Patents

Literature

137results about How to "Precise Trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

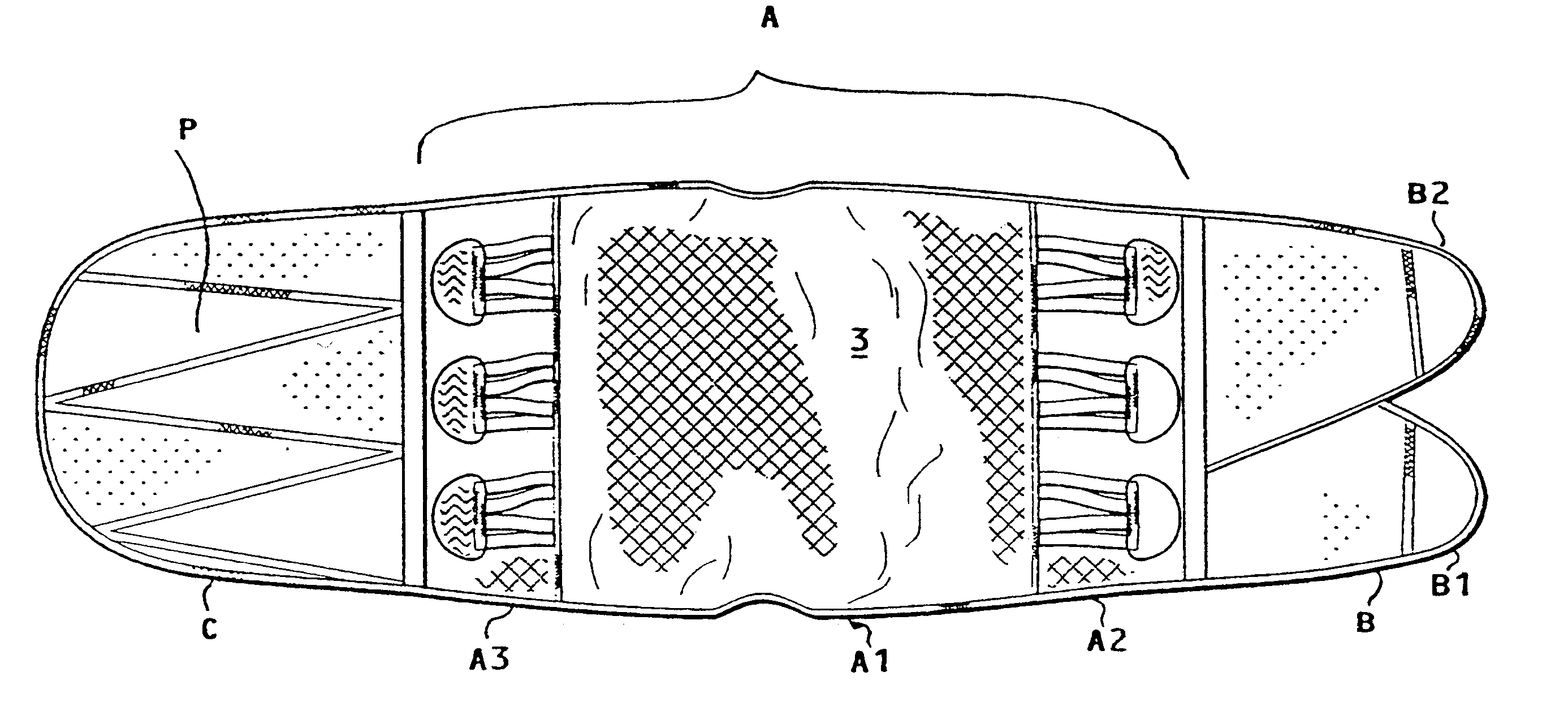

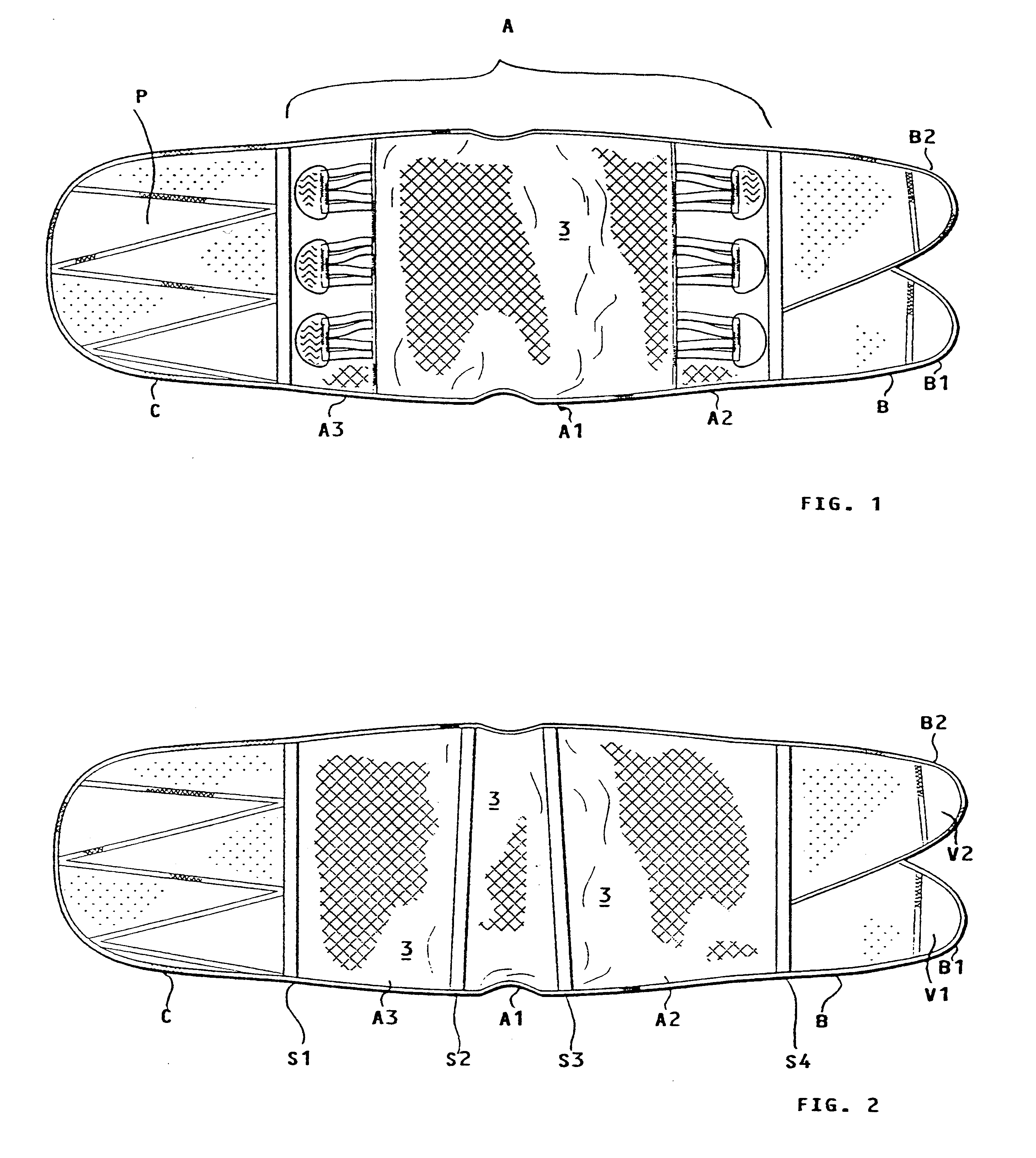

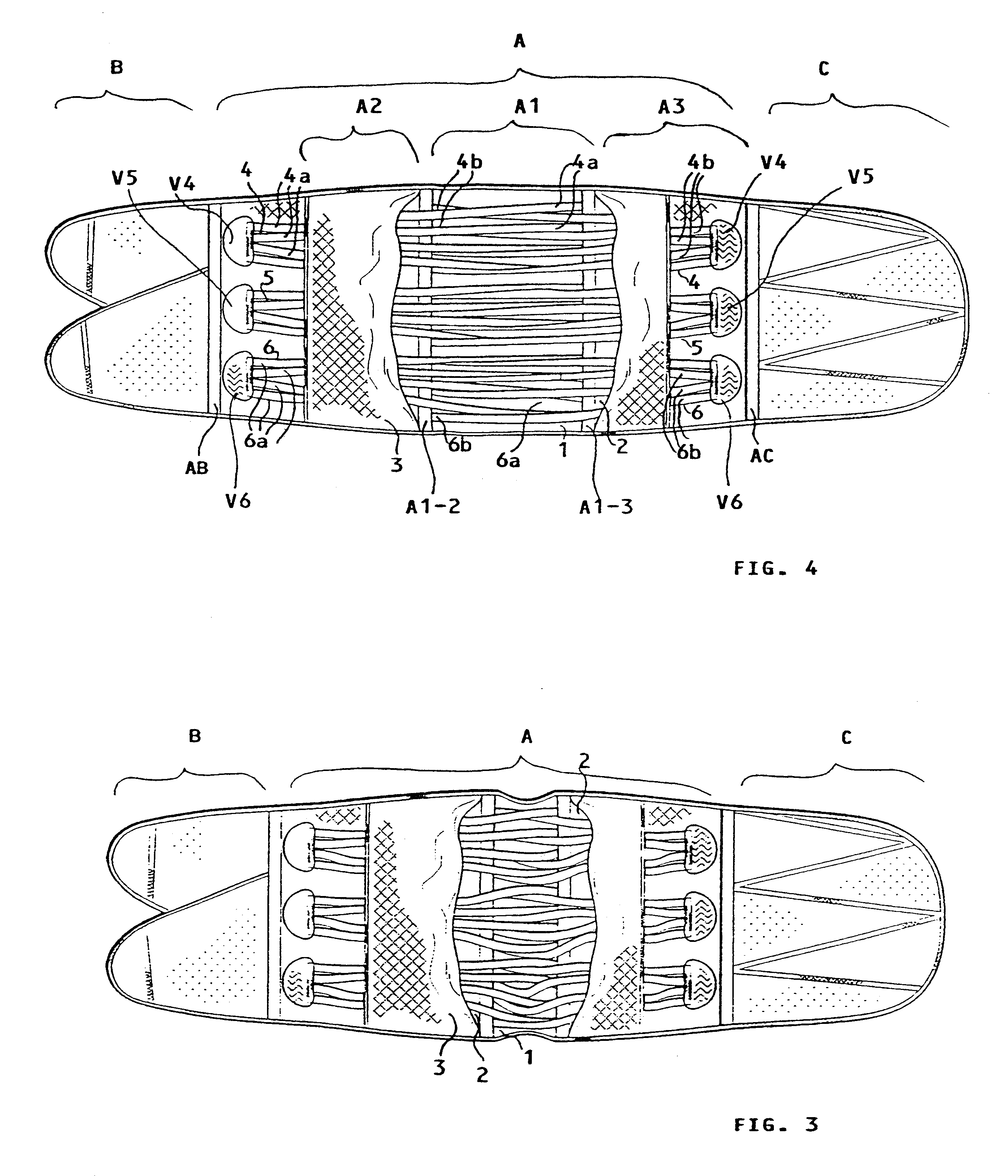

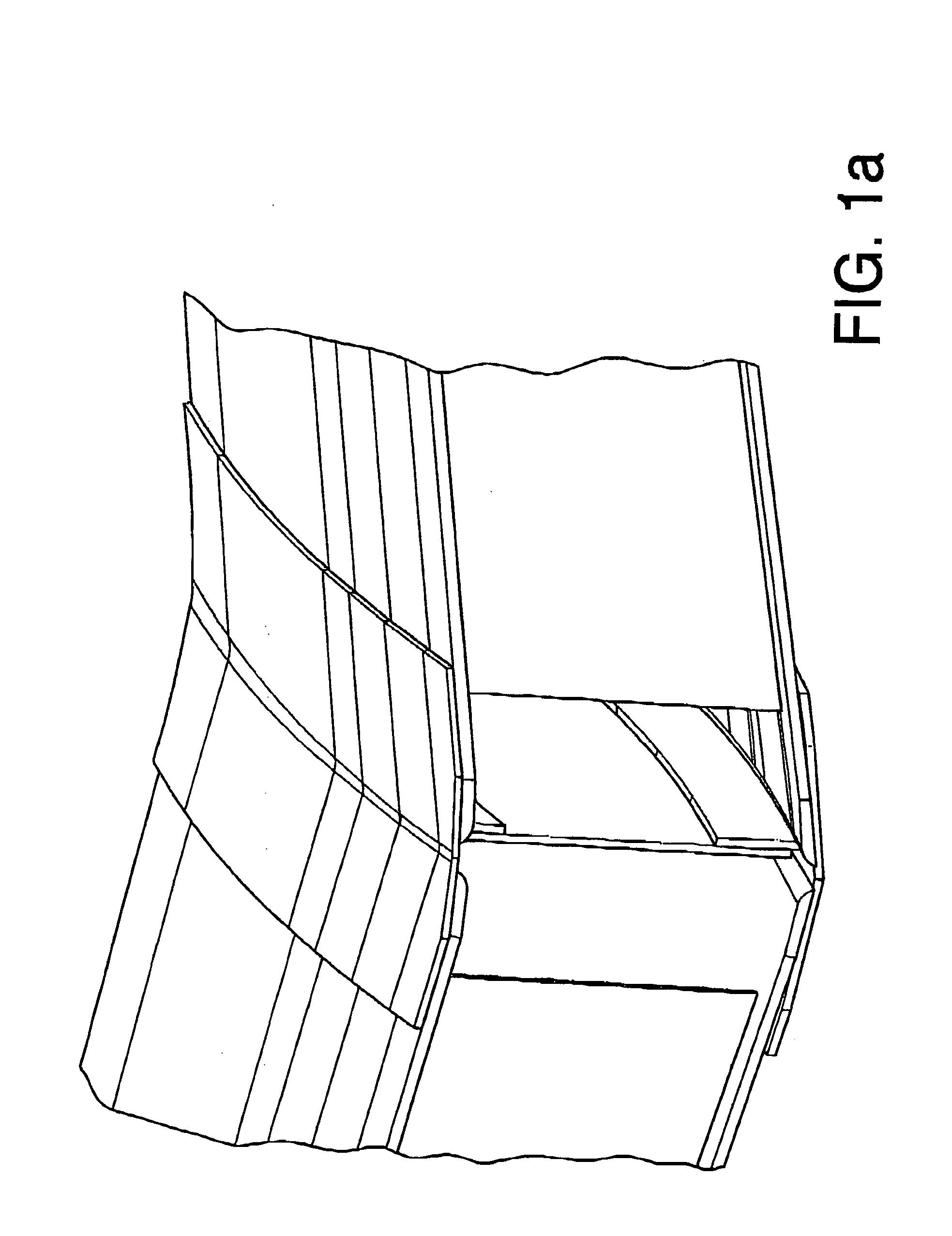

Elastic waistband with transverse stiffeners and tautness adjusting lacings

An elastic waistband comprises at least a main portion (A) made of an elastic fabric, a first end portion (B) in the form of two triangle-shaped tails (B1, B2) joined together to said main portion (A) and having at their free ends with Velcro(R) fasteners (V1, V2) and a second end portion (C) having anchoring felt pads (P) for the Velcro(R) Fasteners (V1, V2). The elastic main portion (A) is composed of a first central portion (A1) of a fabric (1) of greater elasticity than the elasticity of a fabric (2) of two side portions (A2, A3), joined together along transverse sewing lines (A1-2), A1-3). Transverse stiffening inserts (S1, S2, S3, S4) are disposed in correspondence of the transverse sewing lines joining together the first central portion (A1), the side portions (A2, A3) and the first and second end portions (B, C). Secondary elastic tautness adjustment means, runs over the exterior of the elastic portions (A1, A2, A3) and of the inserts and are in the form of a plurality of pairs (4, 5, 6) of interlaced multistrip bands, spacingly arranged along the height of the waistband, each multistrip band being composed of a plurality of parallel textile strips (4a-4b, 5a-5b, 6a-6b) having their free ends joined together to a piece of Velcro(R) fastener material (V4, V5, V6) and the other ends permanently sew along the farthest one from said free ends of said transverse sewing lines (A1-2, A1-3) joining the first central portion (A1) of elastic fabric (1) to a respective side portion (A2, A3) of stiffer elastic fabric (2). The Velcro(R) fasteners (V4, V5, V6) of the opposite free ends of each pair of interlaced bands may b

Owner:MIH INT

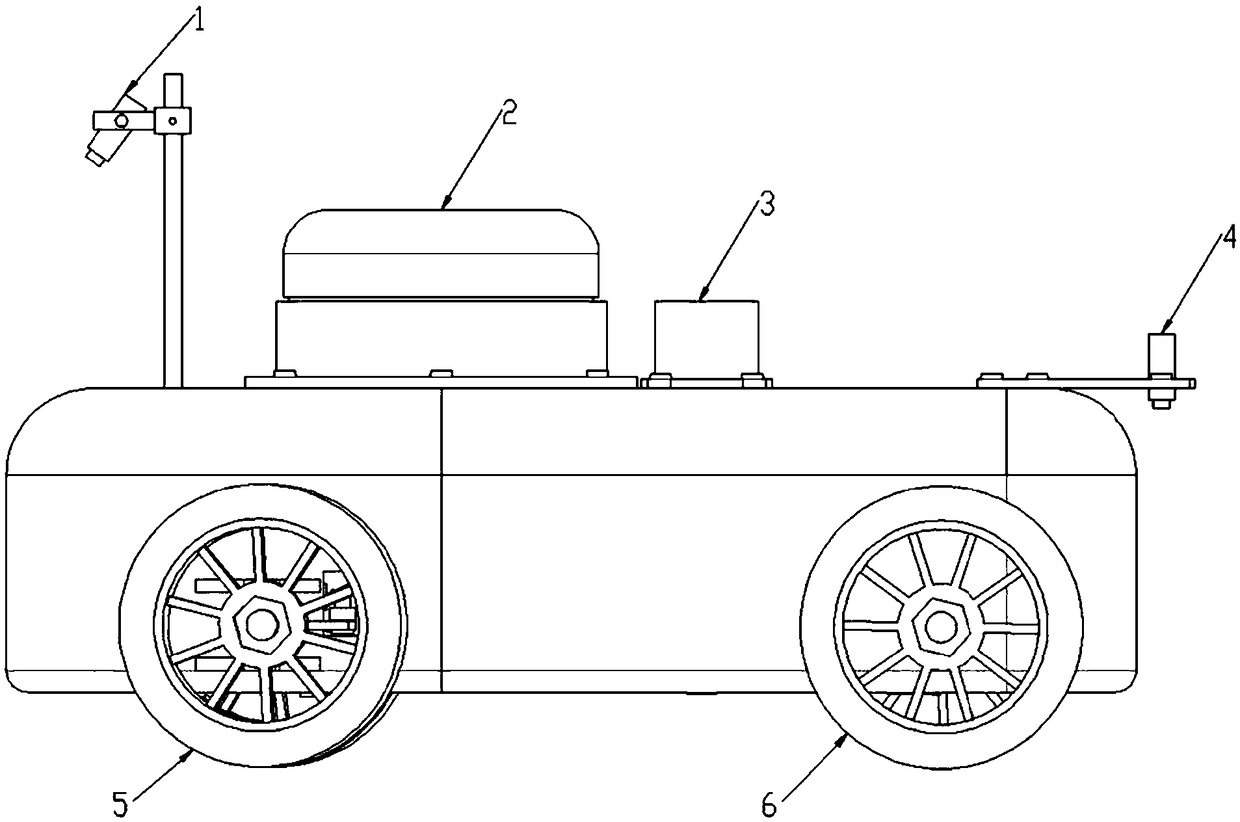

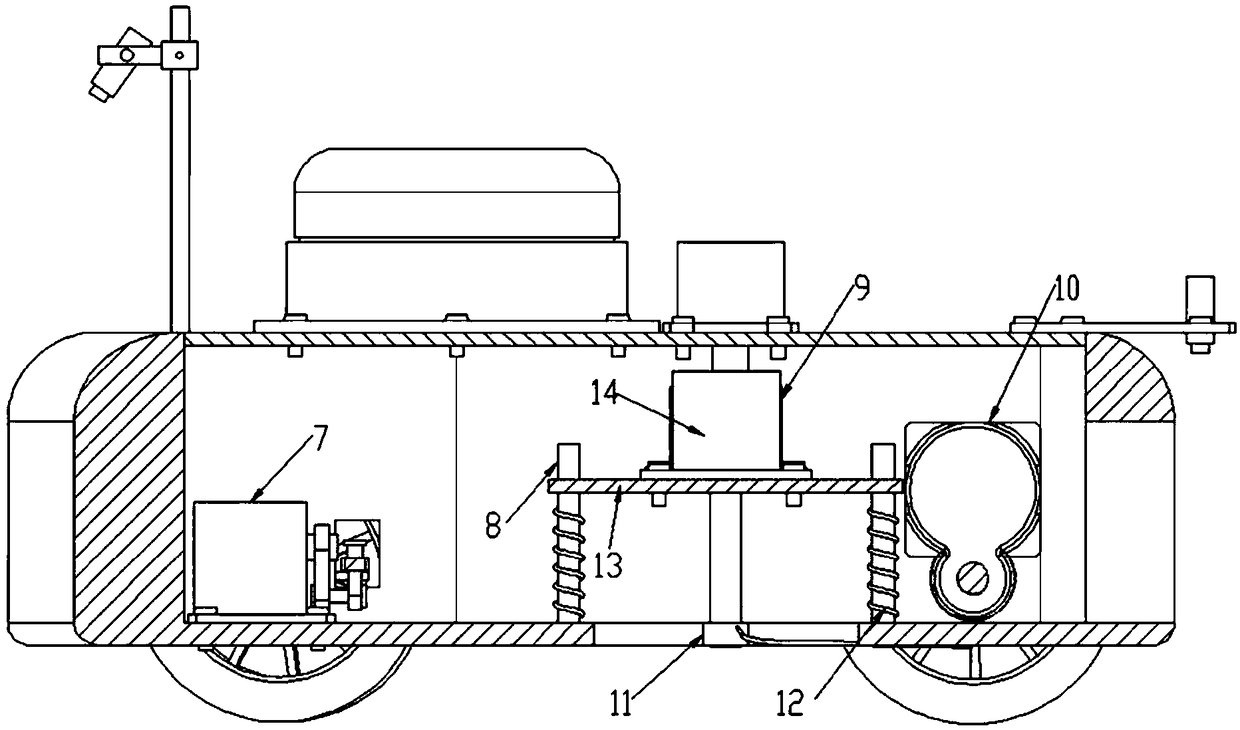

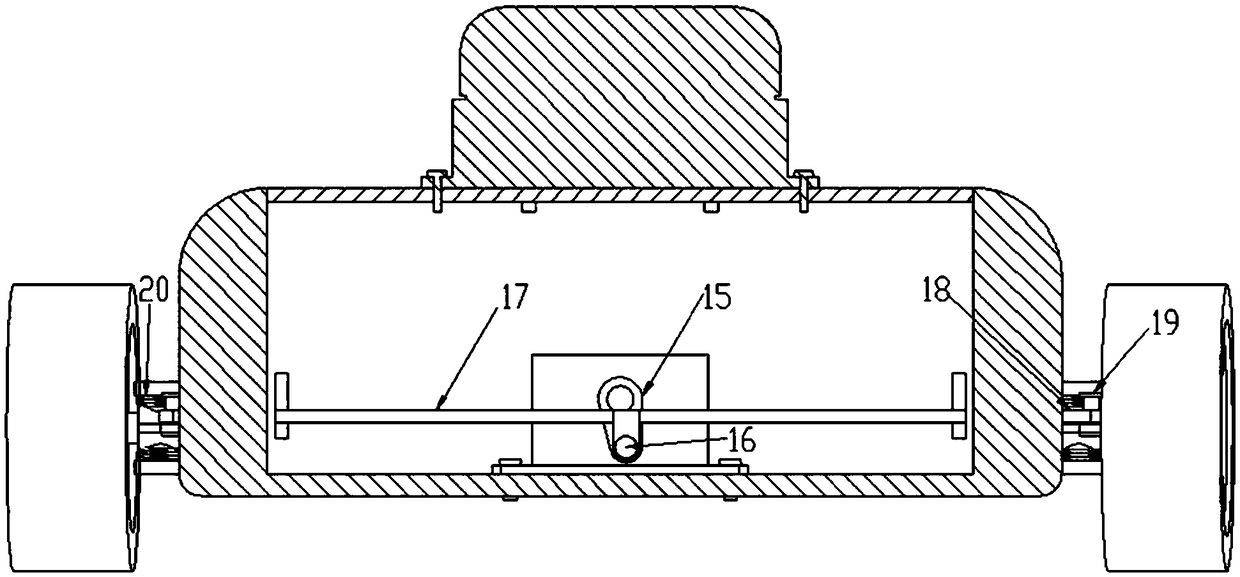

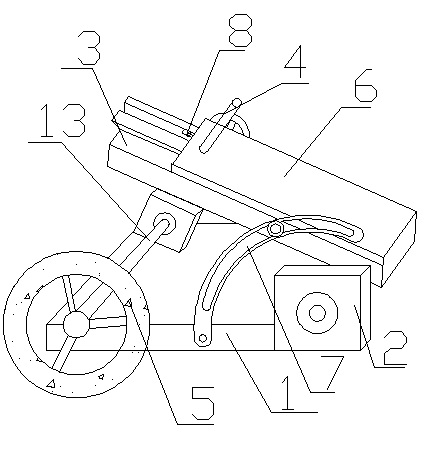

Intelligent mower based on laser scanning radar sensor and control method of intelligent mower

ActiveCN108781705AShorten speedImprove adaptabilityMowersAgricultural undercarriagesRadarLaser scanning

The invention discloses an intelligent mower based on a laser scanning radar sensor and a control method of the intelligent mower. The intelligent mower comprises a mobile cart body, an image collection device, a steering mechanism, a driving mechanism, the laser scanning radar sensor, a controller, a cutting motor and a height adjustment mechanism; a cutting line is installed on an output shaft of the cutting motor through a transmission device; the height adjustment mechanism is arranged on the mobile cart body, and the cutting motor is arranged on the height adjustment mechanism; the signaloutput end of the image collection device and the signal output end of the laser scanning radar sensor are connected with the signal input end of the controller separately, and the signal output endof the controller is connected with the steering mechanism, the driving mechanism, the cutting motor and the height adjustment mechanism separately. According to the intelligent mower, the height of ato-be-cut lawn can be precisely distinguished through the laser scanning radar sensor, the mowing height can be adjusted according to demands, and the intelligent mower has high mowing quality.

Owner:CHANGAN UNIV

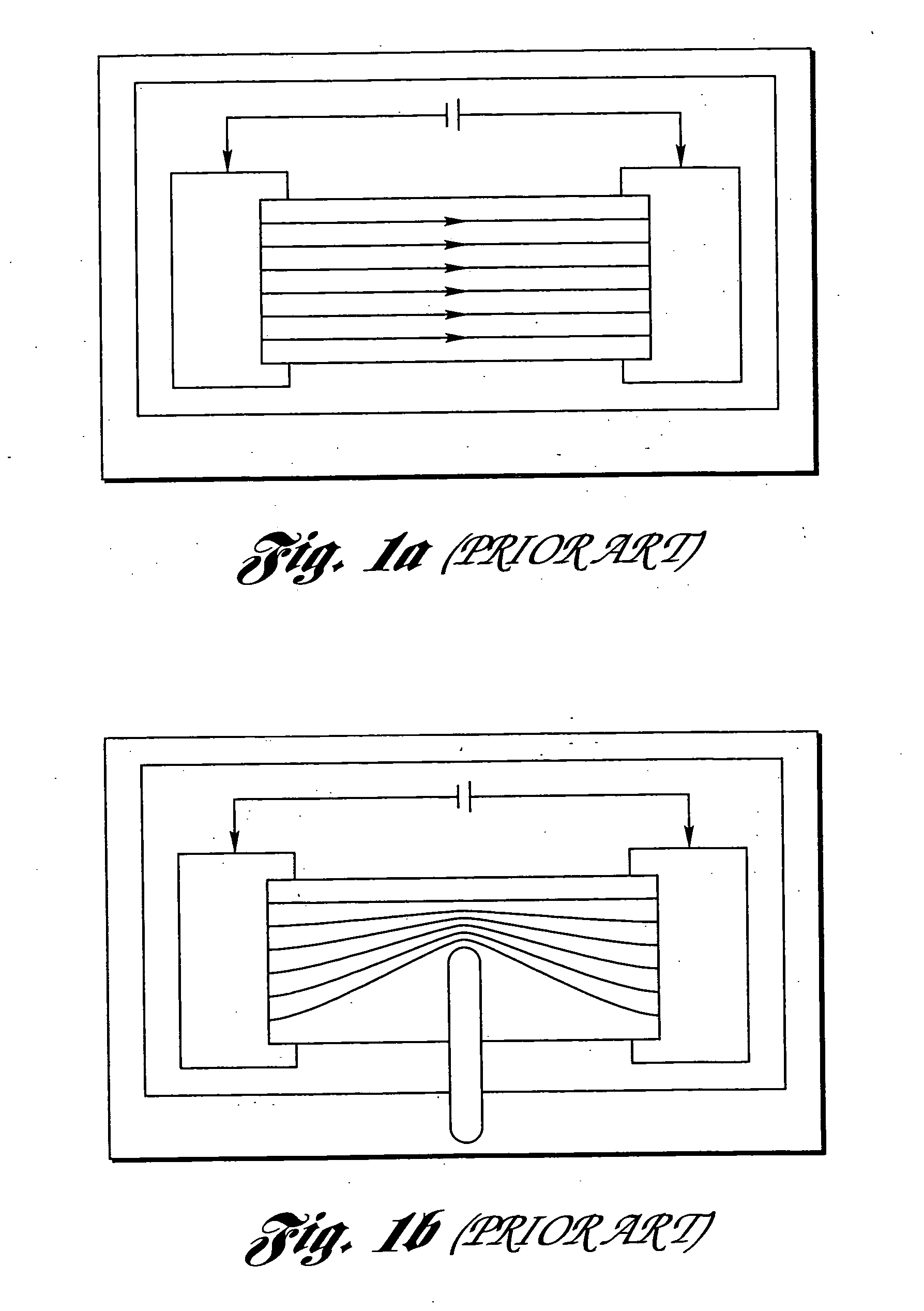

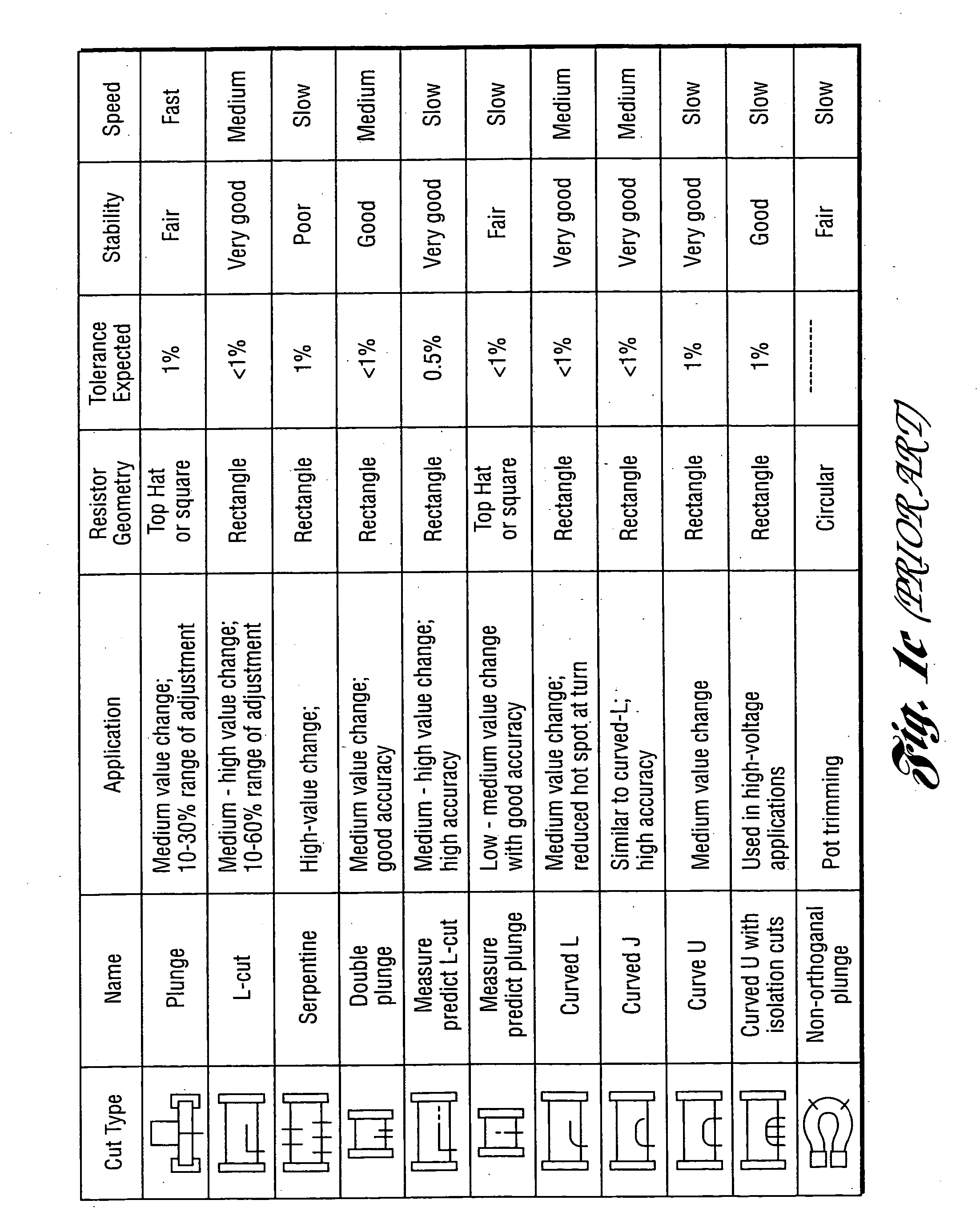

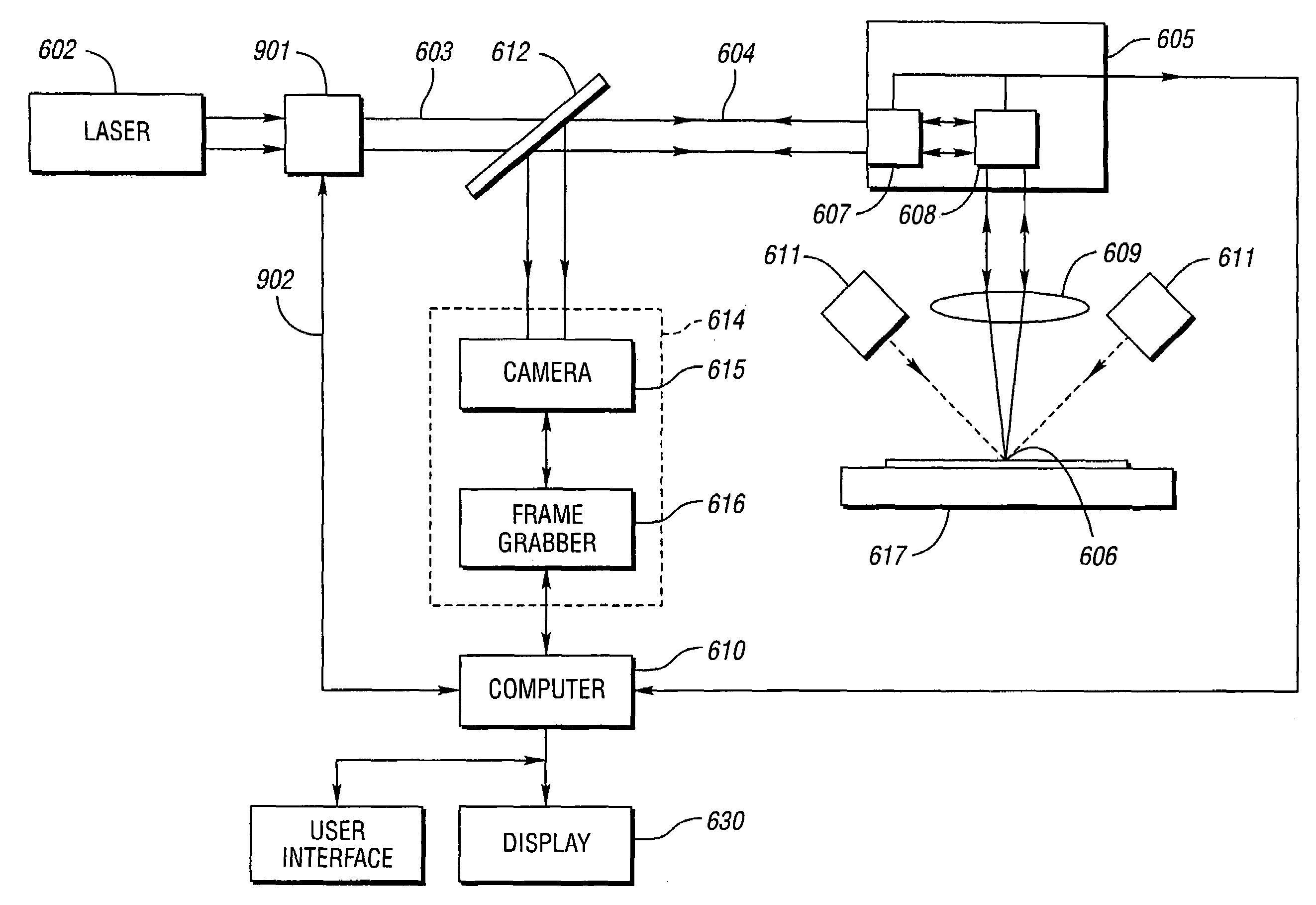

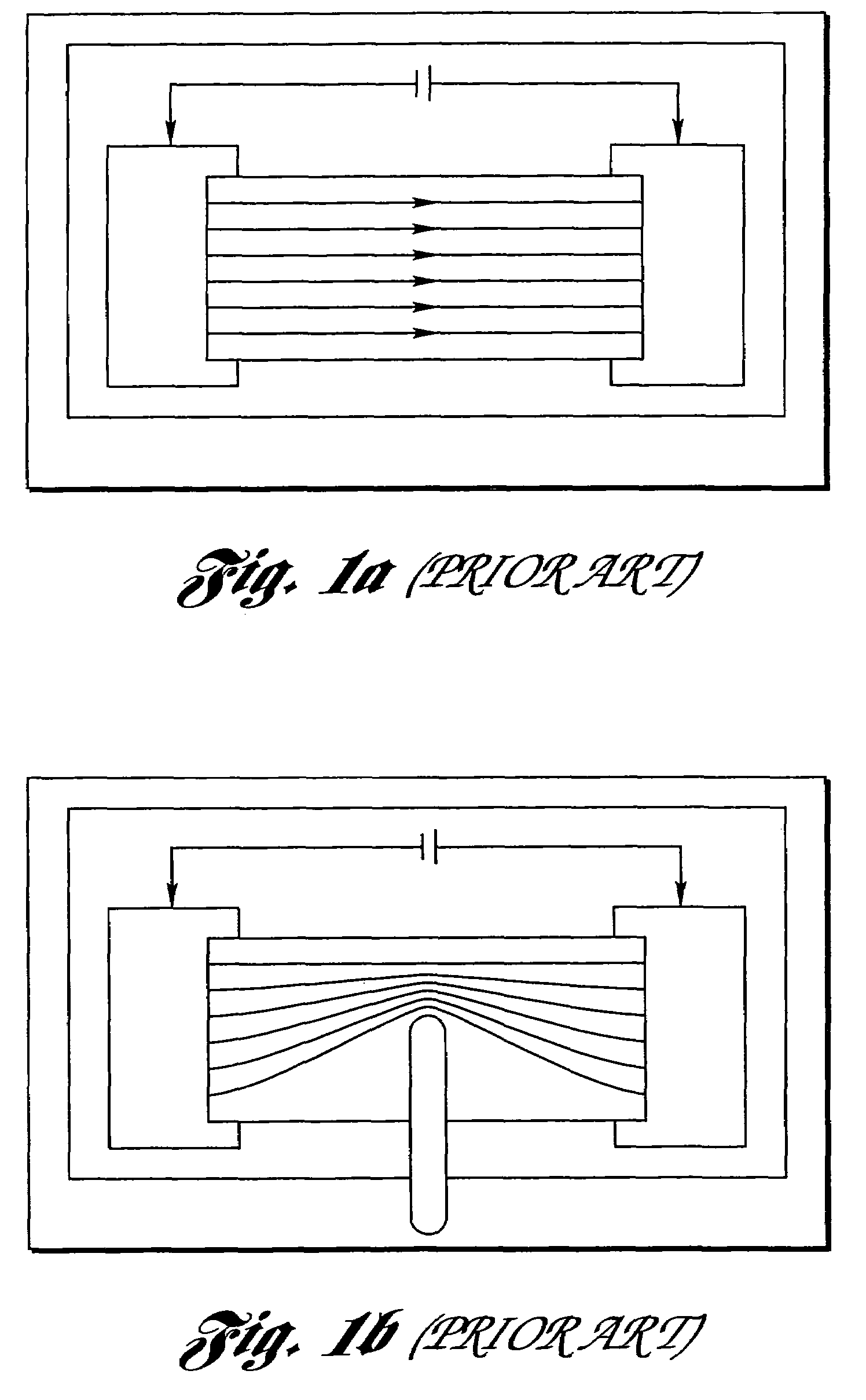

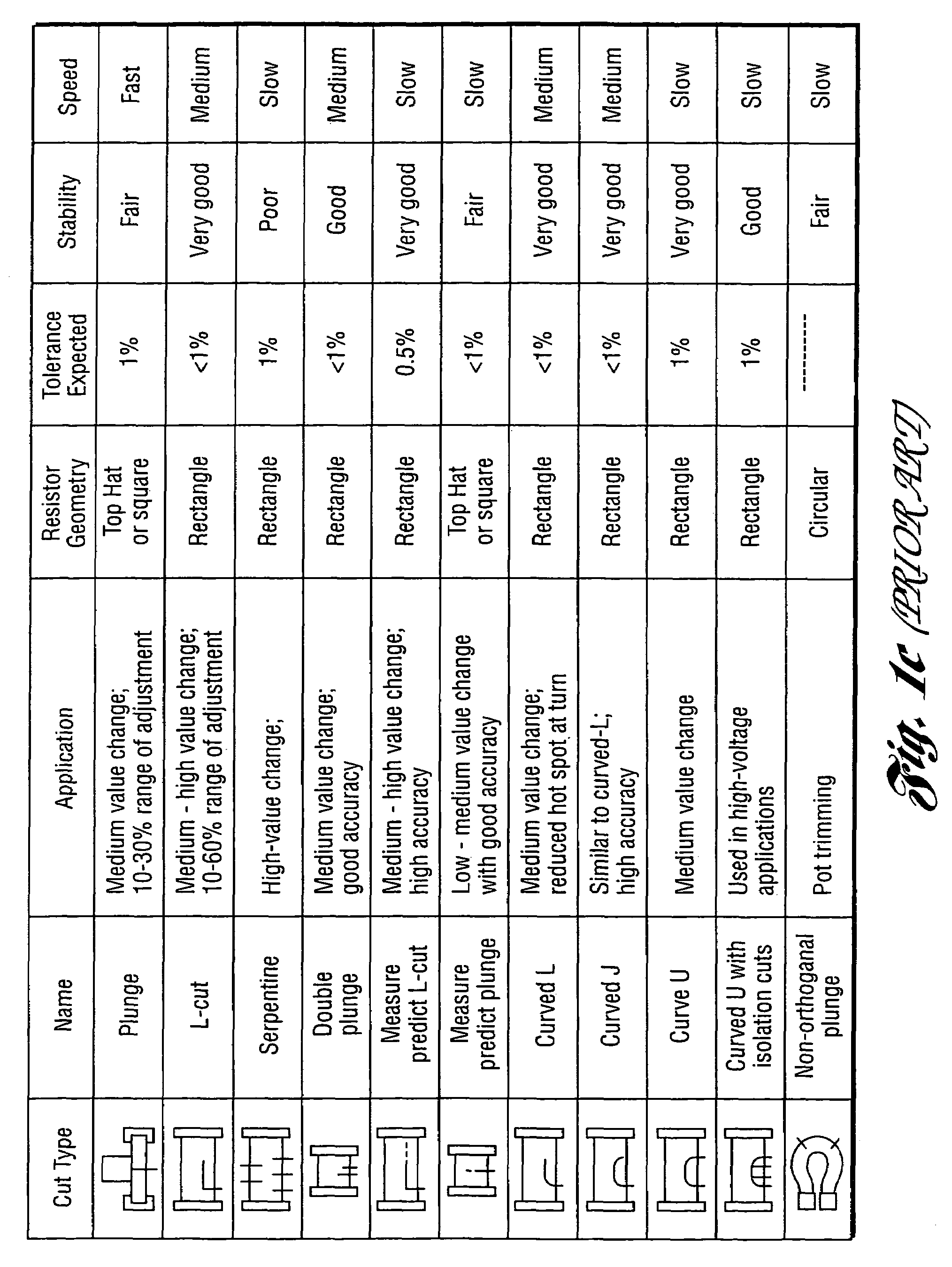

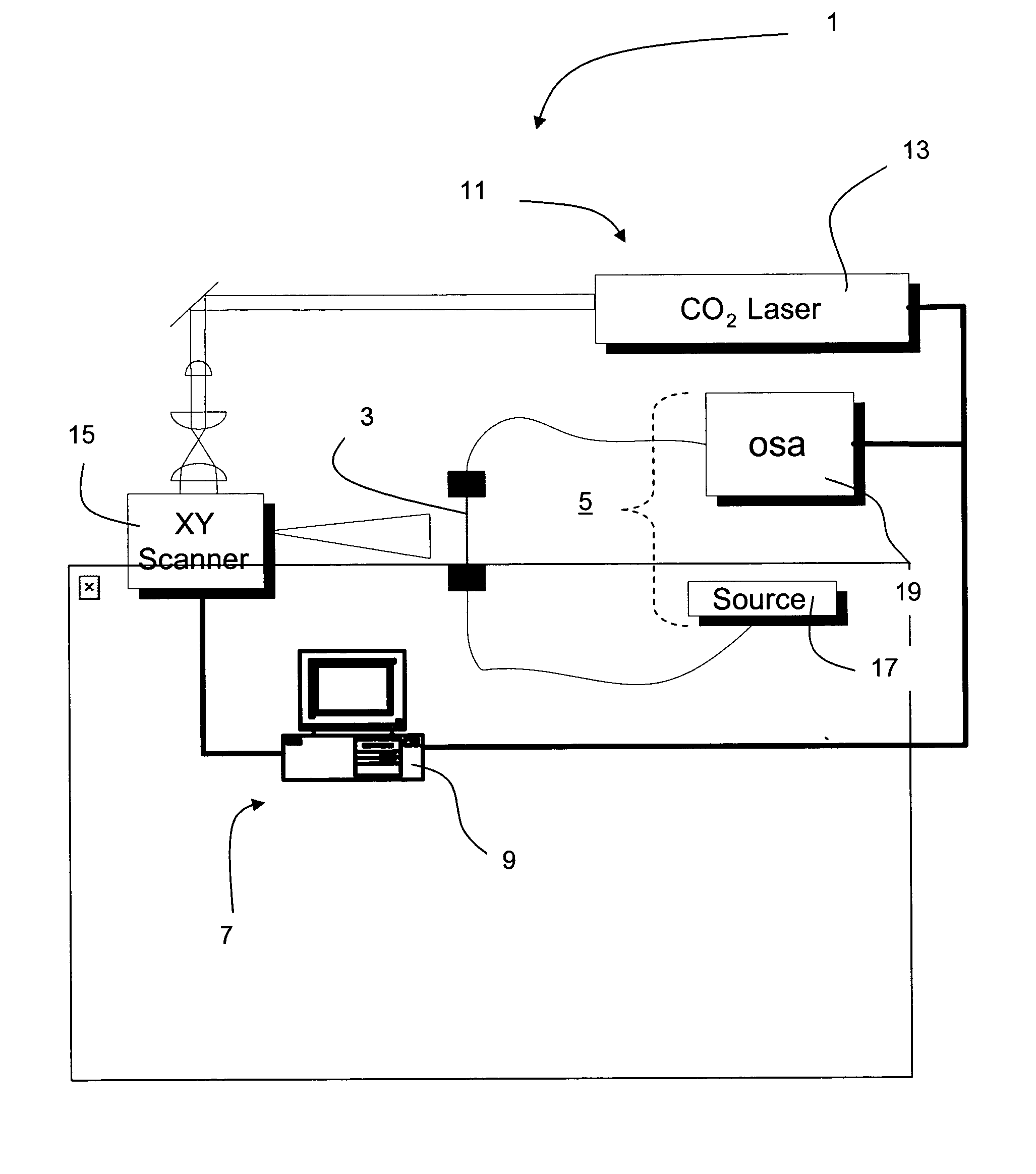

Method and system for high-speed precise laser trimming and scan lens for use therein

InactiveUS20070178714A1Precise TrimmingReduced stabilitySemiconductor/solid-state device manufacturingResistor manufactureHigh absorptionHeat-affected zone

A method, system and scan lens for use therein are provided for high-speed, laser-based, precise laser trimming at least one electrical element along a trim path. The method includes generating a pulsed laser output with a laser, the output having one or more laser pulses at a repetition rate. A fast rise / fall time, pulse-shaped q-switched laser or an ultra-fast laser may be used. Beam shaping optics may be used to generate a flat-top beam profile. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance, high absorption and reduced or eliminated heat-affected zone (HAZ) along the trim path, but not so short so as to cause microcracking. In this way, resistance drift after the trimming process is reduced.

Owner:ELECTRO SCI IND INC

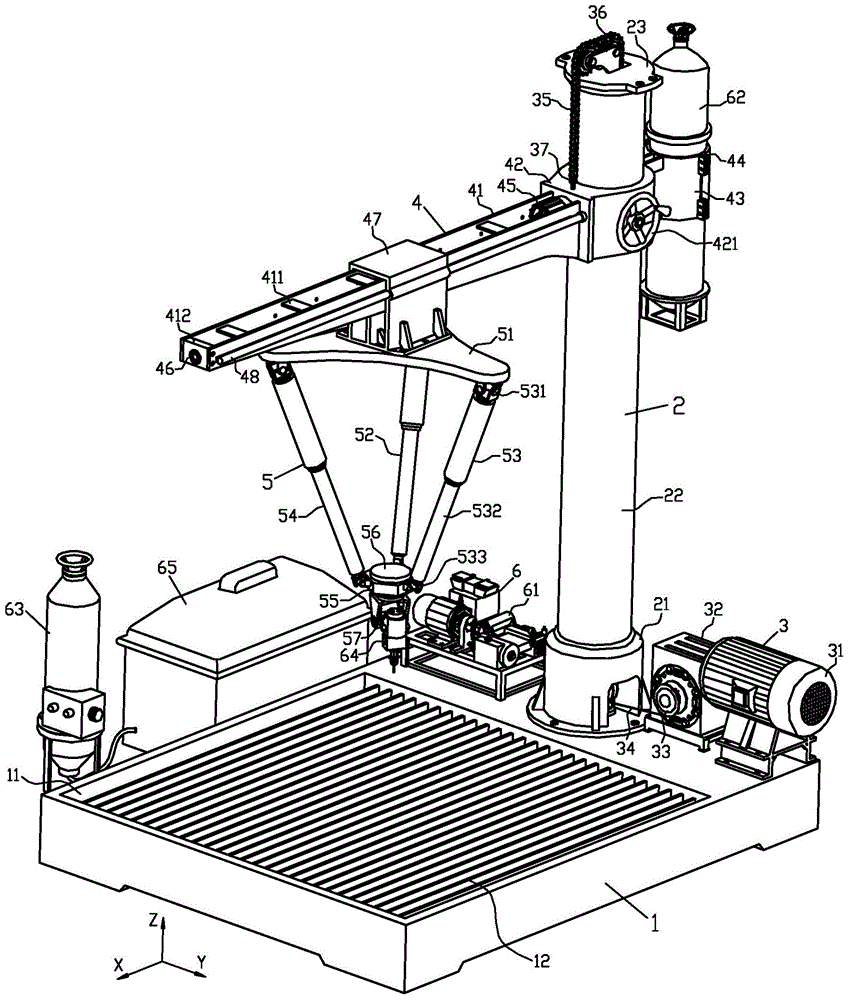

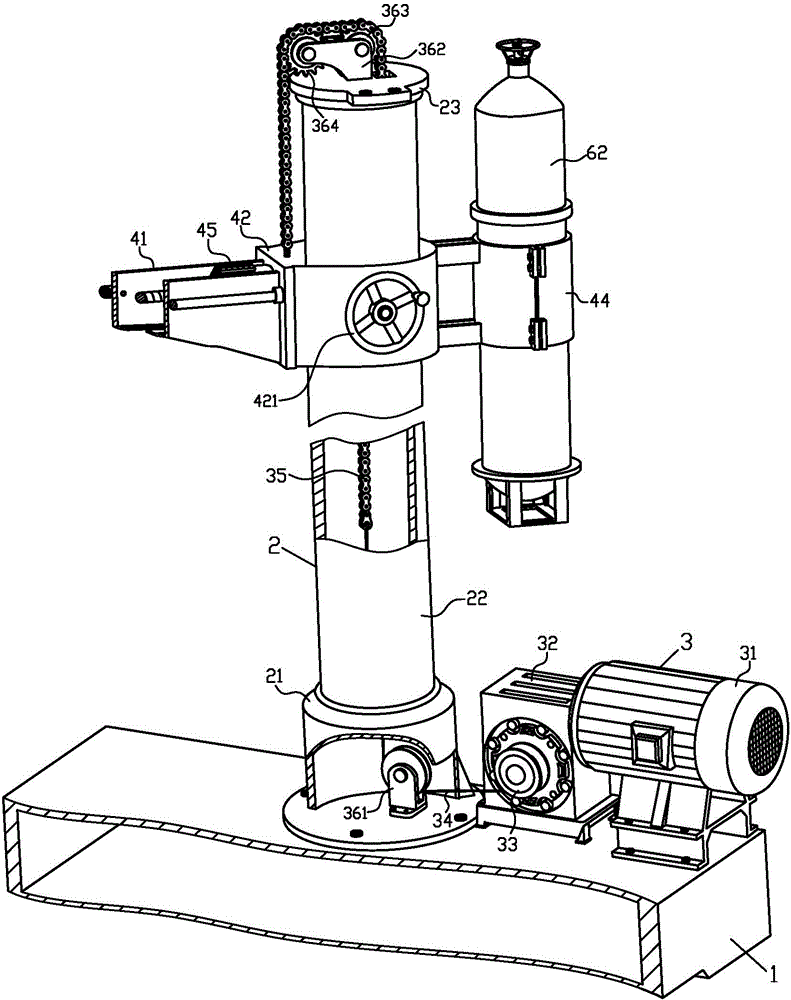

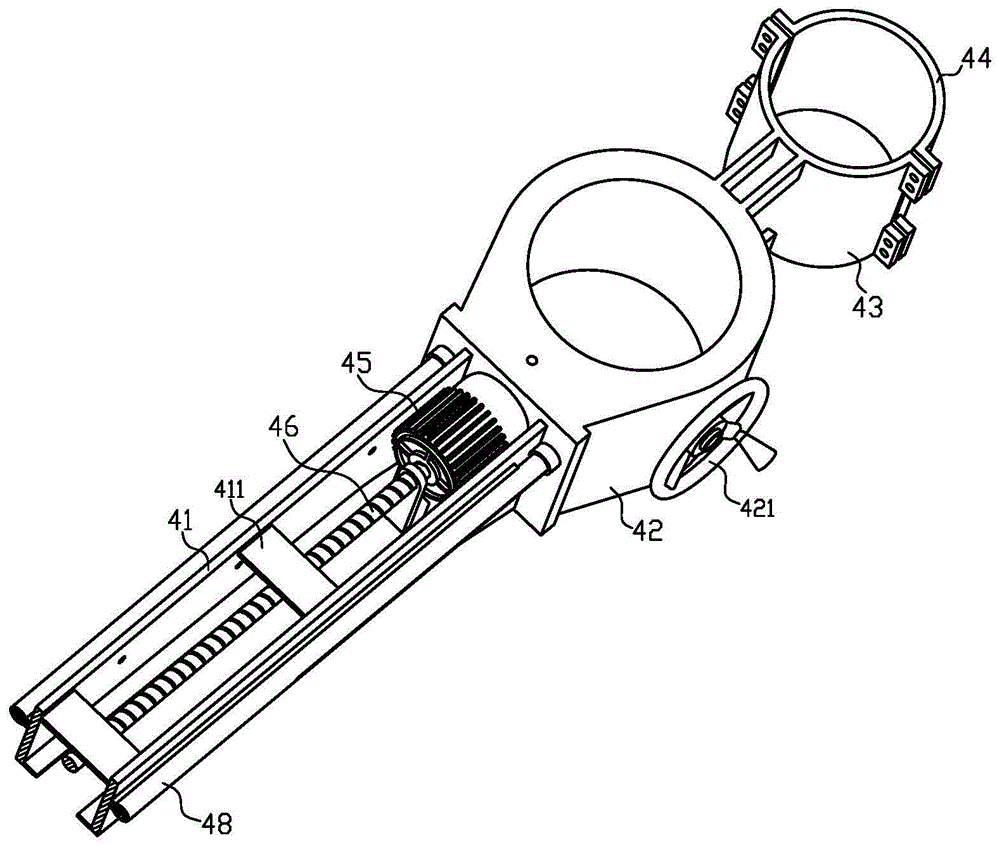

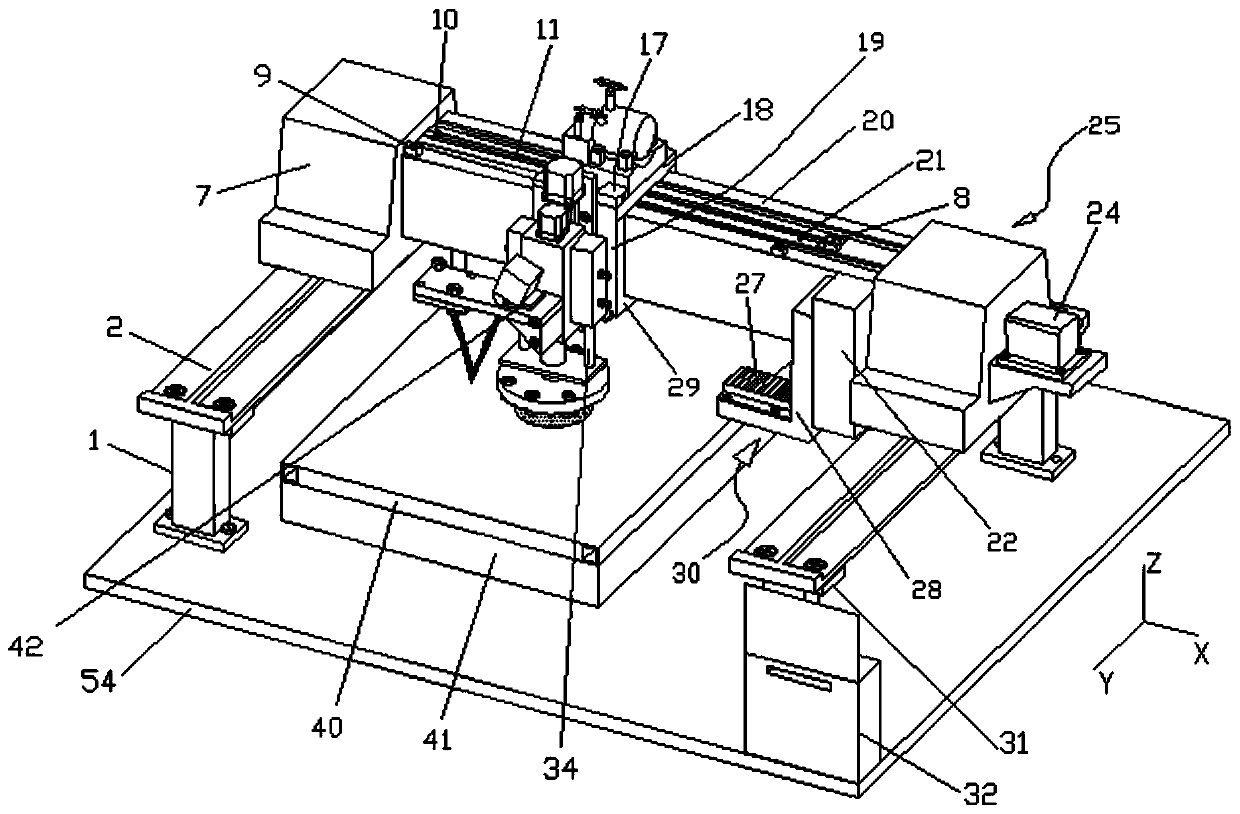

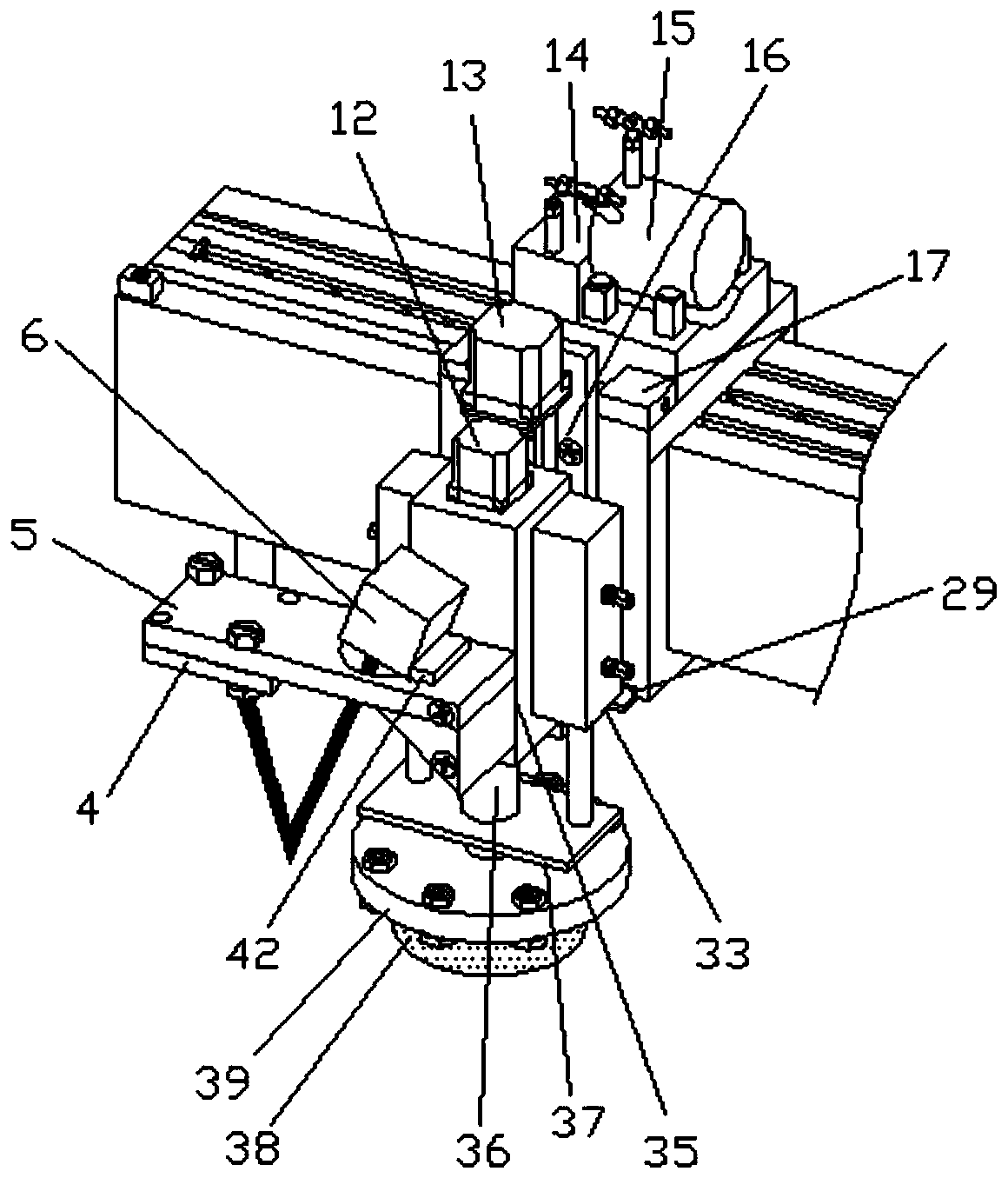

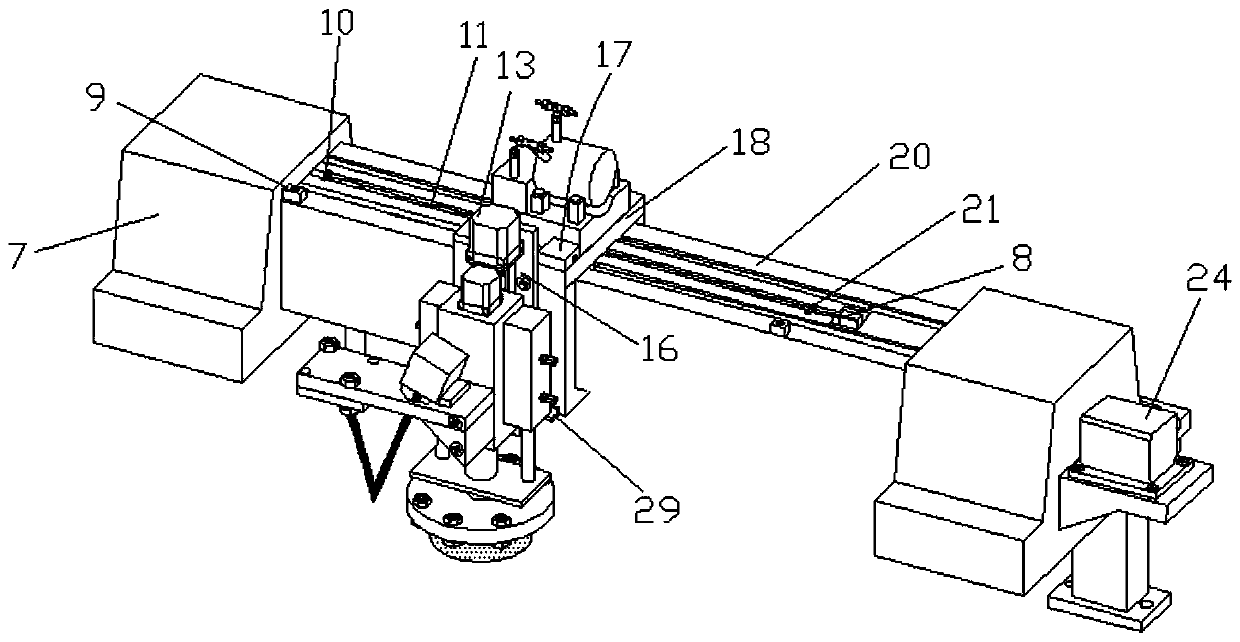

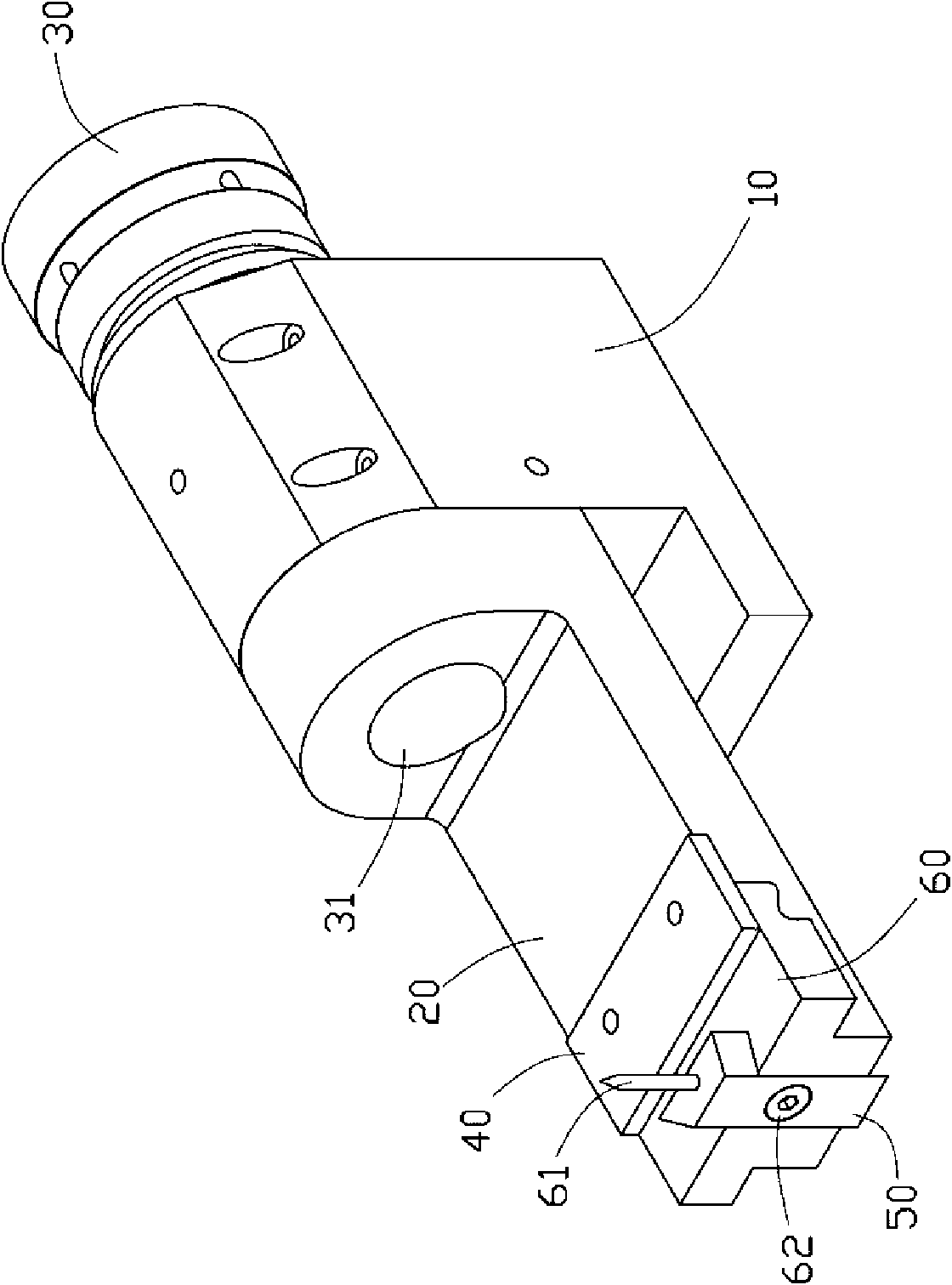

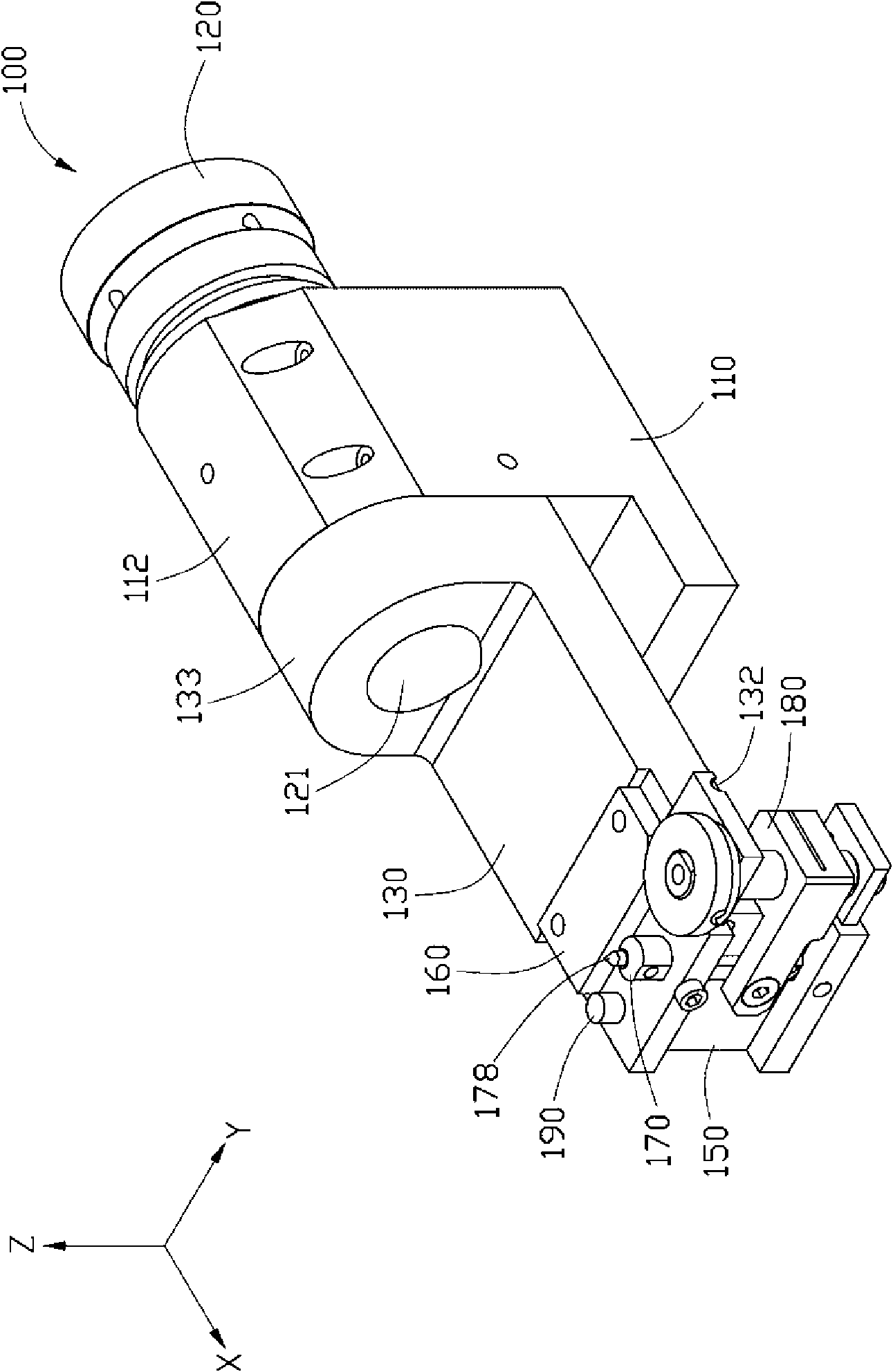

Series-parallel water jet carving robot with six degrees of freedom

InactiveCN104827405AReduce forceNot volatileBlast gunsAbrasive feedersThree degrees of freedomEngineering

The invention discloses a series-parallel water jet carving robot with six degrees of freedom. The robot comprises a mount, a vertical column component, a lifting device, a rocker with six degrees of freedom, a parallel cutter rack with three degrees of freedom and a jet carving device, wherein a water tank is arranged in the mount, the rocker can move upwards and downwards along the vertical column under the driving of the lifting device; and the parallel cutter rack with three degrees of freedom sleeves the rocker with two degrees of freedom and can translate along the rocker with two degrees of freedom; a spraying gun in the jet carving device is arranged on the parallel cutter rack and has six spatial movement degrees of freedom. According to the carving robot, the processing operations such as blanking and cutting, carving, chamfering, routing and trimming of an acrylic product can be realized; the action force of the robot during carving operation is small; a work piece is low in temperature and keeps the shape; the influence of the acrylic material bonding on a cutter or the work piece to the precision and quality of the work piece can be avoided; and the robot further has the advantage of being compact in device structure, stable and reliable in work, convenient and fast to operate and maintain, low in entire machine cost and high in processing precision.

Owner:ANHUI UNIV OF SCI & TECH +1

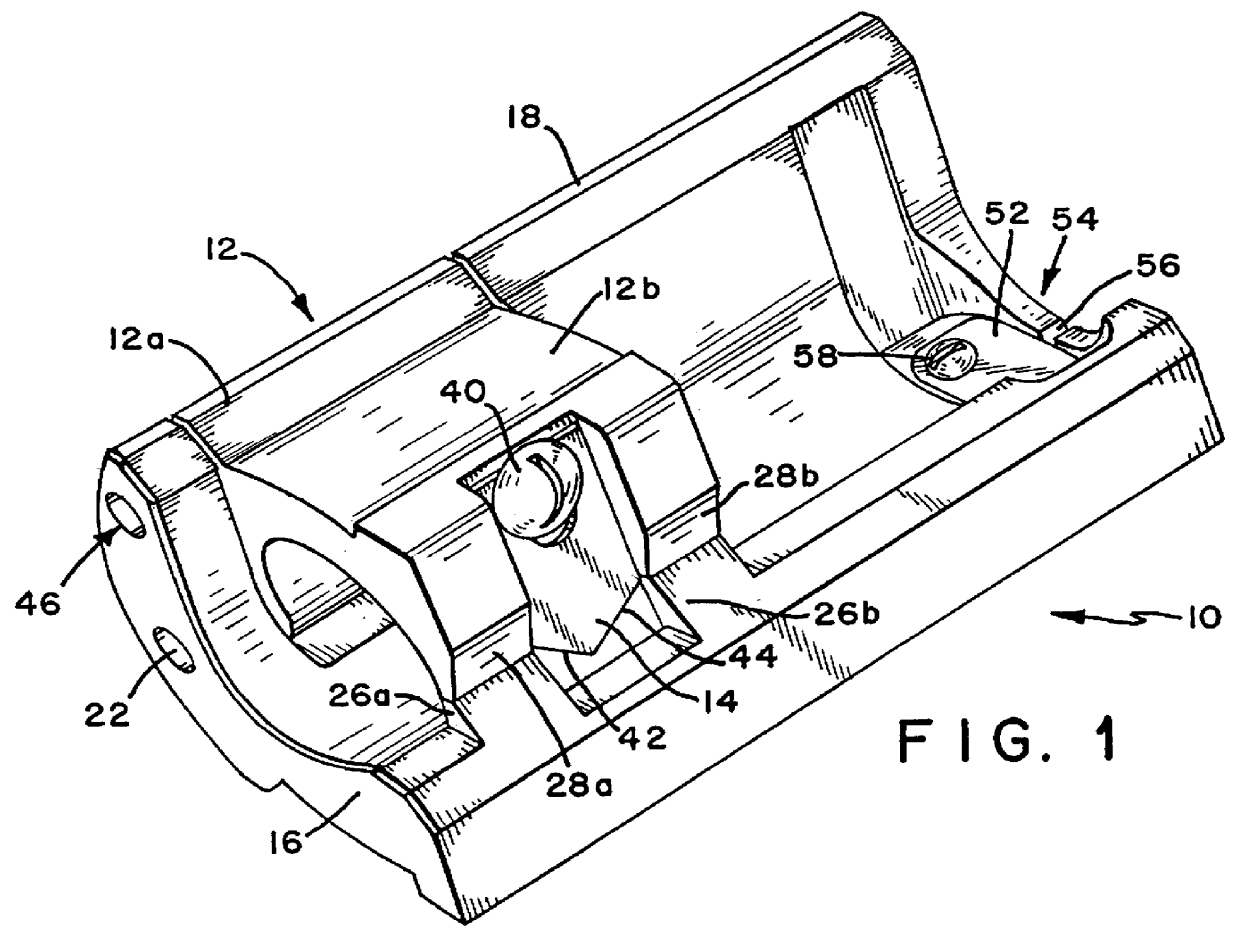

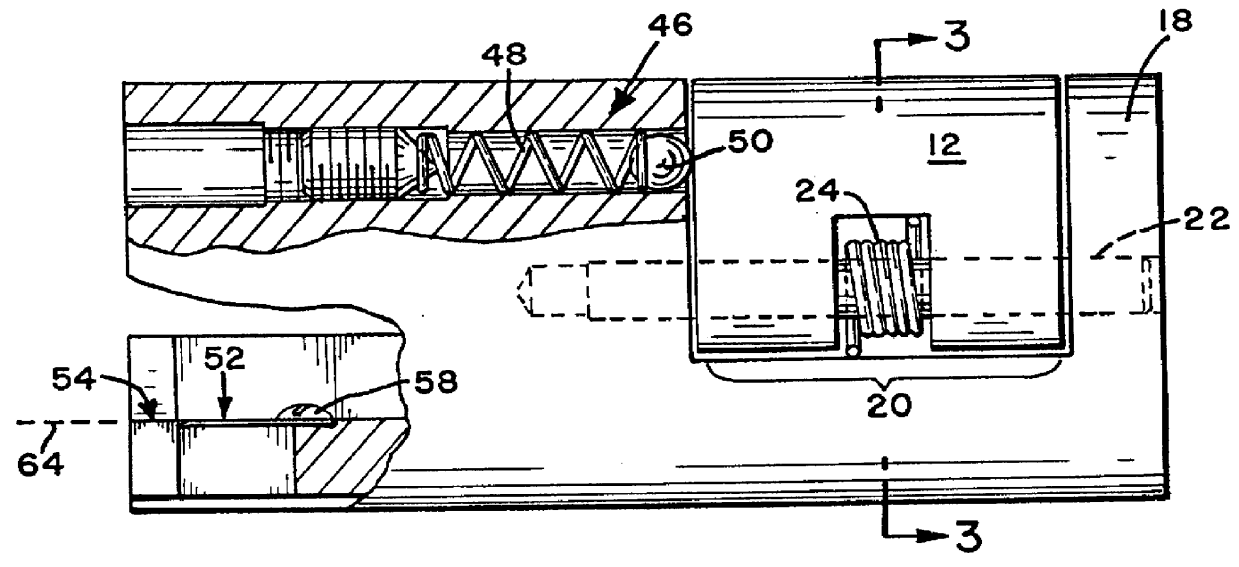

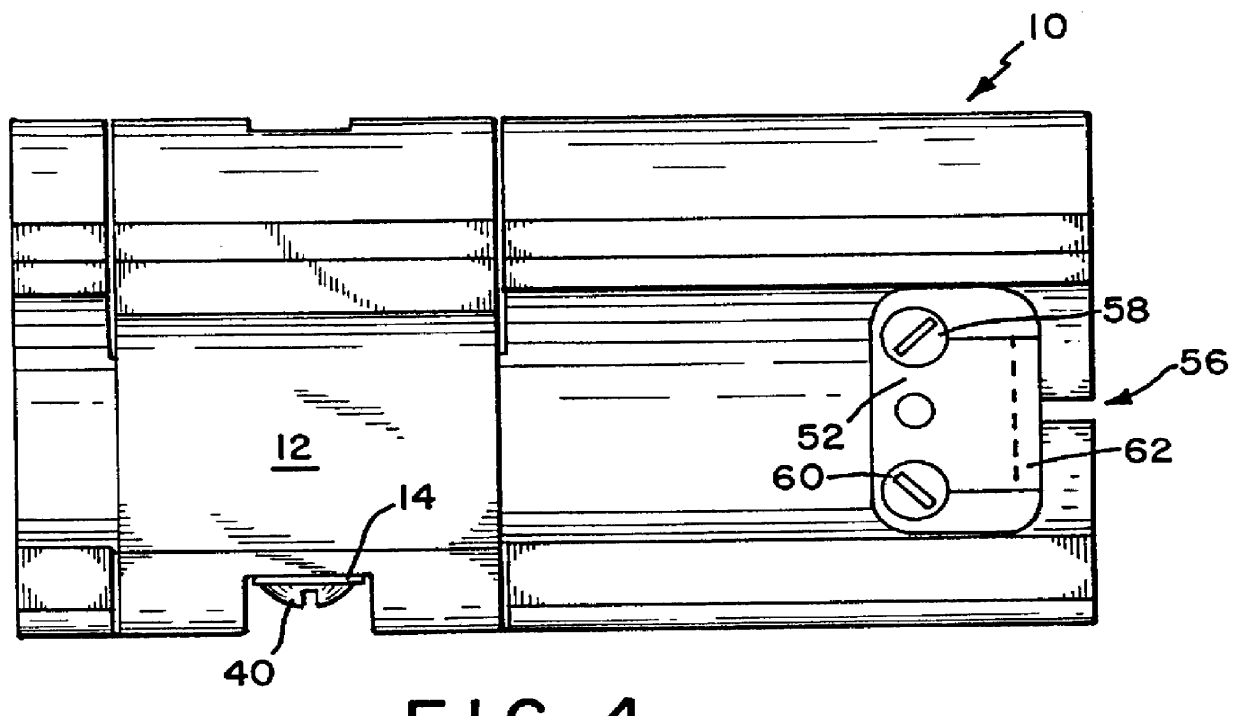

Cable slitter

InactiveUS6131289AEasy to operatePrecise TrimmingMetal working apparatusApparatus for removing/armouring cablesCoaxial cableEngineering

Owner:RIPLEY TOOLS

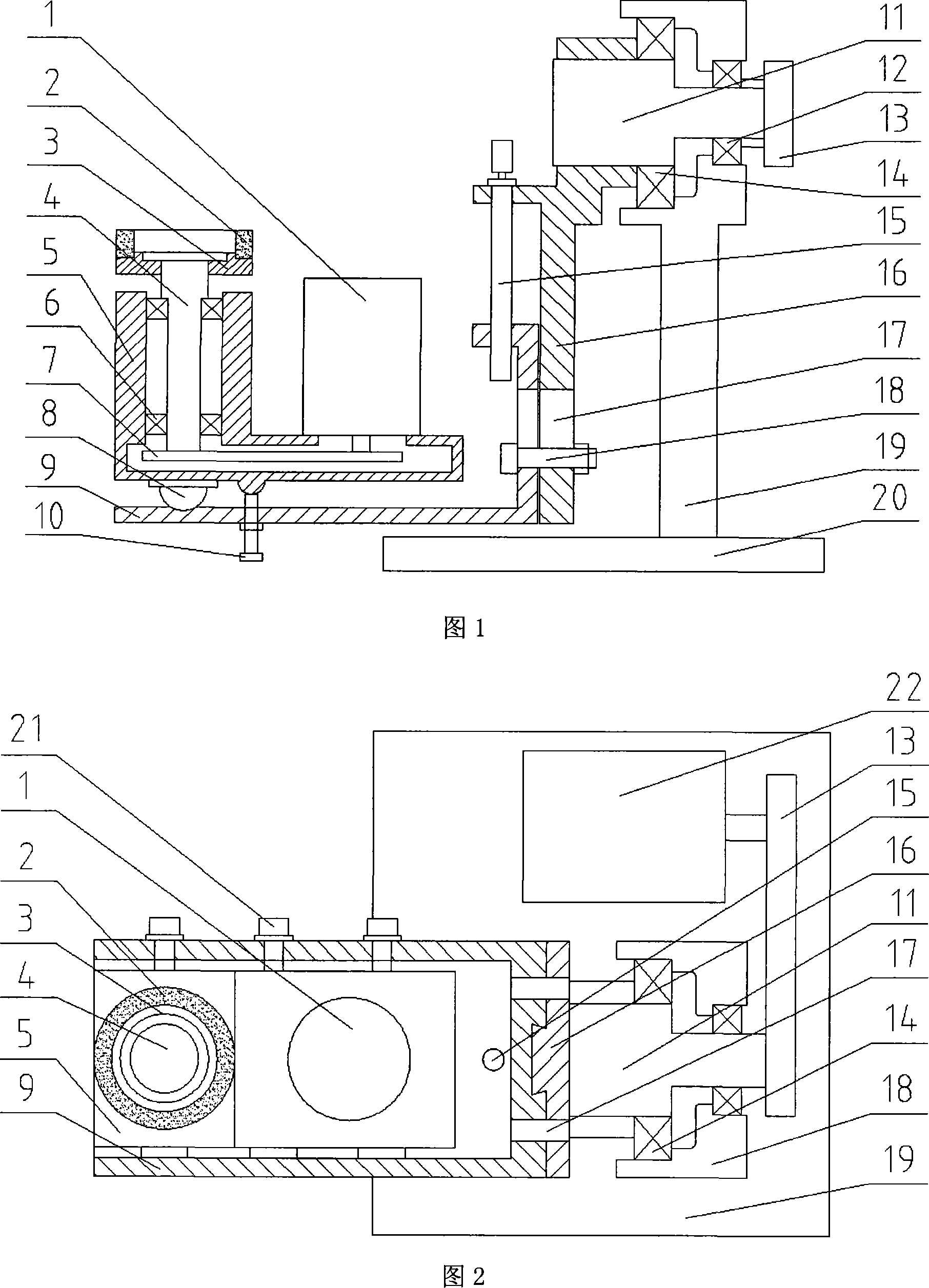

Grinding bed dresser

InactiveCN1428225APrecise TrimmingSimple structureAbrasive surface conditioning devicesControl theoryGrinding wheel

The present invention relates to a grinding wheel dresser for circular grinding machine, including abrasive dresser, base seat and numerical control system. The base seat is mounted on the working table of grinding machine, on the base seat a rotating disk is set, the numerical control system can be used for controlling servo motor to drive the rotating disk and make it rotate, the dresser is mounted on the rotating disk, and said dresser can be used for directly finished grinding wheel. Said invention can accurately finish various curved grinding wheels.

Owner:SHANTOU UNIV

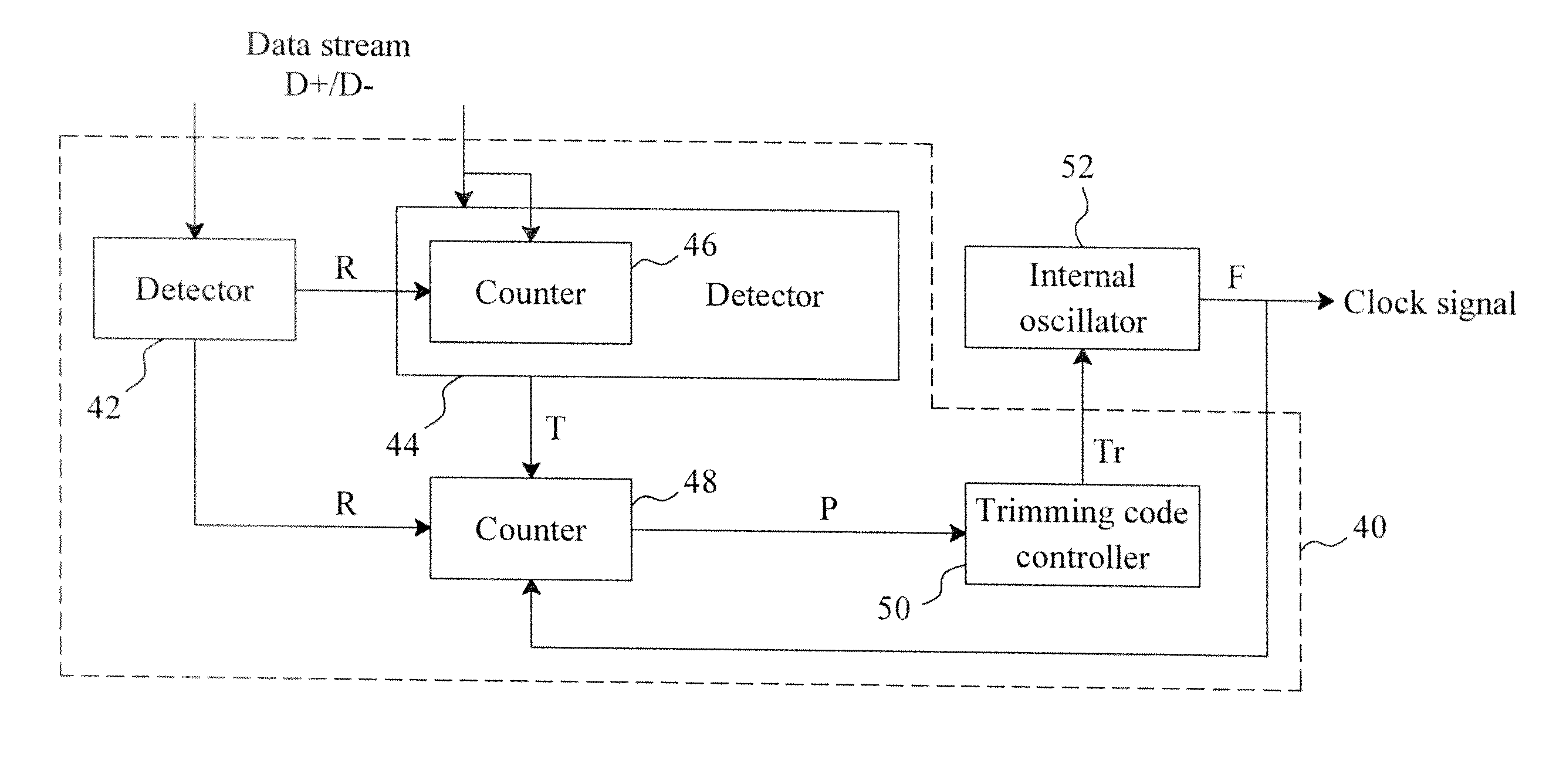

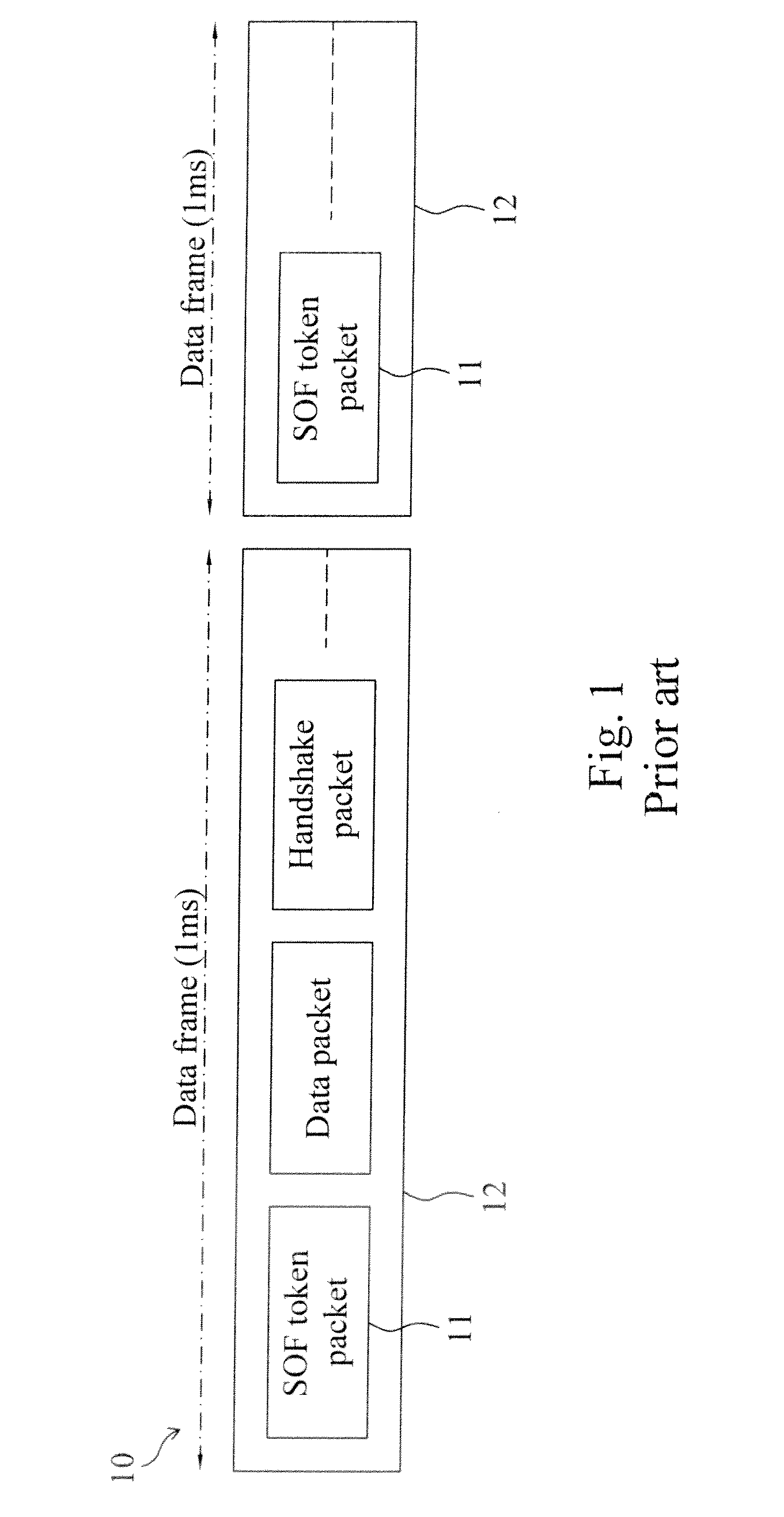

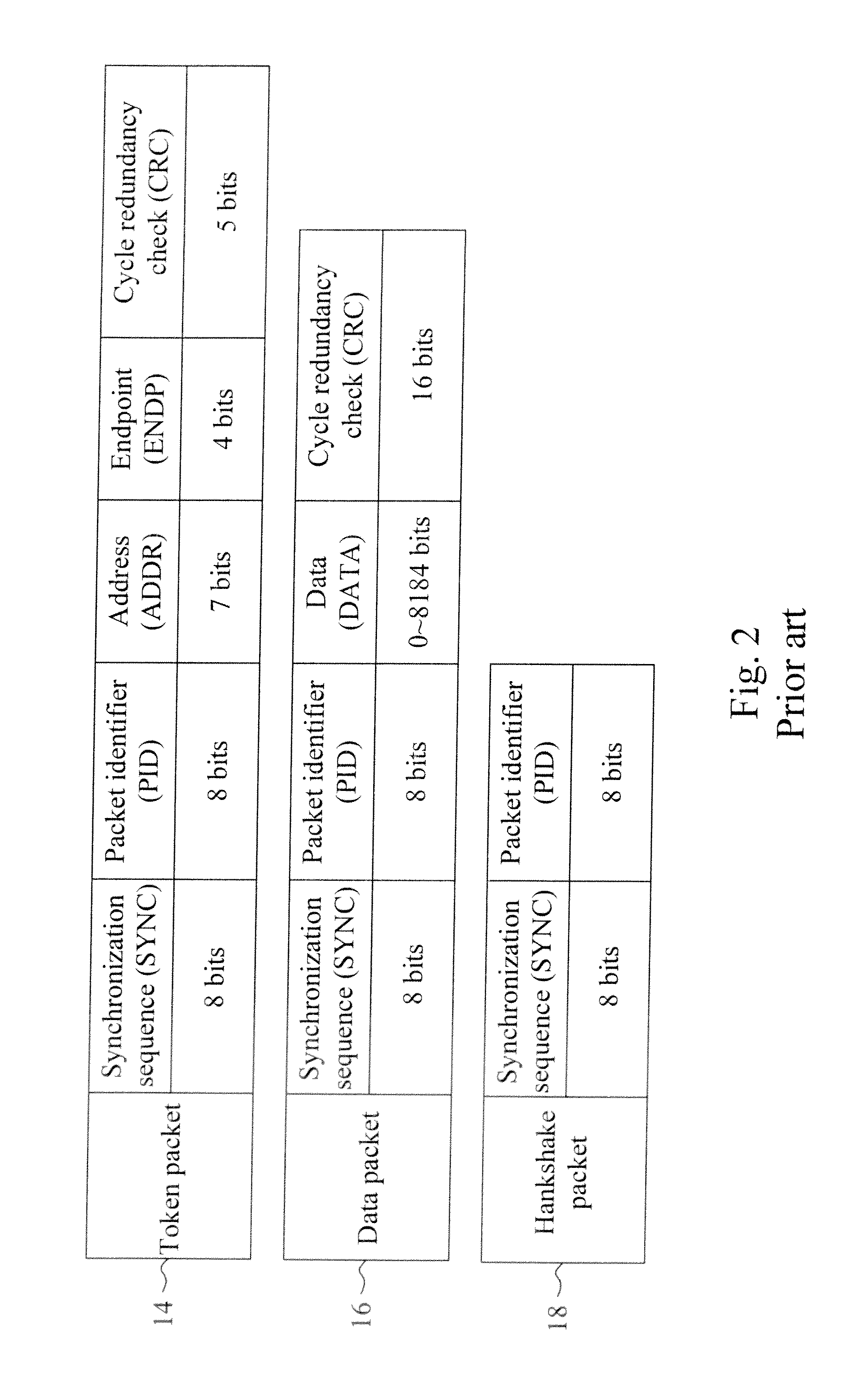

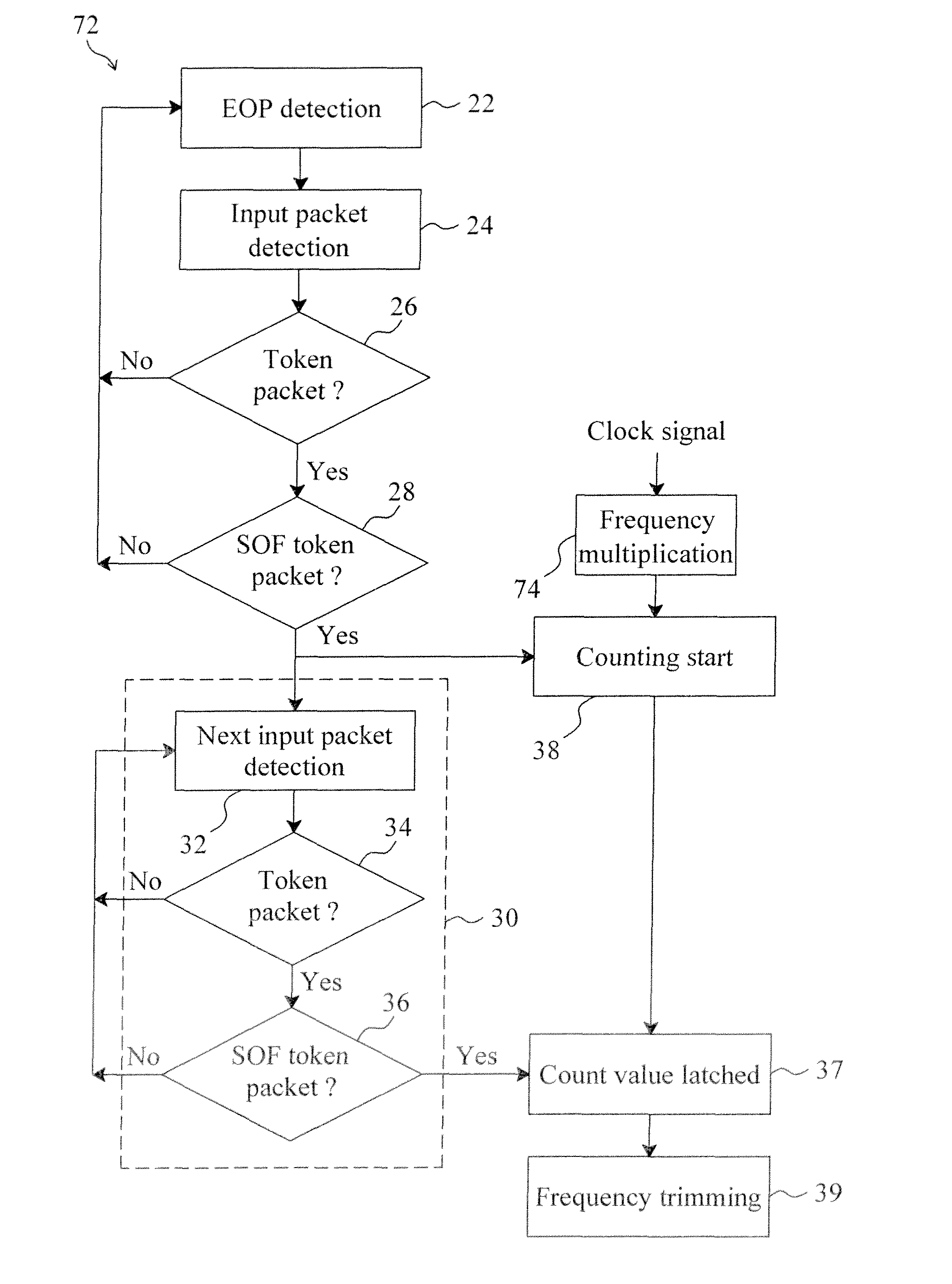

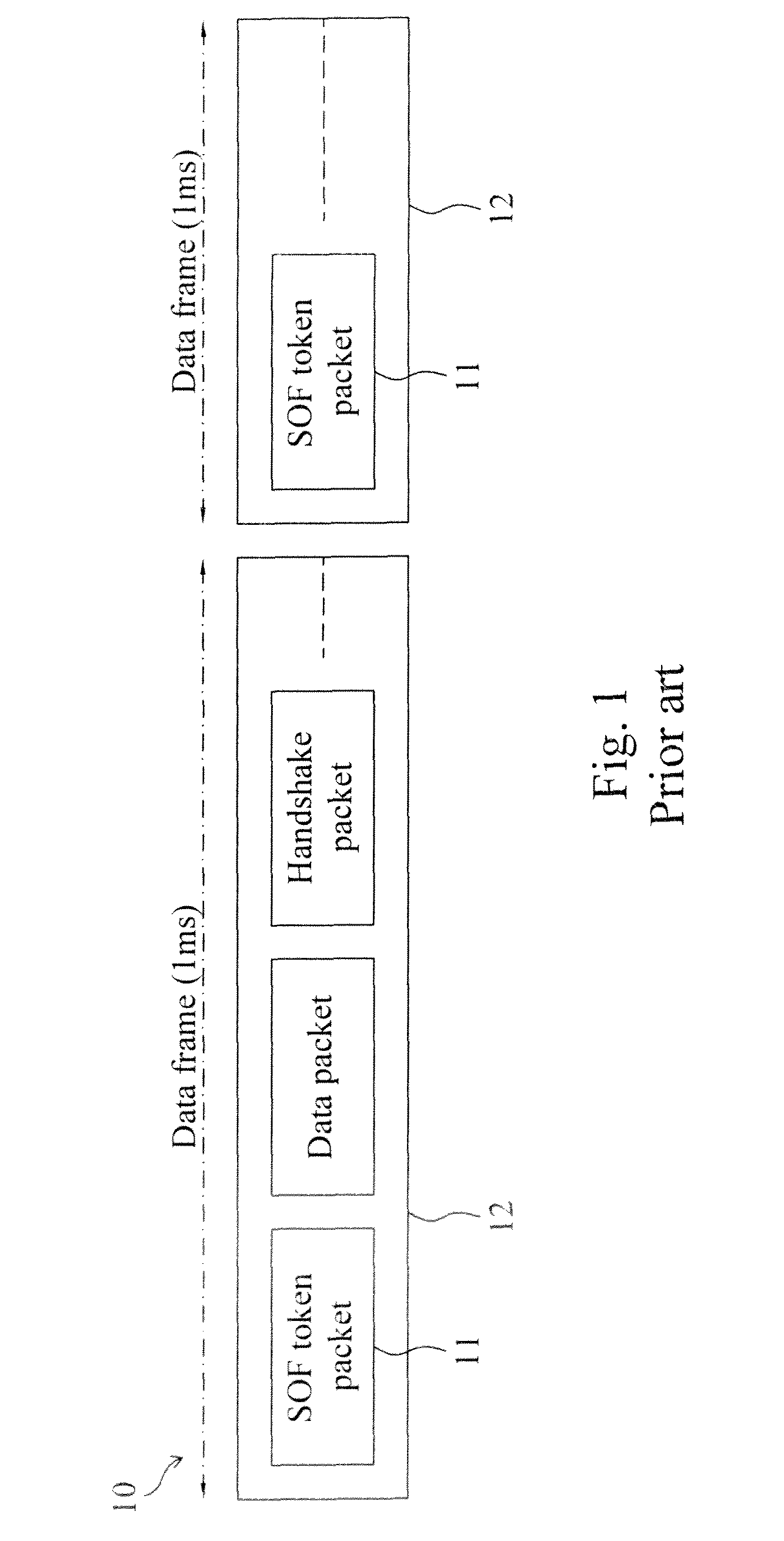

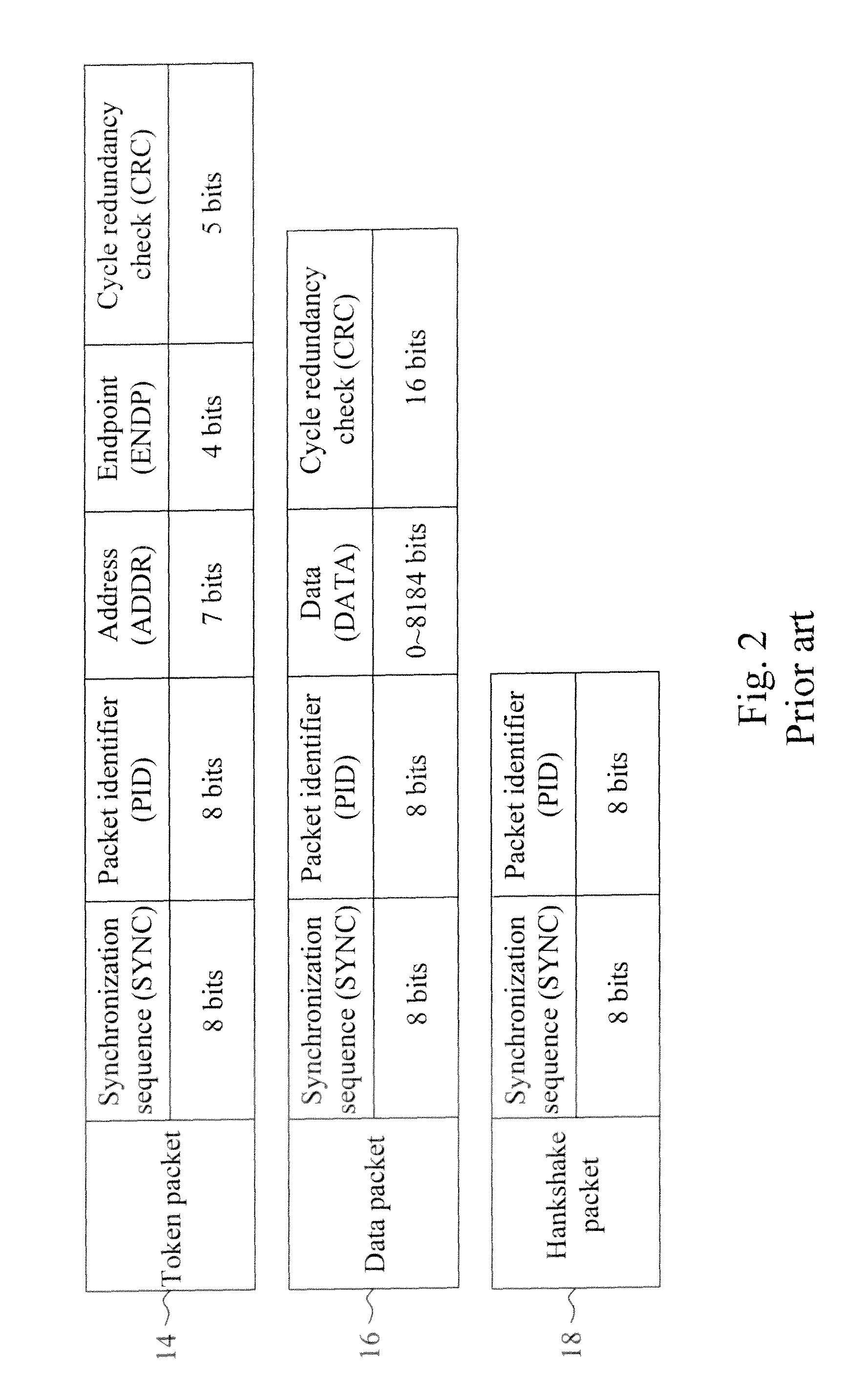

Method and circuit for trimming an internal oscillator of a USB device

InactiveUS20110093736A1Reduce trimming timeSimplifying trimming circuitPulse transformerPulse automatic controlData streamClock rate

A circuit and method for trimming an internal oscillator of a USB device that generates a clock signal as a frequency source of the USB device detect an end of packet from an input data stream to initialize a counter, identify a token packet in the data stream to detect a start of frame token packet for the counter to carry out clock counting on the clock signal to thereby obtain a count value, and compare the count value with a reference value to determine a trimming code for trimming a clock frequency of the internal oscillator.

Owner:ELAN MICROELECTRONICS CORPORATION

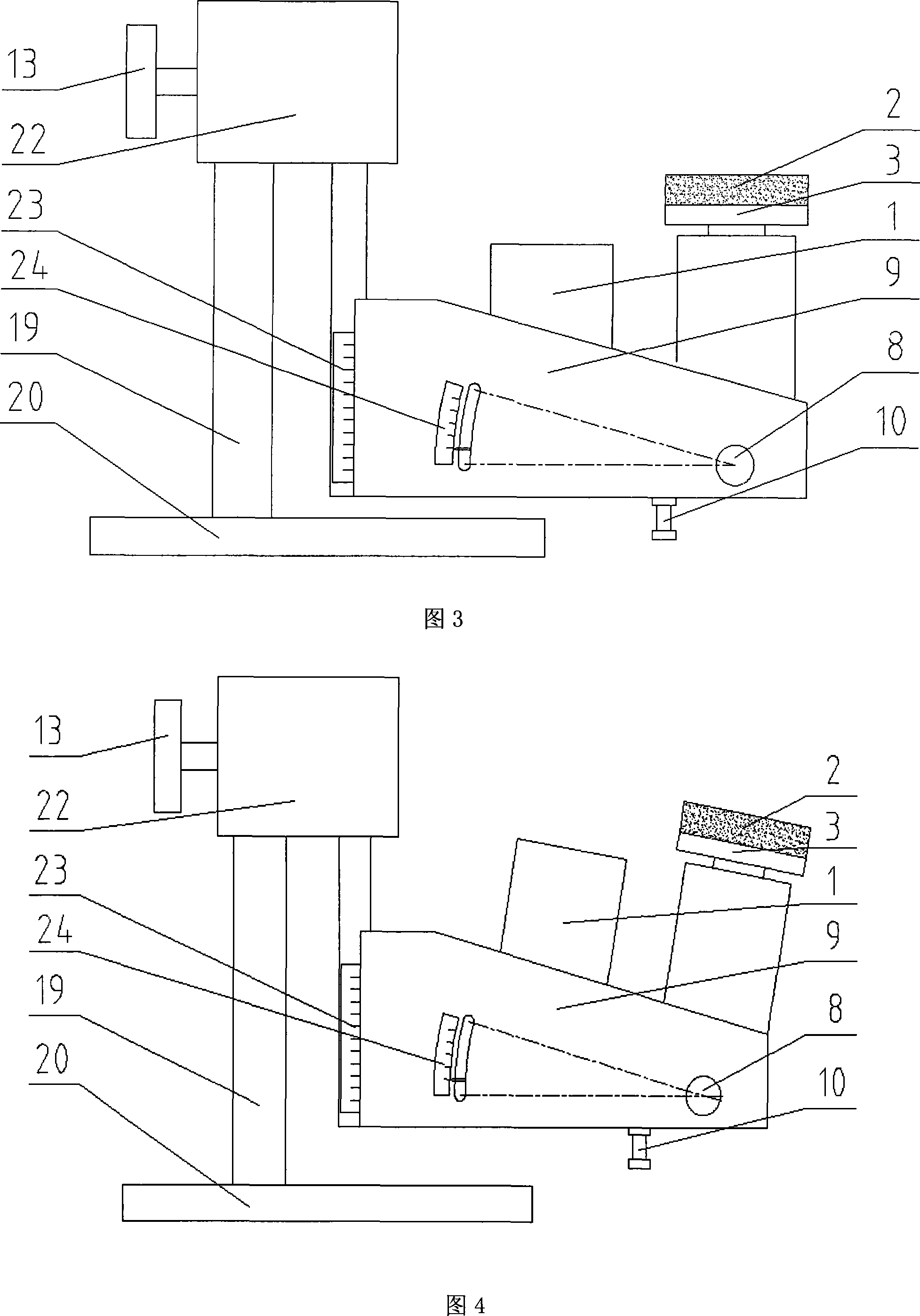

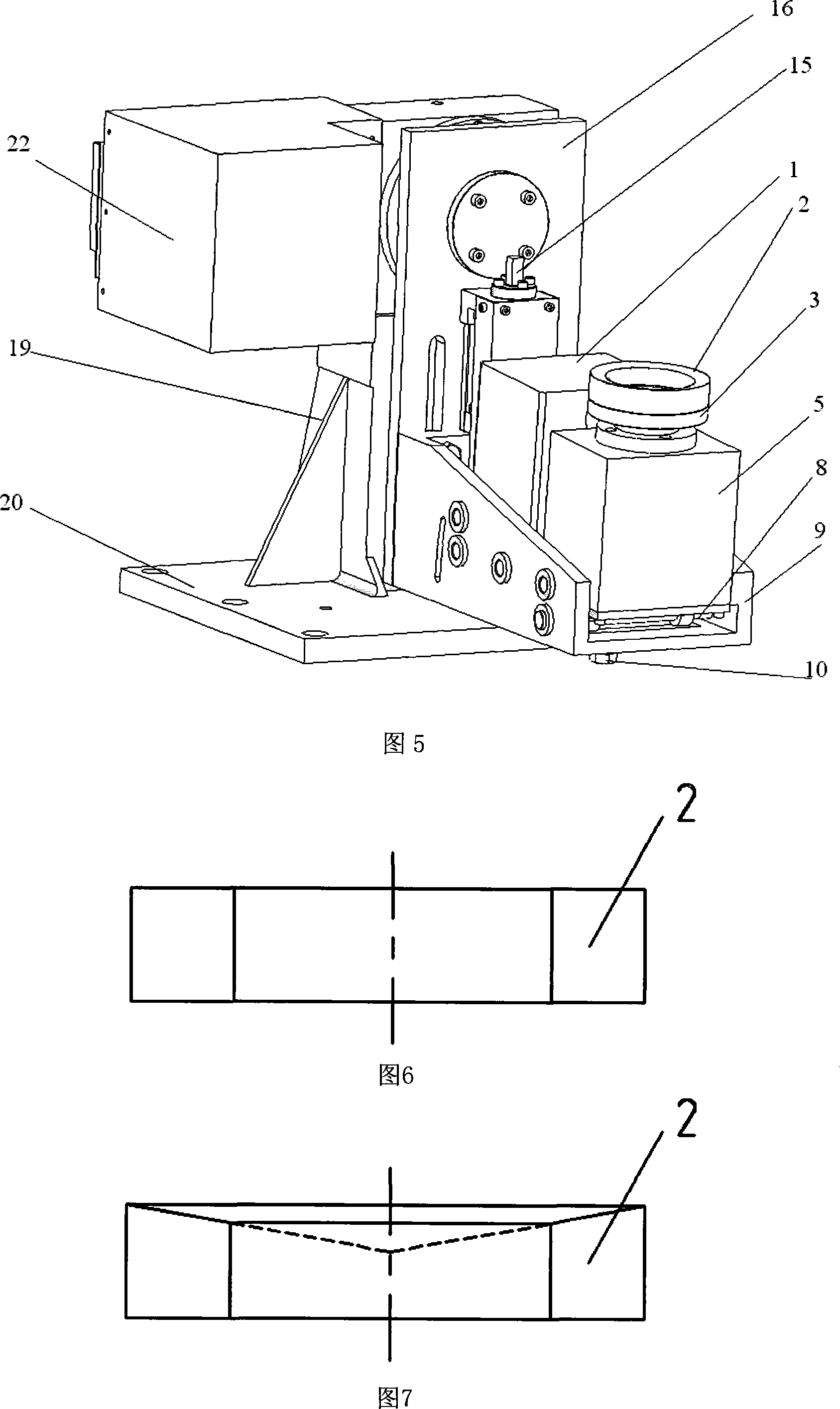

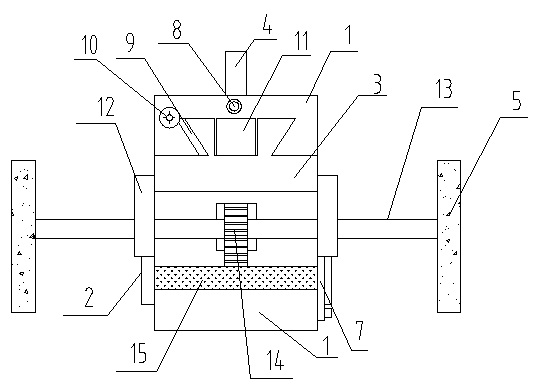

Cup type grinding wheel trimming device

InactiveCN101121250APrecise TrimmingTrim powerfulAbrasive surface conditioning devicesControl systemEngineering

A cup-shaped wheel dresser relates to a non-sphere processing grinding wheel; the wheel dresser provides a cup-shaped wheel dresser; the height and inclination of the wheel dresser are adjustable and the wheel dresser has the oscillating function. The wheel dresser is equipped with a base, an oscillating arm support saddle, an oscillating arm rotary shaft, a dressing grinding wheel, a grinding wheel panel, a main shaft, a main shaft band wheel box, servo motors, transmission mechanisms, a screw, a bolt, a supporting round stick, a triangle support saddle, runners and a numerically controlled system. The oscillating arm is equipped on the base and the oscillating arm base is connected with the oscillating arm rotary shaft. The grinding wheel is connected with the main shaft and the grinding wheel is installed on the main shaft; the main shaft is connected with the main shaft band wheel box; the first servo motor is connected with the main shaft by the first transmission mechanism and the second servo motor is connected with the oscillating arm rotary shaft by the second transmission mechanism. The bottom of the main shaft band wheel box is connected with the triangle support saddle and fixed on the triangle supported saddle; the bolt is equipped under the triangle support saddle and the triangle support saddle is connected with the oscillating arm; the screw is equipped on the oscillating arm and the triangle support saddle is linked with the lower end of the screw; the triangle support saddle and the oscillating arm are equipped with runners and the numerically controlled system is connected with the servo motors.

Owner:XIAMEN UNIV

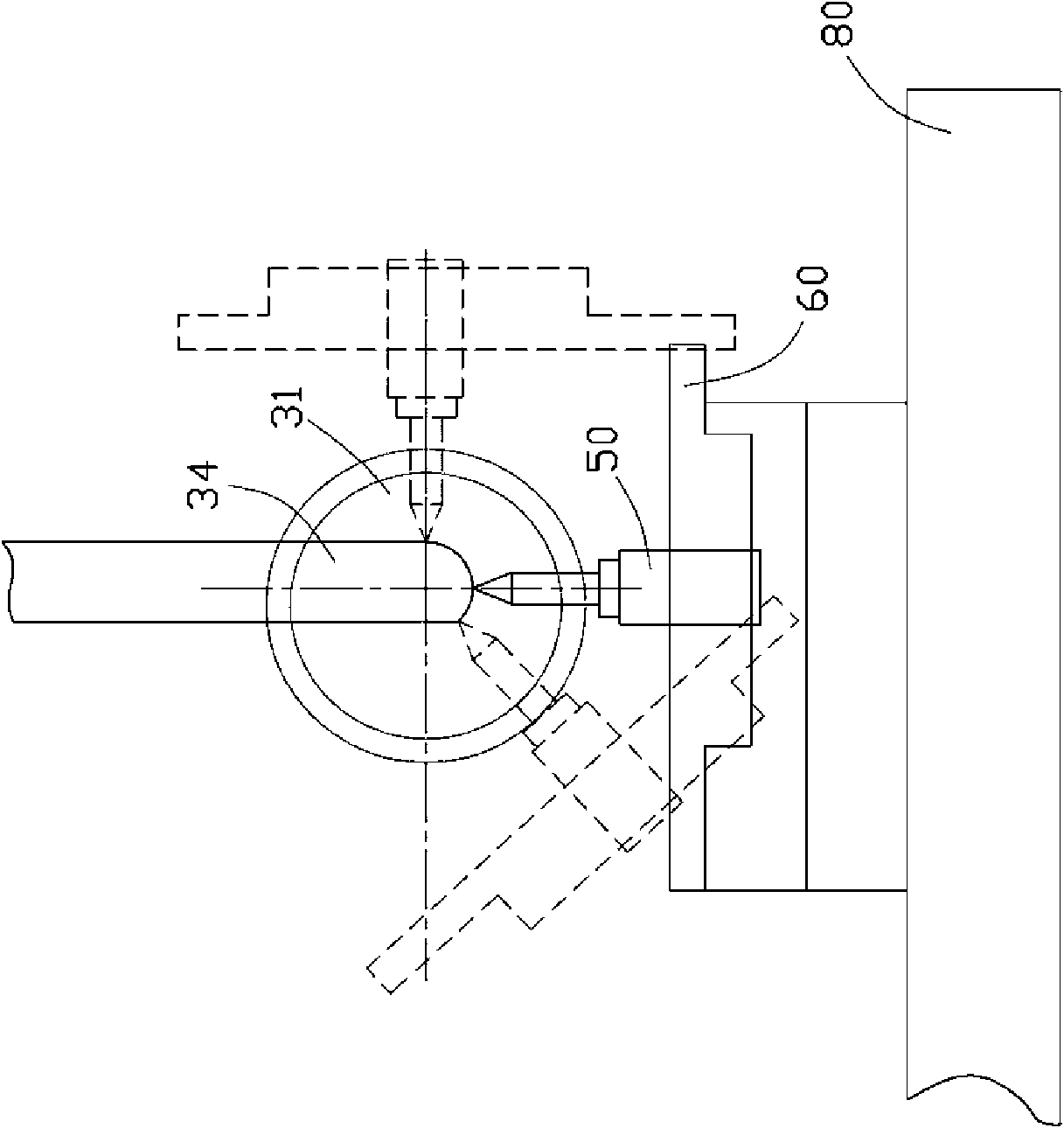

Angular trimmer for grinding wheel of grinding machine

InactiveCN102601737APrecise TrimmingImprove work efficiencyAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention provides an angular trimmer for a grinding wheel of a grinding machine, which comprises a bottom plate, a diamond stylus, a sliding plate, a slider, a circular gear, a rotary rod and an adjusting supporting rod. The sliding plate is provided with a protrusion which is provided with a slot extending through the whole protrusion, the slider is provided with a groove, a strip toothed boss with a toothed opening is arranged at the bottom of the groove, the groove of the slider is slidably fixed with the protrusion of the sliding plate, and the groove is slidably fixed with the toothed boss. The diamond stylus is perpendicularly fixed to one face of the slider, one side of the sliding plate is movably and fixedly connected with the side of the bottom plate through the adjusting supporting rod, an adjusting gasket is arranged on a slide on one side of the sliding plate and fixed by a screw, and connecting blocks with symmetrical through holes are fixedly arranged on two sides of the sliding plate. The rotary rod penetrates through the through holes to be movably fixed with the connecting blocks, the circular gear is fixedly arranged on the rotary rod, the sliding plate is provided with an open slot, and the circular gear is meshed with the toothed boss through the open slot. The position of the slider and the height of the sliding plate are adjusted to fit angular adjustment of large-diameter grinding wheels.

Owner:MAANSHAN JINGHUA MACHINERY KNIFE & MOLD MFR

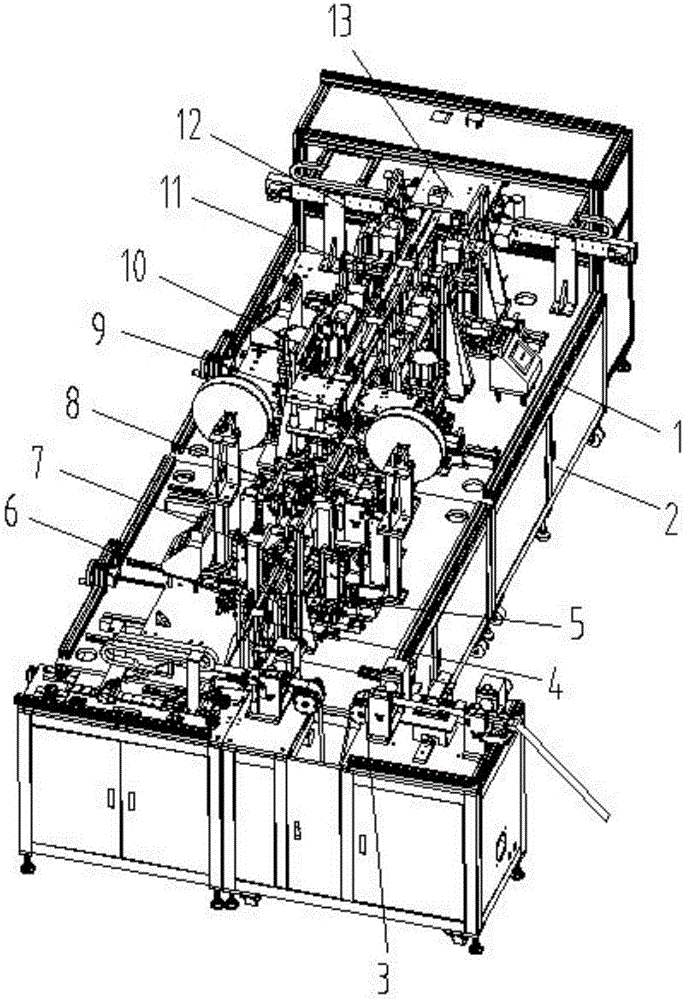

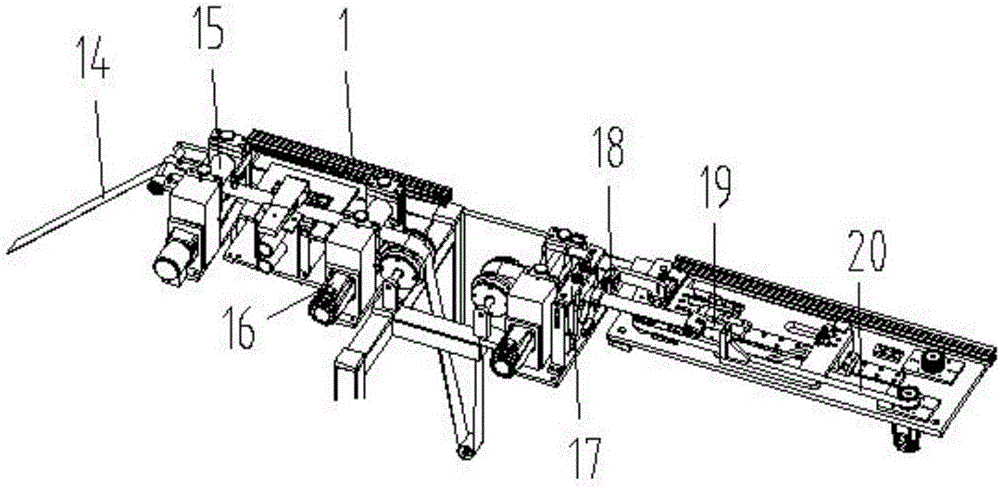

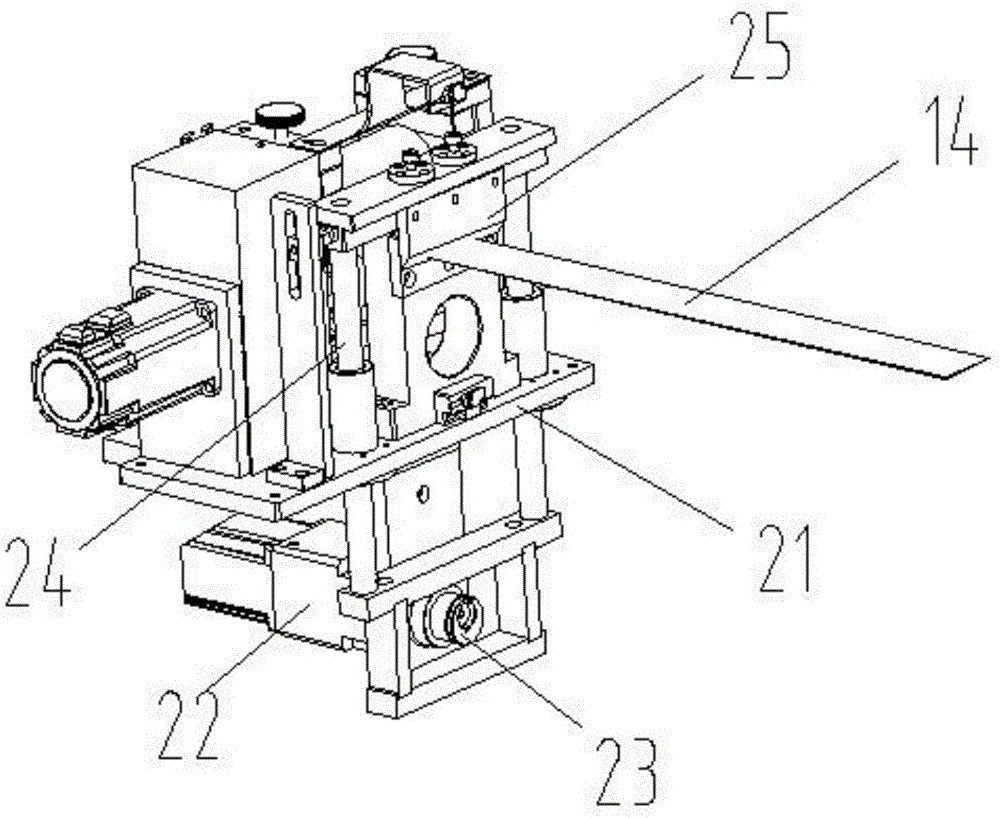

Fully-automated flexible flat cable pipe processing machine

ActiveCN106782888AImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistribution controlVisual inspection

The invention relates to a fully-automated flexible flat cable pipe processing machine. The fully-automated flexible flat cable pipe processing machine comprises a frame and a power distribution control cabinet, wherein the frame is provided with a conveying chute and a feeding device which are matched with each other; the feeding device comprises a feeding forward-backward movement device, and the feeding forward-backward movement device is provided with a feeding left-right movement device; a feeding lifting device is arranged on the feeding left-right movement device, uniformly provided with a feeding clamp matched with products, and provided with a feeding guide rod matched with the conveying chute; the frame is sequentially provided with an edge spacing detecting device, a wire stripping device, an adhesive applying device, a heat pressing device, a trimming device, a visual inspection device and a circuit detecting device, which are matched with the products on the conveying chute. The fully-automated flexible flat cable pipe processing machine achieves fixed-distance product feeding through matching between the feeding device and the conveying chute and further achieves continuous and integrated flexible flat cable processing, thereby greatly improving the processing efficiency and the yield rate.

Owner:大千纺织(安徽)有限公司

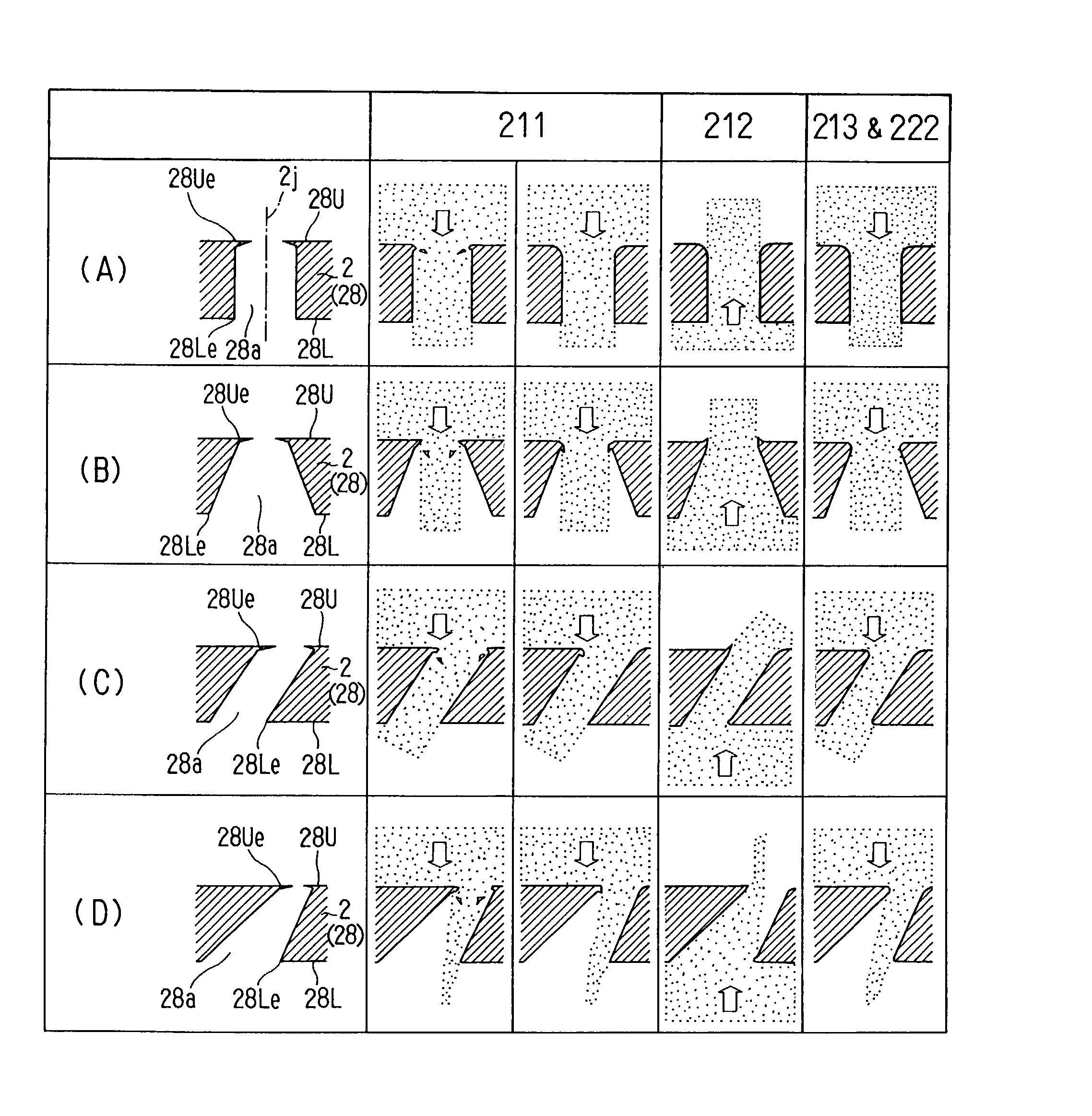

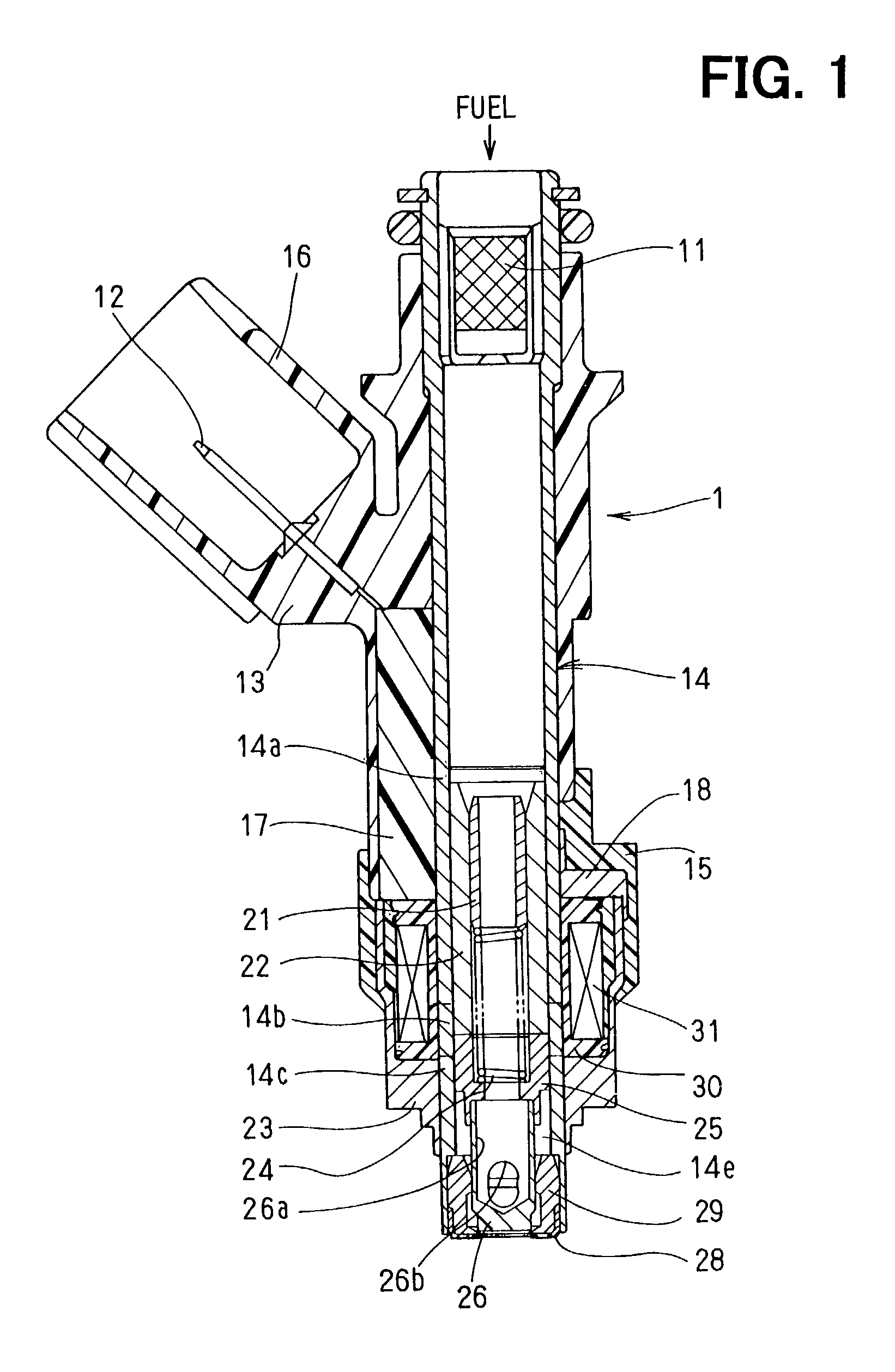

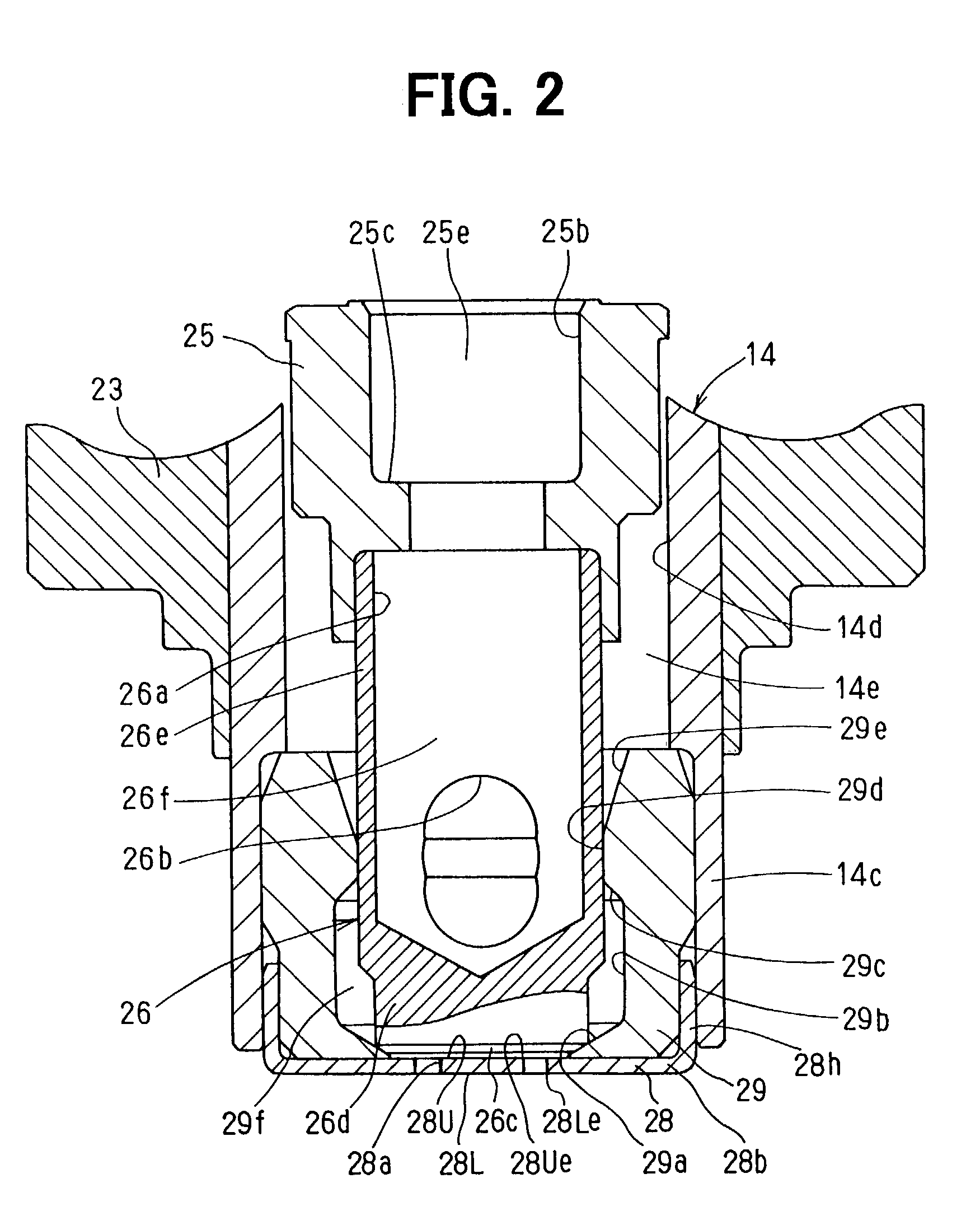

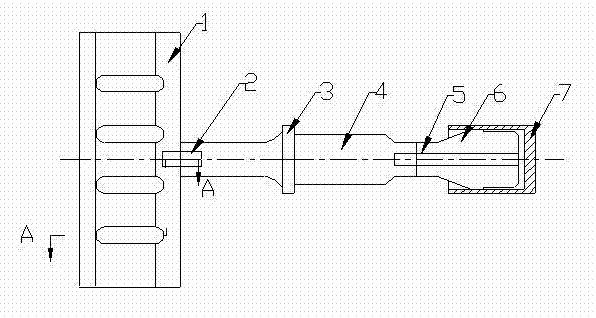

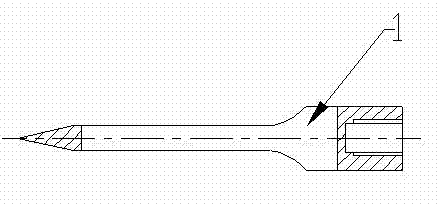

Injector nozzle and method of manufacturing injector nozzle

InactiveUS7003880B2Accurate measurementPrecise TrimmingProgramme controlComputer controlVena contracta diameterInjector nozzle

A fuel injector has an orifice member having an aperture for injecting atomizing and metering fuel. The orifice member is made of a plate material. The orifice member is machined to form the aperture. Then, the orifice member is processed by at least two shot blasting process in opposite directions to remove burrs and trim edges of the aperture. After the process, the orifice plate is inspected by measuring an actual flow rate of the aperture. Then, the orifice plate is processed by a shot blasting process again in accordance with the measured flow rate and a target flow rate.

Owner:DENSO CORP

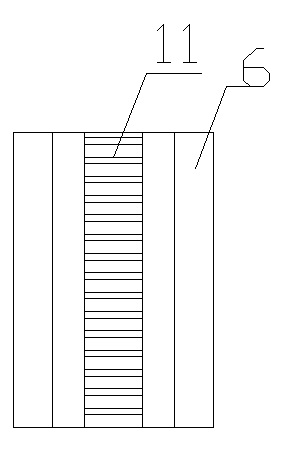

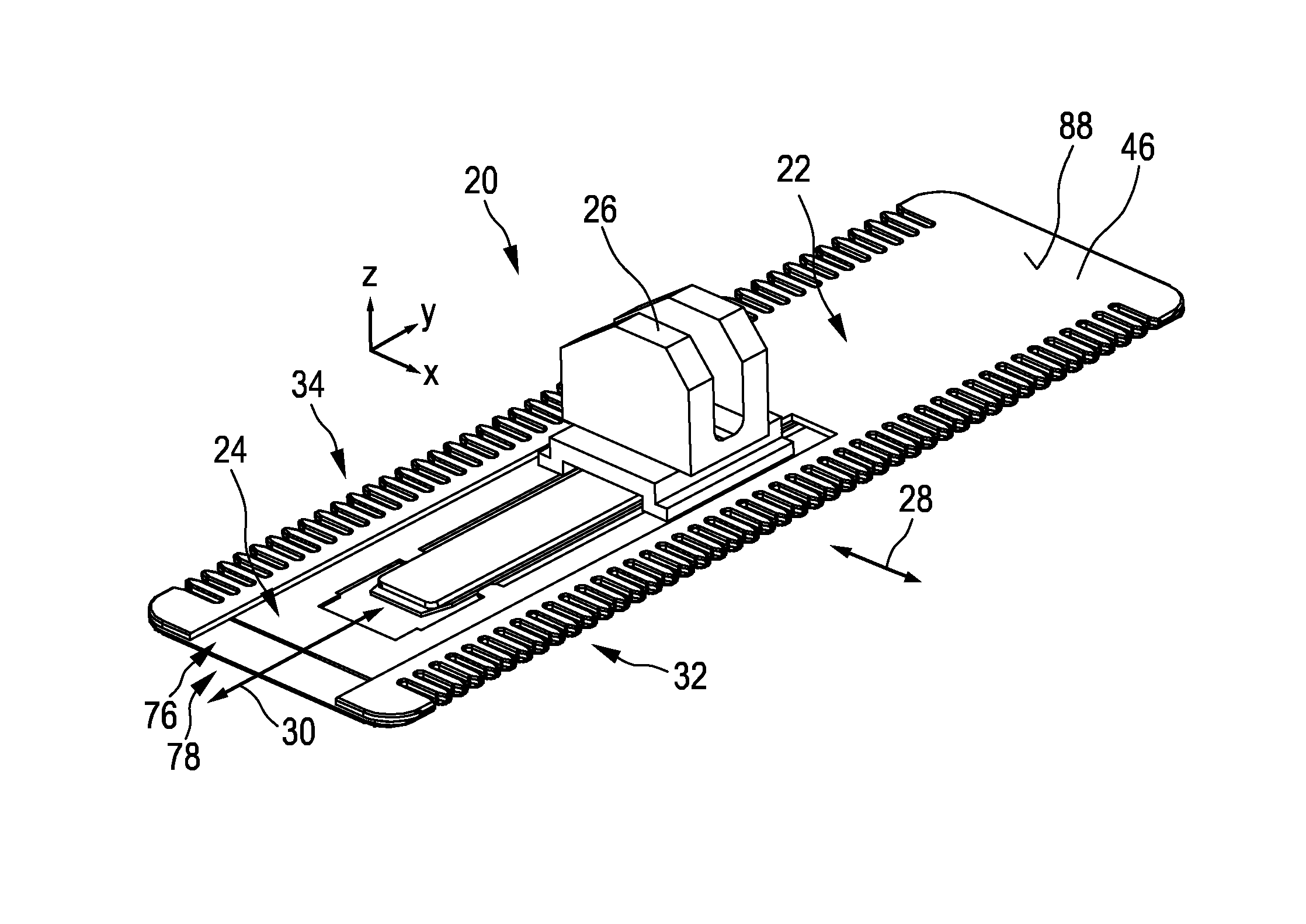

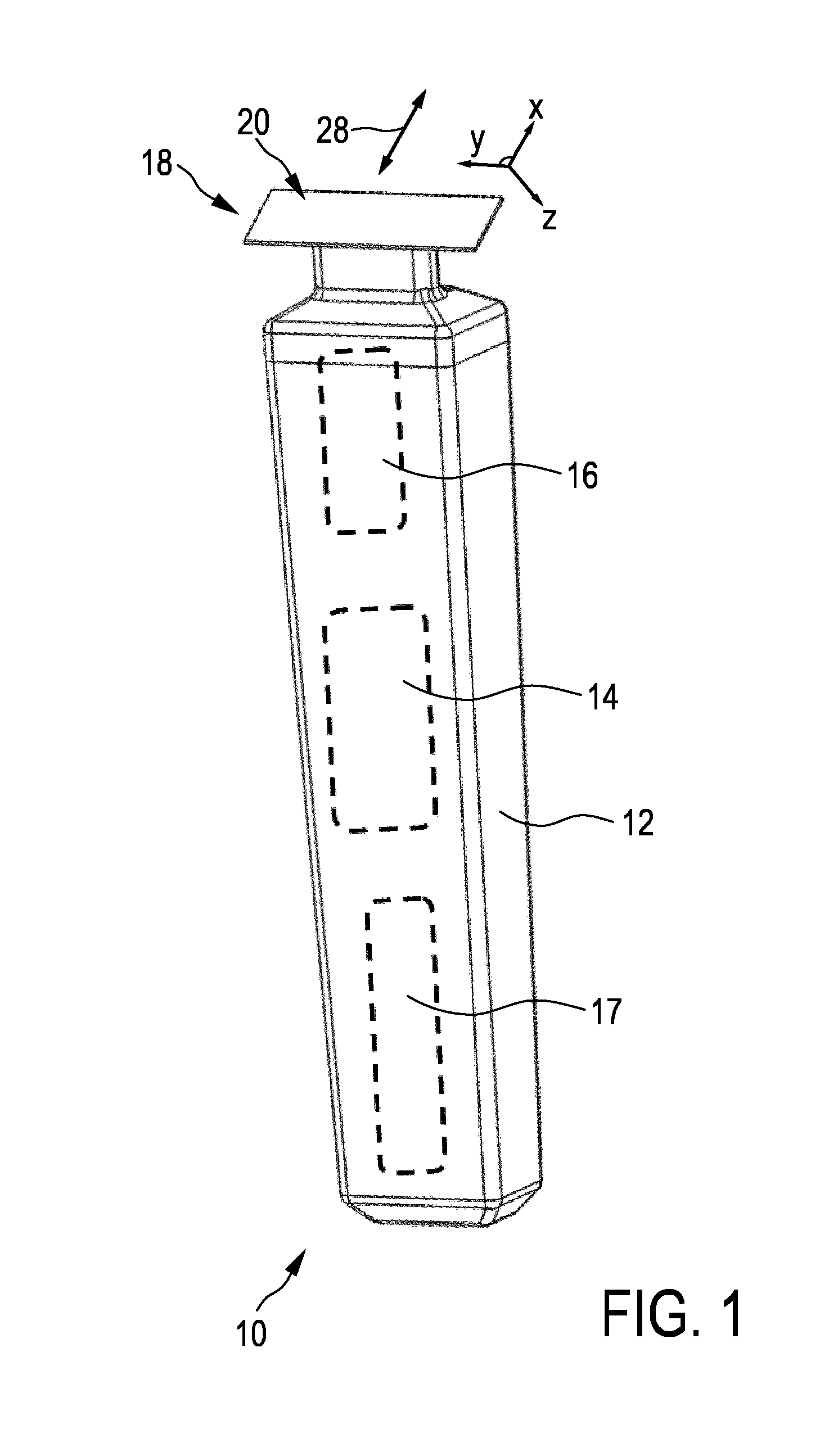

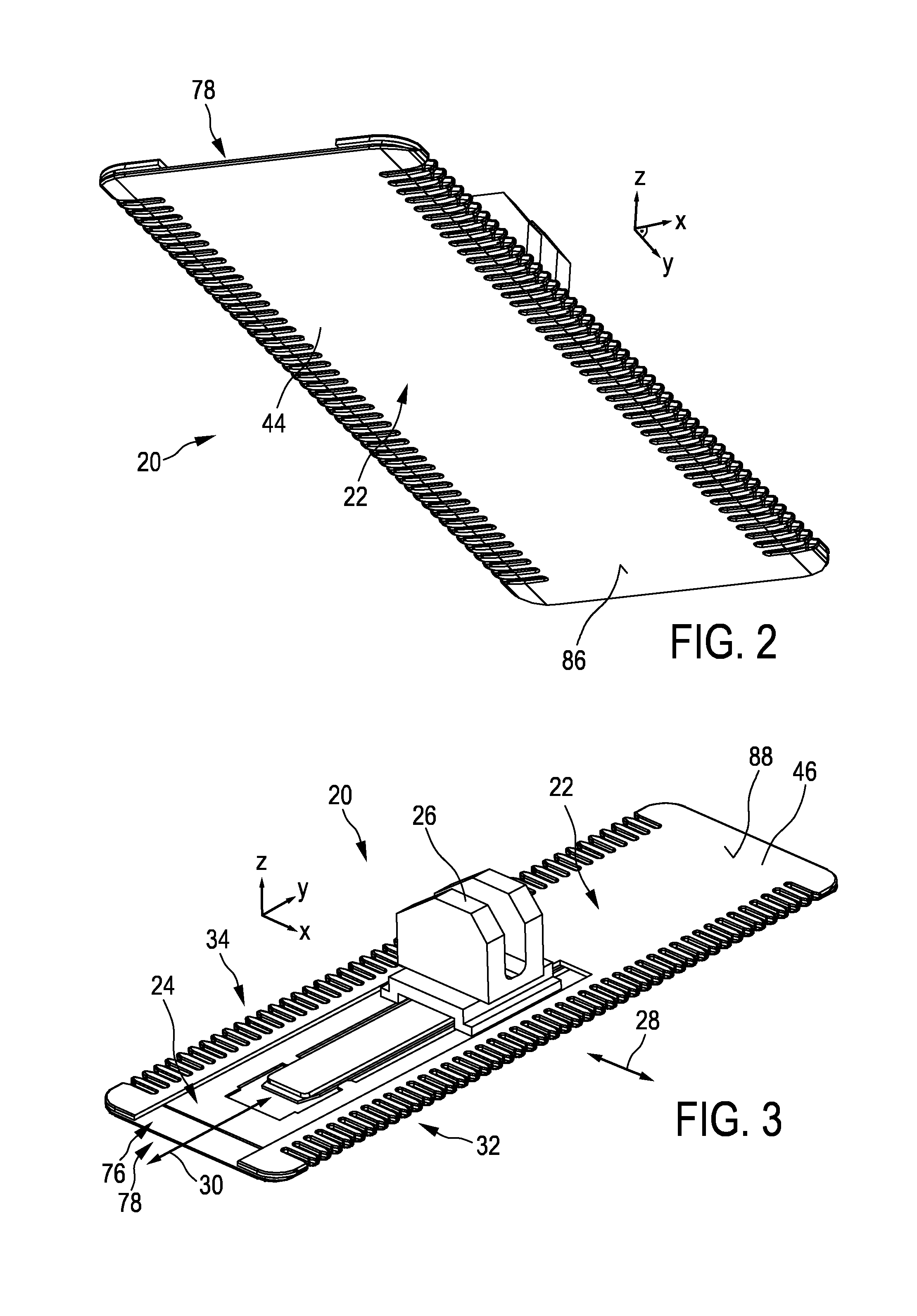

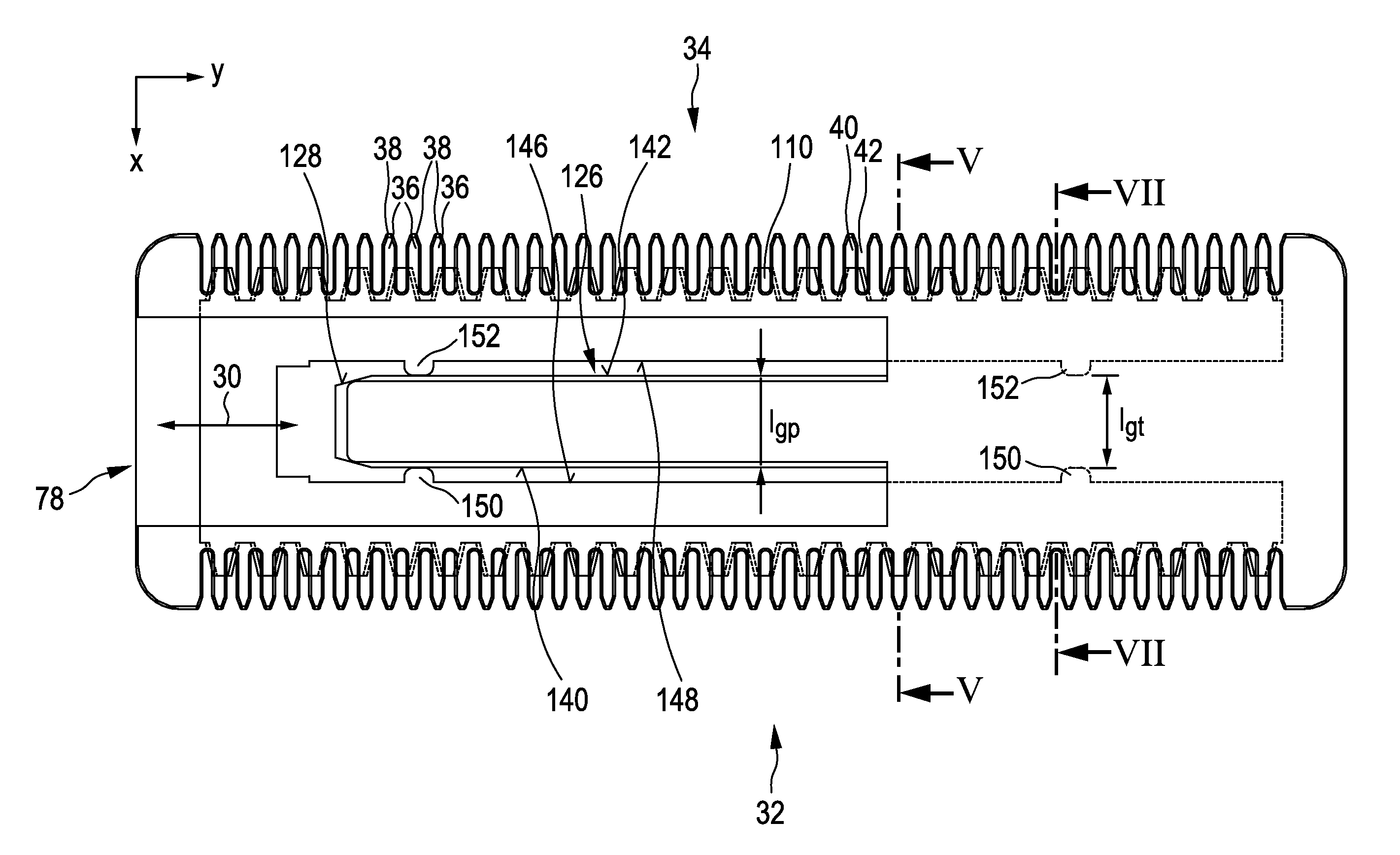

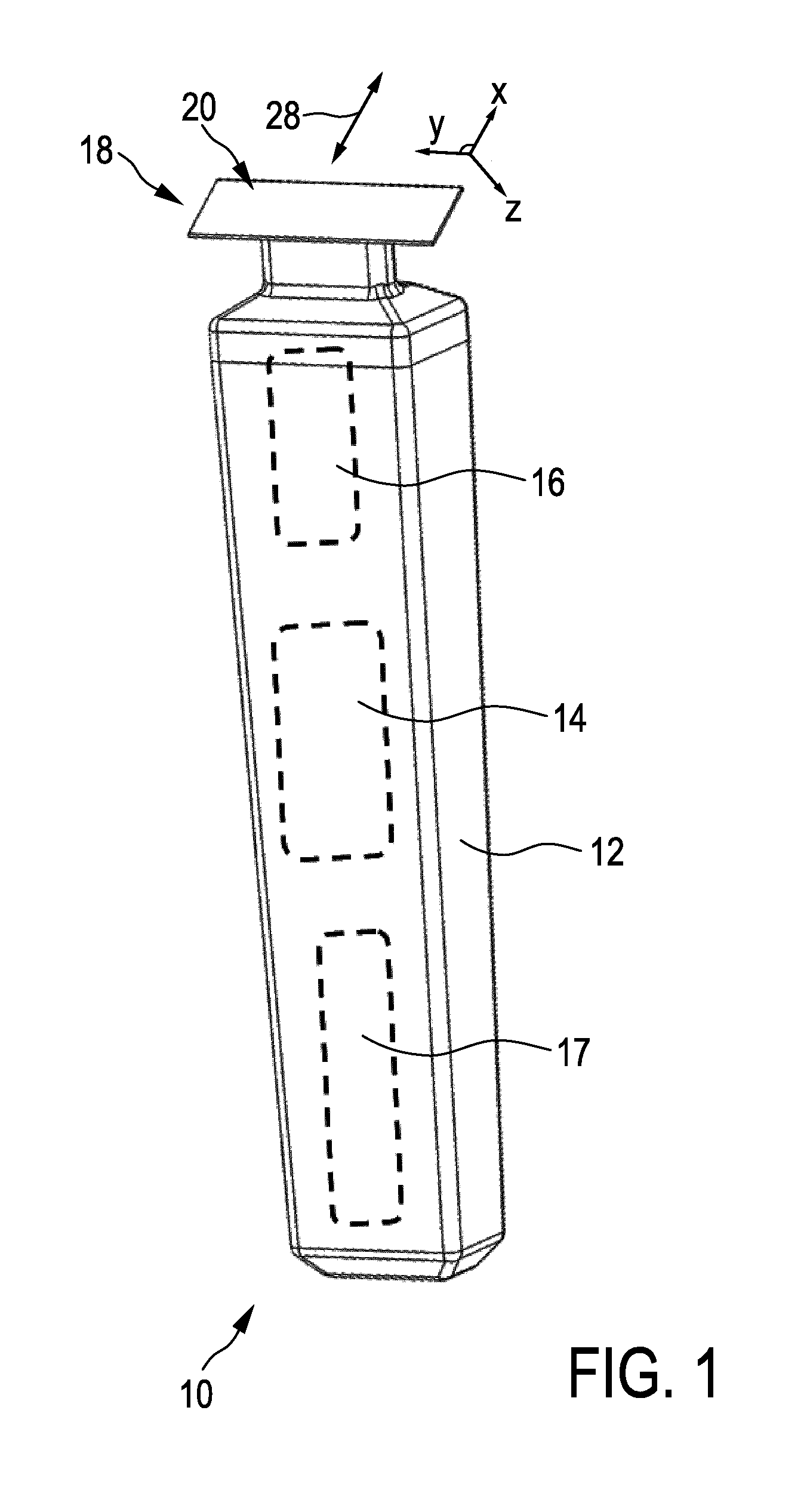

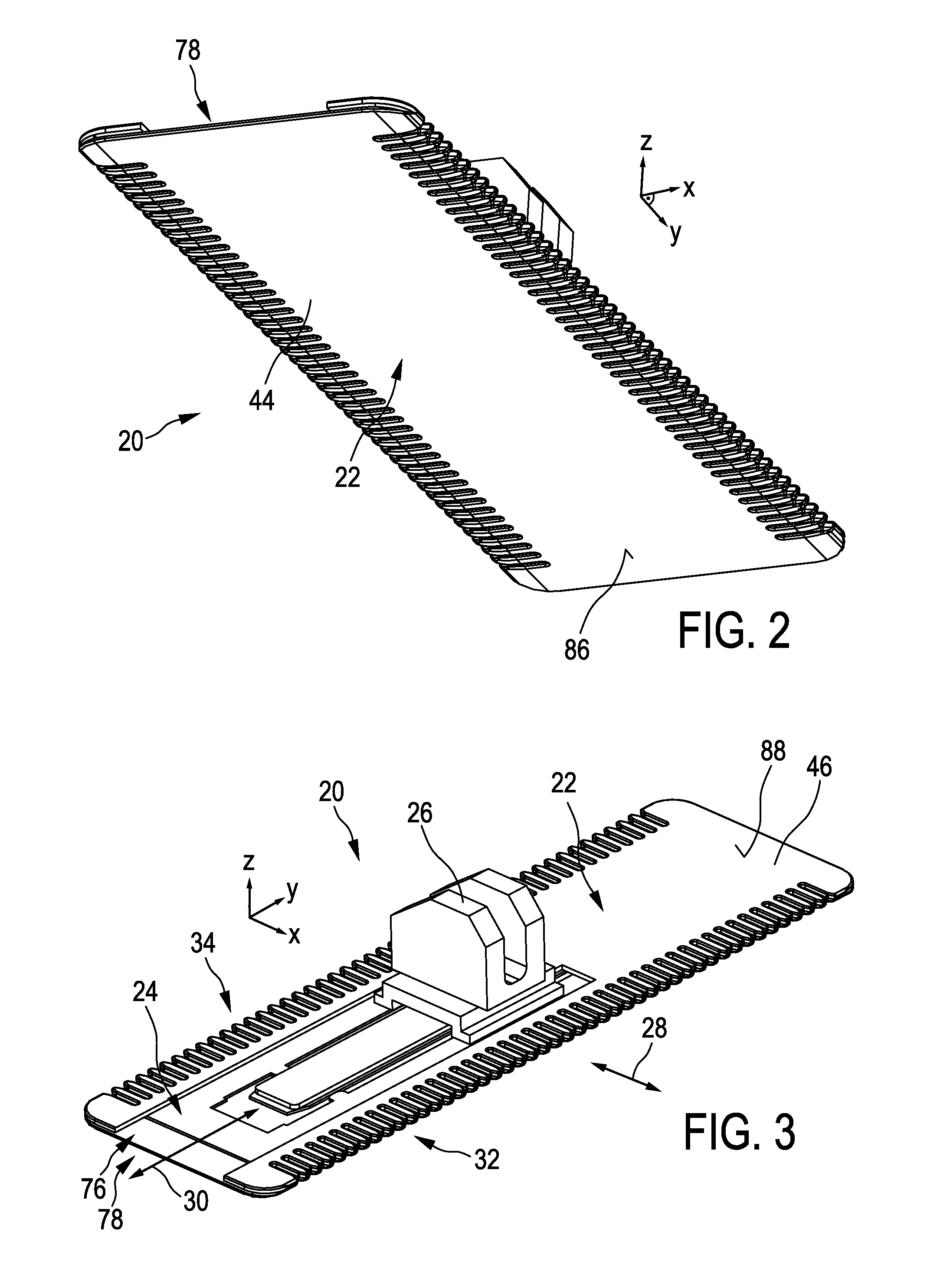

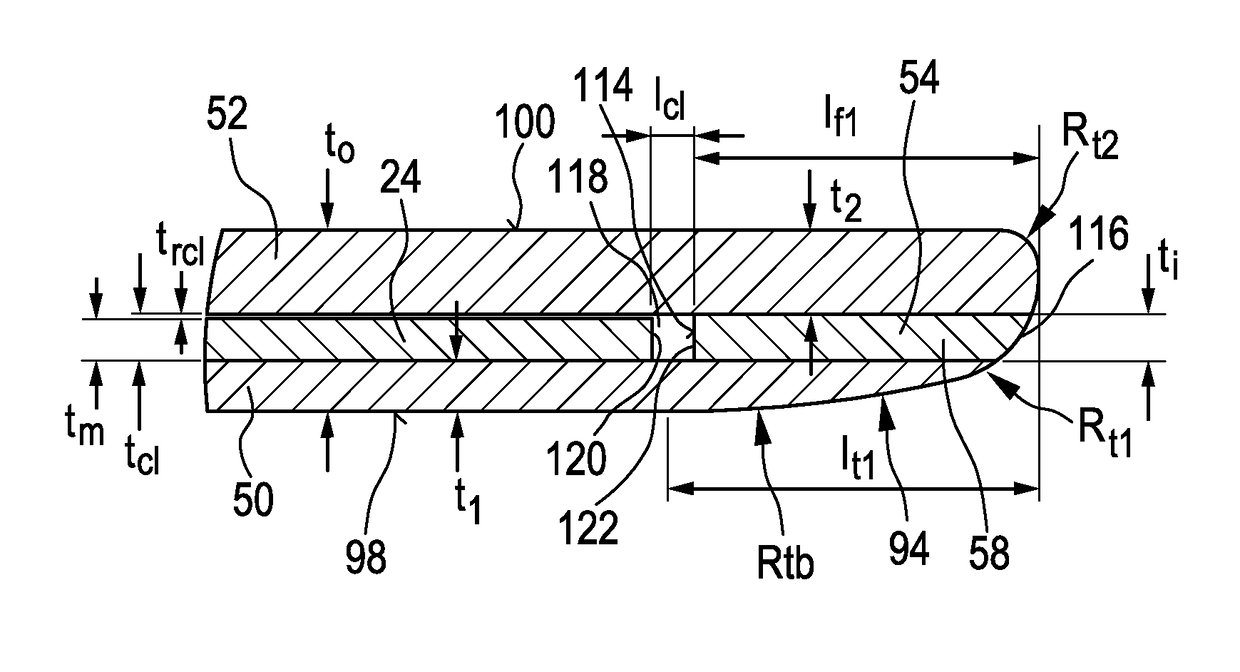

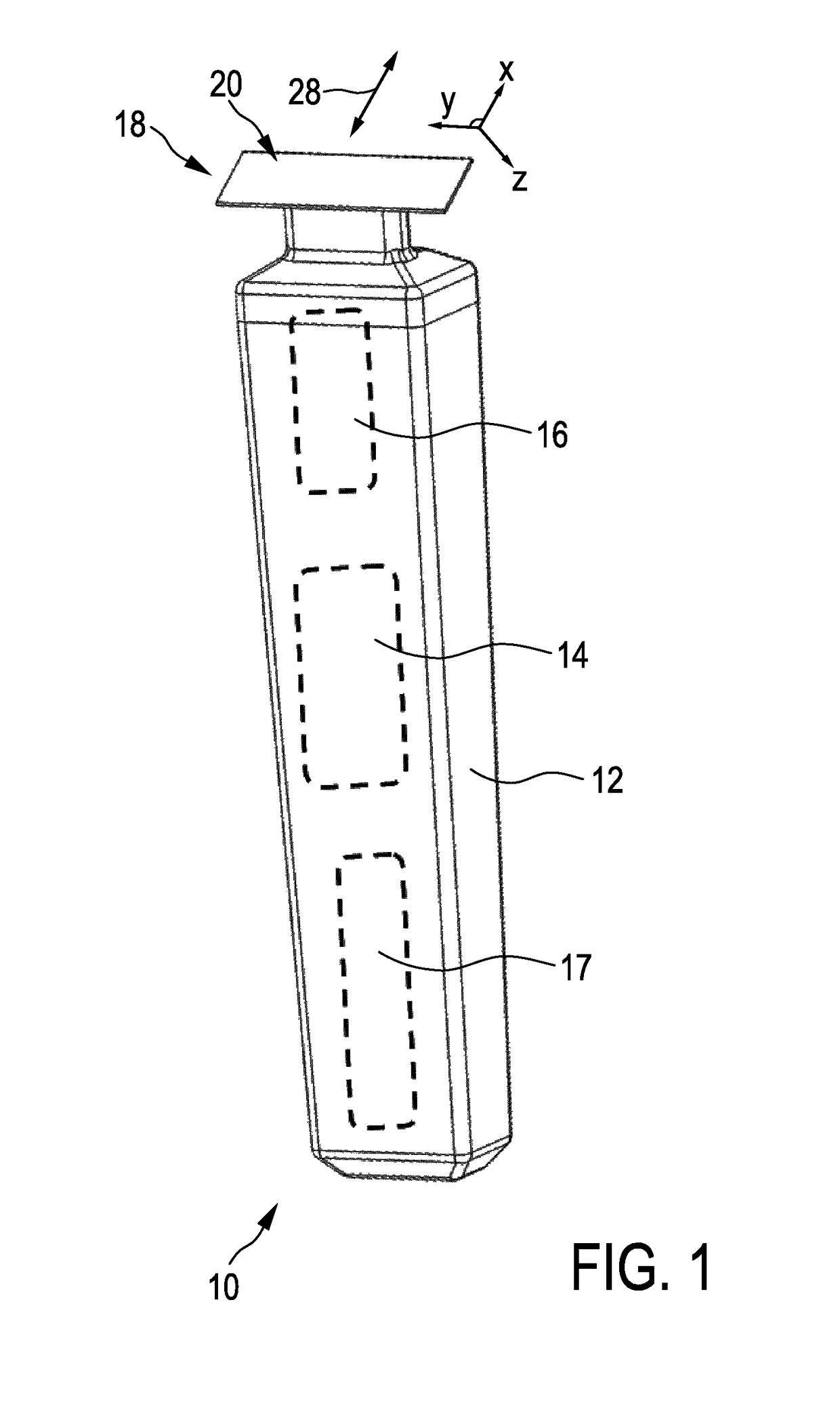

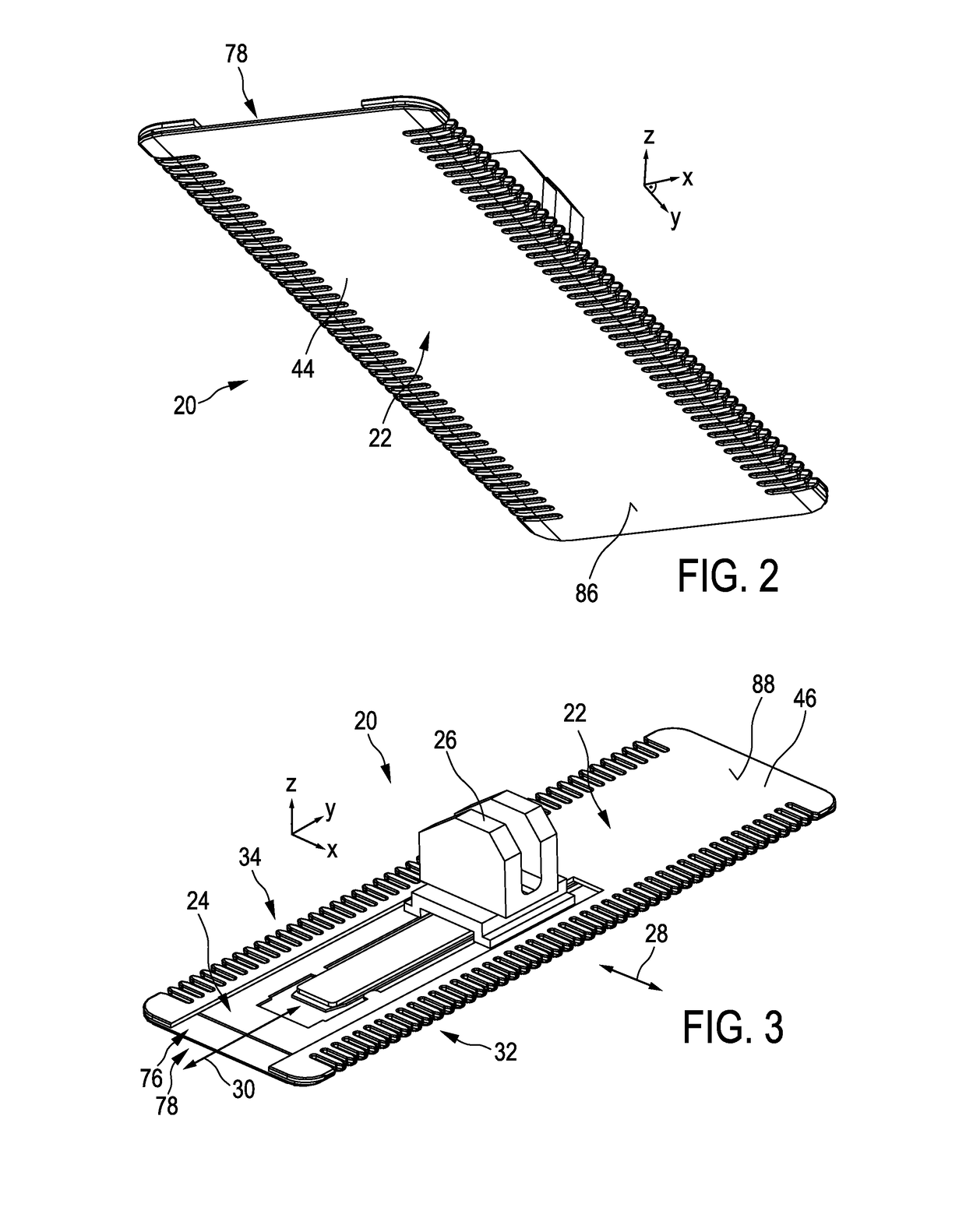

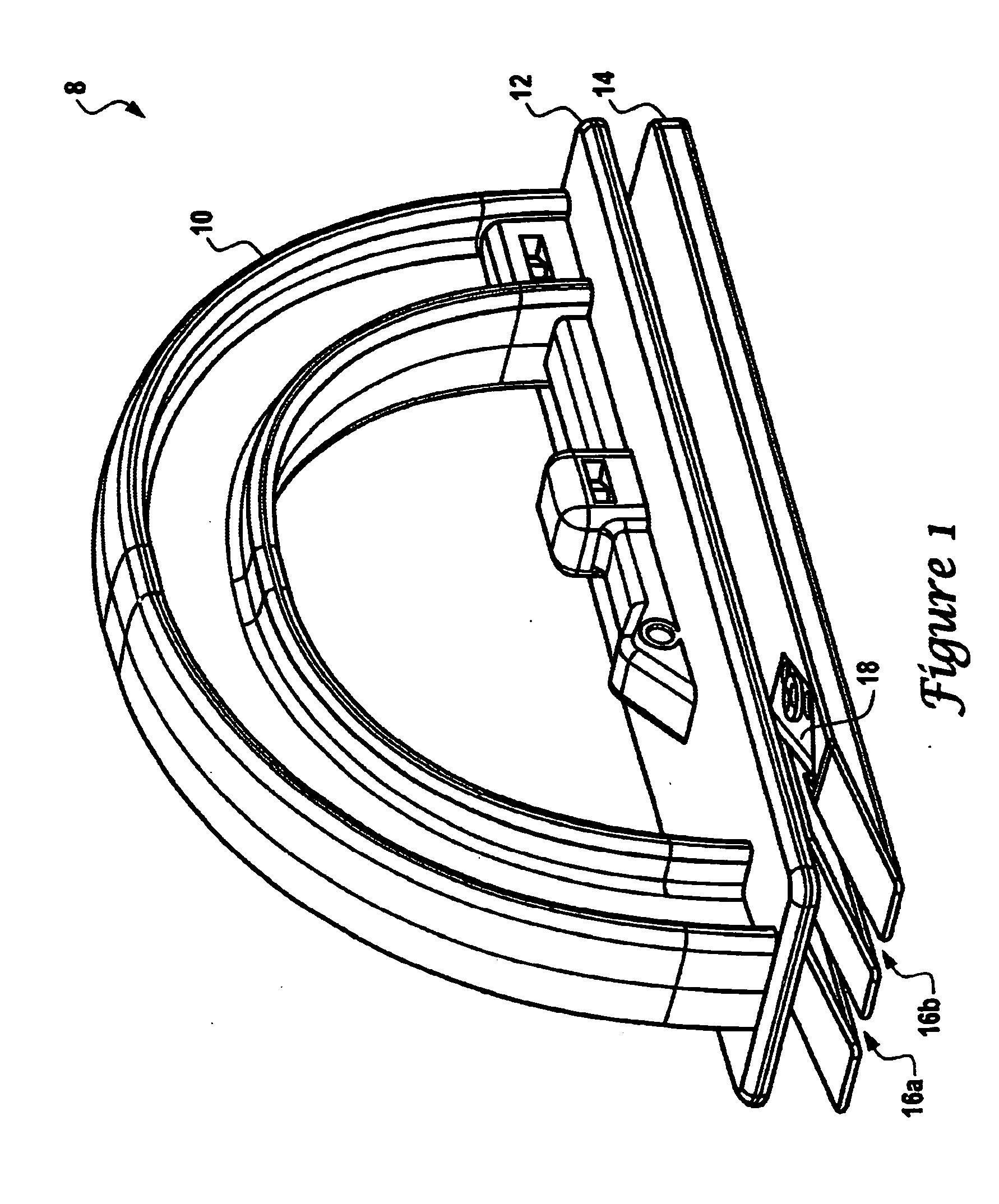

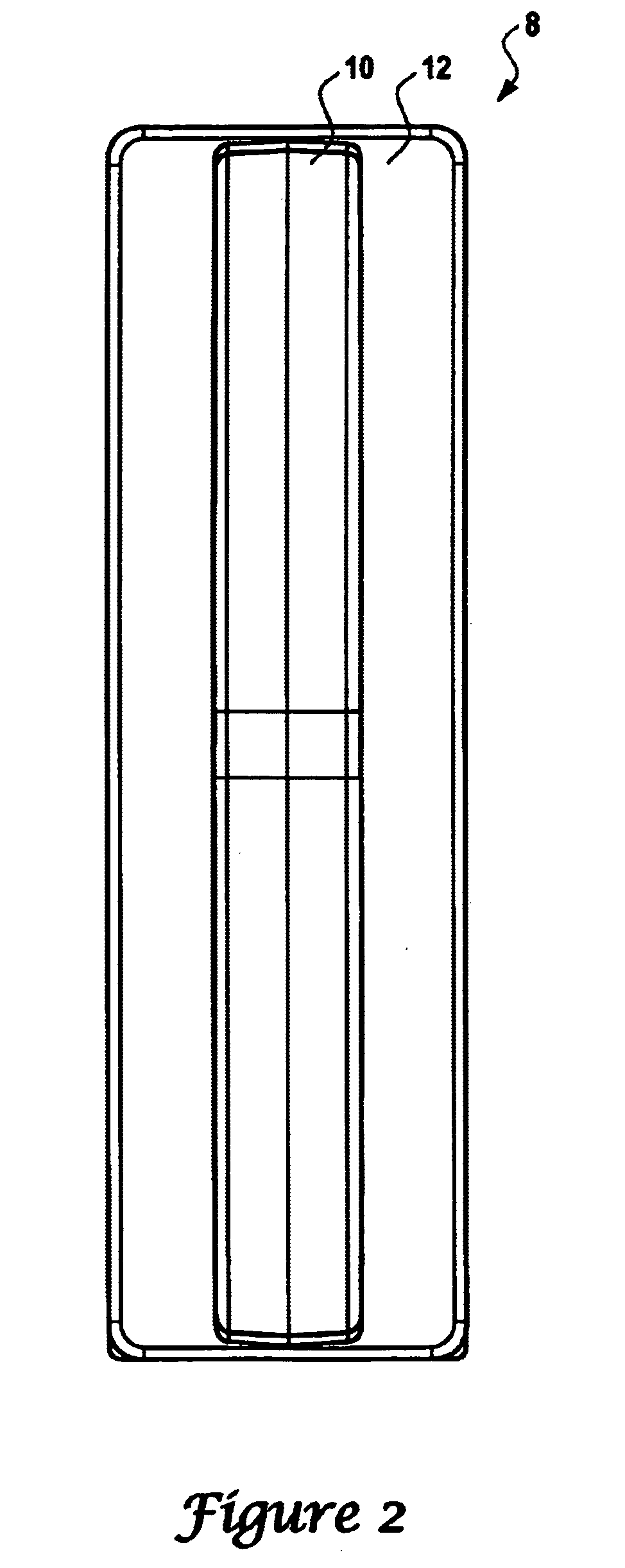

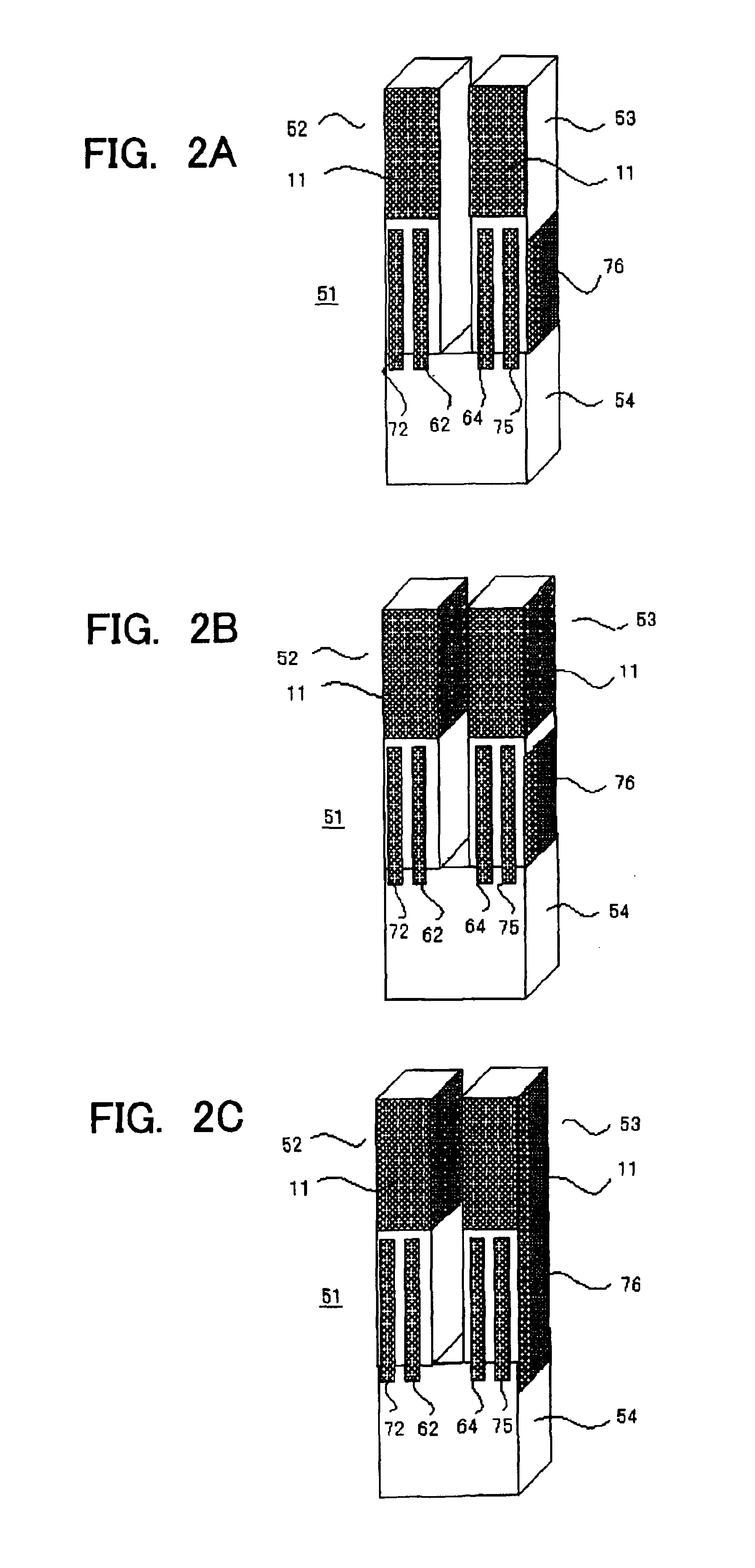

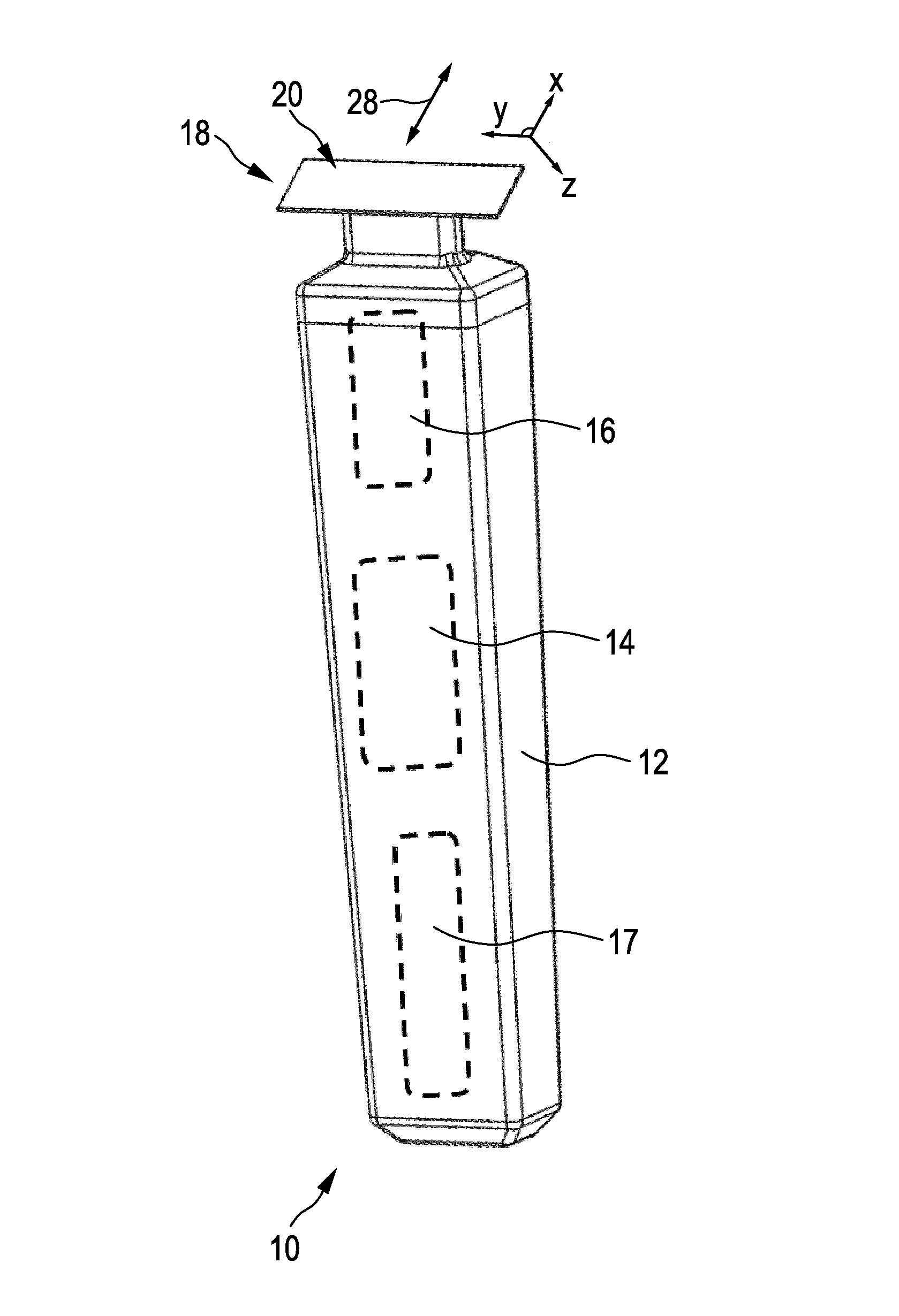

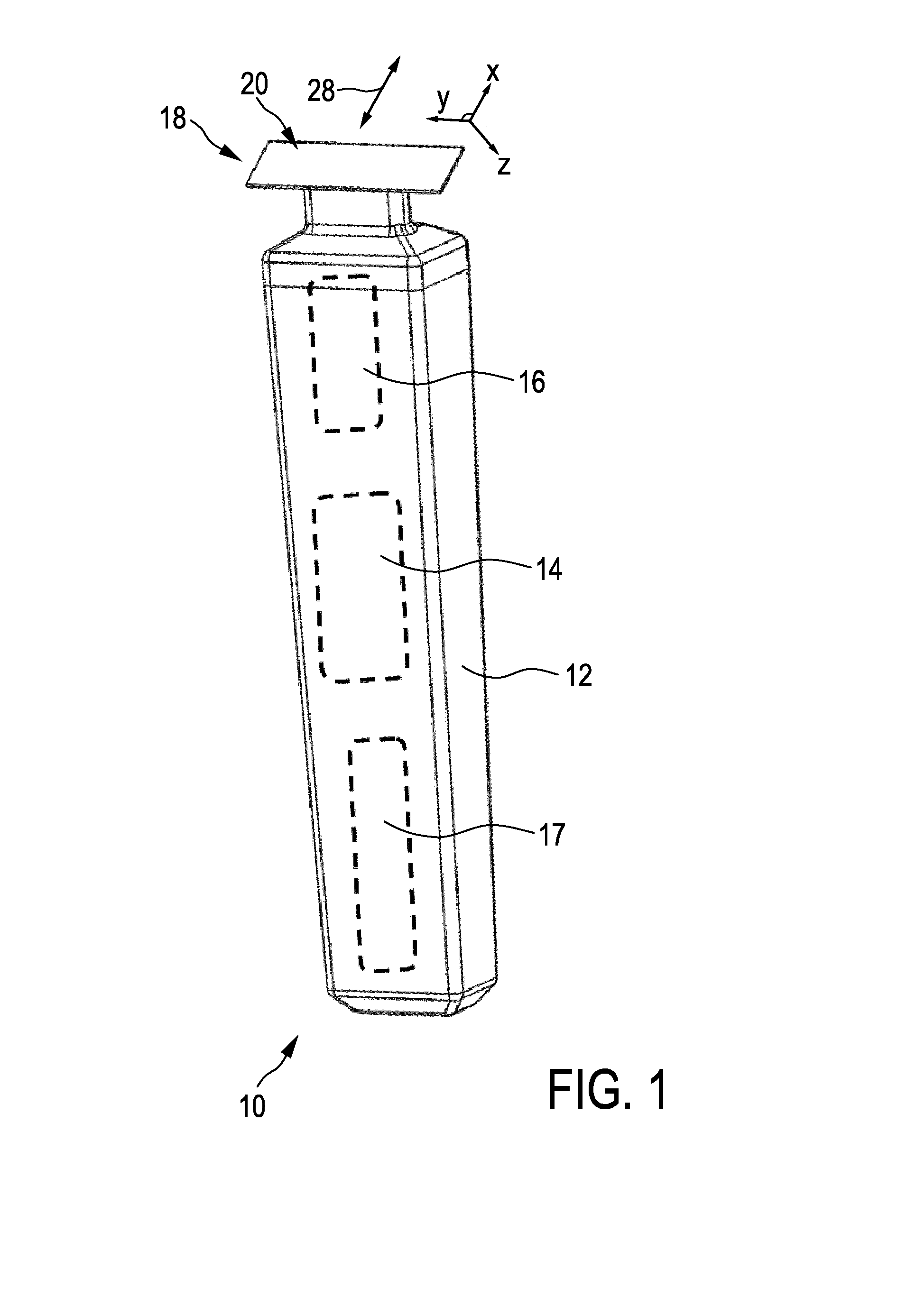

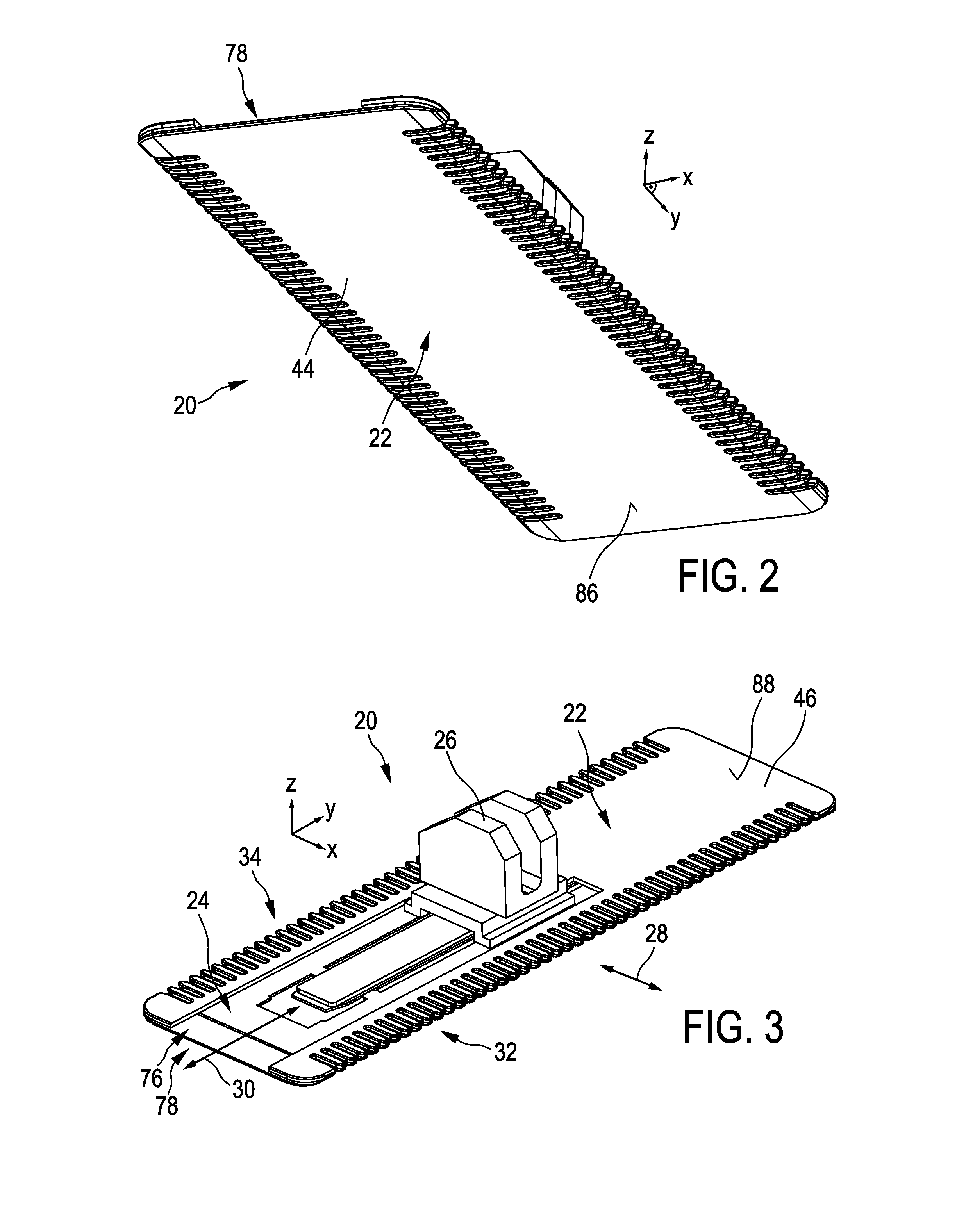

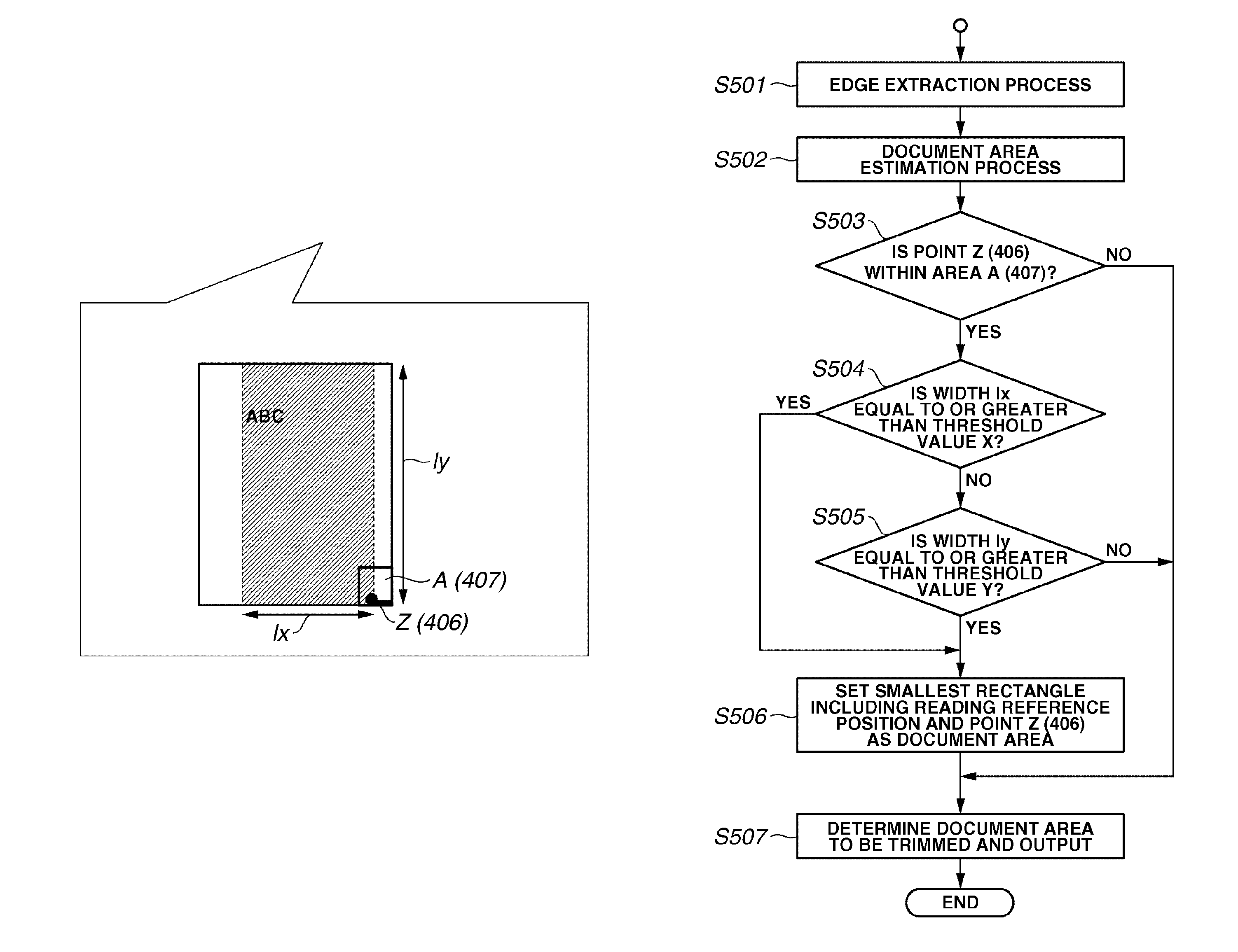

Blade set and hair cutting appliance

The present invention relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10), and to a stationary blade for said blade set (20), said blade comprising a first wall portion (44), a second wall portion (46), and an intermediate wall portion (48), wherein the first wall portion (44), the second wall portion (46), and the intermediate wall portion (48) are fixedly interconnected, thereby forming a segmented stack (56), wherein the intermediate wall portion (48) comprises at least one cutout portion (68) and is disposed between the first wall portion (44) and the second wall portion (46), wherein the first wall portion (44), the second wall portion (46), and the intermediate wall portion (48) jointly form at least one toothed leading edge (32, 34), wherein the toothed leading edge (32, 34) at least partially extends in a transverse direction (Y, t), wherein the toothed leading edge (32, 34) comprises a plurality of mutually spaced apart projections (36) alternating with respective slots, thereby defining a plurality of teeth (40) and respective tooth spaces (42), wherein the mutually spaced apart projections (36) at least partially extend forwardly in a longitudinal direction (X, r) approximately perpendicular to the transverse direction (Y, t), wherein the first wall portion (44), the second wall portion (46) and the at least one cutout portion (68) in the intermediate wall portion (48) define therebetween a guide slot (76) for a movable blade (24), and wherein the guide slot (76) provides for a defined clearance fit mating of the to-be-mounted movable blade (24) in the guide slot (76).

Owner:KONINKLJIJKE PHILIPS NV

Method and system for high-speed precise laser trimming and scan lens for use therein

InactiveUS7563695B2Precise TrimmingReduced stabilitySemiconductor/solid-state device manufacturingResistor manufactureHigh absorptionHeat-affected zone

A method, system and scan lens for use therein are provided for high-speed, laser-based, precise laser trimming at least one electrical element along a trim path. The method includes generating a pulsed laser output with a laser, the output having one or more laser pulses at a repetition rate. A fast rise / fall time, pulse-shaped q-switched laser or an ultra-fast laser may be used. Beam shaping optics may be used to generate a flat-top beam profile. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance, high absorption and reduced or eliminated heat-affected zone (HAZ) along the trim path, but not so short so as to cause microcracking. In this way, resistance drift after the trimming process is reduced.

Owner:ELECTRO SCI IND INC

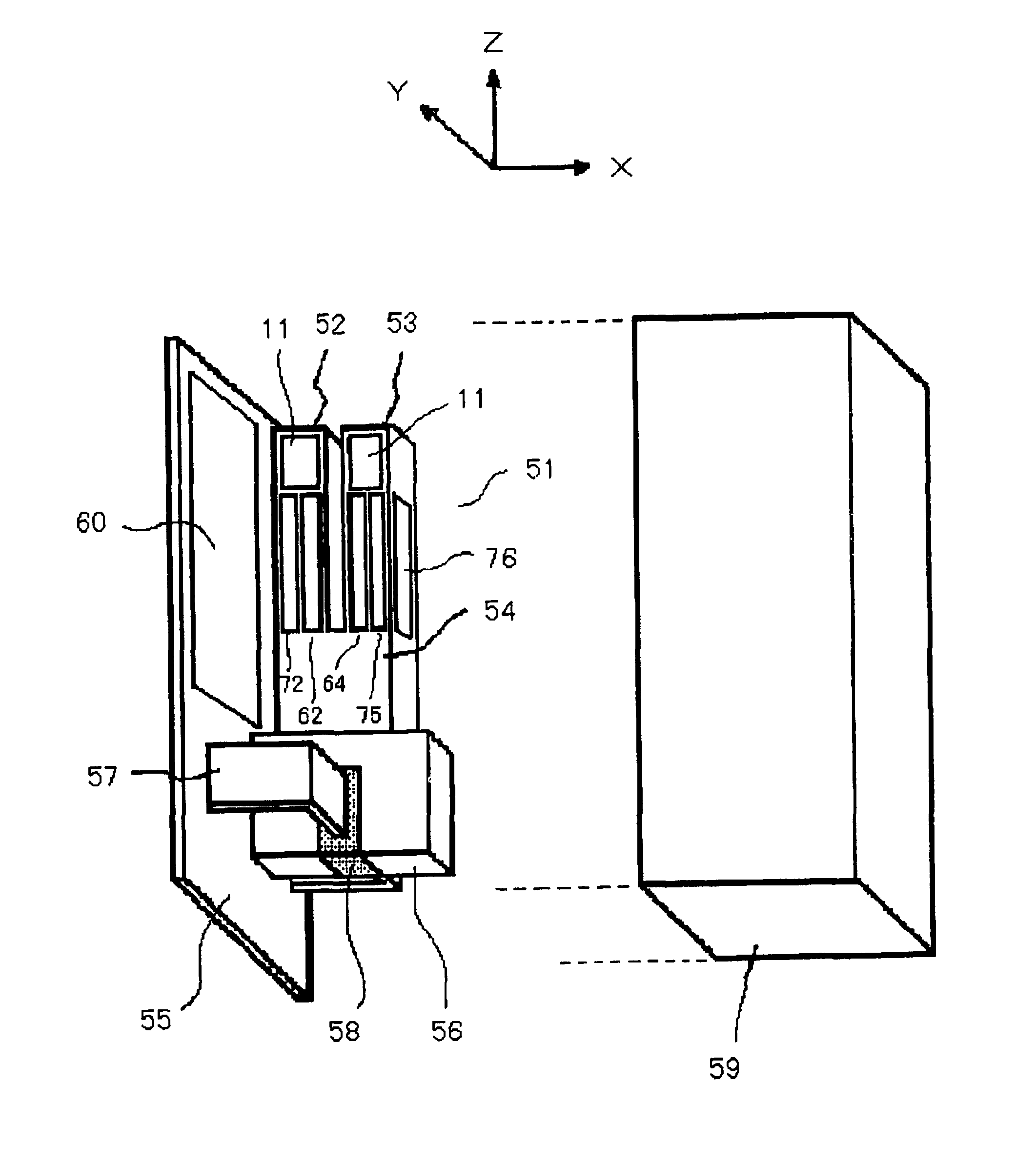

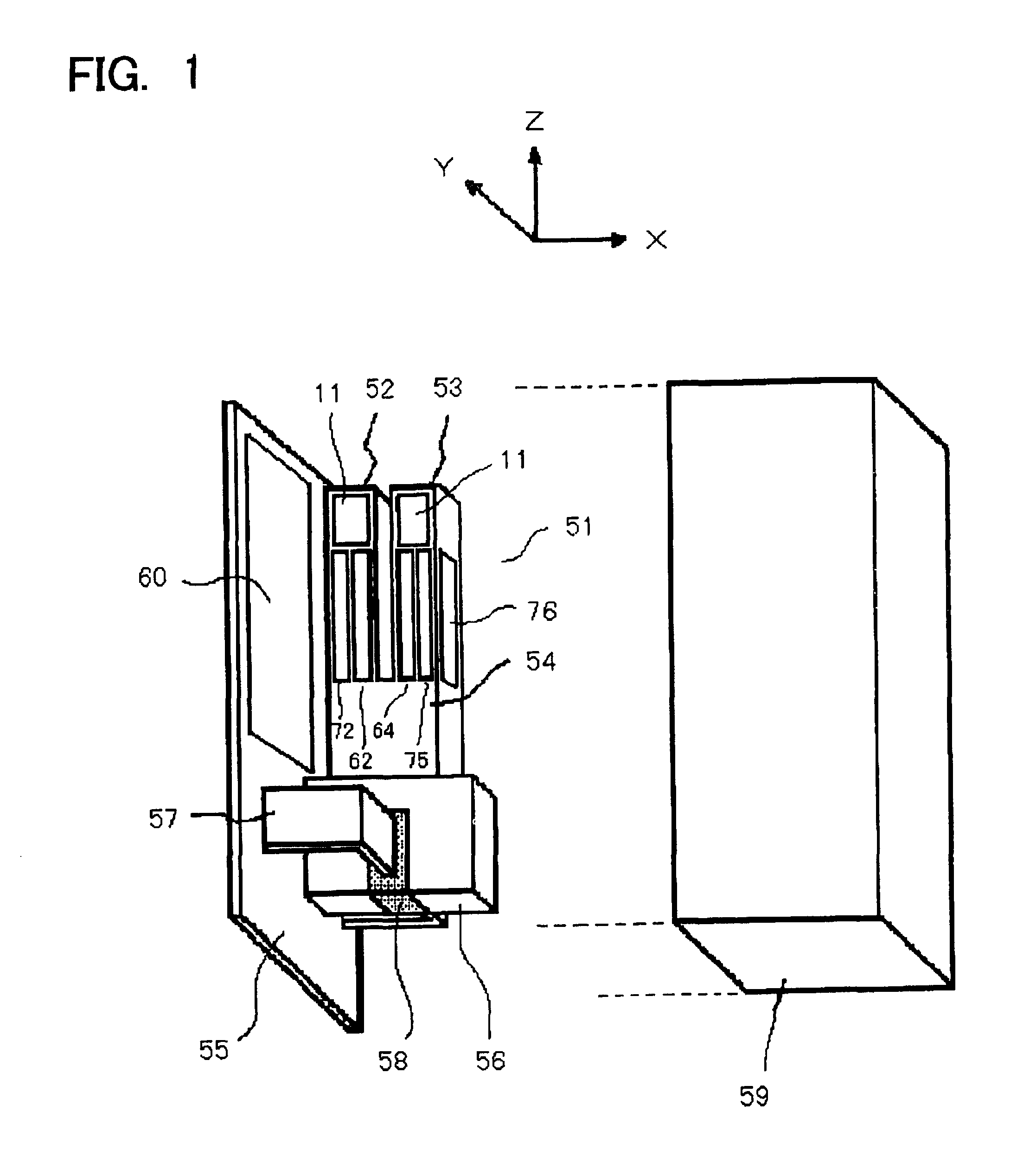

Blade set, hair cutting appliance, and related manufacturing method

ActiveUS20160229072A1Increase degree of freedomAdapt wellMetal working apparatusKnife bladesEngineering

The present invention relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10), and to a stationary blade (22) for said blade set (20), said blade (22) comprising a first wall segment (50), a second wall segment (52), and an intermediate wall segment (54), wherein the first wall segment (50), the second wall segment (52), and the intermediate wall segment (54) are fixedly interconnected, thereby forming a segmented stack (56), wherein the intermediate wall segment (54) is disposed between the first wall segment (50) and the second wall segment (52), wherein the first wall segment (50), the second wall segment (52), and the intermediate wall segment (54) comprise a substantially equivalent overall extension, thereby jointly forming, at an end of the segmented stack (56), at least one toothed leading edge (32, 34), wherein the at least one leading edge (32, 34) comprises a plurality of mutually spaced apart projections (36) defining a plurality of teeth (40) and respective tooth spaces (42), wherein the mutually spaced apart projections (36) at least partially extend forwardly in a longitudinal direction (X, r) approximately perpendicular to the transverse direction (Y, t), wherein the intermediate wall segment (54) comprises at least one cutout portion (68), and wherein the at least one cutout portion (68) in the intermediate wall segment (54), the first wall segment (50) and the second wall segment (52) define therebetween a guide slot (76) for a movable blade (24). The invention further relates to a method for manufacturing a respective blade.

Owner:KONINKLJIJKE PHILIPS NV

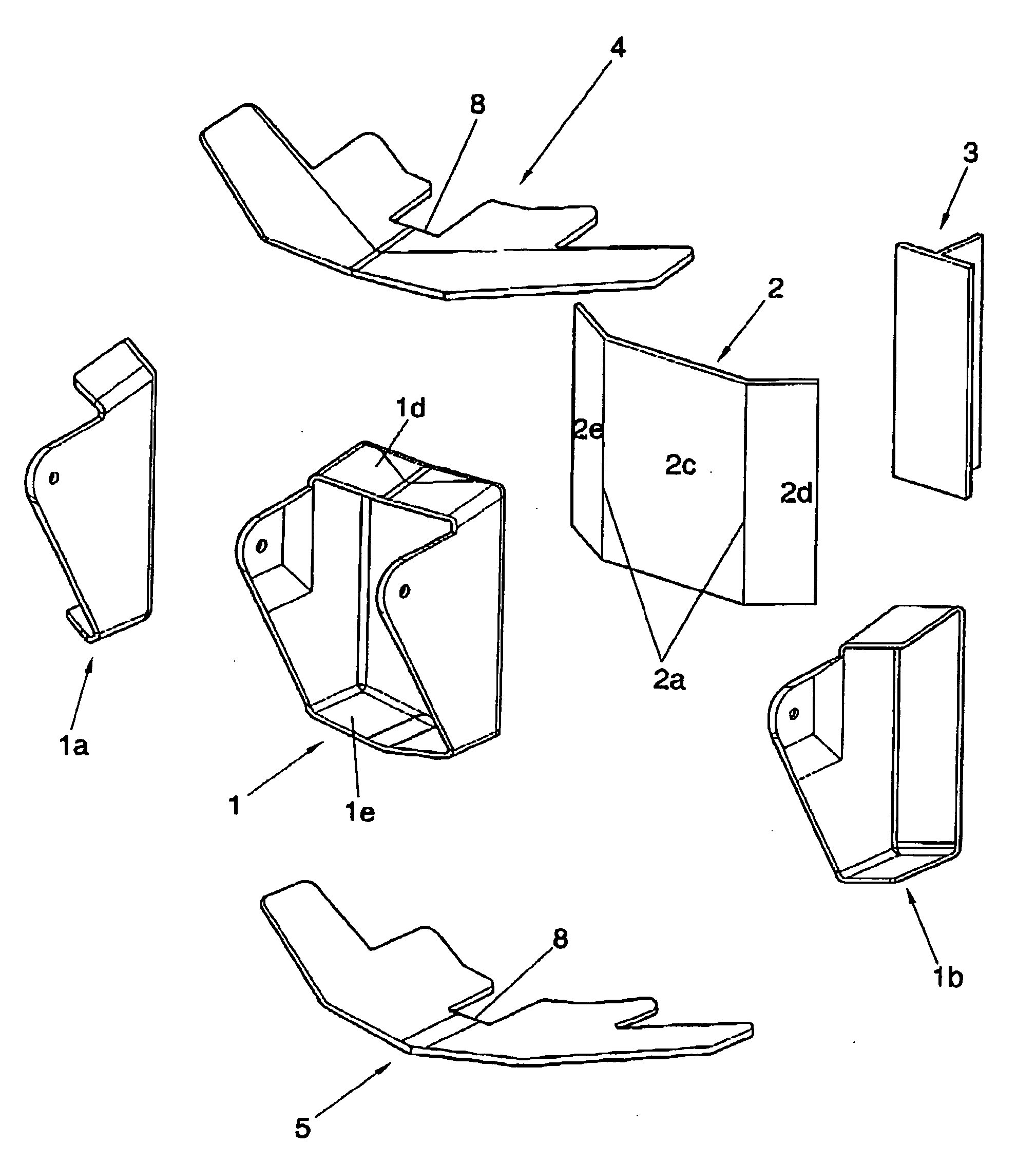

Assembly between a front fitting and the traction coupling of the two lateral boxes of the horizontal stabilizer of an aircraft

ActiveUS20100127127A1Improve the immunityLoad minimizationFuselage framesAircraft stabilisationCouplingAirplane

The invention relates to an assembly between a front fitting and the traction coupling of the two lateral boxes of the horizontal stabilizer of an aircraft comprising a front fitting (1, 1a and 1b), a front shear plate (2), an upper shear plate (4), a lower shear plate (5) and a “rib post” union piece (3) in such a way that the loads being transferred to the lateral boxes are minimized, and at the same time it allows a proper trimming of the horizontal stabilizer. Moreover, the present invention describes a compact front fitting, made of one piece, as a whole, and in composite material.

Owner:AIRBUS OPERATIONS SL

Blade set and hair cutting appliance

The present invention relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10), and to a stationary blade (22) for said blade set (20), said blade comprising a first wall portion (44) and a second wall portion (46), each which defining a first surface (80, 82, 84), and a second surface (86, 88, 90) facing away from the first surface (80, 82, 84), and an intermediate wall portion (48) arranged between the first and the second wall portion (46), wherein the first wall portion (44) the second wall portion (46) and the intermediate wall portion (48) jointly define at least one toothed leading edge (32, 34), wherein the first surfaces (80, 82) of the first wall portion (44) and the second wall portion (46) face each other, at least at their leading edges (32, 34), the first wall portion (44), the second wall portion (46) and the intermediate wall portion (48) are interconnected at their tips (38) to define a plurality of teeth (40), wherein the first surfaces (80, 82) of the first wall portion (44) and the second wall portion (46) define therebetween a guide slot (76) for a movable blade (24) of said blade set (20), wherein the first wall portion (44), the second wall portion (46) and the intermediate wall portion (48) comprise an overall height extension (to), and wherein the overall height extension (to) of the first wall portion (44), the second wall portion (46) and the intermediate wall portion (48), at least at the at least one leading edge (32, 34), is in the range of about 0.3 mm to about 0.75 mm, preferably in the range of about 0.4 mm to 0.5 mm.

Owner:KONINKLJIJKE PHILIPS NV

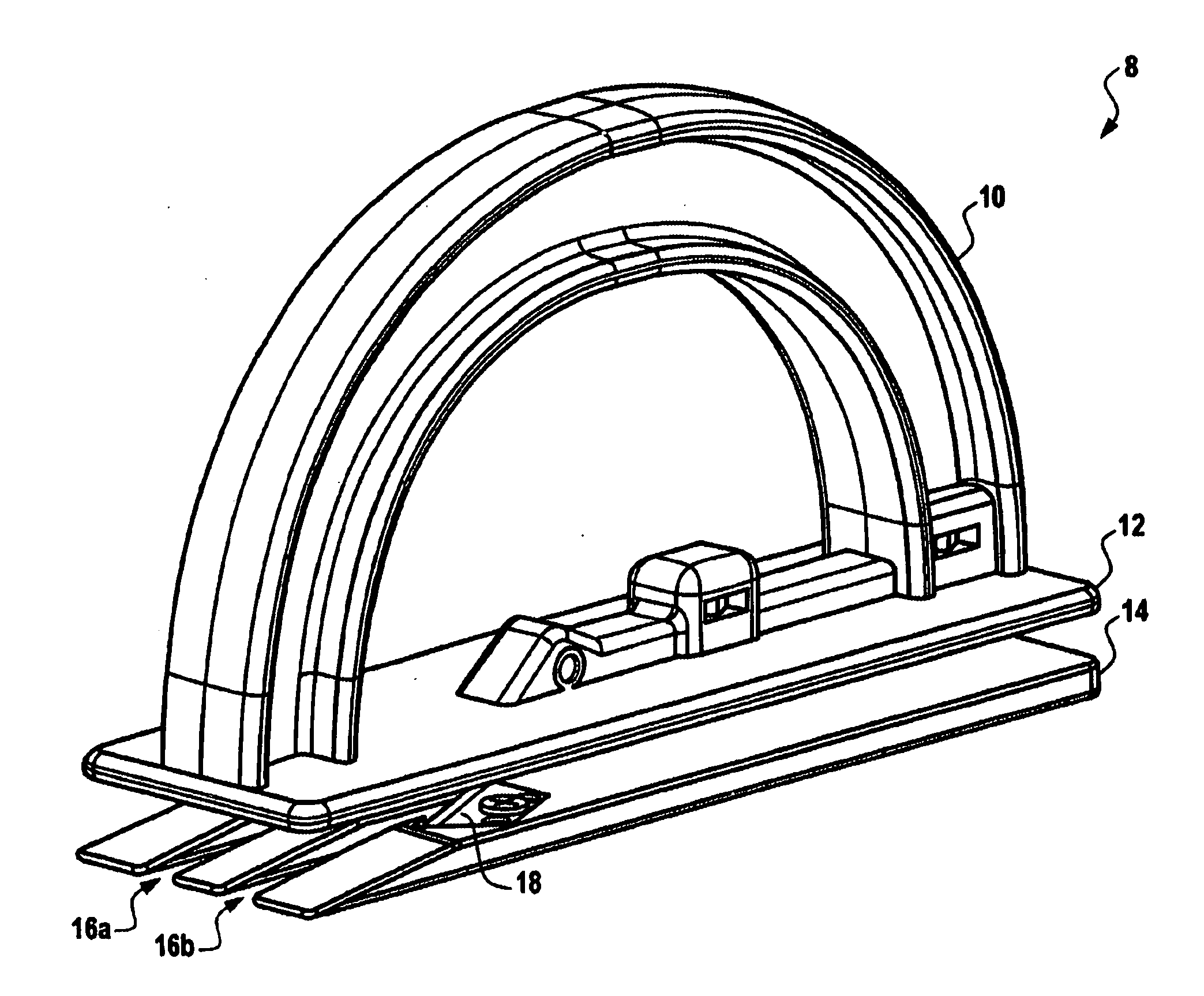

Dental model cutter

InactiveUS7059231B2Improve fitQuicker more finite method of adjustingMetal sawing devicesCross-cut reciprocating sawsEngineeringCutting guide

Owner:GRAHAM NEIL JOHN

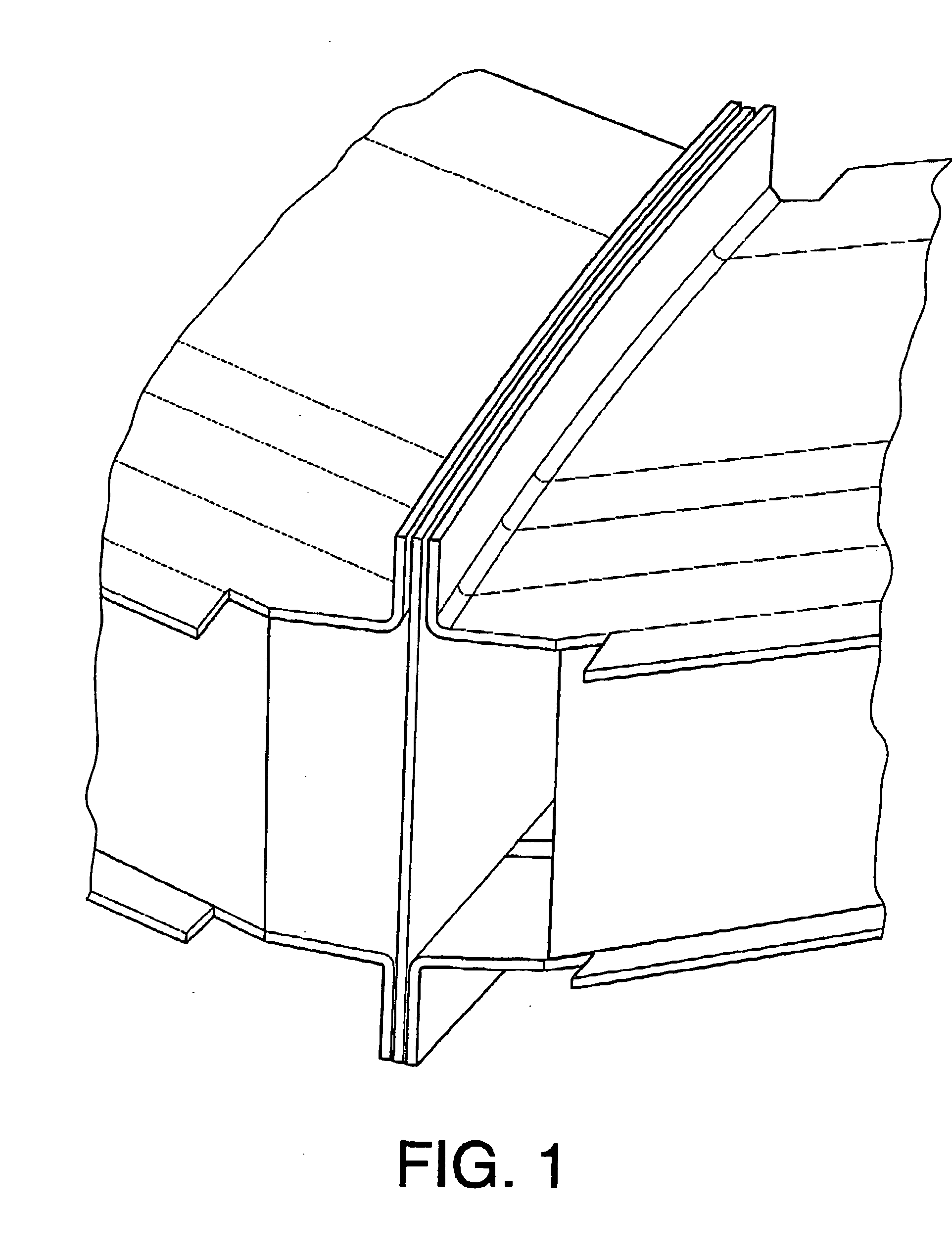

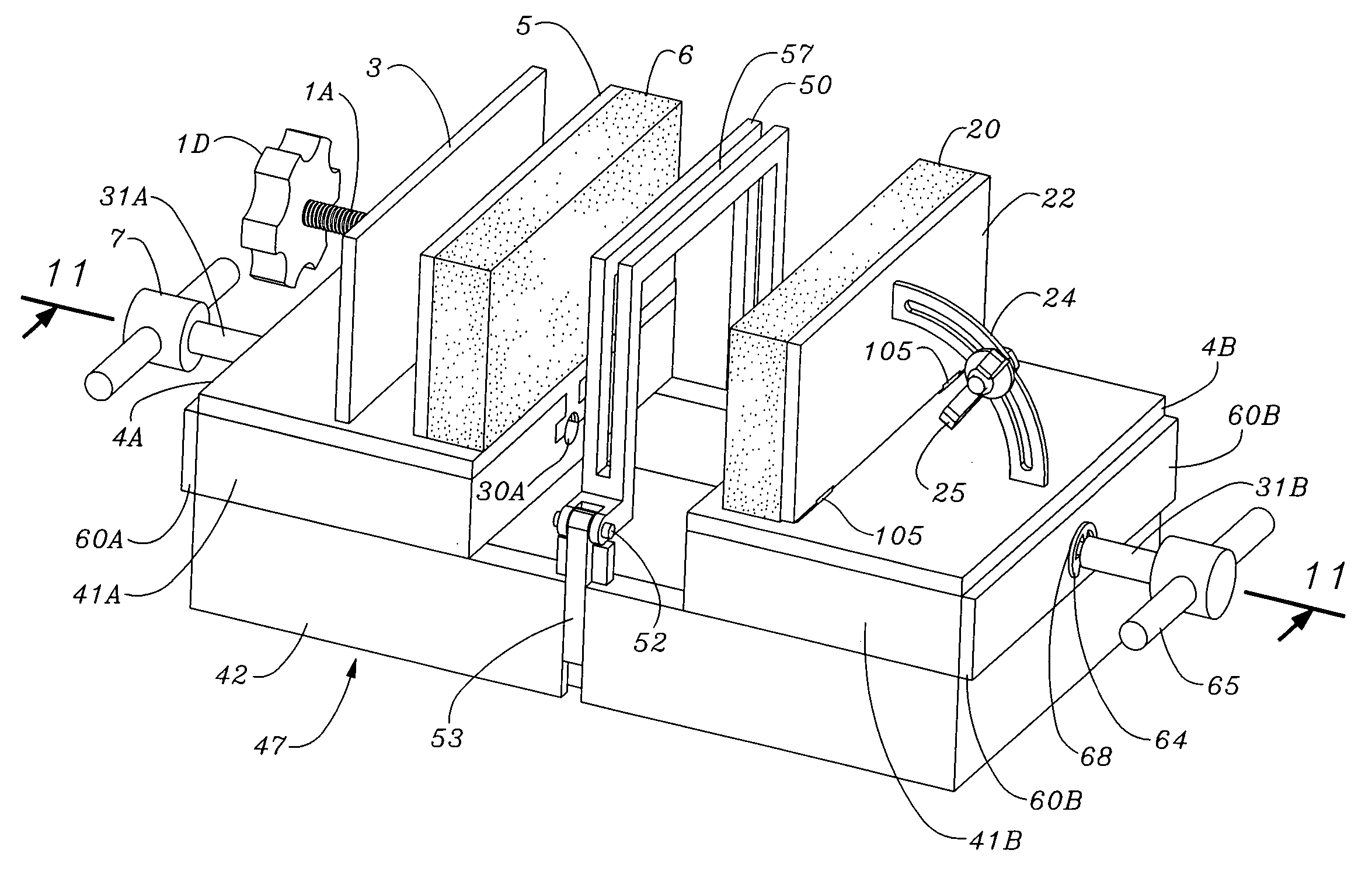

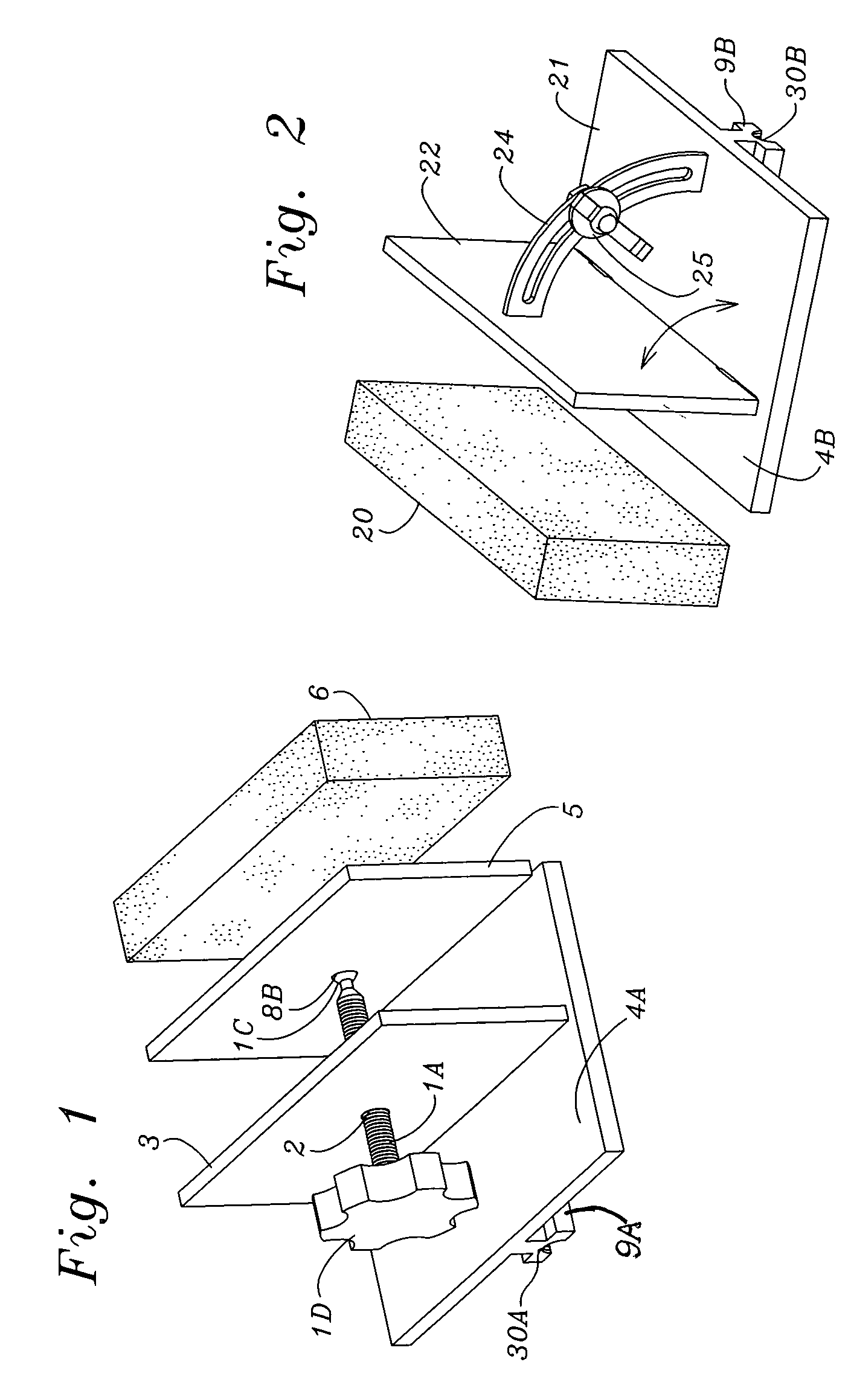

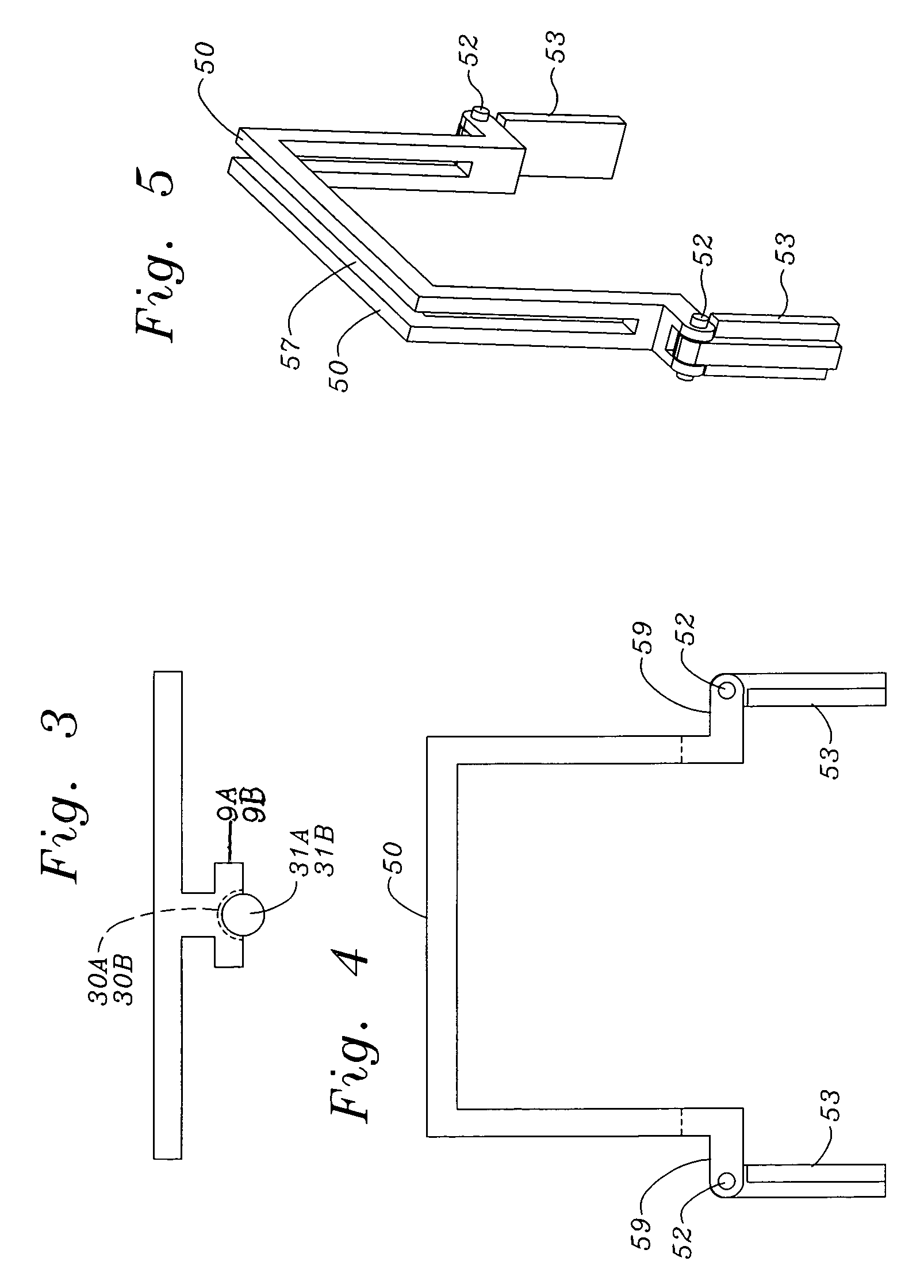

Method and apparatus for cutting materials

InactiveUS20050229403A1For precise cuttingPrecise TrimmingMetal working apparatusEngineeringMechanical engineering

The present invention includes a cutting apparatus, method and system for cutting, trimming and deburring an edge or surface. One embodiment of the present invention includes an apparatus having a first cutting member holder including one or more slots extending inwardly from one or more ends, an upper member attached to the first cutting member holder, whereby a longitudinal grove is formed between the first cutting member holder and the upper member and a cutting surface disposed in or about the first cutting member holder, wherein the cutting surface comprises two or more cutting members which are angled relative to each other and one or more cutting members that extend into the one or more slots.

Owner:DIAZ BOB MANZANO

Tuning fork vibration gyro

InactiveUS6931927B2Reduce vibrationElectrode area is smallAcceleration measurement using interia forcesWave based measurement systemsTuning forkGyroscope

A tuning-fork vibration gyro including a ferroelectric tuning-fork vibration body generating a plurality of sensor signals and a sensor circuit to which the sensor signals generated by the tuning-fork vibration body are input. The sensor circuit includes a differential amplifier having two input terminals between which the sensor signals are input, and a capacitor being connected between the two input terminals of the differential amplifier.

Owner:TAMAGAWA SEIKI CO LTD

Method and device for detecting and dressing quality of end face grinding wheel in real time

ActiveCN110587402AWear monitoringImprove work efficiency and processing qualityGrinding drivesGrinding feed controlWheel wearLimit value

The invention discloses a method and device for detecting and dressing quality of an end face grinding wheel in real time. The device comprises a laser, a receiver, a grinding wheel dresser, the grinding wheel, a grinding wheel seat, a displacement sensor and a three-dimensional driving mechanism. According to the device, a laser beam emitted by the laser is obliquely emitted to the ground surfaceof a workpiece, the receiver continuously receives the reflected laser beam reflected by the ground surface, and the abrasion degree of the grinding wheel is detected in real time by detecting the energy of the reflected laser beam; when the energy of the laser beam reflected by the receiver reaches the corresponding grinding wheel wear limit value, the grinding wheel is triggered to stop grinding, the current grinding position of the grinding wheel is recorded through the displacement sensor, and the grinding wheel is moved to the position of the grinding wheel dresser by a grinding wheel driving mechanism and is dressed in real time; and the dressed grinding wheel returns to the current grinding position, and the grinding stroke of the surface of the workpiece continues. The on-line detection and dressing of the grinding wheel can be quickly and efficiently realized, and the processing quality and the grinding efficiency of end face grinding are improved.

Owner:NANTONG UNIVERSITY

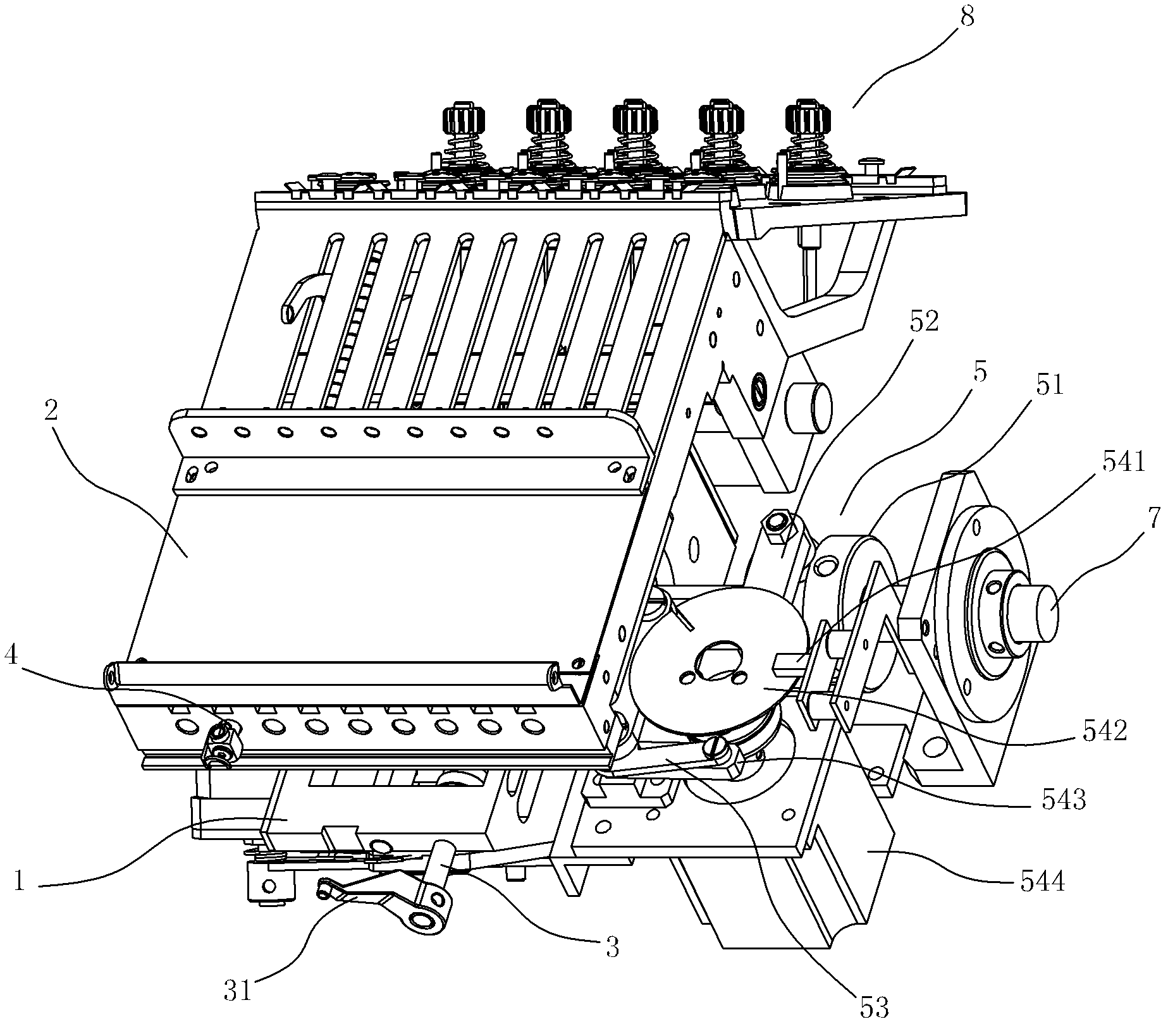

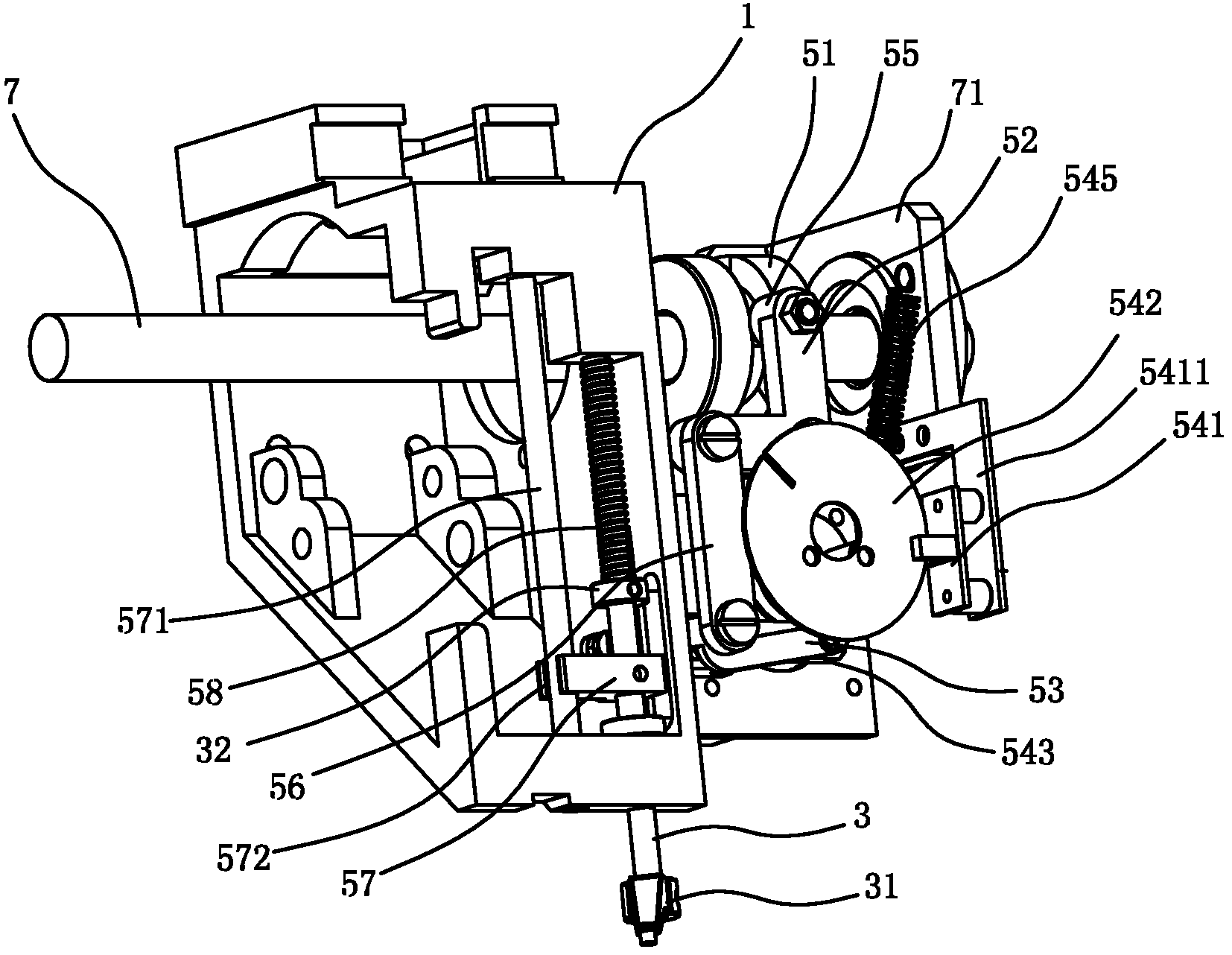

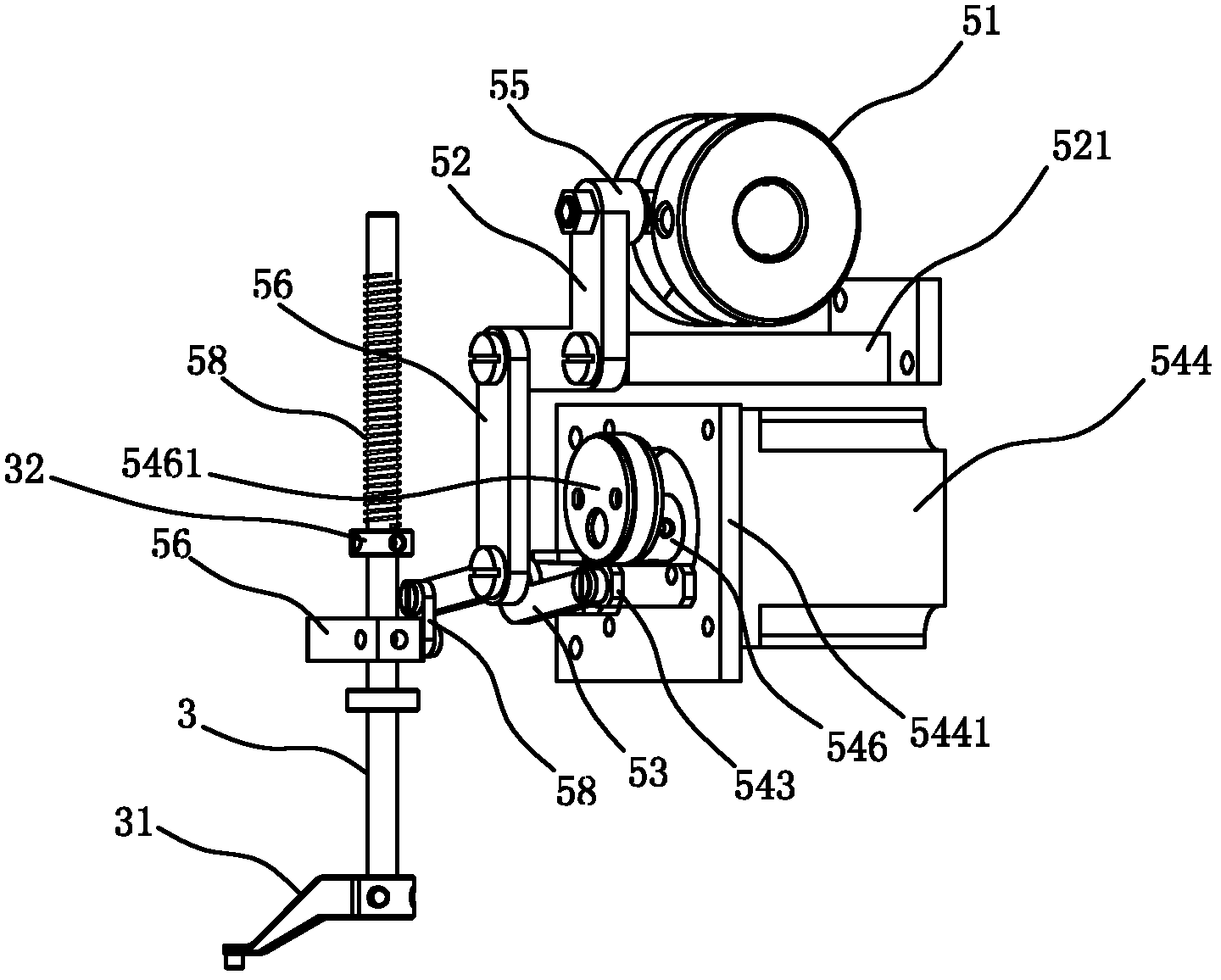

Leather/thick material embroidery machine

ActiveCN102535052AIncrease pressureReduce in quantityAutomatic machinesFeedersBiomedical engineering

The invention relates to a leather / thick material embroidery machine which comprises a frame, a head arranged on the frame, upper and lower shafts transversely arranged on the frame, a needle bar box which is arranged on the head and can move transversely, a plurality of needle bars which are arranged on the needle bar box and can move up and down, a color switching driving mechanism which is connected with the needle bar box and drives the needle bar box to move transversely so as to select a needle bar to work, and a needle bar driving mechanism which is connected with the needle bars and drives the needle bars to move up and down, wherein the lower end of the needle bars is provided with a machine needle, a needle foot bar which is arranged on the head and can move up and down, a needle foot driving mechanism which is connected with the needle foot and drives the needle foot to move up and down, and a shearing device and a trapping device which are applicable to thick threads. By improving the arrangement and drive of the needle foot and matching with the shearing device and trapping device applicable to thick threads, the embroidery machine can be used for embroider a thick material or leather.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

Blade set and hair cutting appliance

The present invention relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10), and to a stationary blade (22) for said blade set (20), said blade comprising a first wall portion (44) and a second wall portion (46), each which defining a first surface (80, 82, 84), and a second surface (86, 88, 90) facing away from the first surface (80, 82, 84), and an intermediate wall portion (48) arranged between the first and the second wall portion (46), wherein the first wall portion (44) the second wall portion (46) and the intermediate wall portion (48) jointly define at least one toothed leading edge (32, 34), wherein the first surfaces (80, 82) of the first wall portion (44) and the second wall portion (46) face each other, at least at their leading edges (32, 34), the first wall portion (44), the second wall portion (46) and the intermediate wall portion (48) are interconnected at their tips (38) to define a plurality of teeth (40), wherein the first surfaces (80, 82) of the first wall portion (44) and the second wall portion (46) define therebetween a guide slot (76) for a movable blade (24) of said blade set (20), wherein the first wall portion ( 44), the second wall portion (46) and the intermediate wall portion (48) comprise an overall height extension (to), and wherein the overall height extension (to) of the first wall portion (44), the second wall portion (46) and the intermediate wall portion (48), at least at the at least one leading edge (32, 34), is in the range of about 0.3 mm to about 0.75 mm, preferably in the range of about 0.4 mm to 0.5 mm.

Owner:KONINKLJIJKE PHILIPS NV

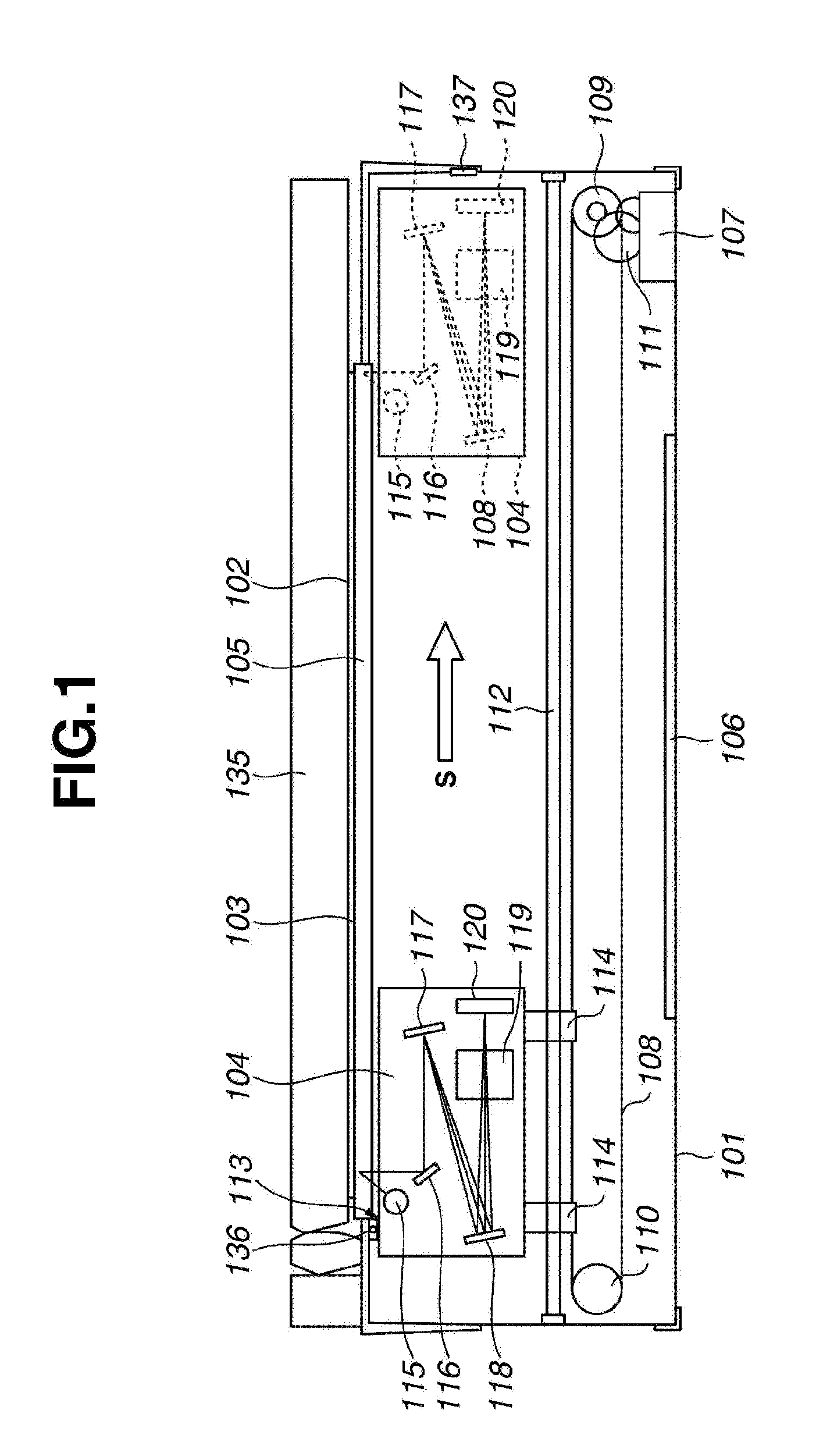

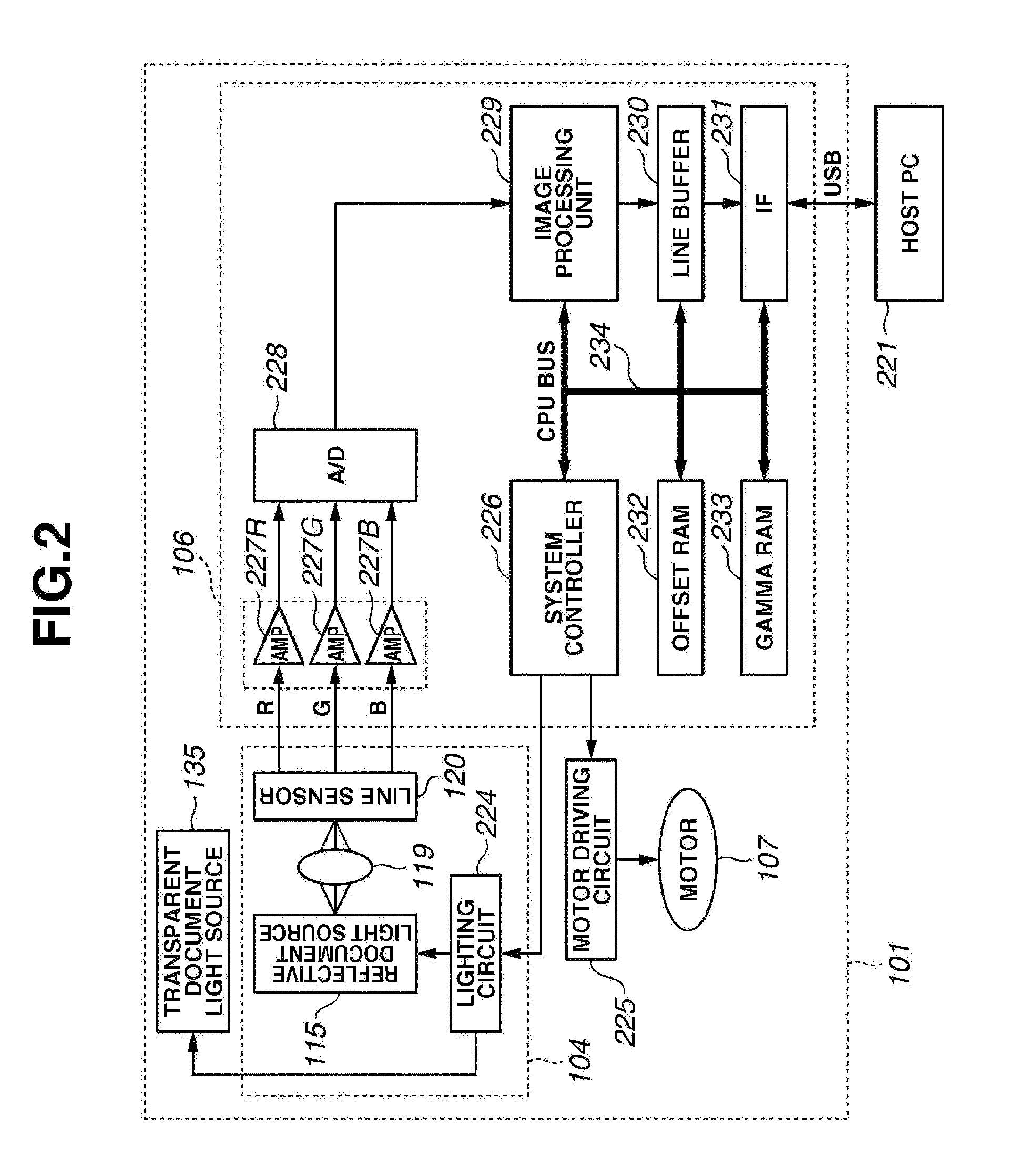

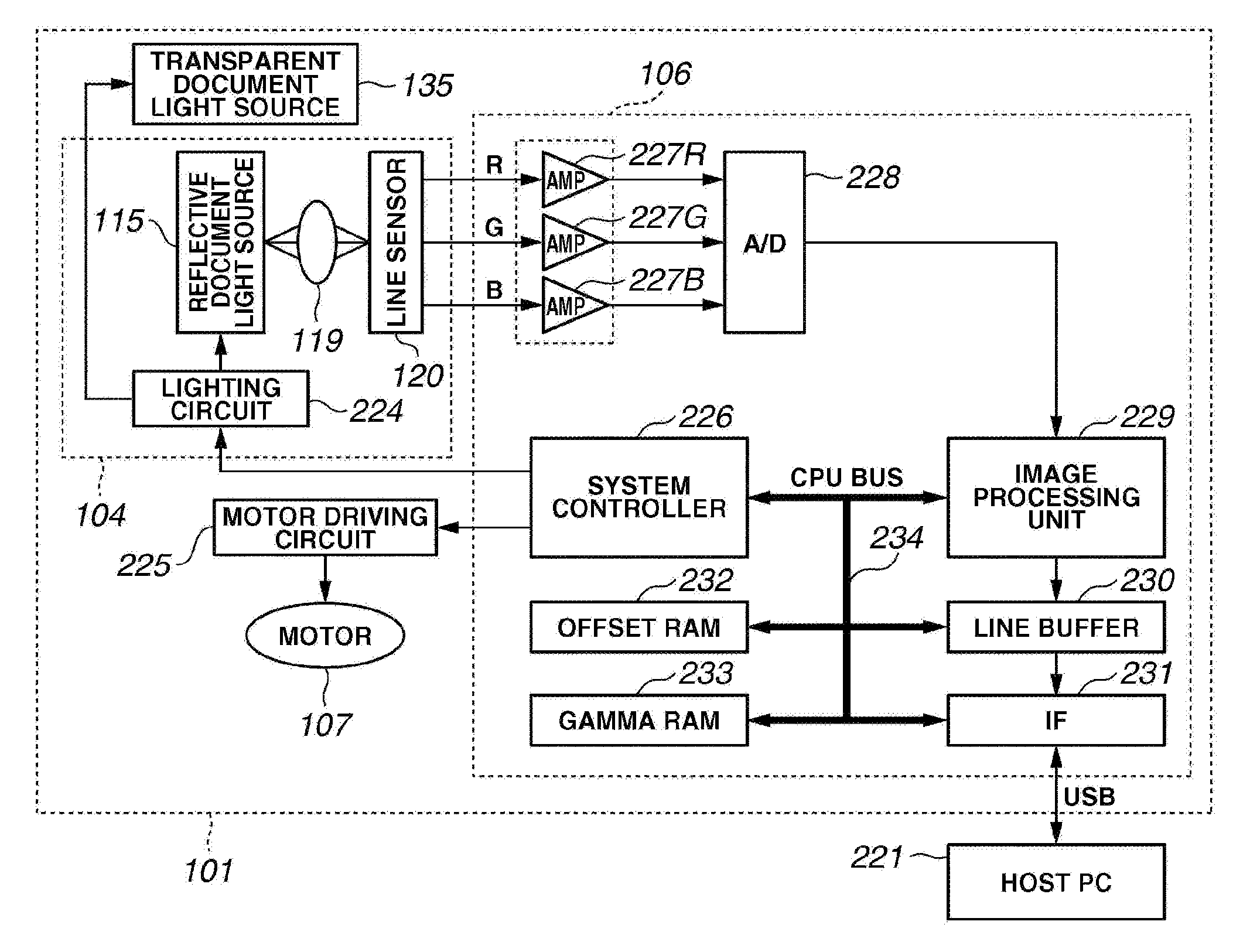

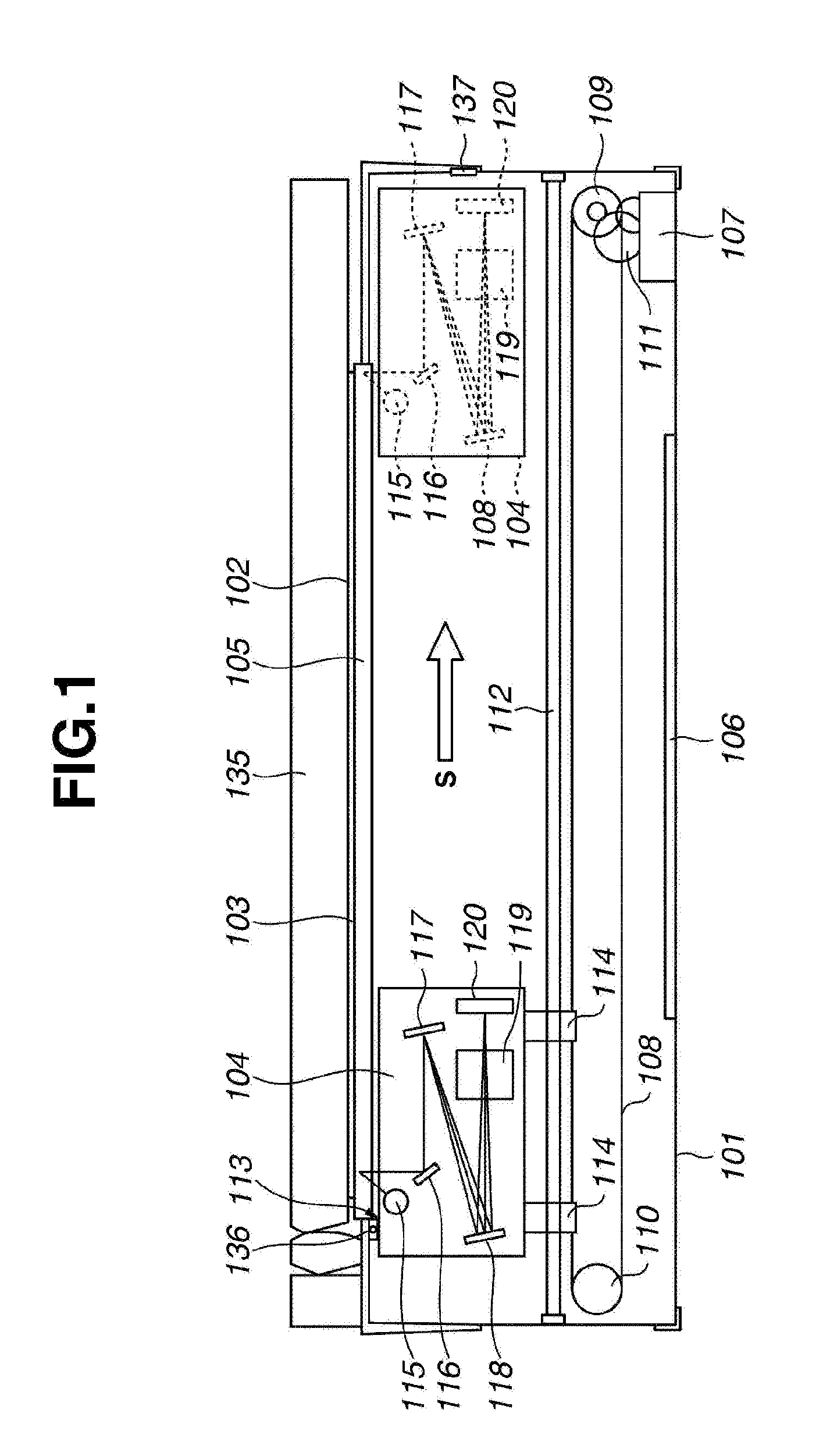

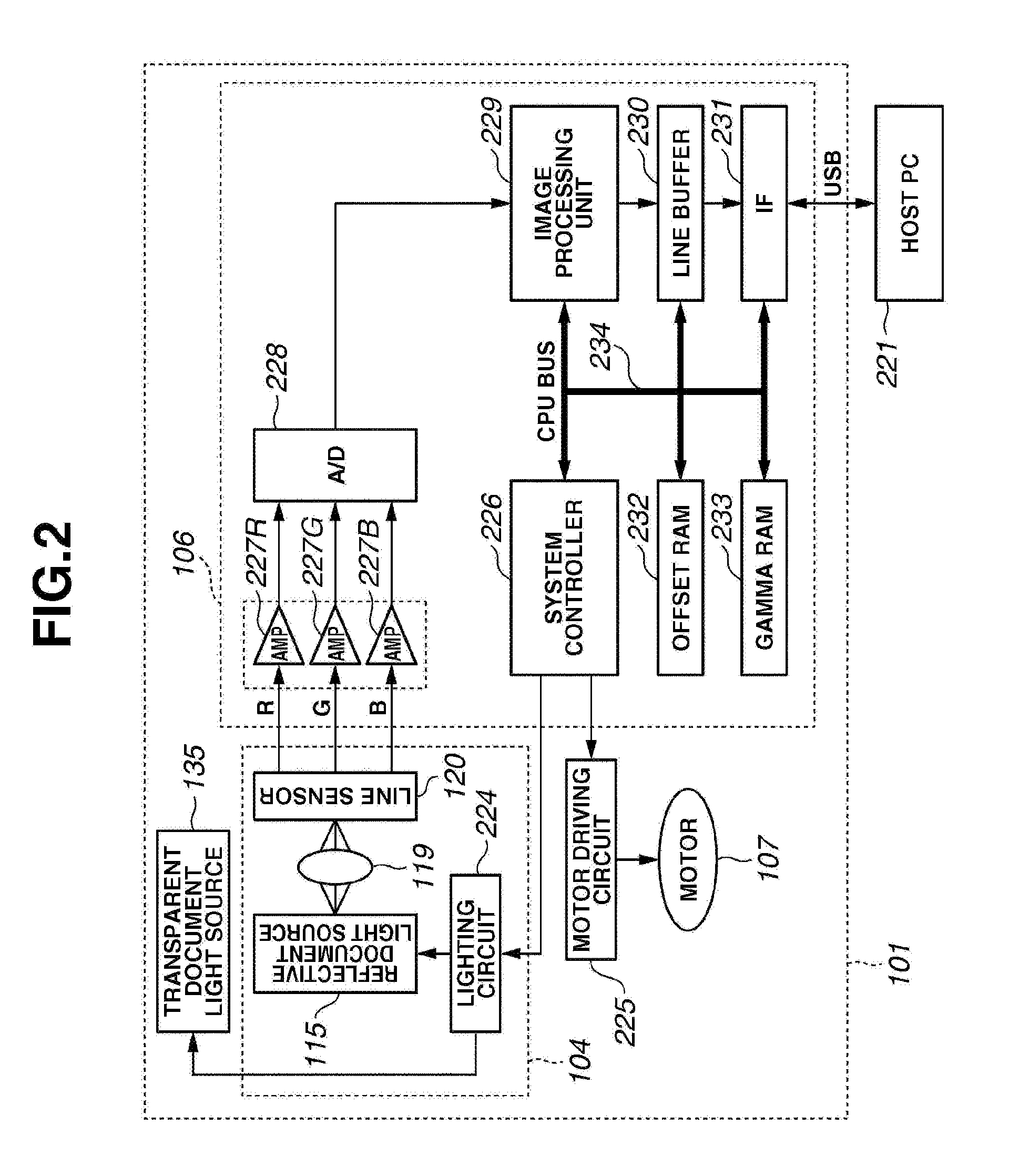

Image processing apparatus and method

InactiveUS8102575B2Precise TrimmingElectrographic process apparatusPictoral communicationImaging processingImaging data

Owner:CANON KK

Grinding wheel arc dresser

InactiveCN101574794AQuick fixThe trimmer is fast with one adjustmentAbrasive surface conditioning devicesEngineeringGrinding wheel

A grinding wheel arc dresser comprises a substrate, an extension board, a rotating body, a tool rest and a finishing tool body, wherein the extension board is fixedly connected with the rotating body in the substrate; the extension board is fixedly connected with the tool rest; the finishing tool body is moveably arranged on the tool rest; and the tool rest is also provided with an adjustment mechanism which can be adjusted to make the finishing tool body move relative to the tool rest. The grinding wheel arc dresser can rapidly and accurately adjust a tool tip of the finishing tool body relative to the height of a reference plane and is favorable for improving the work efficiency and the machining accuracy.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

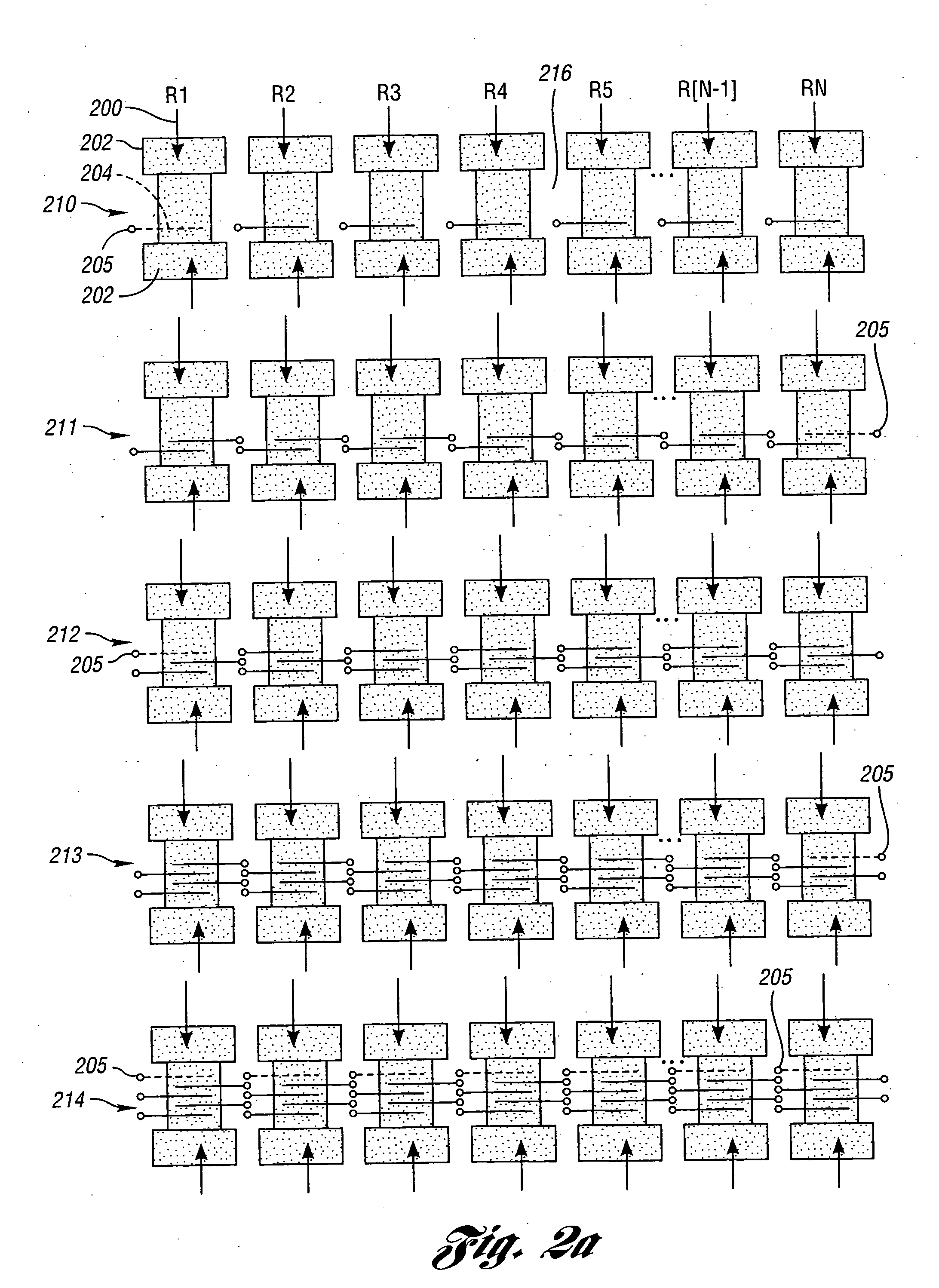

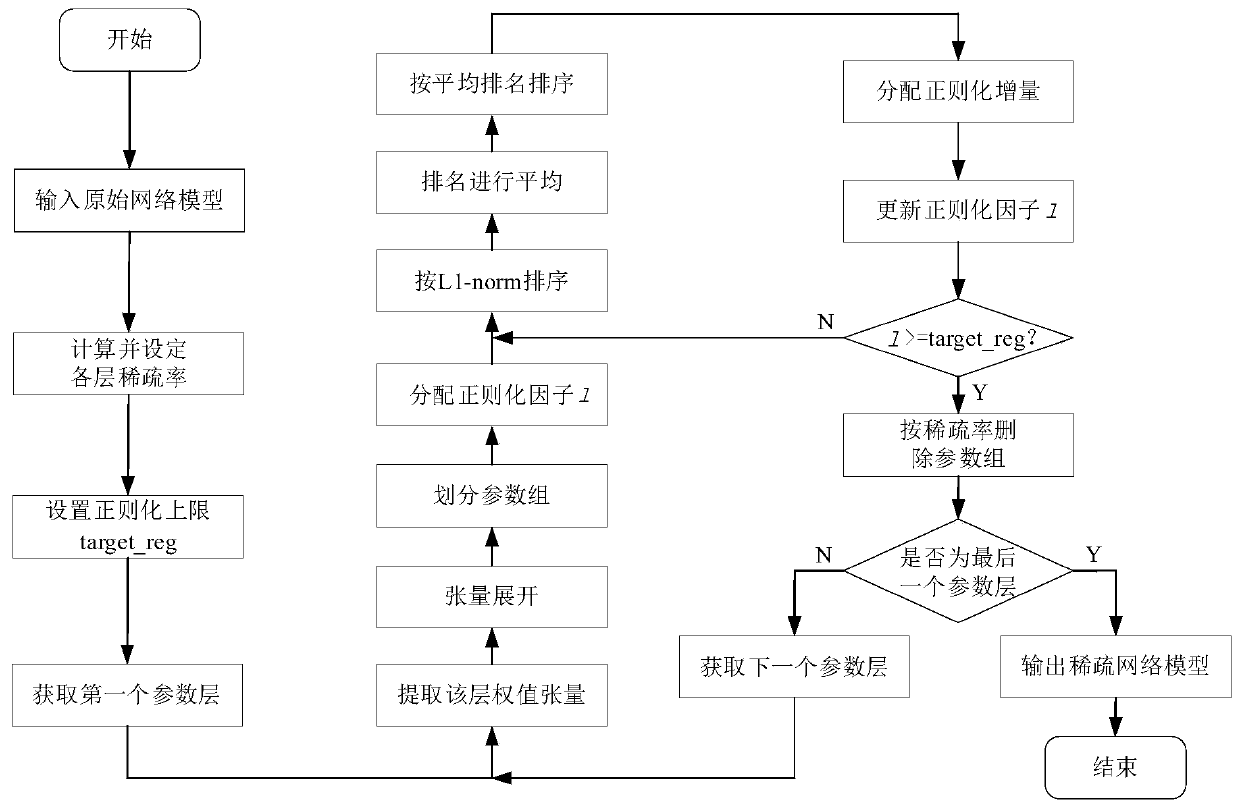

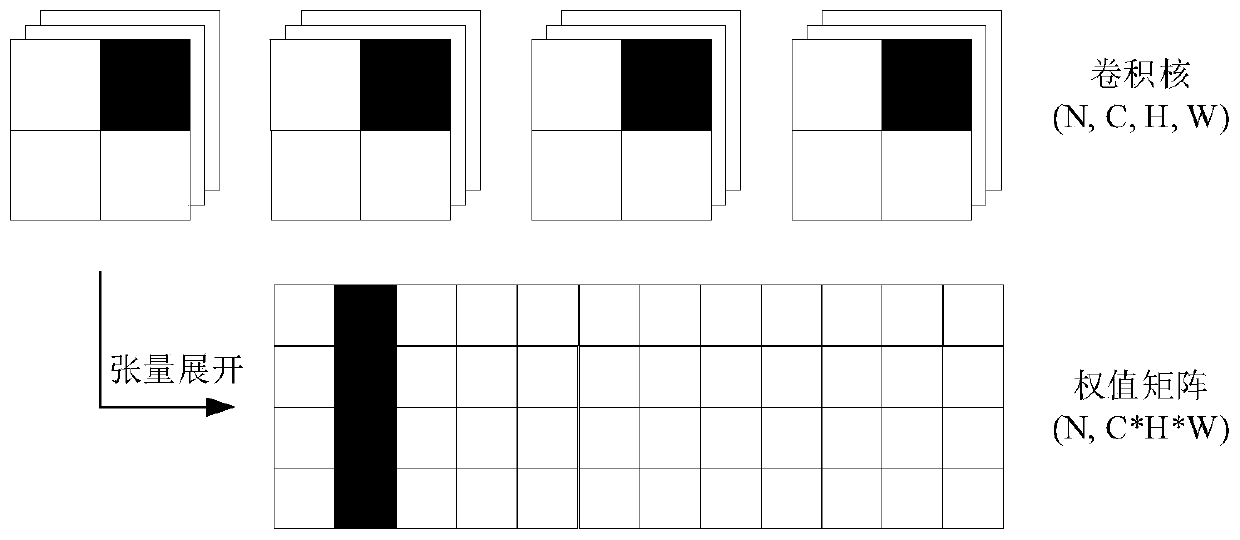

Neural network structured sparse method based on incremental regularization

InactiveCN110197257APrecise TrimmingAvoid problems that cannot bear large penaltiesNeural architecturesNeural learning methodsDimensional regularizationPattern recognition

The invention discloses a neural network structured sparse method based on incremental regularization. The method comprise the steps of when the branches of a neural network are pruned, according to the relative importance of each weight group, distributing different regularization increments to different weight groups step by step, then updating the regularization factors of the weight groups iteratively and continuously, and when the regularization factor of a certain weight group reaches a specified regularization upper limit, deleting the corresponding weight in the network permanently toincrease the structured sparsity of the network model; and when the sparsity of a certain layer reaches a preset sparsity rate, automatically stopping pruning of the layer until the pruning of all thelayers is completed; and finally, retraining the whole network to callback the accuracy, and when the accuracy of the model does not rise any more, stopping retraining to obtain a sparse model. According to the method, a large deep learning model can be deployed on the mobile and embedded equipment, a remarkable actual acceleration effect is obtained, and the application of a deep learning algorithm on a mobile terminal is promoted.

Owner:ZHEJIANG UNIV

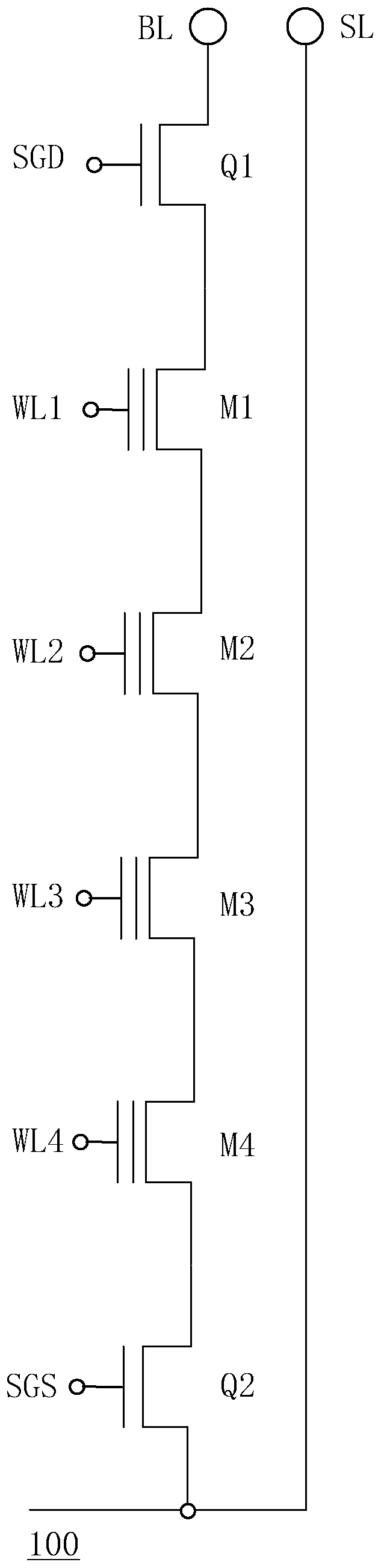

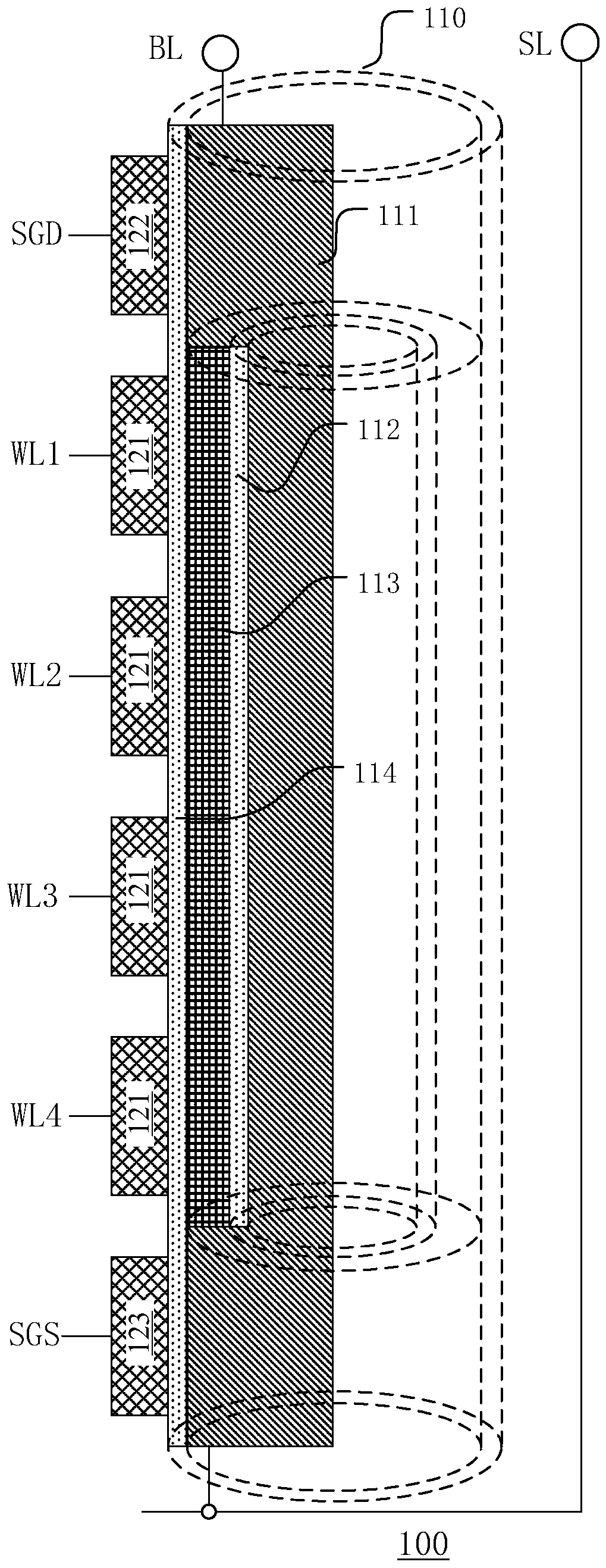

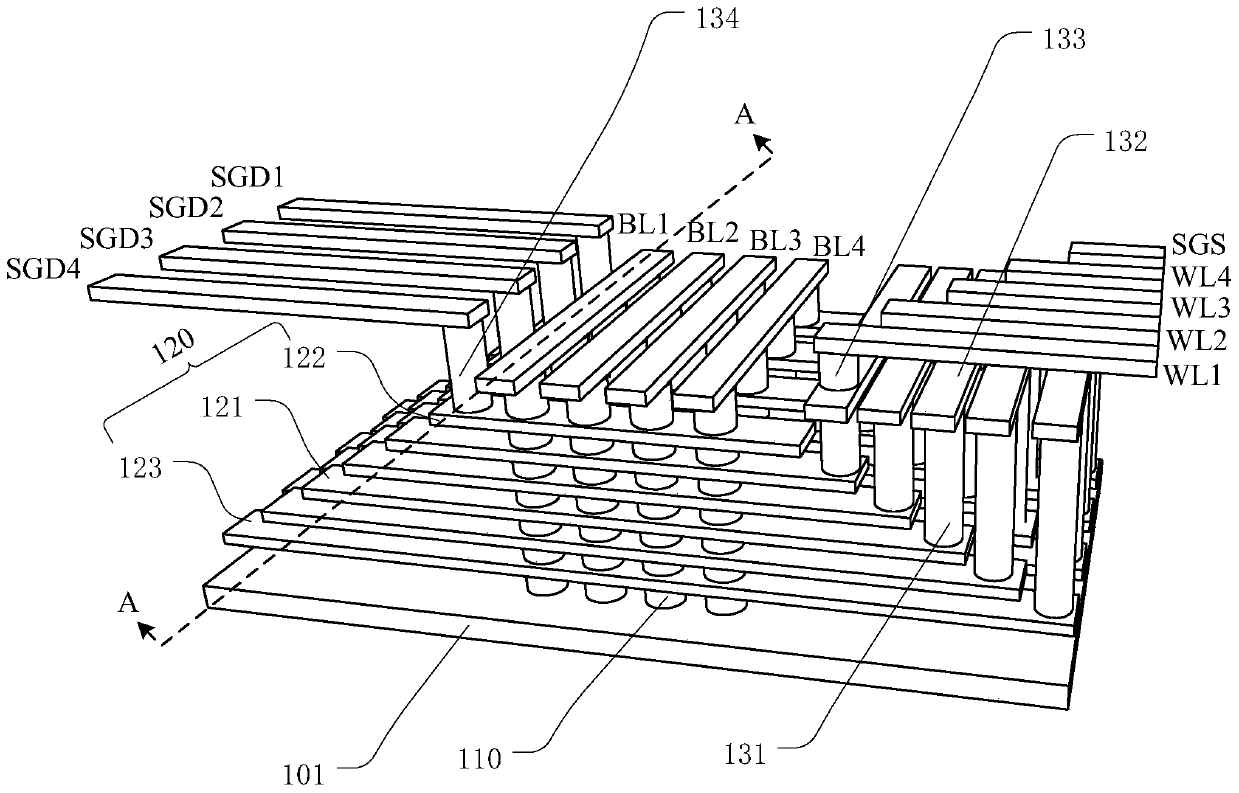

3D memory device and manufacturing method thereof

PendingCN110649032AContinuous adjustment of warpageQuality improvementSolid-state devicesSemiconductor devicesGate stackCondensed matter physics

The invention discloses a 3D memory device and a manufacturing method thereof. The 3D memory device includes a substrate, a gate stack structure, a plurality of channel columns and a plurality of channel holes, a doped region, a first conductive layer and a core part, wherein the gate stack structure is positioned above the substrate and comprises a plurality of gate conductors and a plurality ofinterlayer insulating layers which are alternately stacked; the plurality of channel columns and the plurality of channel holes penetrate through the gate stack structure; the doped region is locatedat the bottom of the channel hole and is formed in the substrate; the first conductive layer covers the inner wall of the channel hole and is in contact with the doped region; and the core part is located in the channel hole and above the doped region, the core part is doped polycrystalline silicon doped with impurity atoms with a certain concentration, and the doping concentration of the impurity atoms is adjusted so as to realize continuous adjustment of the surface warping degree of the 3D memory device. The warping degree of a wafer in an X direction or a Y direction is continuously adjusted by changing the doping concentration of impurity atoms doped in the core part in a grid line gap of the 3D storage device, and the problem of wafer warping is solved.

Owner:YANGTZE MEMORY TECH CO LTD

Ultrasonic food cutter device

InactiveCN102581868AImprove the finishImprove cutting accuracyMetal working apparatusElectricityTransducer

The invention discloses an ultrasonic food cutter device, which mainly comprises a cutter, a screw 1, a compression spring, a variable diameter bar, a screw II, a transducer, a housing and a digital power control box. The cutter is connected with one end of the screw I, and the other end of the screw is connected with the variable diameter bar. The other end of the variable diameter bar is connected with the screw II, and the other end of the screw II is connected with the transducer. The compression ring is disposed in the middle of the variable diameter bar. The transducer is disposed inside the housing and electrically connected with the digital power control box. The ultrasonic food cutter device has the advantages that the device is high in cutting precision, resistant to deformation and sticking, fast in speed, high in efficiency and pollution-free, cut surfaces are smooth, cuts are accurate, a digital power source is adopted so that frequency is automatically tracked and power is adjustable, the device is capable of running continuously for 24 hours and the like.

Owner:河北海拓机电科技有限公司

Method and circuit for trimming an internal oscillator of a USB device according to a counting number between a first and second clock count value

InactiveUS8595543B2Short timeAccurate detectionPulse transformerPulse automatic controlData streamClock rate

A circuit and method for trimming an internal oscillator of a USB device that generates a clock signal as a frequency source of the USB device detect an end of packet from an input data stream to initialize a counter, identify a token packet in the data stream to detect a start of frame token packet for the counter to carry out clock counting on the clock signal to thereby obtain a count value, and compare the count value with a reference value to determine a trimming code for trimming a clock frequency of the internal oscillator.

Owner:ELAN MICROELECTRONICS CORPORATION

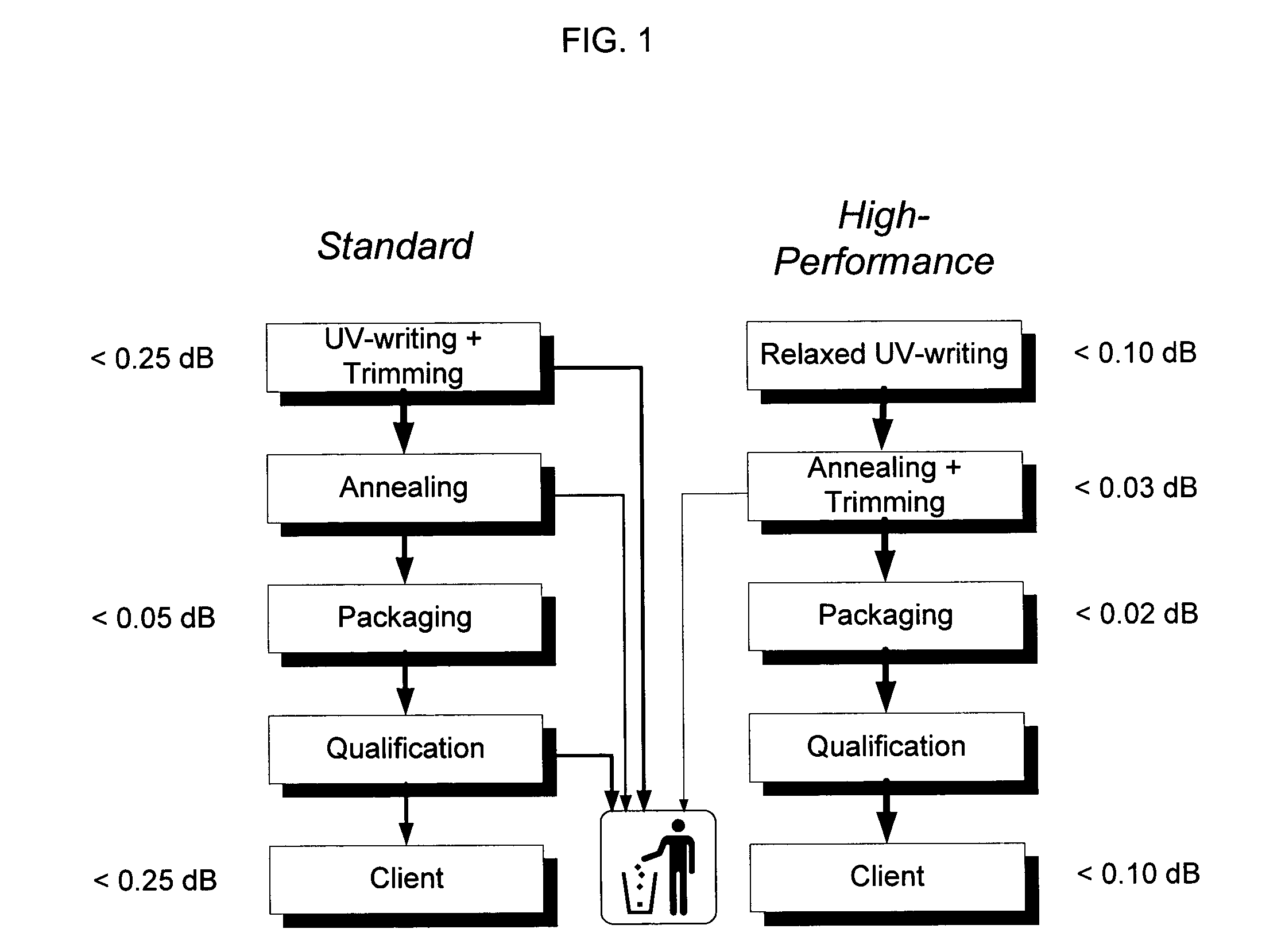

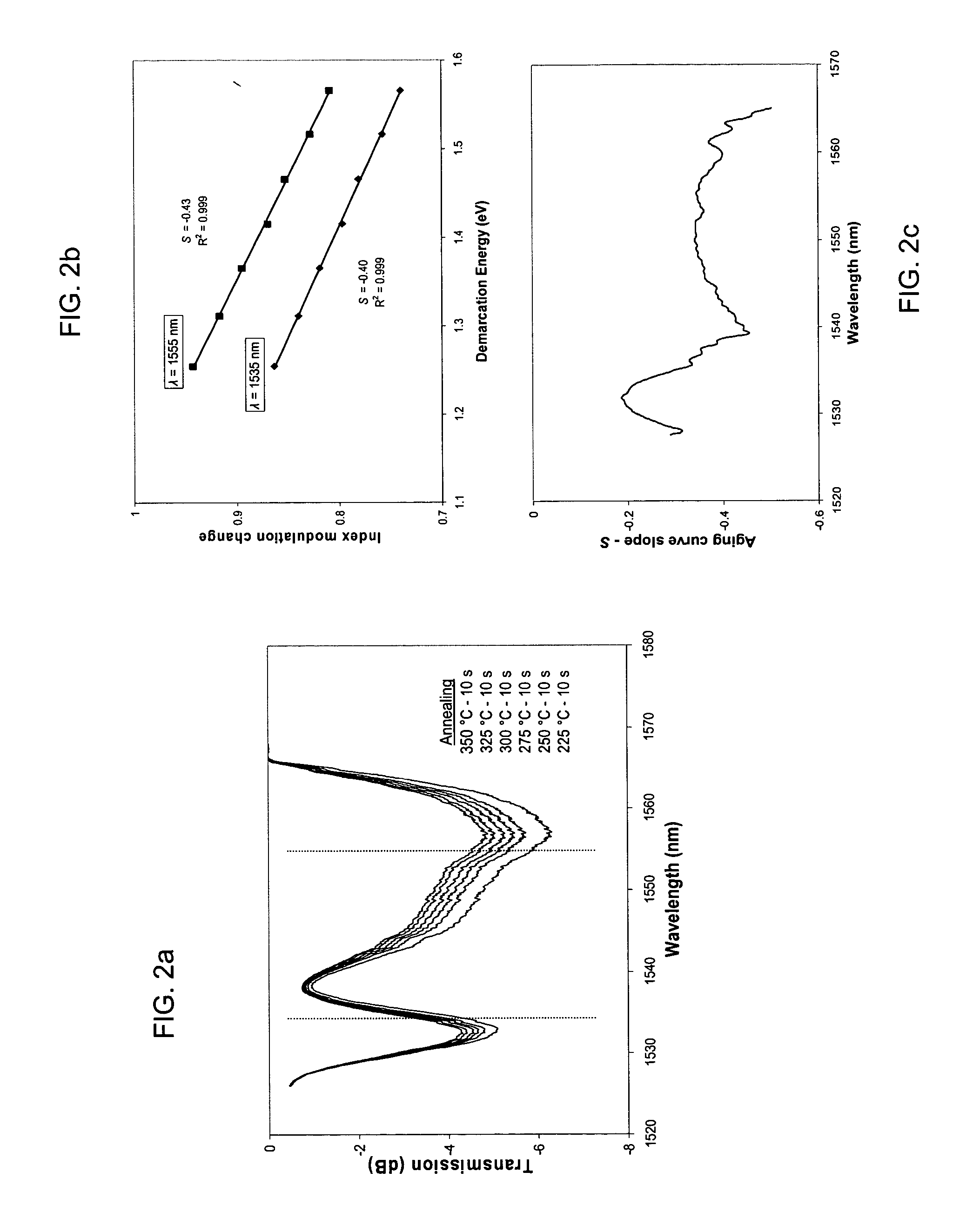

Method for manufacturing a FBG having improved performances and an annealing-trimming apparatus for making the same

ActiveUS20040161195A1Accurately tailoredImprove performanceCladded optical fibreSemiconductor/solid-state device manufacturingSingle processEngineering

A method for manufacturing a FBG having improved performances and an annealing-trimming apparatus for making the same are provided. The trimming and the annealing steps are advantageously combined into a single process in order to efficiently fabricate complex FBG filters with improved performance. The method comprises the steps of UV-writing a FBG in an optical fiber prior to annealing-trimming characteristics of the FBG by performing the sub-steps of monitoring characteristic data of the FBG while generating a controlled complex temperature profile along the FBG with a heating means according to the characteristic data for providing an accurate controlled annealing process of the FBG, thereby providing an accurate trimming thereof.

Owner:TERAXION

Image processing apparatus and method

InactiveUS20080024841A1Accurately trimPrecise TrimmingElectrographic process apparatusPictoral communicationEdge regionImaging data

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com