Patents

Literature

260results about "Hand embroidering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

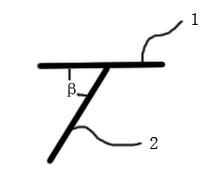

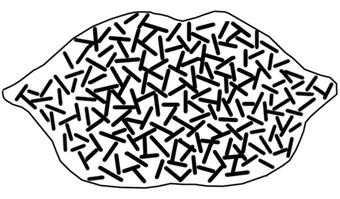

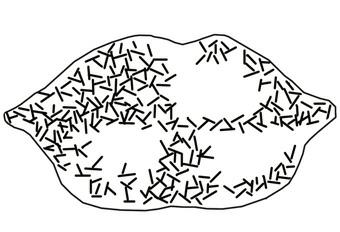

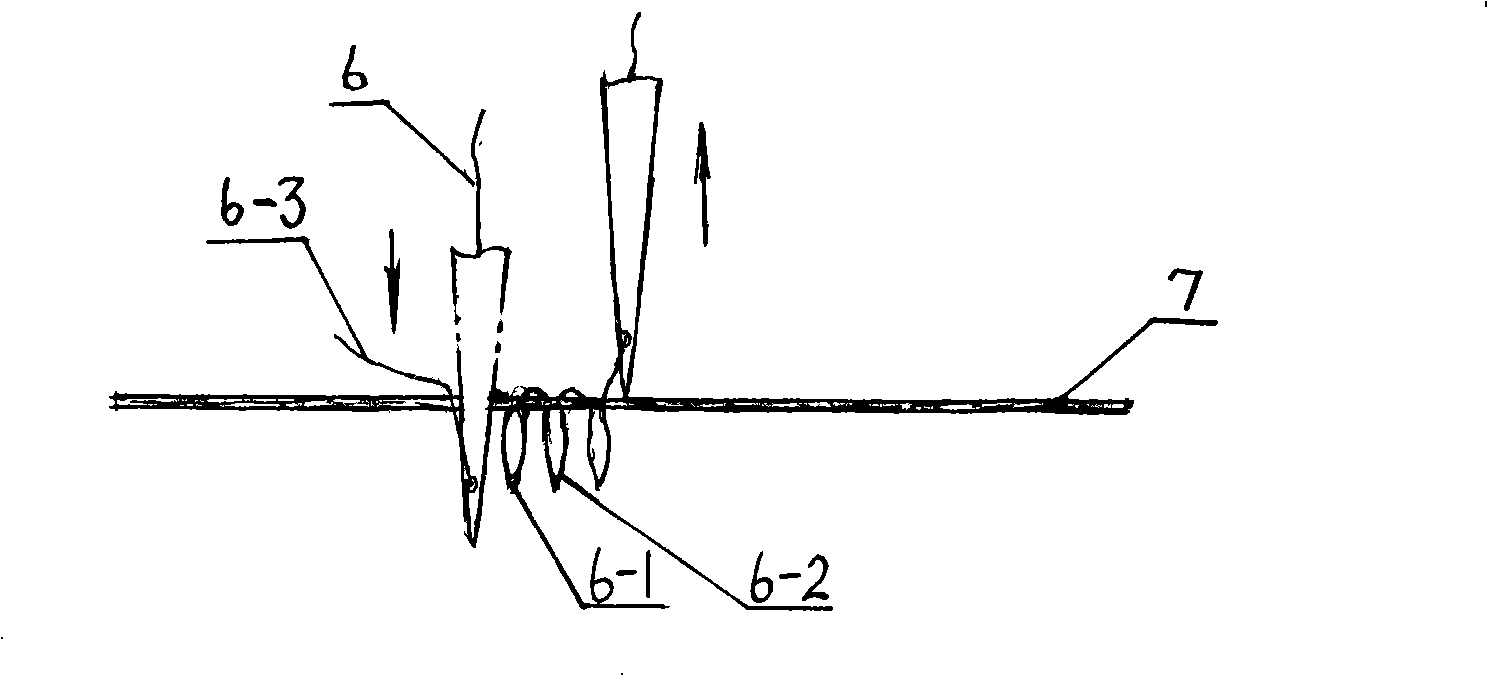

Light-free T-shaped stitch for embroidery and embroidering method

ActiveCN102182023APreserve the characteristics of line lightThere will be no color deviationEmbroidering machines apparatusHand embroideringBiomedical engineeringTextile

The invention discloses a light-free T-shaped stitch for embroidery and an embroidering method. At least three layers of embroidering stitches are embroidered from top to bottom on the front face of an embroidered cloth through an embroidering needle and an embroidering thread, wherein each layer of embroidering stitches is formed by adjacently arranging a group of T-shaped embroidering stitch units with stitches having approximately the same length on the front face of the embroidered cloth; when any T-shaped embroidering stitch unit serves as a standard, the tightly adjacent T-shaped embroidering stitch units around the T-shaped embroidering stitch unit are arranged at angles; the lengths of needle feet of the T-shaped embroidering stitch units in each layer of embroidering stitches aregradually reduced from top to bottom; the stitch of the T-shaped embroidering stitch units consists of first needle feet and second needle feet; the first needle feet and the second needle feet are arranged in a shape of 'T' on the front face of the embroidered cloth; an included angle between the first needle feet and the second needle feet is in a range of between 60 and 90 degrees in the shapeof 'T'; and the ratio of the length of the first needle feet to the length of the second needle feet is in a range of between 1:0.7 and 1:1.3. The problem that faces and limbs of characters reflect light because of inherent thread light and thread textures of silk threads is solved through the T-shaped stitch and the embroidering method, so breakthrough and innovation are made in Suzhou (a province in China) embroidery in the embroidering method for portraits.

Owner:顾金珍

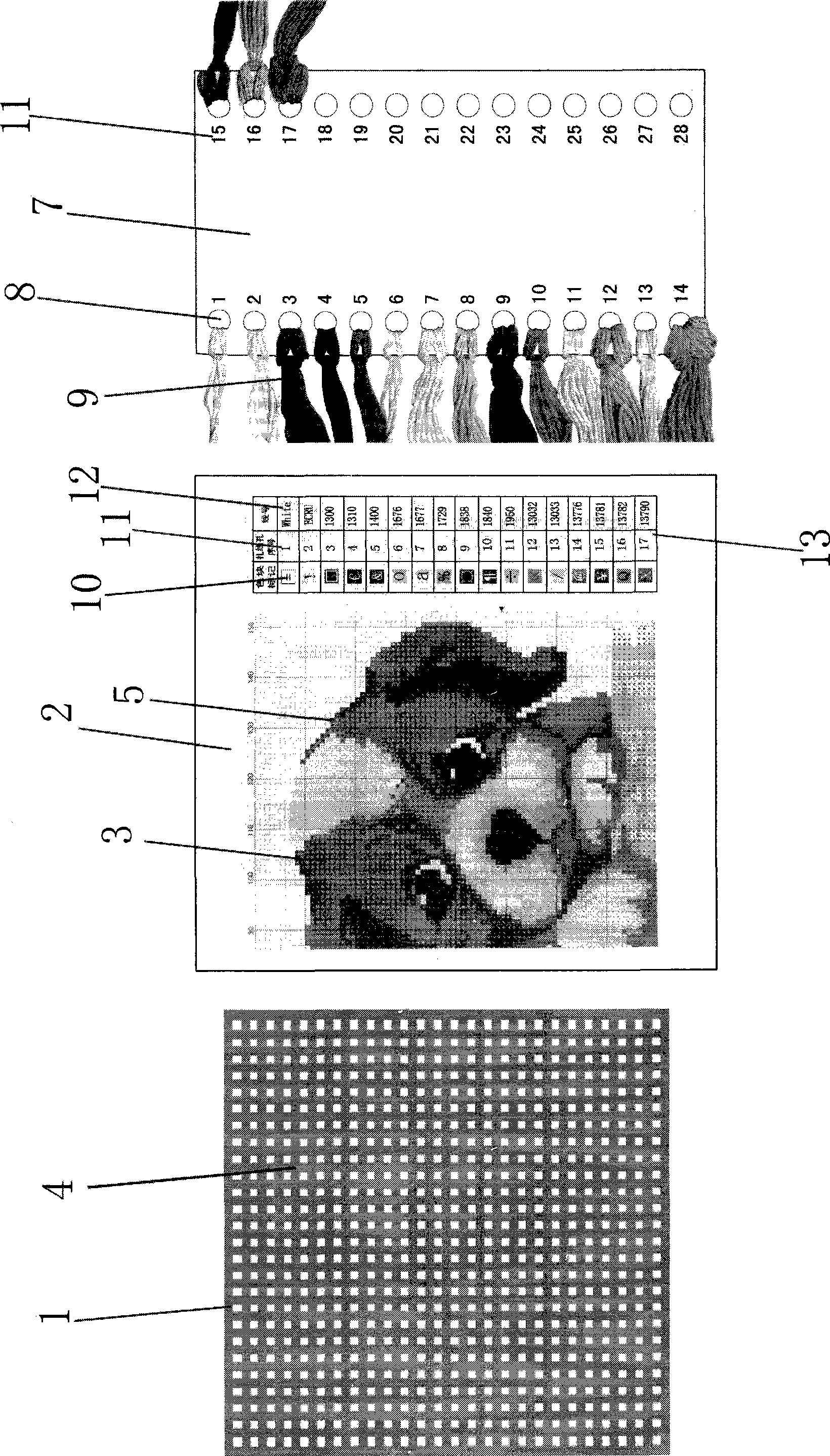

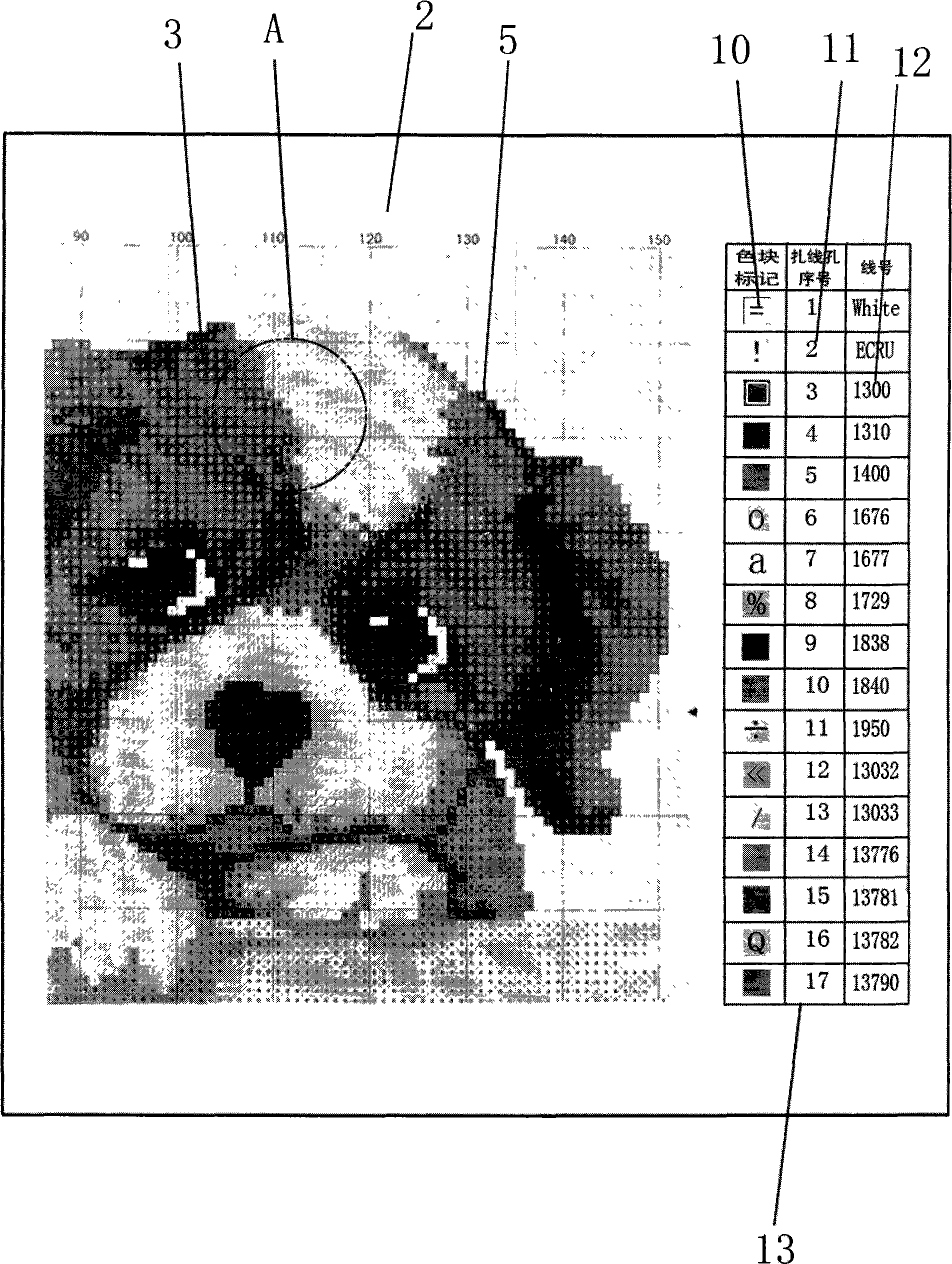

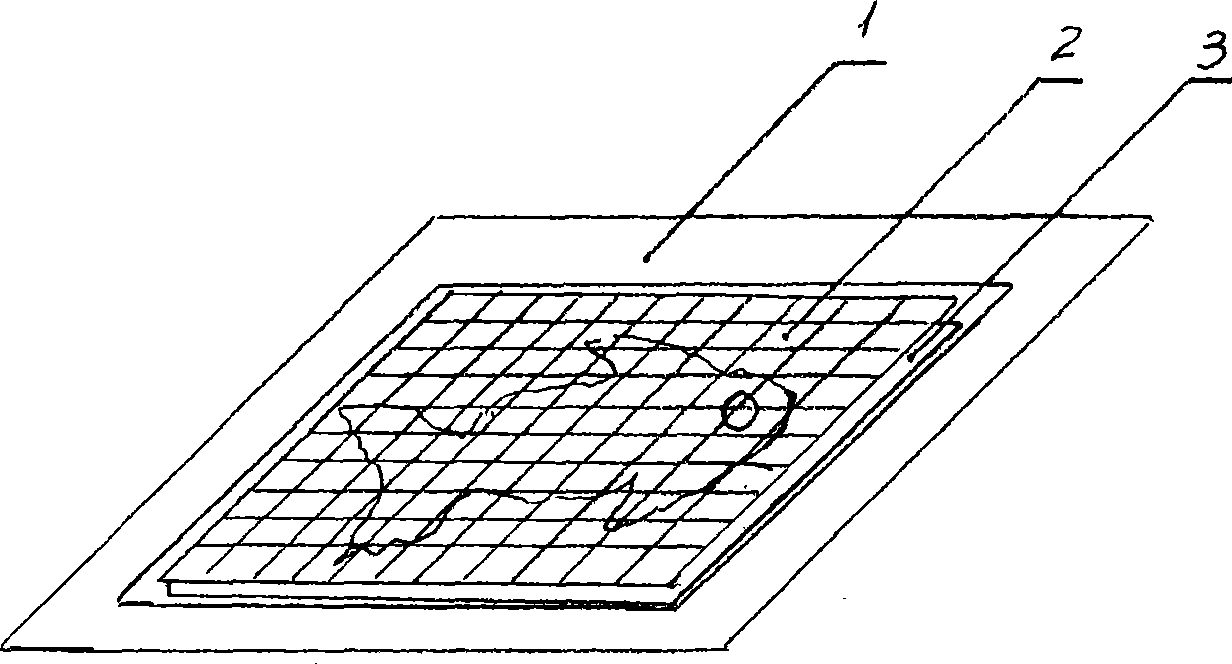

Handwork cross-stitch embroidery set and handwork cross-stitch embroidery method

InactiveCN101476216AEasy alignmentImprove Embroidery EfficiencyHand embroideringComputer scienceMesh grid

The invention relates to a group of handwork cross-stitch parts and a handwork cross-stitch method, belonging to the cross-stitch technique field. the parts comprises a net cloth and a design drawing; The invention is characterized in that: the design drawing consists of the color blocks with similar shapes or sizes with the grids of the grid cloth; marks of a same color is filled in each color block; a thread binding with thread binding holes is also included, each hole of which has a bundle of thread in the same color with a color block on the design drawing; and the thread is night luminous. The method comprises: contrasting the color block on the design drawing, the color block mark on the thread binding board or design drawing, the thread binding hole sequence number or identification number on the thread binding board and the thread number table of the bound thread; taking the corresponding thread from the thread binding hole and performing the cross-stitch. The invention can make the handwork cross-stitch more easy and convenient, and can increase the efficiency of the handwork cross-stitch greatly; in addition, it can make the product luminescence at night, and enable people to appreciate the product without light.

Owner:楼英君

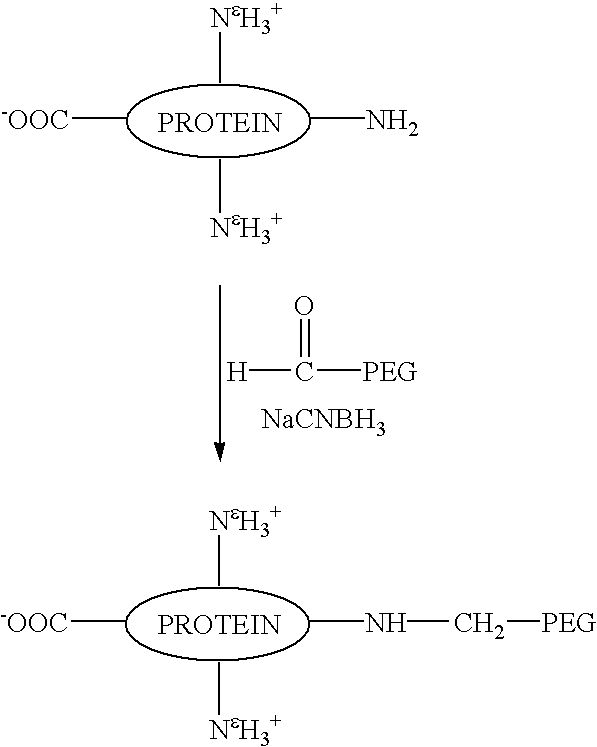

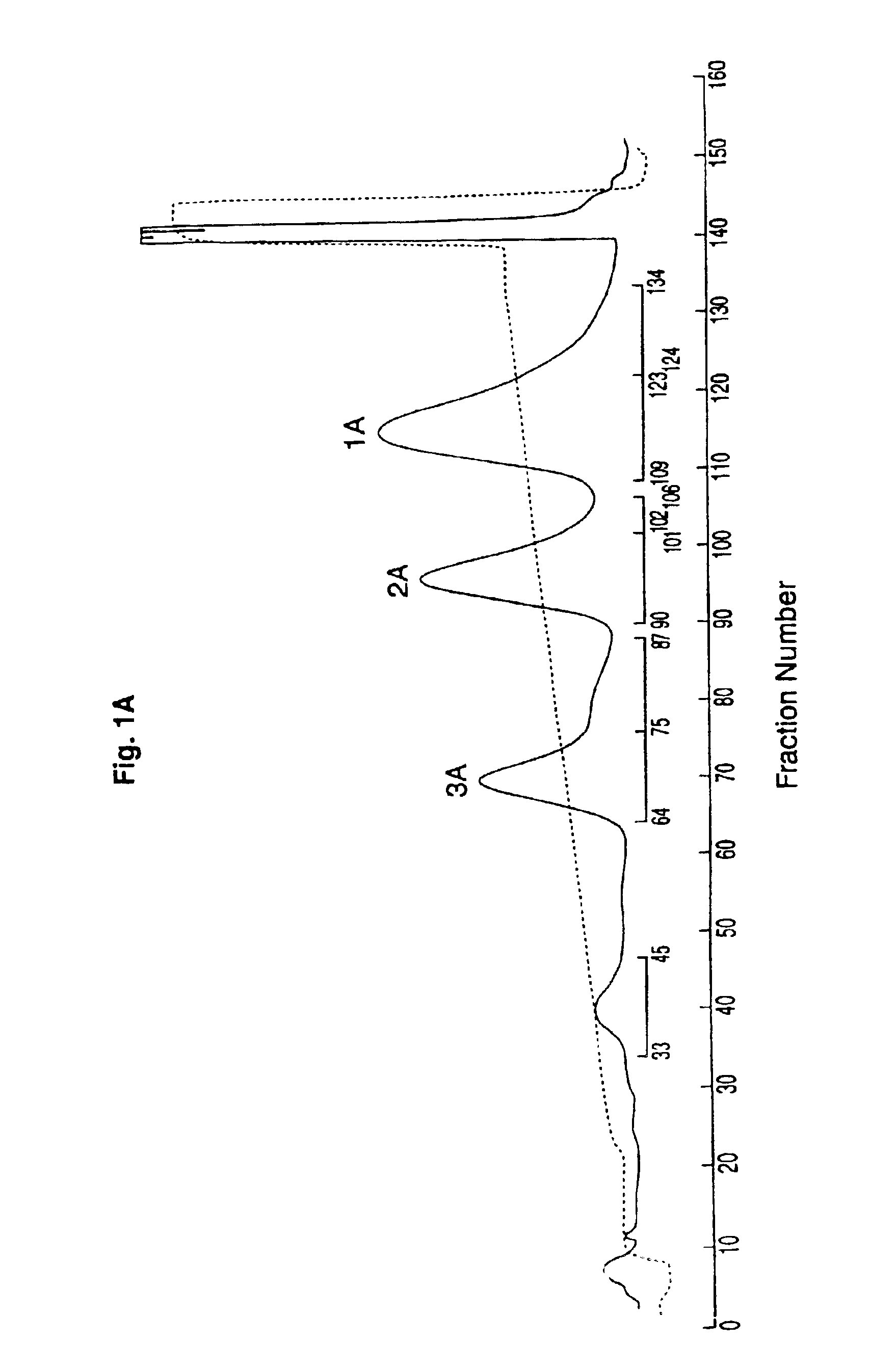

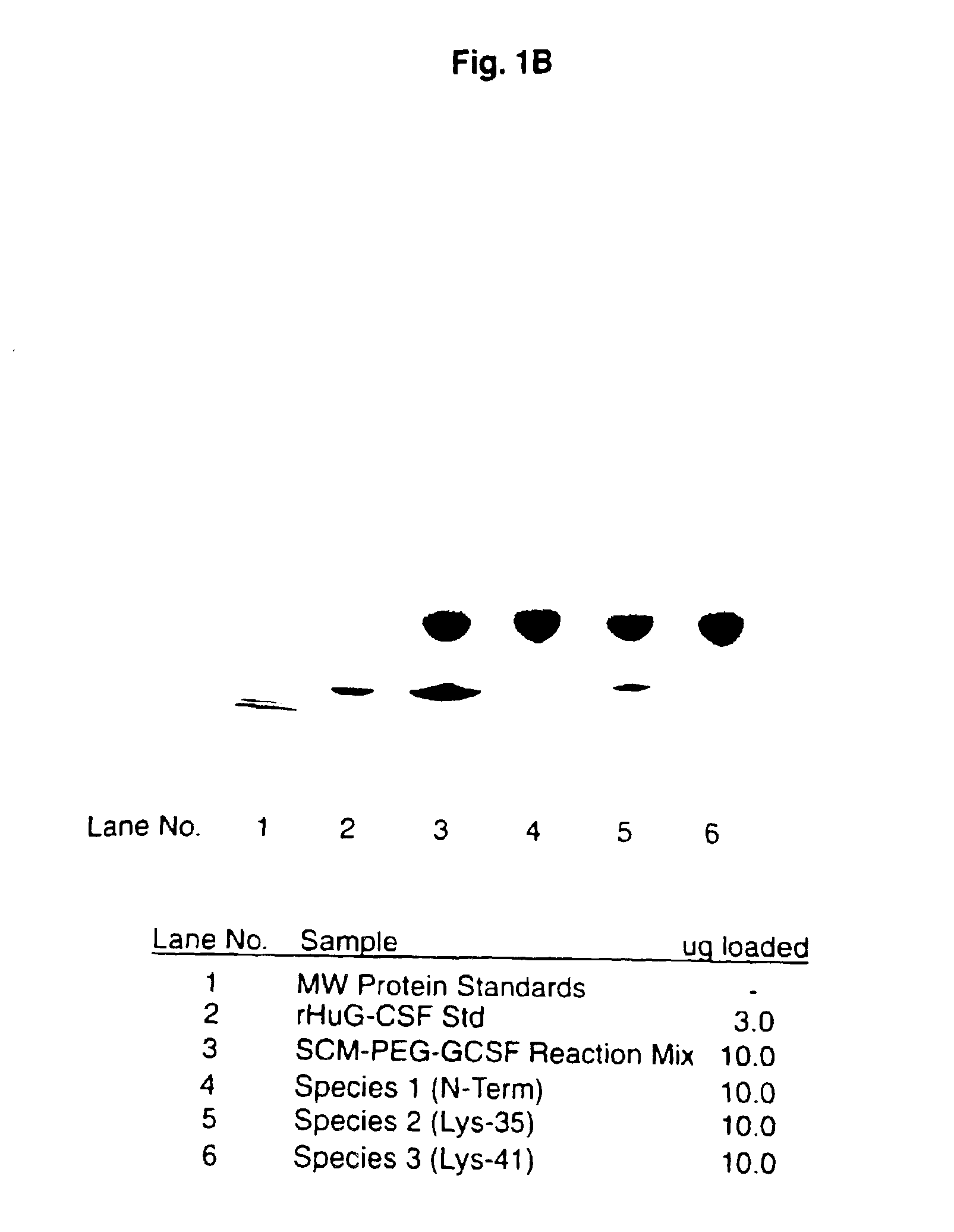

N-terminally chemically modified protein compositions and methods

InactiveUS6956027B2High proportionOrganic active ingredientsPeptide/protein ingredientsProtein compositionWater soluble

Provided herein are methods and compositions relating to the attachment of water soluble polymers to proteins. Provided are novel methods for N-terminally modifying proteins or analogs thereof, and resultant compositions, including novel chemically modified G-CSF compositions and related methods of preparation.

Owner:AMGEN INC

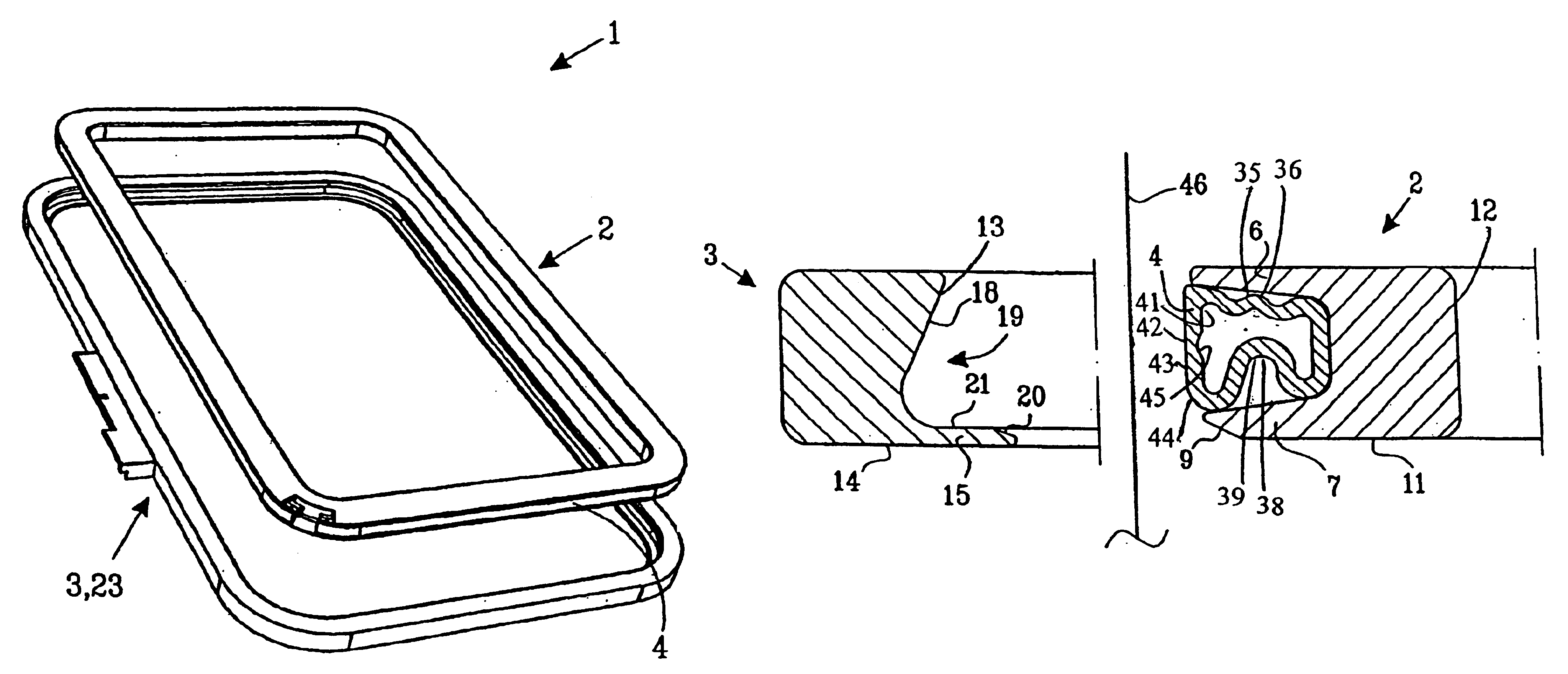

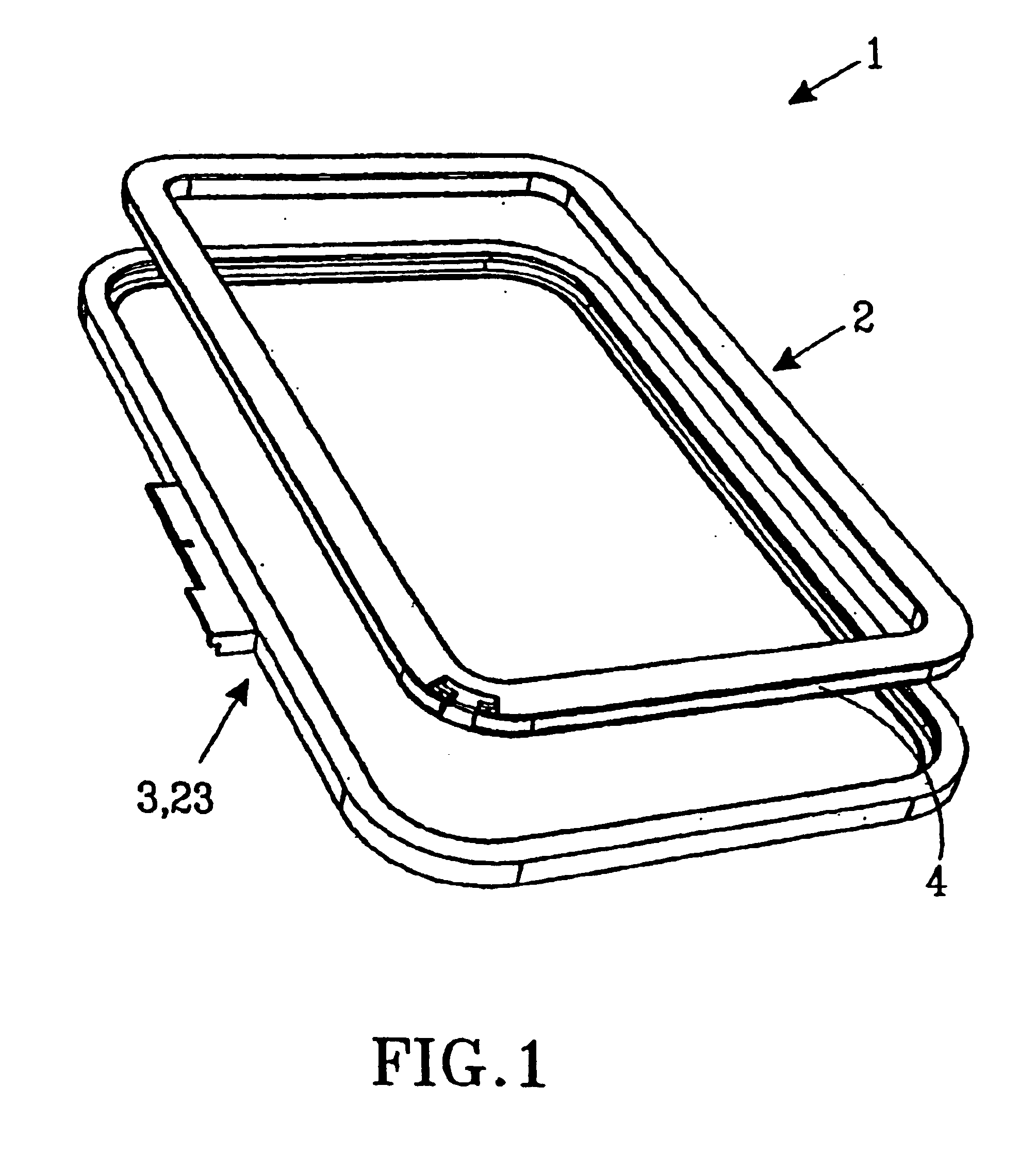

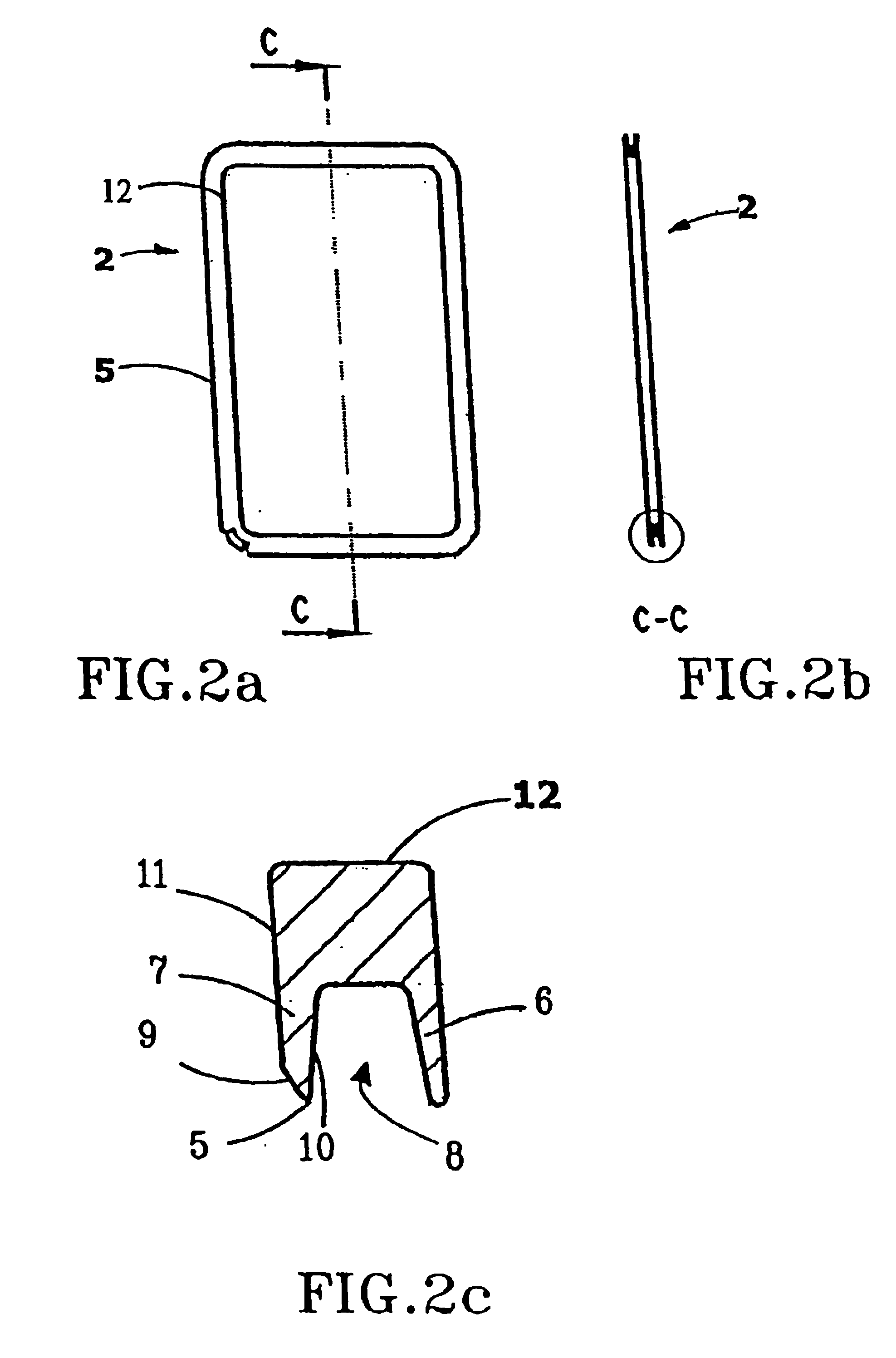

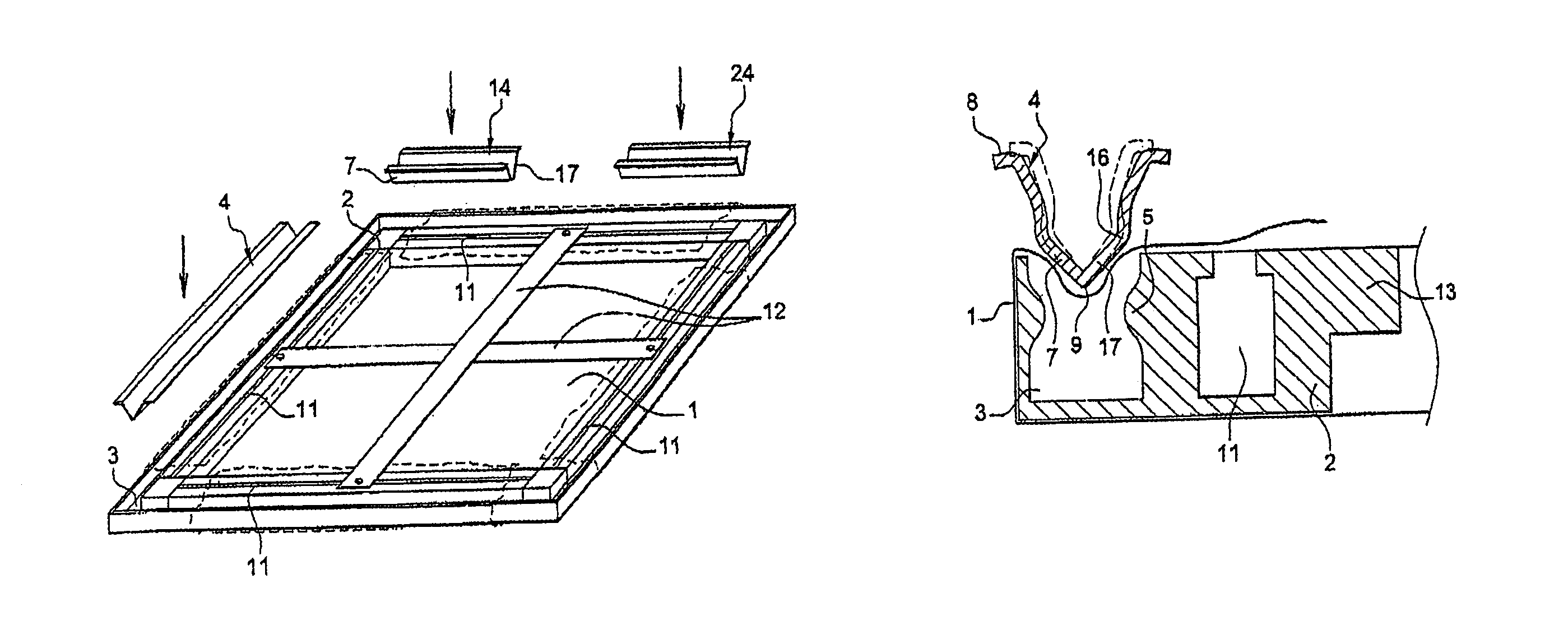

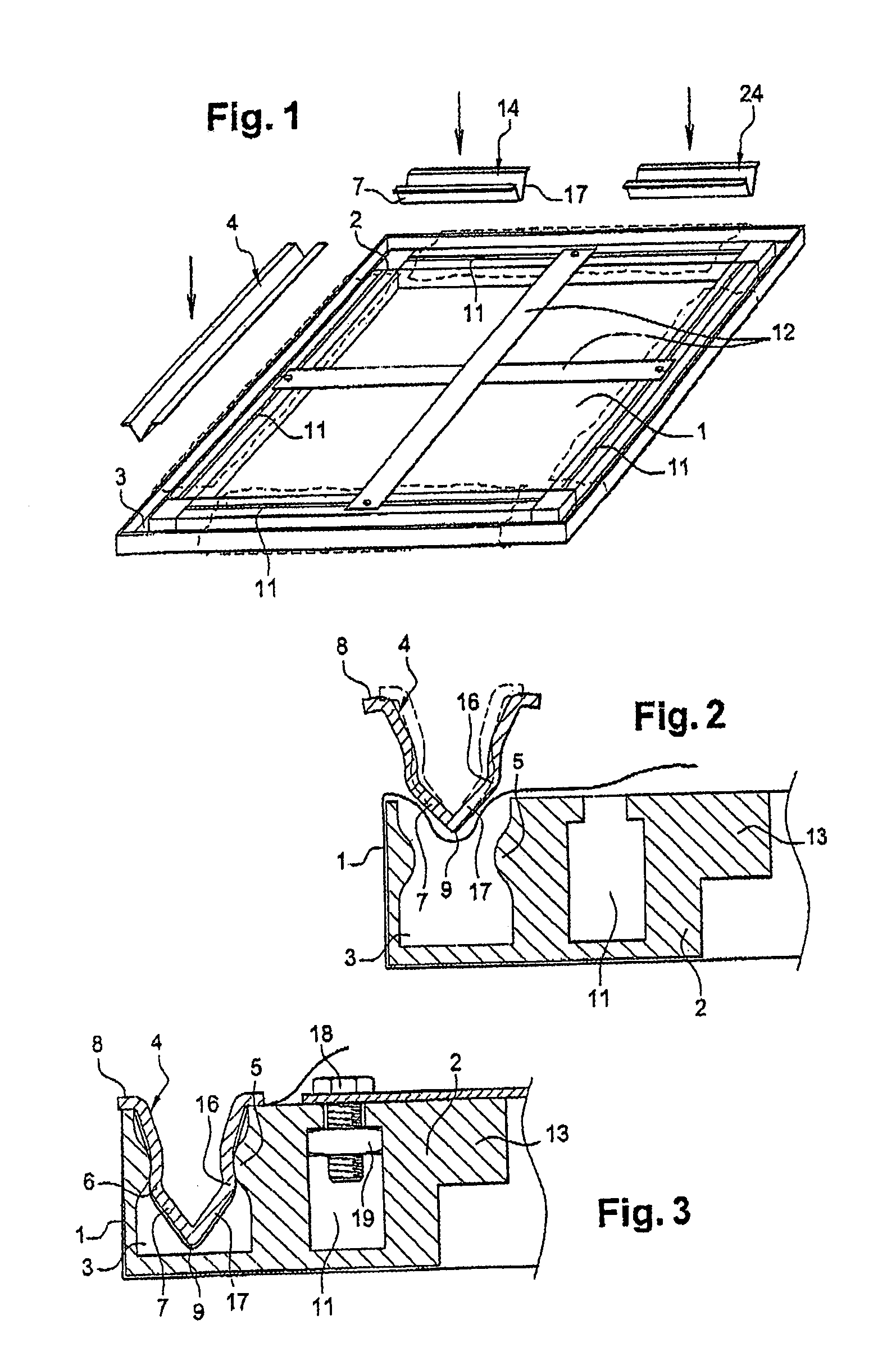

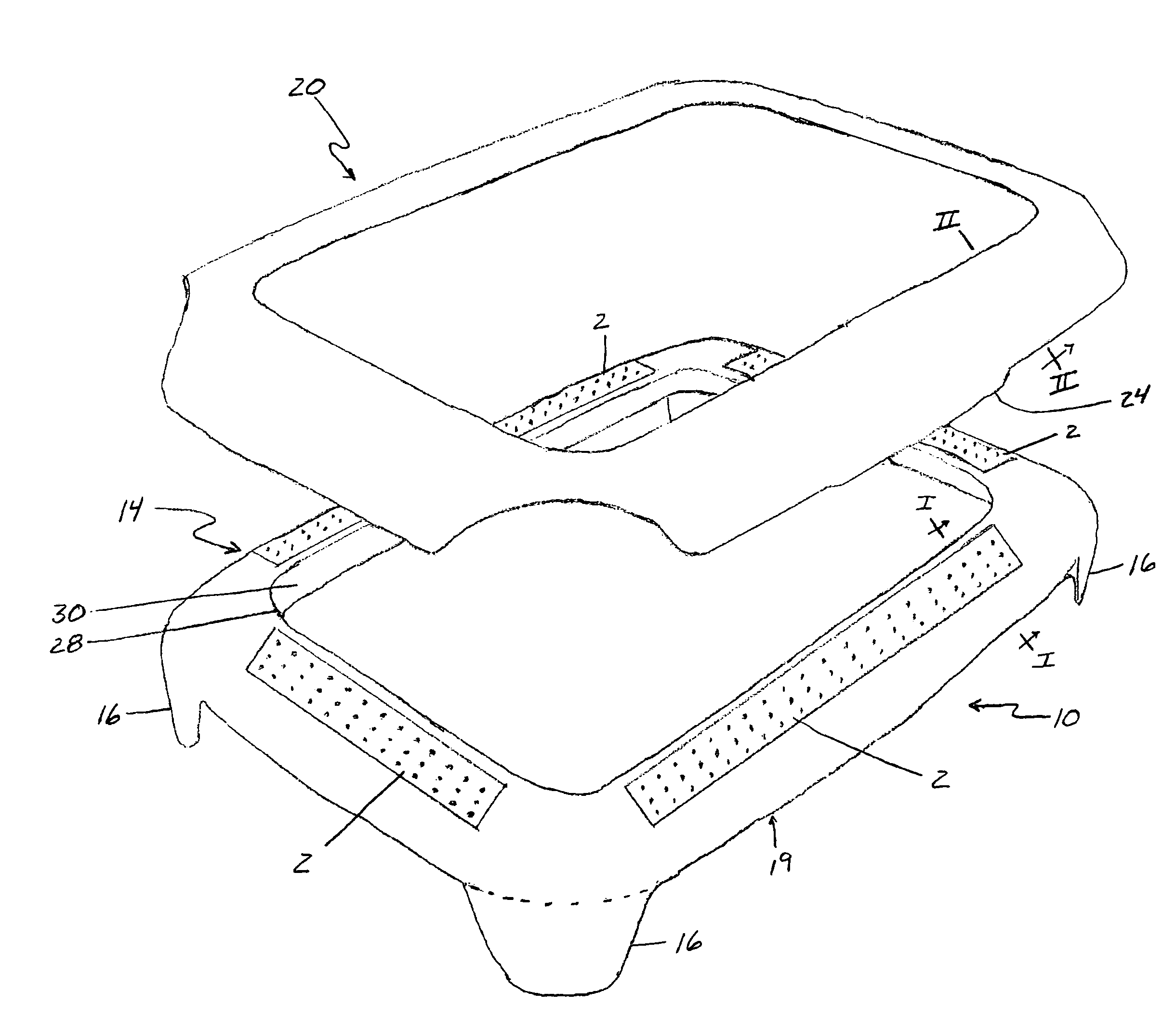

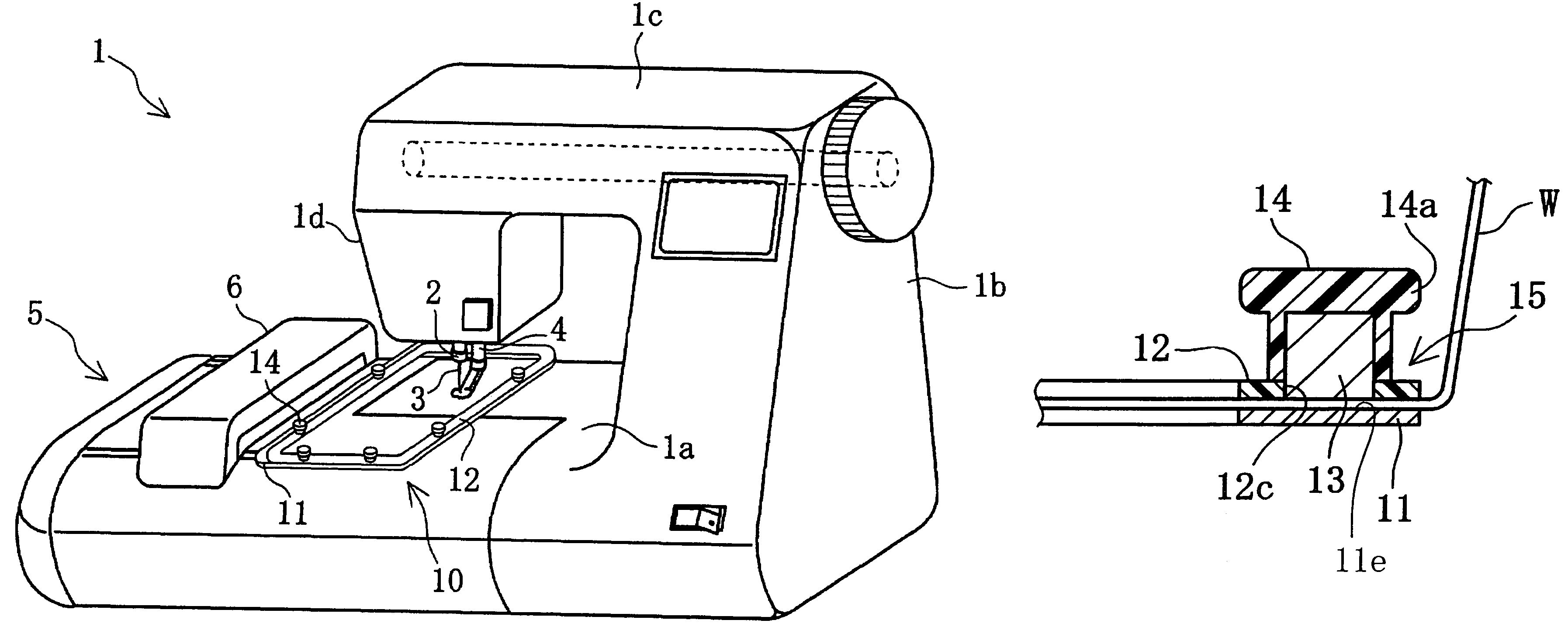

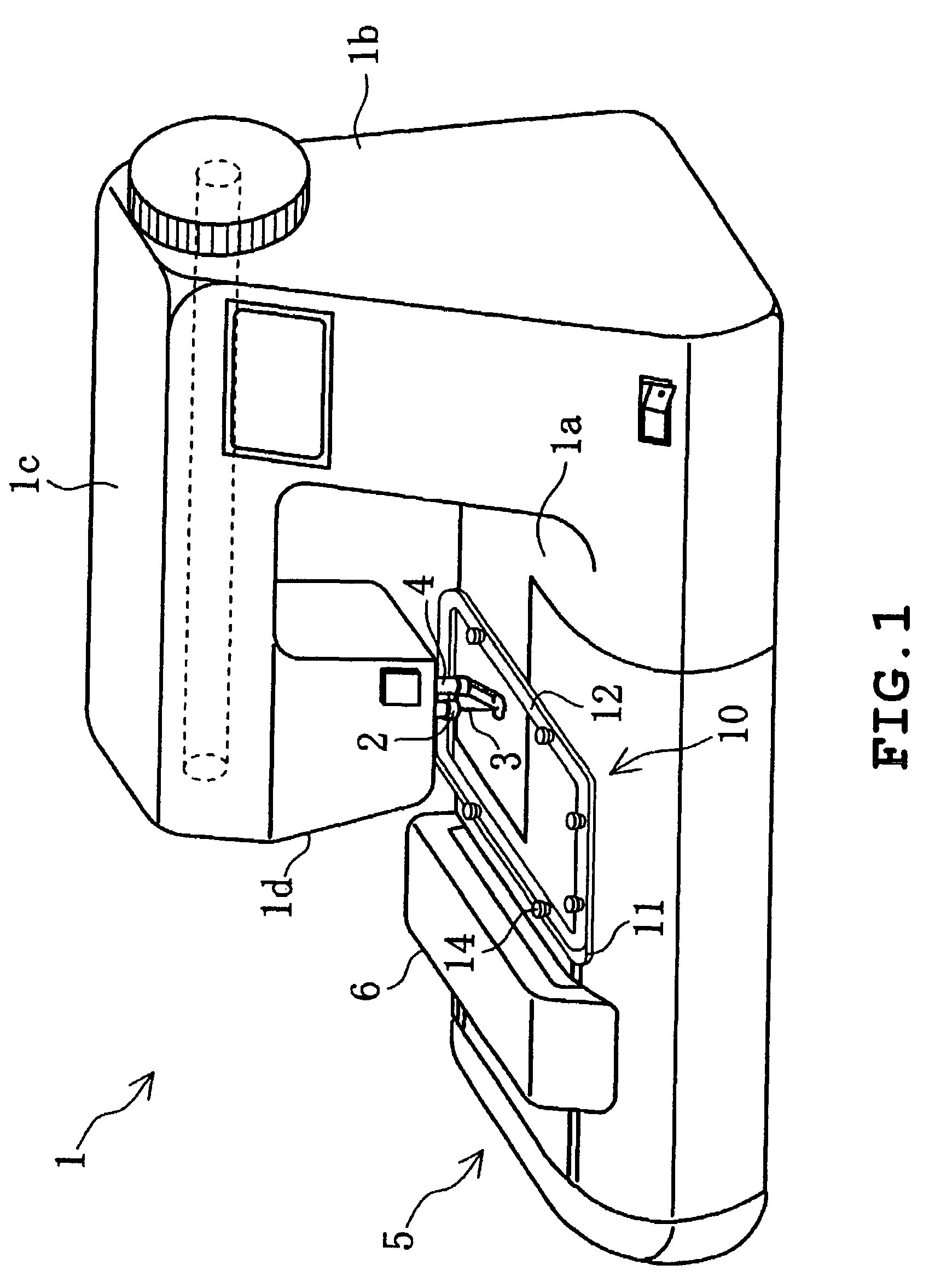

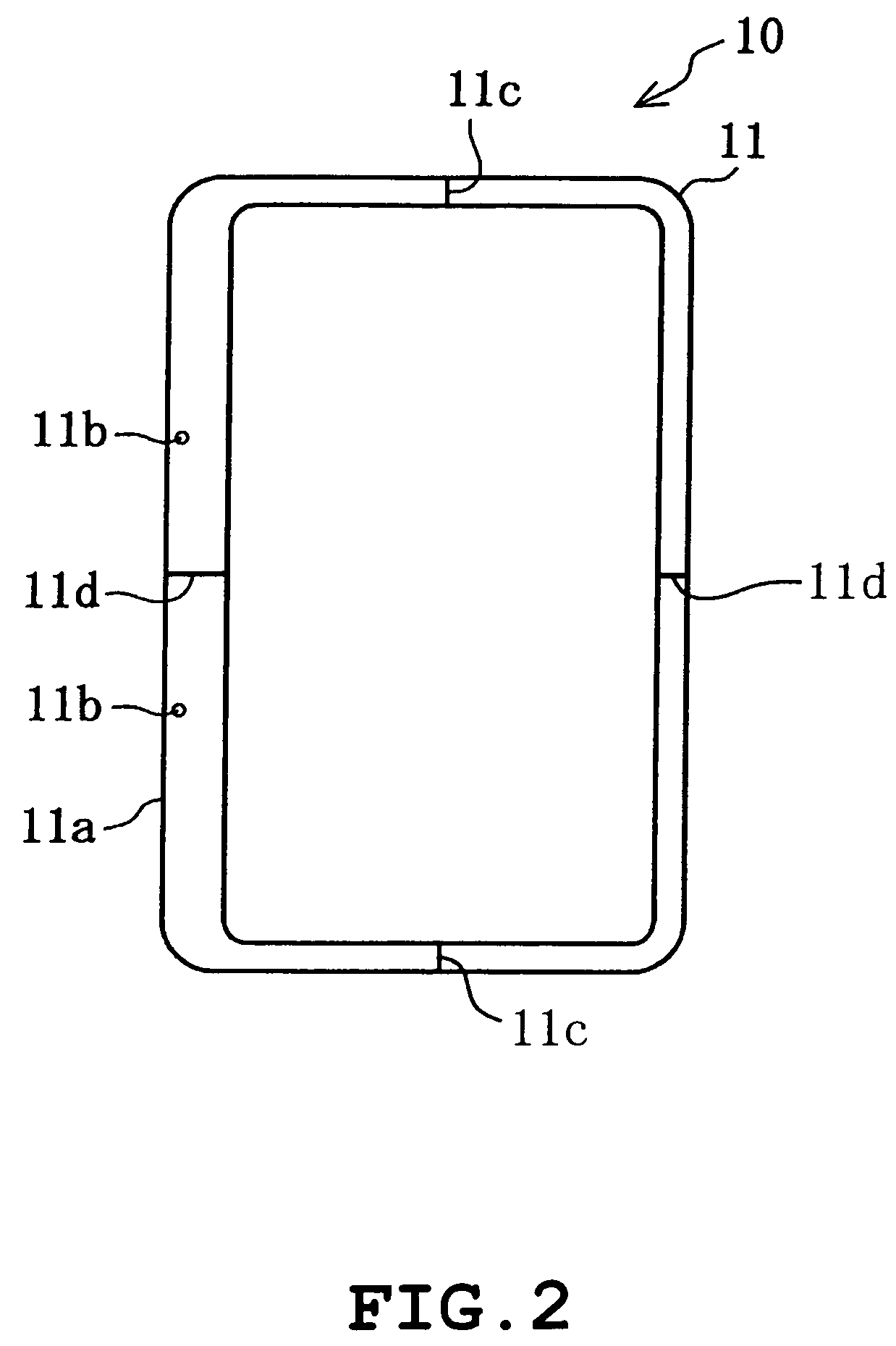

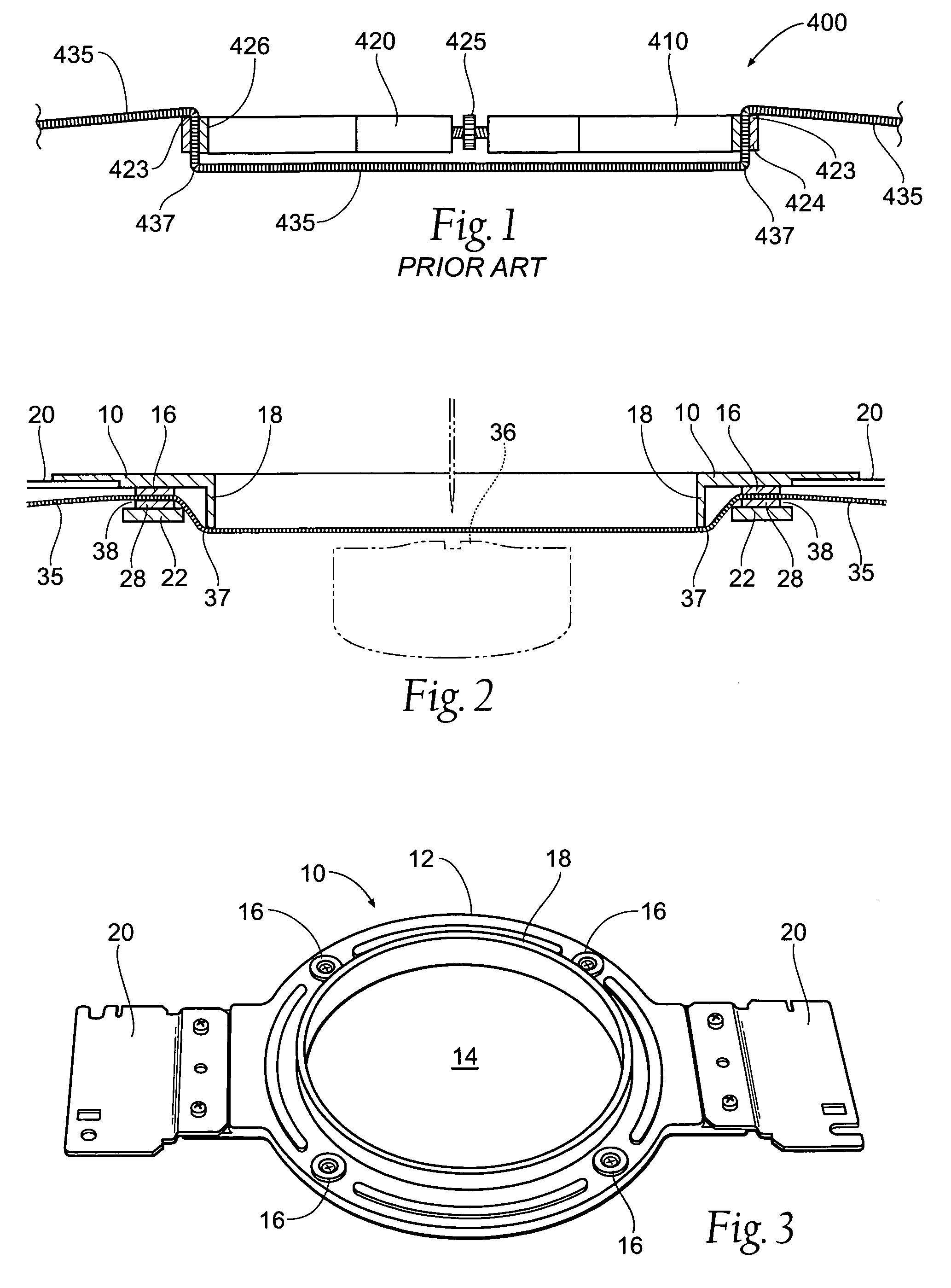

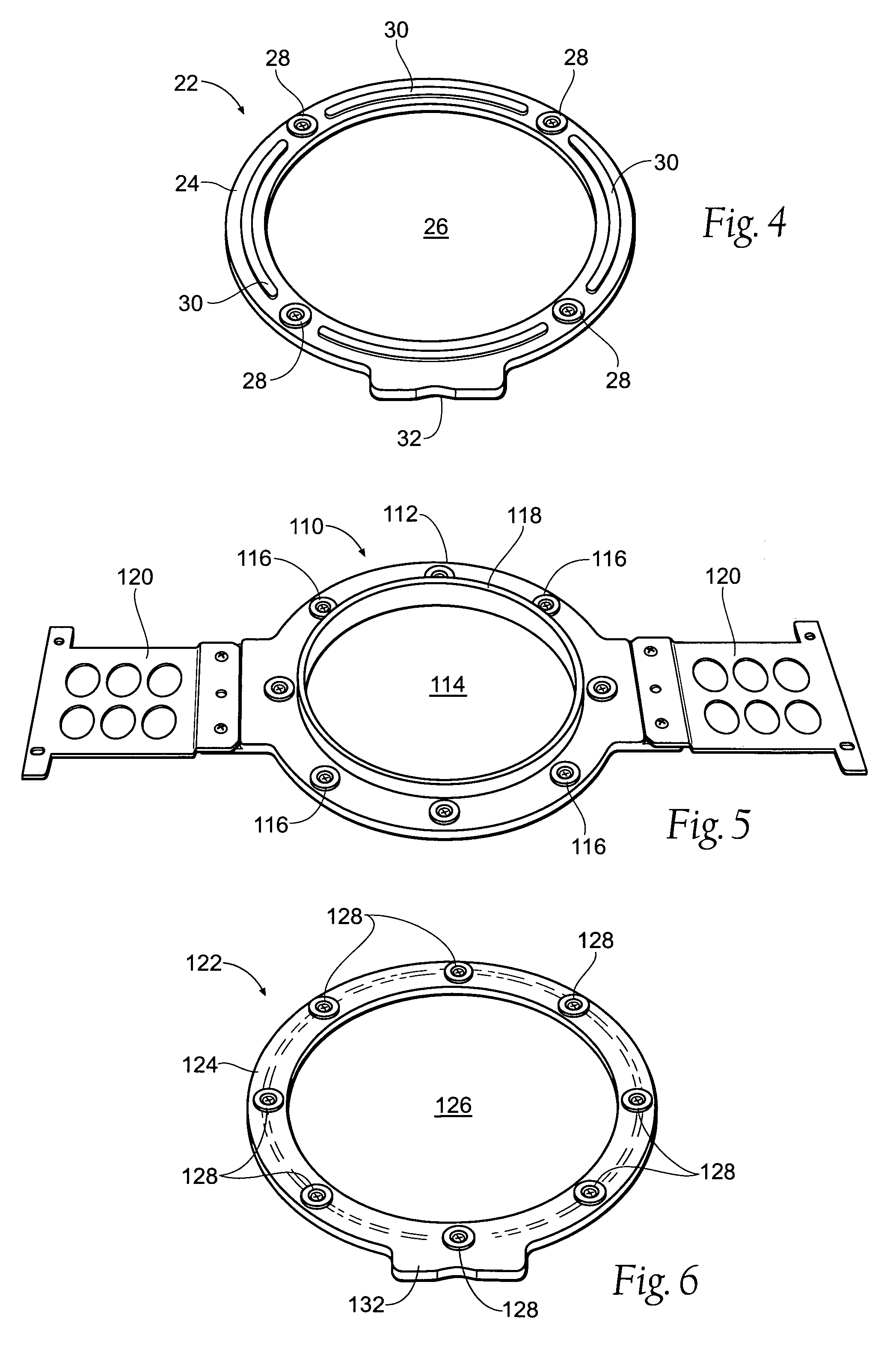

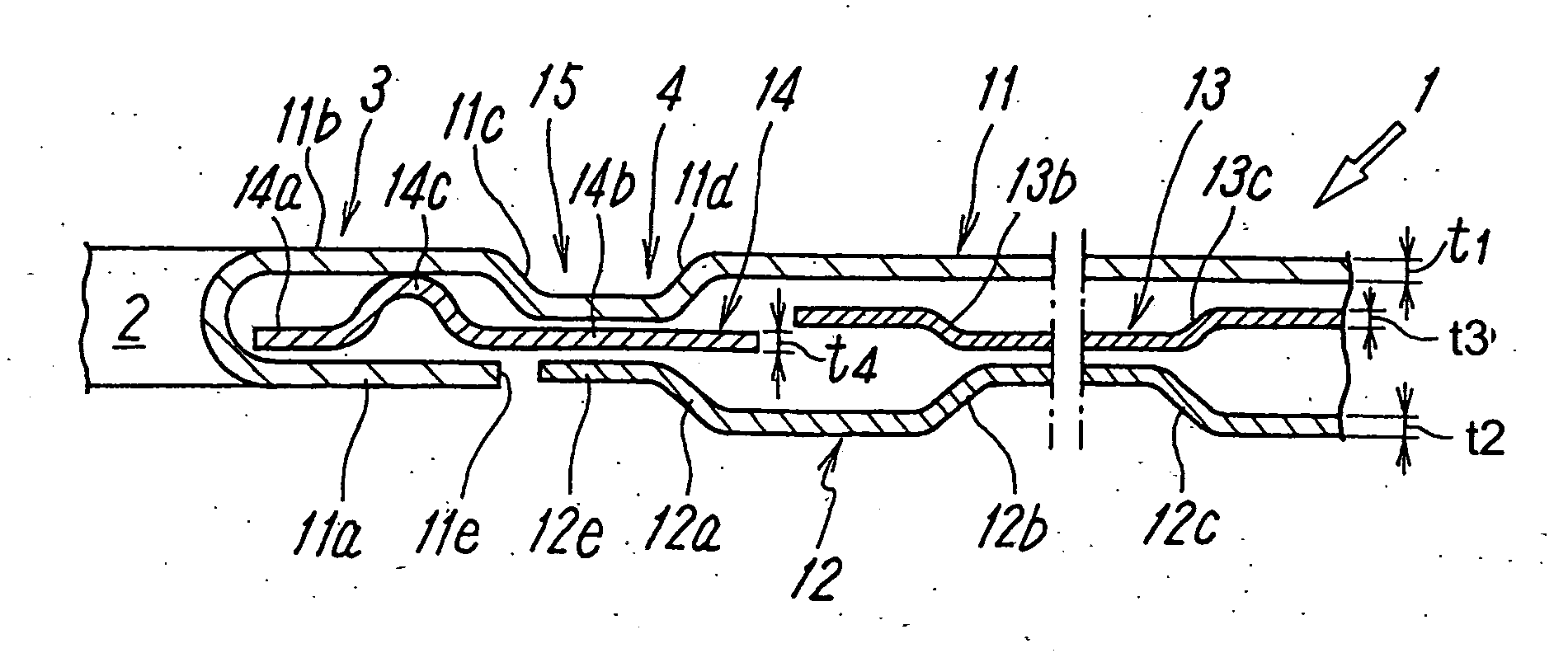

Device at an embroidery frame and method for clamping and tensioning a textile material

InactiveUS6901870B2Straightening of the at least one crease in the upper wall before straightening of the at least one crease in the lower wall is facilitatedTufting apparatusAutomatic machinesEngineeringSewing machine

The present patent application relates to an embroidery frame for a sewing machine and a method for clamping and tensioning a textile material. The embroidery frame comprises an inner frame, an outer frame and a hose arranged between the inner frame and the outer frame, which hose is expandable through pressurization. After manual assembly of the inner frame and the outer frame, a textile material intended for embroidering can be clamped between the hose and the outer frame and tensioned over an area of the textile material intended for embroidering through pressurization of the hose. The hose expands through initial pressurization in an upper part and clamps thereby the textile material between the upper part of the hose and the outer frame. Upon continued pressurization the hose expands in a lower part in a direction towards the outer frame and tensions thereby the textile material.

Owner:KSIN LUXEMBOURG II

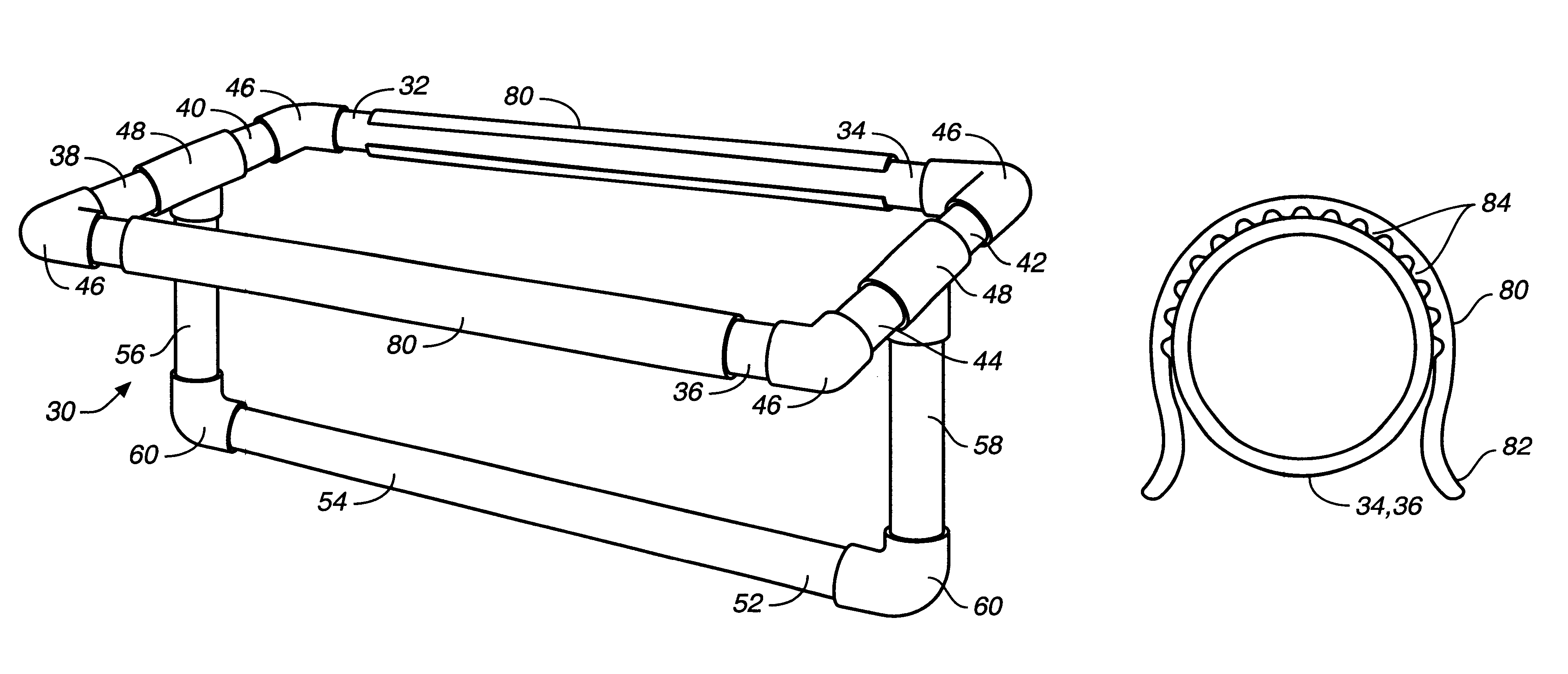

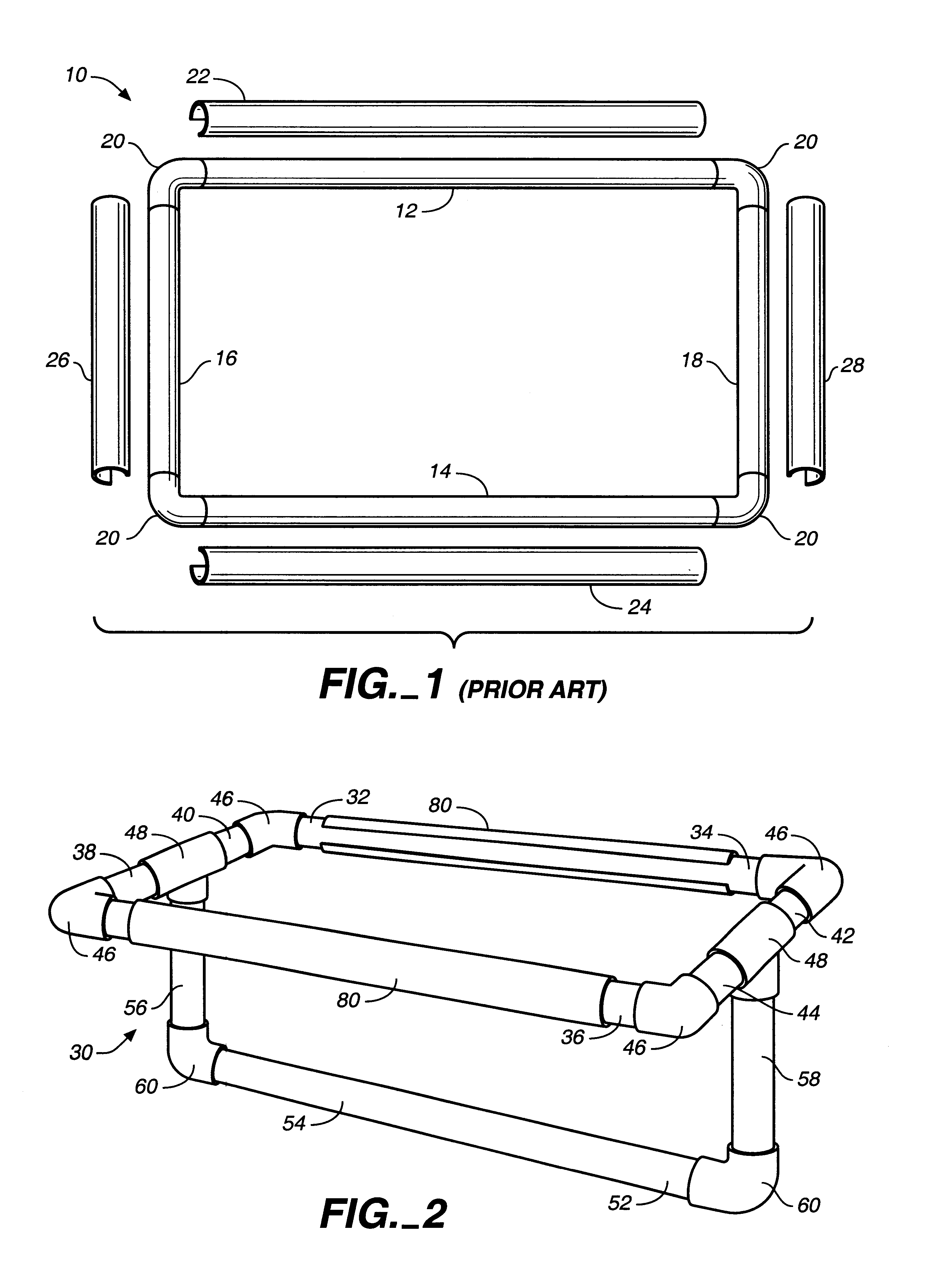

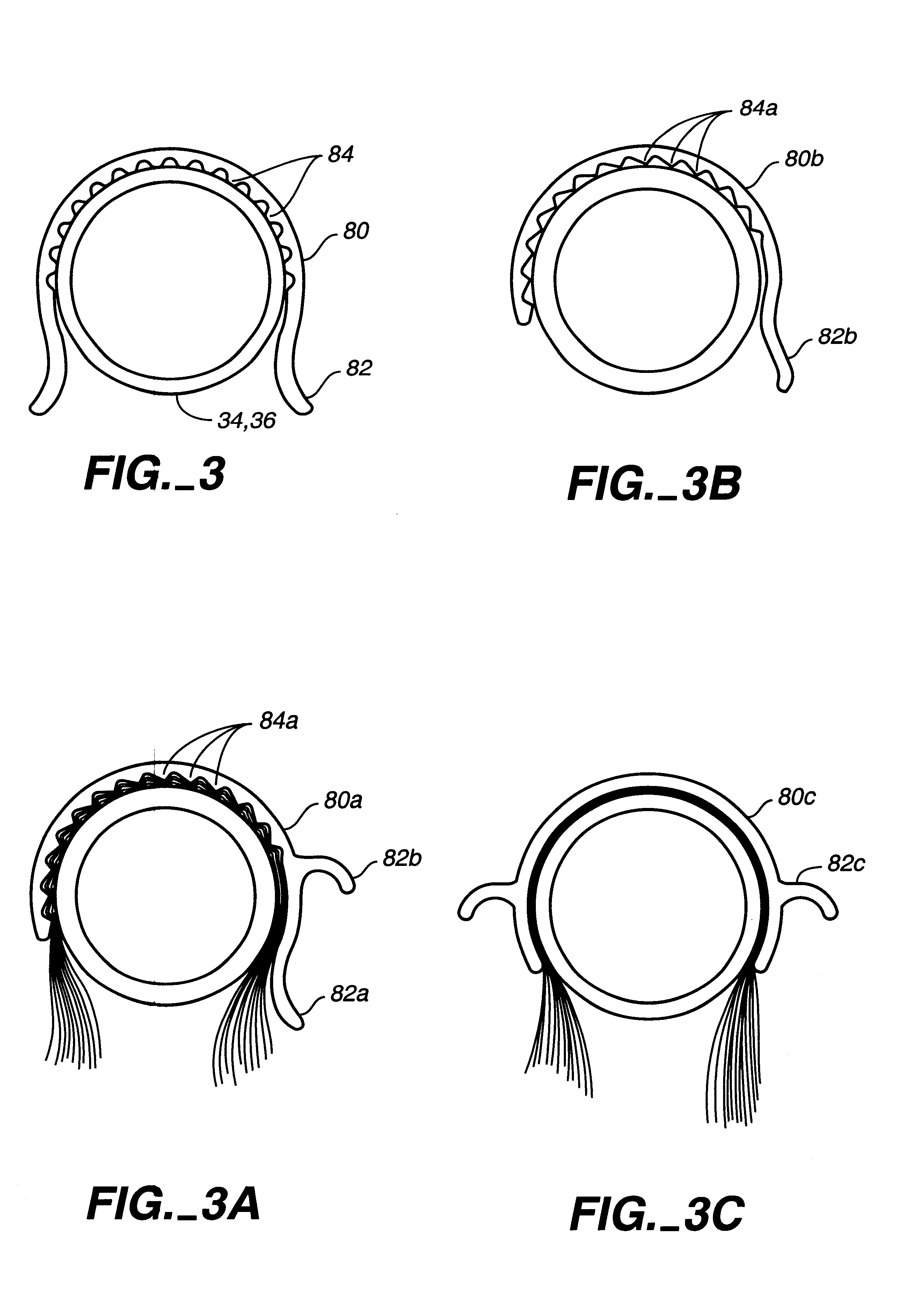

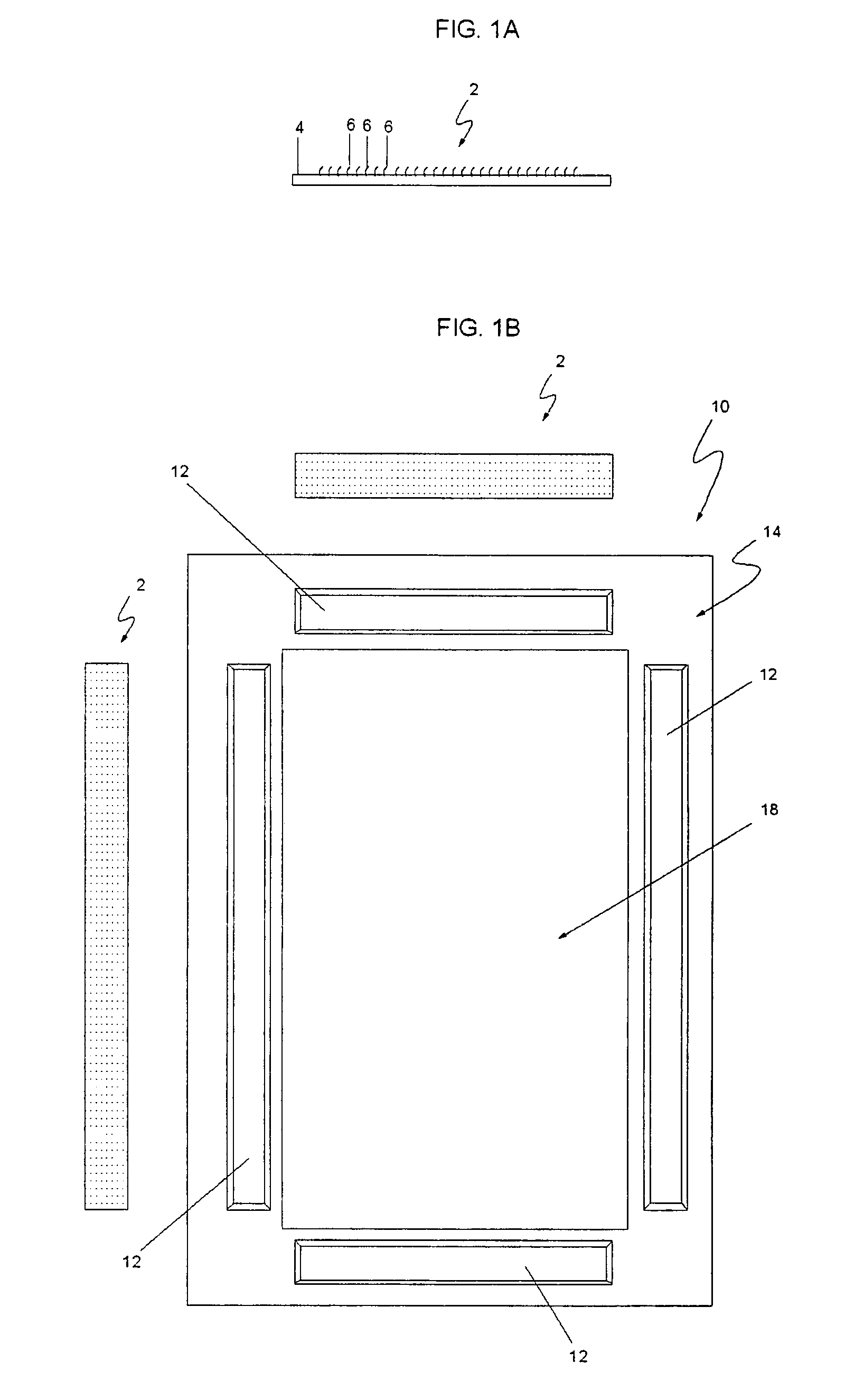

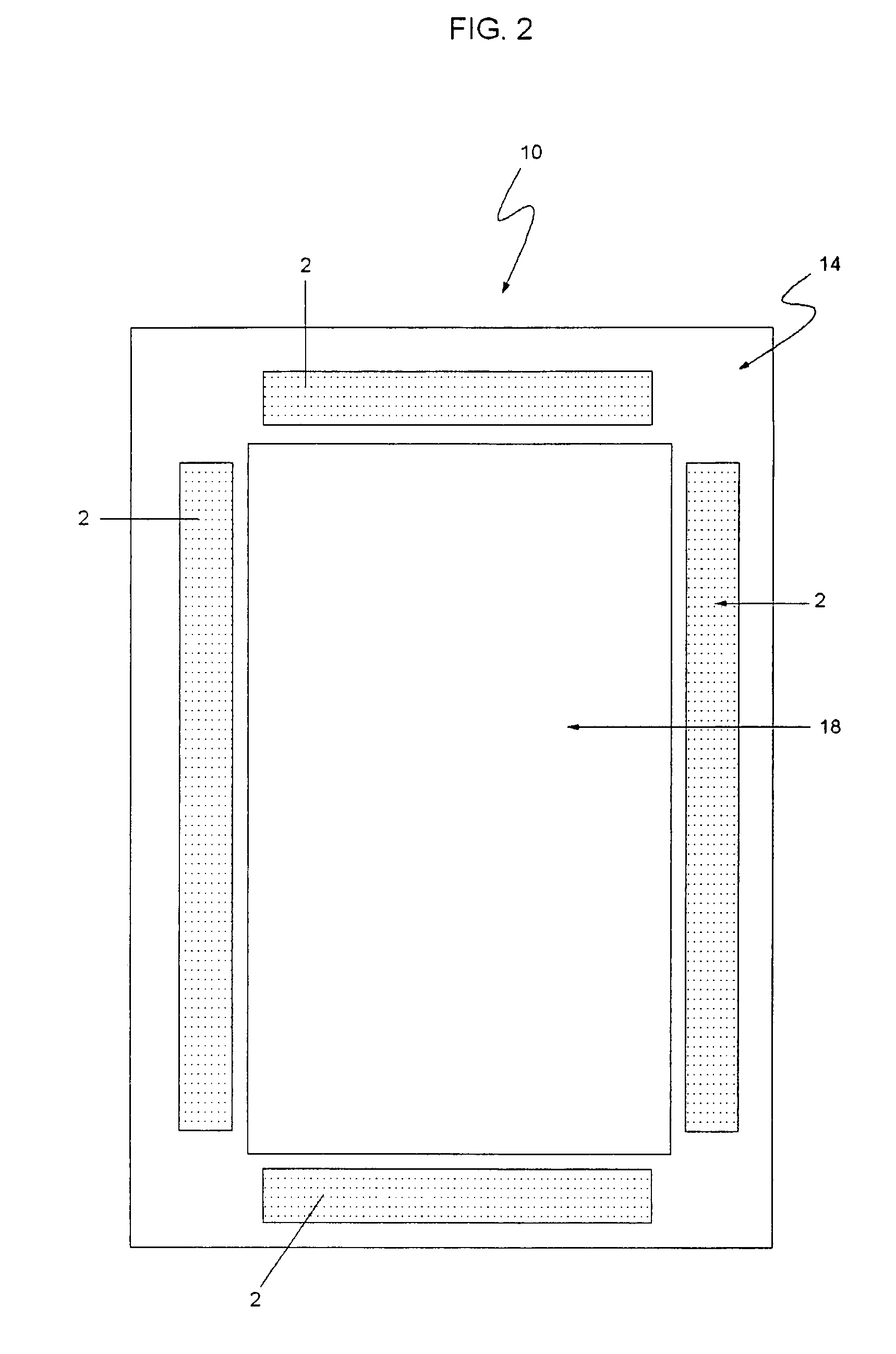

Textile holding frame

InactiveUS6209240B1Improve ease of placement and positioning and removalImprove abilitiesStretchingHand embroideringFixed frameEngineering

A textile or other material holding frame portion having a pair of side members and two or more lateral members extending between the sides to define a generally rectangular configuration. One embodiment uses stationary frame members with retainers for material retention and / or tensioning, and another embodiment uses rotating frame members to provide the desired tensioning. Both embodiments may include pressure joints and / or slip joints, be self-supporting, table supported or utilize a base support.

Owner:ENGLE ROSEMARY E

Device for tensioning and securing a canvas

ActiveUS7293378B2Clearance may become wider and widerEasy to installCurtain rodsOther artistic work equipmentsEngineering

A device for tensioning and maintaining a canvas, comprising a frame having a groove, and at least one deformable batten. The canvas is stretched and maintained on the frame by wedging it between the groove and the deformable batten. The deformable batten comprises a substantially V-shaped section which is oriented towards the bottom of the groove, a sharp edge which is used as a pivot to enable the deformation thereof, and two flanks which are used to wedge the canvas in the groove. The invention is characterized in that the batten is locked in a narrow section of the groove by two enlargements extending on one flank of the batten in the same direction as the batten.

Owner:PRISMAFLEX INT

Tridimensional relief embroidery method

InactiveCN101403171ALifelikeStrong artistic expressionOrnamental structuresSpecial ornamental structuresYarnEngineering

The invention relates to a method of three-dimensional relief embroidery, wherein, a substrate is laid on a working platform of an embroidery frame or an embroidery machine and a pre-embroidery pattern is duplicated on the substrate; the method is characterized in that one or two of materials: cotton, helm, rag, animal wool, feather or saw dust, are firstly soaked and mixed with pulp; when the mixture can be molded, a manual shaping method or a model molding method is adopted to make a three-dimensional model; after the three-dimensional model is arranged and fixed on the substrate so as to be tallied with the outline of the pattern on the substrate, cloth in various shapes and with the same color as that of the yarn is wrapped on the surface of the model by means of pasting and sewing; then embroidery is carried out to the surface of the three-dimensional model. The method of the three-dimensional relief embroidery has the advantages that the statuary art and embroidery technique are integrated; the manufactured embroidery has lifelike images and strong artistic expressive force; three-dimensional visual aesthetic feeling can be expressed; and appreciation and collection values are combined. The embroidery is suitable for being displayed and appreciated in guest houses, hotels, reception rooms, exhibition rooms and households.

Owner:夏丽云

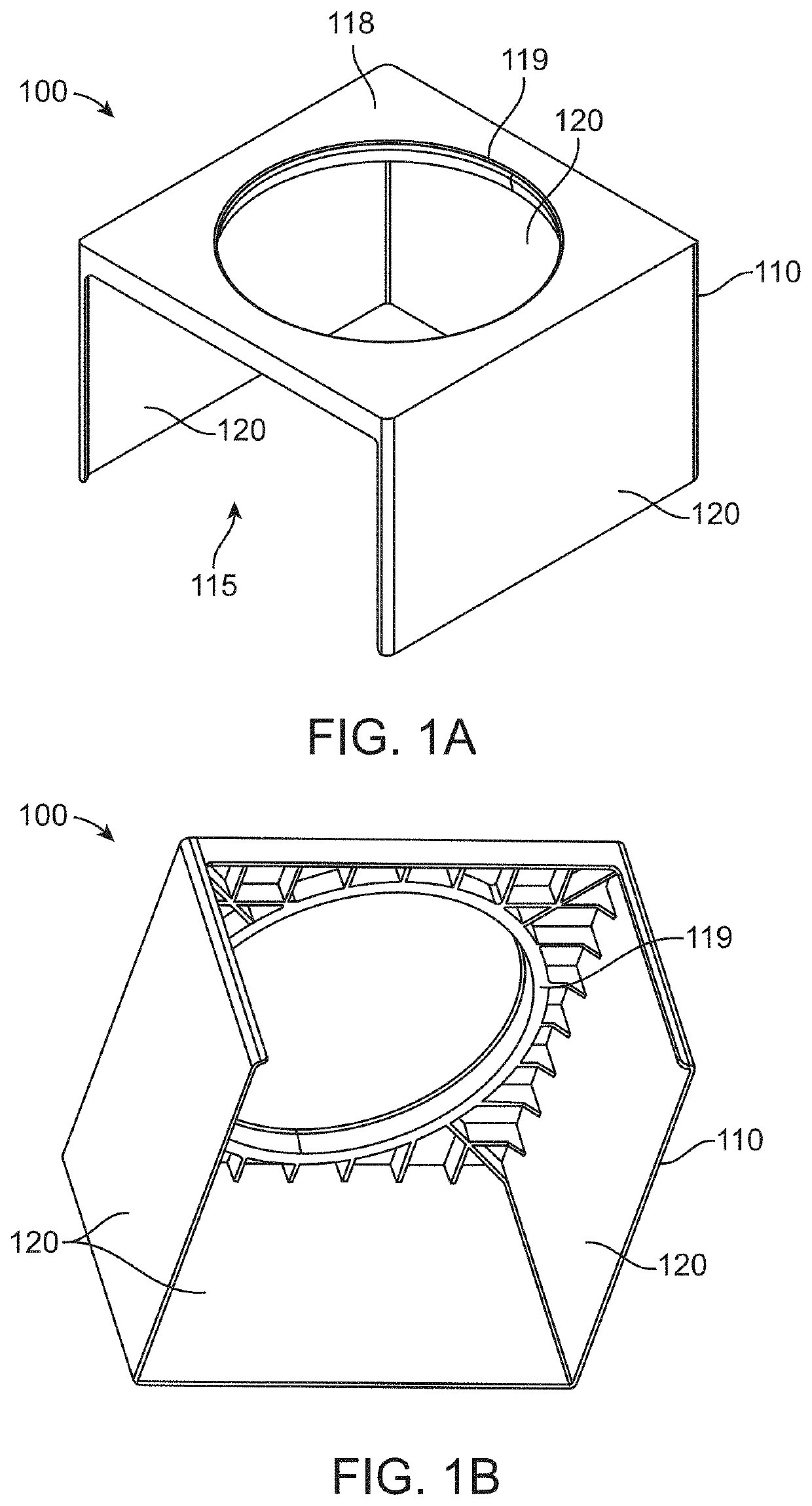

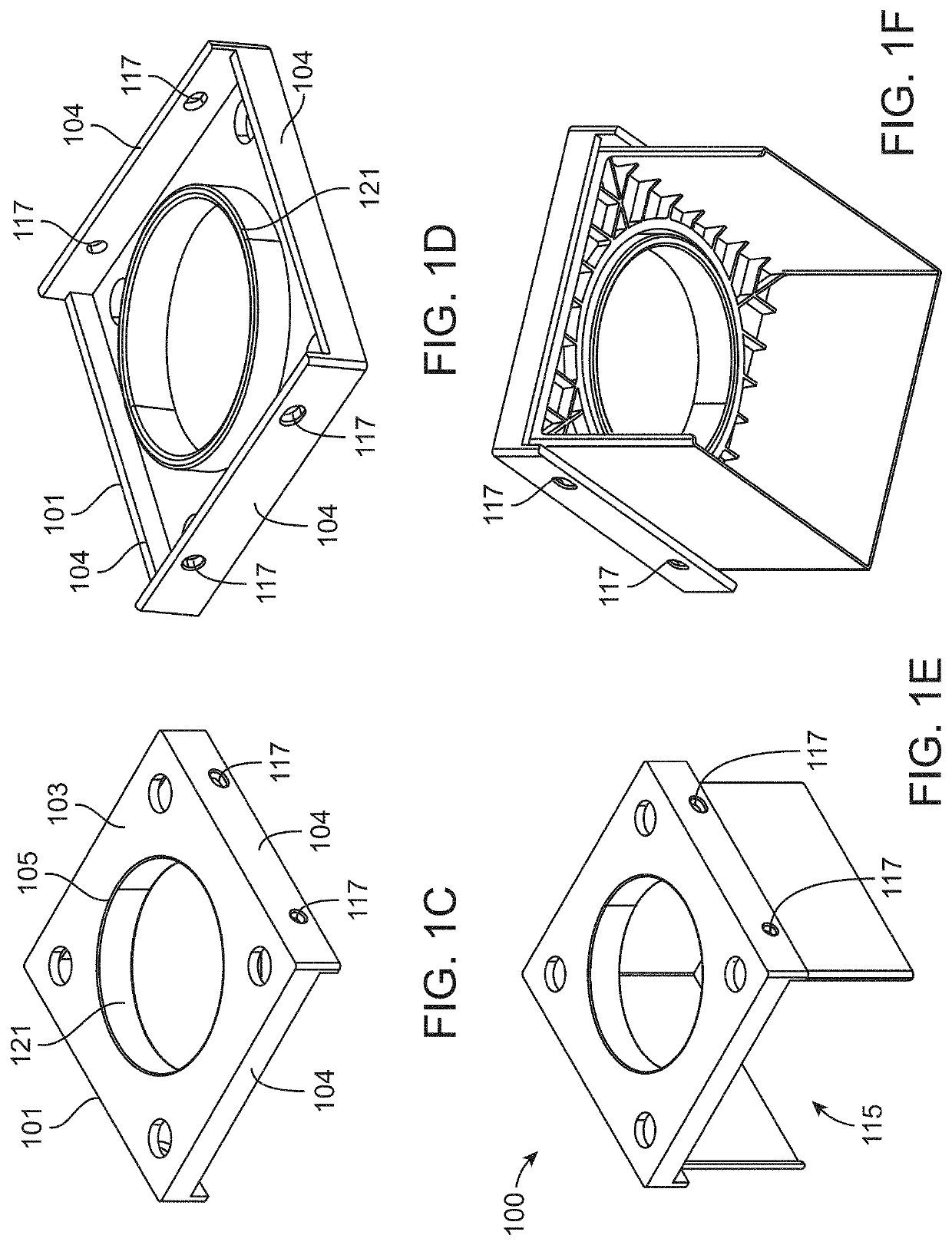

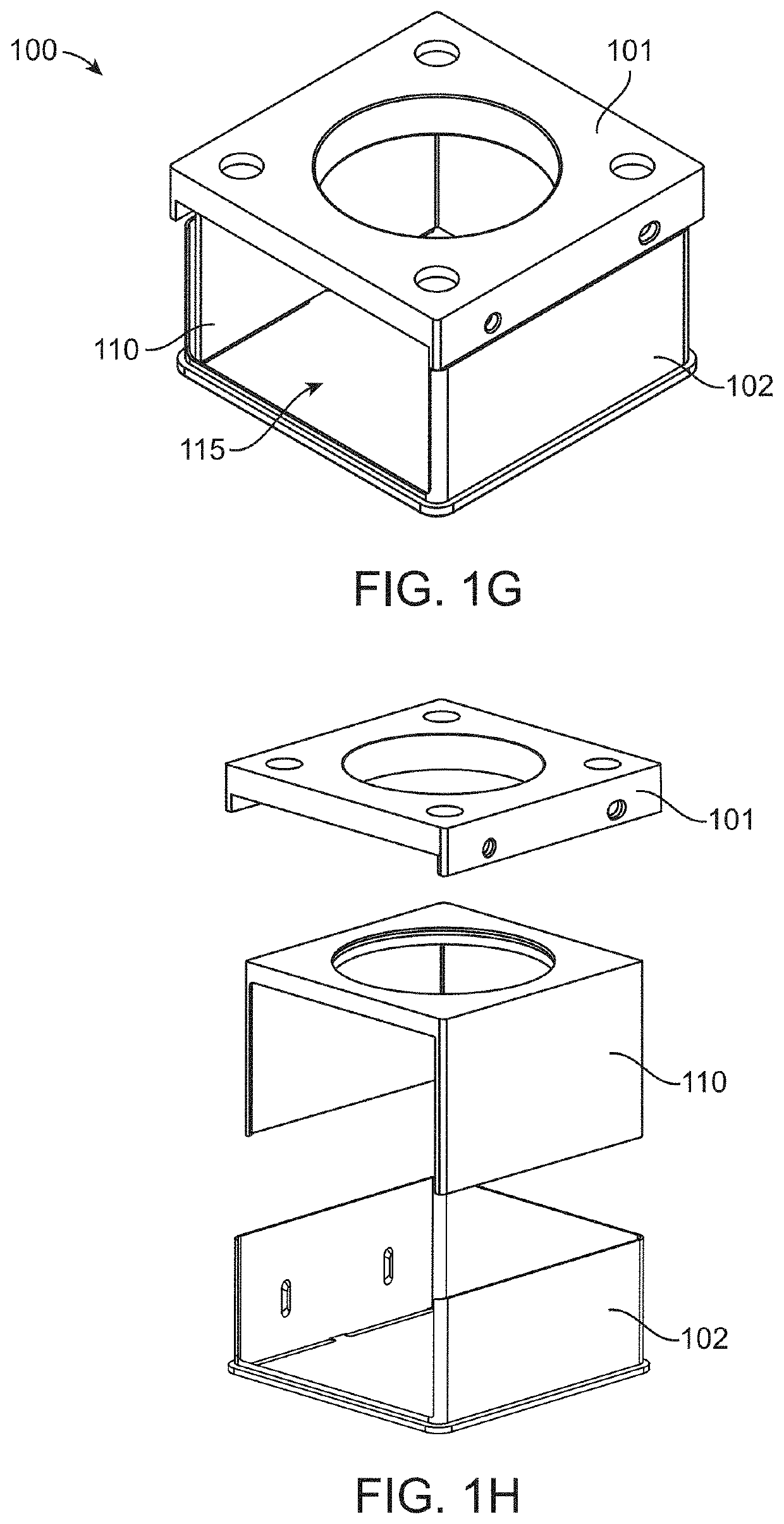

Systems and methods for packaging articles to be embroidered

Packaging is used to store articles to be customized by methods including embroidery, wherein the packaging includes at least two portions defining a window, and wherein the two portions of the packaging hold a portion of the article, for example a fabric panel, taut across the window so that the portion of the article may be embroidered by an embroidery machine while retained by portions of the packaging. The packaging may be in the form of a box during embroidery, or may be converted into the form of a box after embroidery.

Owner:CREATEME TECH LLC

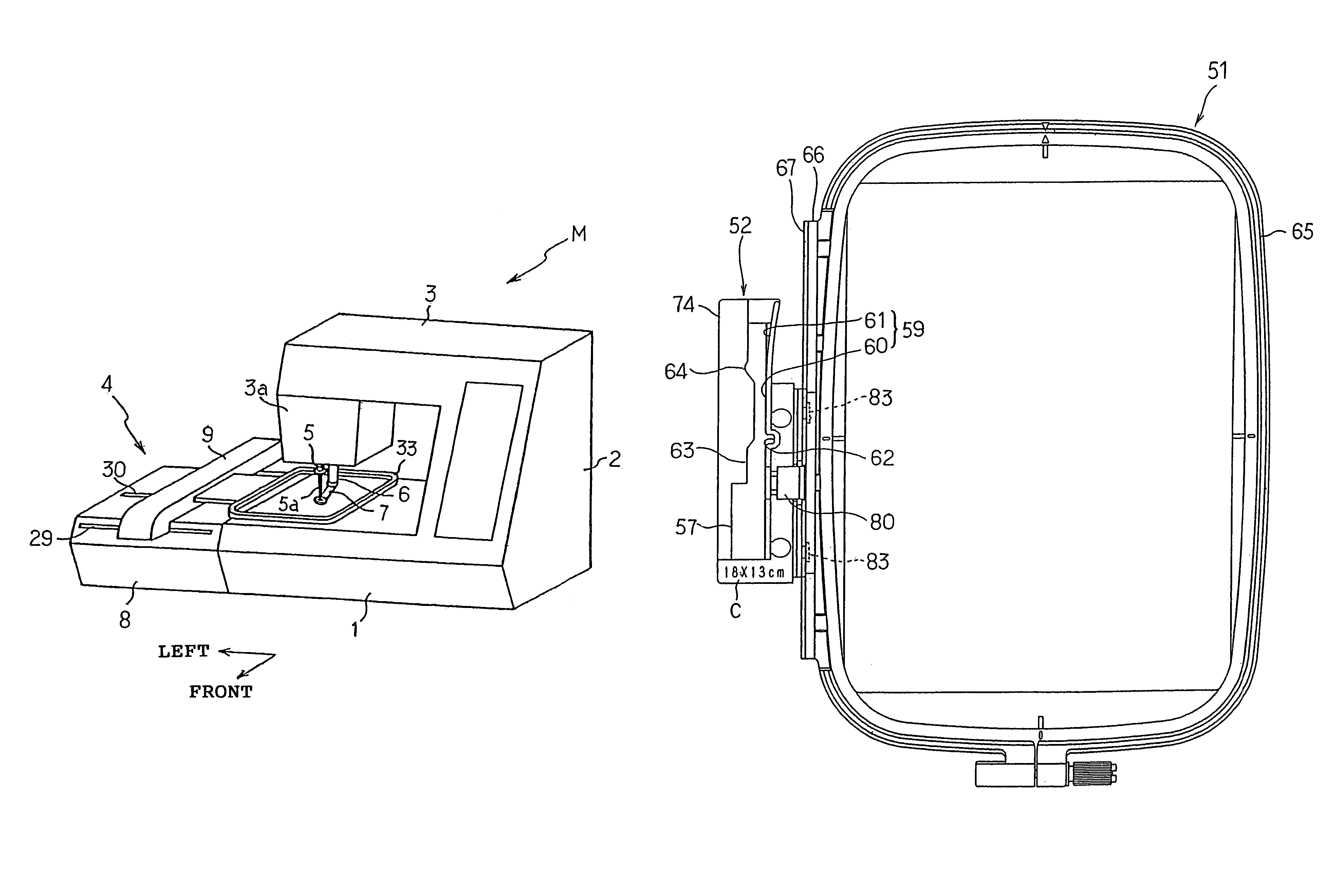

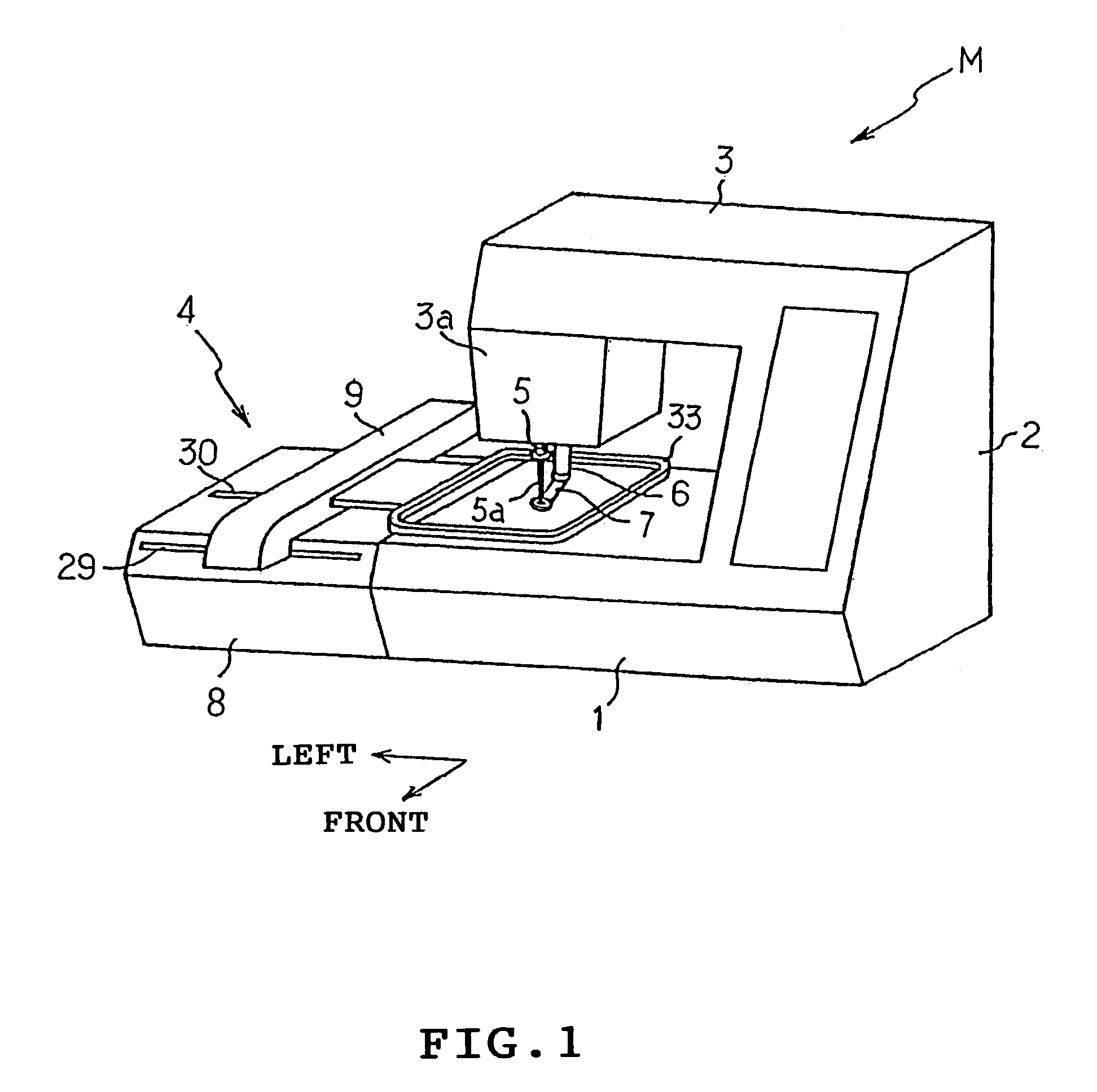

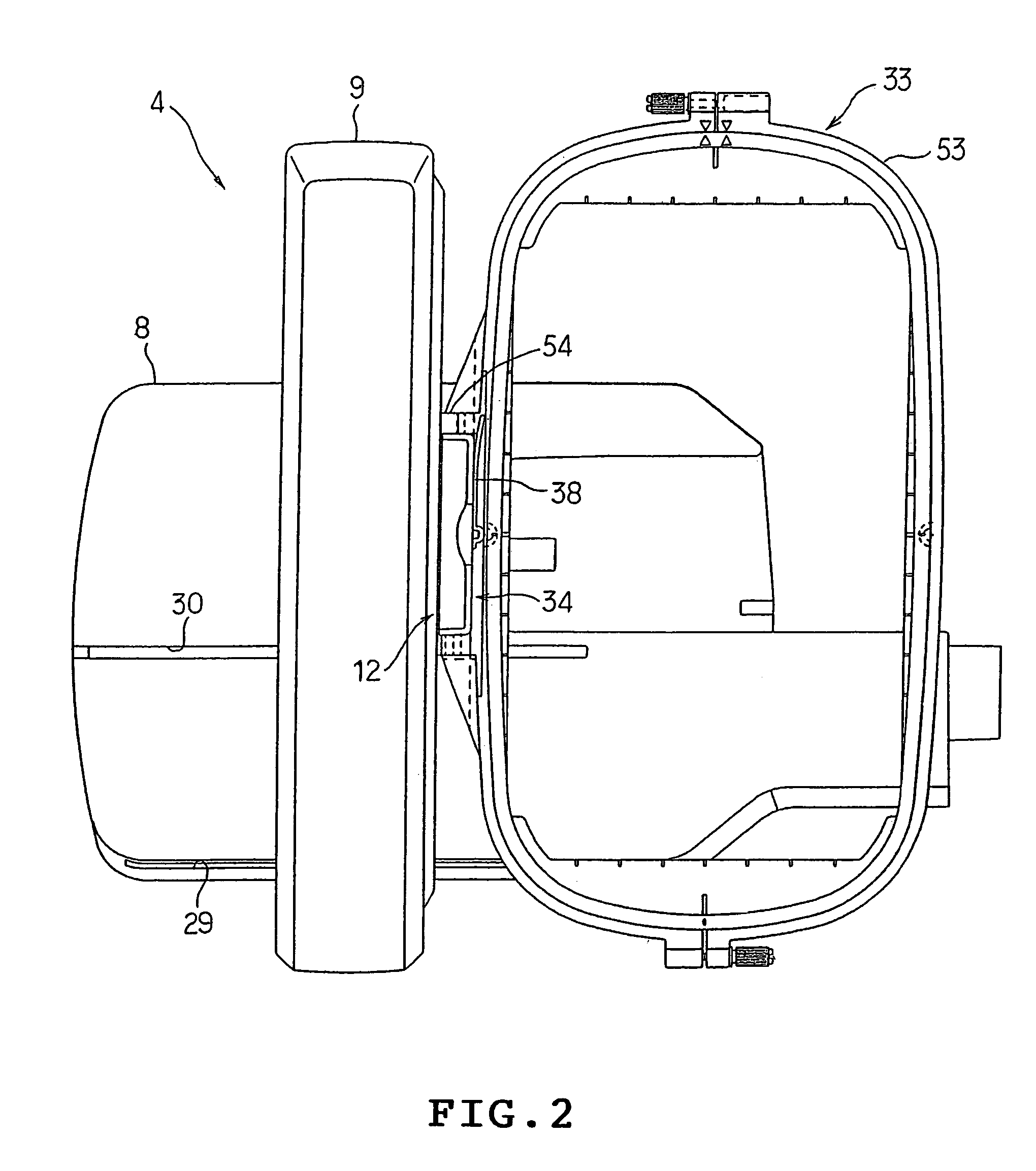

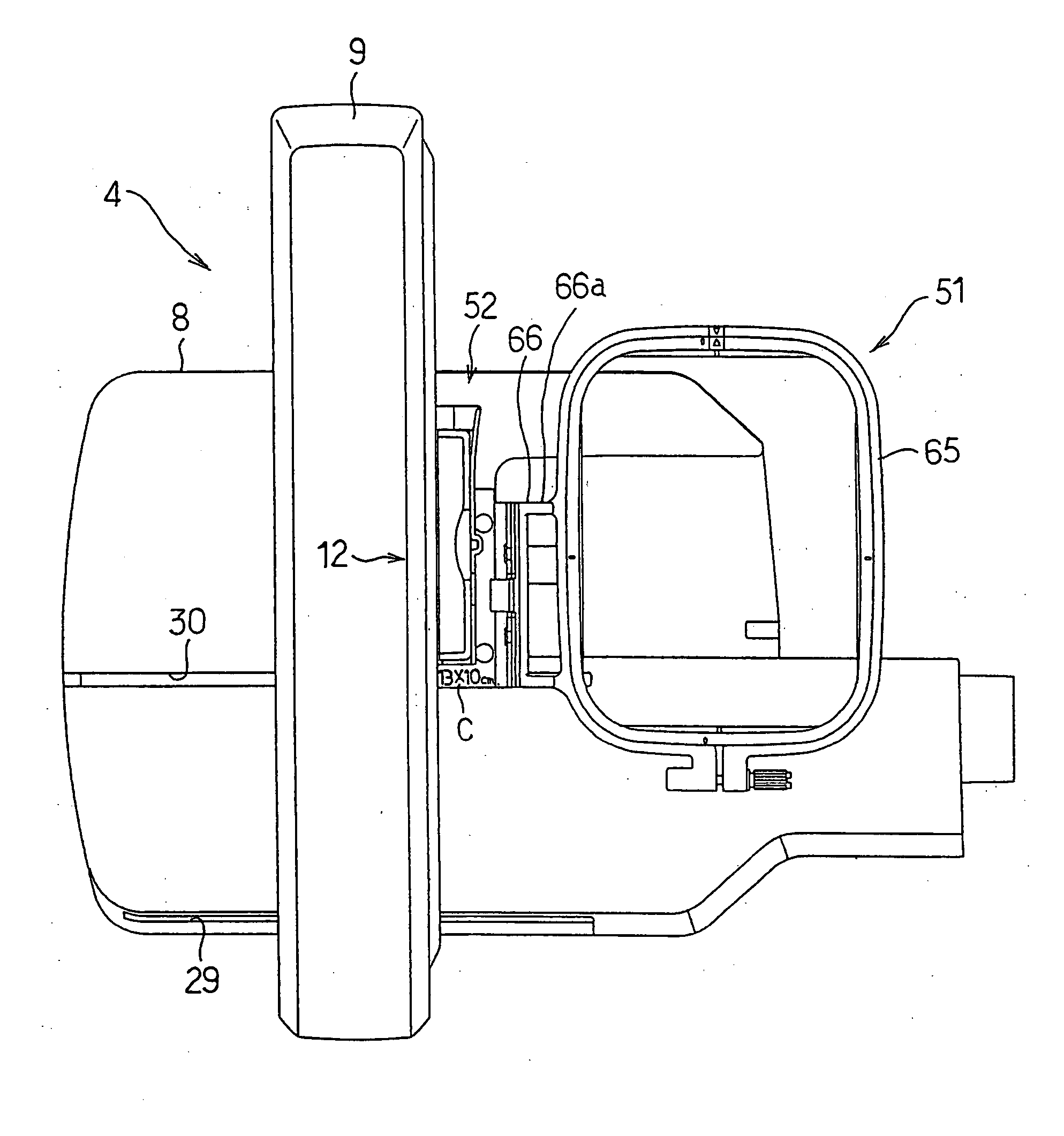

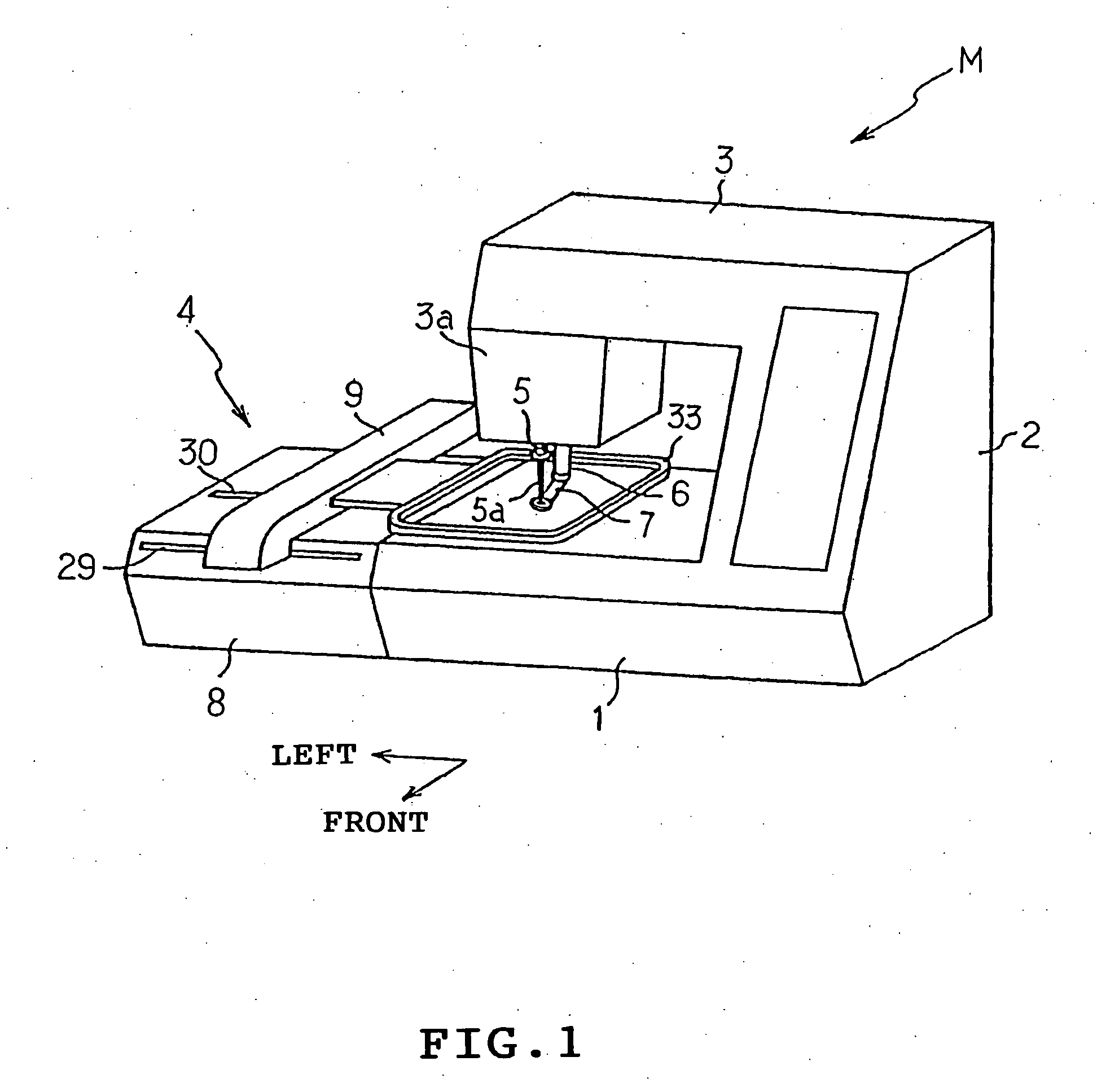

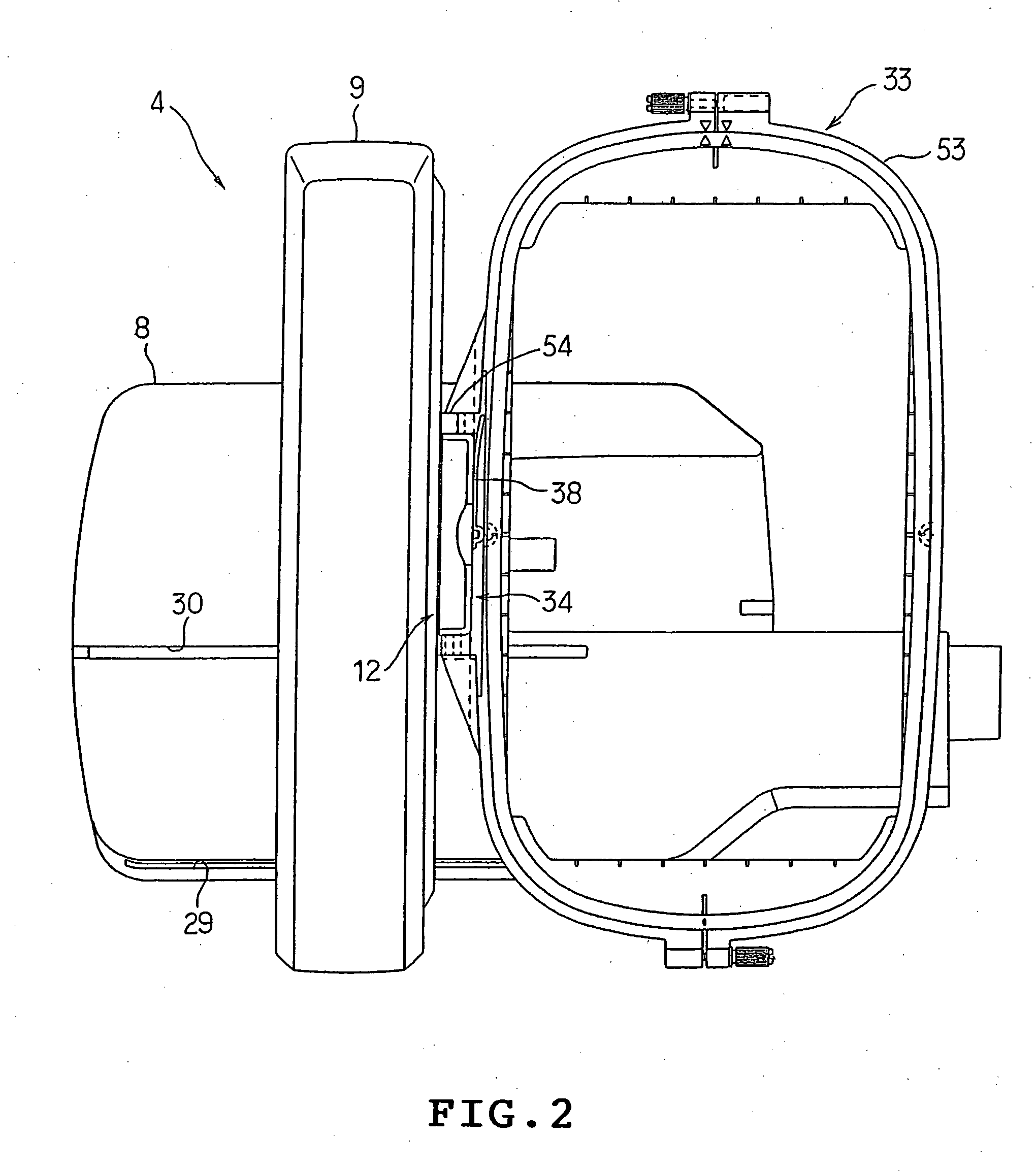

Embroidery frame transfer device and attachment

An attachment 52 comprises: a carriage connecting section 74 connected to a carriage 12 of an embroidery frame transfer device 4; and a metal fastener fixed to an attaching block 32 at the right-hand end portion of the carriage connecting section 74 and having a connecting section of a nonstandard embroidery frame 51 connected thereto. By connecting a connecting section 66 of the nonstandard embroidery frame 51 to the metal fastener 75 of the attachment 52 and by connecting the carriage connecting section 74 of the attachment 52 to the carriage 12, the nonstandard embroidery frame 51 can be mounted indirectly on the carriage 12. Thus, the nonstandard embroidery frame 51 of the type different in construction for attachment to the carriage 12 can be connected to the carriage 12.

Owner:BROTHER KOGYO KK

Improvement of cross embroidering method

InactiveCN1776068ANot out of shapeMaintain accuracyEmbroidering machines apparatusHand embroideringEngineering

This invention relates to the improvement for cross-stitch embroidery, which contains marking point coordinates of various color thread on embroidery pattern drawing made by machine or computer, marking corresponded coordinates in embroidery fabric by aqueous fusion pen, the embroidery point can be accurately found in manual embroidering, the drawn color can be washed by water after embroidering, said invention can raises efficiency by more than 80 %.

Owner:陈文泽

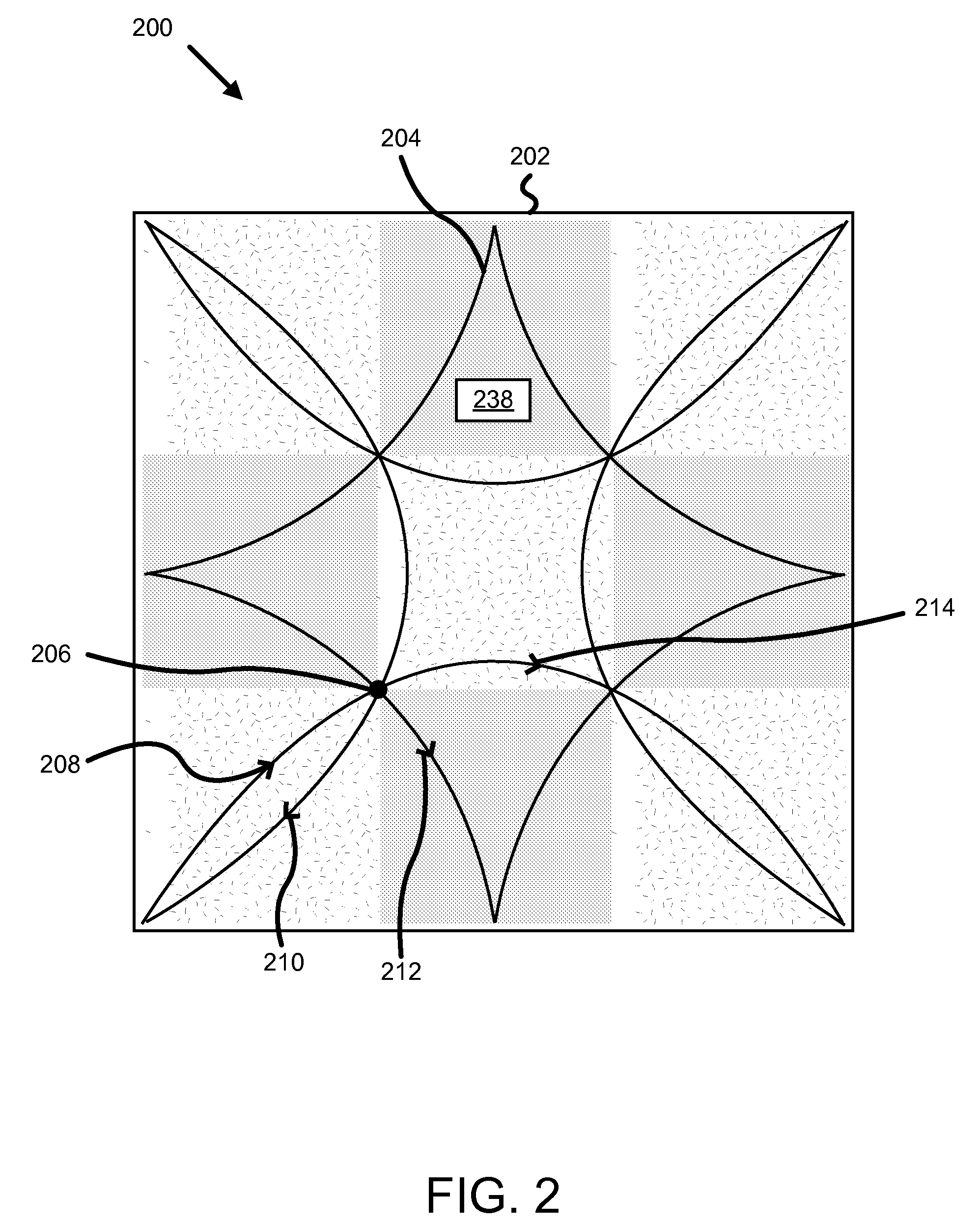

Needle punch stretch hoop

Owner:PROVO CRAFT & NOVELTY

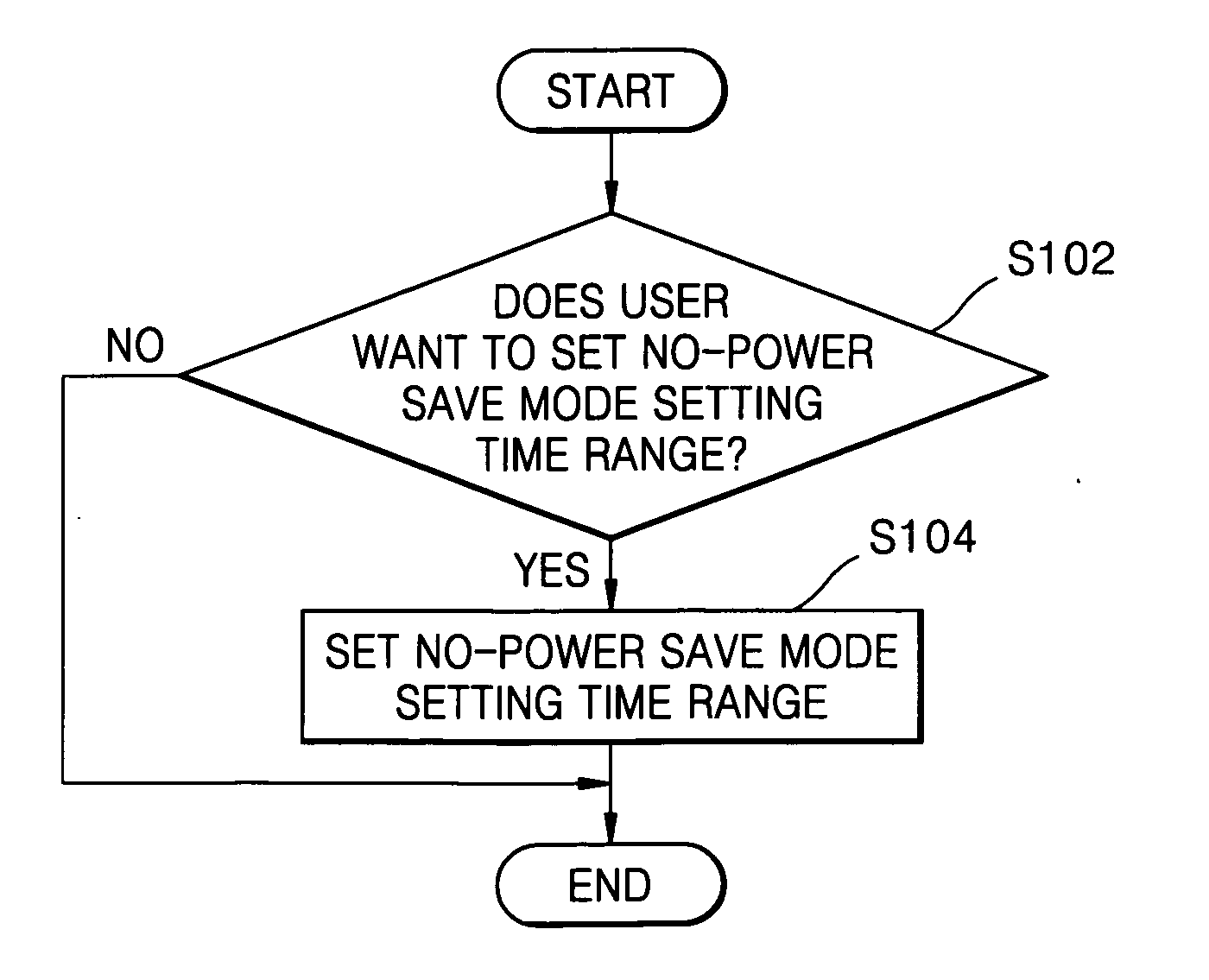

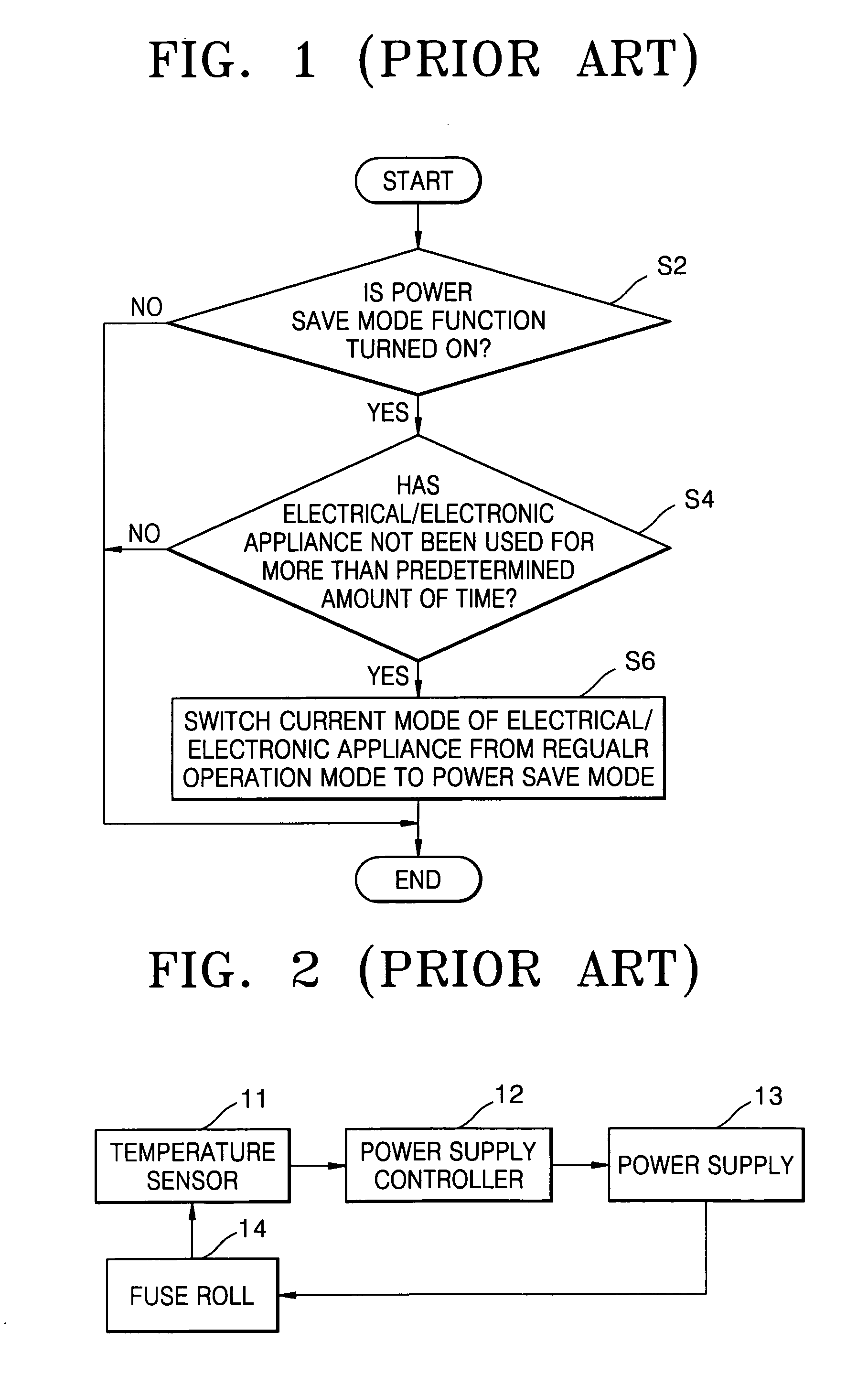

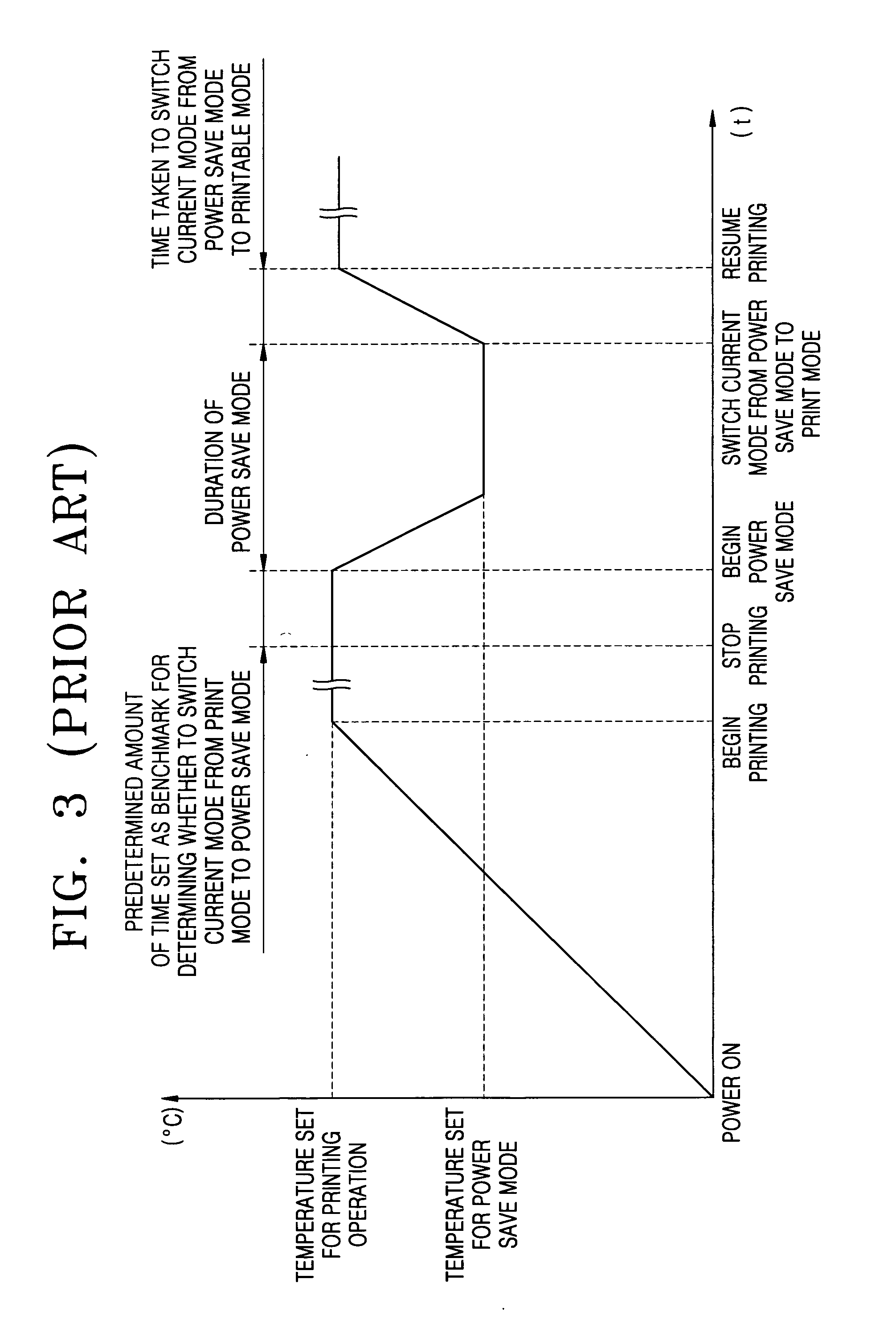

Apparatus and method for controlling power save mode of an electronic appliance

InactiveUS20050154934A1Maximize convenienceAvoid electricityEnergy efficient ICTVolume/mass flow measurementTime rangeControl power

An apparatus and method for controlling a power save mode of an electronic appliance, such as a printer, a photocopier, a multifunctional device, or an electronic oven, are provided. The apparatus comprises a power save mode control unit, which prevents a power save mode from being set in the electronic appliance during a predetermined time range. The apparatus may further comprise a no-power save mode setting time range setting unit, which sets the predetermined time range so that the power save mode can be prevented from being set in the electronic appliance.

Owner:SAMSUNG ELECTRONICS CO LTD

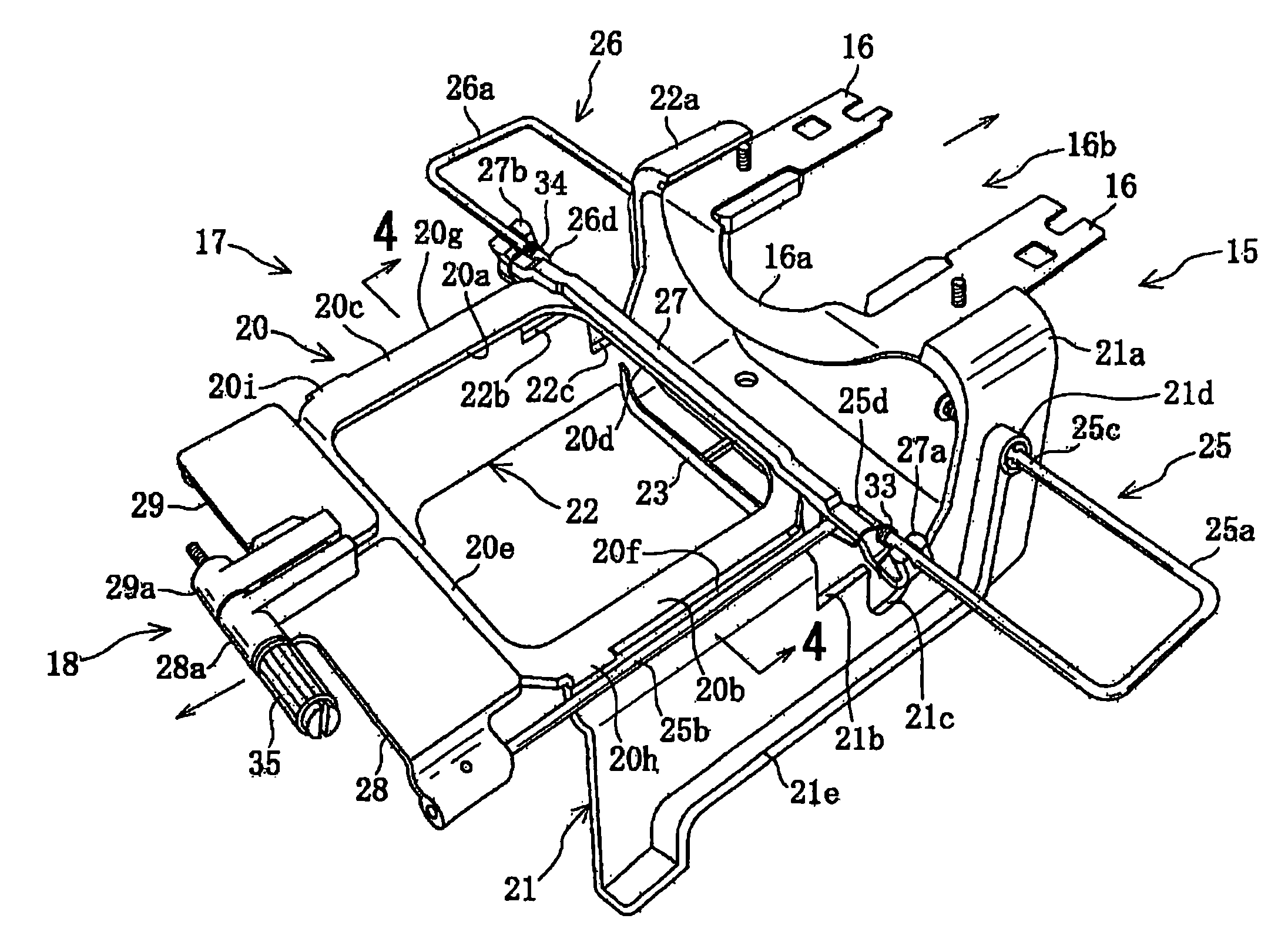

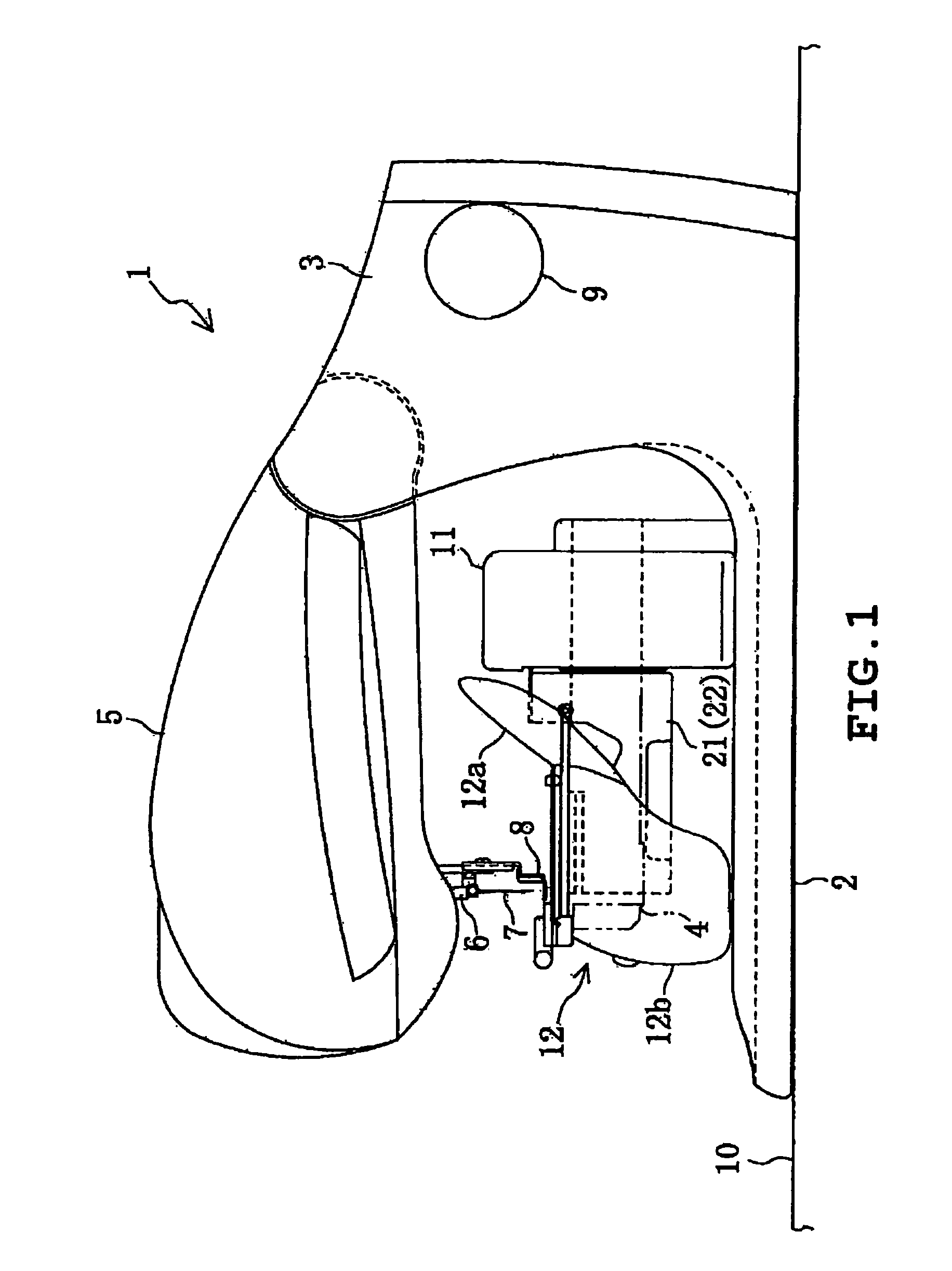

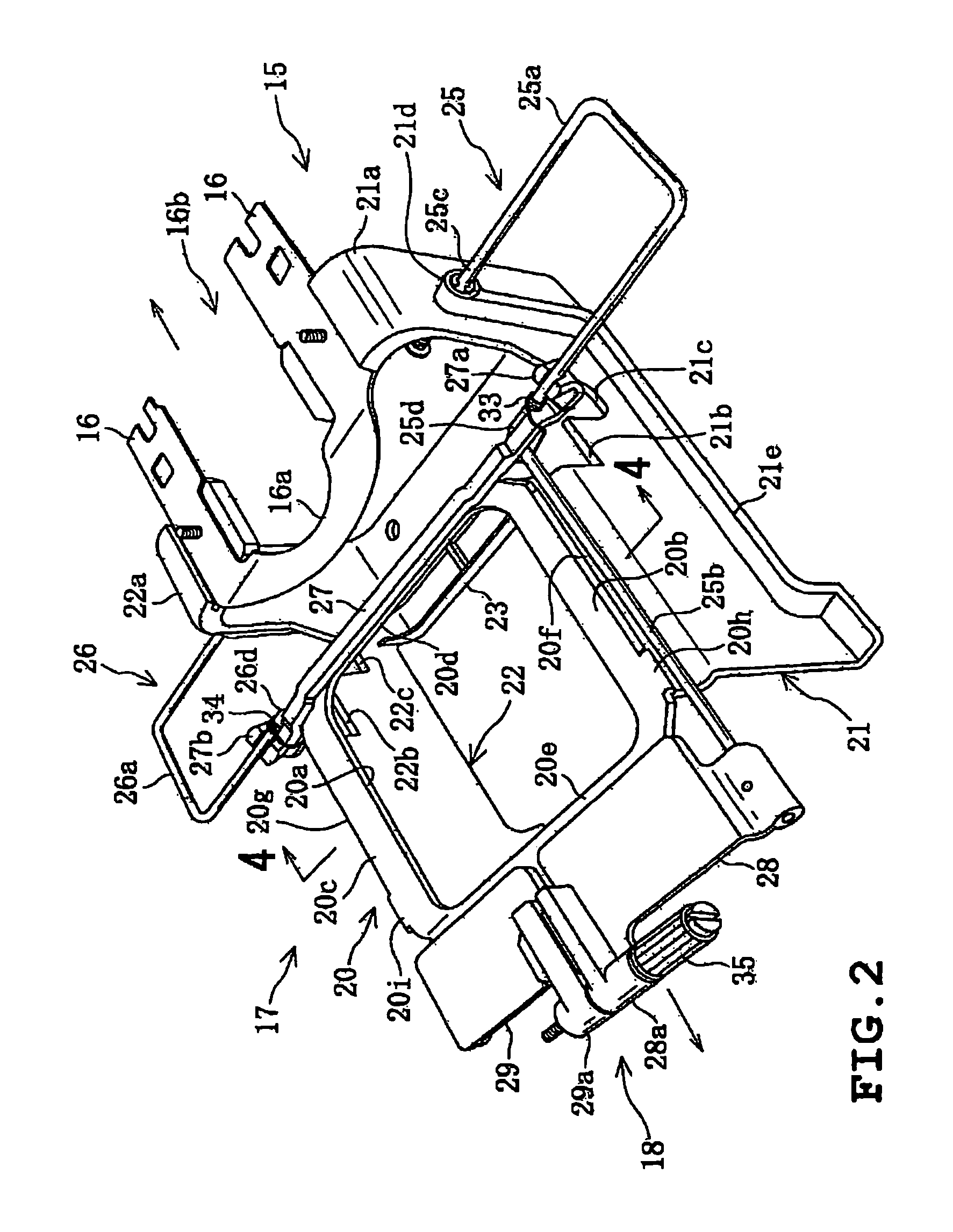

Embroidery frame for caps

An embroidery frame for a cap includes a cap support having a pair of side walls capable of being disposed at both sides of a cylinder bed so that the side walls are parallel to a direction of extension of the cylinder bed, a pair of body supports mounted on the upper ends of the respective side walls for supporting a cap, body, the side walls including a pair of visor supports mounted on upper ends of the proximal ends of the side walls, respectively. The visor supports receive a visor of the cap from below at a position located higher than the body supports, and a pair of visor escapes on the side walls for escaping the visor of the cap, respectively. A cap pressing frame mounted to be contacting with and departing from the cap support.

Owner:BROTHER KOGYO KK

Craft stencil

InactiveUS20050229421A1Fast and simple and convenient meanCreate craft stencils more easily and economicallyUsing mechanical meansPlate printingEngineeringCoating

The craft stencil provides a fast, simple, and convenient way of marking a pattern onto the surface of a workpiece. Useful for, among other tasks, marking a temporary pattern onto a piece of cloth to guide stitching for a needlecraft, the craft stencil is an open mesh material having a coating applied to close the mesh of selected regions of the material, defining a pattern in the uncoated portions. In use, the craft stencil is placed on the surface of the workpiece, and a marking powder is applied to the workpiece surface through open areas in the craft stencil. Guidelines in the stencil transfer registration marks and directional arrows to the workpiece surface along with the pattern in order to assist in aligning the craft stencil and in correctly following the pattern while stitching.

Owner:DEAS MARILYN S +1

Cross-stitch embroidery method and template thereof

InactiveCN101372800AEasy to operateEmbroidery process is simpleHand embroideringLongitudeEngineering

The invention aims at providing a method which has simple embroidering process, is not restricted by the embroidering cloth and can freely embroider a cross-stitch of any size on any target matter as well as a template thereof. The manufacture technique steps of the cross-stitch template are as follows: (1) the drawing of the cross-stitch in an electric version; (2) a film; (3) the template of the cross-stitch. The cross-stitch method is realized by the template which consists of a frame, a longitude template and a latitude template. The longitude template and the latitude template are mutually overlapped and arranged in the frame. The longitude template is a transparent film which is provided with a black horizontal line and a carved vertical line hole. The longitude template is printed with an embroidering pattern. The latitude template is also a transparent film which is provided with a black vertical line and a carved horizontal line hole as well as an embroidering pattern. In the invention, the traditional cross-stitch method is changed; no embroidering frames and embroidering cloth are used; besides, colorful articles can be embroidered on any target matter.

Owner:宋伟丽

Quilt clamp

A clamp for use in quilting that includes a top and a bottom quilt clamp portion that are forced together by a pair of springs to hold multiple layer of quilting materials, such as fabric and batting, firmly together while stitching the quilt pattern. To facilitate movement of the multiple layers in the desired quilt pattern, the quilt clamp is provided with a handle. The bottom surface of the quilt clamp is covered with felt to enhance the slidableness of the clamp on quilting tables and sewing machines.

Owner:HINDSLEY LORA L

Cloth holding device

InactiveUS7484466B2Positioned readily and reliably to positionSimple attachmentAutomatic machinesHand embroideringEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

Technique of floss for embroidery

InactiveCN101319443ABright artistic effectImprove the artistic effectEmbroidering machines apparatusHand embroideringEngineeringCotton material

The invention provides a technique for woolen needlepoint tapestry, belonging to a method for manufacturing embroidered handicraft articles. The technique comprises the following steps that: an embroidery needle is used for embroidering a pattern position of a fabric; embroidery threads in different colors are selected according to pattern requirements; the head of the embroidery needle vertically passes through the fabric from the front of the fabric, and then the embroidery needle is withdrawn to leave a segment of the embroidery threads on the back of the fabric; the previous operations are repeated again and again, so as to embroider the back of the fabric with a part of a pattern in the same color; after embroidering is finished, tail ends of the pattern part on the back of the fabric are sheared off and leveled, then the embroidery threads of the pattern part are brushed uniformly by using a brush so as to become a velvet state. The technique for woolen needlepoint tapestry ensures that: embroidered pattern parts of embroideries show up a hairy stereoscopic sensation, are distinct in gradation, exquisite in expression, bright in color, good in artistic effect and strong in decorative property. The technique improves the aesthetic feeling of embroideries, is simple in stitch, strong in regularity and high in manufacture efficiency, and can manufacture human portraits, various Chinese paintings, calligraphy works and other embroideries.

Owner:牛国秀

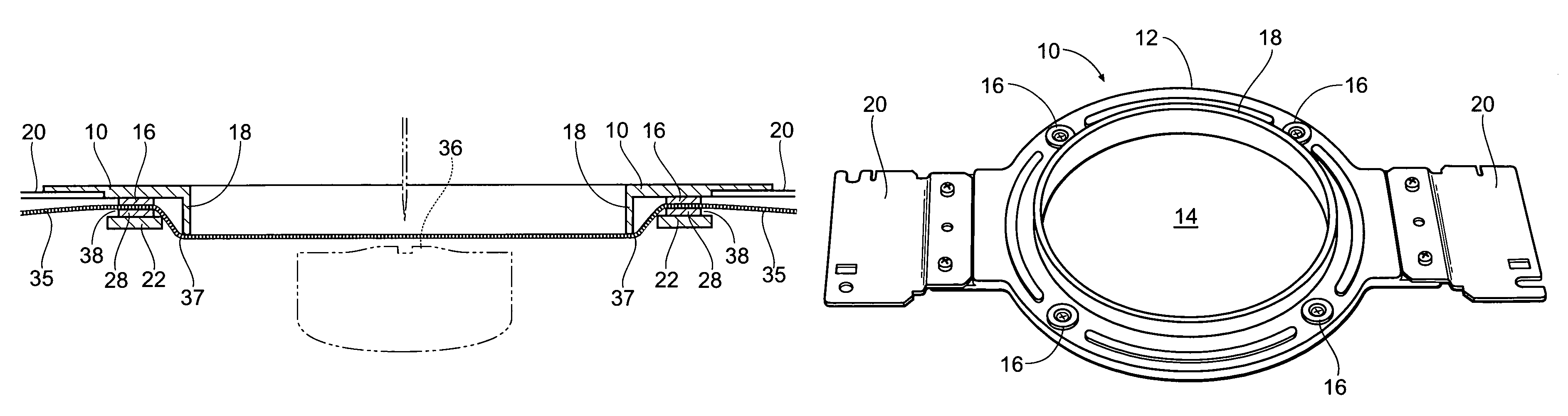

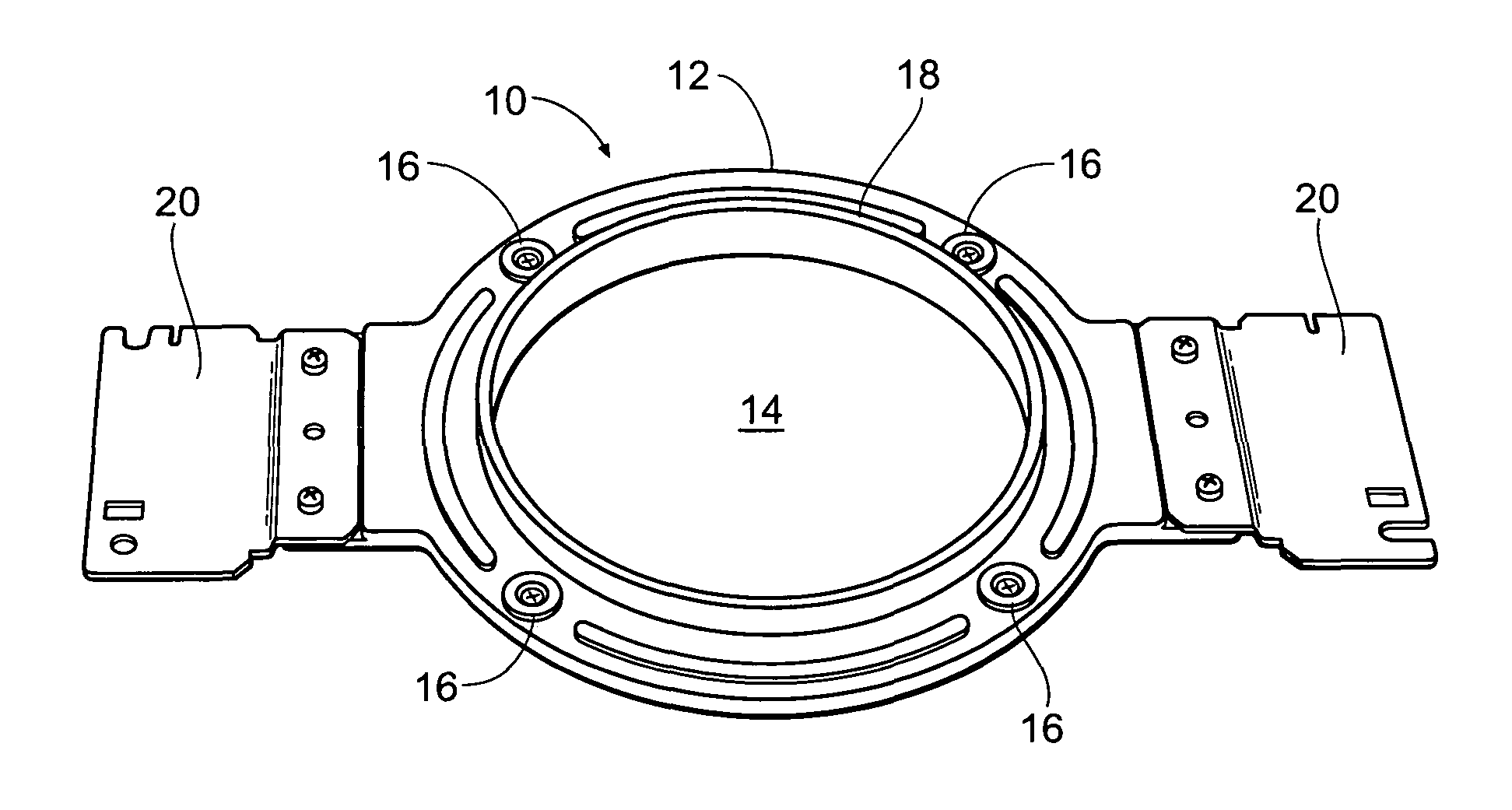

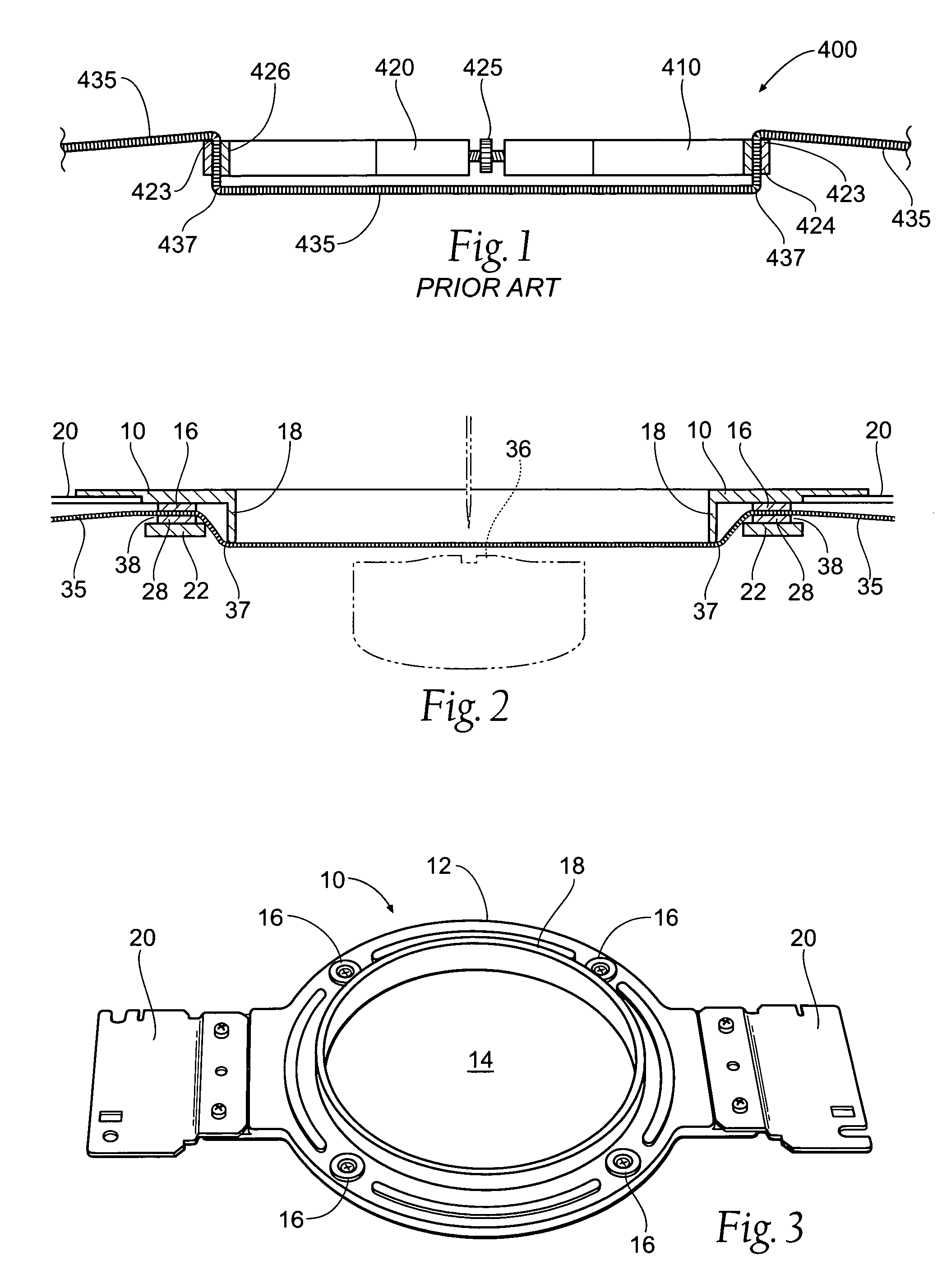

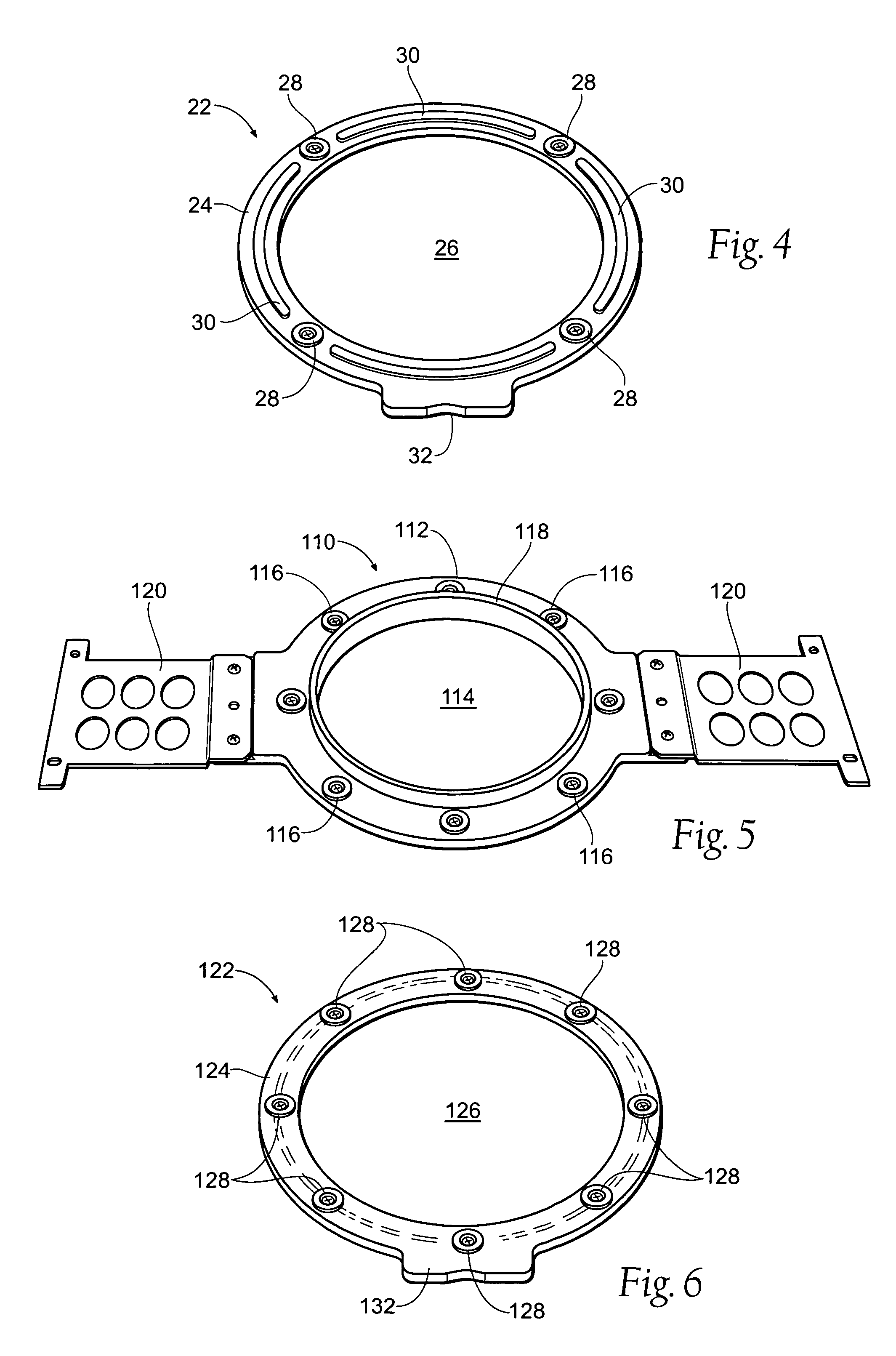

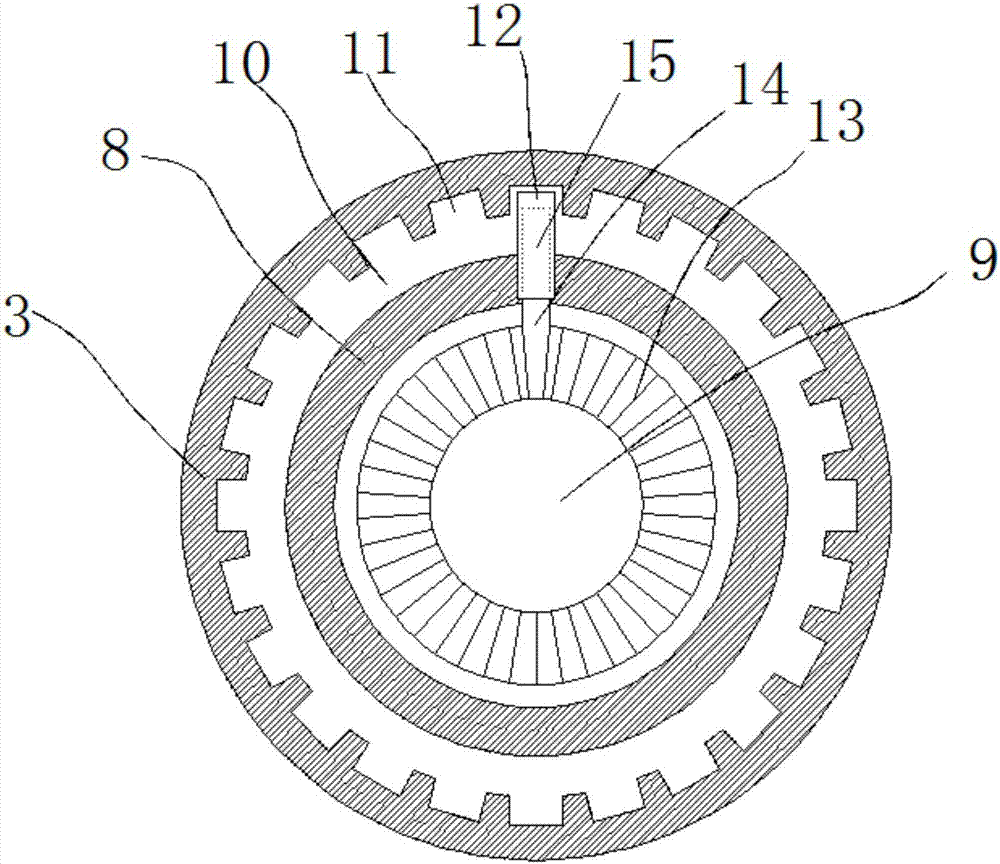

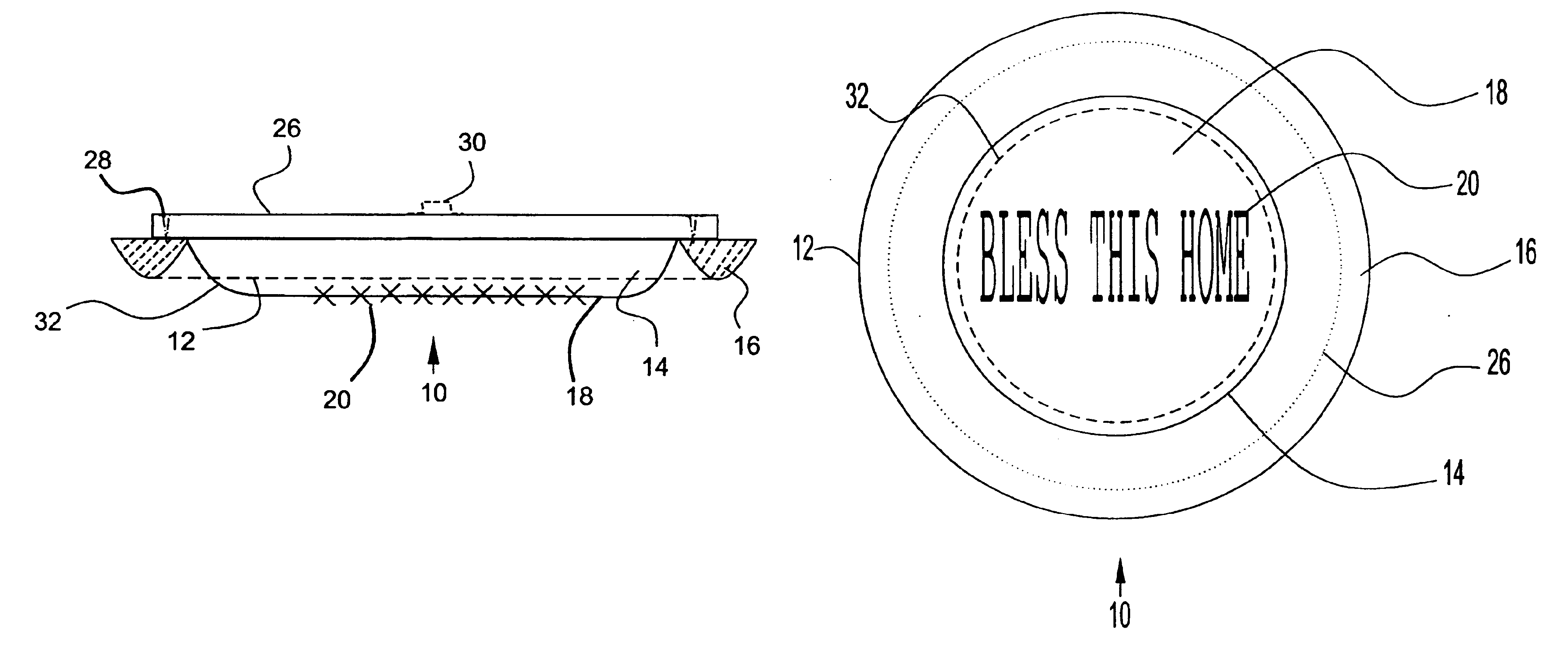

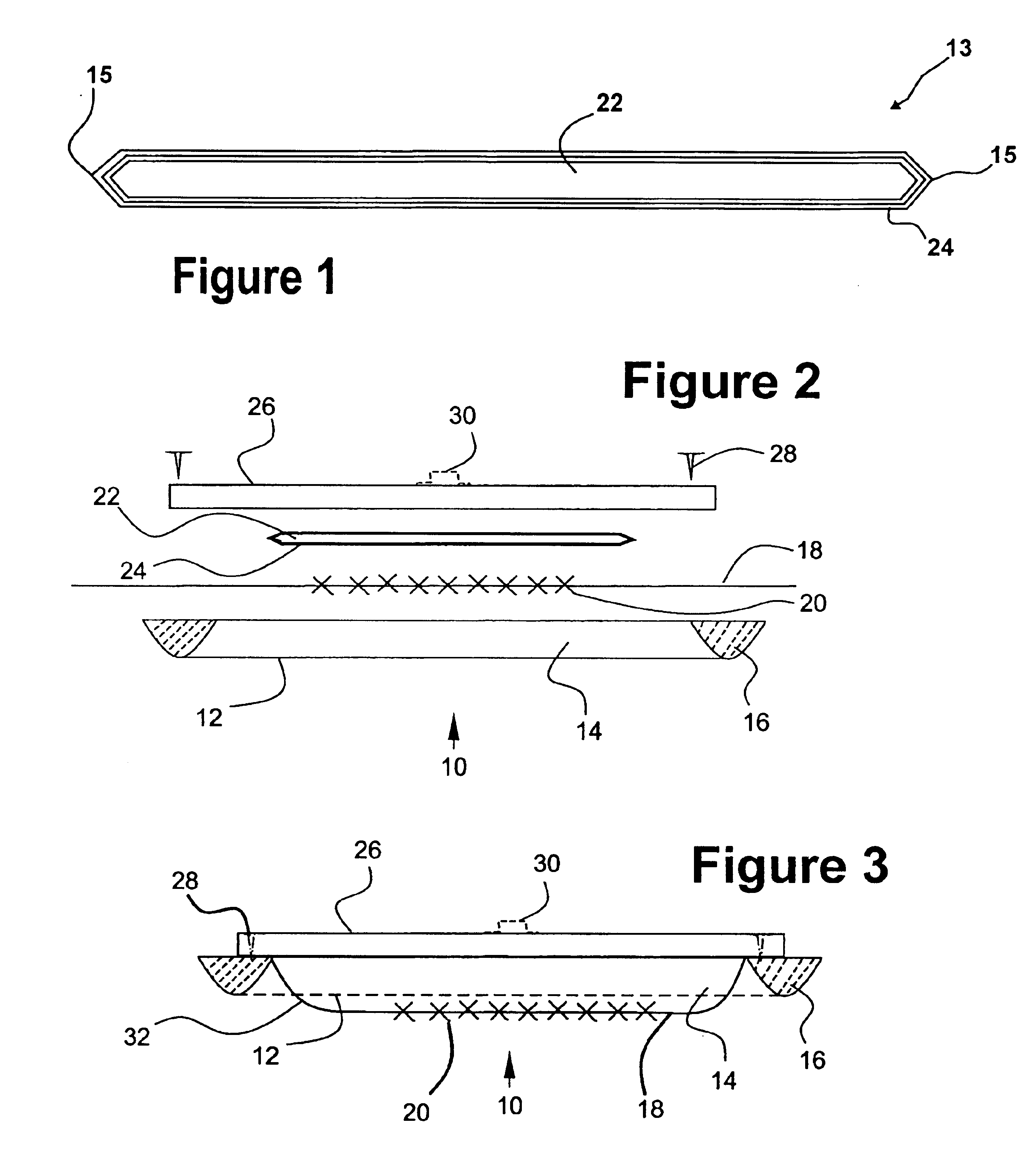

Magnetic fabric retaining device

ActiveUS7607399B2Efficient use ofPrecise alignmentAutomatic machinesHand embroideringRare-earth magnetEngineering

A device for use with an embroidery machine to hold an item or material to be embroidered between upper and lower hooping members, with the hooping members being secured to one another by use of a magnetic force, preferably with rare earth magnets, is disclosed. The magnets provide a solid, secure mating arrangement between the upper and lower hooping members as well as providing proper alignment of the hoping members. A ridge may be formed in at least one hooping member to securely retain the item or material to be embroidered. One hooping member has interchangeable arms for attaching the mating hooping members to different brands of embroidery machines.

Owner:MIDWEST PRODS

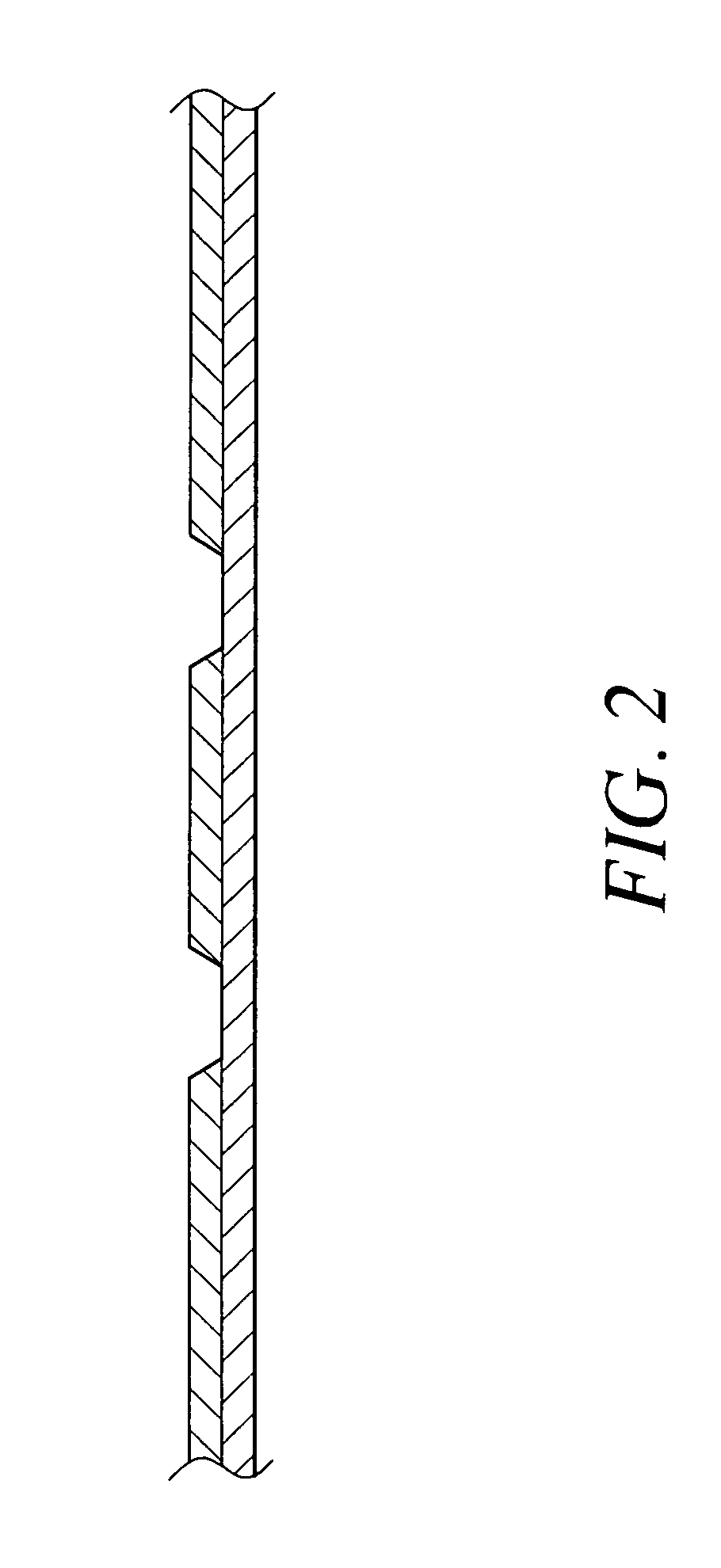

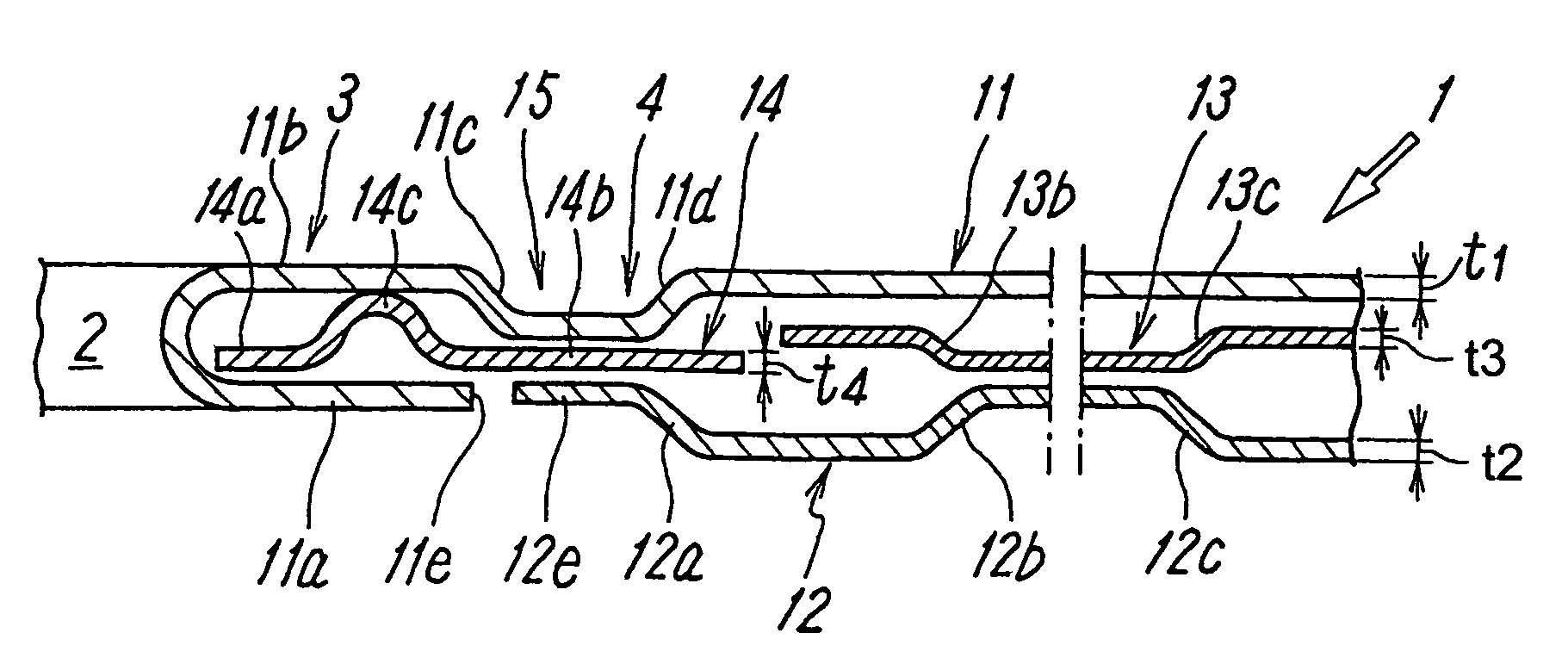

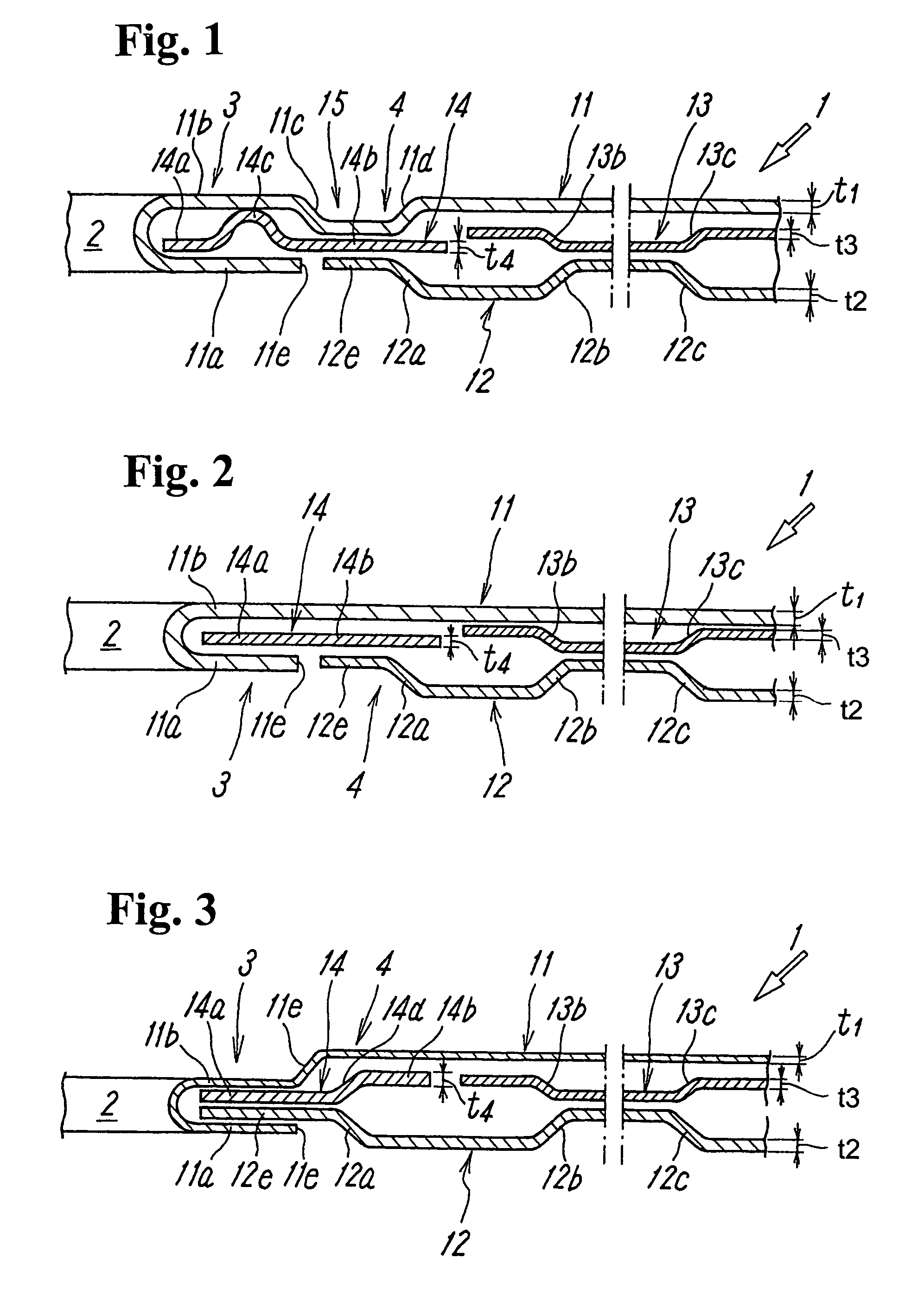

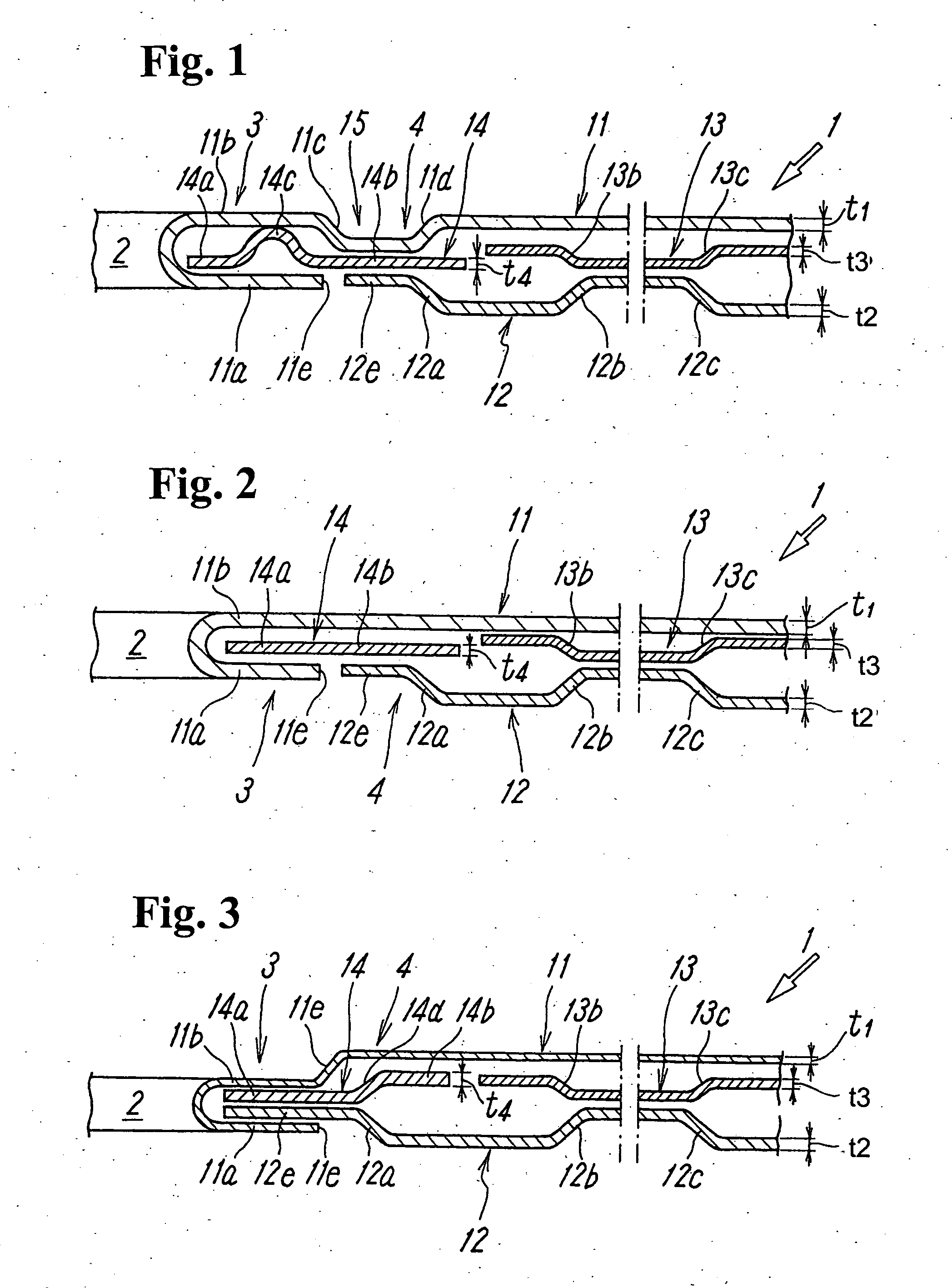

Metal laminate gasket

InactiveUS7290770B2Improve heat resistanceGood followabilityEngine sealsSealing arrangements for enginesCylinder headEngineering

A metal gasket for an internal combustion engine includes a first metal plate with a folded portion; a ring member with a sandwiched portion having a sealing bead and an extension portion, with the sandwiched portion being sandwiched in the folded portion to provide a primary sealing portion; a second metal plate laminated to the folded portion of the first metal plate so as to sandwich the extension portion to provide a secondary sealing portion; and a third metal plate sandwiched between the first metal plate and the second metal plate in a portion of the gasket separate from the sandwiched extension portion. In the event that the cylinder head lift becomes greater than the following capability of the sealing bead in the primary sealing portion, the secondary sealing portion provides excellent following capability relative to the lift.

Owner:ISHIKAWA GASKET CO LTD

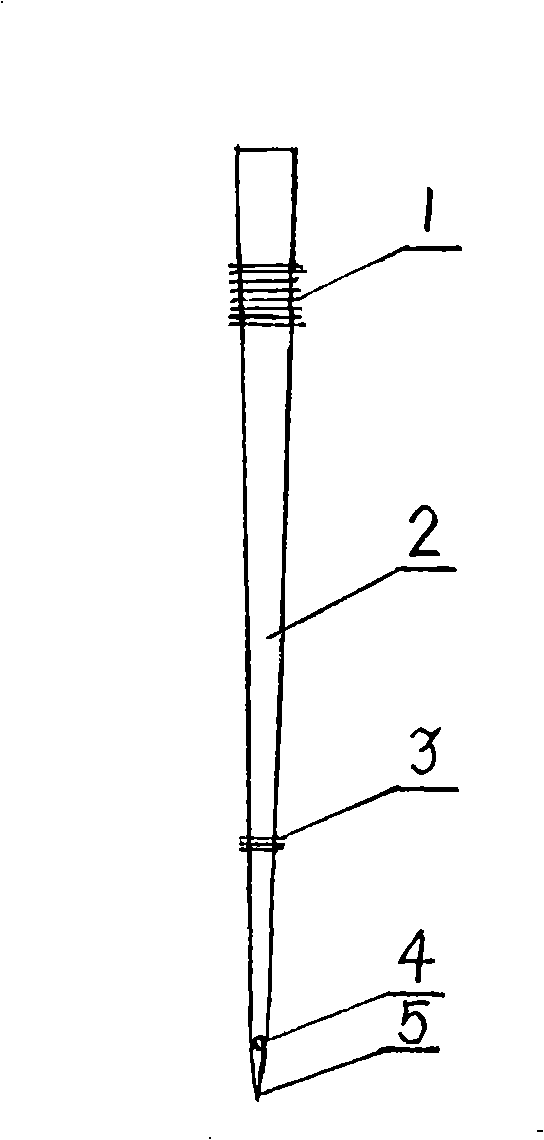

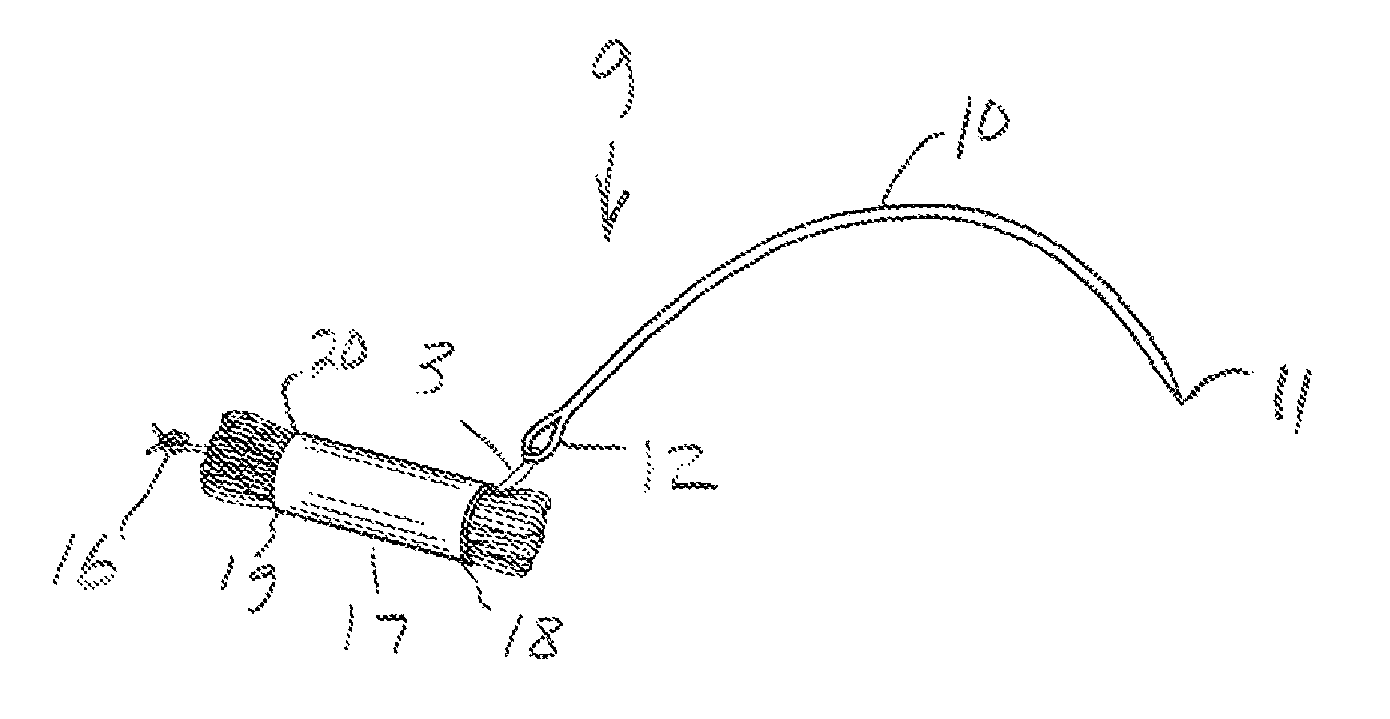

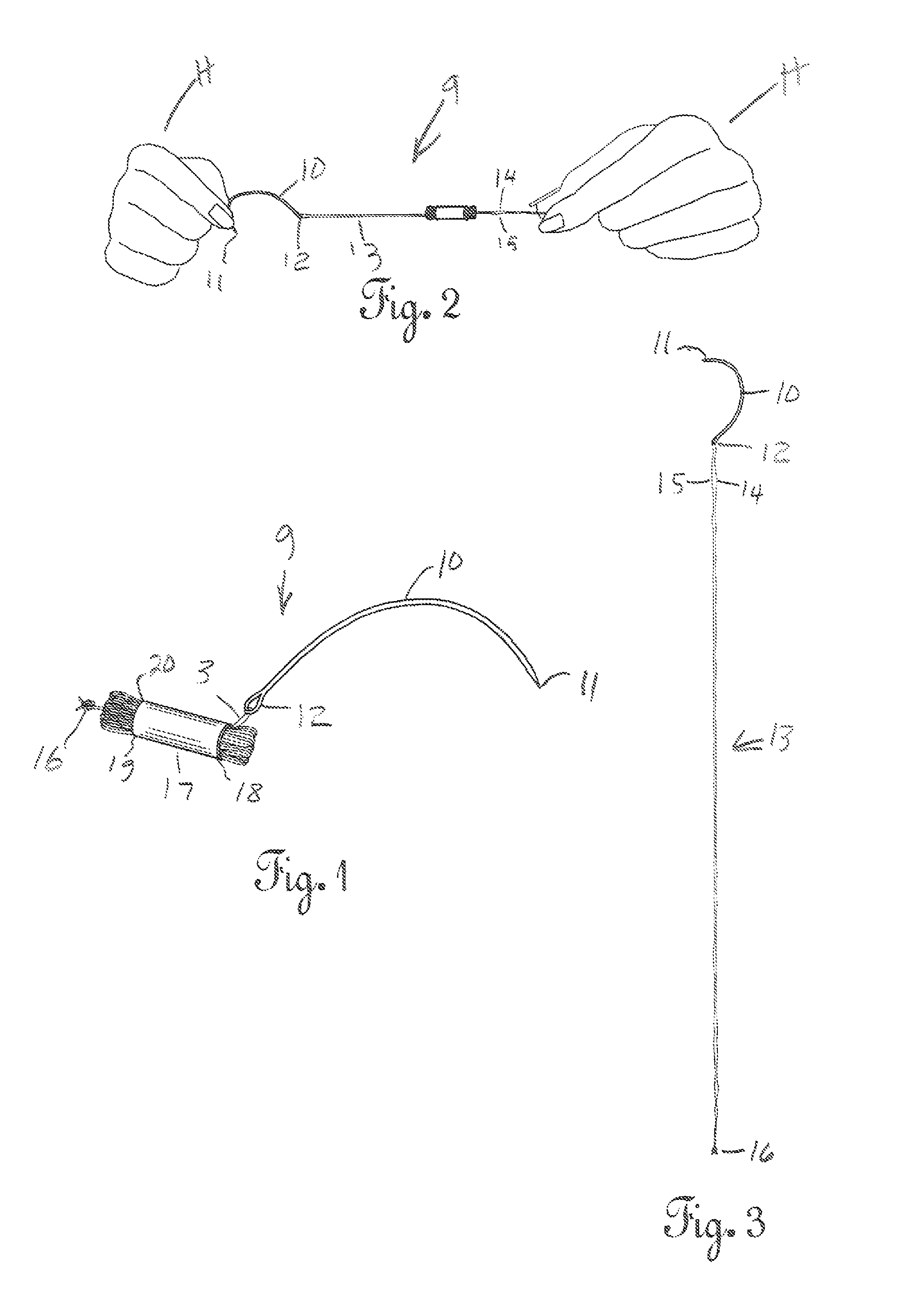

Pre-threaded and knotted hair weaving needle and method

Owner:SMITH TANISHA SHANAE

Embroidering method for expressing veins and texture of sweaters

The invention relates to an embroidering method for expressing veins and texture of sweaters. In the method, embroidering is performed on embroidering cloth by utilizing an embroidering needle and embroidering yarns. The embroidering method is characterized in that: the embroidering yarns consist of twisted yarns formed by twisting at least two strands of silk yarns in the forward direction, stranding and twisting in the reverse direction; the twisted yarns are made in different thickness specifications according to the thickness of yarn diameters; and during the embroidering, fishbone-shapedskeletons which are arranged in parallel are embroidered by using the thickest twisted yarns according to the veins of the sweaters, and darning is performed over and over in gaps of the fishbone-shaped skeletons by using the thinner twisted yarns step by step until the gaps of the fishbone-shaped skeletons are filled up. In the embroidering method, the limit of the conventional plain knitting embroidery is broken, so that the embroidery stitches and veins of the sweaters are clear, high in stereoscopic impression and have the full and vivid effect, the texture of the sweaters is embodied fully, and the expressive force and rendering capacity of the sweaters are improved obviously.

Owner:郁丽勤 +1

Metal laminate gasket

InactiveUS20060163819A1Easy to liftImprove heat resistanceEngine sealsSealing arrangements for enginesCylinder headEngineering

A metal gasket for an internal combustion engine includes a first metal plate with a folded portion; a ring member with a sandwiched portion having a sealing bead and an extension portion, with the sandwiched portion being sandwiched in the folded portion to provide a primary sealing portion; a second metal plate laminated to the folded portion of the first metal plate so as to sandwich the extension portion to provide a secondary sealing portion; and a third metal plate sandwiched between the first metal plate and the second metal plate in a portion of the gasket separate from the sandwiched extension portion. In the event that the cylinder head lift becomes greater than the following capability of the sealing bead in the primary sealing portion, the secondary sealing portion provides excellent following capability relative to the lift.

Owner:ISHIKAWA GASKET CO LTD

Method for making combined embroidery

InactiveCN101748573AShort embroidery timeOrnamentalEmbroidering machines apparatusHand embroideringEngineeringMechanical engineering

The present invention relates to a method for making combined embroidery. The method comprises the following steps: first, an absolute cross stitch grid drawing is made by extracting the cross stitch part of the combined embroidery with software; then, threads are added on a base cloth with the traditional cross stitch method according to grids on the drawing; after the cross stitch part is finished, a ribbon embroidery part is embroidered on the base cloth printed with silk net lines according to lines printed on the cloth; finally, a complete piece of combined embroidery is finished on the accomplishment of the ribbon embroidery part. The present invention has the advantages that the embroidering time of the combined embroidery is shorter than that of the traditional cross stitch, and the combined embroidery having stereoscopic effect combines the fine and smooth cross stitch and the stereoscopic and elegant ribbon embroidery; the finished product has ornamental and collection values.

Owner:丁云

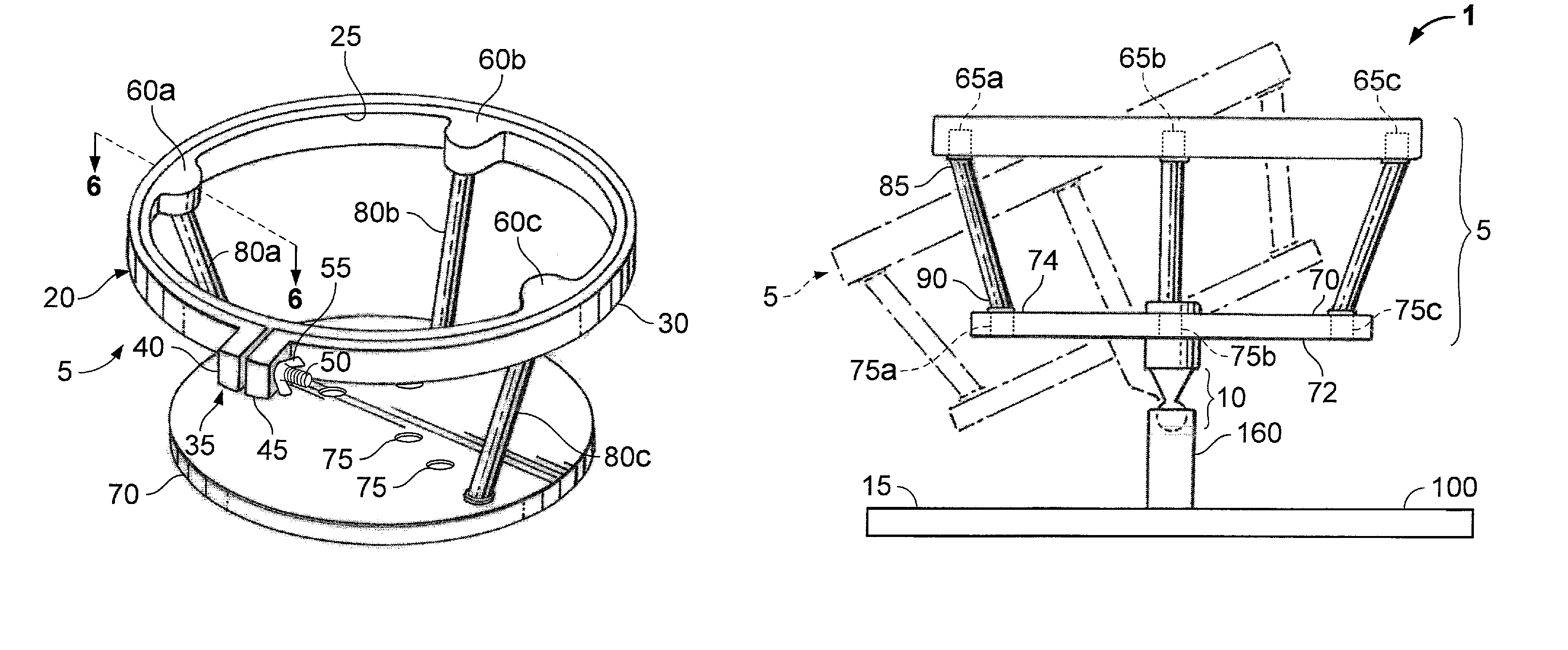

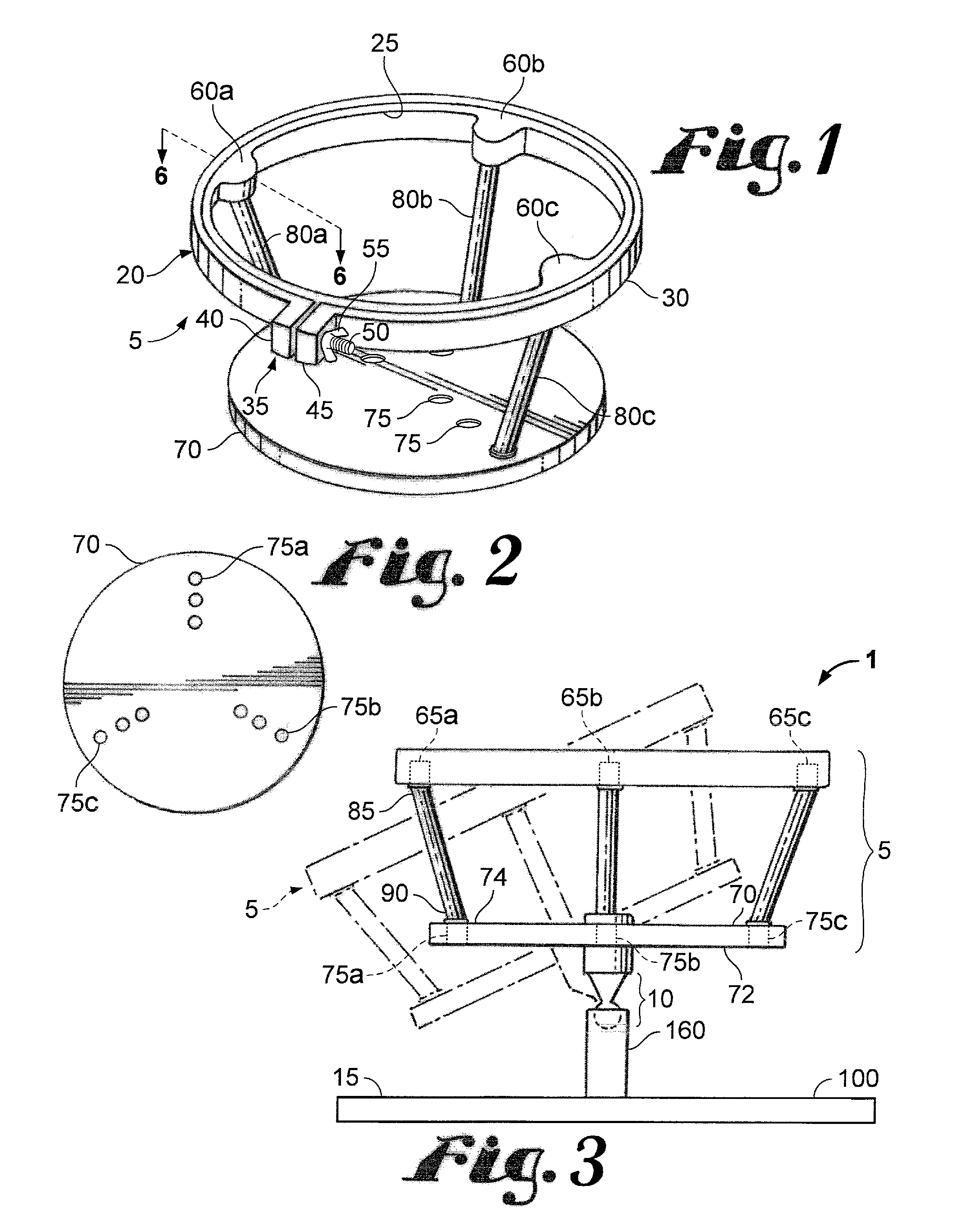

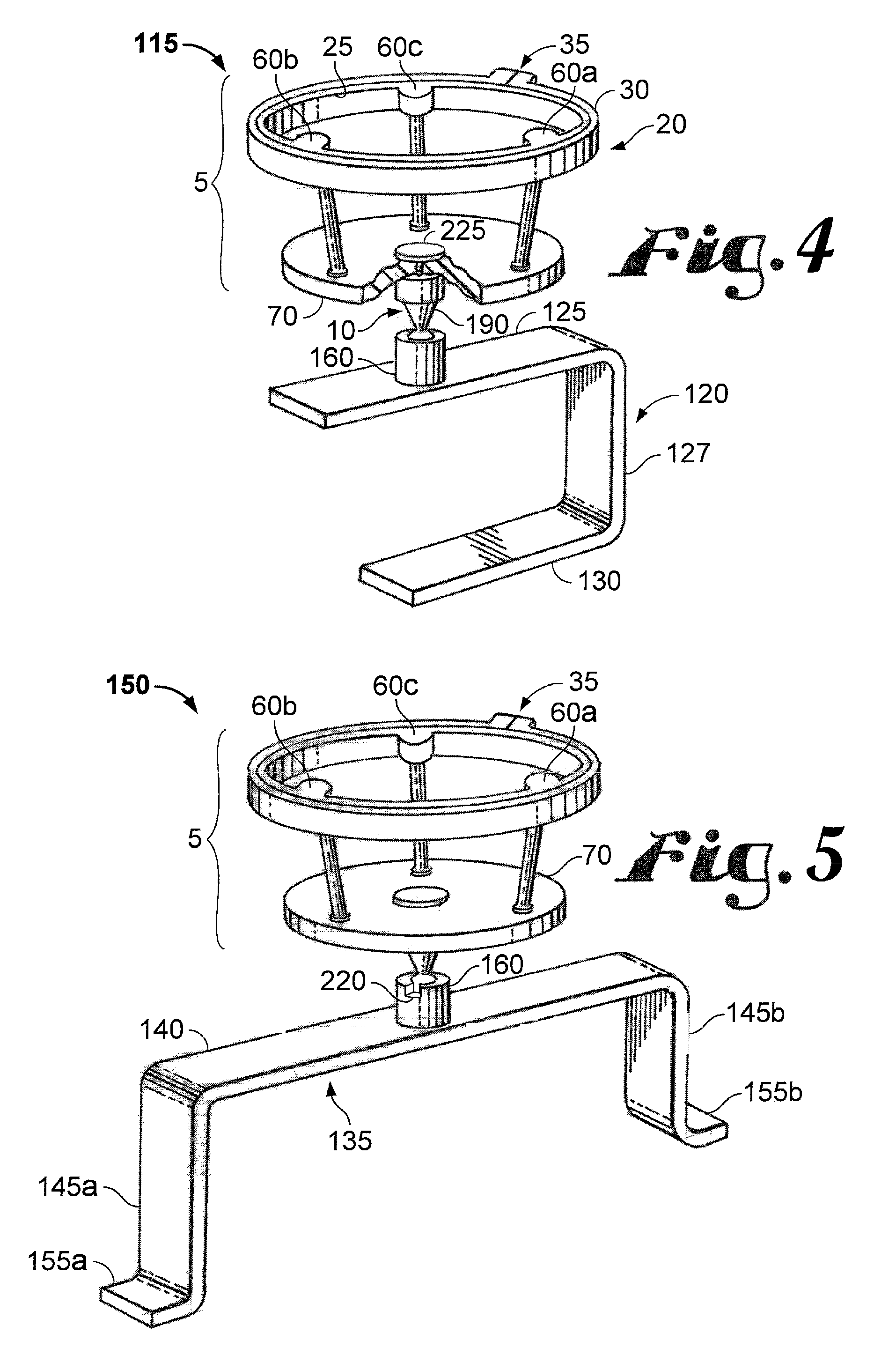

Craft hoop lap stand

A lap stand for supporting a craft frame or hoop upon a user's lap such that the hoop may be swiveled upon a universal joint in a variety of orientations to allow improved user access to the work piece held by the hoop.

Owner:MORGAN ROBERT ELLIOTT

Magnetic fabric retaining device

A device for use with an embroidery machine to hold an item or material to be embroidered between upper and lower hooping members, with the hooping members being secured to one another by use of a magnetic force, preferably with rare earth magnets, is disclosed. The magnets provide a solid, secure mating arrangement between the upper and lower hooping members as well as providing proper alignment of the hooping members. A ridge may be formed in at least one hooping member to securely retain the item or material to be embroidered. One hooping member has interchangeable arms for attaching the mating hooping members to different brands of embroidery machines.

Owner:MIDWEST PRODS

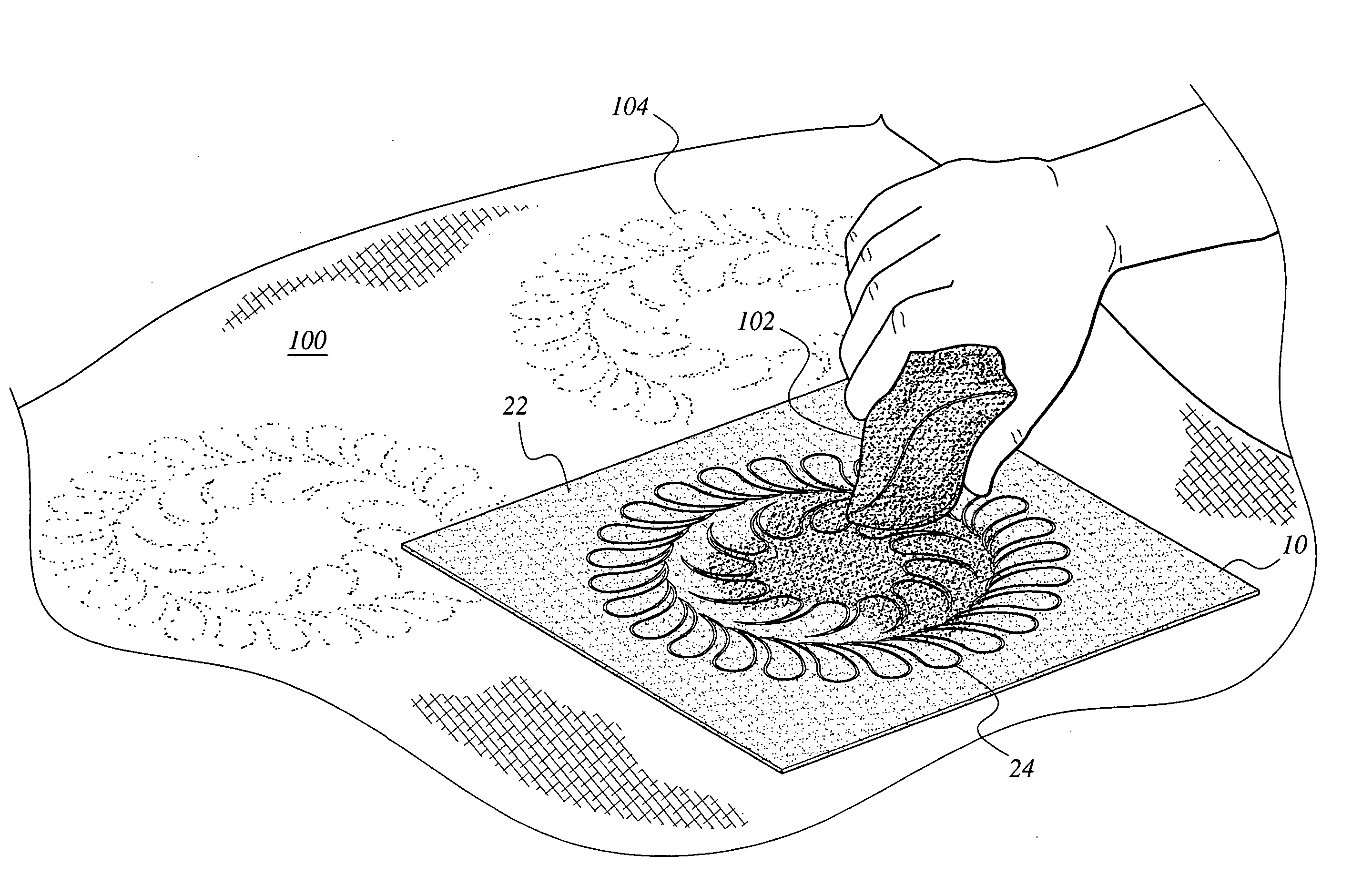

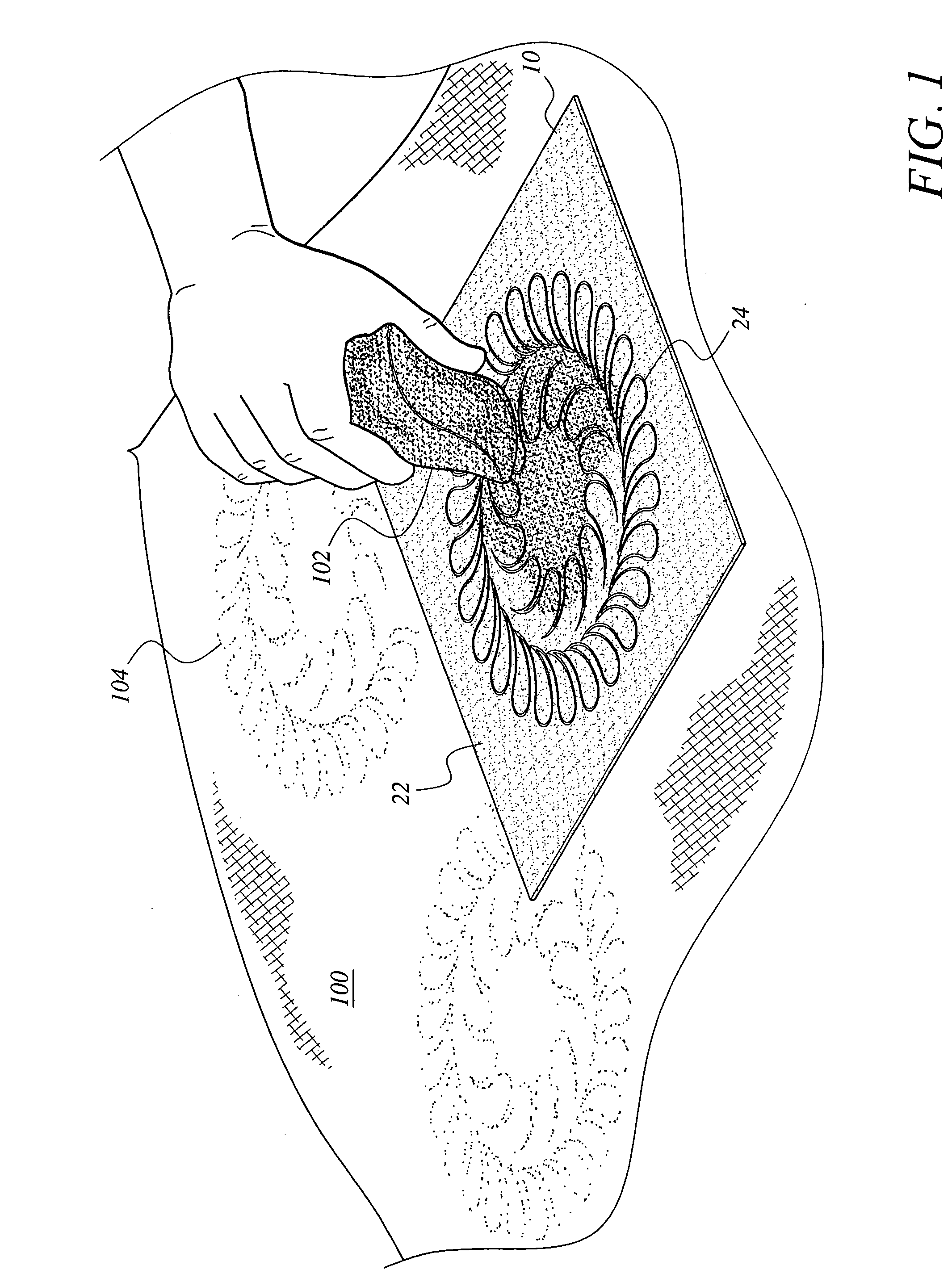

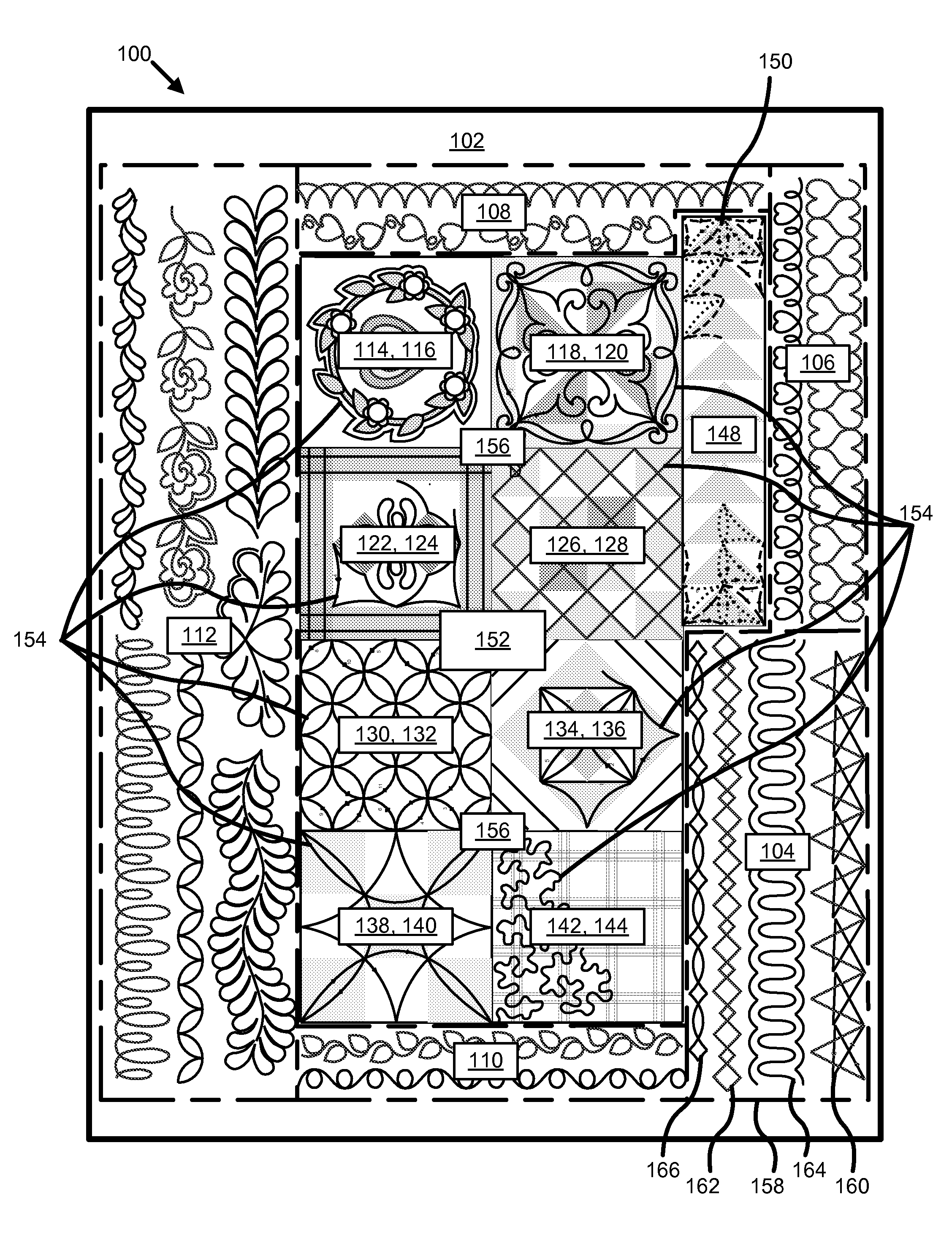

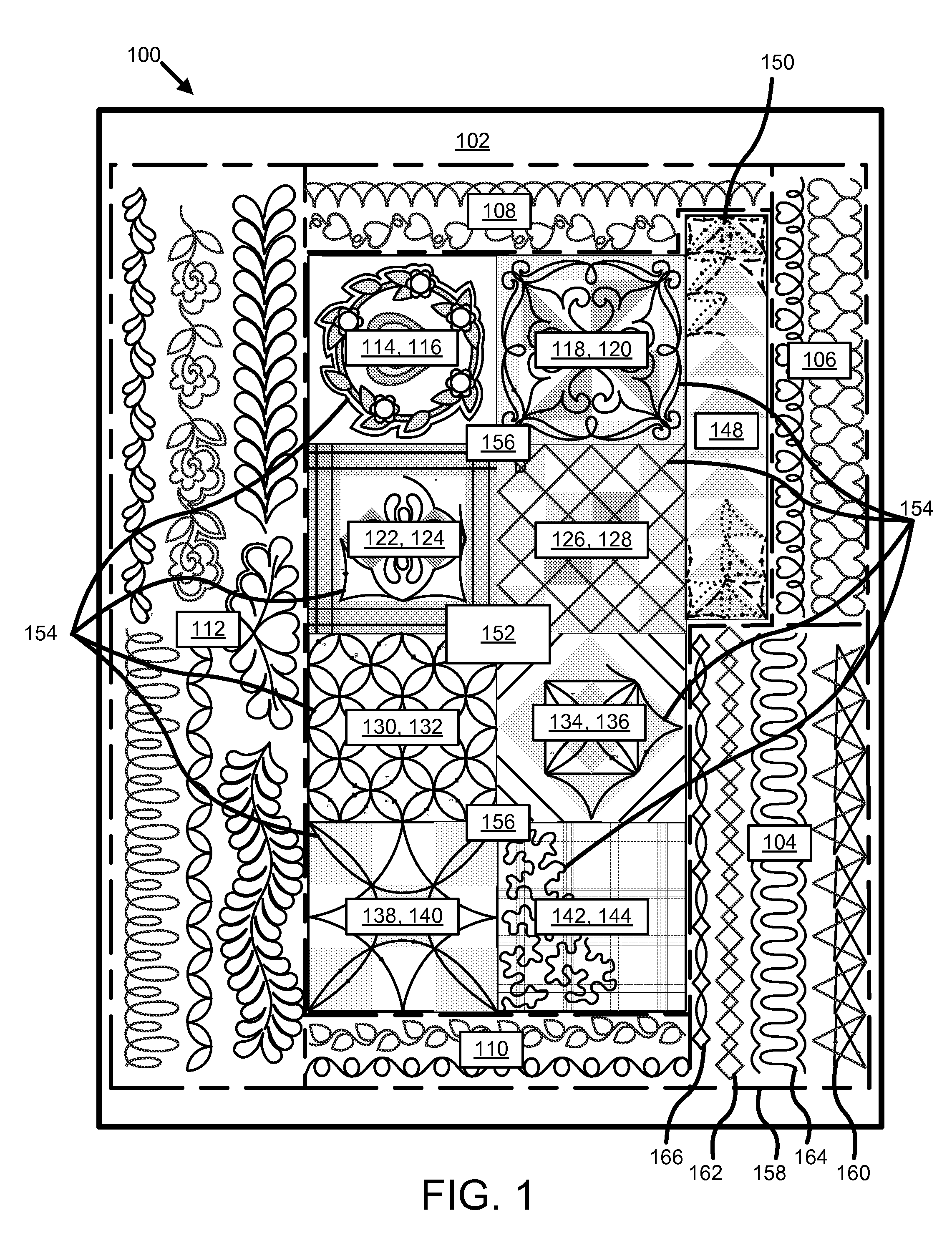

Apparatus, system, and method for facilitating the instruction of quilting techniques

An apparatus to facilitate the instruction of quilting techniques includes a background pattern and a stitching pattern printed on a fabric panel. The fabric panel may be a length of fabric configured to receive inks which define the background pattern and the stitching pattern. The background pattern may be a plurality of geometric shape arranged to simulate one or more quilted fabric designs such as those designs found on a typical quilted fabric. The stitching pattern includes at least one quilting stitching design which defines a guideline for stitching the stitching pattern. The apparatus also includes at least one instructional mark printed on the fabric panel. The instructional mark defines a quilting instruction which guides a user in stitching the stitching pattern.

Owner:ALLEN RENAE GILBERT

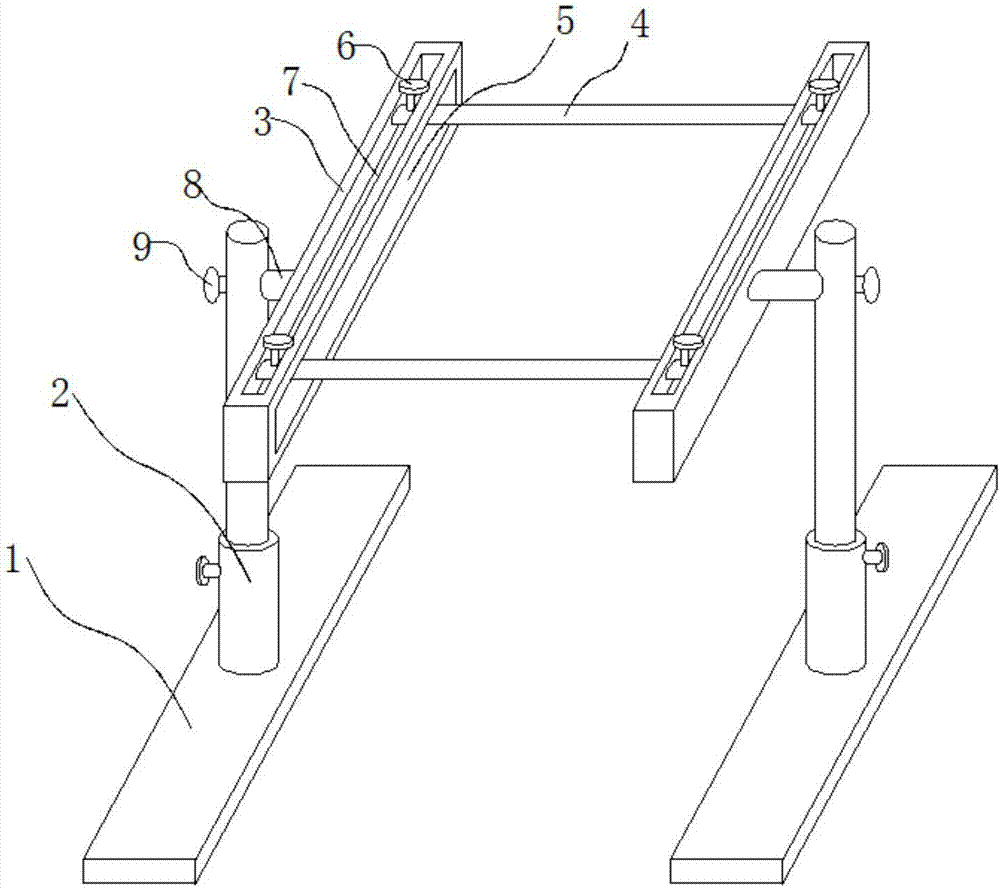

Adjustable embroidery stand

Owner:贵州绣之魂民族服饰有限公司

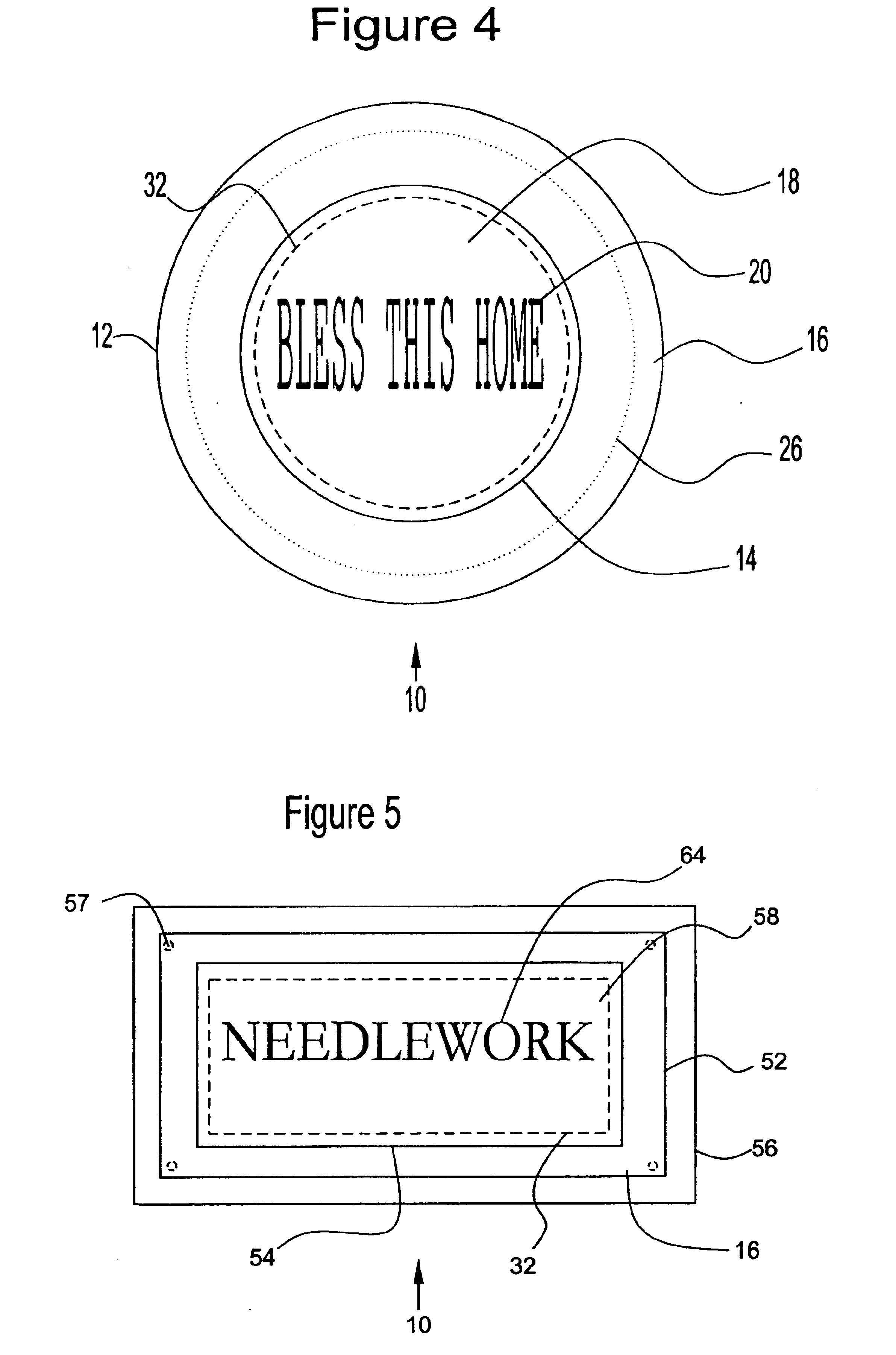

Method and device for mounting needlework

InactiveUS6868626B1Easy and low-cost methodSmooth appearanceStretchingHand embroideringEngineeringMechanical engineering

A mounting system for easily mounting flexible materials, such as needlepoint, is disclosed. The system uses a compressed foam unit placed between the flexible material and a mounting member. The compressed foam unit consists of a foam material sealed between two sheets of air impermeable material with the air having been removed. Once the flexible material is secured to the mounting member, the air impermeable material is punctured and the foam returns to its original state, thereby stretching the material.

Owner:LINKOUS KELVIN

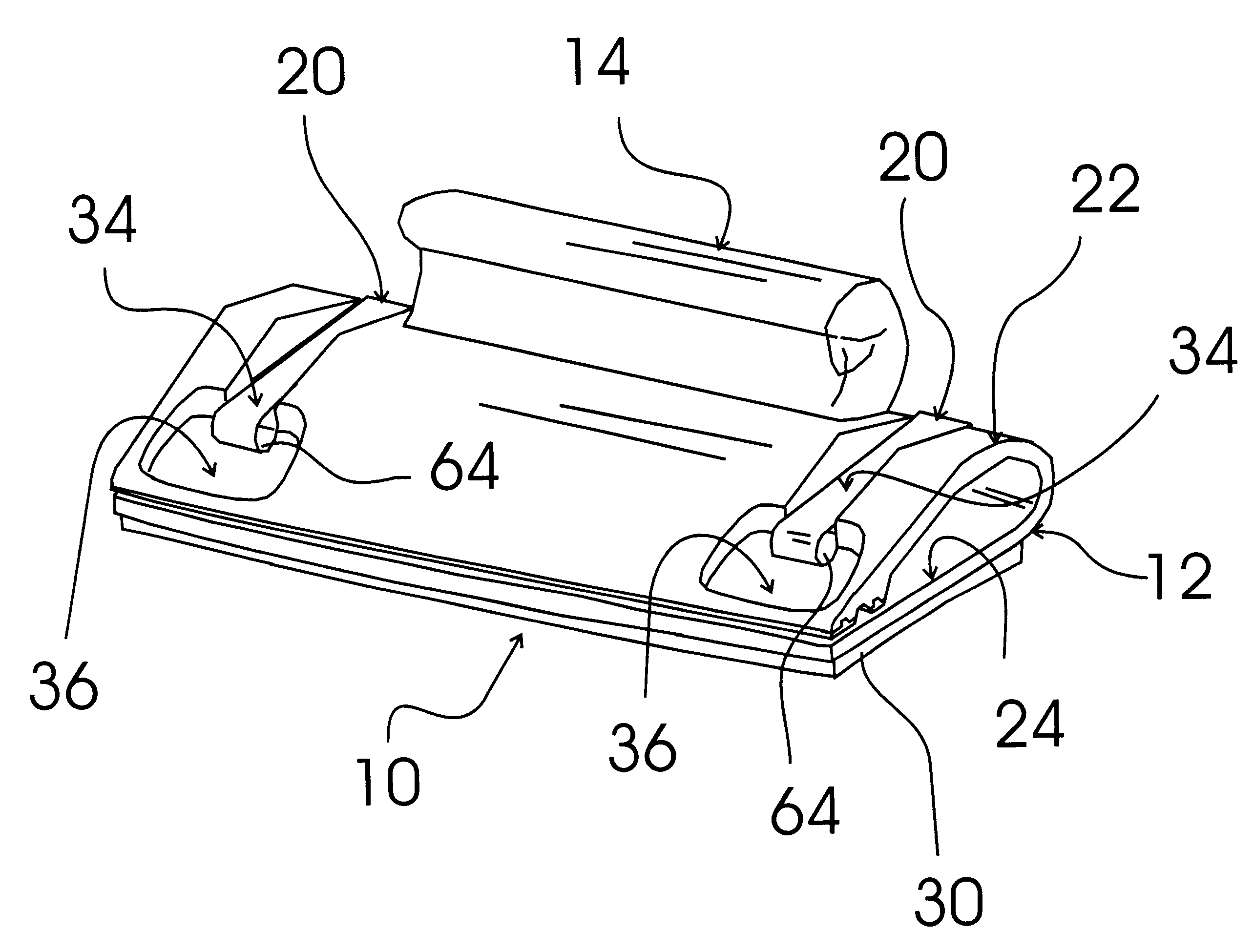

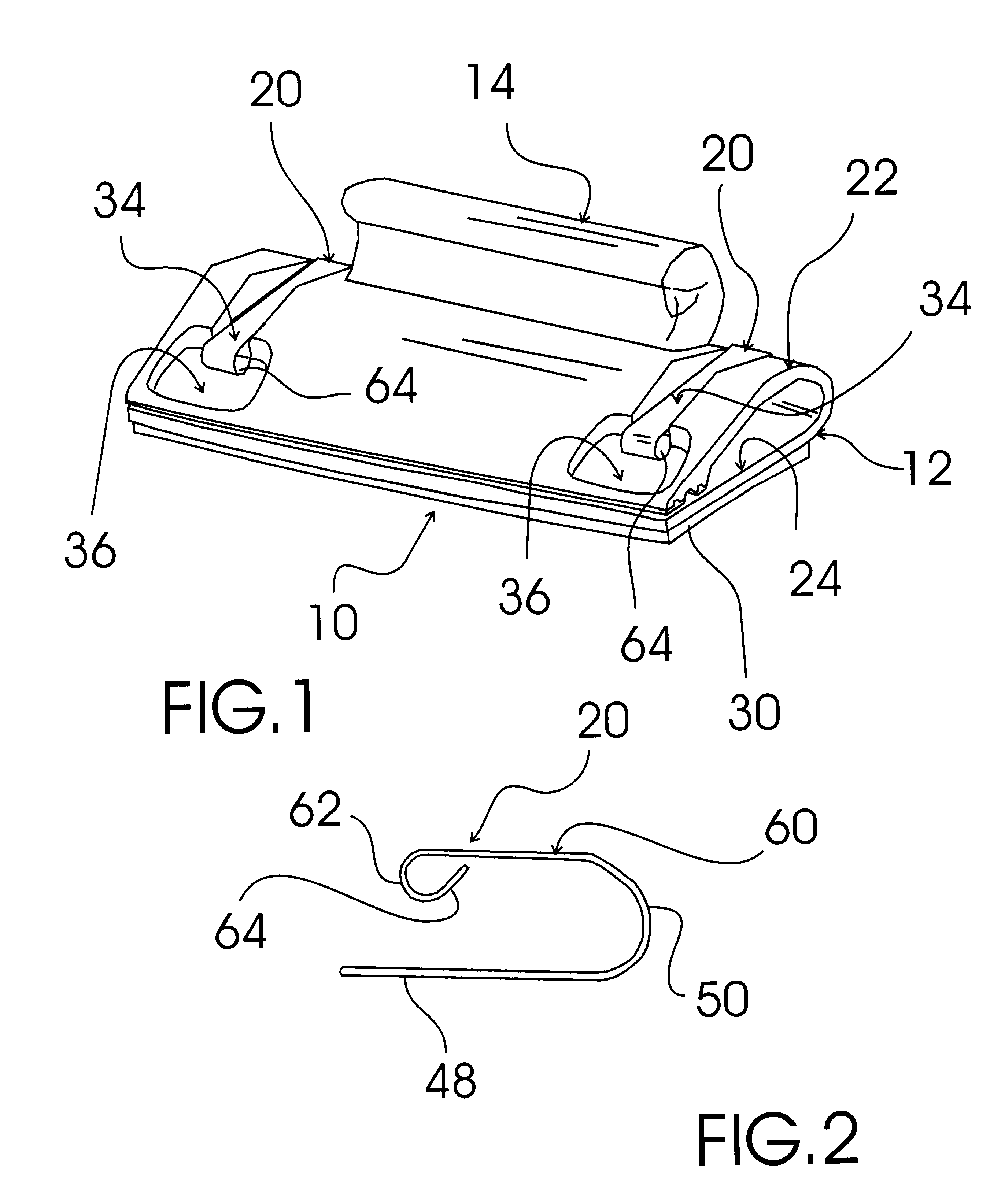

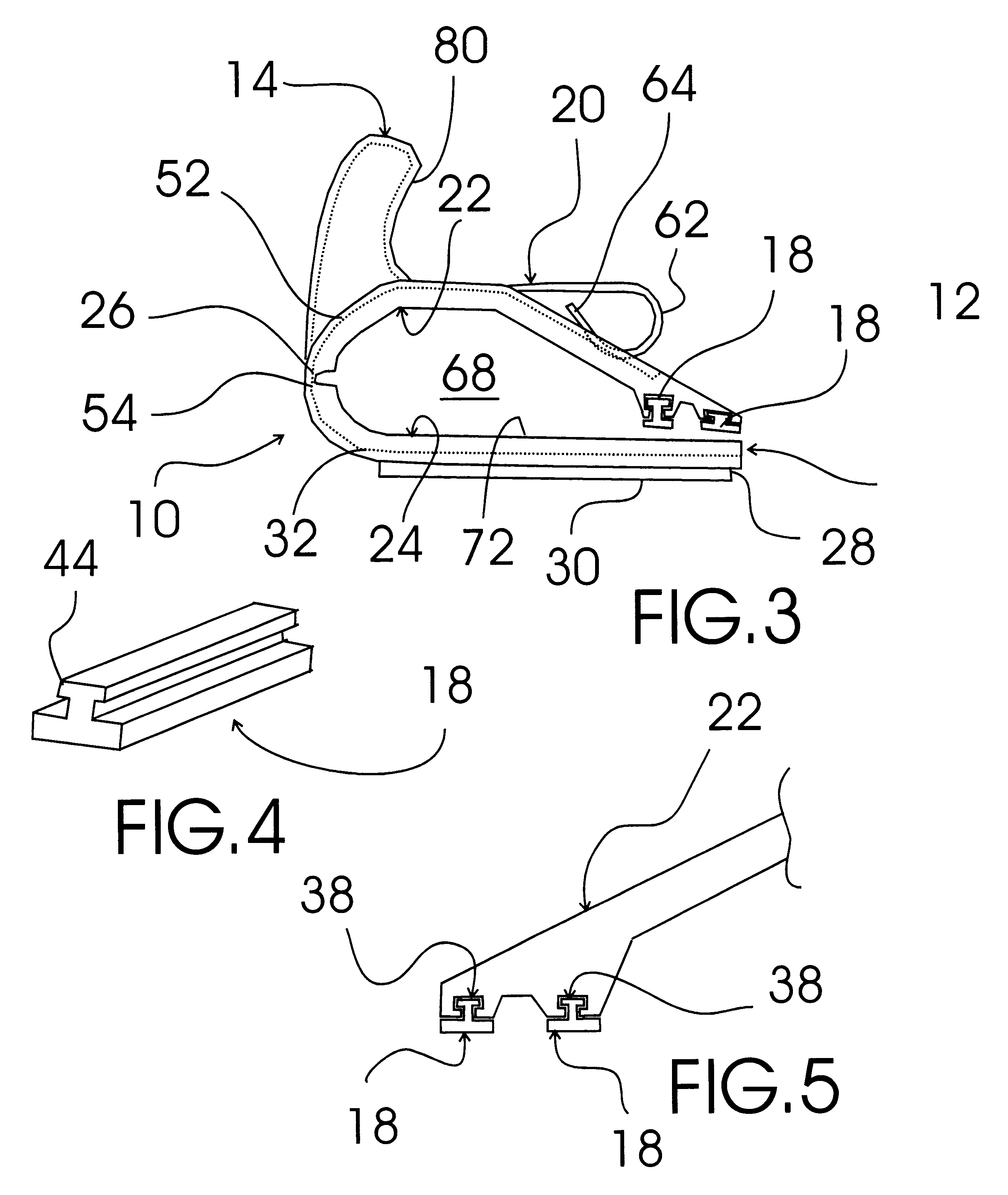

Embroidery frame transfer device and attachment

An attachment 52 comprises: a carriage connecting section 74 connected to a carriage 12 of an embroidery frame transfer device 4; and a metal fastener fixed to an attaching block 32 at the right-hand end portion of the carriage connecting section 74 and having a connecting section of a nonstandard embroidery frame 51 connected thereto. By connecting a connecting section 66 of the nonstandard embroidery frame 51 to the metal fastener 75 of the attachment 52 and by connecting the carriage connecting section 74 of the attachment 52 to the carriage 12, the nonstandard embroidery frame 51 can be mounted indirectly on the carriage 12. Thus, the nonstandard embroidery frame 51 of the type different in construction for attachment to the carriage 12 can be connected to the carriage 12.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com