Method and device for detecting and dressing quality of end face grinding wheel in real time

A technology of real-time detection and face grinding, which is applied in the direction of grinding drive device, grinding automatic control device, grinding machine tool parts, etc., which can solve the workpiece positioning error, affect the processing quality of the workpiece, and it is difficult to accurately determine the time when the grinding wheel needs to be dressed and other issues to achieve the effect of improving work efficiency, improving processing quality, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment describes the method of the present invention in detail in conjunction with the above-mentioned device embodiment:

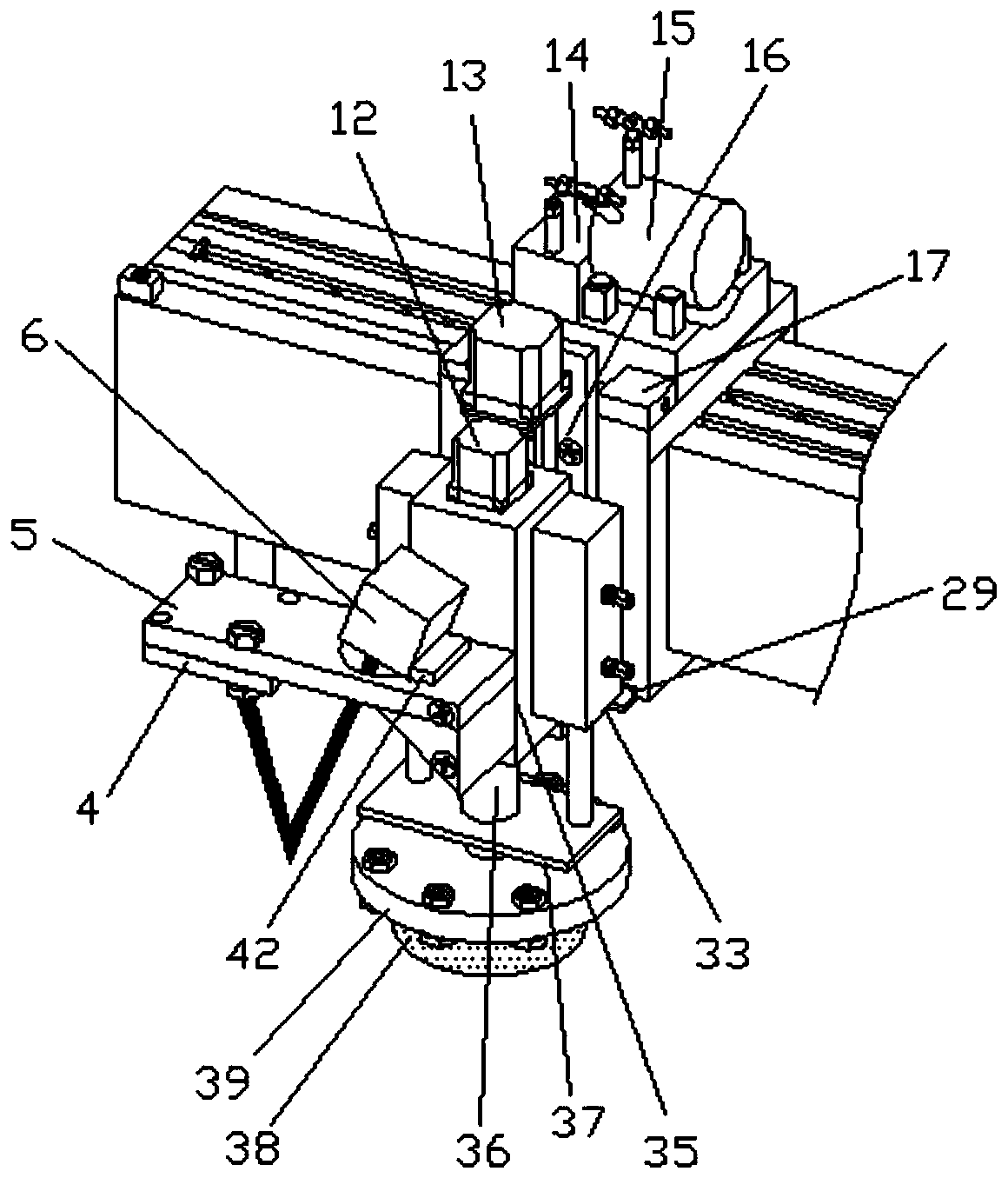

[0045] 1) The laser 6 emits continuous laser light and shoots obliquely to the ground surface of the workpiece 40, so that the laser light is emitted on the ground surface of the workpiece 40, and the receiver 4 receives the reflected laser light and characterizes it by the received energy value The degree of wear of the grinding wheel, so as to realize the real-time detection of the quality of the grinding wheel;

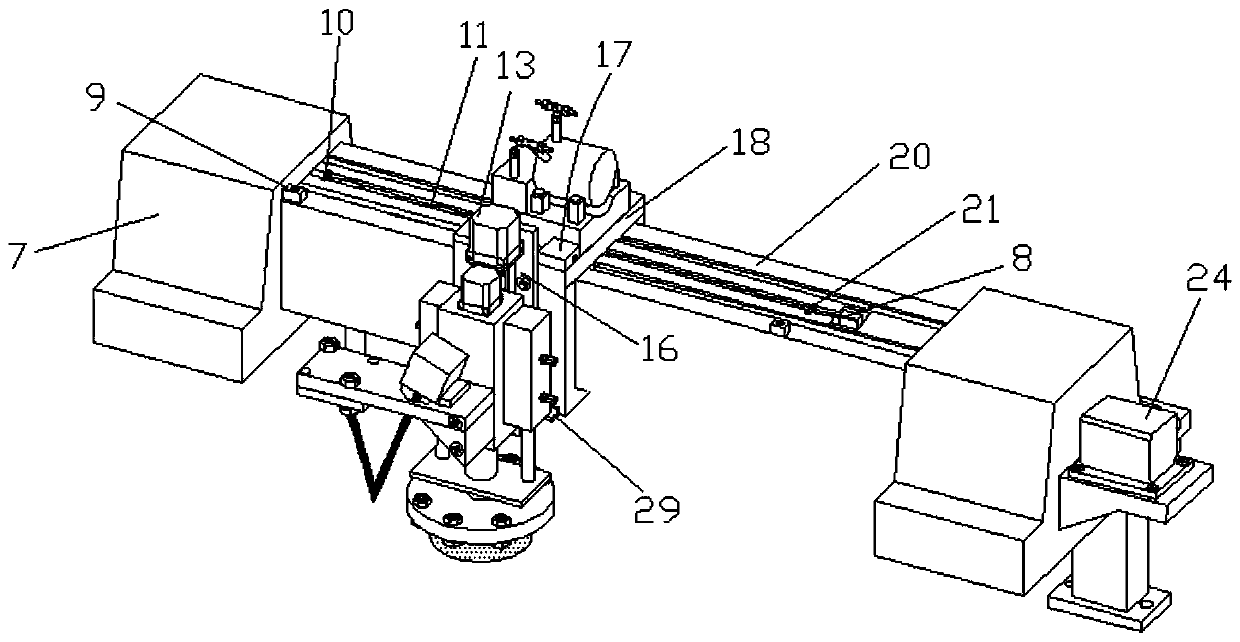

[0046] 2) When the reflected laser energy value received by the receiver 4 exceeds the preset upper limit, it means that the grinding wheel is severely worn, and the dressing action of the grinding wheel is immediately triggered, and the displacement sensor 17 records the position of the grinding wheel before triggering the dressing action as the secondary grinding point ;

[0047] 3) Quickly lift the worn grinding wheel and m...

Embodiment 2

[0052] In this embodiment, the method of the present invention is described in detail in combination with the above-mentioned device embodiment, and taking the chrome corundum grinding wheel as an example:

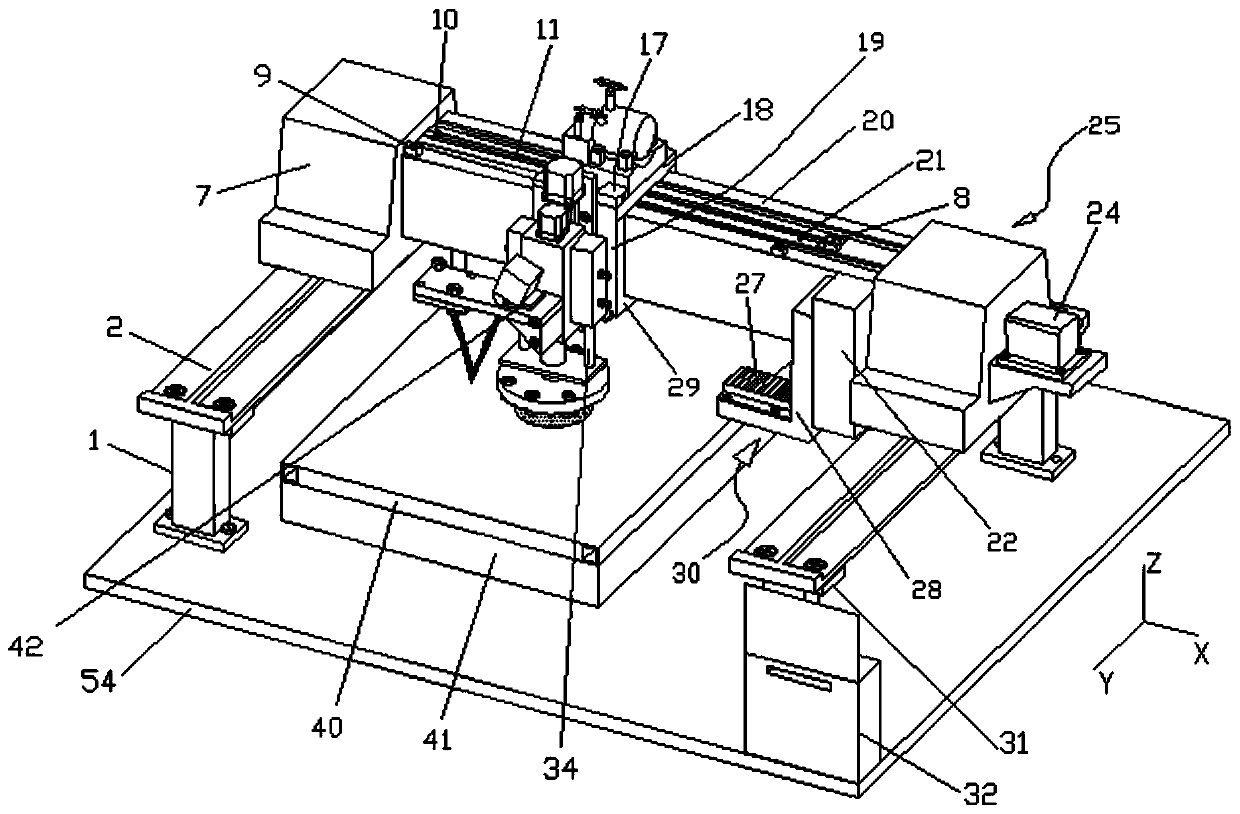

[0053] The grinding wheel in this embodiment is a chromium corundum grinding wheel, the grain size of the grinding wheel is F120, the abrasive grain rate of the grinding wheel is 54%, the bonding agent of the grinding wheel is resin, the hardness of the grinding wheel is G grade, and the distance between the center of the laser and the center of the receiver is 160 mm. The plate (workpiece 40) is a 316L austenitic stainless steel platen with a length of 1600 mm, a width of 1200 mm and a thickness of 10 mm. The distance between the two limit blocks 9 is 1500 mm. The length of the left and guide rail 2 is 2000 mm, and the length of the lifting guide rail 48 is 800mm.

[0054] In order to characterize the relationship between the quality of the grinding wheel and the laser en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com