Technique of floss for embroidery

A process method and velvet embroidery technology, applied in the production field of embroidered handicrafts, can solve the problems of not enough delicate embroidery, low production efficiency, and lack of three-dimensional sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below.

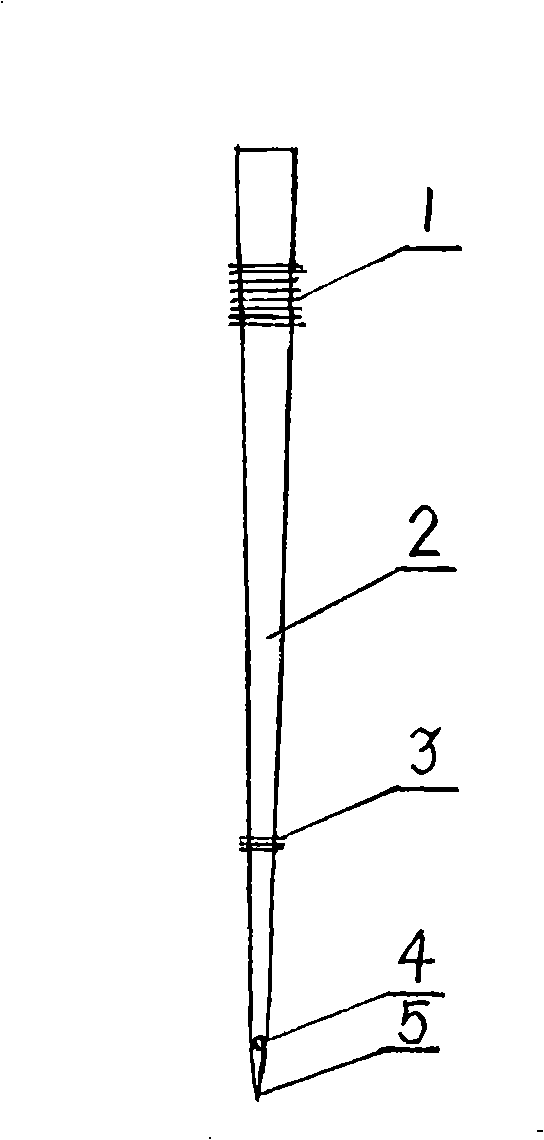

[0014] The said embroidery thread adopts the cotton thread after being twisted. That is, the cotton thread that has been tightened.

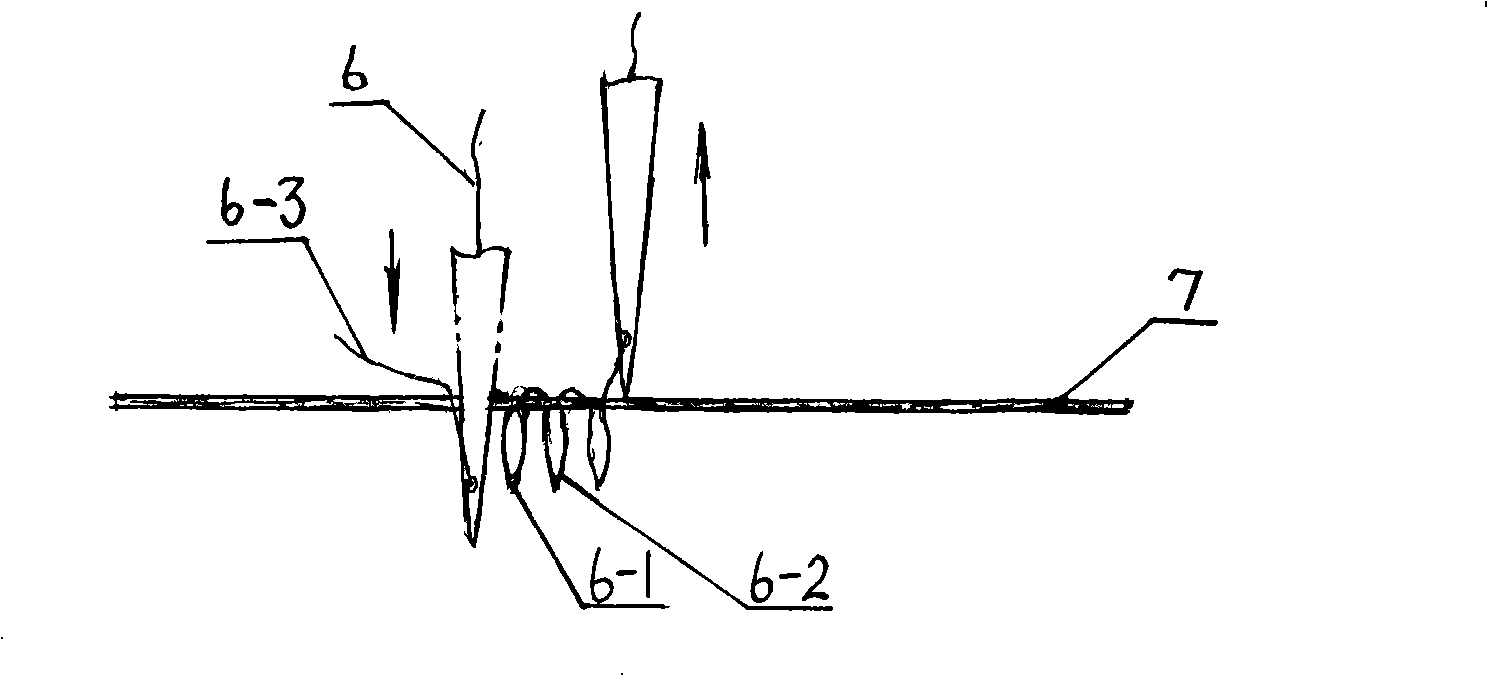

[0015] When making the desired pattern on the cloth, you can draw the pattern directly on the cloth with a brush, or you can paste the patterned rice paper on the cloth to complete the production of the desired pattern. The side of the fabric with the desired pattern is the front side. The back side of the fabric in the present invention refers to the side of the fabric opposite to the front side.

[0016] The cloth used is preferably white cloth.

[0017] When embroidering a pattern, a variety of stitching methods such as horizontal orientation (that is, the stitches at the back and the stitches in the front are on the same horizontal line), vertical orientation, oblique orientation, and curved orientation can be used.

[0018] Compared with embroidery, the gap between stitches in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com