Vapor rust protection type total synthesis ferrous metal grinding fluid

A technology for ferrous metals and grinding fluids, applied in lubricating compositions, petroleum industry, etc., can solve problems such as no obvious effect, achieve high biological stability, excellent water vapor rust resistance, and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

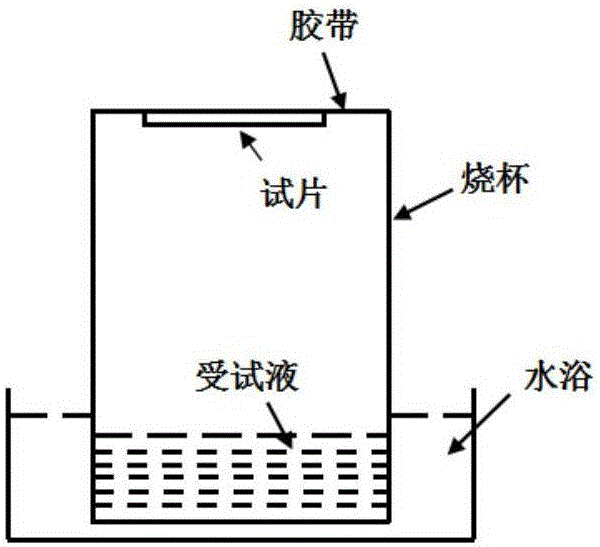

Method used

Image

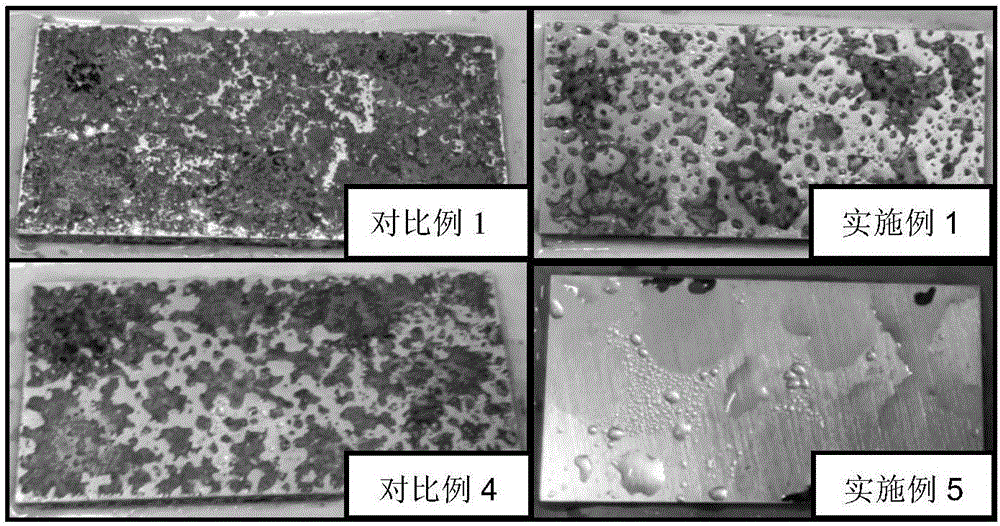

Examples

Embodiment 1

[0035] Preparation of high alkali value water-based fully synthetic metal grinding fluid: put 20g of deionized water into the reactor, add 8g of organic dibasic acid, 5g of benzoic acid, 24g of triethanolamine and 11g of n-propanolamine, stir and heat up to 50°C, react until a transparent and clear solution is formed; remove the heat source, add 5g trans polyether, 4g glycerin, and continue to stir until the solution is uniform; after the solution is cooled to room temperature, add 20.5g deionized water and 2g triazines to sterilize Adding agent and 0.5g of polysiloxane were mixed, and the stirring was continued until the system was clear to obtain the concentrated stock solution of grinding fluid, which was diluted with deionized water to a working solution with a concentration of 5% and a pH value of 9.4.

Embodiment 2

[0037] Preparation of high alkali value fully synthetic metal grinding fluid containing water vapor rust inhibitor reactant: put 20g deionized water into the reaction kettle, add 8g organic dibasic acid, 5g benzoic acid, 24g triethanolamine and 11g n-propanol Amine, stir and heat up to 50°C, react until a transparent and clear solution is formed; remove the heat source, add 5g trans polyether, 4g glycerin, continue stirring until the solution is uniform; after the solution is cooled to room temperature, add 17.5g deionized water , 1.4g triazine carboxylic acid compound, 0.9g ethanolamine and 0.7g n-octanoic acid, 2g triazine fungicide and 0.5g polysiloxane are mixed, continue to stir until the system is clarified, and the concentrated stock solution of the grinding fluid is obtained, and the Deionized water was diluted to a working solution with a concentration of 5% and a pH value of 9.4.

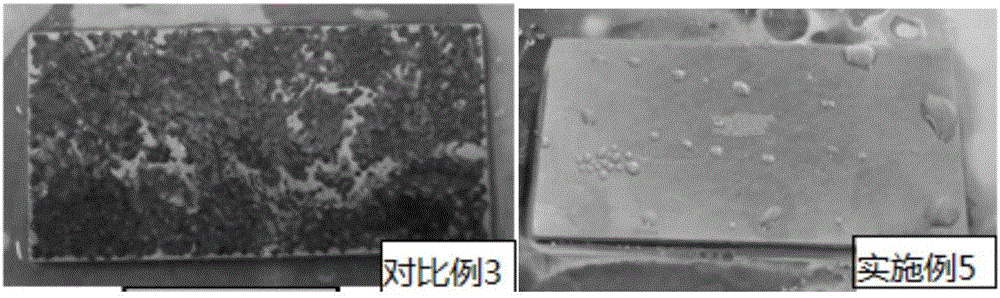

Embodiment 3

[0039] Preparation of neutral fully synthetic metal grinding fluid containing water vapor antirust agent reactants: put 20g deionized water into the reactor, add 8g organic dibasic acid, 5g benzoic acid, 10g triethanolamine and 11g n-propanolamine , stir and heat up to 50°C, and react until a transparent and clear solution is formed; remove the heat source, add 5g trans polyether, 4g glycerin, and continue stirring until the solution is uniform; after the solution is cooled to room temperature, add 31.5g deionized water, Mix 1.4g of triazine carboxylic acid compound, 0.9g of ethanolamine, 0.7g of n-octanoic acid, 2g of triazine fungicide and 0.5g of polysiloxane, and continue to stir until the system is clear to obtain the concentrated stock solution of grinding fluid. Dilute with water to a working solution with a concentration of 5% and a pH value of 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com