Thermoplastic resin composition and adhesive prepared from same, insulation adhesive film used for laminated bus bar and preparation method of insulation adhesive film

A thermoplastic resin, insulating film technology, applied in the direction of adhesives, insulators, adhesive types, etc., can solve the problems of decreased fluidity and wettability, decreased performance of insulating films, decreased yield of finished products, etc., to achieve excellent bonding performance , Excellent high and low temperature bonding performance, the effect of meeting the requirements of low temperature pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A thermoplastic resin composition, comprising 55 parts of polyester polyurethane calculated in parts by mass, 20 parts of saturated polyester resin (L952), 1 part of reactive compatibilizer, 30 parts of antimony trioxide, decabromodiphenyl 55 parts of ethane, 8 parts of aluminum hydroxide, 0.3 parts of antioxidant.

[0030] The thermoplastic resin composition is applied to an insulating adhesive film for a laminated busbar.

[0031] The preparation method of the insulating adhesive film for laminated busbars containing thermoplastic resin composition: first use acetone to adjust the composition of polyester polyurethane, saturated polyester resin, reactive compatibilizer, antimony trioxide, decabromodiphenyl A liquid dispersion (solid content 35%) composed of ethane, aluminum hydroxide, and an antioxidant is mixed to make an adhesive.

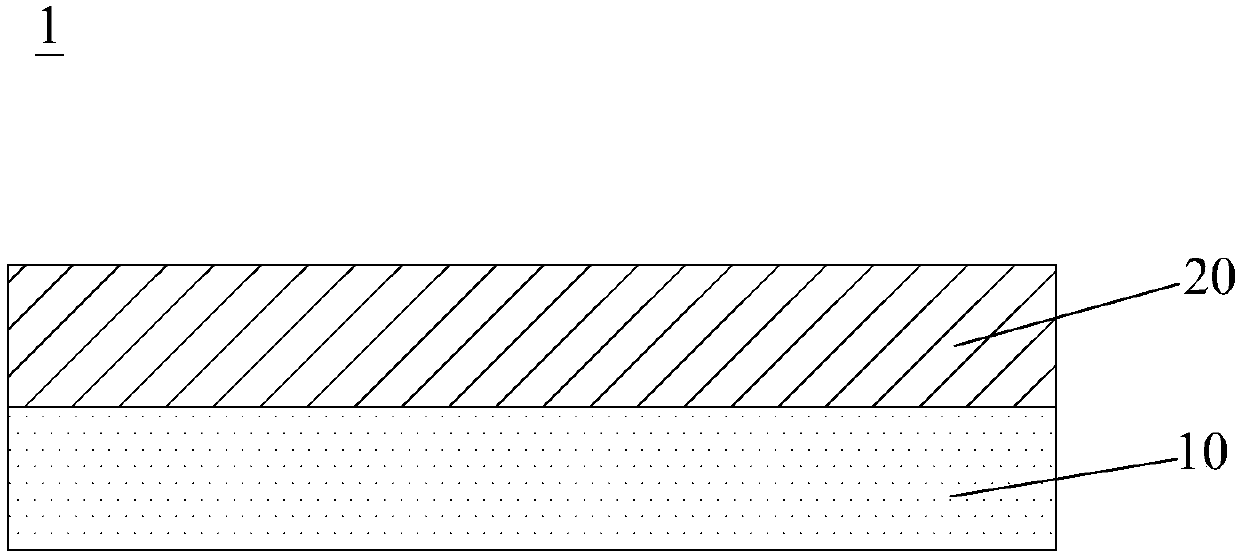

[0032] like figure 1 As shown, the adhesive is coated on one side with a coating machine on a PET insulating film 10 with a thickness...

Embodiment 2

[0036] A thermoplastic resin composition, comprising 63 parts by mass of polyether polyurethane, 13 parts of saturated polyester resin (S1611), 2.4 parts of non-reactive compatibilizer, 21 parts of antimony pentoxide, ethylene bis 40 parts of tetrabromophthalimide, 9 parts of magnesium hydroxide, and 0.6 parts of antioxidant.

[0037] The thermoplastic resin composition is applied to the laminated busbar insulation adhesive film.

[0038] The preparation method of the insulating adhesive film for the laminated busbar containing the thermoplastic resin composition: first use butanone to adjust the polyether polyurethane, saturated polyester resin, non-reactive compatibilizer, antimony pentoxide, ethylene A liquid dispersion (solid content: 48%) composed of bis-tetrabromophthalimide, magnesium hydroxide and an antioxidant is mixed into an adhesive.

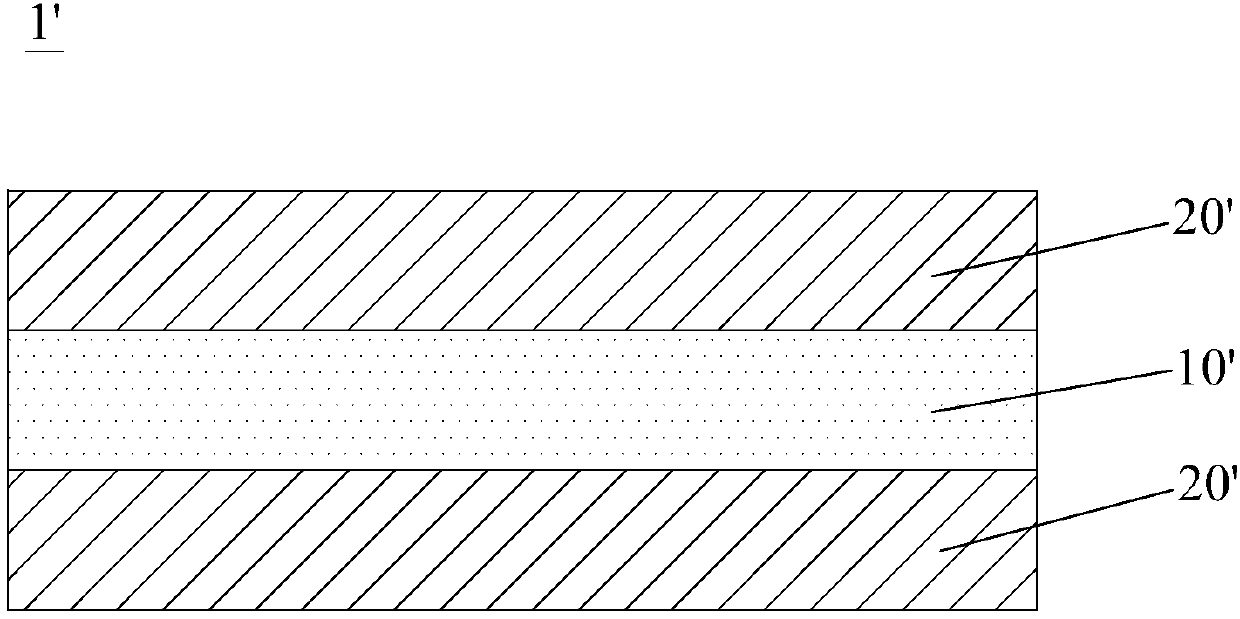

[0039] like figure 2 As shown, the adhesive is coated on both sides of the PBT insulating film 10' with a thickness of 175 μm w...

Embodiment 3

[0043] A thermoplastic resin composition, comprising 70 parts by mass of polyether polyurethane, 8 parts of saturated polyester resin (ES120), 7 parts of non-reactive compatibilizer, 18 parts of antimony trioxide, tetrabromobis 38 parts of phenol A, 12 parts of magnesium hydroxide, 0.8 parts of antioxidant.

[0044] The thermoplastic resin composition is used for an insulating adhesive film for a laminated busbar.

[0045] The preparation method of the insulating adhesive film for laminated busbars containing thermoplastic resin composition: first use dimethylformamide to adjust the polyether polyurethane, saturated polyester resin, non-reactive compatibilizer, antimony trioxide , Tetrabromobisphenol A, magnesium hydroxide, and an antioxidant liquid dispersion (solid content is 48%), mixed into an adhesive.

[0046] Then use a coating machine to coat the adhesive on a PEN insulating film with a thickness of 100 μm on one side, and the coating thickness is 40 μm;

[0047] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com