Patents

Literature

145results about How to "Good aging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

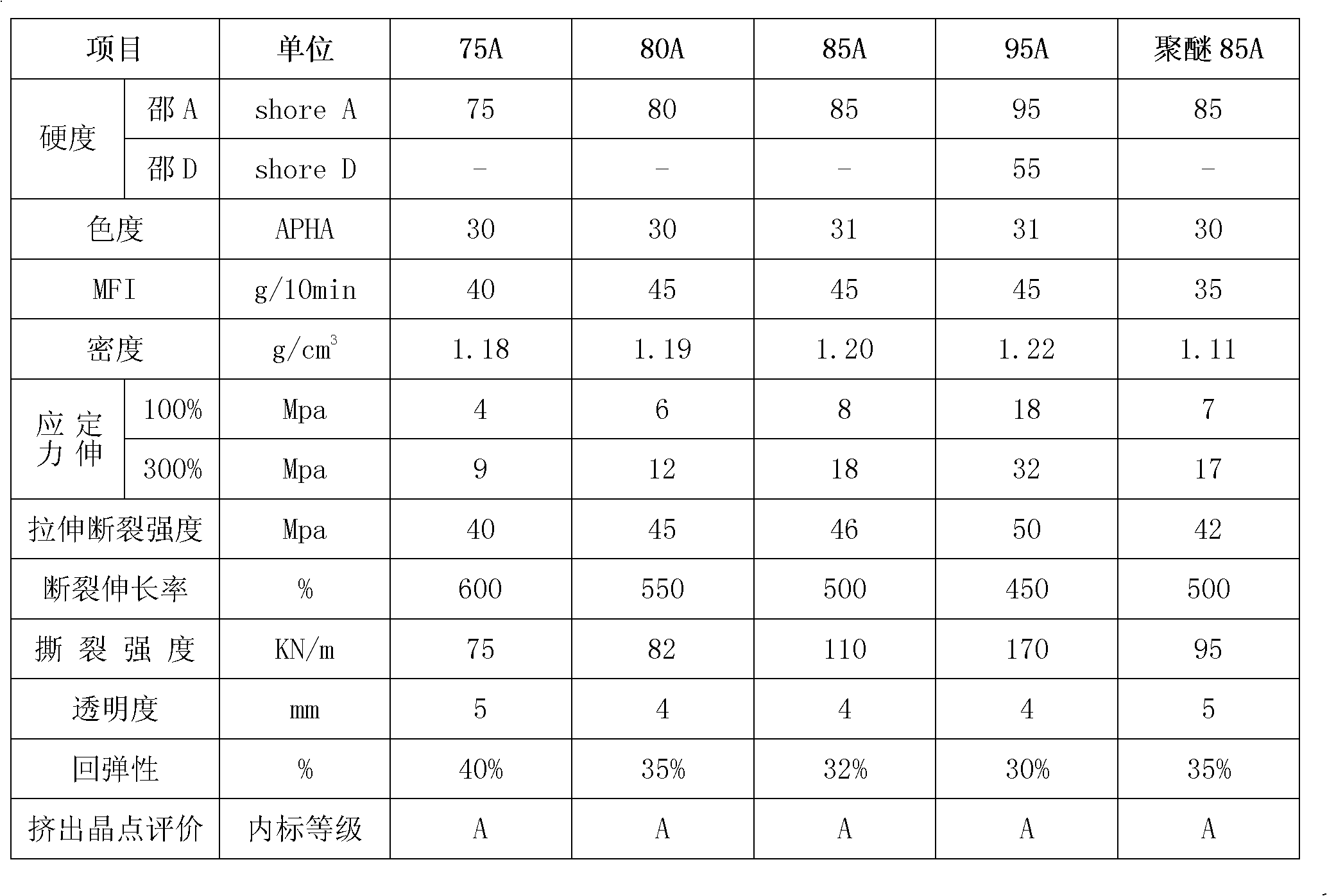

Preparation method of transparent film-grade thermoplastic polyurethane elastomer

The invention relates to the technical field of thermoplastic polyurethane elastomer (TPU), and specifically relates to a formula and a production technology of transparent film-grade TPU. According to the invention, 20-40% of diisocyanate, 45-75% of polymer polyhydric alcohol with a molecular weight of 1000-4000, 4-10% of 1,4-butylene glycol, 0.2-1% of an anti-oxidant, 0.2-1.5% of a lubricant, 0.001-0.02% of an environment-friendly catalyst, 0.2-1.0% of an ultraviolet ray absorbing agent, 0-0.8% of a hydrolysis-resisting agent, 0.1-1% of a light stabilizing agent, and 0-2% of other auxiliary agents are processed through steps such as premixing, reacting, dicing and dehydrating, and drying and curing, such that the transparent film-grade TPU is obtained. According to the invention, with the innovations on formula, equipment and technology, a defect of fisheye generation in TPU preparation processes in prior arts is solved. Factors such as a filling manner, an auxiliary agent adding manner, distributive mixing and dispersive mixing effects of an extruder, extruder retention time, and drying and curing are comprehensively considered, such that a stable product with high quality is produced.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

Processing method of tobacco raw materials for heating non-combustion tobacco products

ActiveCN103445283AIncrease contentGood release effectTobacco preparationTobacco treatmentGlycosideCombustion

A processing method of tobacco raw materials for heating non-combustion tobacco products sequentially includes: adjusting moisture of the tobacco raw materials, heating at 100-300 DEG C for 0.5-8 hours; cooling at room temperature; balancing at 22 DEG C and 60% of moisture for 24-120 hours, applying glycoside aroma precursors, and standing for 48-120 hours to guarantee that the aroma precursors are fully absorbed by the raw materials; applying polyol to the raw materials after perfuming, and standing for 48-120 hours under a seal state to guarantee that the polyol is fully absorbed by the raw materials; balancing for 24-120 hours to obtain the tobacco raw materials for heating the non-combustion tobacco products. The tobacco raw materials processed by the method has the advantages that smoke releasing performance of the tobacco raw materials during heating of the non-combustion tobacco products is increased evidently, sensory quality of the released smoke is improved evidently, and good satisfaction and comfortableness are achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

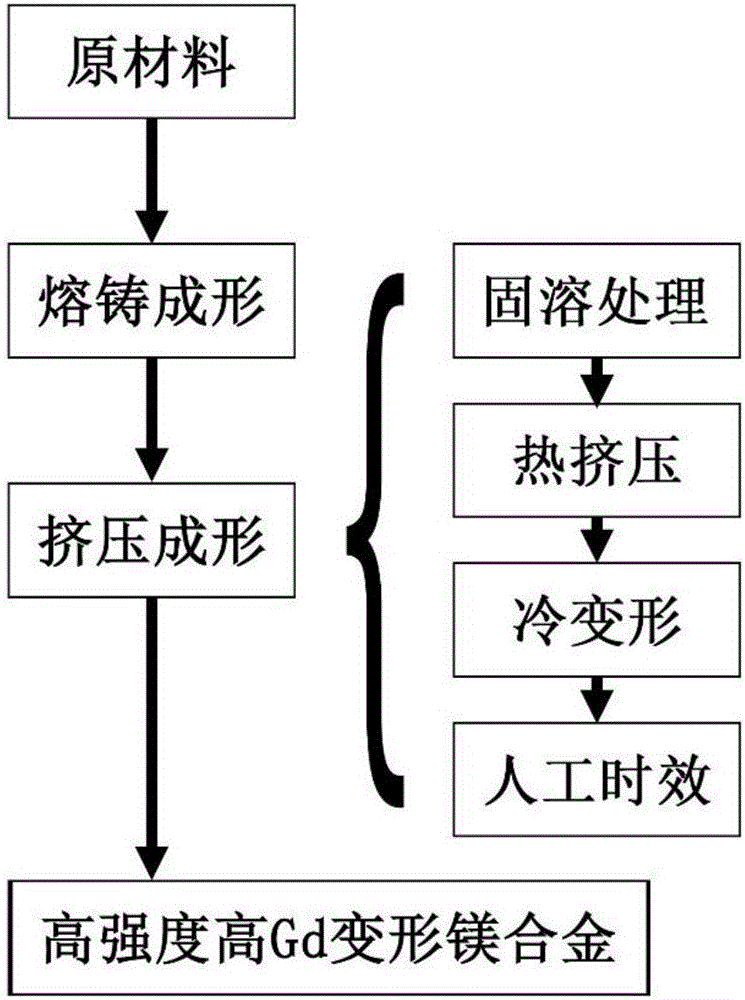

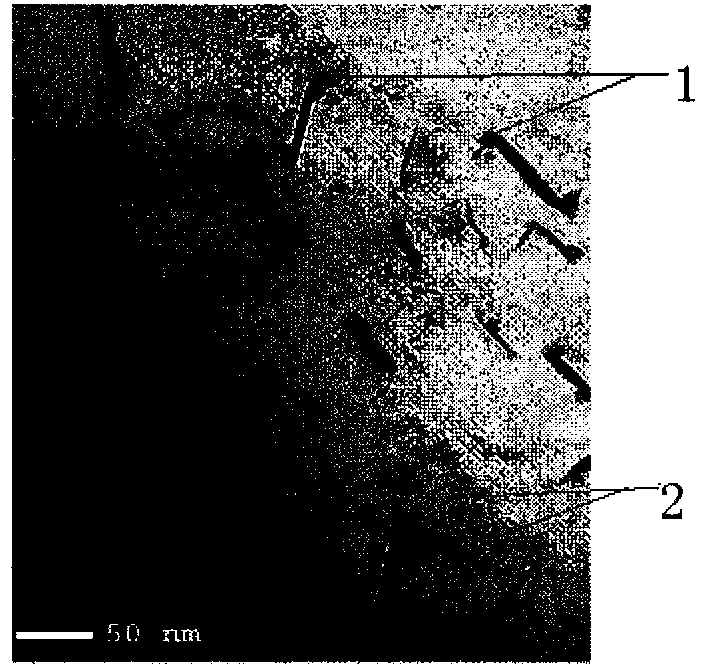

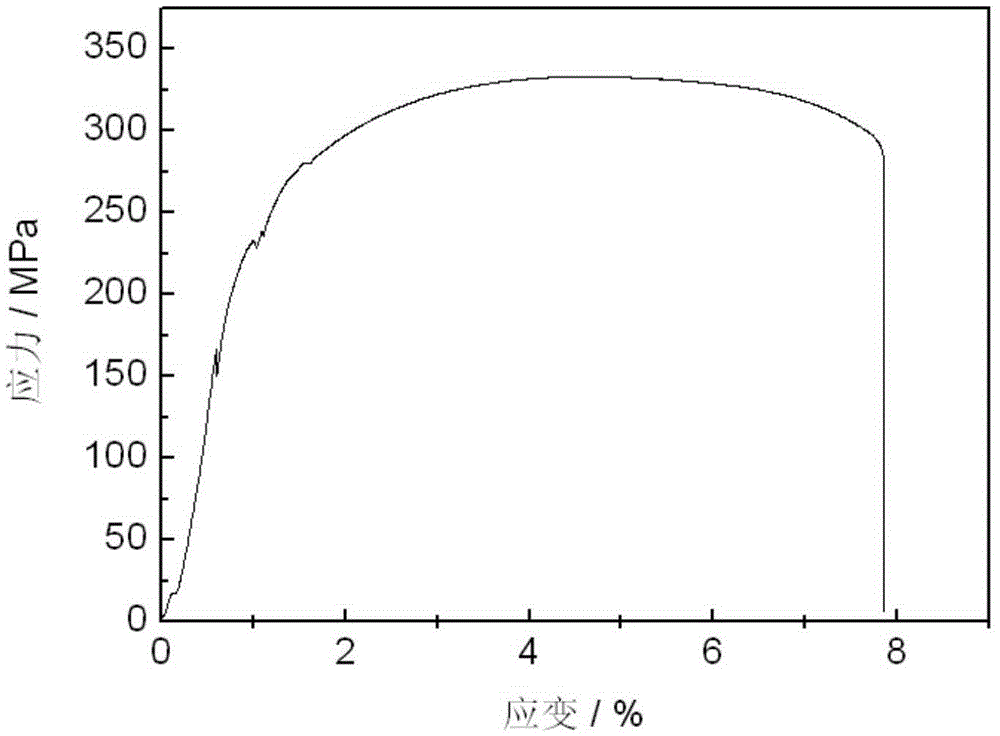

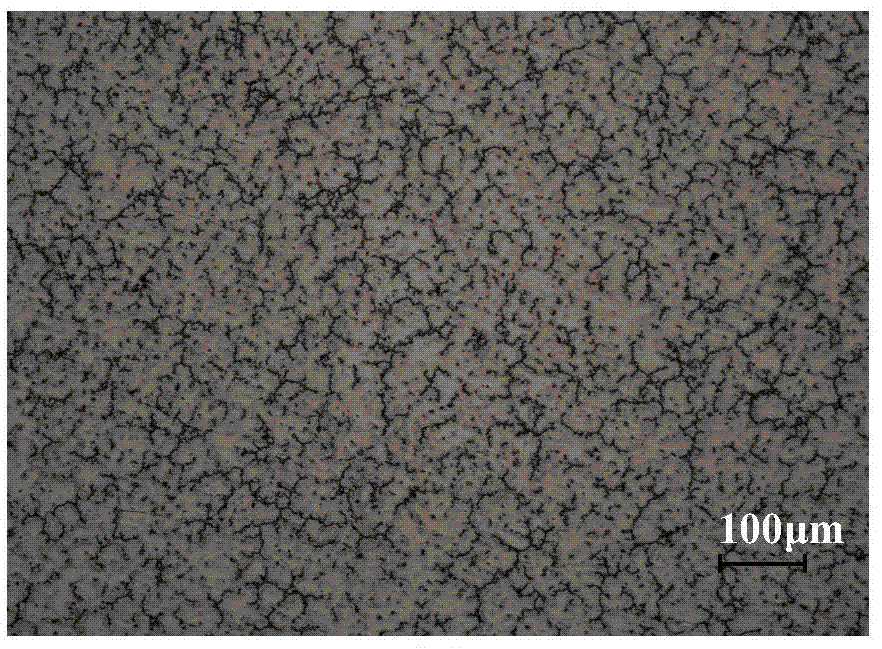

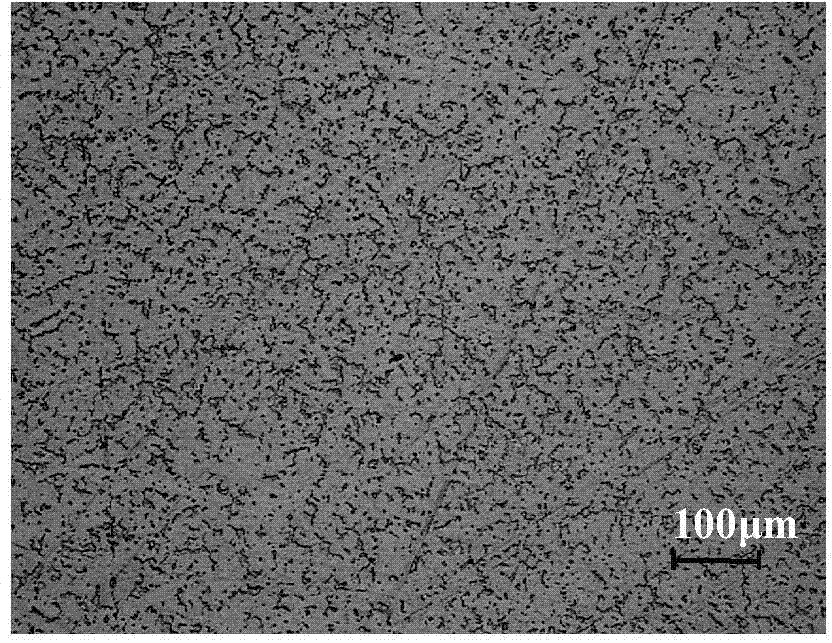

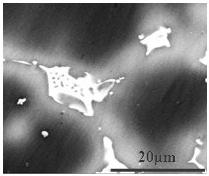

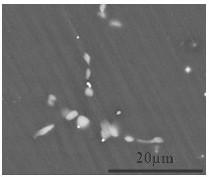

High-strength and high-Gd-content deformed magnesium alloy and preparing method thereof

The invention provides a high-strength and high-Gd-content deformed magnesium alloy and a preparing method thereof. The magnesium alloy comprises the following elements of Mg, Gd, Zn and one or more kinds of Y, Zr and Mn. The preparing method includes the following steps that a magnesium alloy cast ingot high in Gd content is prepared; after the magnesium alloy cast ingot is subjected to two steps of T4 solution treatment, quenching is conducted at the temperature ranging from 80 DEG C to 100 DEG C, and a T4-state magnesium alloy cast ingot is obtained; the T4-state magnesium alloy cast ingot is subjected to different-temperature extrusion forming and is then quenched at the temperature ranging from 15 DEG C to 30 DEG C, and a bar or plate is obtained; and the bar or plate is subjected to cold rolling and cold drawing deformation at the room temperature, then artificial aging is conducted, and a T10-state deformed magnesium alloy, namely the high-strength and high-Gd-content deformed magnesium alloy is obtained. According to the high-strength and high-Gd-content deformed magnesium alloy and the preparing method thereof, the preparing technology is simple, the performance is stable, the success rate is high, the production efficiency is high, and the high-strength and high-Gd-content deformed magnesium alloy and the preparing method thereof are easily applied to industrial production.

Owner:SHANGHAI JIAO TONG UNIV

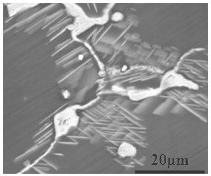

Rare earth-contained heat-resistant magnesium alloy and preparation method thereof

ActiveCN103421999AImprove mechanical propertiesGood mechanical propertiesRare earthUltimate tensile strength

The invention discloses a rare earth-contained heat-resistant magnesium alloy and a preparation method thereof, belongs to the technical field of magnesium alloy preparation. The heat-resistant magnesium alloy disclosed by the invention comprises the following materials by weight: 2 to 8 percent of Sm, 0.5 to 6 percent of Gd, 0.1 to 2 percent of Zn, 0.1 to 1.5 percent of Zr, and Mg and inevitable impurity elements in balancing amount, wherein the total weight of the impurity elements is equal to or smaller than 0.02 percent. By adding ally elements (Sm, Gd and Zn) to replace Y and Nd of WE series alloies, and adjusting corresponding heat treatment processes to ensure that the prepared magnesium alloy has excellent indoor temperature intensity, high-temperature strength and plasticity, the indoor temperature intensity, high-temperature strength and plasticity of the magnesium alloy prepared according to the preparation method are more excellent than those of the conventional WE series commercial magnesium alloies; the preparation method of the magnesium alloy prepared according to the preparation method is lower than that of the conventional WE series commercial magnesium alloies. The process is simple; industrialized application is facilitated.

Owner:CENT SOUTH UNIV

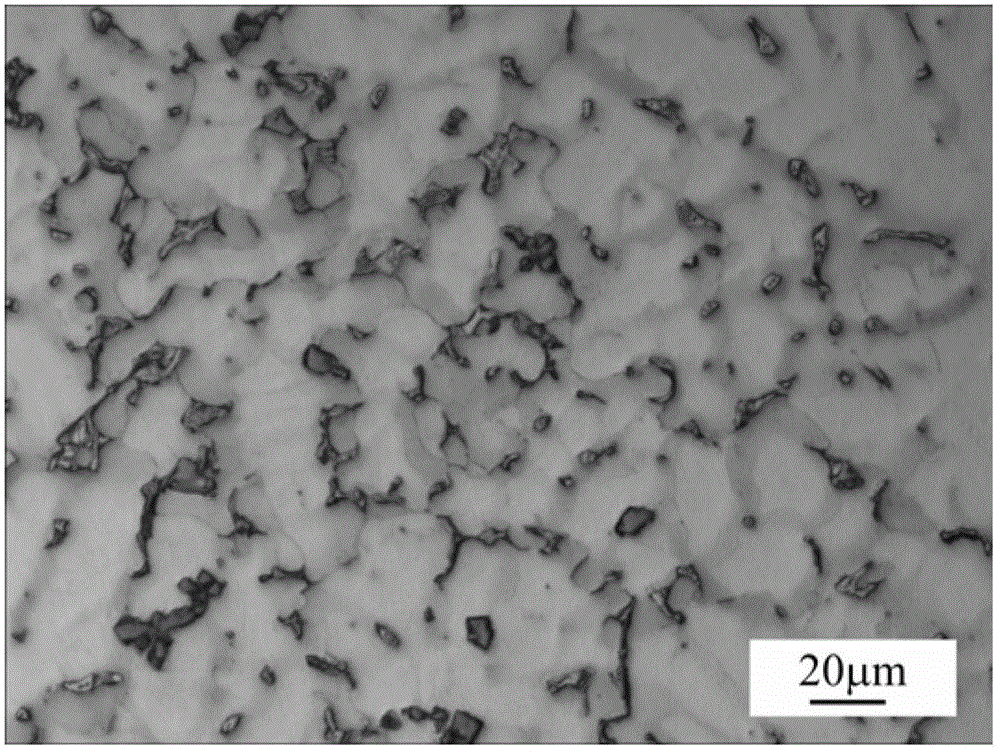

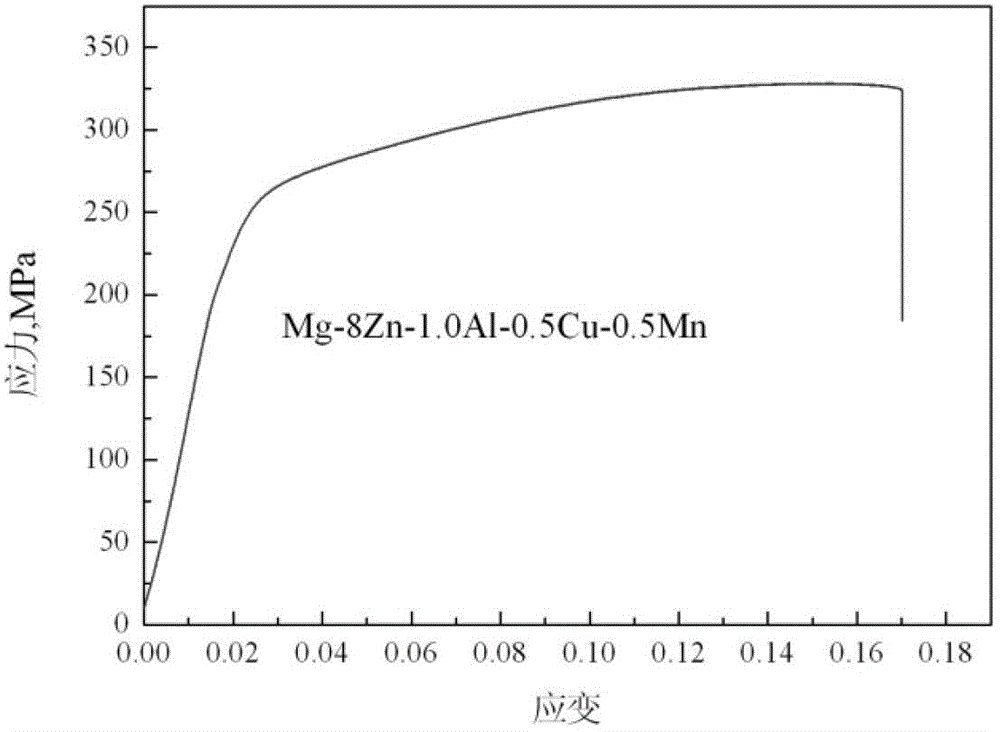

Casting magnesium alloy with high strength and toughness and preparation method thereof

ActiveCN102978497AGood comprehensive mechanical propertiesExcellent aging strengthening abilitySolution treatmentCrucible

The invention relates to the field of magnesium alloy of metal materials, and concretely relates to a casting magnesium alloy containing Zn, Al, Cu and Mn with high strength and toughness. The casting magnesium alloy comprises the following components in percentage by weight: 6.0-8.0% of Zn, 0.5-1.5% of Al, 0.5-1.0% of Cu, 0.3-0.7% of Mn and the balance of Mg and inevitable impurity elements, wherein the content of the impurity elements is less than 0.01%. A preparation method of the casting magnesium alloy comprises the steps of: smelting Mg at the temperature of 740-760 DEG C by using an iron crucible; after pure magnesium is completely smelted, sequentially adding preheated pure metal Zn, Al, Cu and Mg-10wt.% and Mg intermediate alloy for alloying, wherein mixed CO2 and SF6 are used as protective gases in the pure magnesium smelting and alloying processes; stirring, slagging off, standing for 15-20 minutes, adjusting the temperature of an alloy fusant to 700-720 DEG C, and casting into an ingot; and carrying out solution treatment on the alloy for 24-64 hours at 350-400 DEG C, quenching by warm water at 40-60 DEG C, then preageing for 8-24 hours at 50-70 DEG C, and finally preageing for 2-6 hours at 150-200 DEG C to obtain the casting magnesium alloy with high strength and toughness. In room temperature extension tests of the casting magnesium alloy, the yield strength is not less than 205MPa, the tensile strength is not less than 305MPa, the elongation rate is not less than 10%, and the casting magnesium alloy has excellent comprehensive mechanical property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

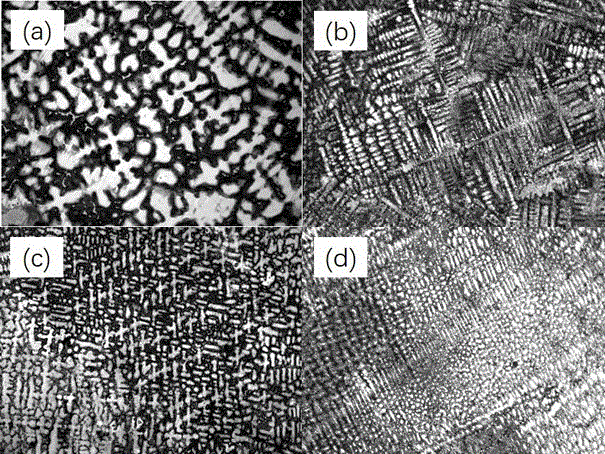

Preparation method of high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

InactiveCN106834795ASolve segregationImprove plastic processing performanceIncreasing energy efficiencyWear resistantWater cooling

The invention relates to a preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The preparation method comprises the following steps: vacuum induction melting or covering protection type non vacuum melting of a Cu-Ni-Sn ternary alloy, application of electromagnetic stirring until alloy melt is solidified completely in the subsequent solidification process, and homogenization annealing-water cooling-solid solution-cold deformation-aging treatment of as-cast alloy. Through use of the preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy, crystal grains can be refined, dendrite spacing can be reduced, macrosegregation and microsegregation of the series of alloy can be eliminated, aging strengthening effect is excellent, plastic processing property of the series of alloy can be improved, the service life of the alloy can be improved, by the application of electromagnetic stirring in the solidification process, the segregation degree of the obtained as-cast structure is small, the segregation is easy to remove, and the method has the advantages of saving energy, improving production efficiency and reducing production cost.

Owner:JIANGYIN SANLING METAL PROD

Copper strip preparation process for high-end frame material

Provided is a copper strip preparation process for a high-end frame material. According to the weight percentage of components in a smelting furnace, the total content of standard electrical cathode copper and Cu in all alloys is 96.5% or above, iron Fe accounts for 2.1-2.6%, phosphor P accounts for 0.015-0.15%, zinc Zn accounts for 0.05-0.20%, stannum Sn accounts for 0.005-0.050%, magnesium Mg accounts for 0.008-0.05%, the sum of impurities does not exceed 0.1%, the sum of alloy elements and impurities is 0.15% or below, and the weight sum of the above components is 100%; then, the followingsteps of smelting, casting, saw cutting, hot rolling, face milling, cold rolling, edge cutting, annealing, rolling of finished products, cleaning, shearing of finished products and package and warehousing are carried out. The problem of high temperature softening and other aspects of an original TFe2.5 and other frame material copper strips is solved, the high-end frame material has the obvious advantages of high strength, excellent electrical conductivity, good subsequent processing performance and the like compared with frame materials prepared by adopting an original process, the chemical composition of the material is stable, and the surface is clean, smooth and free of oxidation and discoloration.

Owner:中铝洛阳铜加工有限公司

Convenient nutritional porridge and preparation method thereof

The invention discloses convenient nutritional porridge prepared by combining a traditional formula and a scientific formula and taking the essence of cereal grains; the nutritional porridge is prepared as follows: preparing different taste, different varieties and different colors of food into convenient cooked food by frying, freeze-drying and other processes; preparing solid convenient porridge by rational combination and mixing with auxiliary materials; the nutritional porridge can be prepared into dozens of varieties such as eight treasure porridge, nutrition porridge, dietotherapy porridge, flavor porridge and other series. The product is low in cost and convenient to eat, does not contain preservatives and artificial color, can keep the shape and flavor of traditional porridge food, keeps nutrition components of raw materials, has the health functions of physique enhancement and the like, is in line with the modern diet concept, and is an ideal convenient food for home life, travels and field operation.

Owner:廖少波

Method for producing instant vermicell made of potato and the like

The production method of sweet potato fast food vermicelli includes the following steps: mixing raw materials and making slurry, spraying, coating on the steaming cloth band, forming, steaming, cloth-removing, predrying, cooling, cutting, forming and drying. The prepared starch slurry can be uniformly coated on the steaming cloth band by spray-forming machine, and the coated thickness is 1.0-1.2 mm. Said method can implement industrial automatic production, can raise production efficiency, and can produce high-quality high-nutrient sweet potato fast food vermicelli.

Owner:GUOJI IND SICHUAN

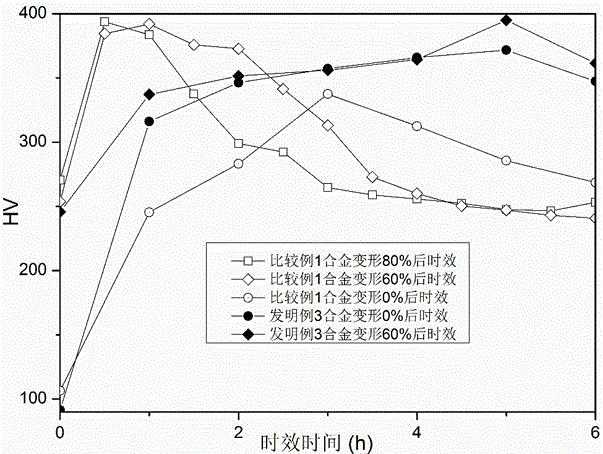

Wrought magnesium alloy material with low cost, high performance and heat resistance, and preparation method thereof

InactiveCN108385007AHigh strengthImprove mechanical propertiesRare-earth elementChemical composition

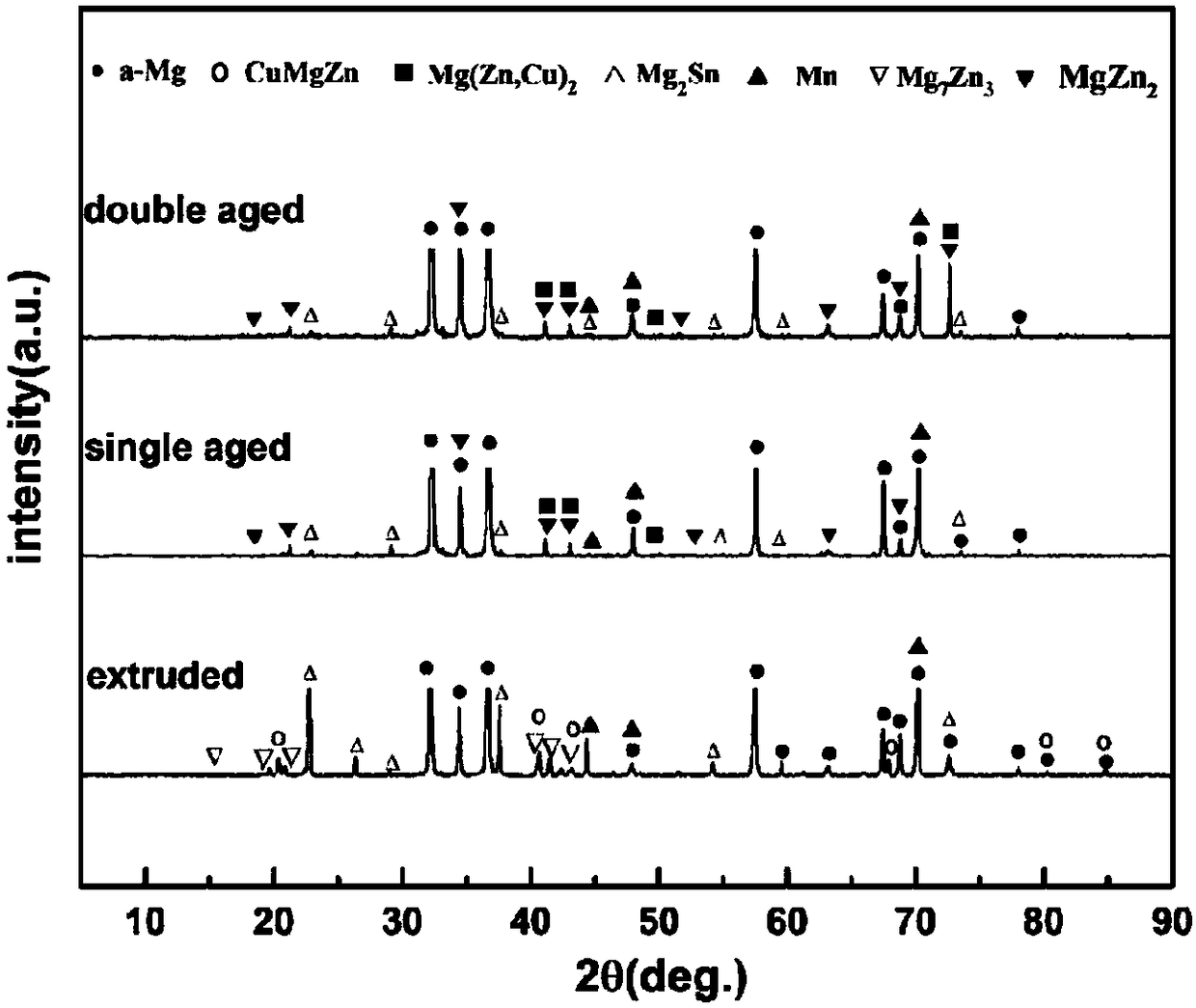

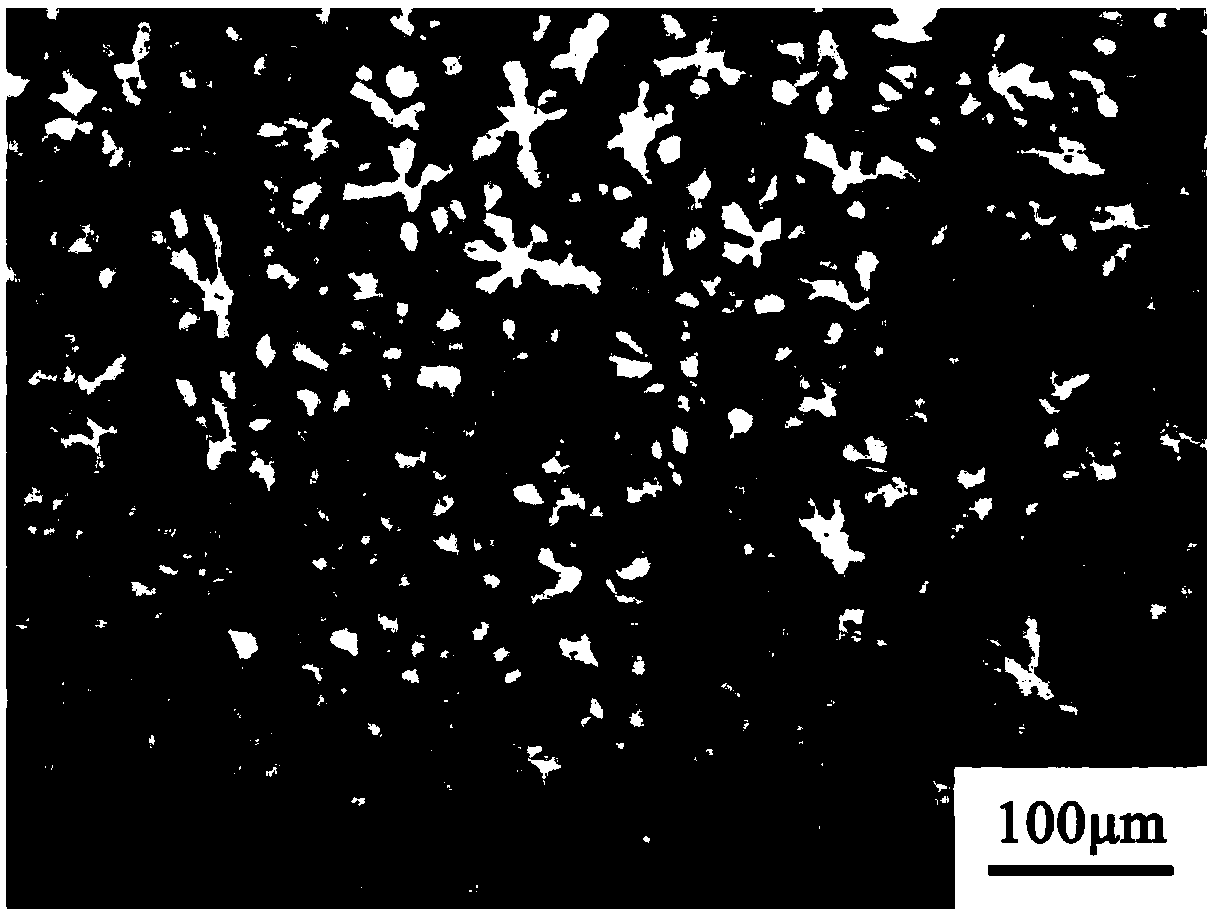

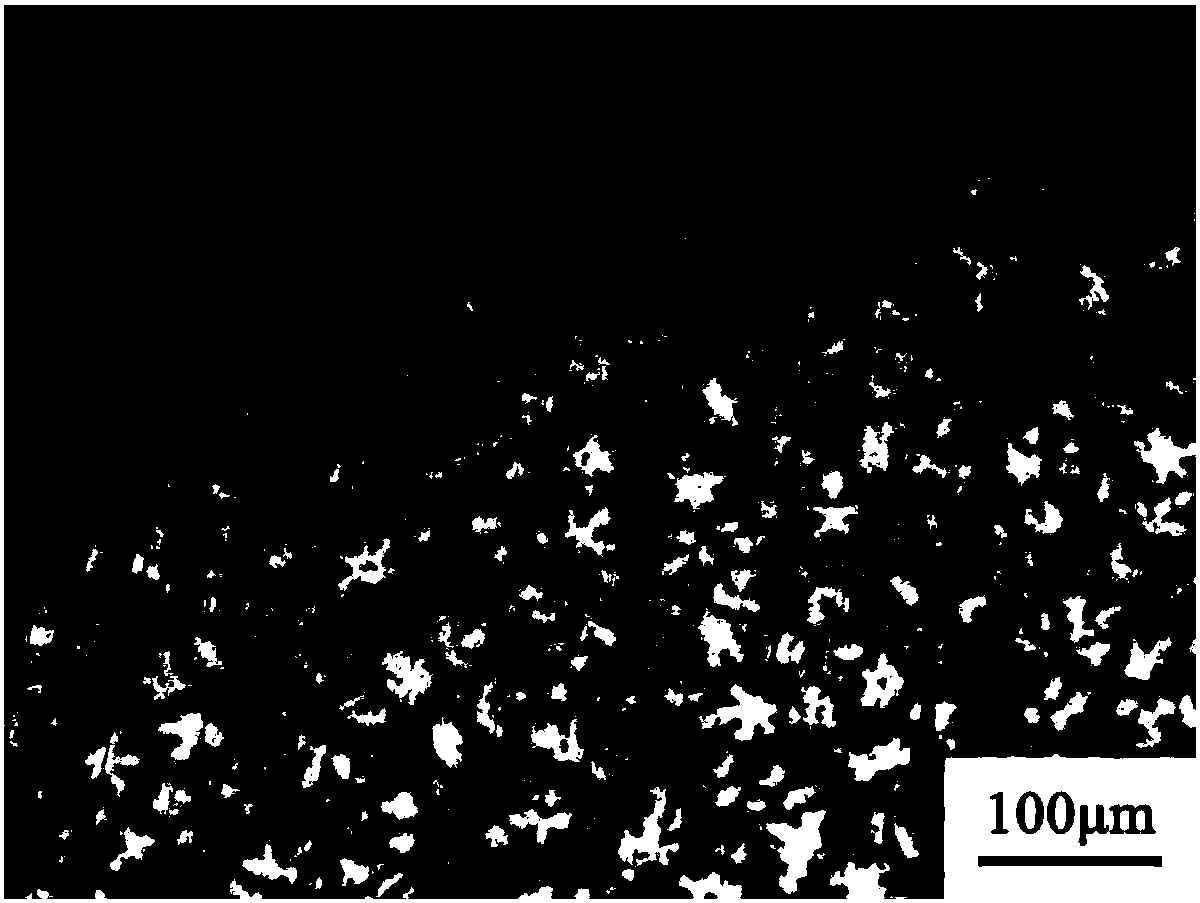

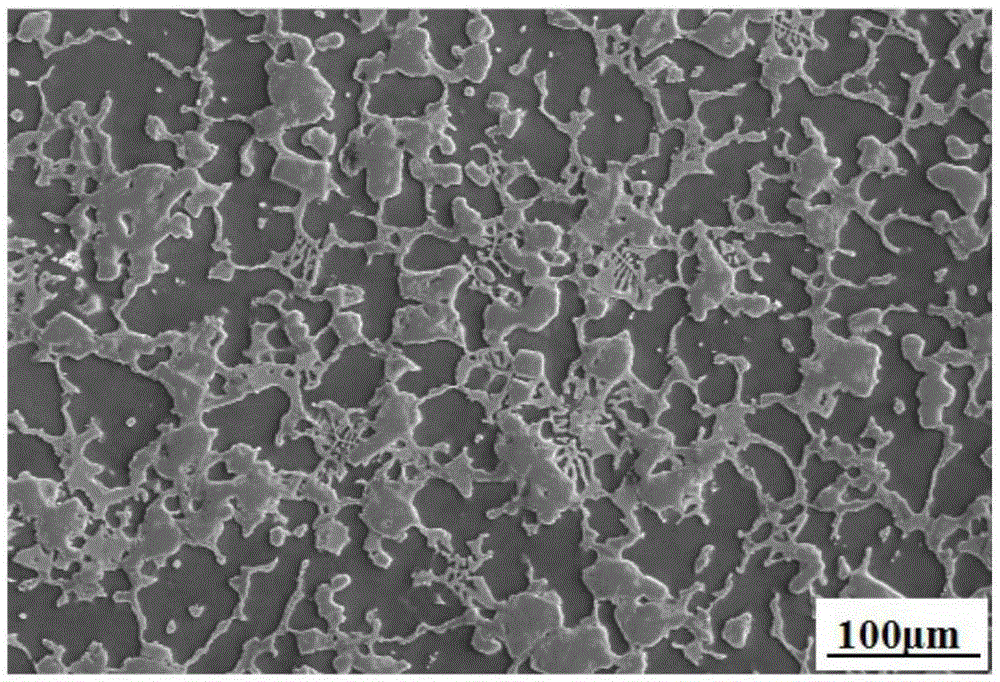

The invention provides a wrought magnesium alloy material with low cost, a high performance and heat resistance, and a preparation method thereof. The wrought magnesium alloy material is prepared fromthe chemical components in percentage by weight: 4.0 to 9.0 percent of Zn, 0.5 to 8 percent of Sn, 0.1 to 5 percent of Cu, 0.5 to 2 percent of Mn, and the balance magnesium and inevitable impurities.According to the wrought magnesium alloy material with the low cost, the high performance and the heat resistance, and the preparation method thereof provided by the invention, the problems that an existing high-strength heat-resistant wrought magnesium alloy material uses a rare earth element and a high-price alloy material, so that complicated processes such as large plastic deformation (rapidsolidification, powder metallurgy and the like) are higher in cost and the like are solved; and the element components of the alloy are reasonably blended, a conventional smelting and casting processis adopted, and reasonable heat treatment process conditions are selected after conventional plastic deformation and forming, so that the wrought magnesium alloy material with an excellent mechanicalproperty and a performance being remarkably superior to a high-strength ZK60 wrought magnesium alloy can be obtained. The wrought magnesium alloy material provided by the invention has the characteristics of low cost, high performance, no rare earth, and excellent high temperature and room temperature properties, and has a great application prospect.

Owner:XIANGTAN UNIV

Heated and reinforced high-strength cast magnesium alloy and preparation method thereof

The invention provides a heated and reinforced high-strength cast magnesium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 8.0-10.0 of Zn, 1.0-5.0 of Al, 1.0-5.0 of Sn, 0.1-1.0 of Cu, 0.3-0.8 of Mn, 0.3-0.5 of Ca, and the balance of Mg and inevitable impurity elements. According to the high-strength cast magnesium alloy, under a room-temperature stretch test, the tensile strength reaches 320-350 MPa, and the yield strength reaches 220-260 MPa. A heat treatment process of the magnesium alloy comprises solution treatment by 4-8 hours at a temperature of 330-380 DEG C, air cooling, aging by 8-16 hours at a temperature of 150-220 DEG C and obtaining of the high-strength cast magnesium alloy. The heat treatment process of the alloy is simple and easy to realize; and the aging treatment can form a lot of nanoscale strengthening phases in an alloy structure, so that the alloy strength can be prominently improved. The alloy contains no such noble metal as rare earth, and is an alloy system with low cost and wide applicability.

Owner:山东山科智镁新材料科技有限公司

Local thermal aging and vibration-assisted local thermal aging method

InactiveCN102146504ALower resonance frequencyReduce the amplitudeProcess efficiency improvementManufacturing technologyEngineering

The invention provides a local thermal aging and vibration-assisted local thermal aging method. The method mainly comprises the following steps of: analyzing the internal elastic performance and the residual stress distribution of a part needing aging treatment by using experience judgment or a computer modeling virtual manufacturing technology according to parameters such as a part material, construction geometry, a primary machining and treating process and the like to determine process parameters such as a stress distribution centralized region and the like of the part; and performing thermal aging or thermal aging and vibration aging combined treatment on the part according to the parameters. By adopting the local thermal aging and vibration-assisted local thermal aging method, the aims of removing residual stress and homogenizing tissues are fulfilled. Compared with conventional thermal aging and vibration aging processes, the method has the advantages of effectively utilizing heat energy, saving energy sources and enhancing the aging effect, and ensures that the natural frequency of the part subjected to local heating is lowered, so that the vibration aging noises are greatly reduced.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and preparation method thereof

The invention discloses a magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and a preparation method thereof. Mass percent of components of the alloy is that 4 to 10% of zinc, 2 to 4% of aluminum, 0.1 to 0.5% of chromium, 0.1 to 1.0% of bismuth, 0.5 to 2.0% of calcium, the remaining is magnesium, and the total mass is 100%. The preparation method of the alloy comprises the following steps of preheating prepared alloy furnace materials, communicating a carbon dioxide and sulfur hexafluoride mixed gas to be served as a protection gas to perform smelting, performing diffusion annealing on obtained magnesium, zinc, aluminum, chromium, bismuth and calcium as-cast-condition alloy materials for 48 hours under 380 degrees, performing linear cutting to obtain aging thermal treatment samples and plate-shaped tensile samples, preserving heat of the above samples, performing water quenching and manual aging to obtain the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening. The preparation method can obtain preparation the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and relatively thin in as-cast structure and high in thermal stability and mechanical property.

Owner:NORTHEASTERN UNIV LIAONING

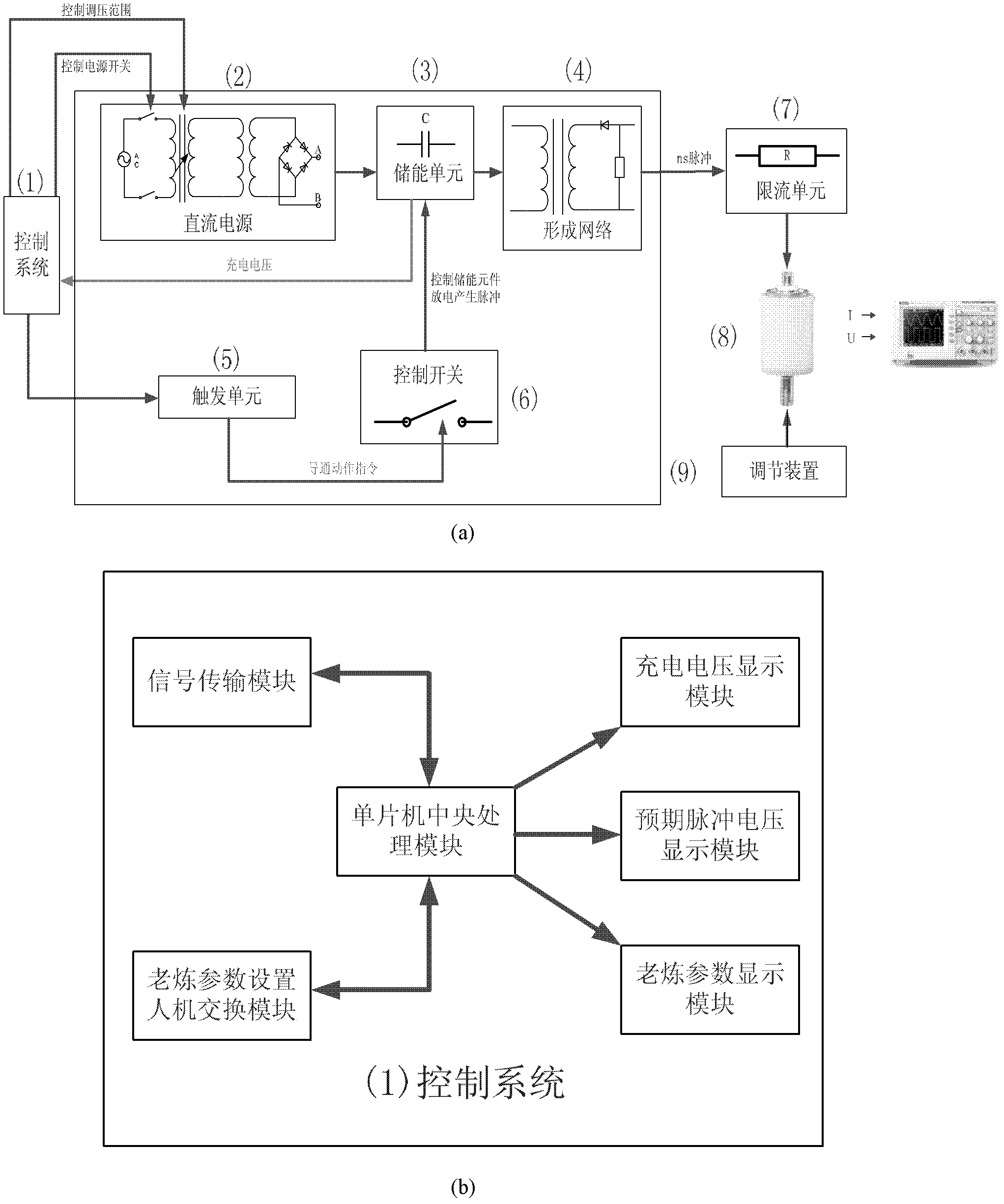

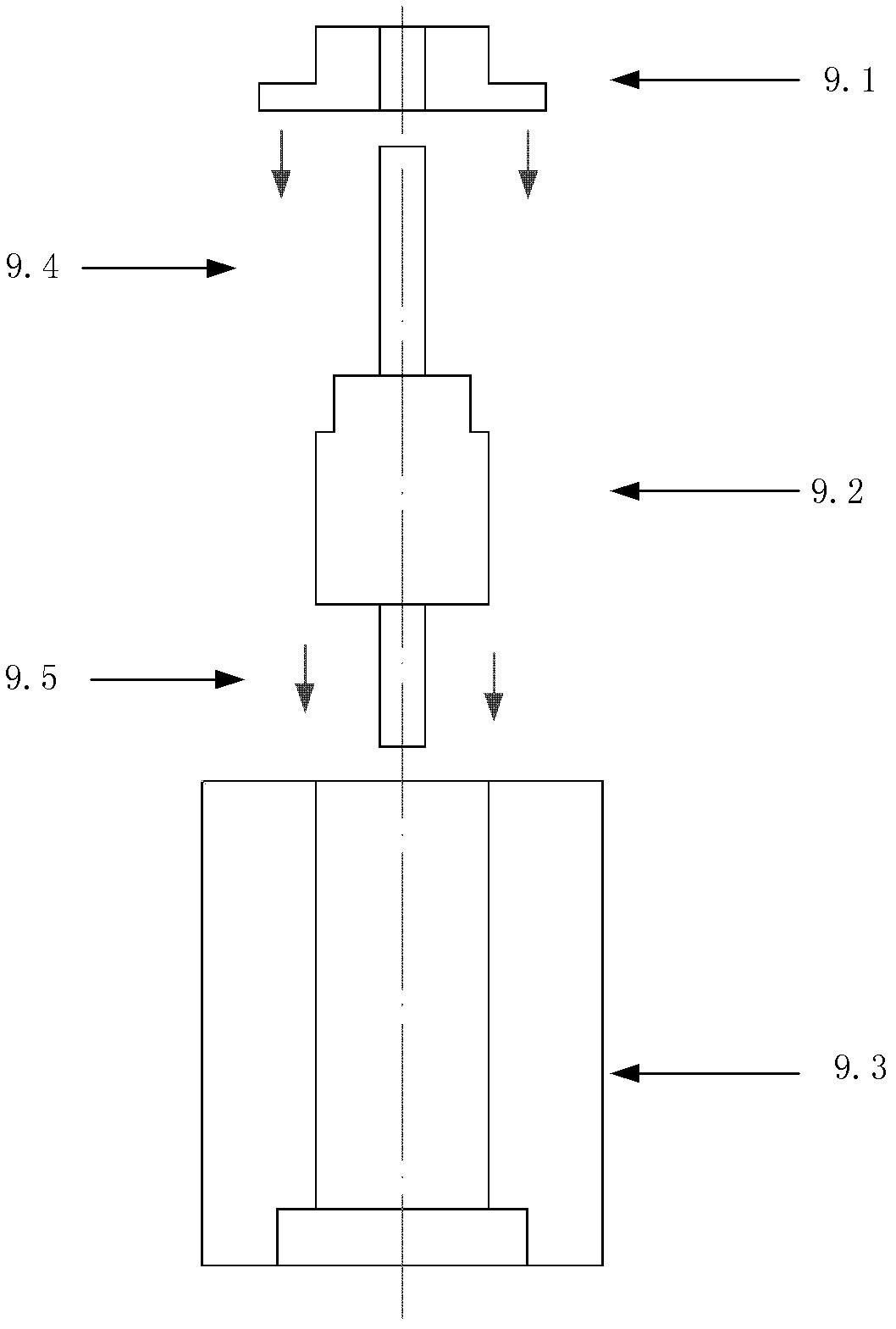

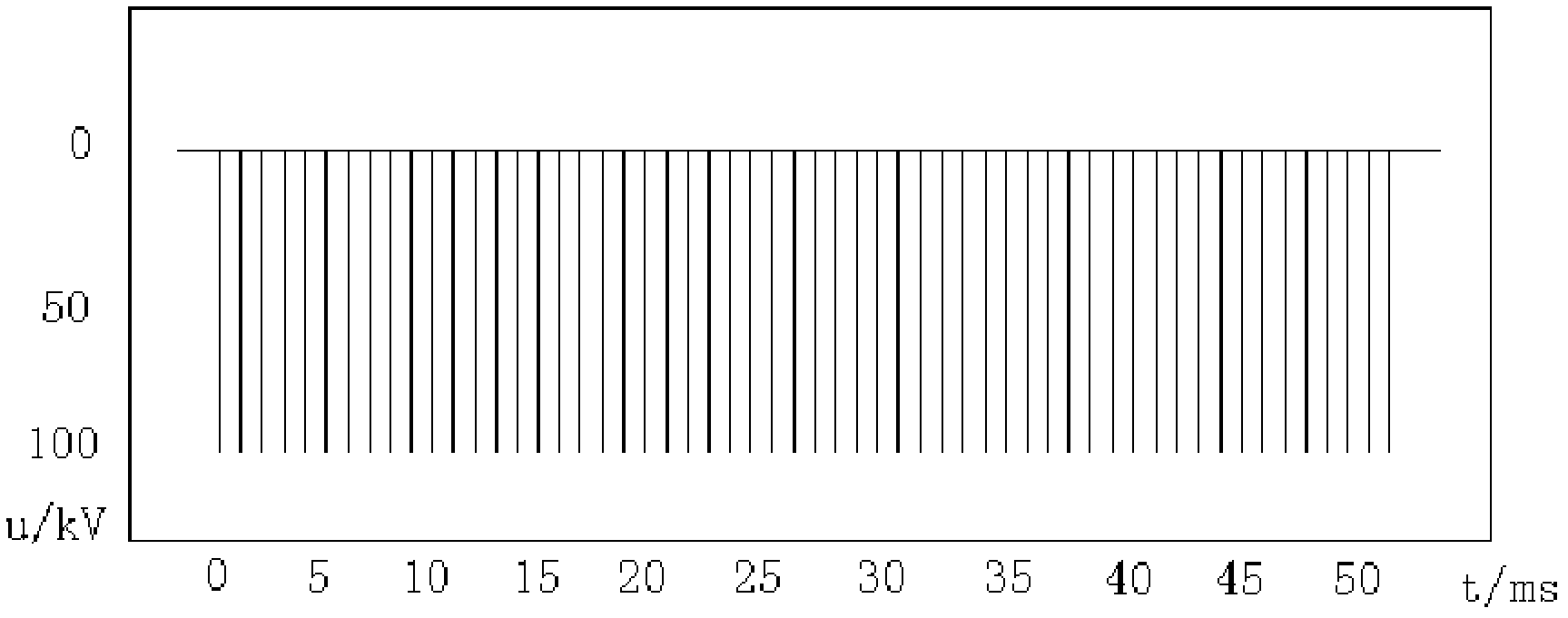

Nanosecond continuous pulse ageing device and method of vacuum interrupter

InactiveCN102426954AGood aging effectImprove insulation withstand voltage performanceElectric switchesCurrent limitingNanosecond

The invention relates to a nanosecond continuous pulse ageing device and method of a vacuum interrupter. The nanosecond continuous pulse ageing device comprises a control system, a direct-current power supply, an energy storage unit, a forming network, a triggering unit and a control switch part, wherein the control system is connected to the direct-current power supply and the triggering unit; the output end of the direct-current power supply is connected with the energy storage unit and the triggering unit is connected with the control switch; the energy storage unit is connected with the forming network and the forming network is used for outputting a pulse voltage to the vacuum interrupter through a current limiting unit; the control unit is connected with the energy storage unit and the lower part of the vacuum interrupter is provided with an adjusting device. According to the method provided by the invention, by adjusting the energy of one time of the discharging process and controlling discharging times in the unit time, the ageing degree and the ageing tendency are controlled and the ageing uniformity of the vacuum interrupter is improved. In the invention, a nanosecond-grade continuous pulse source is taken as an ageing power supply of the vacuum interrupter. The best ageing effect of the vacuum interrupter can be achieved by controlling the discharging energy of single pulse, the repetition frequency and the action time of the continuous pulse.

Owner:XI AN JIAOTONG UNIV

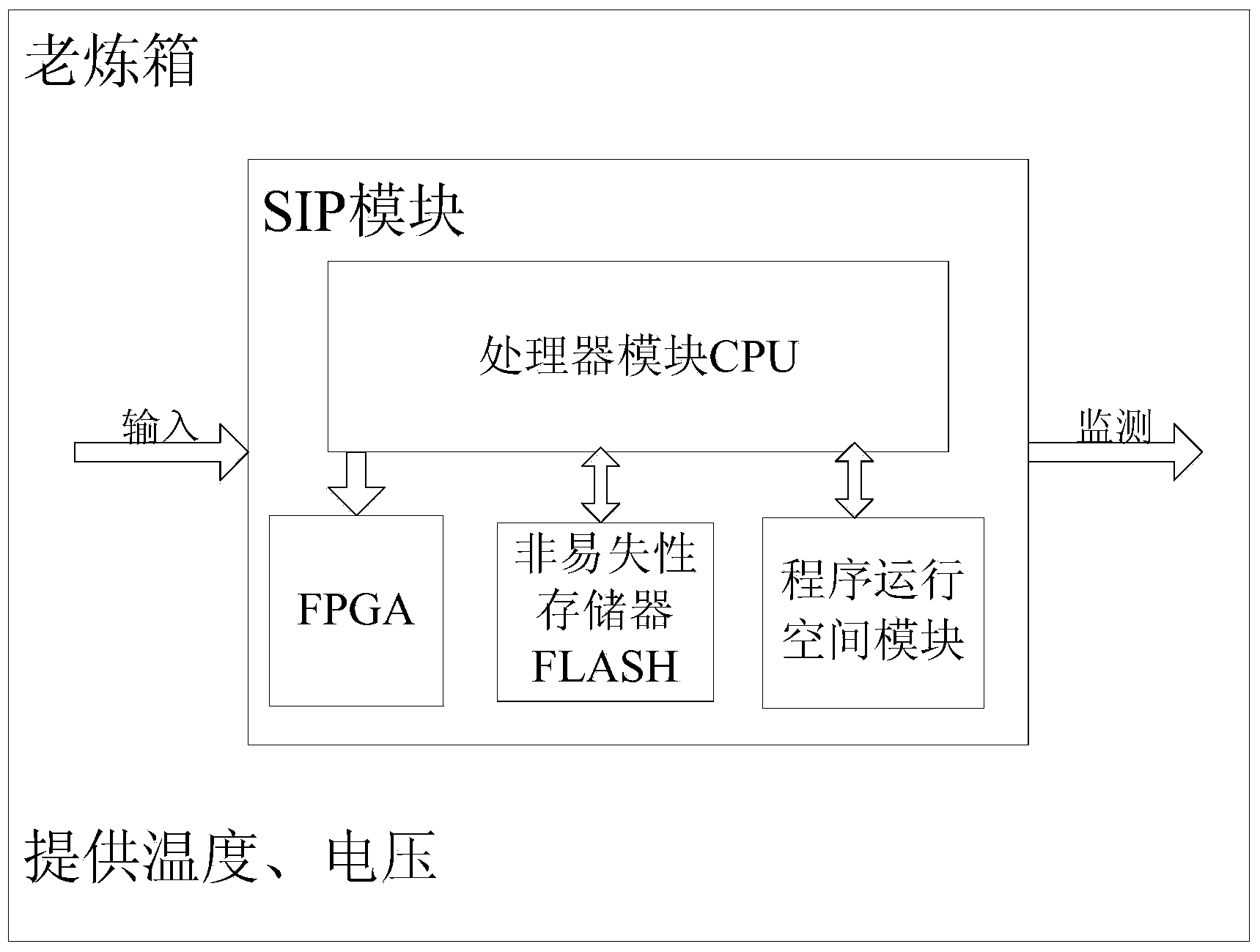

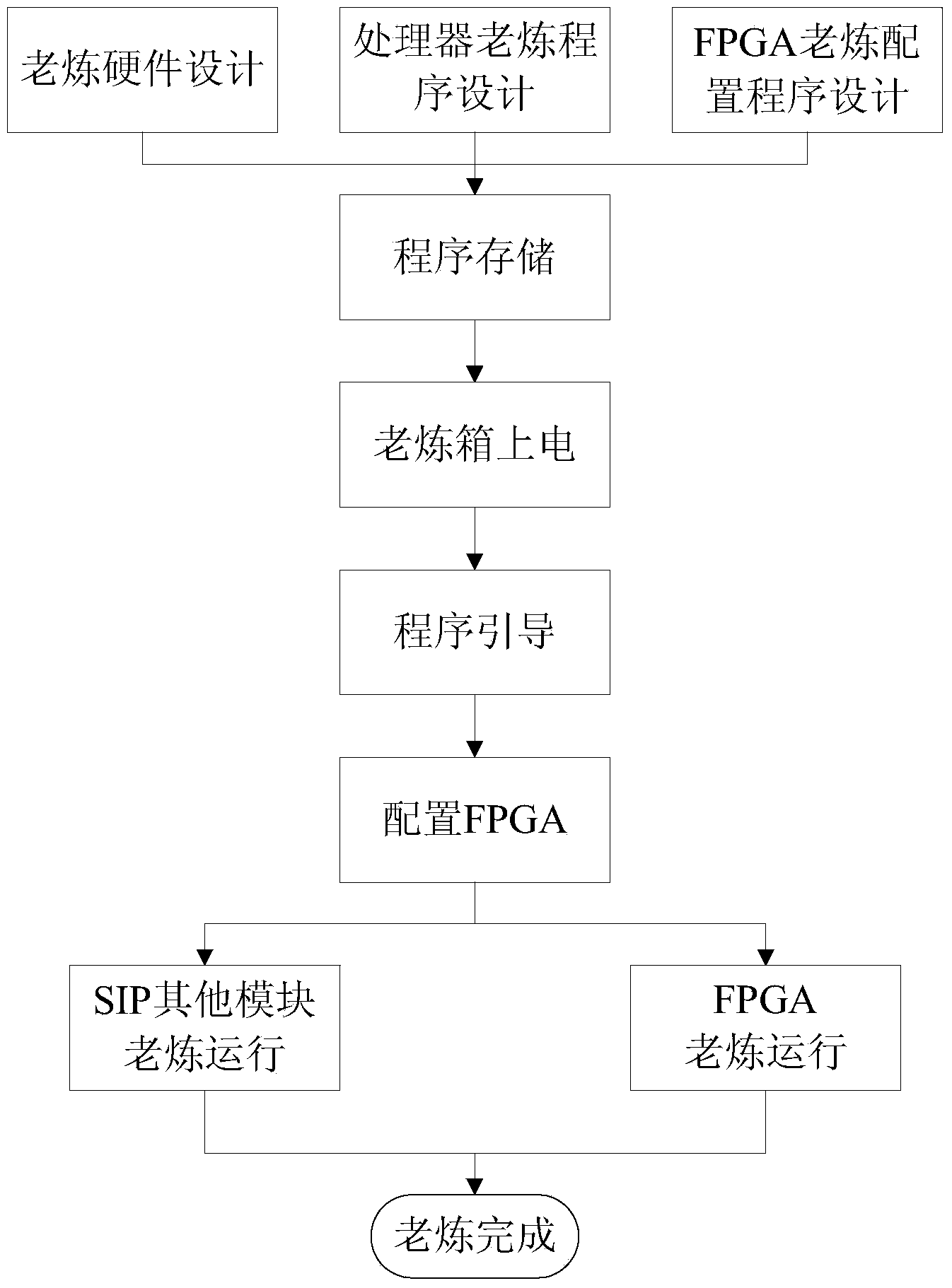

Burn-in method based on SIP module

The invention relates to a burn-in method based on an SIP module. The burn-in method is achieved in a burn-in box. The burn-in method is based on the SIP module comprising a processor module CPU, a program running space module, an FPGA module and a nonvolatile memory FLASH. According to the designed burn-in method, a burn-in program is written in the SIP module in a programmed mode, a power-on program automatically runs, the FPGA module is automatically configured, and running, access and control of all the modules are executed inside the tested SIP module in the burn-in process. The connecting circuit between the SIP module and the burn-in box is simple. According to the method, burn-in of the SIP module is achieved by fully using the functions of the SIP module, the complexity of the connecting circuit between the SIP module and the burn-in box is greatly lowered, the influences of an external circuit on the SIP module are reduced in the burn-in process, and meanwhile fault analysis can be conveniently conducted.

Owner:BEIJING MXTRONICS CORP +1

High-efficiency flame retardant EPS foam production technology

The invention discloses a high-efficiency flame retardant EPS foam production technology. The EPS foam production technology is superior in curing effect, high in product forming speed and high in stability. Moreover, production cost is low, water-cooling time is greatly shortened, the moisture content of produced products is low and can be controlled to be smaller than or equal to 3%, and product quality is greatly improved. Meanwhile, production efficiency of the products is improved.

Owner:WUHU MEIWEI PACKAGING PROD

Method for alcoholizing cigar leaf

The invention discloses a cigar leaves alcoholizing method, which is characterized in that the method sequentially steps that: an additive which contains wintergreen glue is dissolved in the water and evenly sprayed on the cigar leaves; the cigar leaves are positioned in a cellar where the temperature is below 42 DEG C and the humidity is smaller than 30 percent for the ferment of 60 to 90 days; the additive is added with the wintergreen glue with the amount ranging from 2 to 5 per mill, herbal medicament with the amount ranging from 1 to 8 per mill and biological active enzyme with the amount ranging from 0.5 to 8 per mill. By the method of the invention, the cigar leaf taste is increased, the alcoholizing time is short, the alcoholizing result is good, the alcoholizing quality is stable and the alcoholizing cost is low.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

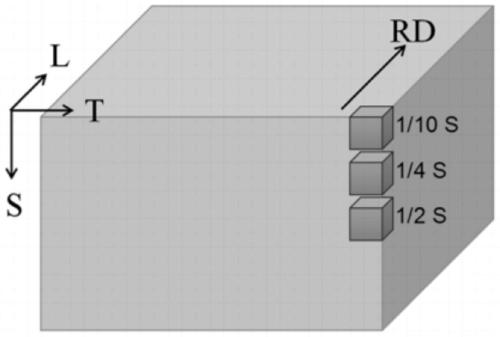

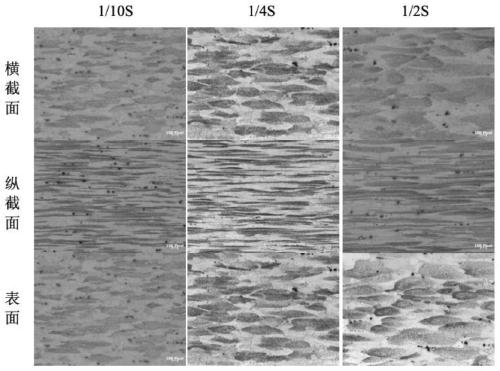

Preparation process of high-strength 7150 aluminum alloy medium plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of a high-strength 7150 aluminum alloy medium plate. Raw material ingredients comprise: Si <= 0.50%, Fe <= 0.50%, Cu: 2.10-2.20%, Mn <= 0.01%, Mg: 2.15-2.35%, Cr <= 0.02%, Zn <= 6.65%, Ti <= 0.03%, Zr: 0.10-0.12%, single impurity <= 0.01%, total <= 0.15%, and the balance Al. The product formulation and casting process are optimized, the homogenization system is improved, initial rolling temperature is improved, high rolling-reduction rolling is adopted, the solid solution processis optimized, quenching delay time is strictly controlled, the quenching speed is improved, stretching delay time is strictly controlled, the optimal amount of stretching is selected, the aging process is improved, and finally the 7150 medium plate with excellent properties is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

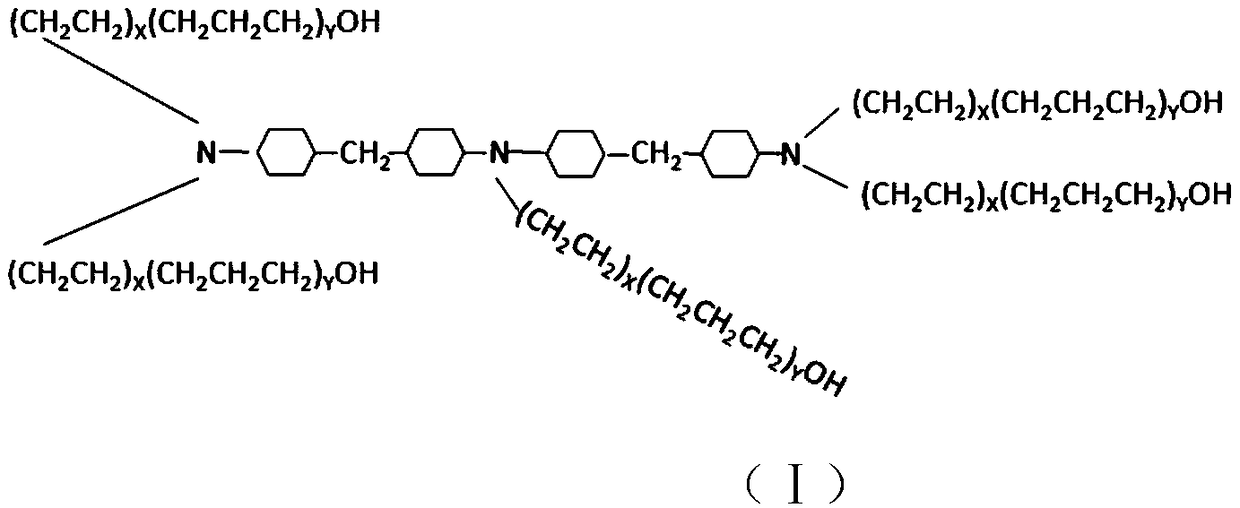

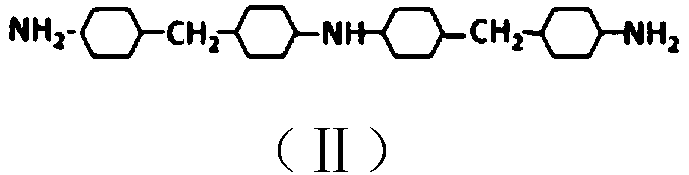

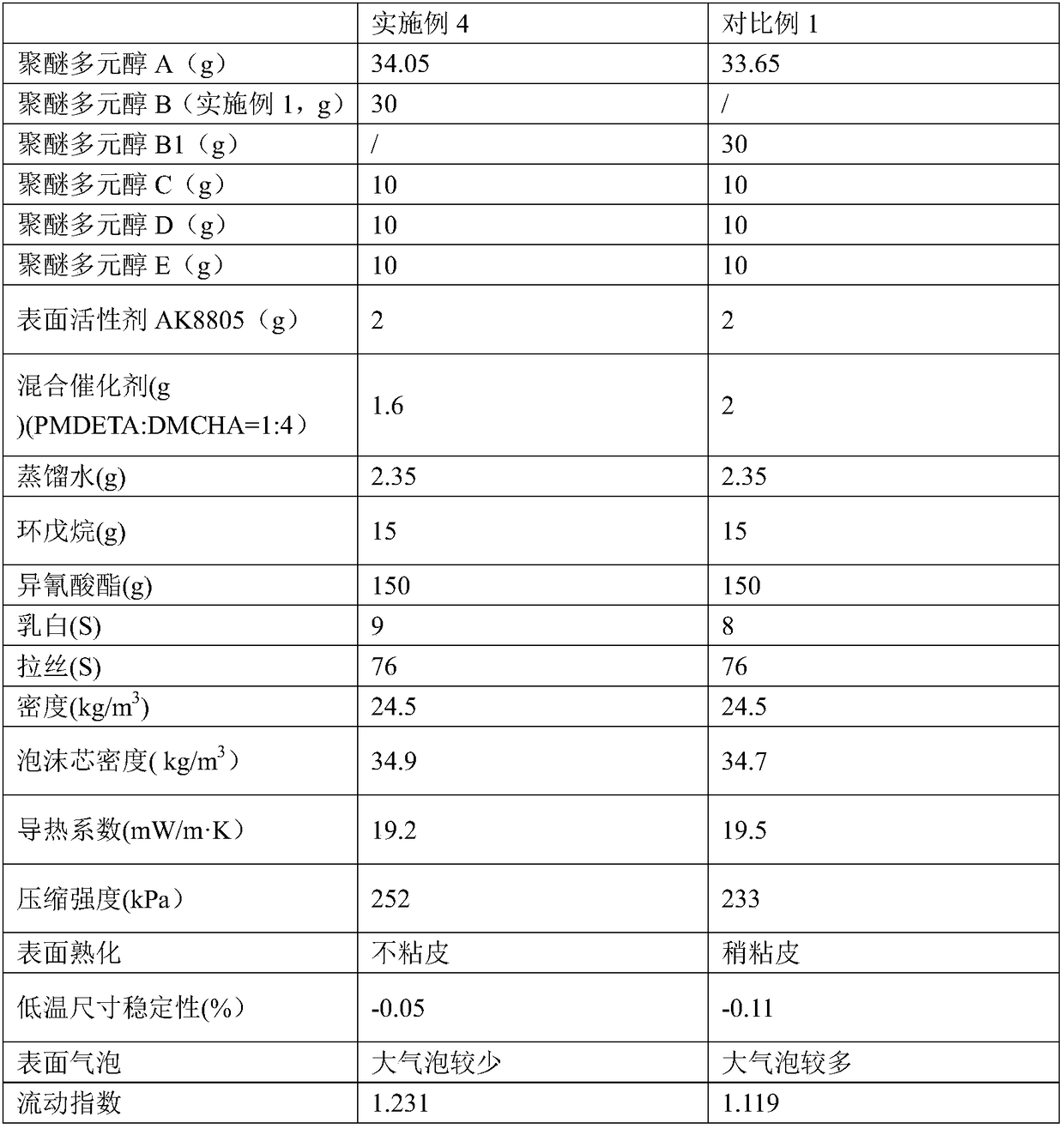

Amino polyether polyol, preparation method thereof, polyurethane rigid foam and preparation method thereof

The invention relates to an amino polyether polyol, a preparation method thereof, a polyurethane rigid foam and a preparation method thereof. The amino polyether polyol is prepared by taking 4, 4'-methylene biscyclohexylamine coupling agent as a starting material to react with oxidized alkenes. The structure formula of the amino polyether polyol is shown as formula I, wherein X is an integer selected from 1-3, and Y is an integer selected from 4-10. The amino polyether polyol can be applied to preparing the polyurethane rigid foam, particularly to high-standard application such as to refrigerators, and compared with traditional OTDA (orthotoluenediamine) polyethers, is higher in properties such as energy consumption, fluidity, surface blistering and strength.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

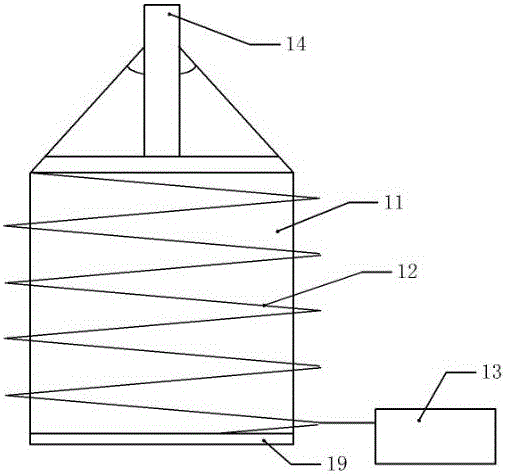

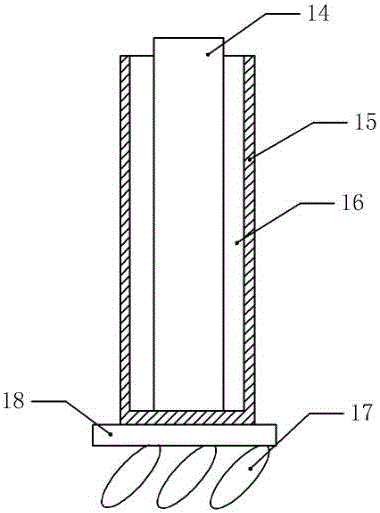

Liquor aging device

InactiveCN106281937APromote esterificationSoft tasteAlcoholic beverage preparationElectrical conductorHeat conducting

The invention belongs to the technical field of liquor aging and particularly relates to a liquor aging device. The liquor aging device comprises an aging barrel externally wound with an electromagnetic induction coil, wherein an alternating current power supply is connected to the end part of the electromagnetic induction coil, a stirring rod is arranged in the aging barrel, an interlayer is arranged in the middle of the bottom of the aging barrel, and a magnet is arranged in the interlayer; the stirring rod is a conductor and is externally sleeved by a heat-conducting stirring sleeve, and anion oxidizing particles are arranged between the stirring rod and the stirring sleeve; and a chassis is connected to the bottom end of the stirring rod in a rotating way, stirring blades are fixedly mounted on the chassis, and a filtering hole with the diameter smaller than diameters of the anion oxidizing particles is formed in the outer wall of the stirring sleeve. According to the liquor aging device, the problem that the aging effect is poor when air is directly introduced into the liquor is solved.

Owner:贵州省仁怀市茅台镇汉室酒业(集团)有限公司

650-DEG C-high-temperature-resistant titanium alloy

ActiveCN110484774AGuaranteed StrengthGuaranteed creep resistanceFurnace typesHeat treatment furnacesStable elementTitanium alloy

The invention discloses 650-DEG C-high-temperature-resistant titanium alloy. The 650-DEG C-high-temperature-resistant titanium alloy comprises, by mass percentage, 5.5%-6.5% of Al, 5.5%-9.0% of the combination of Zr and Sn, smaller than or equal to 0.8% of each of two or more elements of Mo, Nb and Ta, 2%-3% of W, 0.3%-0.4% of Si, 0.05%-0.1% of Y, 0.1%-0.15% of the combination of C and O and the balance Ti and inevitable impurities. The ratio of the mass percentage of Sn to the mass percentage of Zr is 0.5-1, the mass percentage of C is larger than or equal to 0.03%, and the mass percentage ofO is smaller than or equal to 0.09%. According to the 650-DEG C-high-temperature-resistant titanium alloy, the multi-element reinforcement mode is adopted, the high-content Al is added as the Zr alloy element, the Sn alloy element, beta stable elements such as Nb, Mo and Ta, W and Y are added, and therefore the titanium alloy has the high temperature strength and plastic matching performance, andthe comprehensive mechanical properties of the titanium alloy are improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

Processing method of tobacco raw materials for heating non-combustion tobacco products

ActiveCN103445283BIncrease contentGood release effectTobacco preparationTobacco treatmentPolyolProcess engineering

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Health-care product capable of assisting in nourishing faces, beautifying faces and delaying senescence for women, and preparation method of health-care product

InactiveCN108030072AAnti agingAdjust metabolic capacityFood ingredient functionsGLEDITSIA SINENSIS FRUITTragacanth

The invention provides a health-care product capable of assisting in nourishing faces, beautifying faces and delaying senescence for women, and a preparation method of the health-care product, and relates to the technical field of health-care products. The health-care product is mainly prepared from the following raw materials in parts by weight: 1-8 parts of gum tragacanth, 8-18 parts of peach gum, 8-24 parts of gleditsia sinensis fruits, 3-18 parts of white funguses, 12-29 parts of lotus seeds, 20-60 parts of red jujubes, 7-25 parts of lily bulbs and 40-110 parts of papayas, wherein throughthe papayas, the health-care product has the main functions of assisting in nourishing faces, beautifying faces and delaying senescence for women; the gum tragacanth, the peach gum, the gleditsia sinensis fruits and the white funguses concurrently pay attention to nourishing and absorption and adjust the metabolic capability of human bodies, so that the metabolism functions of each region can be performed in different ways in accordance with different nutrient substances, and the efficacy of the health-care product for nourishing faces, beautifying faces and delaying senescence can be strengthened; and the lotus seeds, the red jujubes and the lily bulbs are combined for use, so that the health-care product concurrently pays attention to nutrition and circulation, each region under blood circulation absorbs specific nutrient components, the nutrition of the human bodies is balanced, and better effects of nourishing faces and beautifying faces can be achieved.

Owner:贵州健瑞安药业有限公司

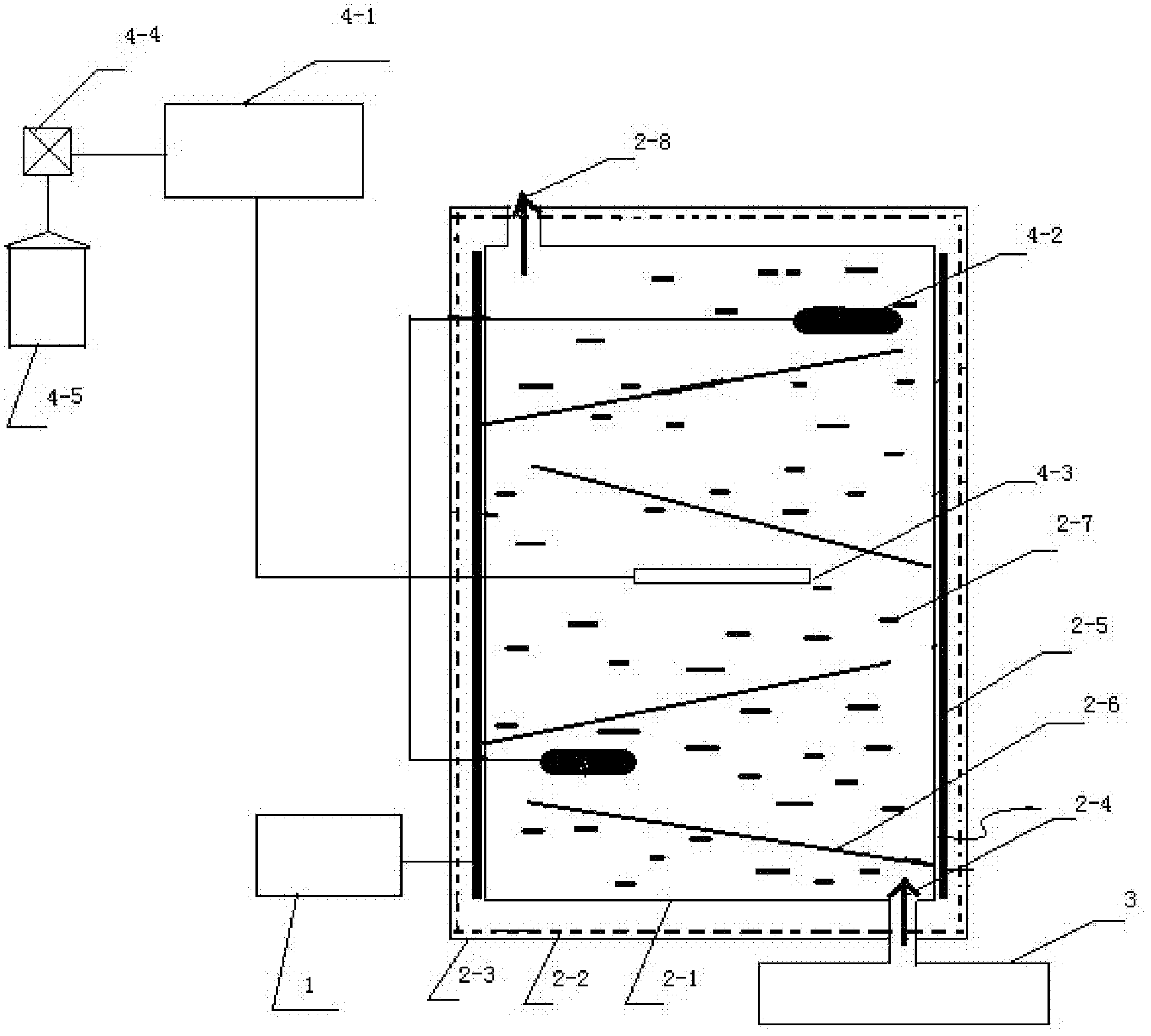

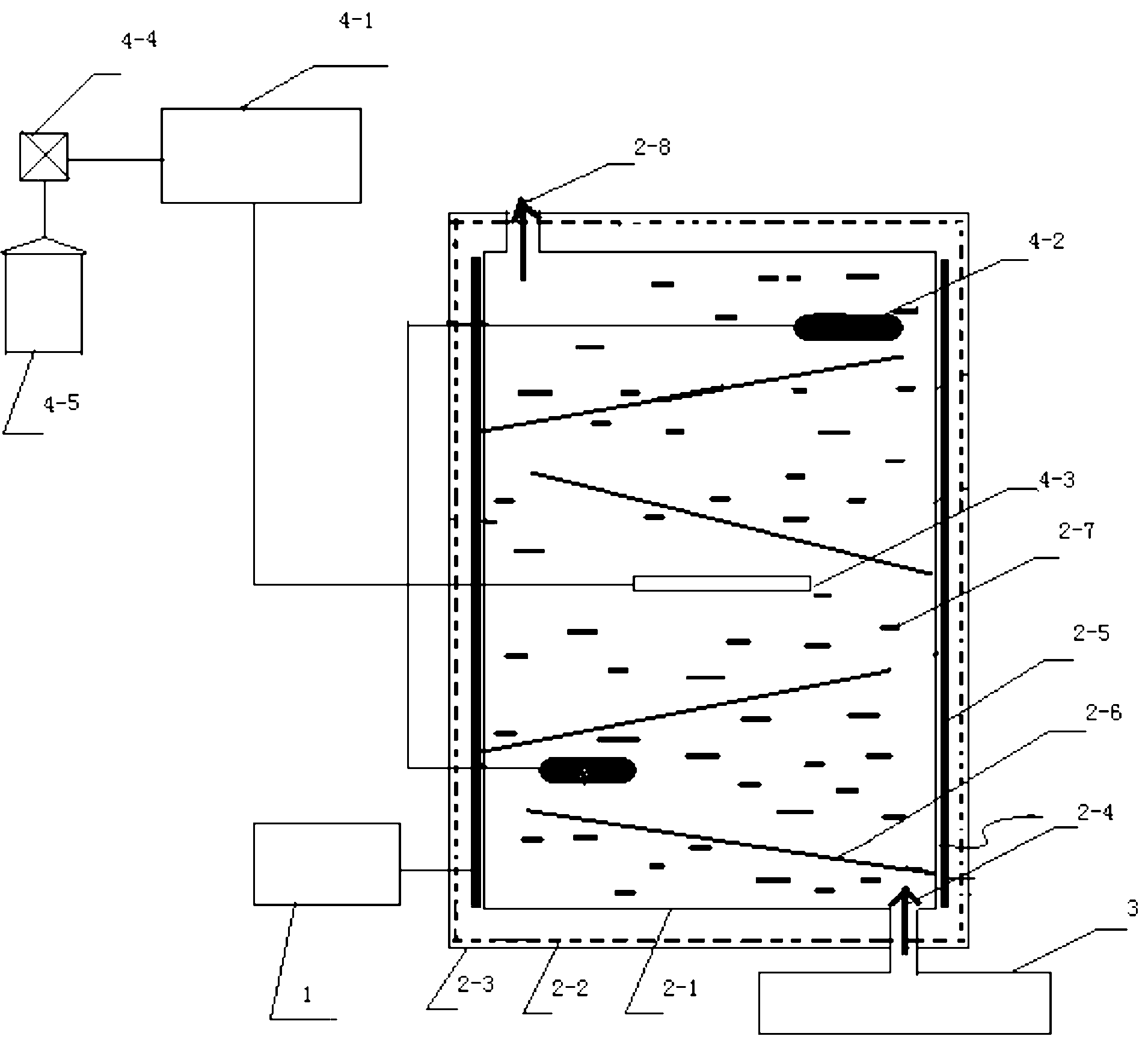

Method and device for ageing wine by micro-aerobic synergism of electromagnetic field

ActiveCN102634437AImprove processing efficiencyNo relapseAlcoholic beverage preparationOxygen tankEngineering

The invention discloses a method and a device for ageing wine by micro-aerobic synergism of electromagnetic field. The method comprises the following steps of: switching on a micro-aerobic control system, so that oxygen in an oxygen tank enters into a treatment chamber through an oxygen distributor, and a micro-aerobic condition is formed in the treatment chamber; switching on a high-voltage magnetic field conditioning system; setting a voltage and a field intensity between two polar plates through a voltage adjusting amplifier, and setting a frequency between the two polar plates through a frequency adjustor, so that a high-voltage electromagnet field environment is formed in the treatment chamber; after filling the wine in a wire temperature control system for cooling, injecting the wine into the treatment chamber to be treated, so as to obtain rapid aged wine. According to the invention, the quality of the aged wine prepared by using the method and the device is obviously improved; and the method and the device are simple and convenient to operate and short in treatment time, and the treated wine has no retro-gradation.

Owner:陆河国泰青梅产业发展有限公司

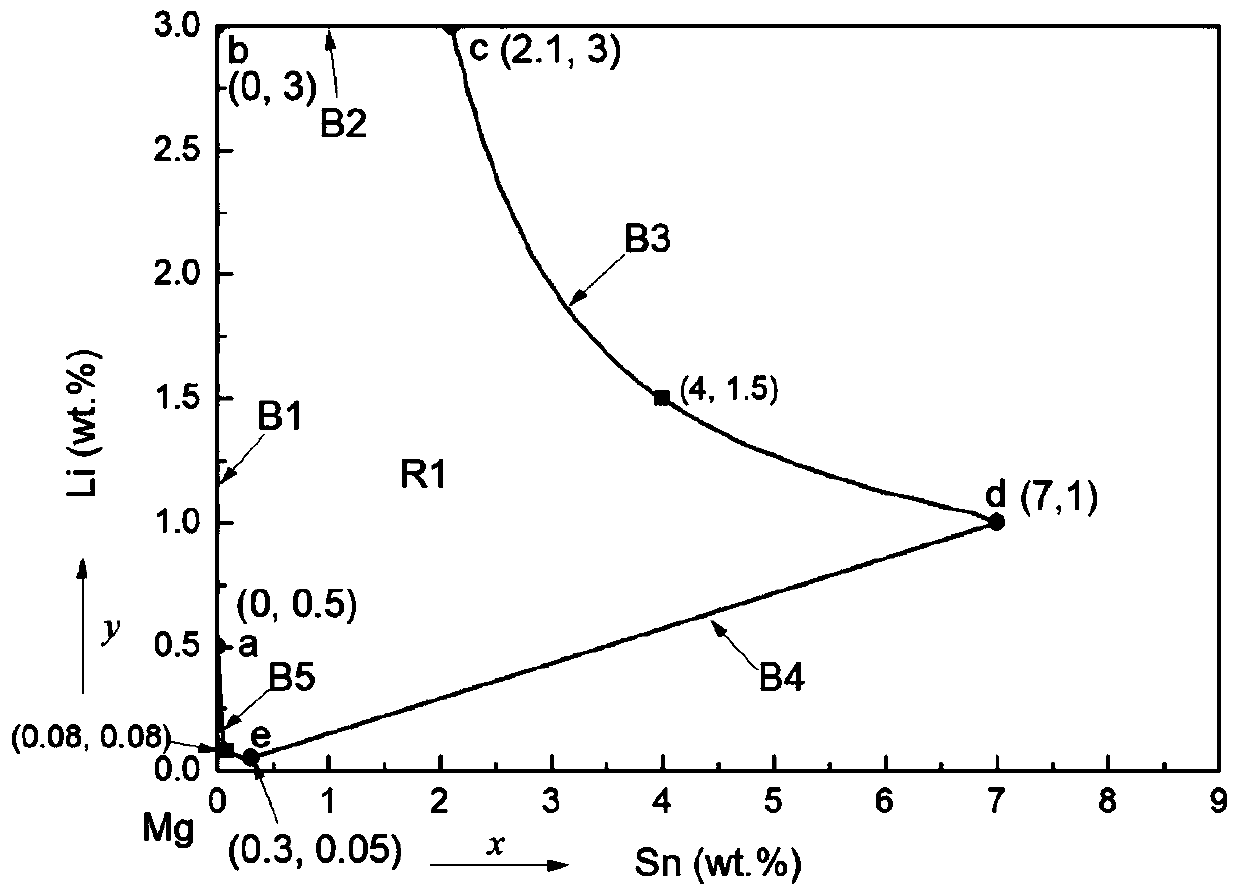

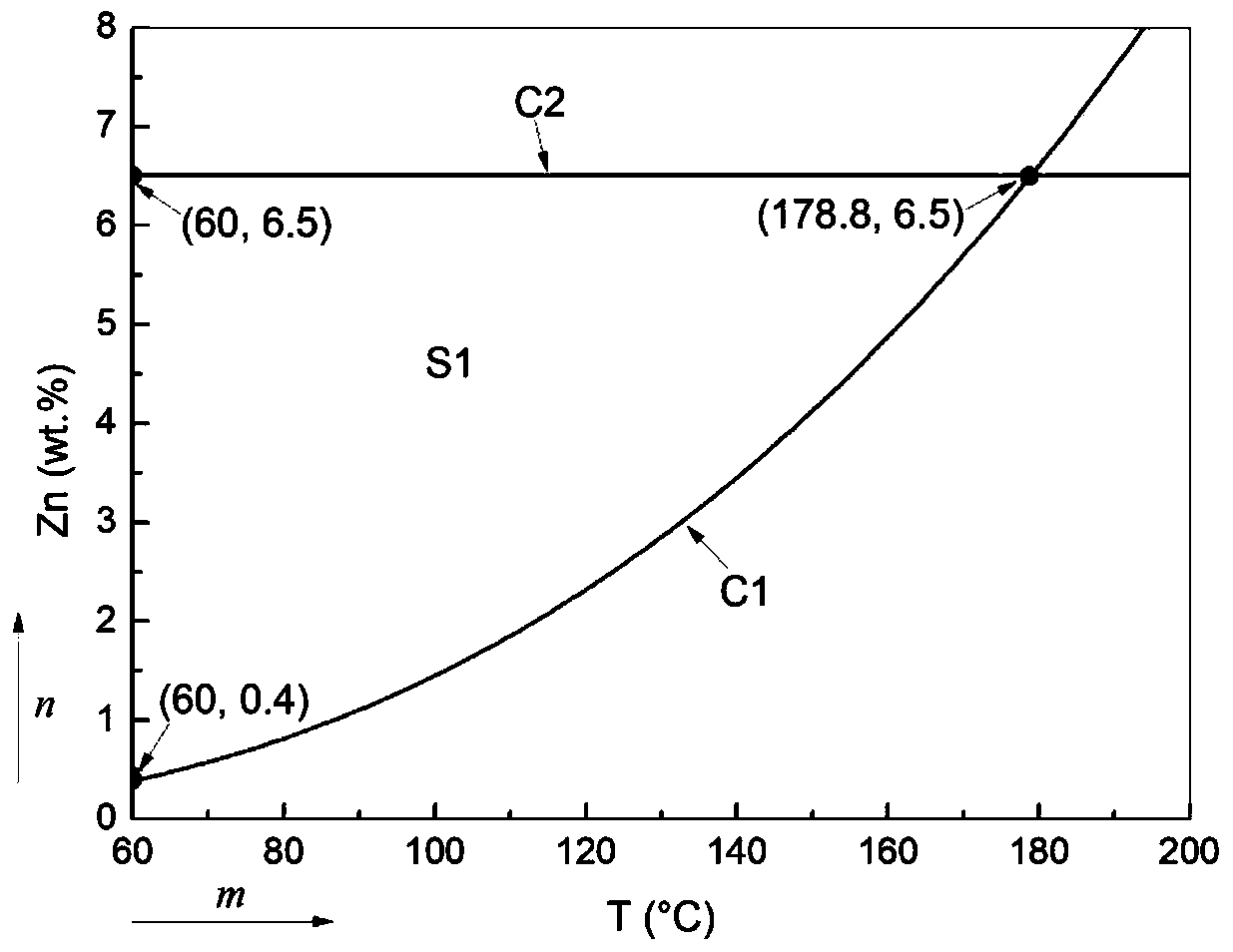

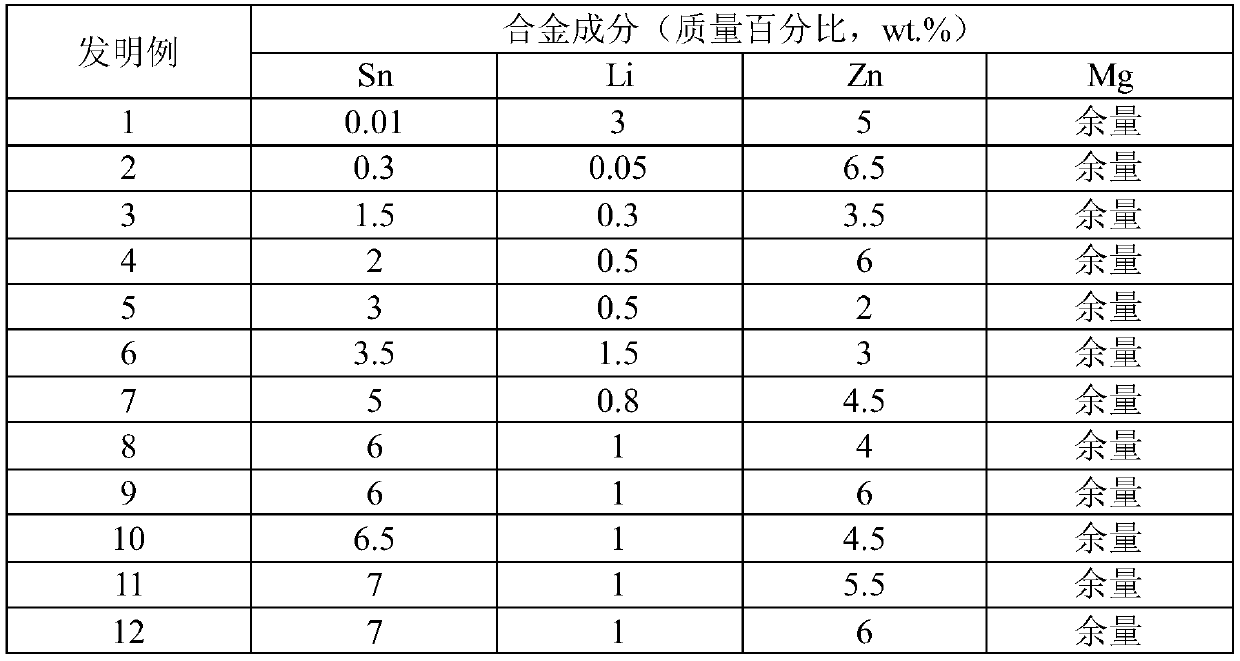

Mg-Sn-Li-Zn magnesium alloy capable of double-stage aging strengthening and preparation method thereof

The invention provides a Mg-Sn-Li-Zn magnesium alloy capable of double-stage aging strengthening and a preparation method thereof. The design of the alloy composition is guided by scientific calculation, the content of Sn and Li is in the specific region of the Mg-Sn-Li phase diagram, and the Zn content is in the specific region of the Mg-Zn phase diagram. According to the Mg-Sn-Li-Zn magnesium alloy capable of double-stage aging strengthening and the preparation method thereof, Li2MgSn is used as the main precipitation phase of the alloy, and the nanometer-scale Li2MgSn nucleation is promotedby the nano Zn rich metastable phase formed in the first-stage aging, so that the aging strengthening effect is improved; and combined with a plastic deformation processing method, grains are refinedand a dislocation substructure is introduced to further improve the mechanical properties of the alloy. At least one of the following elements of Ca, Mn, Na, Sr, Si, and Zr is contained in the alloyas well, so that the combination property of the alloy is good; and the alloy is not only applicable to conventional occasions where a magnesium alloy serves as a structural material, but also used for preparing body implant medical devices.

Owner:UNIV OF SCI & TECH BEIJING

A kind of preparation method of 0cr17ni4cu4nb precipitation hardening stainless steel bar

Owner:有研金属复材技术有限公司

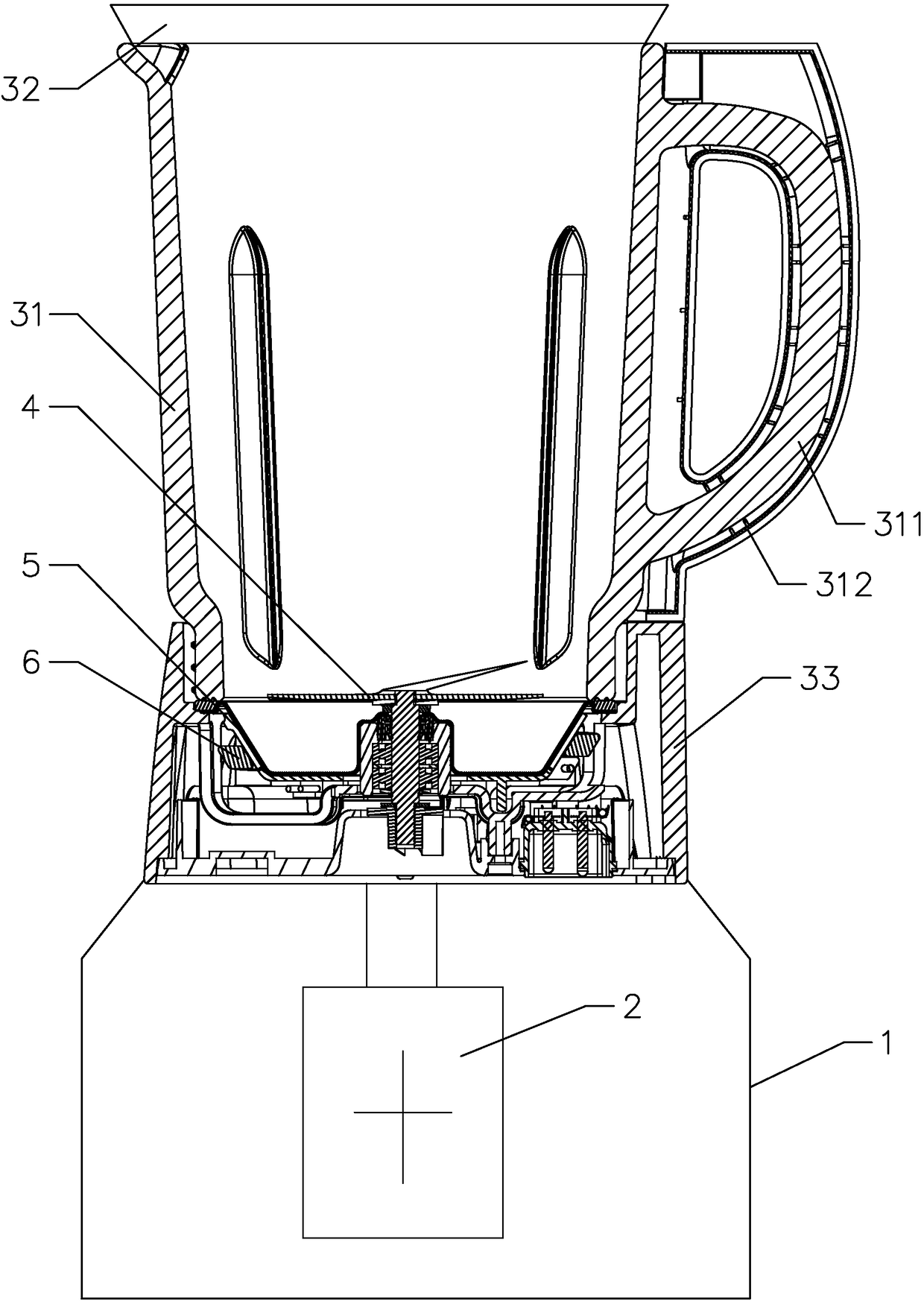

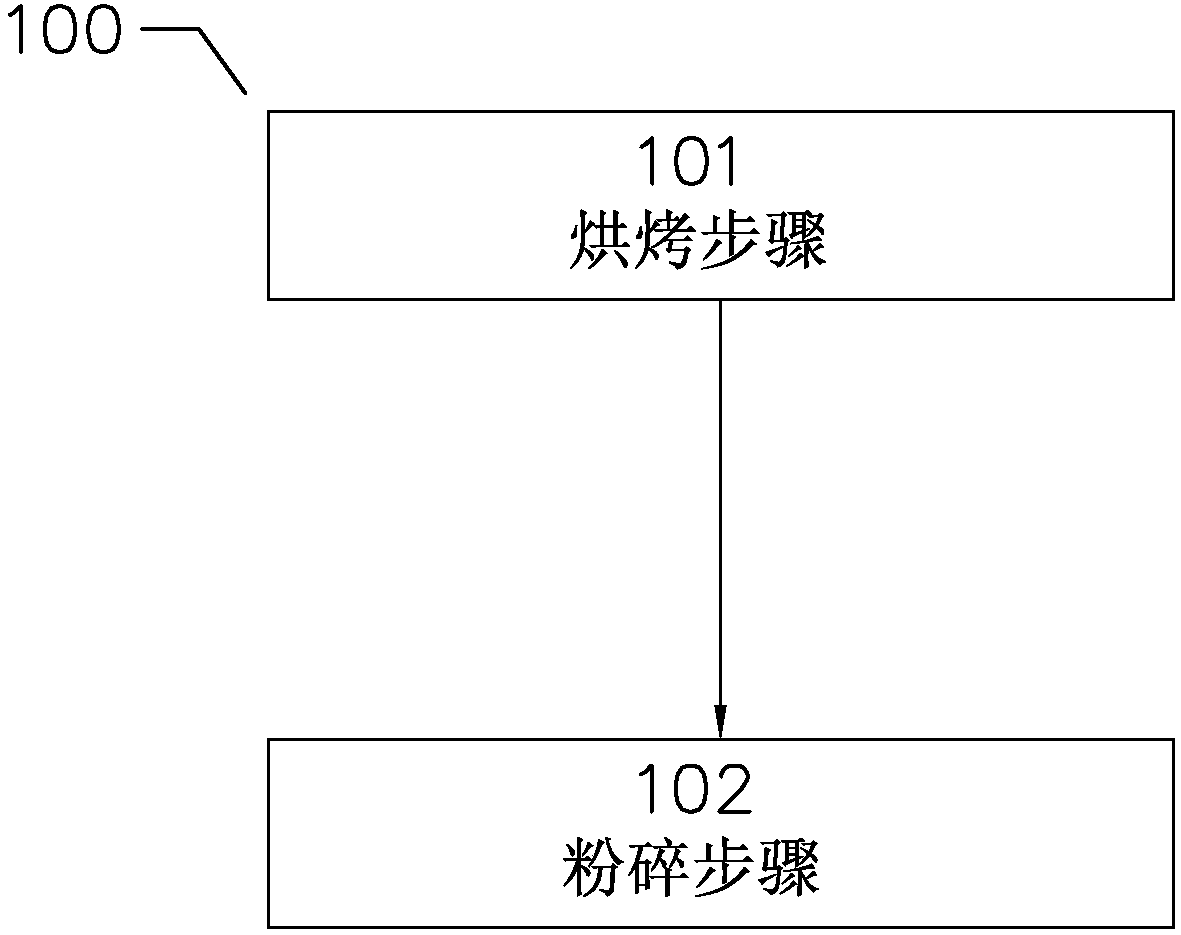

Nut paste processing method of food processer

The invention provides a nut paste processing method of a food processer. The method includes the following steps of braking and crushing, wherein in the braking step, a heating plate is used for heating nuts in a cup body until the nuts are cooked, and in the crushing step, a motor drives a crushing blade to rotate so as to crush the nuts in the cup body. The food processor is used for preparingnut paste, compared with a traditional household making method, the method is more convenient and faster, preparation steps are few, required utensils are few, the preparation process is pleasant, pleasure obtained by users in the preparation process is greatly increased, and the DIY fun of the users is increased. Meanwhile the heating plate is arranged at the lower end of the cup body, the heating plate includes a heating plate body and a heating pipe arranged on the side wall of the heating plate body, in this way, the nuts on the bottom are not burnt, the nuts are heated from the side face,the nuts can thus be heated more uniformly, it is ensured that the nuts are cooked, have no scorched flavor and also can produce strong nut fragrance, and therefore the made nut paste is more delicious and mellow.

Owner:JOYOUNG CO LTD

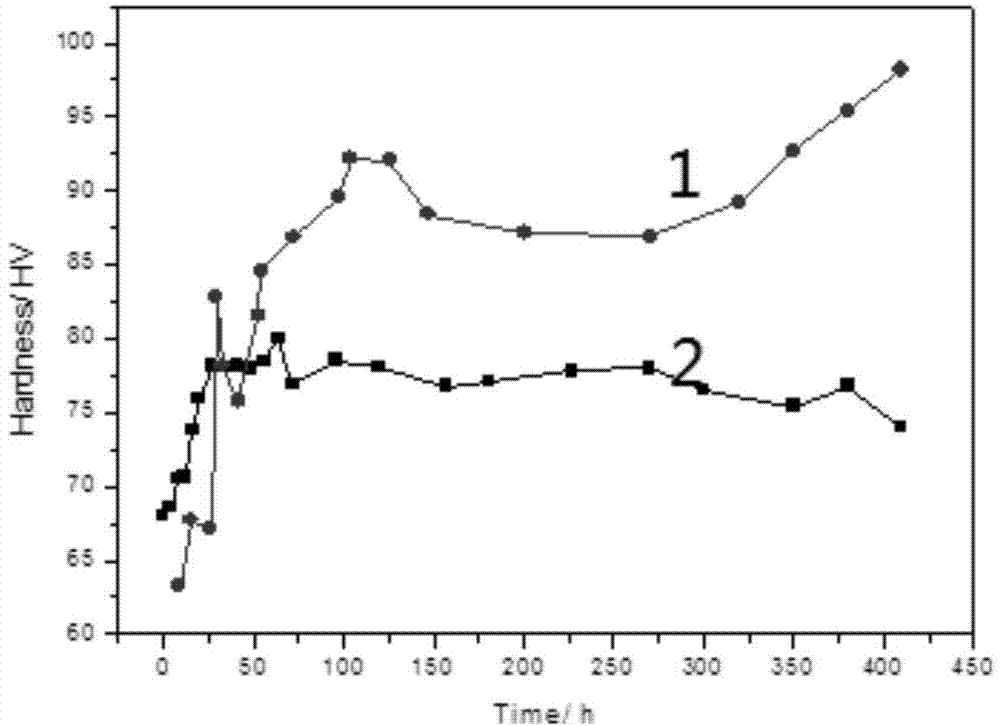

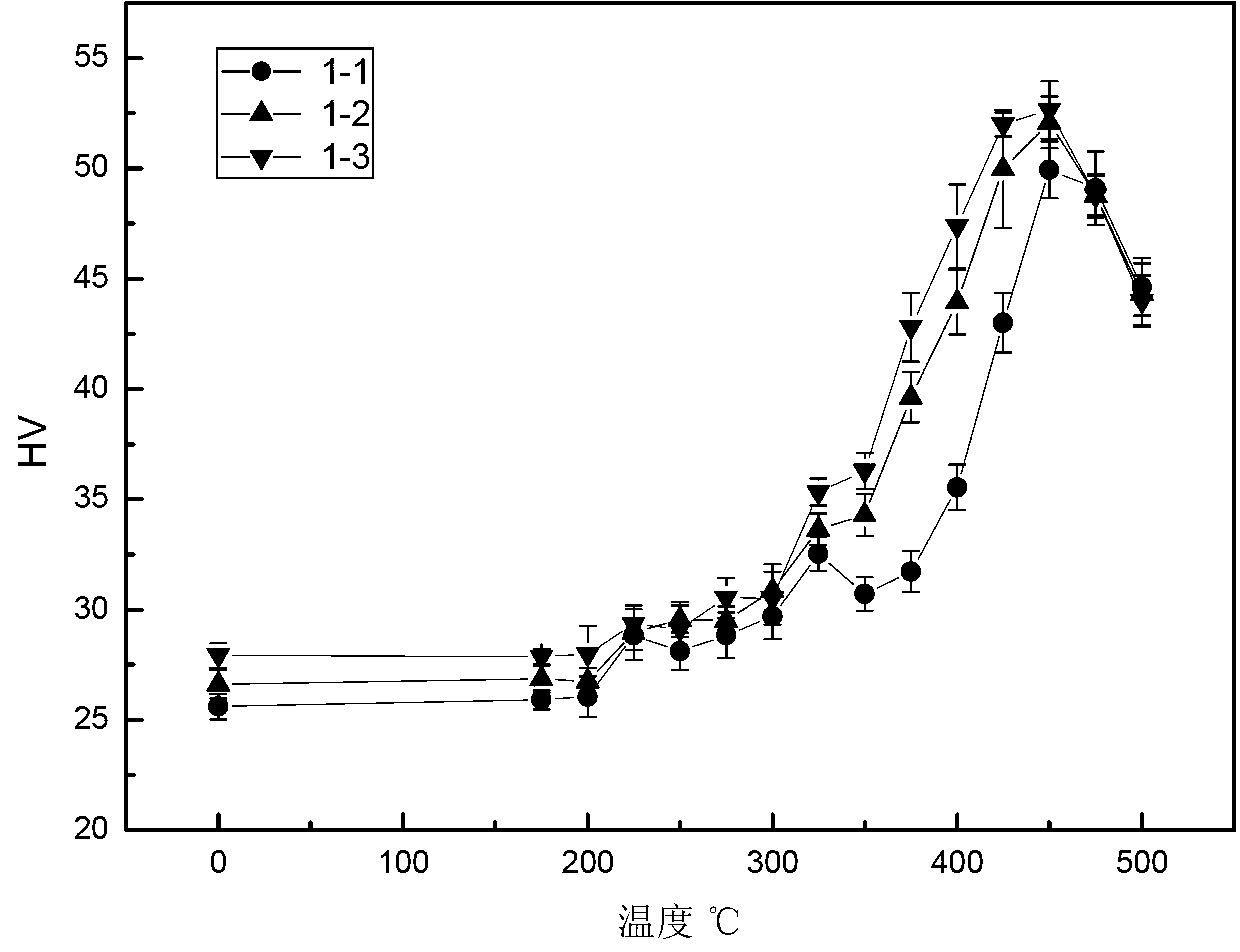

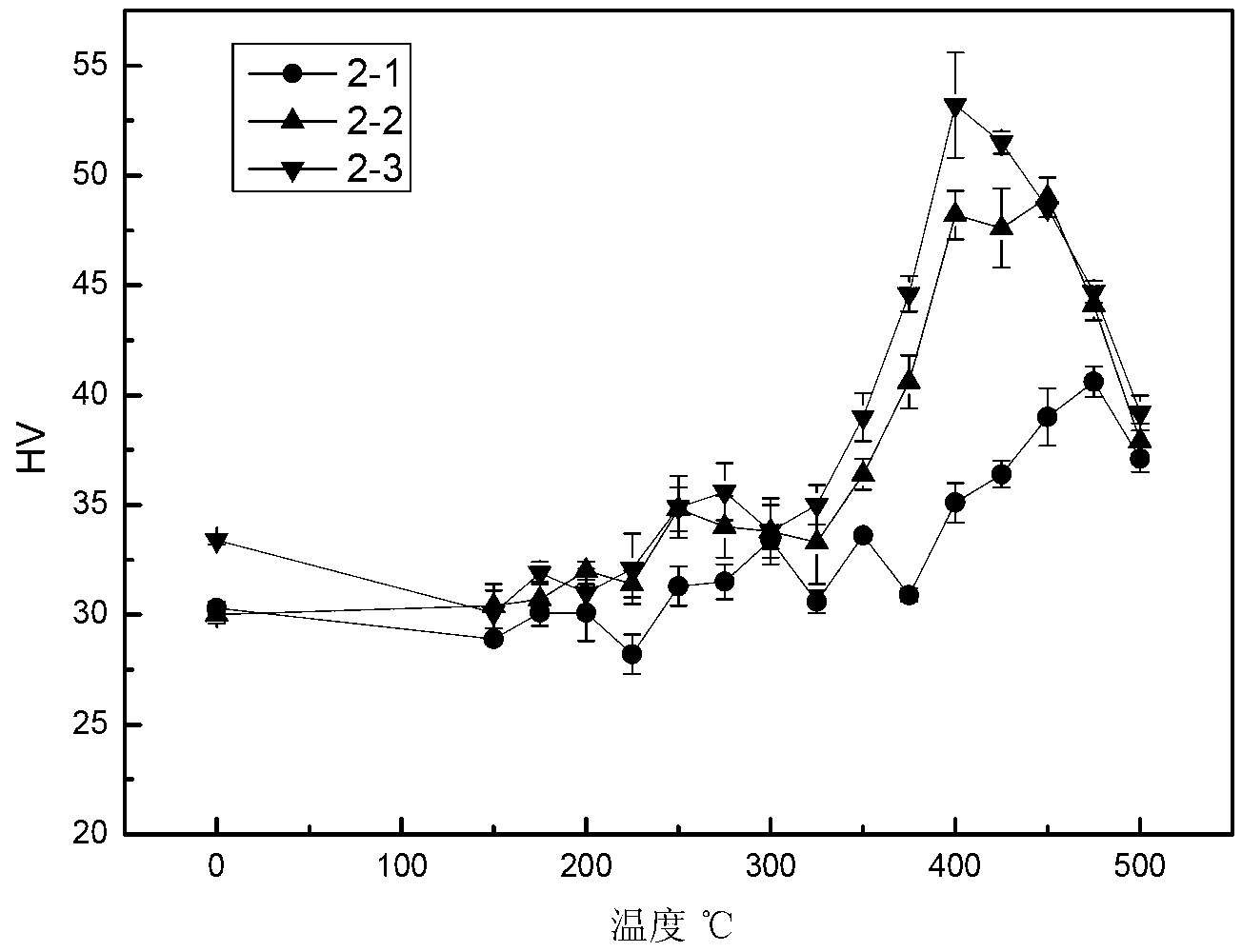

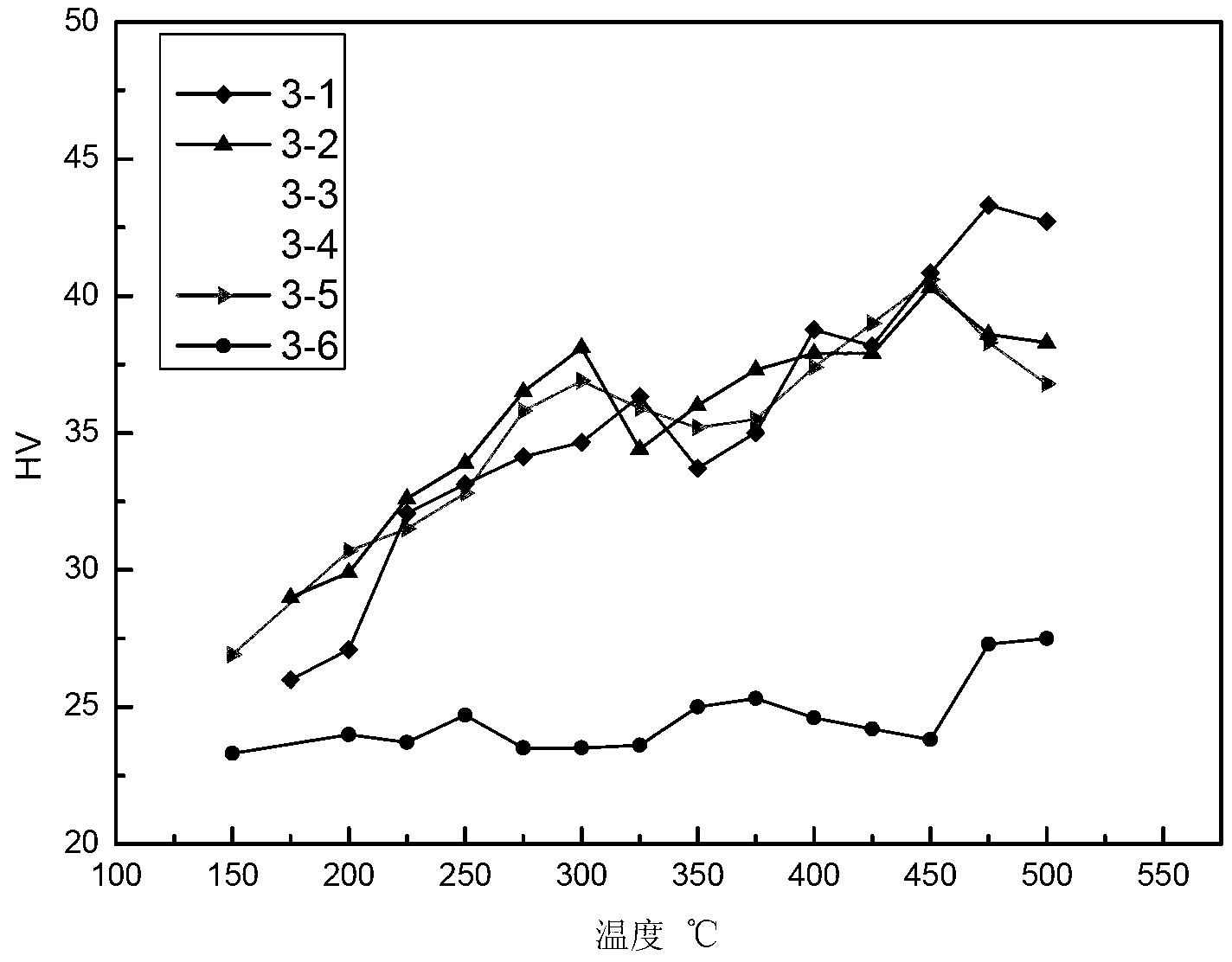

Al-Er-Zr-Si aluminum alloy and heat treatment process

The invention relates to an Al-Er-Zr-Si aluminum alloy and a heat treatment process and belongs to the technical field of metal alloys. The Al-Er-Zr-Si aluminum alloy contains the following components in percentage by weight: 0.05-0.07 percent of Er, 0.2-0.3 percent of Zr and 0.062-0.16 percent of Si. The heat treatment process comprises the following steps of: carrying out solid solution for 48 hours at 640+ / -10 DEG C, then carrying out water quenching to room temperature, then carrying out isochronous aging between 150 DEG C and 550 DEG C, wherein the time interval is 2 hours. Relative to a Si-free Al-Er-Zr alloy, the Al-Er-Zr-Si aluminum alloy has the peak hardness improved by about 25 percent.

Owner:BEIJING UNIV OF TECH

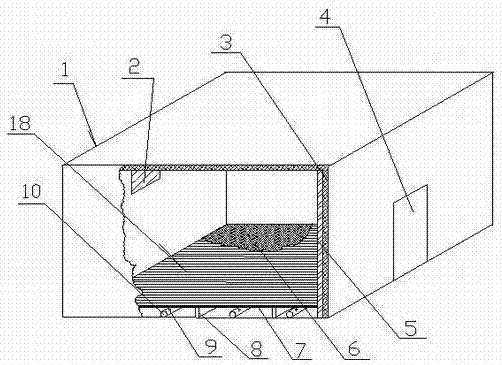

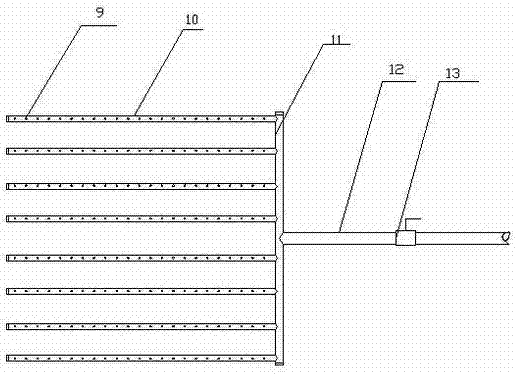

Secondary fermentation method of black tea and fermentation house used thereby

PendingCN107279345ALarge amount of fermentationGood synchronization of fermentationPre-extraction tea treatmentProcess engineeringBiology

The invention relates to a fermentation process and apparatus of black tea, in particular to a secondary fermentation method of black tea and a fermentation house used thereby. The method includes: spreading crude tea evenly in the fermentation house the bottom of which allows uniform introduction of steam; introducing steam evenly to the bottom of the crude tea spread evenly in the fermentation house so as to perform steaming until the uppermost layer of tea softens and may not be pinched apart by hand; after steaming, piling in the integrity for 8-24 hours, loosening, and drying. The fermentation house comprises a frame that is provided with walls, a plurality of steam pipes are arranged evenly at the bottom of the frame in parallel and are evenly provided with steam holes, and a breathable pad is arranged on the steam pipes. The secondary fermentation method of black tea and the fermentation house have the advantages that fermentation quantity is high, about 1 ton of tea leaves can be fermented at a time, fermentation is well synchronous, no time differences occur, fermentation can be finished at a time with no need for pile fermentation in halfway, the fermentation is uniform, mellowing effect is good, the finished black tea can be 1-2 higher in grade, the method is simple to perform, and the production cost is low.

Owner:湖南清山月茶业有限公司

High-strength high-plastic rare earth magnesium alloy and preparation method thereof

The invention discloses high-strength high-plastic rare earth magnesium alloy and a preparation method thereof. The alloy is prepared from the following components in percentage by mass: 7-10% of Gd,0.01-3% of Y, 0.01-0.2% of Nd, 0.01-4% of Er, 0.01-1% of Sm, 0.01-1% of La, 0.01-1% of Ce, 0.3-0.7% of Zr, wherein total content of Gd, Y, Nd, Er, Sm, La and Ce is less than or equal to 15%, and totalcontent of Sm, La and Ce is less than or equal to 1.5%, less than or equal to 0.02% of impurity element Al, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Fe, less than or equal to0.02% of N, less than or equal to 0.05% of Si, not more than 0.1% of total content of impurities, and the balance of Mg. The preparation method comprises alloy melting and casting, and thermal treatment. The alloy cast-T6 state prepared by the preparation method has room-temperature tensile strength exceeding 350 MPa, and has elongation not lower than 5.0%.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com