Patents

Literature

211 results about "Wheel wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding wheel wear is an important measured factor of grinding in the manufacturing process of engineered parts and tools. Grinding involves the removal process of material and modifying the surface of a workpiece to some desired finish which might otherwise be unachievable through conventional machining processes.

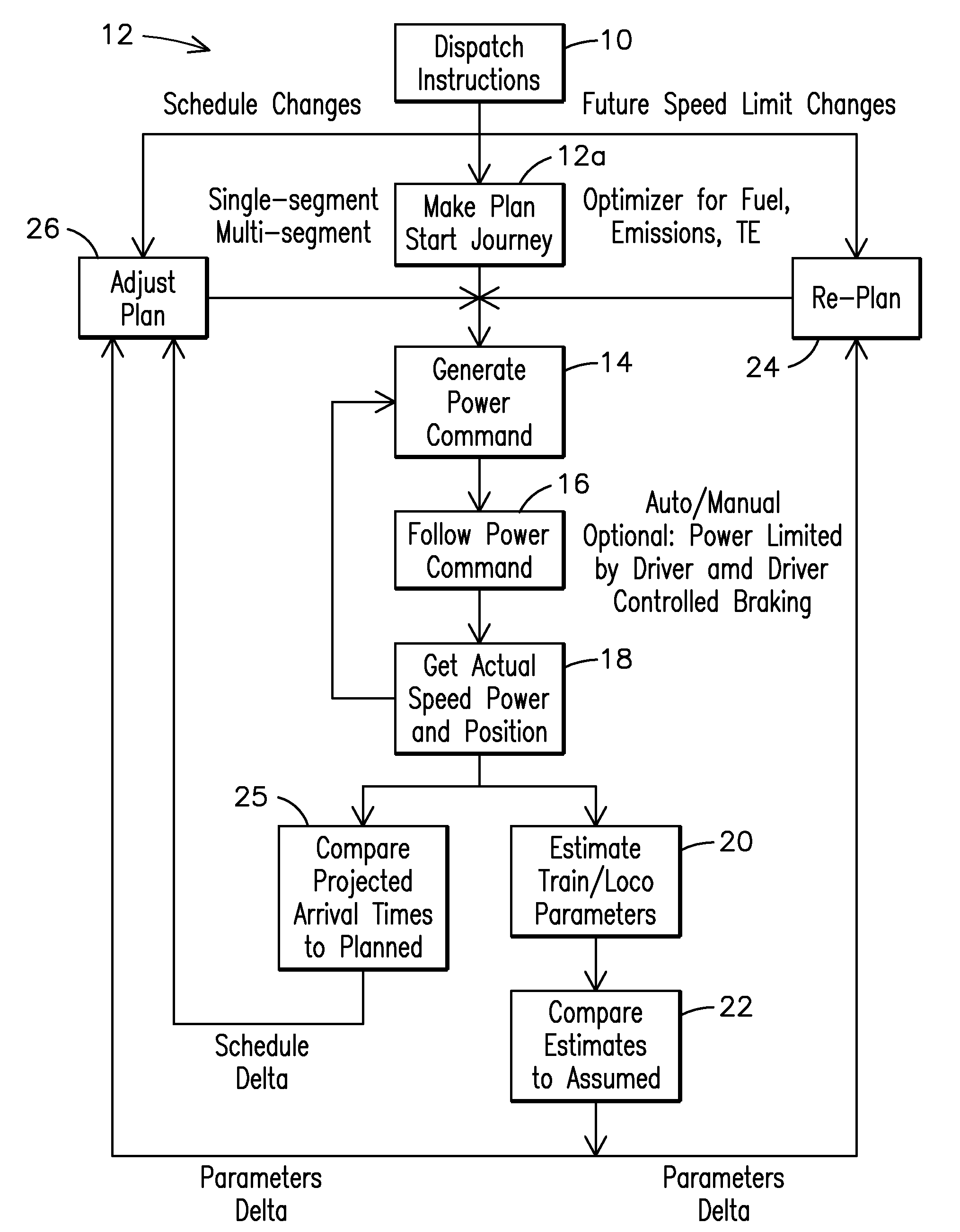

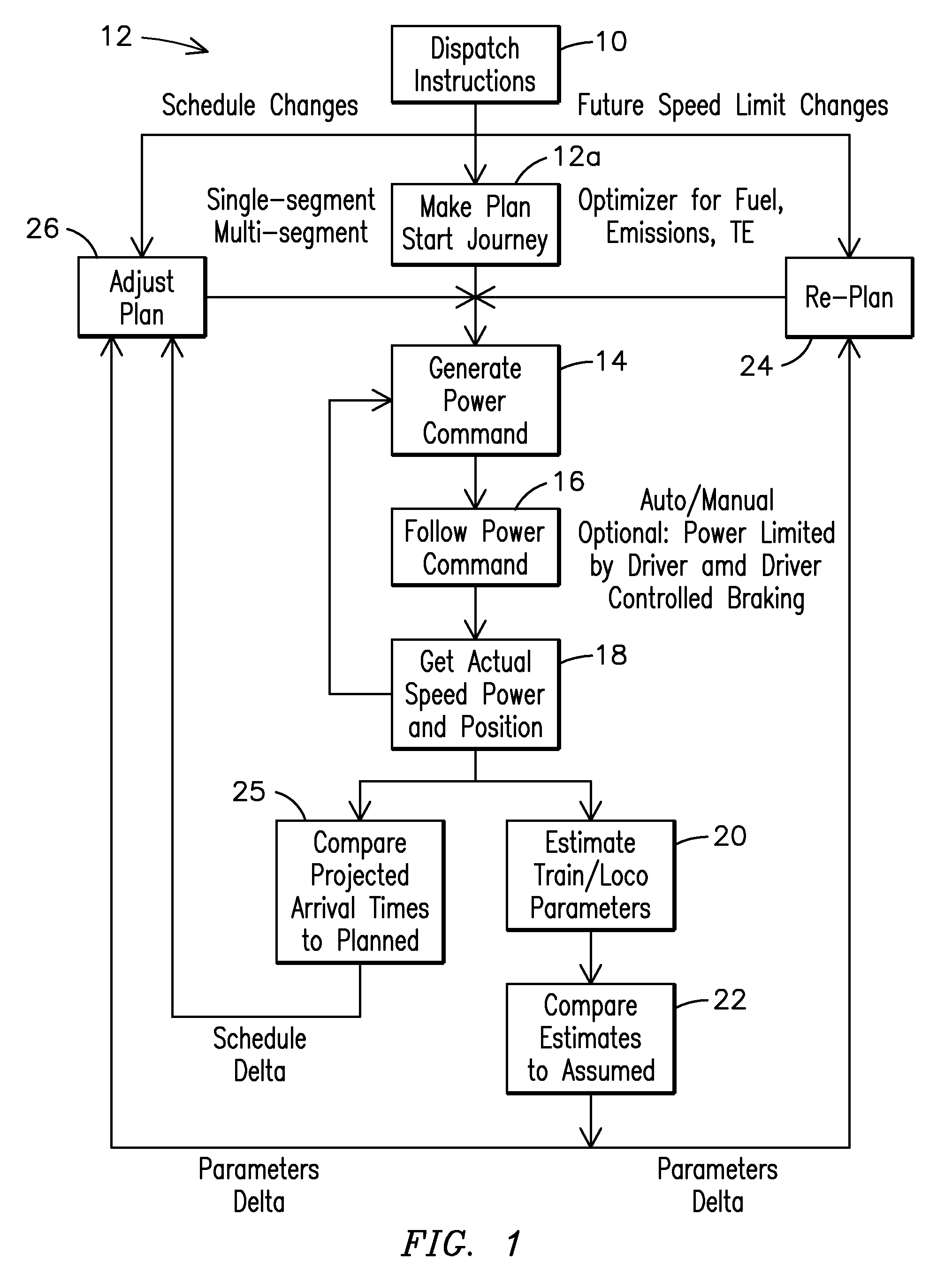

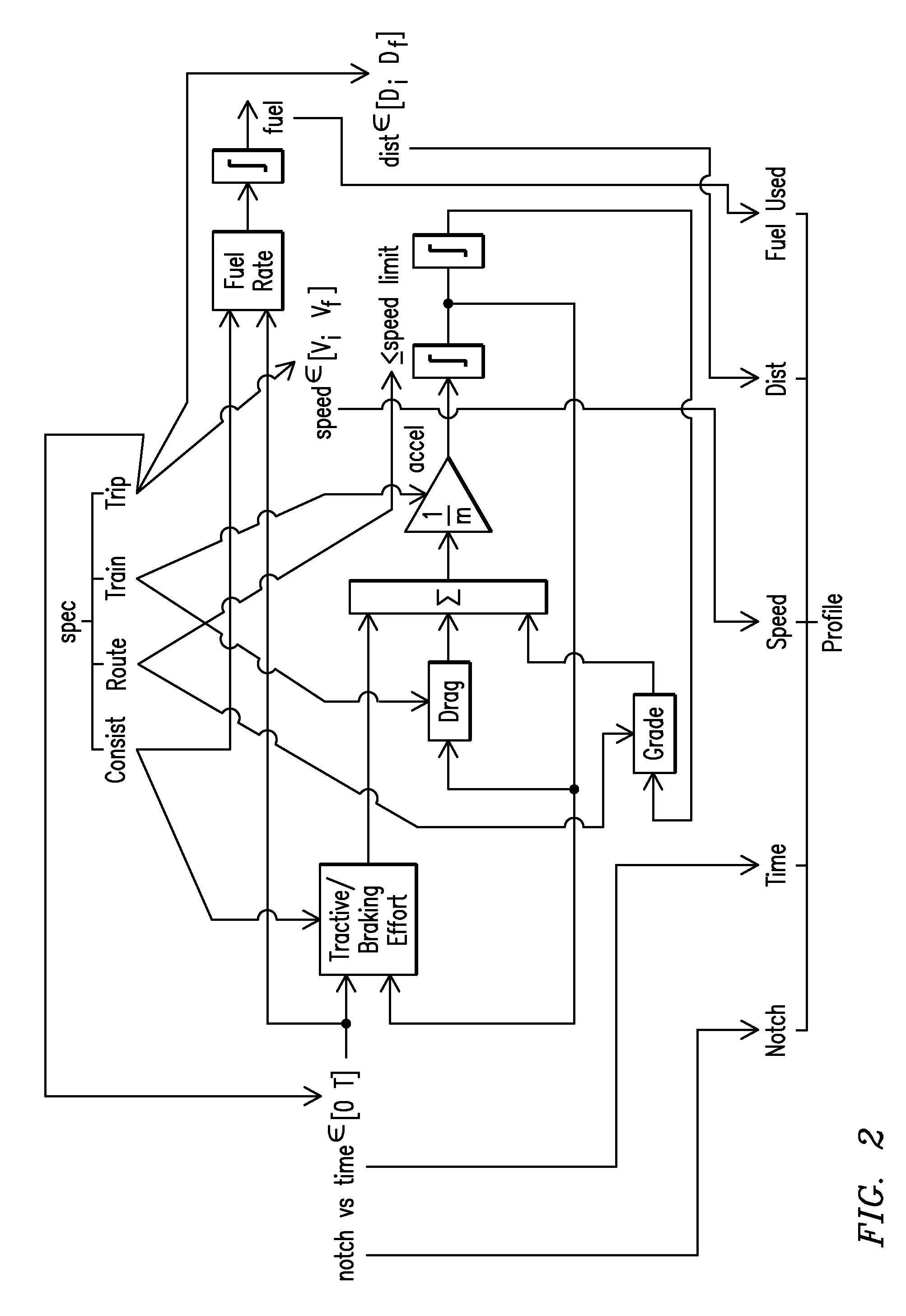

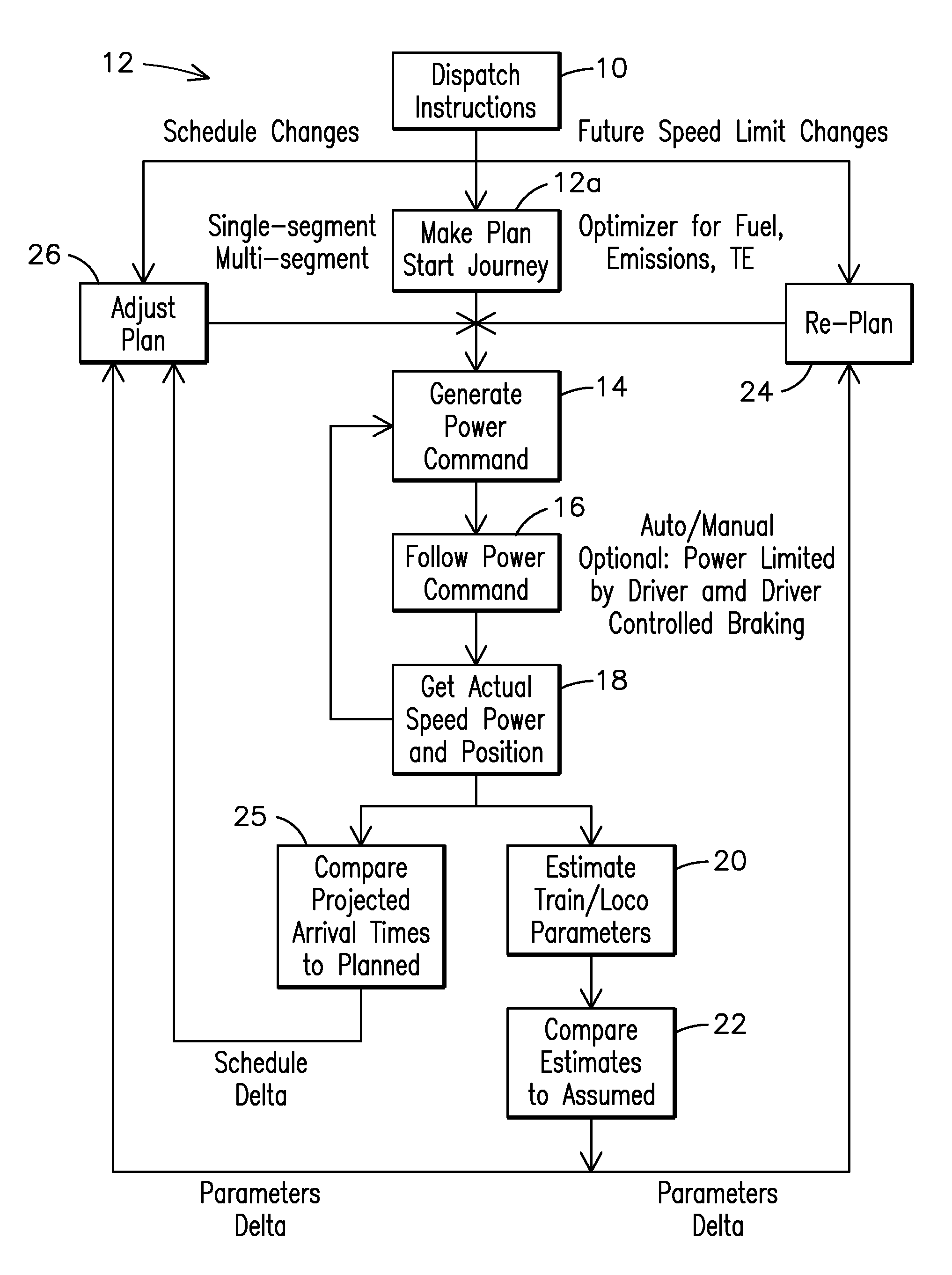

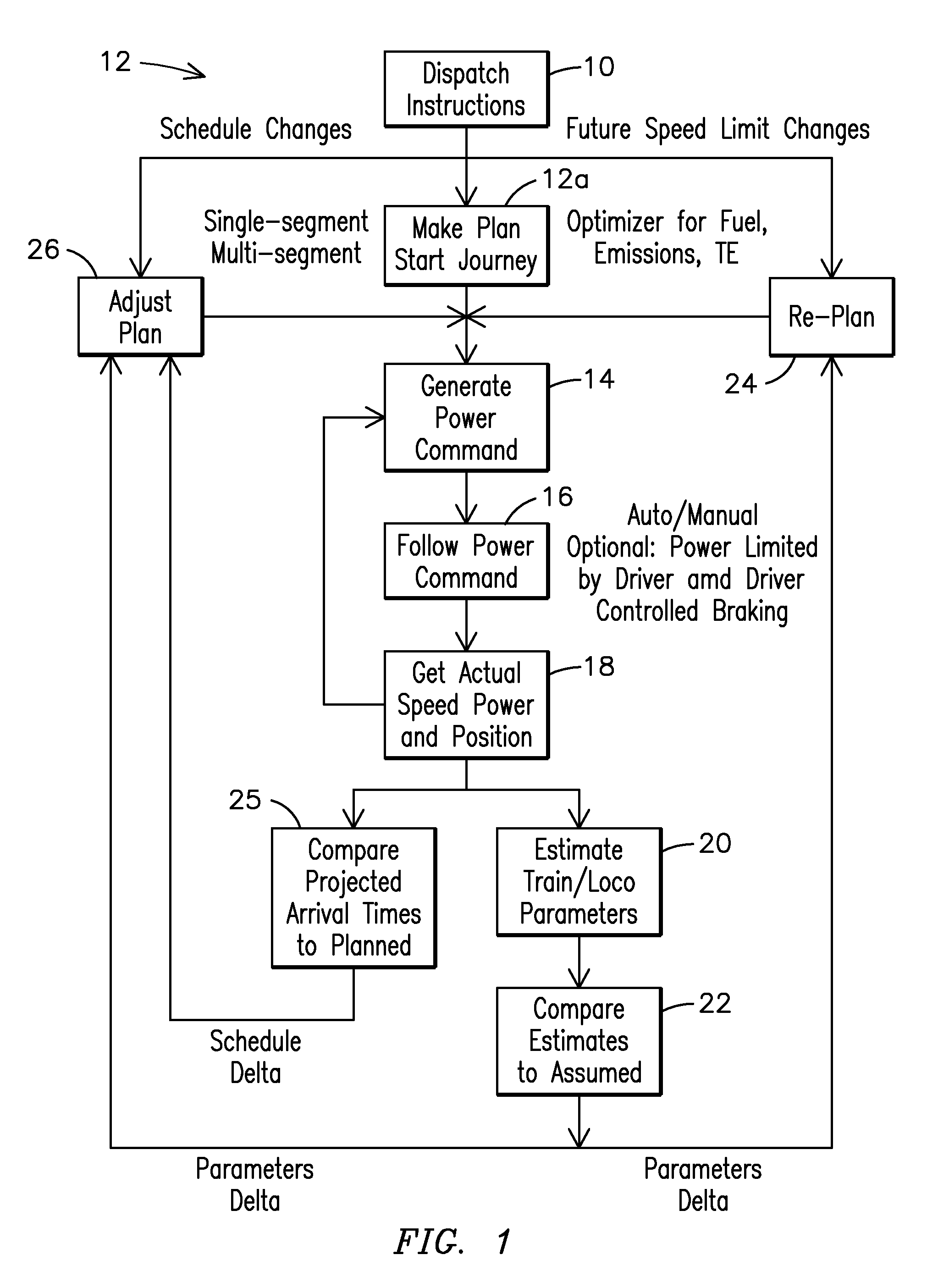

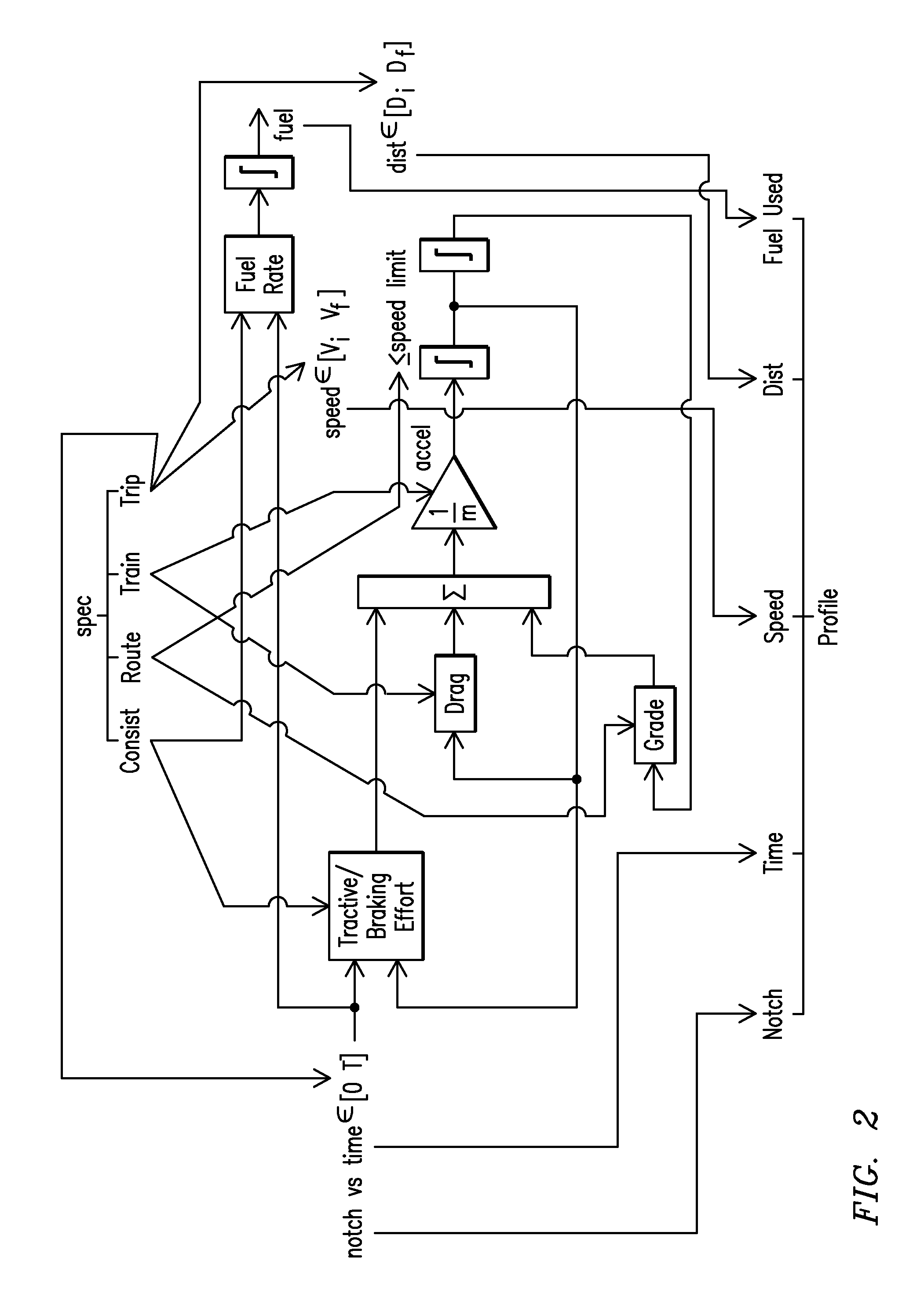

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS20100023190A1Reduce the overall heightShorten speedDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

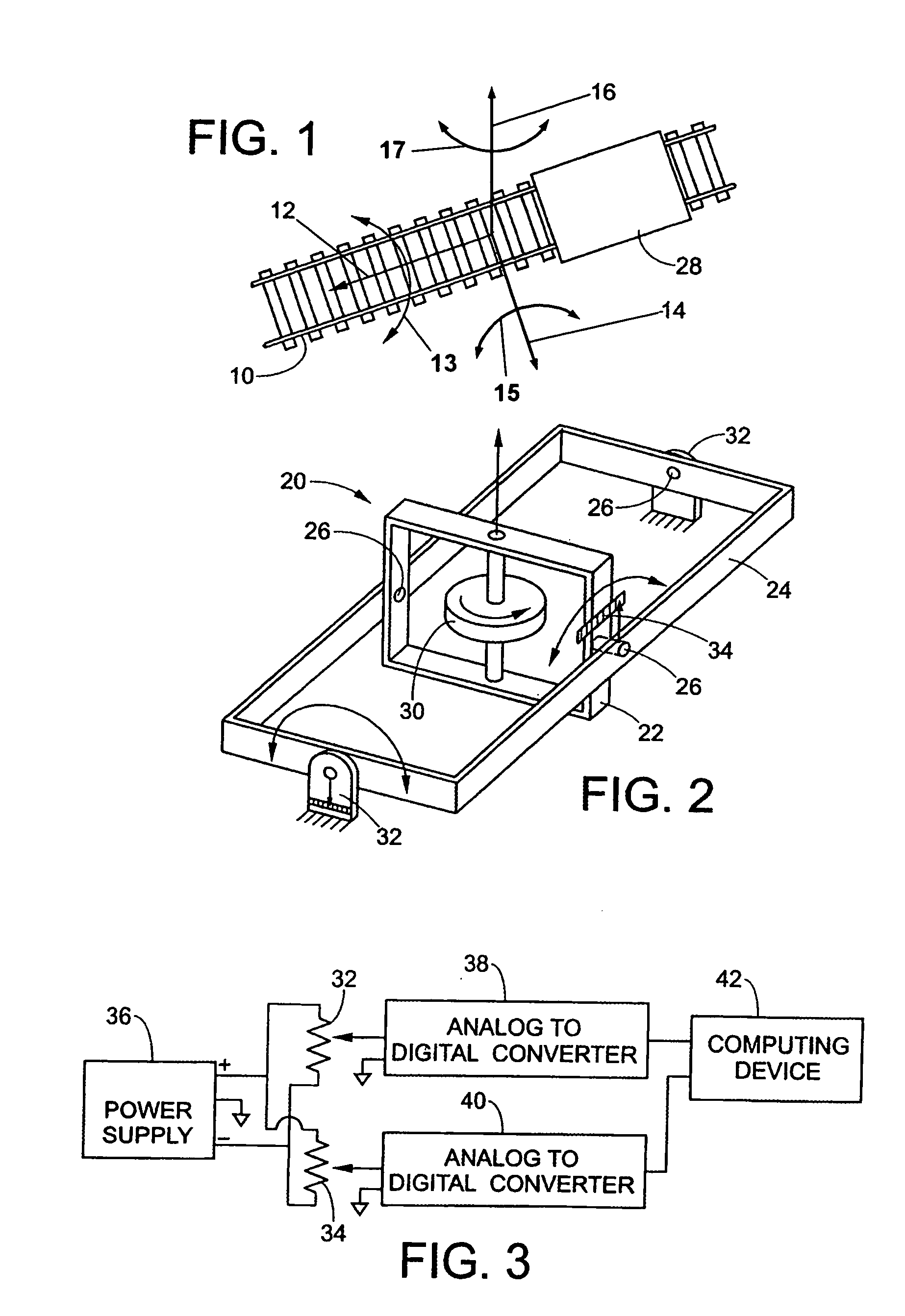

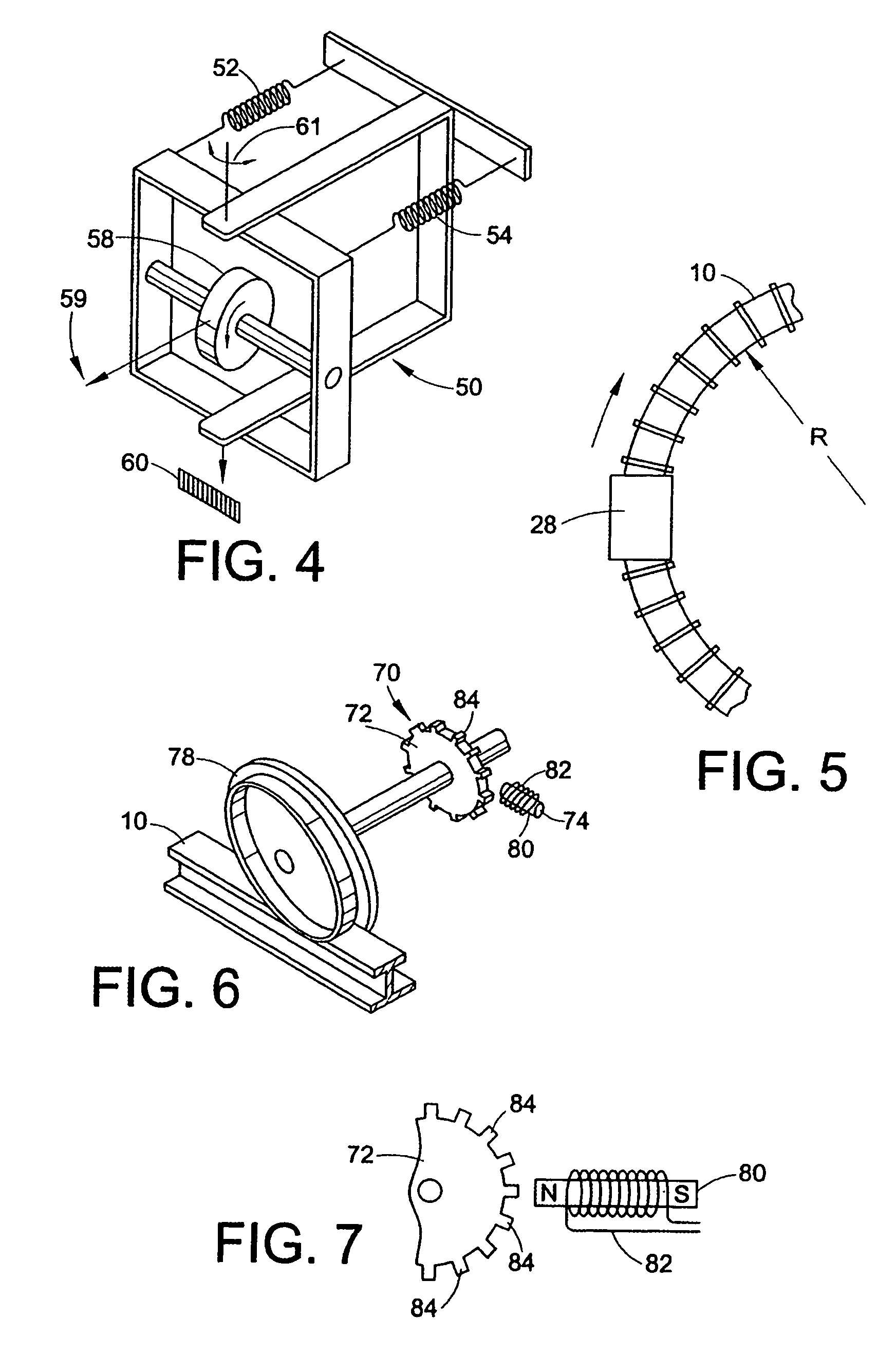

Geometric track and track/vehicle analyzers and methods for controlling railroad systems

InactiveUS7164975B2Reduce flanging forceIncreasing locomotive tractive forceDigital data processing detailsTrack side maintainanceReal time analysisVehicle detector

Track and track / vehicle analyzers for determining geometric parameters of tracks, determining the relation of tracks to vehicles and trains, analyzing the parameters in real-time, and communicating corrective measures to various control mechanisms are provided. In one embodiment, the track analyzer includes a track detector and a computing device. In another embodiment, the track / vehicle analyzer includes a track detector, a vehicle detector, and a computing device. In other embodiments, the track / vehicle detector also includes a communications device for communicating with locomotive control computers in lead units, locomotive control computers in helper units, and a centralized control office. Additionally, methods for determining and communicating optimized control, lubrication, and steering strategies are provided. The analyzers improve operational safety and overall efficiency, including fuel efficiency, vehicle wheel wear, and track wear, in railroad systems.

Owner:ANDIAN TECH

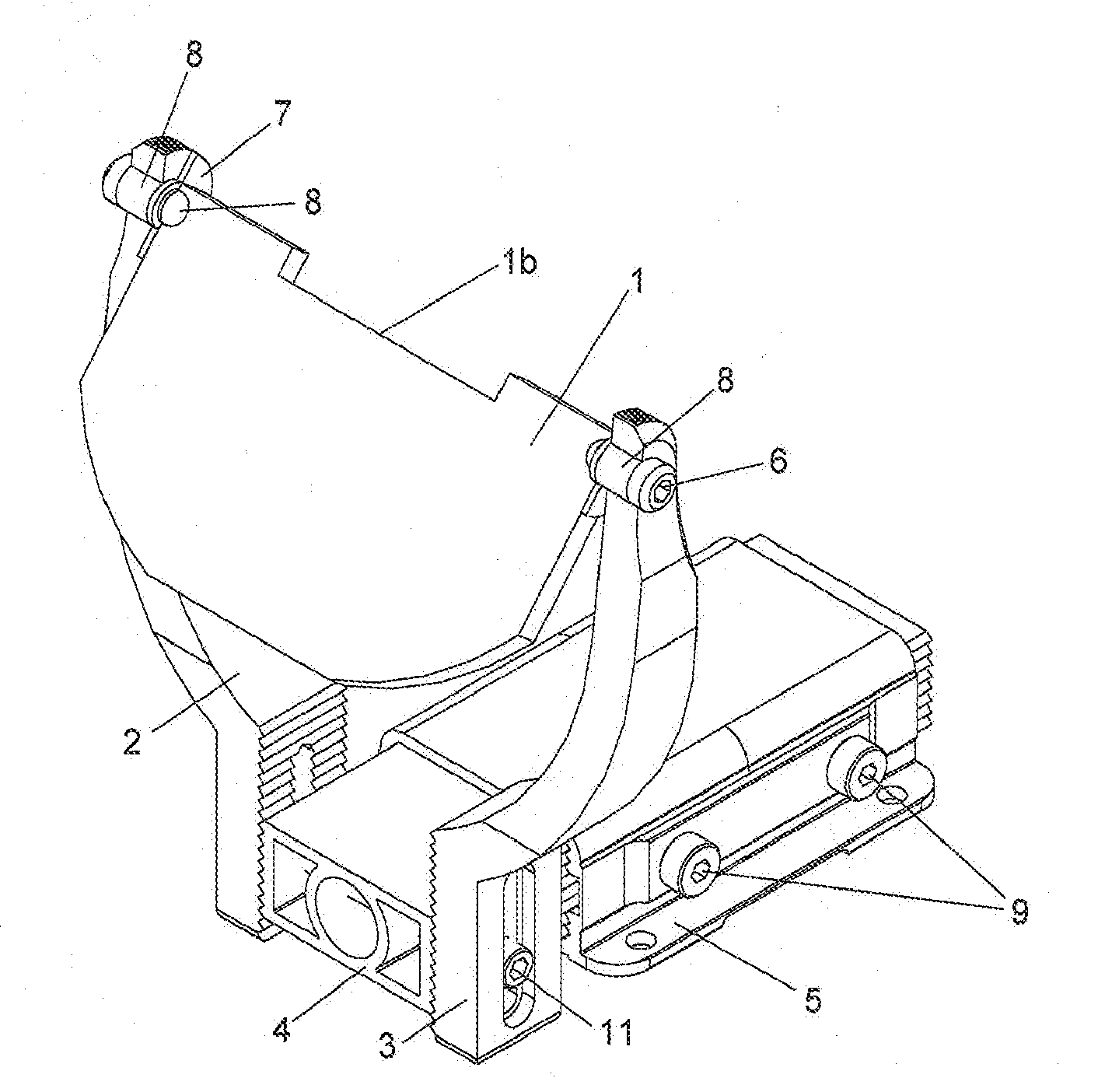

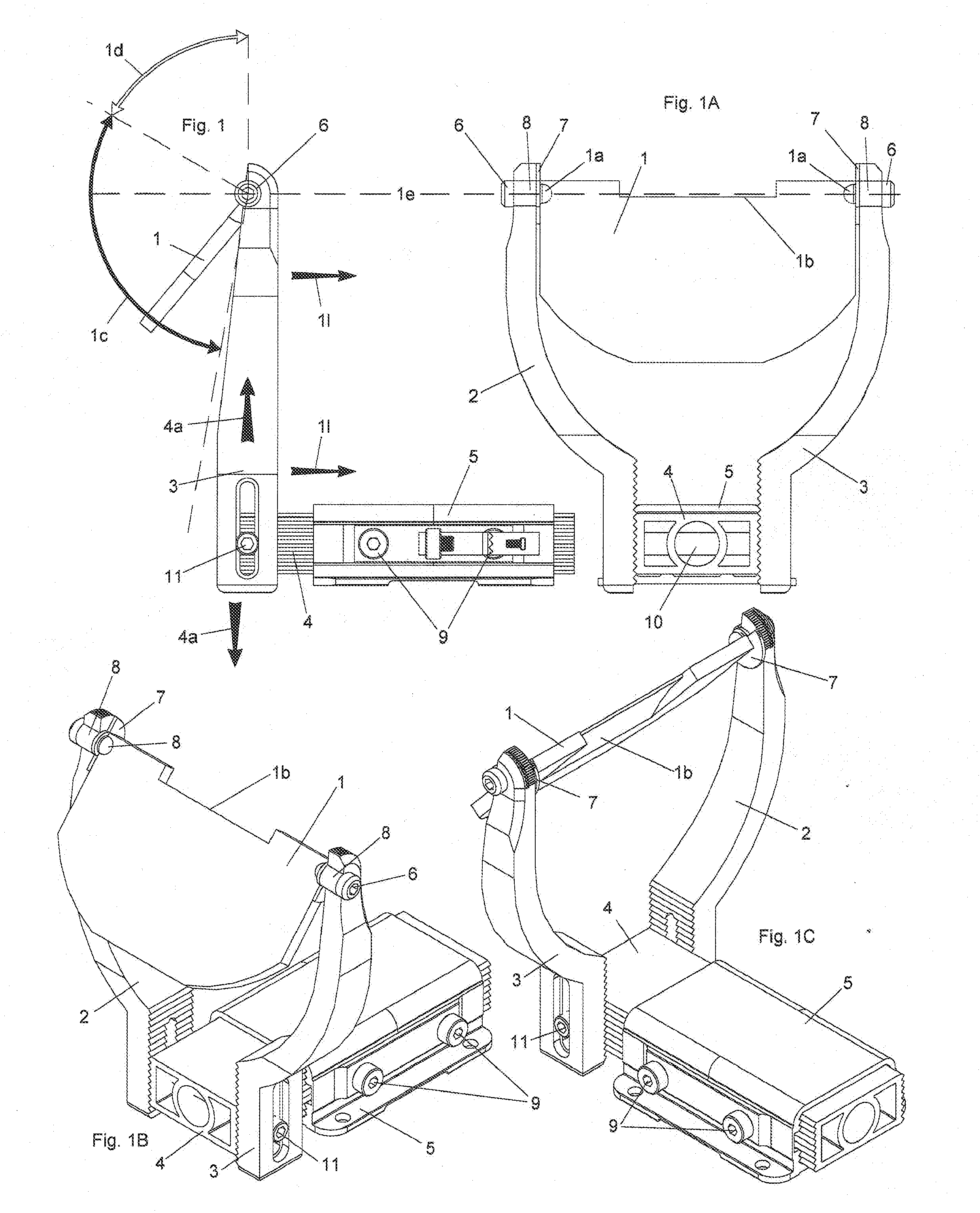

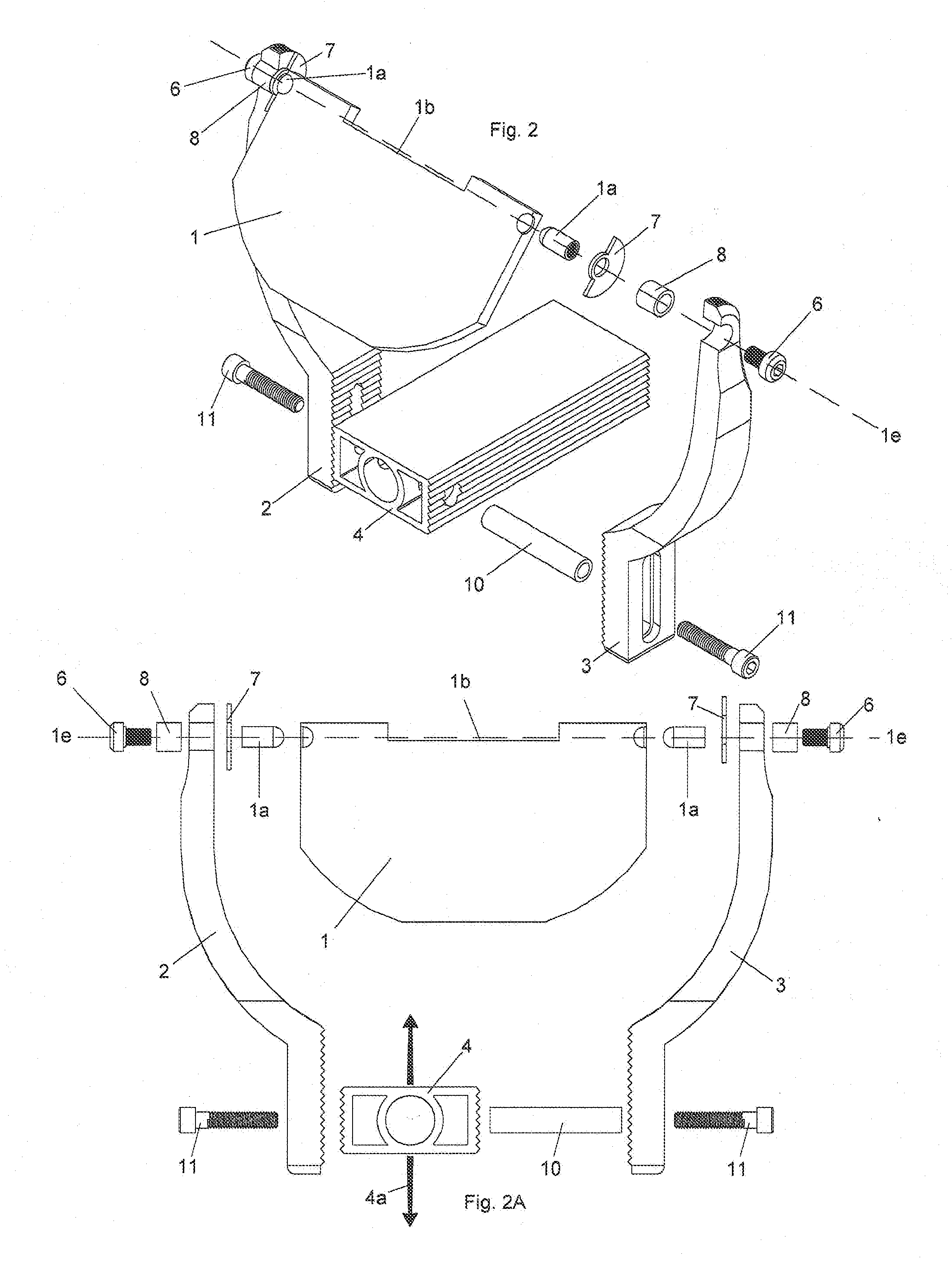

Adjustable Grinding Platform and Mounting Assembly

InactiveUS20120270479A1Accurately determineBelt grinding machinesGrinding feed controlVernier scaleEngineering

Owner:BATTY STUART

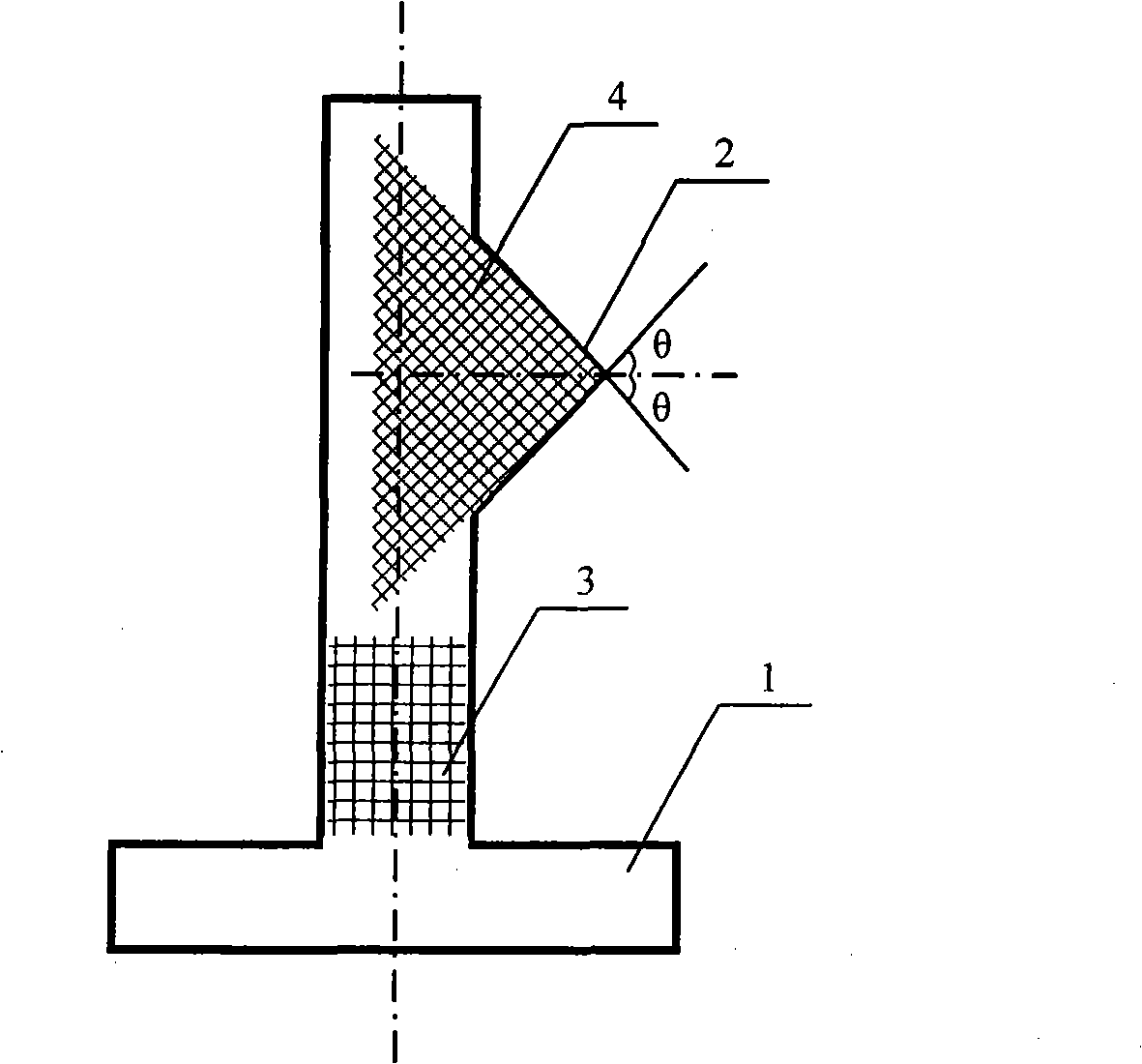

Ceramic base compound material bolt preparation method

The invention discloses a preparation method for a ceramic matrix composite bolt, which is characterized in that the method comprises the following steps: producing a fiber prefabricated product by shaping with a graphite plate after alternatively laminating a 1K carbon fiber 0 / 90 degree positive ply and a plus / minus Theta inclined ply; depositing a pyrolysis carbon interface layer on the prefabricated product and then depositing a silicon carbide matrix on the two-dimensional sheet with a deposited pyrolysis carbon interface layer to produce a semi-finished product of ceramic matrix composite sheet which is cut to form a bolt blank; grinding wheel and tapping the bolt blank; lastly obtaining the product of C / SiC composite bolt after many times of infiltration pyrolysis of polycarbosilane and continuing CVI depositing of SiC anti-oxidation coating. By the method, the bolt is processed and tapped on the semi-finished ceramic matrix composite prefabricated product which is not fully deposited and dense, so that the diamond grinding wheel wear is slow and the production cost is reduced. The technology of CVI combining with PIP process enables the elongation breaking strength of composite bolts to improve from 180 to 190MPa in prior art to 210 to 230MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

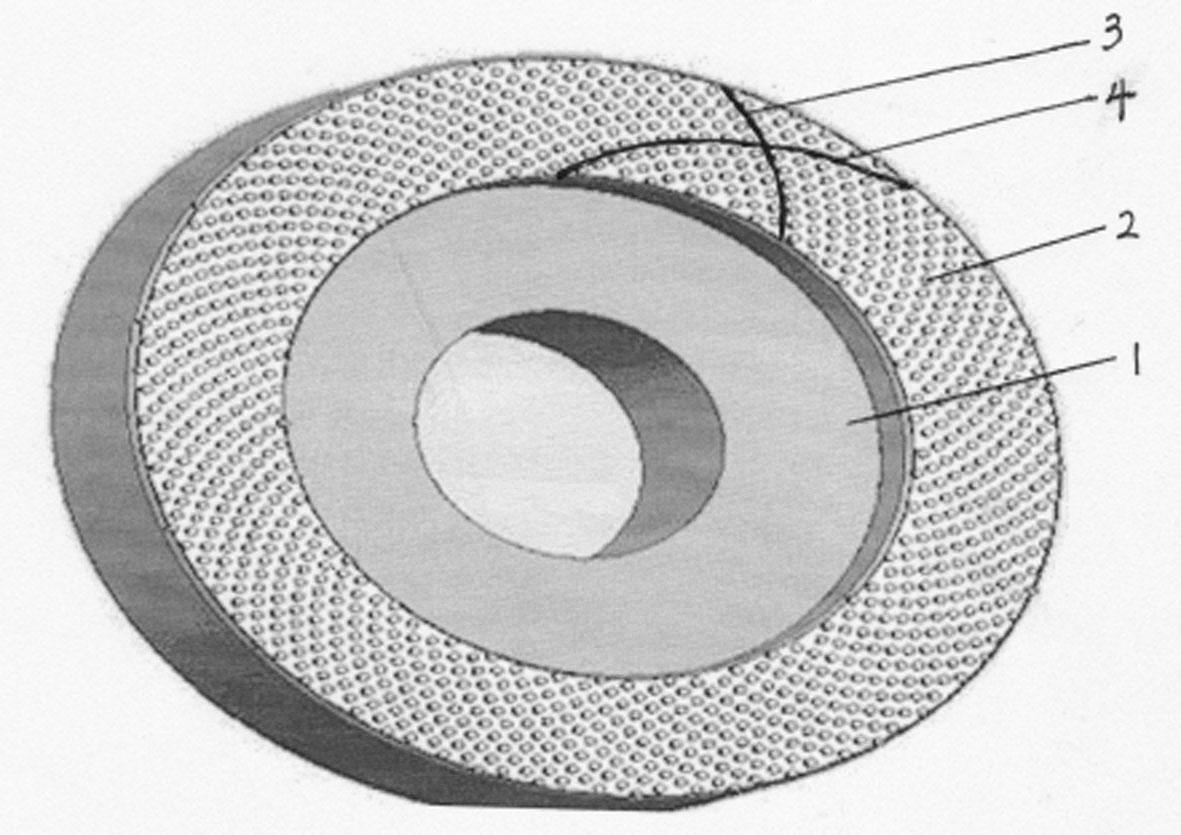

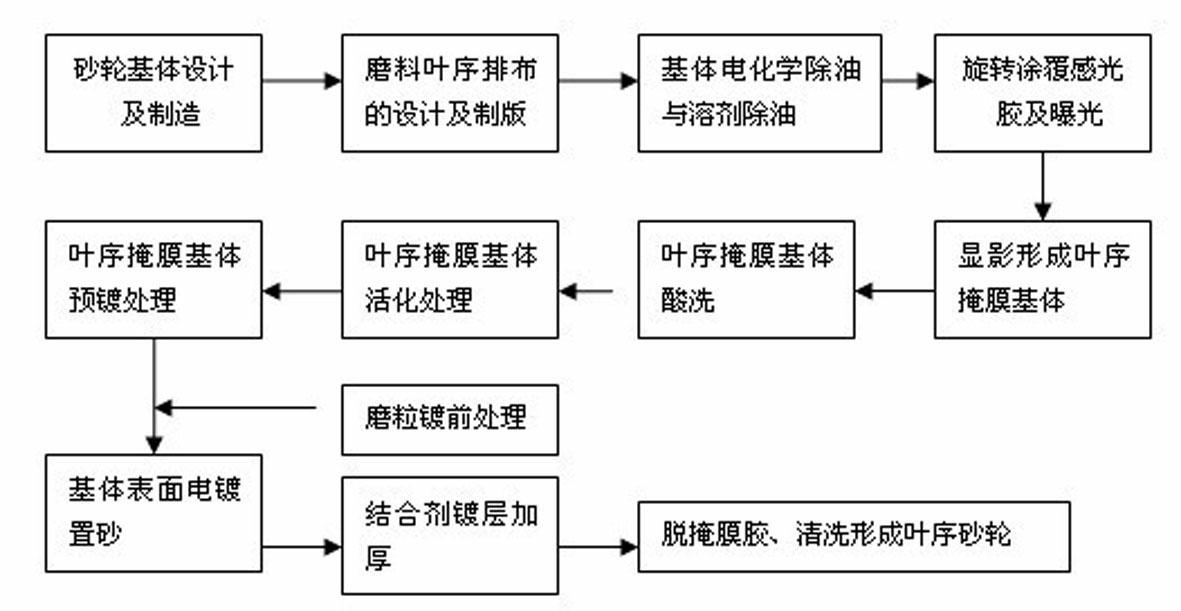

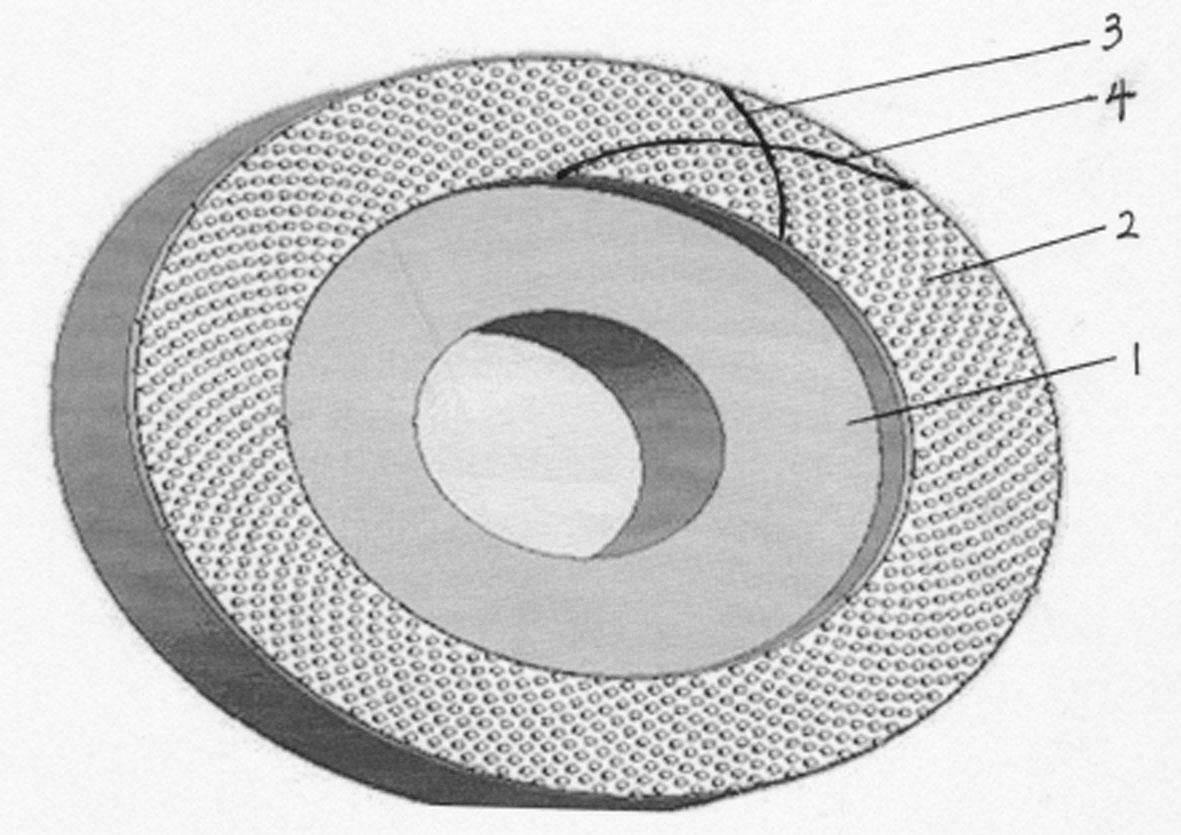

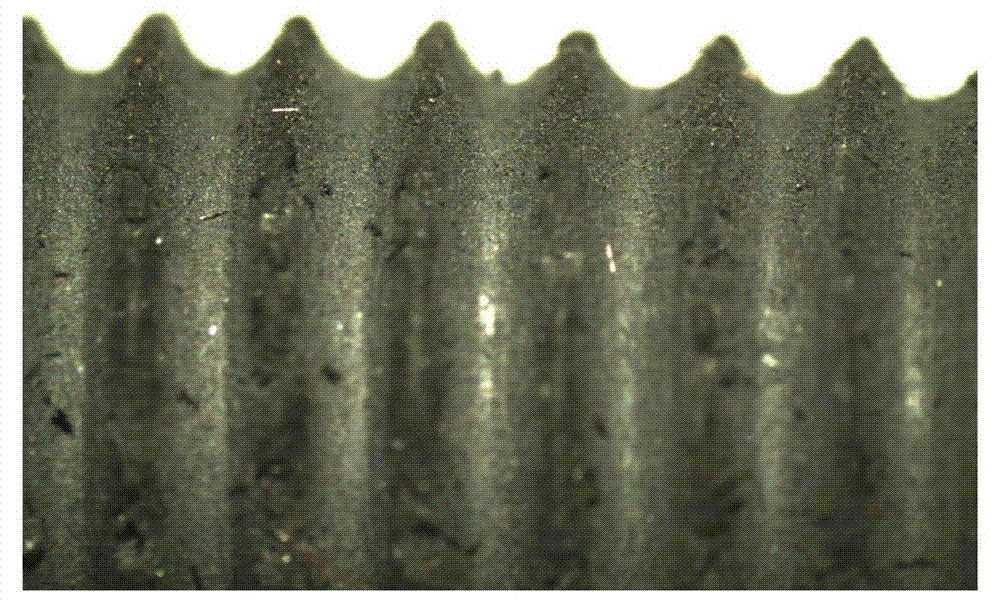

Super-hard abrasive grinding wheel with head face having abrasives in phyllotaxis arrangement and production method thereof

InactiveCN102198641AReduce wearAchieving landform controllabilityBonded abrasive wheelsGrinding devicesWheel wearControllability

The invention discloses a super-hard abrasive grinding wheel with a head face having abrasives in a phyllotaxis arrangement, comprising a grinding wheel basal body. The working surface of the grinding wheel basal body is provided with a plurality of abrasive particles or abrasive particle groups fitting with the biological phyllotaxis theory. The plurality of abrasive particles or abrasive particle groups are fixed on the grinding wheel basal body through a metal bonding agent. According to the biological phyllotaxis theory, the plurality of abrasive particles or abrasive particle groups forma plurality of anticlockwise leaf column line grooves and a plurality of clockwise leaf column line grooves. By means of the invention, the arrangement of the abrasive particles or the abrasive particle groups on the working surface of the grinding wheel fits with the H.Vogel model of the phyllotaxis theory so as to realize the physiographic controllability of the working surface of the grinding wheel. Nickel or nickel-cobalt alloy is adopted to serve as the bonding agent so as to fixedly bond the abrasives. The grinding wheel is capable of controlling the cutting state of the abrasive particles in a grinding region, the cooling liquid distribution and the grinding temperature distribution, and achieving lowest grinding force and specific energy consumption, lowest grinding temperature and burn, lowest abrasion of the grinding wheel, optimal work-surface surface integrity, and the like. The comprehensive grinding performance of the head face grinding of the super-hard abrasive grinding wheel is improved.

Owner:SHENYANG LIGONG UNIV

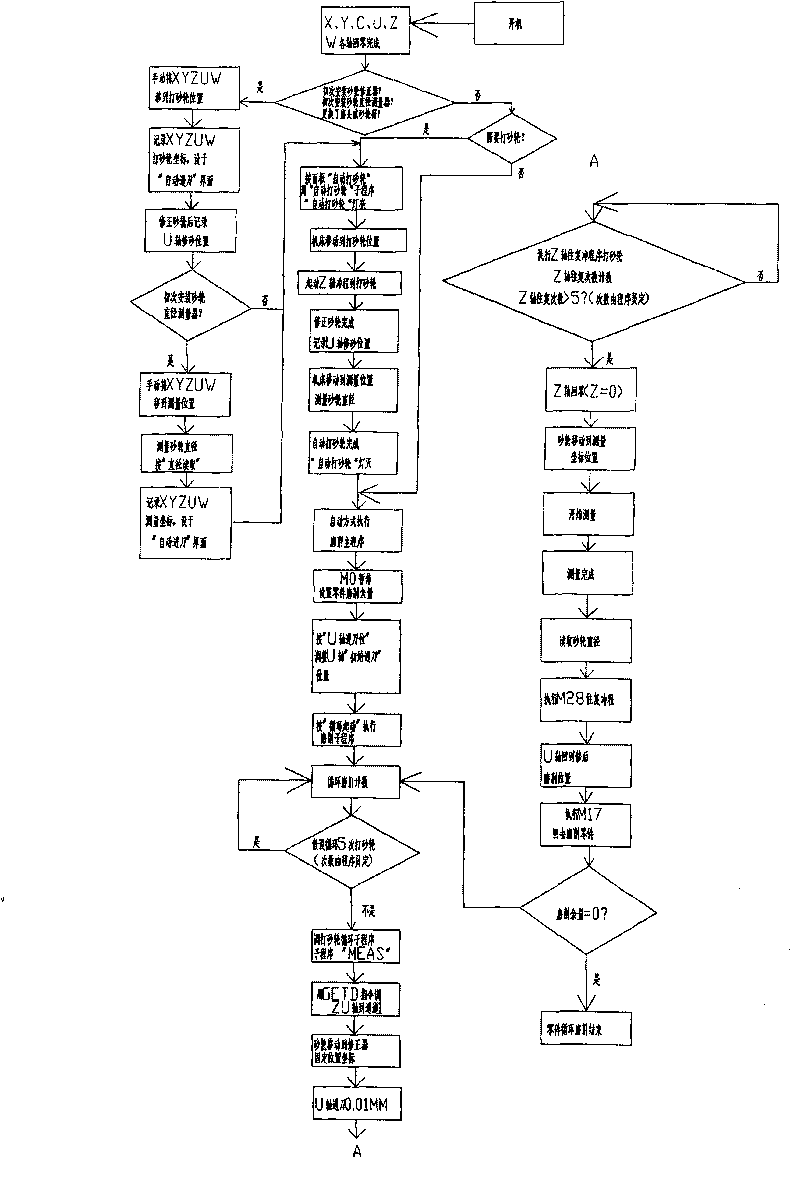

Method for detecting and compensating for abrasion of grinding wheel automatically

InactiveCN101733705ARealize automatic compensationFully automatedGrinding feed controlWheel wearGrinding wheel

The invention discloses a method for detecting and compensating for abrasion of grinding wheel automatically and relates to the technical field of a grinding method of grinding wheels. A grinding wheel dresser is adopted to automatically dress and circulate ground grinding wheels, a grinding wheel diameter detector is adopted to perform on-line detection on diameters of machining grinding wheels, and diameter data, acquired after detection, of the grinding wheels is transmitted to a numerical control system; the numerical control system compares the diameter data of the grinding wheels with the original diameter data of the grinding wheels to acquire the abrasion loss and correction of the grinding wheels; and the numerical control system controls the amount of feed of a machine tool to realize the automatic compensation of the grinding wheels. By adopting the method, when precision moulds are ground, the precision of grinding outlines can be ensured effectively, the efficiency is high, and the automation and datamation control in the process of grinding the precise moulds are realized; and automatic and digital processing of quenched complex parts, such as plane graphic sample plates with any curves, mould cavities, mould punches and the like can be realized.

Owner:四川普什宁江机床有限公司

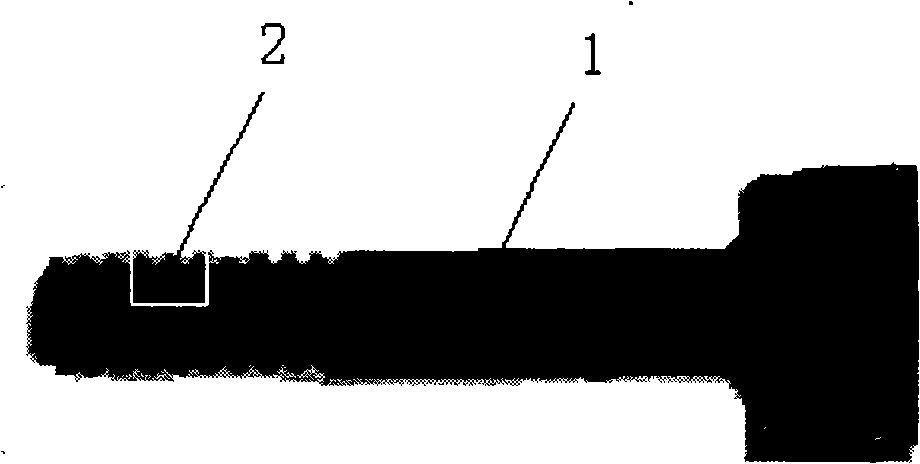

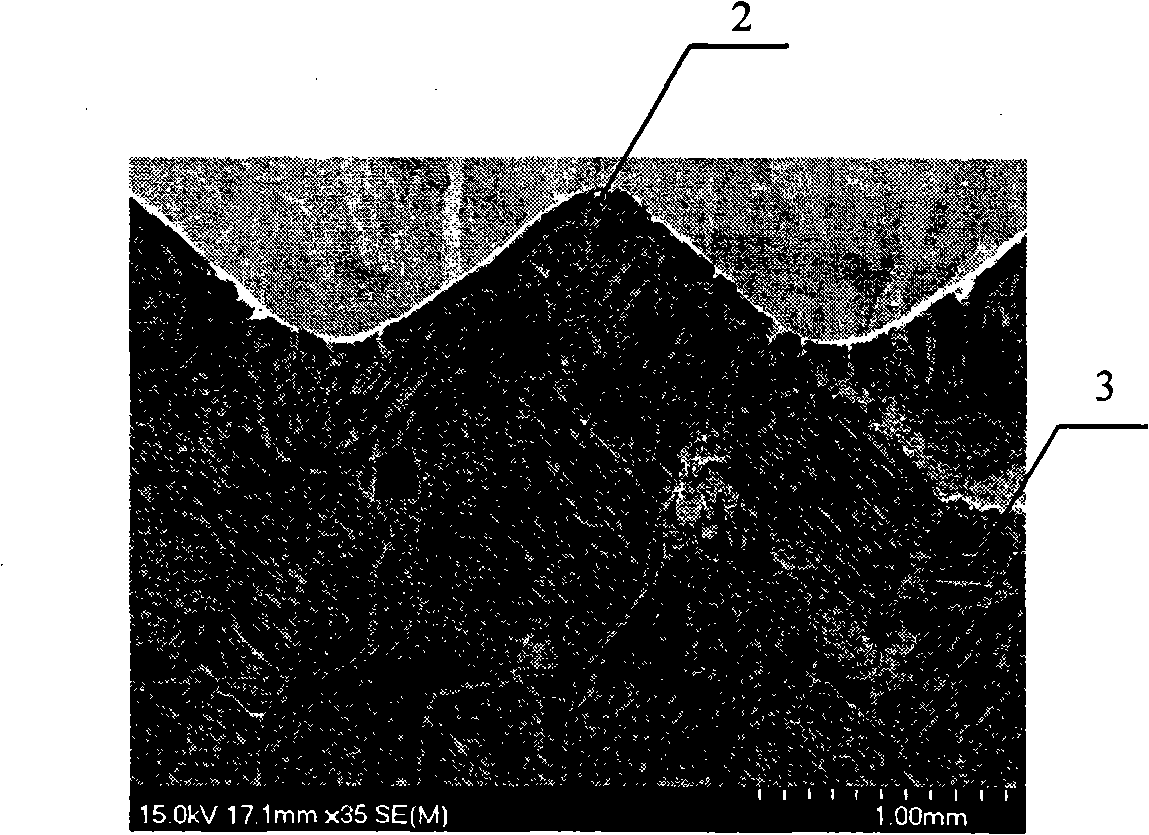

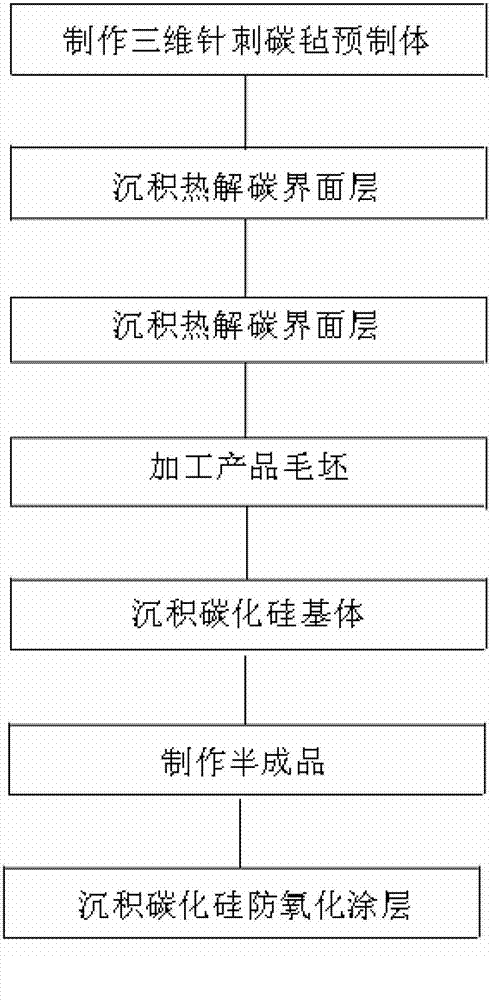

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

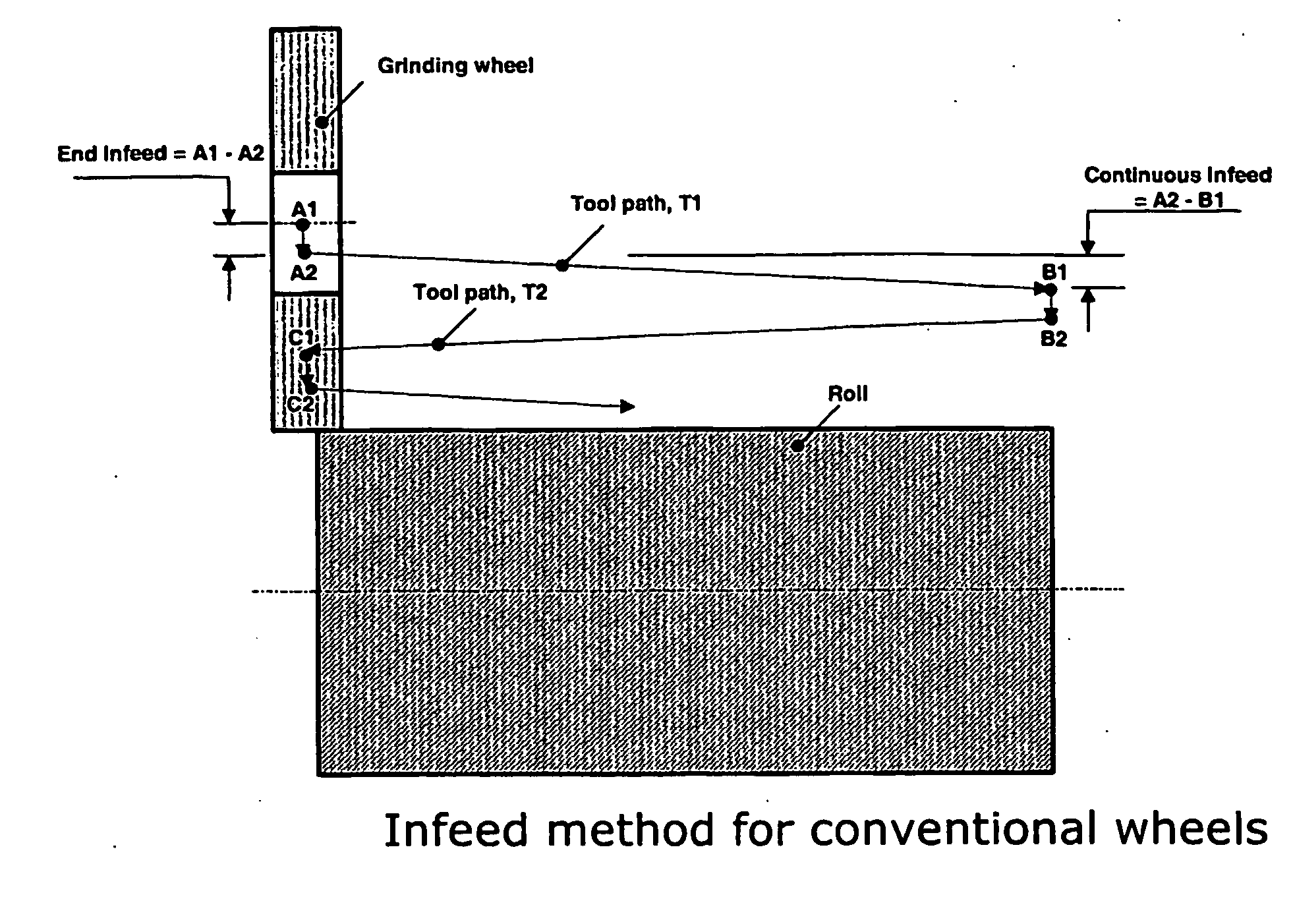

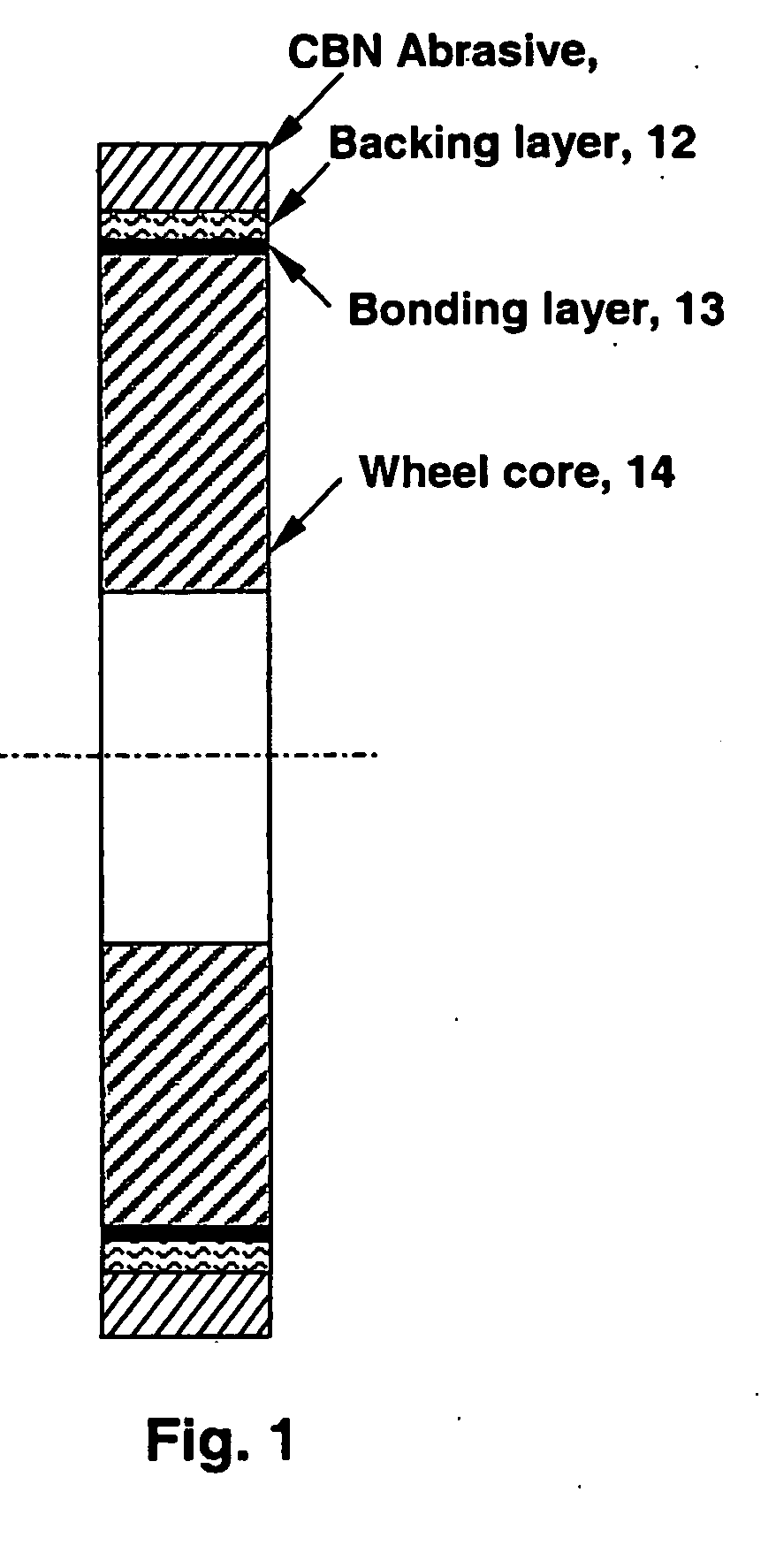

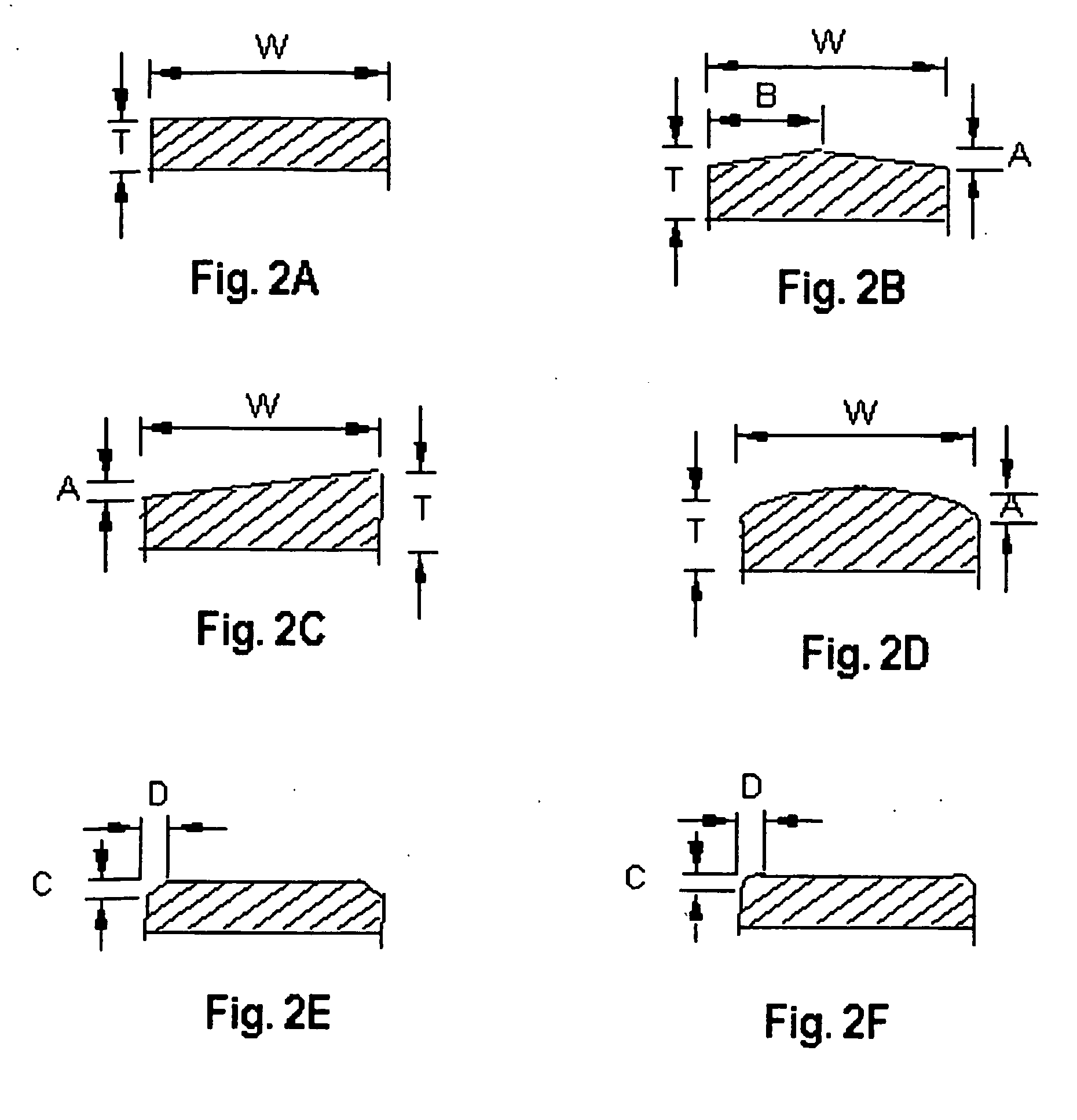

Grinding wheel for roll grinding application and method of roll grinding thereof

ActiveUS20070099548A1Constant speed ratioLong grinding lifeRevolution surface grinding machinesRolling equipment maintainenceBoron nitrideWheel wear

Iron and steel rolls are ground to production quality requirements with a grinding wheel that requires minimal wheel wear compensation, profile error compensation or taper error compensation during the grinding process. The grinding wheel consists essentially of a superabrasive material selected from the group of natural diamond, synthetic diamond, cubic boron nitride, and mixtures thereof, in a bond system, for a grinding wheel with extended wheel life, and which removes minimum amount of stock off the roll to achieve desired roll geometry.

Owner:DIAMOND INNOVATIONS INC

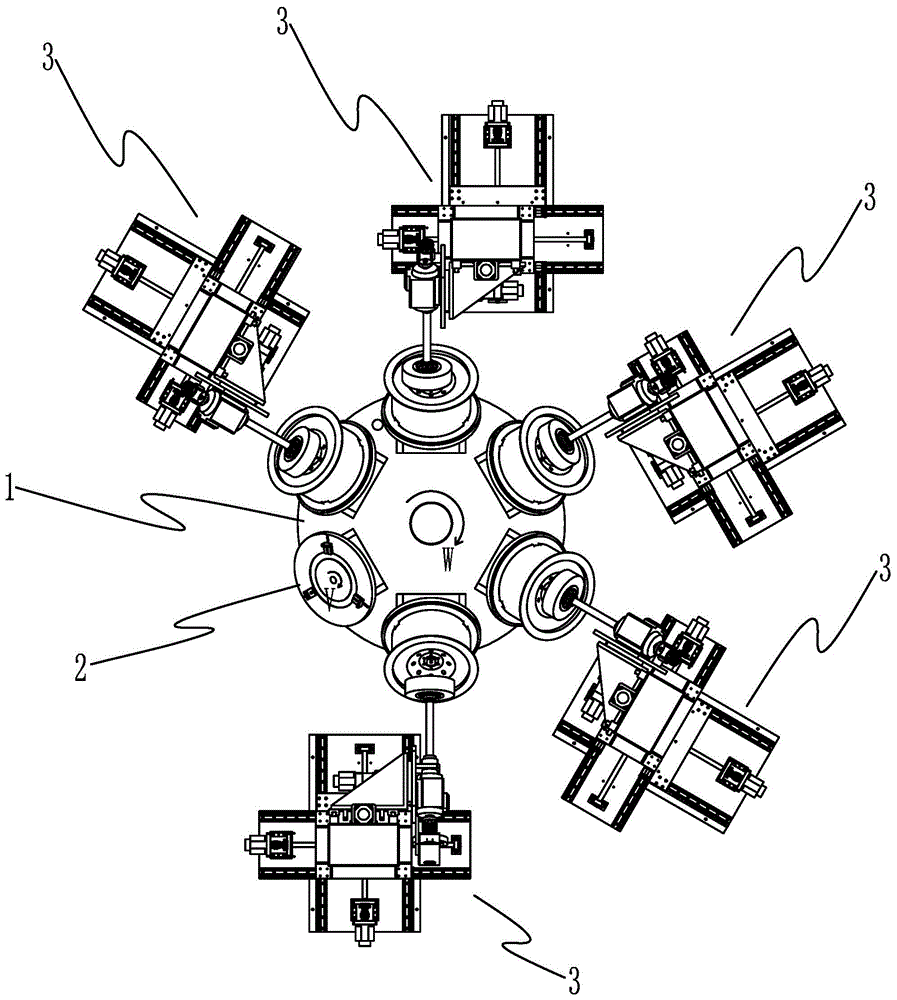

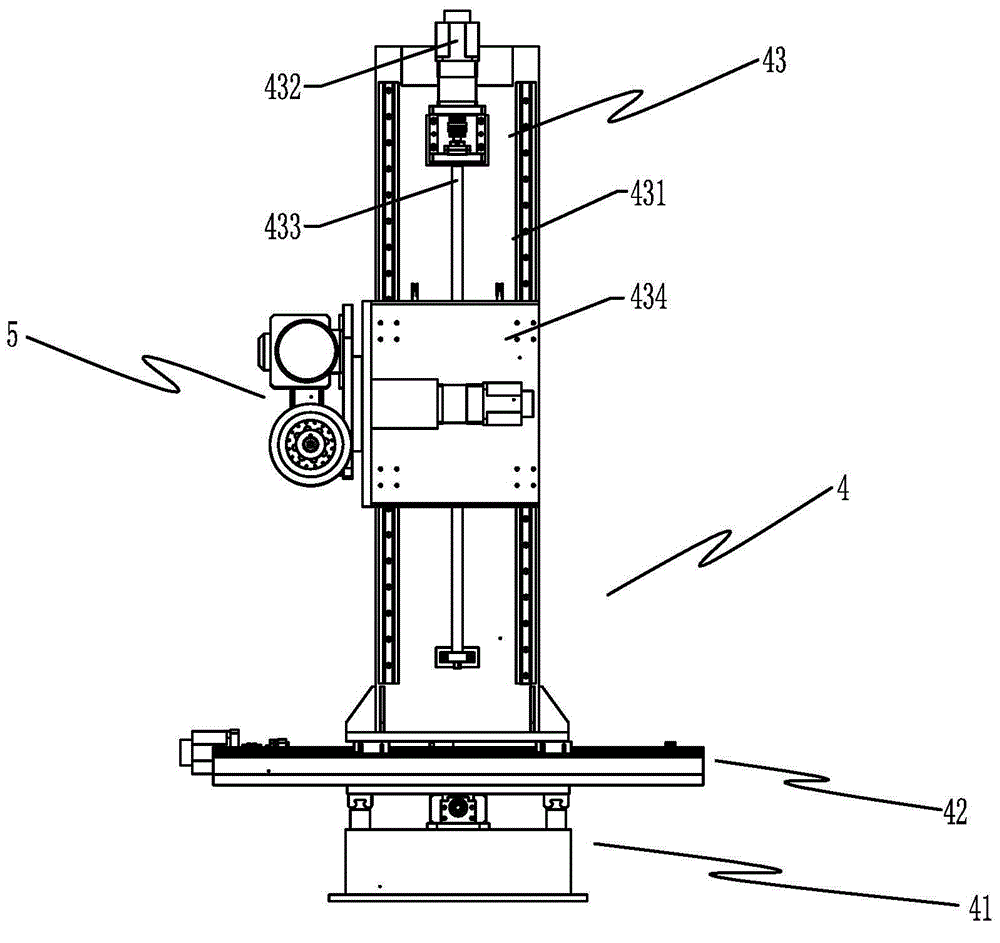

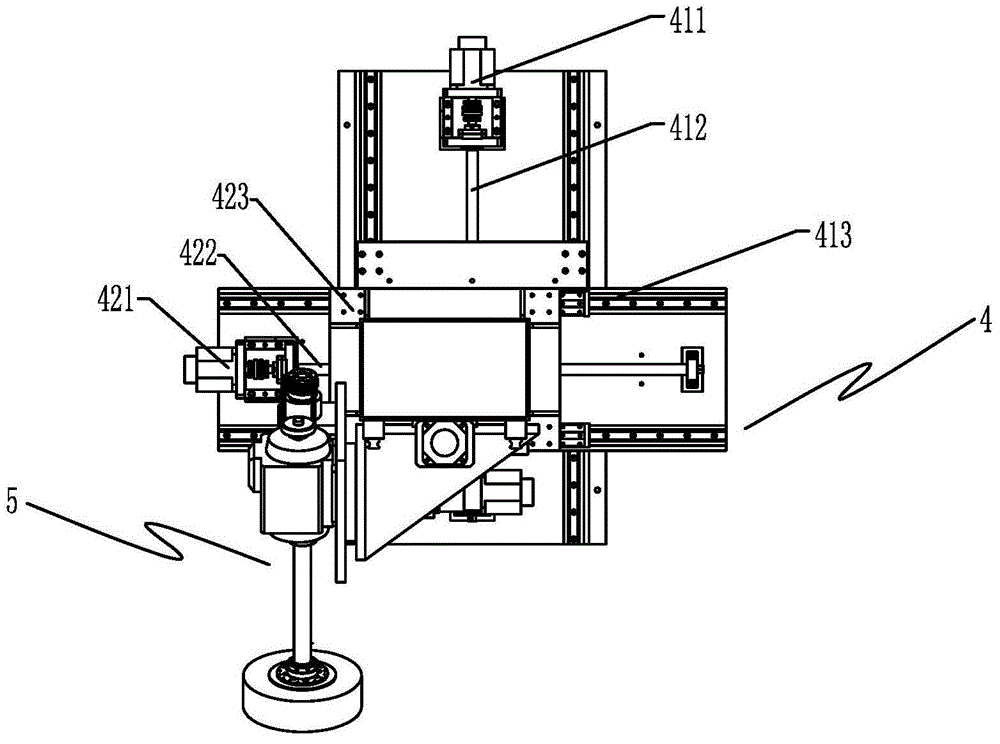

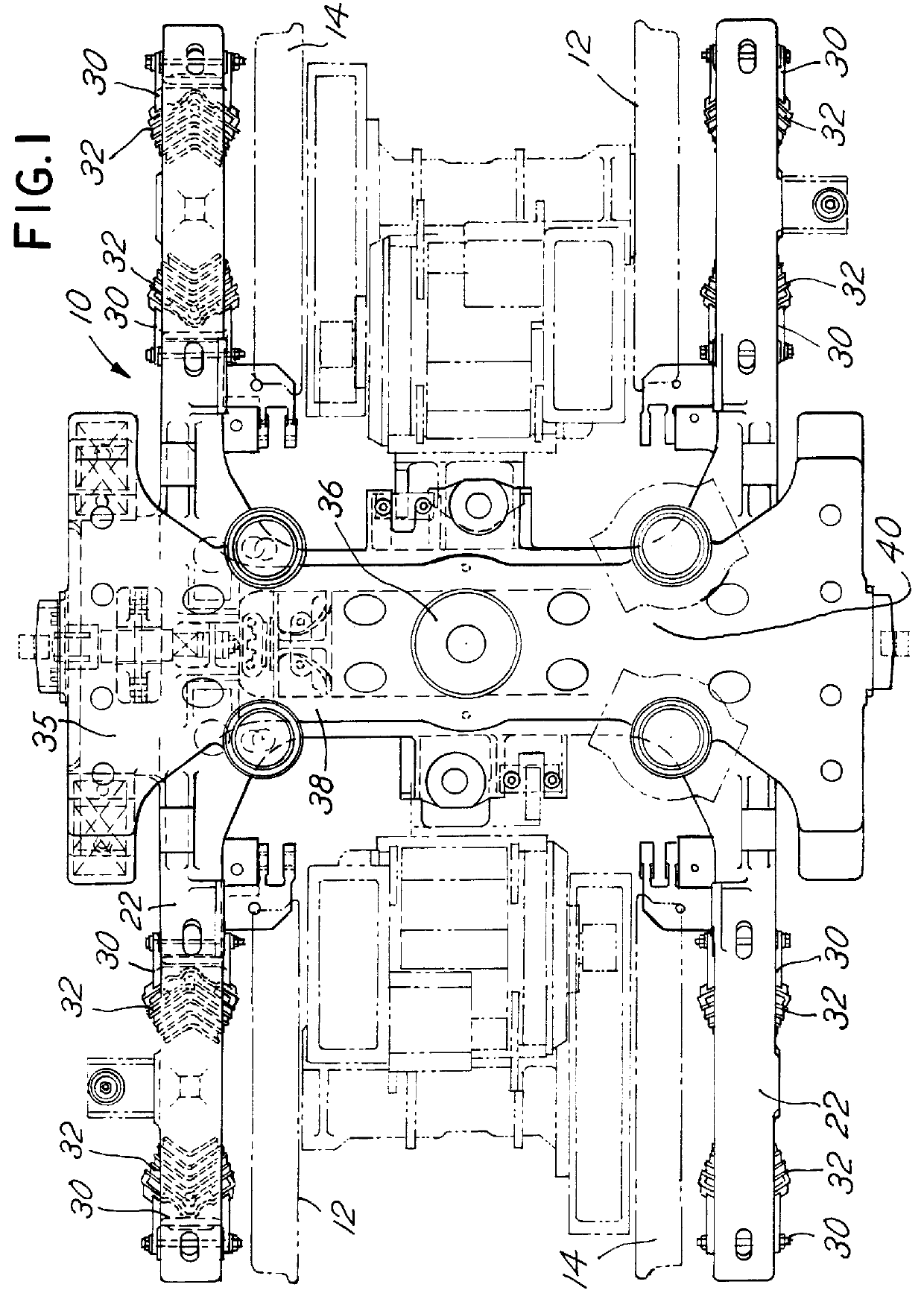

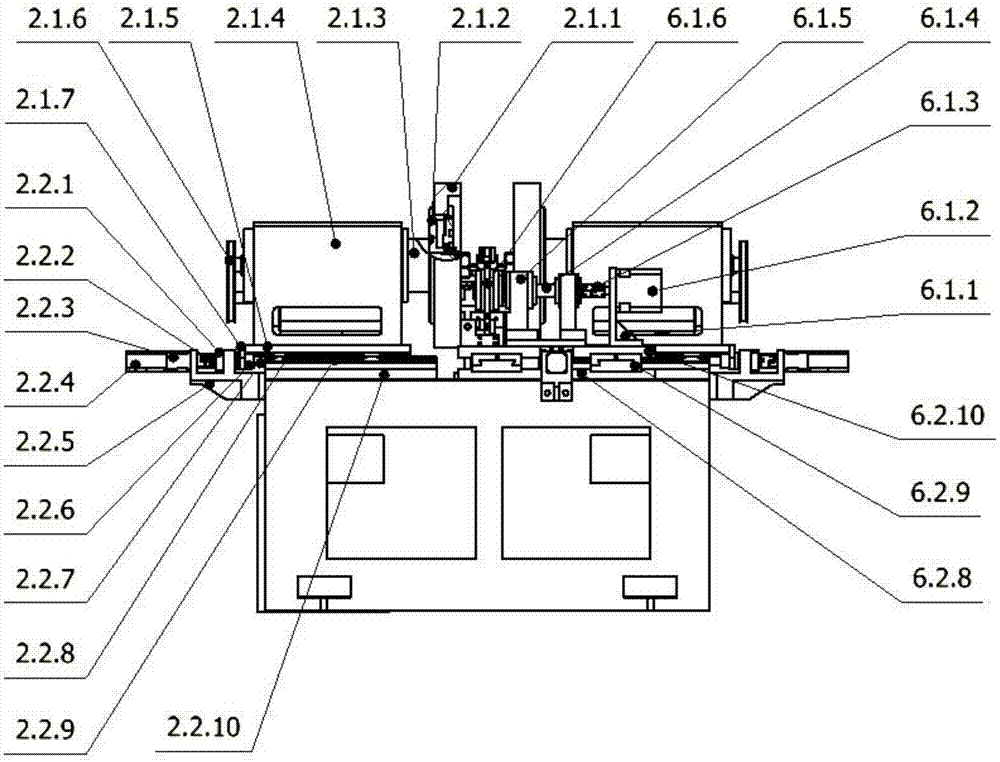

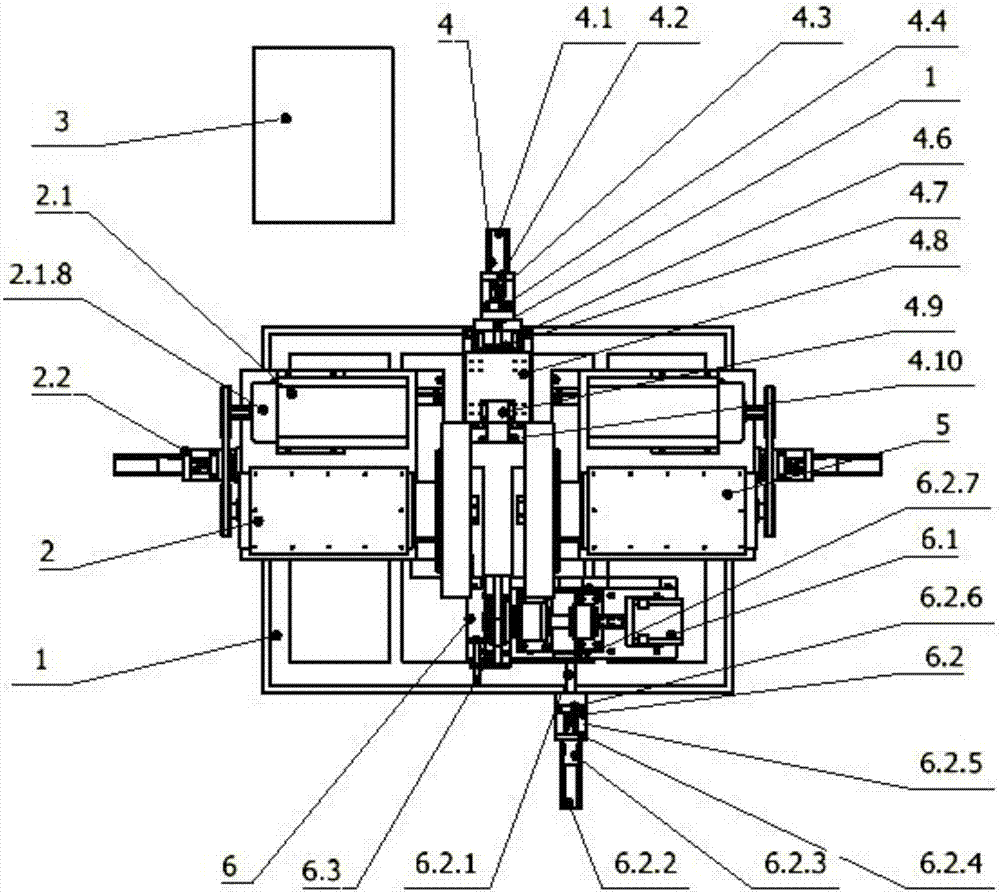

Multi-station circular-disc type novel numerical control automobile hub polishing machine

ActiveCN105014511AStable polishing qualityEnsure continuous and stable workPolishing machinesGrinding drivesNumerical controlCircular disc

The invention discloses a multi-station circular-disc type novel numerical control automobile hub polishing machine. The multi-station circular-disc type novel numerical control automobile hub polishing machine comprises a revolution circular disc assembly in the middle. Autoroatation hub clamp assemblies of multiple stations are evenly arranged on the revolution circular disc assembly in the circumferential direction at equal angles. Asynchronous polishing wheel assemblies of the stations and a loading and unloading station of one station are arranged around the autoroatation circular disc assemblies and correspond to the autoroatation hub clamp assemblies of all the stations. The polishing wheel assembly of each station comprises a three-direction displacement component and a polishing wheel machine head component deflecting at the preset angle along the horizontal axis and arranged on the three-direction displacement component. The polishing machine can achieve four-axis linkage and automatic compensation for the polishing wheel wear radius, and therefore production efficiency is improved greatly; meanwhile, the application range of complex-spoke hub polishing is enlarged, and the stable and consistent hub polishing quality is guaranteed; and the requirement on the experience of operators is lowered, and thus production efficiency and economic benefits are improved.

Owner:广东博科数控机械有限公司

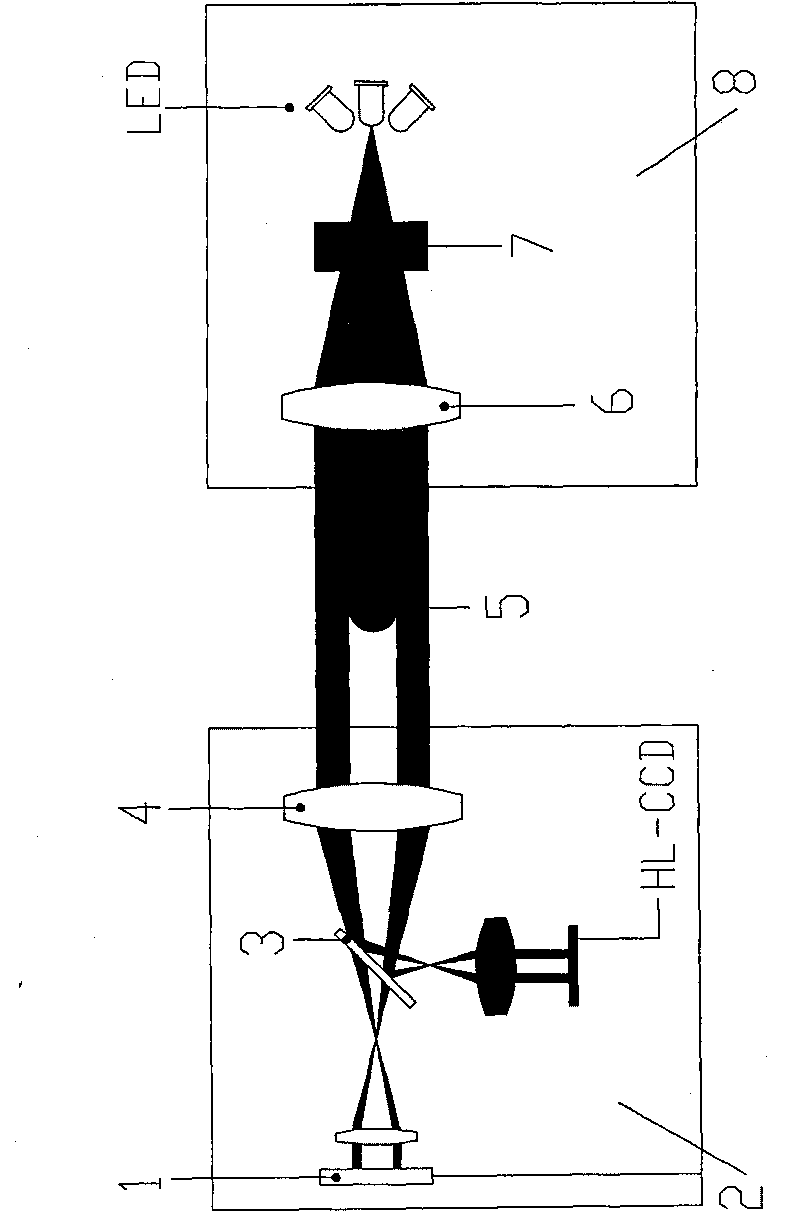

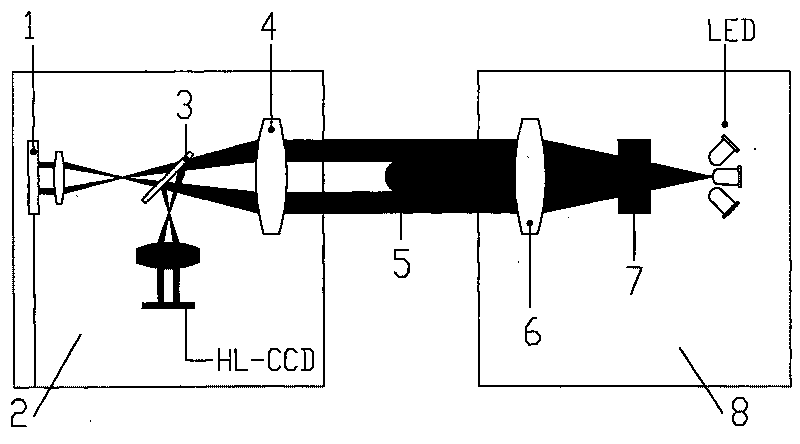

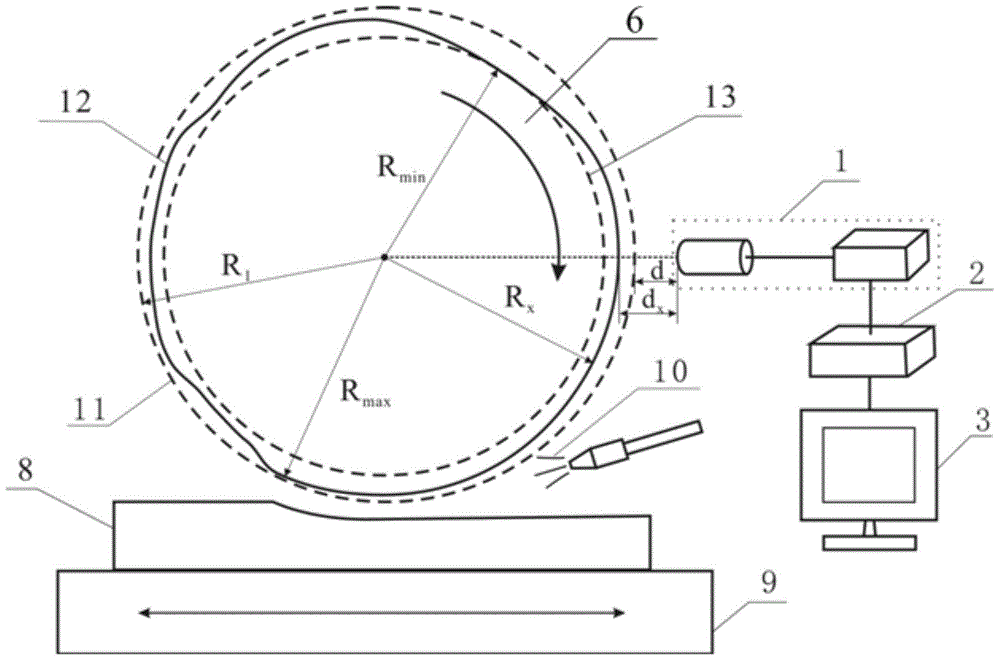

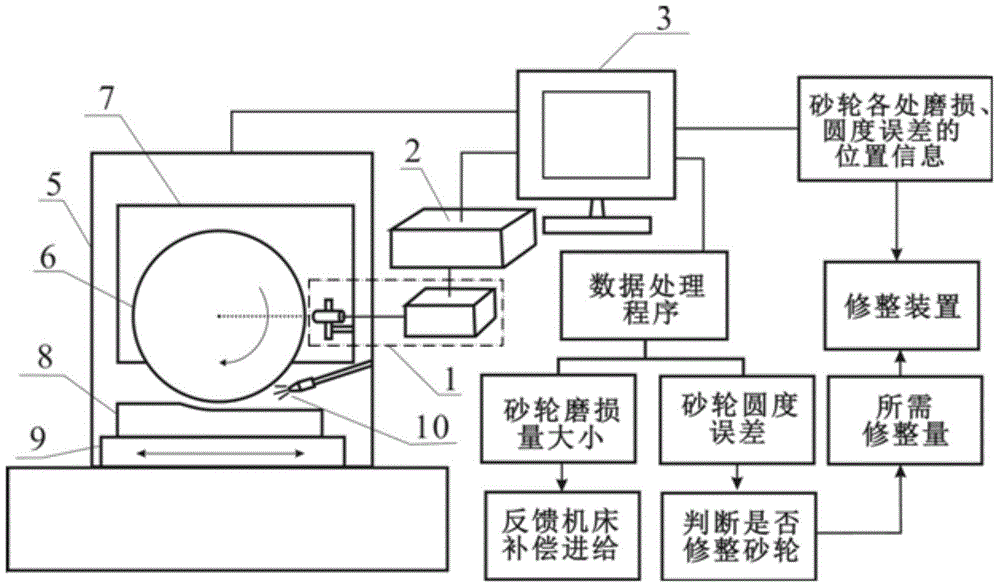

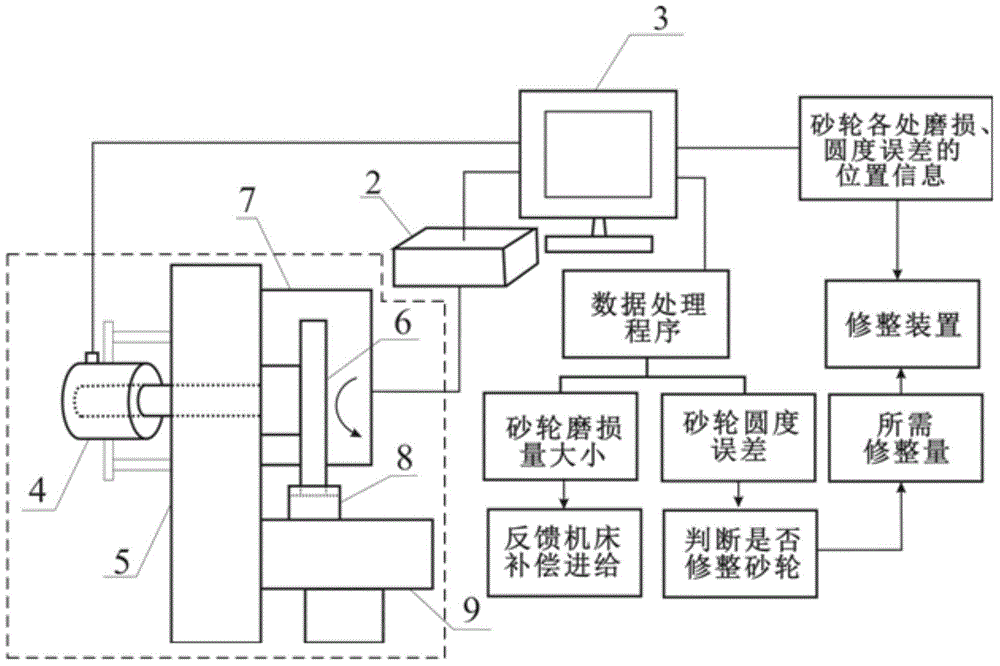

Non-contact online detection method for circular degree error and abrasion loss of metal based abrasion wheel and device for achieving method

ActiveCN105234820AHigh sensitivityImprove detection accuracyGrinding feed controlElectricityWheel wear

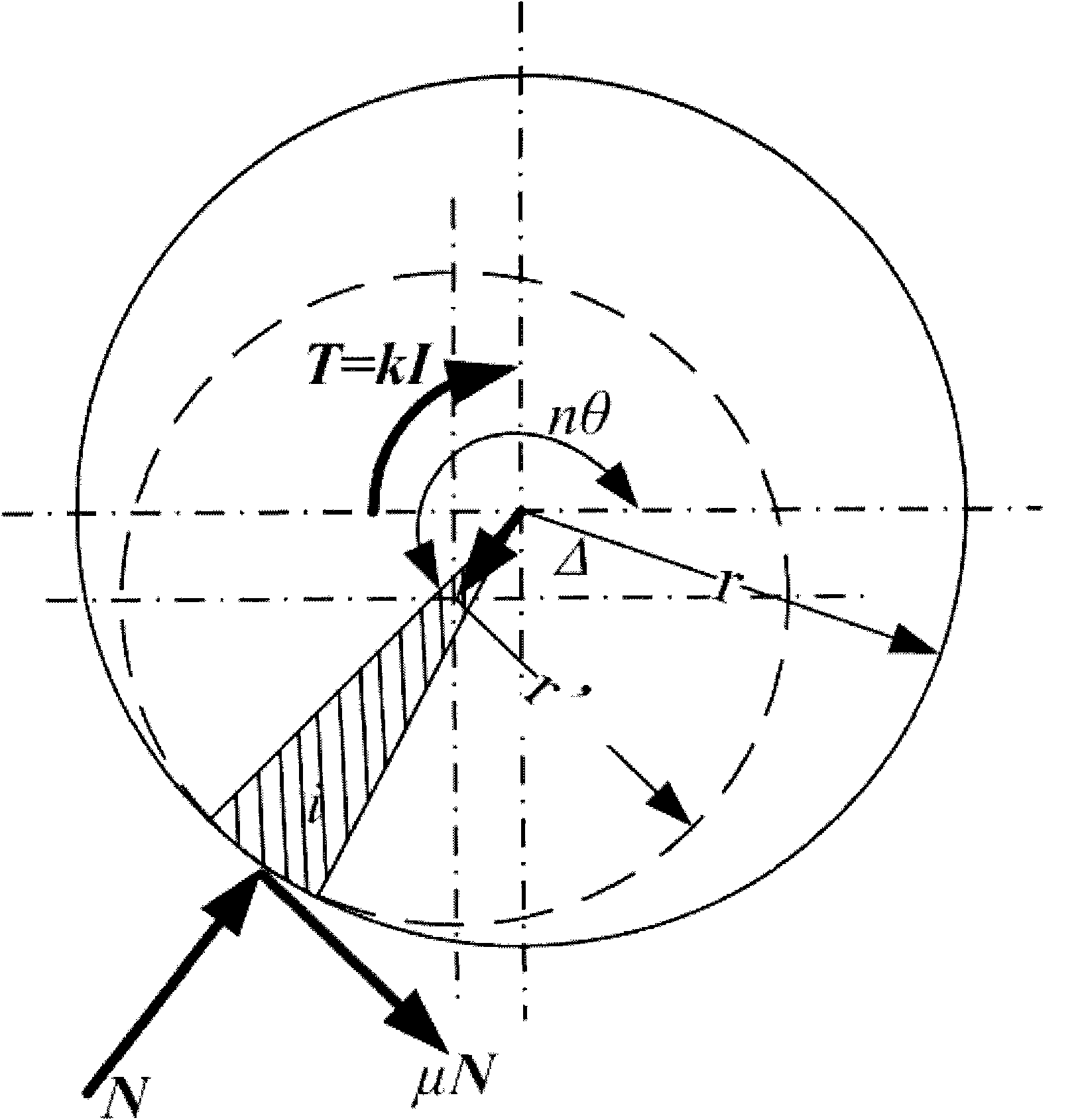

The invention discloses a non-contact online detection method for the circular degree error and the abrasion loss of a metal based abrasion wheel and a device for achieving the method and relates to the online detection technology of the circular degree error of the metal based abrasion wheel and the abrasion loss of a abrasion wheel of the abrasive machining field. The problem that the application range of an existing method for measuring the circular degree error of the metal based abrasion wheel and the abrasion loss of the abrasion wheel is narrow is solved. According to the scheme, the position of an eddy current sensor is fixed, the distance between a measuring head of the eddy current sensor and the surface of the metal based abrasion wheel is detected online through the eddy current sensor, and the change conditions of the radius of the abrasion wheel in different positions are obtained through calculation, so that a circular degree error curve for the metal based abrasion wheel to rotate one circle is obtained. The abrasion loss of different positions of the surface of the metal based abrasion wheel is obtained through calculation by comparing the changes of the radius of corresponding positions after a period of grinding time. The non-contact online detection method for the circular degree error and the abrasion loss of the metal based abrasion wheel and the device for achieving the method are capable of detecting the abrasion loss of the metal based abrasion wheel and the circular degree error of the abrasion wheel in the grinding process in a non-contact mode in real time; the detection precision is high and the application range is broad.

Owner:HARBIN INST OF TECH

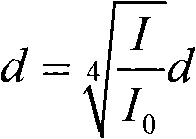

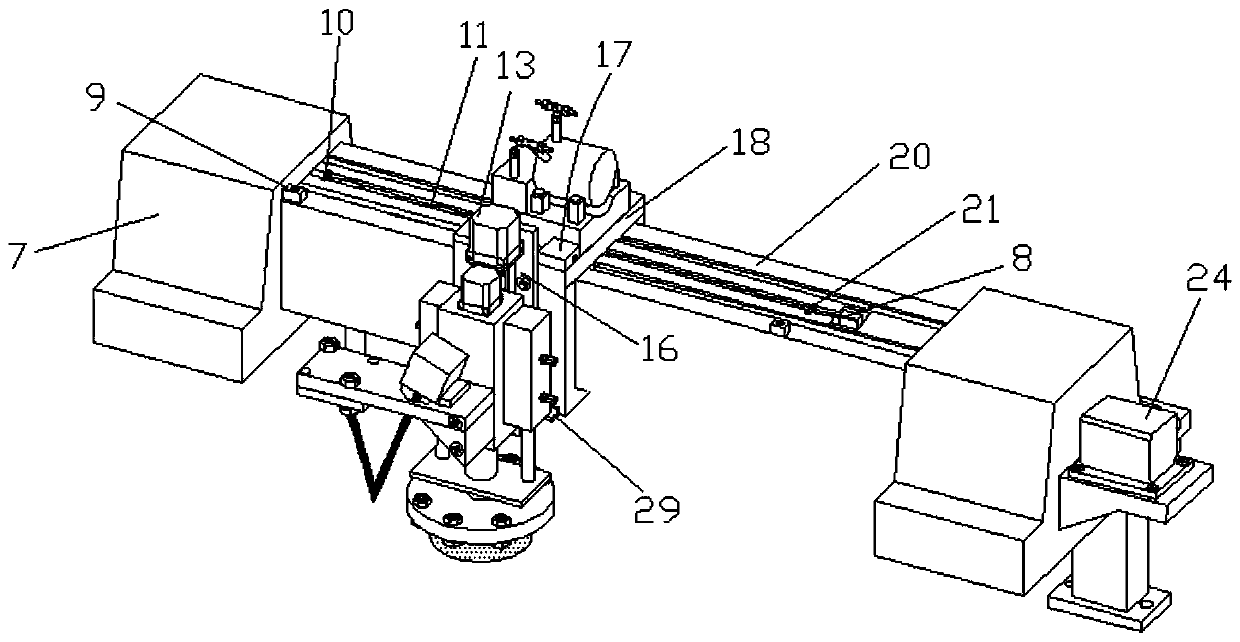

Polishing wheel diameter and polishing force detection method and polishing wheel wear compensating method

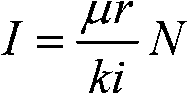

The invention provides a polishing wheel diameter and polishing force detection method, relating to real-time polishing force detection, polishing wheel diameter detection and polishing wheel wear compensation. The size of a polishing force in a polishing process is indirectly measure and a polishing wheel diameter is measured when a main motor is started by adopting a current sensor according to the proportionate relationship between measured factors and read values of the current sensor; and in a real-time polishing process, because a polishing wheel is worn to cause the reduction of the polishing force, the normal direction of a contact surface of the polishing wheel and a workpiece is calculated according to the position of a polishing contact fan sector appointed by a current user in the polishing wheel and the corner of a rotating shaft at the tail end of the current polishing wheel so that the compensation distance of each movable joint can be rapidly figured out in real time.

Owner:BEIHANG UNIV

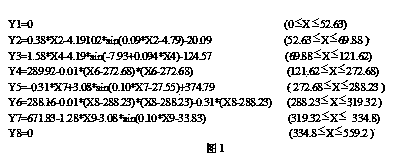

High-precision cylinder sleeve inner wall enclosed special-shaped curve groove processing method

ActiveCN103645677AAvoid step size stepAccurate coordinatesProgramme controlComputer controlVibration controlMathematical model

The invention relates to a high-precision cylinder sleeve inner wall enclosed special-shaped curve groove processing method, wherein the method is especially suitable for high-precision milling and grinding processing of a cylinder sleeve inner wall enclosed special-shaped curve groove with a large breadth-depth ratio. A mathematical model establishment method for cylinder sleeve inner wall enclosed special-shaped curve groove numerical-controlled programming is brought forward; a self-adaption screening method is used for determining a feed step length calculation method; a method of VC++ program code generation is utilized; and a numerical control system is used for carrying out parameter configuration and a program instruction programming method is used. Therefore, problems processing tool deformation during numerical-controlled milling and grinding wheel wearing and correction during tool vibration control and grinding can be solved; and precise processing of the cylinder sleeve inner wall enclosed special-shaped curve groove with large and variable bound feet is realized. The practical processing result demonstrates that the processing precision and efficiency of the cylinder sleeve inner wall enclosed special-shaped curve groove are improved based on the method.

Owner:CHANGCHUN EQUIP TECH RES INST

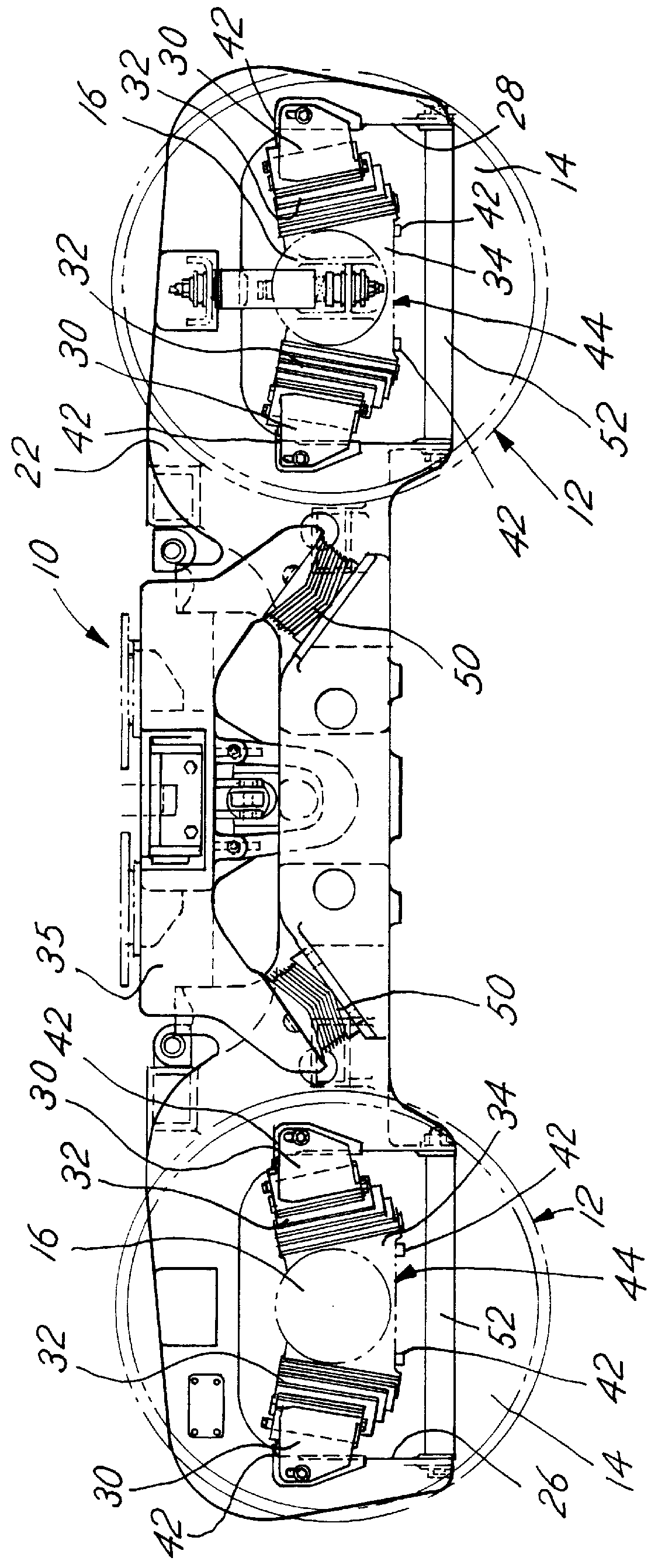

Shimming of railway car primary suspensions

There is disclosed a method for compensating for wheel wear to maintain a constant car floor height above the railroad track where the compensating shim is at all times attached to the railway truck. The method comprises generally the steps of providing a wheel wear compensating shim that, when not being used, is removably attached to the underside of the bearing housing or other suitable location, lifting of the side frame away from the primary suspension, disposing the compensating shim between the side frame and the primary suspension, and finally lowering the side frame back onto the shim and primary suspension. The railway truck can thus be shimmed for wheel wear at any location where the side frame and accompanying car body can be lifted without the need to take the railcar to a retrofit service shop.

Owner:BSC ACQUISTION INC

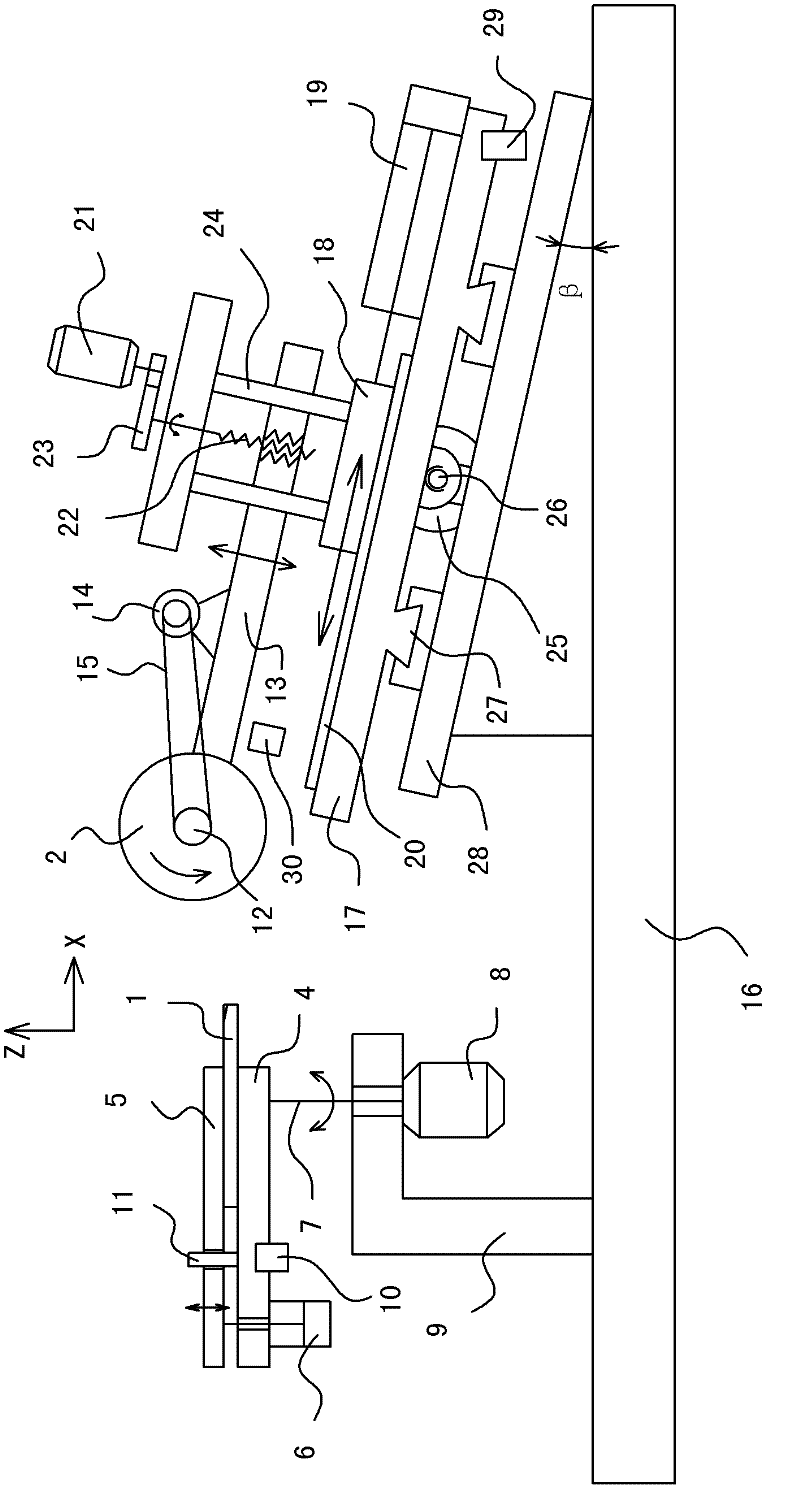

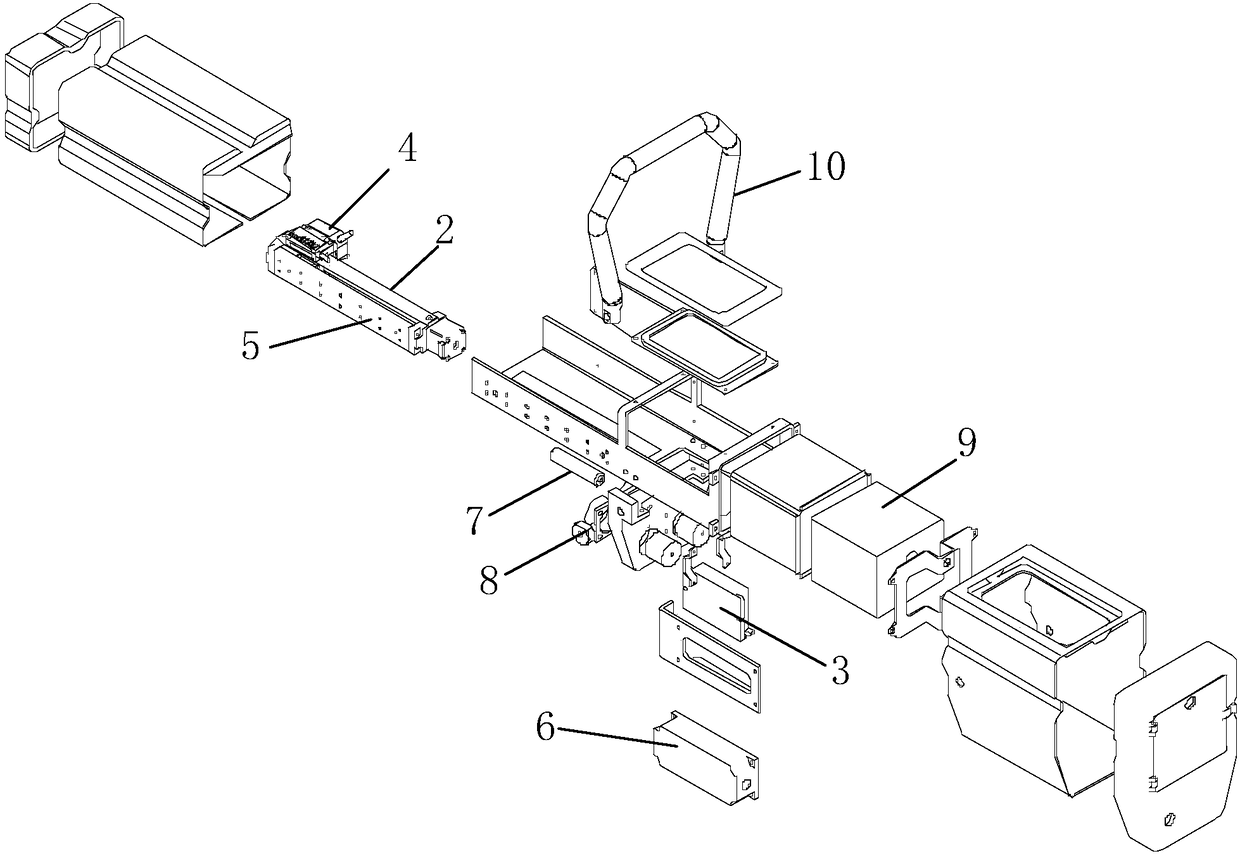

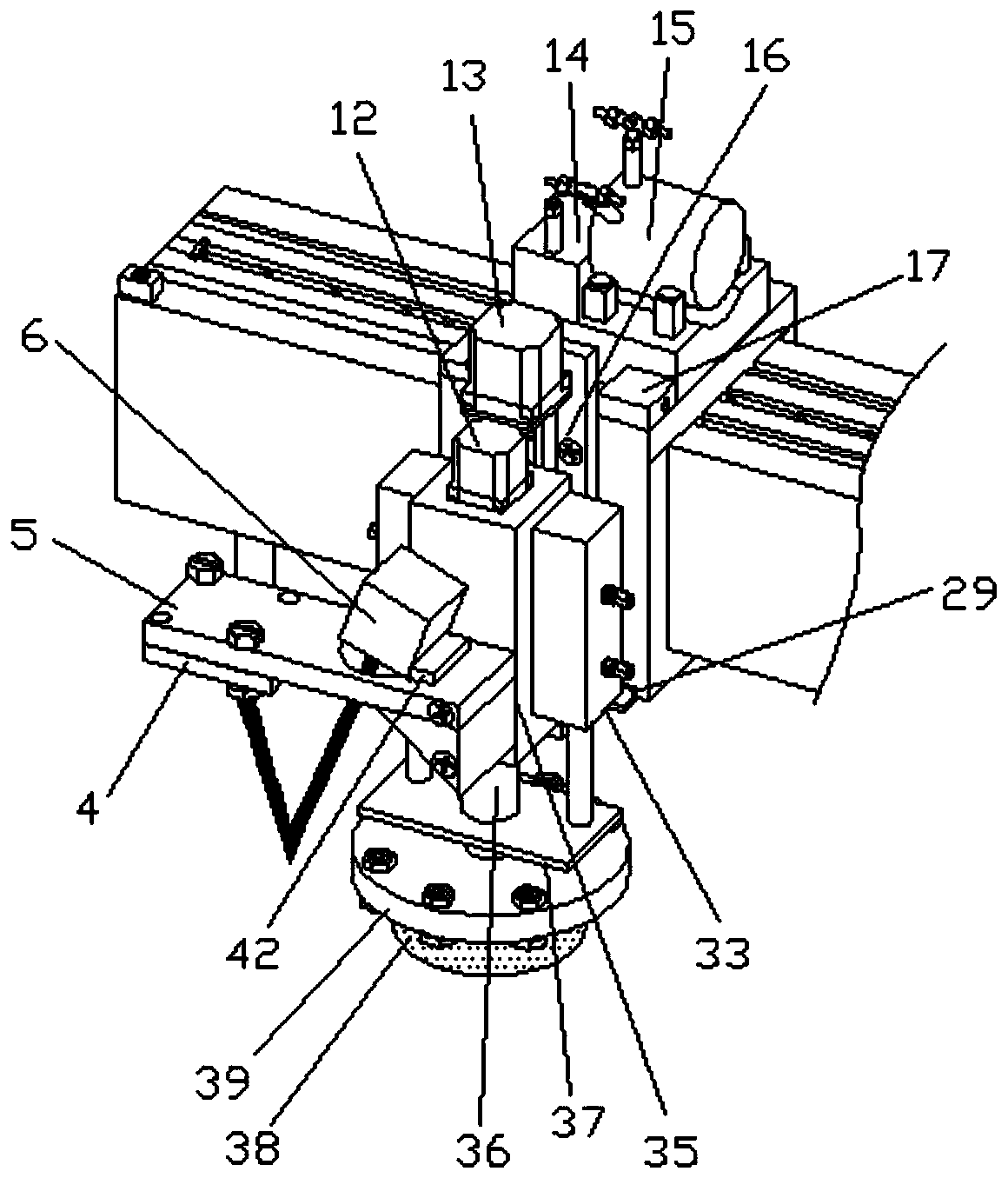

Automatic grinding machine for cutting edge of surgical knife blade

ActiveCN102328247ARealize automatic grindingAchieve grindingOther manufacturing equipments/toolsSurgical bladeElectric machinery

The invention relates to an automatic grinding machine for a cutting edge of a surgical knife blade, which is provided with a rotation knife holder mechanism and a grinding head mechanism, wherein the rotation knife holder mechanism is used for clamping the knife blade; the grinding head mechanism is used for grinding the cutting edge; the two mechanisms are effectively combined in space; after the knife blade is clamped, a grinding wheel is driven by a grinding head motor to rotate at high speed; the grinding wheel is pushed to the position of the cutting edge by a first linear driving mechanism to carry out grinding; the grinding wheel is driven by a second linear driving mechanism to feed grinding quantity and compensate the abrasion loss of the grinding wheel relative to the knife blade; the grinding wheel is driven by a third linear driving mechanism to carry out linear cutting edge section grinding relative to the knife blade; and the knife blade is driven by a rotation control motor to carry out circular arc cutting edge section grinding relative to the grinding wheel. The automatic grinding machine for the cutting edge of the surgical knife blade is capable of breaking through the limitation of traditional manual grinding, carrying out automatic grinding on the surgical knife blade with a linear circular arc cutting edge, a circular arc cutting edge and a linear cutting edge, greatly reducing the labor strength and improving the production efficiency and the processing quality, and has very high practical value.

Owner:STERILANCE MEDICAL SUZHOU

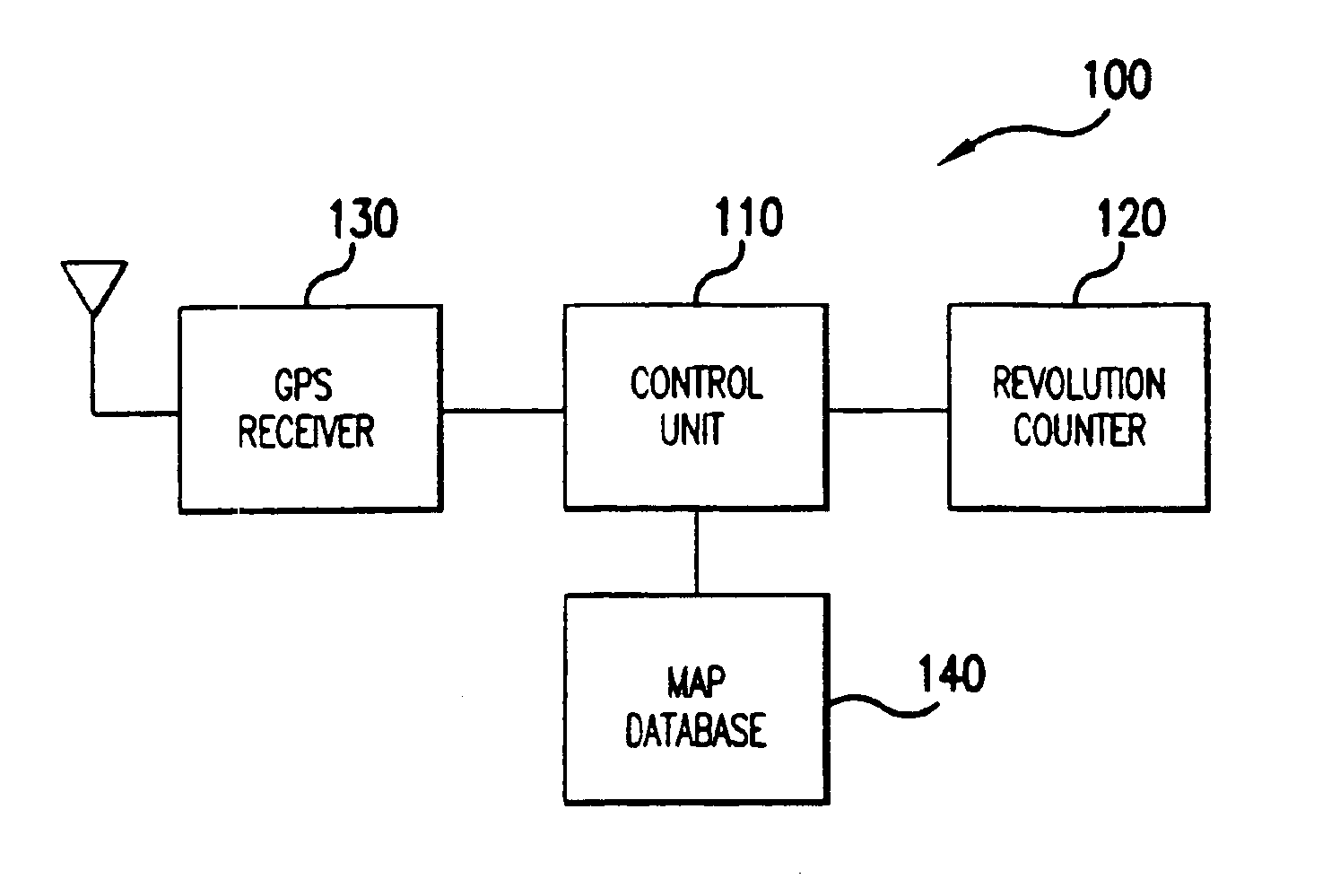

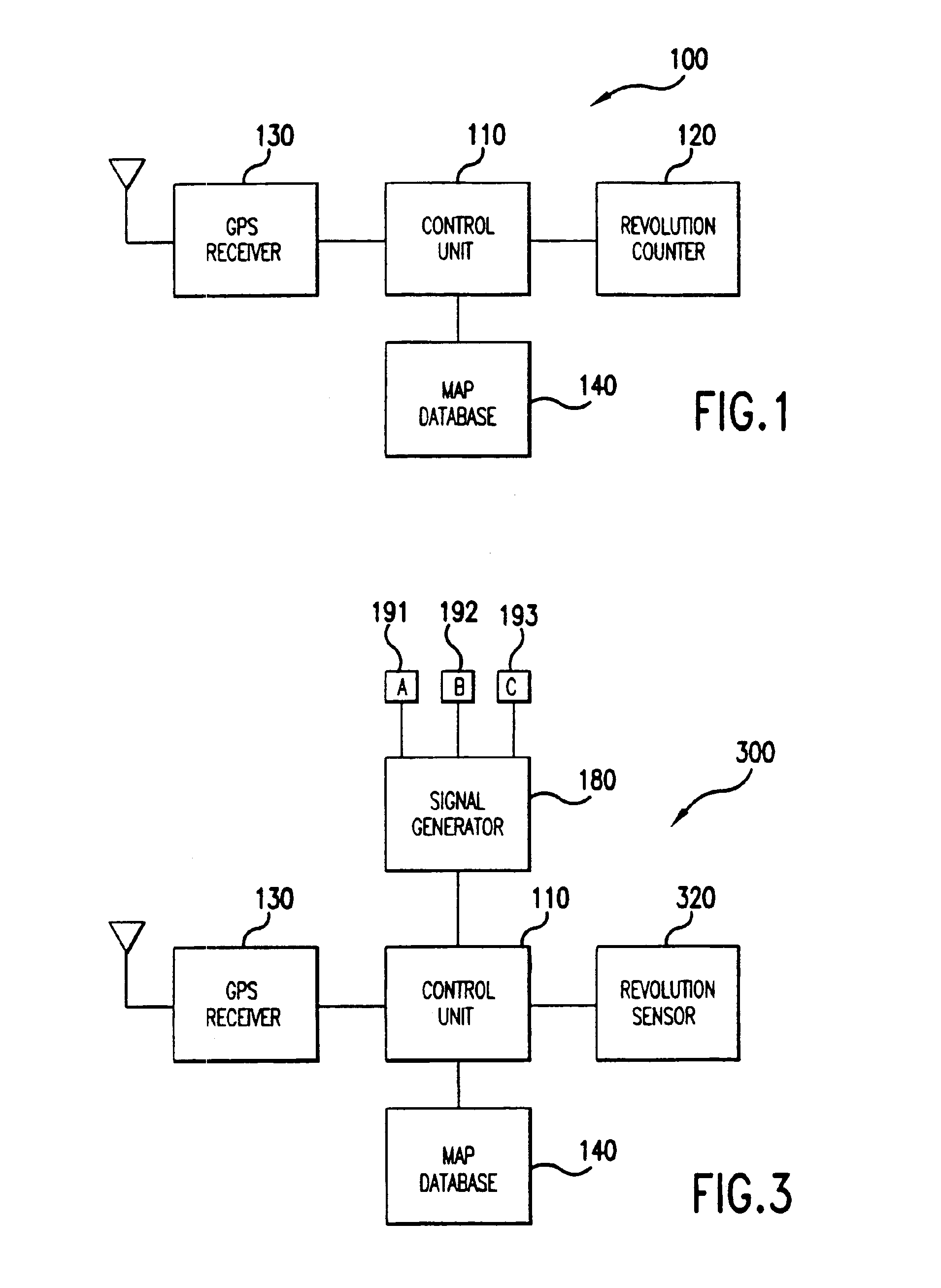

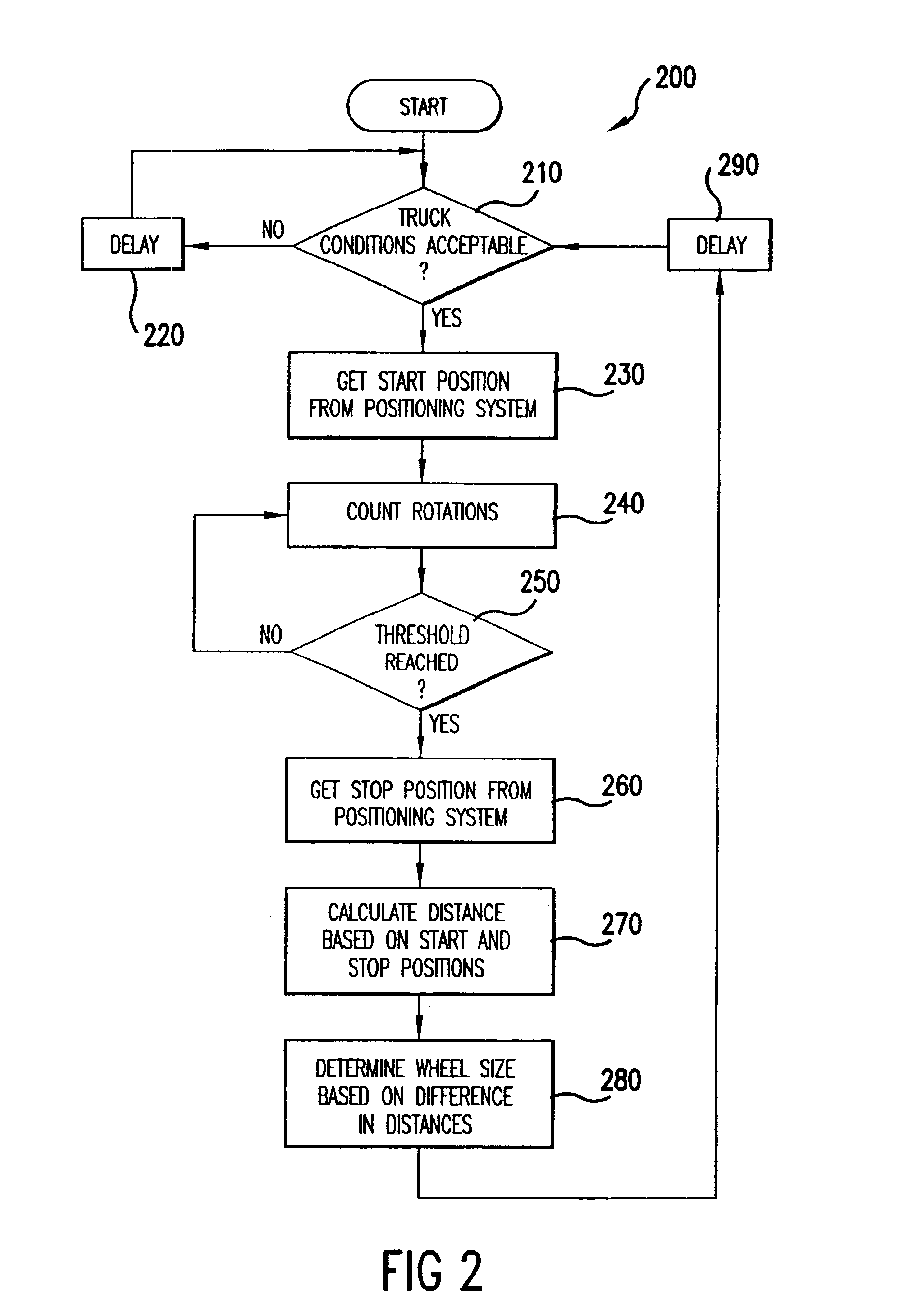

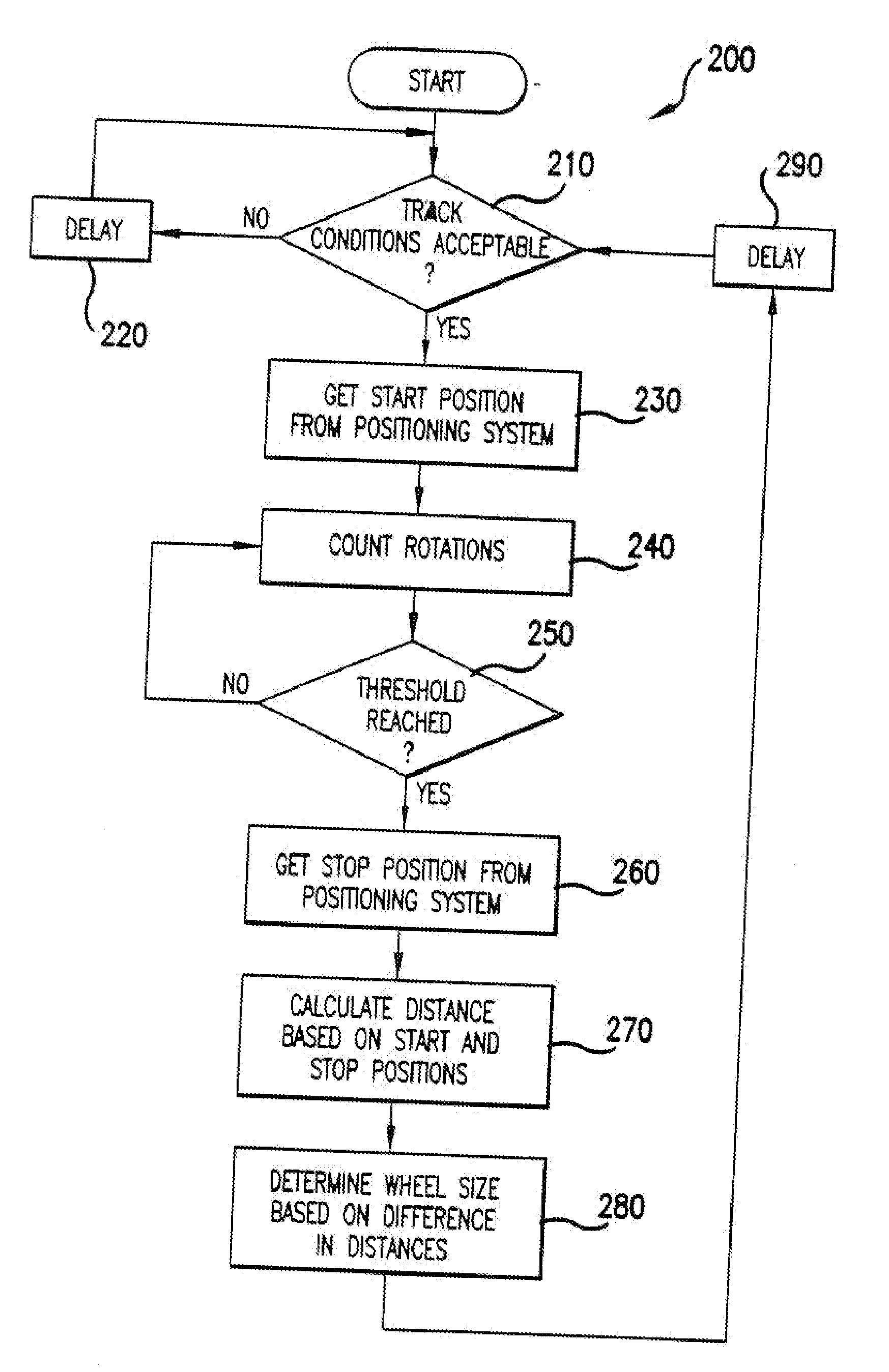

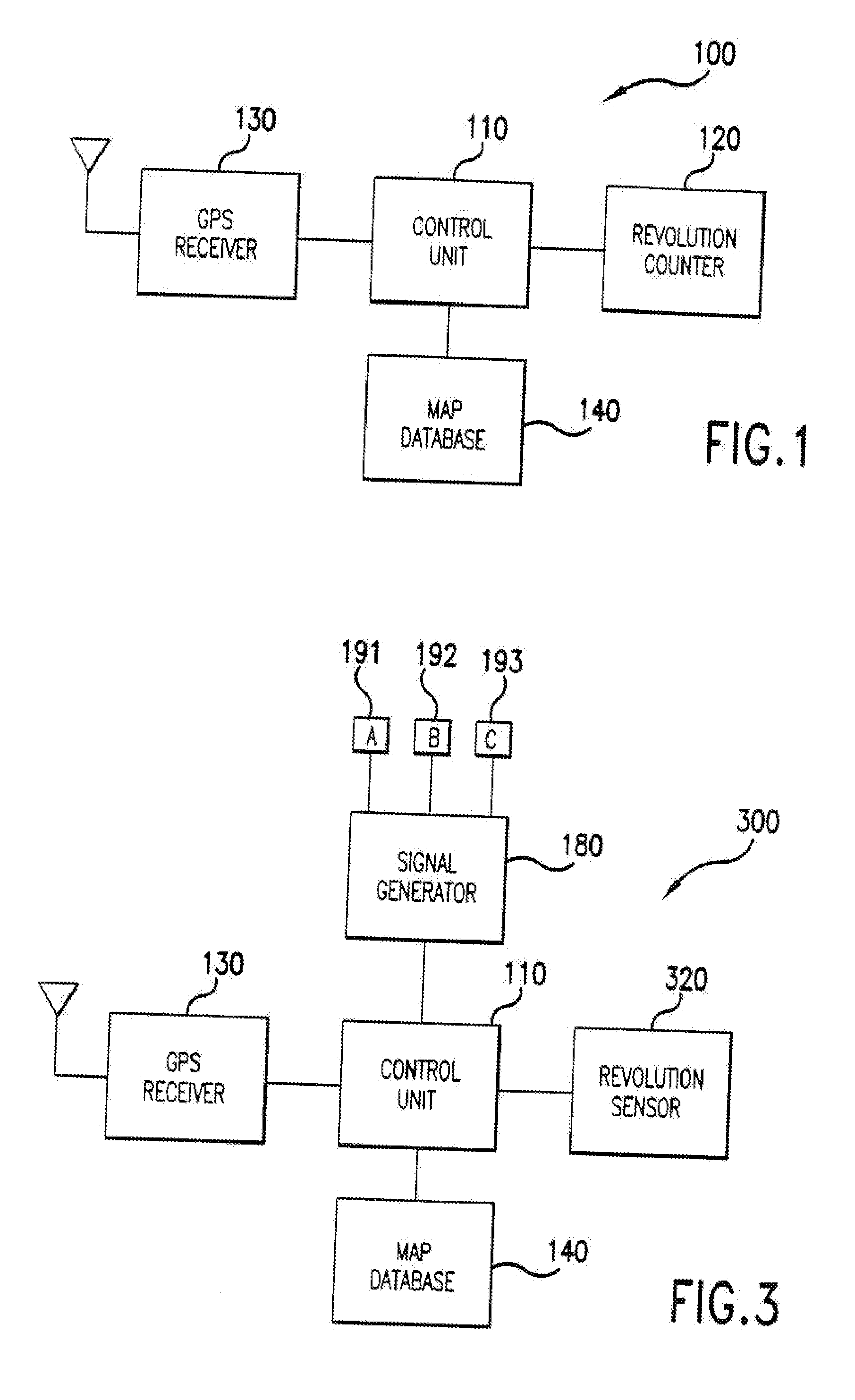

Method and system for compensating for wheel wear on a train

InactiveUS6970774B2Minimize known errorDigital data processing detailsDigital computer detailsEngineeringWheel wear

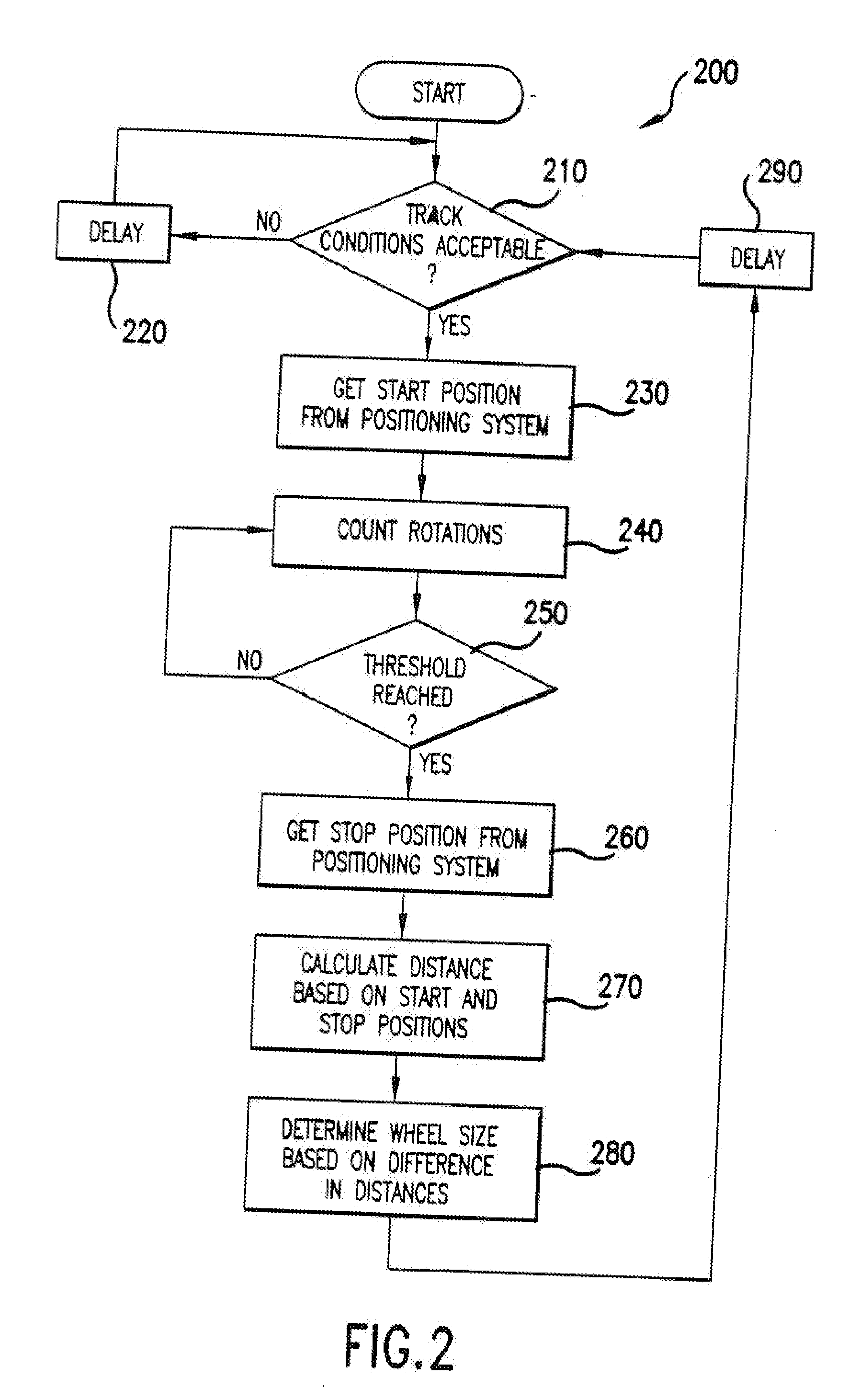

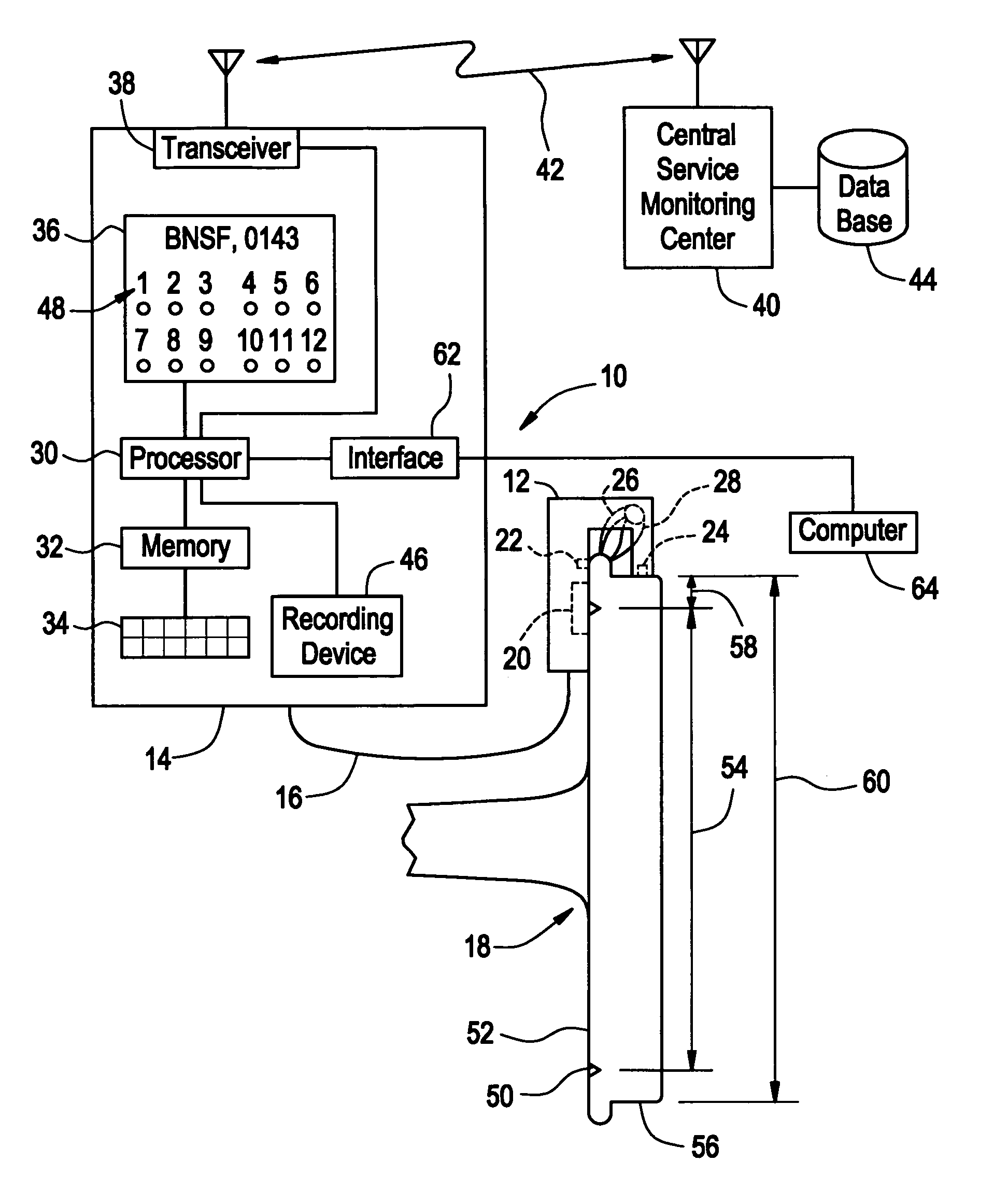

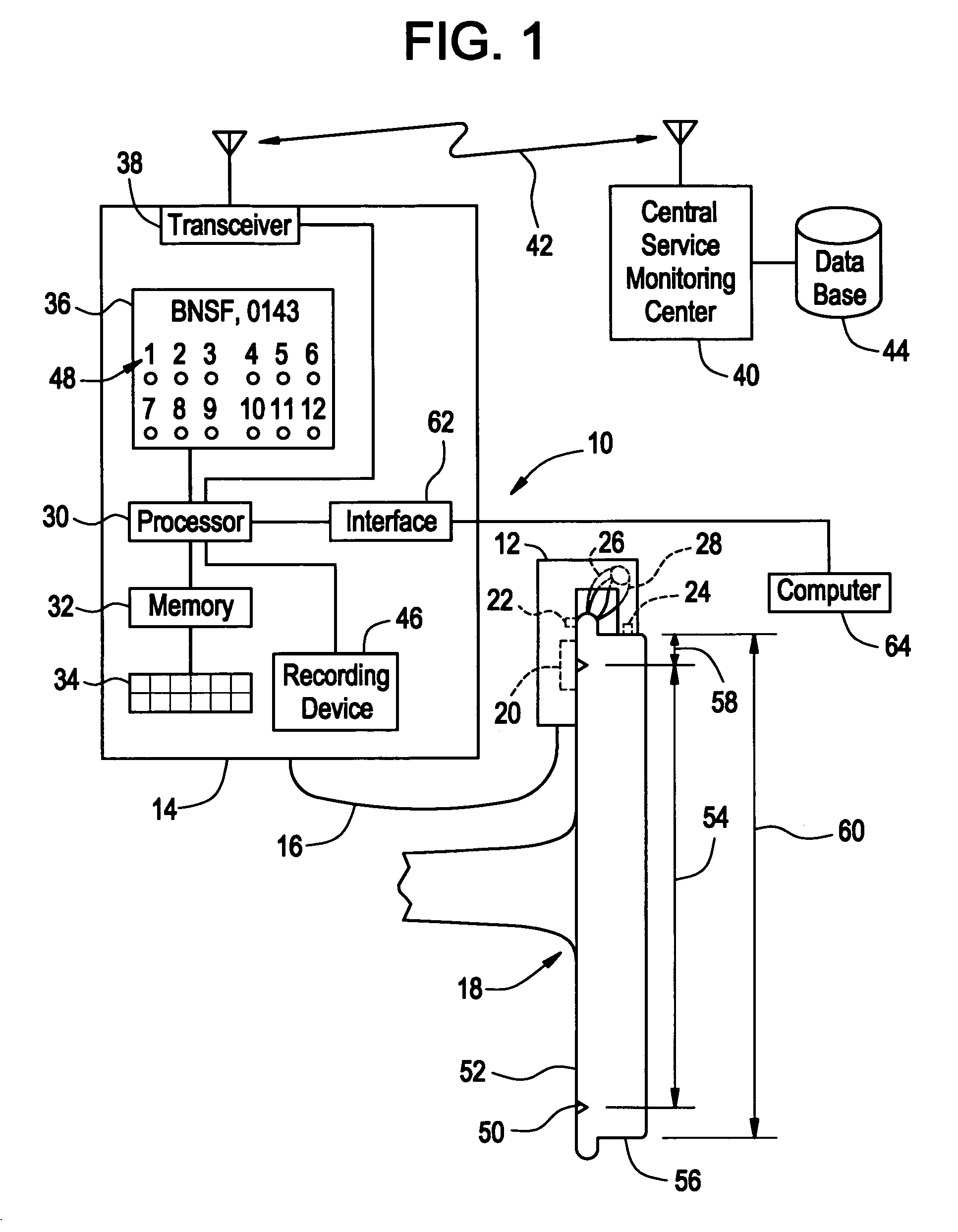

A method and system for compensating for wheel wear uses position and / or speed information from an independent positioning system to measure some distance over which the train has traveled. Wheel rotation information and / or distance and speed from a wheel sensor over the distance is also collected. The wheel rotation information and distance and / or speed information are then used to determine the size of the train wheels and / or a correction factor that can be used to correct the information from the wheel sensor for wheel wear. The method is performed periodically to correct for changes in wheel size over time due to wear so that the wheel rotation information can be used to determine train position and speed in the event of a positioning system failure.

Owner:SIEMENS MOBILITY INC

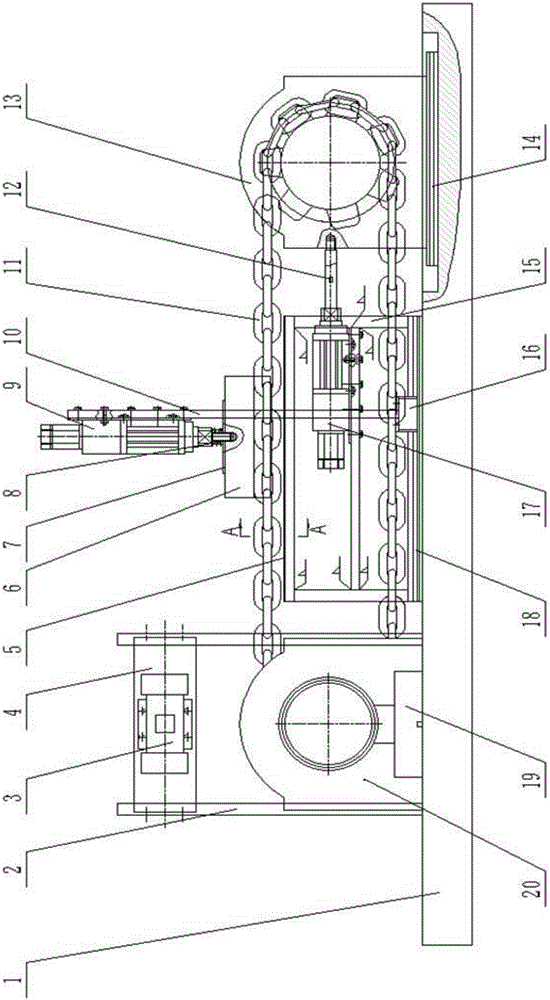

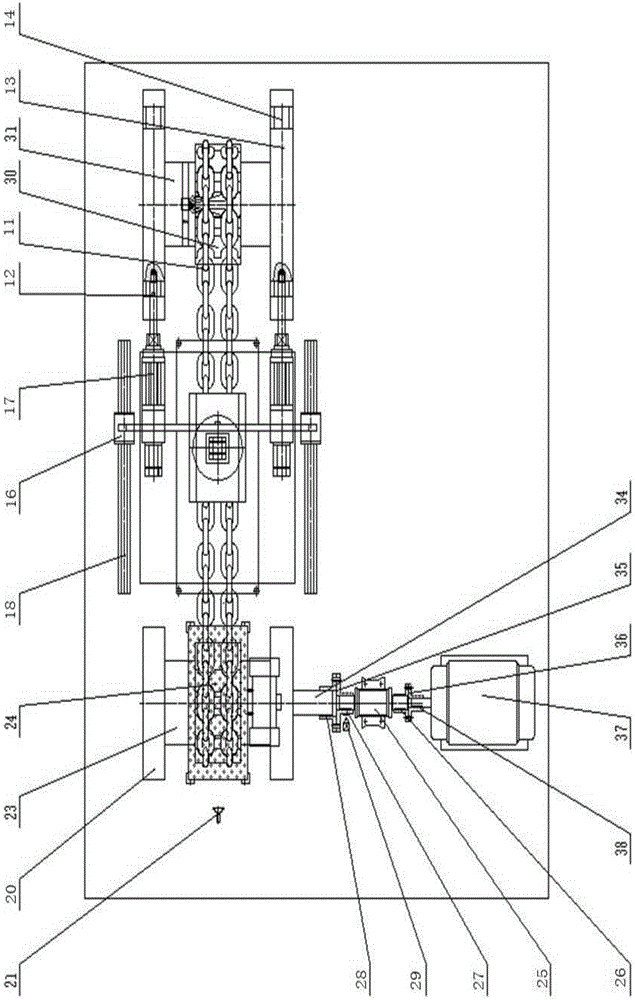

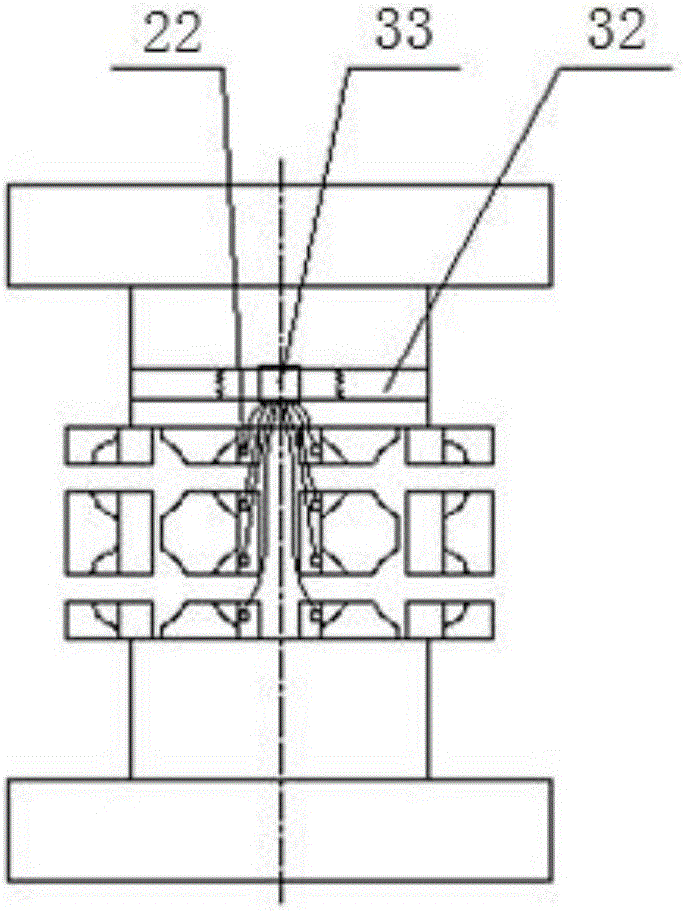

Friction fatigue monitoring device and method of heavy-loading scraper conveyer chain wheels under vibration impact

ActiveCN106404570AMonitor fatigue damageMonitor wearMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceFatigue damageLow speed

The invention discloses a friction fatigue monitoring device and a method of heavy-loading scraper conveyer chain wheels under vibration impact. The friction fatigue monitoring device comprises a base support, a driving system, a circular chain tensioning system, an impact loading system, a coal slime scattering system, and a monitoring system; the driving system comprises a low-speed servo motor, a first low-speed coupler used for connecting the low-speed servo motor with a torque sensor, a second low-speed coupler used for connecting the torque sensor with a transmission shaft, a roller A connected with the transmission shaft, driving chain wheels connected with the roller A, driven chain wheels connected with a roller B via key connection, a circular chain used for winding the driving chain wheels and the driven chain wheels; the circular chain tensioning system comprises a liner and a horizontal electric cylinder connected with a tail frame; the impact loading system comprises an impacting plate connected with a vertical electric cylinder; and the coal slime scattering system comprises a sieve and a vibration exciter. The friction fatigue monitoring device is capable of stimulating friction fatigue fracture of heavy-loading scraper conveyer chain wheels under vibration impact, and monitoring chain wheel fatigue damage and chain wheel wear situations.

Owner:CHINA UNIV OF MINING & TECH

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS9233696B2Reduce problemsReduce wearDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

Method and System for Compensating for Wheel Wear on a Train

InactiveUS20070095988A1Eliminate errorsMinimize known errorWheel-rims surveying/measuringRoute devices for controlling vehiclesEngineeringWheel wear

A method and system for compensating for wheel wear uses position and / or speed information from an independent positioning system to measure some distance over which the train has traveled. Wheel rotation information is also collected over the distance. The wheel rotation information and distance and / or speed information are then use to determine the size of the train wheels. The method is performed periodically to correct for changes in wheel size over time due to wear so that the wheel rotation information can be used to determine train position and speed in the event of a positioning system failure.

Owner:QUANTUM ENG

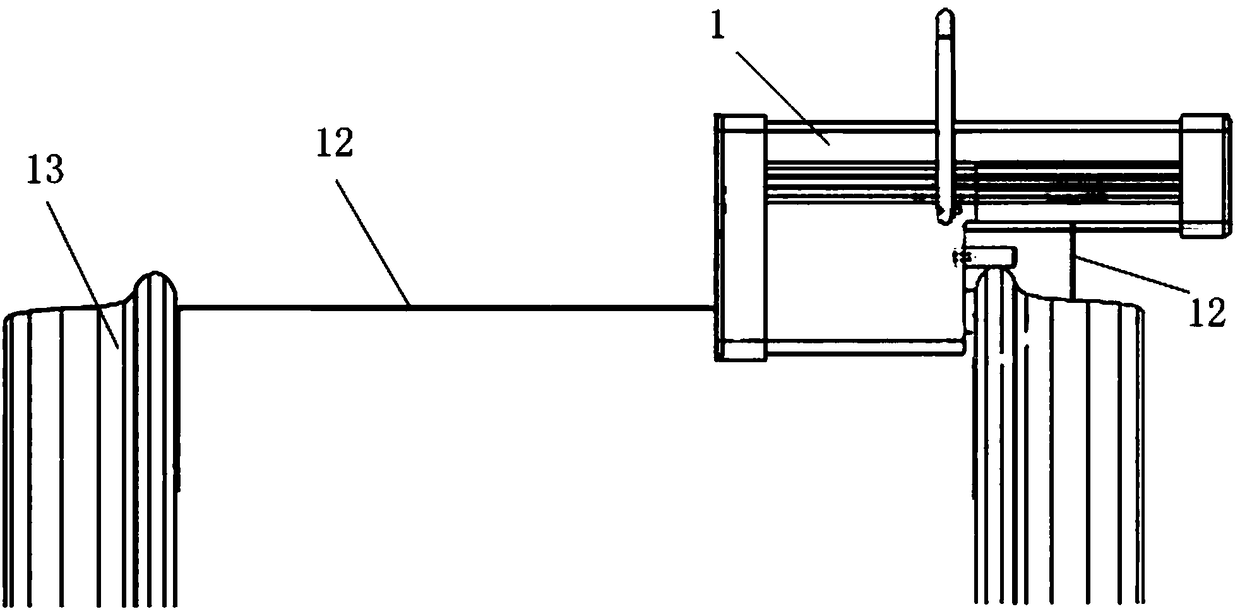

Rail wheel measurement

InactiveUS20070043486A1Wheel-rims surveying/measuringRegistering/indicating working of vehiclesWheel wearResidual service life

A method of determining a remaining service life for a rail wheel (18) of a railway vehicle using an electronic rail wheel (18) wear gauge (10) mountable on the rail wheel for measuring at least one rail wheel dimension. The method includes measuring a rail wheel dimension and processing the measured wheel dimension relative to an allowable wear dimension. The method also includes accessing a historical wheel wear rate database (44) relating to the rail wheel and predicting a remaining service life of the wheel based on the historical wheel wear rate data and the processed wheel dimension.

Owner:GENERAL ELECTRIC CO

Vapor rust protection type total synthesis ferrous metal grinding fluid

ActiveCN106590908AImprove the lubrication effectImprove cooling effectLubricant compositionWater vaporThermal deformation

The invention provides vapor rust protection type total synthesis ferrous metal grinding fluid. The vapor rust protection type total synthesis ferrous metal grinding fluid comprises, by weight, 5-20 parts of an antirust agent, 5-30 parts of a lubricating agent, 1-2 parts of a sterilizing agent, 0.1-2 parts of an antifoaming agents, 5-30 parts of a pH stabilizer, 1-20 parts of a vapor rust protection agent and 30-50 parts of water. The vapor rust protection type total synthesis ferrous metal grinding fluid is poisonless, harmless and free of pollution, has the effect of lubrication, cooling, washing and rust protection, has the high biological stability, can effectively prevent thermal deformation and grinding wheel wear of machined materials, improves the grinning quality and is extremely long in service life.

Owner:超滑科技(佛山)有限责任公司

Airplane turning limitation control method through differential braking

Disclosed is an airplane turning limitation control method through differential braking. The ground friction is utilized to the utmost extent, on the premise of guaranteeing the stable and safe airplane turning process, according to different turning requirements, the engine thrusting force and braking torque state parameters controlling the airplane turning most efficiently are provided to pilots correspondingly, the airplane turns in the highest turning speed, the airplane operating potential is played to the utmost extent, the front and main wheel wearing is reduced during turning, the engine oil consumption is low, and the airplane is prevented from skidding and tipping. Thus, the maximum friction coefficient of the wheels and runway is of the input amount, and the method has the advantages of high turning speed and stability, safety and efficiency of the turning process.

Owner:XIAN AVIATION BRAKE TECH

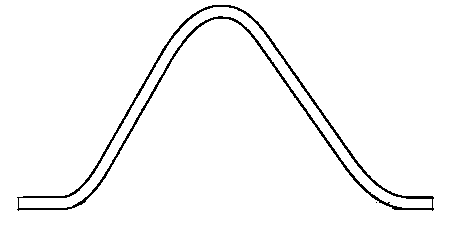

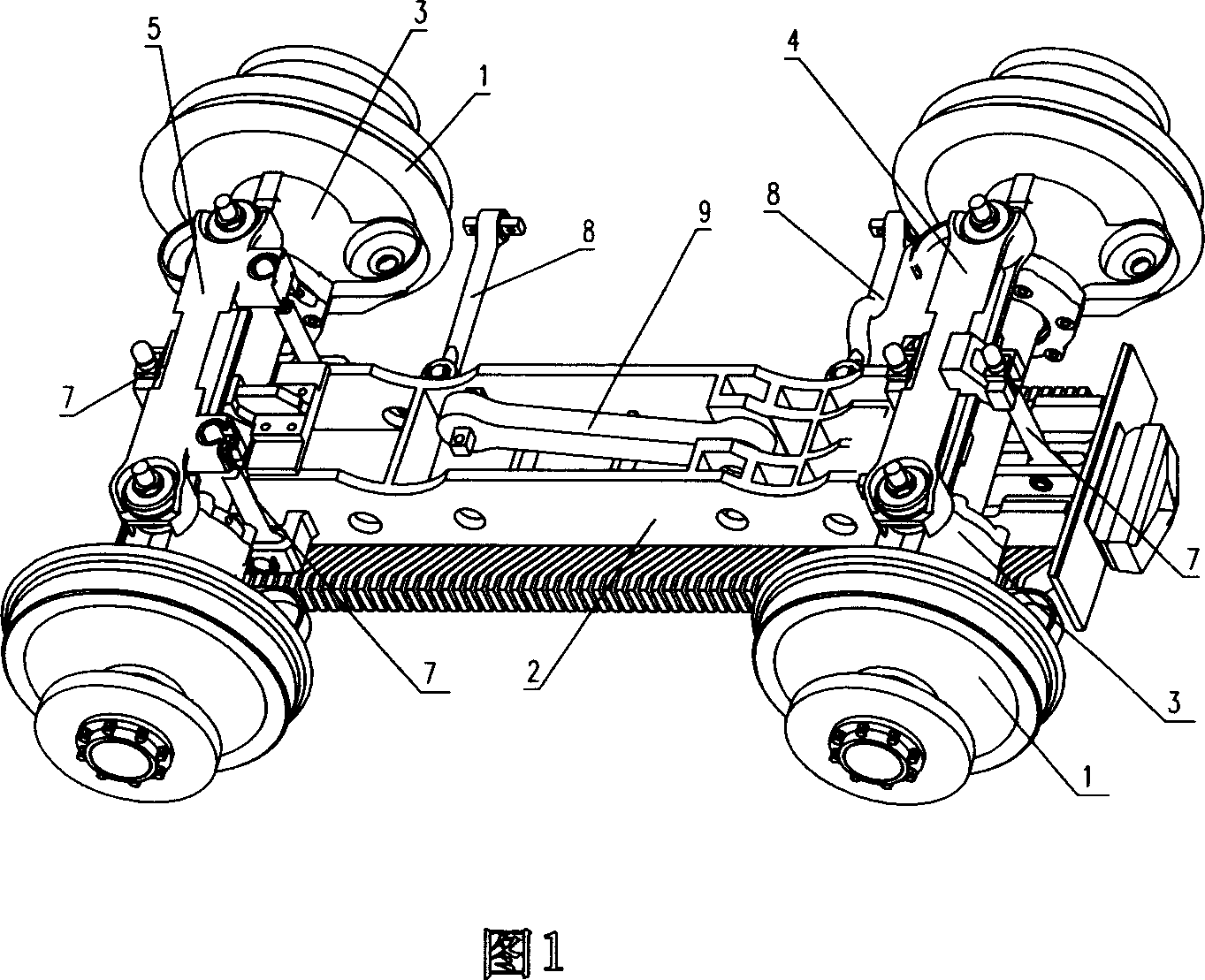

Optimal design method of low-wear high-speed train wheel profile

InactiveCN104036089AReduce lateral forceReduce touch pointsSpecial data processing applicationsTransverse forceEngineering

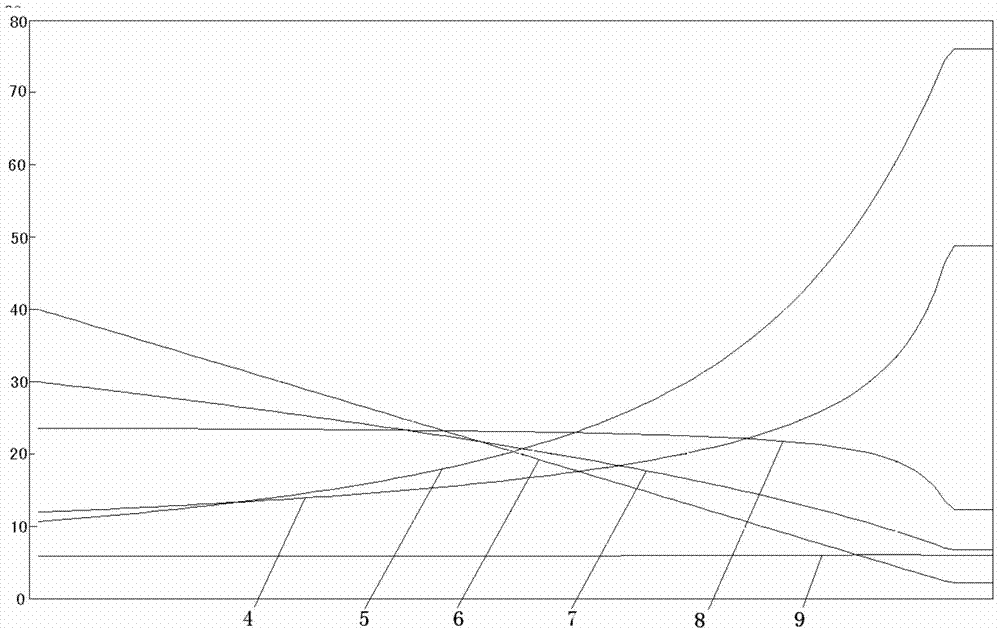

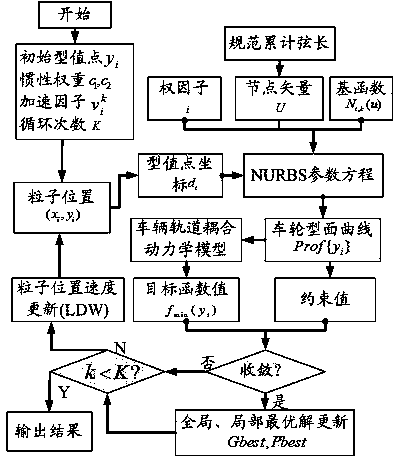

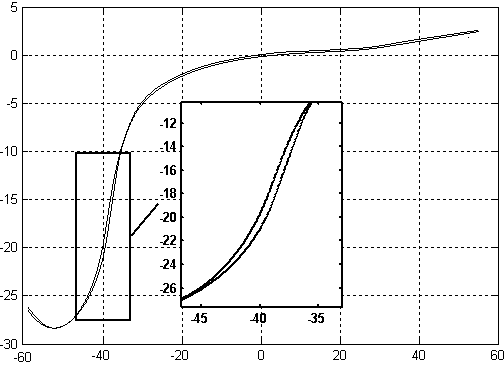

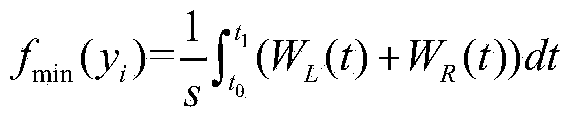

An optimal design method of a low-wear high-speed train wheel profile is characterized in that a curve of the high-speed train wheel profile is divided via equal arc length, N discrete coordinate points are used as data points, and a wheel profile curve is reconfigured; vertical coordinates of N data apexes are used as design variables, a circuit average for reducing wheel wear consumption and wheel track transverse force are used as target functions, wheel profile wear statistics and concavity and continuity of the profile curve are used as geometric constraints, a high-speed train wheel profile multi-target optimization model is established, and the model is subjected to multi-target optimizing calculation. Results show that contact points of a rim portion of the profile and the side of a track are significantly reduced, and line average of each single wheel for low wear consumption is 26.8% lower than that of the original standard profile; the wheel track transverse force of the wheel is reduced; root-mean-square values of the wheel track transverse forces of left and right wheels are decreased by 17.6% and 18.3% respectively; root-mean-square values of maximum contact stresses of the left and right wheels are decreased by 21.6% and 19.8% respectively; root-mean-square values of derailment coefficients of the left and right wheels are decreased by 9.5% and 6.2% respectively.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

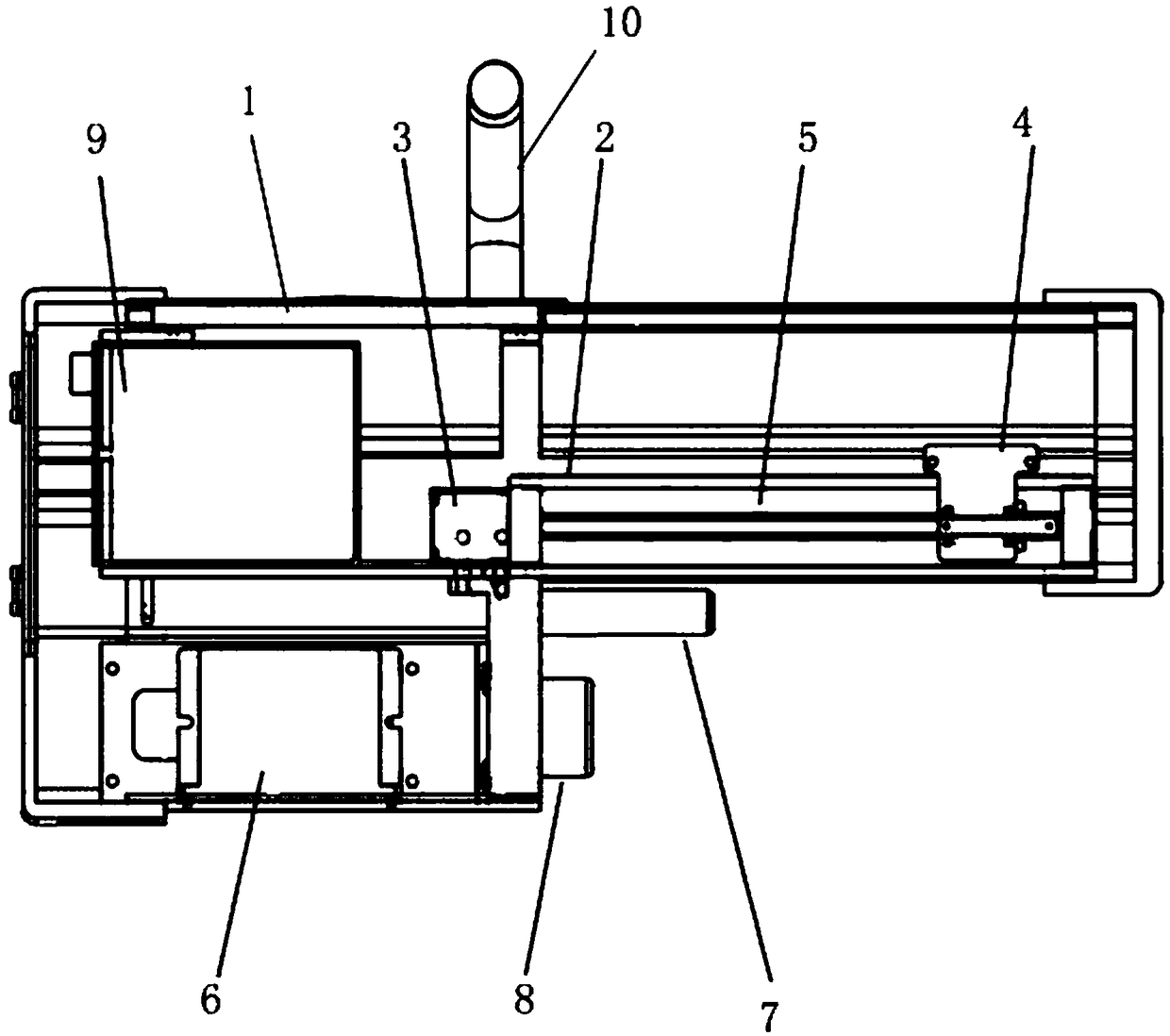

Rail vehicle wheel set size measuring instrument and method for determining optimal turning amount

PendingCN108303021AExtended service lifeMeet limit requirementsUsing optical meansMechanical measuring arrangementsContact highLaser ranging

The invention discloses a rail vehicle wheel set size measuring instrument which comprises a body, a module slide guide rail arranged at the front part of the body, a motor driver coaxially connectedto the module slide guide rail, a laser displacement sensor fixed to the module slide guide rail, a grating scale which is parallelly arranged on the module slide guide rail, a ranging sensor arrangedat the back part of the body, a positioning rod arranged at the lower part of the body, an electromagnet arranged at the lower part of the body, and a power supply which is arranged in the machine and supplies power to the measuring instrument. The measuring instrument of the invention is based on the principle of laser triangulation, and the non-contact high-precision measurement of parameters such as a wheel tread shape, a rim thickness, a rim height, a qR value, a wheel wear amount, a wheel diameter and a wheel set inner distance can be achieved. The present invention also provides a method of determining an optimal turning amount by using the measuring instrument.

Owner:中铁科学研究院有限公司

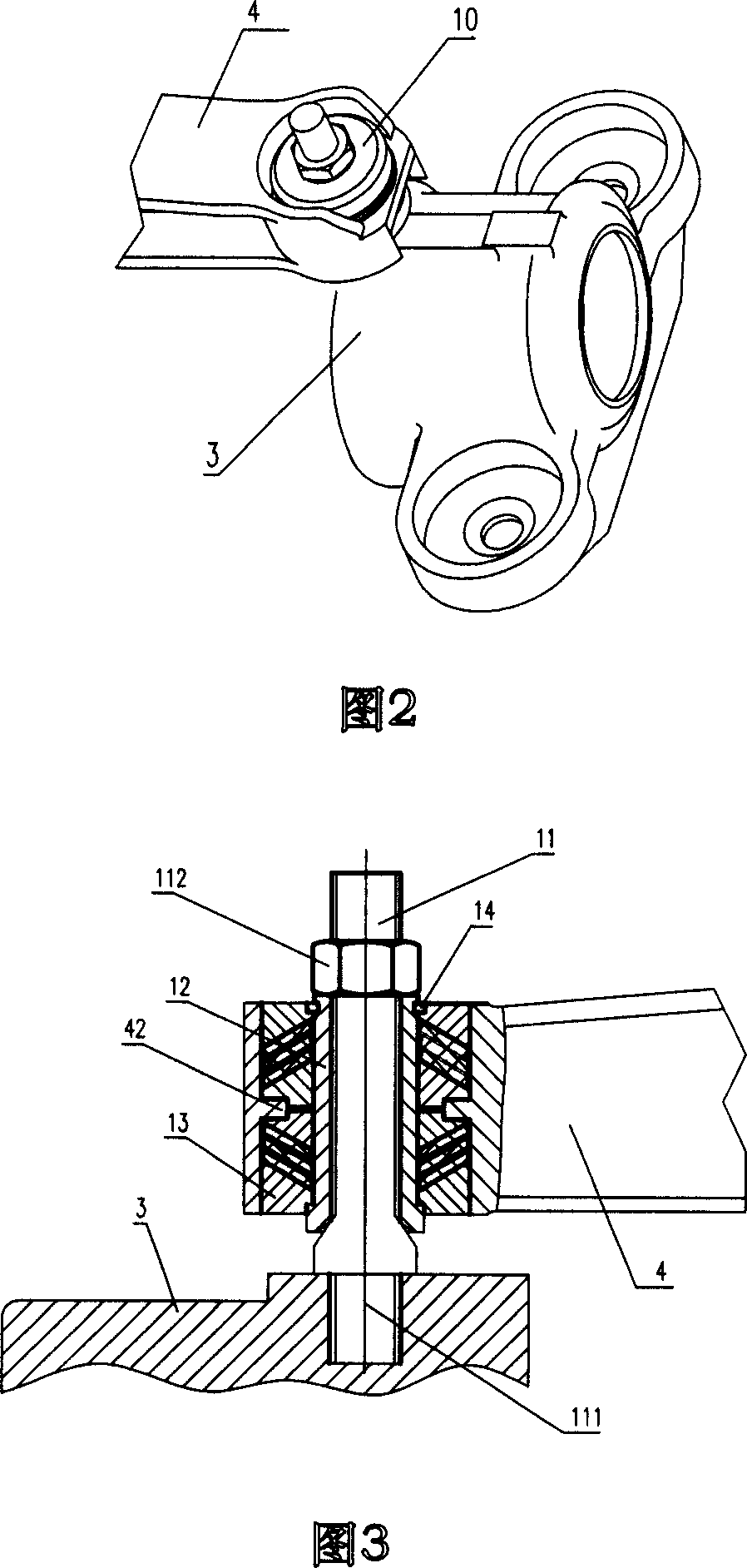

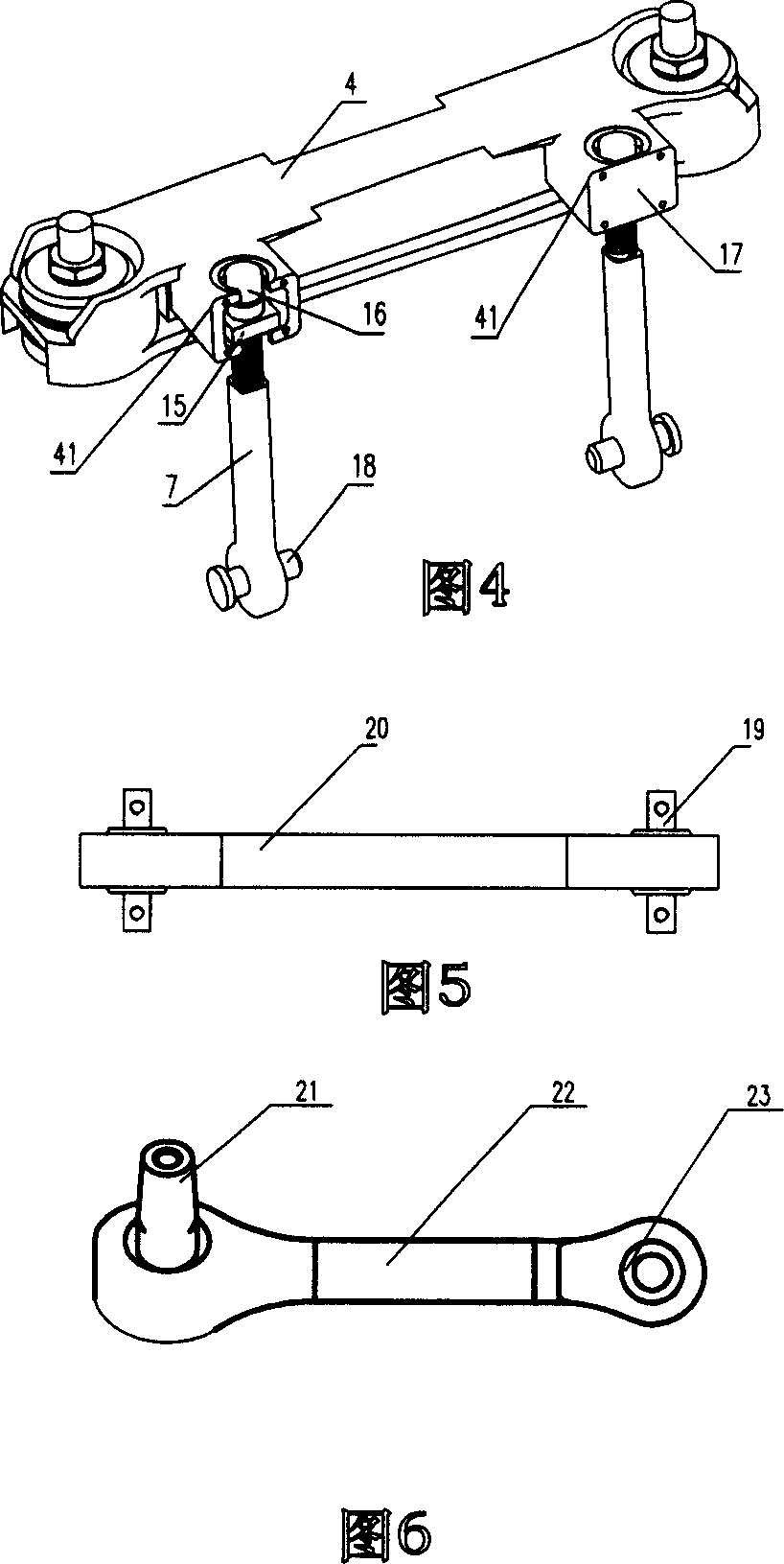

Tension rod type hanging and height adjusting mechanism

ActiveCN101117124AGuaranteed heightNot affected by elastic ups and downsElectric locomotivesAxle-boxes mountingBogieElectric machinery

The tie rod type hanging and height adjustment mechanism of the invention adopts a special separate type design in the vertical direction of the movement between a linear motor and a truck frame, and the tie rod type hanging and height adjustment mechanism is arranged at the joint between the linear motor and a supporting beam. An elastic connection between the supporting beam and the axle box of front and rear wheel pairs is adopted to provide the hanging elasticity of the linear motor and realize the bending and twisting of the truck within an allowable range. When height adjustment is required, the linear motor can be adjusted through the height adjustment mechanism to enable the clearance between the linear motor and a rail induction board to meet design requirements. That is to say, the linear motor can be adjusted to any required height within the wheel wear range. The invention not only realizes simple and stepless adjustment of the linear motor but also reduces the maintenance time of railway vehicles to the farthest degree. Additionally, the invention also ensures the tractive of the linear motor on the truck and the high-speed running of railway vehicles.

Owner:CRRC QINGDAO SIFANG CO LTD

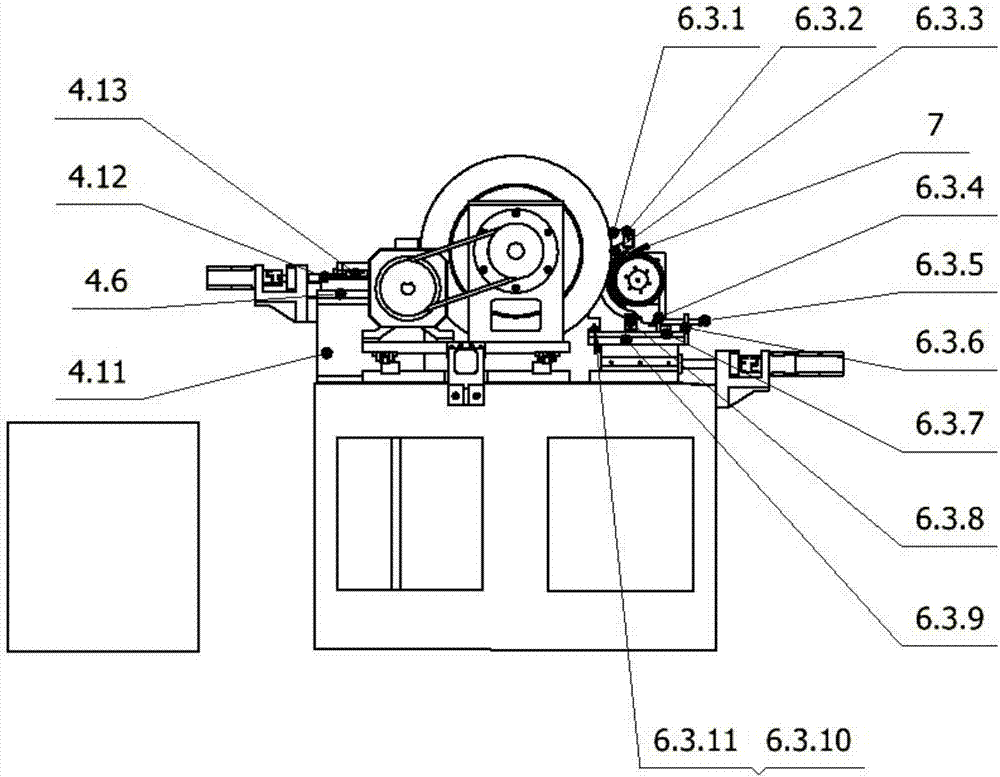

Method for utilizing self-made grinding machine to grind two end faces of aligning roller simultaneously

ActiveCN107363691AHigh precision of finished productImprove grinding qualityGrinding carriagesAbrasive surface conditioning devicesNumerical controlElectrical control

The invention provides a method for utilizing a self-made grinding machine to grind the two end faces of an aligning roller simultaneously. The self-made grinding machine comprises a lathe bed, a left grinding wheel device, a right grinding wheel device, a die rotary disc device, a grinding wheel dressing device and an electrical control box. The electrical control box implements control and enables the self-made grinding machine to achieve numerical control. The self-made grinding machine can grind the two end faces of the aligning roller simultaneously, abrasion to two grinding wheels is corrected by means of the grinding wheel dressing device assembled on the self-made grinding machine, and the self-made grinding machine is integrated and has multiple functions. By means of the self-made grinding machine, the condition of grinding the two end faces of the aligning roller simultaneously is improved, the self-made grinding machine operates stably, the deviation of the length of the finished product aligning roller is reduced, the finished product precision of the aligning roller is improved, the quality of grinding the two end faces of the aligning roller is improved, and the precision of the two end faces of the aligning roller obtained after grinding can be up to over the national standard level II through detection.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

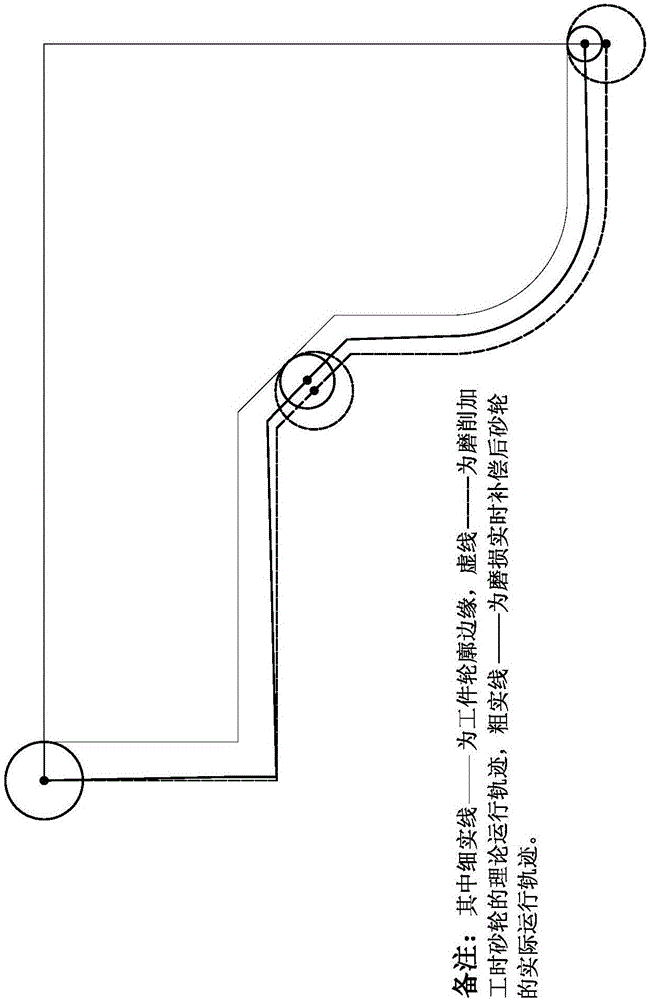

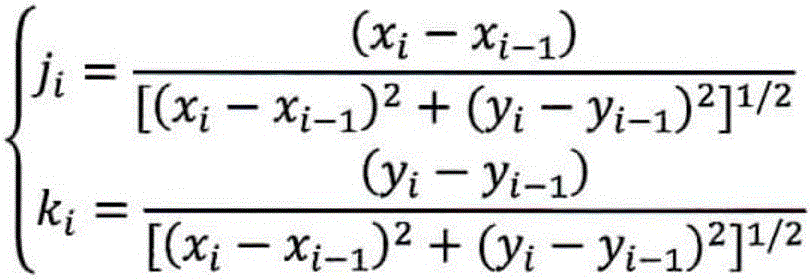

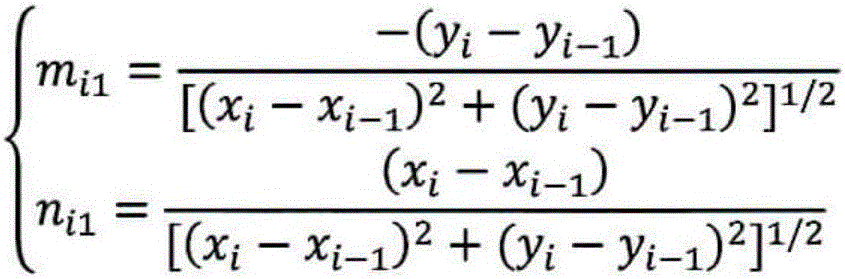

Grinding wheel wear real-time compensation method based on numerical control system

ActiveCN106707963ALow retrofit costImprove grinding efficiencyProgramme controlComputer controlElectric machineryWheel wear

The present invention discloses a grinding wheel wear real-time compensation method based on a numerical control system. The grinding wheel wear extent is calculated and updated in real time according to the changing of the current of a spindle motor, the second development interface, at an interpolator layer, of the numerical control system is employed to correct G-code theory operation track points according to the real-time updated grinding wheel wear extent so as to realize the real-time compensation of the grinding wheel wear, the correction of the current device mechanical structure is not needed, the corresponding secondary development of the numerical control system is needed to realize the real-time grinding wheel wear compensation, and the device improvement cost is low; because the parameters of a cutter and cutter compensation cannot be frequently corrected so as to greatly improve the grinding processing efficiency and improve the grinding processing precision and the consistency of the polishing effect; the grinding wheel wear real-time compensation method based on the numerical control system combines a matching automatic programming module to be applied to the grinding wheel wear real-time compensation function requirement of different industries and different technology requirements with wide application markets and especially applied to the face profile curve edging field of complex shapes of materials such as stones, ceramics and glass, etc.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG

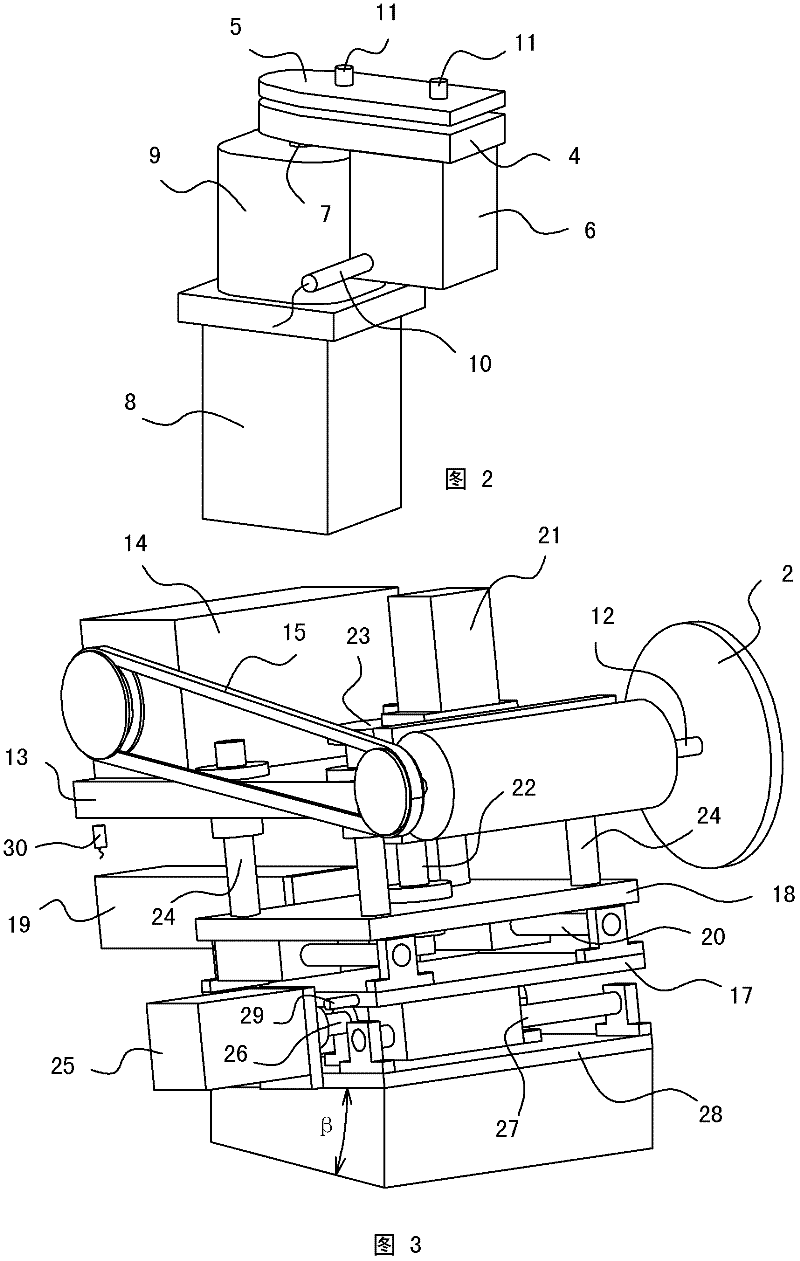

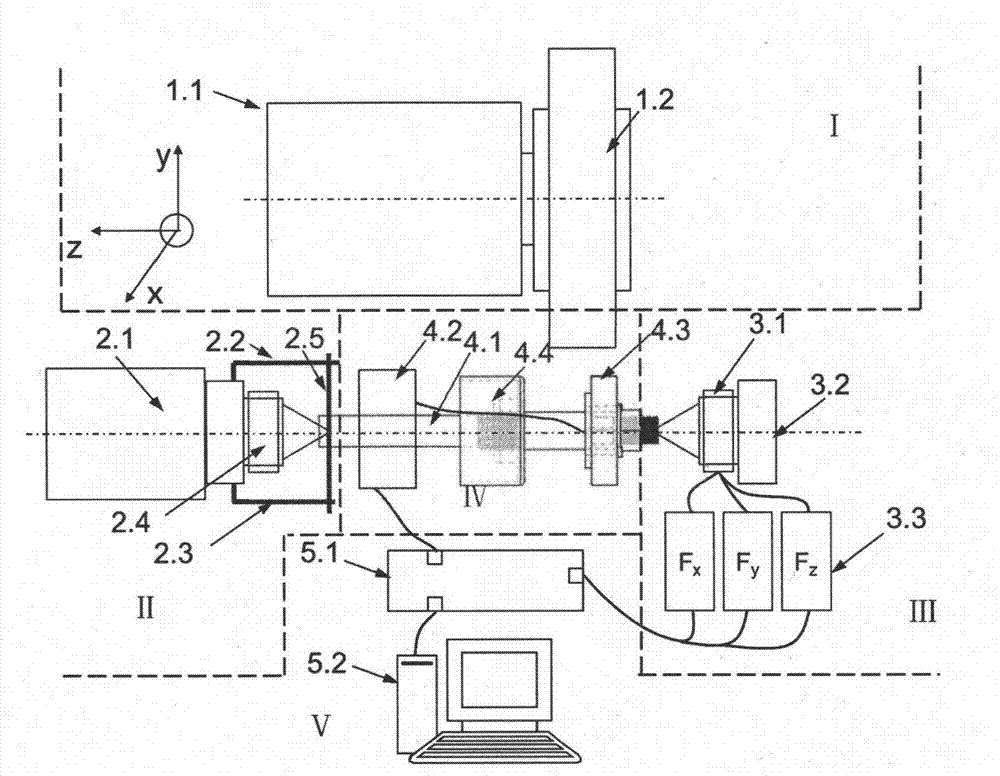

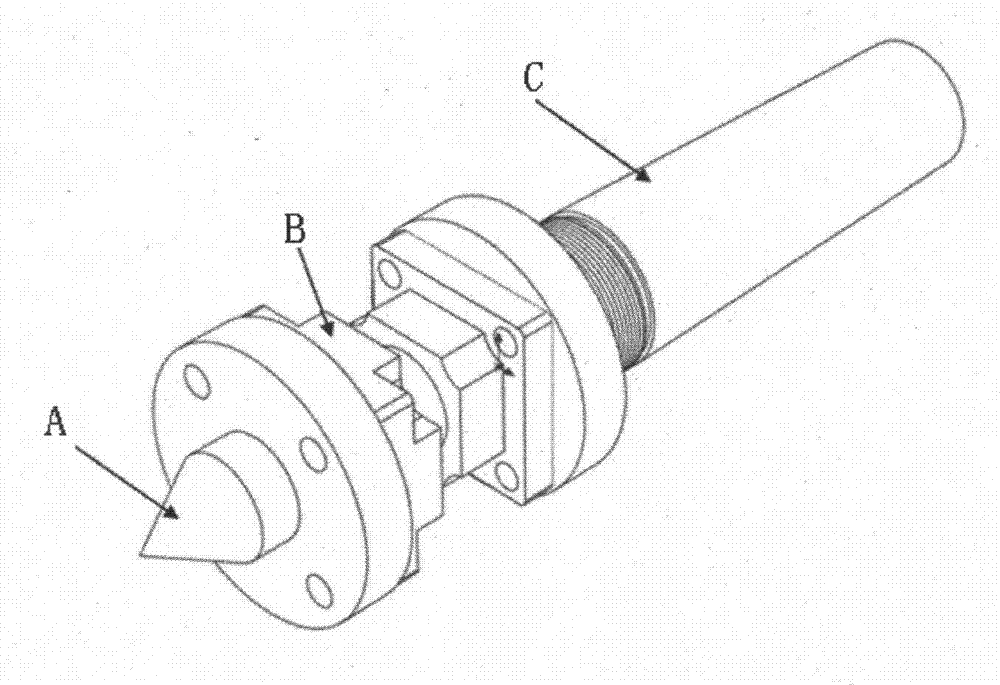

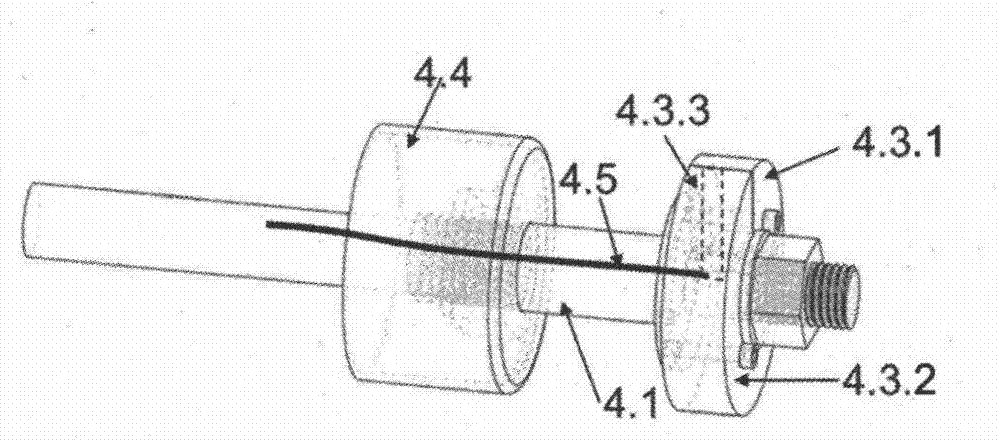

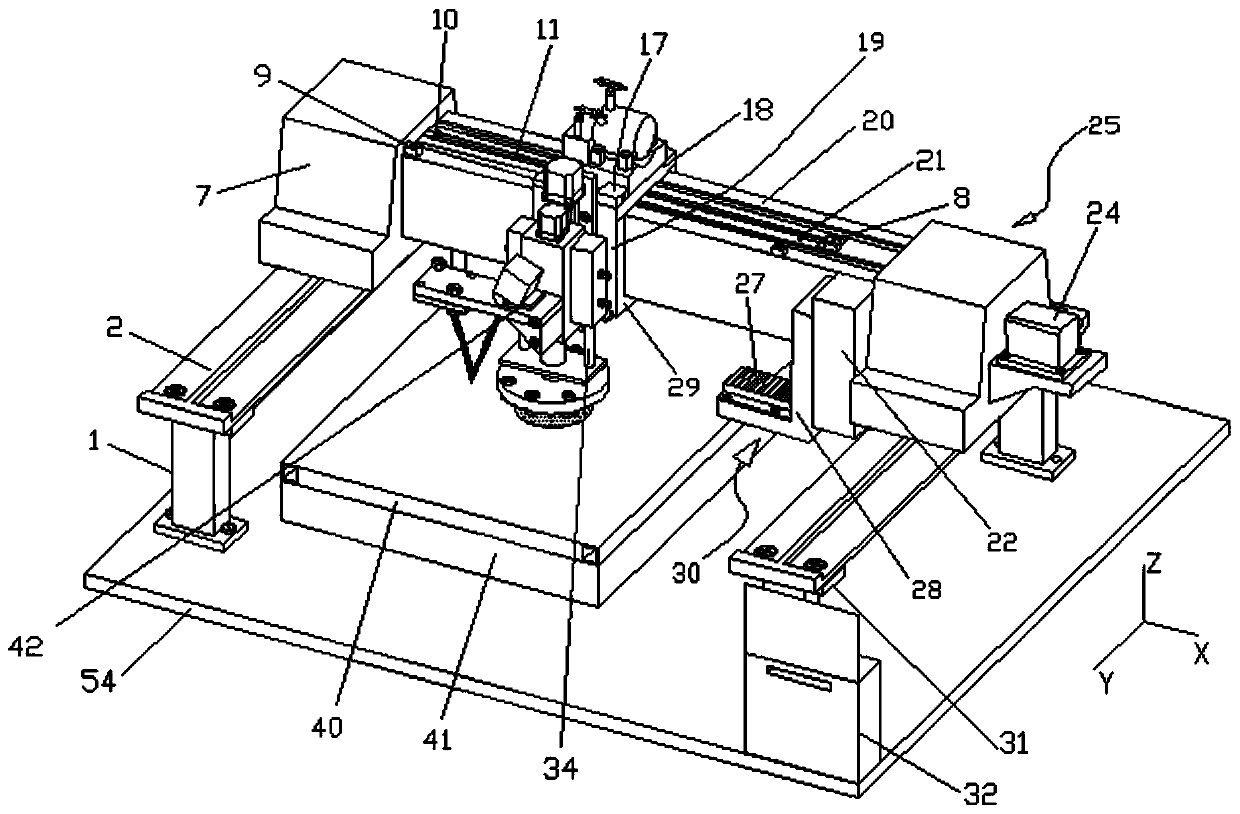

Device and method for analysis and test of high-speed grinding characteristic of rotary part

InactiveCN102928337ASimple structureRealize measurementUsing mechanical meansMaterial analysisMeasurement deviceHeat flux

The invention relates to a device and method for analysis and test of a high-speed grinding characteristic of a rotary part. The device mainly comprises a high-speed grinding wheel spindle system, a workpiece spindle system, a force measurement device for testing cylindrical grinding force, a cylindrical grinding workpiece and a temperature test device of the cylindrical grinding workpiece, and the device is used for analyzing and researching grinding force, grinding heat, a computing method of a coupling effect and a software system. Simultaneously, the grinding force and the grinding heat in a high-speed grinding process of the rotary part are collected so as to discriminate effect of mechanical energy and heat energy in the high-speed grinding process on workpiece surface quality and grinding wheel wear mechanism, and testing accuracy and efficiency of the grinding force of the rotary part are improved greatly. By means of a reverse heat flux calculation method and an algorithm, heat flux entering the workpiece, the grinding wheel and the like is obtained, effect of a high-speed grinding process on the workpiece surface quality and the grinding wheel wear mechanism is disclosed, grinding process parameters and the like are optimized further, high-speed grinding characteristics of different workpiece materials can be disclosed, and further optimization design of the high-speed grinding process and main configuration of the process is performed.

Owner:DONGHUA UNIV

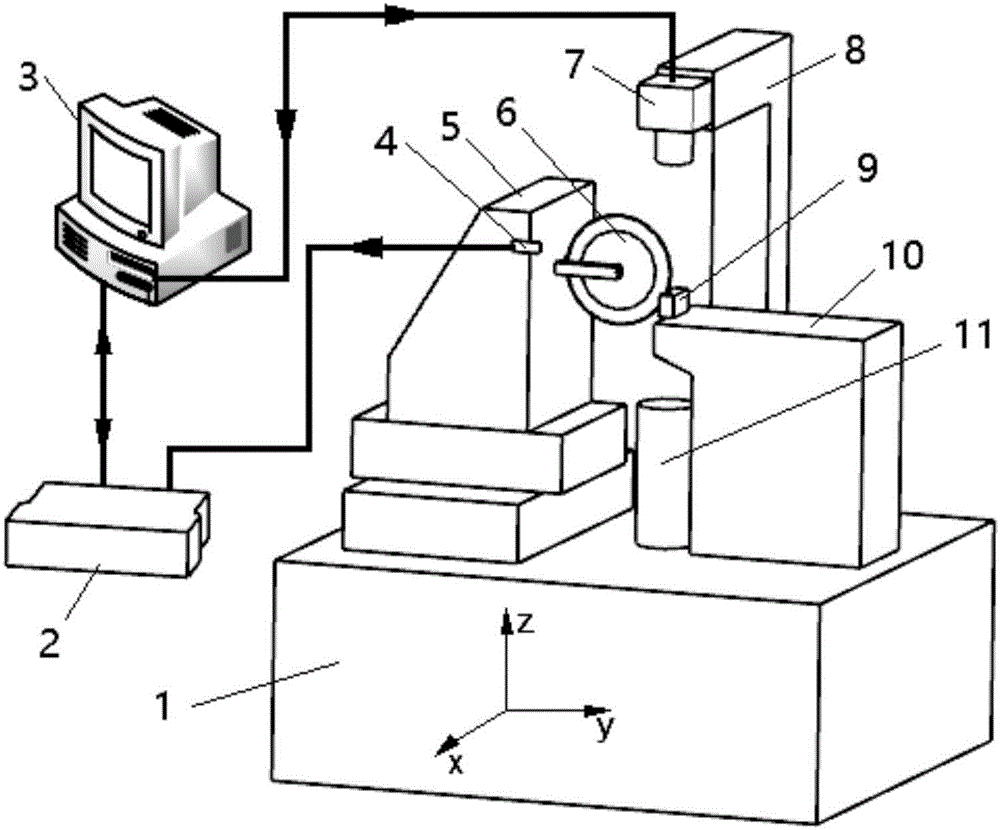

Complex profile curve grinding error in-situ detection device and method

ActiveCN106239368AImprove machining accuracyComprehensive detectionGrinding feed controlGeometric errorMotion controller

The invention discloses a complex profile curve grinding error in-situ detection device and method. The detection device includes a motion controller, a computer, a position measurement member, a slide table assembly, a tool nose arc grinding wheel, and an image acquisition member. The detection method includes: calculating a machining error and determining reasons for the error according to different relative positions among a tool nose arc center theoretical position of the front end of the tool nose arc grinding wheel, a work piece theoretical machining point position and a work piece actual profile; and adopting different method to further determine the direction and the size of the error according to different reasons for the errors if the machining error exceeds an error limit. The detection device can detect the size and the directions of multiple errors such as grinding wheel abrasion, machine tool geometric errors, machine tool thermal errors during a curve grinding machining process, is comprehensive in detection, is high in precision, and can provide a basis for later error compensation so as to improve the machining precision of curve grinding.

Owner:SHANGHAI JIAO TONG UNIV

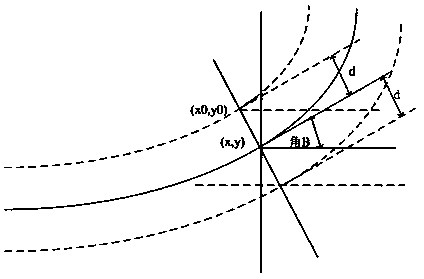

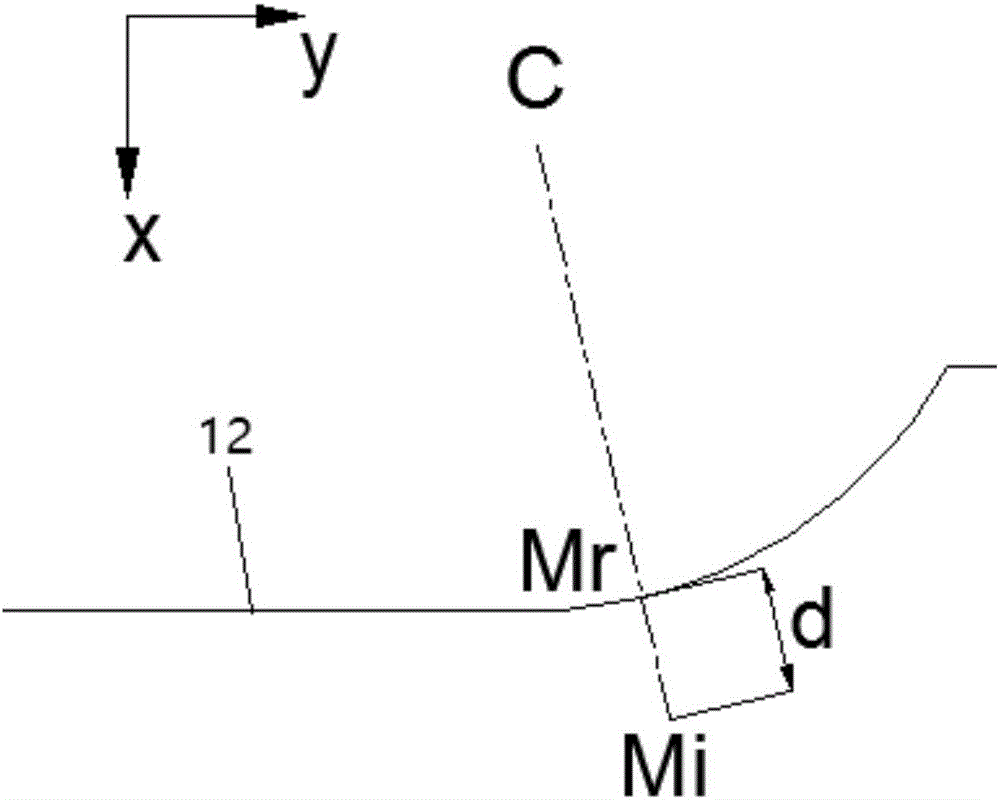

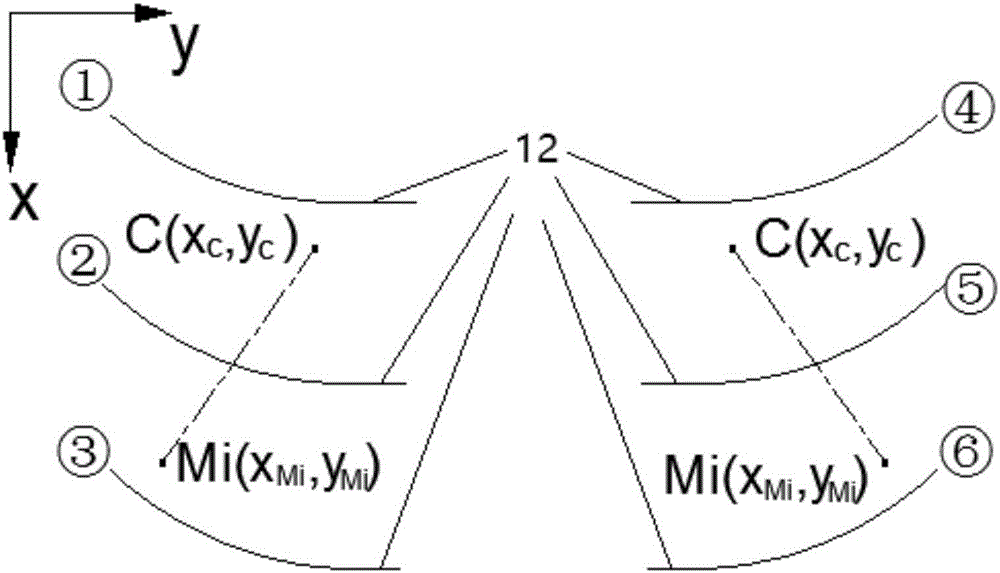

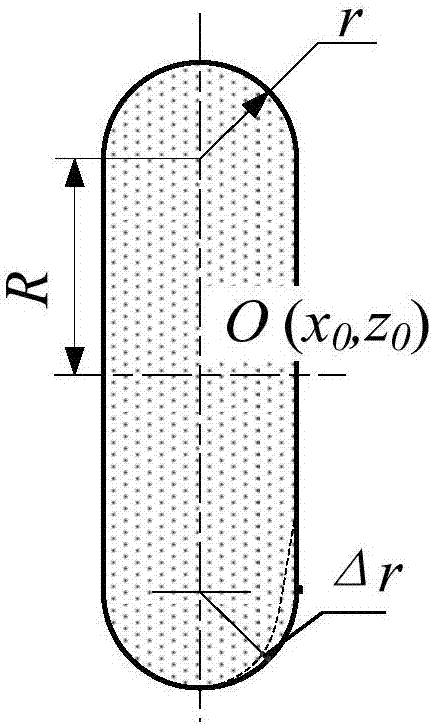

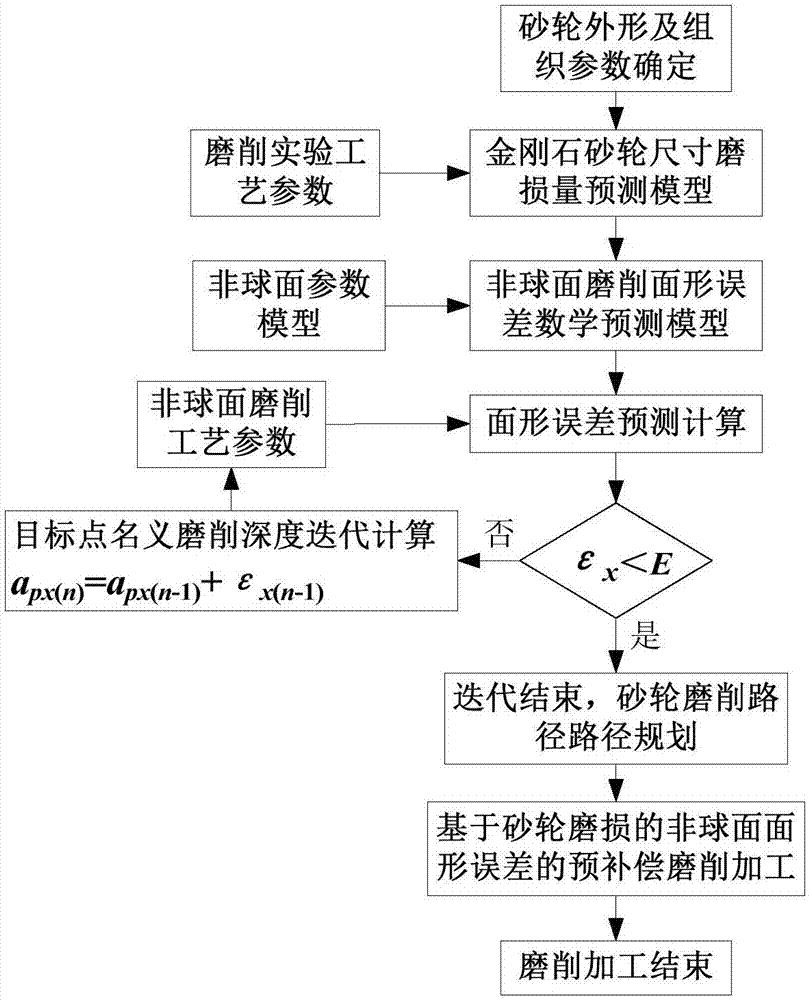

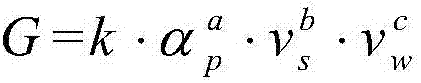

Large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction

ActiveCN107378687AExtended service lifeHigh precisionOptical surface grinding machinesTarget surfaceNumerical control

The invention relates to a large-caliber reflection mirror iterative precompensation grinding method, in particular to a large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction. In order to solve the problems that in the prior art, under the fixed nominal grinding depth, the target surface figure accuracy is achieved through repeated replacement of a grinding wheel for repeated grinding, consequently, the grinding wheel losses are serious, the surface figure accuracy is poor, and wear efficiency is low, the method comprises the steps of building a predication model of the grinding wheel grinding ratio G about the grinding parameter, secondly, building a radial size wear amount predication model at the grinding wheel wear point in the grinding process, thirdly, building a non-spherical-face surface-shape error predication model, fourthly, through the iterative precompensation method, calculating wear surface-shaped error values of all points on a non-spherical-face generatrix until the requirements are met and fifthly, recording nominal grinding depth final predication values of all contact points in the iterative process, and carrying out numerical control grinding machining programming and subsequent machining. The method is used for the technical field of grinding machining of an optical non-spherical-face reflection mirror.

Owner:HARBIN UNIV OF SCI & TECH

Method and device for detecting and dressing quality of end face grinding wheel in real time

ActiveCN110587402AWear monitoringImprove work efficiency and processing qualityGrinding drivesGrinding feed controlWheel wearLimit value

The invention discloses a method and device for detecting and dressing quality of an end face grinding wheel in real time. The device comprises a laser, a receiver, a grinding wheel dresser, the grinding wheel, a grinding wheel seat, a displacement sensor and a three-dimensional driving mechanism. According to the device, a laser beam emitted by the laser is obliquely emitted to the ground surfaceof a workpiece, the receiver continuously receives the reflected laser beam reflected by the ground surface, and the abrasion degree of the grinding wheel is detected in real time by detecting the energy of the reflected laser beam; when the energy of the laser beam reflected by the receiver reaches the corresponding grinding wheel wear limit value, the grinding wheel is triggered to stop grinding, the current grinding position of the grinding wheel is recorded through the displacement sensor, and the grinding wheel is moved to the position of the grinding wheel dresser by a grinding wheel driving mechanism and is dressed in real time; and the dressed grinding wheel returns to the current grinding position, and the grinding stroke of the surface of the workpiece continues. The on-line detection and dressing of the grinding wheel can be quickly and efficiently realized, and the processing quality and the grinding efficiency of end face grinding are improved.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com