Tool and workpiece matching verification system and machining and controlling method of numerically-controlled machine tool

A technology of CNC machine tools and inspection systems, applied to computer parts, metal processing equipment, metal processing machinery parts, etc., to achieve the effects of ensuring safety, improving work efficiency, and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

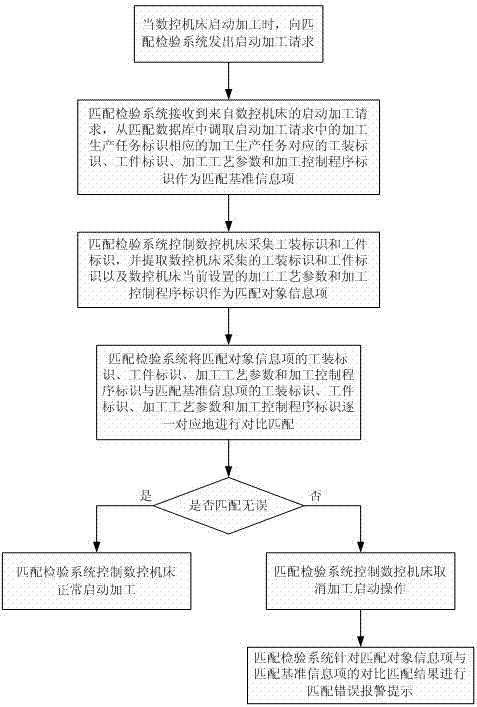

[0046] This embodiment uses the CNC machine tool tooling and workpiece matching inspection and processing control method of the present invention, and takes the CNC high-speed gear hobbing machine model YS3120CNC6 produced by Chongqing Machine Tool (Group) Co., Ltd. as the control object CNC machine tool to control the start-up processing of the CNC machine tool . The six-axis control and four-axis linkage CNC high-speed gear hobbing machine produced by Chongqing Machine Tool (Group) Co., Ltd., model YS3120CNC6, adopts Siemens (SIEMENS) 840D digital control system, and its motion axes are driven by independent AC servo motors and electronic gearboxes. Control indexing movement and differential compensation to realize generating method machining, suitable for cylindrical spur gears, helical gears (shaft gears, disk gears), worm gears, small taper gears, drum gears, splines, different modules and helix angles Double or multiple gears with different directions, single indexing, m...

Embodiment 2

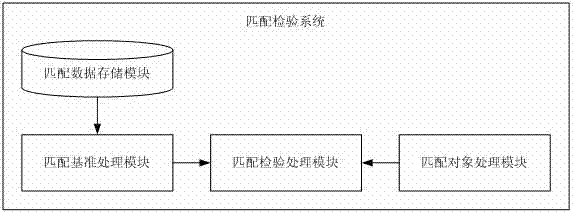

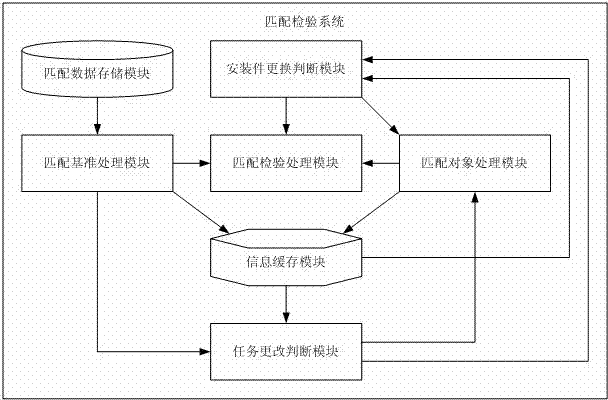

[0055] This embodiment is an optimization scheme proposed based on the first embodiment. The CNC machine tool that is the control object in this embodiment is still the CNC high-speed gear hobbing machine model YS3120CNC6 that has undergone integrated transformation of tooling and workpiece identification functions in Embodiment 1, and also builds a matching inspection system based on a programmable device platform through logic programming; However, the difference from Embodiment 1 is that the matching verification system based on the programmable device platform in this embodiment not only includes the matching data storage module, matching reference processing module, matching object processing module, and matching verification processing described in Embodiment 1. module, and further added an information cache module, a task change judgment module, and an installation part replacement judgment module. The system architecture is as follows: image 3 shown. In the matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com