Patents

Literature

730results about "Feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

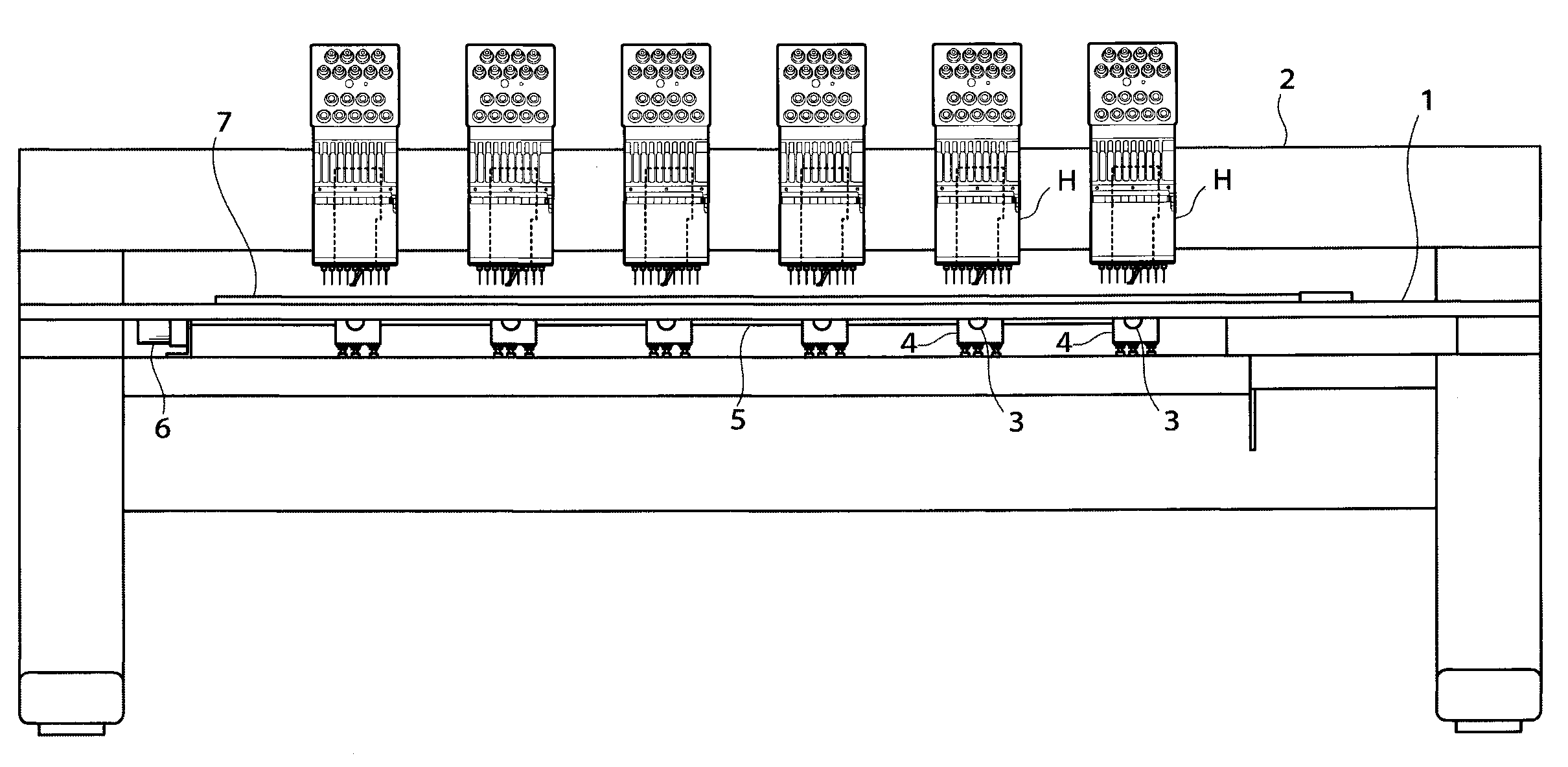

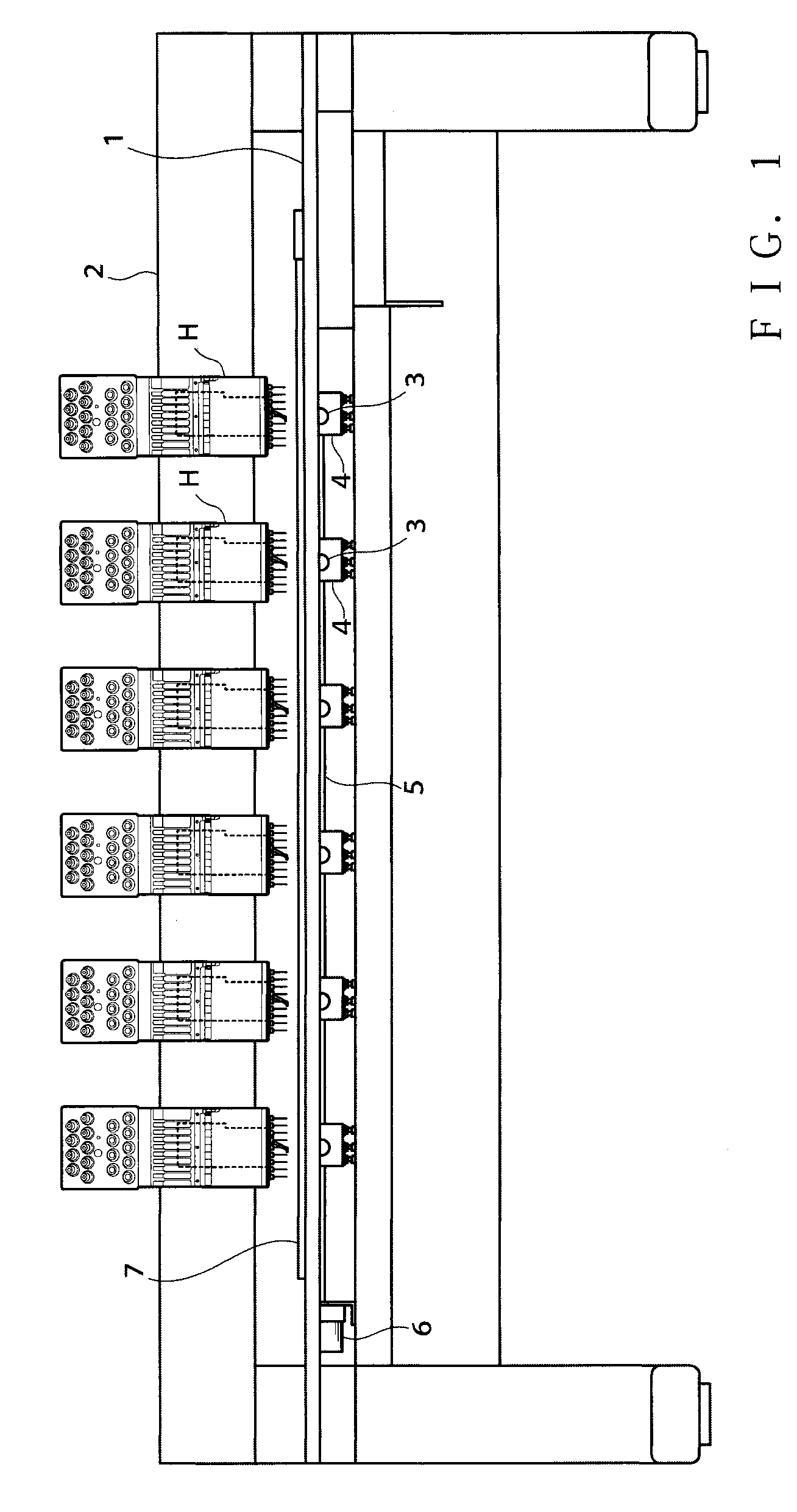

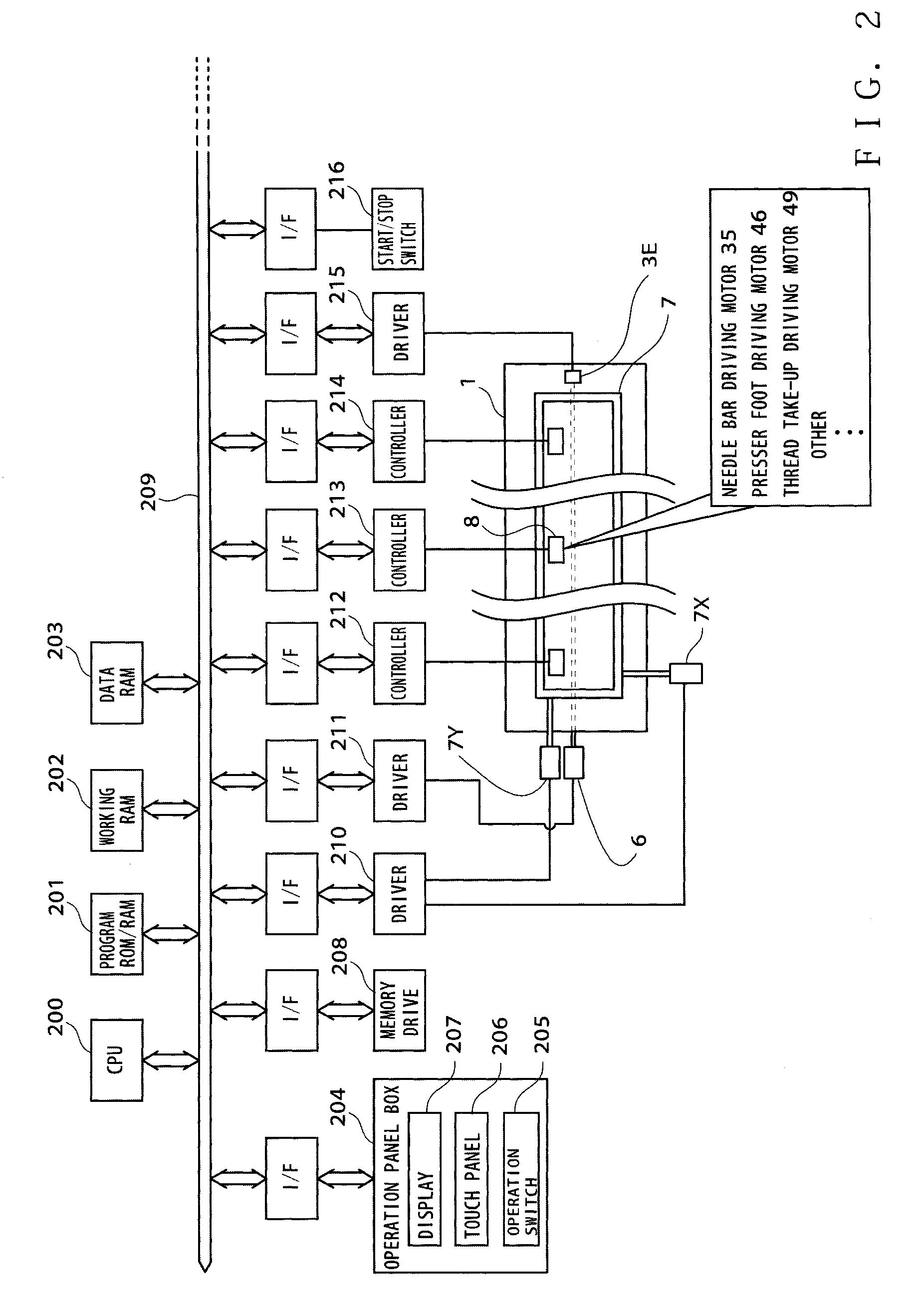

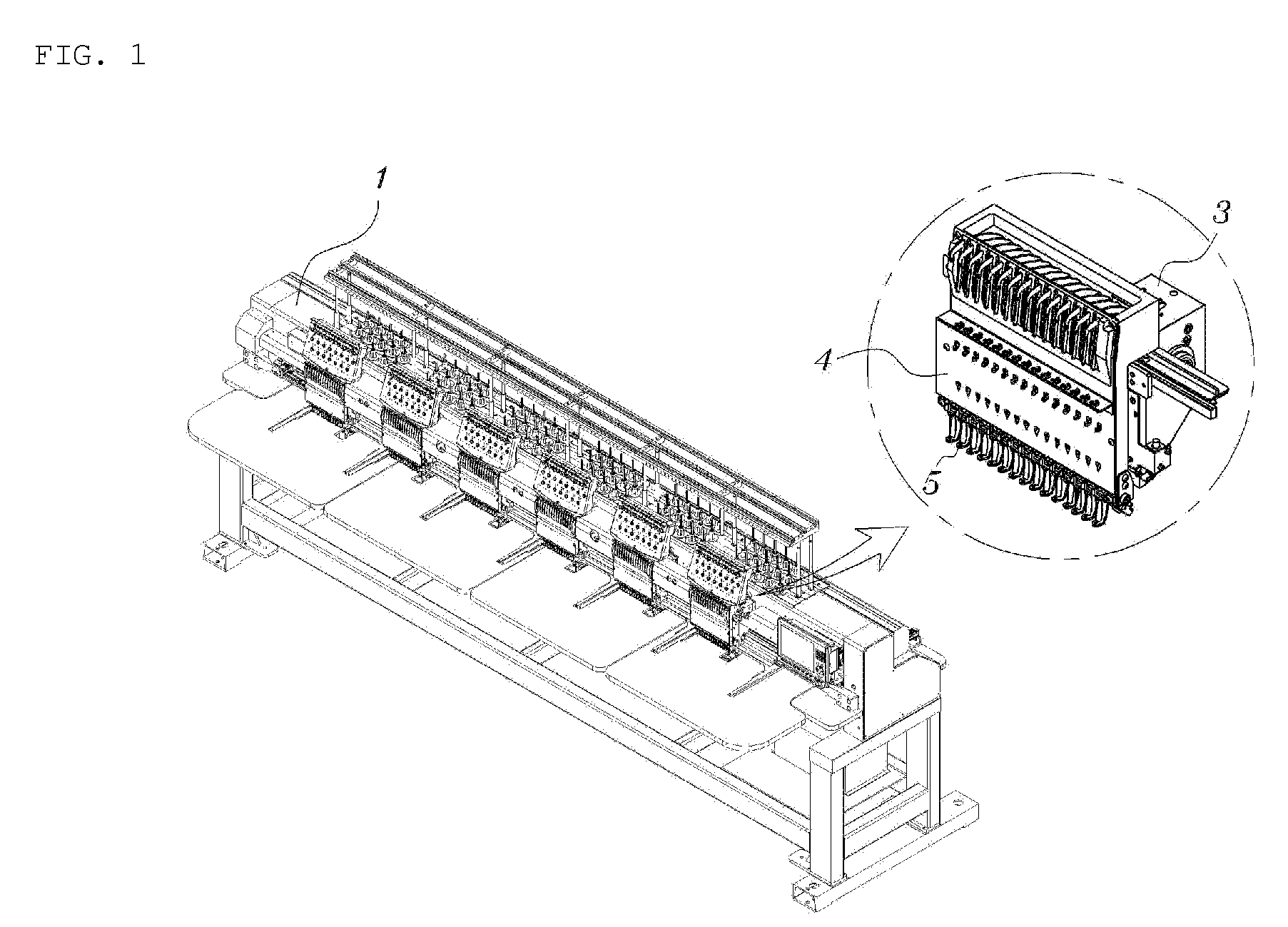

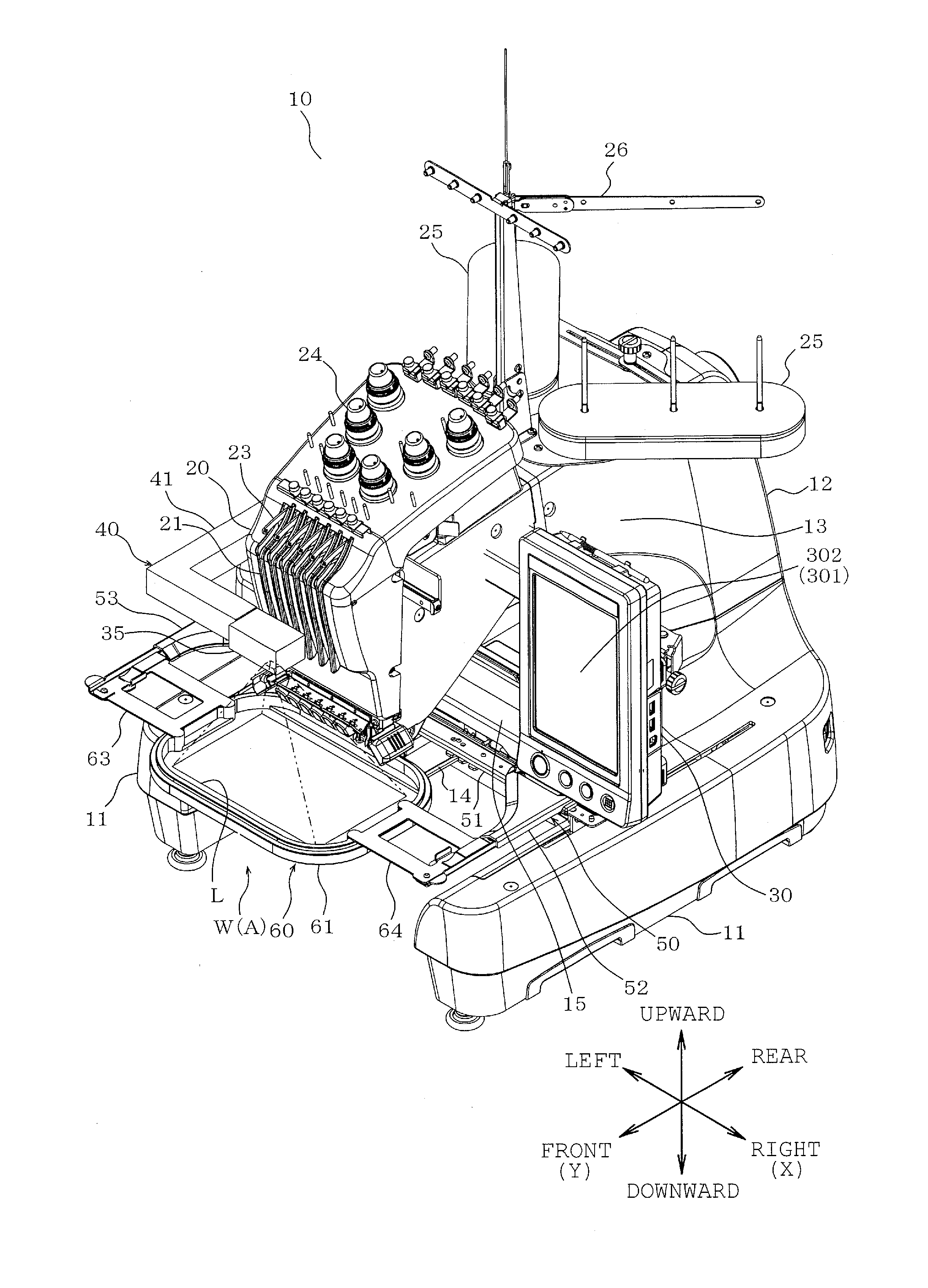

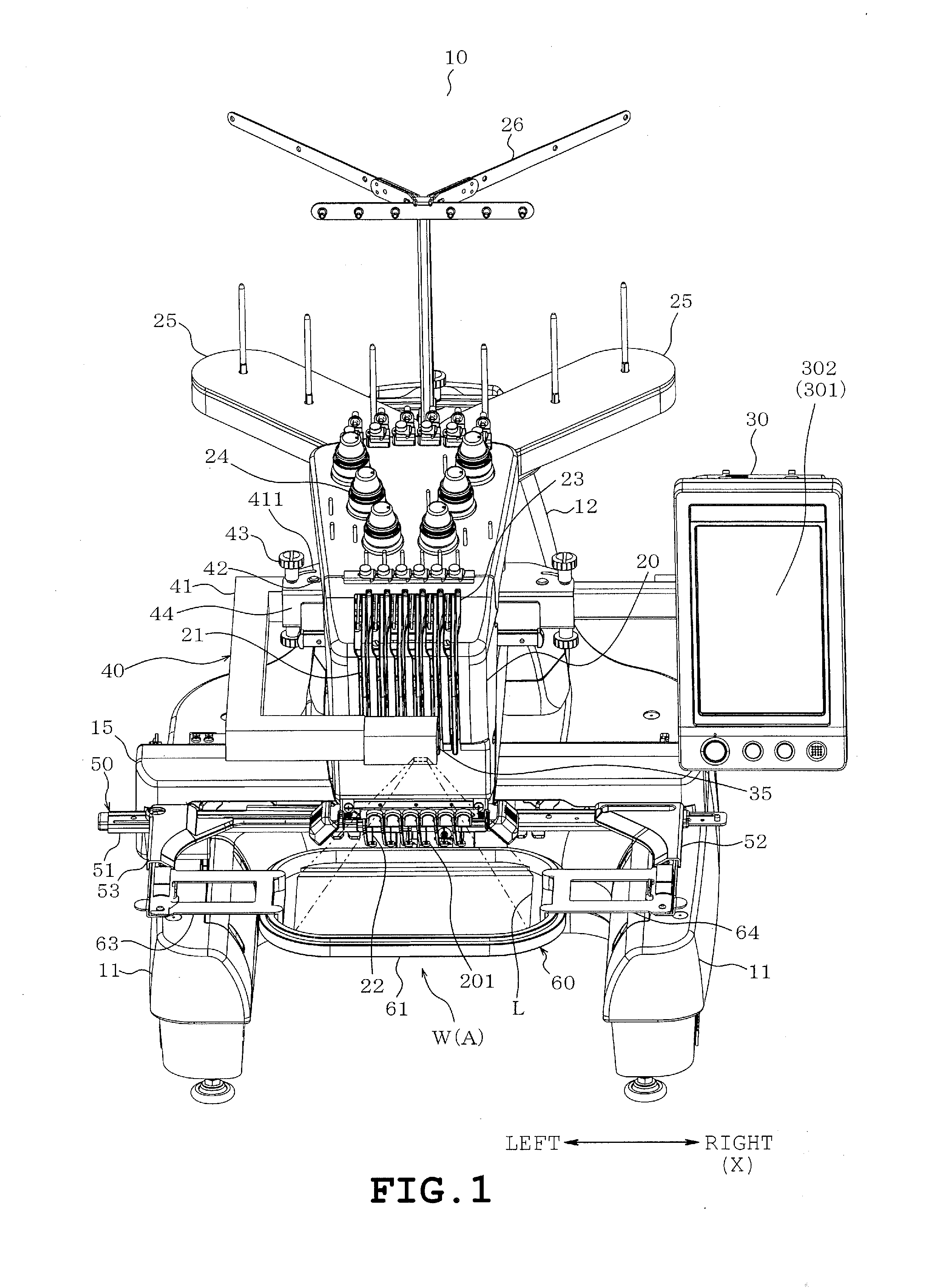

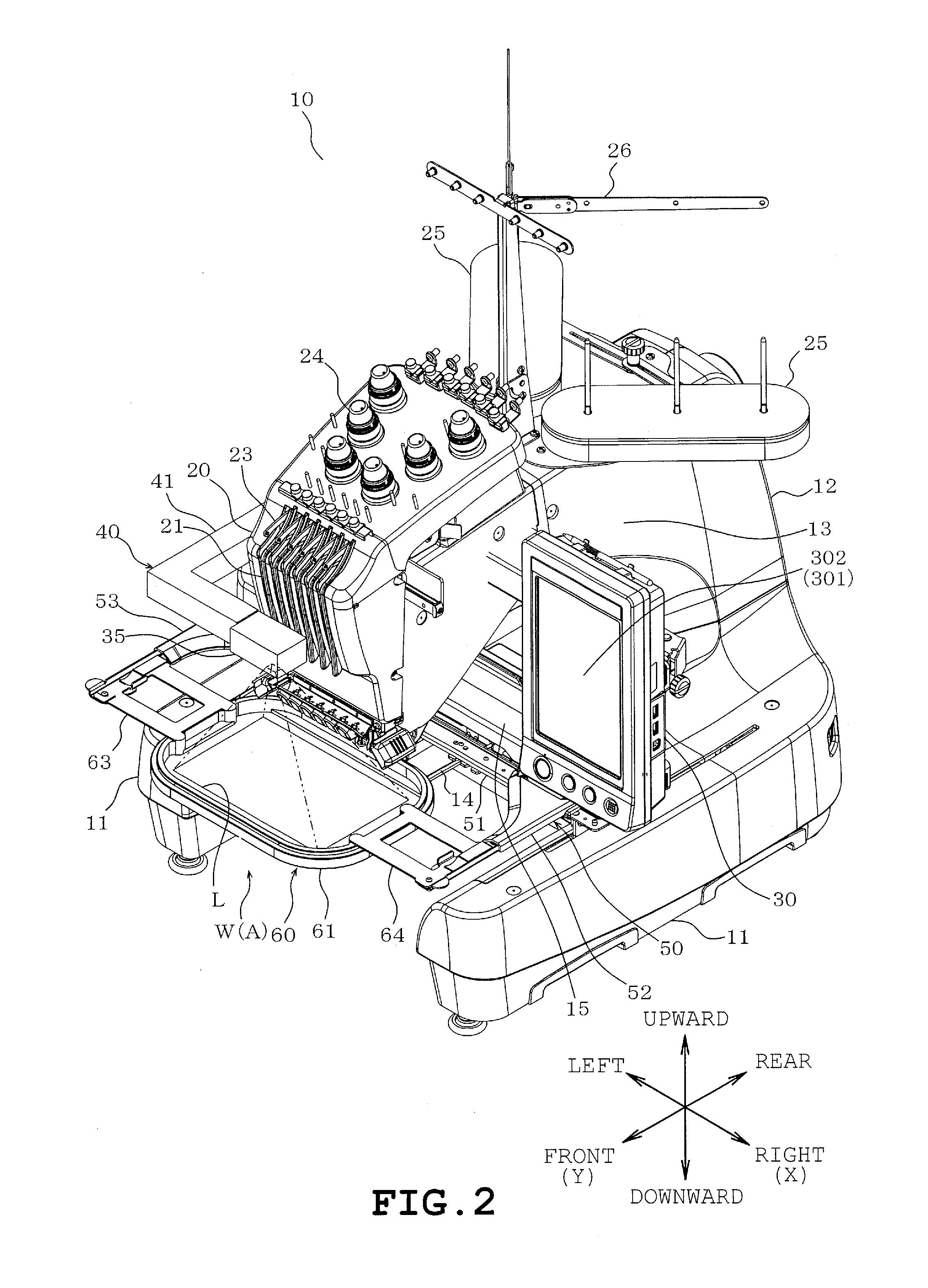

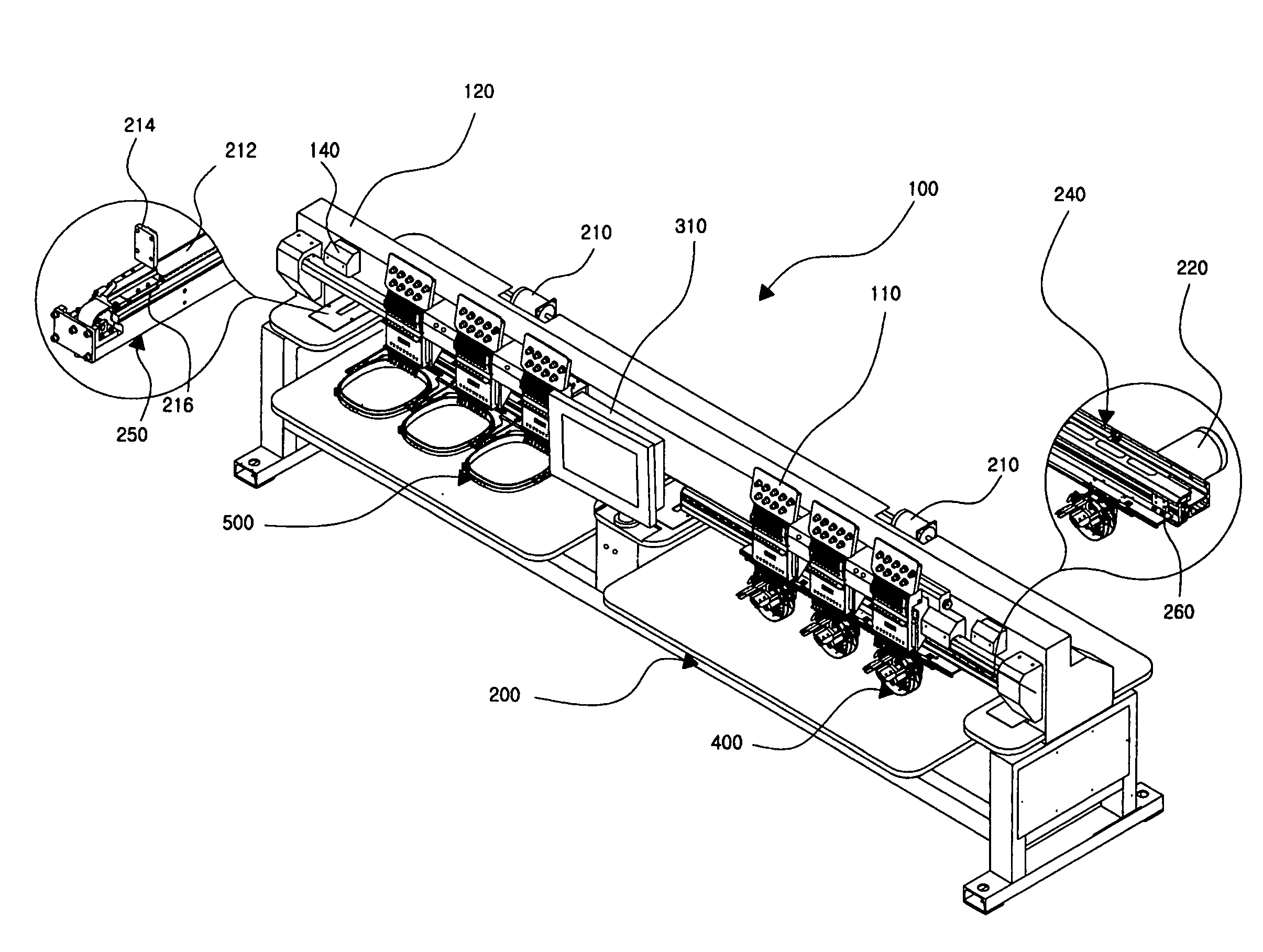

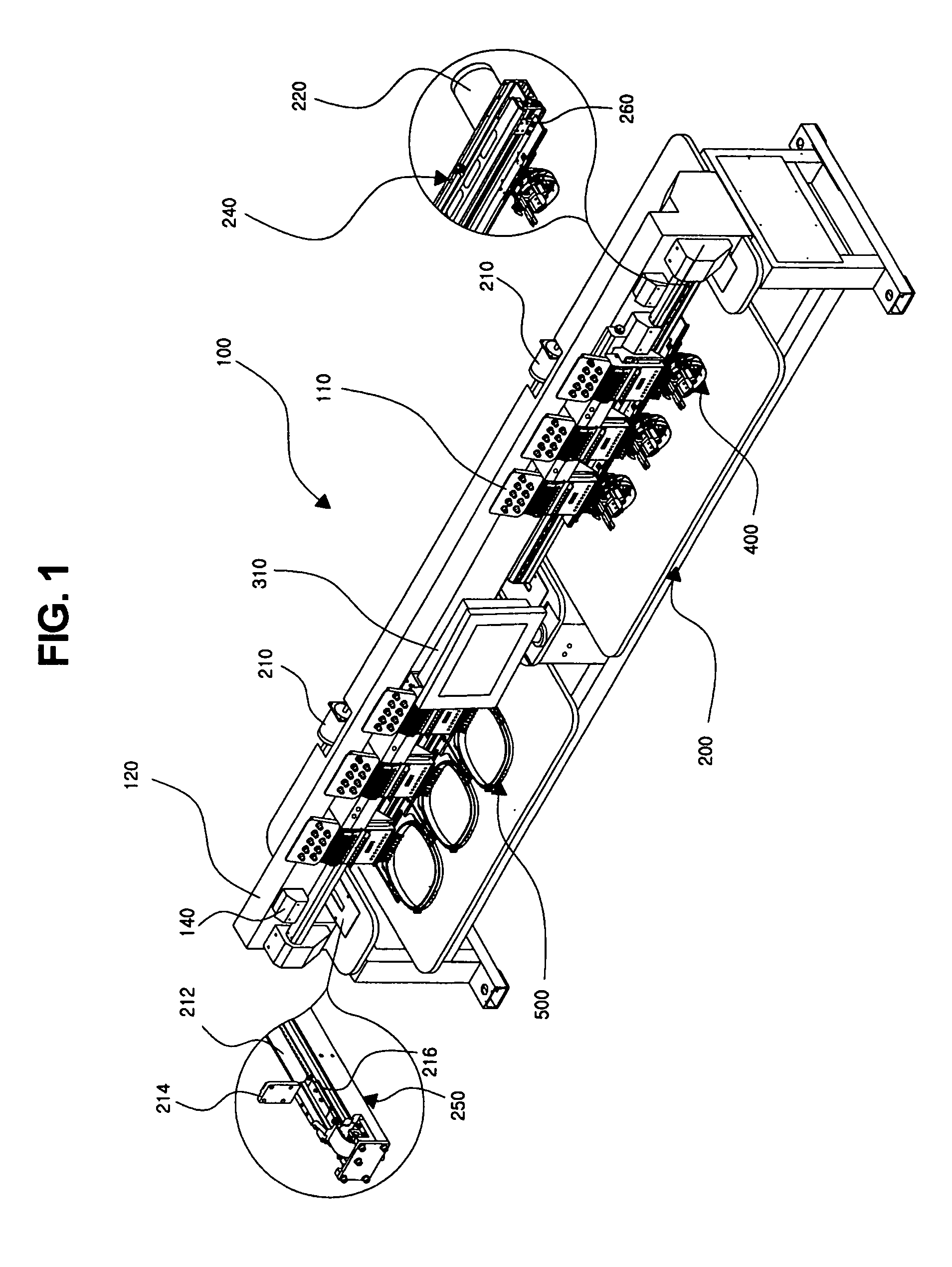

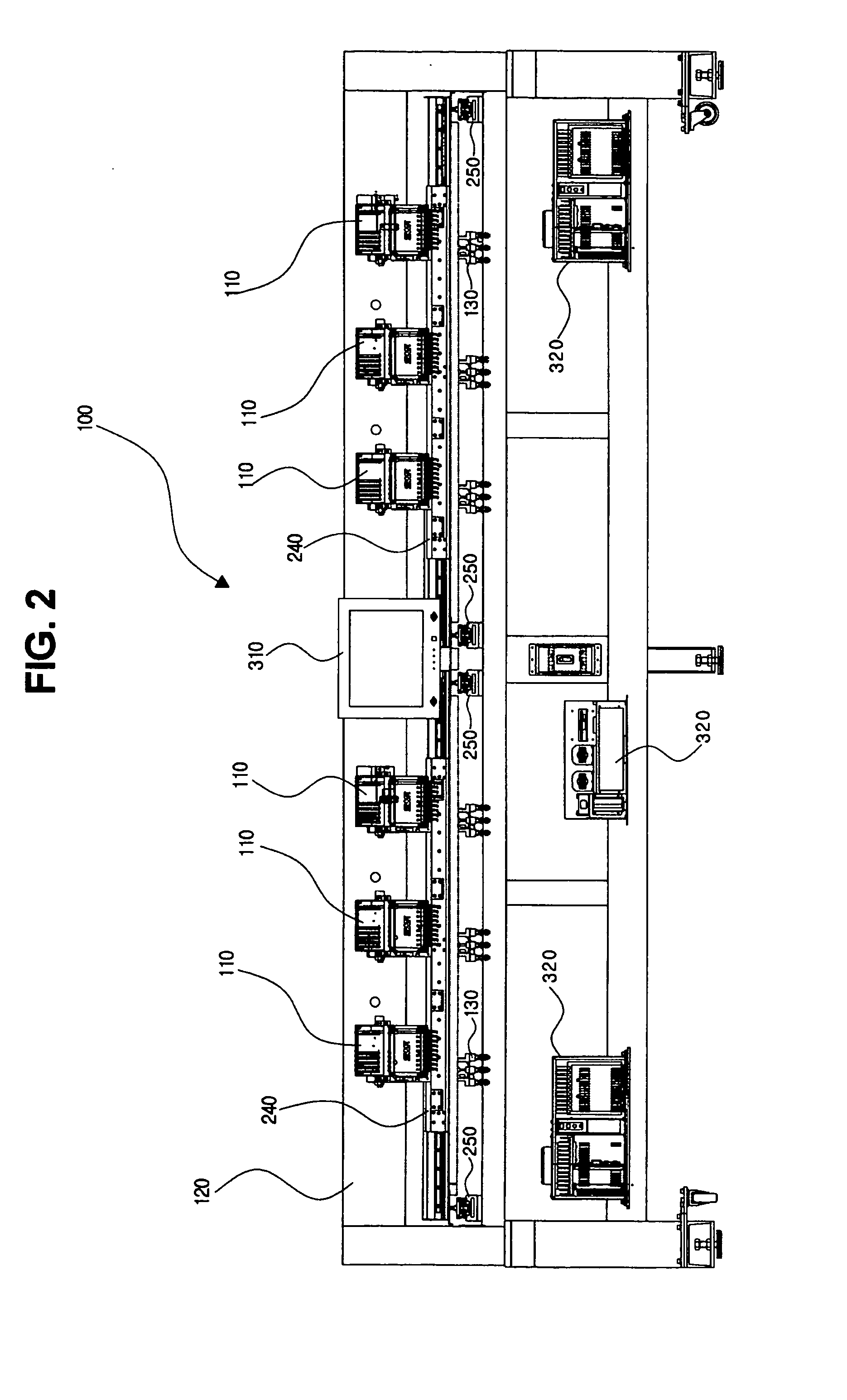

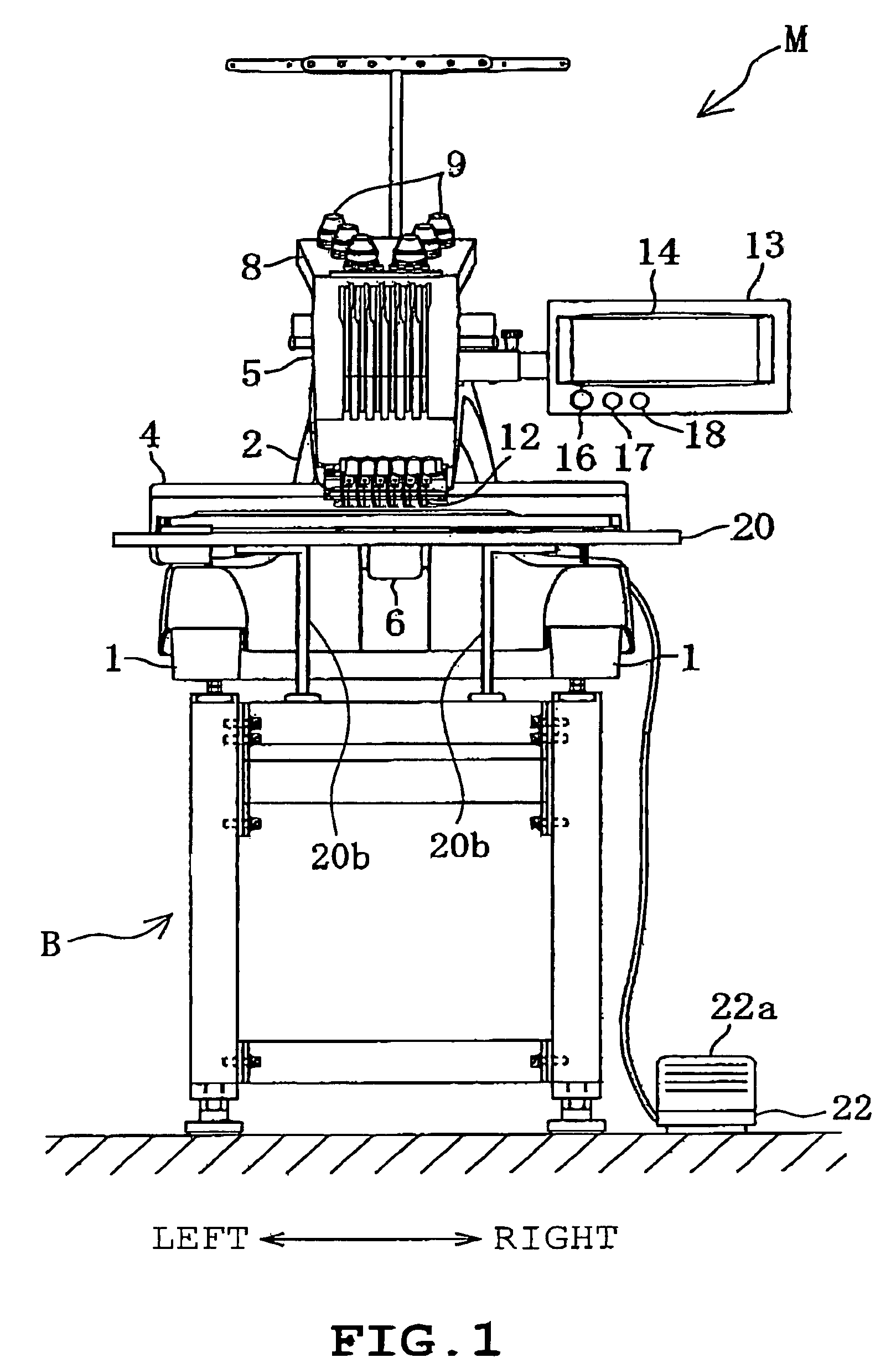

Multi-head embroidery sewing machine

InactiveUS20070261621A1Avoid unevennessEasy to switchPressersSewing-machine control devicesMechanical componentsEngineering

Individual motors in a sewing machine of the invention are provided, for each of a plurality of machine heads, for individually driving respective mechanical components, such as a needle bar driving mechanism, thread take-up lever and presser foot mechanism. A plurality of rotary hooks are driven by a common motor. Even in a case where embroidering workpieces set on the individual machine heads differ in material between the heads and upper threads used for the machine heads differ in characteristic between the heads, the sewing machine can make, in a concurrent, parallel fashion, embroidery products of different texture suited for the respective materials, characteristics, etc., by setting independent stitch formation per machine head.

Owner:TOKAI IND SEWING MACH CO LTD

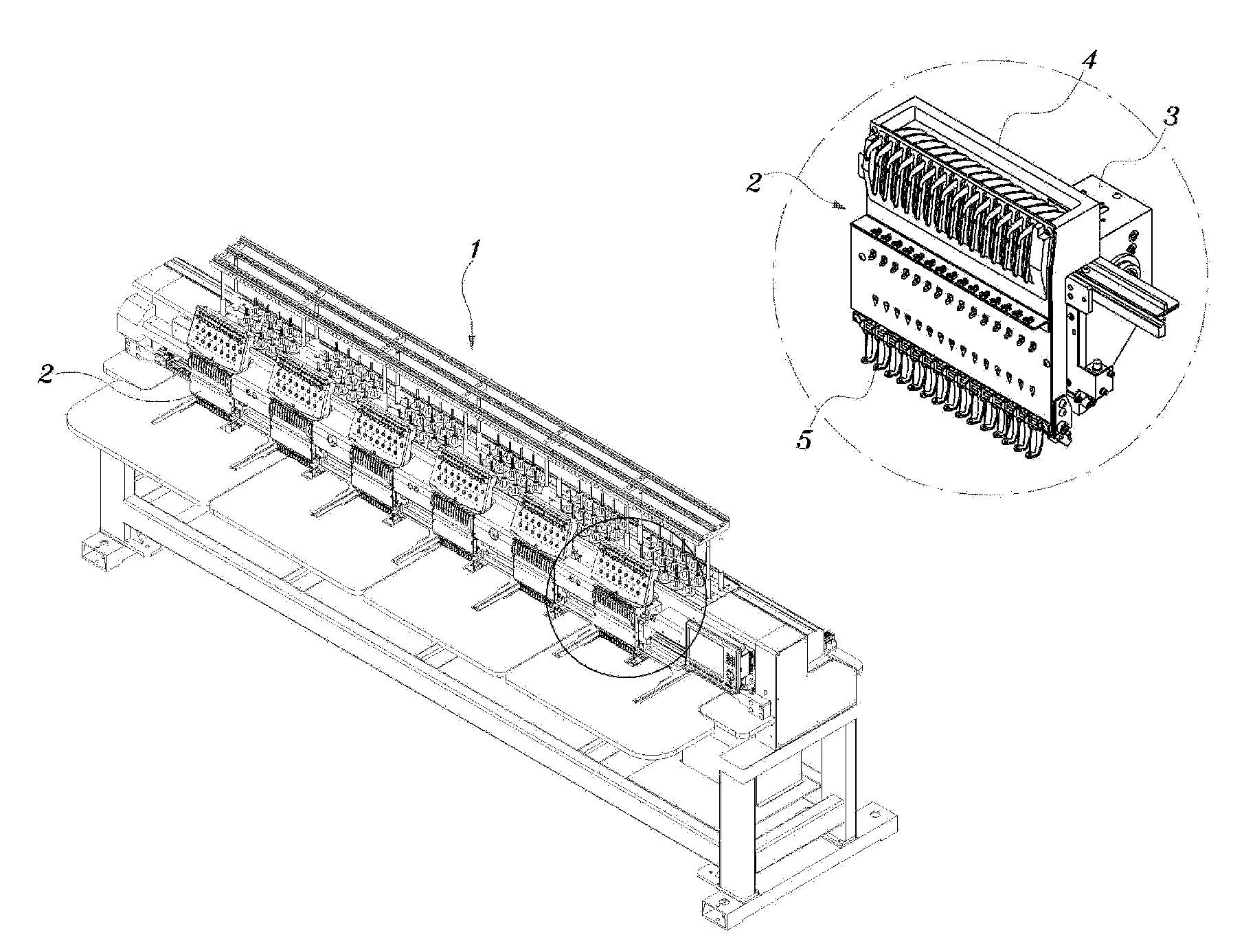

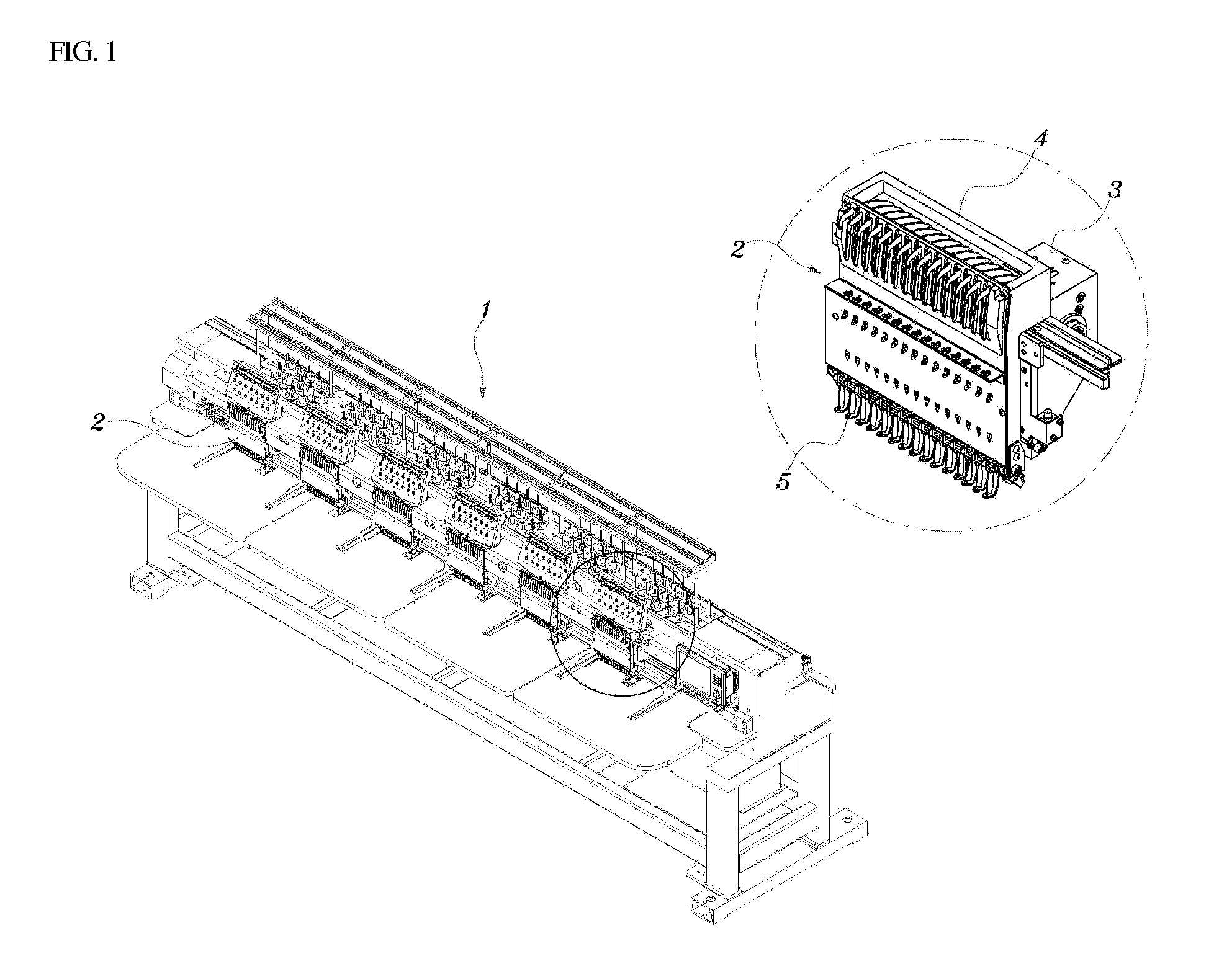

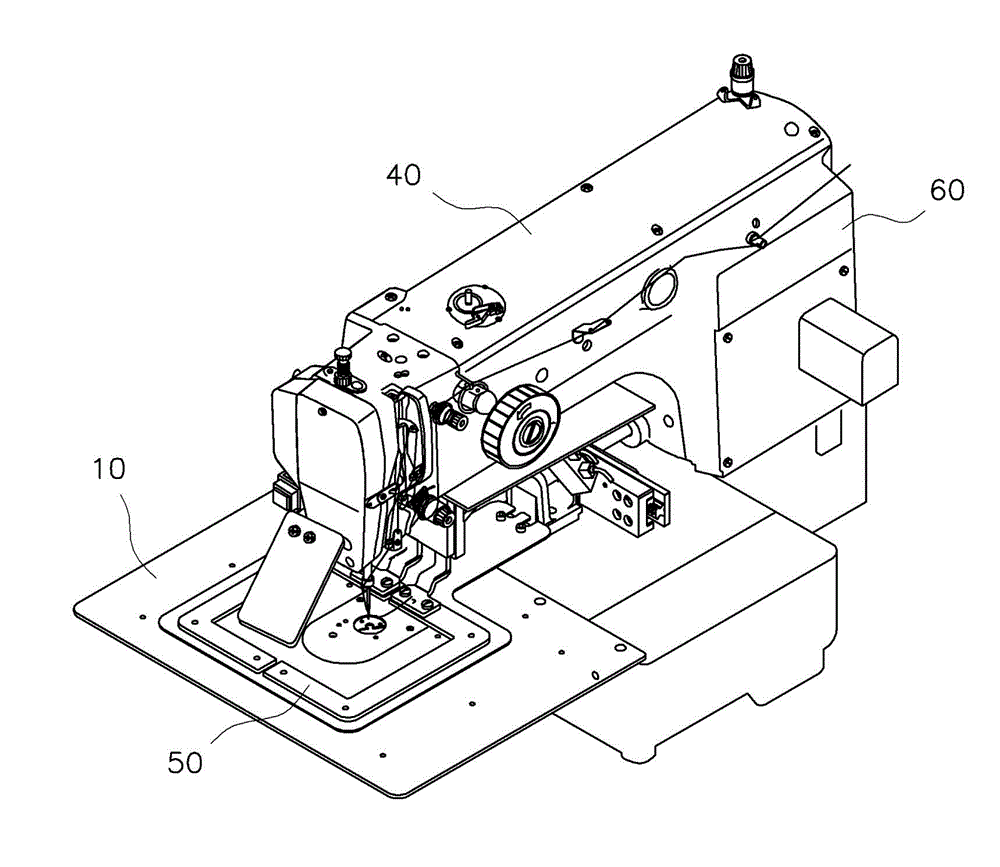

Embroidery machine

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Embroidery Machine

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

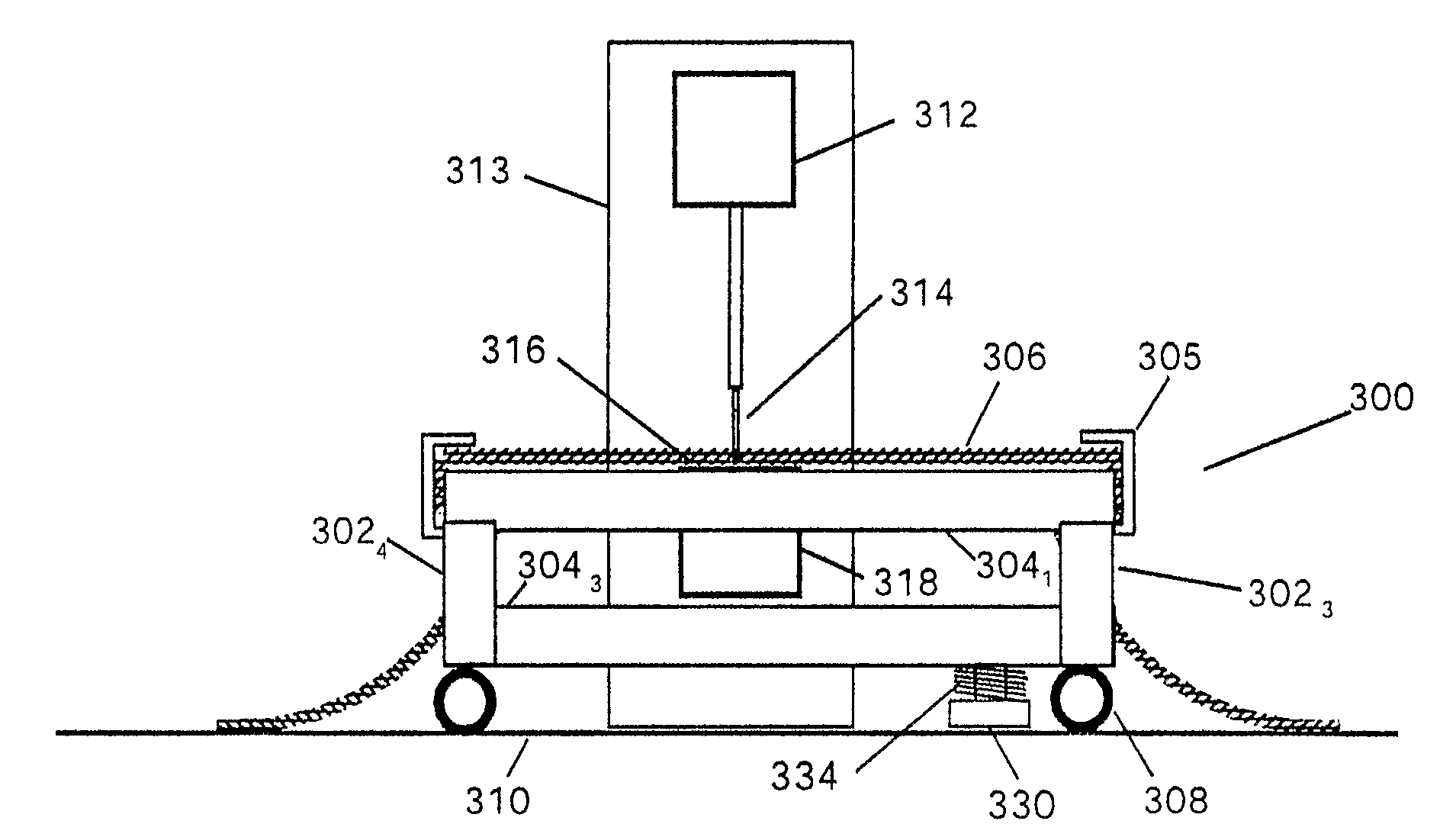

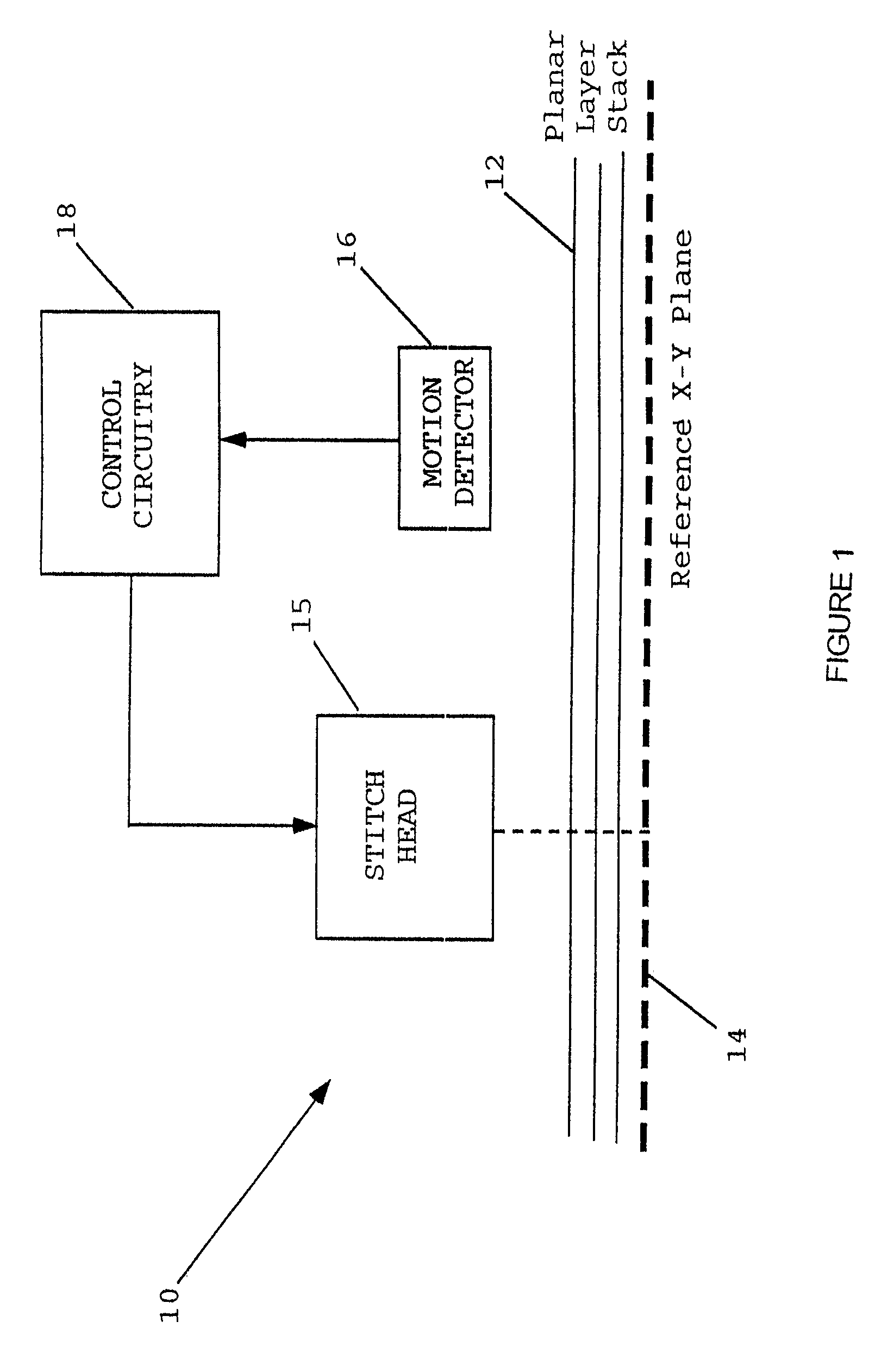

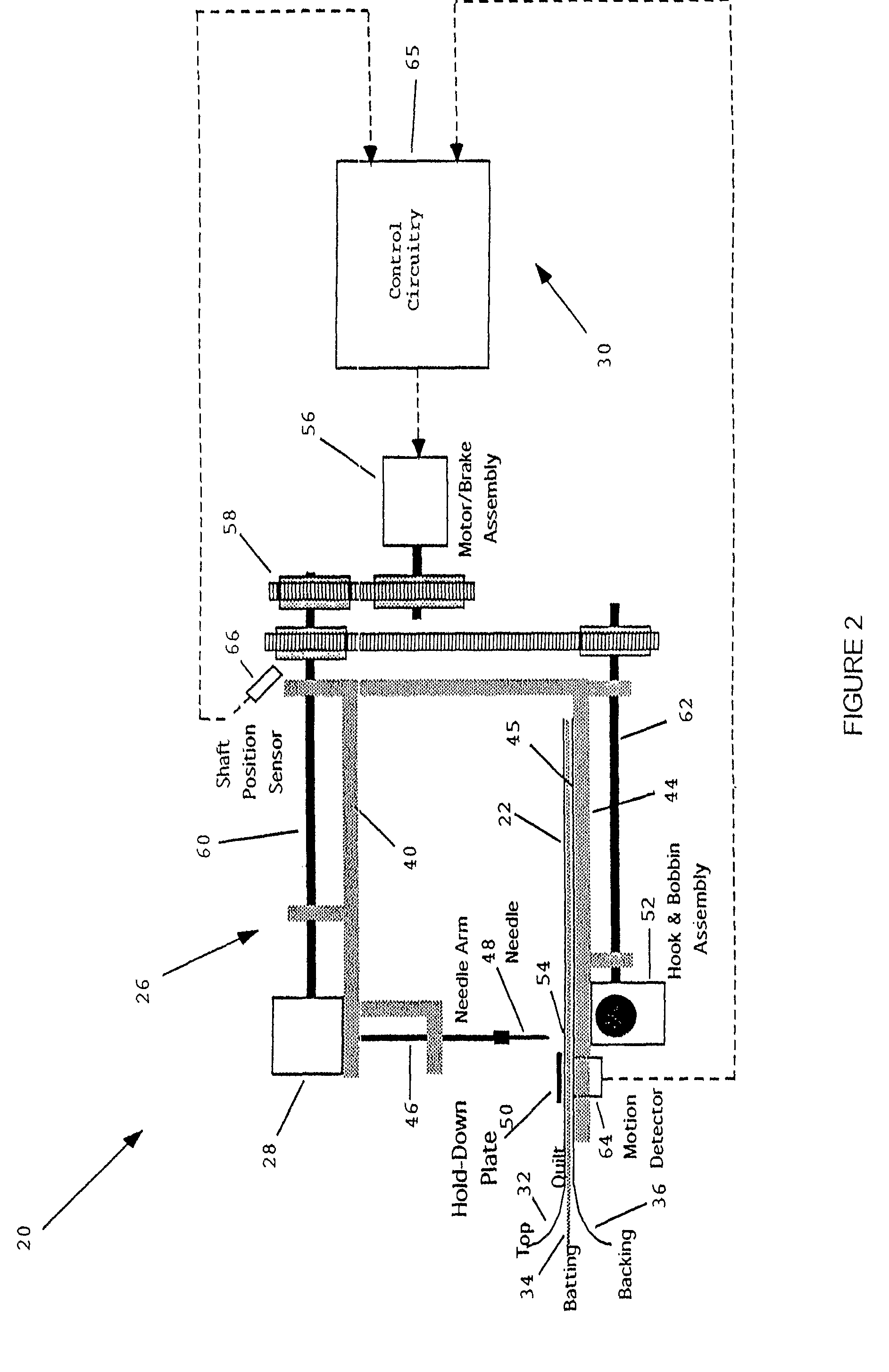

Quilting method and apparatus using frame with motion detector

Owner:KOERNER RALPH J

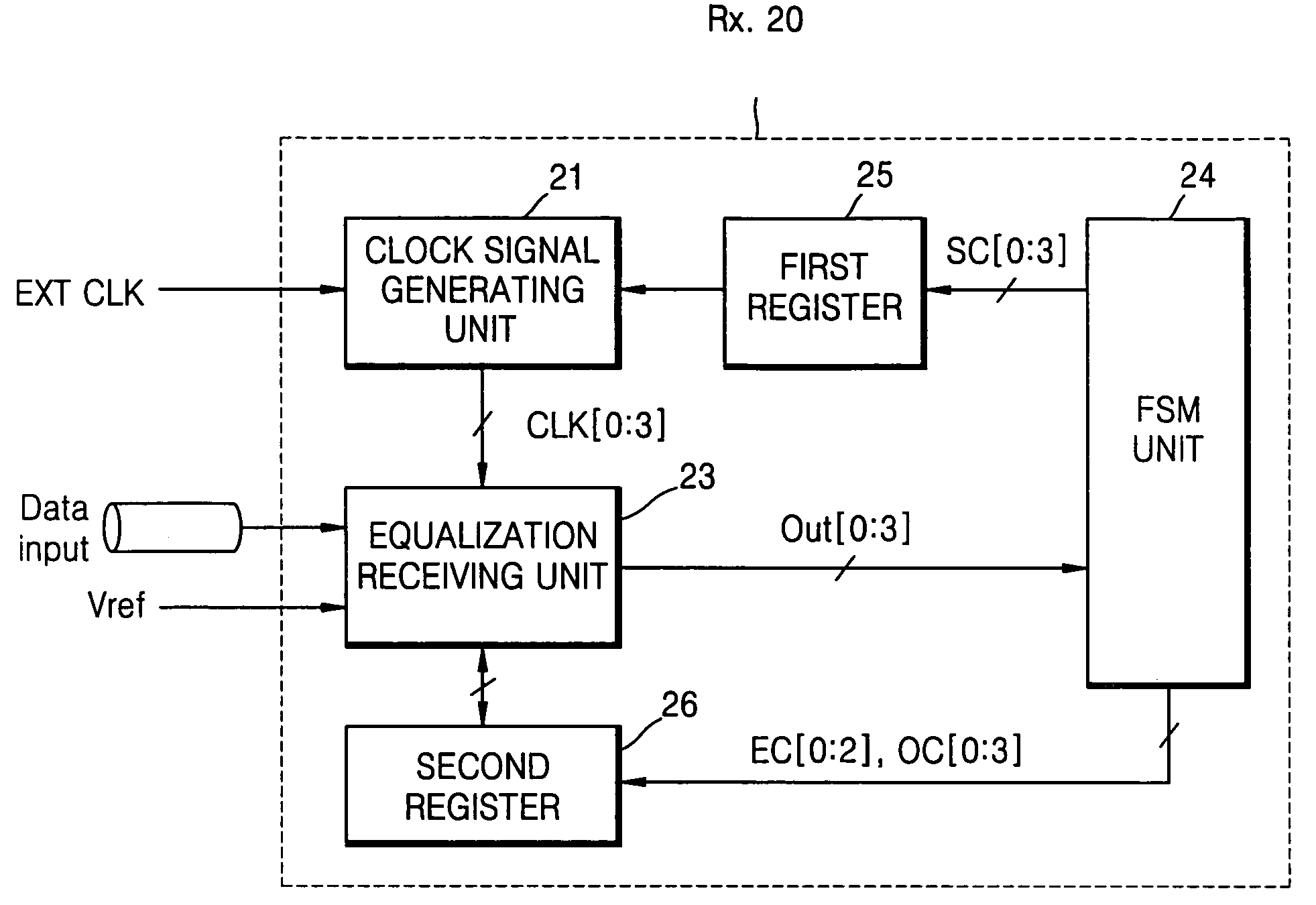

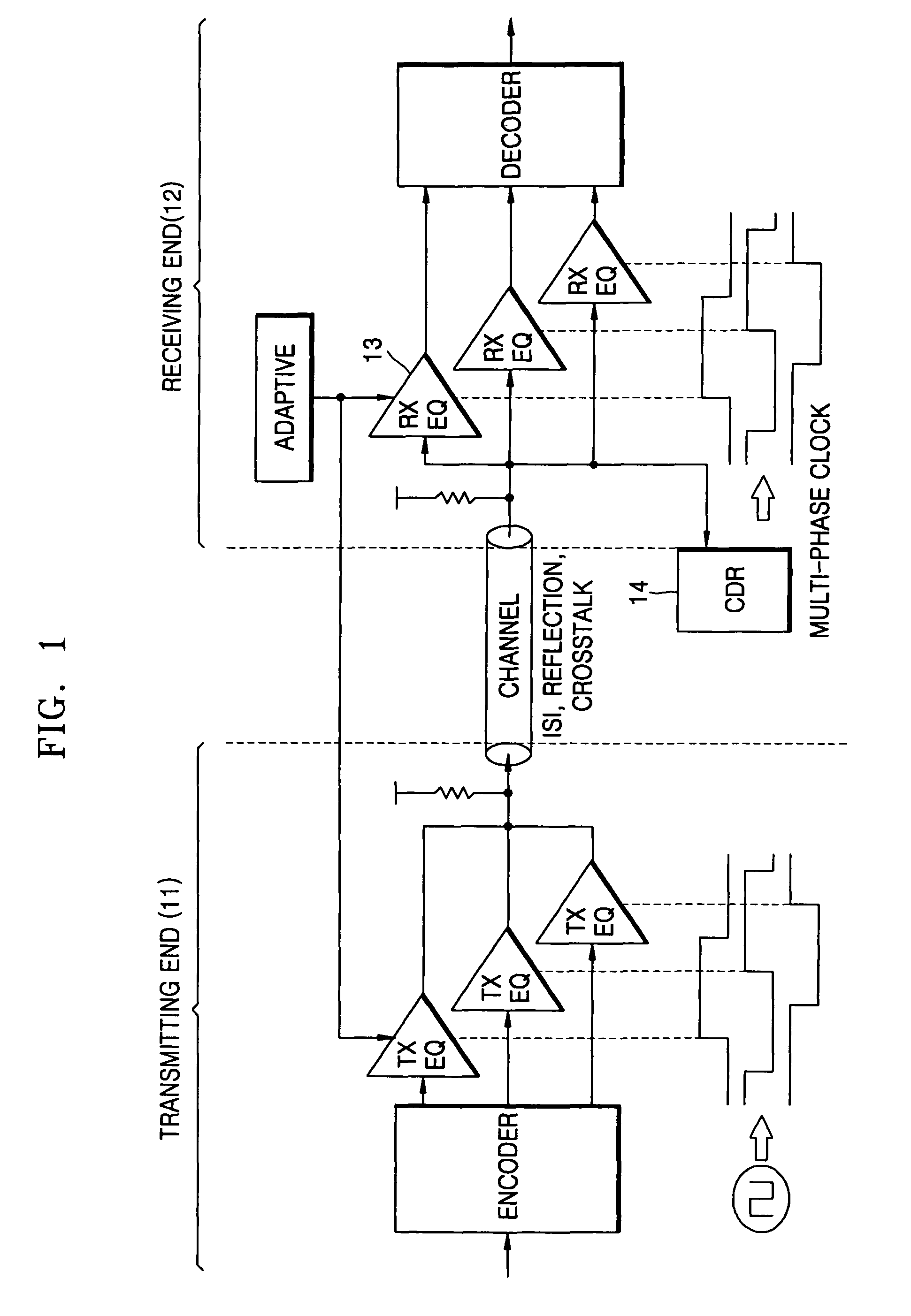

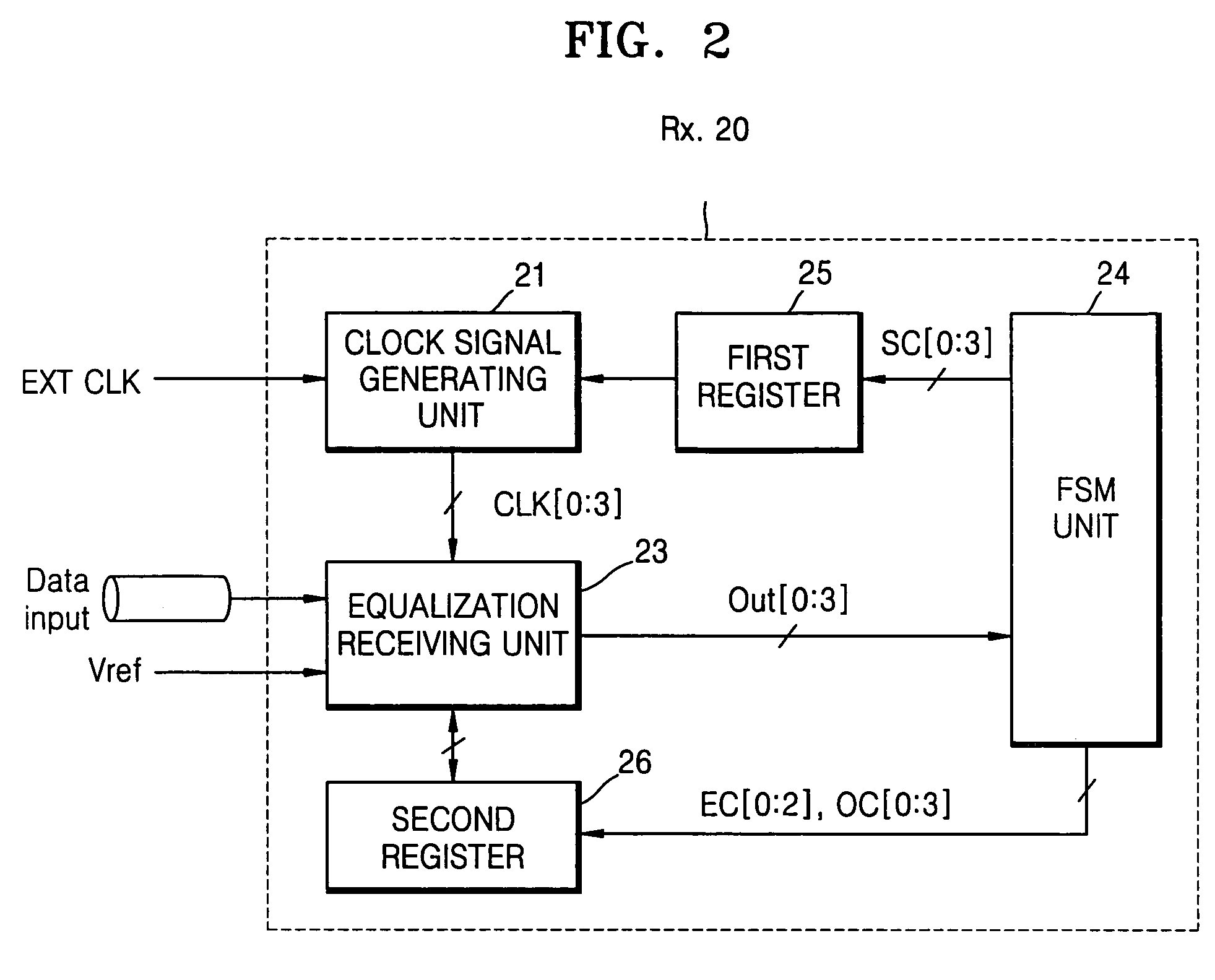

Receiving apparatus and method thereof

ActiveUS7822111B2Reduce power consumptionReduce chip areaMultiple-port networksError preventionData signalEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

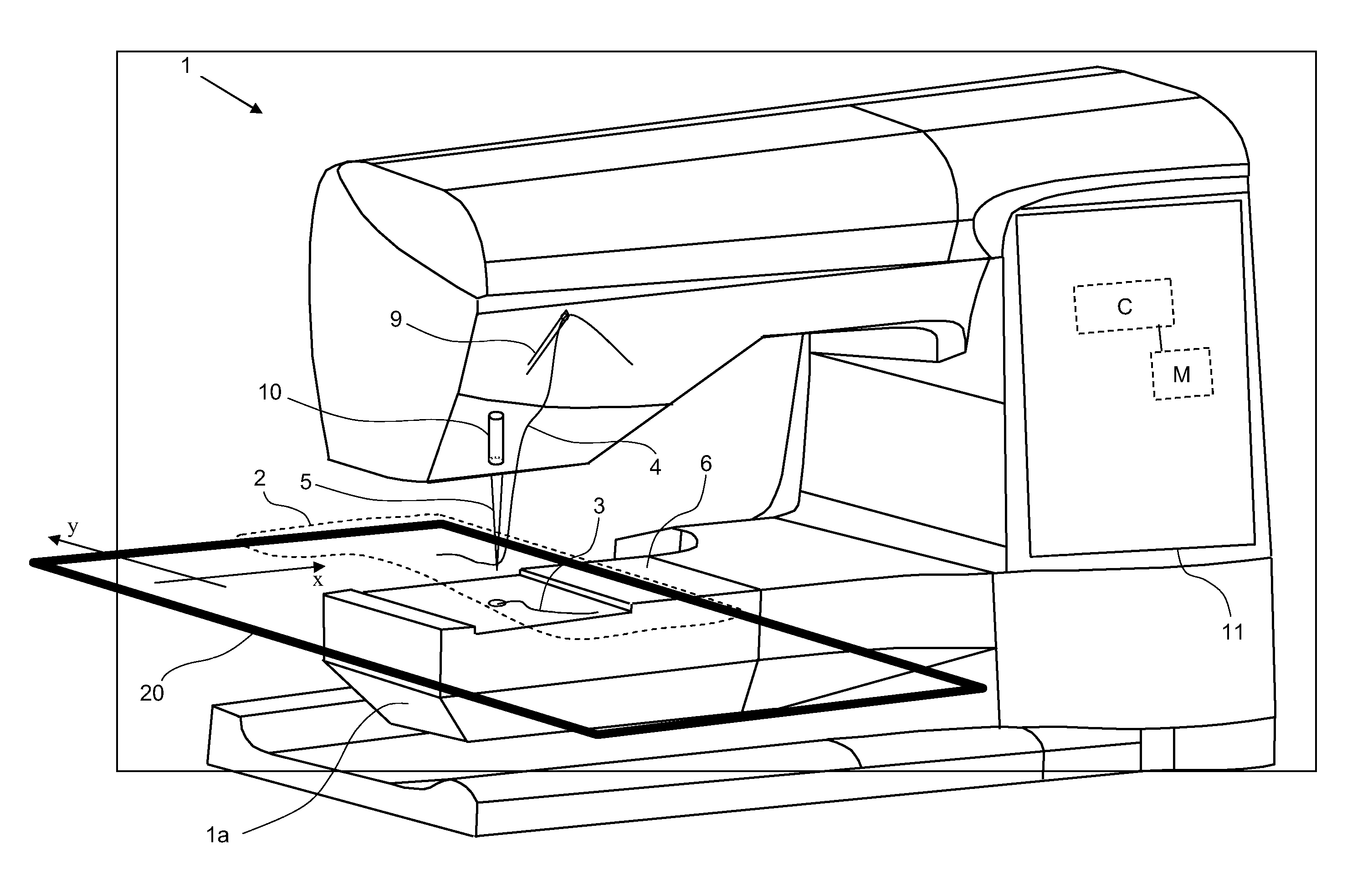

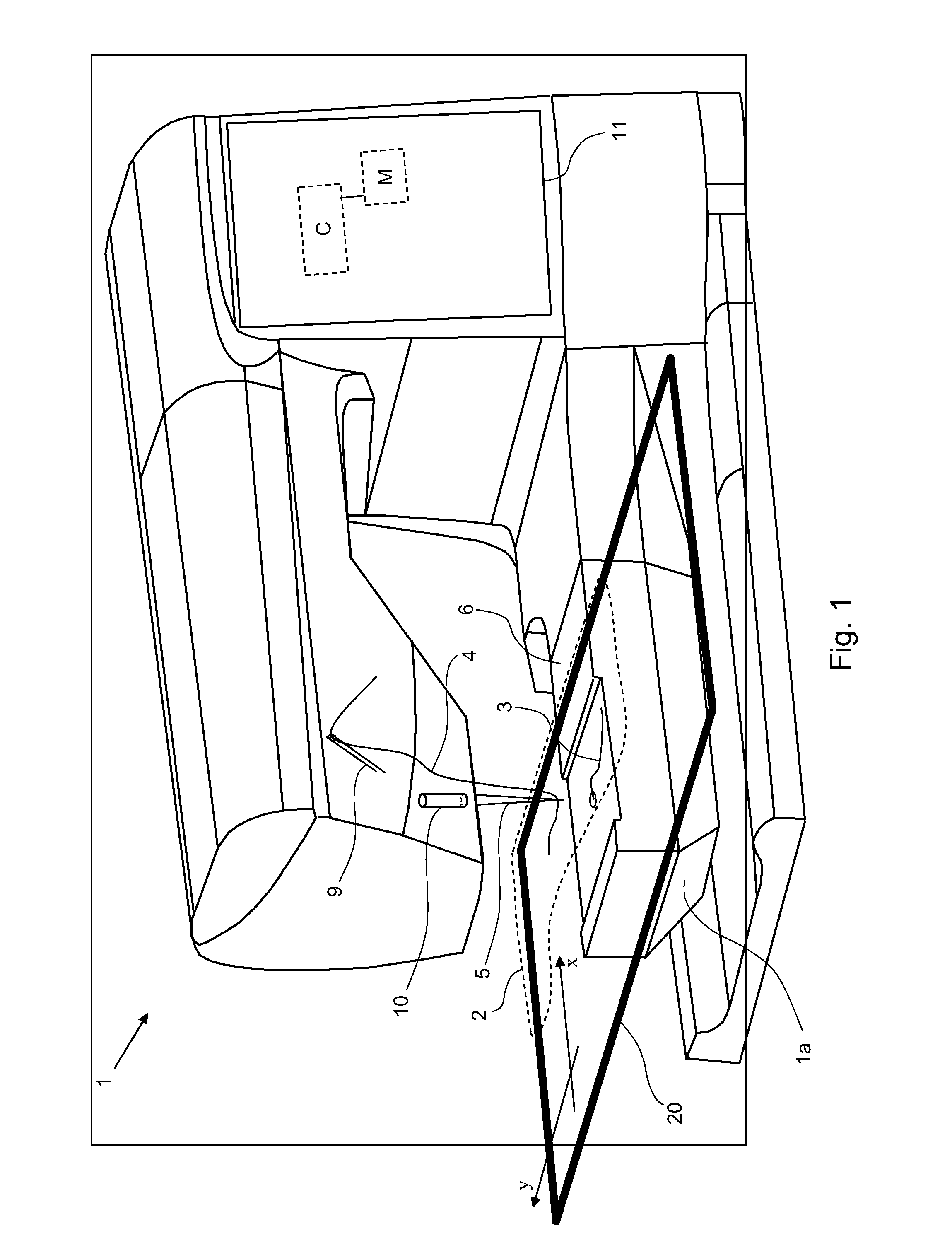

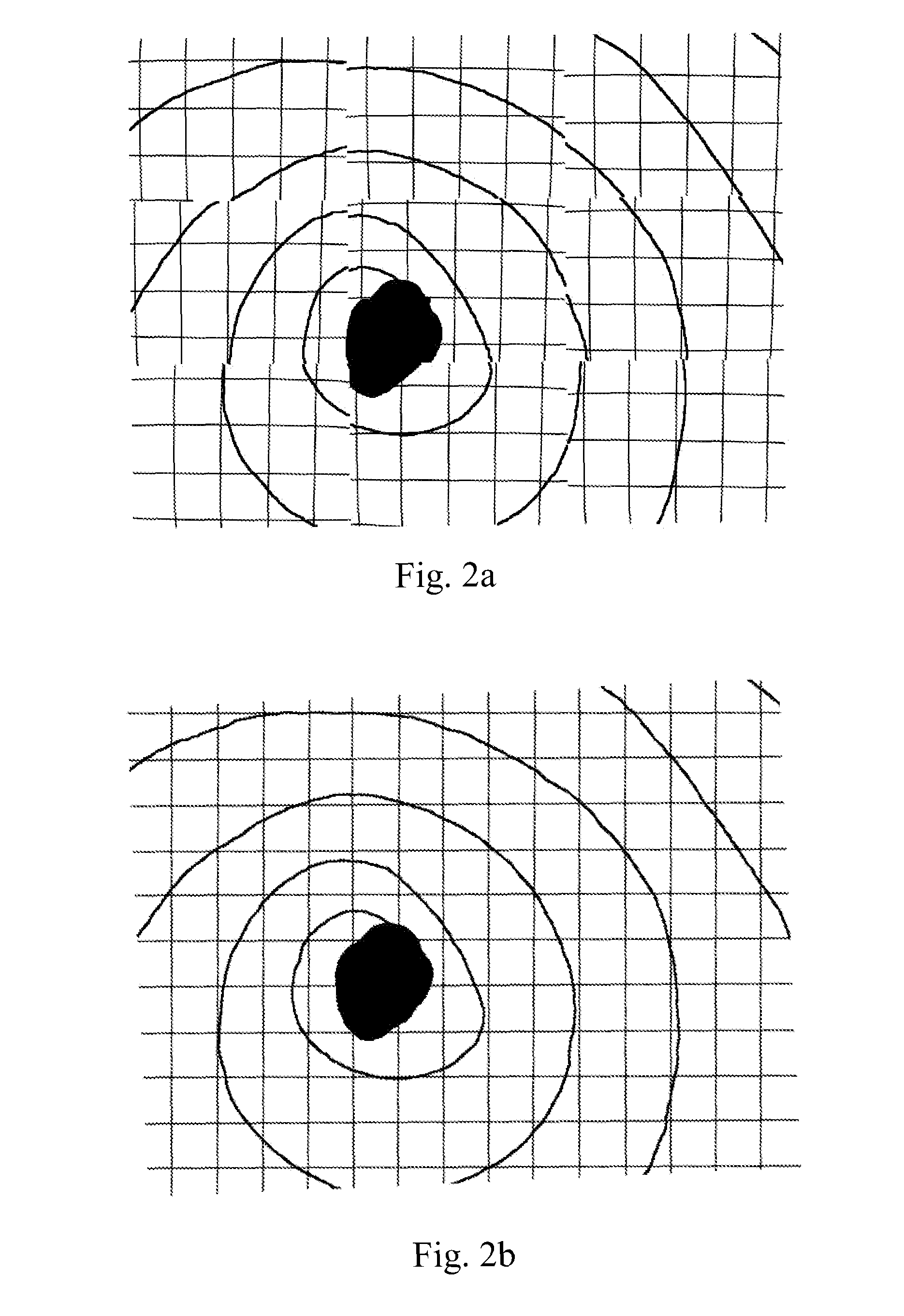

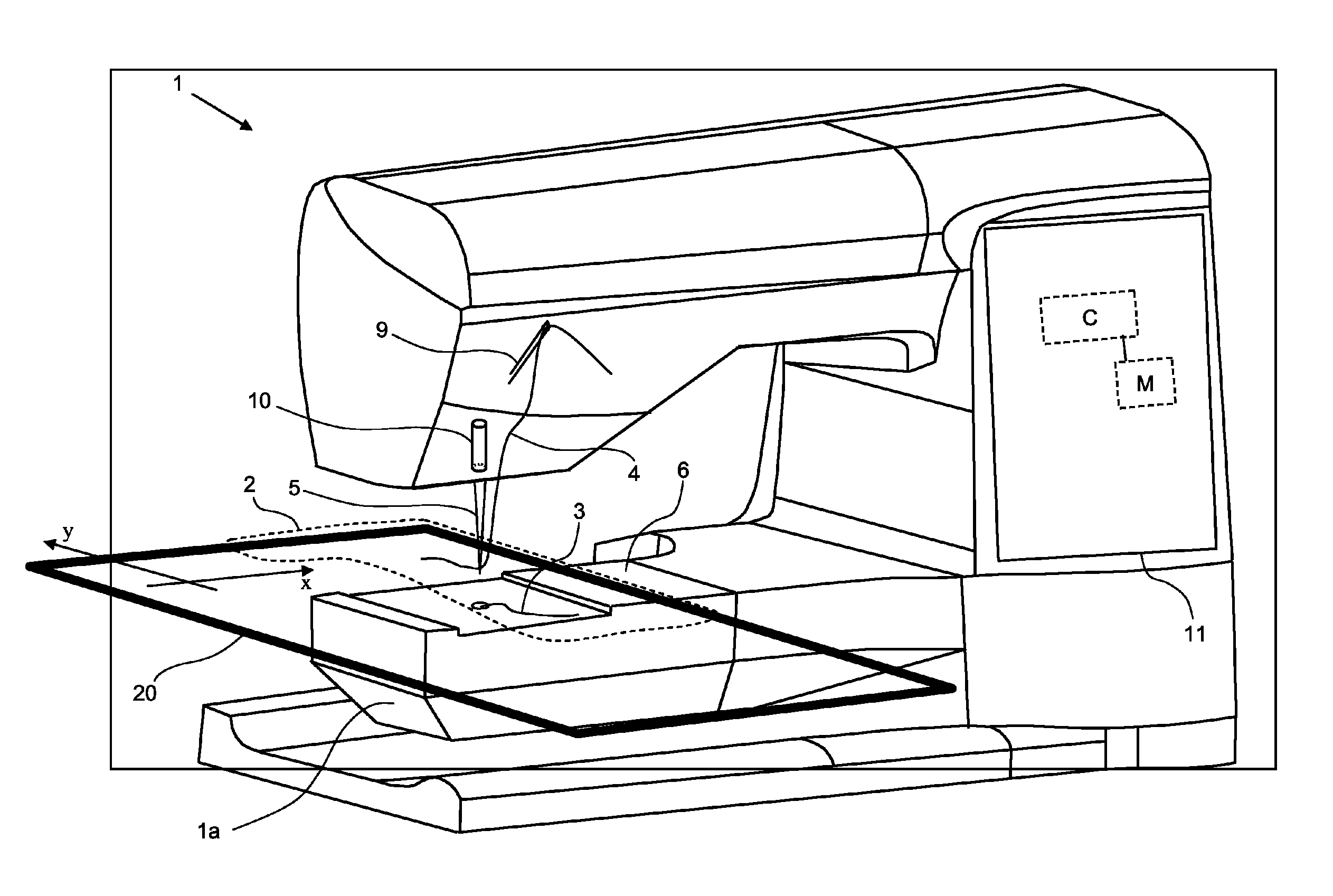

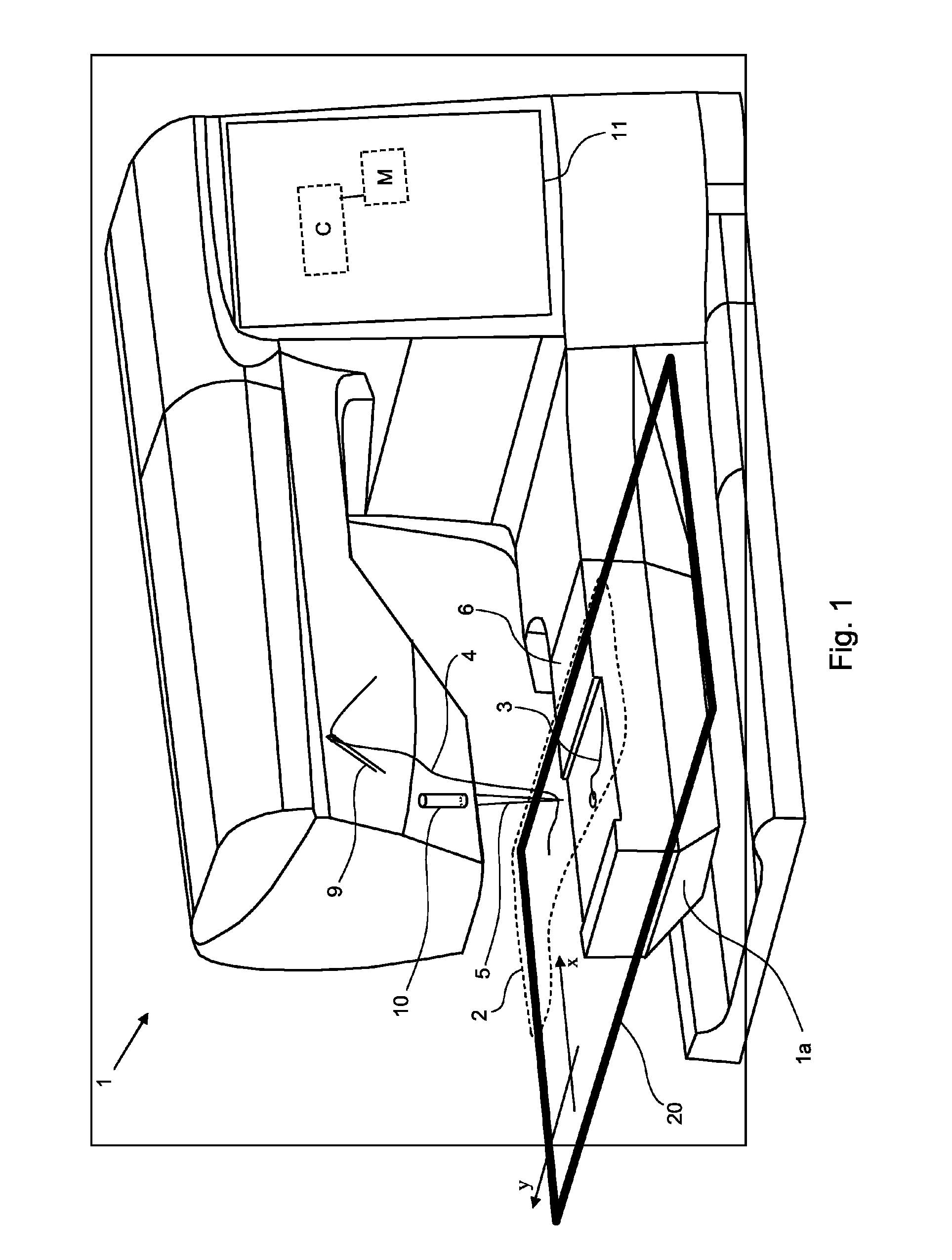

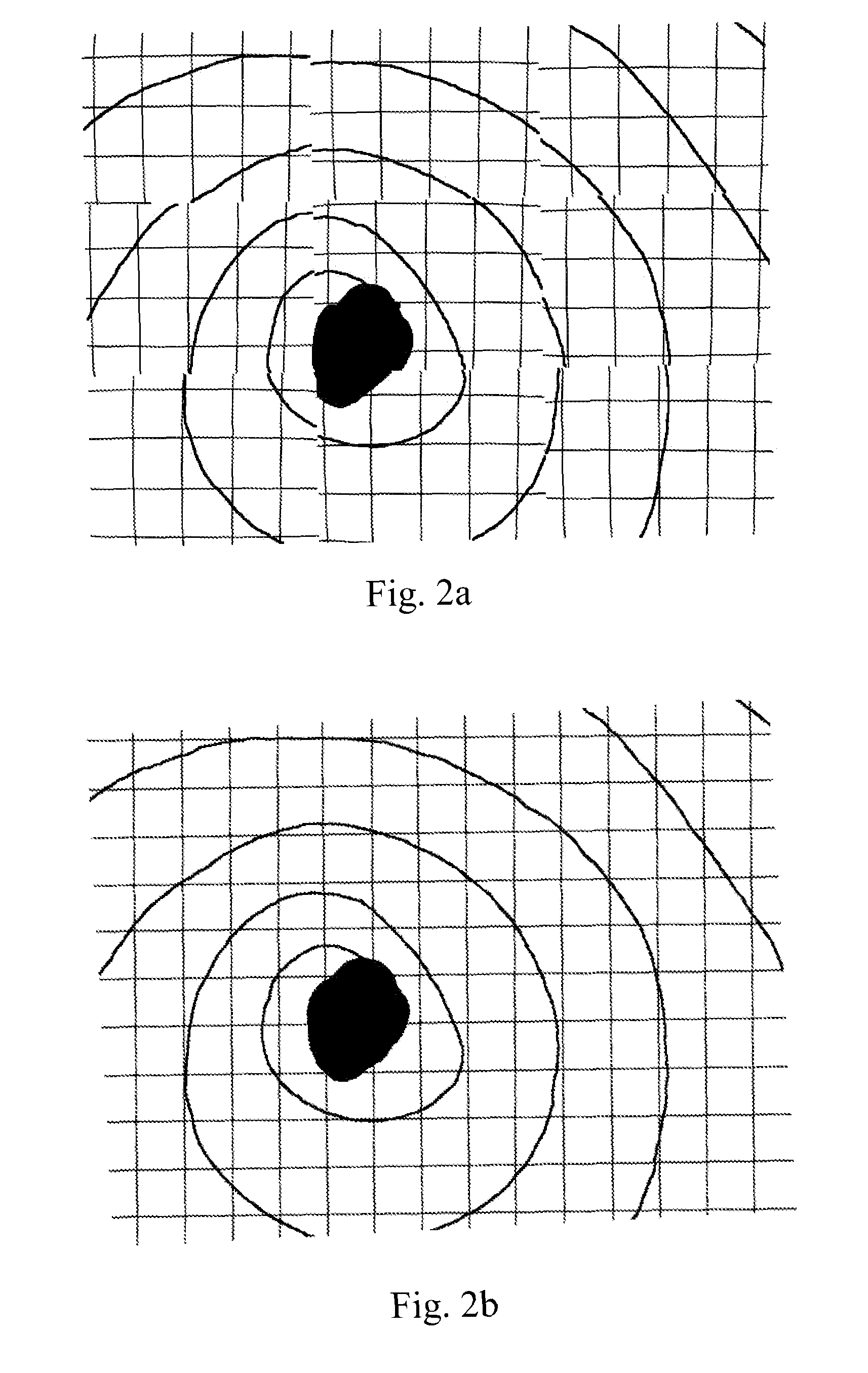

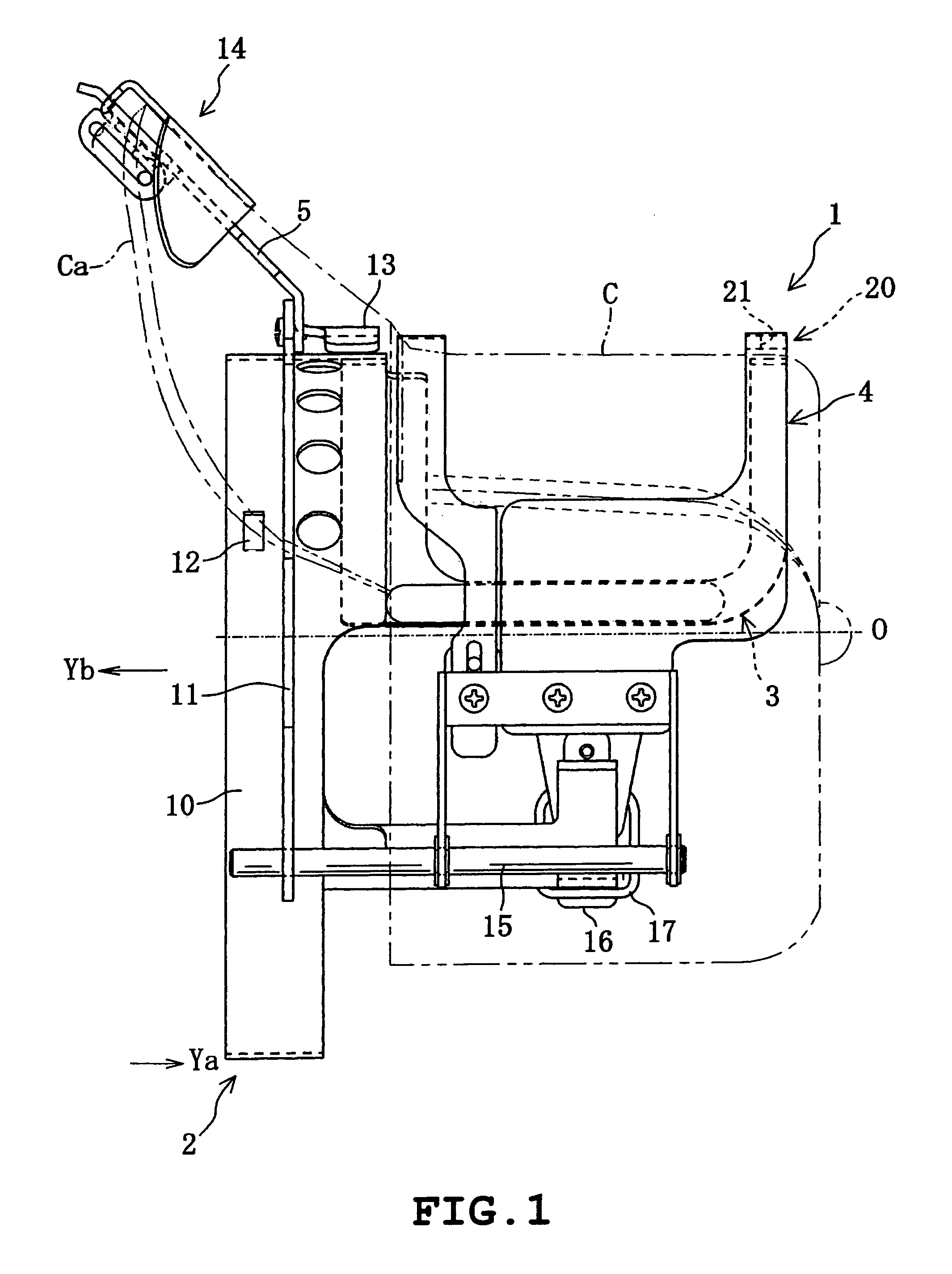

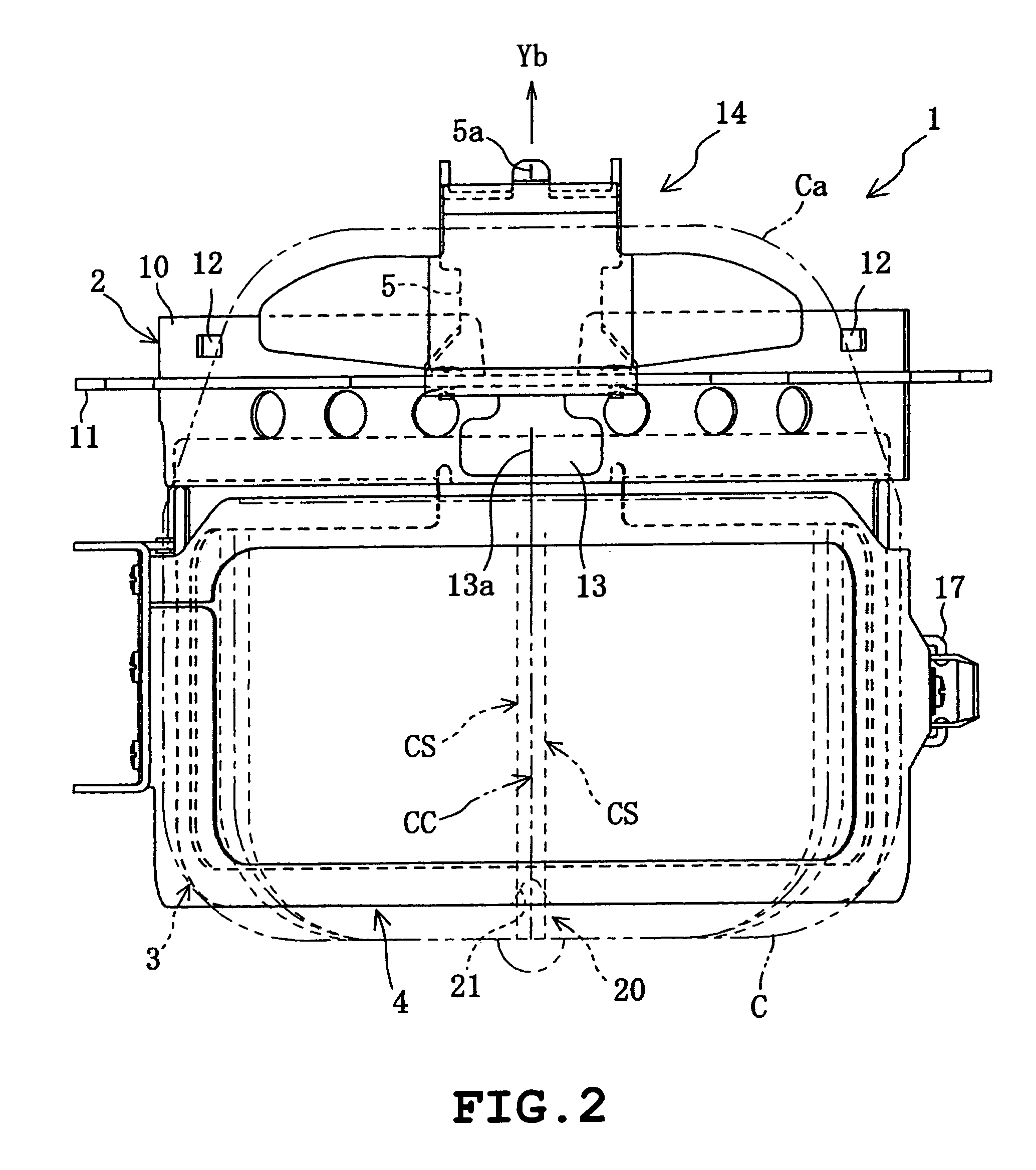

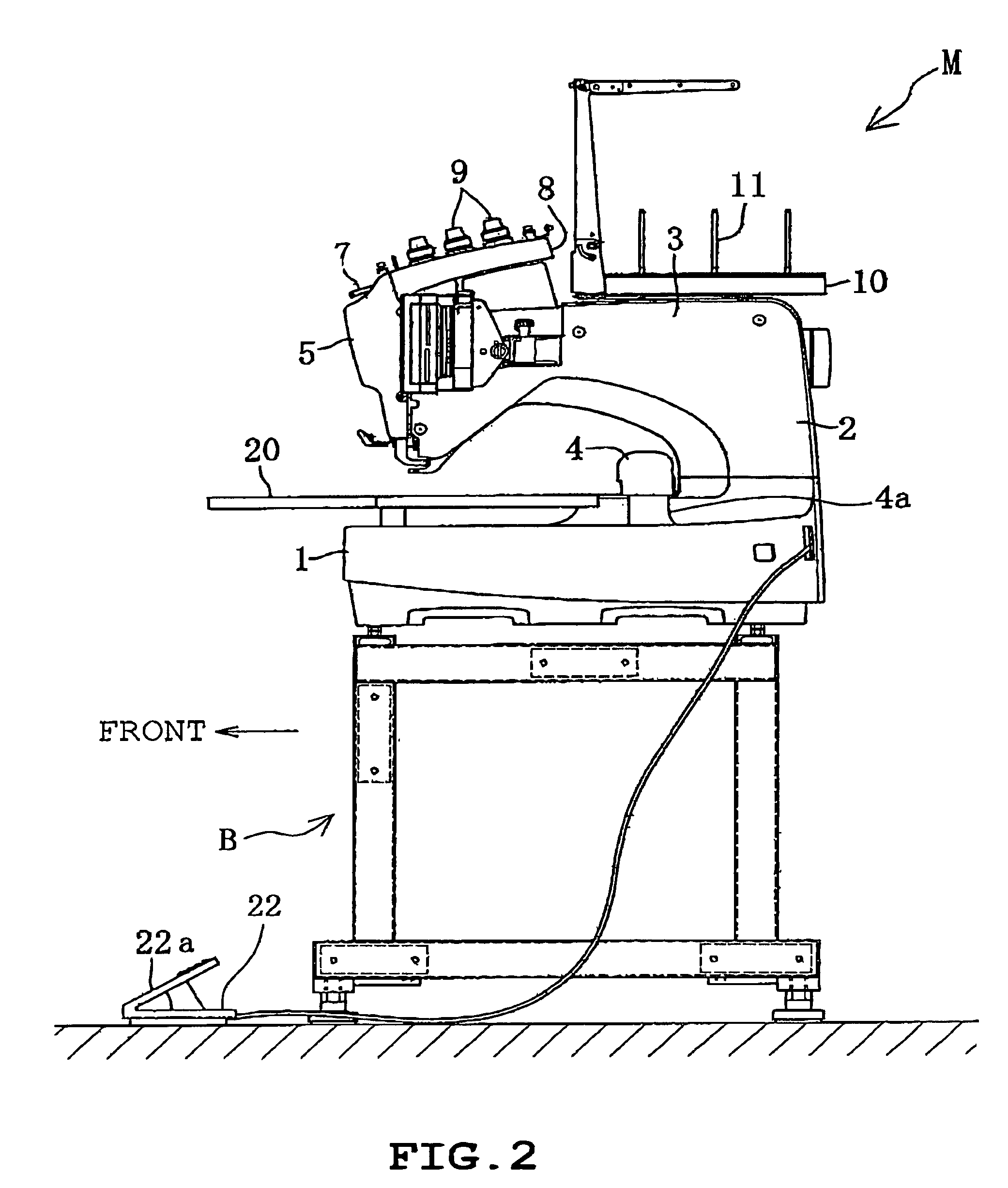

Sewing machine having a camera for forming images of a sewing area

ActiveUS20110146553A1Simplifying and enhancing sewingProgramme-controlled sewing machinesAutomatic machinesEngineeringPhysics

A sewing machine (1) has access to a memory (M) for stitch data and a processor (C) for reading said stitch data and for operating the sewing machine (1) to execute stitches according to stitch data, wherein the sewing machine (1) has a hoop (20) for framing a pattern of the sewing material (2), and for moving the framed pattern in a direction comprising a component of at least one of a first coordinate (x) and a second coordinate (y) and wherein further the processor (C) controls movements of the hoop (20) according to said direction in relation to the position of a needle (5) of the sewing machine and synchronously with the movement of the needle for executing stitches, wherein: —the stretched sewing material (2) is clamped to the hoop (20) for forming a framed pattern in the hoop, —the framed pattern of the sewing material (2) is scanned by means of a camera (10) mounted in the sewing machine (1) and directed towards the sewing material (2) for the purpose of taking pictures of part views of said framed pattern, —said part views are tiled together for forming on a display an image of the pattern framed in the hoop, whereby a coordinate of the image of a display (11) refers to a corresponding coordinate of the pattern framed in the hoop (20).

Owner:SINGER SOURCING LTD LLC

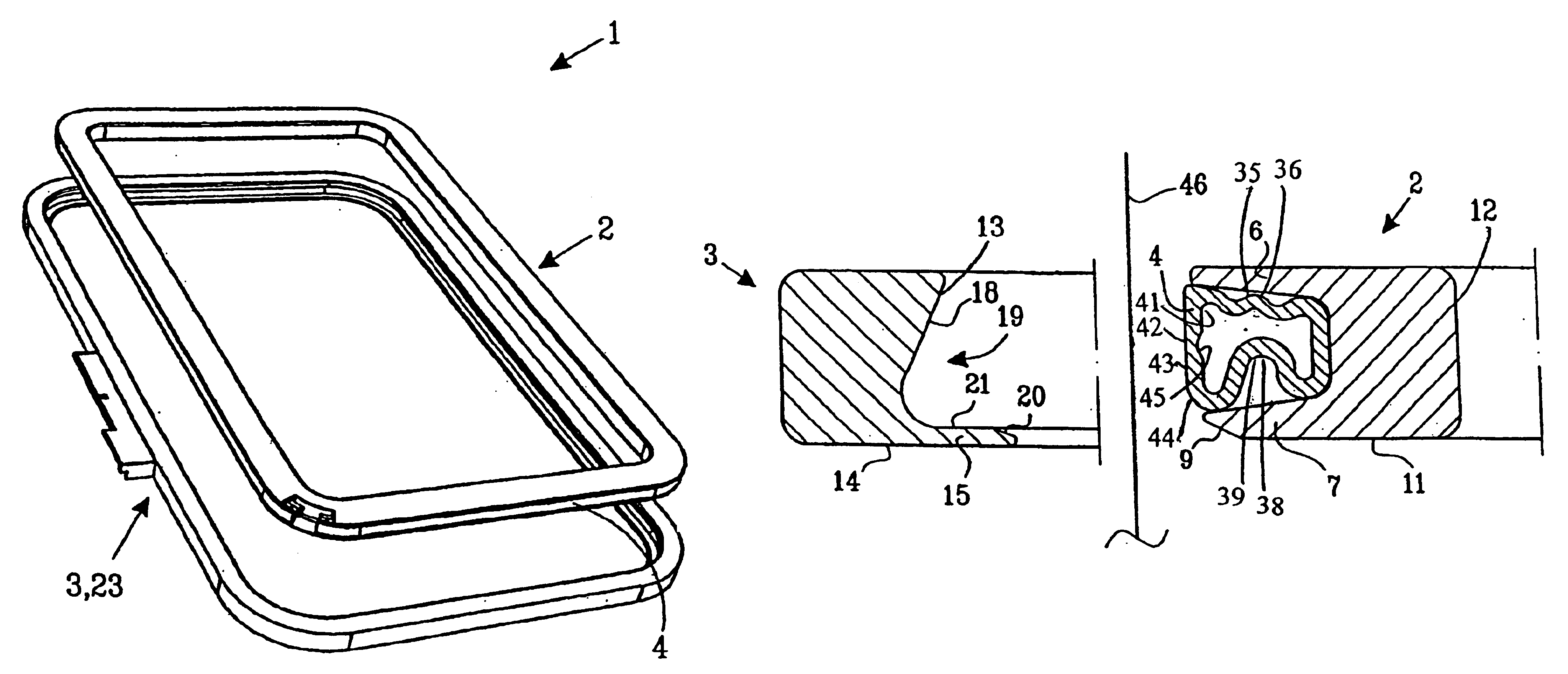

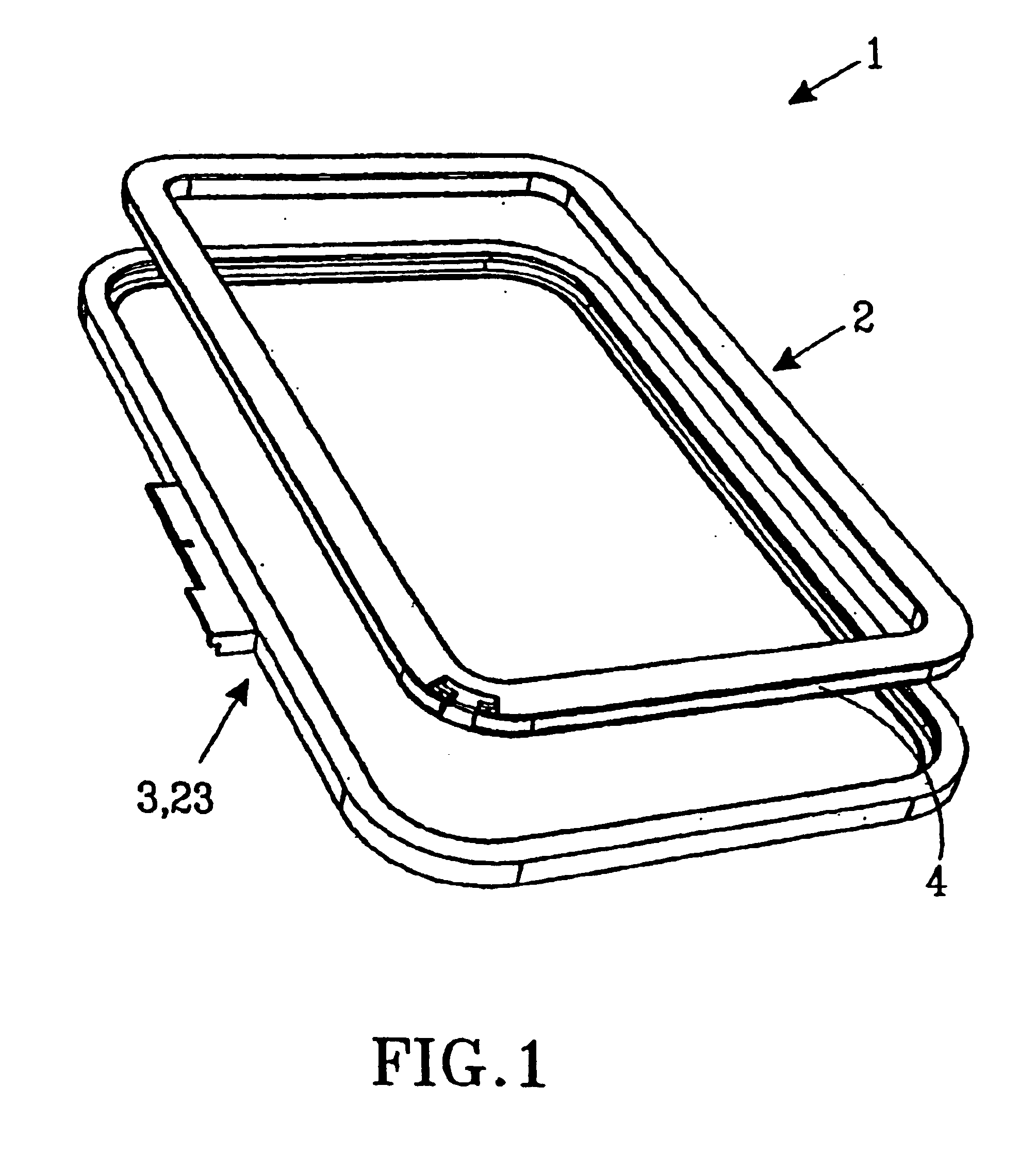

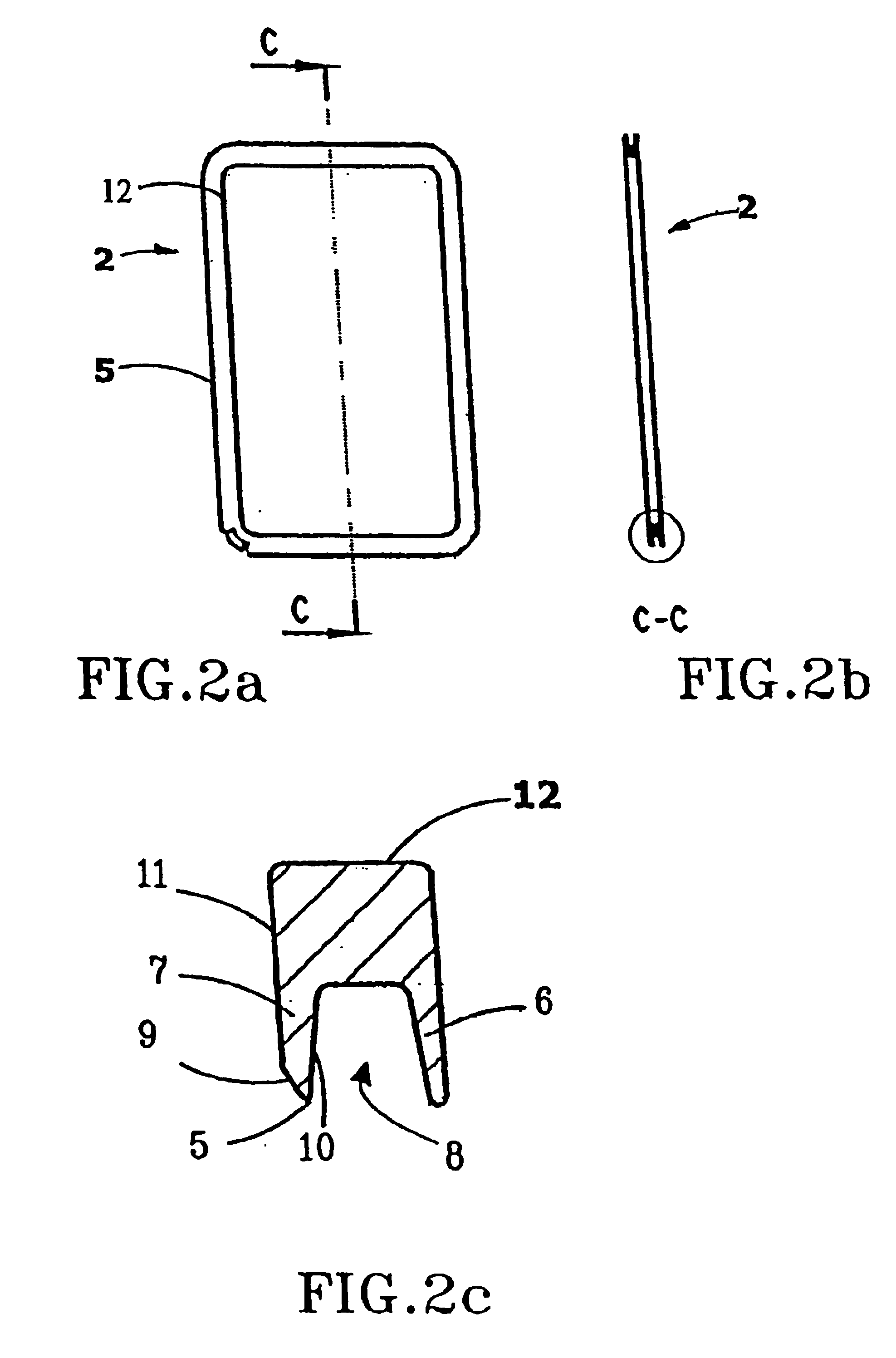

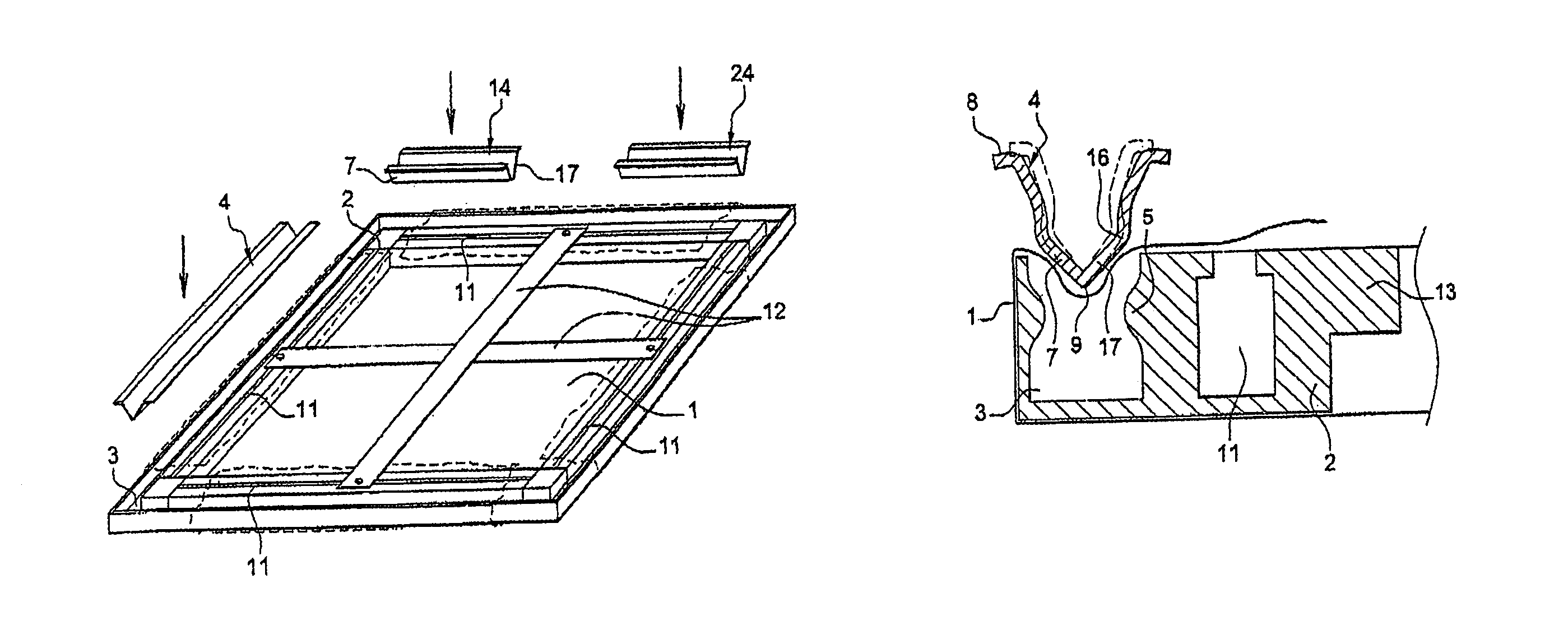

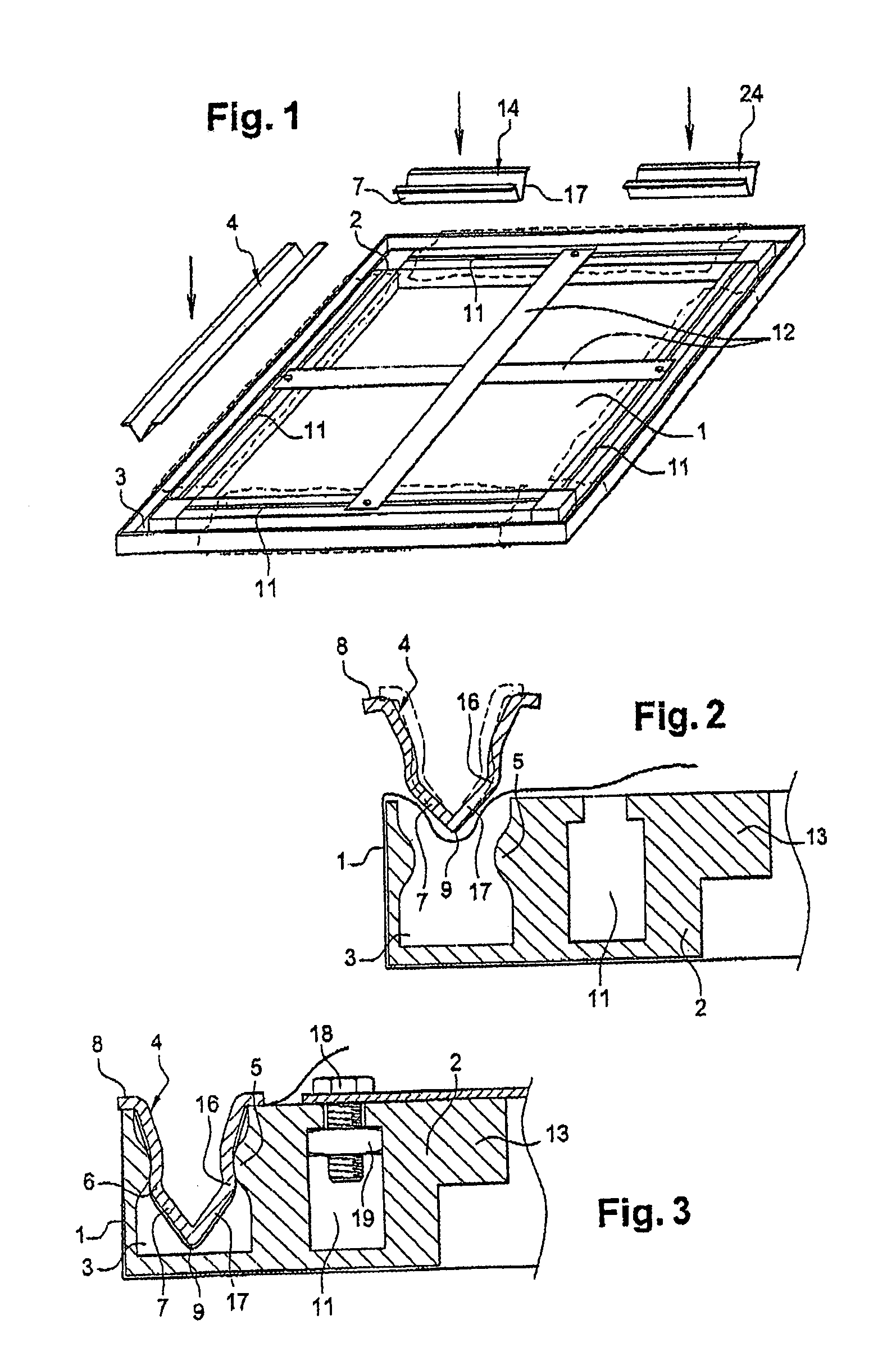

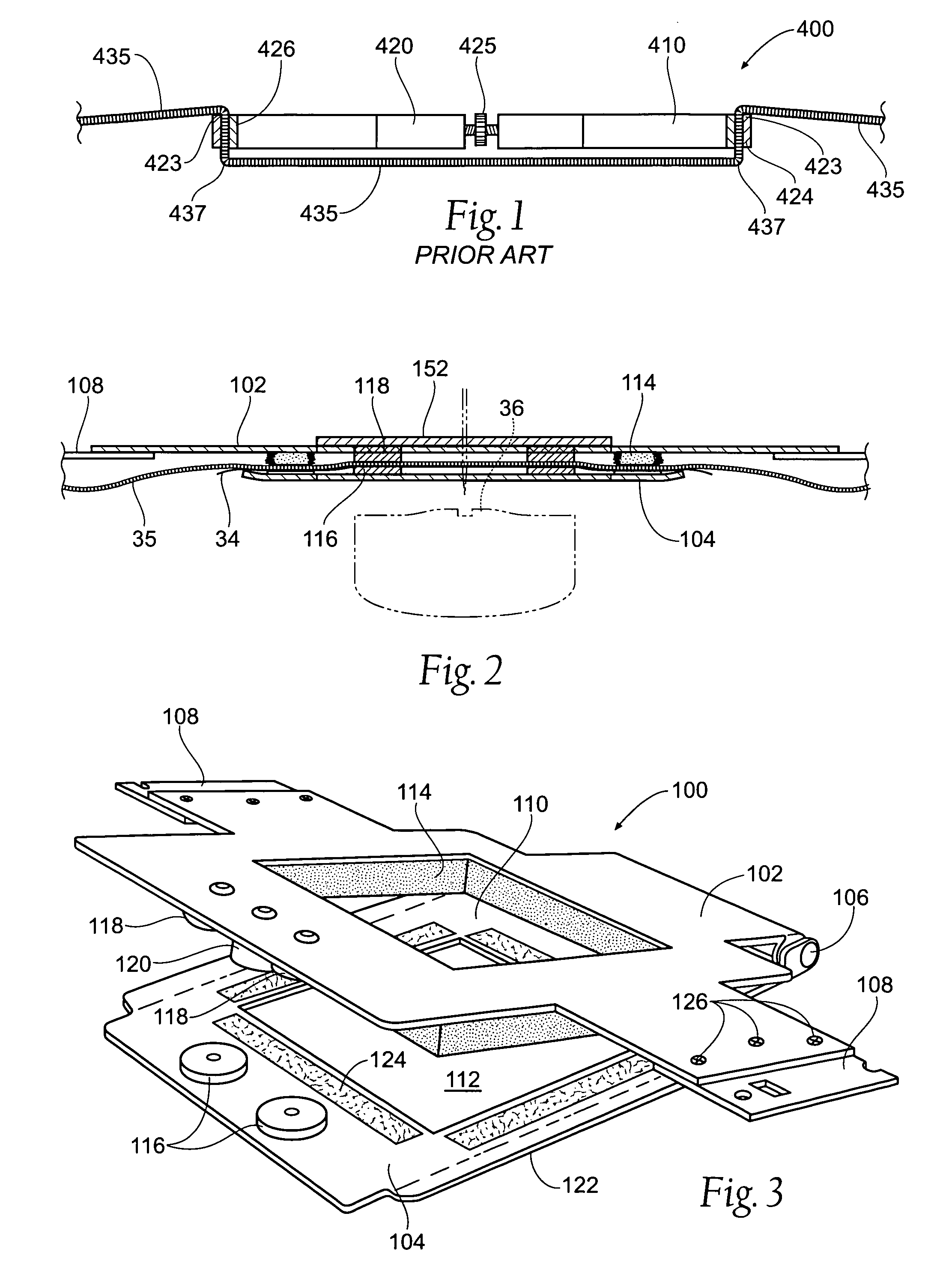

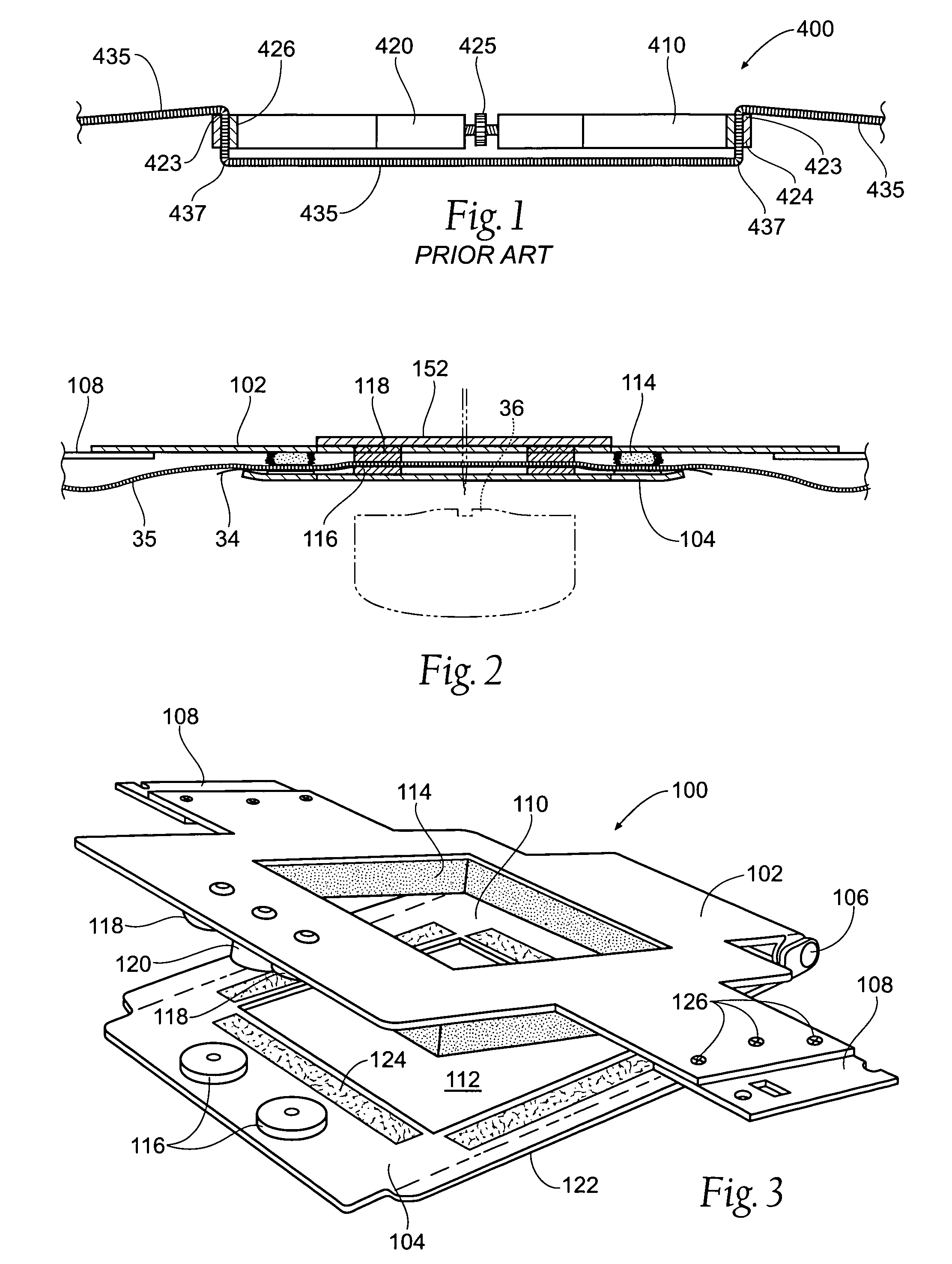

Device at an embroidery frame and method for clamping and tensioning a textile material

InactiveUS6901870B2Straightening of the at least one crease in the upper wall before straightening of the at least one crease in the lower wall is facilitatedTufting apparatusAutomatic machinesEngineeringSewing machine

The present patent application relates to an embroidery frame for a sewing machine and a method for clamping and tensioning a textile material. The embroidery frame comprises an inner frame, an outer frame and a hose arranged between the inner frame and the outer frame, which hose is expandable through pressurization. After manual assembly of the inner frame and the outer frame, a textile material intended for embroidering can be clamped between the hose and the outer frame and tensioned over an area of the textile material intended for embroidering through pressurization of the hose. The hose expands through initial pressurization in an upper part and clamps thereby the textile material between the upper part of the hose and the outer frame. Upon continued pressurization the hose expands in a lower part in a direction towards the outer frame and tensions thereby the textile material.

Owner:KSIN LUXEMBOURG II

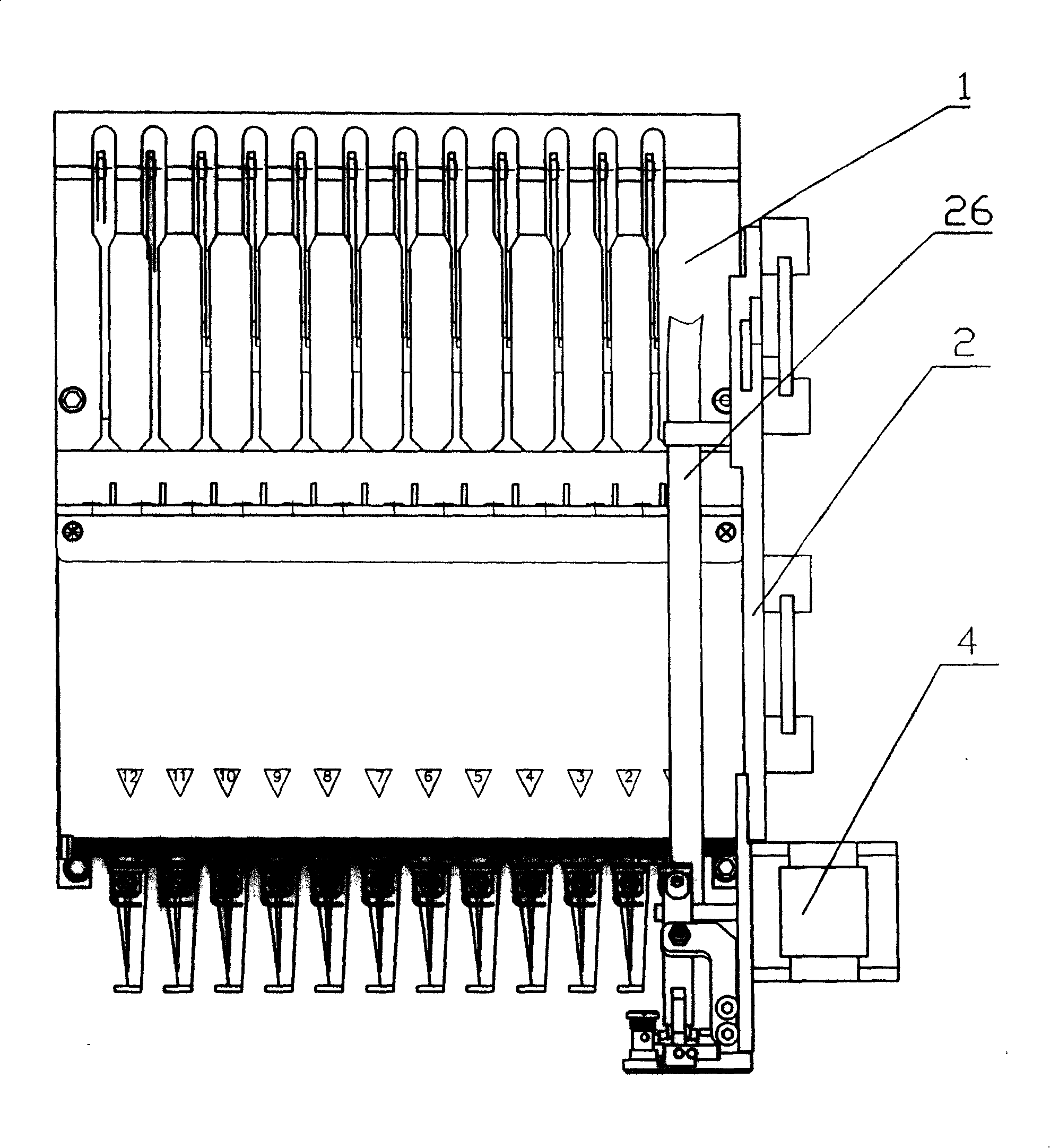

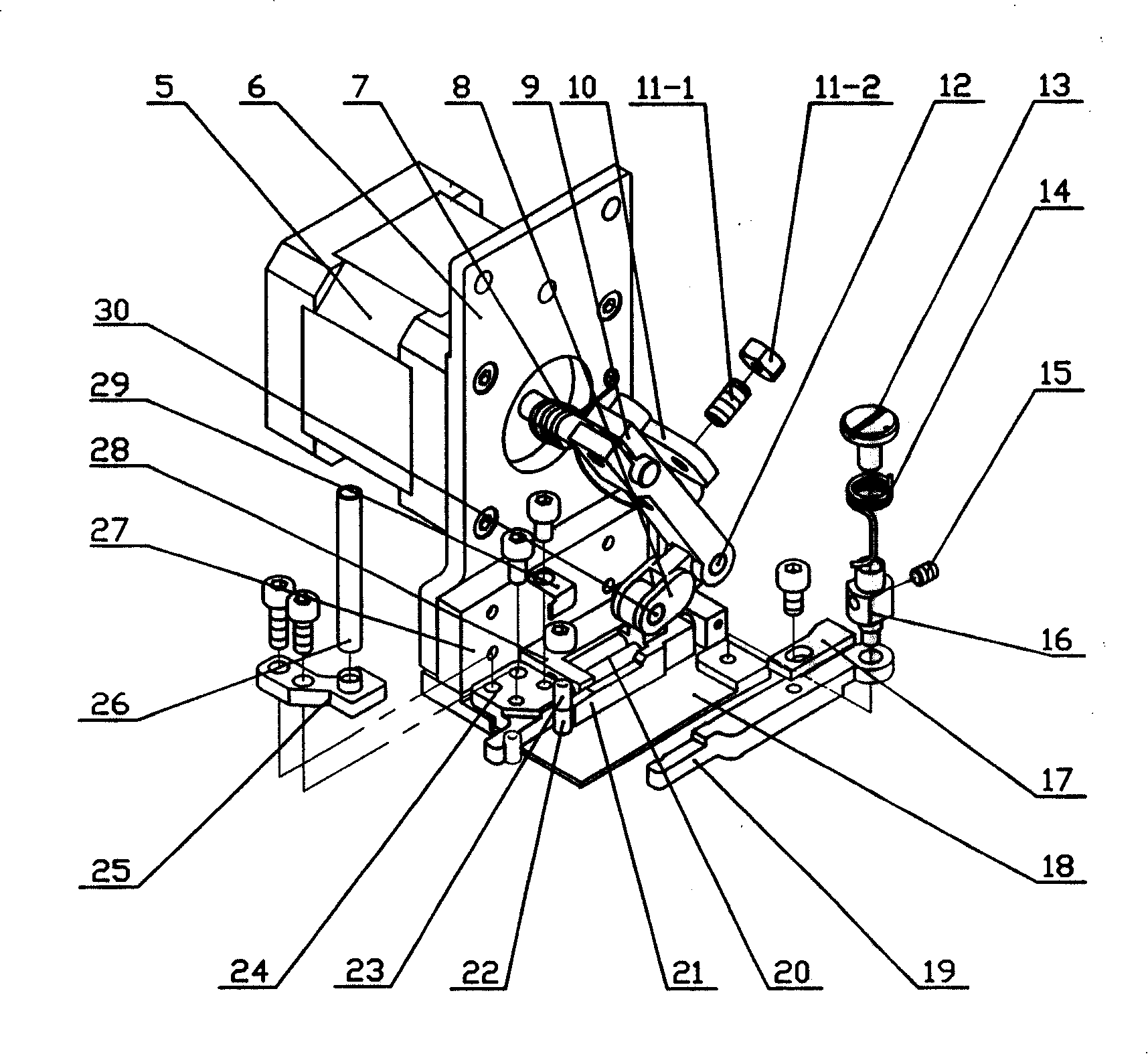

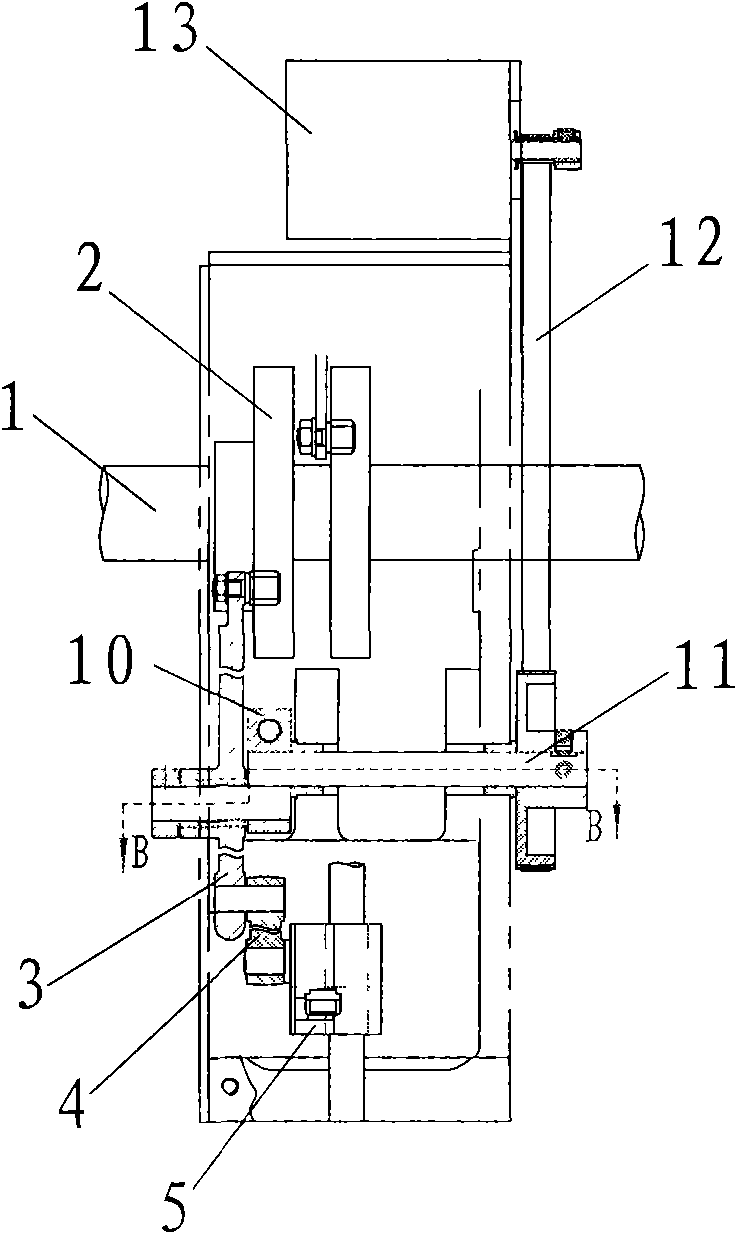

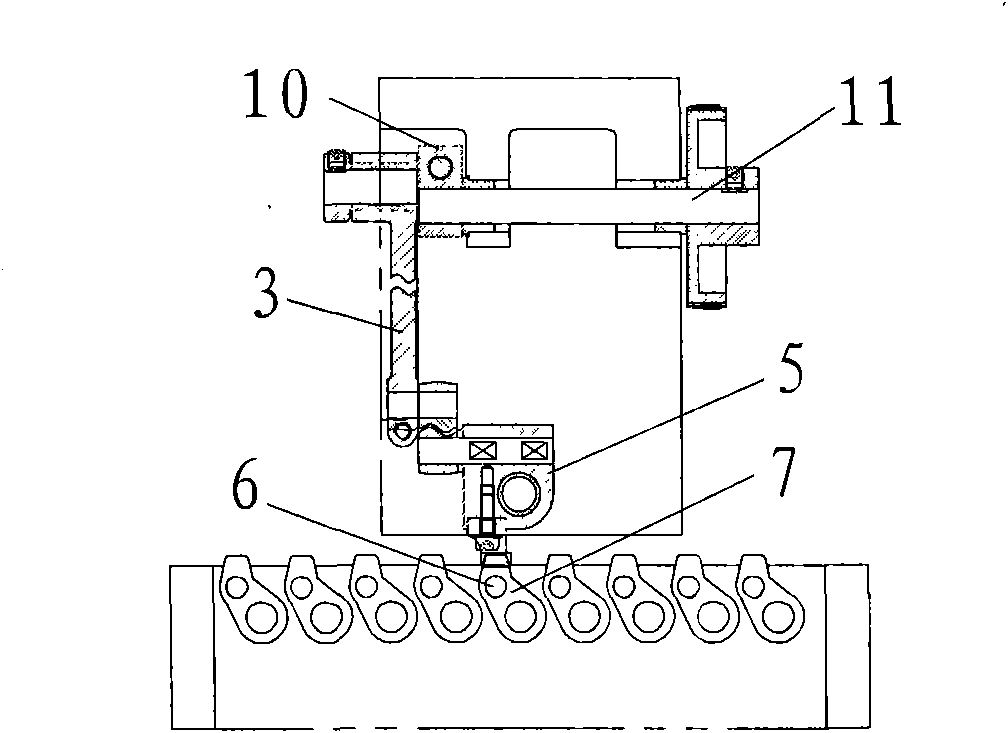

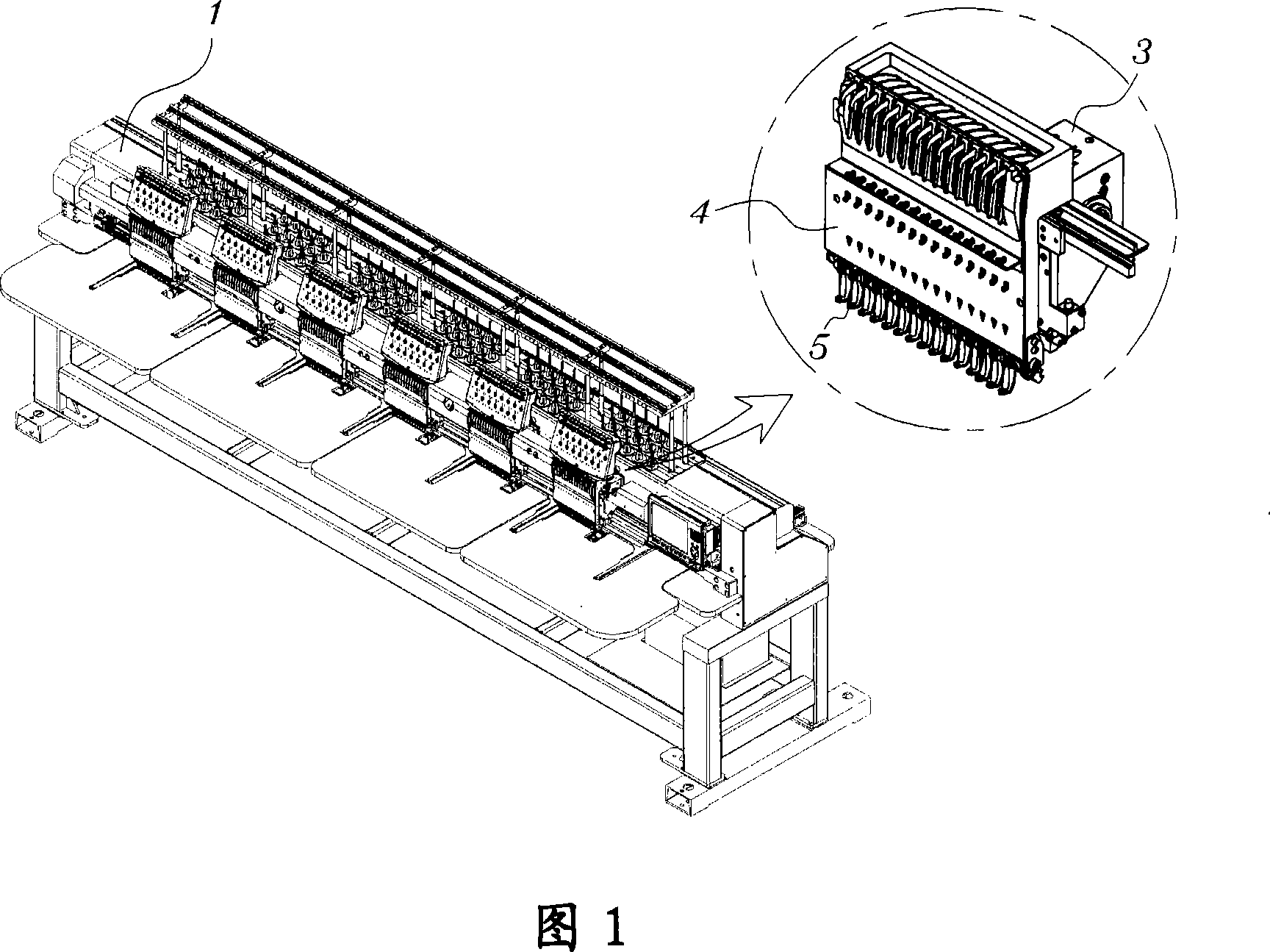

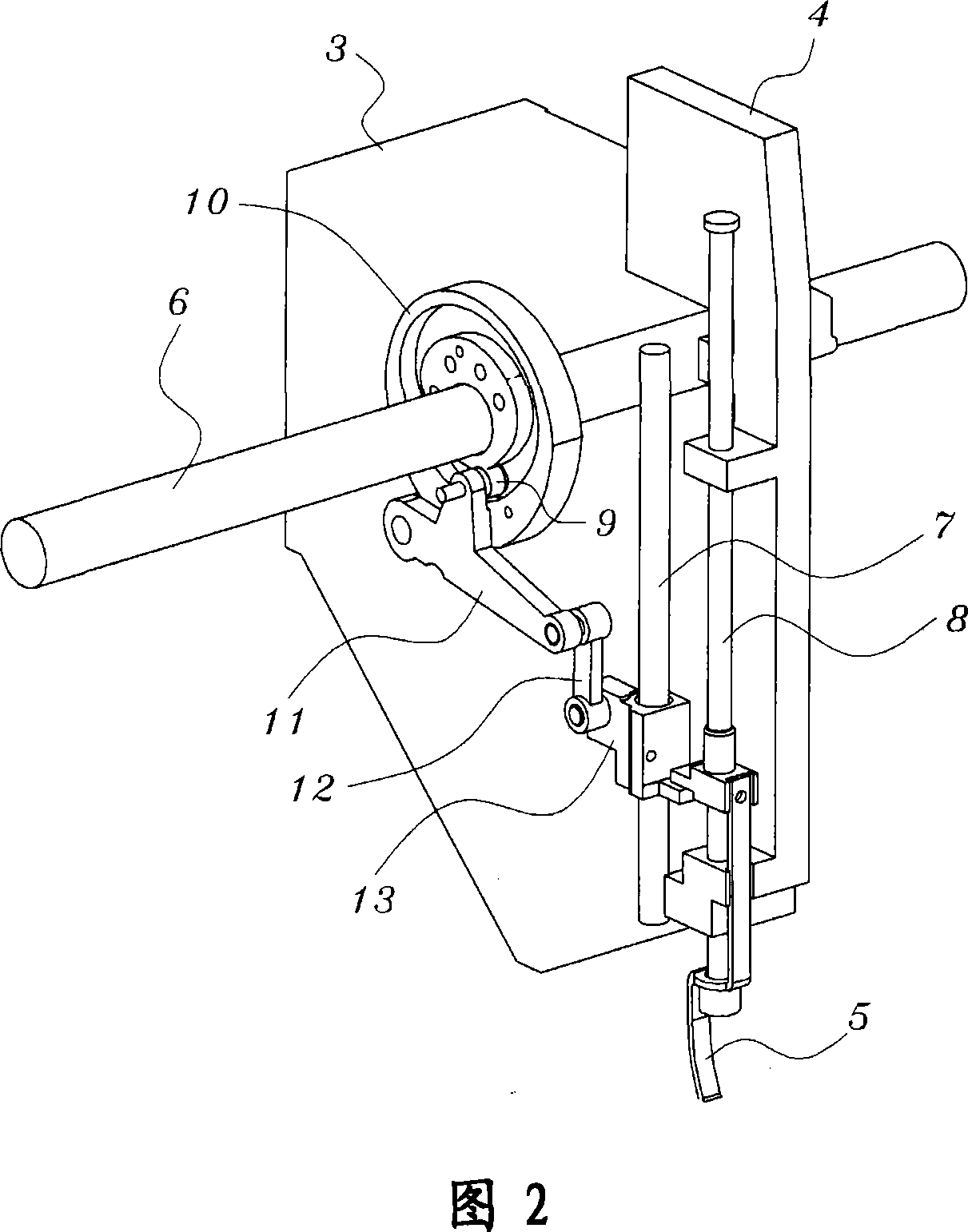

Bead embroidering mechanism for computer embroidering machine

InactiveCN101235583ARealize automatic deliveryIncrease productivityAutomatic machinesFeedersElectric machineryEngineering

The invention relates to a beads enchasing mechanism of a computerized embroidery machine, which is characterized in that a stepping motor which is only controlled by a computer is installed on frame work which is composed of a bottom board and a motor plate, a motor connecting bar is installed on a shaft of the motor, the other end of the motor connecting bar is hinged with an actuation link, the other end of the actuation link is hinged with a bead push-rod, a fixed lever component is installed on the bottom board on one side of the push-rod, a rotatable lever component is installed on the other side, and a connecting base which is provided with a discharge port and is connected with a material feeding pipe is arranged on the fixed lever, The mechanism can be installed on a needle bar frame of the computerized embroidery machine in match with various lifting devices and can realize automatic enchasing of the beads on various embroideries.

Owner:浙江珠光集团临海电脑刺绣设备有限公司

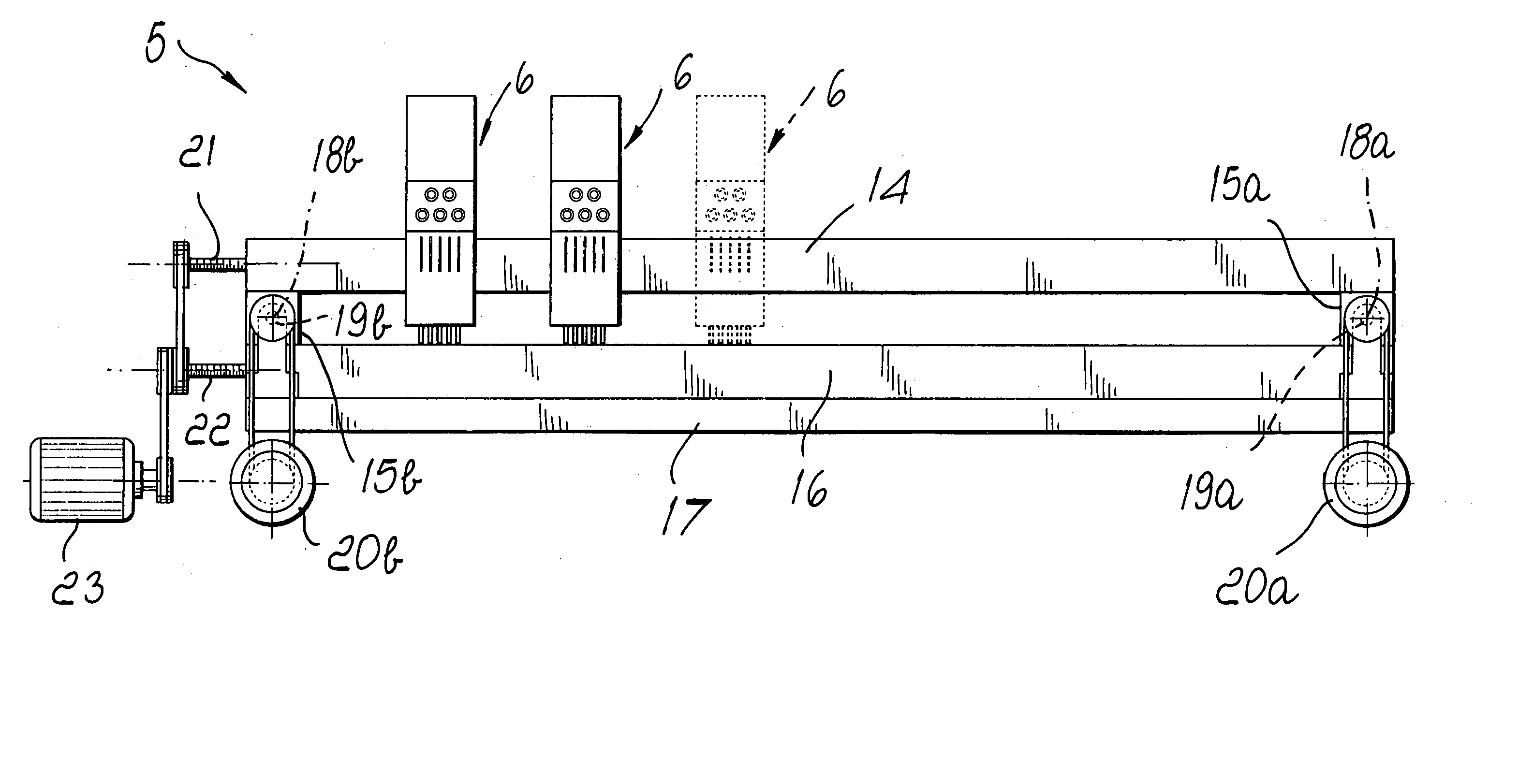

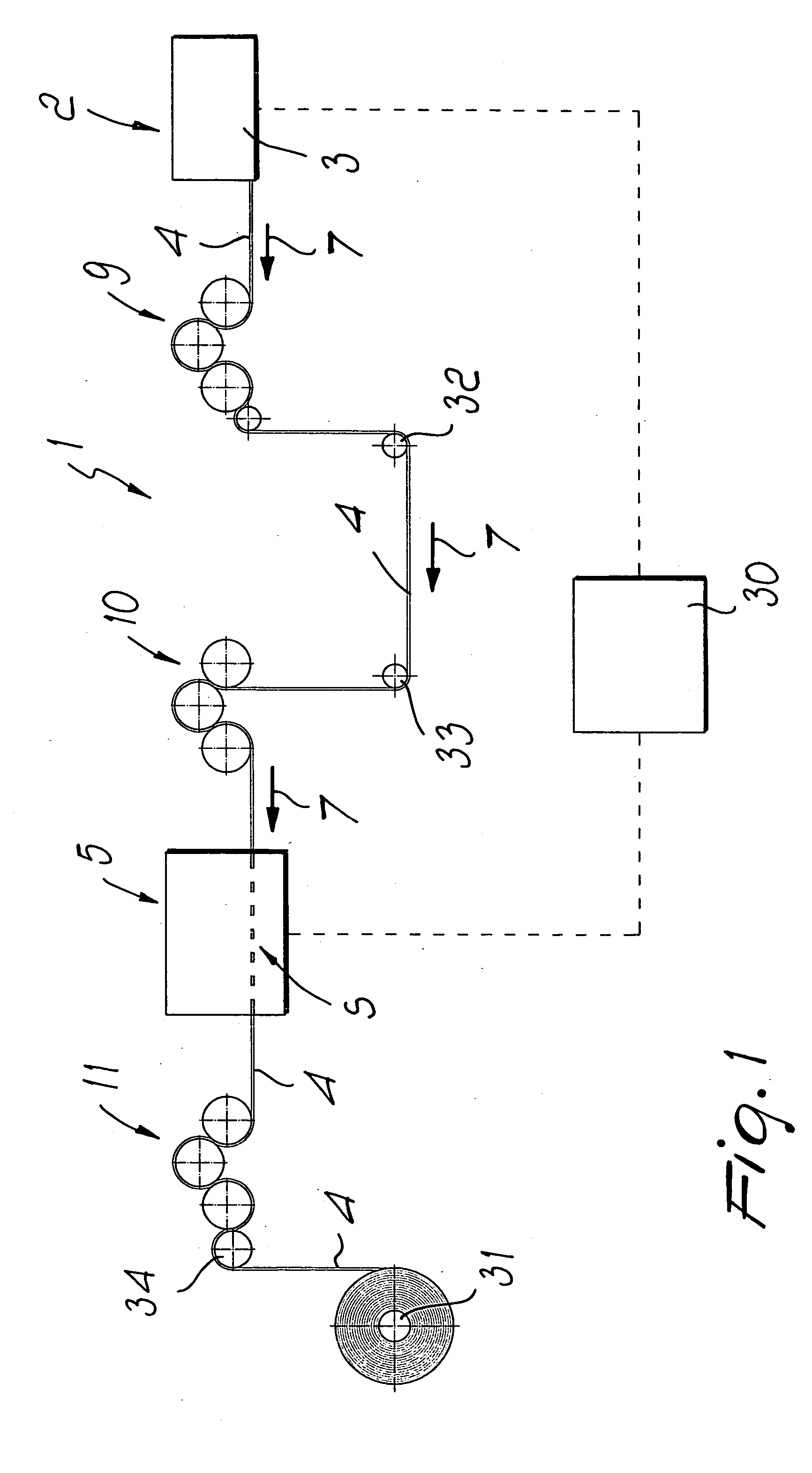

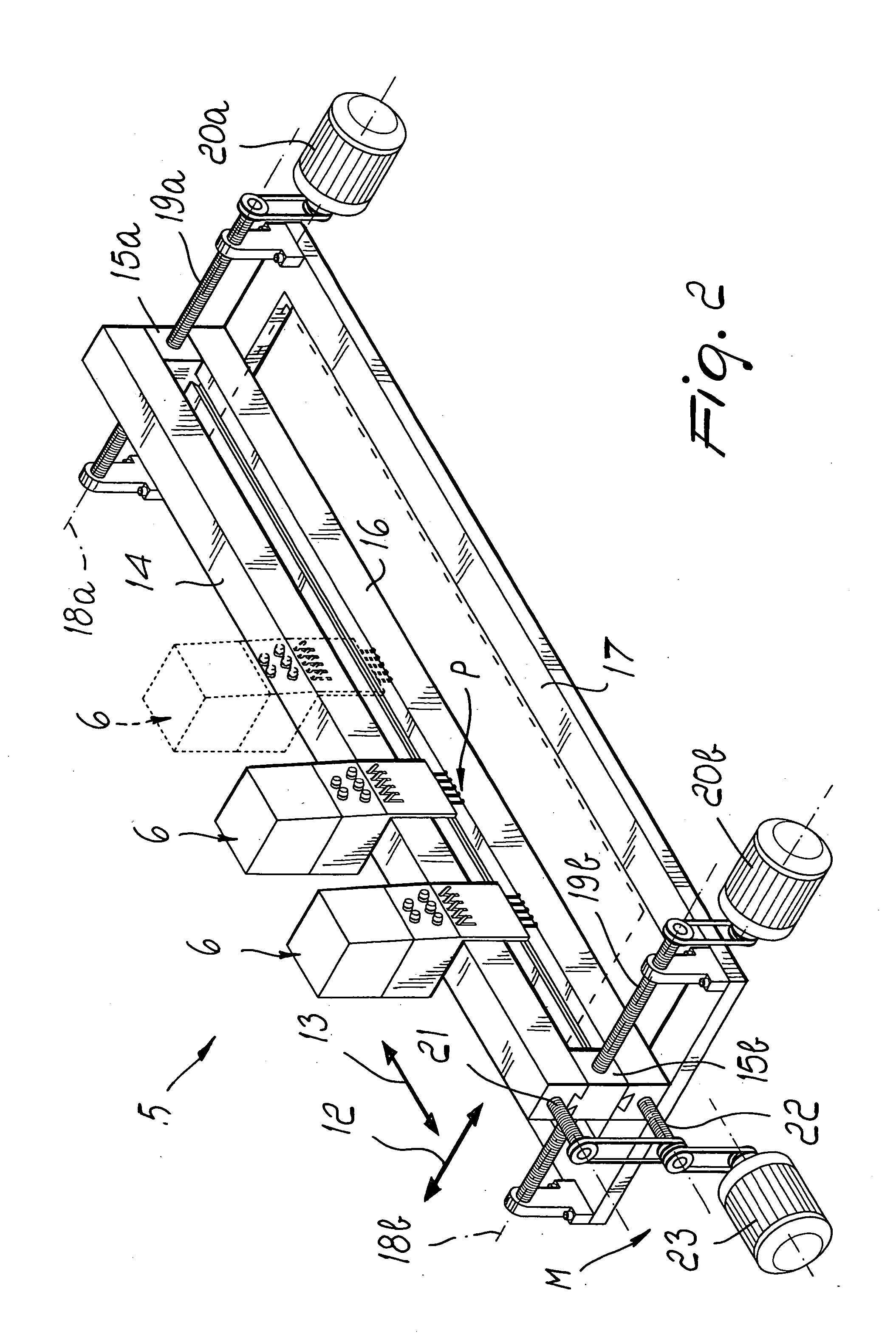

Machine for producing decorated loom-woven fabrics

InactiveUS20050066866A1Improve accuracyApplication performanceTufting apparatusAutomatic machinesEngineeringHead parts

A machine for producing loom-woven fabrics decorated by embroidery or by applying decorative elements, comprising a first working station, and a second working station, with at least one head for embroidering and / or for applying decorative elements to the sheet of fabric produced in the first working station. The sheet longitudinal advancement elements for supporting the sheet of fabric on a working surface that is substantially horizontal at least at the second working station, and a movement device for moving the head for embroidering and / or for applying decorative elements along at least one direction transversely to the advancement direction of the sheet of fabric on the working surface.

Owner:PEDERZINI CESARE

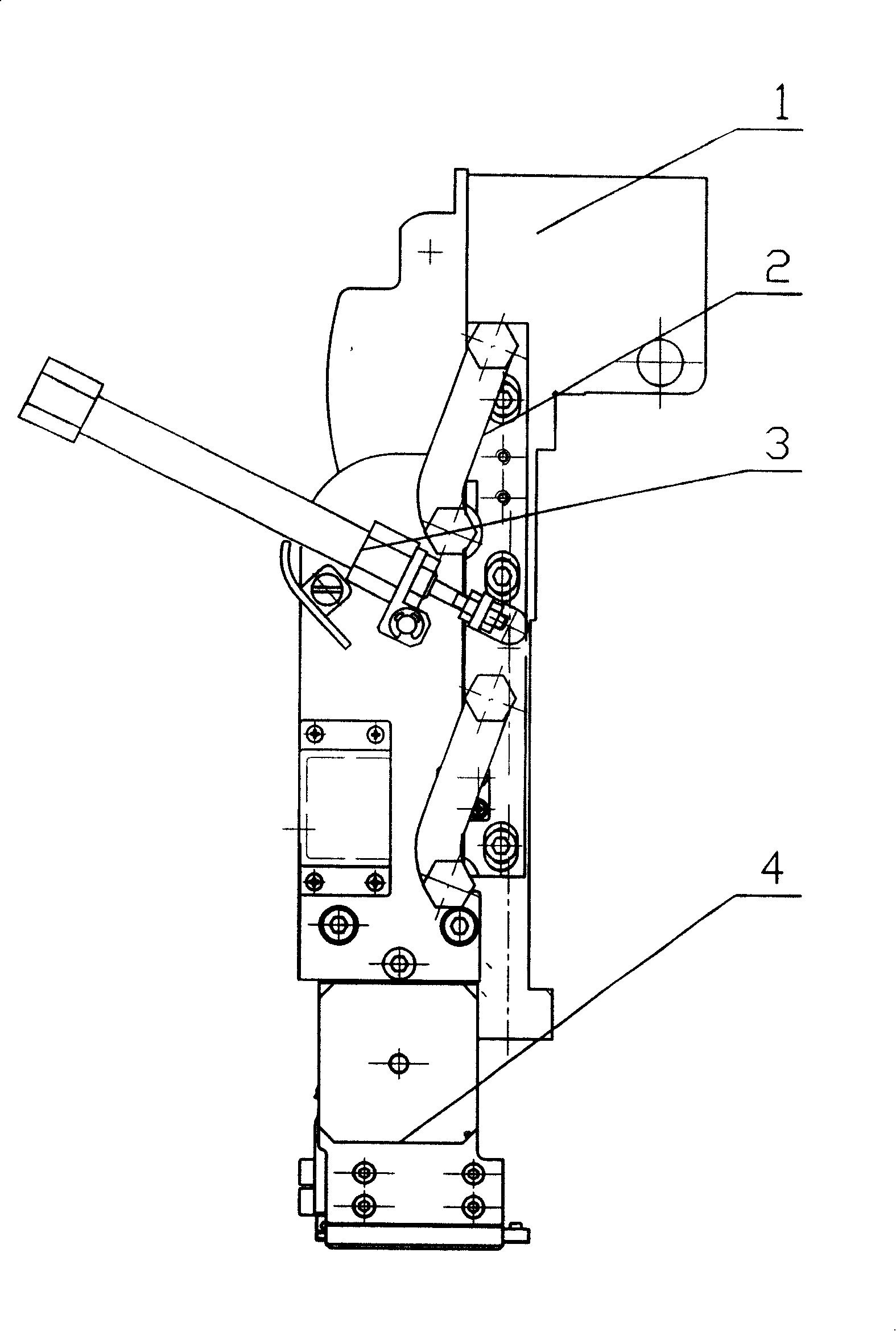

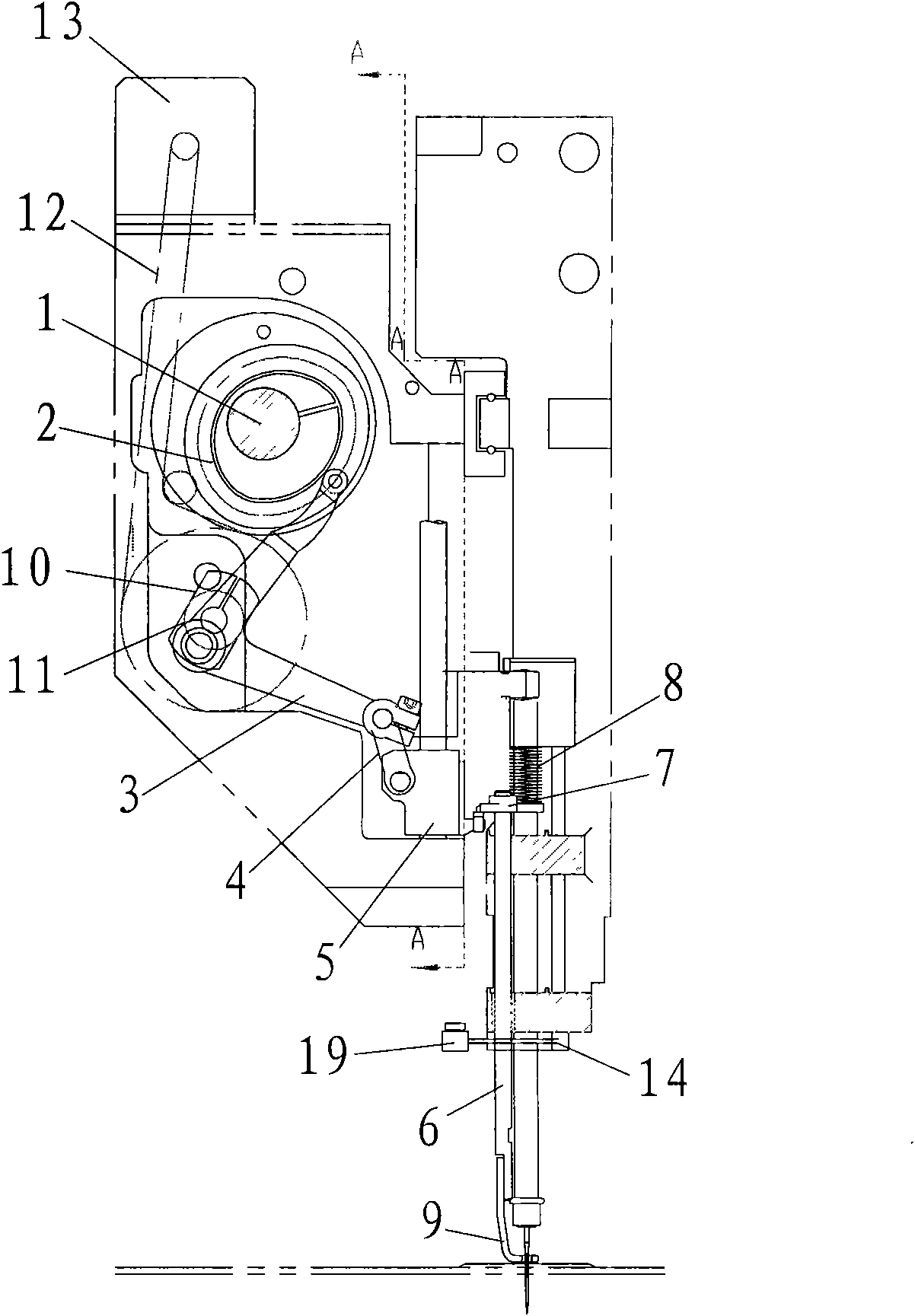

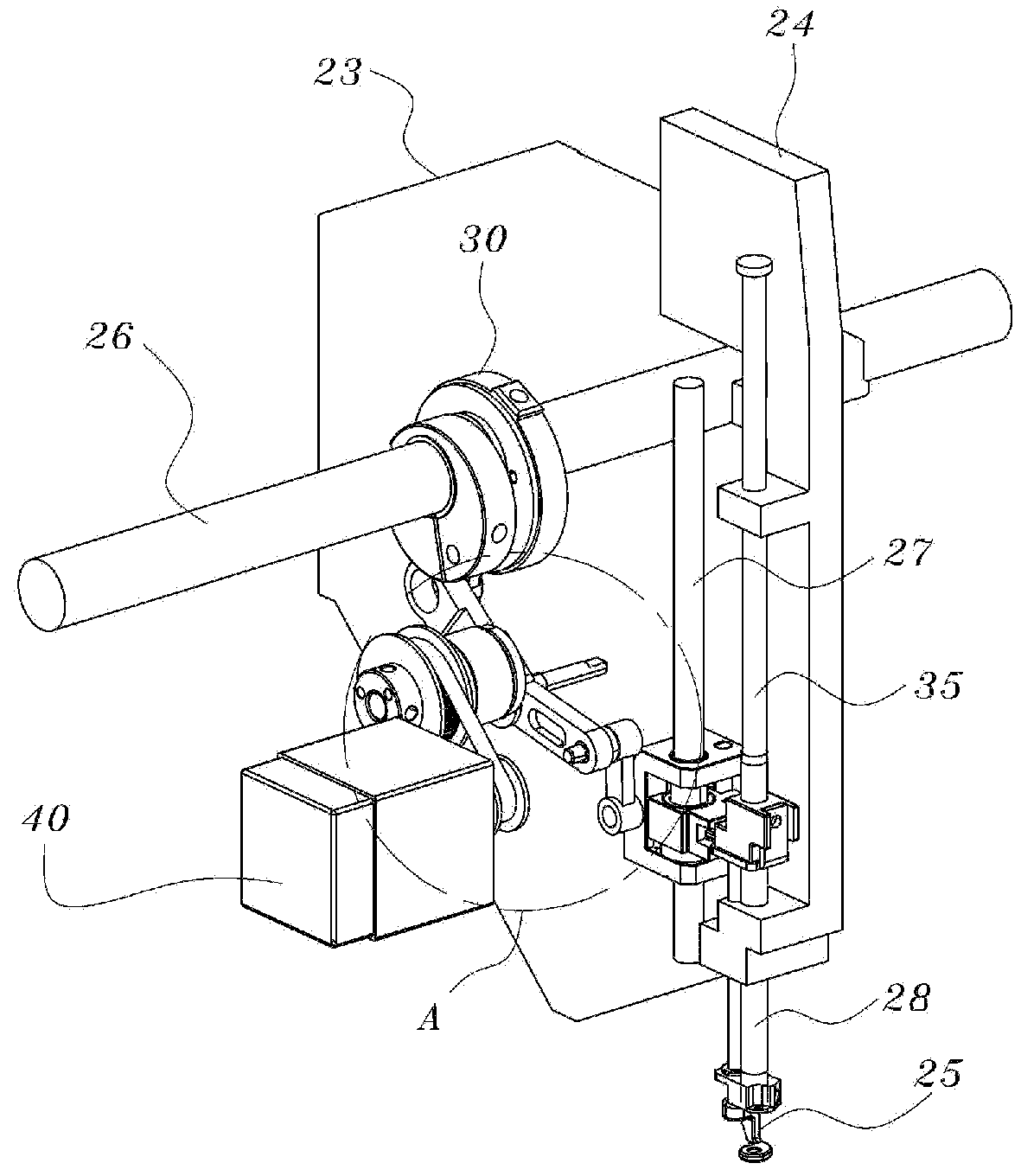

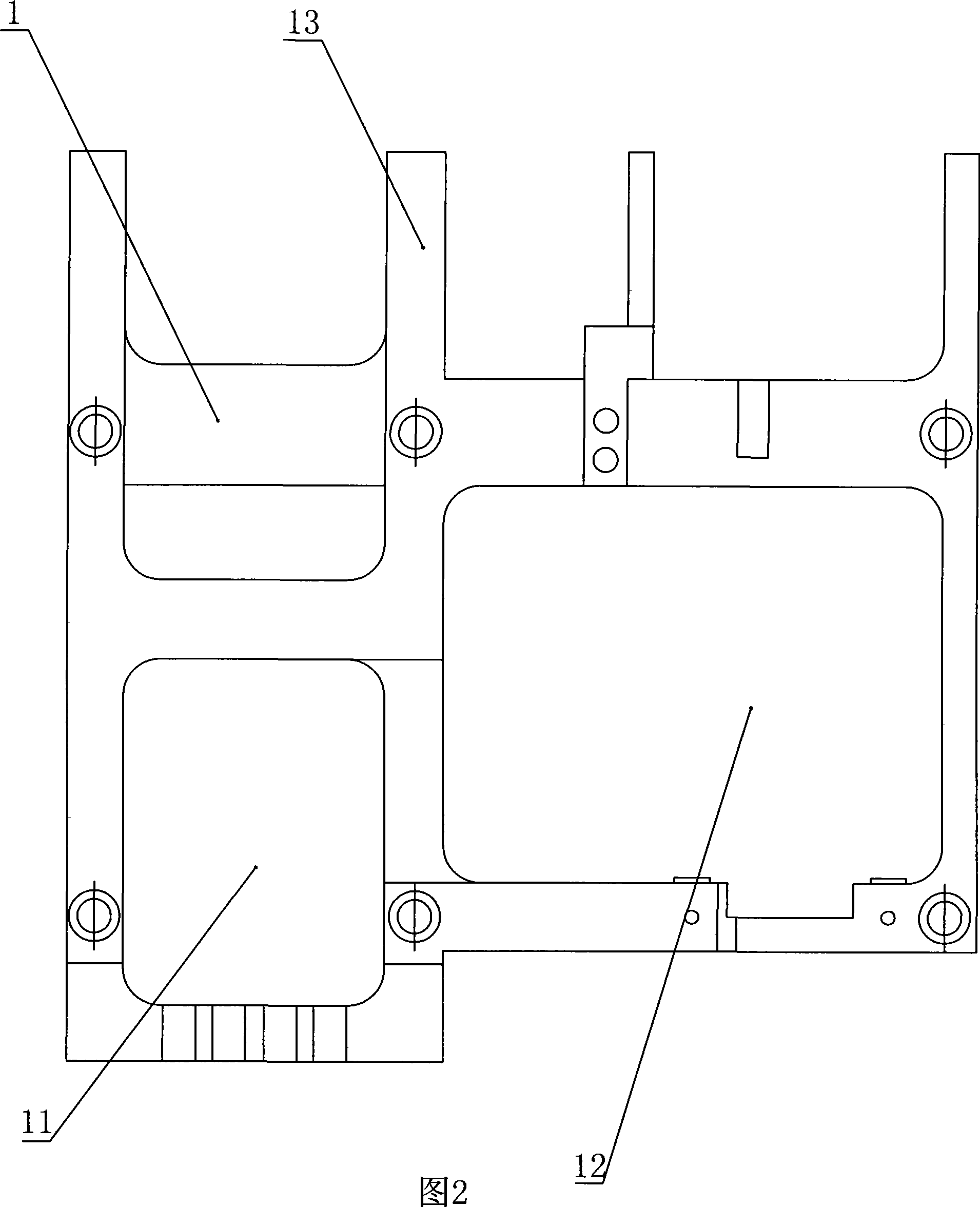

Presser foot independent driving mechanism for embroidery machine

The invention discloses a presser foot independent driving mechanism for an embroidery machine, which comprises a main driving shaft, a presser foot cam and a presser foot rod. The main driving shaft is horizontally installed on the embroidery machine and is driven by a driving device to rotate; the presser foot cam is arranged in a nose of the embroidery machine, sleeved on the driving main shaft and connected with a rocker, and the rocker is movably connected with a presser foot driving slider through a small connecting rod; and the presser foot rod is arranged on the nose of the embroiderymachine, the top of the presser foot rod is fixedly sleeved with a connecting base with two hole positions, a needle rod is sleeved in the other hole position of the connecting base, a needle rod joint is arranged at the top of the needle rod, a spring is sleeved outside the needle rod and is arranged between the connecting base and the needle rod joint; a presser foot is arranged at the lower part of the presser foot rod, and the presser foot driving slider is connected with the bottom surface of the connecting base on the presser foot rod in a separable way. The invention has reasonable structure, is convenient for embroiling thick materials, can improve embroidery quality and prolong the service life of the whole embroidery machine. The presser foot independent driving mechanism can bewidely applied to embroidery machines.

Owner:陈启聪

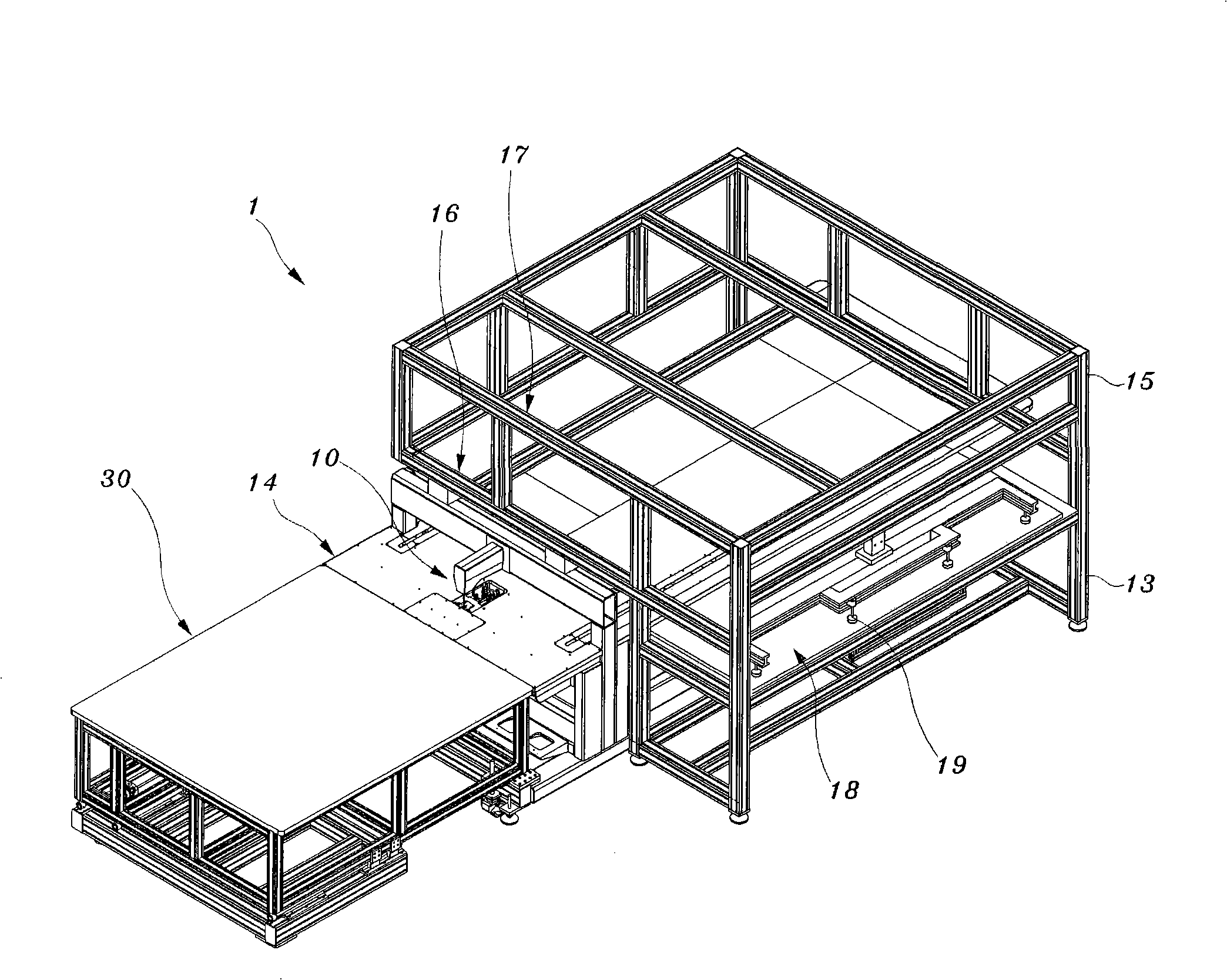

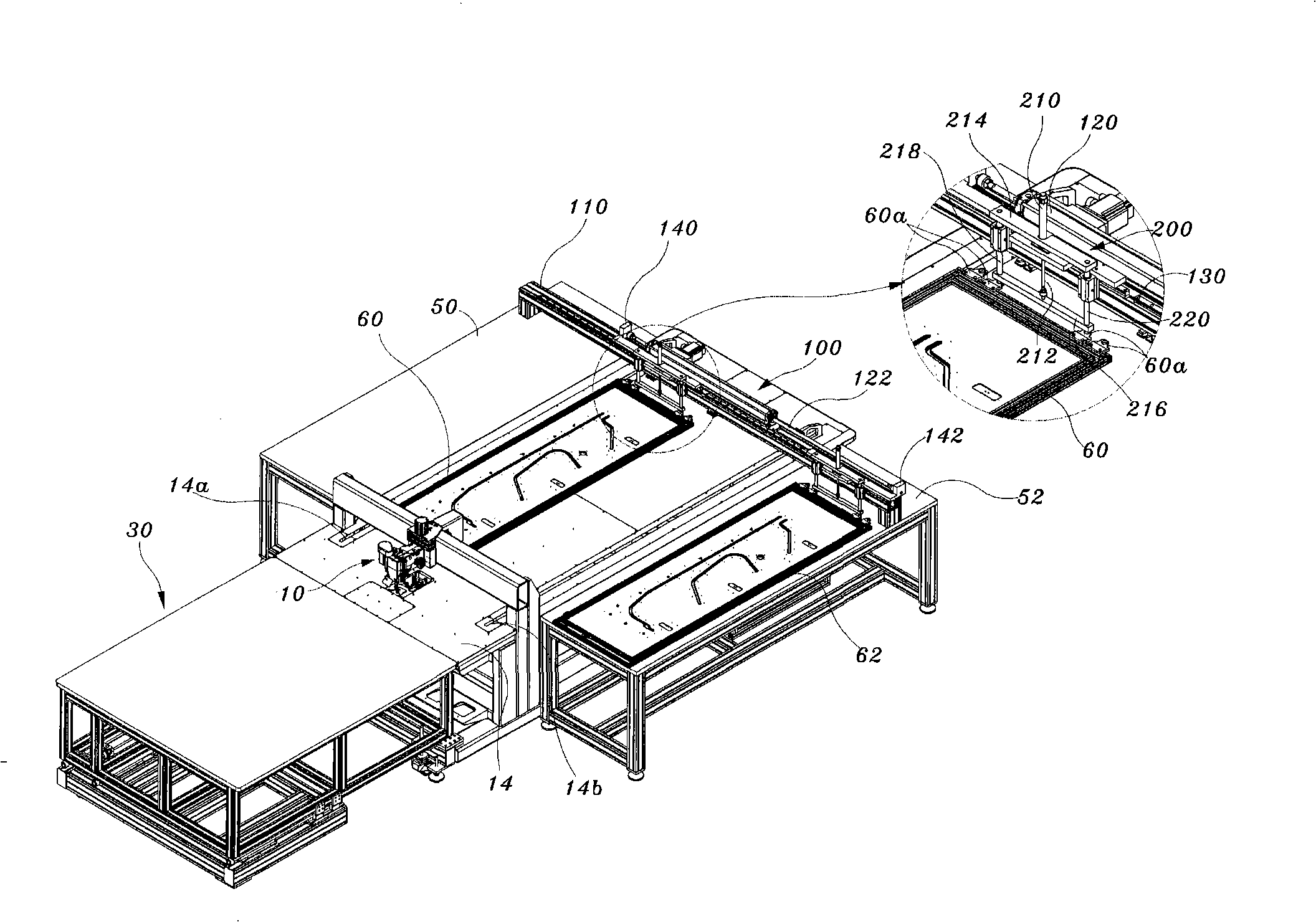

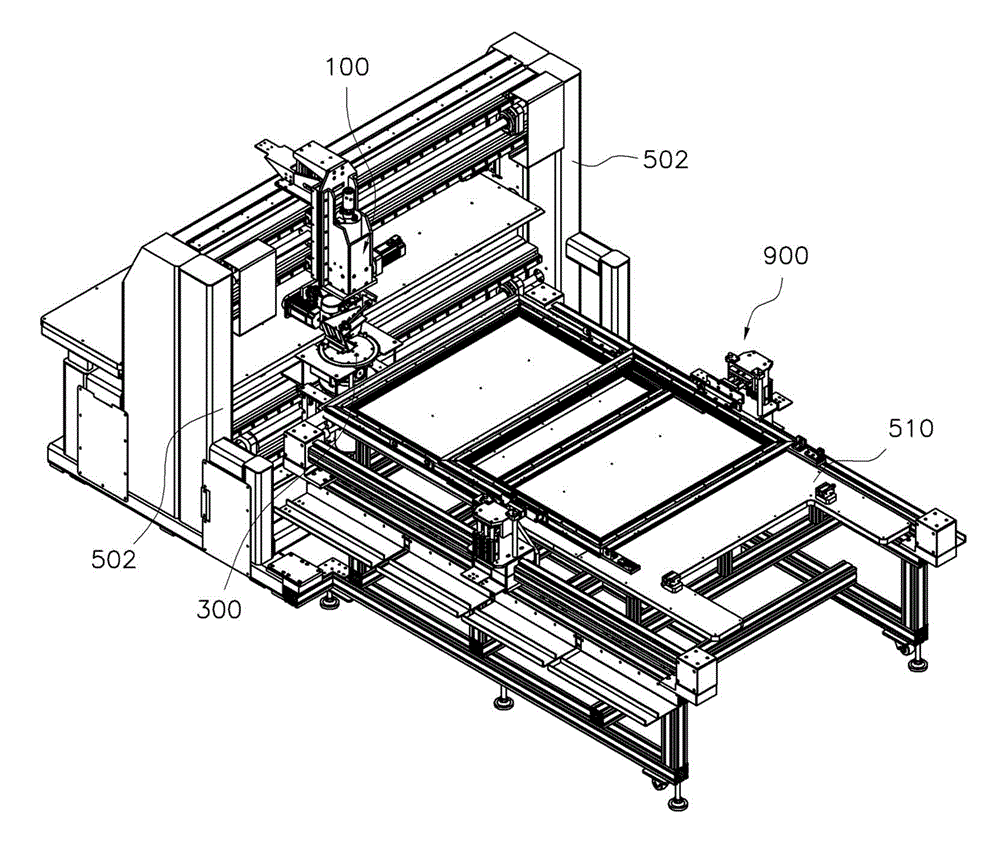

Embroidering frame moving device of sewing machine

InactiveCN101348974ASimple structureReduce maintenance costsWork-feeding meansFeedersEngineeringSewing machine

The invention discloses a sewing machine embroidering frame moving device. The sewing machine is equipped with a workbench for placing CAB embroidering frame and an auxiliary workbench for supporting the fabrics connected on the workbench. The device comprises: an embroidering frame mounting-demounting component for mounting and demounting the embroidering frame; a embroidering frame replacing component connected with the embroidering frame mounting-demounting component capable of making the embroidering frame connected with the embroidering frame mounting-demounting component reciprocate between the workbench and one of the side workbenches disposed on both sides of the workbench; an embroidering frame X axis direction moving component to control the embroidering frame to move along the X axis on the workbench; a Y axis direction moving component for control the embroidering frame to move along the Y axis on the workbench; and a control component for controlling the operations of above mentioned components.

Owner:MOBASE SUNSTAR CO LTD

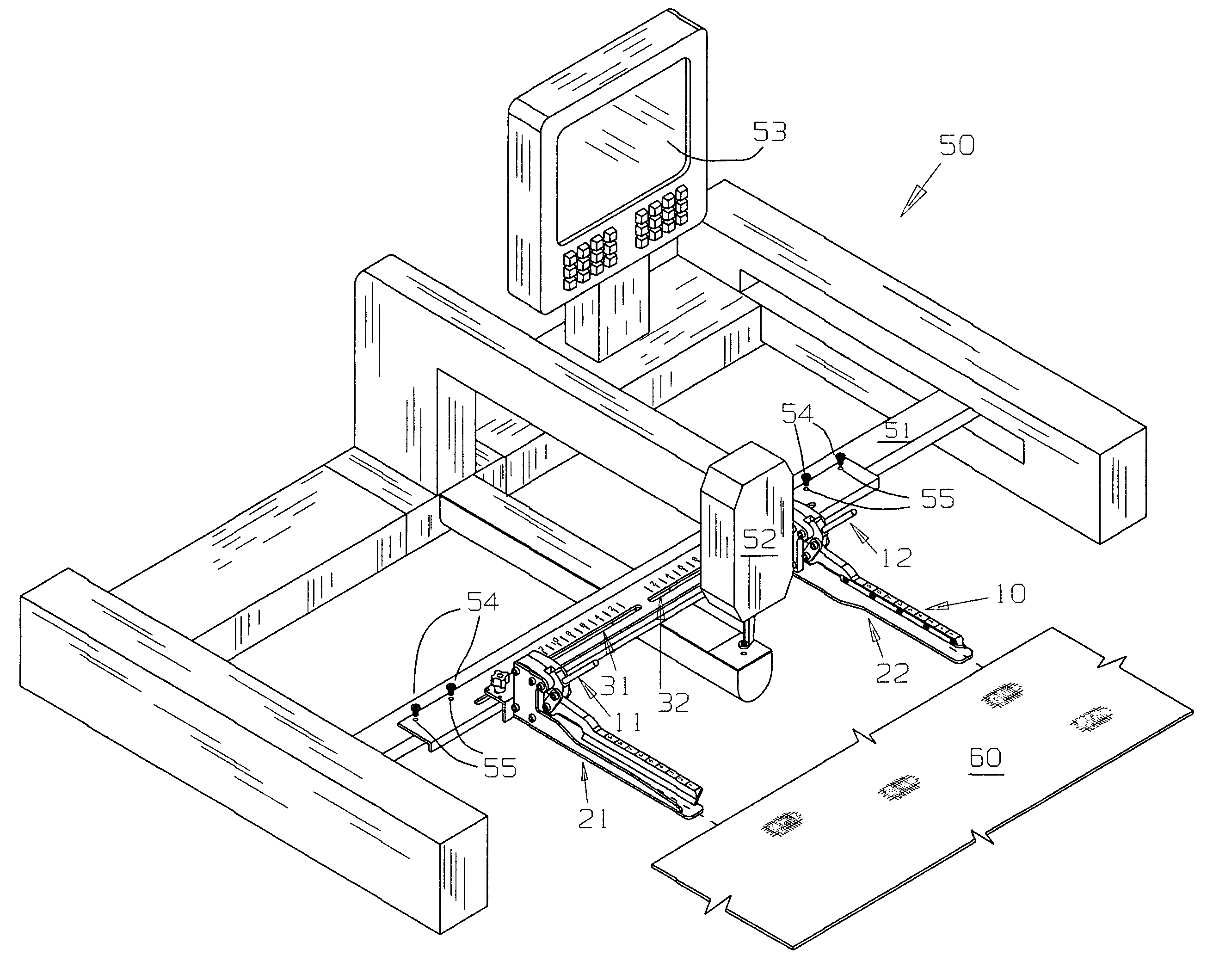

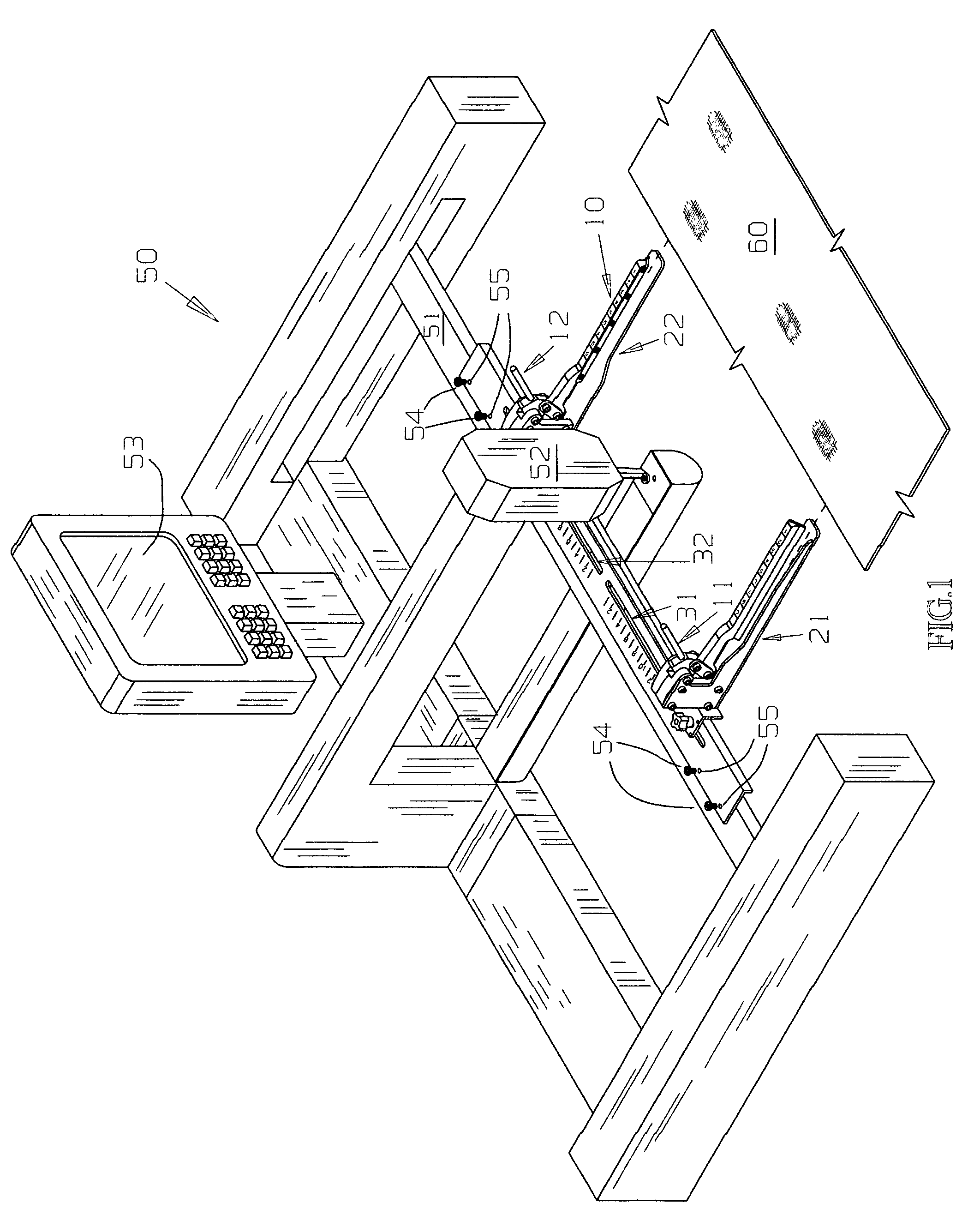

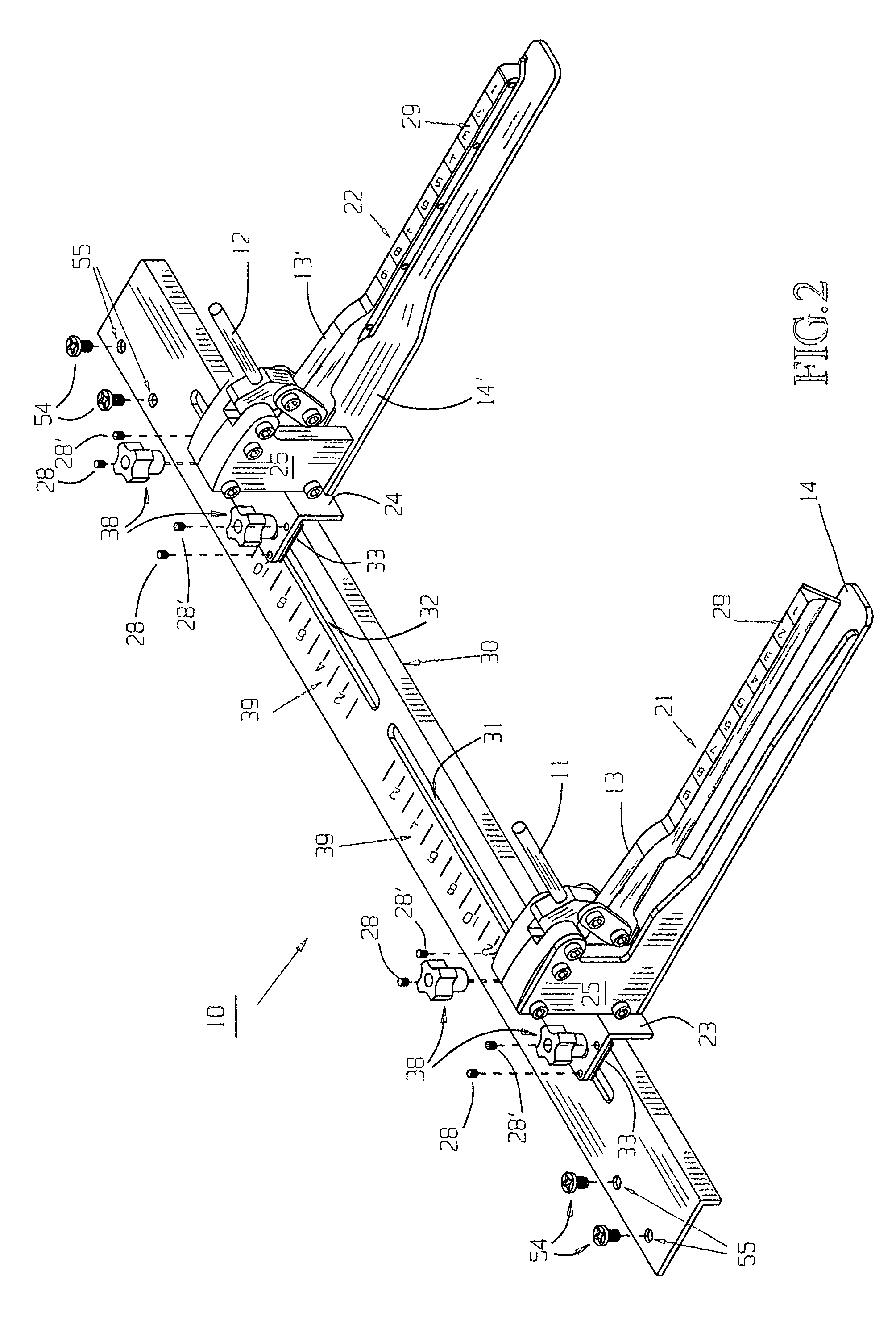

Clamping device for a sewing machine and method

ActiveUS7377222B1Assures speed and efficiencyWork-feeding meansTake-up devicesEngineeringSewing machine

A clamping device and method for a conventional sewing or embroidery machine has a pair of movable arms. Each of the arms includes a fixed section and a movable section for receiving material or item to be embroidered therebetween. A manual lever allows the movable arm to be raised for insertion of the material and a scale on the arm allows the depth of insertion to be easily determined for accurate insertion. Each arm is movable along a slotted mounting plate affixed to the sewing machine proximate the sewing head. The clamping device provides uniform, taut material for accurate, smooth embroidering.

Owner:EFP INC

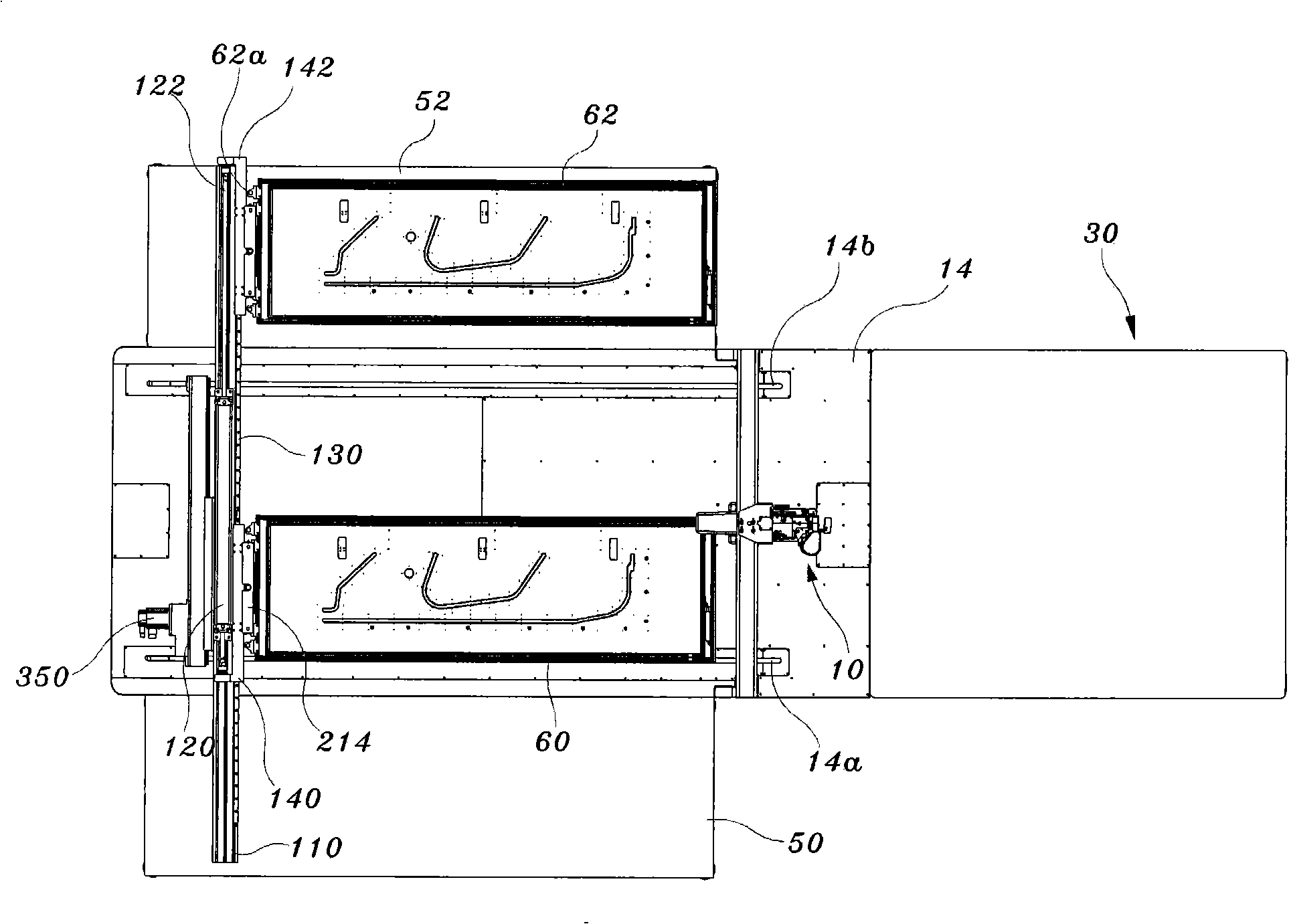

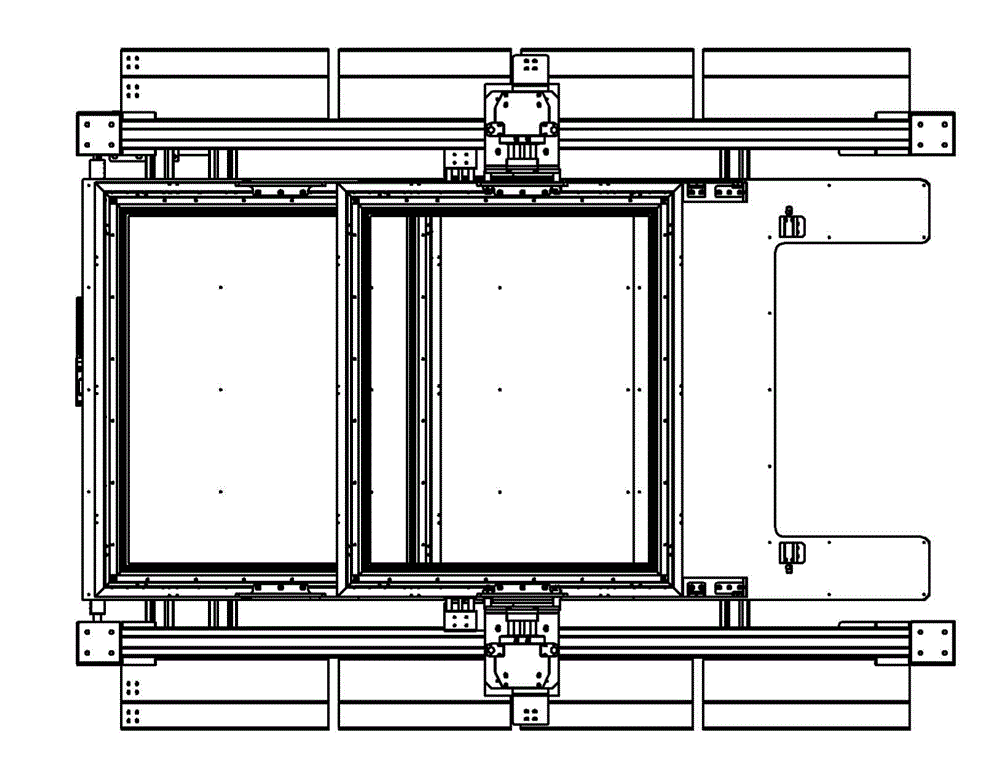

Sewing box replacing device, driving method thereof and sewing machine

InactiveCN102797118AShorten working timeImprove work efficiencyWork-feeding meansFeedersEngineeringSewing machine

The present invention relates to a sewing box replacing device, a driving method thereof and a sewing machine comprising the sewing box replacing device. The sewing box replacing device of the invention comprises sewing boxes used for fixing the above sewed objects and arranged in a Y-shaft direction on the upper surface of a workbench; a Y-shaft conveying unit conveying the sewing boxes to the Y-shaft to execute the sewing performance, conveying the finished sewing boxes backwards at the same time, and conveying the to-be-sewed sewing boxes to a head side to execute the sewing performance to thereby realize the replacement of the sewing boxes. By replacing the sewing boxes automatically, even though a lot of sewing performance is executed, the sewing box replacement time can be shortened substantially, and the work efficiency is improved substantially; by spacing a Y-shaft driving part of the sewing machine apart from a bottom frame, the work region towards Y-shaft direction ( the front and back length directions) can be expanded without limited by the size of the sewing machine, so that the sewing box replacing device, the driving method thereof and the sewing machine have the effects of sewing large-scale sewed objects.

Owner:SUNSTAR KK

Device for tensioning and securing a canvas

ActiveUS7293378B2Clearance may become wider and widerEasy to installCurtain rodsOther artistic work equipmentsEngineering

A device for tensioning and maintaining a canvas, comprising a frame having a groove, and at least one deformable batten. The canvas is stretched and maintained on the frame by wedging it between the groove and the deformable batten. The deformable batten comprises a substantially V-shaped section which is oriented towards the bottom of the groove, a sharp edge which is used as a pivot to enable the deformation thereof, and two flanks which are used to wedge the canvas in the groove. The invention is characterized in that the batten is locked in a narrow section of the groove by two enlargements extending on one flank of the batten in the same direction as the batten.

Owner:PRISMAFLEX INT

Clutch Structure for Presser Foot of Embroidery Sewing Machine

InactiveUS20080282953A1Relieve noiseRelieve vibrationSewing-machine control devicesPressersFoot supportsClutch

A clutch structure for a presser foot in an embroidery sewing machine is provided. The clutch structure includes a guide member, to which the presser foot drive link is rotatably connected, and through which the needle bar guide shaft passes, a spring connecting member mounted on the outer circumference of the needle bar guide shaft and inside the guide member, a resilient member mounted on the outer periphery of the spring connecting member, and a pivot member mounted inside the guide member so as to be pivotable around the needle bar guide shaft within a certain angular range by the height adjusting mechanism and the resilient member. Upon a head-interval adjusting operation, the unnecessary driving of the presser foot is prevented, so that the occurrence of vibrations and noise as well as the unnecessary wear of a needle bar, a presser foot support, and a presser foot holder can be prevented.

Owner:SUSR PRECISION CO LTD

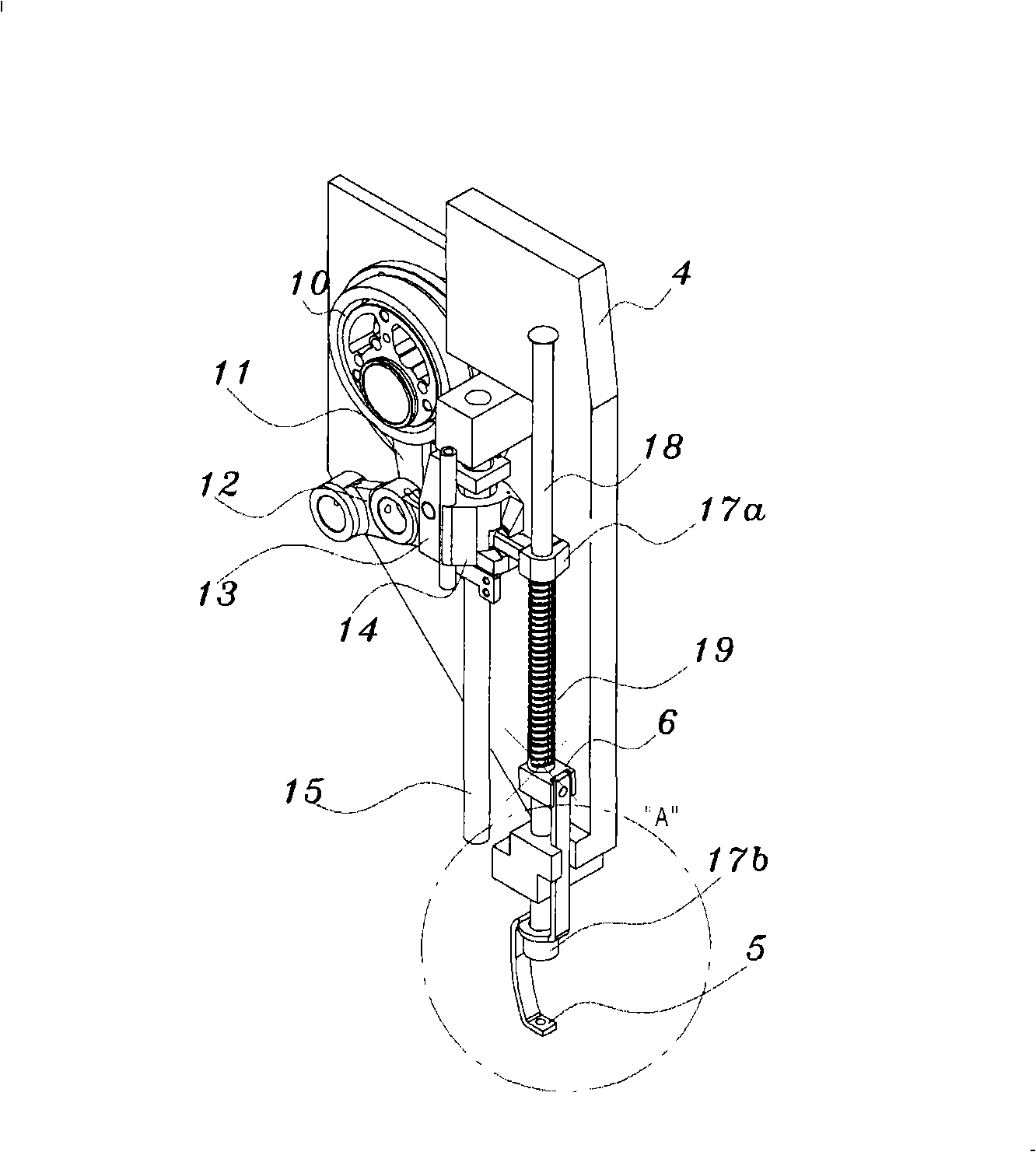

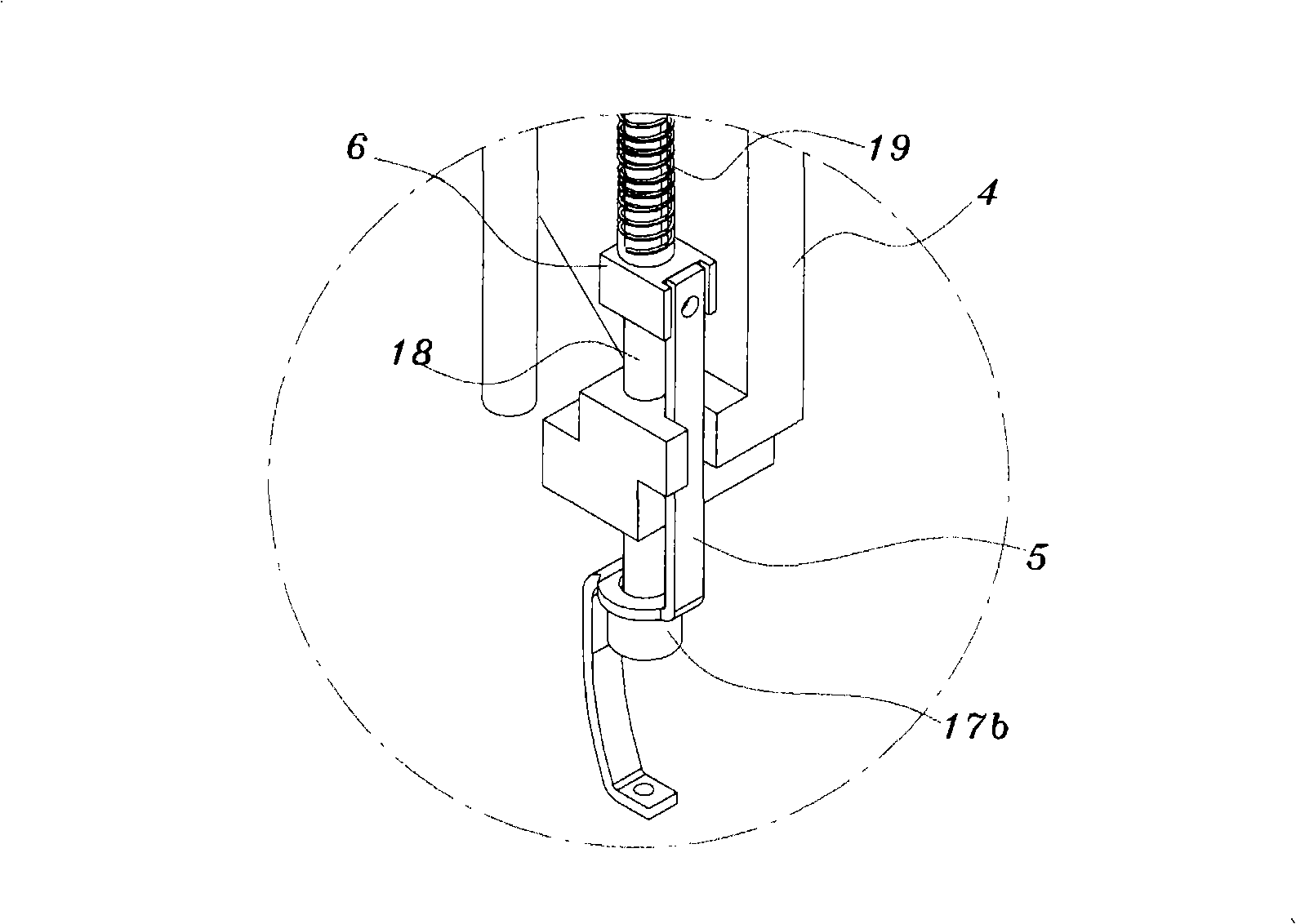

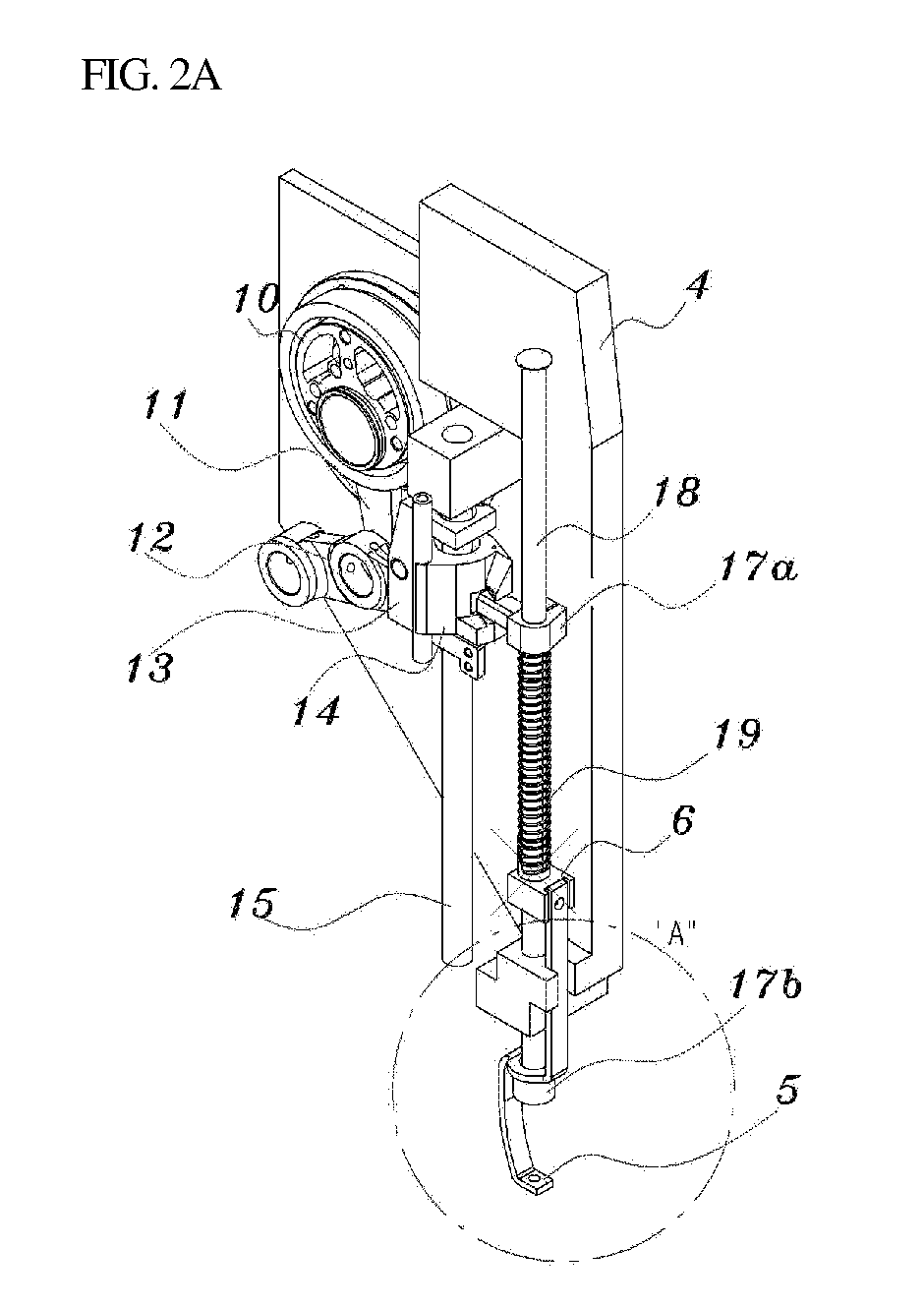

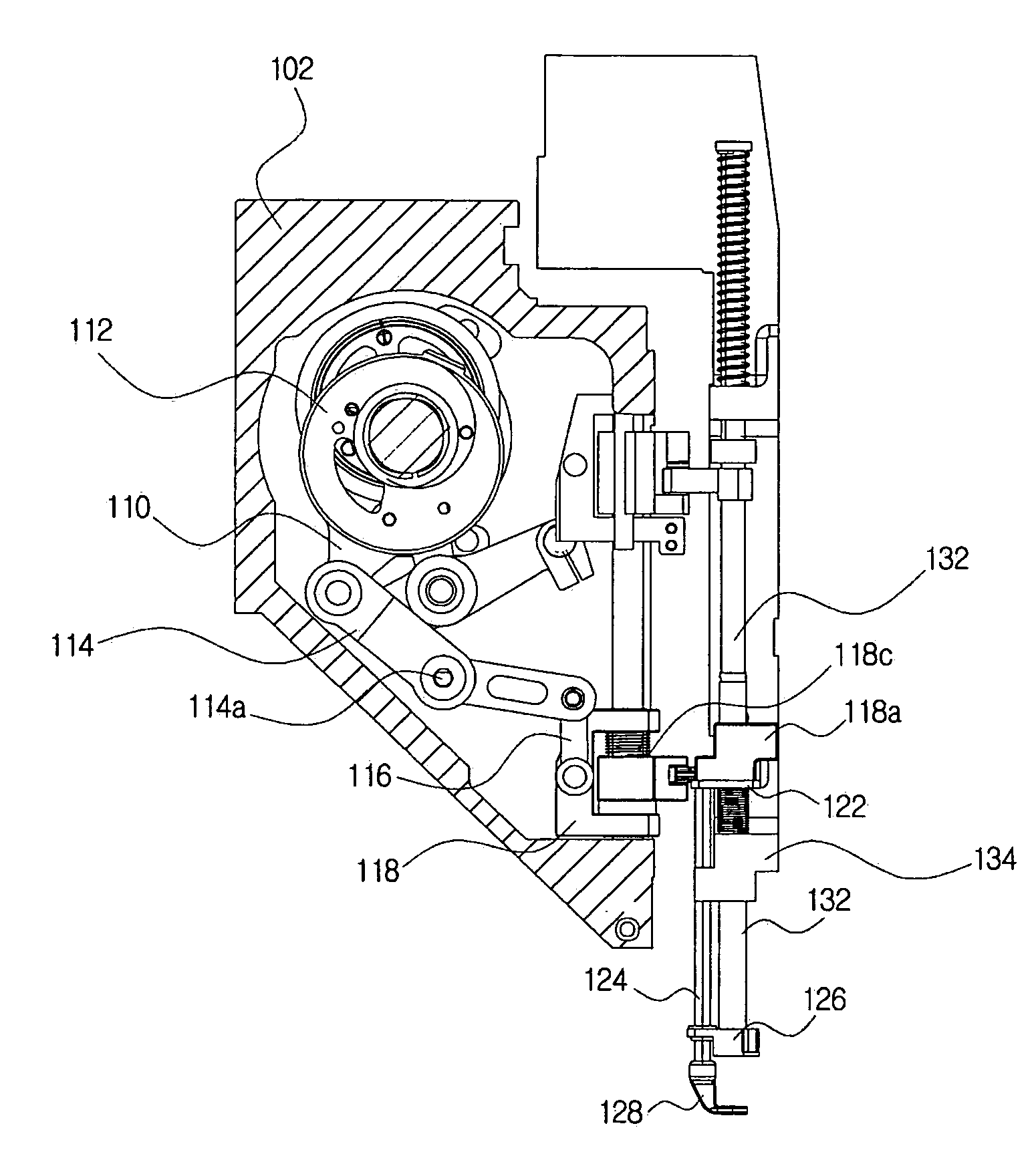

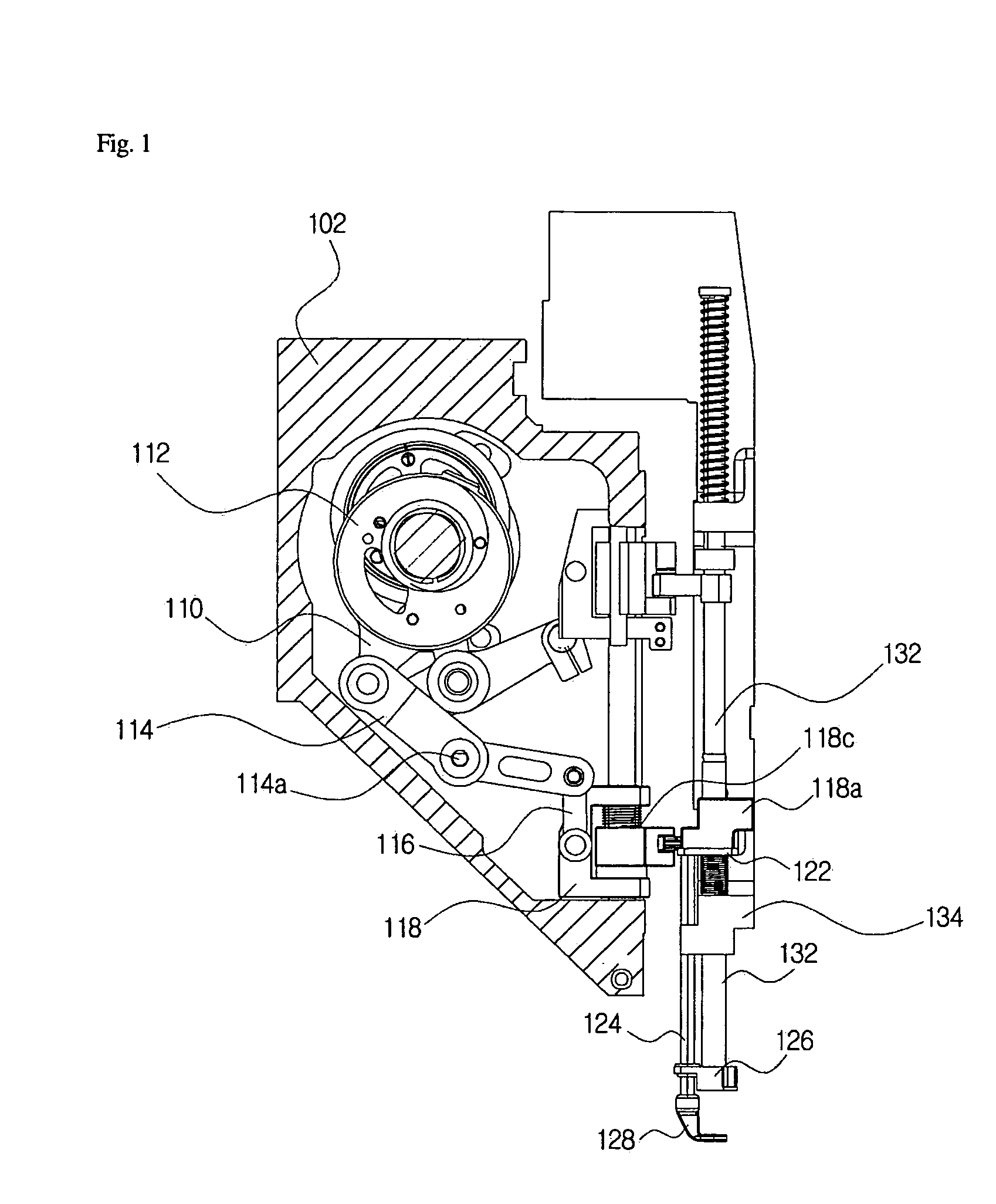

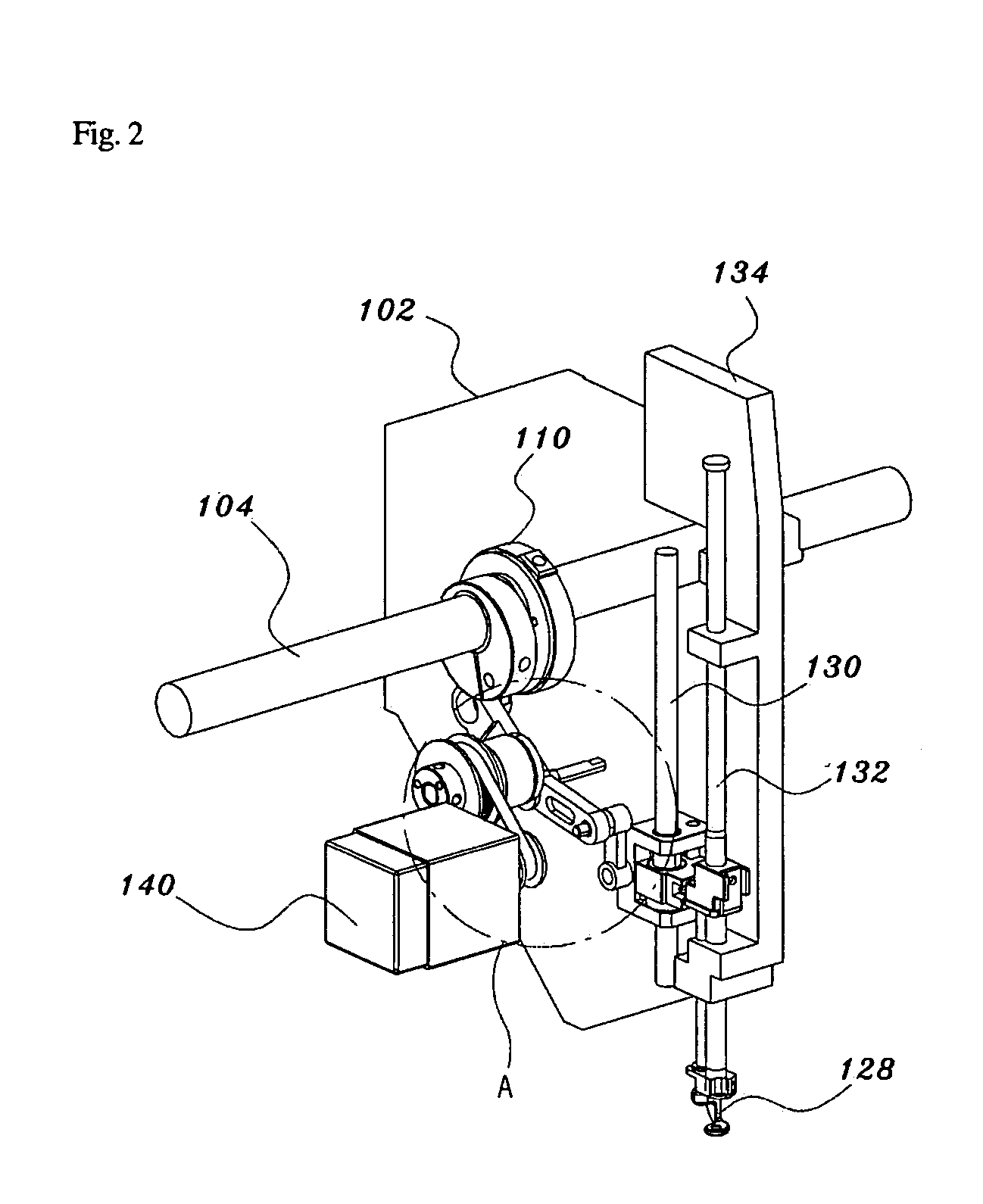

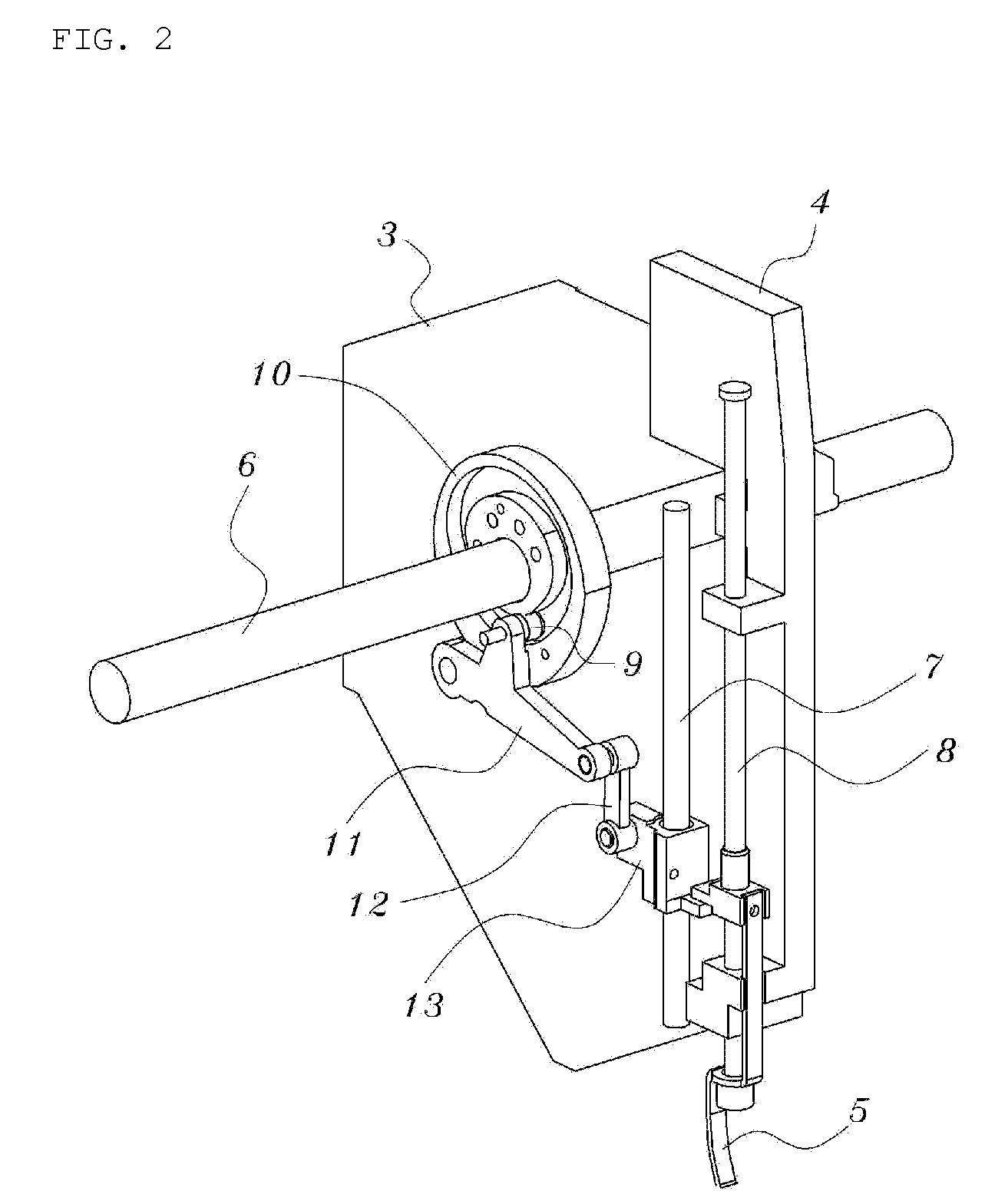

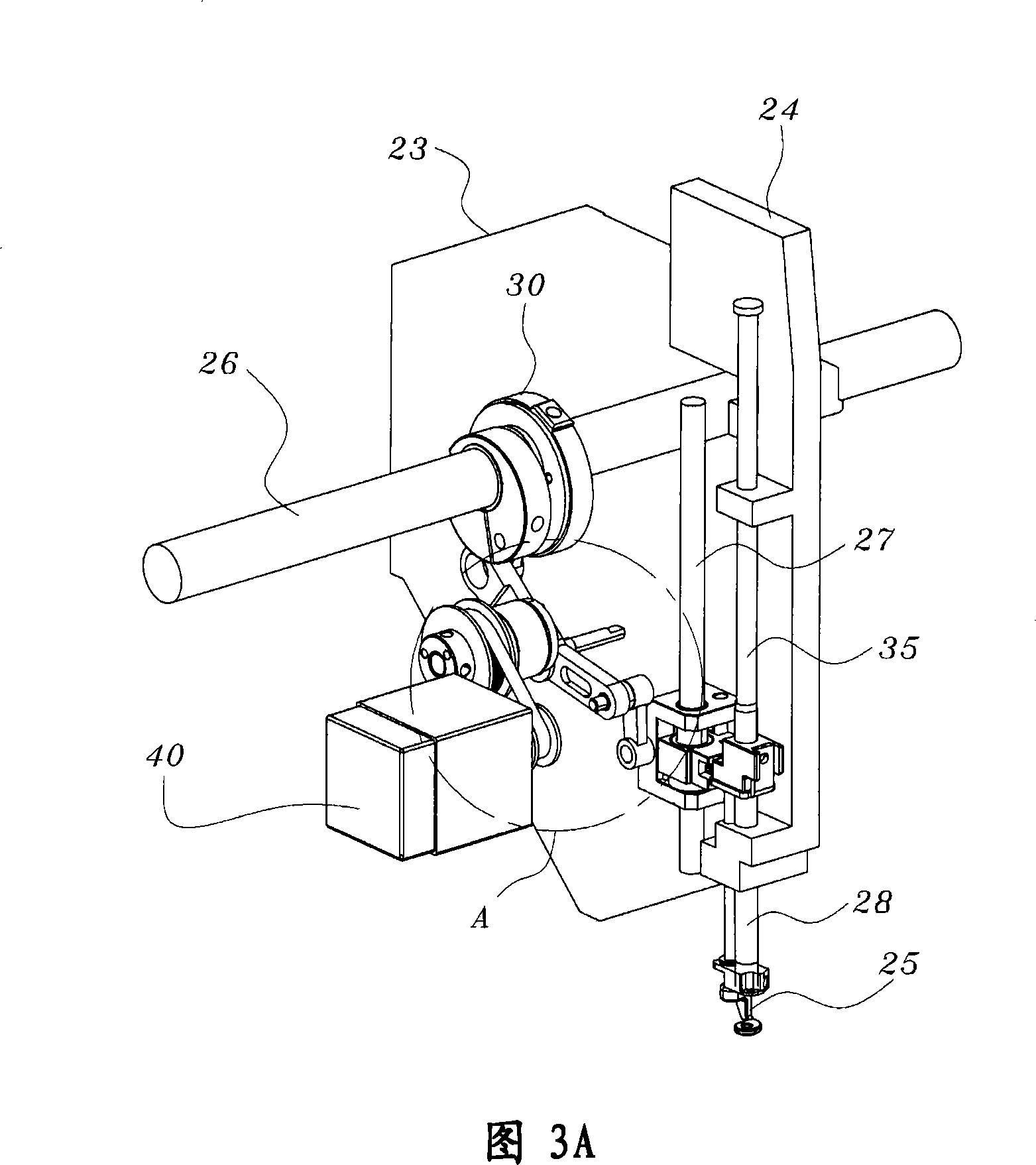

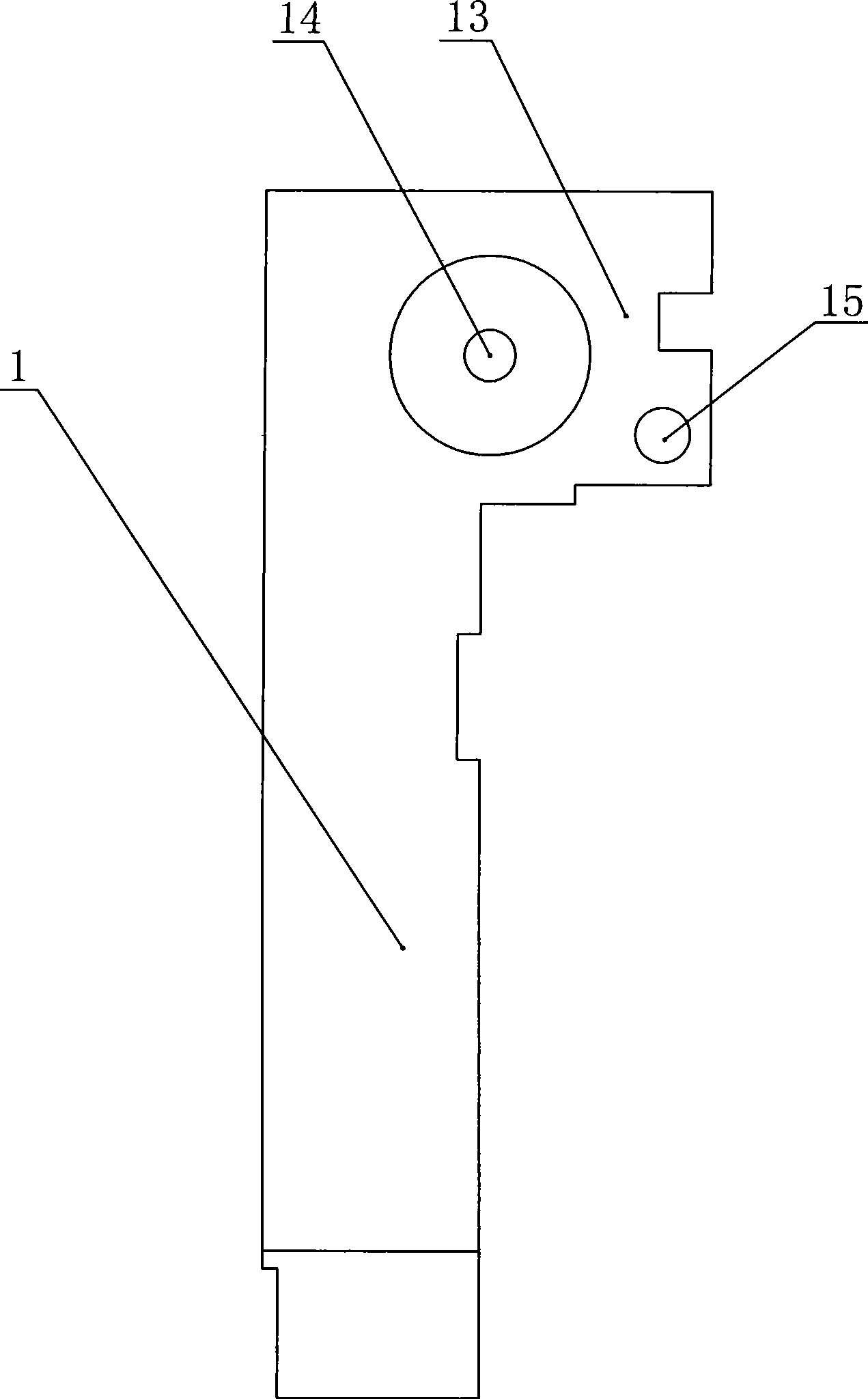

Apparatus for Lifting Presser Foot of Embroidery Machine

InactiveUS20080257242A1Easily replaces sewing material and sewing framePressersFeedersReciprocating motionEngineering

An apparatus for lifting the presser foot of an embroidery machine includes an arm having an upper shaft providing a driving force, a presser foot driving cam mounted on the upper shaft, a transmission member coupled to the presser foot driving cam and making an oscillating motion, a presser foot driving lever connected to the transmission member and pivoting around a predetermined pivoting point thereof in a vertical direction, a presser foot driving block reciprocating along a needle bar guide shaft according to an amount that the presser foot driving lever is pivoted and moving the presser foot in a vertical direction, and a presser foot height adjustor, displacing the pivoting point of the presser foot driving lever to adjust a height of the presser foot.

Owner:SUSR PRECISION CO LTD

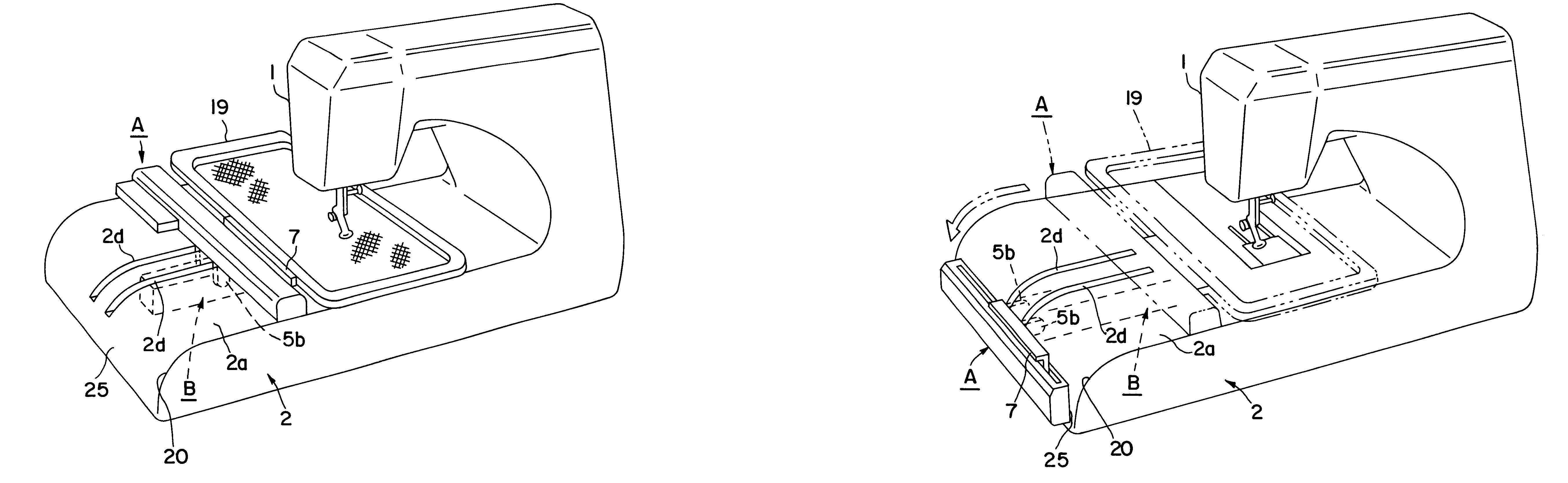

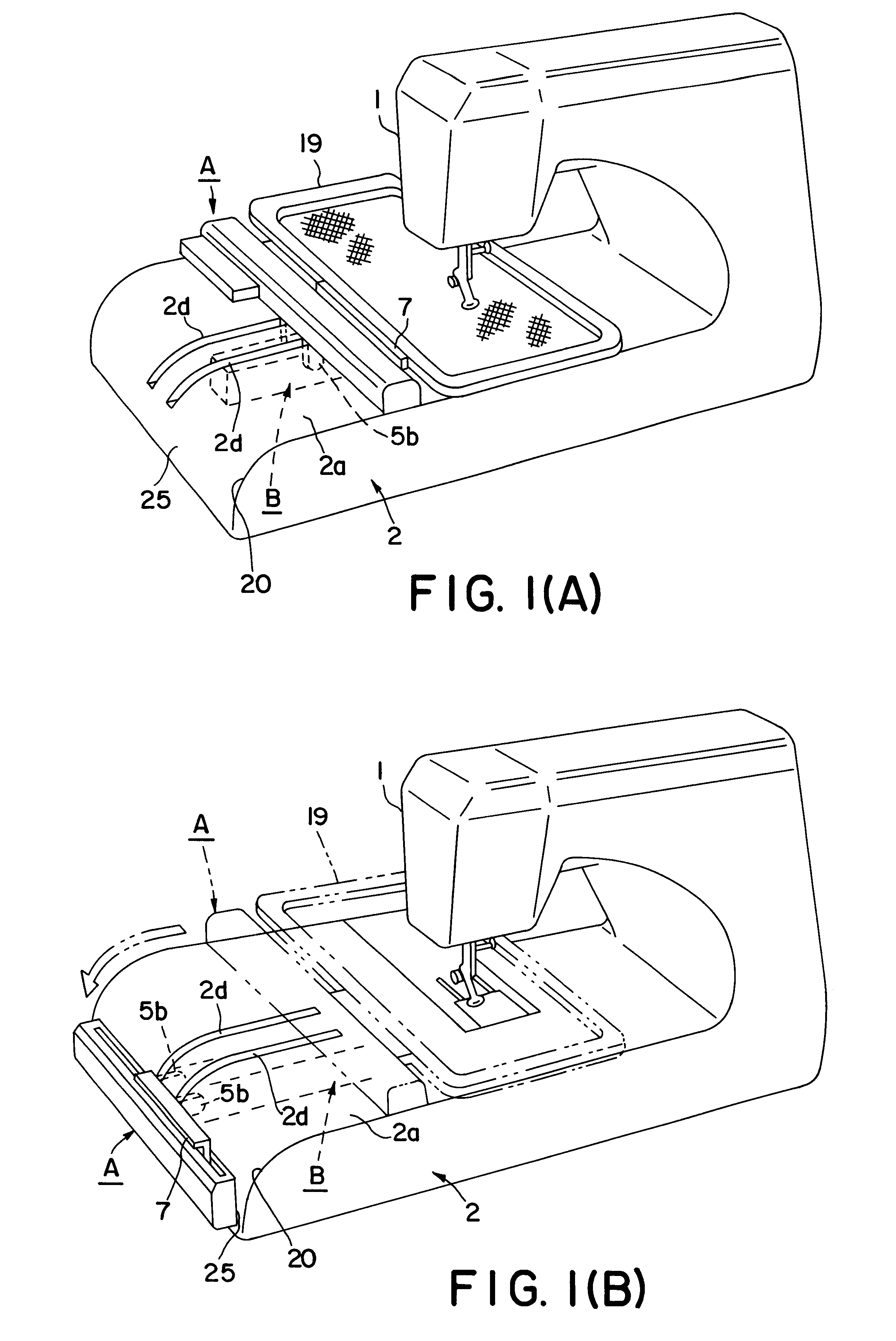

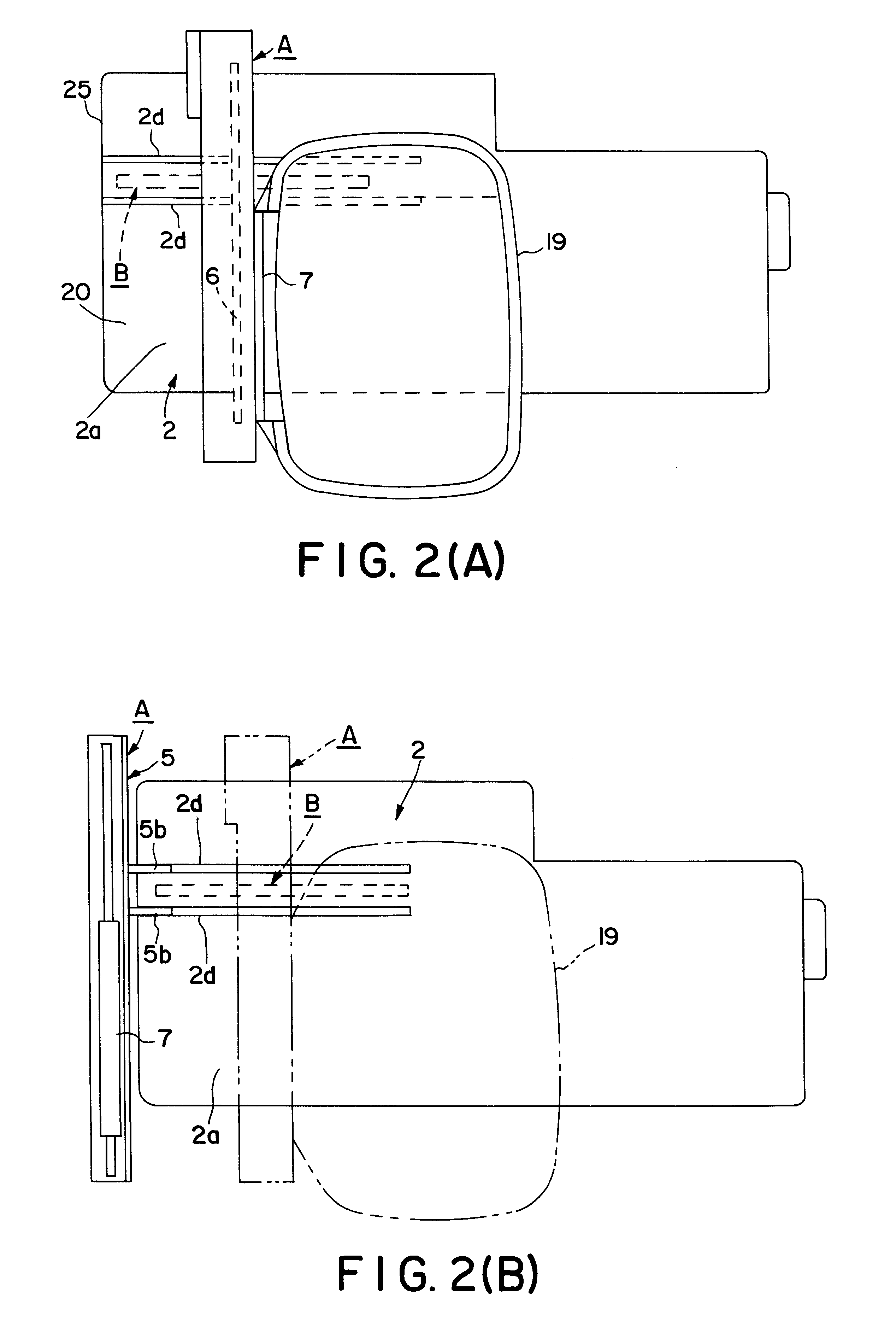

Sewing machine with an embroidery stitching function

A sewing machine with an embroidery stitching function is disclosed, wherein a needle is vertically reciprocated to form stitches on a work held by an embroidering frame (19) which is moved in X-Y directions by a frame moving device relative to the needle on a working surface (2a) of a working bed (2), the frame moving device being composed of composed of a first mechanism (A) for moving said embroidering frame in the Y direction and a second mechanism (B) for moving the embroidering frame in the X direction, the first mechanism (A) being located on the working surface and connected to the embroidering frame (19) and the second mechanism (B) being housed in the sewing machine, the first mechanism (A) being moved by the second mechanism (B) to one end of the working bed (2) where the first mechanism (A) is rotated to a retreated position at the time of carrying out the ordinary stitching operation.

Owner:JANOME CORP

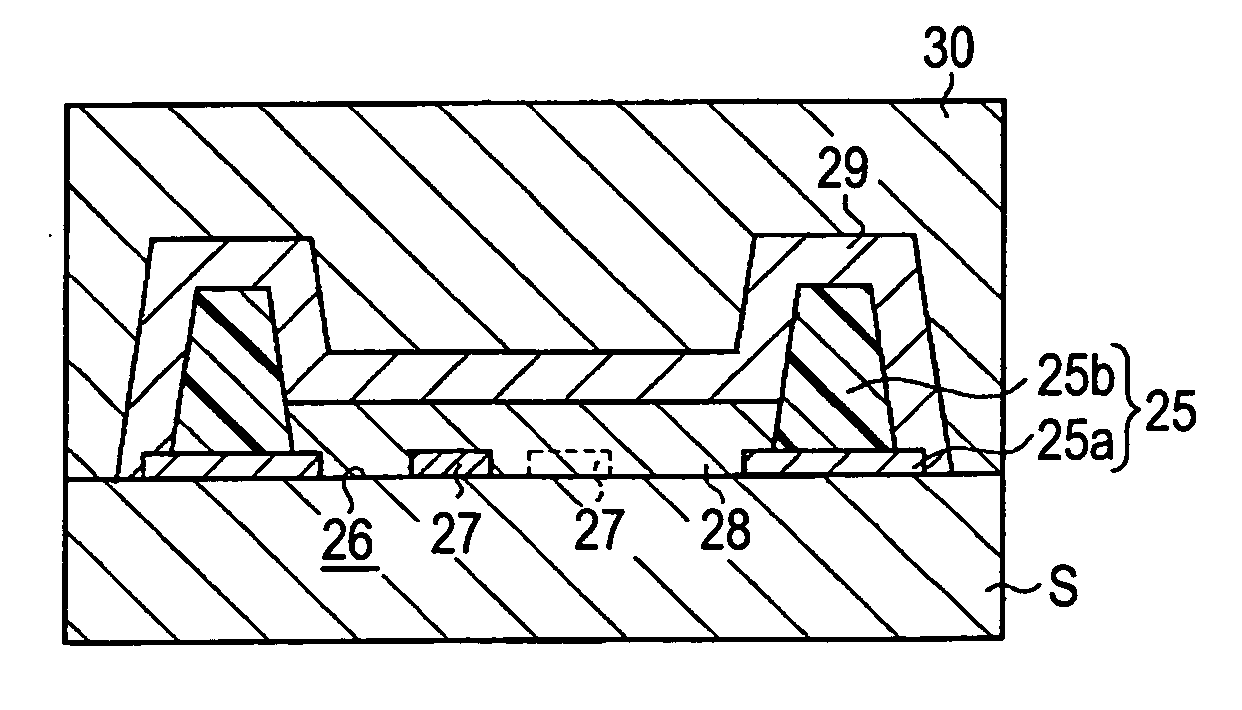

Electrooptical apparatus and method of manufacturing electrooptical apparatus

InactiveUS20060220532A1Improve the immunityGood reproducibilityDischarge tube luminescnet screensElectroluminescent light sourcesLight emissionElectro-optics

An electrooptical apparatus includes a light emission element array in which a plurality of light emission elements are arranged, and a barrier rib which surrounds the light emission element array.

Owner:SEIKO EPSON CORP

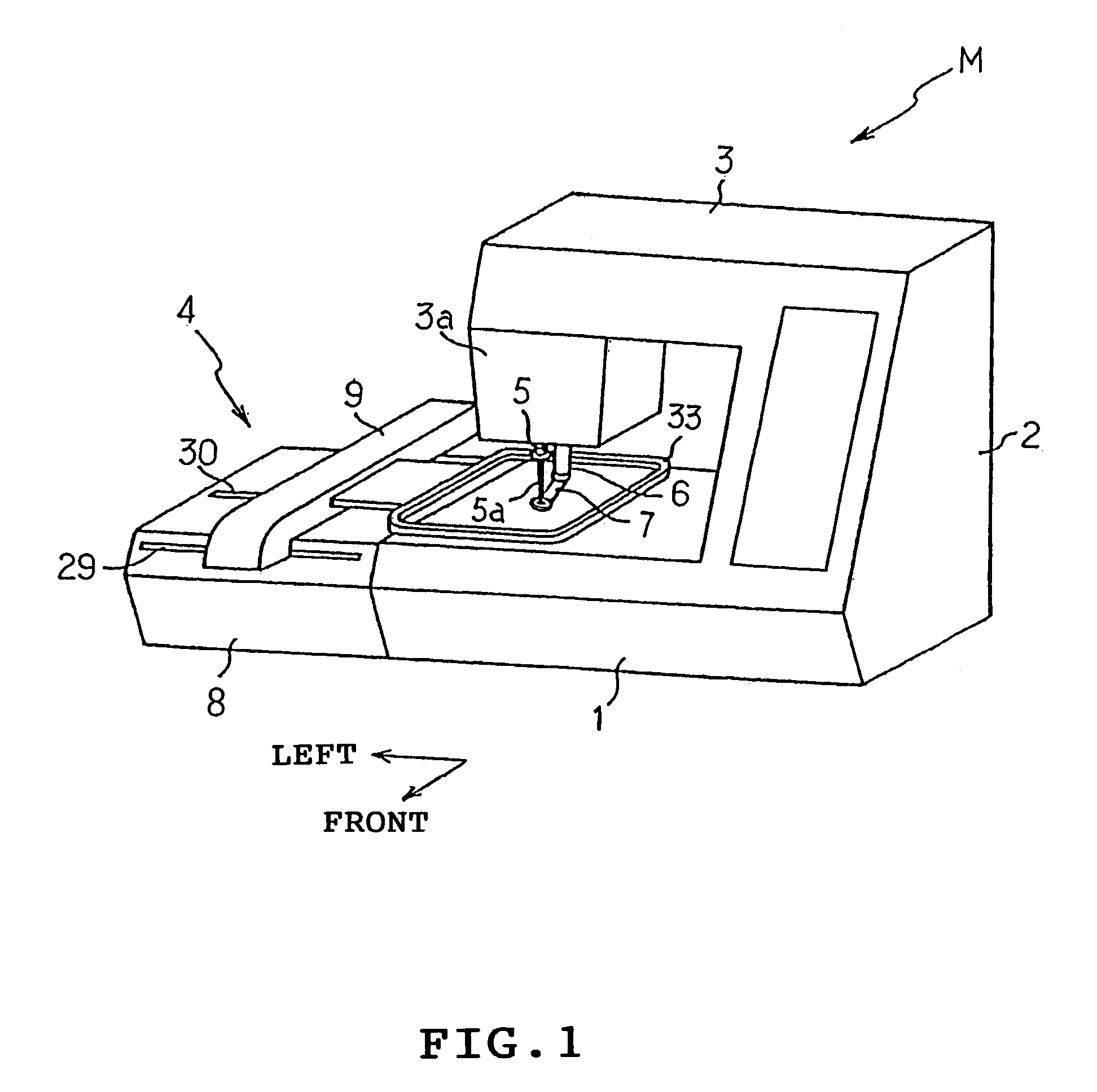

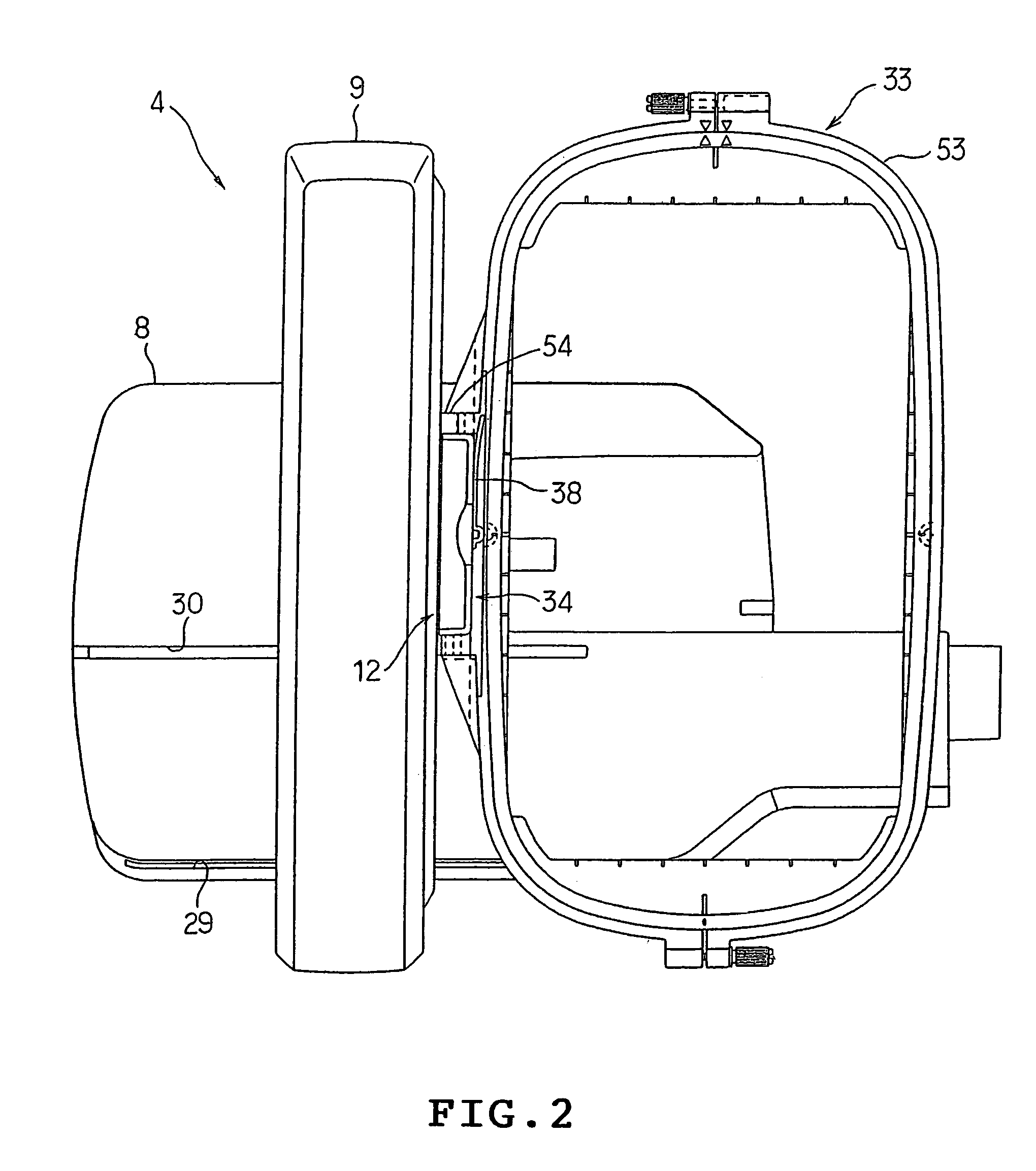

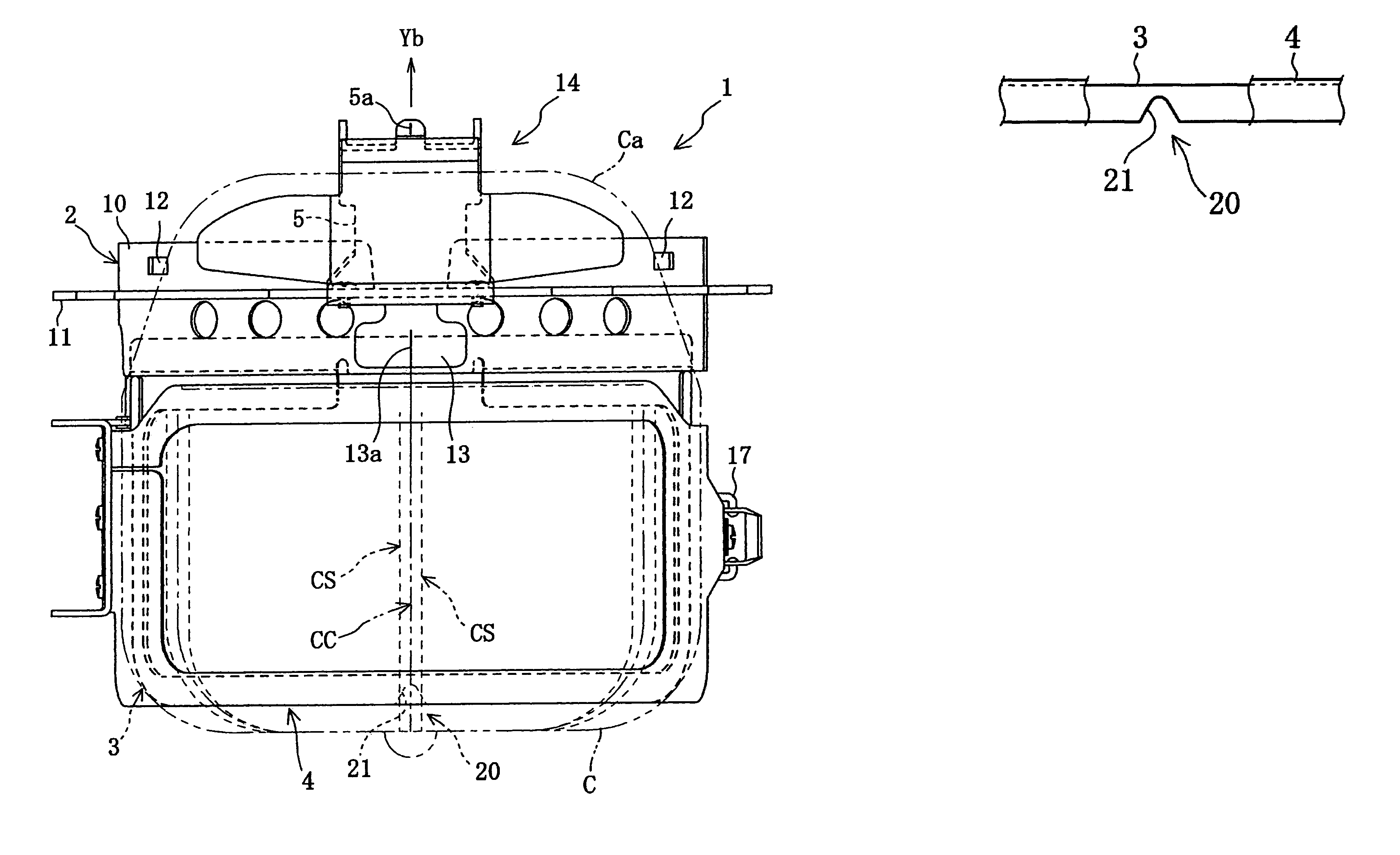

Sewing machine having a camera for forming images of a sewing area

ActiveUS8606390B2Simplifying and enhancing sewingProgramme-controlled sewing machinesAutomatic machinesDisplay deviceEngineering

A sewing machine (1) has access to a memory (M) for stitch data and a processor (C) for reading said stitch data and for operating the sewing machine (1) to execute stitches according to stitch data, wherein the sewing machine (1) has a hoop (20) for framing a pattern of the sewing material (2), and for moving the framed pattern in a direction comprising a component of at least one of a first coordinate (x) and a second coordinate (y) and wherein further the processor (C) controls movements of the hoop (20) according to said direction in relation to the position of a needle (5) of the sewing machine and synchronously with the movement of the needle for executing stitches, wherein: —the stretched sewing material (2) is clamped to the hoop (20) for forming a framed pattern in the hoop, —the framed pattern of the sewing material (2) is scanned by means of a camera (10) mounted in the sewing machine (1) and directed towards the sewing material (2) for the purpose of taking pictures of part views of said framed pattern, —said part views are tiled together for forming on a display an image of the pattern framed in the hoop, whereby a coordinate of the image of a display (11) refers to a corresponding coordinate of the pattern framed in the hoop (20).

Owner:SINGER SOURCING LTD LLC

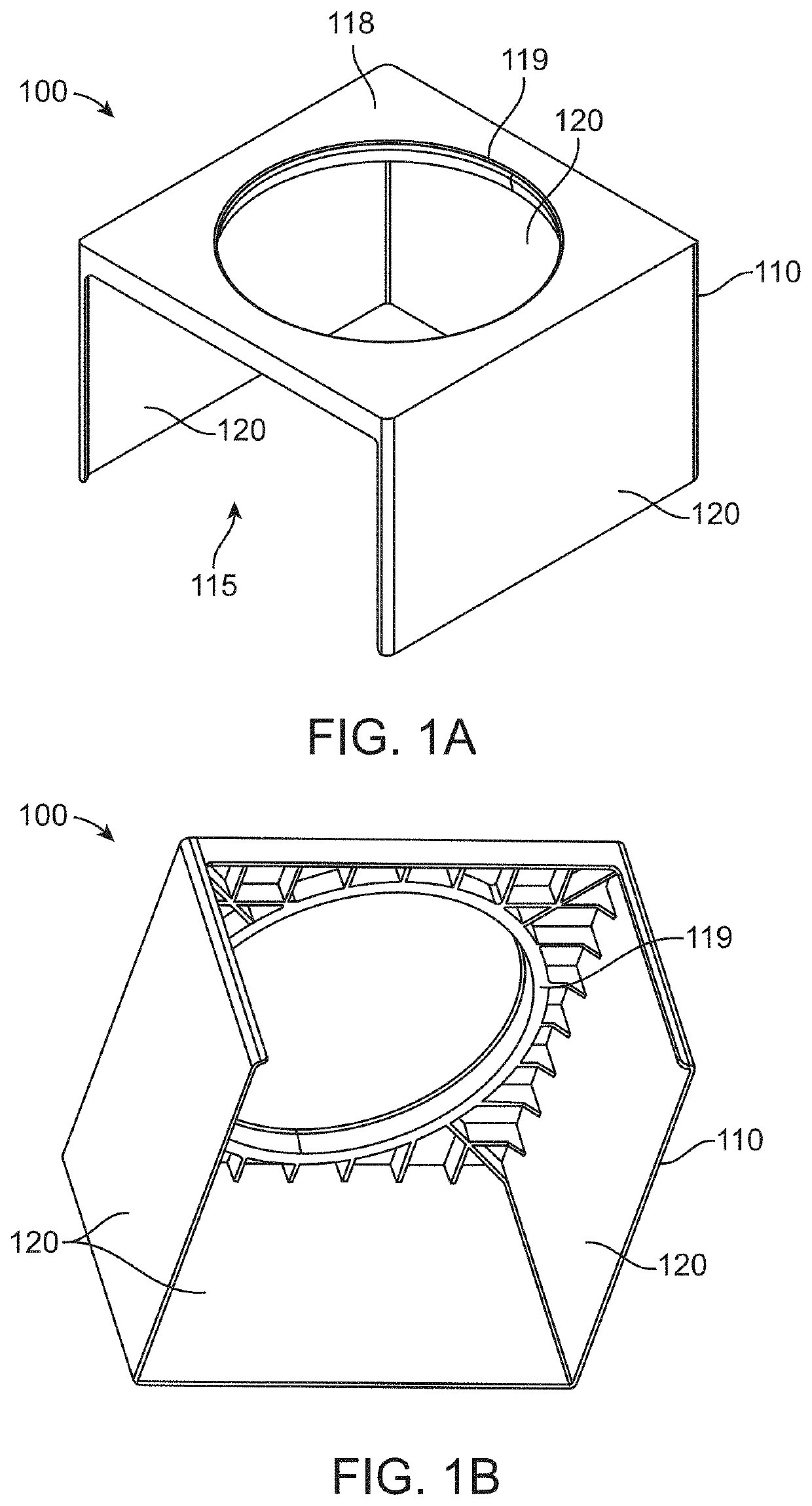

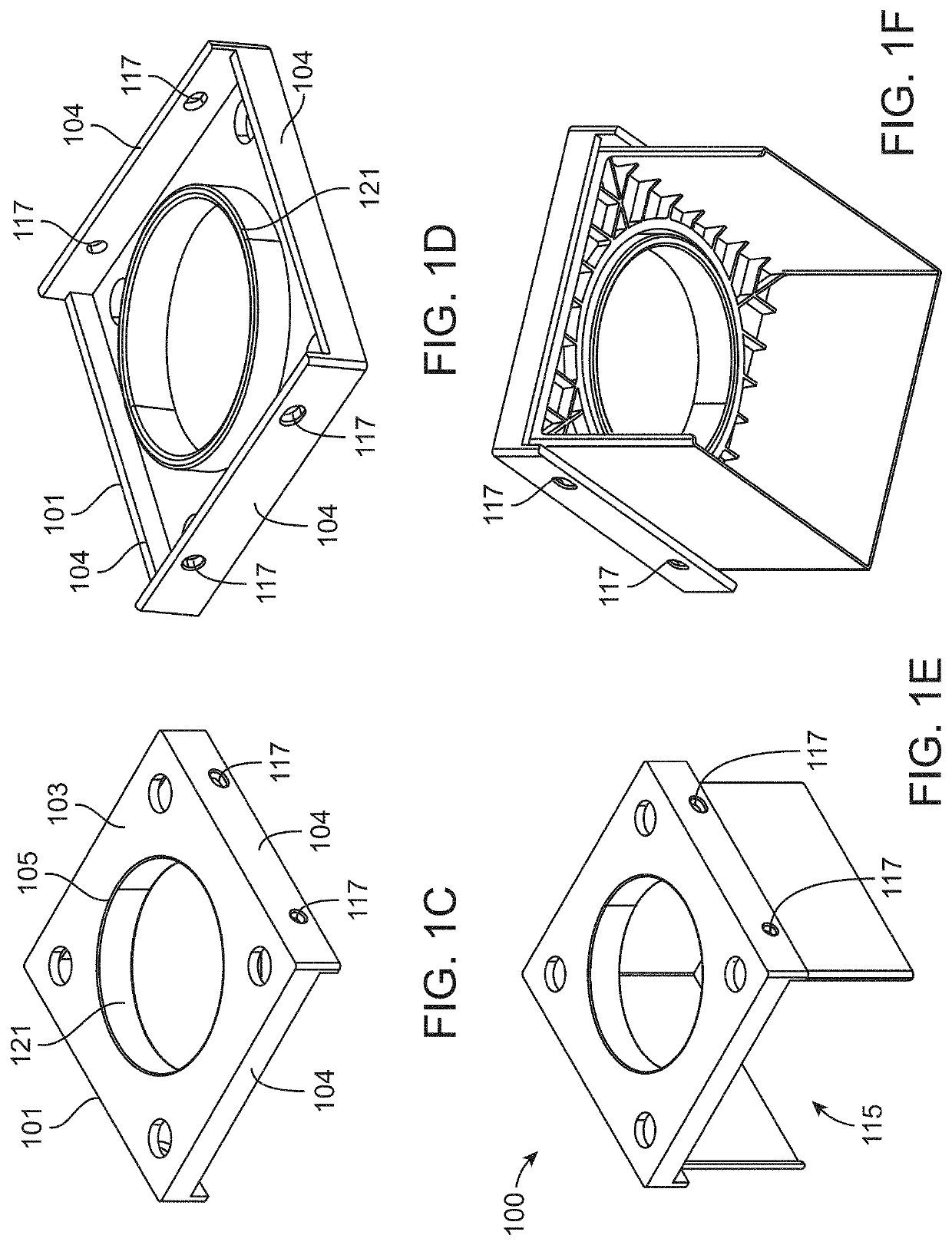

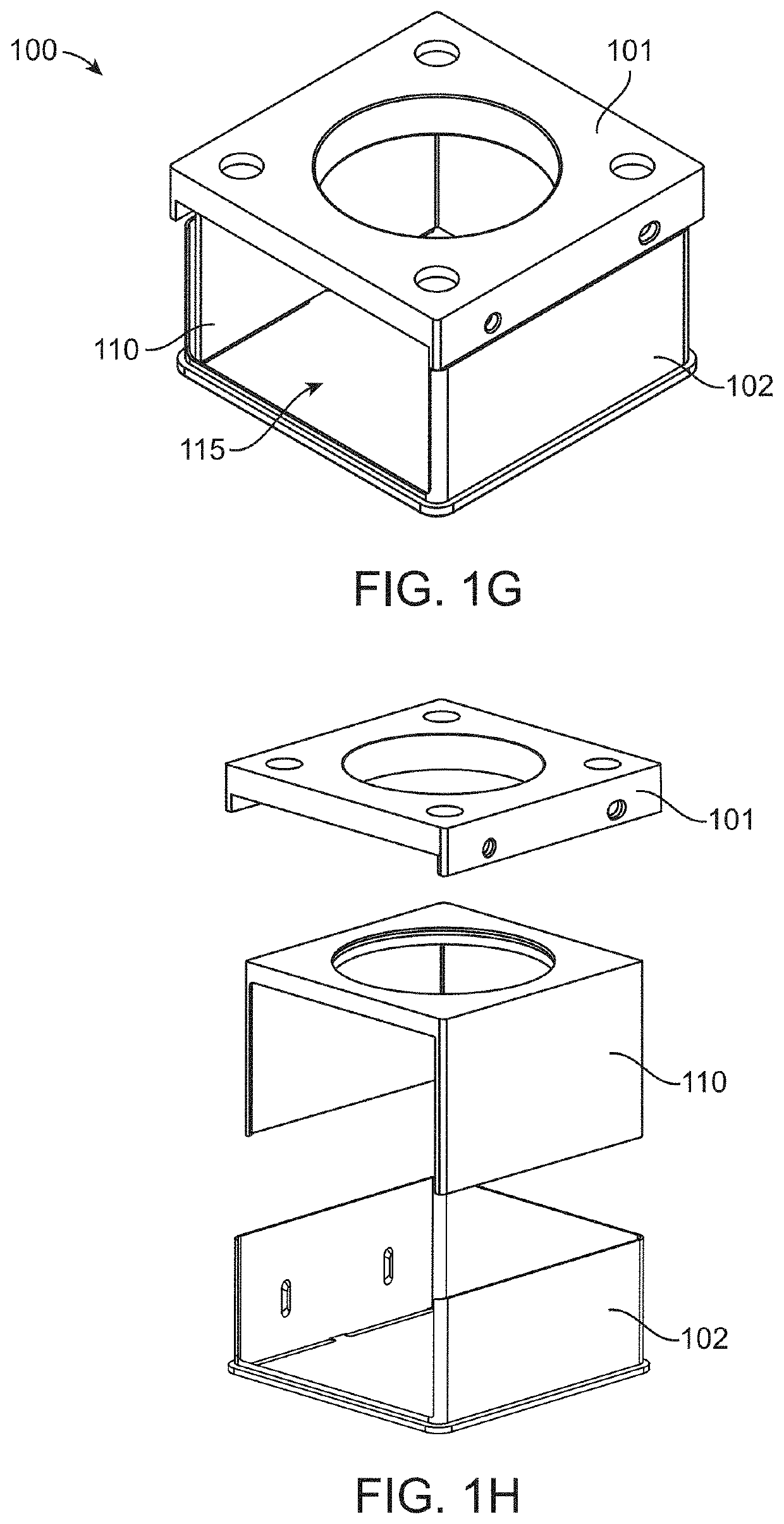

Systems and methods for packaging articles to be embroidered

Packaging is used to store articles to be customized by methods including embroidery, wherein the packaging includes at least two portions defining a window, and wherein the two portions of the packaging hold a portion of the article, for example a fabric panel, taut across the window so that the portion of the article may be embroidered by an embroidery machine while retained by portions of the packaging. The packaging may be in the form of a box during embroidery, or may be converted into the form of a box after embroidery.

Owner:CREATEME TECH LLC

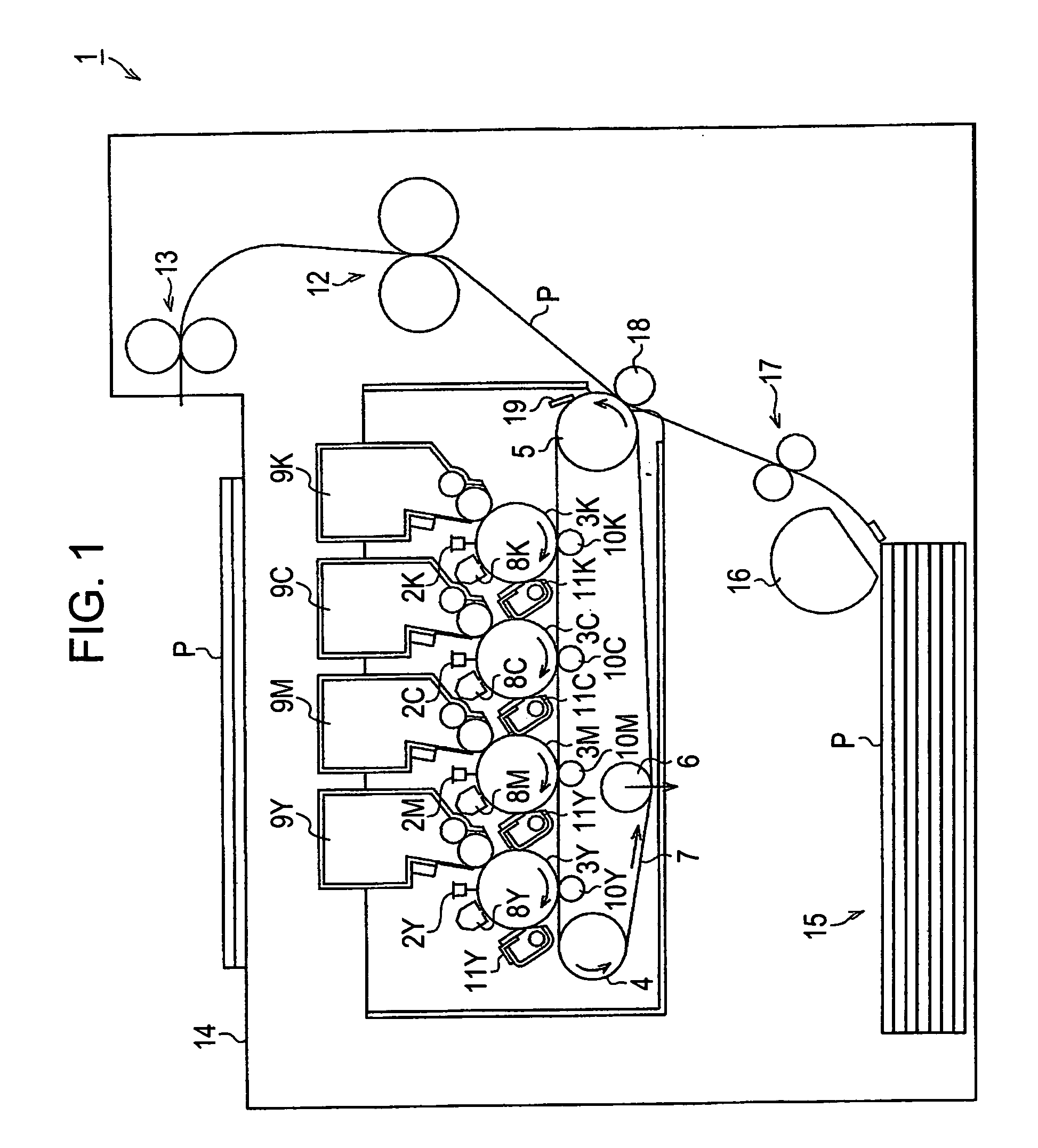

Sewing machine

InactiveUS20150259841A1Programme-controlled sewing machinesSewing-machine elementsEngineeringControl unit

A sewing machine includes a plurality of types of embroidery frames having respective holding parts holding workpiece cloth, the holding parts having forms differing from one type of embroidery frame to another, a carriage to which one of the embroidery frames is selectively attached, the carriage being configured to transfer the embroidery frame, a projector configured to project an image onto the workpiece cloth, a detector configured to detect a type of the embroidery frame attached to the carriage, a storage unit configured to store frame information set for every type of embroidery frame, a setting unit configured to read the frame information according to result of detection by the detector and to set a projection region for an image to be projected, based on the frame information, and a control unit configured to control the projector so that the projector projects the image onto the set projection region.

Owner:BROTHER KOGYO KK

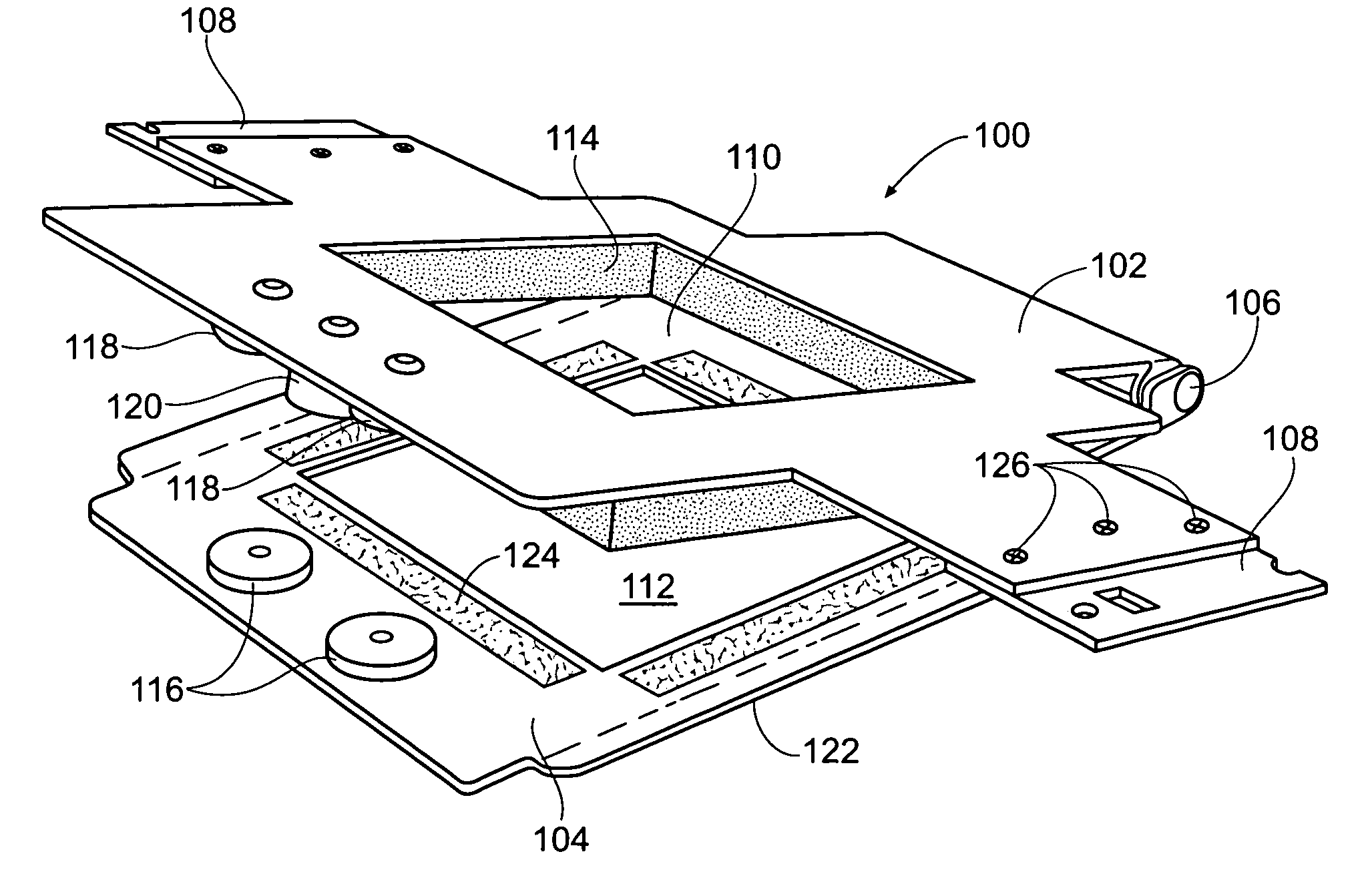

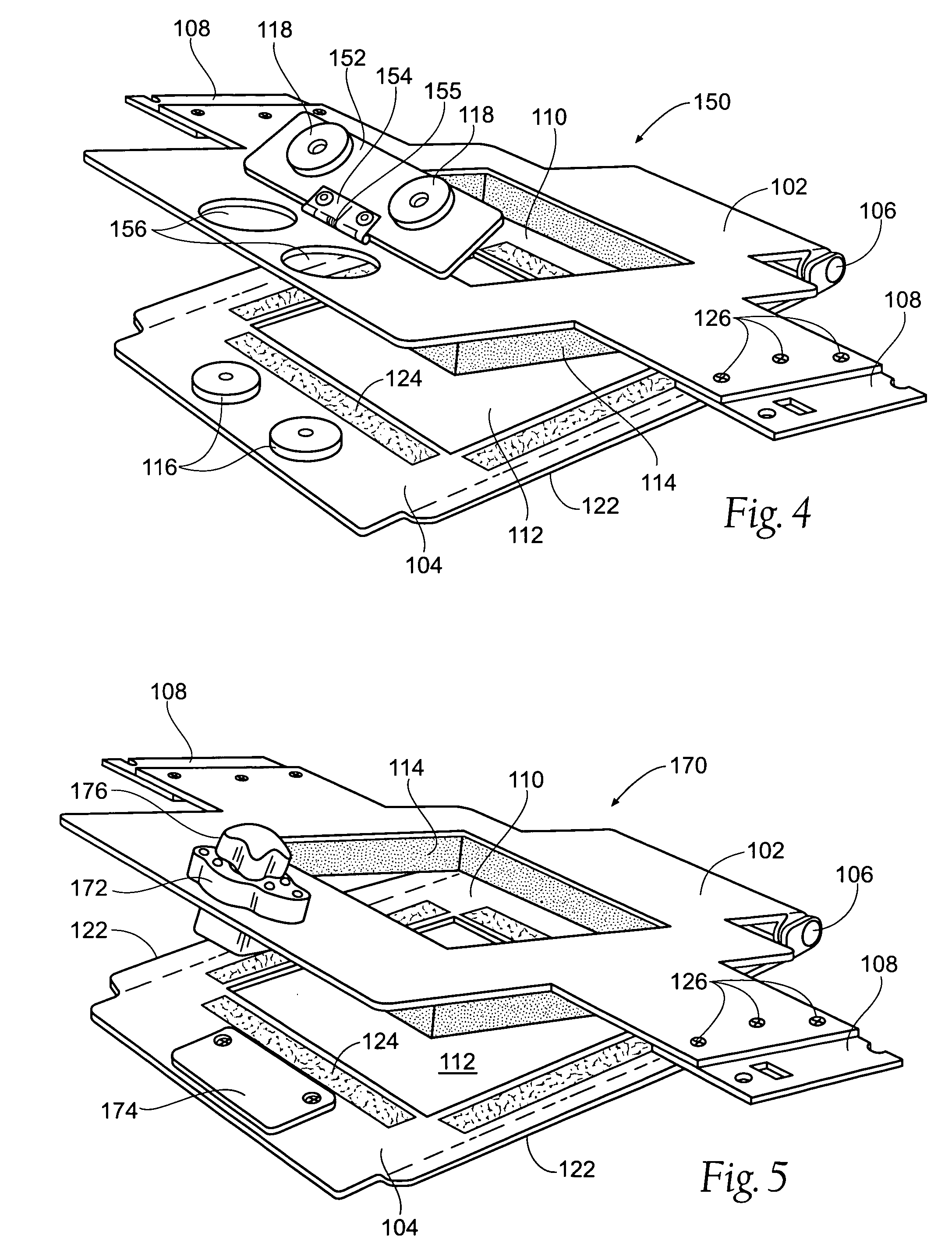

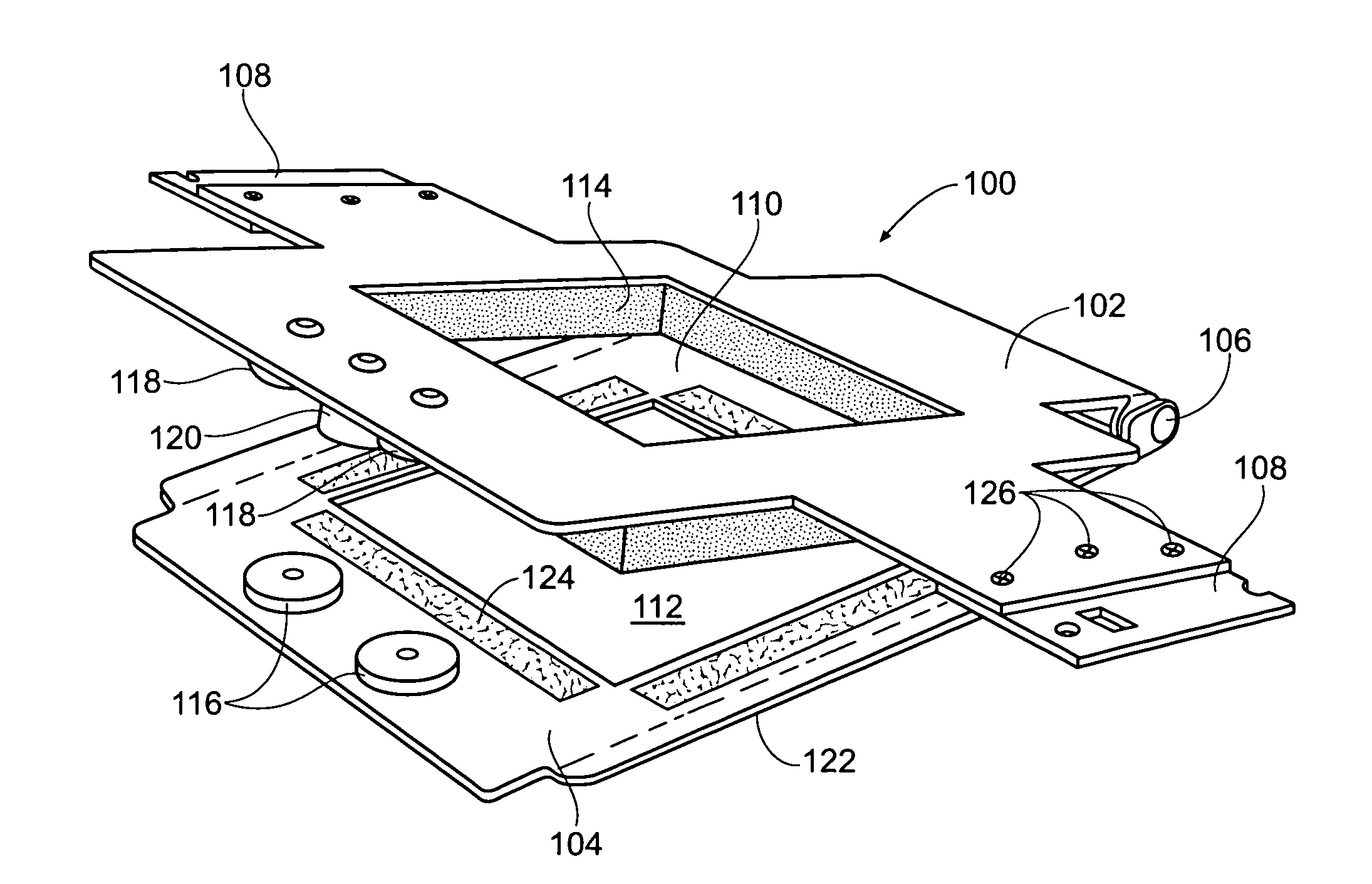

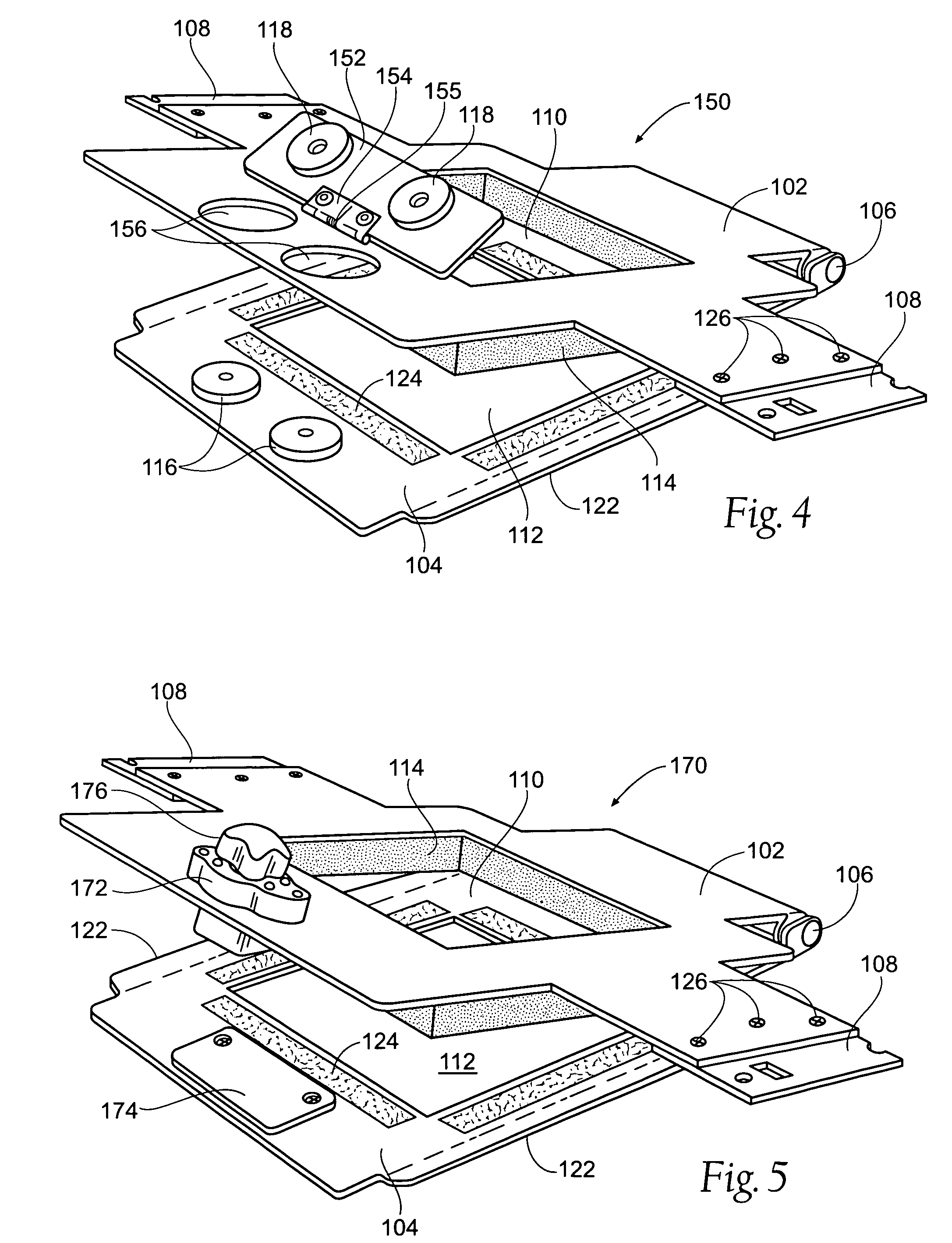

Magnetic fabric retaining device

ActiveUS20080276849A1Easy to apply to garmentEasy alignmentAutomatic machinesFeedersEngineeringRare-earth magnet

A device for use with an embroidery machine to hold an item or material to be embroidered between upper and lower hooping members, with the hooping members being secured to one another by use of a magnetic force, preferably with rare earth magnets, is disclosed. The magnets provide a solid, secure mating arrangement between the upper and lower hooping members without the need to adjust for different thicknesses of material. Compressible and / or frictional material may be attached to at least one hooping member to securely retain the item or material to be embroidered. One hooping member has interchangeable arms for attaching the mating hooping members to different brands of embroidery machines. One hooping member may also include a locating device for attaching the hooping members to a hooping device such as a hooping board.

Owner:MIDWEST PRODS

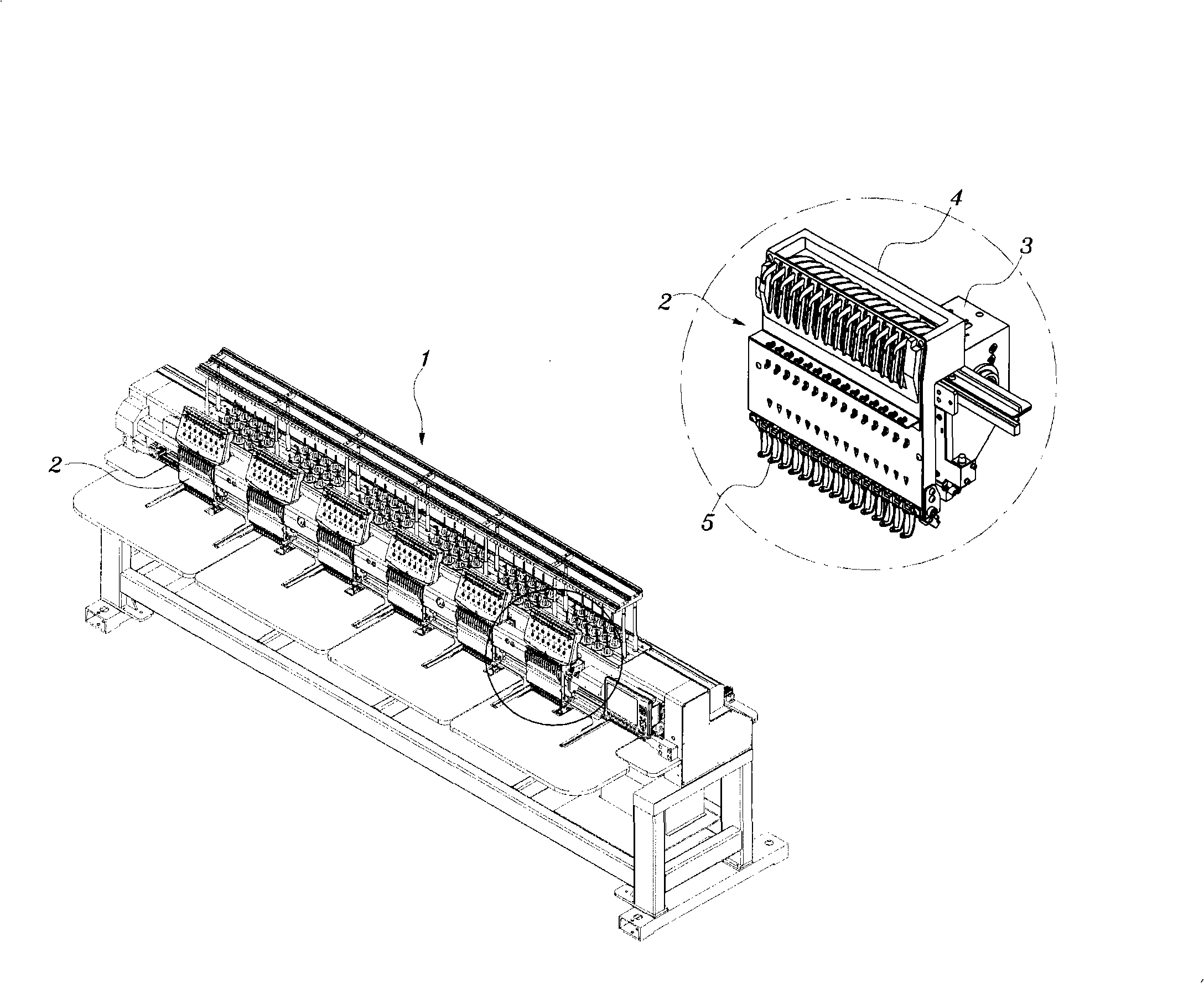

Embroidery machine

InactiveUS6925946B1Reduce manufacturing costEasy to produceCombination sewing machinesAutomatic machinesEngineeringMechanical engineering

An embroidery machine can simultaneously embroider sewing objects having various shapes, including a flat object, an object having a shape of a usual processed cloth, an object having a shape of a cap, etc. The embroidery machine comprises a plurality of sewing heads grouped into at least two working groups, and the embroidering frames, each of which is arranged for one of the working groups. The embroidering frames have structures either identical to each other or different from each other. Therefore, one conventional embroidery machine can simultaneously embroider more than one kind of sewing objects, including at least two of a flat sewing object, a tubular sewing object, and a cap-shaped sewing object.

Owner:SUSR PRECISION CO LTD

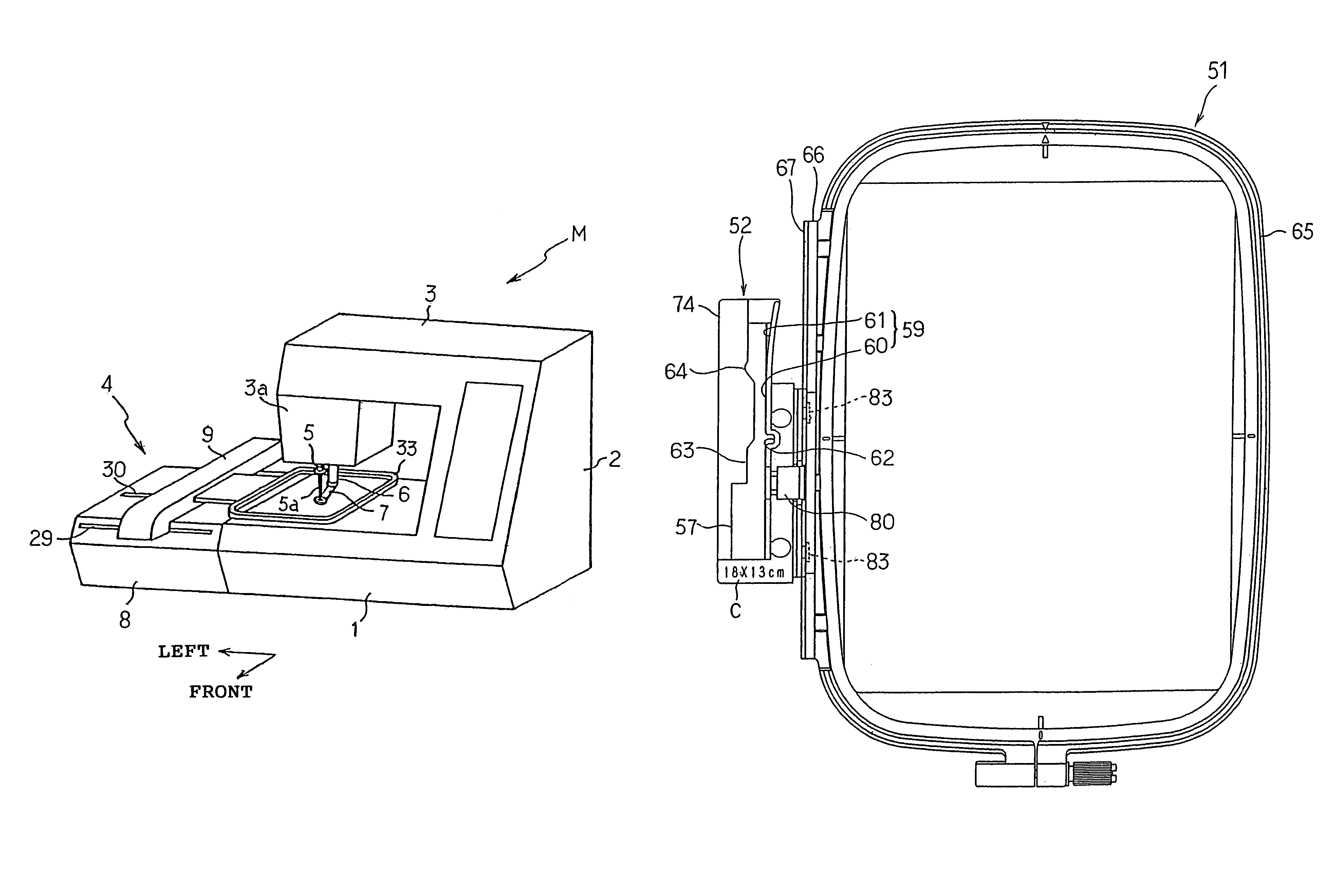

Embroidery frame transfer device and attachment

An attachment 52 comprises: a carriage connecting section 74 connected to a carriage 12 of an embroidery frame transfer device 4; and a metal fastener fixed to an attaching block 32 at the right-hand end portion of the carriage connecting section 74 and having a connecting section of a nonstandard embroidery frame 51 connected thereto. By connecting a connecting section 66 of the nonstandard embroidery frame 51 to the metal fastener 75 of the attachment 52 and by connecting the carriage connecting section 74 of the attachment 52 to the carriage 12, the nonstandard embroidery frame 51 can be mounted indirectly on the carriage 12. Thus, the nonstandard embroidery frame 51 of the type different in construction for attachment to the carriage 12 can be connected to the carriage 12.

Owner:BROTHER KOGYO KK

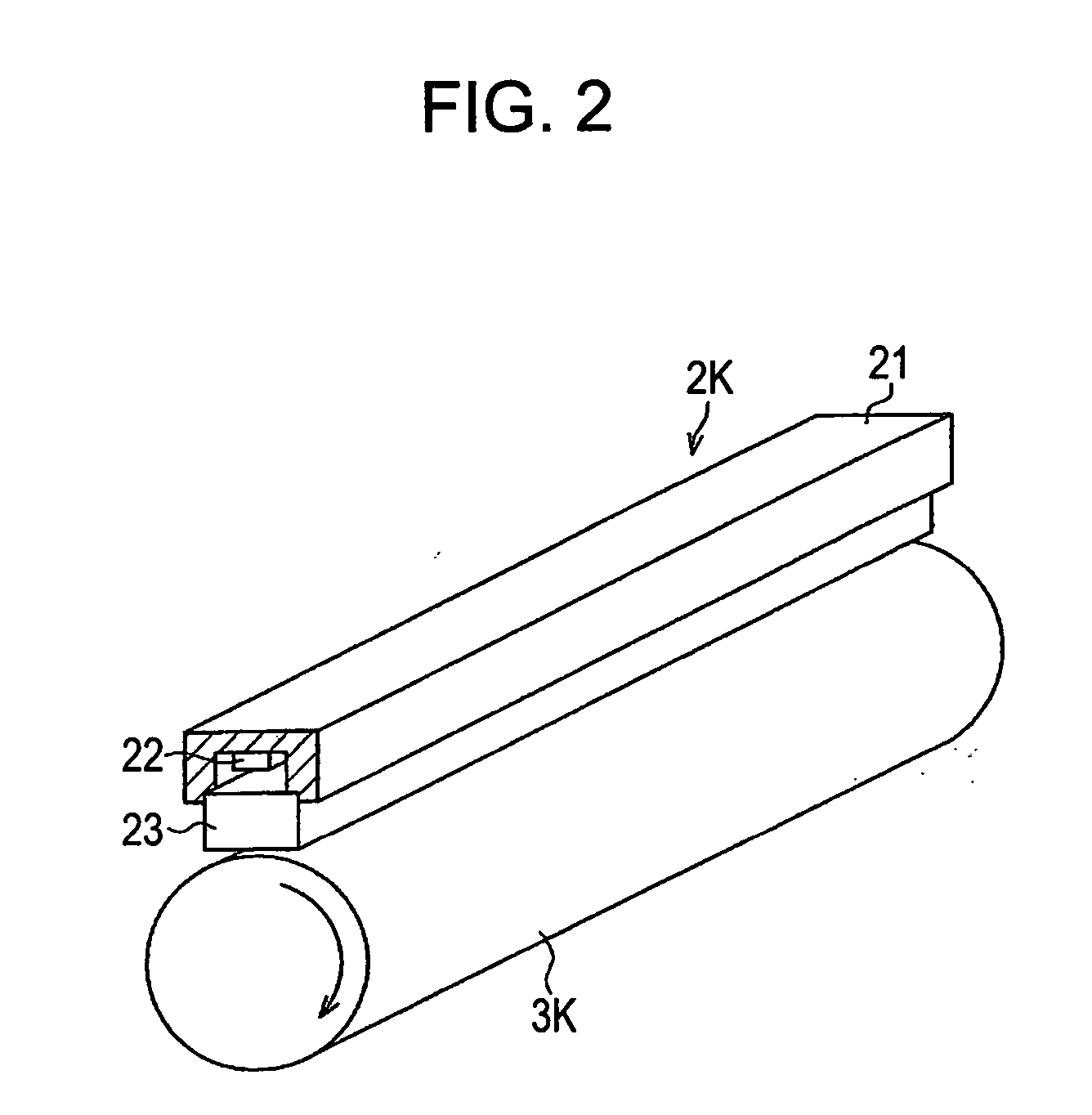

Cap frame and cap-frame setting frame

A cap frame of an embroidery sewing machine includes a ring-shaped cap frame body to be detachably coupled with a moving mechanism of the embroidery sewing machine, a cap supporting segment attached to the cap frame body having a curved frame shape in which the cap is set, a holding-down member for holding down the vicinity of the area to be embroidered of the cap onto the cap supporting segment, and a cap central reference area formed at a circumferential center of a front edge on a cap top side of the cap supporting segment, which is tactually recognizable in touch with it from the outside surface of the cap put on the cap supporting segment. The cap central reference area includes a recess formed by cutting a part of the front edge on the cap top side of the supporting segment.

Owner:BROTHER KOGYO KK

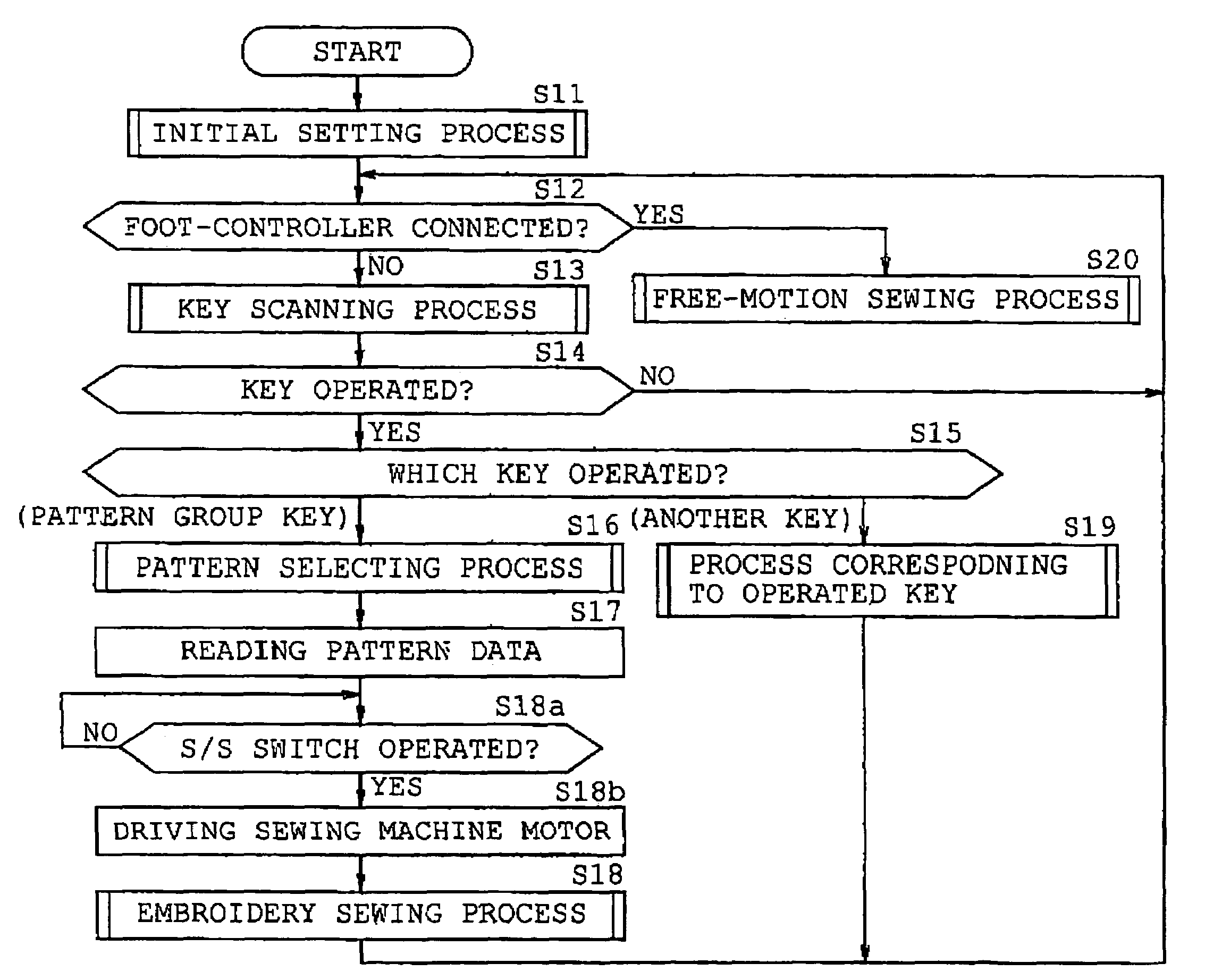

Embroidery sewing machine

ActiveUS7460925B2Programme-controlled sewing machinesDigital differential analysersEngineeringControl theory

An embroidery sewing machine includes an embroidery frame, a carriage transferring the embroidery frame, a drive unit moving the carriage, a sewing machine motor, a control unit controlling the drive unit and the motor so that an embroidery sewing mode is executed in which an embroidery pattern is sewn or a manual-feed sewing mode is executed in which a sewing operation is carried out with manual cloth feed while the carriage is moved to and held at a predetermined evacuative position, a foot controller, a connecting part connecting the foot controller to the control unit, and a mode switching unit which selectively switches between the embroidery sewing mode and the manual feed sewing mode. The mode switching unit switches to the embroidery sewing mode when the foot controller is non-connected to the connecting part, and to the manual-feed sewing mode when the foot controller is connected to the connecting part.

Owner:BROTHER KOGYO KK

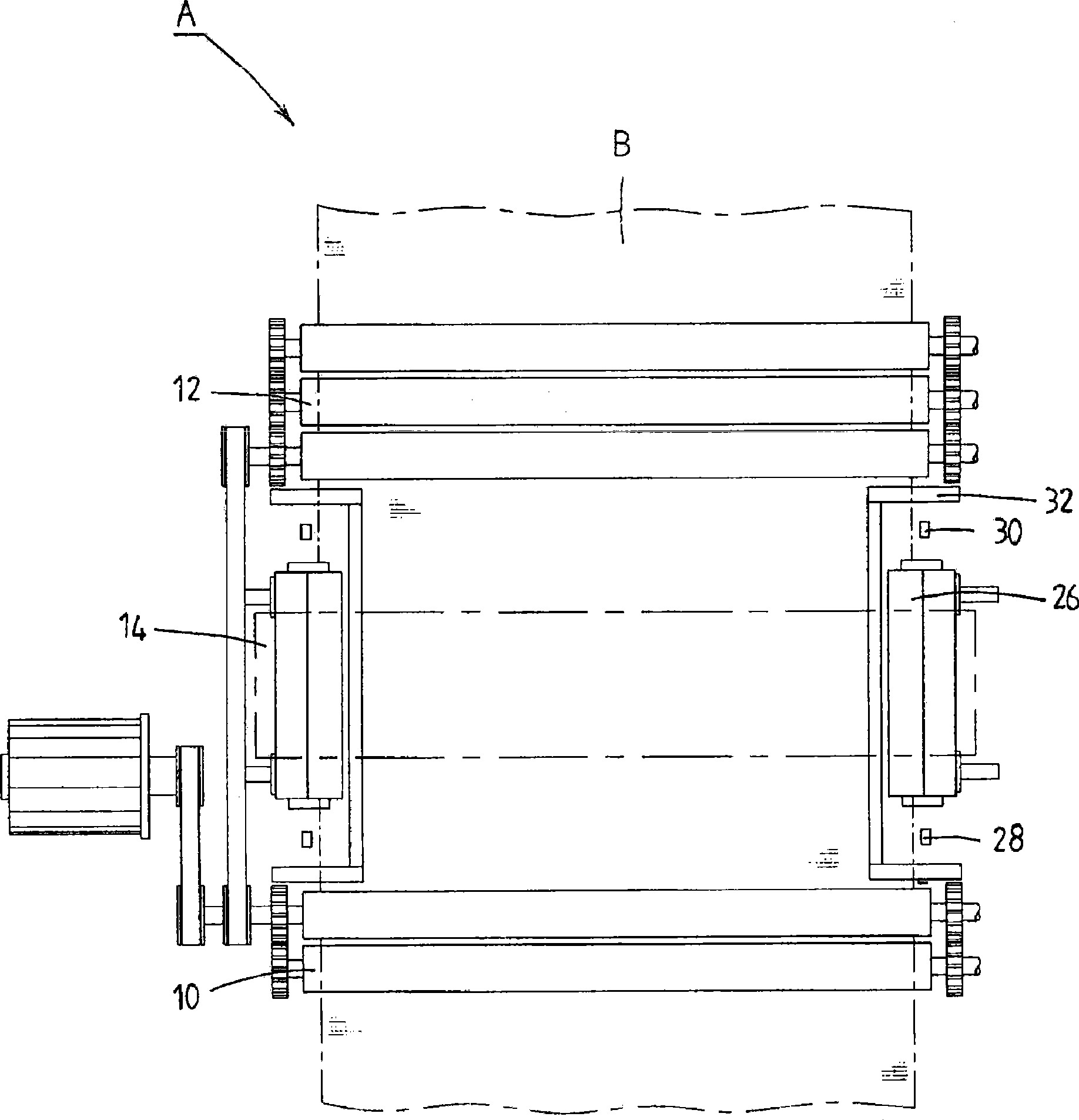

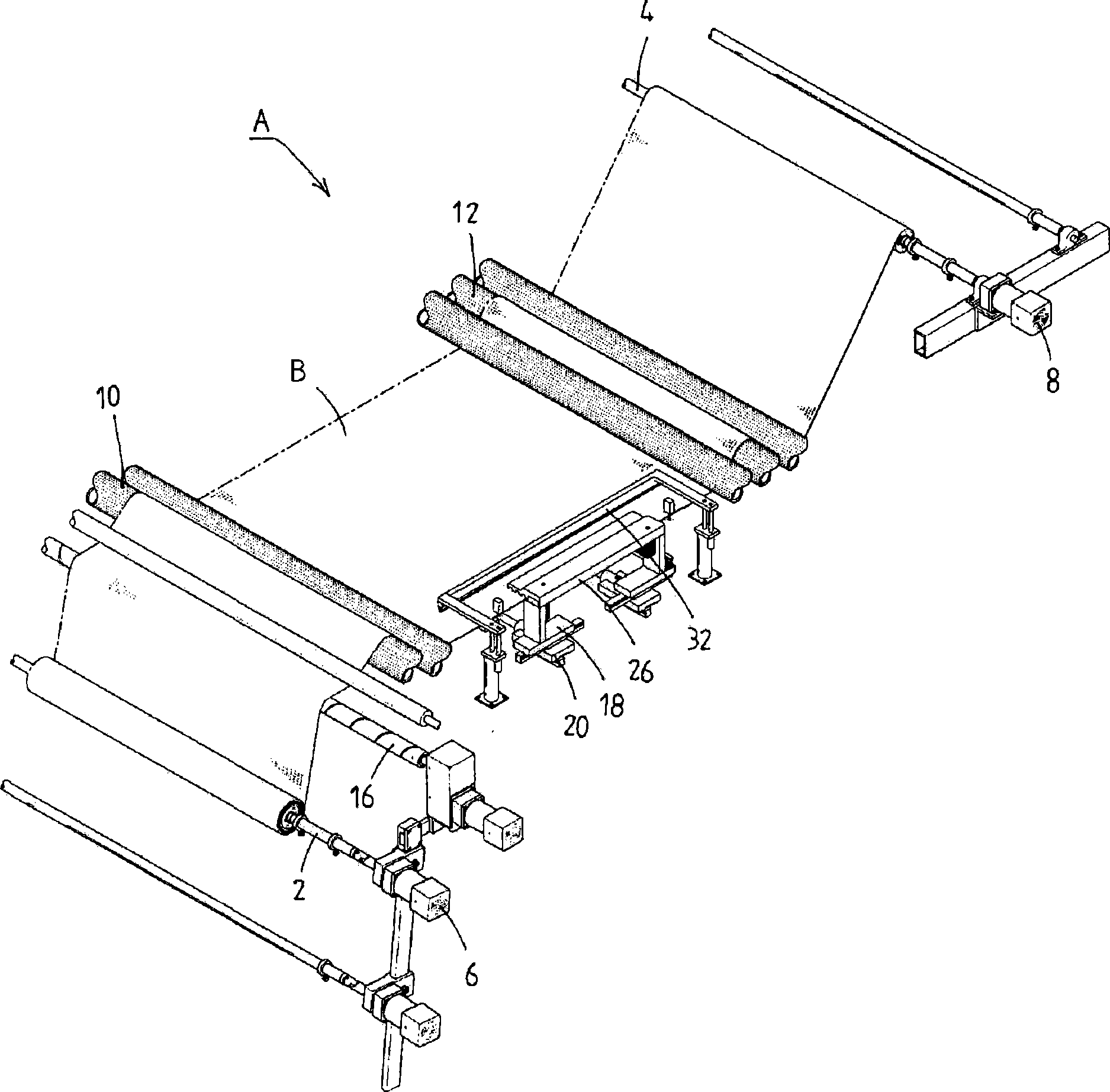

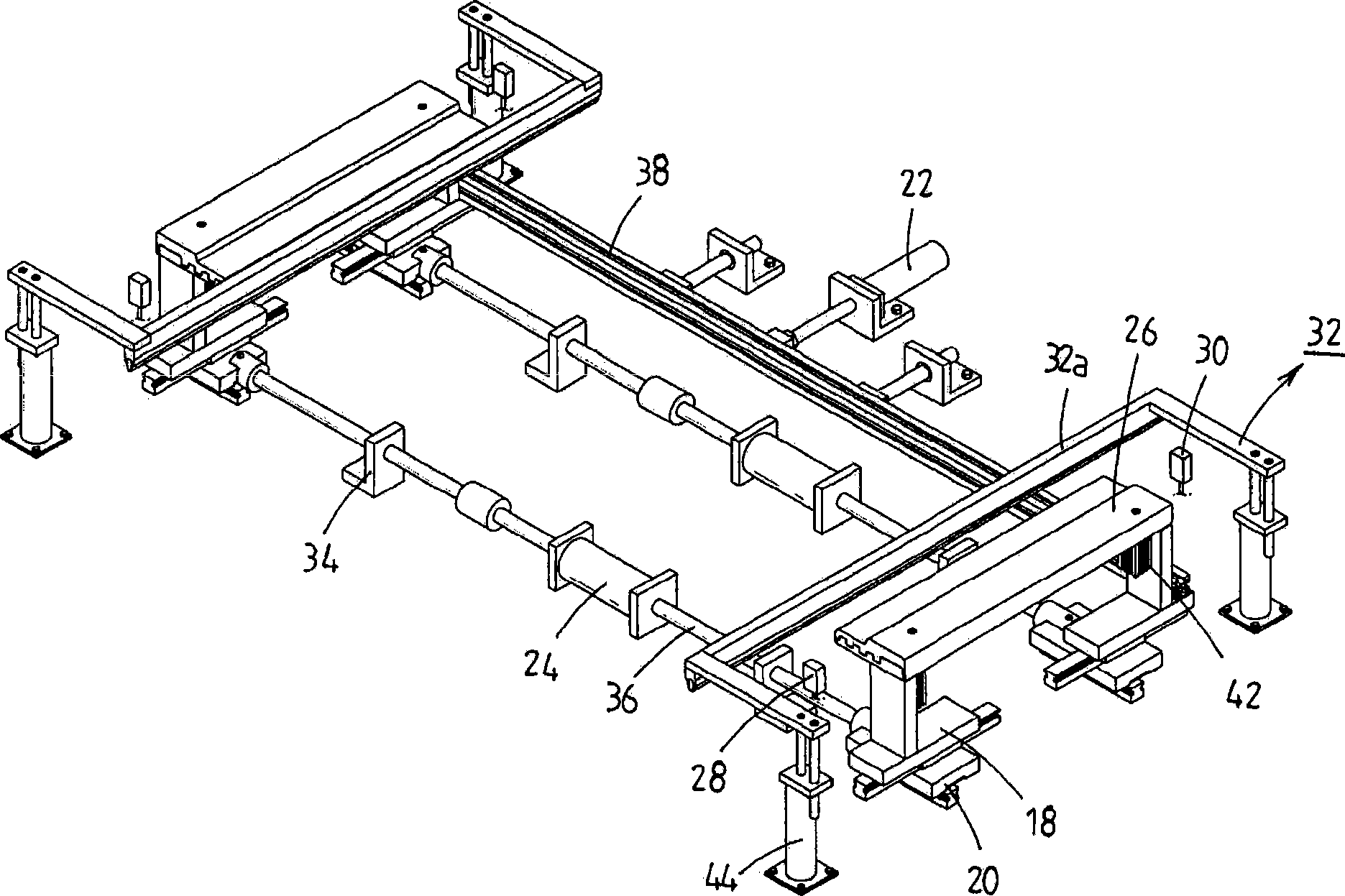

Cloth tensioning apparatus in embroidering machine

Disclosed is a cloth tensioning apparatus in an embroidering machine (A), which includes nipper units (26) to be moved forward and rearward and leftward and rightward by LM guides (18, 20), sensors (28, 30) for determining a forward and rearward movement distance of the nipper units (26), and pressure members (32) having pressure portions (32a) located inside the nipper units (26). Thereby, an embroidering operation is performed in a state wherein the nipper units (26) seize the cloth (B) while continuously applying a tension in an X-axis direction of the cloth (B). The embroidering operation is temporarily stopped if the nipper units (26) are deflected forward, and the nipper units (26) are returned in a state wherein the cloth (B) is tensioned by the pressure members (32). The nipper units (26) are again operated to seize the cloth (B) at their returned positions. As a result, a constant tension is continuously applied even in the X-axis direction of the cloth (B) during the embroidering operation.

Owner:金台基

Device for lifting presser foot of embroidering machine

Owner:SUSR PRECISION CO LTD

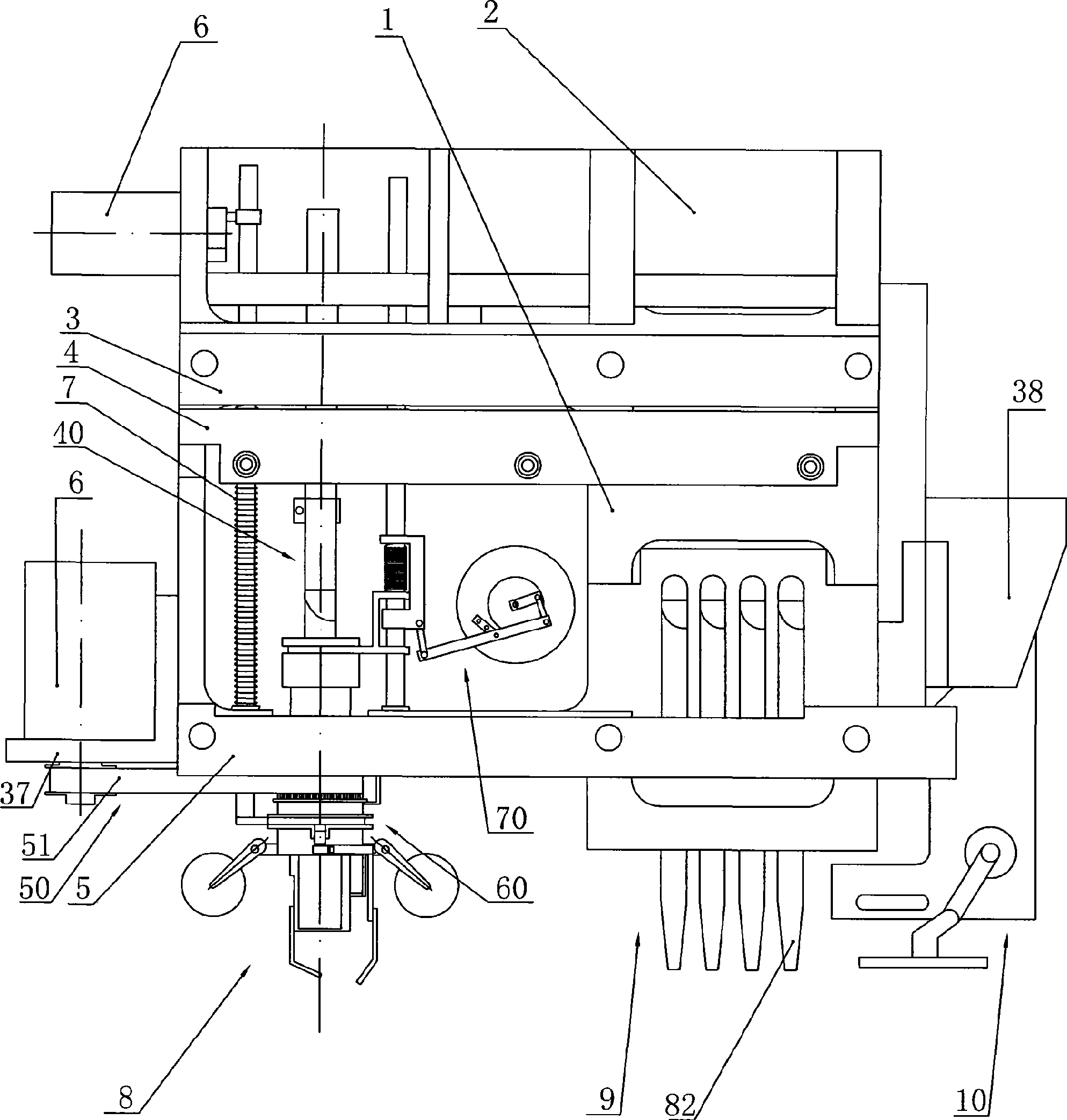

Main drive shaft sharing integrated embroidery machines

InactiveCN101397732AEasy to switchAchieve embroidery effectAutomatic machinesAuxillary devicesState of artDrive shaft

The invention relates to an all-in-one sharing embroidery machine that shares a main transmission shaft, integrates braid embroidery, flat embroidery and spangle embroidery and adopts the same transmission shaft for control, which solves the defects that the prior art needs a plurality of transmission shafts and has complicated structure and large size. The embroidery machine is mainly characterized in that a braid embroidery module, a flat embroidery module and a spangle embroidery module are fixed on an overall frame, arranged on a chassis by a back transmission seat and connected with the main transmission shaft so as to share the same main transmission shaft; the overall frame is divided into a braid embroidery module frame and a flat embroidery module frame; the braid embroidery module comprises a strip rotating mechanism, a braid wobbler mechanism, a presser foot height controlling mechanism and a pricker stretching and drawing control mechanism; each mechanism is provided with an independent driving device, integrated as a whole and connected by the transmission seat, thereby sharing the same main transmission shaft, having simple structure and conveniently reducing size and switching between embroidery methods of various characteristics.

Owner:浙江科宇缝制设备制造有限公司

Magnetic fabric retaining device

ActiveUS7966957B2Efficient use ofPrecise alignmentAutomatic machinesFeedersEngineeringRare-earth magnet

A device for use with an embroidery machine to hold an item or material to be embroidered between upper and lower hooping members, with the hooping members being secured to one another by use of a magnetic force, preferably with rare earth magnets, is disclosed. The magnets provide a solid, secure mating arrangement between the upper and lower hooping members without the need to adjust for different thicknesses of material. Compressible and / or frictional material may be attached to at least one hooping member to securely retain the item or material to be embroidered. One hooping member has interchangeable arms for attaching the mating hooping members to different brands of embroidery machines. One hooping member may also include a locating device for attaching the hooping members to a hooping device such as a hooping board.

Owner:MIDWEST PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com