Technology for wine storage in pit and pottery jar

A cellar and wine storage technology, applied in the field of winemaking, can solve problems such as the inability to achieve the effect of aging, and achieve the effects of improving the body and taste of wine, improving the efficiency of aging, and increasing the complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

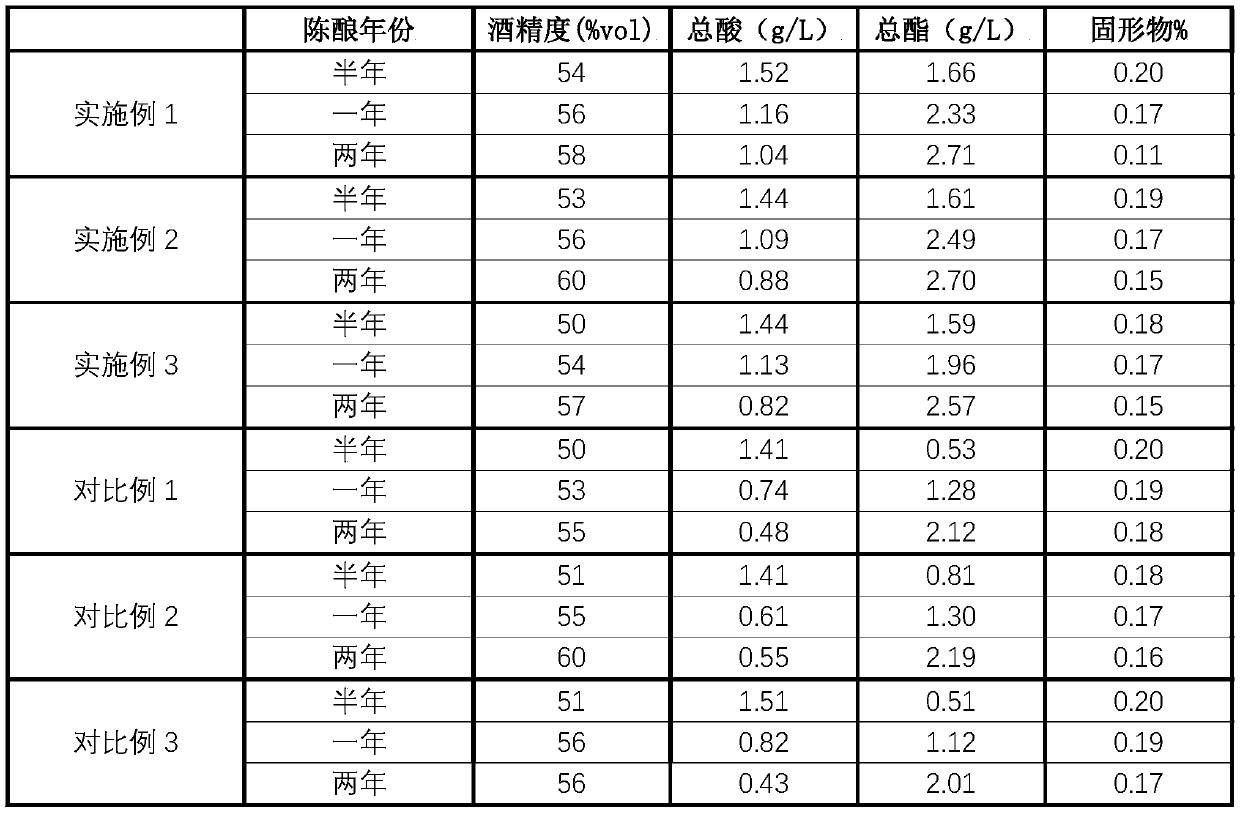

Embodiment 1、2、3 and comparative example 1、2、3

[0044] Examples 1, 2, 3 and comparative examples 1, 2, 3 all use the new wine produced by the applicant in 2019

Embodiment 1

[0046] A cellar pottery altar wine storage process, comprising the following steps:

[0047] S1 Mud making: Excavate a mud-making tank with length × width × height = 8m × 8m × 6m, fully dry 55 parts of yellow mud, sterilize at high temperature and mix with 15 parts of old pit mud, 4.8 parts (bean cake, refined glucose powder, refined Industrial starch, dry wine tank) mixed into primary mud, add pure water to 45% water content of primary mud, seal and ferment for one month, get cooked mud after passing the test, mix 0.2 parts of binder and 3.5 parts of inorganic loose components After stirring, add it to the cooked mud and stir evenly, and finally add 6 parts of organic loose components, mix well to obtain the protective mud;

[0048] S2 tank making: prepare a storage tank with length × width × height = 8m × 8m × 6m, carry out high-temperature steam sterilization, lay 8cm protective mud on the bottom and four walls, and mix the quality of protective mud into the protective mud ...

Embodiment 2

[0053] A cellar pottery altar wine storage process, comprising the following steps:

[0054] S1 Mud making: Excavate a mud-making tank with length × width × height = 8m×8m×6m, fully dry 50 parts of yellow mud, sterilize at high temperature, mix with 20 parts of old pit mud and 3 parts of refined industrial starch to form primary mud, Add pure water until the water content of the initial mud is 50%, seal and ferment for one month, get cooked mud after passing the test, mix 0.1 part of binder and 5 parts of inorganic loose components, add them to the cooked mud and stir evenly, and finally add 4 Parts of organic loose components, mix well to obtain protective mud;

[0055] S2 tank making: prepare a storage tank with length × width × height = 8m × 8m × 6m, perform high-temperature steam sterilization, lay the bottom and four walls to 5cm protective mud, and mix protective mud into the protective mud before adding the protective mud 2% distiller's grains by mass, sealed for at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com