Clutch stroke monitoring system

A clutch travel and monitoring system technology, applied in the field of clutches, can solve the problems of not being able to understand the number and state of clutch clutches, not being able to effectively judge the mechanical failure of the sensor, and being unable to effectively judge the mechanical failure of the sensor, so as to achieve automatic fault diagnosis and reduce labor intensity , Realize the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

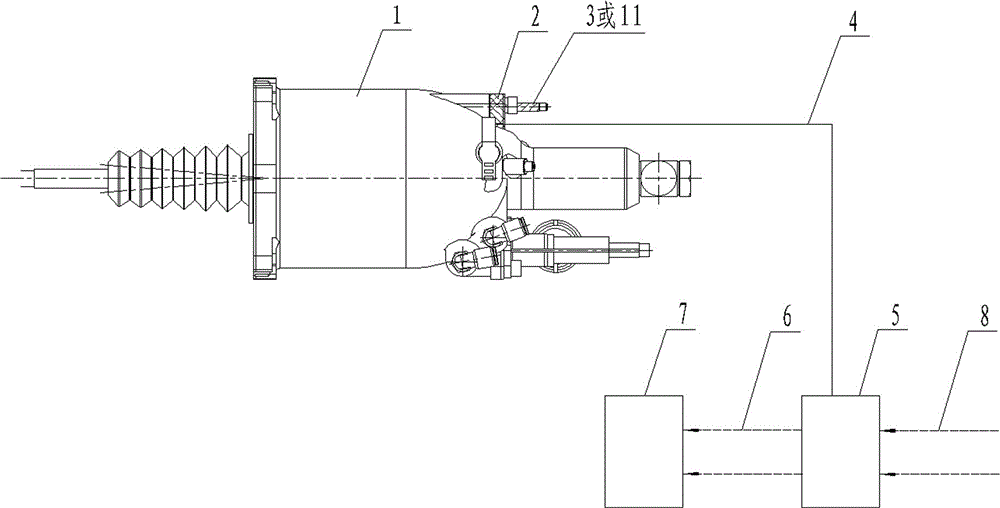

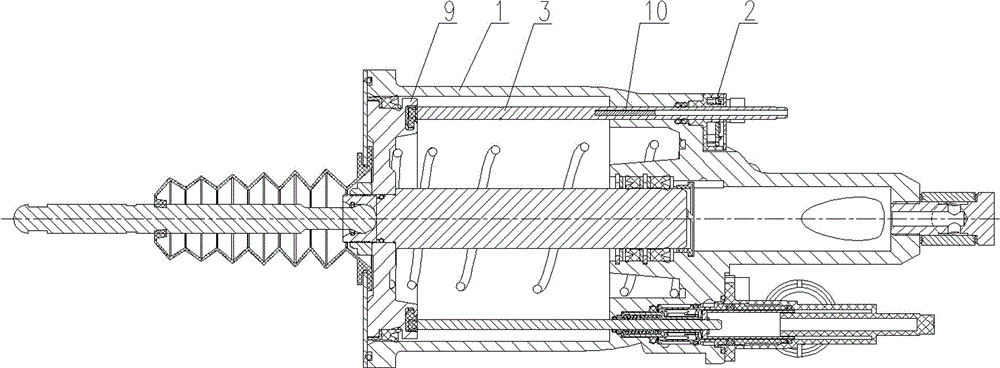

[0039] Such as figure 1 and figure 2As shown, the clutch stroke monitoring system includes a clutch booster 1, and the clutch booster 1 is equipped with a push plate 9 and a linked marking ruler 3. The left end of the linked marking ruler 3 is connected with the push plate 9, and the right end A blind hole is opened and installed at the right end of the housing of the clutch booster 1. A magnetic cylinder 10 is installed in the blind hole, and a sensor 2 is installed on the outer wall of one end of the blind hole. The sensor 2 is connected to the wiring harness 4, and the wiring harness 4 Connected with ECU5, described ECU5 is provided with input wiring harness 8 and output wiring harness 6, and output wiring harness 6 is connected with display unit and control unit 7, and display unit and control unit 7 include signal lamp, instrument panel, driving recorder and ATM, the sensor 2 adopts a displacement sensor, and the displacement sensor adopts a magnetostrictive displacemen...

Embodiment 2

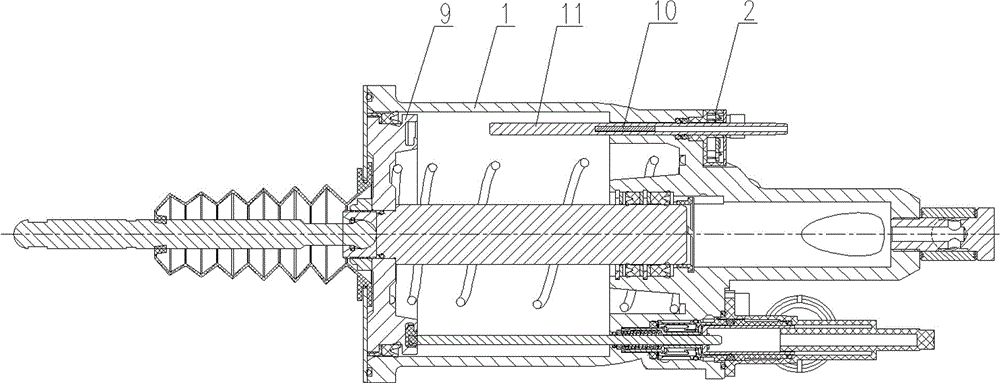

[0041] Such as figure 1 and image 3 As shown, the clutch stroke monitoring system is similar to Embodiment 1, the difference is that the linkage marking ruler 3 is replaced by the non-linkage marking ruler 11, and the left end of the non-linkage marking ruler 11 is not connected with the push plate 9, and its The right end has a blind hole and is installed on the right end of the housing of the clutch booster 1. A magnetic cylinder 10 is installed in the blind hole, and a sensor 2 is installed on the outer wall of one end of the blind hole. The sensor 2 has an external wiring harness 4, and the wiring harness 4 is connected with ECU5, and said ECU5 is provided with input wiring harness 8 and output wiring harness 6, and output wiring harness 6 is connected with display unit and control unit 7, and display unit and control unit 7 include signal indicator light, instrument panel, driving recorder and ATM, the sensor 2 adopts a displacement sensor, the displacement sensor adopt...

Embodiment 3

[0048] The clutch stroke monitoring system is similar to Embodiment 1 or 2, except that the magnetostrictive displacement sensor uses an anti-corrosion magnetostrictive displacement sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com