Rail vehicle wheel set size measuring instrument and method for determining optimal turning amount

A rail vehicle and measuring instrument technology, applied to measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of high maintenance cost, large impact, and fast wheel scrapping, so as to save the amount of repairing, prolong the service life, and achieve high maintenance efficiency. Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

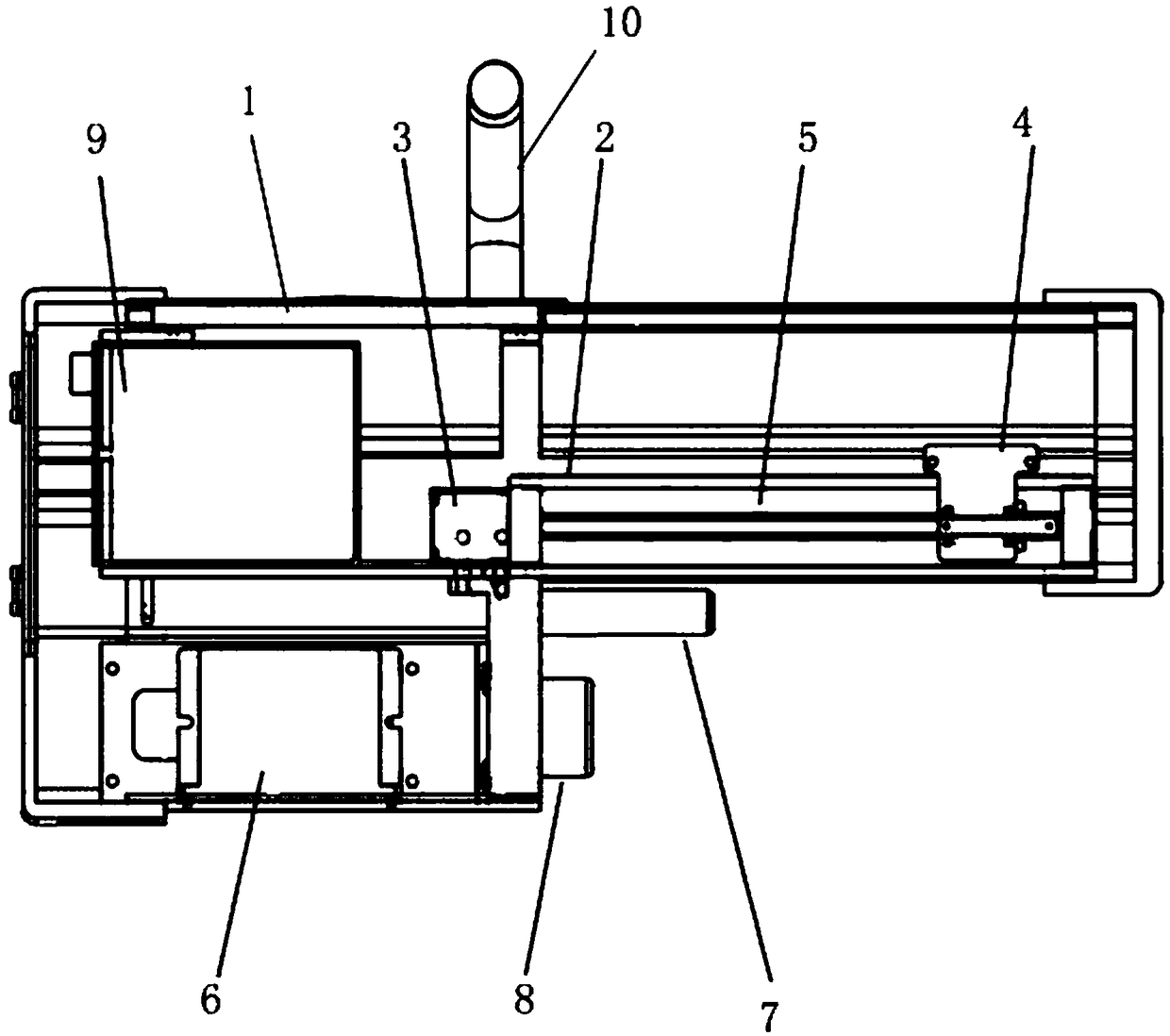

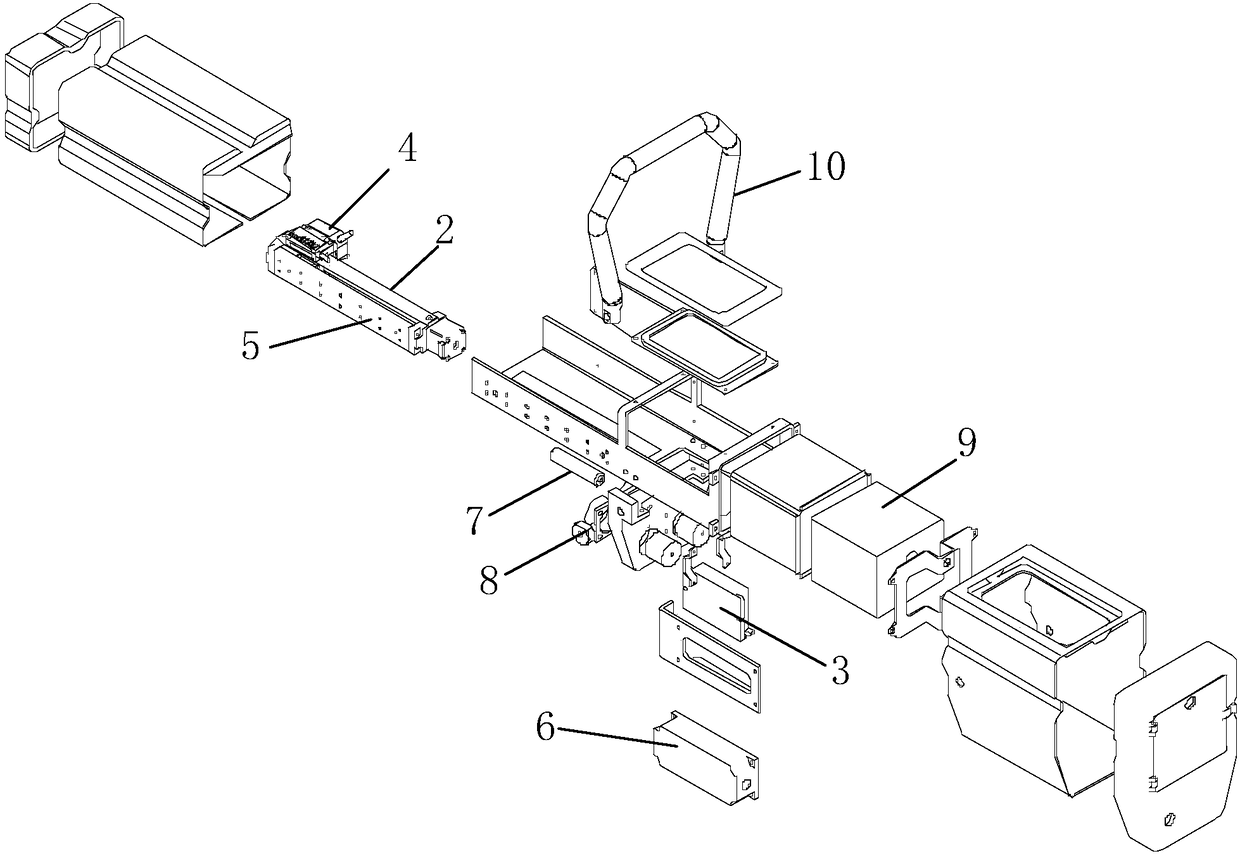

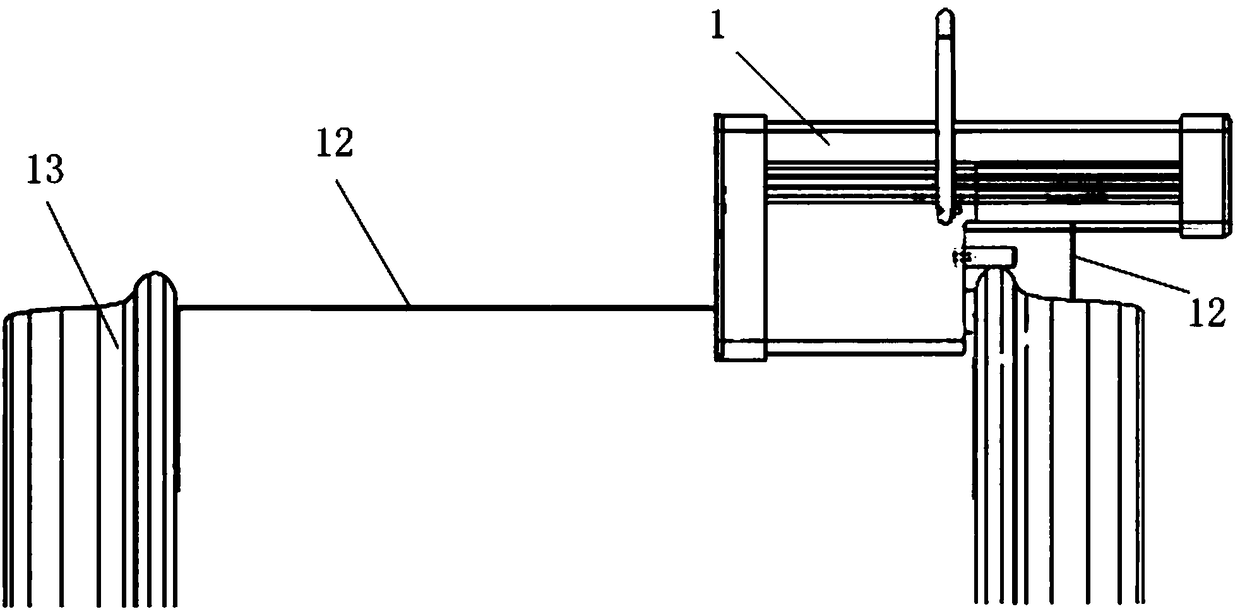

[0035] Such as Figure 1~3 As shown, a rail vehicle wheel set size measuring instrument includes a body 1, the body 1 is a conventional structure, and the specific structure is as follows figure 2 As shown in the exploded view, the module sliding table guide rail 2 arranged at the front of the body 1 is coaxially connected with the module sliding table guide rail 2 and drives the motor driver 3 of the module sliding table guide rail 2 to move horizontally. The laser displacement sensor 4, which is on the sliding table of the module sliding table guide rail 2 and moves with the horizontal movement of the sliding table, and is used to obtain the characteristic parameters of the wheel tread shape, is arranged in parallel on the module sliding table guide rail 2, and used The grating ruler 5 for measuring the horizontal movement displacement of the laser displacement sensor 4 is arranged at the rear of the body 1 and used for measuring the inner distance of the wheel set. The las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com