Patents

Literature

91results about How to "Improve high temperature fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

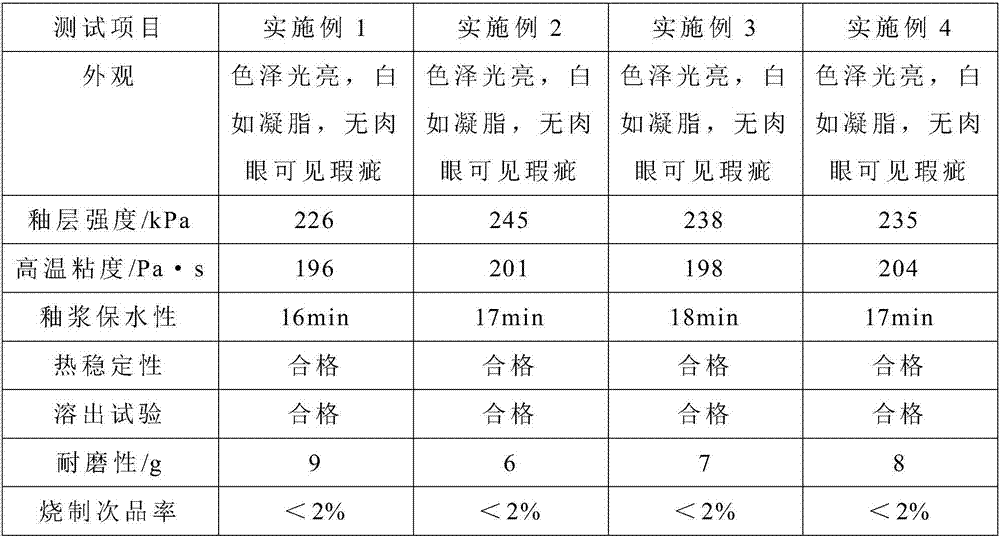

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

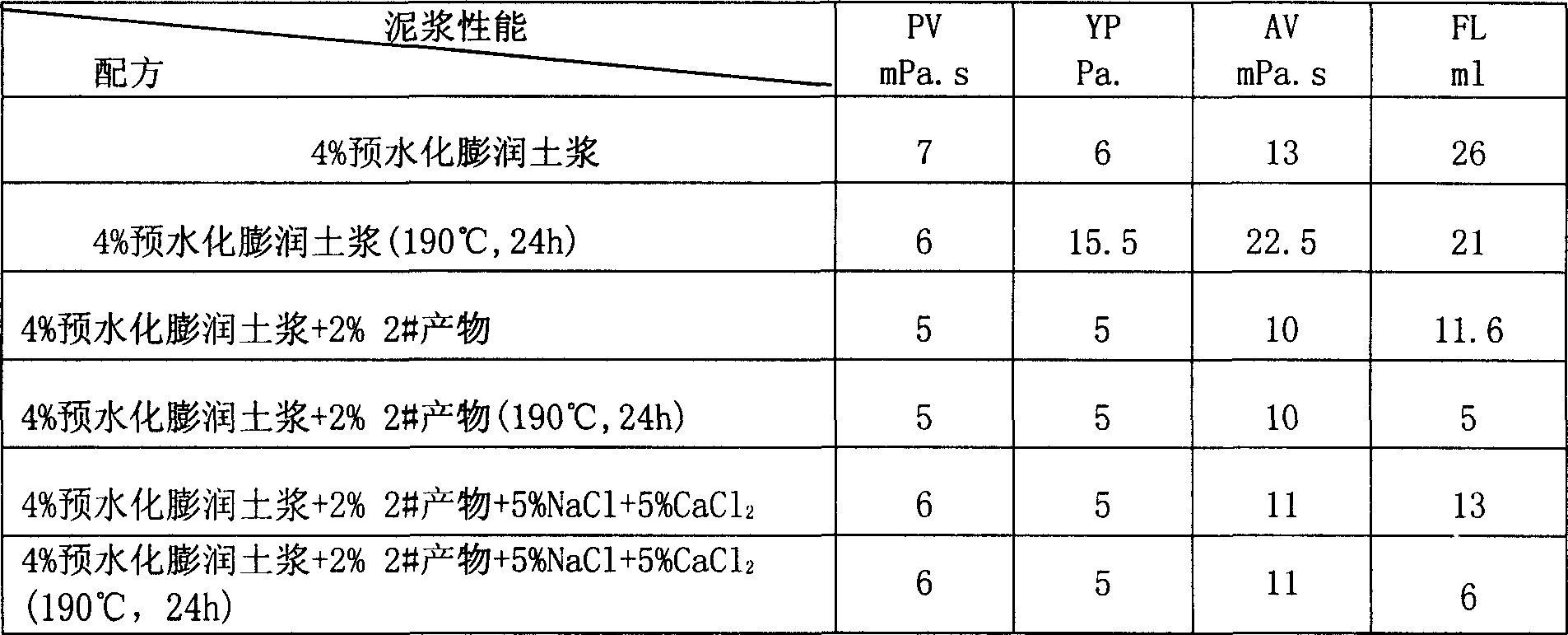

Filtrate reducer for oil field well drilling fluid

ActiveCN101054512AImprove anti-slump inhibitionImprove collapse resistanceDrilling compositionFragilityMonomer

The invention relates to an oil field fluid loss additive for drilling liquid and its producing method and the application of the treating agent in the process of producing drilling liquid system. The treating agent utilizes the cation monomer dimethyl diallyl ammonium chloride can make the sodium lignin sulfonate and the sulfonated-methyl brown coal graft induced by FeCl3 so as to produce a new fluid loss agent with the resistance to salt and collapse at high temperature. The composed product integrates the brown coal and lignin. The cation introduction improves the resistance to collapse. The weak crosslinking function of the Fe3+ makes the heat resistance improved further based on the brown coal. Therefore, the product can be widely applied in different complicated conditions such as high temperature deep well, gypsum / slat bed, stratum with a bad water sensitivity, fragility stratum and etc. and has a good prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

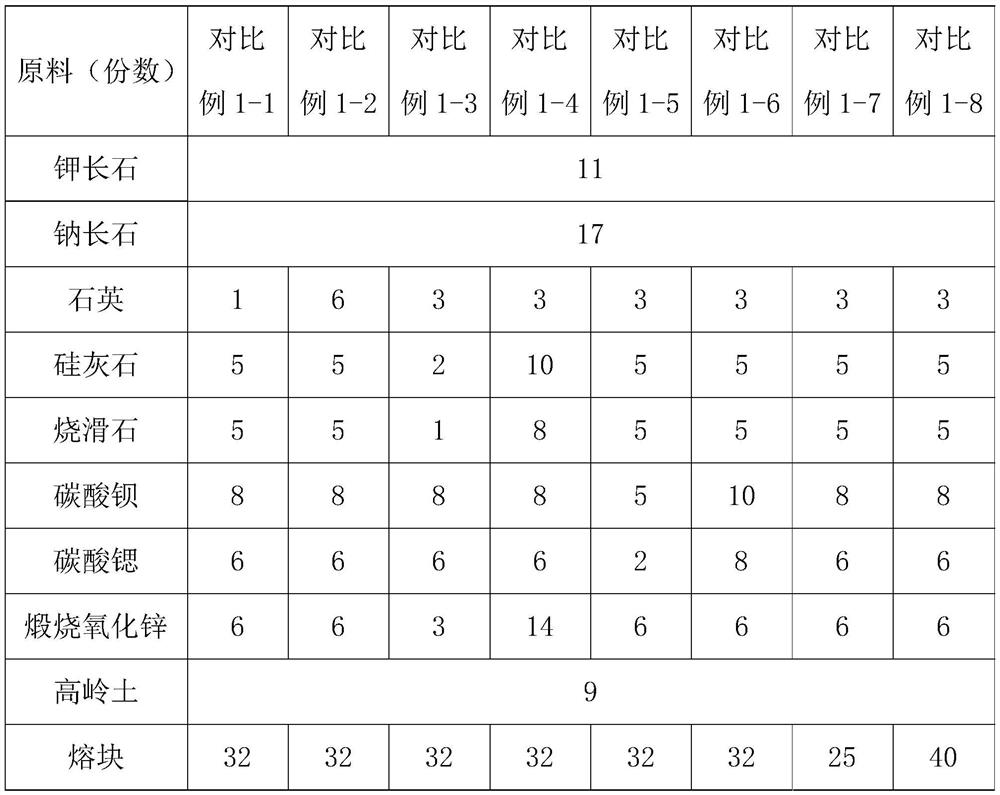

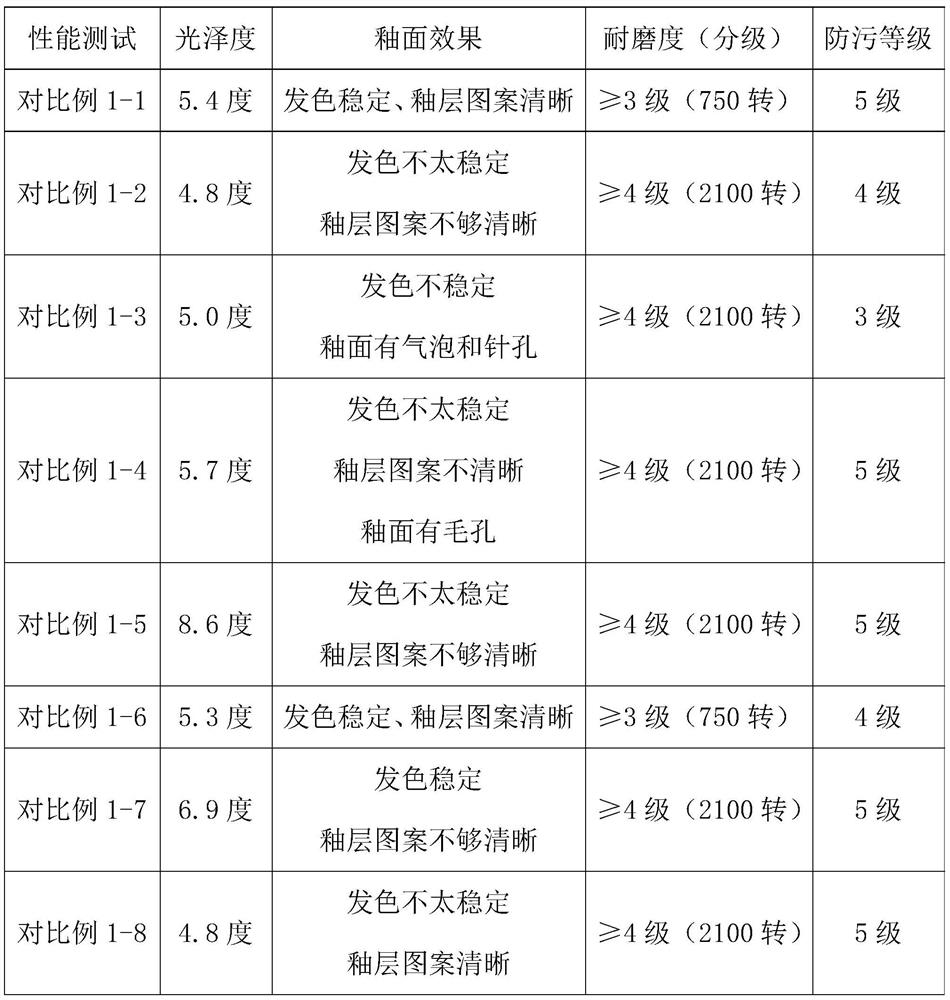

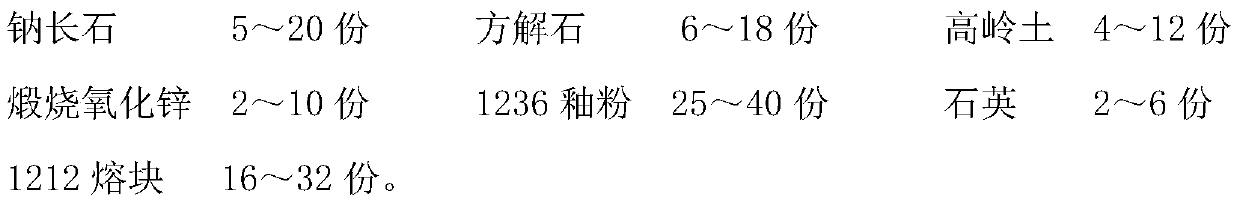

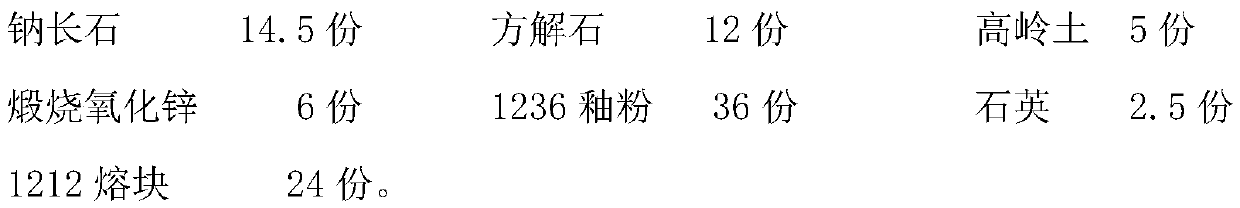

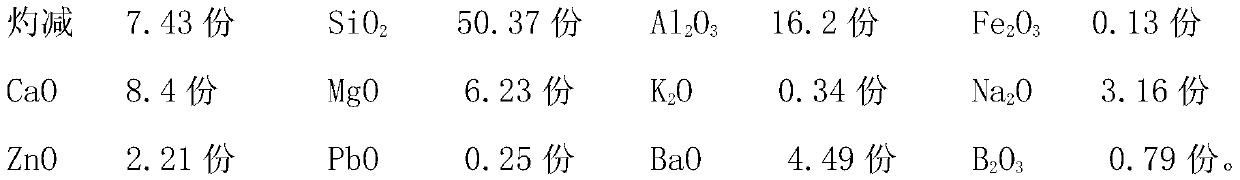

Low-gloss transparent glaze, ceramic tile using low-gloss transparent glaze and preparation method of ceramic tile

The invention discloses low-gloss translucent glaze, a ceramic tile using the low-gloss translucent glaze and a preparation method of the ceramic tile. The low-gloss transparent glaze is prepared from the following raw materials in parts by mass: 26-30 parts of feldspar, 2-4 parts of quartz, 4-6 parts of wollastonite, 4-6 parts of calcined talc, 7-9 parts of barium carbonate, 5-7 parts of strontium carbonate, 5-7 parts of calcined zinc oxide, 8-10 parts of kaolin and 30-33 parts of frit. According to the low-gloss transparent glaze provided by the technical scheme, the surface gloss of a fired glaze layer is low, the 3D layering sense is clear, the color development range of the glaze is wide, the production cost is low, and the defects in the prior art are overcome. The invention further provides a preparation method of the ceramic tile using the low-gloss transparent glaze, which has the advantages of simple steps and high operability, and is beneficial to ensuring the stable color development of the ceramic tile and enhancing the 3D stereoscopic effect of the ceramic tile. The technical scheme further provides the ceramic tile prepared by the preparation method of the ceramic tile, and the ceramic tile is stable in color development and strong in transparency.

Owner:肇庆乐华陶瓷洁具有限公司

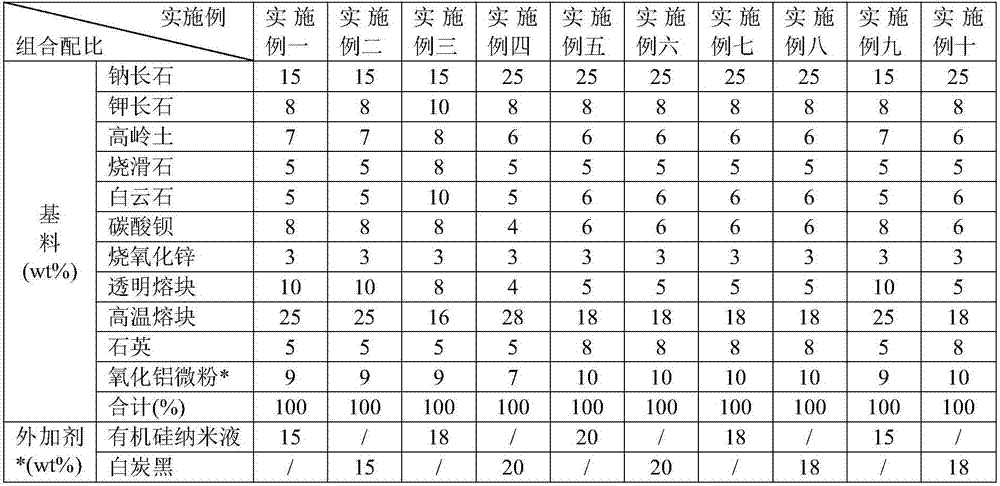

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

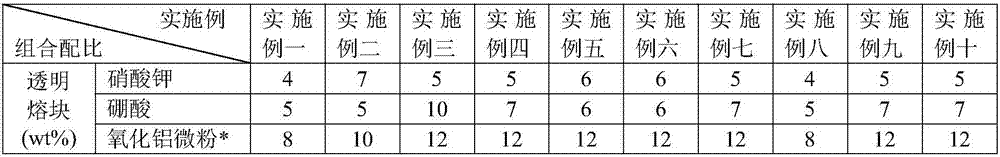

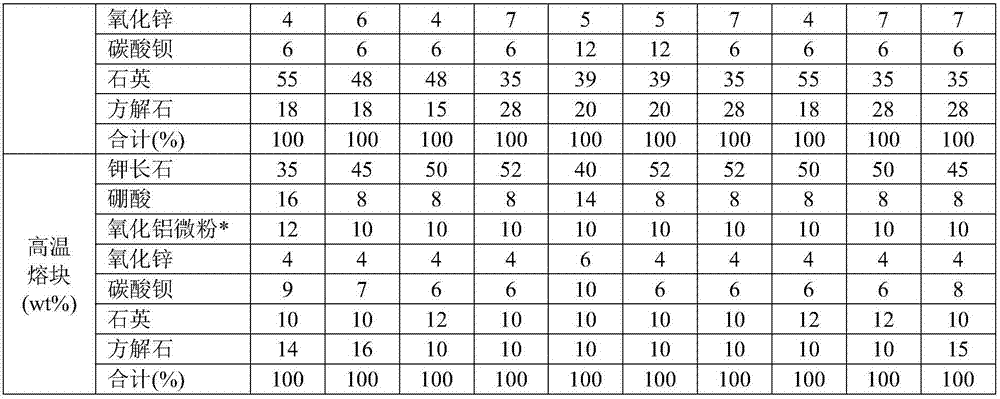

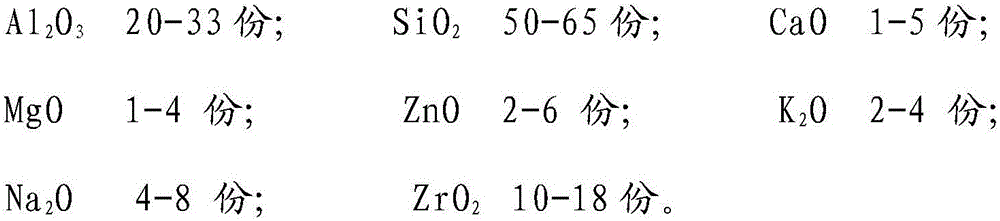

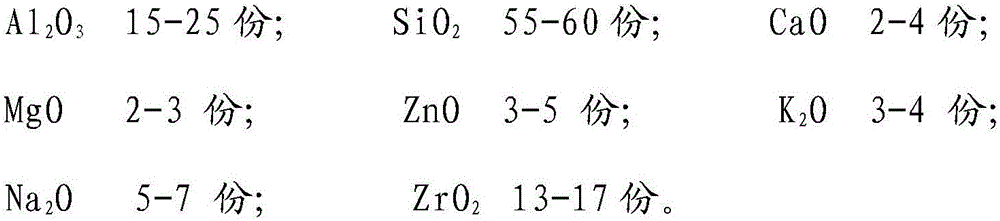

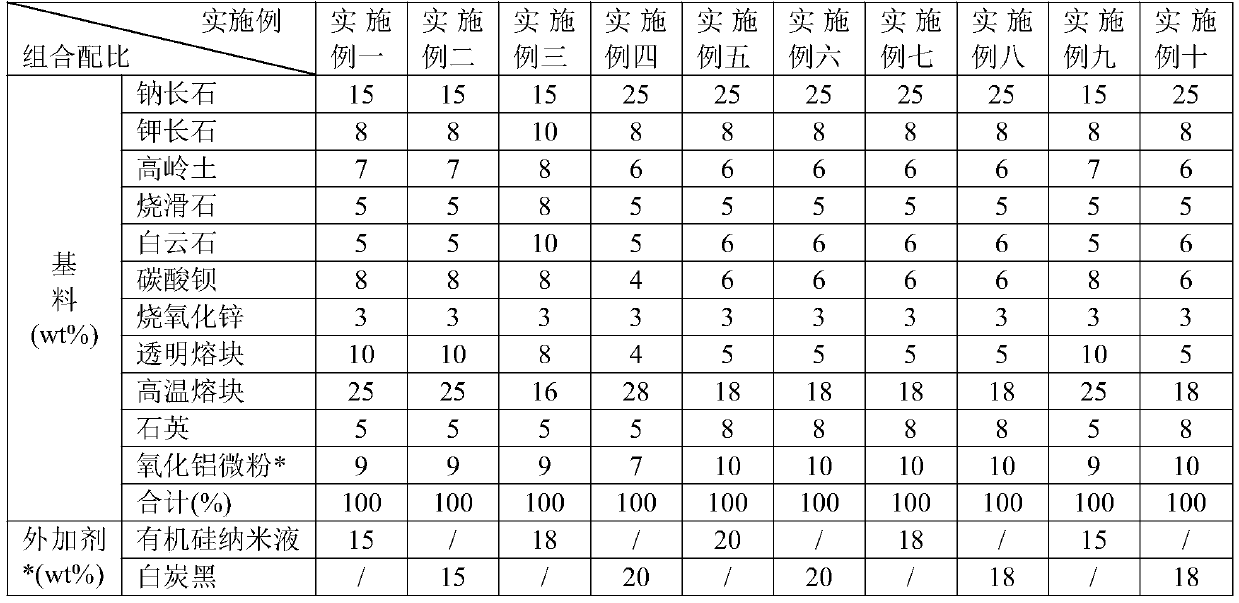

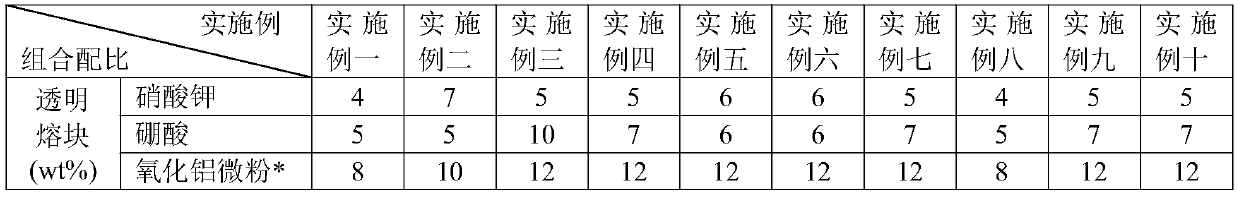

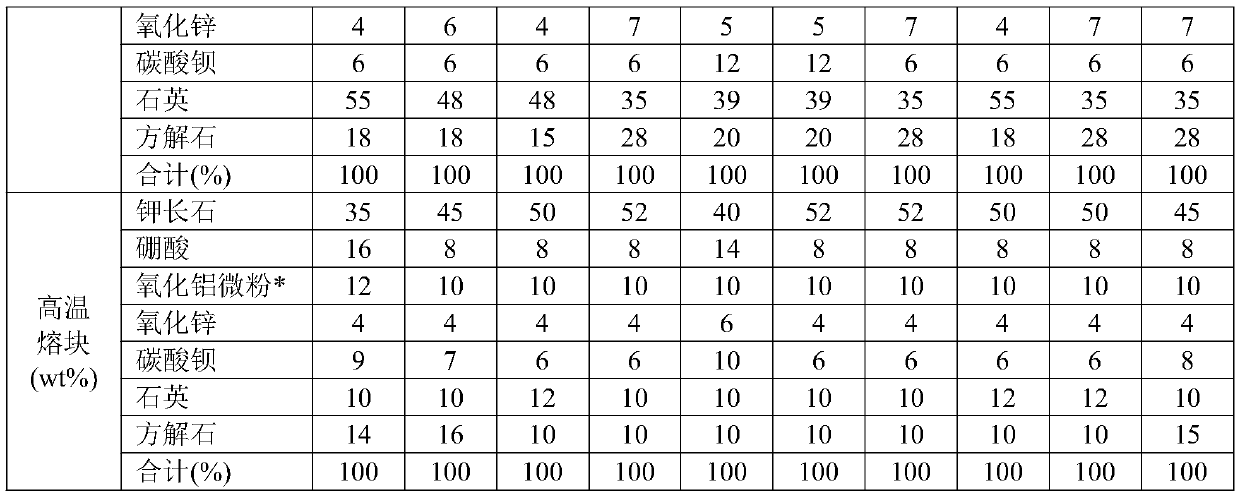

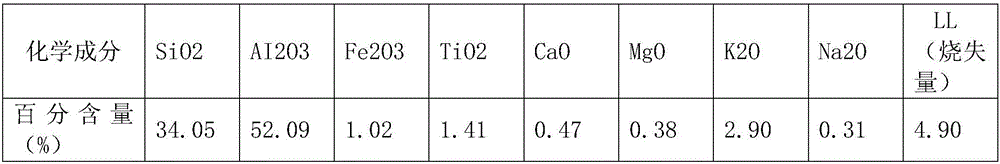

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

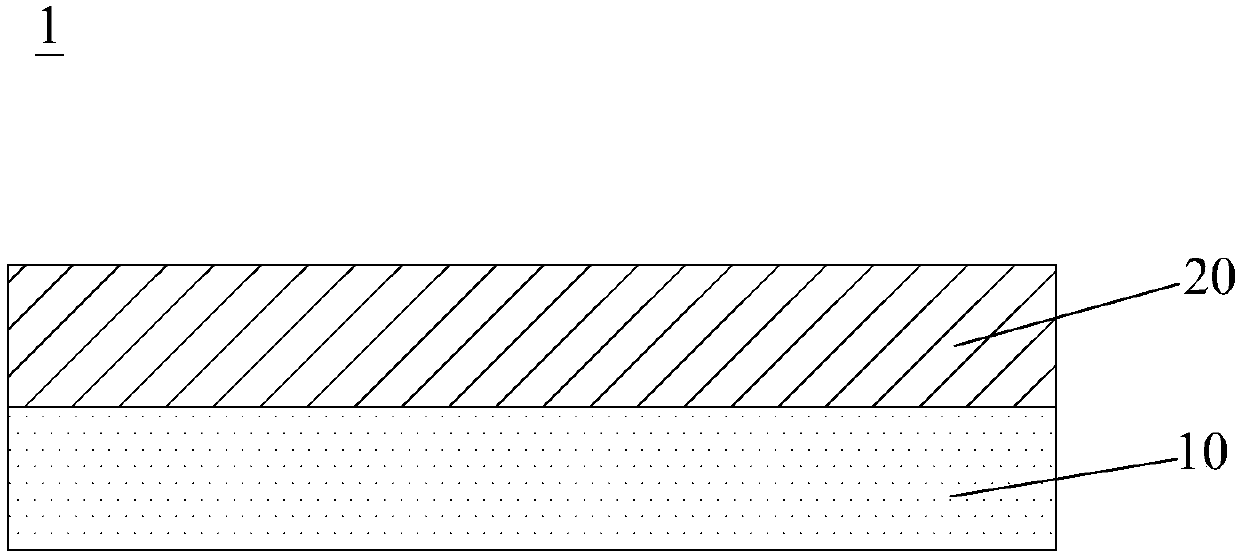

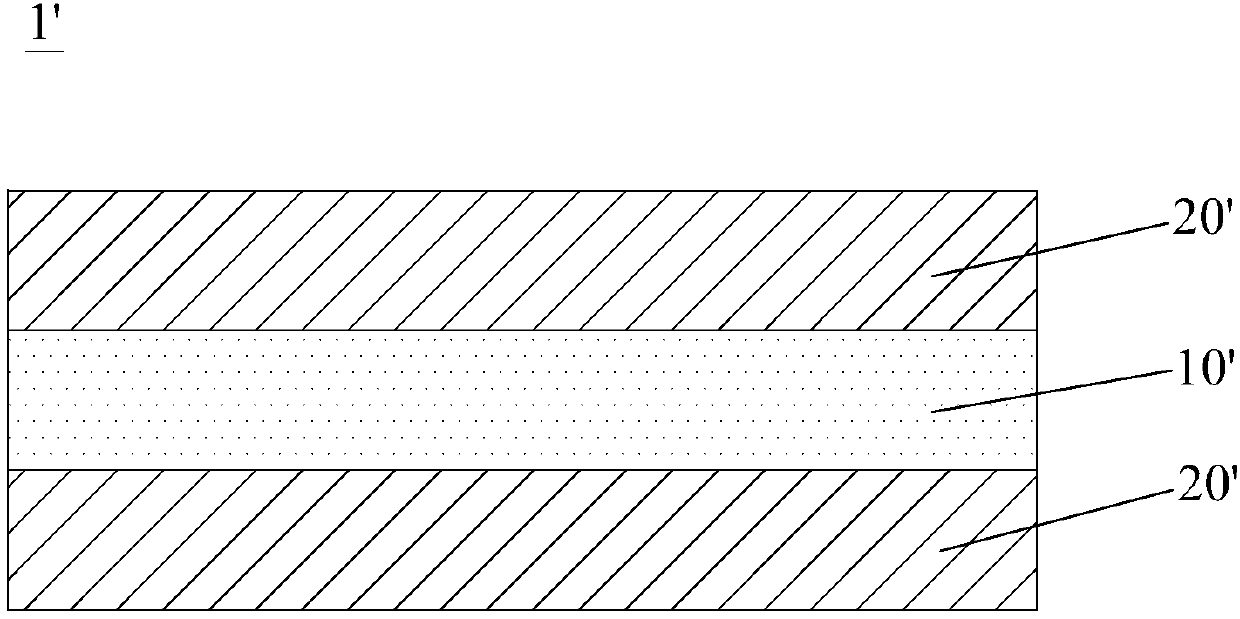

Super-flat glazed brick

ActiveCN106007377AStrong three-dimensional senseImprove the honor rateCeramic glazeMohs scale of mineral hardness

The invention provides a super-flat glazed brick. The super-flat glazed brick comprises a blank body and a glazed layer, wherein the glazed layer is attached to the upper surface of the blank body; the glazed layer comprises ground glaze and surface glaze; the surface glaze is located on the ground glaze; the thickness of the ground glaze is 0.1 to 0.8 mm; the thickness of the surface glaze is 0.5 to 1.0 mm; the ground glaze and the surface glaze are both prepared from specific ingredients. The super-flat glazed brick provided by the invention is high in Mohs hardness, large in breaking strength and low in water absorption.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

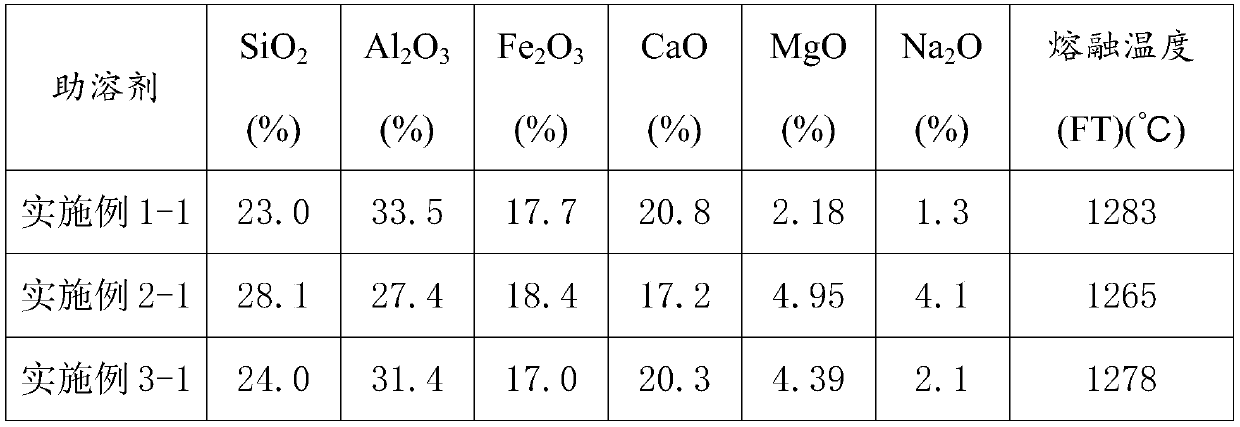

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

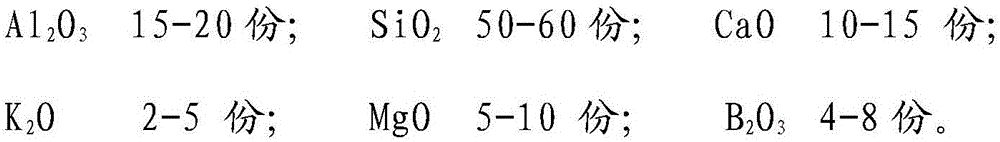

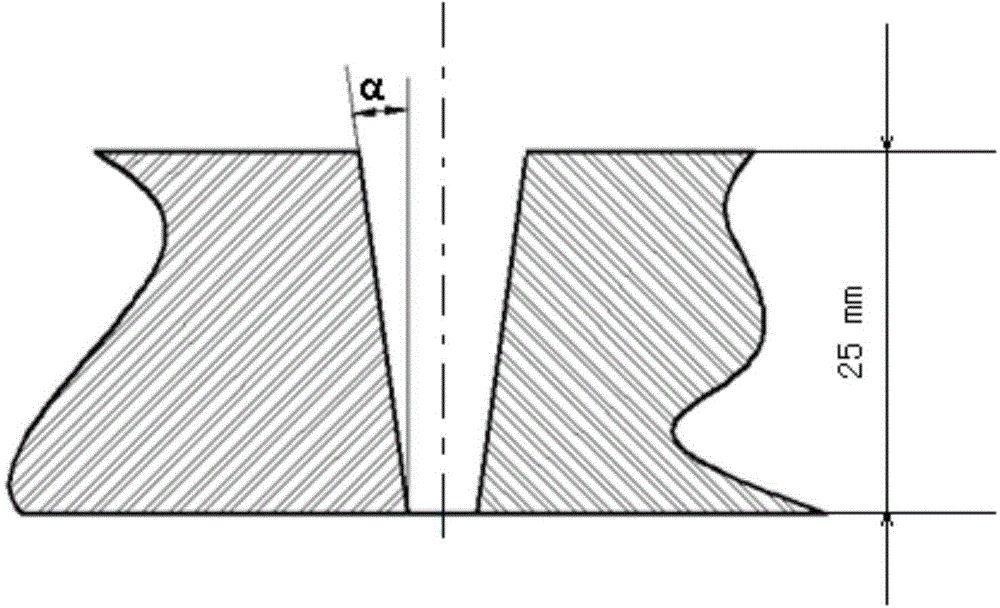

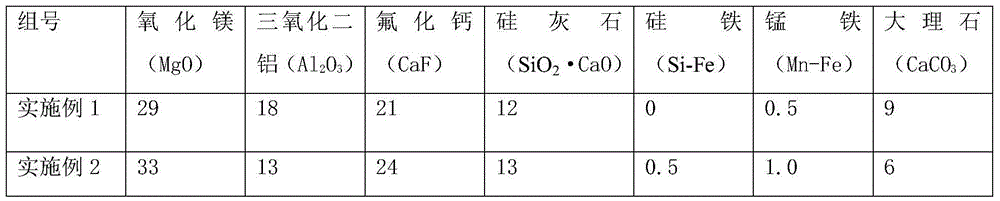

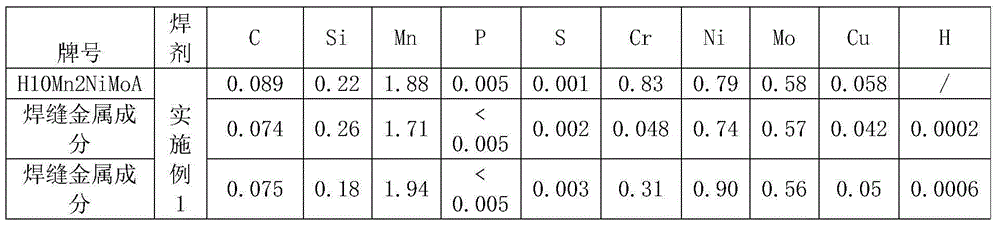

ActiveCN104668816AExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Black inkjet full-polished ceramic tile and preparation method thereof

InactiveCN109761583APlay the role of turning waste into treasureLower firing temperatureCeramic materials productionClaywaresBrickSlurry

The invention relates to a black inkjet full-polished ceramic tile and a preparation method thereof. The ceramic tile is of a composite layer structure consisting of a green body layer, a ground glazelayer, a pattern layer and a full-polished layer. The preparation method comprises the following steps: (1) ball milling of raw materials: placing ingredients into a ball mill, adding water to perform ball milling on the ingredients to obtain slurry, screening the slurry, and storing the screened slurry into a slurry pool for later use; (2) preparation of a powder compact by spray drying: conveying the slurry to a spray tower, drying the slurry into powder, controlling the moisture of the slurry at 5.8 to 7 percent, and performing dry pressing with a brick press; (3) green body drying: conveying the pressed green body into a drying kiln for drying at a temperature of 180 to 270 DEG C for 40 to 60 minutes; (4) spraying of ground glaze: conveying the ingredients into the ball mill, and adding 42 percent of water to perform ball milling to obtain glaze slurry; and (7) burning: implementing burning at a temperature of 1,080 to 1,150 DEG C for 45 to 60 minutes.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +3

Raw full-polish glaze with high abrasion resistance and method for preparing raw full-polish glaze

The invention discloses raw full-polish glaze with high abrasion resistance and a method for preparing the raw full-polish glaze. The raw full-polish glaze comprises, by weight, 28-38 parts of potassium feldspar, 4-7 parts of kaolin, 5-10 parts of sintered talc, 5-10 parts of dolomite, 16-22 parts of barium carbonate, 5-8 parts of sintered zinc oxide, 10-18 parts of fused quartz, 3-12 parts of corundum micro-powder, 1-5 parts of lithium-containing mineral and 5-10 parts of additives. The raw full-polish glaze and the method have the advantages that corundum particles and fused quartz particles are led into the raw full-polish glaze, accordingly, the availability of partial original abrasion-resistant particles can be guaranteed, large quantities of anorthite and celsian micro-crystals further can be generated, and the abrasion resistance of glaze surfaces can be improved; the lithium-containing mineral is added into the raw full-polish glaze, and accordingly liquid phases can be generated by the raw full-polish glaze at the low temperatures; lithium element ions have small radiuses, tight glass networks can be formed, and accordingly the abrasion resistance of the glaze surfaces can be improved.

Owner:JIANGSU BAIFU TECH CO LTD

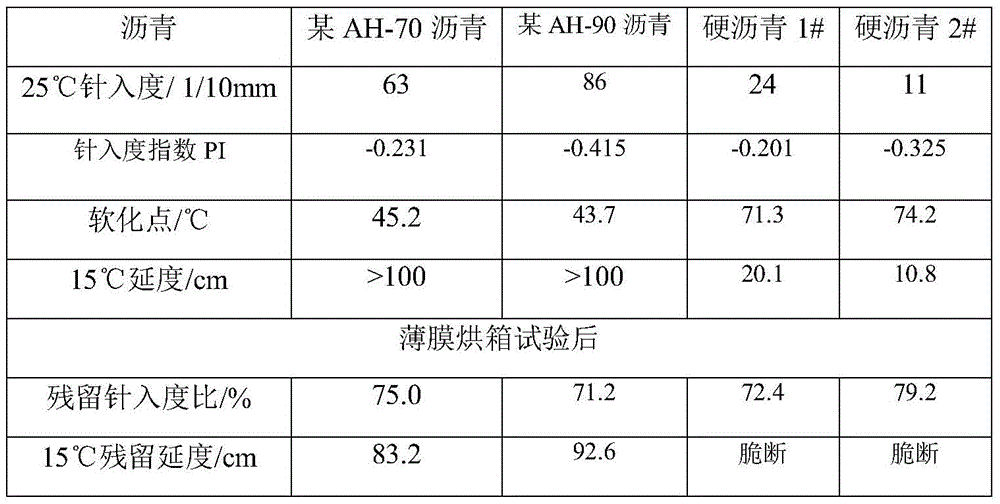

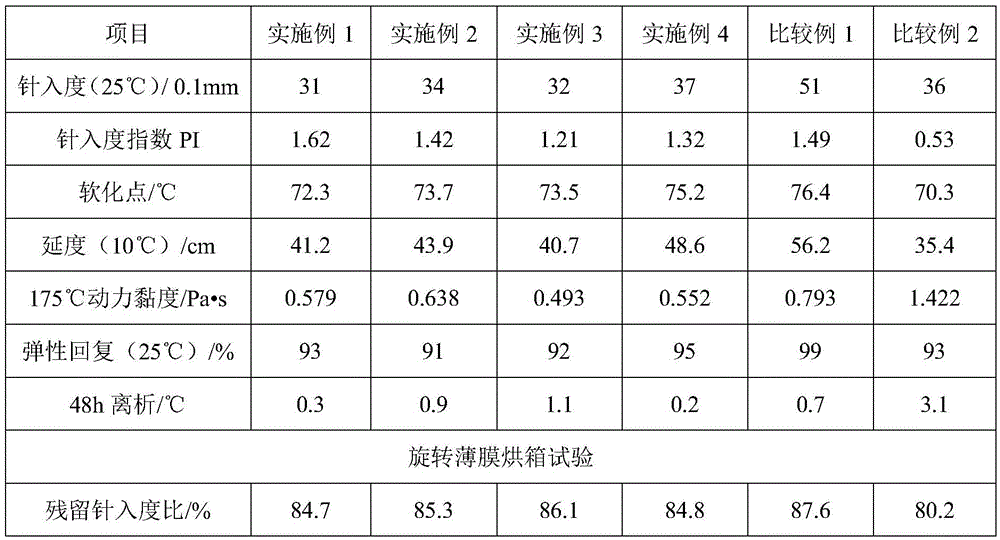

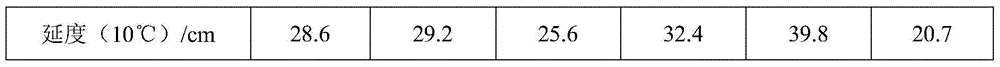

Composite modified hard asphalt and preparation method thereof

InactiveCN105482475ALow costGood high and low temperature performanceBuilding insulationsAging resistanceAsphalt

The invention discloses composite modified hard asphalt and belongs to the technical field of hard asphalt modification. The modified hard asphalt comprises components in parts by weight as follows: 100 parts of matrix asphalt, 3-8 parts of a compatilizer, 10-20 parts of rubber powder, 1-3 parts of polymers, 0.1-0.4 parts of an aid and 10-30 parts of hard asphalt. The invention further discloses a preparation method of the composite modified hard asphalt. The composite modified hard asphalt has the characteristics of high-and-low temperature performance, stability in storage, excellent ageing resistance, good construction workability and the like, is resistant to rutting, cracking, fatigue and ageing and has good high-temperature liquidity. The preparation method of the composite modified hard asphalt adopts simple steps, is easy to operate and low in cost and has better popularization and application prospect in actual engineering.

Owner:HOHAI UNIV

Carbon-free steel ladle drainage agent for extremely-low carbon steel

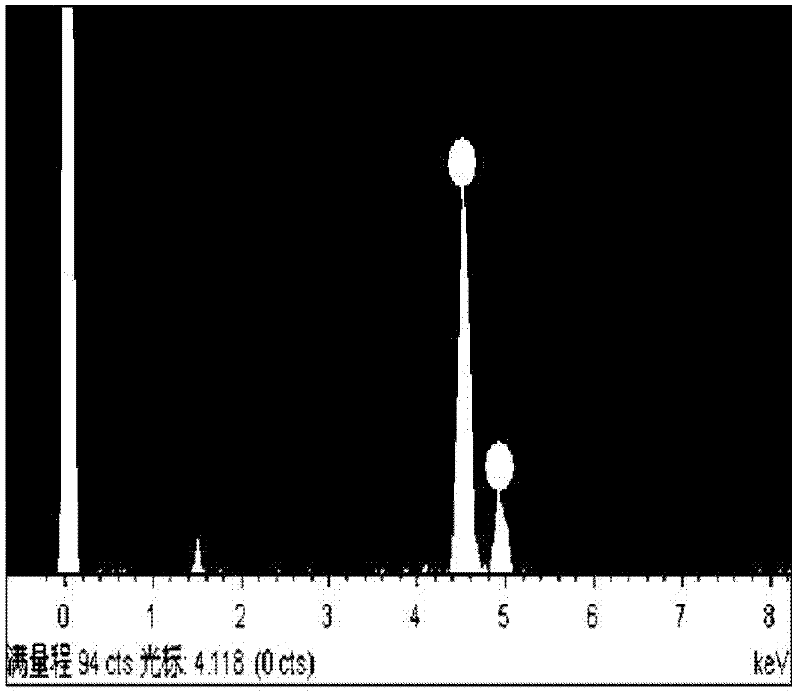

ActiveCN102233412AReasonable particle size matchingImprove high temperature fluidityMelt-holding vesselsTO-18BULK ACTIVE INGREDIENT

The invention discloses a carbon-free steel ladle drainage agent for extremely-low carbon steel. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients in percentage by mass: 20 to 36 percent of Cr2O3, 10 to 40 percent of SiO2, 10 to 25 percent of Fe2O3, 5 to 18 percent of Al2O3 and 10 to 20 percent of MgO. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients of 31.28 percent of Cr2O3, 23.52 percent of SiO2, 14.71 percent of MgO, 19.09 percent of Fe2O3 and 9.86percent of Al2O3. The carbon-free steel ladle drainage agent for the extremely-low carbon steel is prepared from the following raw materials in percentage by mass: 50 to 80 percent of chromite sand, 10 to 30 percent of white quartz and 8 to 20 percent of electro-fused magnesia.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Thermal-state mending material taking forsterite as raw material for converters and preparation method thereof

The invention relates to a thermal-state mending material taking forsterite as a raw material for converters and a preparation method thereof. The technical scheme is as follows: adopting 45-70wt% of sintered magnesia particles, 5-15wt% of graphite and 15-40wt% of forsterite fine powder as raw materials; adding simple substance silicon powder accounting for 1-10wt% of the weight of the raw materials and liquid pitch modified phenolic resin accounting for 15-25wt% of the weight of the raw materials; and stirring for 5 to 30 minutes to obtain the slurry thermal-state mending material taking forsterite as the raw material for converters. While being used, the thermal-state mending material is poured into the converter, the converter is rotated to enable the mending material to flow to the charging position, the tapping position, the bedding face and the furnace bottom of the steelmaking converter which are in need of thermal-state mending and the mending material is sintered by the heat in the converter. The material has the characteristics of abundant raw materials, low production cost, excellent hydration-proof performance, easiness in sintering at a high temperature and convenience in combination with the converter lining and is beneficial for prolonging the service life of materials of the converter lining.

Owner:北京炜润达冶金材料有限公司 +1

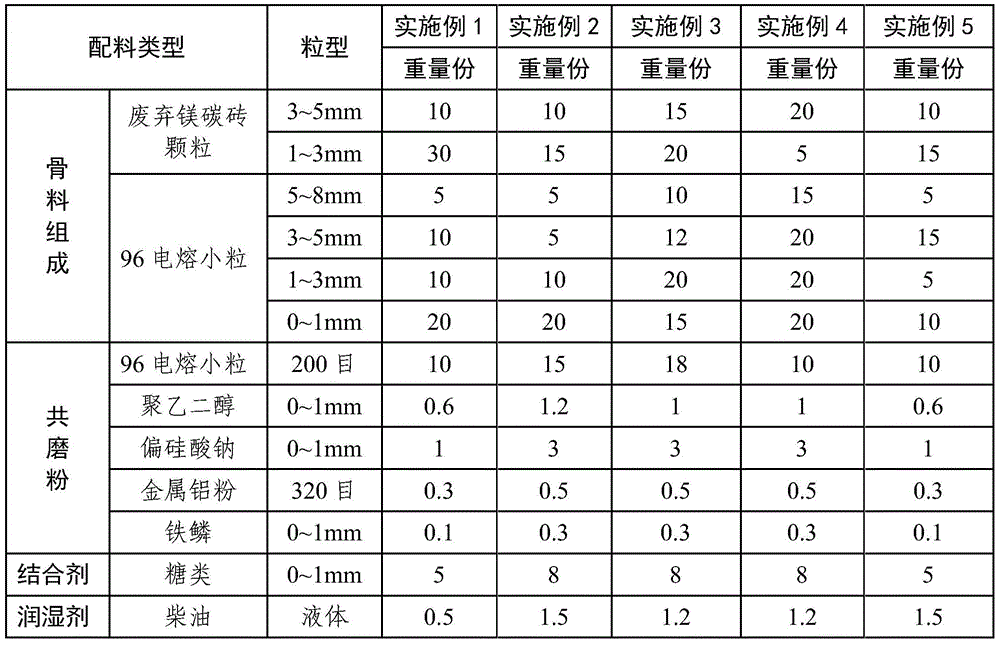

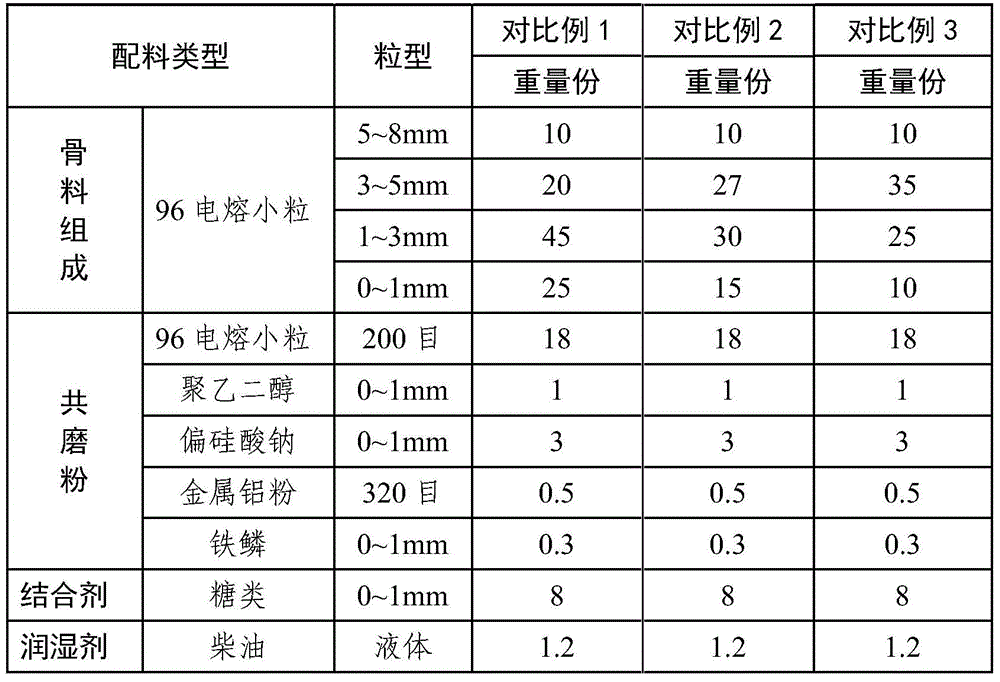

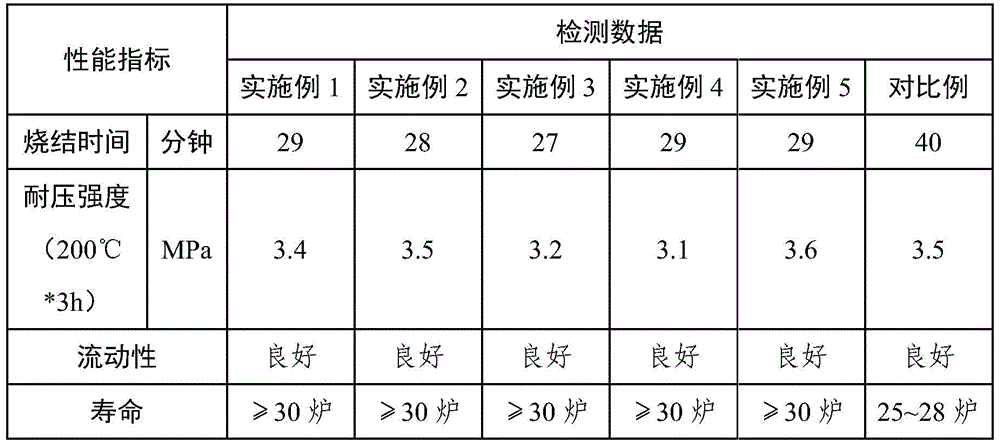

Converter repairing mass and preparation method thereof

The invention relates to the technical field of unshaped refractory materials in converter steelmaking and particularly relates to a converter repairing mass and a preparation method thereof. The converter repairing mass is prepared from the following raw materials in parts by weight: 70-110 parts of mixture of fused magnesite and waste magnesia carbon brick particles, 10-30 parts of fused magnesite fine powder, 5-8 parts of bonding agent and 2-5 parts of filler, wherein the mixture of fused magnesite and waste magnesia carbon brick particles at least comprises 10-30 parts of fused magnesite fine powder. The preparation method of the converter repairing mass comprises the following steps of: adding 0.5-1.5 weight parts of wetting agent into the raw materials of the converter repairing mass, and mixing and stirring to obtain loose, dry and uniform aggregate. According to the converter repairing mass and preparation method thereof, the waste magnesia carbon brick serves as a raw material, and the converter lining built by the magnesia carbon bricks realizes a better protection effect; the converter repairing mass has the advantages of good high-temperature fluidity, short sintering time, high sintering strength, long service life, environmental protection and the like.

Owner:北京利尔高温材料股份有限公司

Bright and injection-molding wood plastic composite and method for preparing the same

The invention discloses a bright and injection-molding wood plastic composite and method for preparing the same and belongs to a wood plastic composite and a method for preparing the same. The wood plastic composite comprises the following components in percentage by mass: 50 to 70 percent of renewable PP or HDPE, 30 to 50 percent of wood powder, 5.0 to 10.0 percent of nanometer absorbent, 5.0 to 10.0 percent of surfactant, 1.0 to 2.0 percent of super lubricant, 1.0 to 2.0 percent of titanate coupling agent, 0.5 to 5.0 percent of polyethylene wax, 2.0 to 5.0 percent of stearic acid or stearate, and 5.0 to 15 percent of maleic anhydride-grafted PE or PP grafted with a molecular weight of between 5,000 and 30,000. The wood powder and the nanometer absorbent are mixed at a high rotation speed of 1,500 to 2,500 r / m for 10 to 15 minutes, then the titanate coupling agent is added and mixed at a high rotation speed of 1,500 to 2,500 r / m for 5 to 6 minutes, and finally other components are added to be mixed at a rotation speed of 1,500 to 2,500 r / m for 20 to 30 minutes and then mixed at a rotation speed of 300 to 600 r / m for 5 to 10 minutes so as to obtain the premix. The premix is extruded and pelletized by an extruder to obtain the bright and plastic injection wood plastic composite. The wood plastic composite has the advantages of high surface glossiness, excellent high-temperature flow performance, high strength and toughness, low cost and the like, can widely substitute plastics and is used for production of products with complex shapes.

Owner:JIANGSU HENGFAMU PLASTIC SCI & TECH

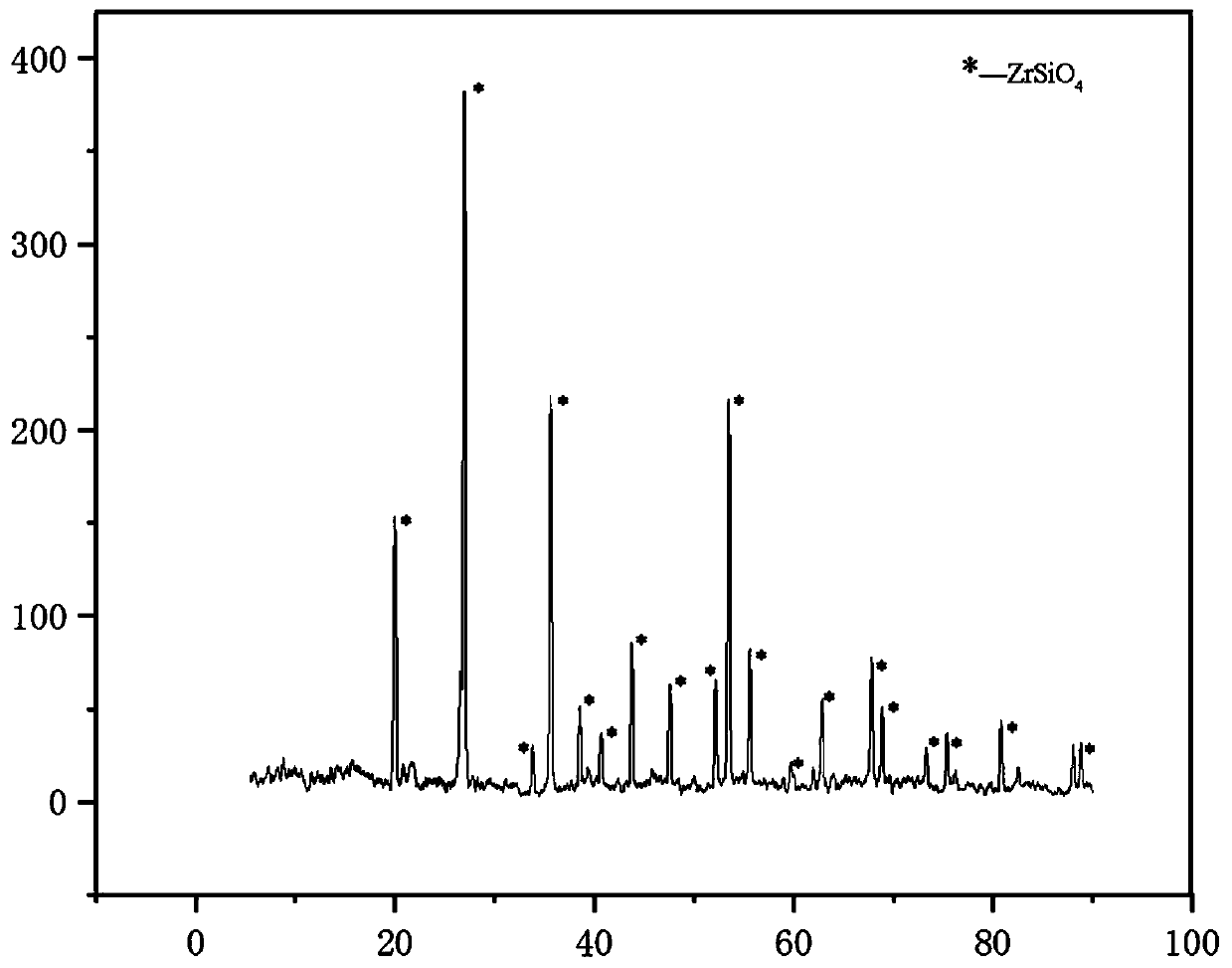

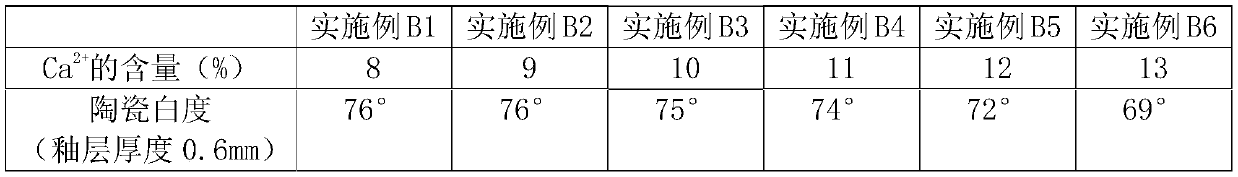

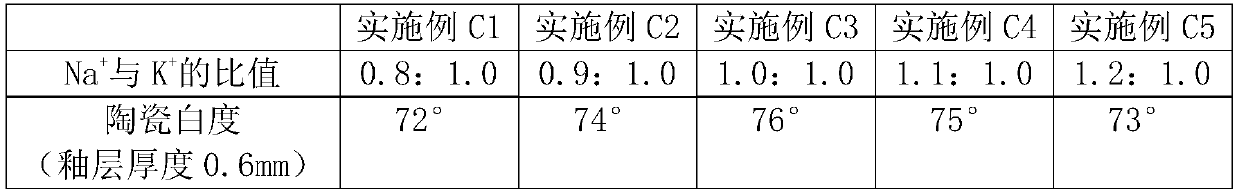

Low-zirconium white glaze for sanitary ceramic and preparation process of low-zirconium white glaze

The invention discloses a low-zirconium white glaze for a sanitary ceramic. The low-zirconium white glaze comprises the following raw materials in percentage by mass: 6.5-7.5% of zirconium silicate, 24-27% of quartz, 5-7% of kaolin, 2.5-3.5% of aluminum oxide, 12-18% of potassium feldspar, 9-15% of albite, 6-8.5% of calcite, 9-13% of wollastonite, 2-5% of dolomite, 2-3.5% of sintered talc, 2-3.5%of zinc oxide and 1.5-4% of frit. The low-zirconium white glaze is prepared by using a preparation process through operation of steps (1)-(3). Under a condition of a low zirconium silicate content, high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity of the low-zirconium white glaze can be still maintained, and the low-zirconium white glaze has the effects of high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity.

Owner:FOSHAN DONGPENG CERAMIC +3

Thermoplastic phenol formaldehyde resin for ultrathin resin grinding tools and preparation method thereof

ActiveCN103739798AImprove high temperature fluidityImproved cutting and grinding efficiencyPolymer sciencePtru catalyst

The invention provides a thermoplastic phenol formaldehyde resin for ultrathin resin grinding tools with high molecular weight dispersion coefficient and favorable high temperature fluidity and a preparation method thereof. The phenol formaldehyde resin comprises 200 parts of phenol, 35-65 parts of formaldehyde, 0.1-1.0 part of strong acid catalyst and 0.1-1.8 part of weak acid catalyst. The preparation method comprises the following steps: in the first stage, the 100 parts of phenol, 20-35 parts of formaldehyde and 0.1-1.0 part of strong acid catalyst are added; and in the second stage, the 100 parts of phenol, 15-30 parts of formaldehyde and 0.1-1.8 parts of weak acid are added. The thermoplastic phenol formaldehyde resin prepared by sectional polycondensation reaction has higher molecular weight dispersion coefficient and favorable high temperature fluidity; the resin grinding tool manufacturing hardening curve is set more easily; and the grinding wheel prepared from the powder phenol formaldehyde resin has lower property attenuation, and is beneficial to prolonging the service life. The method is applicable to the field of manufacturing of resins.

Owner:ZHUHAI BONDRIGHT SYNTHETIC MATERIAL

Method for growing large-sized rare-earth-doped barium yttrium fluoride single crystals

InactiveCN104562183ALimit heightImprove integrityPolycrystalline material growthBy pulling from meltRare earthPt element

The invention provides a method for growing large-sized rare-earth-doped barium yttrium fluoride single crystals. The method comprises the following steps: in a heating furnace, putting polycrystals of {xReF3+(1-x)YF3} and BaF2 into a crucible according to a mass ratio, vacuumizing, and introducing argon gas into the heating furnace successively, wherein the mass ratio of {xReF3+(1-x)YF3} to BaF2 is 2 to 1 and x is 0-100%; controlling the heating power by a temperature control instrument to melt the polycrystals, performing heat exchange by flowing of a liquid surface in the crucible and the gas in the furnace to form an axial temperature difference, and forming a radial temperature difference of temperature on a wall of the crucible and temperature in the center of the crucible to cause natural convection of a melt; fixing BaY2F8 seed crystals to a seed crystal rod by a platinum chuck, and lowering the seed crystals to be contacted with the melt for fluoride crystal growth; when fluoride crystals grow to have set sizes, annealing, cooling to the room temperature at a speed of 20 DEG C / hour, adjusting the rotary speed and the heating power, separating the crystals from the melt until the crystal growth is ended, and annealing in the crucible to obtain the large-sized fluoride crystals. The method solves the problems of negative growth factors of difficulty for crystal growth, a large amount of air bubbles in the crystals and the like caused by poor flowability of the fluoride melt.

Owner:SOUTH WEST INST OF TECHN PHYSICS

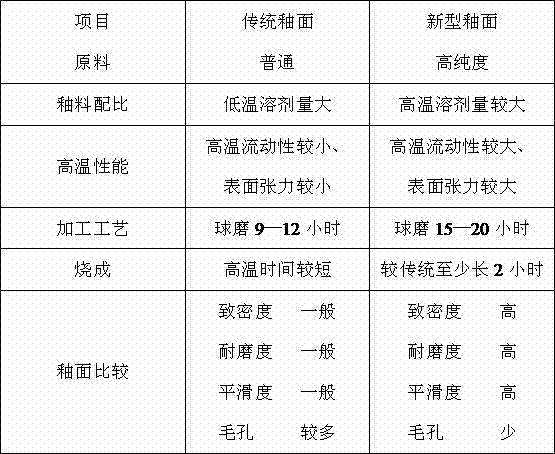

Novel glaze and manufacture process thereof

InactiveCN102531679AImprove high temperature fluidityImprove wear resistanceAlkaline earth metalHardness

The invention discloses novel glaze and a manufacture process thereof, wherein the glaze is high in compactness and abrasion resistance, good in smoothness and small in pore. The manufacture process includes steps of selecting of raw materials, matching, hard fire and the like, the manufactured glaze is good in high-temperature flowing property, and further the raw materials are large in surface tension, so that in high-temperature melting of the glaze, the surface tension of the glaze is higher than that of traditional glaze materials, and smooth effect of the glaze is achieved through interaction of the high-temperature flowing property and the surface tension. In addition, gas in the glaze can be discharged easily without leaving marks, and no small pores can be left, the glaze is easy to clean. Solvents used in the formula are mostly alkaline-earth metals, so that use amount of alkaline metals of potassium oxide and sodium oxide is reduced, rigidity of the glaze is improved, and abrasive resistance of the glaze is improved.

Owner:GUANGDONG SUNCOO TECH

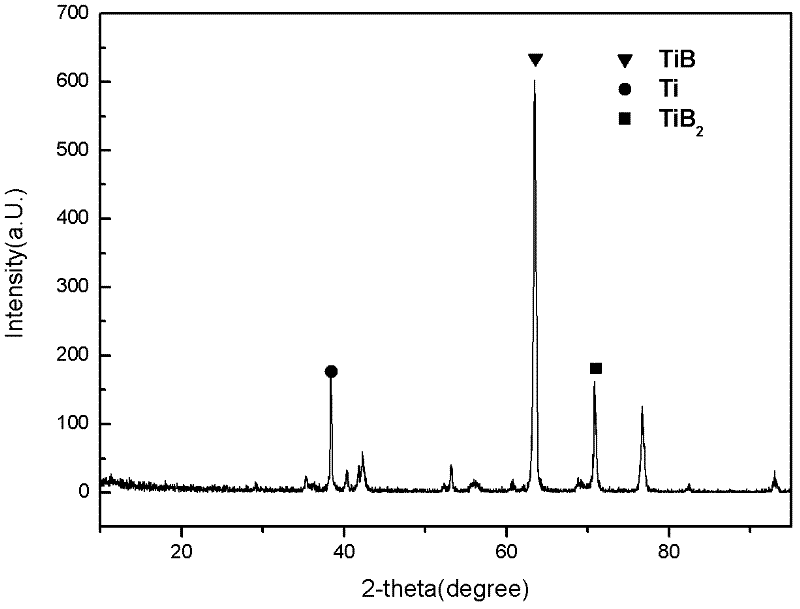

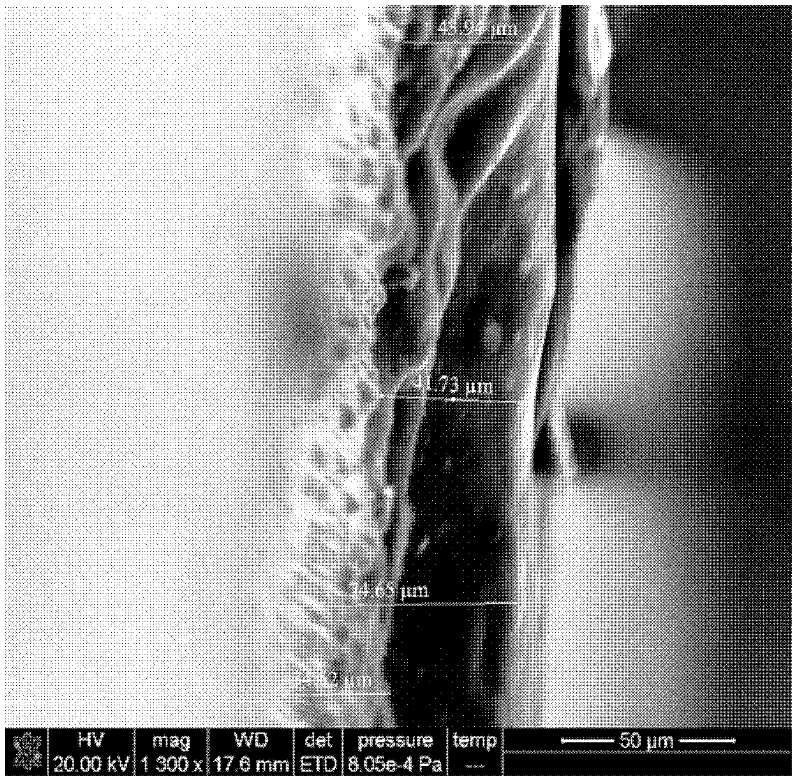

Boriding agent for boriding on metallic titanium surface and boriding technique

The invention discloses a boriding agent for boriding on a metallic titanium surface and a preparation method thereof. The boriding agent comprises the following ingredients in mass percent: 20-35% of Na2B4O7, 10-20% of H3BO3, 10-20% of B4C, 15-25% of KCl, 15-25% of NaCl, and 1-5% of KBF4. The boriding technique of the invention comprises the steps of: firstly putting a metallic titanium sample in a boriding agent fused mass with special ingredients, maintaining the temperature for a period to form a boriding layer on the surface of the metallic titanium sample; and then, performing a quenching treatment to cure the boriding layer so as to obtain a thick and uniform boriding layer with high hardness and good bonding force on the surface of the metallic titanium sample, and the fused salt on the surface of the metallic titanium sample is easy to treat. The boriding technique of the invention has the advantages of simple and easy control operation, little boriding agent loss, short operation duration and low energy consumption, so that the boriding technique is suitable for industrial production.

Owner:江苏奇纳新材料科技有限公司

Large-dimension aromatic ring structure-containing polyester for powder coating and preparation method of polyester

InactiveCN104211930ASolve heat resistanceSolve balance problemsPowdery paintsEpoxy resin coatingsAdipic acidGlass transition

The invention discloses a large-dimension aromatic ring structure-containing polyester for a powder coating and a preparation method of the polyester. The adopted technical scheme is that 1,8-anthracenedicarboxylic acid dimethyl ester is selected as a synthesis raw material to introduce a large-dimension anthracene ring to the polyester so that the glass transition temperature of the polyester can be increased; the polyester resin is prepared from the following major components in parts by weight: 12.0-25.5 parts of 1,8-anthracenedicarboxylic acid dimethyl ester, 10.0-32.0 parts of terephthalic acid, 6.5-17.0 parts of m-phthalic acid, 0.5-3.0 parts of adipic acid, 18.0-41.0 parts of C2-C6 polyhydric alcohol and 0.02-2 parts of catalyst through the steps of heating at different stages to arouse an esterification reaction, a condensation polymerization reaction and an acidolysis reaction. The large-dimension aromatic ring structure-containing polyester for the powder coating has the beneficial effects that the obtained polyester resin is capable of solving the contradiction between heat resistance and melting manufacturability to a certain extent, and has the characteristics of high glass transition temperature, low melt viscosity, good storage stability and the like; and an epoxy / polyester powder coating prepared from the polyester is resistant to acids and bases, and also resistant to boiling in water, and has excellent adhesion to metal substrates.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

Abrasion-resistant white glaze, wearproof white glaze ceramics prepared through white glaze, and preparing method of wearproof white glaze ceramics

The invention relates to abrasion-resistant white glaze, wearproof white glaze ceramics prepared through the white glaze, and a preparing method of the wearproof white glaze ceramics, and belongs to the technical field of ceramics. The melting temperature of the abrasion-resistant white glaze is 800 DEG C + / -5 DEG C, the abrasion-resistant white glaze is fluid at the temperature of 1,200 DEG C, and the abrasion-resistant white glaze is specifically prepared from, by mass, 35-45 parts of feldspar, 20-30 parts of calcium oxide, 5-15 parts of quartz, 2-6 parts of water glass, 3-8 parts of kaolin,2-5 parts of zinc oxide, 2-6 parts of barium carbonate and 5-10 parts of heavy calcium carbonate. The raw materials are mixed and subjected to ball milling according to the composition, and are thenmixed into glaze slip with the needed concentration, and then glaze dipping and sintering are conducted to obtain the wearproof white glaze ceramics. Through a reasonable composition and a simple preparing method, the obtained wearproof white glaze ceramics are fine, bright and smooth, attractive in glaze surface, resistant to abrasion, and long in service life; meanwhile, the energy is saved, emission is reduced, and the wearproof white glaze ceramics are green and environmentally friendly.

Owner:泉州市德化得利工艺有限公司

Cracked jun porcelain plum green glaze and preparation method thereof

The invention discloses a cracked jun porcelain plum green glaze, which is prepared from the following raw materials by weight: glaze 34-40 parts of glaze stone, 10-14 parts of glaze ash, 3-5 parts ofkaolin, 12-16 parts of calcined kaolin, 16-22 parts of quartz, 2-4 parts of fluorite, 1.5-2.5 parts of calcined talc, 1.5-2.5 parts of dolomite, 0.1-0.3 part of chromium oxide, and 5-9 parts of woodash. The preparation method of the cracked jun porcelain plum green glaze includes the steps of: (1) crushing the raw materials, performing mixing, then putting the mixture into a ball mill for ball milling, adding water to make the mass concentration of glaze reach 54-56%, conducting wet grinding for 10-12h, and sieving the slurry subjected to wet grinding with a 200-300mesh sieve to obtain a glaze slurry; (2) conducting glazing by glaze dipping to a glaze thickness of 1.5mm-2.0mm; and (3) performing firing at a temperature of 1300-1320DEG C.

Owner:禹州市大龙山钧瓷文化有限公司

Glass fiber felt reinforced thermoplastic composite material and preparation method thereof

ActiveCN109912880AIncreased tensile strength and notched impact strengthImprove high temperature fluidityHot pressingPolyresin

The invention discloses a glass fiber felt reinforced thermoplastic composite material, which is mainly formed by carrying out hot pressing on 35-60 wt% of a glass fiber felt and 40-65 wt% of a resinmatrix, wherein the glass fiber felt comprises 90-97 wt% of a glass fiber bundle and 3-10 wt% of a binder, the glass fiber bundle has a length of 15-70 mm and a fiber diameter of 5-20 [mu]m, the binder of the glass fiber felt is at least one selected from a thermosetting adhesive, the thermosetting adhesive at least one selected from an unsaturated polyester type adhesive, a polyurethane type adhesive and a urea formaldehyde resin, and the melt mass flow rate of the thermoplastic resin is 25-60 g / 10 min at a temperature of 190 DEG C under a load of 2.16 Kg. According to the present invention,the glass fiber felt reinforced thermoplastic composite material has advantages of low odor, excellent tensile strength, excellent notched impact strength and excellent compression moldability.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

A low-temperature, high-hardness, high-wear-resistant full-polish glaze and its preparation method

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC UNIV

High-voltage porcelain insulating semiconductor glaze

The invention relates to the technical field of semiconductor glaze, and in particular relates to a high-voltage porcelain insulating semiconductor glaze. The semiconductor glaze is prepared from the following components in parts by weight: 25-35 parts of high-potassium and low-iron feldspar, 8-14 parts of mud, 4-10 parts of Dongsheng soil, 1-4 parts of calcined talc, 20-30 parts of quartz powder, 2-4 parts of barium carbonate, 12-18 parts of iron oxide red, 1-3 parts of chrome oxide green, 9-12 parts of titanium dioxide and 1-2 parts of spodumene. The semiconductor glaze is high in structure stability, fine in surface and glossy in surface, the eutectic point is reduced, and the melting efficiency is improved; and meanwhile, the combining capacity of the semiconductor glaze after being glazed is improved by adopting the Dongsheng soil and mud.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Thermoplastic resin composition and adhesive prepared from same, insulation adhesive film used for laminated bus bar and preparation method of insulation adhesive film

InactiveCN106700498AGood aging performanceGood bonding performanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryAging property

The invention provides a thermoplastic resin composition. The thermoplastic resin composition comprises the following components in parts by mass: 50-85 parts of thermoplastic polyurethane resin, 5-20 parts of saturated polyester resin, 0.5-8 parts of a compatilizer, 0.1-1 part of an antioxidant and 20-100 parts of a flame retardant, wherein the thermoplastic polyurethane resin has excellent flexibility and high and low temperature resistance; and the saturated polyester resin has low melting point, poor high temperature resistance, good aging property and excellent adhesive property with metal and an insulation film. The thermoplastic polyurethane resin and the saturated polyester resin are blended and modified, a small amount of the compatilizer is added, polymer alloy with excellent compatibility can be obtained, and the polymer alloy has good high and low temperature impact property, aging property and adhesive property. The resin composition does not contain a curing agent, has good high temperature liquidity and can meet low temperature lamination requirements. The invention also provides an adhesive made by adopting the thermoplastic resin composition, an insulation adhesive film used for a laminated bus bar and a preparation method of the insulation adhesive film.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of fine sand antiskid ceramic rock plate and prepared fine sand antiskid ceramic rock plate

The invention relates to a preparation method of a fine sand antiskid ceramic rock plate. The preparation method comprises the steps of (1) grinding and polishing a formed planar green body; (2) keeping constant temperature and heat, and controlling the surface temperature of the green body to be 80-90 DEG C; (3) applying ground coat with a wide high-temperature high-viscosity firing range; (4) conducting ink-jet printing decoration, specifically, jet-printing the pattern on the surface of the ground coat layer through a digital ink jet machine to form rich colors; (5) spraying protective glaze, wherein the glazing specific gravity of the protective glaze is 1.15-1.20, and the glazing amount is 30-35g / m<2>; and (6), firing, wherein the firing temperature is 1180-1200 DEG C, and the firingtime is 120 minutes.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +1

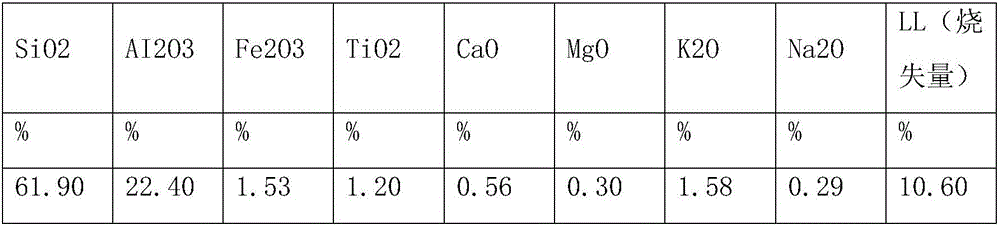

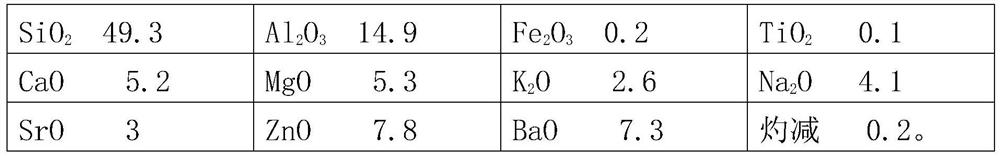

Fluxing agent for reducing melting point of coal ash

InactiveCN111534355AImprove high temperature fluidityImprove mass transfer effectSolid fuelsFuel additivesSlagCoal

The invention discloses a fluxing agent for reducing the melting point of coal ash. The fluxing agent is composed of the following components in percentage by weight: 20-90% of organic matter, 0-70% of CaO, 1-40% of MgO, 0-50% of Fe2O3, 0-30% of Na2O and 0-30% of K2O. The fluxing agent effectively increases the amount of a liquid phase generated by ash fusing, and improves the high-temperature fluidity of ash slag; the softening point is low, and the formation of an eutectic system can be promoted; the ash melting point can be reduced, and meanwhile, organic hazardous wastes are used for producing H2 / CO and the like to save feed coal; organic matters are used as a binder and a water repellent agent, so that the addition amount of the ash melting point reducing additive can be greatly higher than that of other ash melting point reducing additives, and the yield of effective gas is not influenced; the phenomenon that the addition amount of limestone is increased and the melting point ofcoal ash is increased is avoided. The fluxing agent solves the problems of high coal ash melting point, high treatment cost and the like of difficult-to-gasify coal (such as Huainan coal) with high ash melting point.

Owner:绍兴凤登环保有限公司

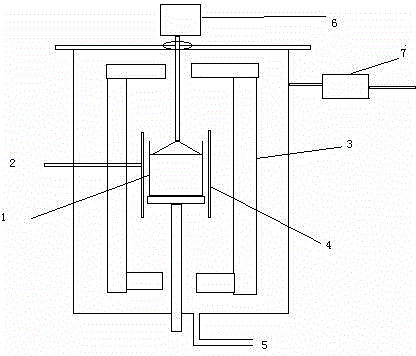

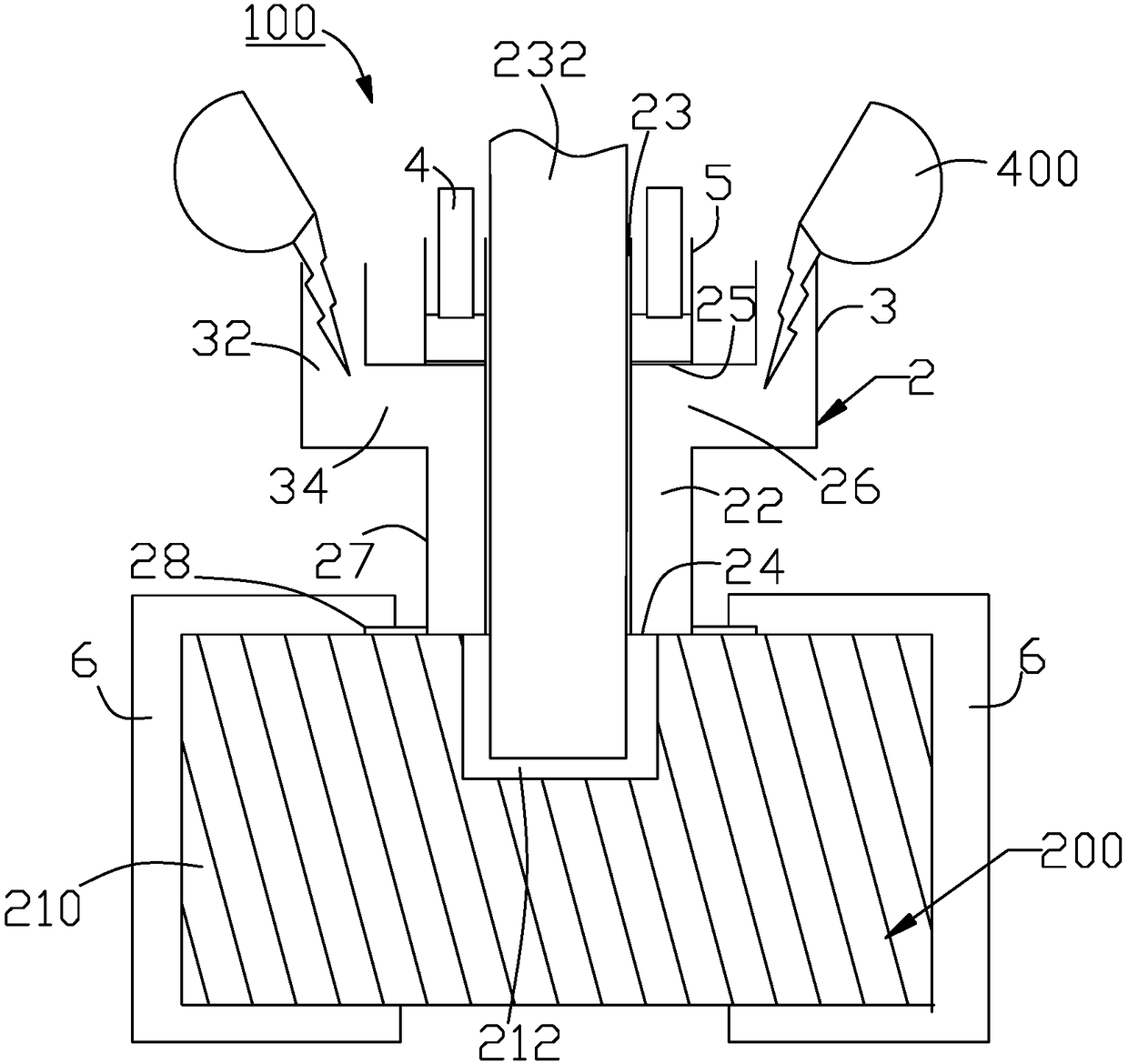

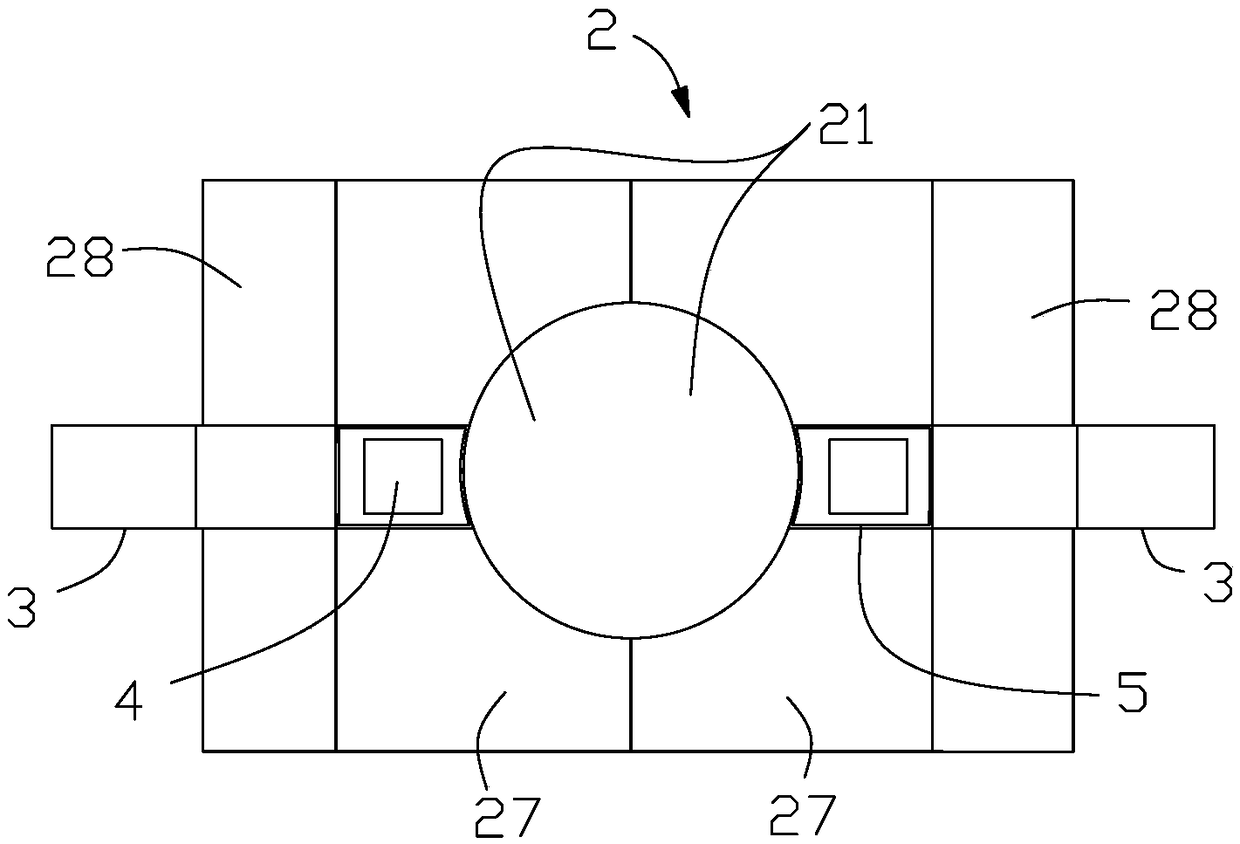

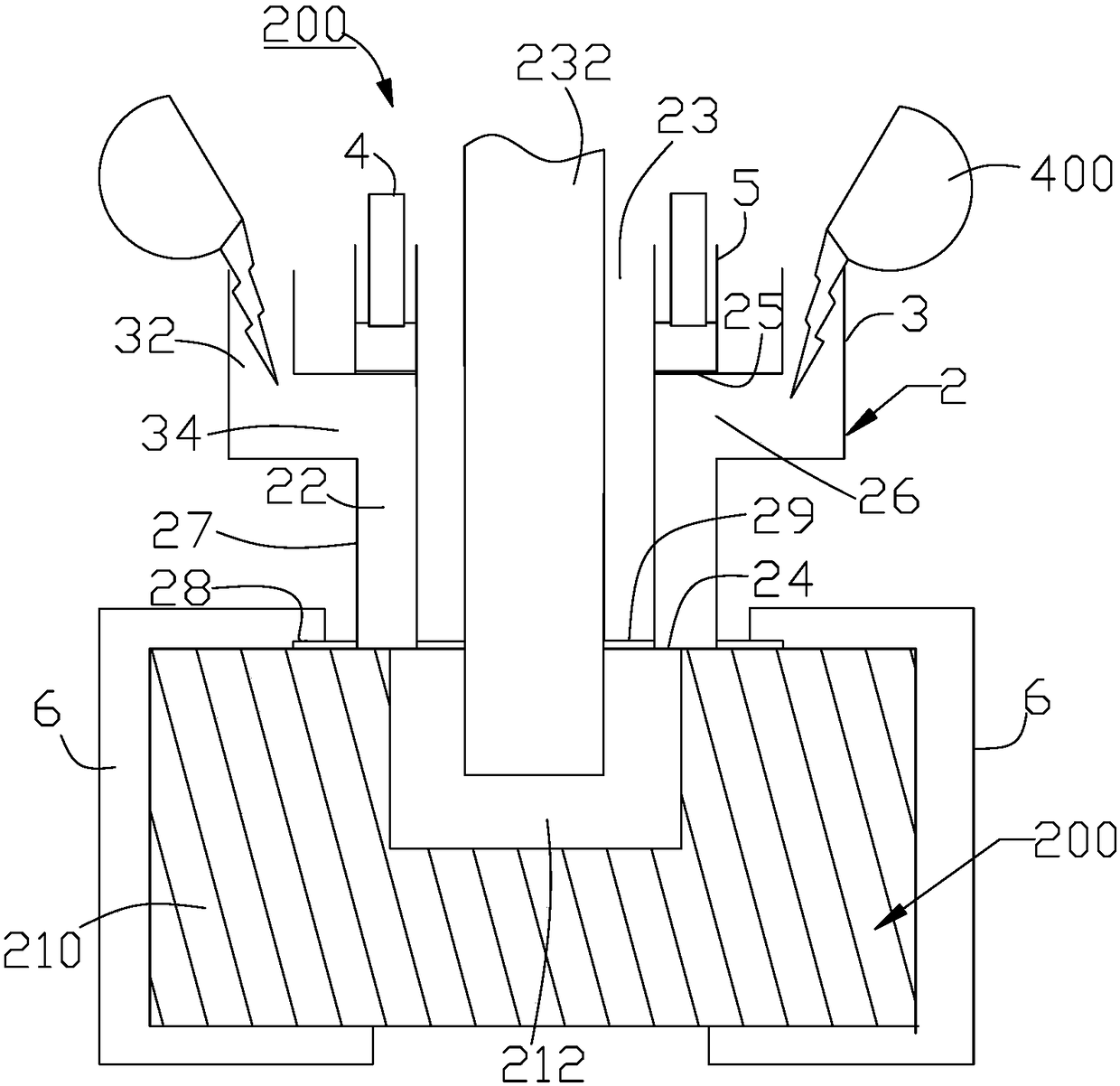

Pressure pouring device for phosphoric pig iron for assembling prebaked anode and pouring method of pressure pouring device

The invention provides a pressure pouring device for phosphoric pig iron for assembling a prebaked anode. An opening of a carbon bowl is closed through a pouring mold so that the carbon bowl can be inthe closed state; and the liquid phosphoric pig iron is pressure-poured into the portion, between the prebaked anode and a steel claw, of the carbon bowl through a pressure jet punch so that the mold-filling capacity of the liquid phosphoric pig iron can be improved, close connection between the prebaked anode and the steel claw can be achieved, the tension resistance can be improved, and connection pressure reduction can be lowered. The invention further provides a pouring method of the pressure pouring device for the phosphoric pig iron for assembling the prebaked anode.

Owner:BAISE UNIV

Converter repairing material and production method thereof

InactiveCN112794700AReduce usageImprove high temperature fluidityMagnesium AluminatePotassium feldspar

The invention relates to a converter repairing material and a production method thereof. The converter repairing material is prepared from the following raw materials in parts by weight: 73-100 parts of 200-mesh dead burnt magnesia, 20-30 parts of 1-3 mm macrocrystalline fused magnesite, 20-30 parts of 200-mesh macrocrystalline fused magnesite, 2-5 parts of metal aluminum powder, 2-5 parts of zirconium oxide powder, 2-5 parts of magnesium aluminate spinel, 2-4 parts of calcite powder, 2-4 parts of potassium feldspar powder, 3-5 parts of forsterite powder, 5-10 parts of asphalt, 5-8 parts of sodium oleate and 5-12 parts of magnesium trisilicate. The environment pollution caused by the asphalt is reduced, the characteristics of good high-temperature fluidity and good spreadability of the asphalt are retained, the sintering time is short, and the bonding strength is high. The converter repairing material can be suitable for pouring operation of molten steel with relatively low alkalinity and also can be suitable for pouring operation of molten steel with relatively high alkalinity. The converter repairing material has the advantages of good fluidity, high density, short sintering time and long service life.

Owner:海城利尔麦格西塔材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com