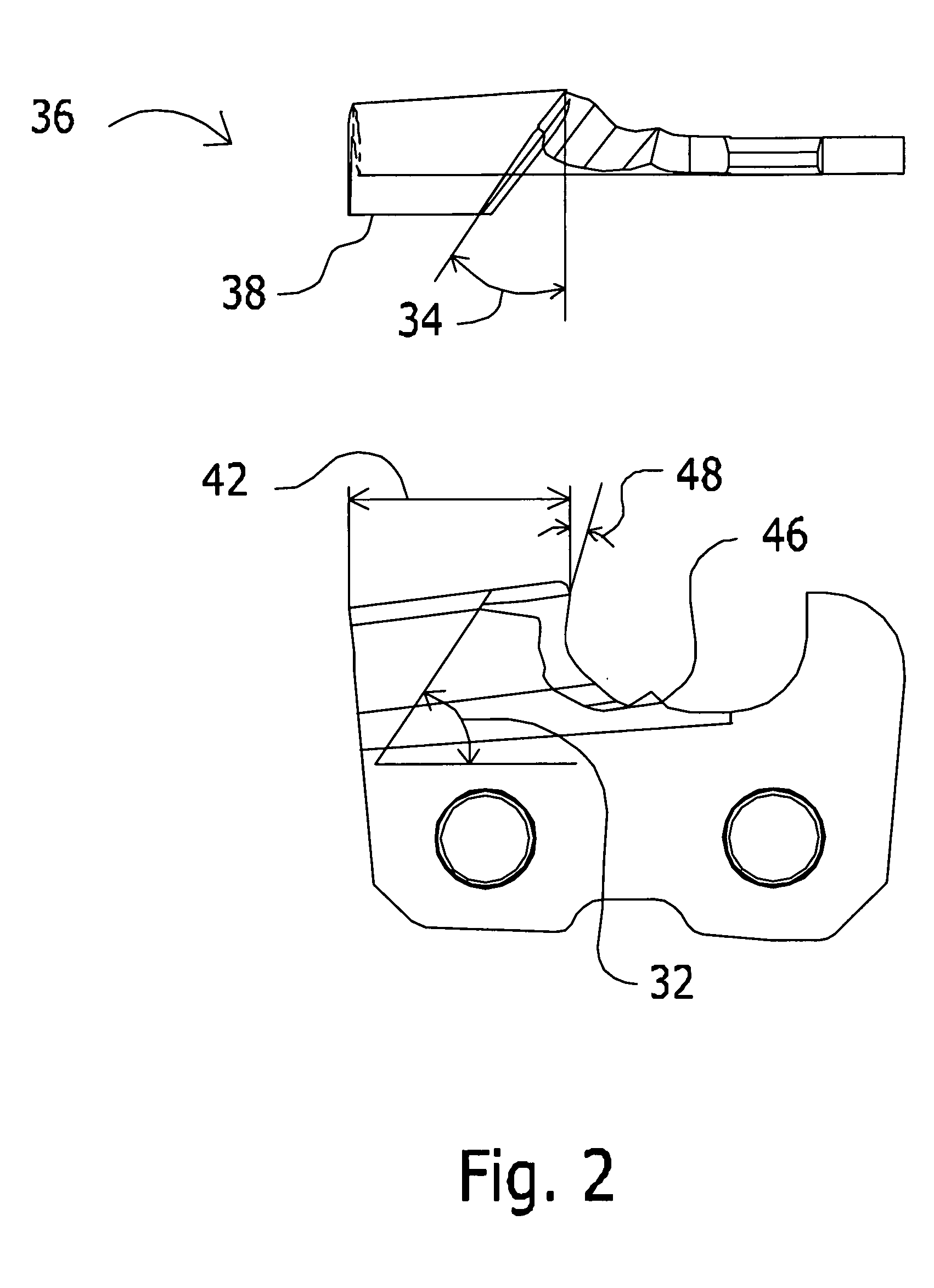

Cutting chain grinder and method of grinding

InactiveUS20050183545A1Edge grinding machinesSawing tools dressing arrangementsRotational axisBench grinder

A cutting chain bench grinder includes a self-centering vise that centers the cutting chain on an axis of rotation of the vise base. By centering the cutting chain to intersect the vise base axis of rotation, consistent top plate lengths and hook angles can be ground into left and right-hand cutters on a cutting chain. The vise base may also be adjusted horizontally in and out from the grinder base to align the vise base axis of rotation with the axis of rotation of the grinding wheel. The vise base may also be adjusted vertically relative to the vise base to vertically compensate for grinding wheel wear and to control grinding depth. A light tension spring may be used to bias the grinding head in both grinding and dressing positions. A down angle positioner may also be provided that rotates the cutting chain in the vise around a longitudinal centerline of the cutting chain.

Owner:OREGON TOOL INC

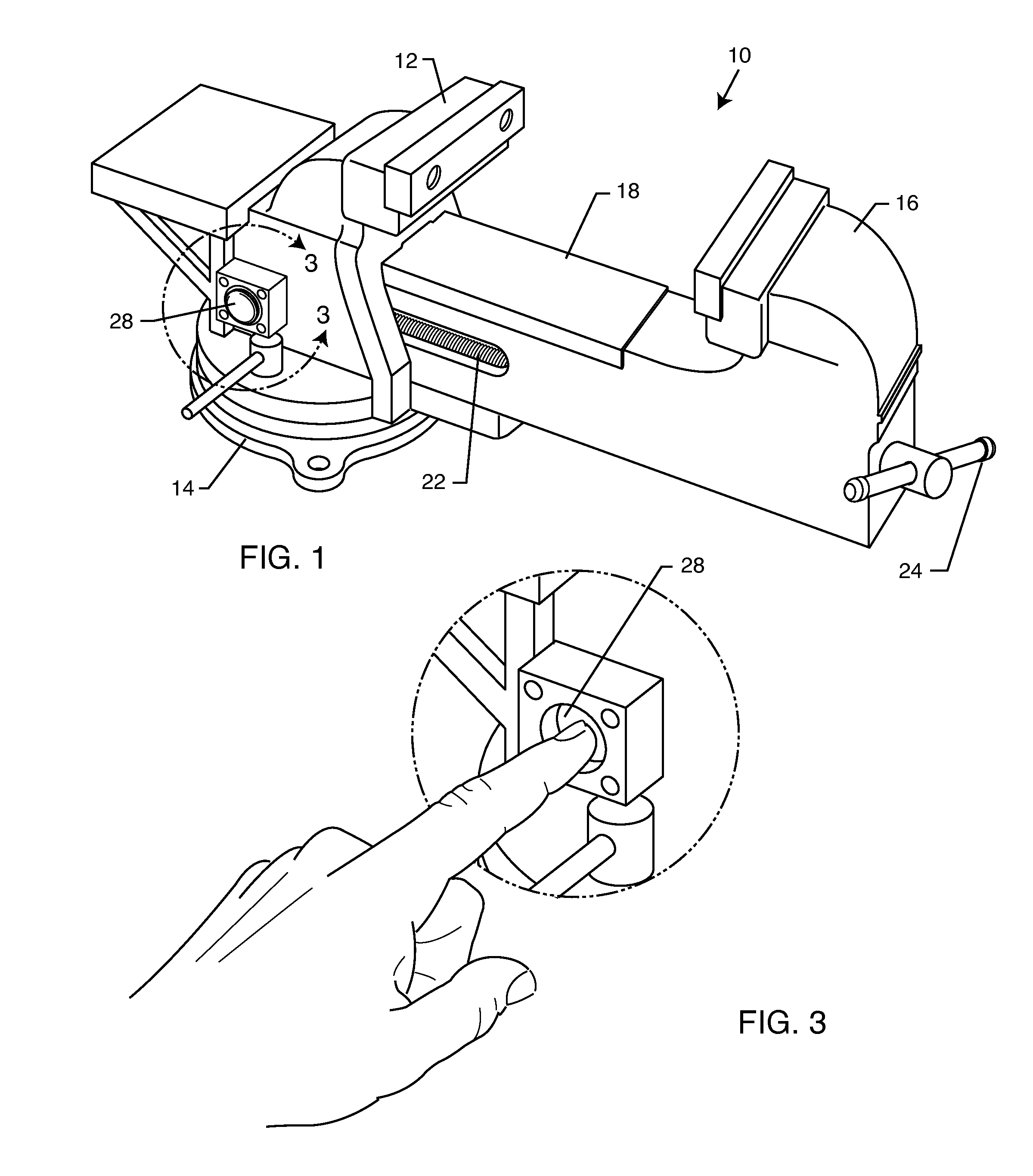

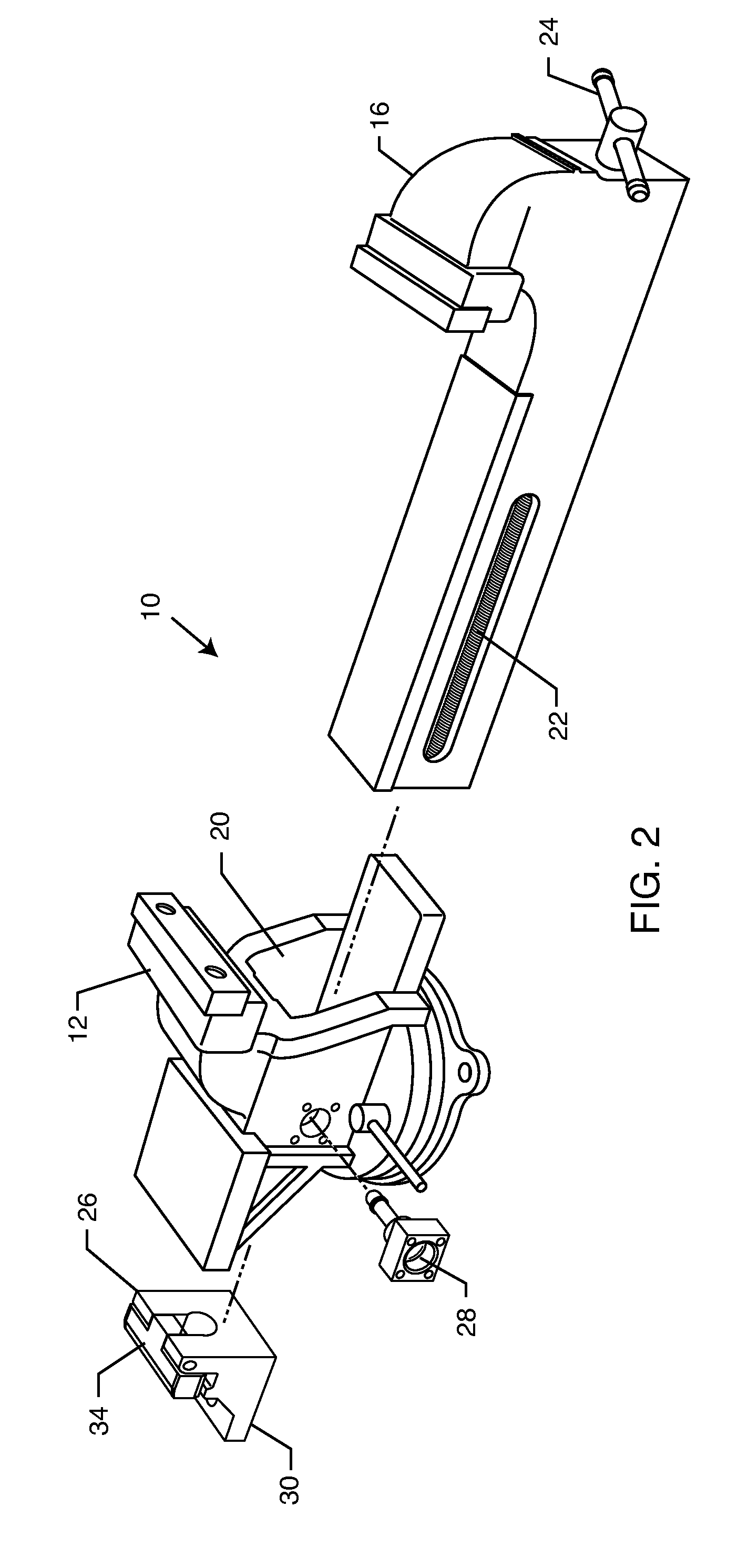

Vise with quick release feature

A method and apparatus for clamping a workpiece in a vise. The apparatus generally includes a stationary jaw with a first gripping surface and a moveable jaw with a second gripping surface connected and operated by a spindle. The spindle moves the stationary jaw and the moveable jaw toward and away for each other when rotated. The vise includes an actuation rod configured to engage and disengage a semi-nut from the spindle thereby engaging and disengaging the moveable jaw from the fixed jaw in order to allow an operator to quickly move the moveable jaw by hand.

Owner:THORSEN TOOLS

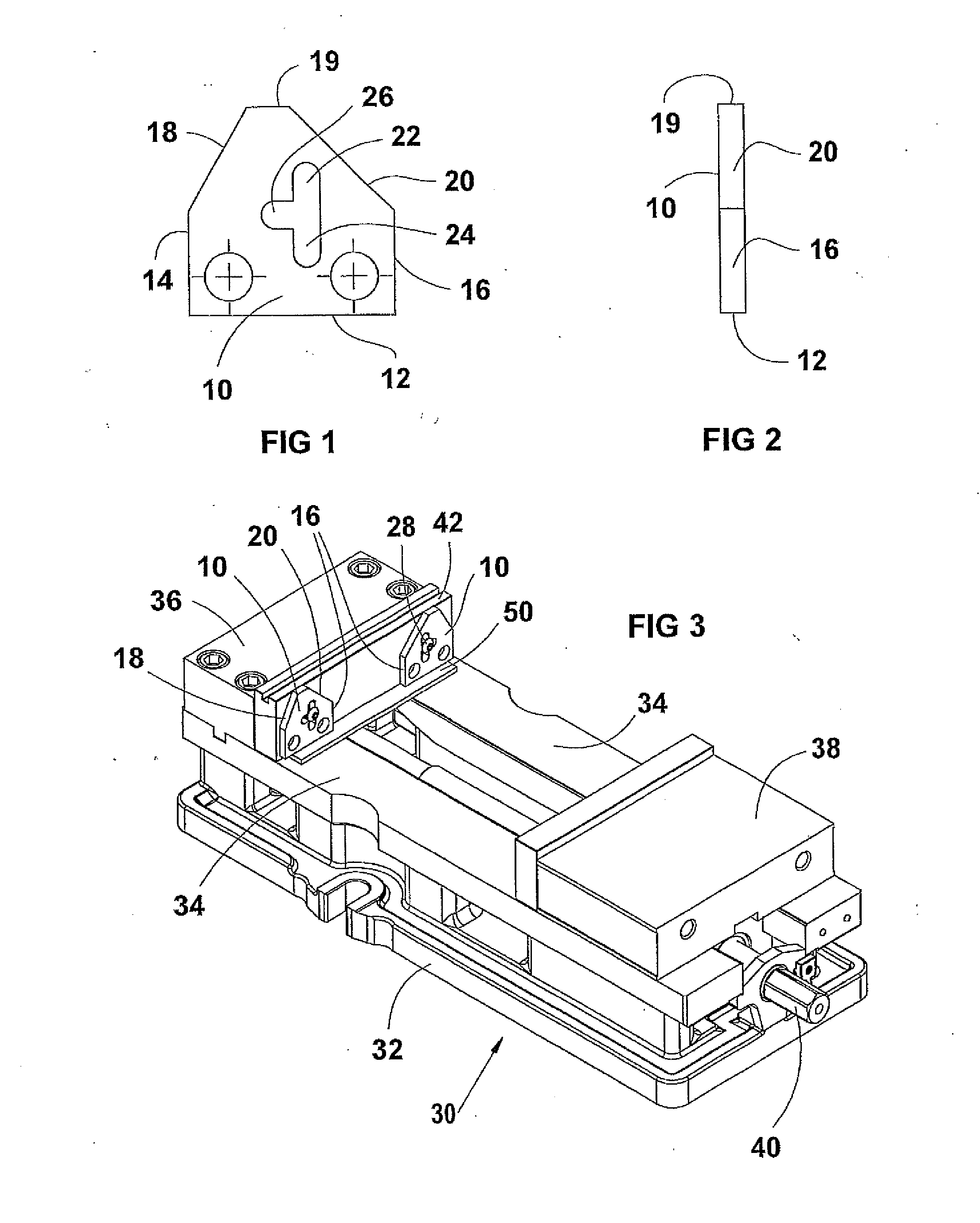

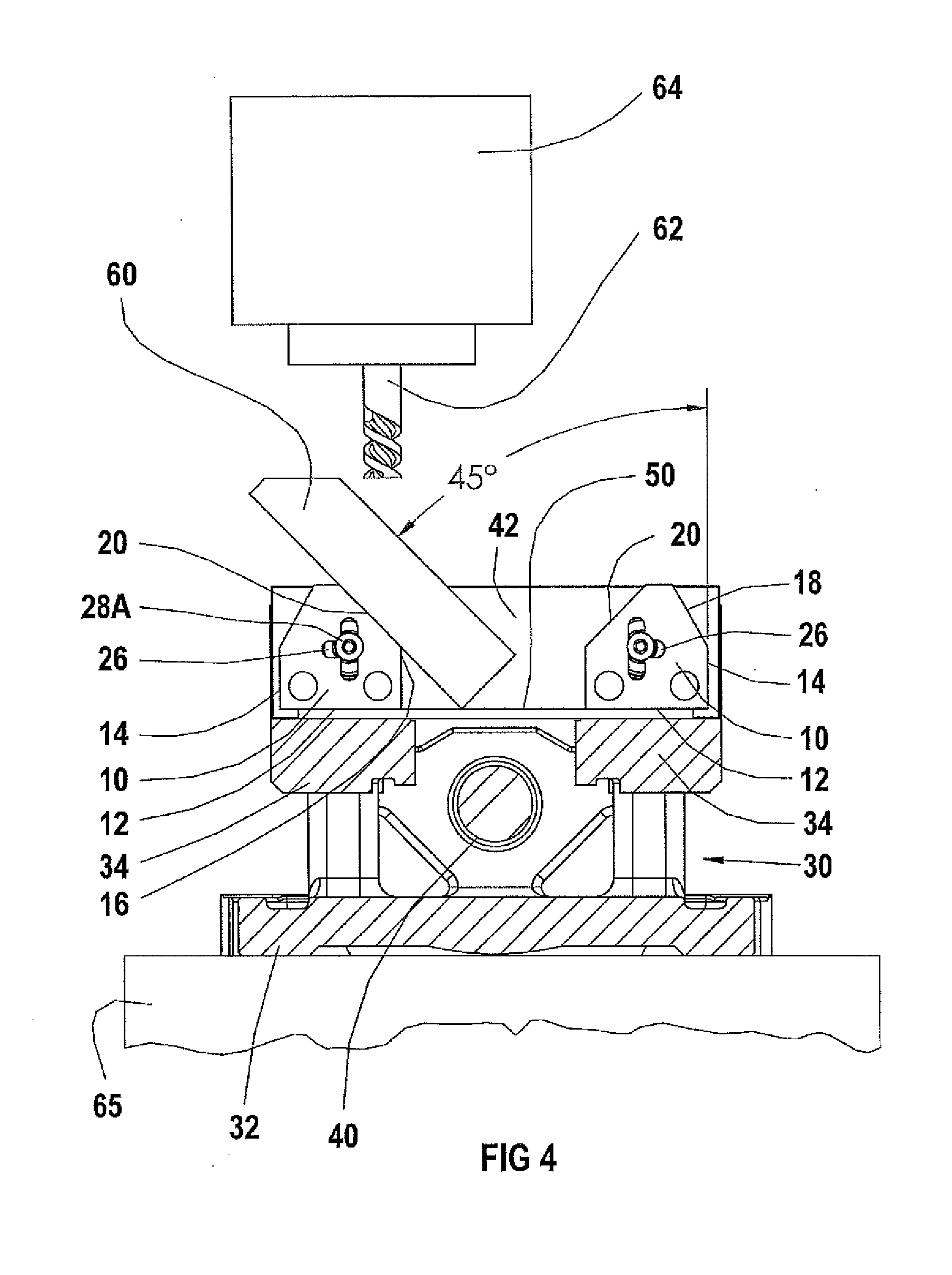

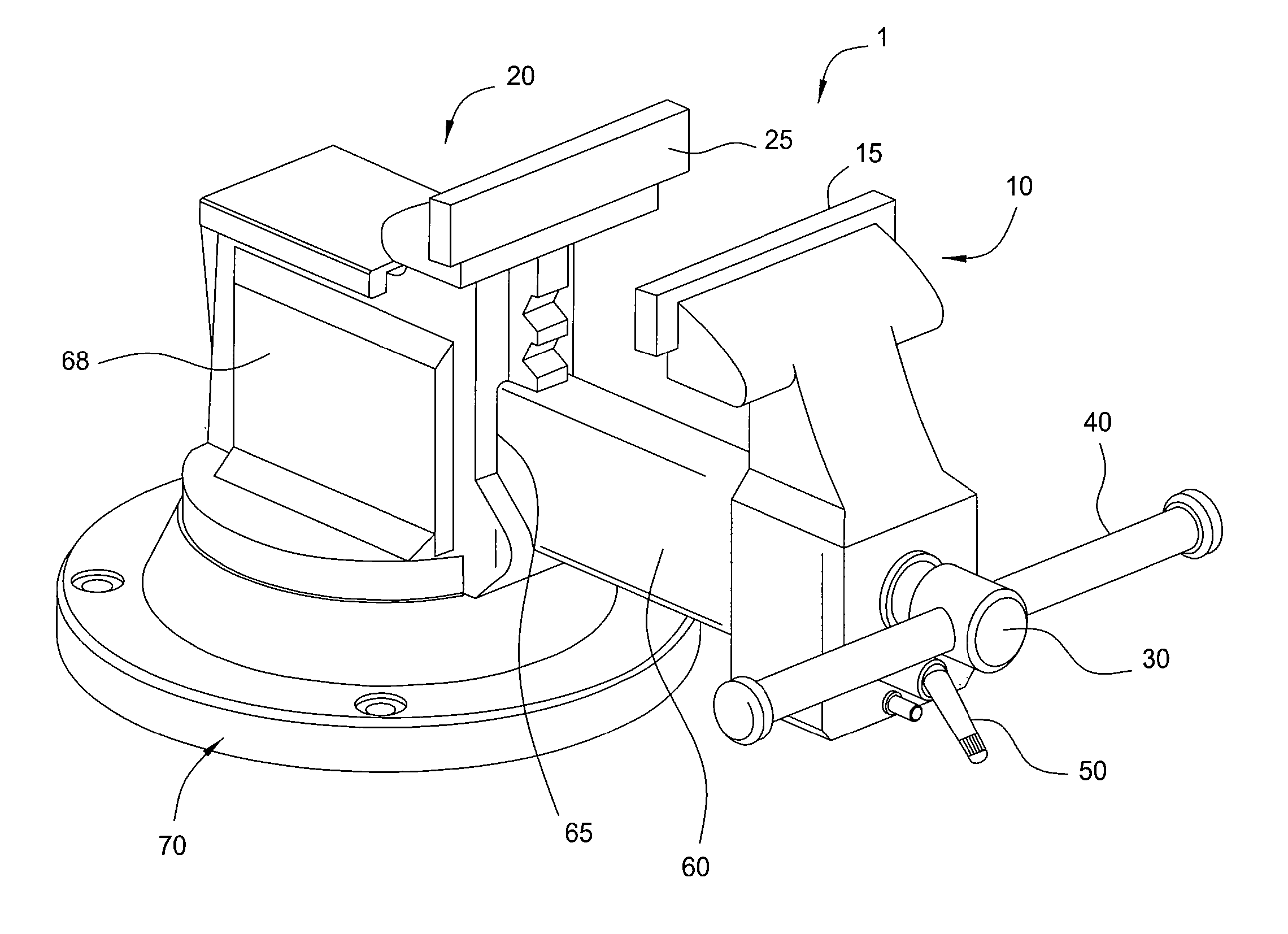

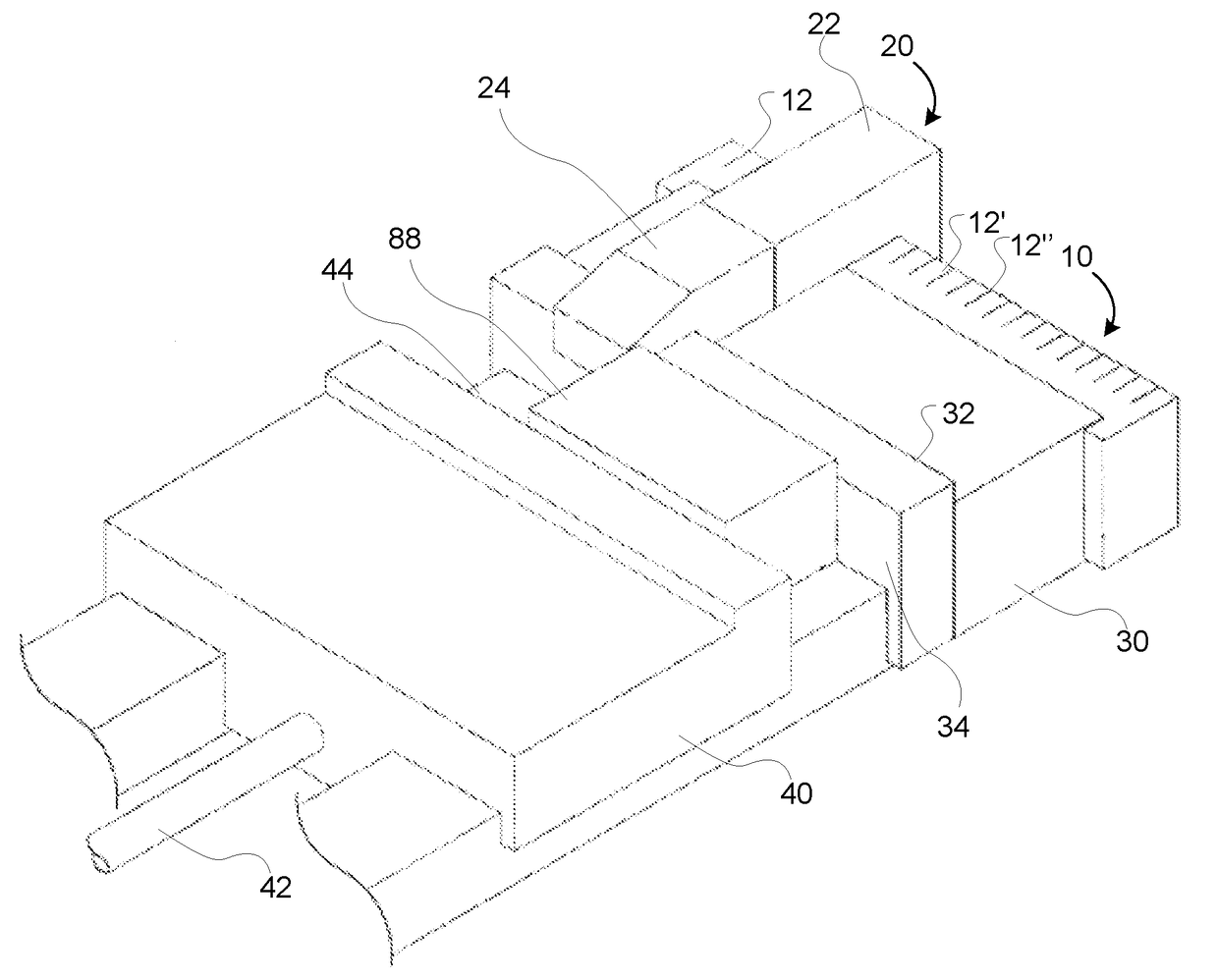

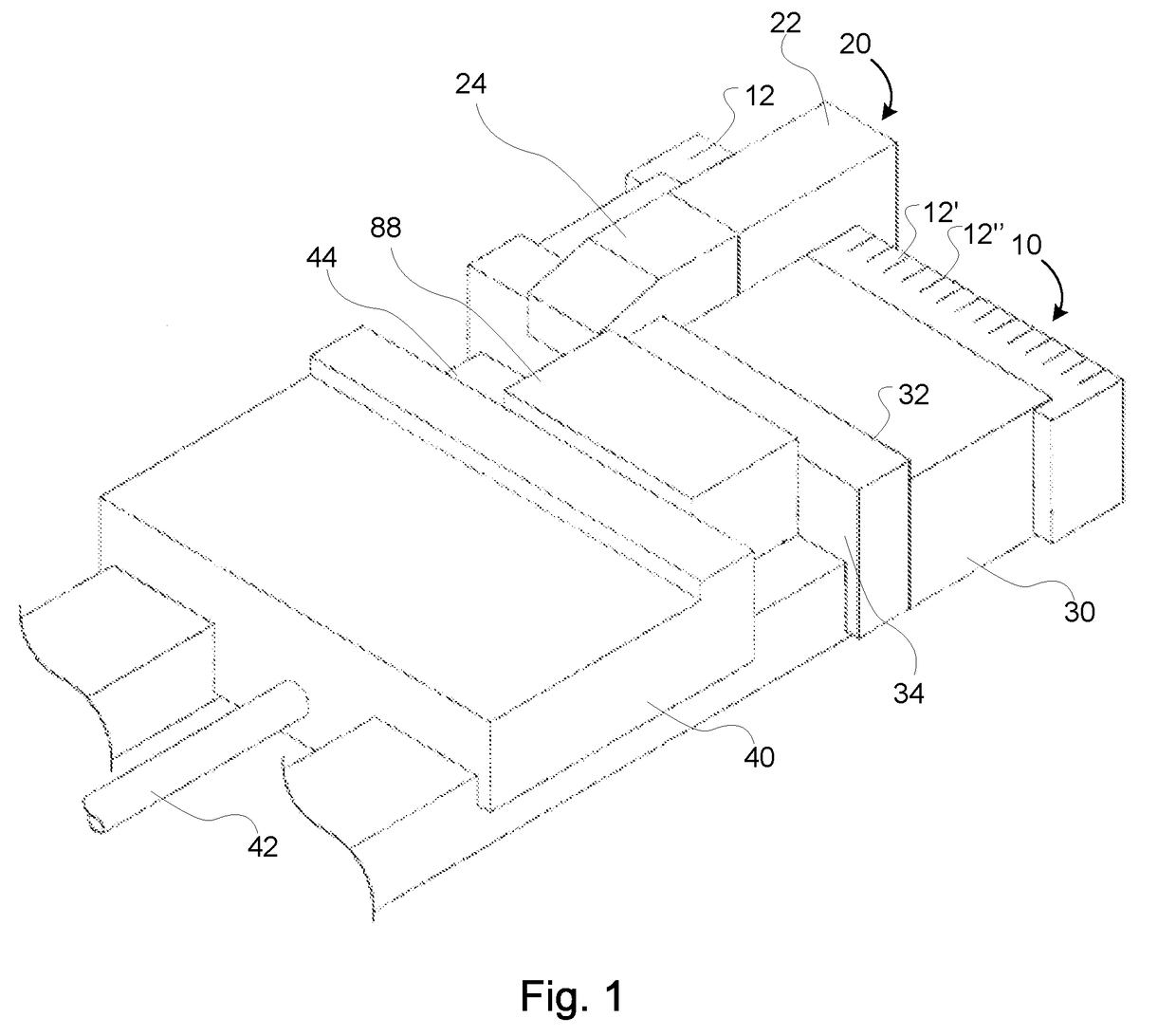

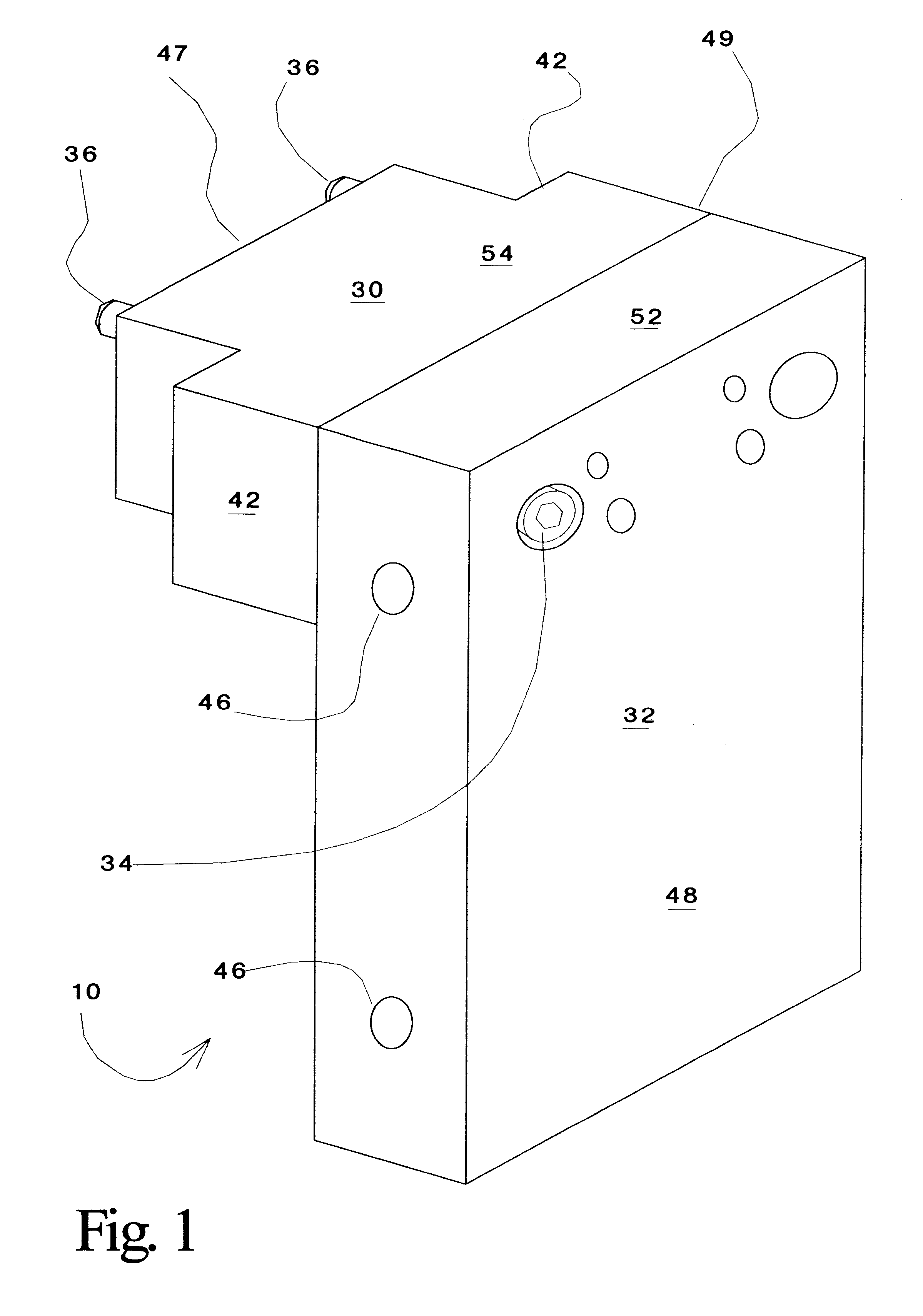

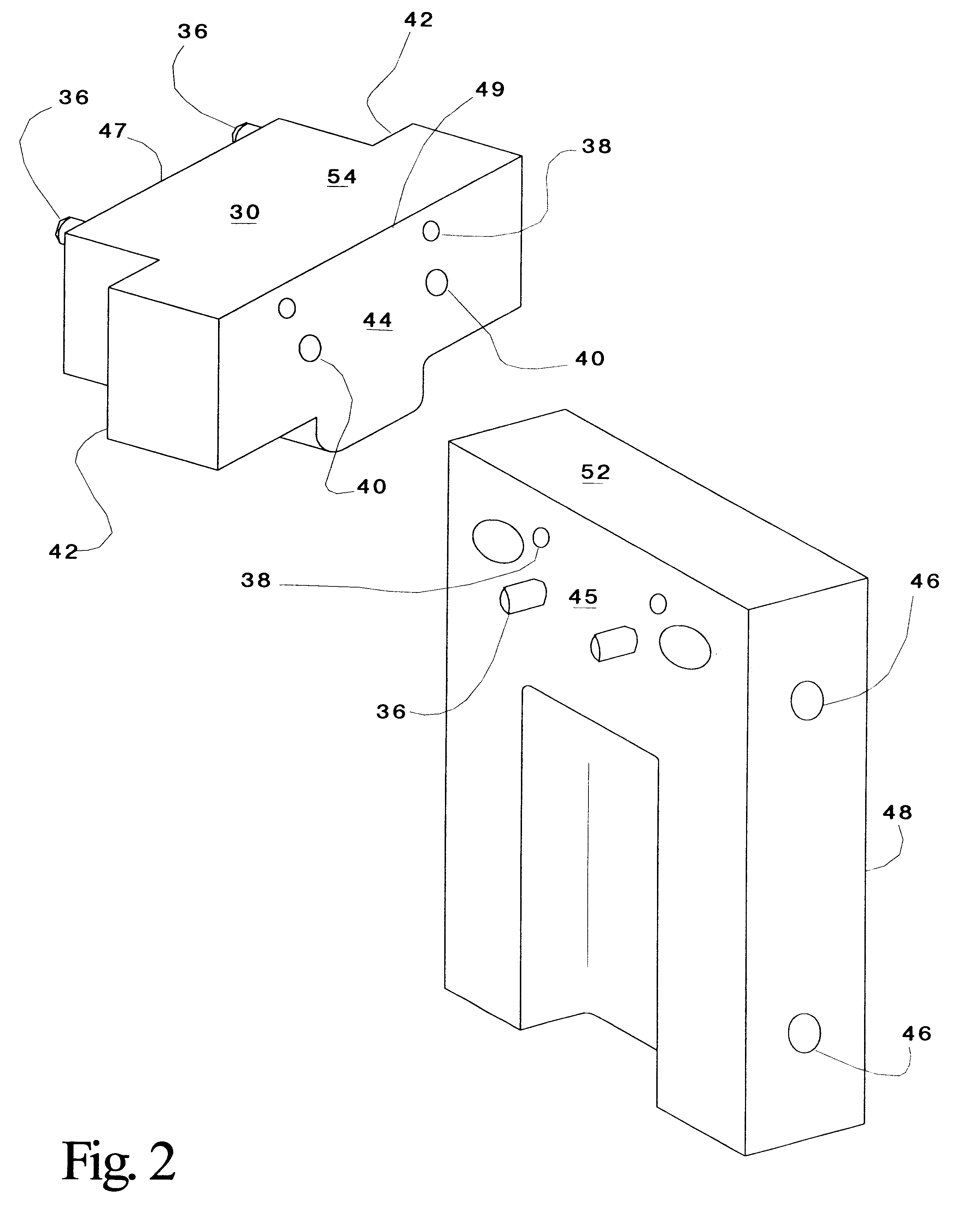

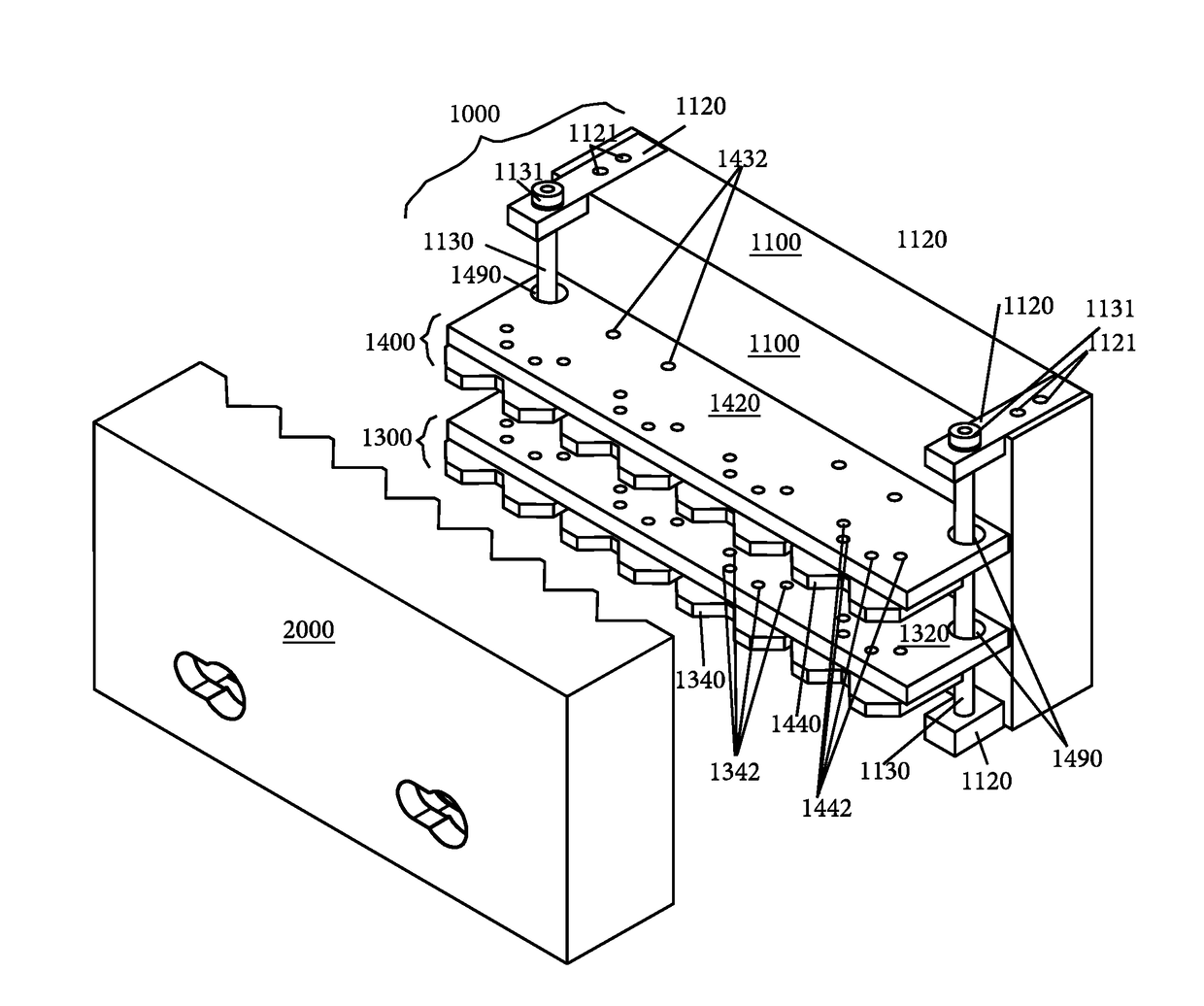

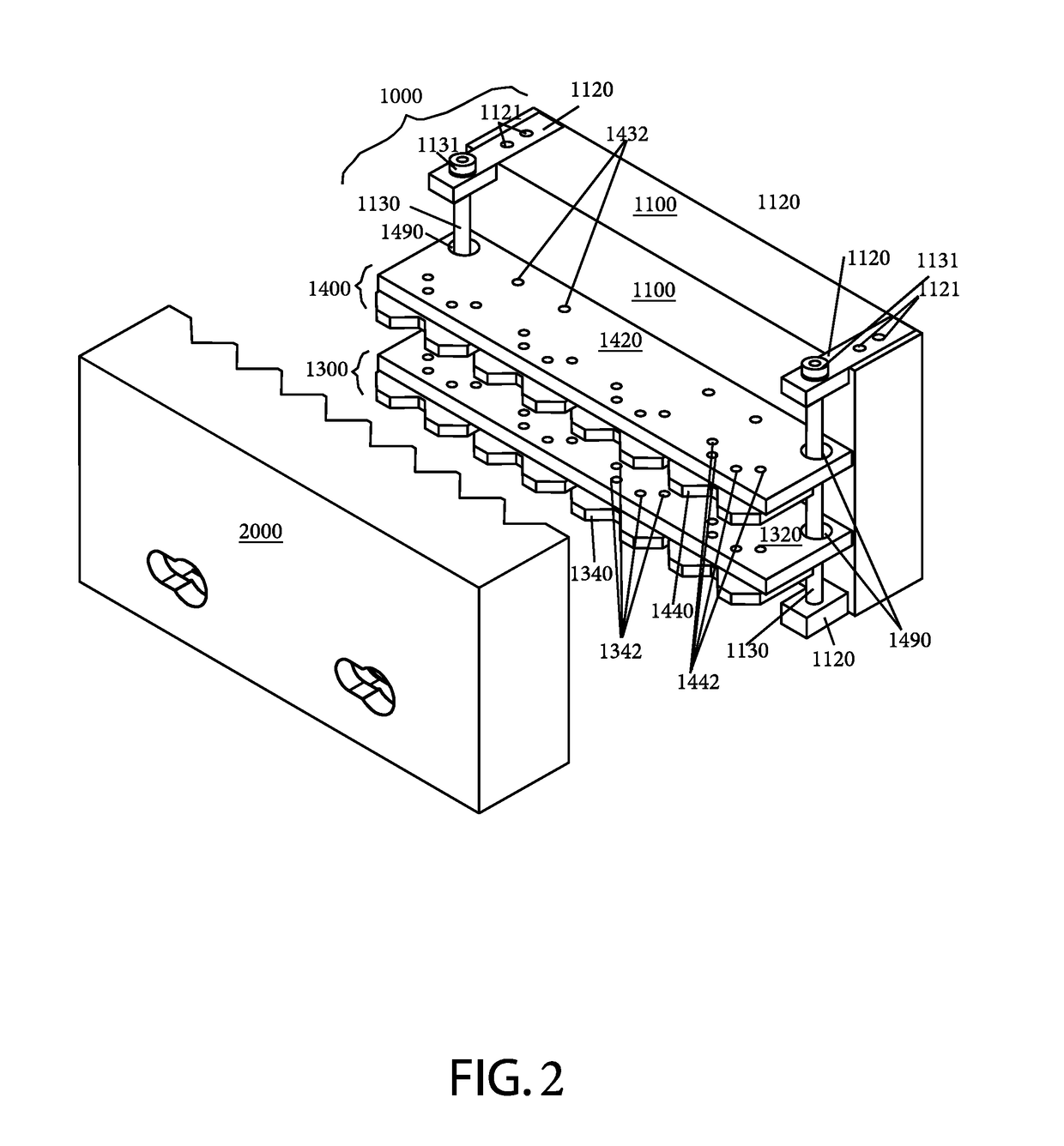

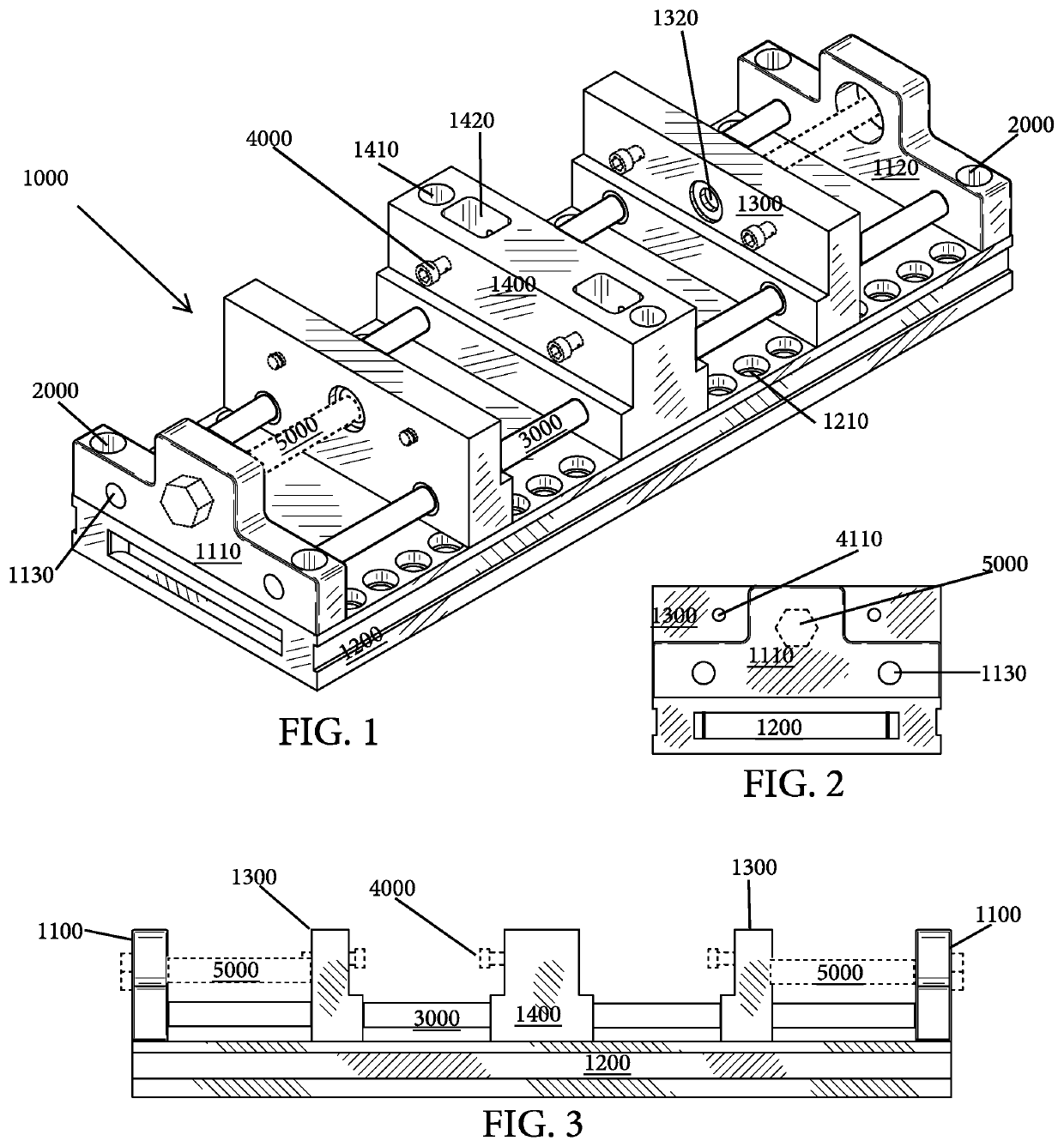

Five axis machine vise

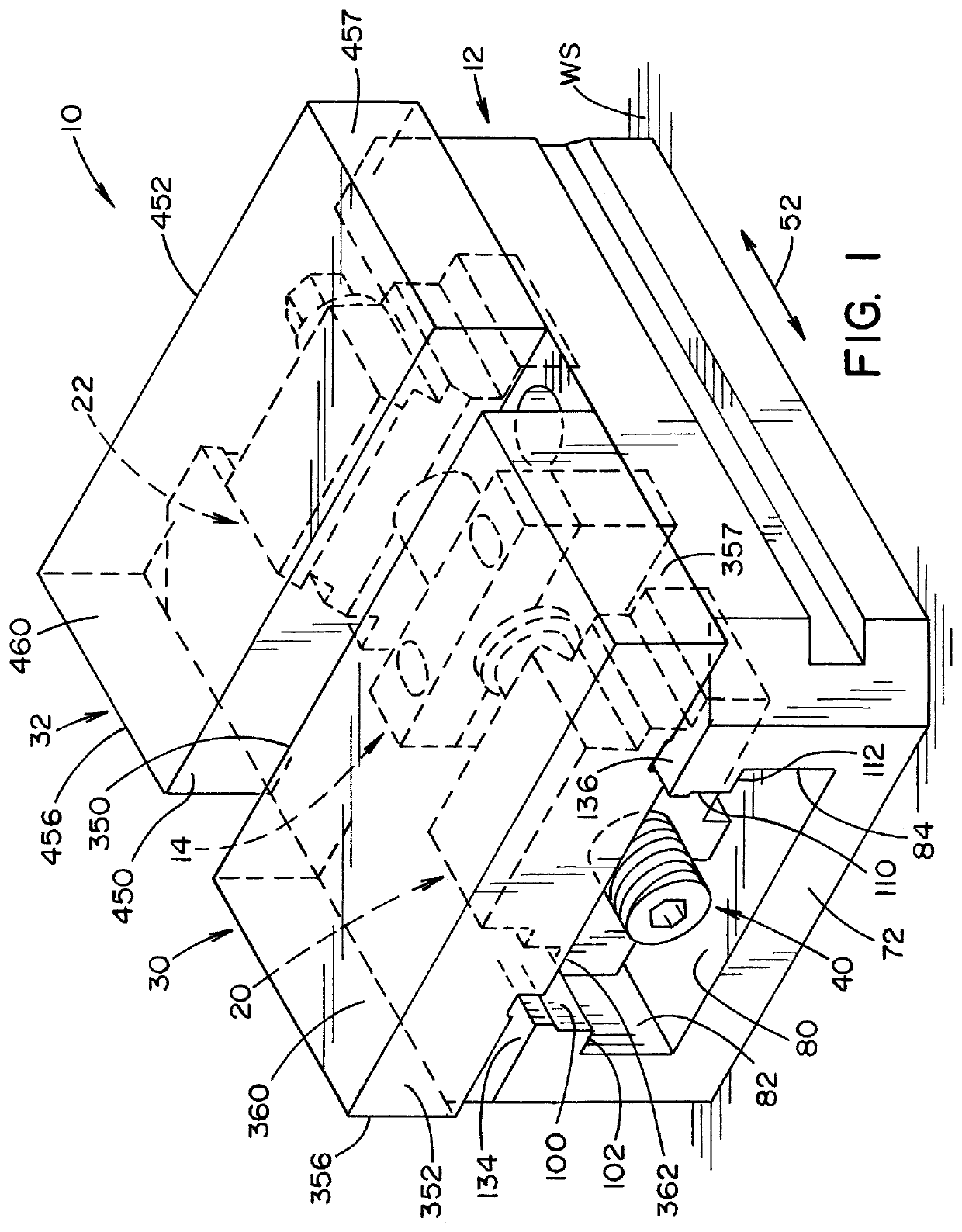

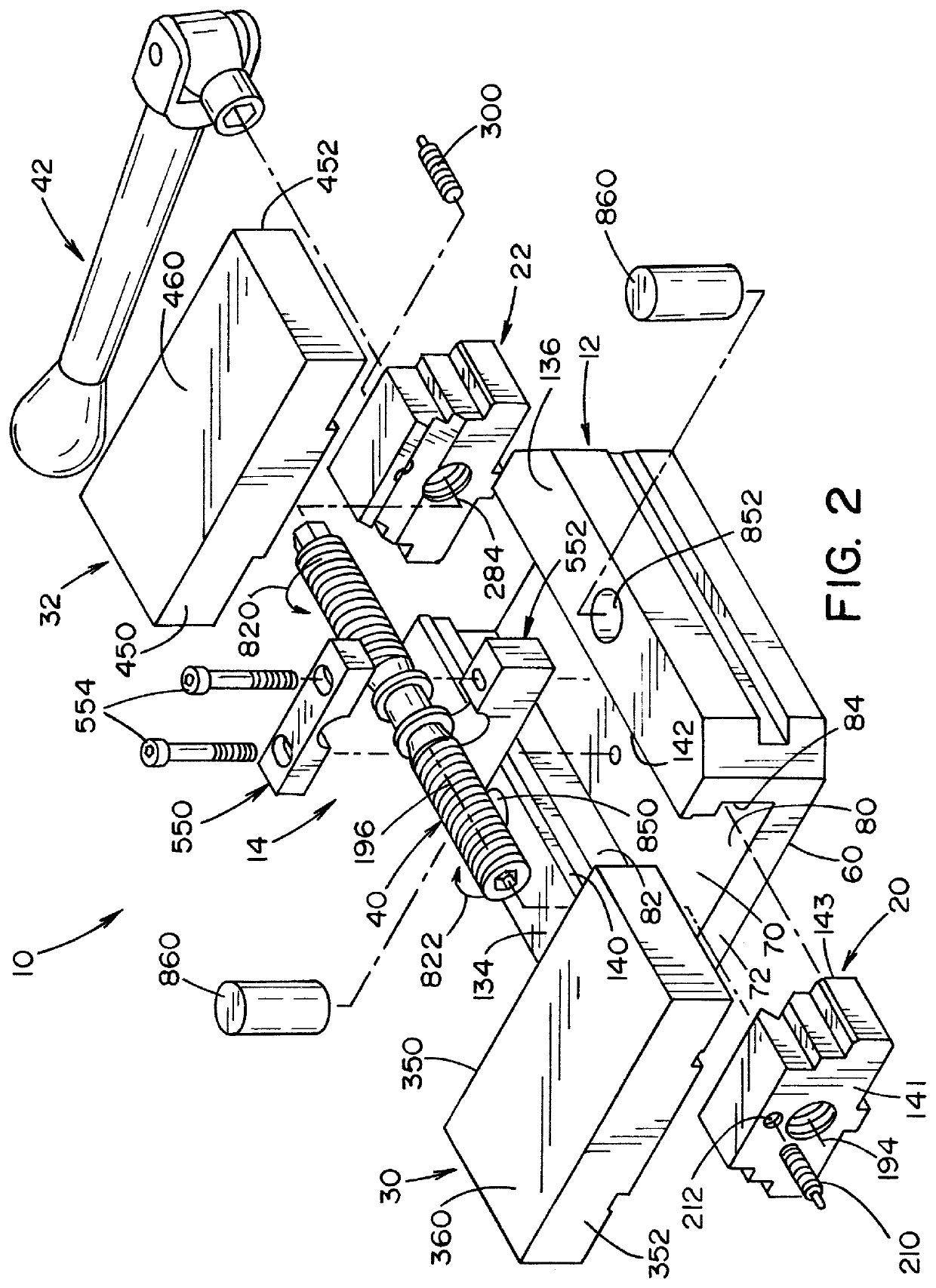

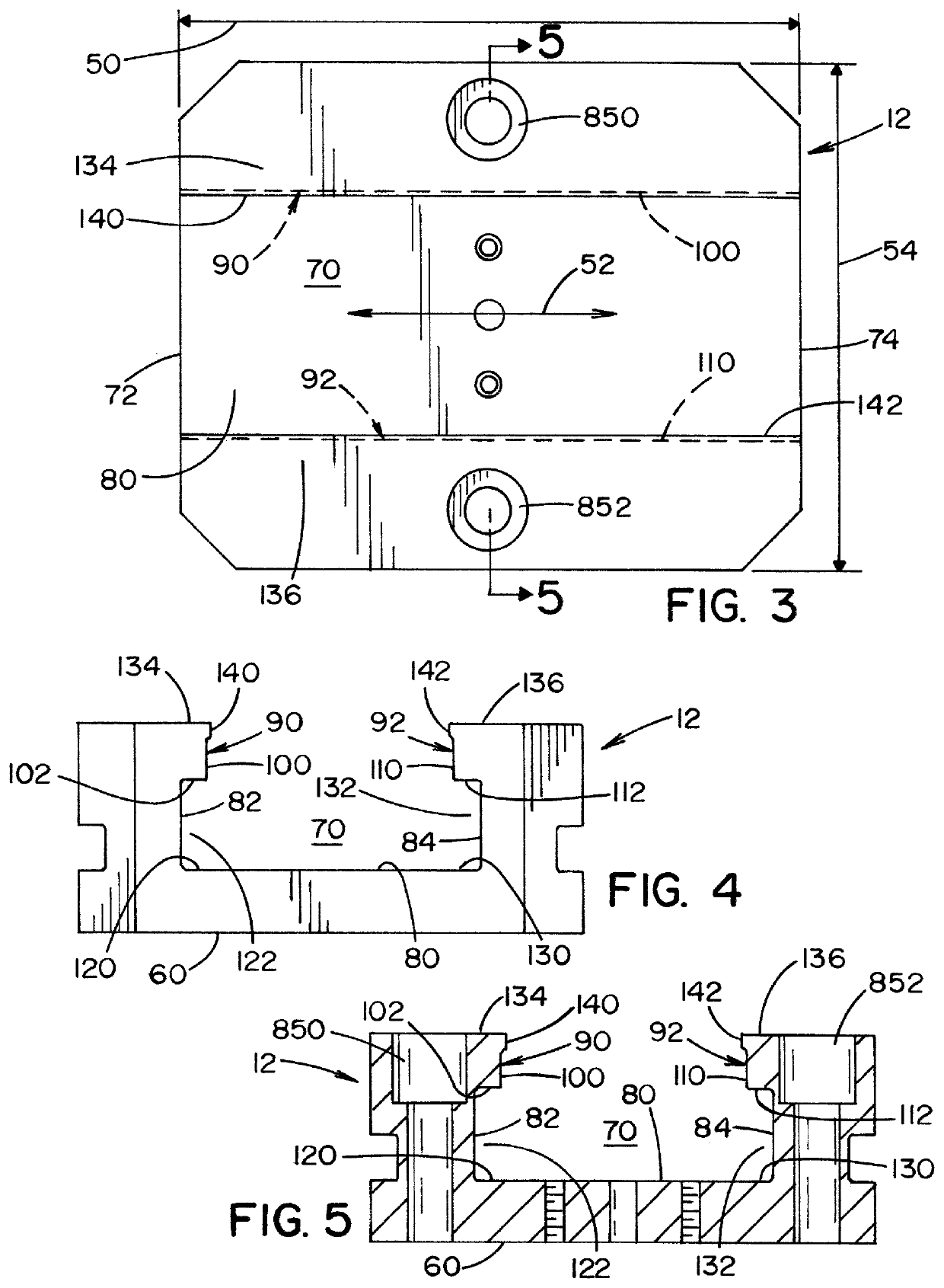

ActiveUS9004472B2Prevent substantial deflectionAvoid supportPositioning apparatusVicesMachine toolThreaded rod

A five axis vise includes two separated vise body portions that are supported on a machine tool table or other support that fixes the vise body portions in position. The vise body portions have jaws spaced up from the machine tool table sufficiently to permit machining five surfaces of a work piece held in the jaws. A vise screw is rotatably mounted in one of the vise body portions, and extends to the other vise body portion to actuate a movable jaw on the other vise body portion. The vise screw is threaded into a jaw nut that has a drive surface that engages and drives a driven surface on the movable jaw, with the drive and driven surfaces being inclined relative to the axis of force application to provide a downward force component on the movable jaw as it is tightened. The vise screw is an assembly of a threaded shank or shaft and a hub that is rotatably mounted in one of the body portions, with the threaded shank or shaft being locked in position in the hub.

Owner:KURT MANUFACTURING COMPANY INC

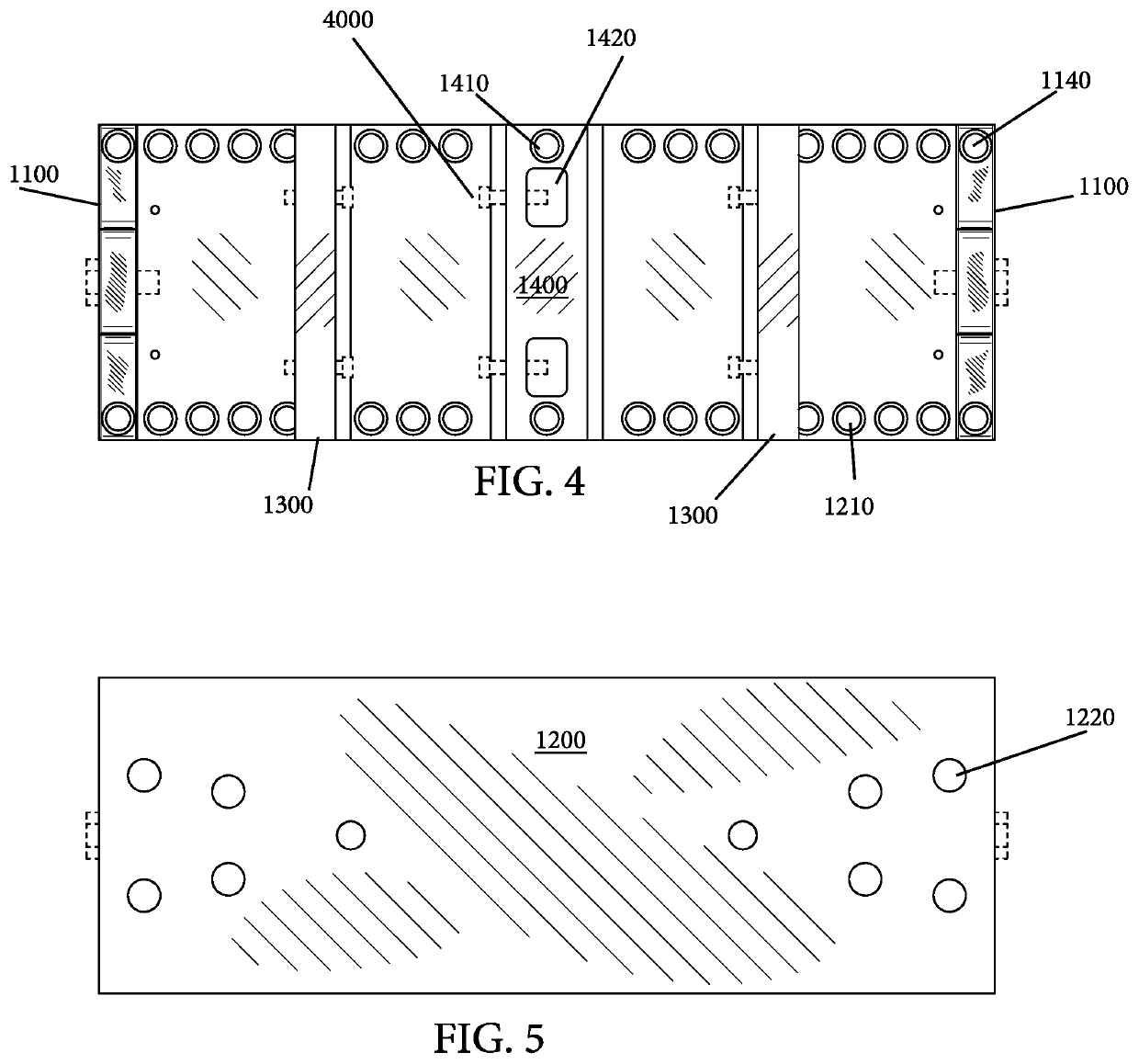

Vise

A vise for holding a workpiece that reduces jaw lift having a vise base with a longitudinally extending guide channel that includes vise base flanges with base flange guide surfaces, the vise having vise trucks that move longitudinally within the guide channel, the vise having jaws that are selectively securable relative to the trucks wherein the jaws and the trucks include lift surfaces that move the trucks toward the jaws transversely to the longitudinal direction as the jaws engage the workpiece to lock the jaws and the trucks relative to the guide channel when the workpiece is clamped in the vise.

Owner:JERGENS

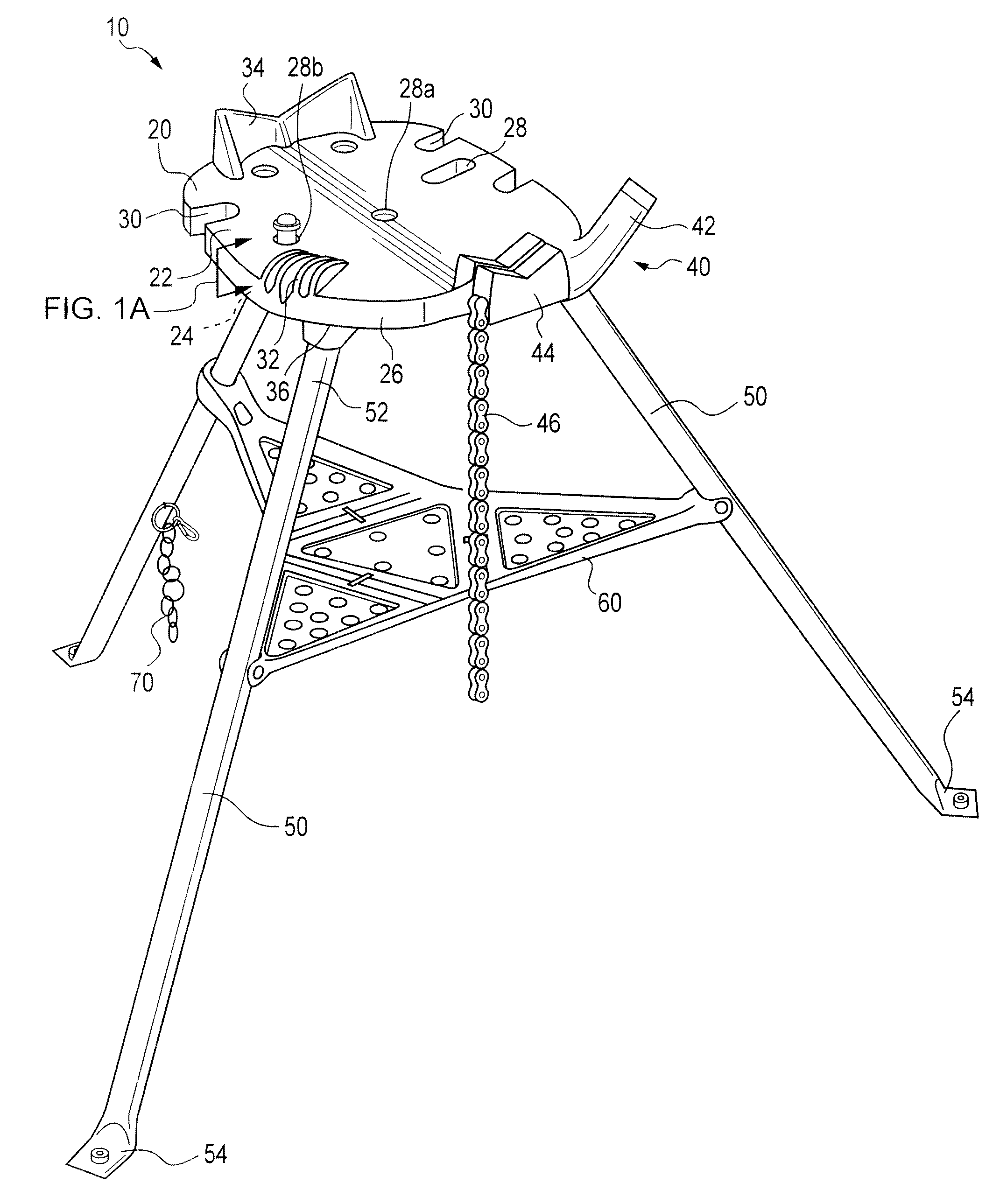

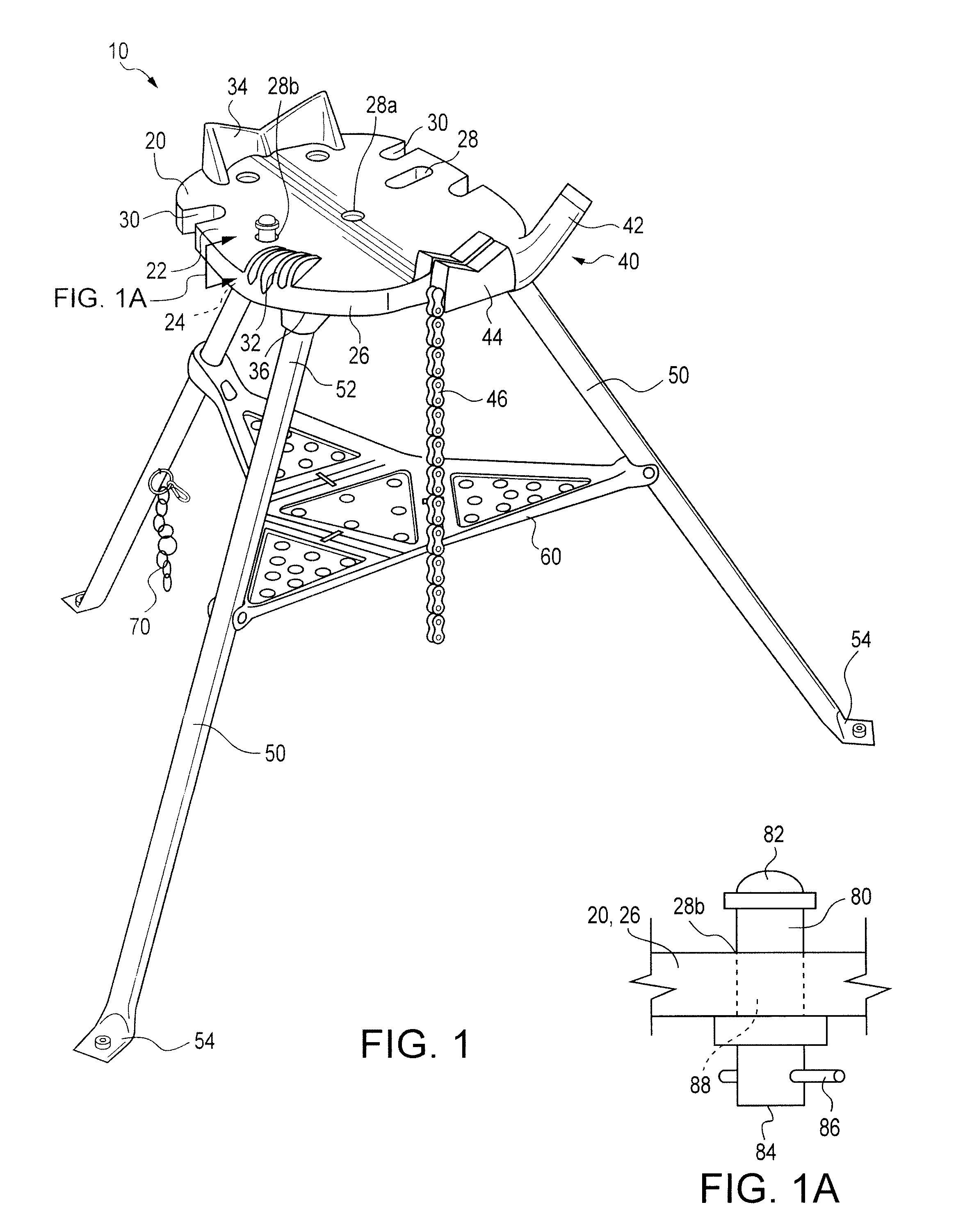

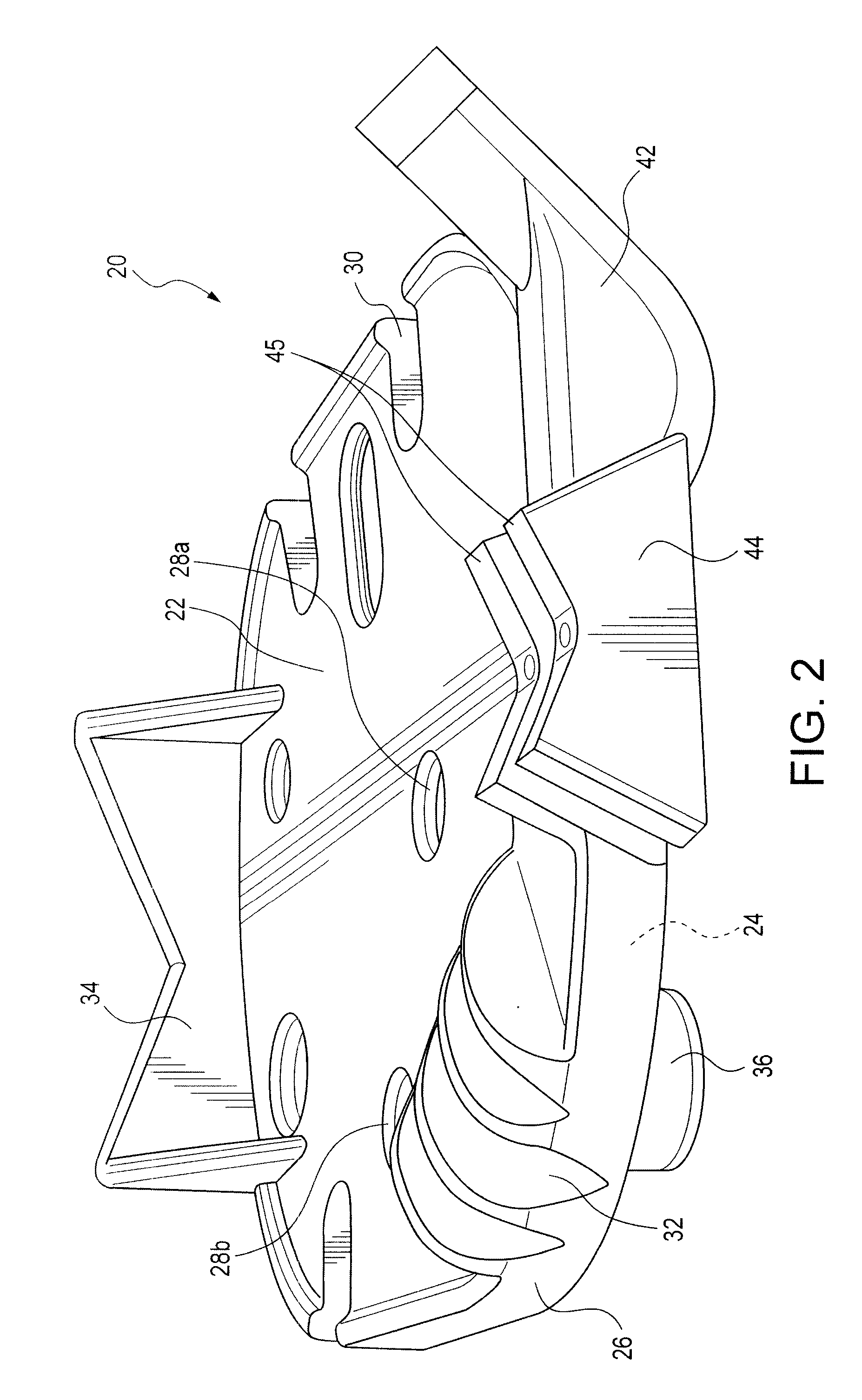

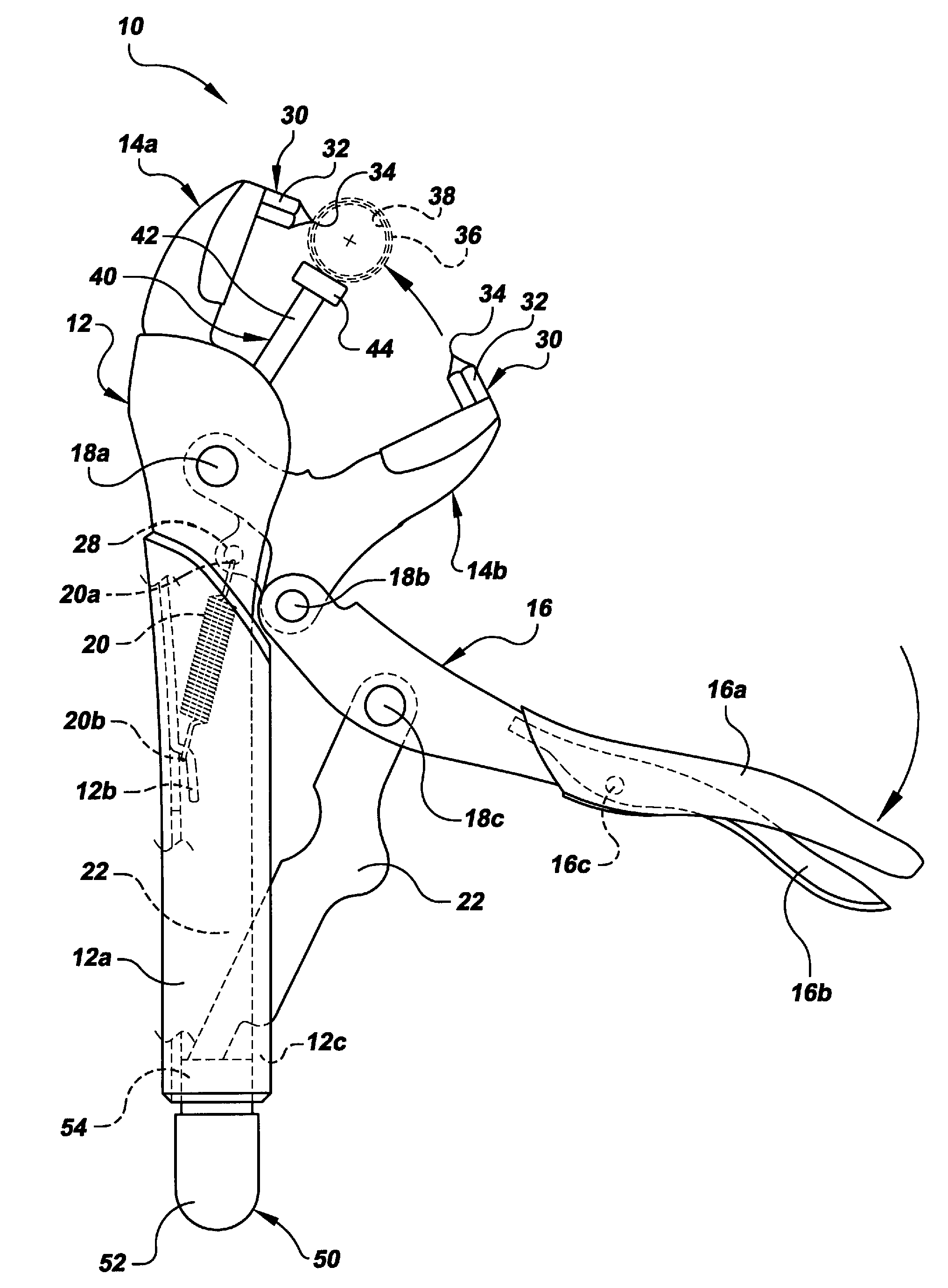

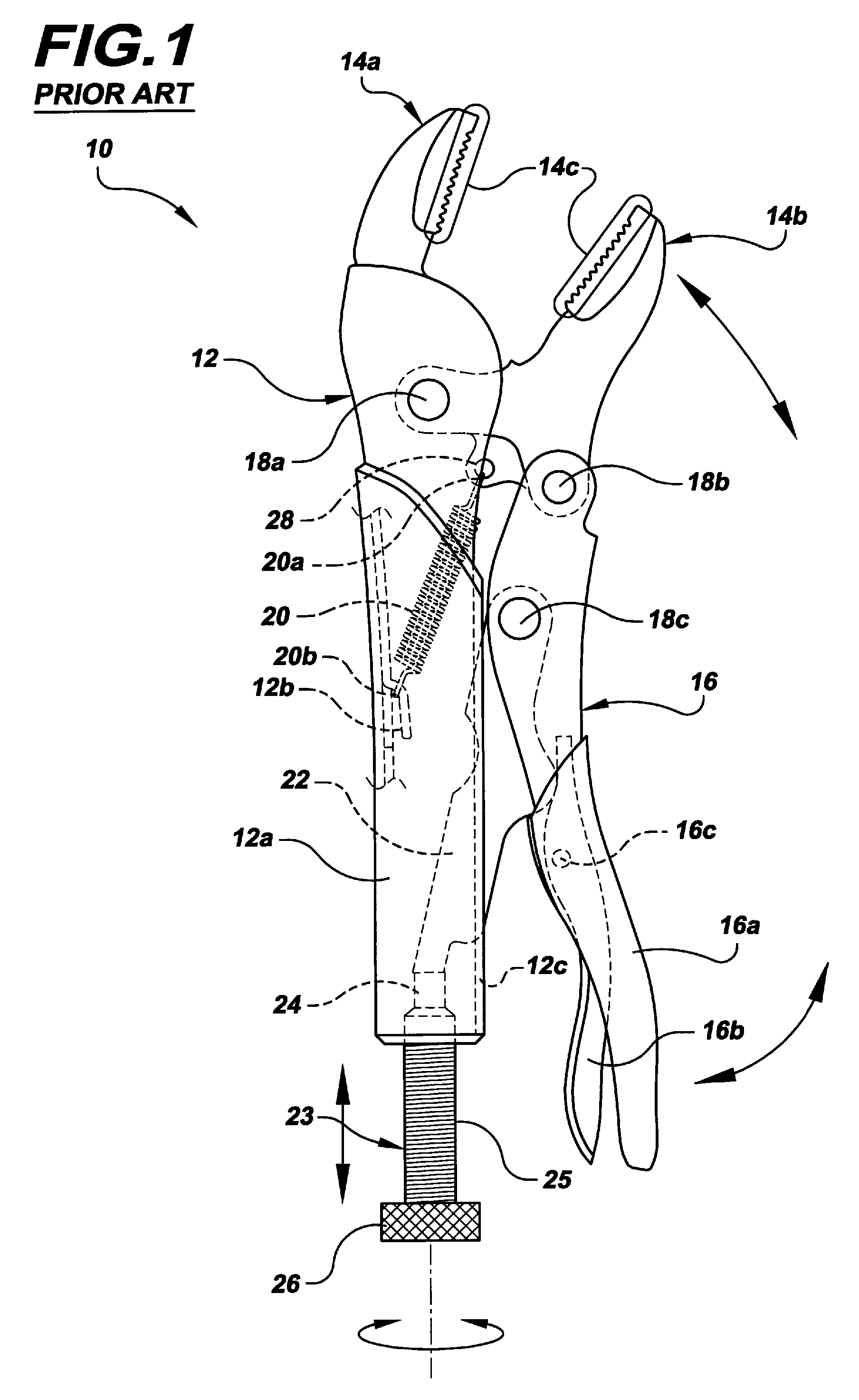

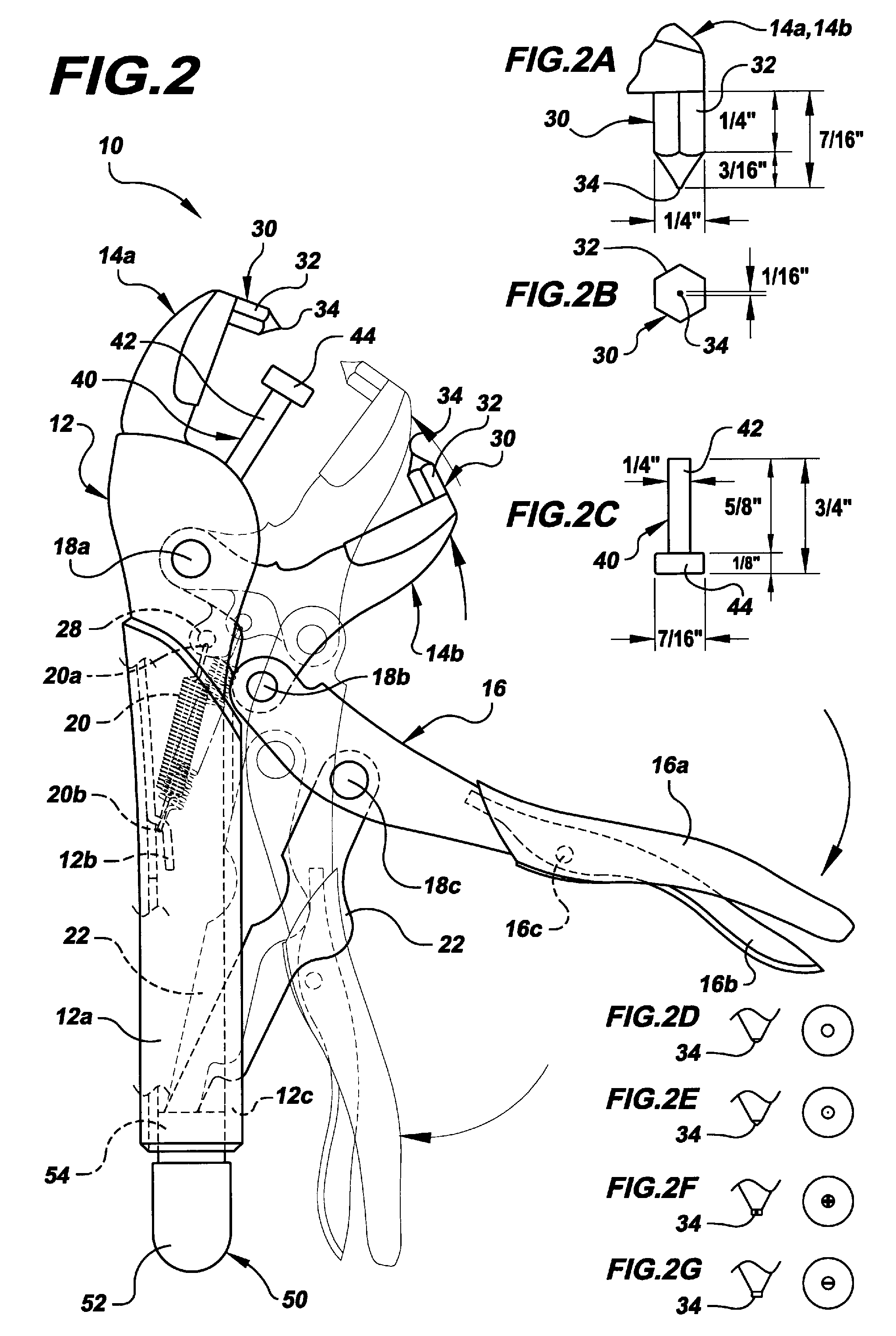

Pipe vise stands and components for increasing capacity thereof

A pipe vise stand and system for increasing the size capacity of the pipe vise stand are described. Upon incorporation of the system in a pipe vise stand, the stand can accommodate pipes of significantly larger diameter. The system includes a pipe support member which is configured to be positioned on a vise base of the stand. The system also includes a jackscrew extender that provides or relocates a jackscrew associated with the stand to a lateral position alongside the stand. Related provisions and methods are also described.

Owner:EMERSON ELECTRIC CO

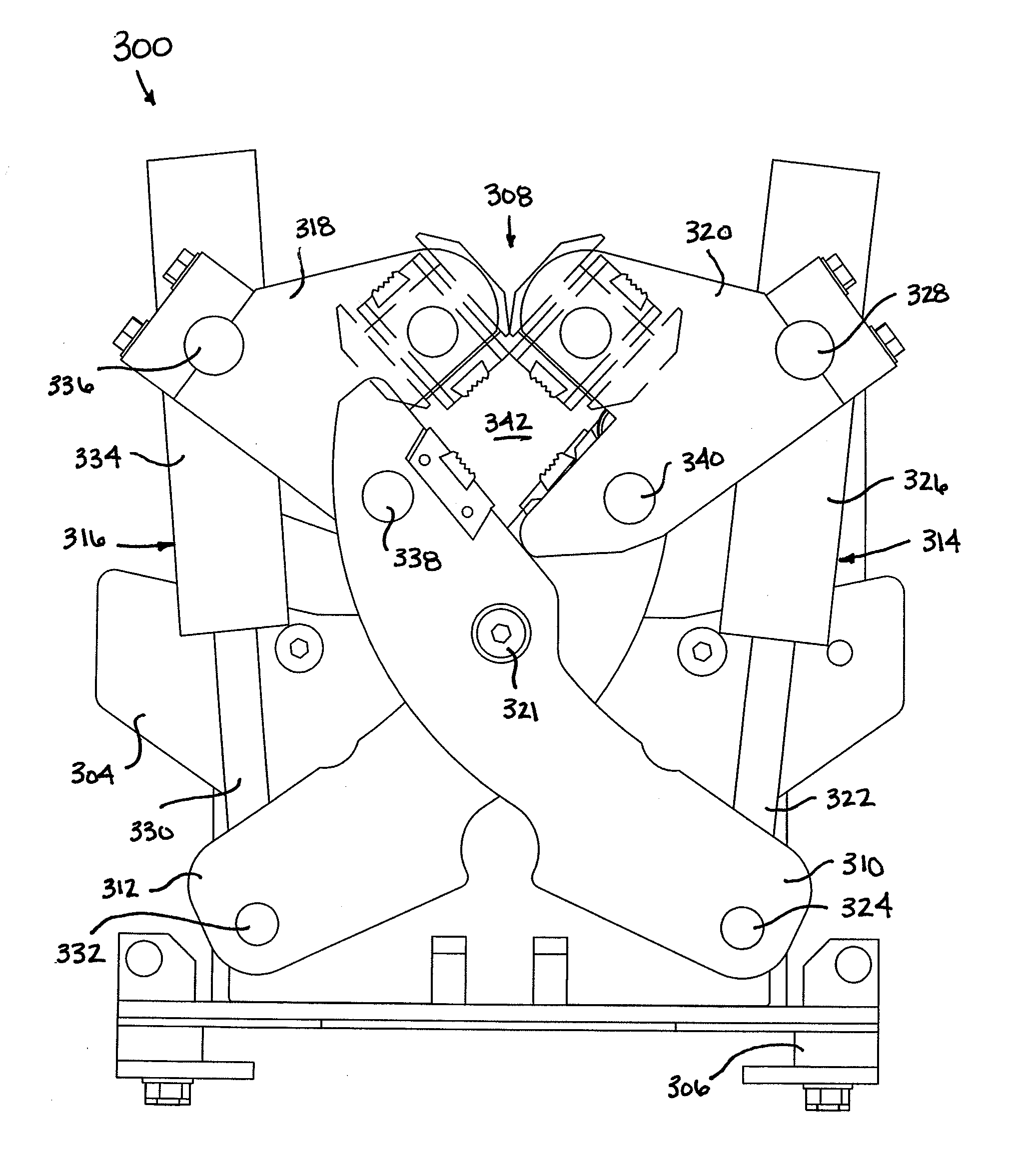

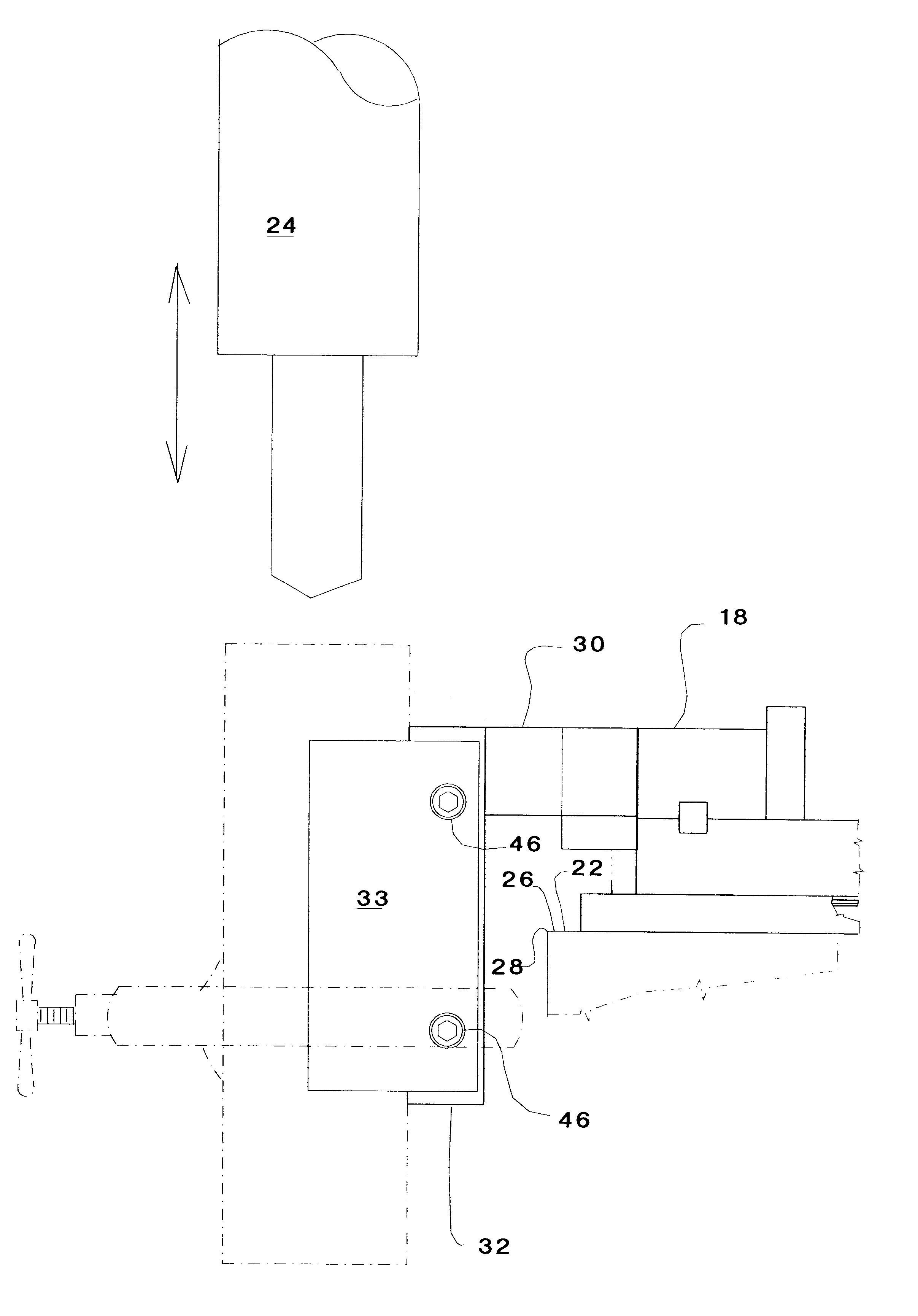

Vise for a directional drilling machine

A vise apparatus includes a vise die assembly that is pivotally mounted to tong heads of a vise mechanism. The vise die assembly includes a plurality of vise die and a mounting block having a first face and an oppositely disposed second face. Each of the plurality of vise die includes a gripping surface. A first vise die of the plurality of vise die is mounted to the first face of the mounting block while a second vise die is mounted to the second face. The first and second vise die are mounted such that the gripping surface of first vise die faces opposite the gripping surface of the second vise die.

Owner:VERMEER MFG CO

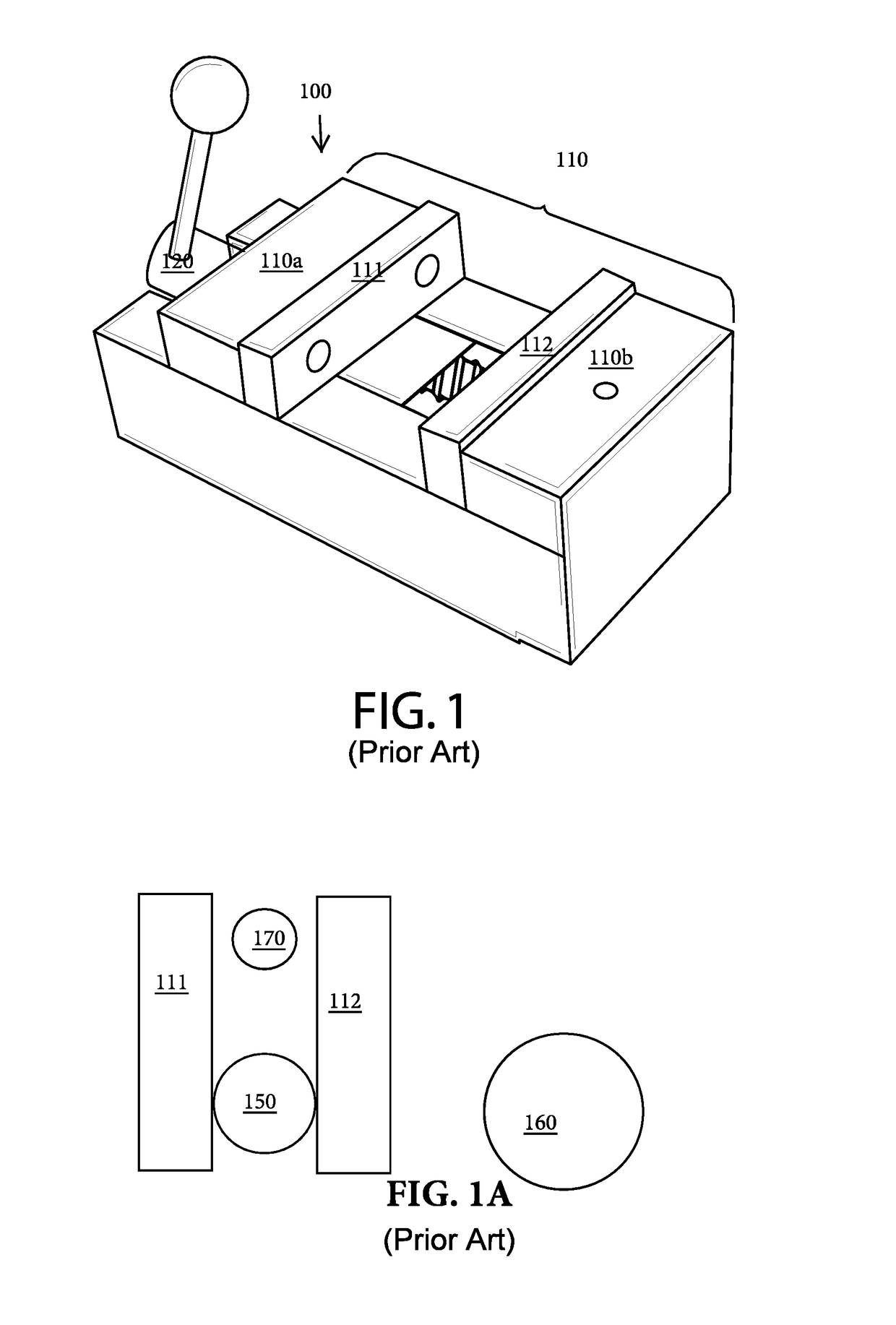

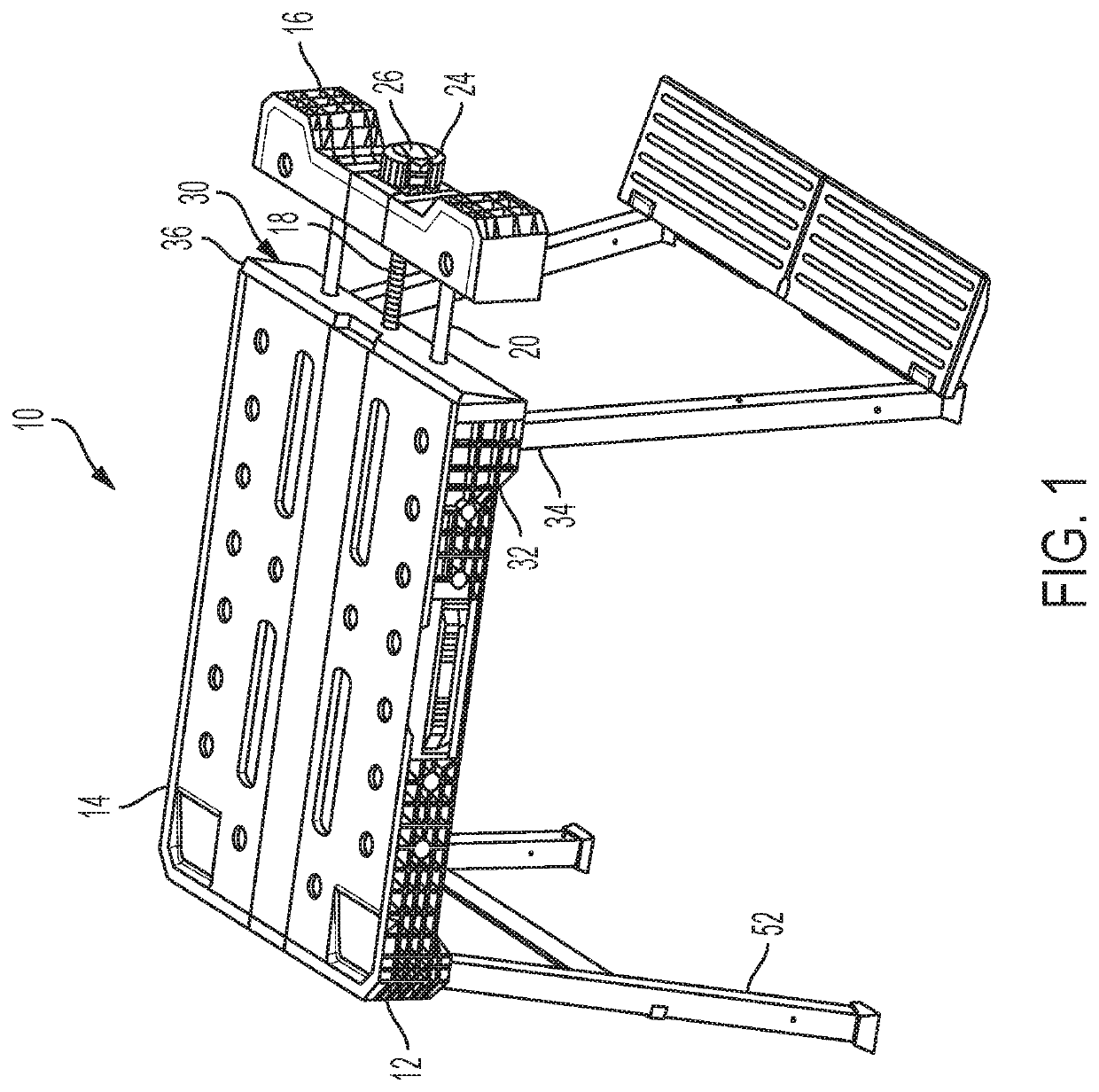

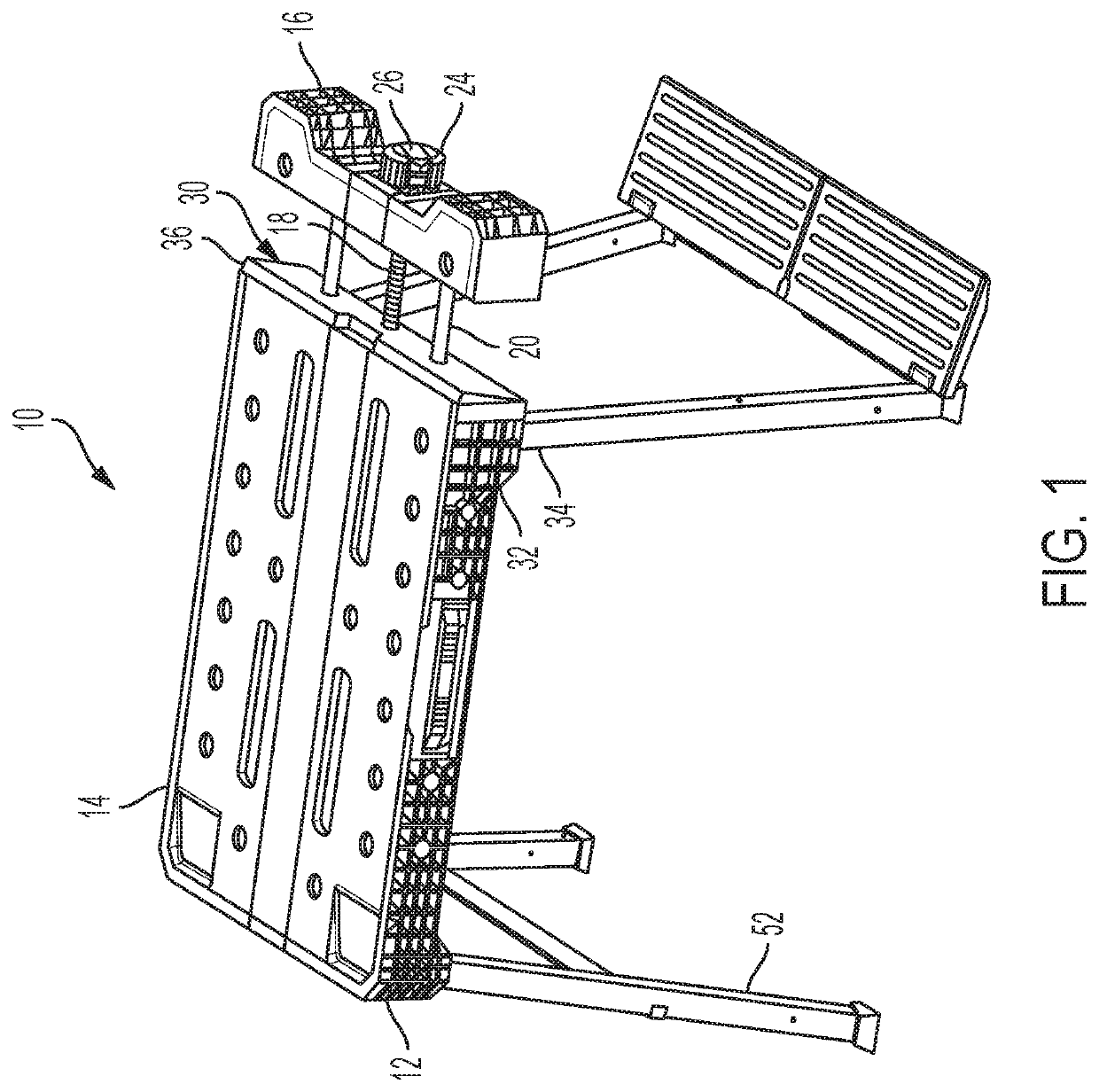

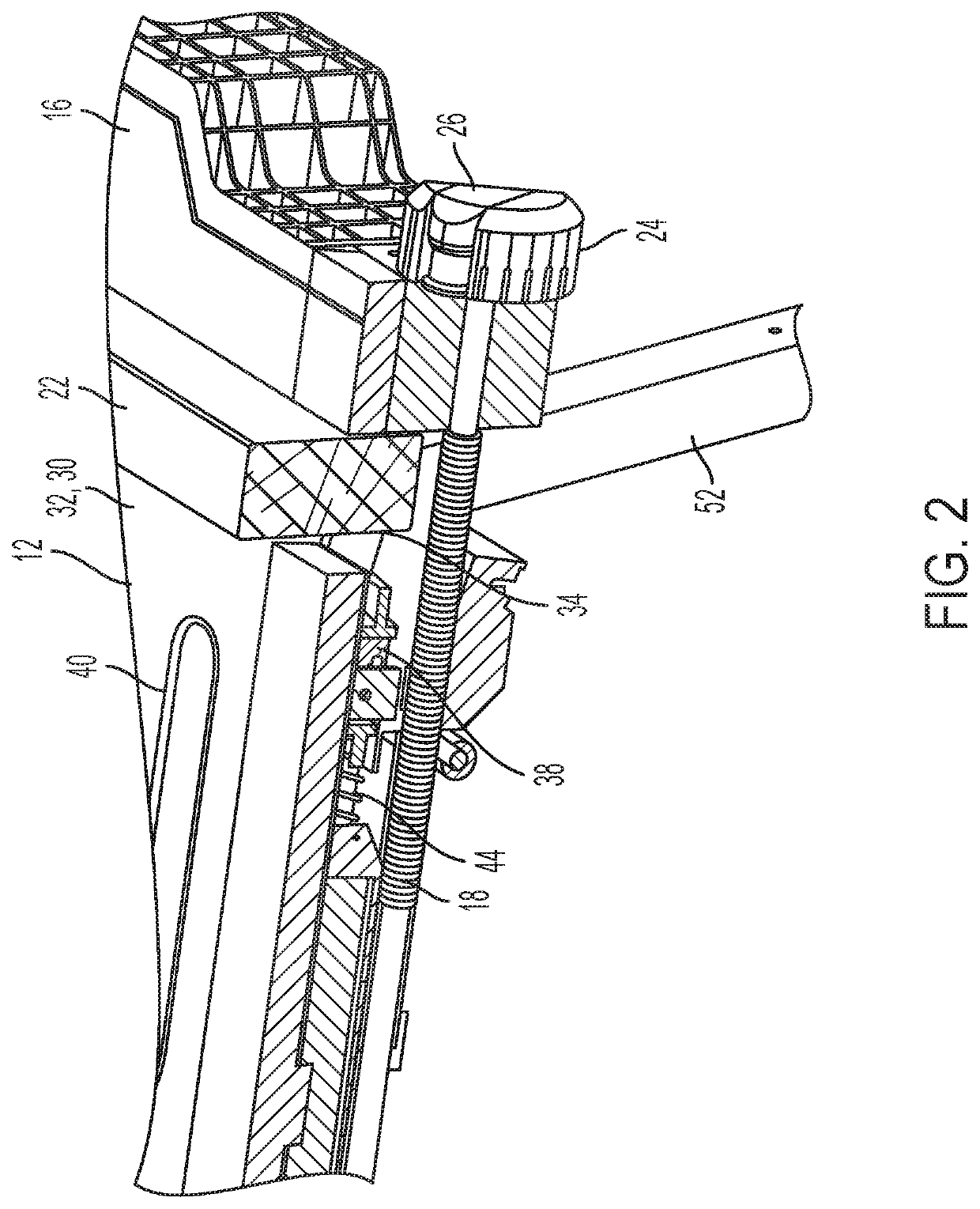

Vise stop arrangement

An arrangement of a carrier plate and vise stop which provide an abutment against which a workpiece rests laterally when being milled. The carrier plate affixes to a rear portion of a fixed jaw of a milling machine, the carrier plate having a forward recess for receiving the rear portion of the fixed jaw which nestles into the recess as the recess is dimensioned for receiving at least three sides of the fixed jaw. The carrier plate includes a plurality of locator chambers sized for receiving dowel pins of a vise stop, whereby adjacent locator chambers are spaced at a constant distance apart from one another. The interlocking of the dowels of the vise stop and the carrier plate may occur at varied lateral locations between the sides of the milling machine. A nose of the vise stop extends into the work area of the milling machine, providing the abutment.

Owner:CONCEPTS TO SOLUTIONS LLC

System and method for supporting a workpiece from a milling vise

A system that allows support of a work piece from the body of a vise, the vise being attached to the bed of a mill. The system an extender block that attaches to one of the jaws of the vise; and an angular surface plate attached to the extender block. The angular surface plate provides a surface that extends along a plane that extends next to and below the bed of the mill.

Owner:STEVEN JOHN R

Leverage handle

A leverage handle tool includes a handle and a seat block. In use, a slot in the seat block is located upon a handle such as a vice handle, and the tool is pulled toward the handle end. As the tool is pulled toward the handle end the slot grips the handle due to the frusto-conical configuration thereof. The tool may then be acted upon such that the tool increase the leverage upon handle.

Owner:SNAP JAWS MFG

Vise pads for accurate work piece alignment

The present disclosure general relates to vise pads which provide accurate alignment of work pieces in a vise. The movement of internal members of these pads eliminates the need for manual adjustment such as with the use of a hammer to ensure alignment. The vise pads include wedge bars in combination with connectors which reduce friction and thus provide for longer life and efficient operation. In another embodiment, the vise pads include elastomeric bars which act as sealant to reduce entry of dust resulting from machining of a work piece.

Owner:JANG MAN SUNG

Compensating Face Plate Vise Jaws and Related Methods

Disclosed generally is a face plate for a vise that is capable of gripping multiple work-pieces of different sizes at the same time. In one embodiment, the disclosed subject matter may be a vise face plate comprising: a base with an upper compensation structure and a lower compensation structure; and, wherein the upper and lower compensation structures define two sets of working surfaces. In use, the plate may be secured to a movable jaw so that the working surfaces may be employed to clamp a plurality of work pieces between the working surfaces and a fixed jaw.

Owner:CHICAGO EQUIP LEASING SERVICES CO

Vise with push device

A vise includes a body and a fixed jaw connected to the body, a movable jaw, a driving unit, and a push unit. The body has a guide member and the driving unit has a threaded rod which is co-axially connected to the movable jaw. A locking member is threadedly mounted to the threaded rod. The push device has a slide mounted to the guide member, a joint member connected to the slide and a cylinder connected to the slide. The slide has a groove and the joint member has a pivot which is engaged with the groove. When activating the cylinder, the movable jaw is moved toward to or away from the fixed jaw by the joint member and the locking member, and the clamping force is magnified.

Owner:LEE CHIN YUAN

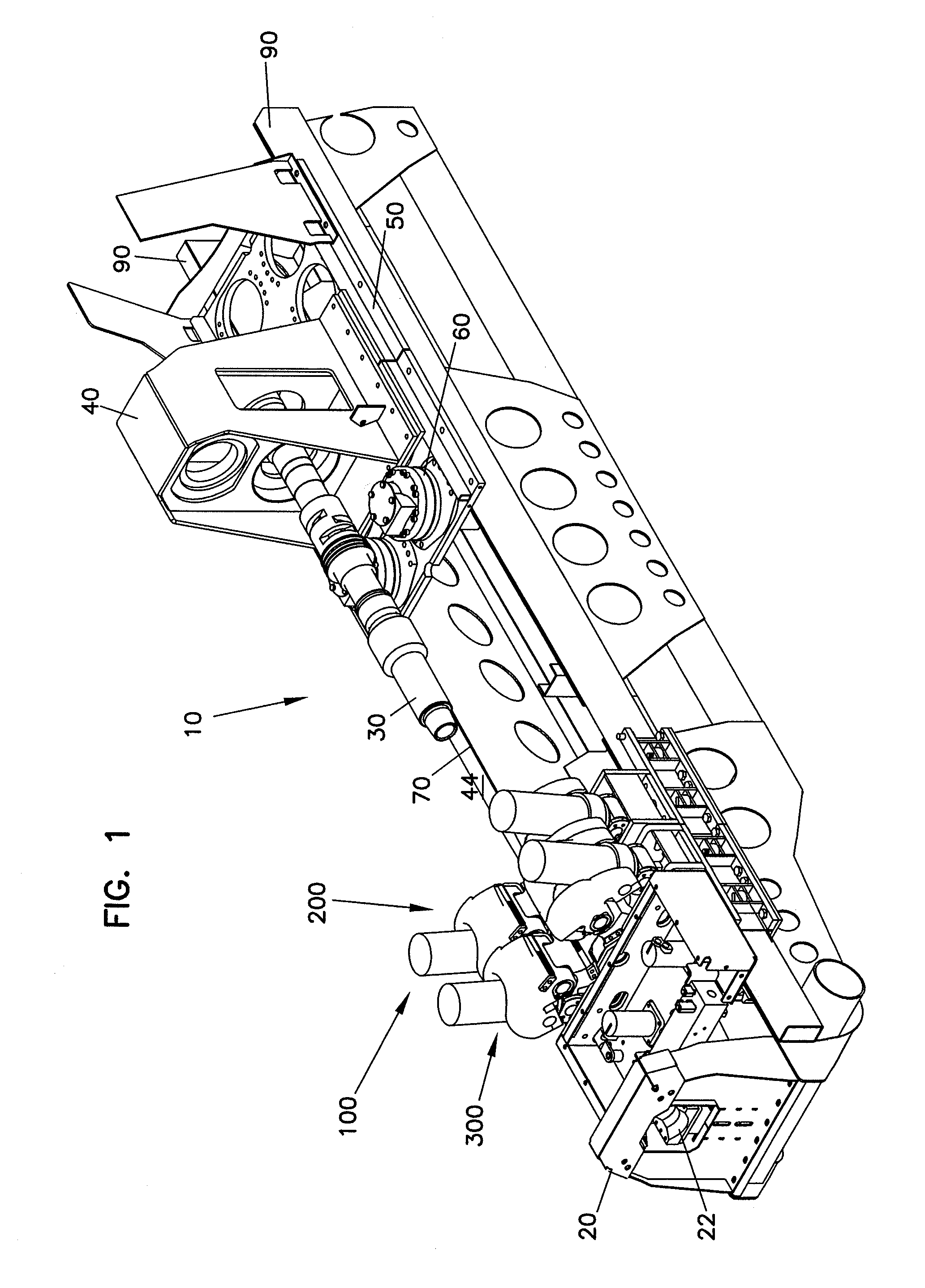

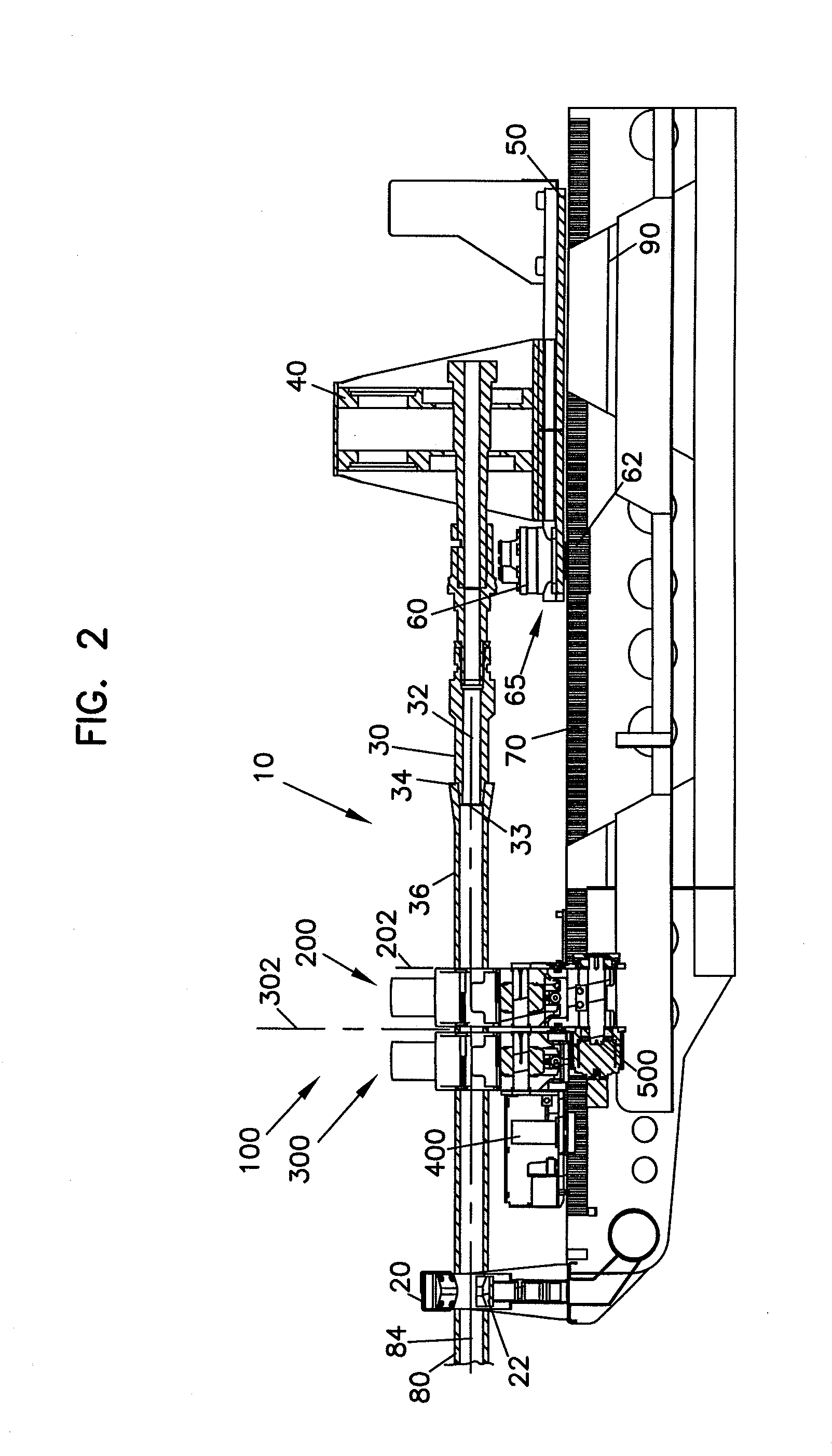

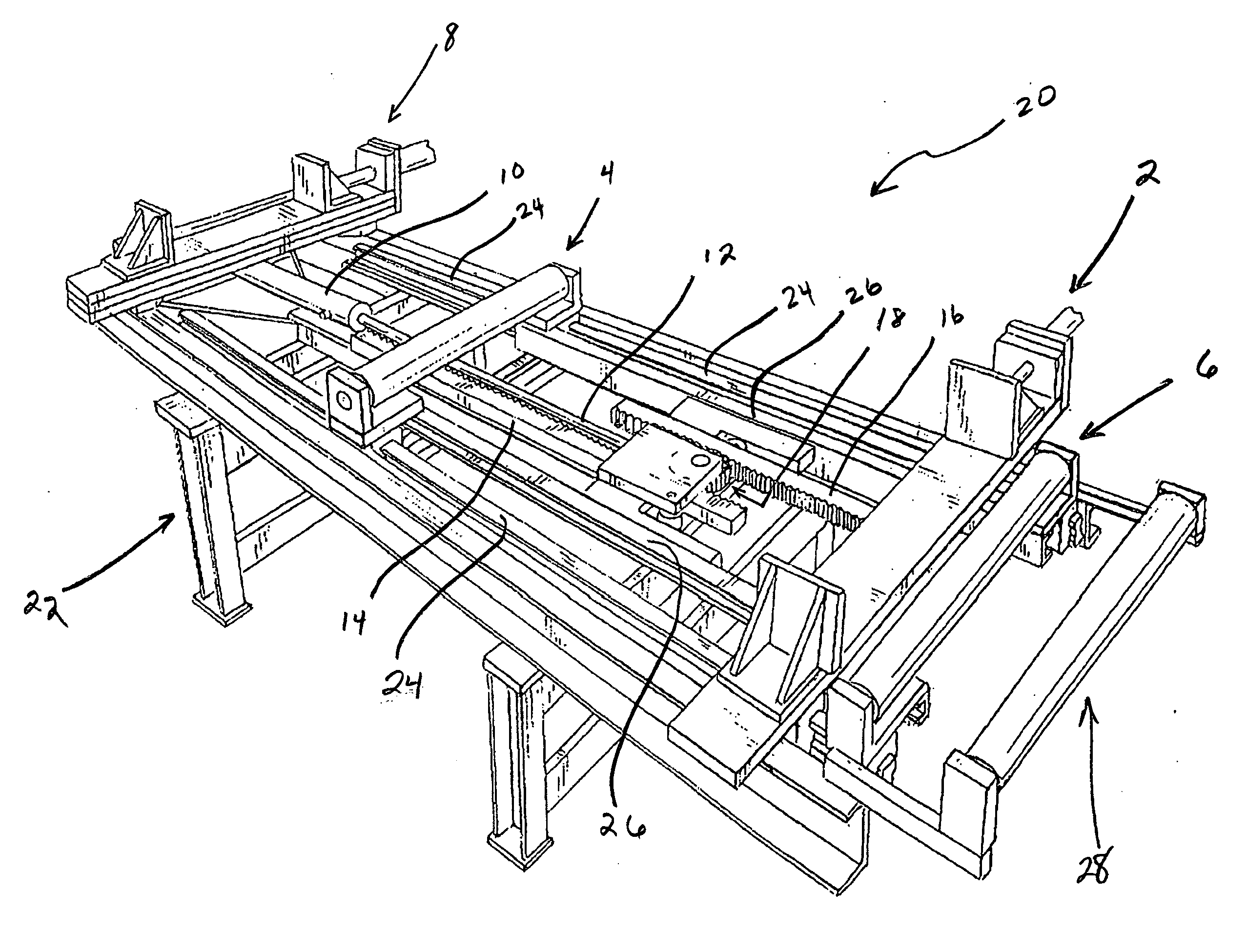

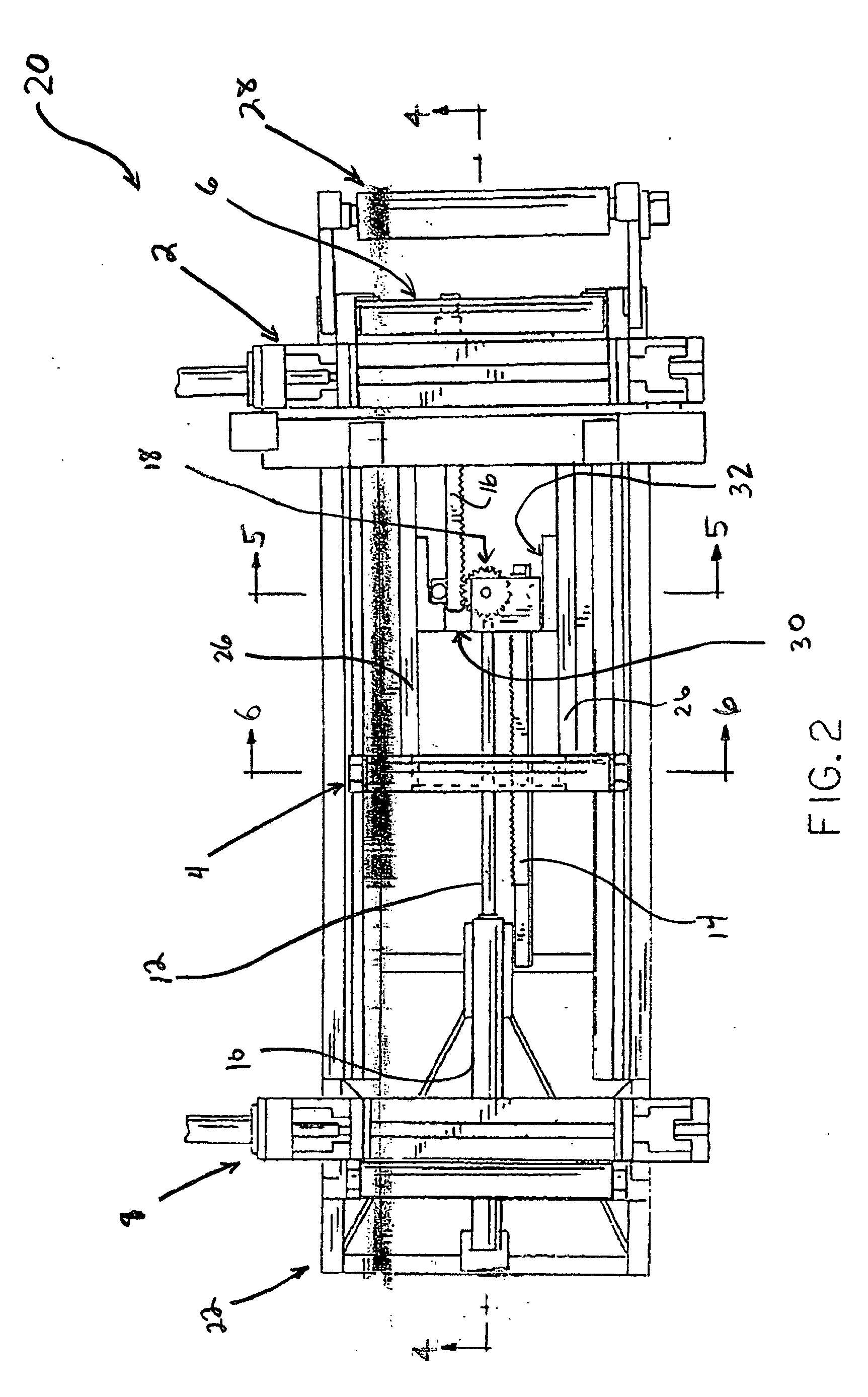

Vise carriage and support mechanism

ActiveUS20060048620A1Avoid loadIncrease the total strokeMetal sawing devicesConveyorsHydraulic cylinderGear wheel

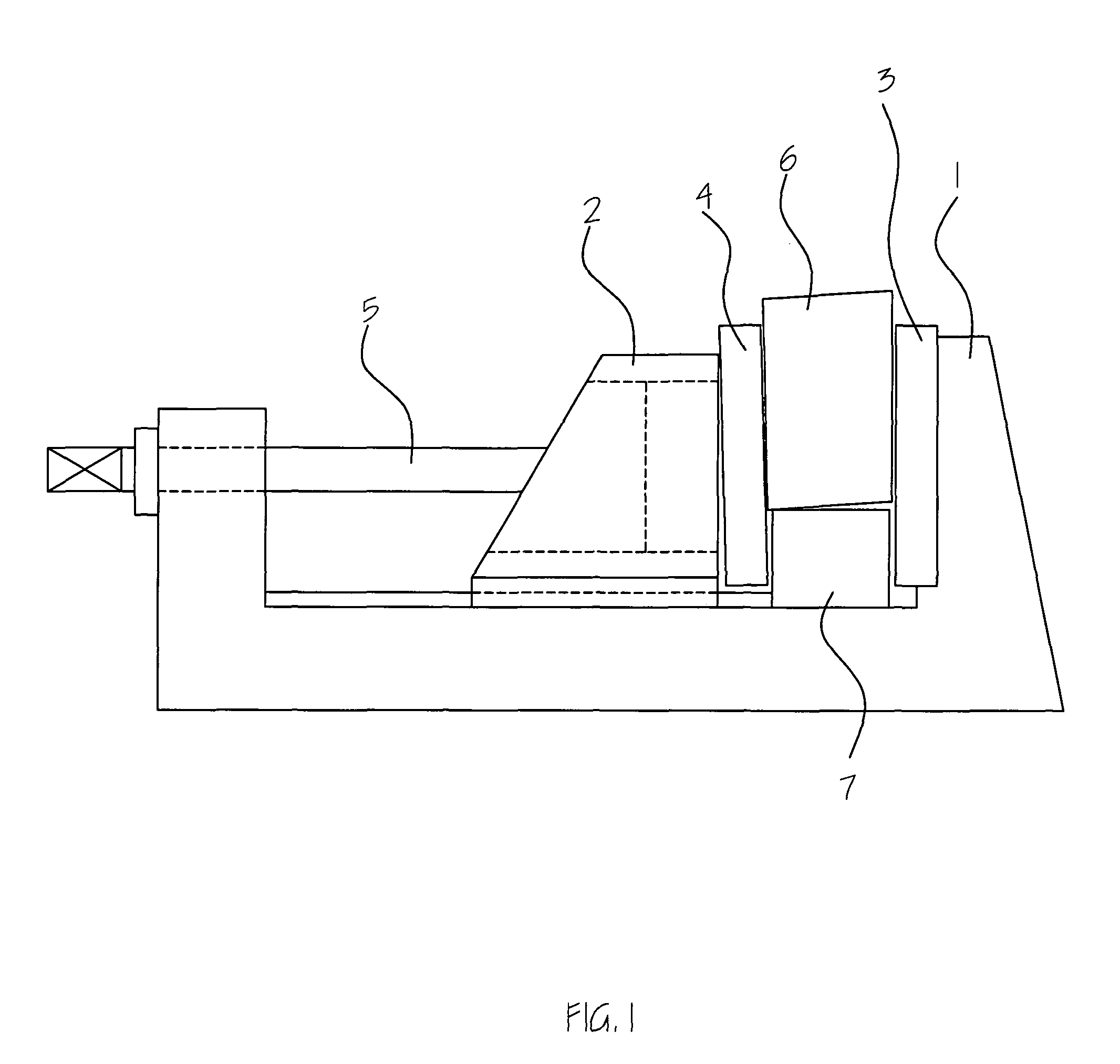

A roller table with a vise carriage and movable roller supports for moving, positioning, and supporting material. In the preferred embodiment, a hydraulic cylinder and piston rod are used in conjunction with a rack and pinion system such that there is a doubling effect on the piston rod stroke for effectuating differential positioning of two movable roller supports and the vise carriage. One movable roller support is disposed at approximately the midpoint between the vise carriage and a fixed vise. For a given displacement of the vise carriage, the movable roller support travels half as far so as to remain essentially at the midpoint of the span. The second movable roller support is disposed on the other side of the vise carriage, more or less at the midpoint between the vise carriage and a fixed roller support. The second movable roller support is integral with the first movable roller support and, thus, also travels half as far as the vise carriage for a given displacement so as to remain essentially at the midpoint between the vise carriage and the fixed roller.

Owner:MARVEL MFG

Vise table

The present invention relates to an integrated vise and work table. The disclosed vise table allows an operator to clamp an object in place so that the same can worked on in a hands-free method. The vise table includes a table block, a vise head block, a threaded guide, a rotator, and an activation mechanism that allows the operator to selectively vise in a threaded mode or in an unthreaded mode. In the threaded mode, the vise head block may only be moved by rotating a threaded guide. In the unthreaded mode, the vise head block may only be moved by applying force to the vise head block in the desired direction of movement.

Owner:THE STANLEY WORKS ISRAEL

Indentation vise-wrenches

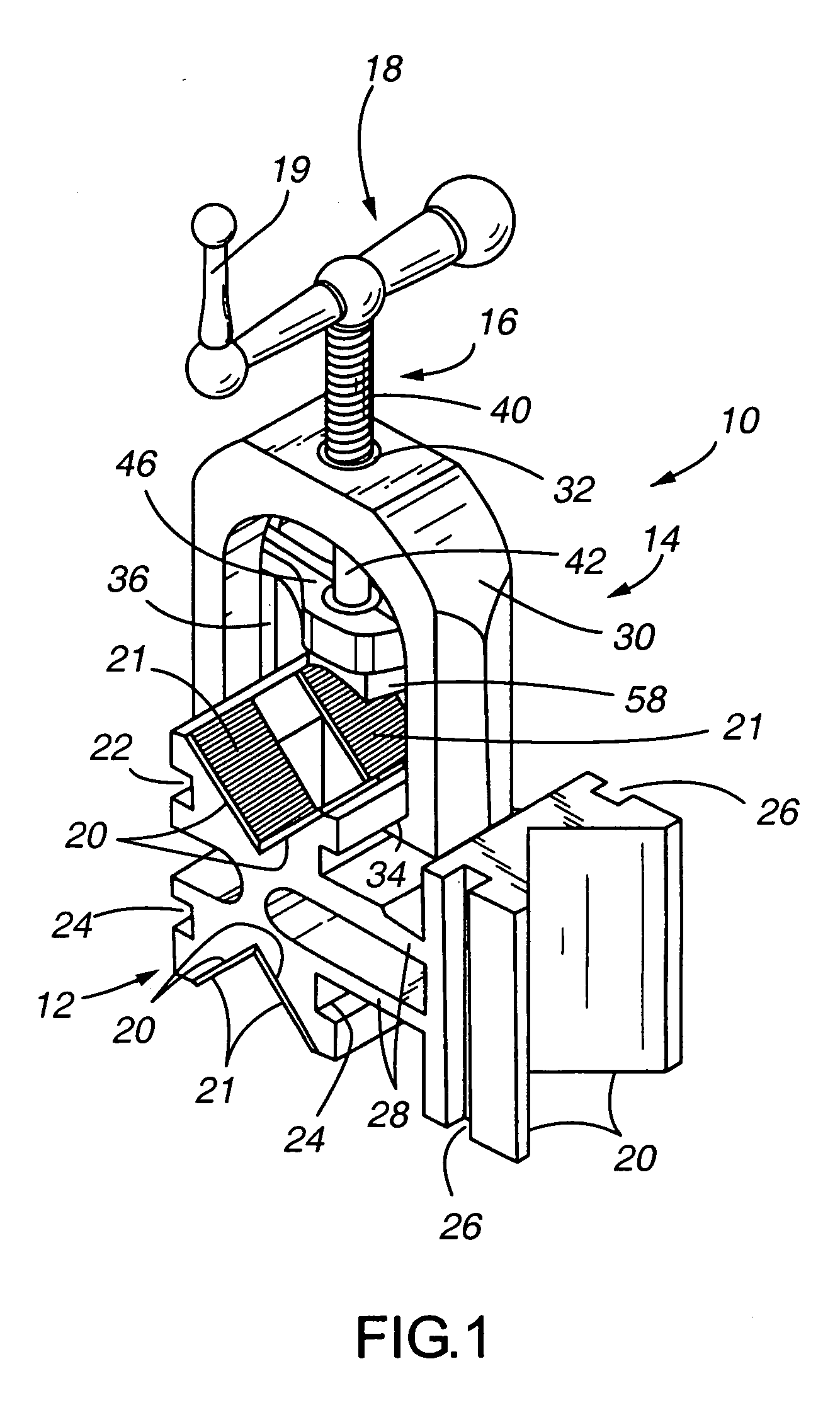

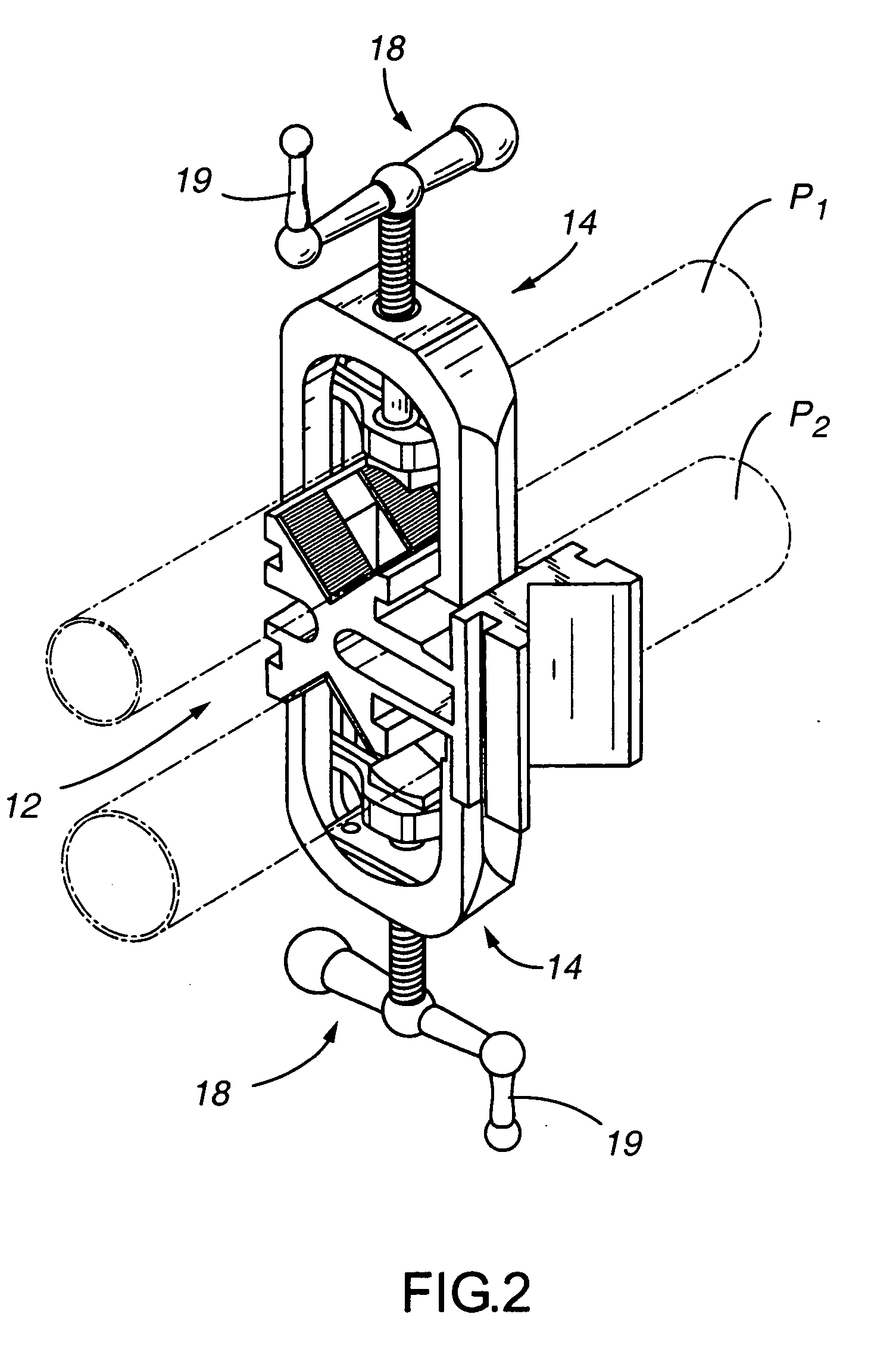

The invention relates to indentation vise-wrenches; in use, interlocking pushed-out areas (“exdentations”) / pushed-in areas (“indentations”) of a fitting's inner surface / a pipe's outer surface are created by indenting units at indentation vise-wrenches' jaws. Neither pipes nor fittings of interlocked pipe-fitting combinations will move with respect to each other; even after total separation between the indentation vise-wrench and the interlocked combination. Embodiments include a tool comprising an indentation vise wrench; a tool kit comprising a set having at least two indentation vise-wrenches; a process comprising making indentation vise-wrenches; a process of interlocking pipe-fitting combinations; etc.

Owner:LAVALLEE MICHAEL J

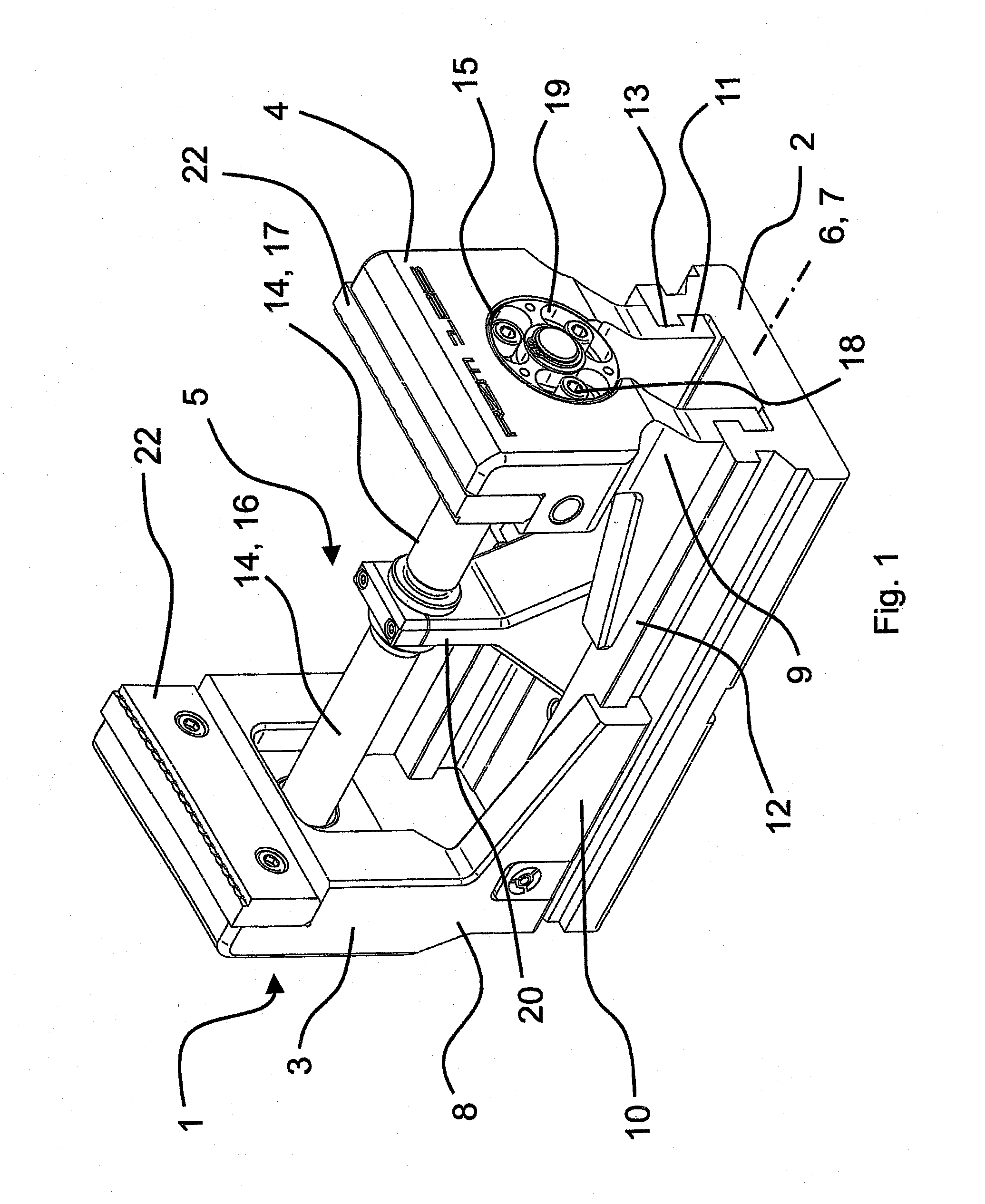

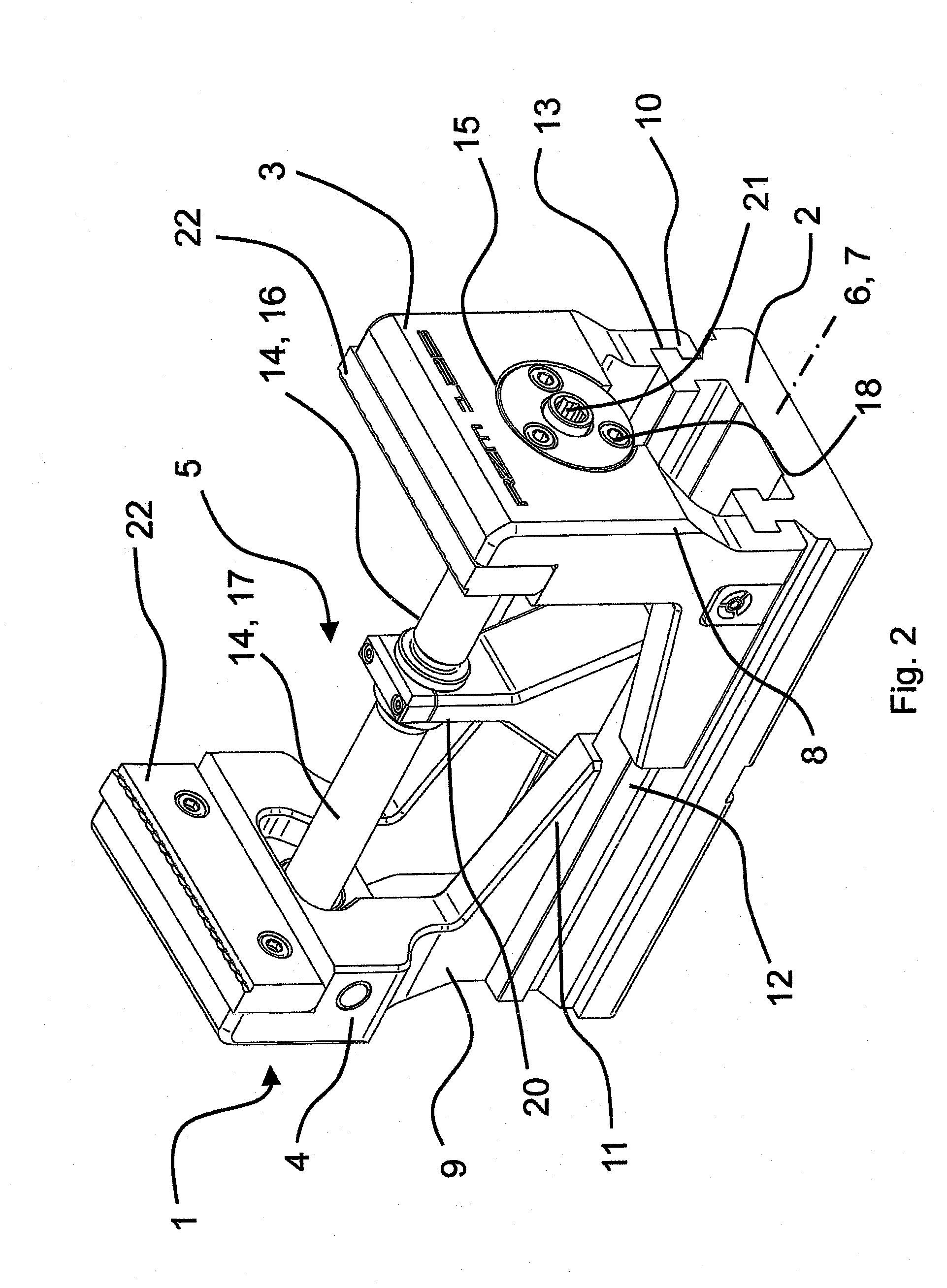

Centric clamping vice

A centric clamping vice for centric clamping of workpieces is provided that includes a base support having a longitudinal axis, on which a first jaw mount, guided by a first carriage, and a second jaw mount, guided by a second carriage, are adjustably supported along an adjustment path oriented parallel to the longitudinal axis with the aid of a spindle drive. A pair of first slides is assigned to the first carriage, and a pair of second slides is assigned to the second carriage, and the difference between the track width of the first slides and the track width of second slides is greater than the width of second slides.

Owner:ROHM GMBH

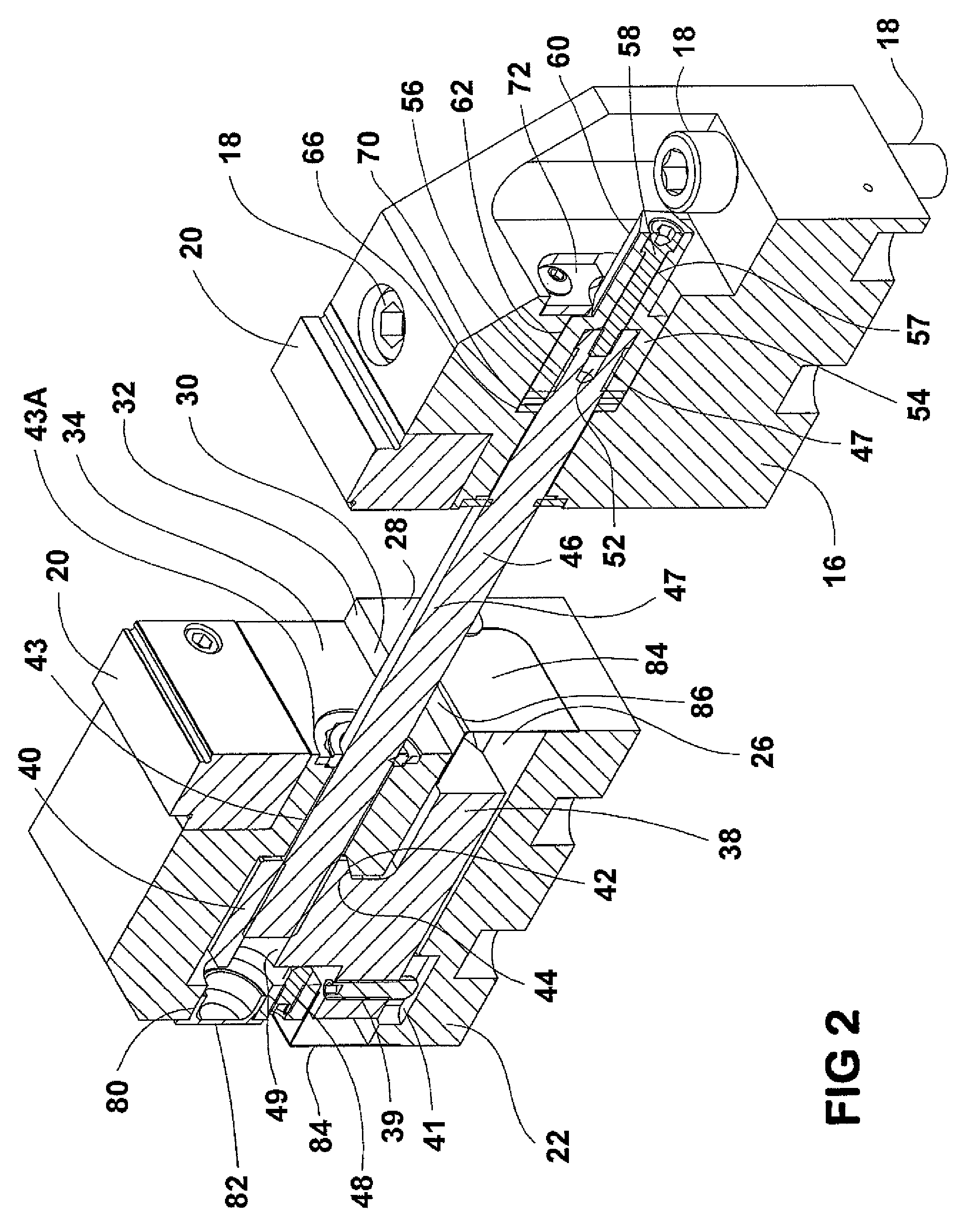

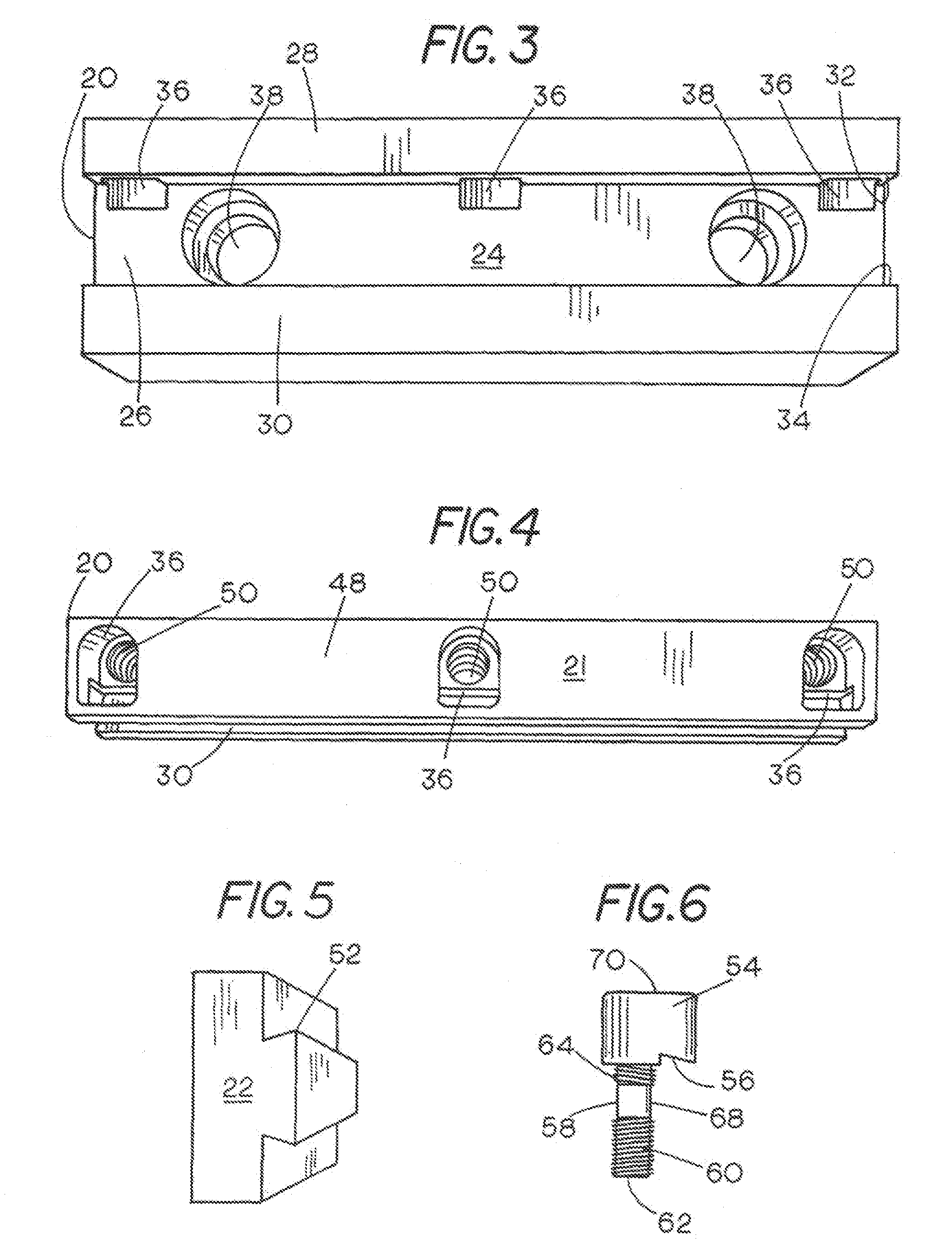

Quick change vise jaw system

A master jaw assembly used in a vise including a locking jaw, a detachable jaw and a clamping device disposed in the locking jaw, securely clamping the detachable jaw to the locking jaw. The locking jaw has a groove extending along an inner surface of the locking jaw defined by a first and second edge. The second edge is tapered inward and downward toward the base. The detachable jaw has a dovetail protrusion along one side surface thereof. The clamping device includes a plurality of specially-shaped nuts having a downwardly tapered edge, said nuts designed to receive one end of a double-ended threaded stud. The detachable jaw becomes fixed to the locking jaw by inserting the protrusion into the groove and torquing the studs to tighten the nuts downward against the protrusion such that the protrusion is clamped between the taper of the second edge and the nuts.

Owner:BELLATEX INDS

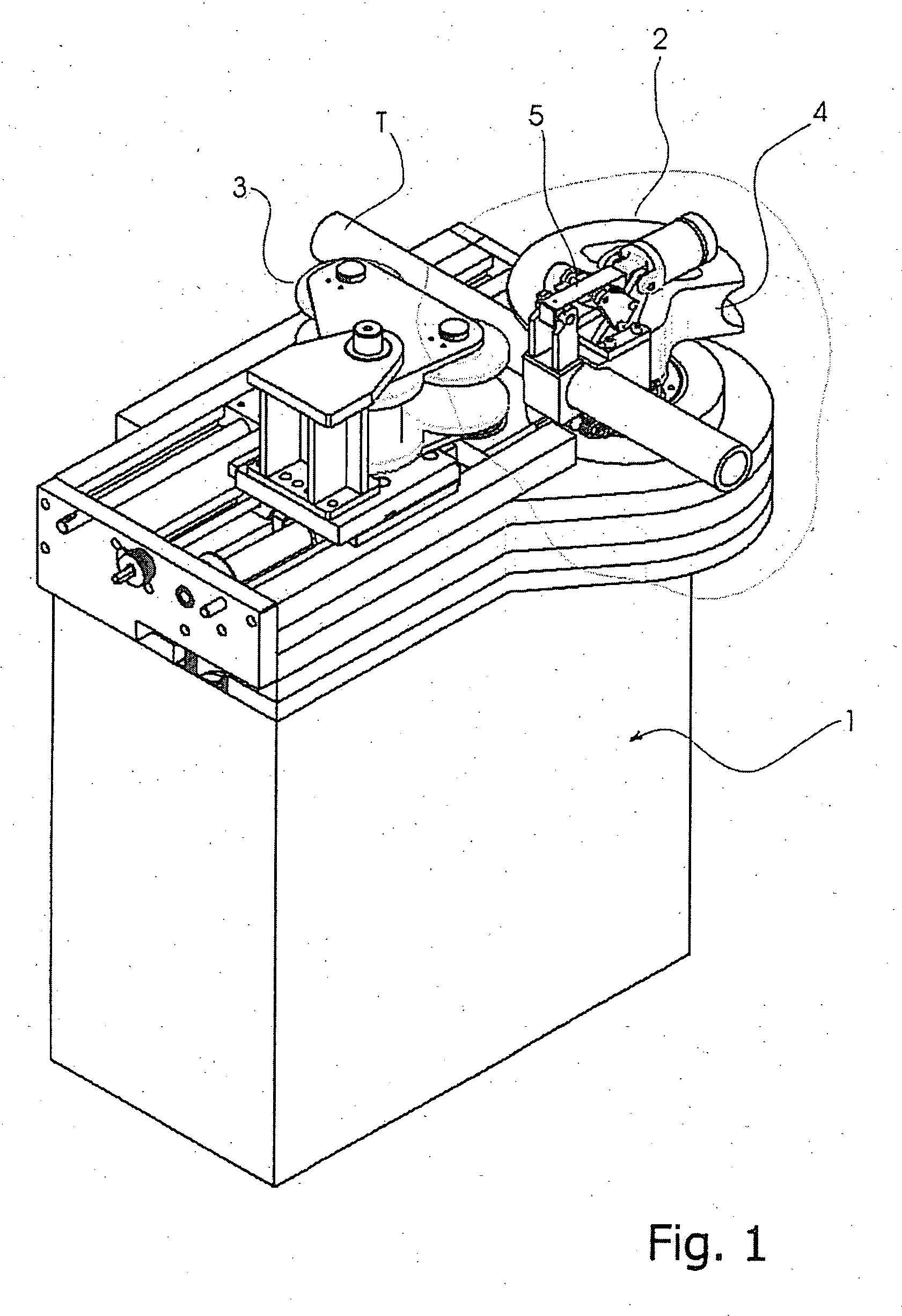

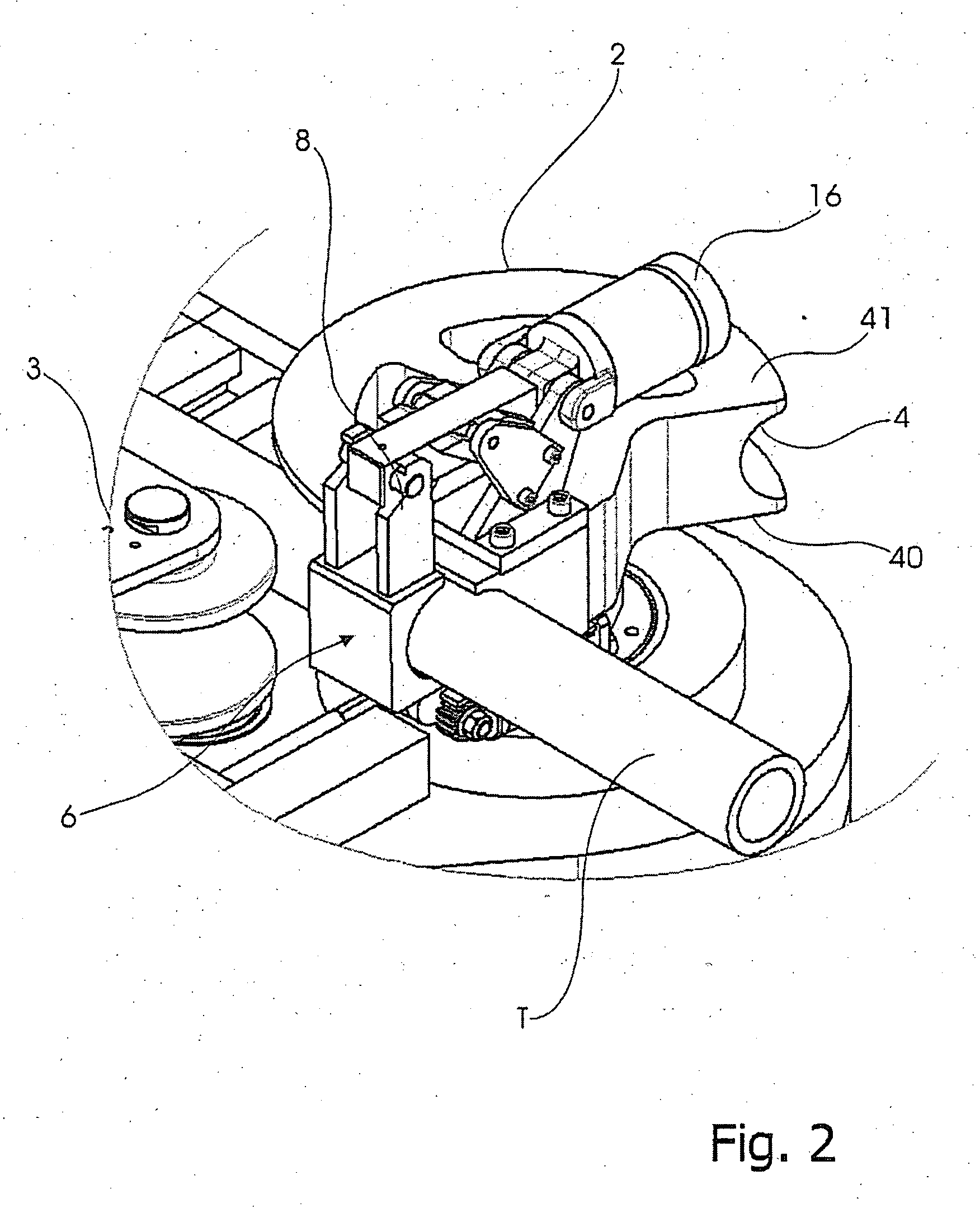

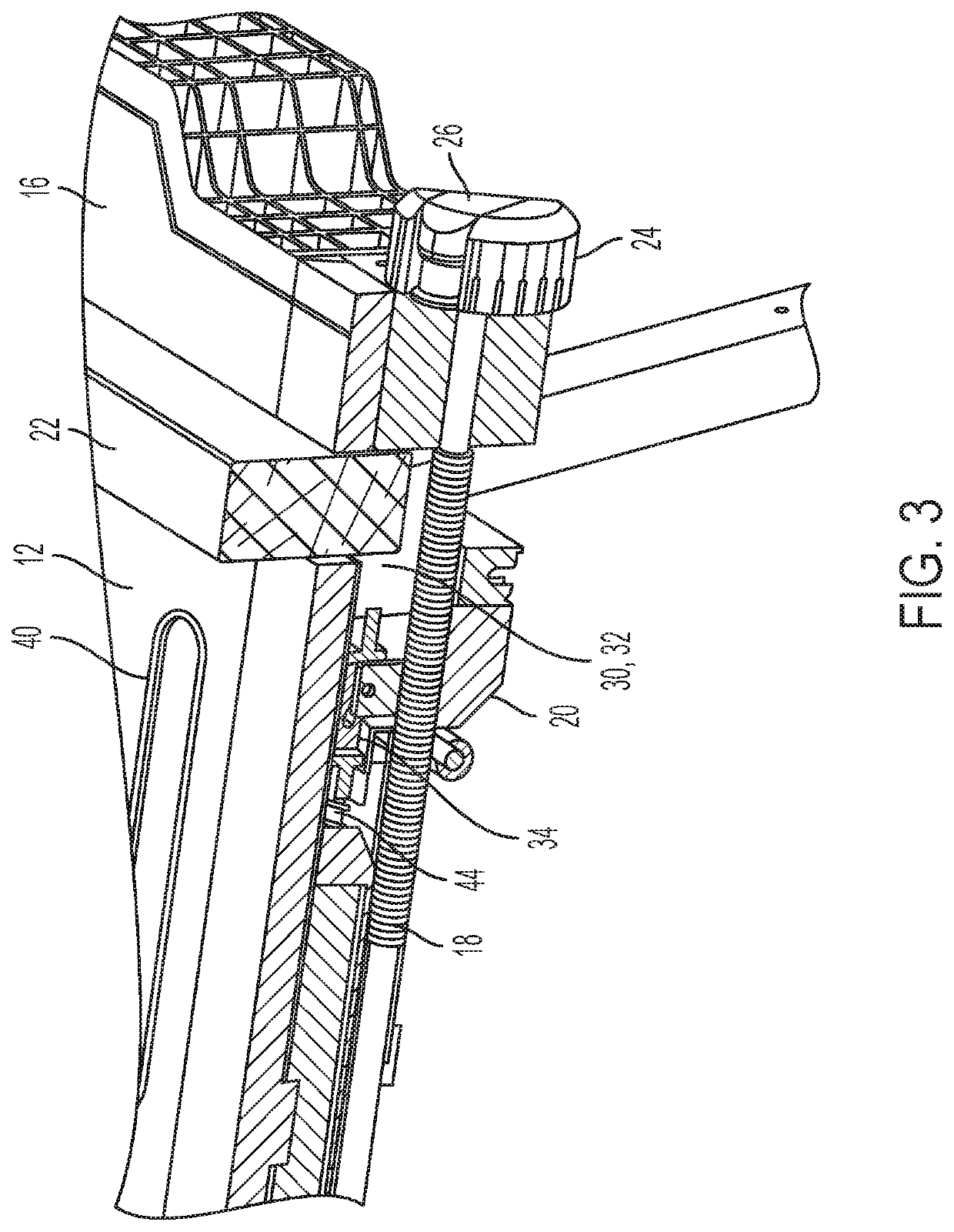

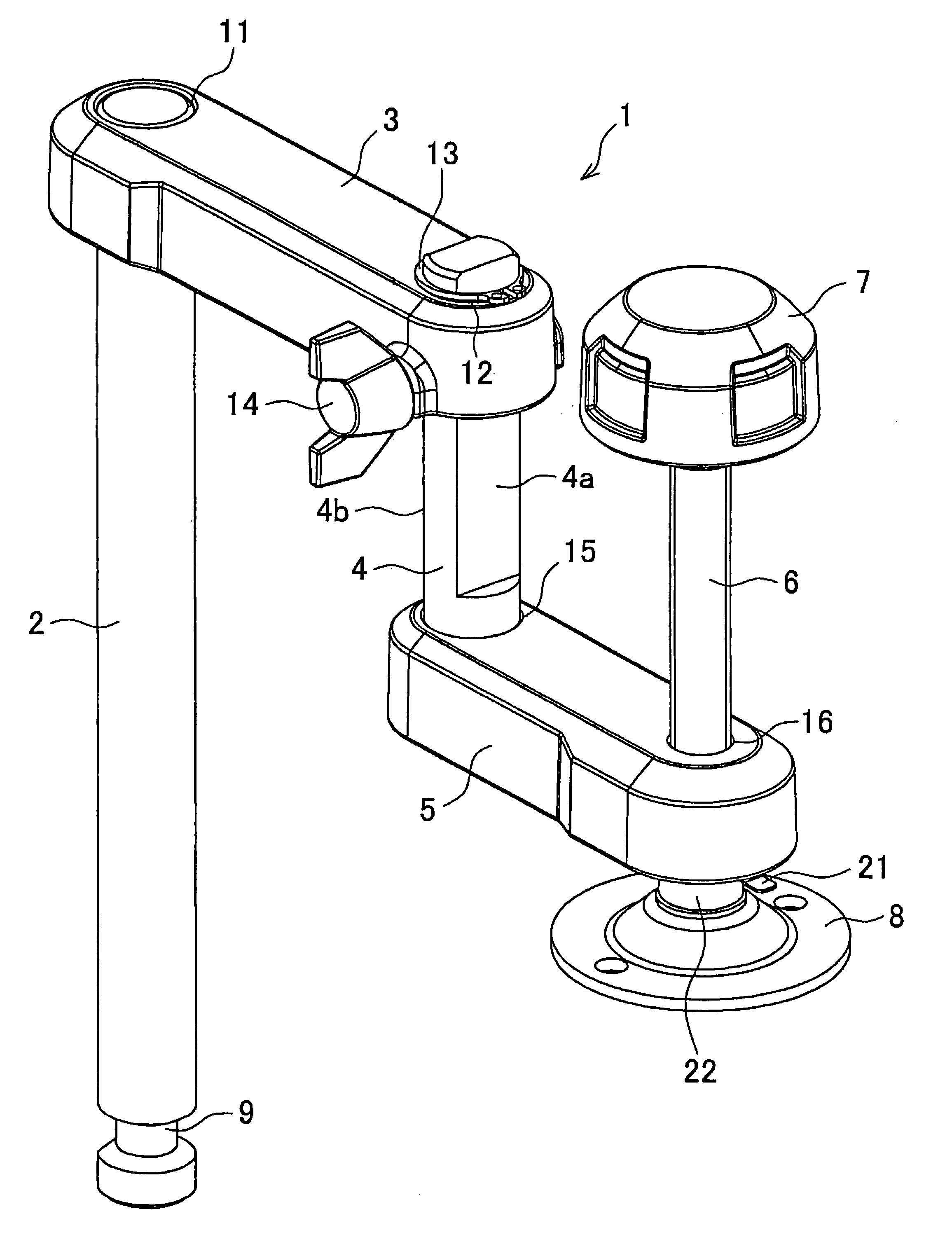

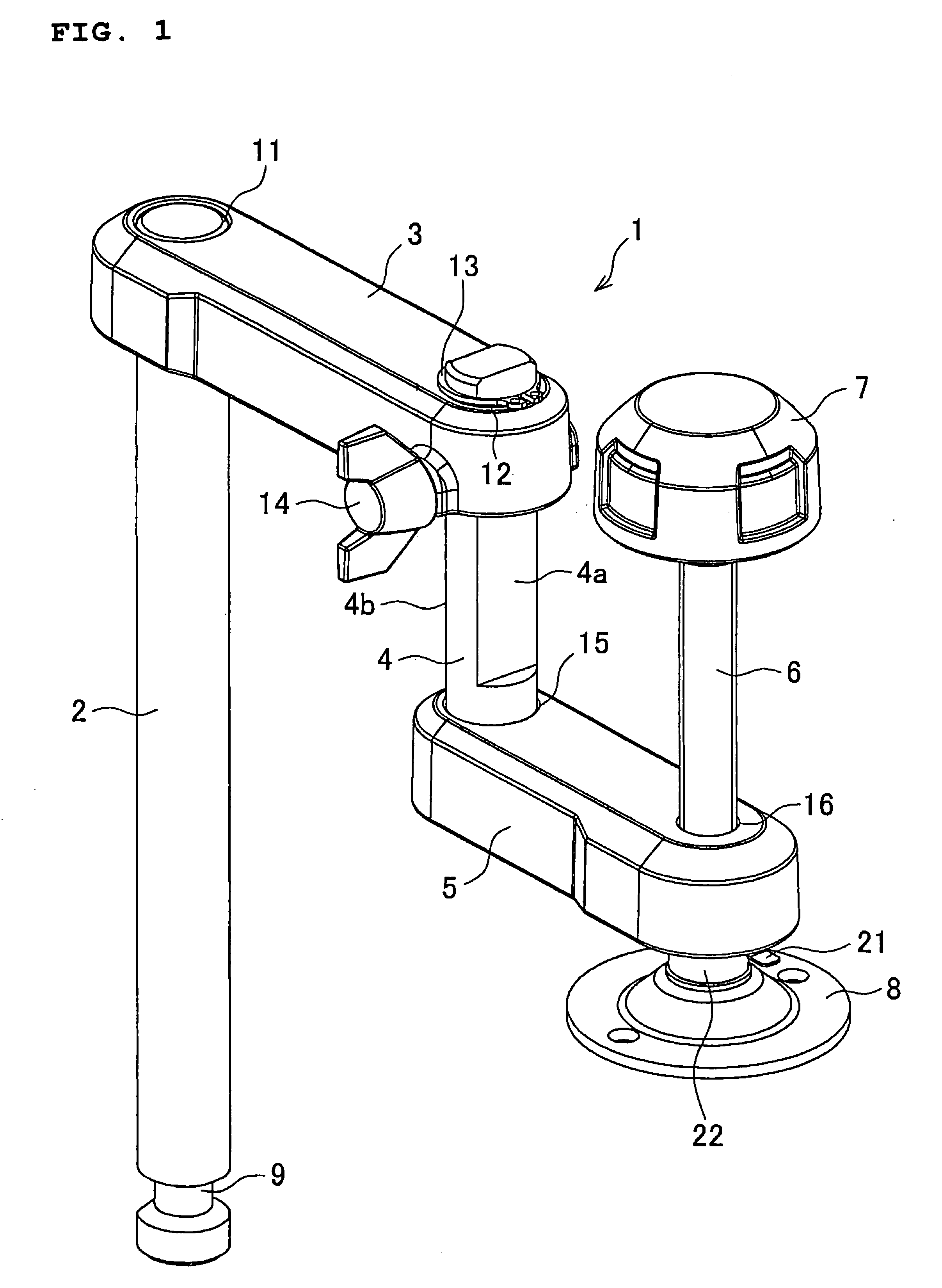

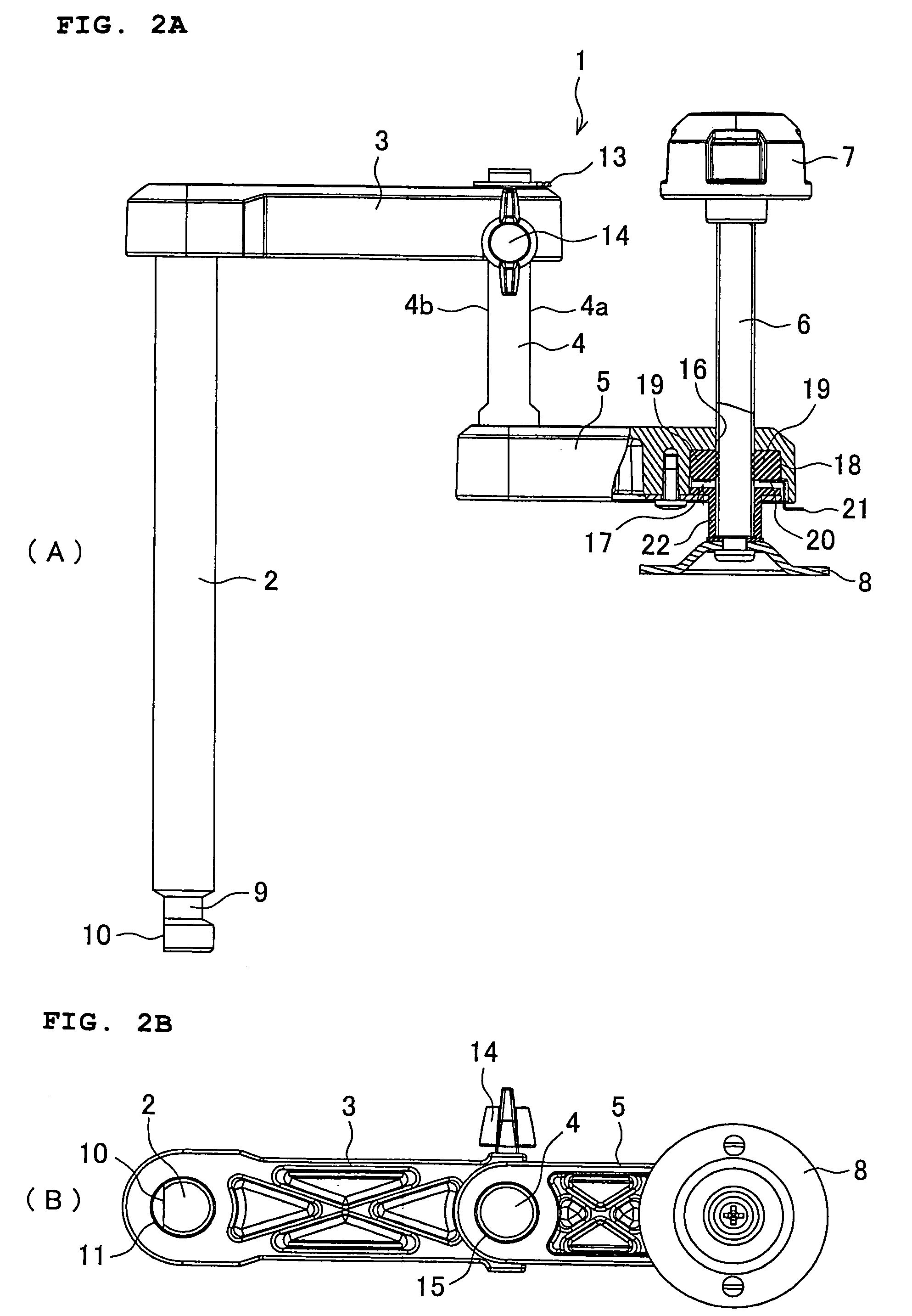

Vise assembly and bench circular sawing machine

ActiveUS8246025B2Increase flexibilityImprove usabilityMetal sawing devicesGuide fencesCircular sawVise

Owner:MAKITA CORP

Vice

There is disclosed a vice including a workbench, a stationary jaw installed on the workbench, a seat installed on the workbench, a screw inserted through the tunnel and a movable jaw attached to the screw. The seat defines a tunnel, a space in communication with the tunnel and a cavity in communication with the space. A lock is put in the space for movement between an engagement position and a disengagement position. In the engagement position, the lock is engaged with the screw so that rotation of the screw relative to the lock causes their relative movement. In the disengagement position, the lock is disengaged from the screw so that the screw can be moved relative to the lock freely. A key is put in the cavity for moving the lock between the engagement position corresponding to a fine-tuning step and the disengagement position corresponding to a quick adjustment step.

Owner:LIN KUO CHUAN

Quick release bench vise system

A quick release vise includes a first and second jaw moveable relative to the first jaw, and a threaded shaft rotatably fixed to the second jaw. A shaft receiver is fixed relative to the first jaw and includes a boss and a boss cover that is moveable relative to the boss. The boss and the boss cover have channels which cooperatively define an at least partially threaded shaft-receiving bore. The boss cover is moveable between a first position wherein the threads of the shaft engage threads within the shaft-receiving bore, and a second position wherein the threads of the shaft are disengaged from the threads within the shaft-receiving bore.

Owner:SEBER DESIGN GROUP

Vise table

The present invention relates to an integrated vise and work table. The disclosed vise table allows an operator to clamp an object in place so that the same can worked on in a hands-free method. The vise table includes a table block, a vise head block, a threaded guide, a rotator, and an activation mechanism that allows the operator to selectively vise in a threaded mode or in an unthreaded mode. In the threaded mode, the vise head block may only be moved by rotating a threaded guide. In the unthreaded mode, the vise head block may only be moved by applying force to the vise head block in the desired direction of movement.

Owner:THE STANLEY WORKS ISRAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com