Novel glaze and manufacture process thereof

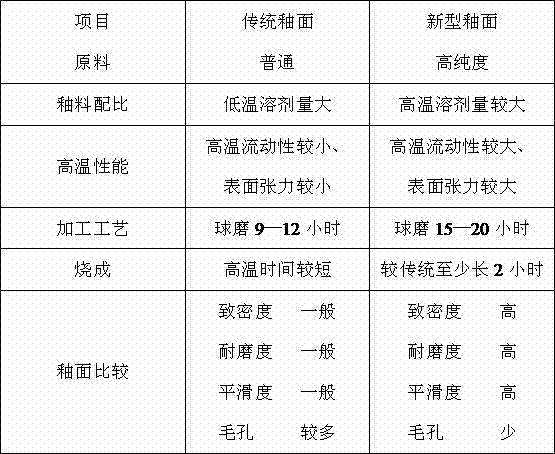

A manufacturing process and glaze technology, which is applied in the field of glaze manufacturing process, can solve the problems of easy scratches and unevenness on the surface, and achieve the effects of easy cleaning, increased wear resistance, and good high-temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A new type of glazed surface and its manufacturing process, including formula preparation-ball milling and sieving-firing, wherein the ball milling and sieving is obtained by putting the above-mentioned raw materials into a ball mill until they pass through a 325-mesh sieve:

[0019] 1) Modulation formula

[0020] Described raw material composition weight percent is:

[0021] SiO 2 50—70%, Al 2 o 3 5-15%,

[0022] K 2 O+ Na 2 O 0-2%, CaO 5-15%,

[0023] MgO 0—5%, ZnO 2—5%,

[0024] BaO 0—3%, ZrO 2 5-15%;

[0025] 2) Ball milling and sieving

[0026] The raw material is a powder of 200 mesh or more, and the raw material is put into a ball mill for ball milling. During processing, the quartz is pre-ground for 8-10 hours, and then other raw materials are added for ball milling for 3-5 hours.

[0027] 3) firing

[0028] Fire at a temperature of 1230°C-1250°C, and keep the temperature at the highest temperature for more than 2 hours.

[0029] The raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com