Sewing machine having a camera for forming images of a sewing area

a sewing machine and camera technology, applied in the field of sewing machines, can solve the problems of no method and adherent devices, cannot, of course, be used on fabrics, and may be difficult to place embroidery or seams in question in such a desired position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

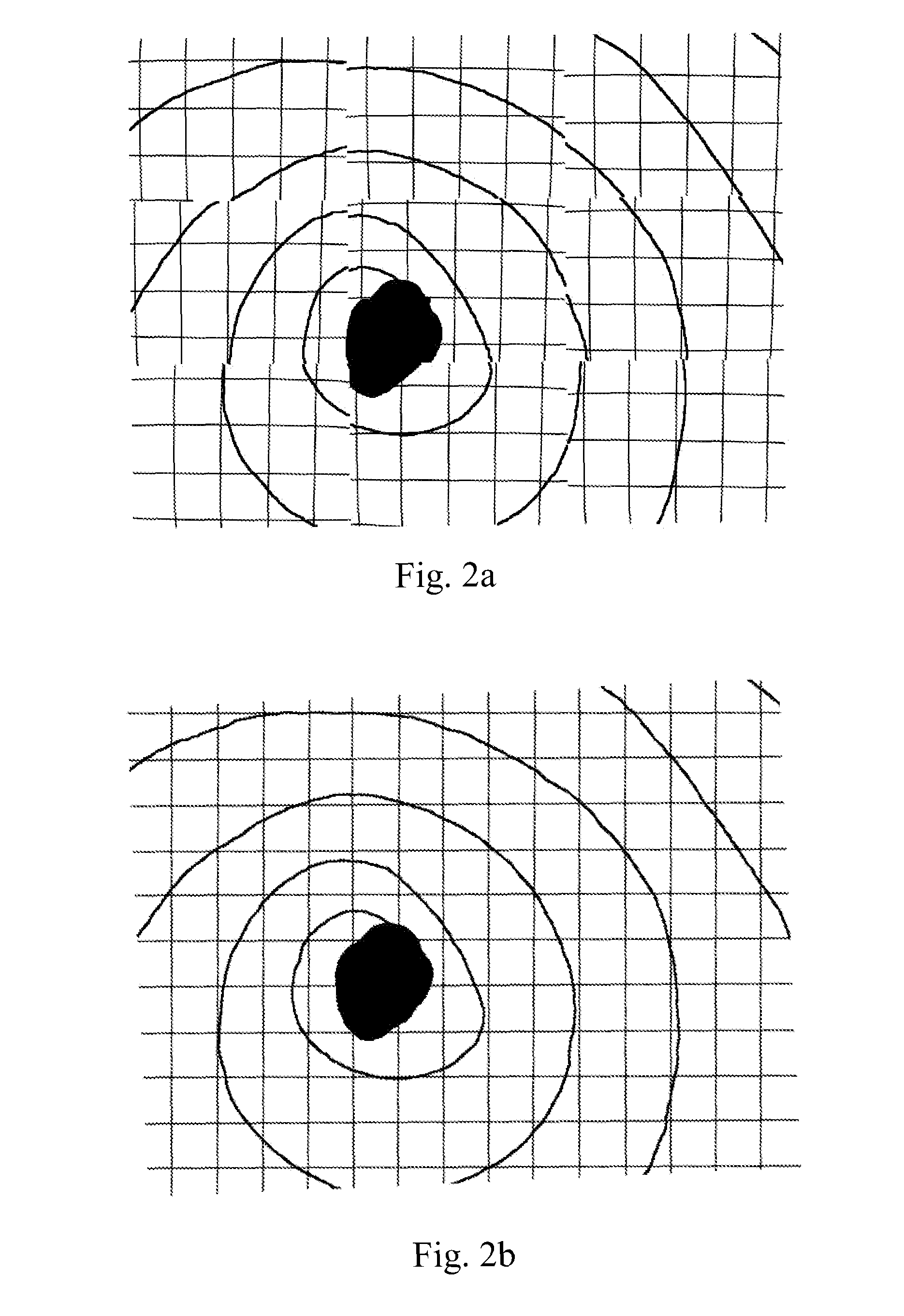

[0008]It is an object of the present invention to present a method and a device for providing in a sewing machine an image of a sewing area of a fabric, wherein the coordinates of the image refer to corresponding coordinates of the sewing area.

[0009]It is a further object of the present invention to suggest a method and a device for coordinating predetermined positions in a simple manner, for example positions for seams or embroidery elements on a fabric, with corresponding positions stored in an electronic memory for display on a screen.

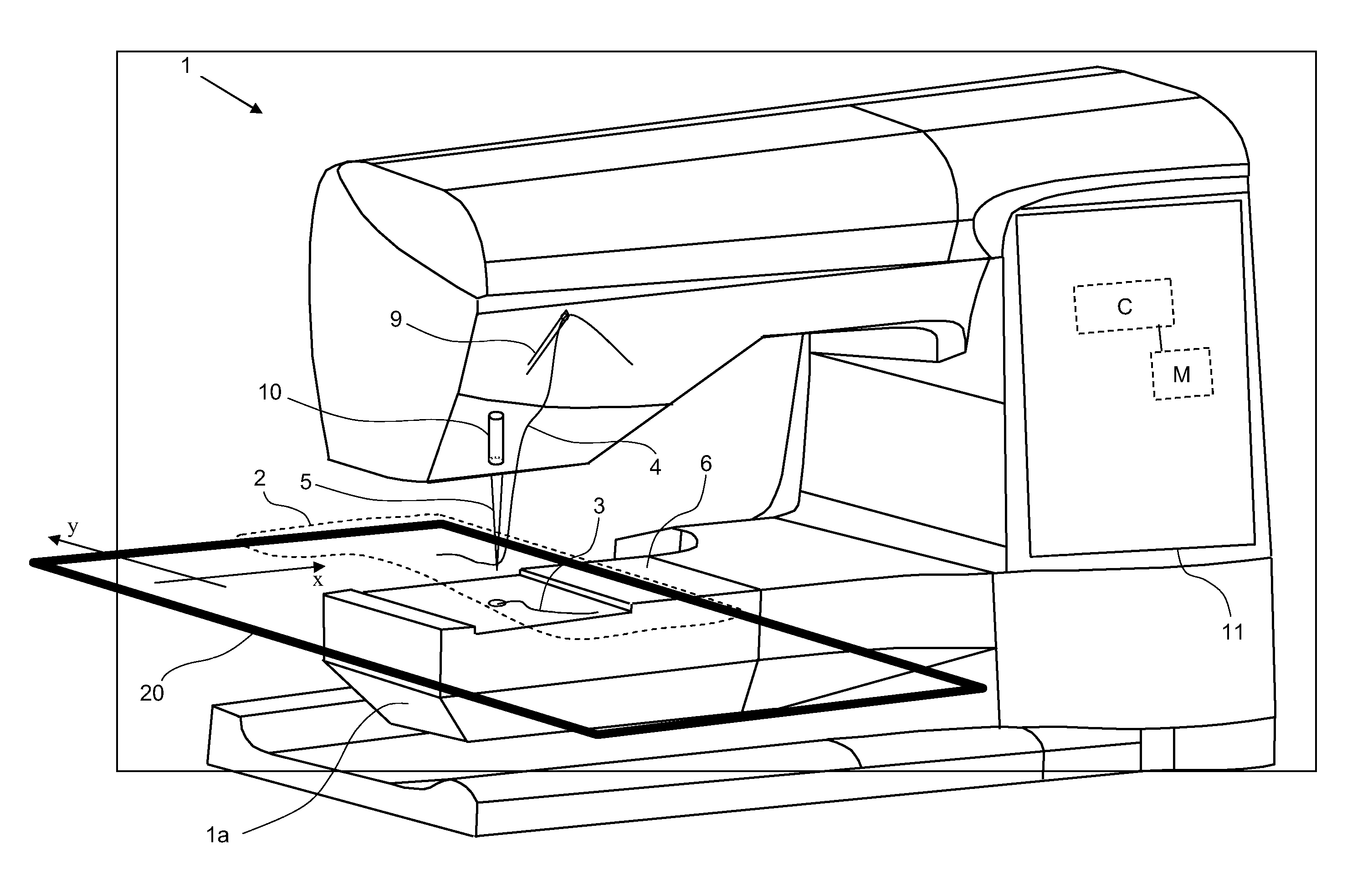

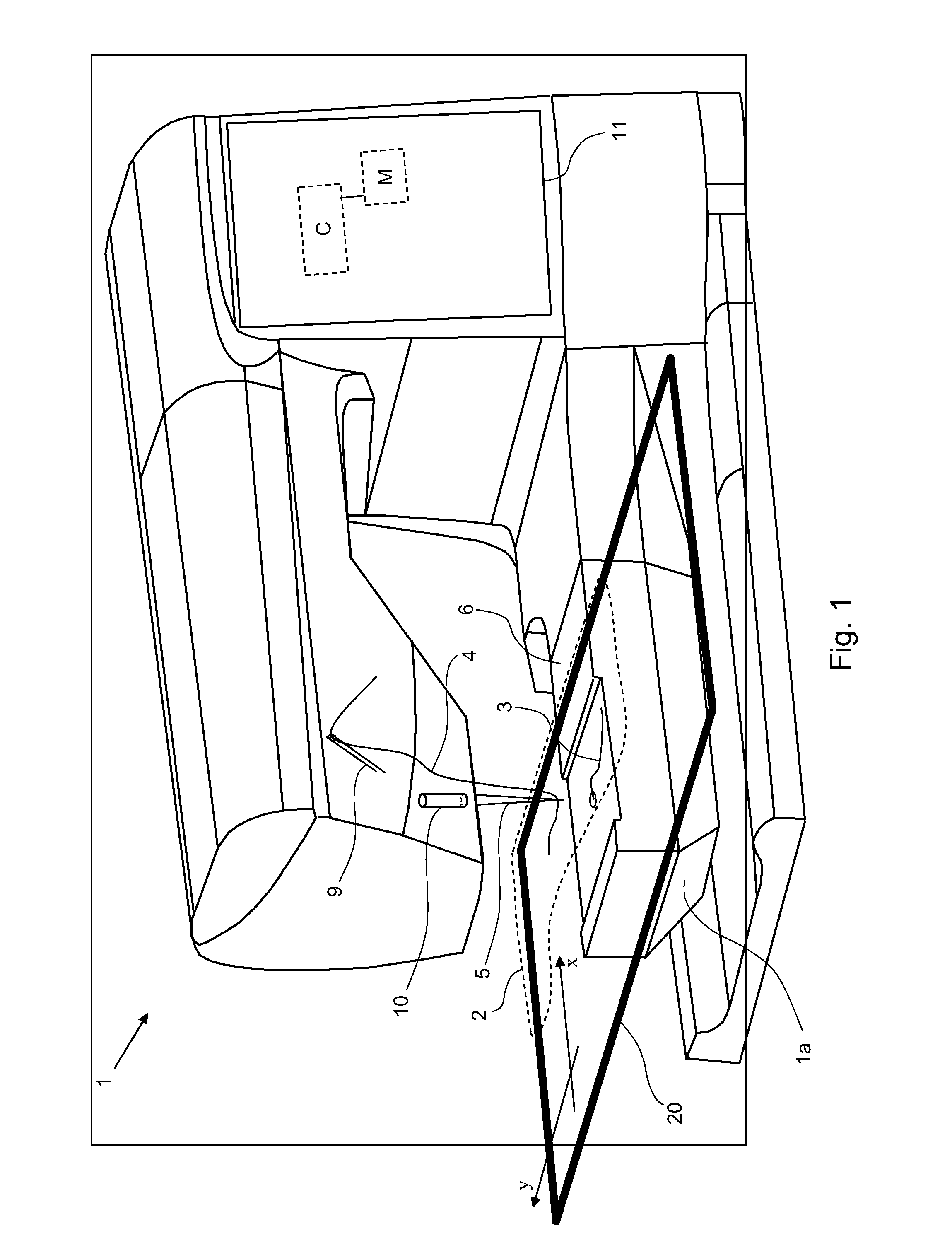

[0010]According to the objects of the invention there is provided a sewing machine with a vision system, which consists of a normal embroidery machine with a small built-in camera that is used for different purposes simplifying and enhancing the sewing. The camera is as small as possible, built-in, e.g., to an extent where it is barely noticeable.

[0011]According to one aspect of the invention, a method is presented which has the characteristic featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com