Secondary fermentation method of black tea and fermentation house used thereby

A technology for secondary fermentation and fermentation room, applied in the field of dark tea fermentation process and its equipment, can solve the problems of complex process and high production cost, and achieve the effects of good fermentation synchronization, low production cost and uniform fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: black tea secondary fermentation method, adopts the following steps:

[0037] a. Material preparation: According to the product’s requirements for raw materials, prepare raw tea materials;

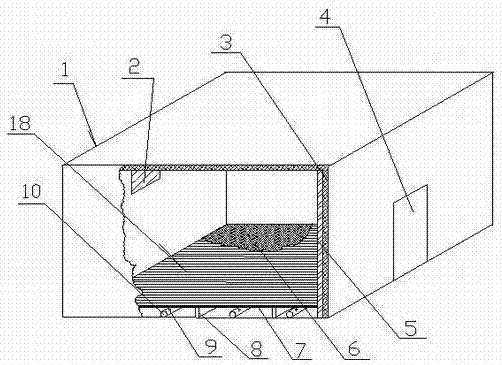

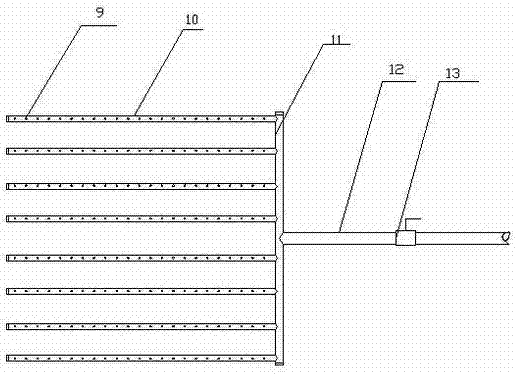

[0038] b. Entering the room: spread the raw tea raw material 17 in step a to the fermentation room 15 where the bottom can be evenly ventilated with steam;

[0039] c. Steaming: evenly spread steam from the bottom of the tea raw materials spread in the fermentation room for 15 miles. When steaming until the top layer of tea is softened, it can be squeezed by hand, then turn off the steam and stop steaming;

[0040] d. Fermentation: After the steaming is completed, it should be piled up for 8-24 hours;

[0041] e. Deblocking: use manual or deblocking machine to deblock the fermented tea leaves into loose tea;

[0042] f. drying: drying the tealeaves after the above-mentioned unblocking to a water content of 13% for subsequent use.

Embodiment 2

[0043] Embodiment 2: black tea secondary fermentation method, adopts the following steps:

[0044] a. Material preparation: According to the product’s requirements for raw materials, prepare raw tea materials;

[0045] b. Entering the room: spread the tea raw material 17 of step a into the fermentation room 15 where the bottom can be evenly ventilated with steam.

[0046] c. Steaming: evenly spread steam from the bottom to the raw tea raw materials that are evenly spread in the fermentation room. The temperature of the steam is 100°C and steamed for 10 hours;

[0047] d. Fermentation: After the steaming is completed, it should be stacked for 23 hours without any change;

[0048] e. Deblocking: use manual or deblocking machine to deblock the fermented tea leaves into loose tea;

[0049] f. drying: drying the tealeaves after the above-mentioned unblocking to a water content of 12% for subsequent use.

Embodiment 3

[0050] Embodiment 3: black tea secondary fermentation method, adopts the following steps:

[0051] a. Material preparation: According to the product’s requirements for raw materials, prepare raw tea materials;

[0052] b. Entering the room: the raw tea raw materials of step a are all spread to the fermentation room 15 where the bottom can evenly pass through the steam, the thickness h of the uniform spread is 1.8m, and the natural fiber cloth 16 is covered on the tea.

[0053] c. Steaming: evenly spread steam from the bottom to the raw tea raw materials spread in the fermentation room, the temperature of the steam is 130°C, and steam for 5 hours;

[0054] d. Fermentation: After the steaming is completed, it should be piled up for 9 hours without any change;

[0055] e. Deblocking: use manual or deblocking machine to deblock the fermented tea leaves into loose tea;

[0056] f. drying: drying the tealeaves after the above-mentioned unblocking to a water content of 10% for subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com