Magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and preparation method thereof

An age-hardening and alloying technology, which is applied in the field of metal material engineering, can solve problems such as low hardness and poor plasticity and toughness of alloys, and achieve the effect of increasing yield limit and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

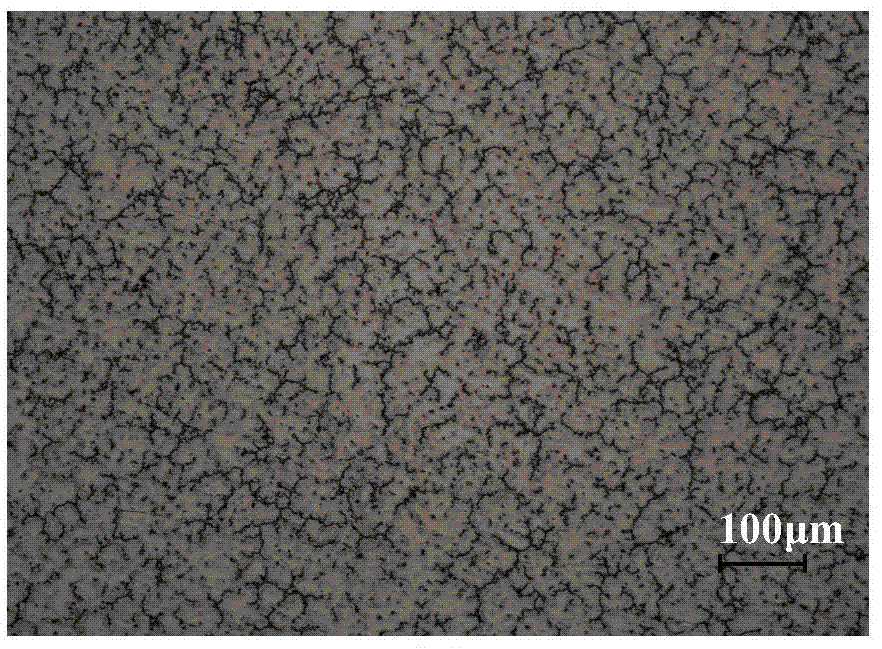

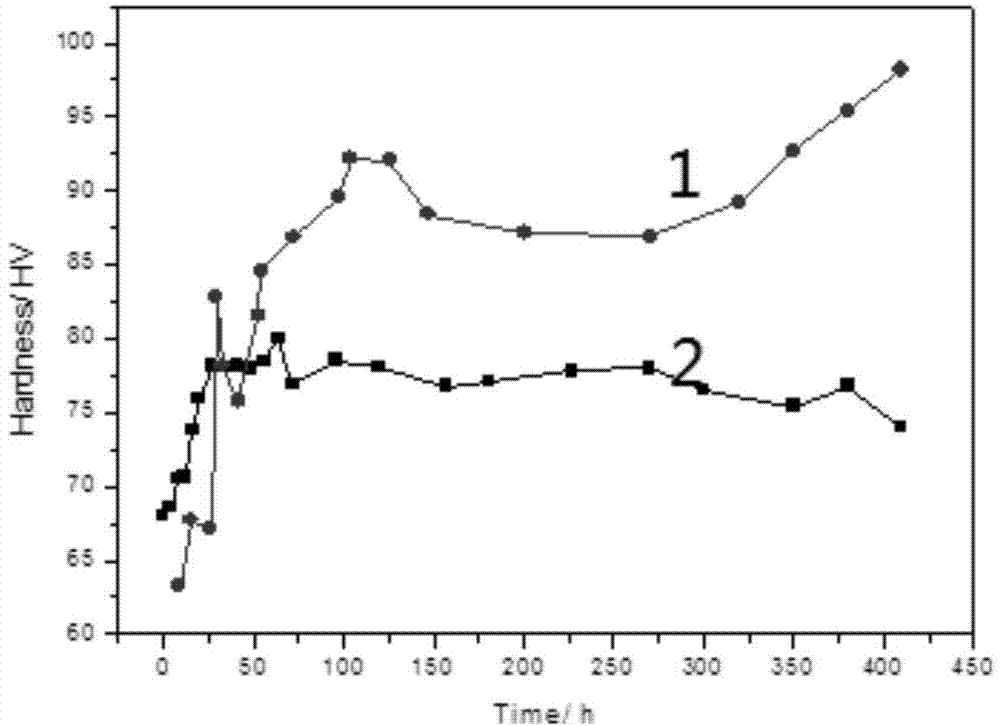

[0043] An age-hardenable Mg-Zn-Cr-Bi-Zr alloy, its components and mass percentages are: Zn7.85%, Al4.02%, Cr0.20%, Ca1.05%, Bi0.8% , the balance is Mg, and the total mass is 100%.

[0044] Its preparation method is as follows:

[0045] 1. Calculated based on the mass percentage of the melt, and considering the burning loss rate of alloying elements during the smelting process, weigh 87% of pure magnesium ingot (purity is 99.9%), zinc ingot (purity is 99.9%) 8.5%, aluminum ingot ( Purity is 99.9%) 4.5%, pure metal Cr (purity is 99.9%) 0.21%, pure metal Bi (purity is 99.9%) 0.9% and pure metal Ca (purity is 99.9%) 1.2%;

[0046] 2. Put the raw materials into SX3-2.5-12 crucible resistance furnace after preheating and baking at 200°C;

[0047] 3. Set the heating temperature of the crucible resistance furnace to 760°C. When the temperature of the crucible rises to 400°C, first add magnesium ingots, zinc ingots, aluminum ingots and metal Cr to the crucible, and start feeding 0.1%...

Embodiment 2

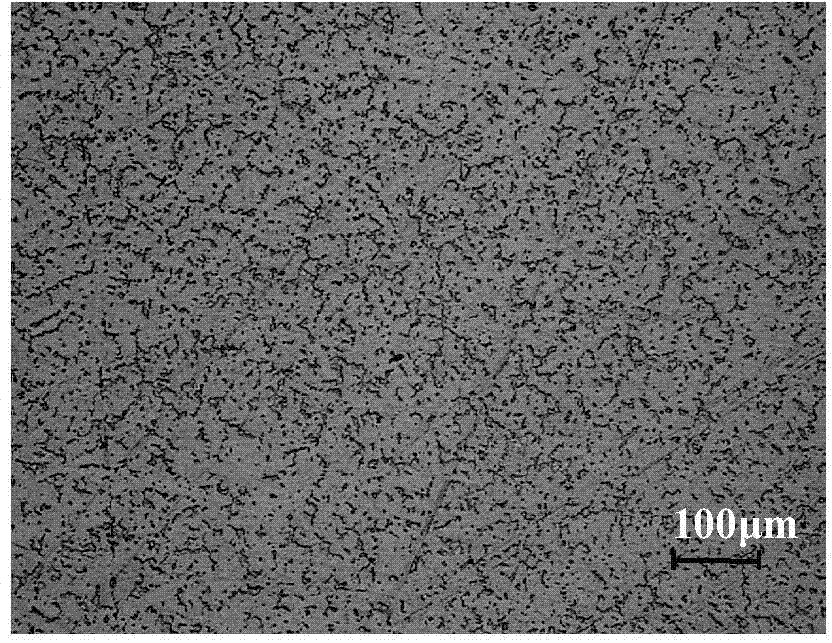

[0051] An age-hardenable Mg-Zn-Cr-Bi-Zr alloy, its components and mass percentages are: Zn4%, Al2%, Cr0.1%, Ca0.5%, Bi0.1%, and the balance is Mg, total mass 100%.

[0052] Its preparation method is as follows:

[0053] 1. Calculated based on the mass percentage of the melt, and considering the burning loss rate of alloy elements in the smelting process, weigh 93% of pure magnesium ingot (purity is 99.9%), 4.5% of zinc ingot (purity is 99.9%), aluminum ingot ( Purity is 99.9%) 2.5%, pure metal Cr (purity is 99.9%) 0.11%, pure metal Bi (purity is 99.9%) 0.15% and pure metal Ca (purity is 99.9%) 0.6%;

[0054] 2. Put the raw materials into SX3-2.5-12 crucible resistance furnace after preheating and baking at 200°C;

[0055] 3. Set the heating temperature of the crucible resistance furnace to 740°C. When the temperature of the crucible rises to 350°C, first add magnesium ingots, zinc ingots, aluminum ingots and metal Cr to the crucible, and start feeding 0.1% SF 6 -99.9% CO 2...

Embodiment 3

[0059] An age-hardenable Mg-Zn-Cr-Bi-Zr alloy, its components and mass percentages are: Zn10%, Al6%, Cr0.5%, Ca2%, Bi1%, the balance is Mg, the total mass 100%.

[0060] Its preparation method is as follows:

[0061] 1. Calculated on the basis of the mass percentage of the melt, and considering the burning loss rate of alloying elements during the smelting process, weigh 82.5% of magnesium ingot (purity is 99.9%), zinc ingot (purity of 99.9%) 11%, aluminum ingot (purity 99.9%) 6.5%, metal Cr (purity 99.9%) 0.52%, metal Bi (purity 99.9%) 1.1% and metal Ca (purity 99.9%) 2.2%;

[0062] 2. Put the raw materials into the crucible resistance furnace after preheating and baking at 200°C;

[0063] 3. Set the heating temperature of the crucible resistance furnace to 750°C. When the temperature of the crucible rises to 380°C, first add magnesium ingots, zinc ingots, aluminum ingots and metal Cr to the crucible, and start feeding 0.1% SF 6 -99.9% CO 2 (volume fraction) mixed gas as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com