Aging equipment for electronic dobby electromagnet

An electronic multi-arm and aging equipment technology, applied in the direction of dobby, measuring electricity, measuring electrical variables, etc., can solve the problems of high failure rate of electromagnets, failure to restore working conditions, and large human factors, etc., to improve aging efficiency , avoid waste of equipment resources, and avoid uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the description of the embodiments is not a limitation on the technical solution, and any changes in form but not in substance according to the concept of the present invention should be regarded as the protection scope of the present invention.

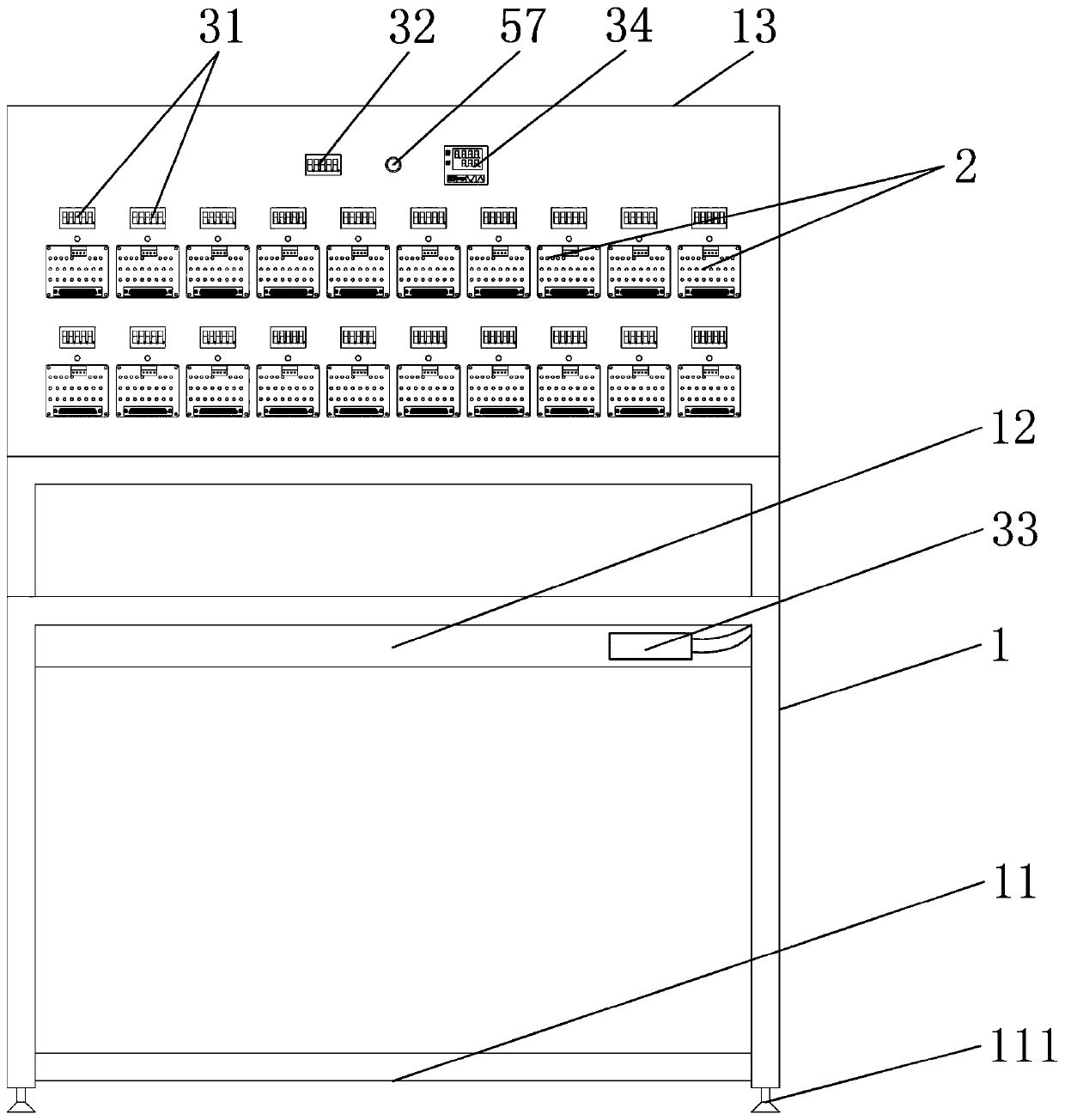

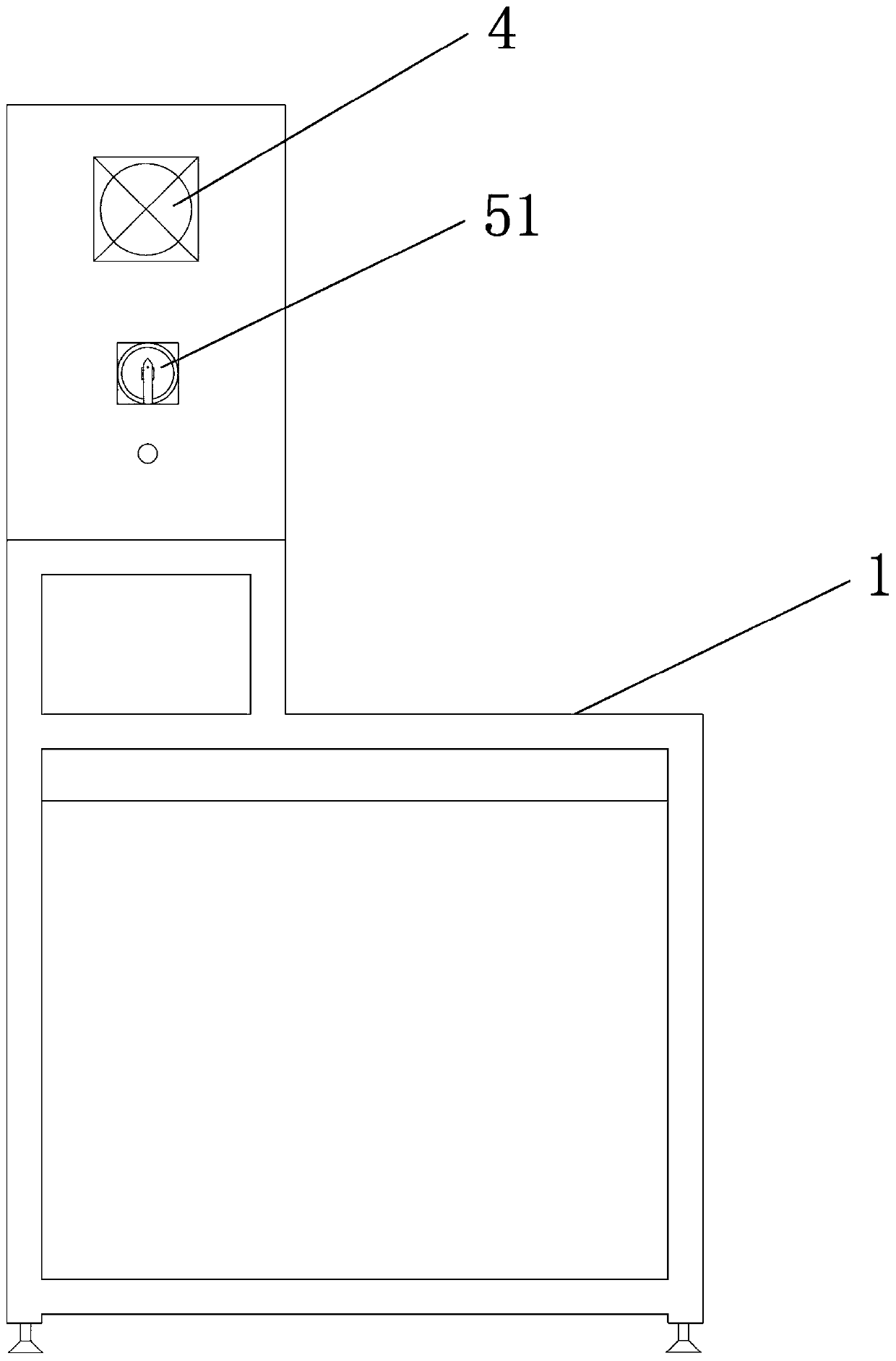

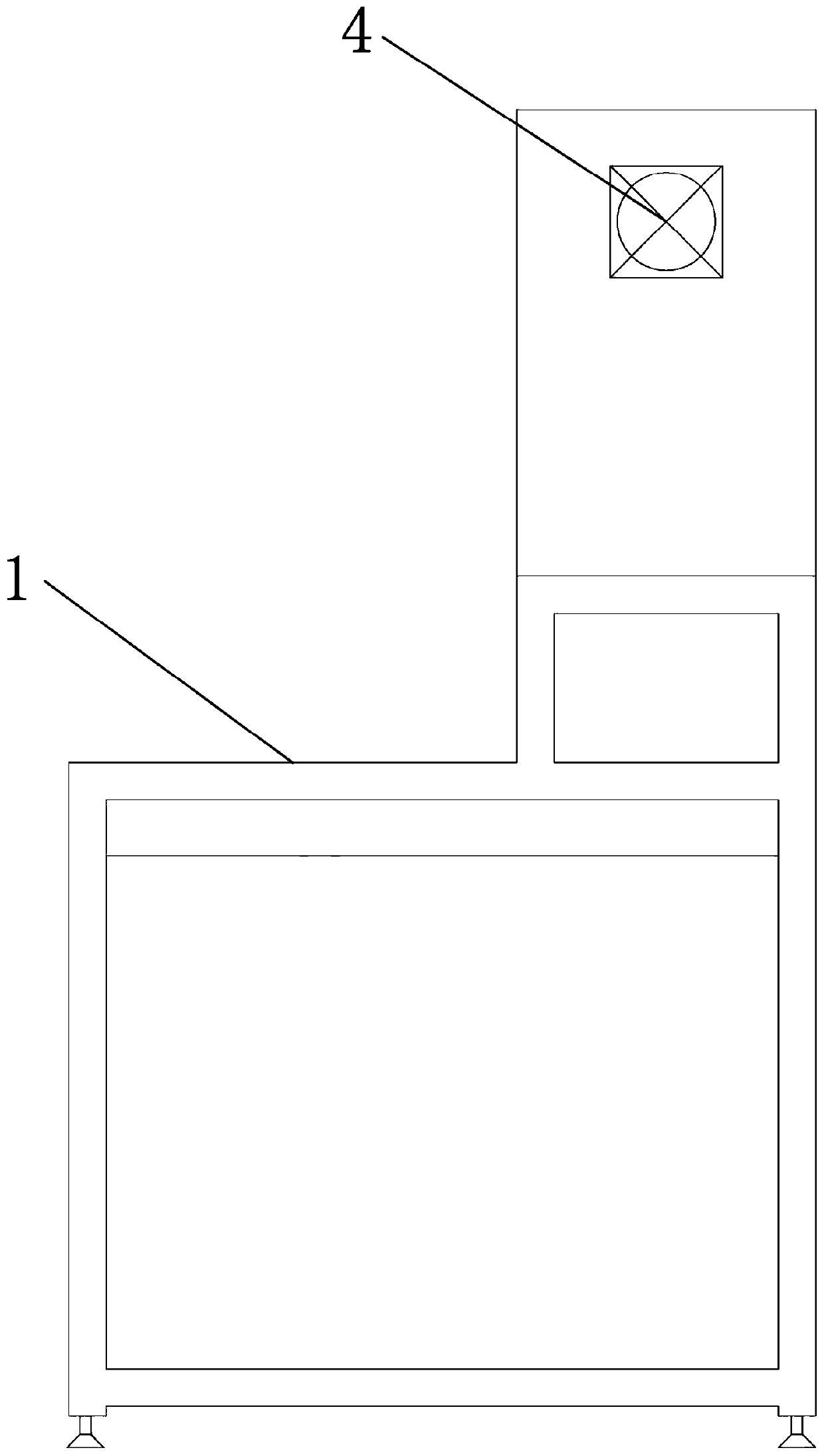

[0024] see Figure 1 to Figure 3 An electronic multi-arm electromagnet aging device includes a workbench 1, an electromagnet aging control board 2, a monitoring mechanism, a power supply mechanism and a heat dissipation mechanism. The workbench 1 includes a bracket 11 , an oil tank 12 and a box body 13 . The support 11 is located at the bottom of the workbench 1 , and the four corners of the support 11 are respectively provided with anchor bolts 111 . The fuel tank 12 is fixed in the middle of the bracket 11 by welding to simulate the real working environment of the electromagnet, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com