Patents

Literature

32results about How to "No time difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

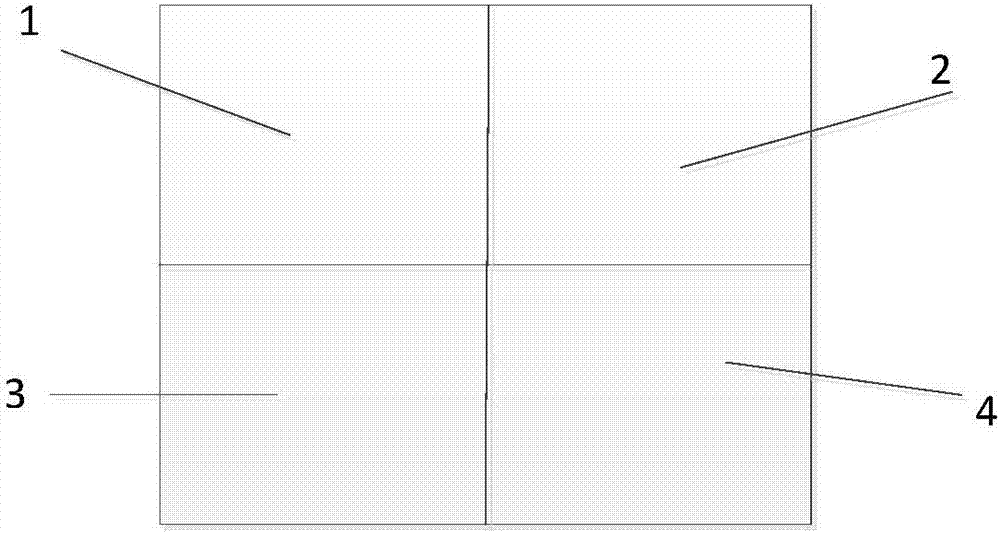

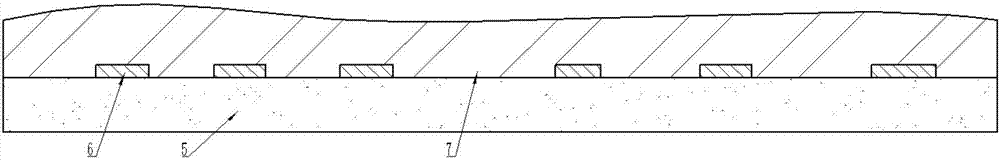

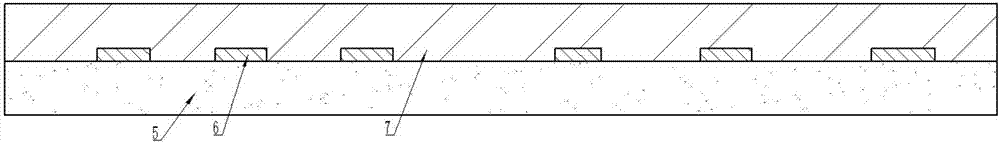

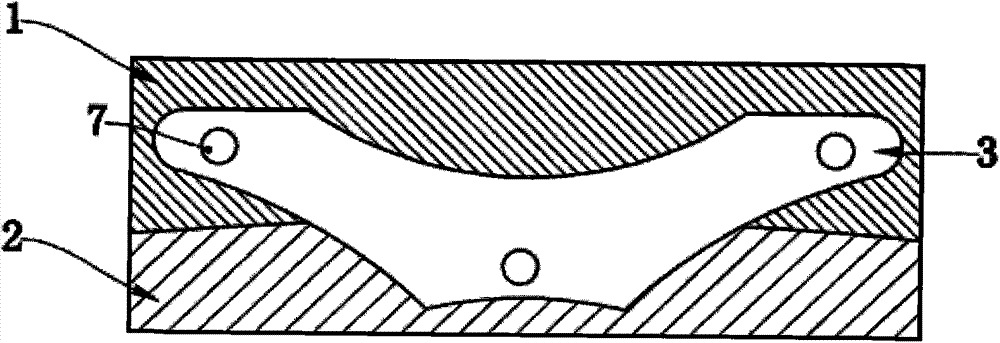

Uncooled dual-color polarization infrared bolometer and manufacture method thereof

ActiveCN107101728AReduce difficultyLow costDecorative surface effectsChemical vapor deposition coatingResonant cavityOptoelectronics

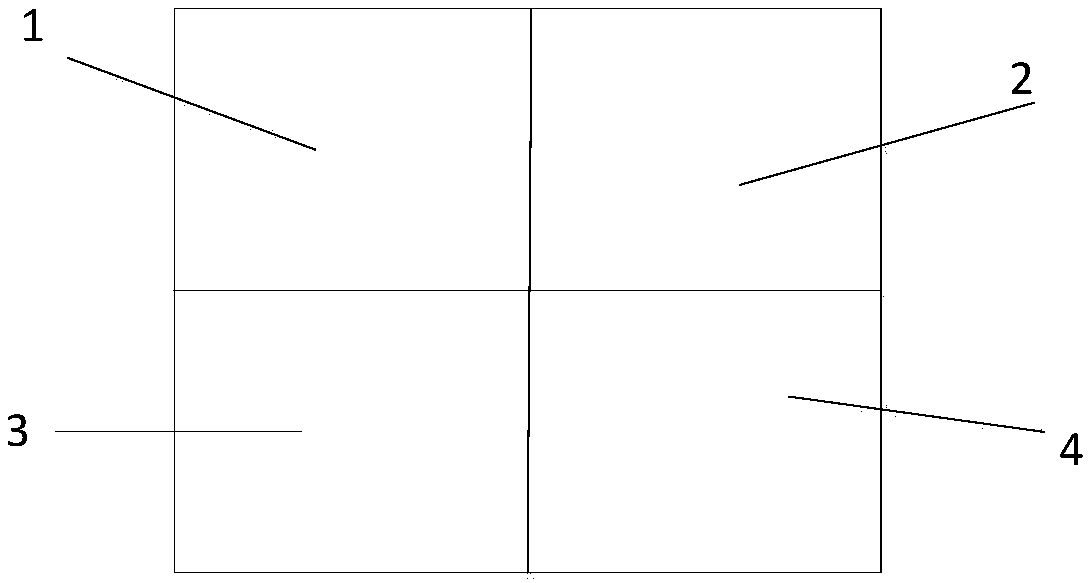

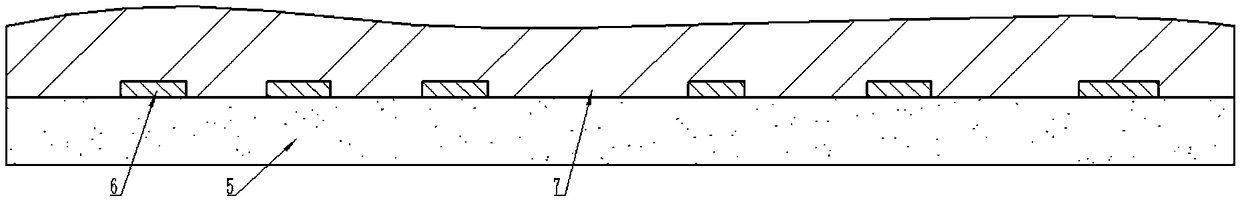

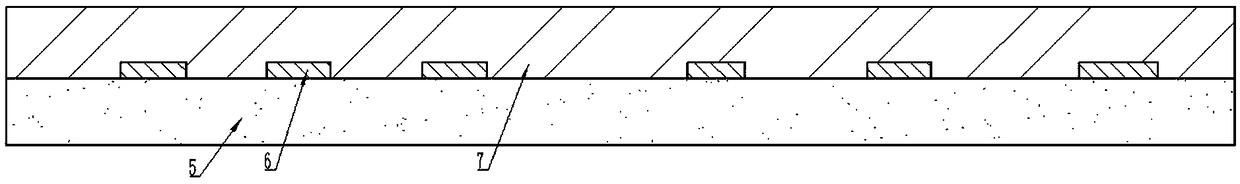

The invention relates to an uncooled dual-color polarization infrared bolometer. Two polarization structures are prepared on a uncooled dual-color infrared bolometer which comprises four regions arranged in a matrix and including first and third regions and second and fourth regions. Resonant cavities with different heights are formed in the first and third regions and the second and fourth regions. The invention also relates to a method for preparing the bolometer. The method comprises steps of: preparing the resonant cavities with different heights in the first and third regions and the second and fourth regions; sputtering thermosensitive films with different square resistance values, and preparing the two polarization structures in the first and third regions and the second and fourth regions of the uncooled dual-color infrared bolometer respectively. The uncooled dual-color polarization infrared bolometer can operate in an ultralow temperature environment (-80 to -60 degrees centigrade) and an ultrahigh temperature environment (85 to 100 degrees centigrade, and has a polarization characteristic.

Owner:YANTAI RAYTRON TECH

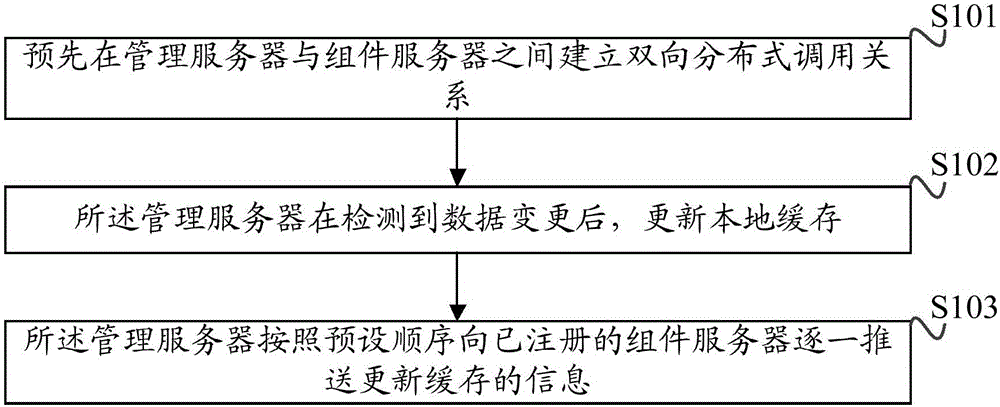

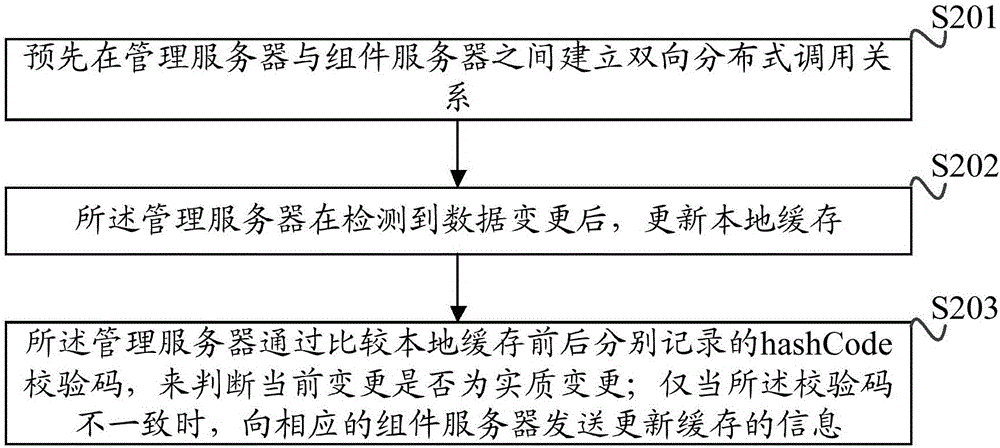

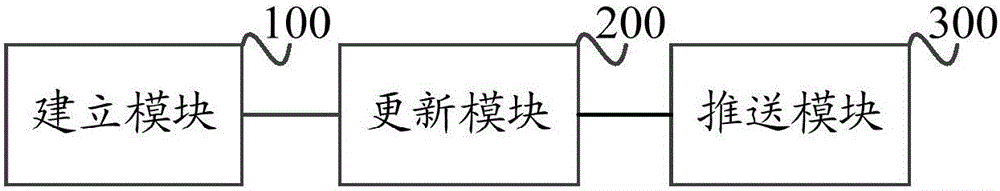

Main push serialized cache management method and system

InactiveCN106126568ANo time differenceAvoid access stressDatabase updatingDatabase distribution/replicationSerializationCache management

The present invention discloses a main push serialized cache management method and system. The method comprises the steps that a bidirectional distributed invoking relationship between a management server and a component server is established in advance, wherein the management server and the component server perform transmission in a manner of serializing objects; after the management server detects that data is changed, the management server updates a local cache; and the management server pushes the updated cache information piece by piece according to a preset sequence to the registered component server. According to the main push serialized cache management method and system, extra system deployment nodes are not added, a new cache technology is not needed, and extra learn cost is saved. A manner of real-time main pushing and serializing objects is adopted for cache and updating so as to realize unified management of the memory, so that the cache objects are ensured to be totally consistent in all sub-systems, and have no time difference.

Owner:杭州财人汇网络股份有限公司

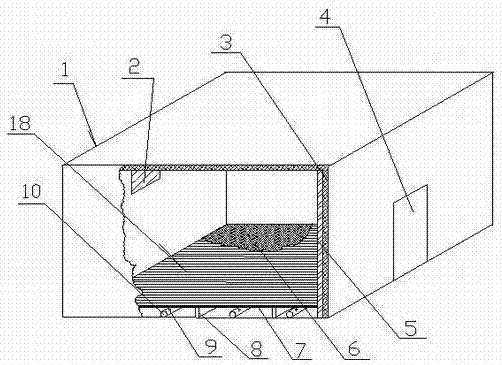

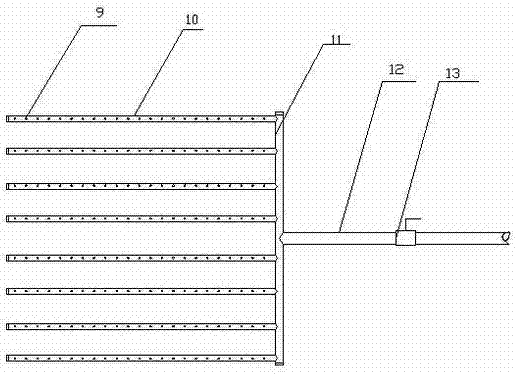

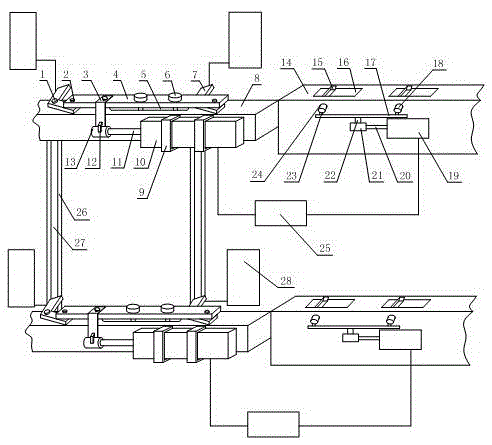

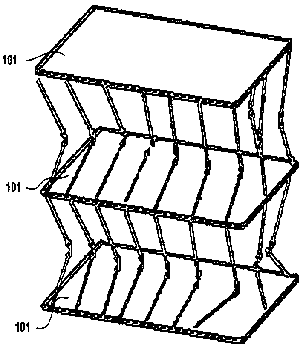

Secondary fermentation method of black tea and fermentation house used thereby

PendingCN107279345ALarge amount of fermentationGood synchronization of fermentationPre-extraction tea treatmentProcess engineeringBiology

The invention relates to a fermentation process and apparatus of black tea, in particular to a secondary fermentation method of black tea and a fermentation house used thereby. The method includes: spreading crude tea evenly in the fermentation house the bottom of which allows uniform introduction of steam; introducing steam evenly to the bottom of the crude tea spread evenly in the fermentation house so as to perform steaming until the uppermost layer of tea softens and may not be pinched apart by hand; after steaming, piling in the integrity for 8-24 hours, loosening, and drying. The fermentation house comprises a frame that is provided with walls, a plurality of steam pipes are arranged evenly at the bottom of the frame in parallel and are evenly provided with steam holes, and a breathable pad is arranged on the steam pipes. The secondary fermentation method of black tea and the fermentation house have the advantages that fermentation quantity is high, about 1 ton of tea leaves can be fermented at a time, fermentation is well synchronous, no time differences occur, fermentation can be finished at a time with no need for pile fermentation in halfway, the fermentation is uniform, mellowing effect is good, the finished black tea can be 1-2 higher in grade, the method is simple to perform, and the production cost is low.

Owner:湖南清山月茶业有限公司

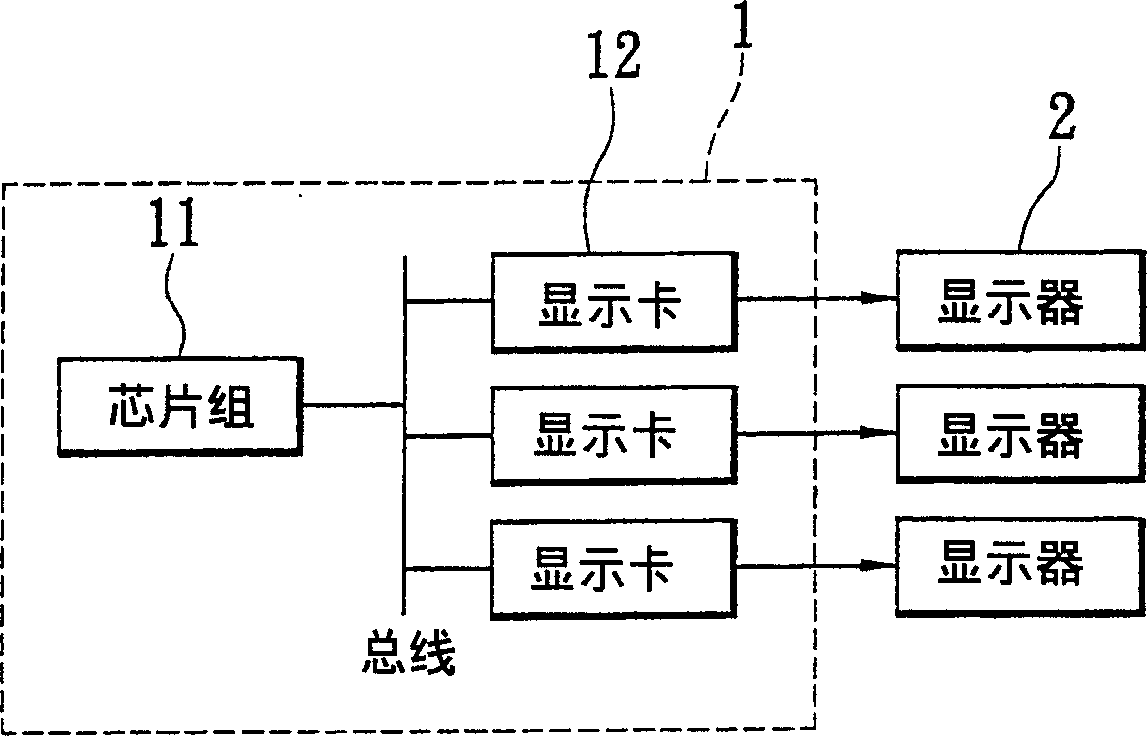

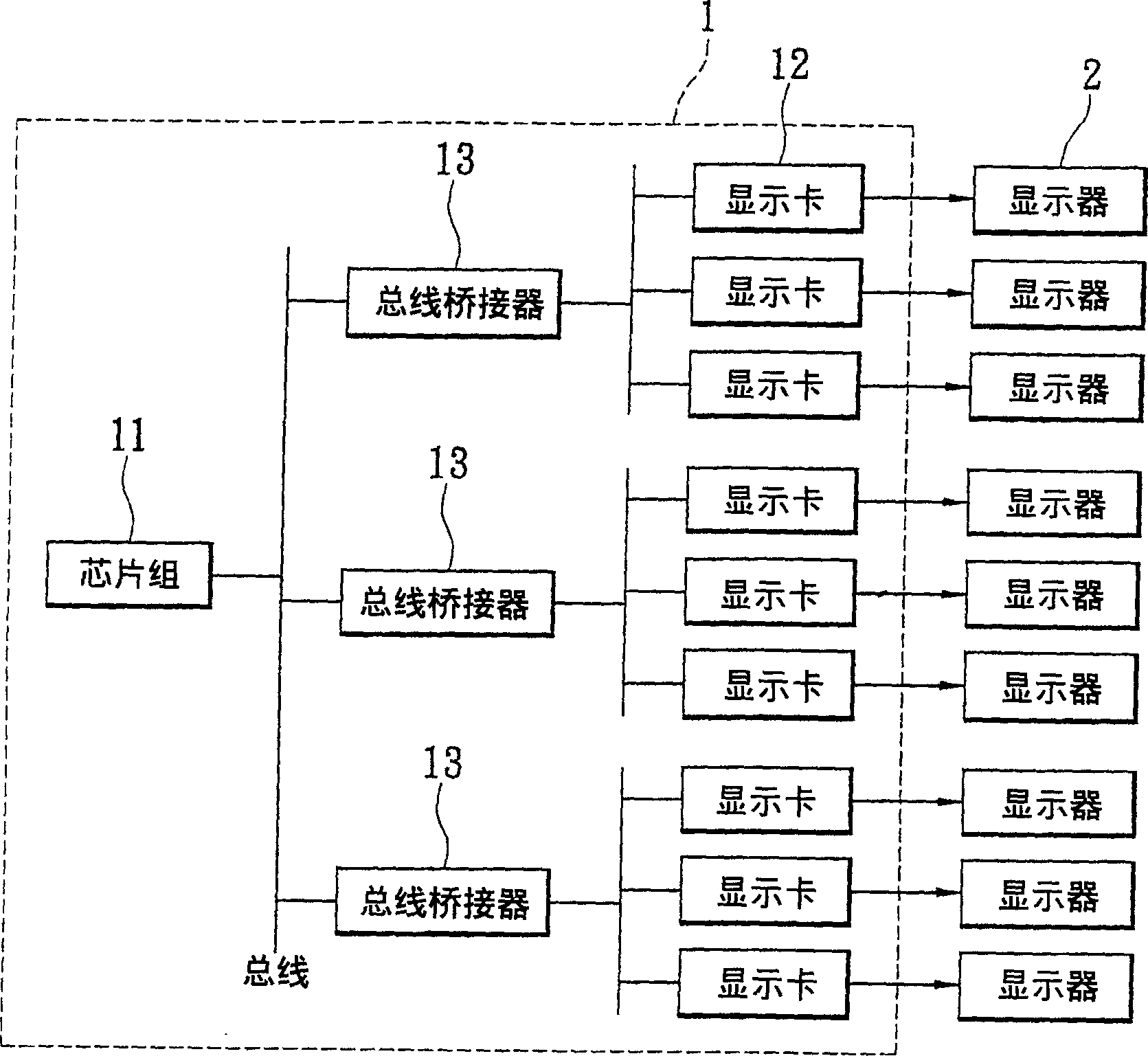

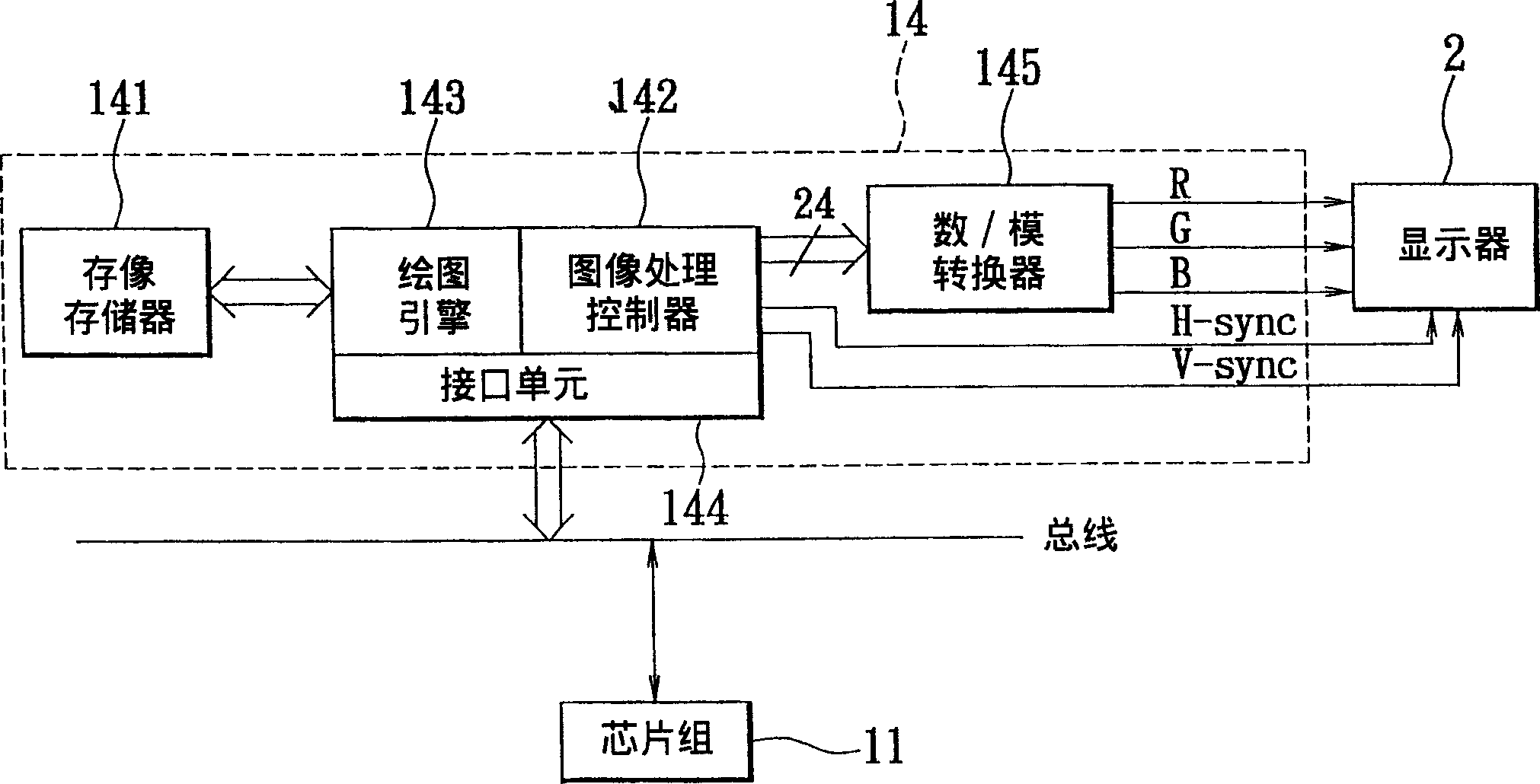

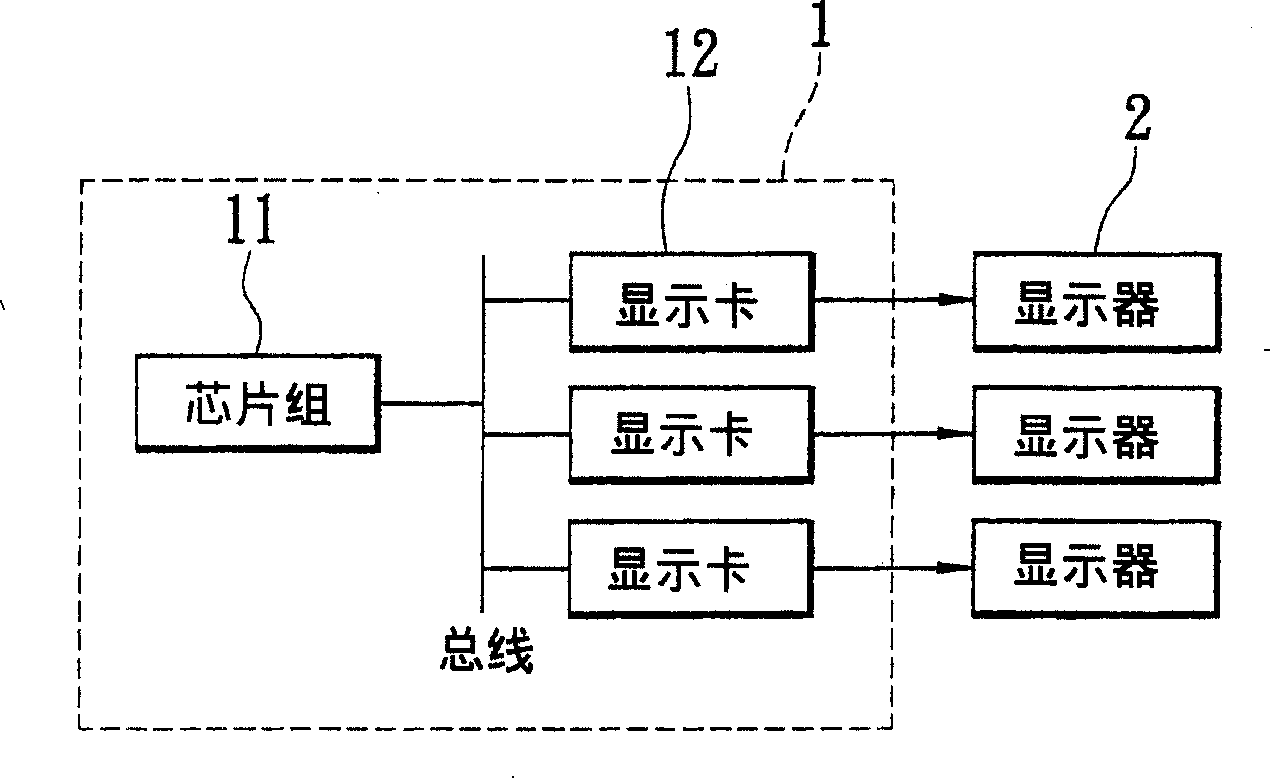

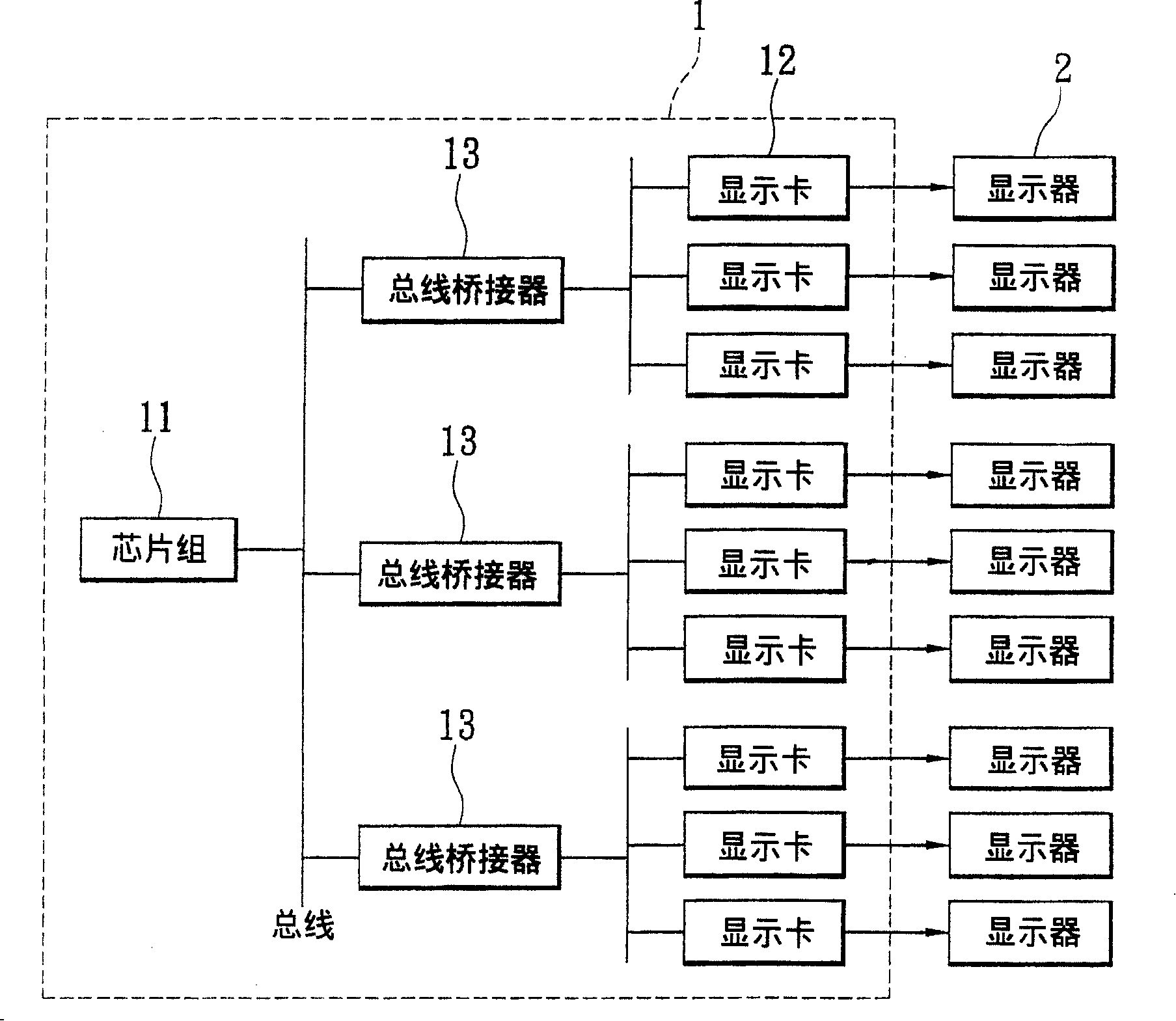

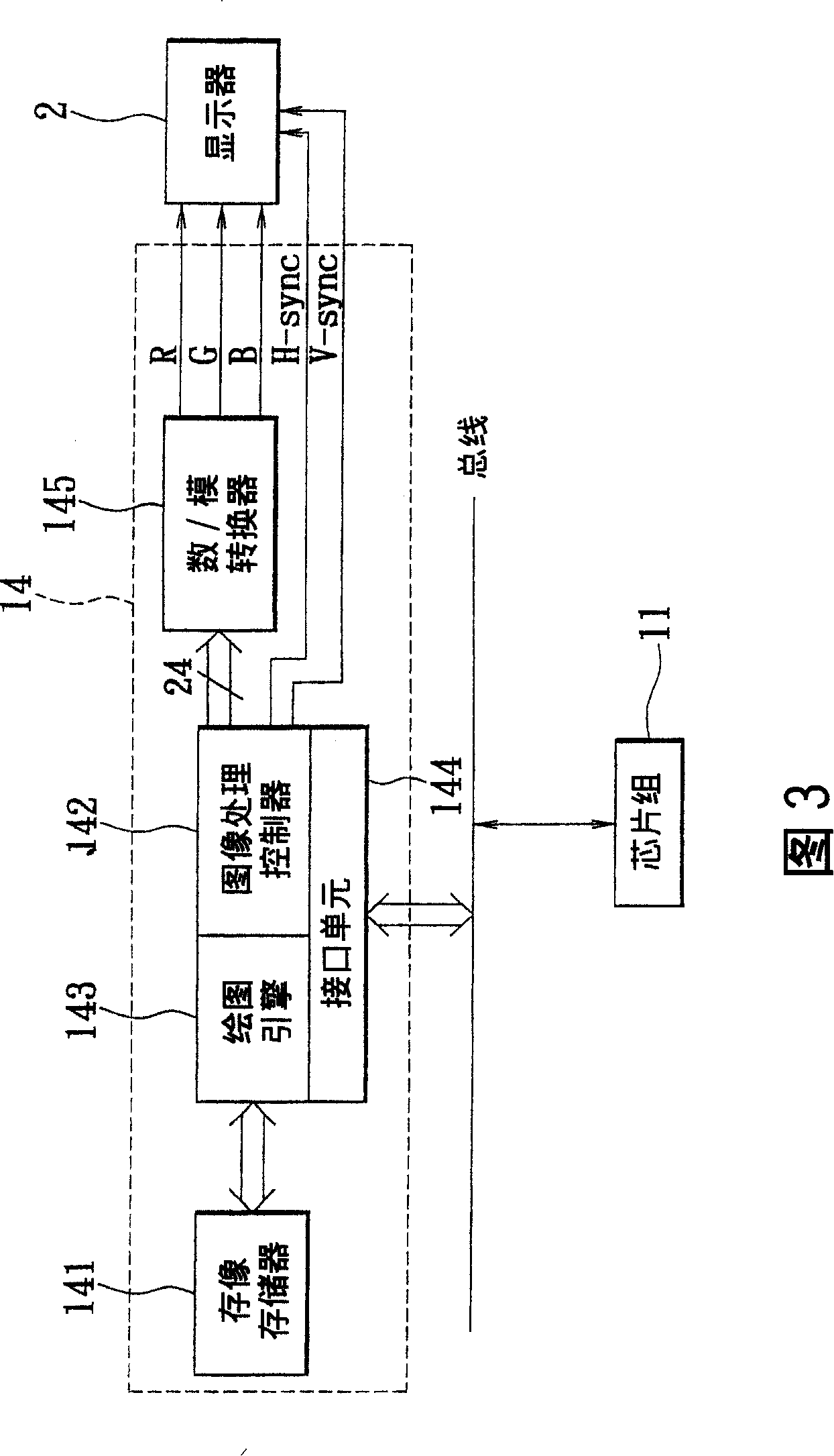

Driver module and driving method of display with multi-path display output

It is a kind of display drive module and method that with multiple display output. It can solve the problem that single display drive module cannot drive multiple displays. The display drive module can process and convert multiple image signals that in image memory to multiple digital video signals and output them by image processing controller. The output of image processing controller connects to multiple analog-digital converter, which can convert the digital video signal to analog R, G, B signal and output them. The output of each analog-digital converter connects to display, and enables the displays to display the image data according to the received signal. So this single display drive module drives multiple displays and updates image of them simultaneously.

Owner:VIA TECH INC

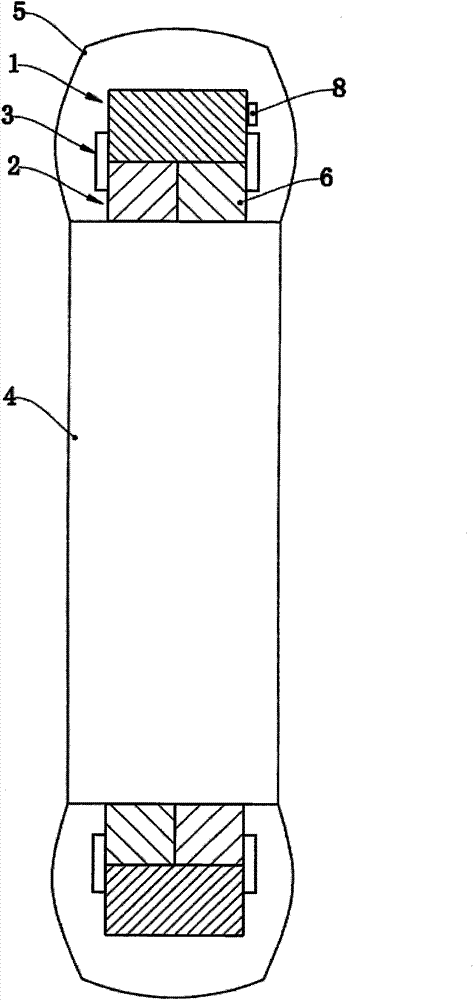

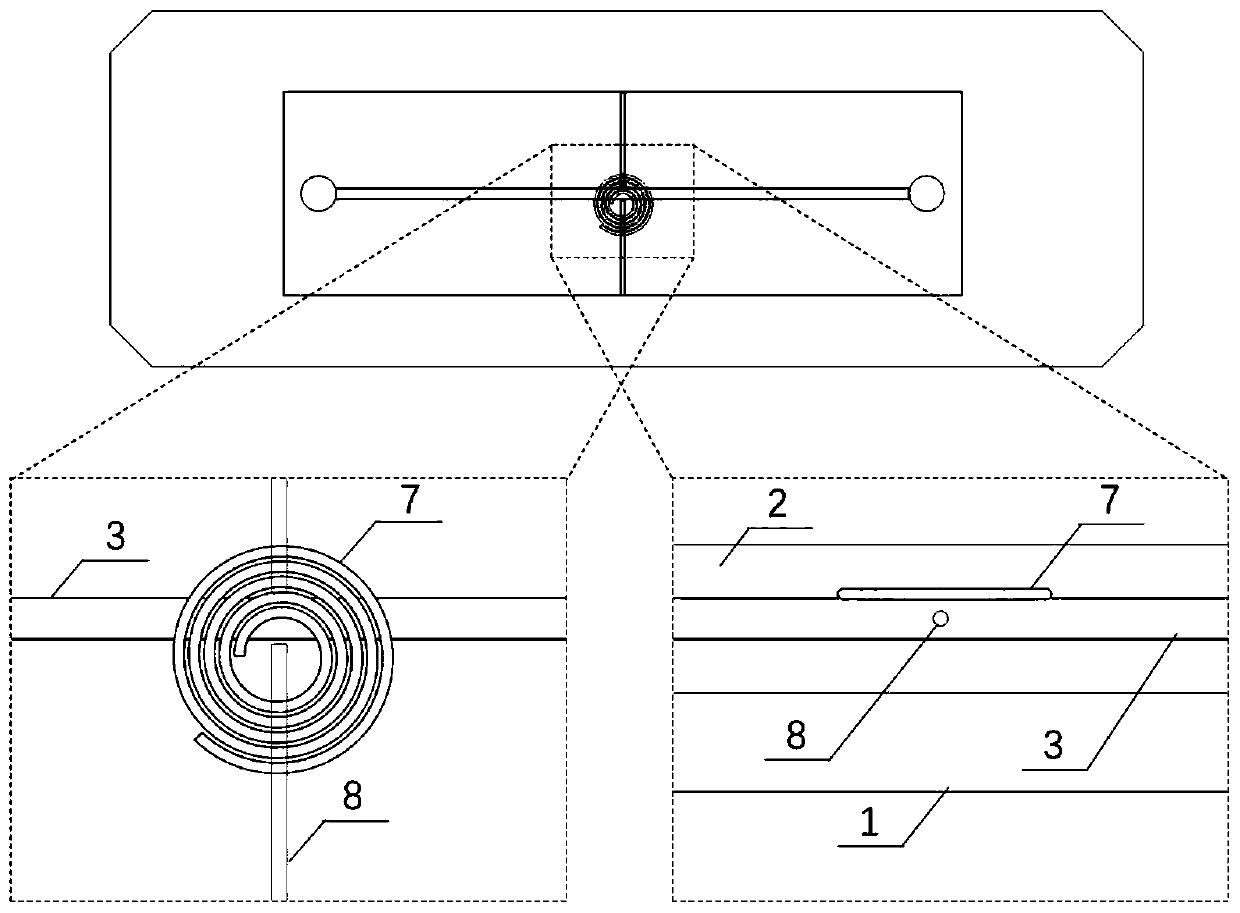

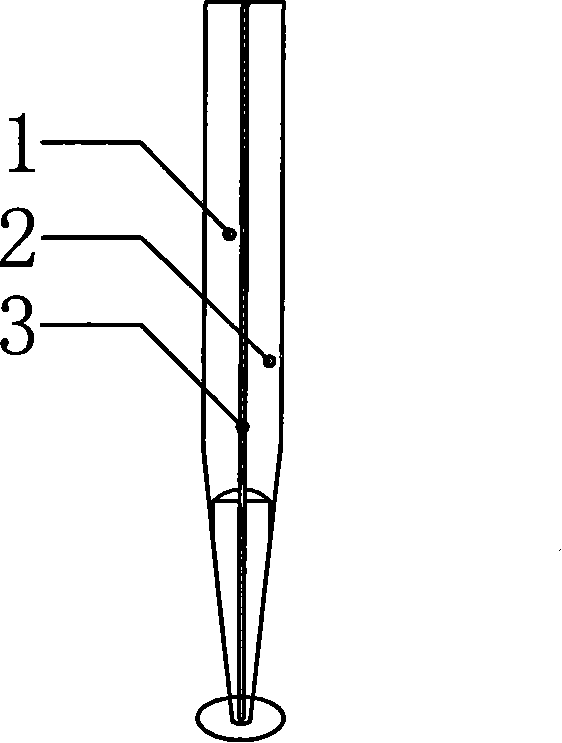

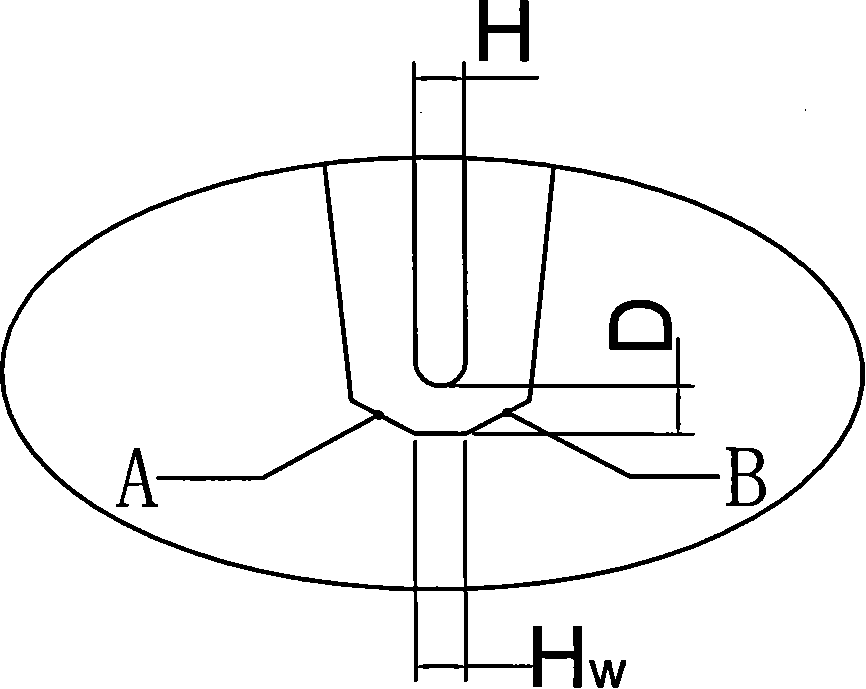

An uncooled two-color infrared detector mems chip and its manufacturing method

ActiveCN107117578BDivision to achieveSignal no time difference noTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesResonant cavityResonance

The invention relates to an uncooled two-color infrared detector MEMS chip, which is divided into four regions arranged in a matrix: the first and third regions and the second and fourth regions, and the first and third regions are formed with different heights from the second and fourth regions The resonant cavity, and the heat-sensitive layer films with different resistance values are sputtered on it, which can better absorb infrared energy of different bands, and then convert it into electrical signals for processing and image output. The present invention also relates to a method for preparing the above-mentioned chip, including the steps of manufacturing resonant cavities of different heights in the first and third regions and the second and fourth regions respectively, the steps of sputtering the heat-sensitive layer films with different resistance values, and packaging In the step of testing, the chip can work in an ultra-low temperature (-80°C--60°C) environment and an ultra-high-temperature (85°C-100°C) environment.

Owner:YANTAI RAYTRON TECH

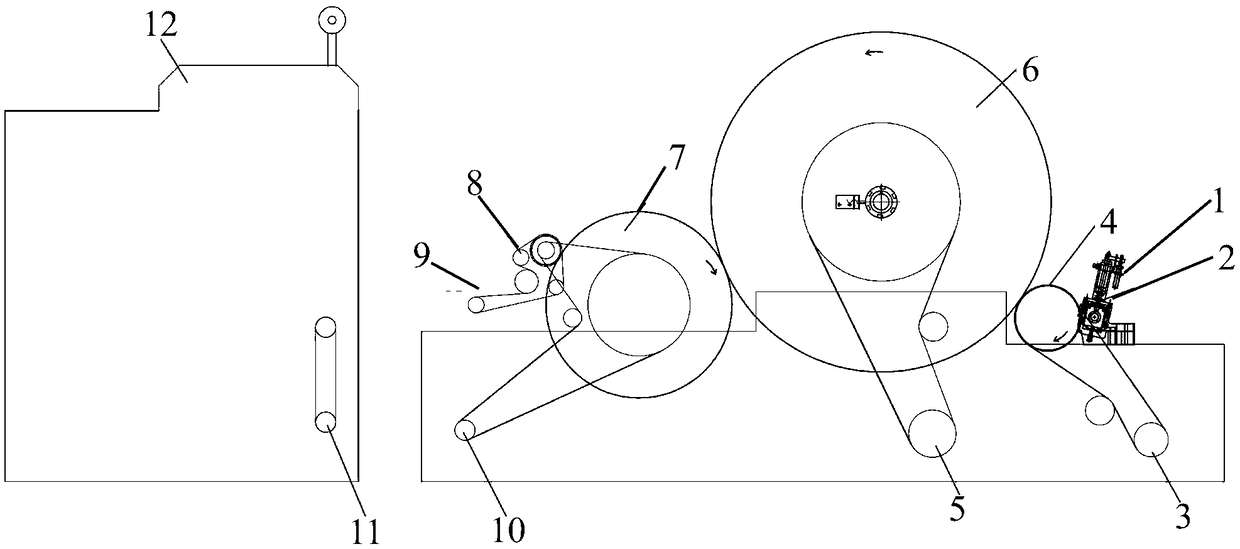

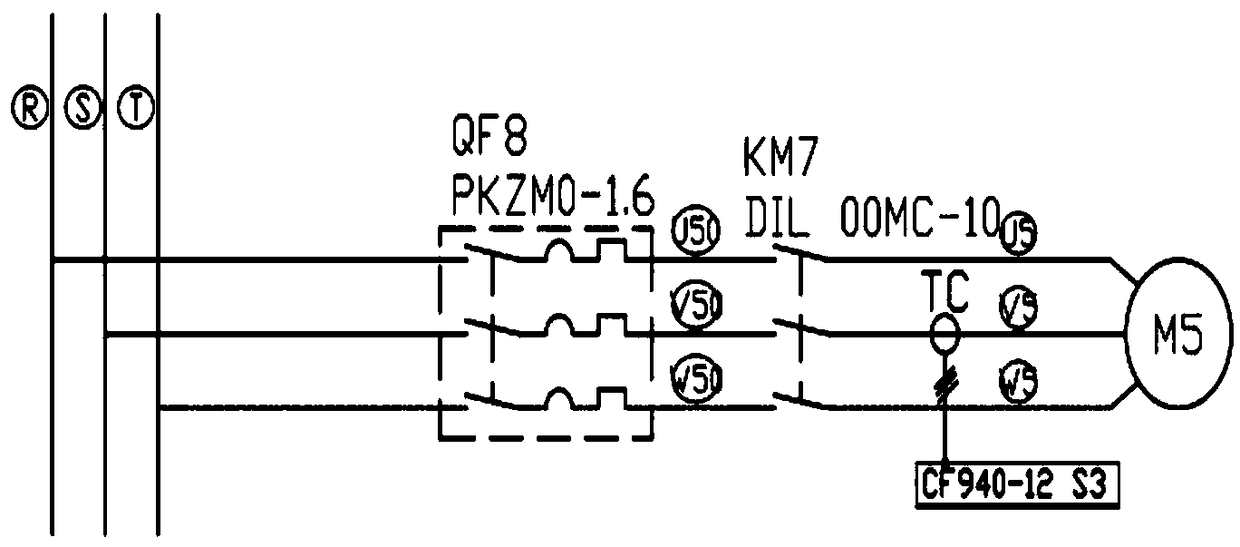

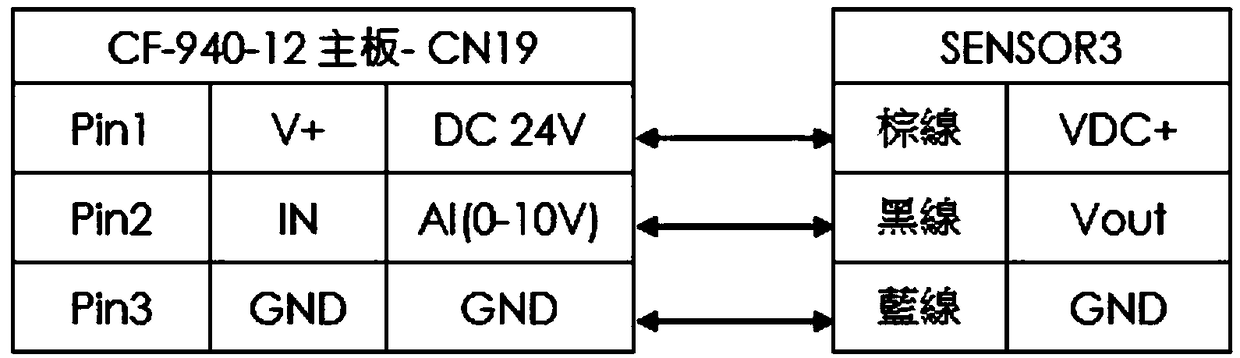

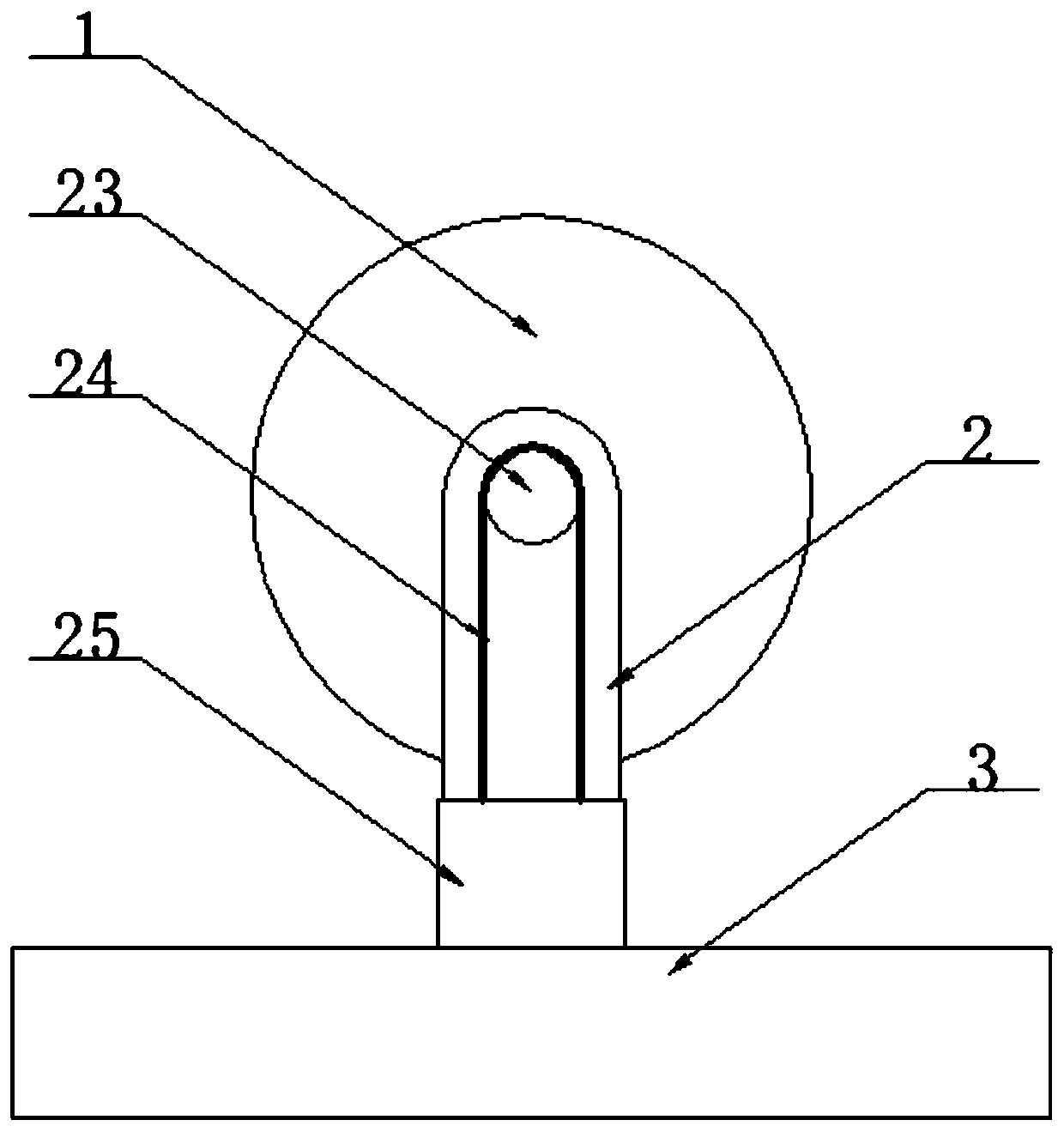

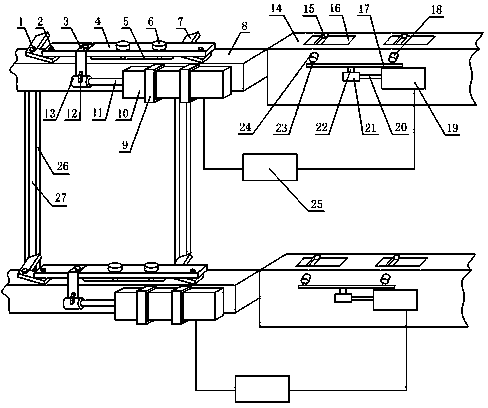

Licker-in micro-current leveling device of automatic cotton carding machine

The invention discloses a licker-in micro-current leveling device of an automatic cotton carding machine. The device comprises an independent motor and a micro-current inductor; the independent motoris installed on the automatic cotton carding machine, any power supply line of the independent motor is connected with the input end of the micro-current inductor, the output end of the micro-currentinductor is connected with the input end of a main control board, the input end of the main control board is connected with the input end of a frequency converter, and the output end of the frequencyconverter is connected with the input end of a speed reduction motor of a cotton feed roller. The cotton supply roller can directly enter the licker-in through the cotton feed procedure, the licker-incan directly send cotton feed changes, and therefore the cotton feed roller speed can be accurately adjusted in time.

Owner:YANCHENG KINGDA TEXTILE MACHINERY MFG

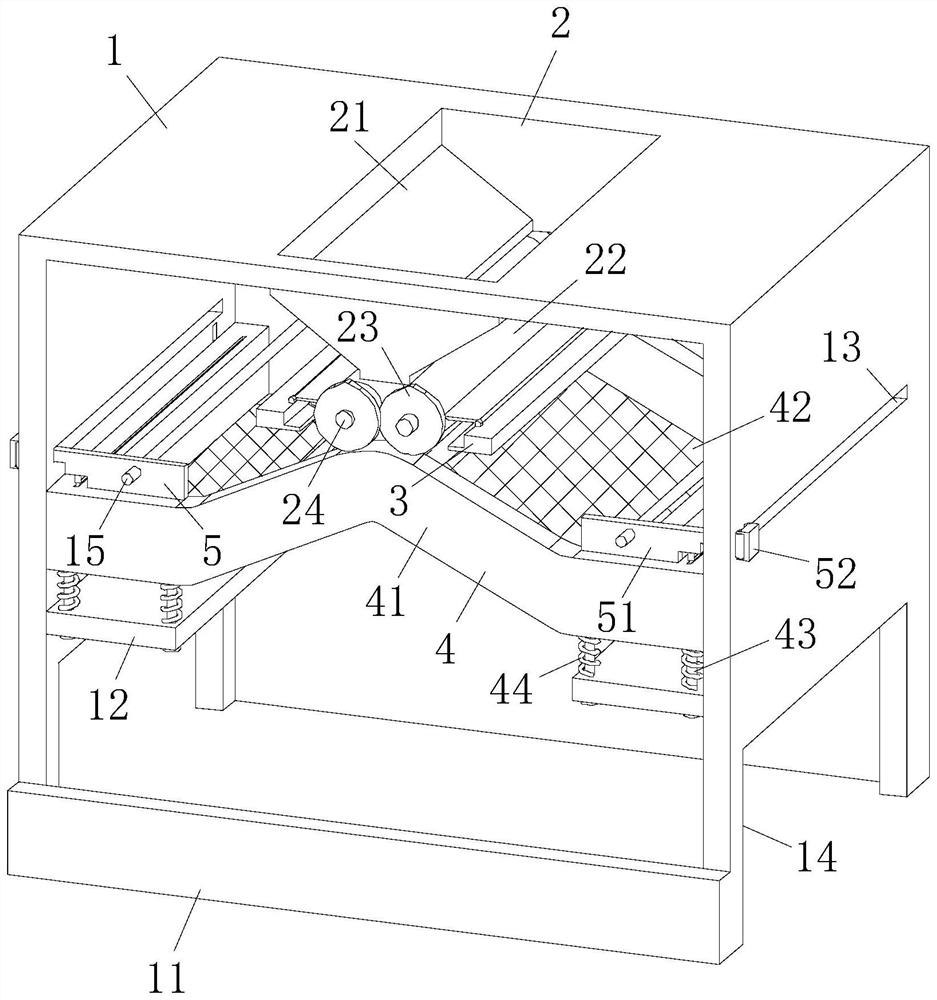

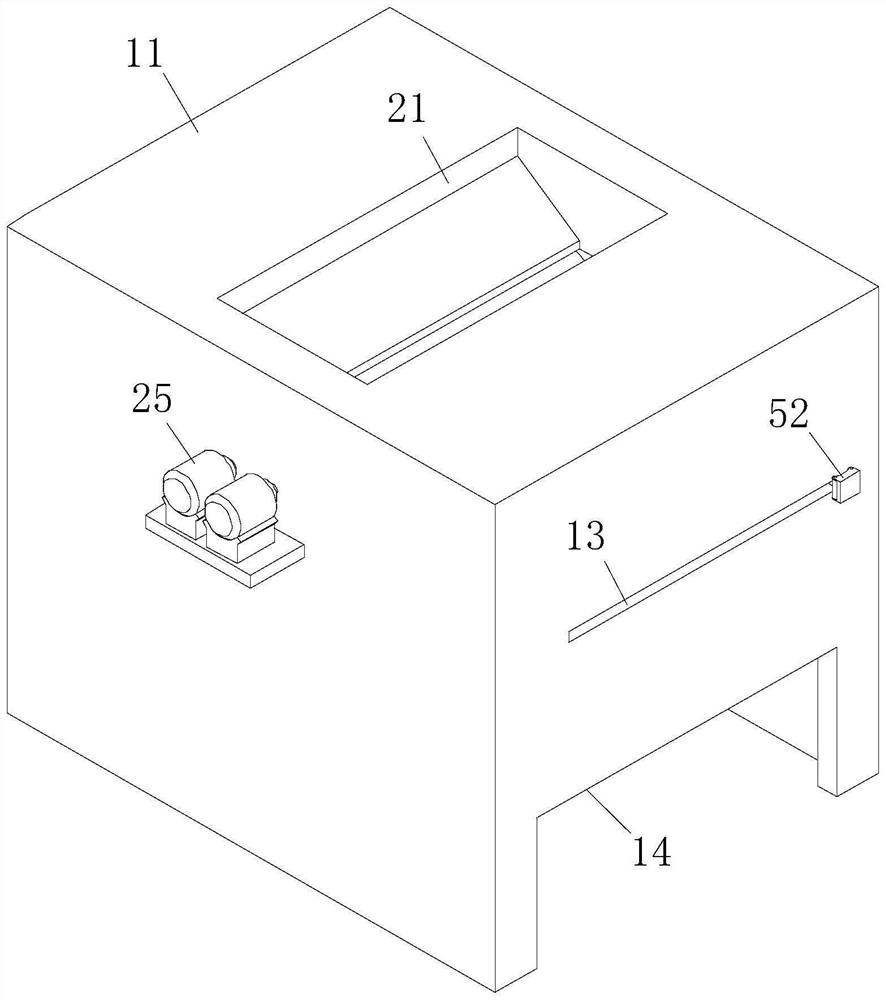

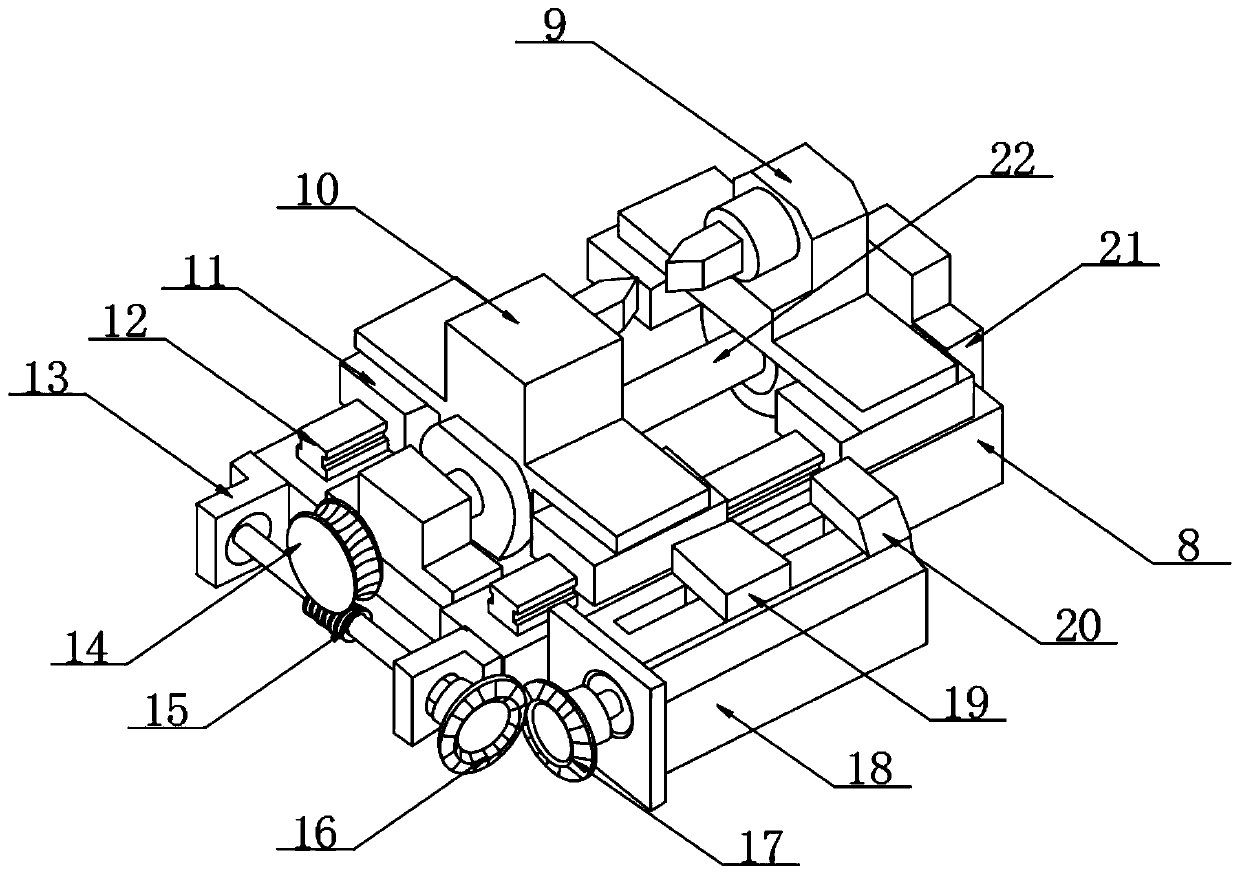

Manufacturing method and manufacturing equipment of inorganic gelling building material

ActiveCN114192220AImprove filtering effectAvoid cloggingSievingSolid waste managementConstruction engineeringFilter effect

The invention relates to the field of building material manufacturing equipment, in particular to an inorganic gelling building material manufacturing method and manufacturing equipment which specifically comprises a device body, a smashing structure, a first cleaning structure, a filtering structure and a second cleaning structure. The smashing structure is arranged on the upper portion of the device body, and first cleaning structures are arranged on the two sides of the smashing structure correspondingly. A filtering structure is arranged below the smashing structure, and second cleaning structures are arranged on the two sides of the filtering structure. When the driving disc rotates along with the rotating shaft, the supporting frame can be pushed to move downwards by a certain section, after the protruding block is separated from the supporting frame, the supporting frame in the filtering structure restores to the original position under the action of the elastic force of the reset spring, and when the device is used, the supporting frame continuously moves up and down to assist materials on the filtering net to be continuously filtered. The filtering effect of the filter screen is improved, large particles which cannot pass through the filter screen can slide to the two sides of the supporting frame along the filter screen to be cleaned, and the filter screen is prevented from being blocked.

Owner:江苏唐盾材料科技有限公司

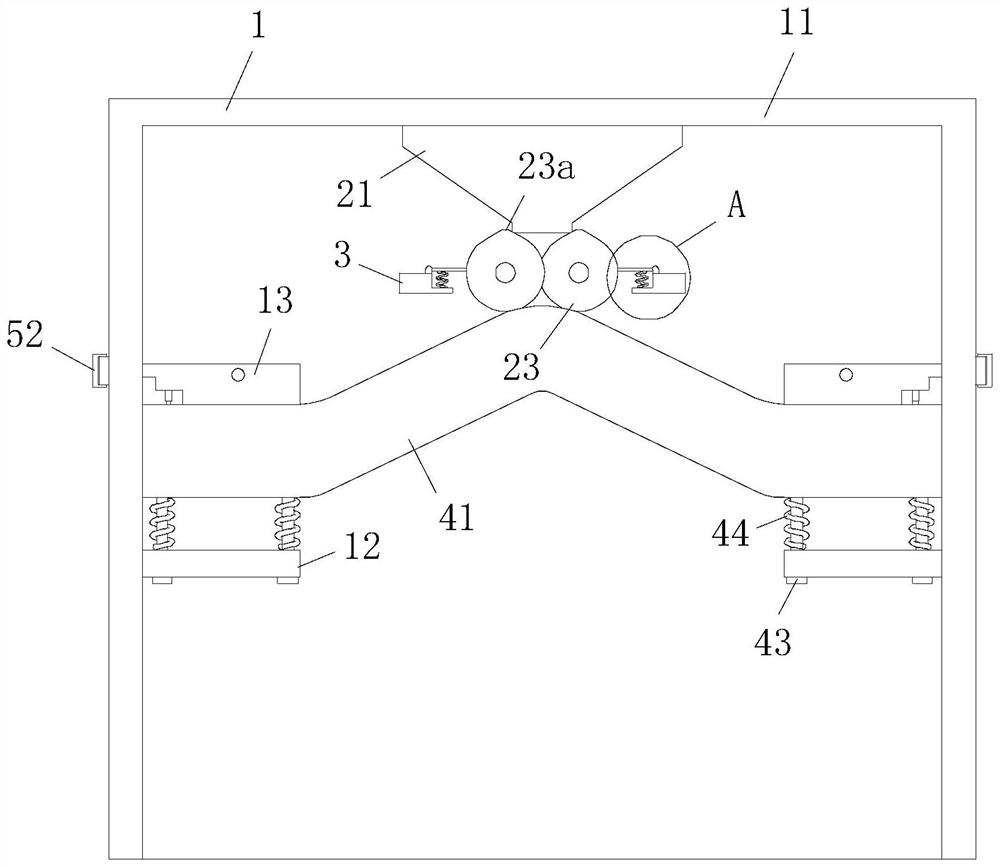

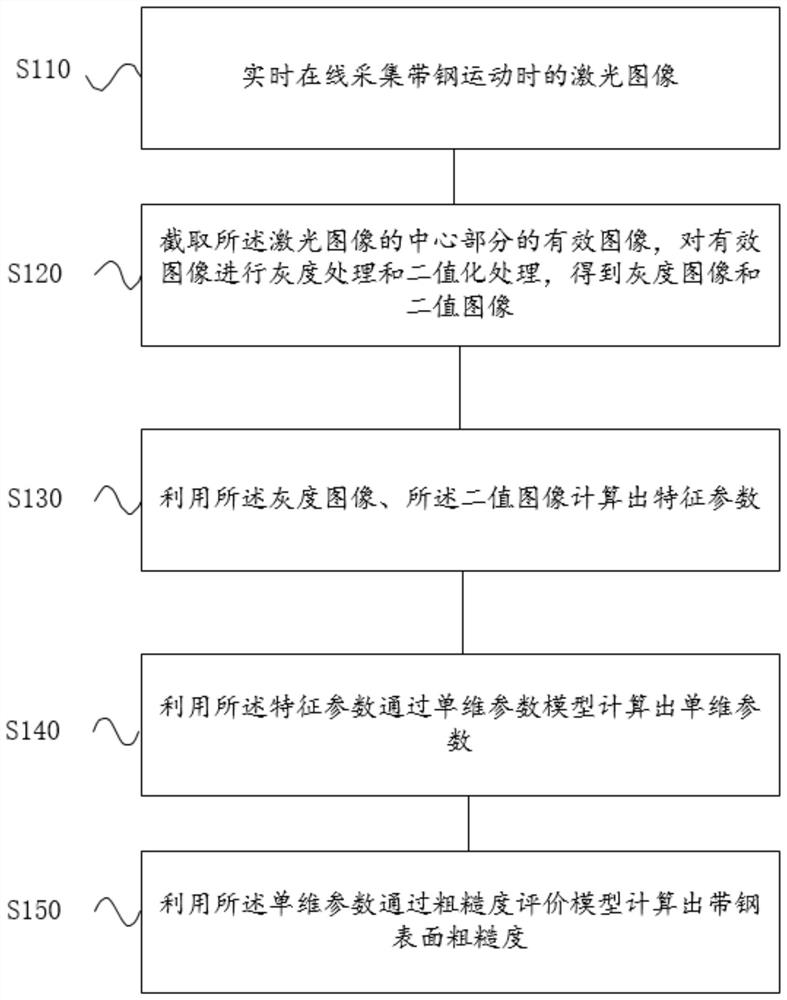

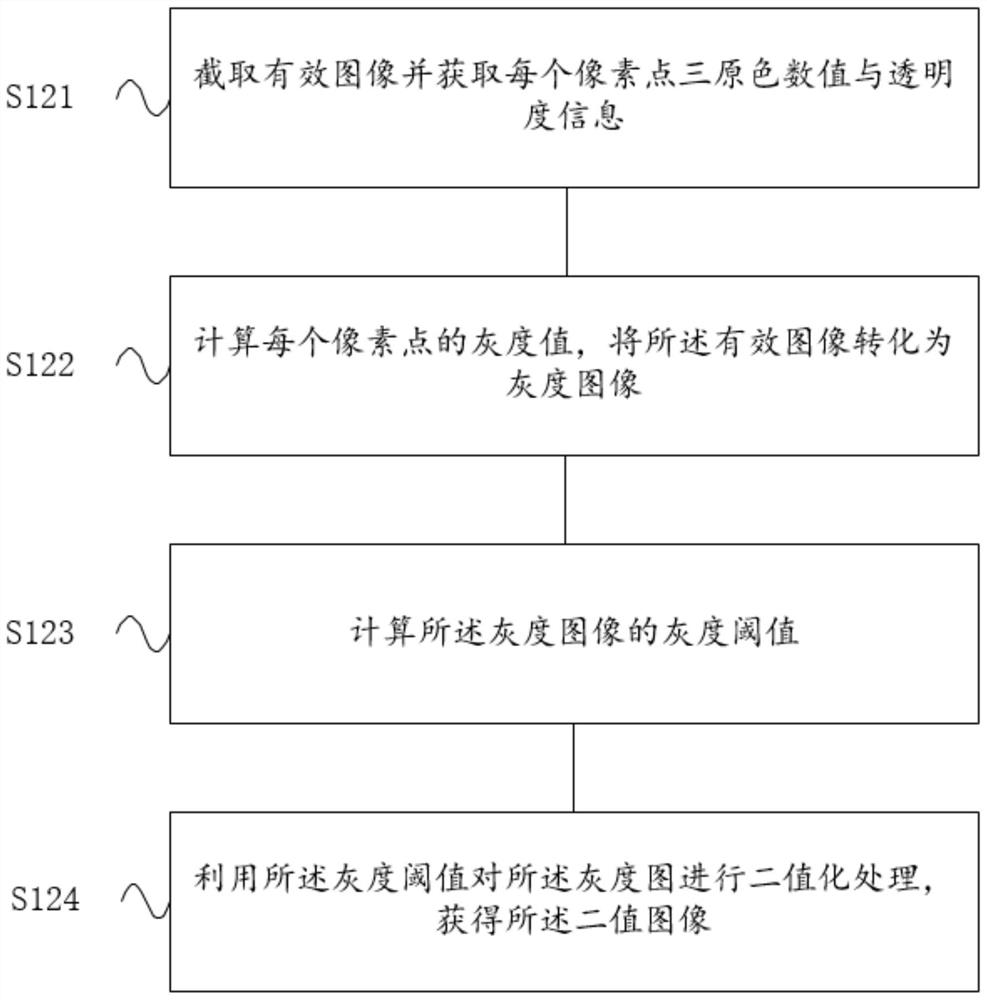

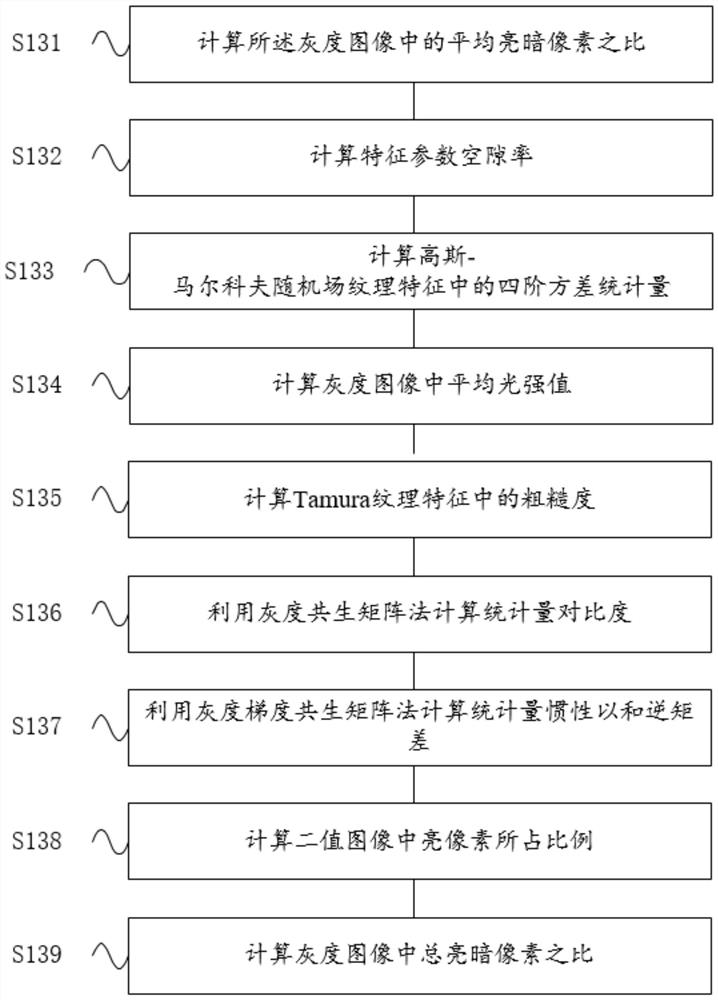

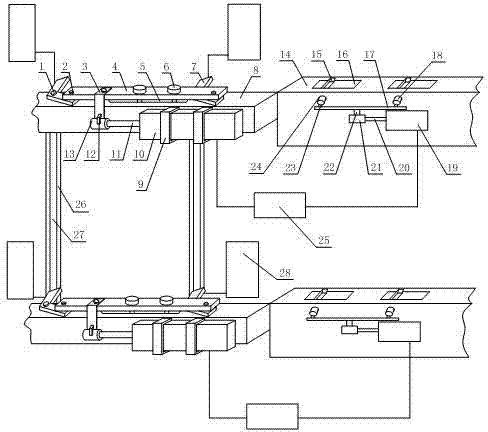

On-line detection device and method for surface roughness of strip steel

ActiveCN114210741AImprove efficiencyImprove surface qualityImage enhancementImage analysisLaser beamsBinary image

The invention discloses an online detection device and method for the surface roughness of strip steel. The method comprises the following steps: acquiring a laser image during movement of the strip steel online in real time; intercepting an effective image of the central part of the laser image, and performing gray processing and binarization processing on the effective image to obtain a gray image and a binary image; feature parameters are calculated by using the grayscale image and the binary image; calculating a single-dimensional parameter through a single-dimensional parameter model by utilizing the characteristic parameter; and calculating the surface roughness of the strip steel through the roughness evaluation model by using the single-dimensional parameters. The detection device comprises a supporting and driving roller way, a laser generator and a combined lens, laser beams emitted by the laser generator irradiate the surface of the strip steel after passing through the combined lens, and the high-speed industrial area-array camera collects laser images generated when the strip steel moves online in real time and transmits the laser images to the server. Real-time online detection of the surface roughness of the strip steel is achieved, no time difference exists, the strip steel with abnormal roughness can be monitored in real time, and efficiency is high.

Owner:UNIV OF SCI & TECH BEIJING

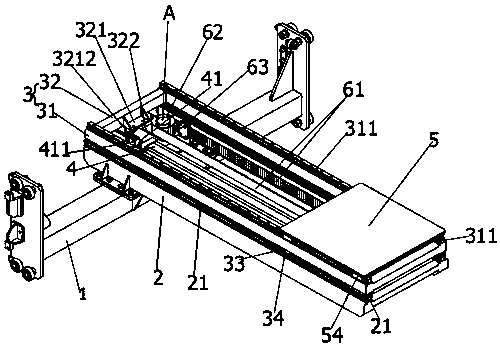

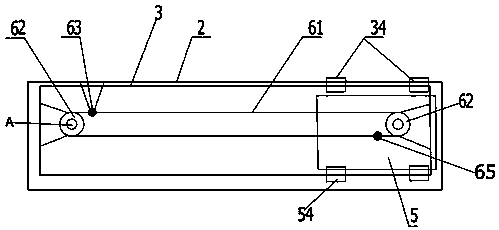

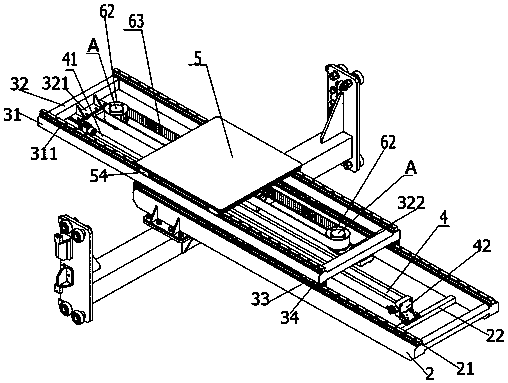

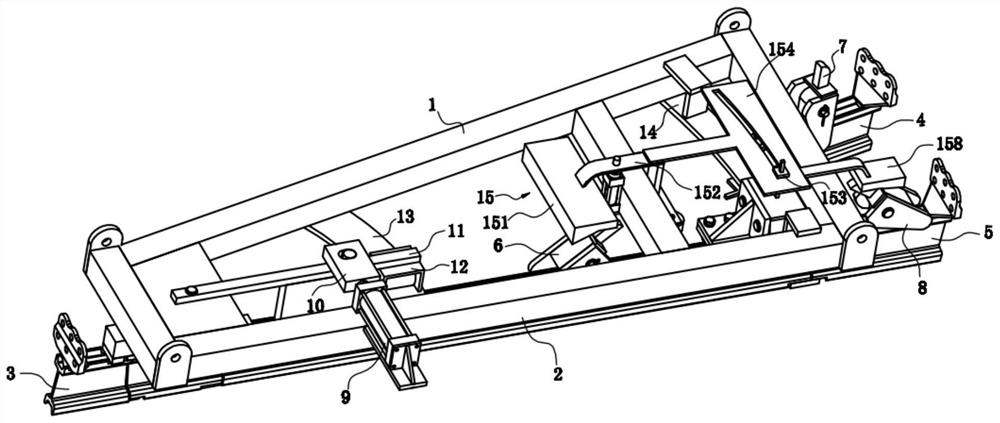

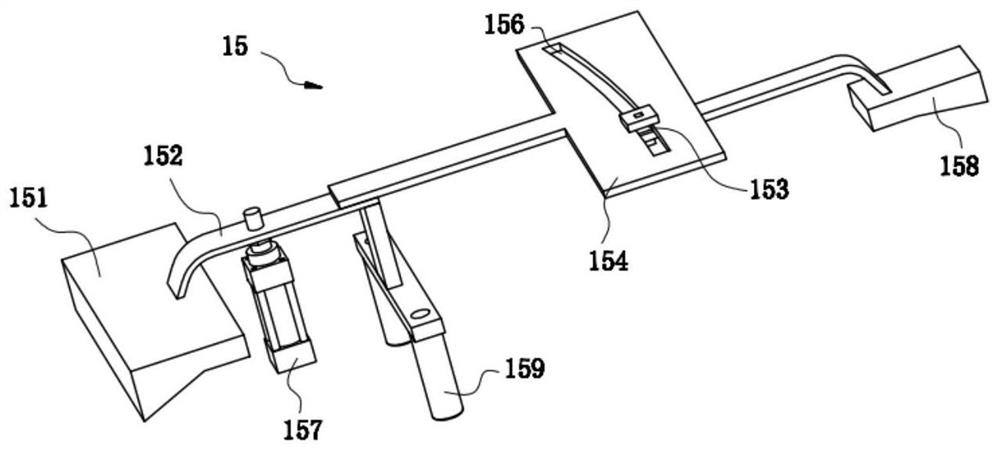

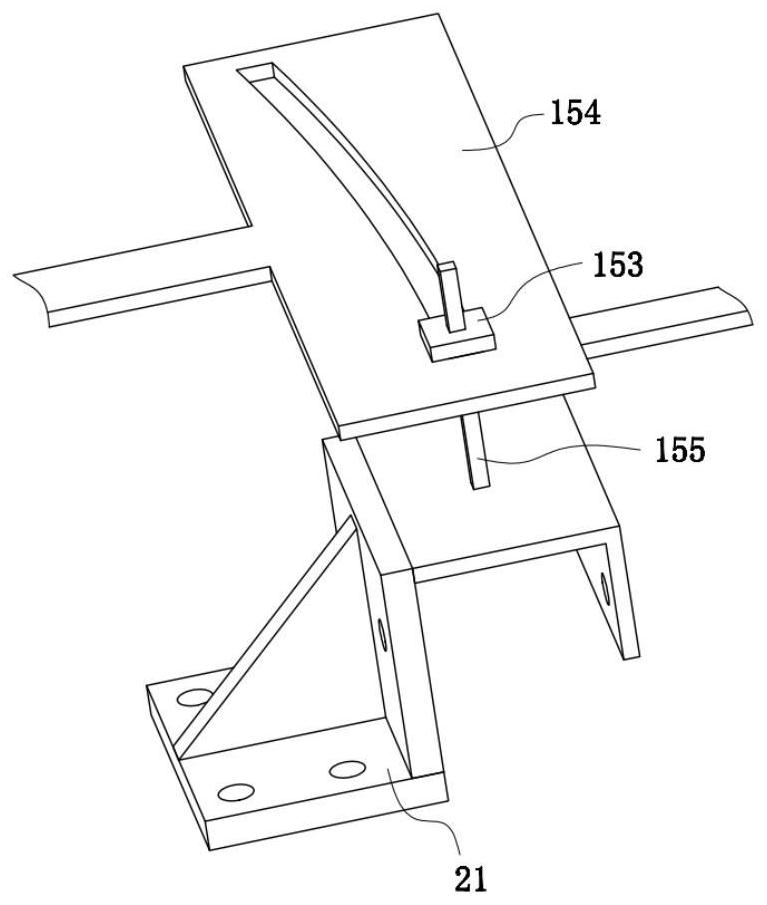

Linkage multi-level telescopic blank receiving device

PendingCN108327056ASimplify the molding process actionShorten the transfer time for mold removalDischarging arrangementGear wheel

Owner:TANGSHAN HEXIANG INDAL

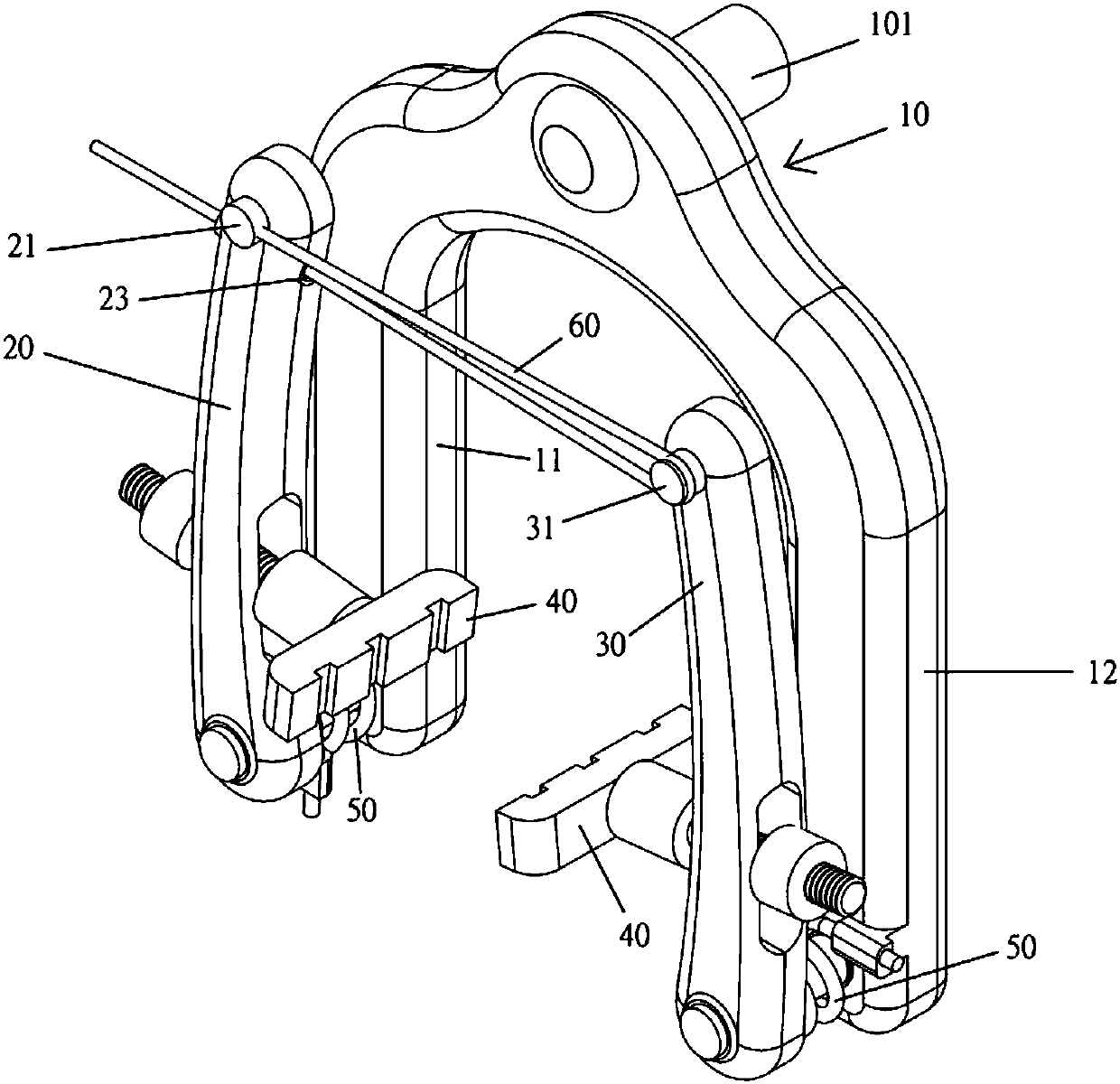

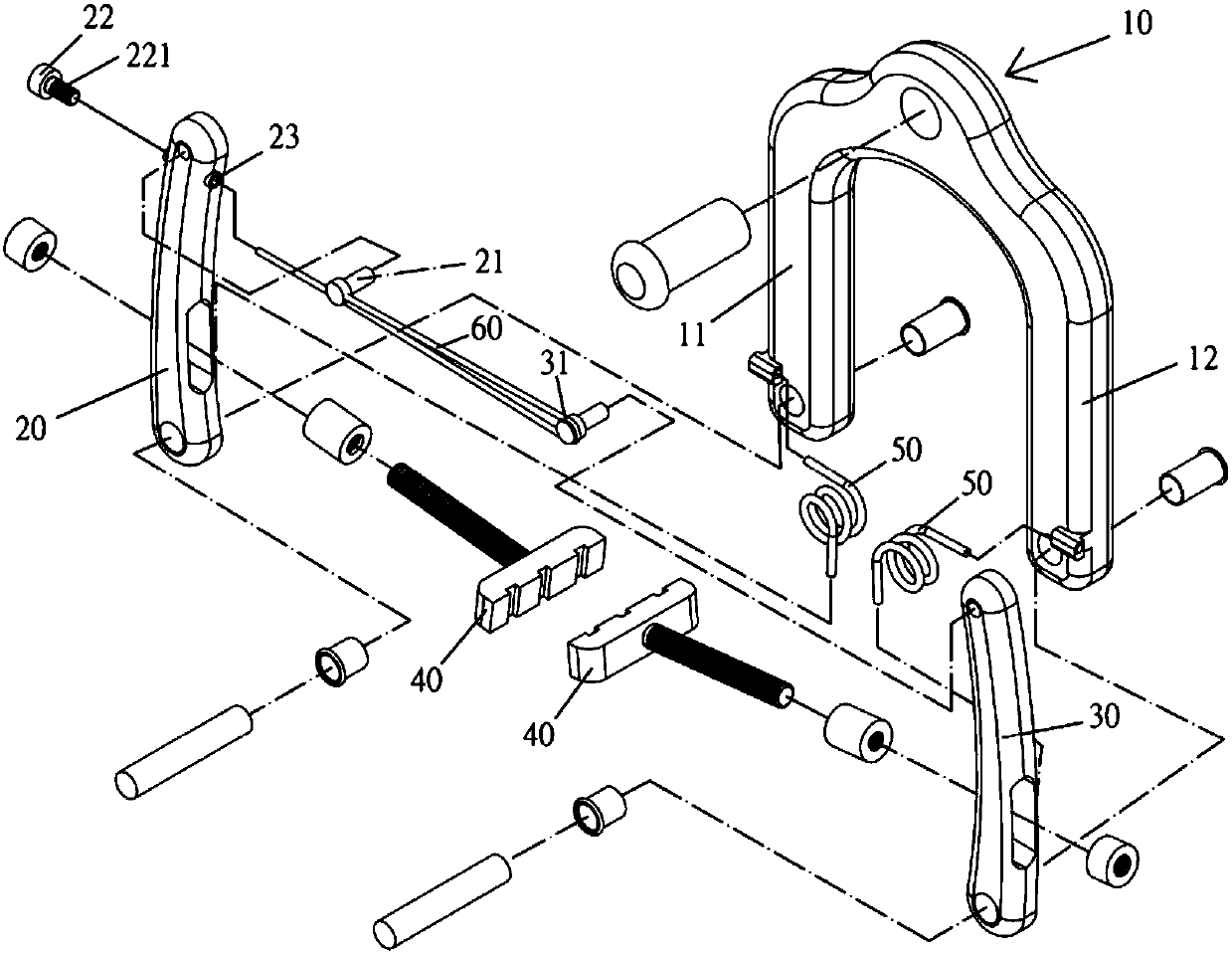

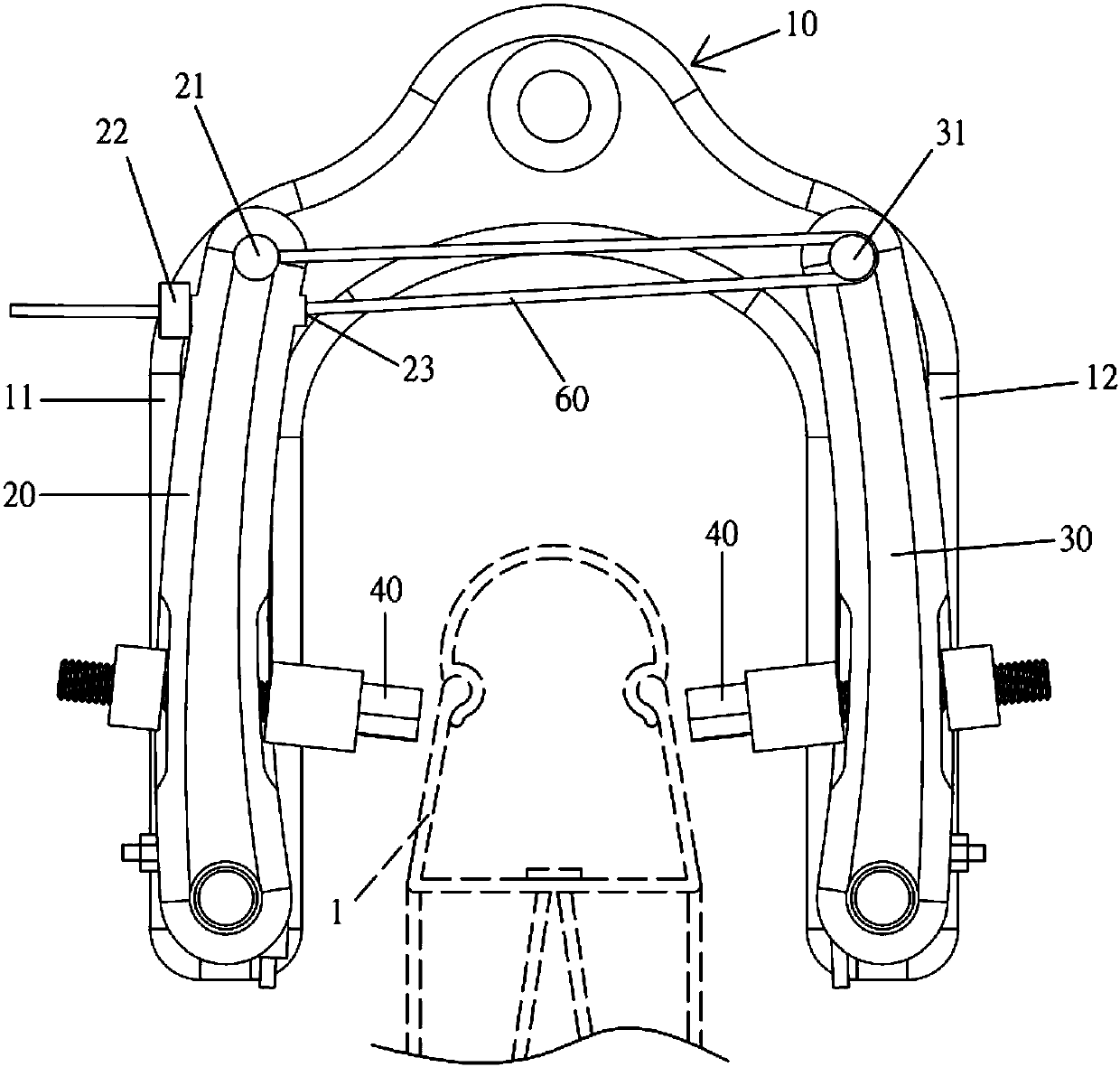

A bicycle brake

A bicycle brake us disclosed. The bicycle brake includes a base fixedly connected to a preset position of a bicycle frame at least through a fixing bar, and extending downward to form a first extending arm and a second extending arm. The first and second extending arms are at two sides of a rim correspondingly. Lower ends of the first and second extending arms are pivoted to lower ends of first and second clamping arms respectively. One side and an edge side of the upper end of the first clamping arm are fixedly connected to a fixing member and a wire hole member respectively. The upper end ofthe second clamping arm is pivoted to a pulley at the fixing member side. The first and second clamping arms are bonded to braking members respectively. Accordingly, the braking members can be abutted against two sides of the rim in a synchronous and balanced manner, coincident braking actions are achieved so that effective braking is achieved, and the assembling cost and machining cost when braking members are mounted to a bicycle frame are reduced.

Owner:陈逸伟

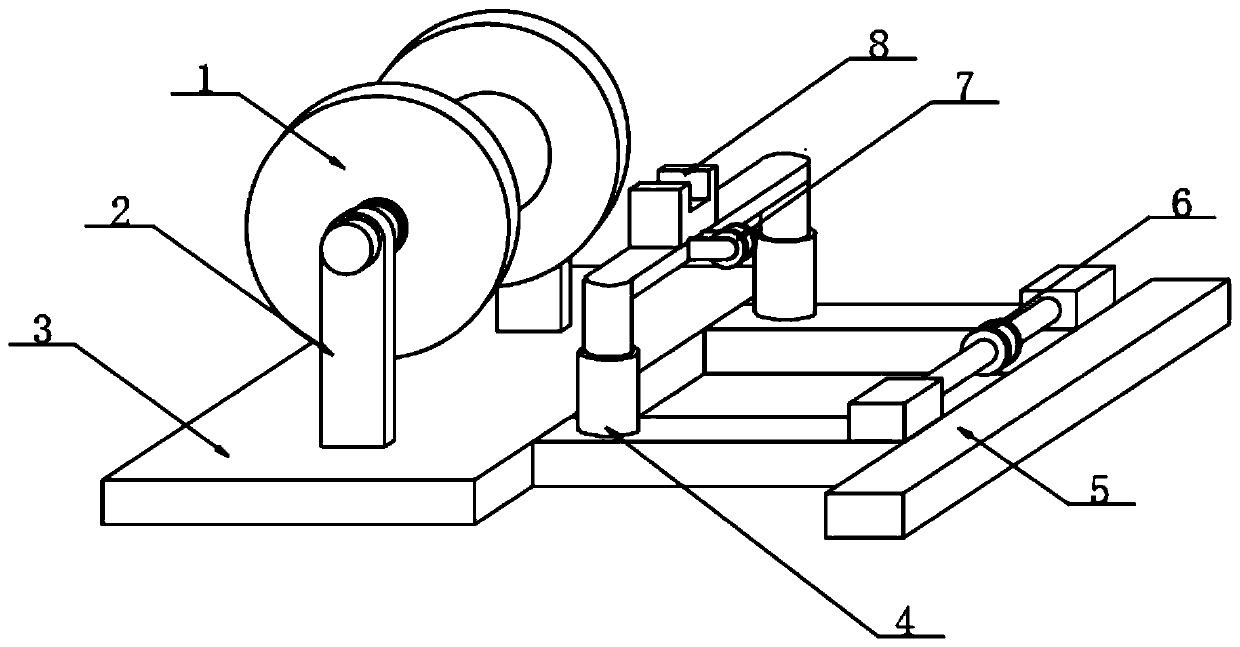

Cable shearing mechanism for power construction

ActiveCN111555173AControl precisionGuaranteed synchronous motionApparatus for cutting/splicing cablesClassical mechanicsMachine

The invention relates to the technical field of power construction, in particular to a cable shearing mechanism for power construction. The cable shearing mechanism comprises a chassis, a support is erected at the top of the chassis, and a rotating shaft is arranged on the support. A winding disc sleeves the rotating shaft, one side of the chassis is connected with a truss, and a telescopic rod isinstalled at the end, close to the chassis, of the truss. A shearing base is installed at the top of the telescopic rod, and a pressing wheel is installed at the top of the telescopic rod and is located at the bottom end of the shearing base. According to the cable shearing mechanism, the traditional manual shearing is changed into the machine shearing, personal injury caused by errors of workersis avoided, and meanwhile, it is ensured that a shearing surface is flat and smooth; it is ensured that the shearing mechanism moves faster than the clamping mechanism by controlling the tooth numberratio of transmission components of the clamping mechanism and the shearing mechanism, after the clamping mechanism is attached, the shearing mechanism is just attached to cut off, so that it is ensured that the cable is fixed and sheared, and the situation that the cable is extruded and damaged due to excessive force of the clamping mechanism, is also prevented.

Owner:NANJING NINGAN ELECTRIC POWER ENG CO LTD

Cyclic material containing system with automatic counting function

The invention discloses a cyclic material containing system with an automatic counting function. A conveying guide rail is arranged between an upper production line and a lower production line, a transmission guide rail is connected with the upper production line and the lower production, a guide nail is arranged on a connecting plate, a first air cylinder is arranged on guide plates, a first piston rod is fixed with the connecting plate, a support frame is arranged between the guide plates and the connecting plate, a first rotating pin is arranged between the support frame and the connecting plate, a second rotating pin is arranged between the guide plates and the support frame, a clamping system comprises mutually parallel support plates, the support plates are arranged between the guide plates, the guide plates are in contact with the support plates, the support plates are provided with through holes, a baffle plate is arranged in a groove, a second air cylinder is arranged on the support plates, and is connected with a control box, the control box is connected with the first air cylinder, and the transmission guide rail is connected with the guide plates. The cyclic material containing system has the advantages that the cyclic replacement on the box body is realized, the replacing efficiency is improved, the time difference does not occur in the replacing process, each box of workpieces can realize the automatic weighing counting, and the accurate number can be obtained.

Owner:SICHUAN RUITENG ELECTRONICS

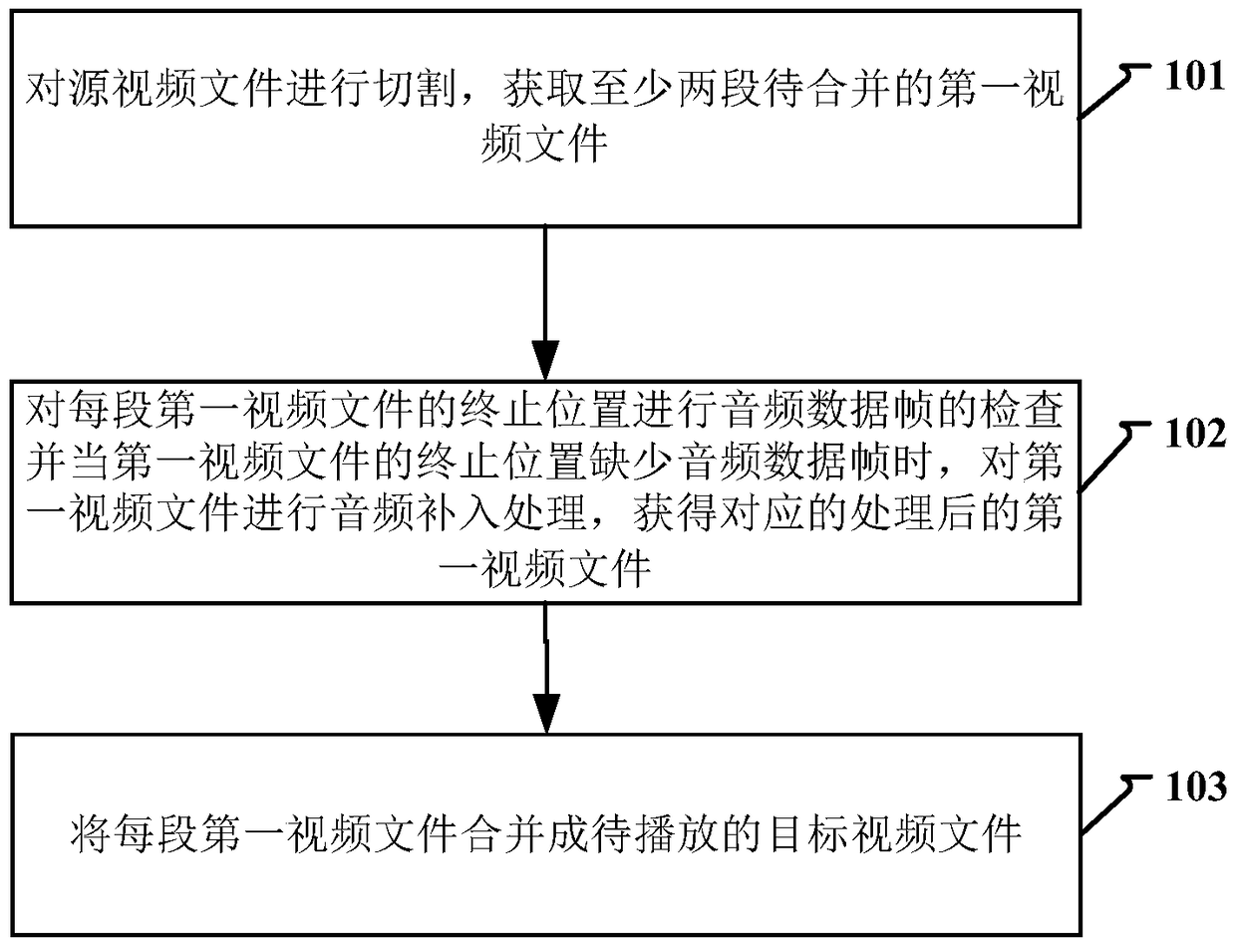

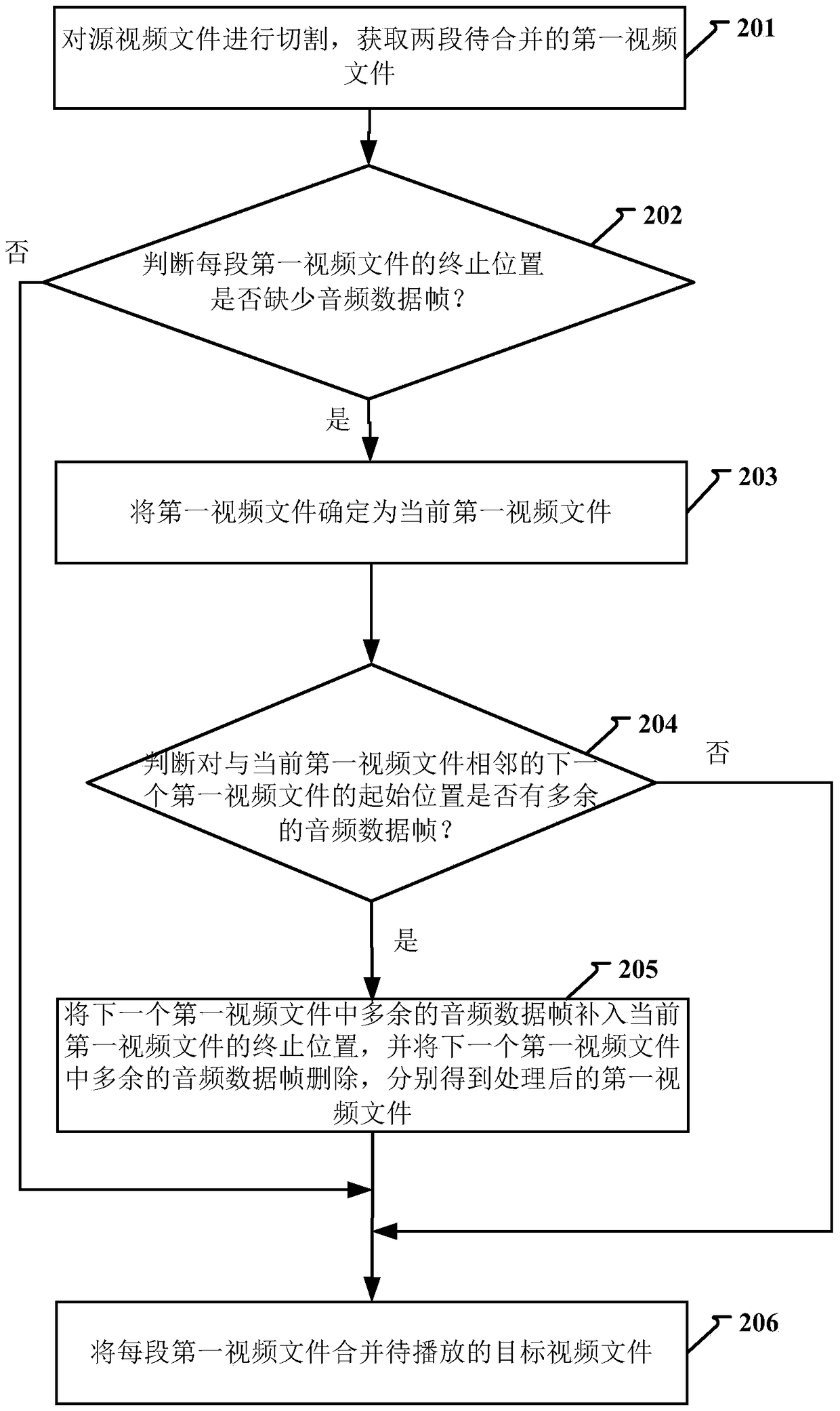

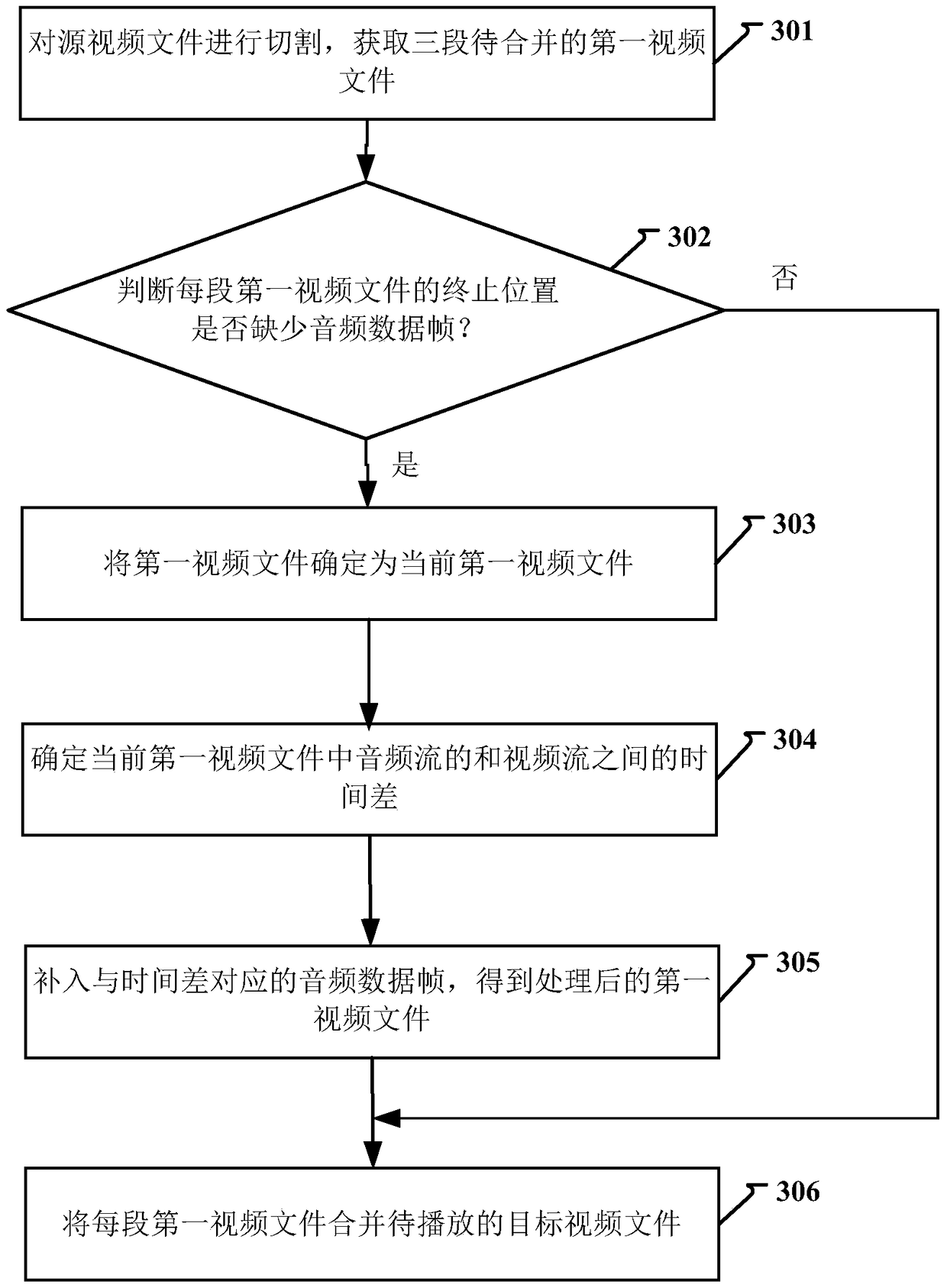

Method and device for video editing

InactiveCN105611401BImprove playback qualityNo time differenceSelective content distributionTime differenceVideo editing

Owner:WUXI TVMINING MEDIA SCI & TECH

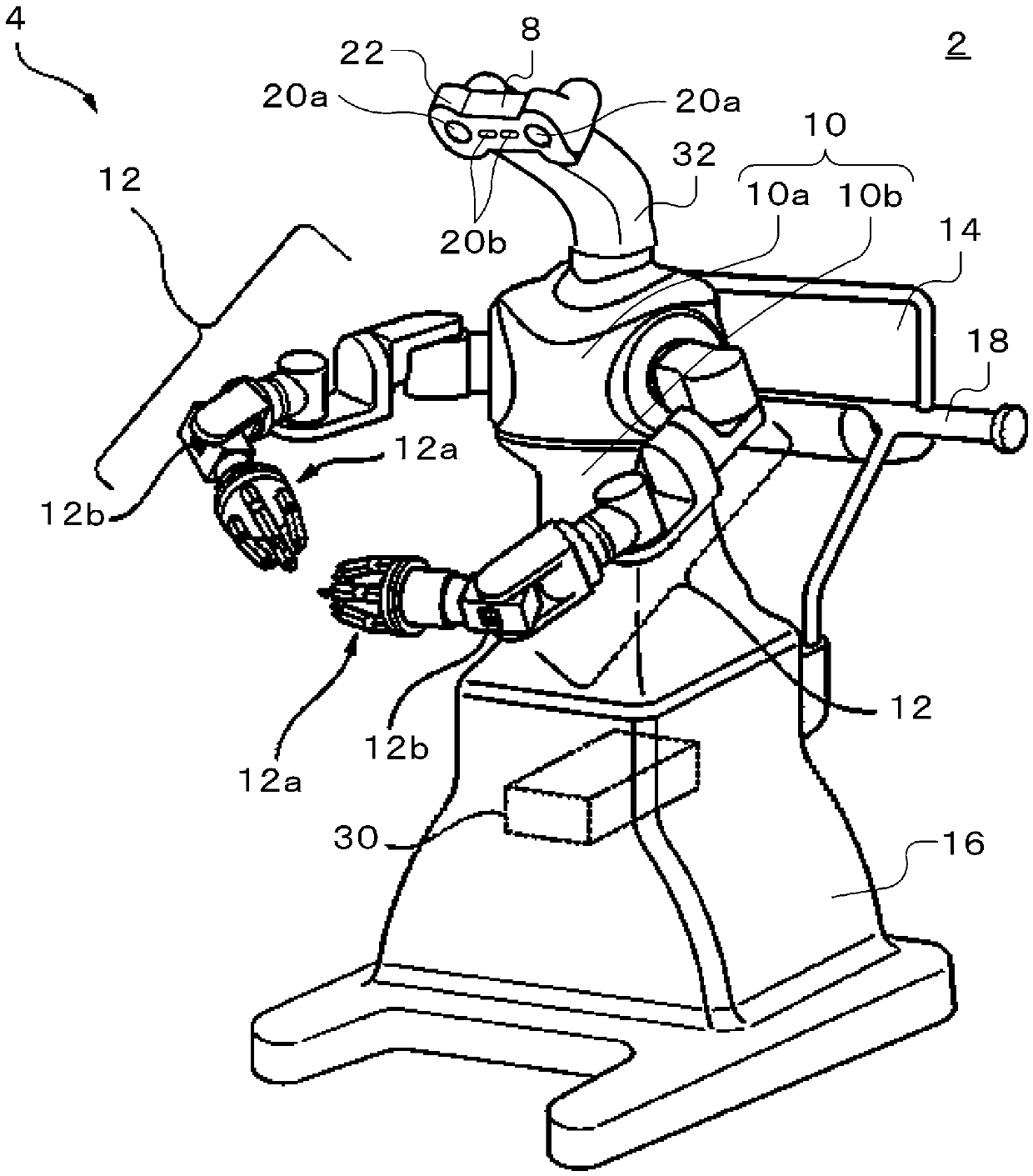

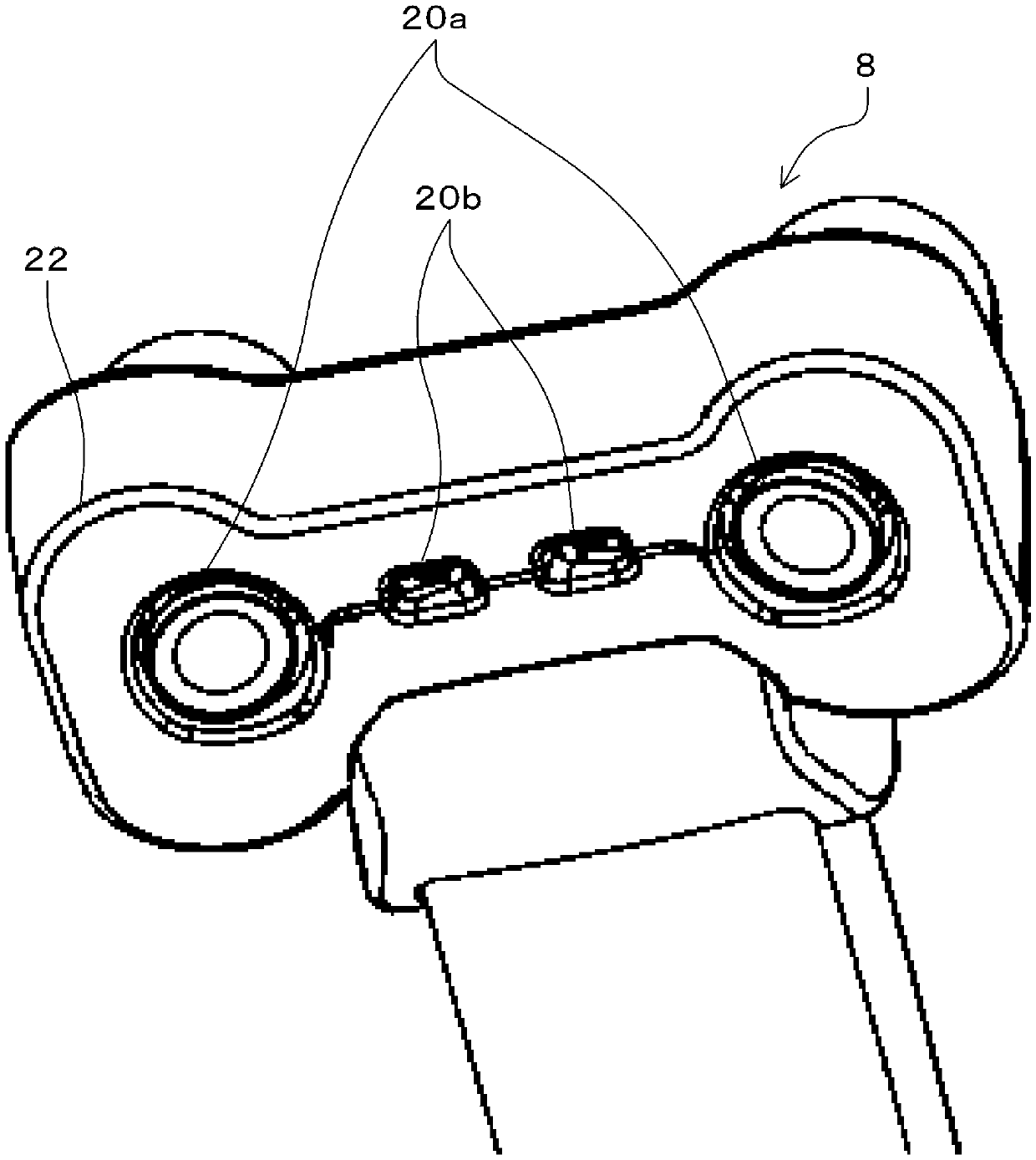

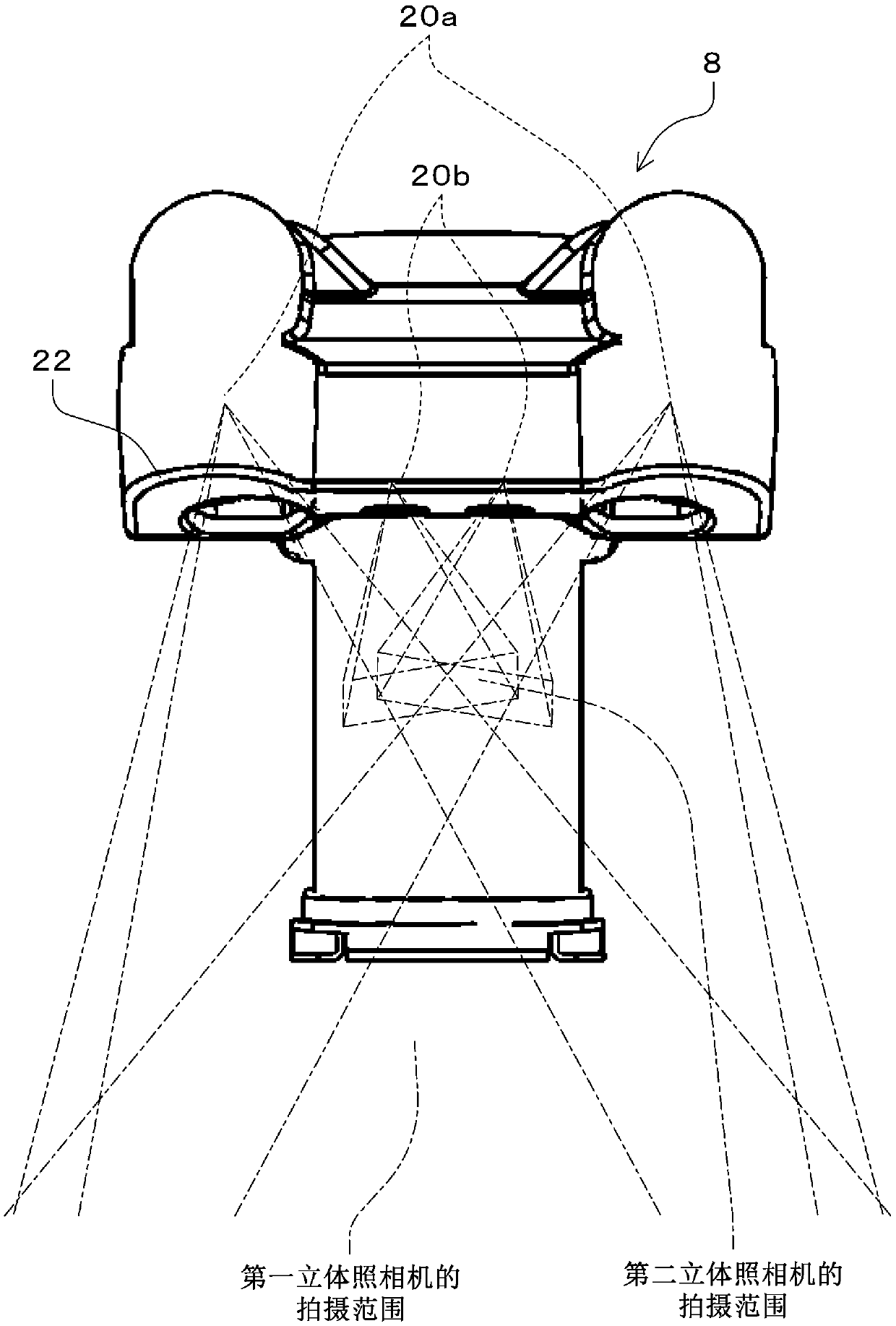

Robot and robot system

PendingCN109794961ANo time differenceProgramme controlProgramme-controlled manipulatorRobotic systemsStereo cameras

A robot includes a shoulder, an arm connected to the shoulder, an imaging device that is connected to the shoulder via a support, and an image receiver that receives a captured image captured by the imaging device, and a robot controller that controls the arm based on the captured image, and in which the imaging device is two sets of stereo cameras having different depths of field.

Owner:SEIKO EPSON CORP

Cable Partial Discharge Test Equipment Based on Optical Electric Field Sensor Voltage Phase Synchronization Technology

ActiveCN103809091BRandomFlexible measurement methodsTesting dielectric strengthElectric field sensorTransducer

The invention discloses test equipment for partial discharge of a cable based on a voltage phase synchronization technology of an optical electric field transducer. The test equipment comprises a handhold insulated tool and instrument, a high voltage BGO optical crystal, a high voltage optical fiber, a photoelectric conversion and output unit, a partial discharge test instrument and a synchronous signal transmission wire. The test equipment disclosed by the invention has the advantages that: the test equipment emphatically solves the difficulty in acquirement and synchronization of a voltage signal in a major network during live line test works of field high voltage equipment, is also applicable to any work that needs acquirement of the voltage signal during electrical test; the test equipment is simple and firm in structure, light in weight (less than 1kg), small in volume and convenient in operation on a basis that functional requirements are met, and is applicable to the requirements on live tests of equipment on a pole and a tower as well as ground equipment.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

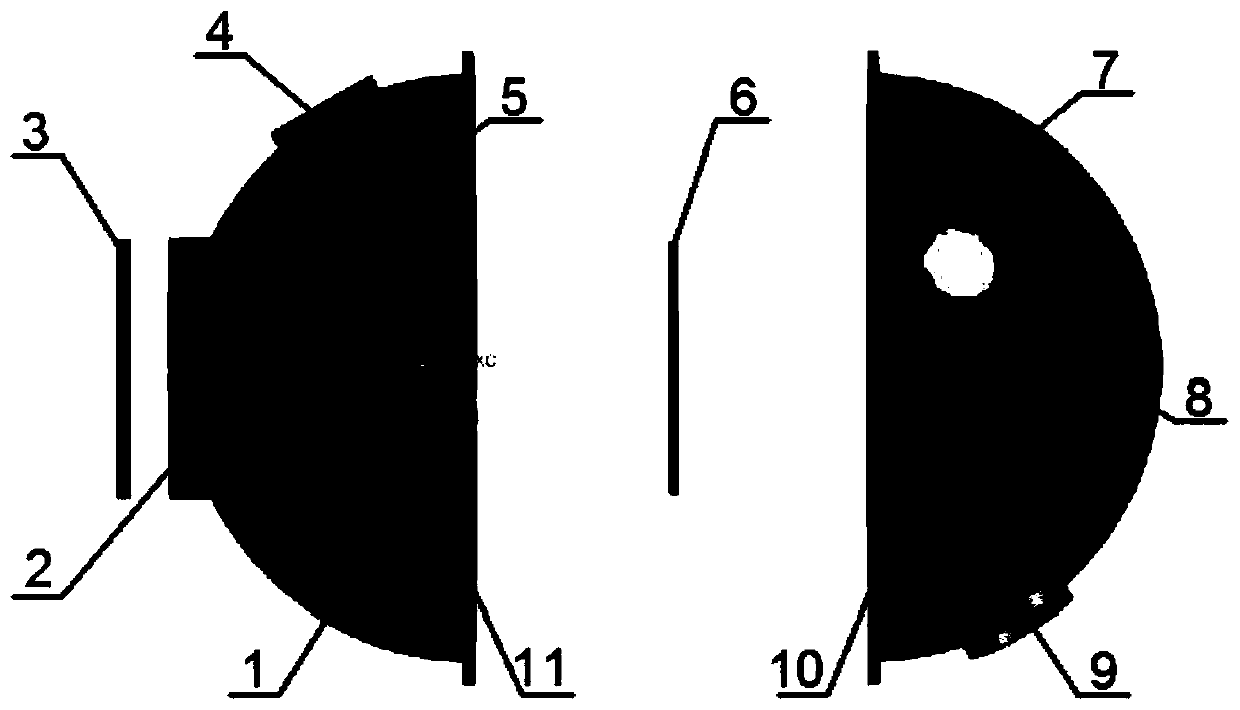

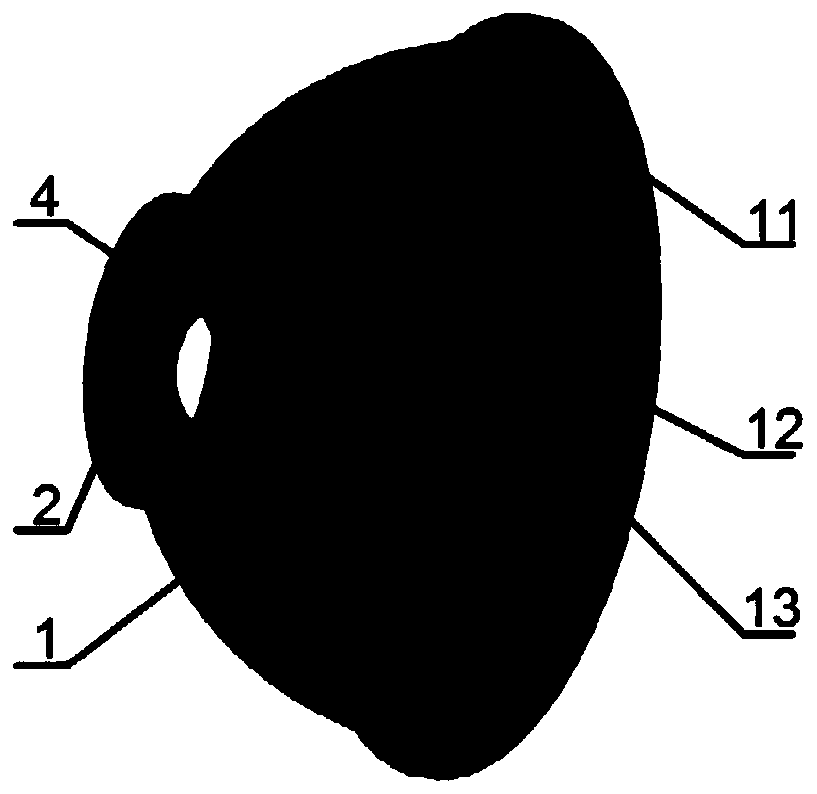

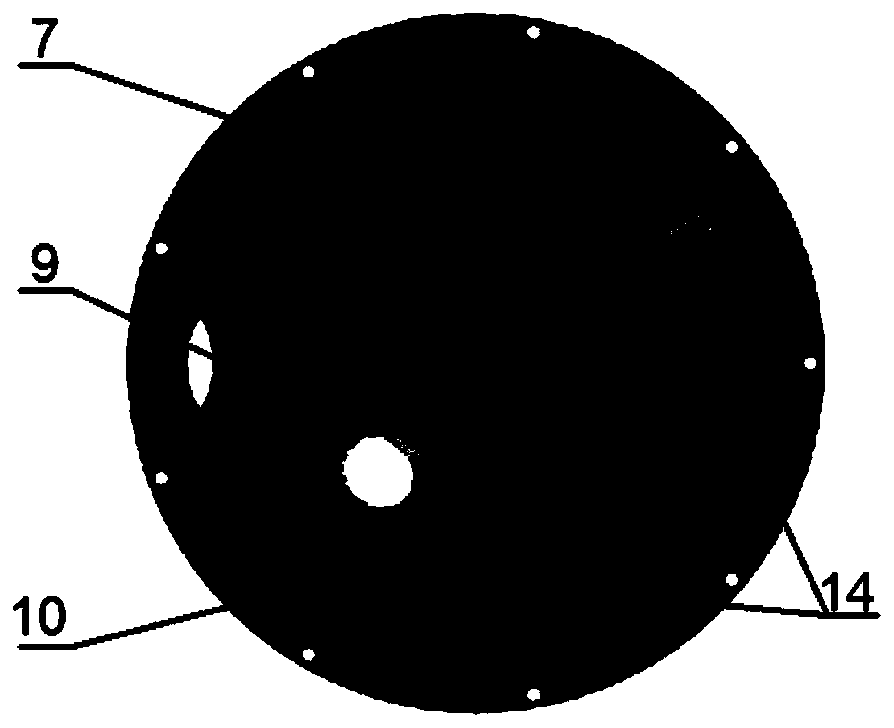

A two-chamber quasi-airtight container experimental device

The invention discloses a two-cabin type quasi closed container experiment device, which is mainly applied to the measurement of multifunctional energetic material impact energy release. The device comprises a front hemispheric shell, a first cylindrical ring, an annular cover plate, a front window, a front sensor mounting hole, a target plate fixed ring, a target plate, a rear hemispheric shell,a rear sensor mounting hole, a rear window, a second cylindrical ring, a third cylindrical ring, a front protective wind cap and a rear protective wind cap. The initial speed of a test sample is obtained through the loading modes such as a ballistic rifle and a light-gas gun, the test sample enters a container after penetrating through a thin iron plate, the target plate in the middle of the container is struck to perform a chemical reaction, and generated energy cause that the air pressure inside the container is increased. The pressure change is captured by using a sensor, and then the energy release level of the sample is balanced. The device has the advantage that the excess pressure values before and after the target are measured by a front hemispheric container and a rear hemisphericcontainer respectively, and time difference of data of the respective hemispheric containers does not exist in theory. The protective wind caps can preferably protect the sensor from being damaged bybroken plates.

Owner:NANJING UNIV OF SCI & TECH

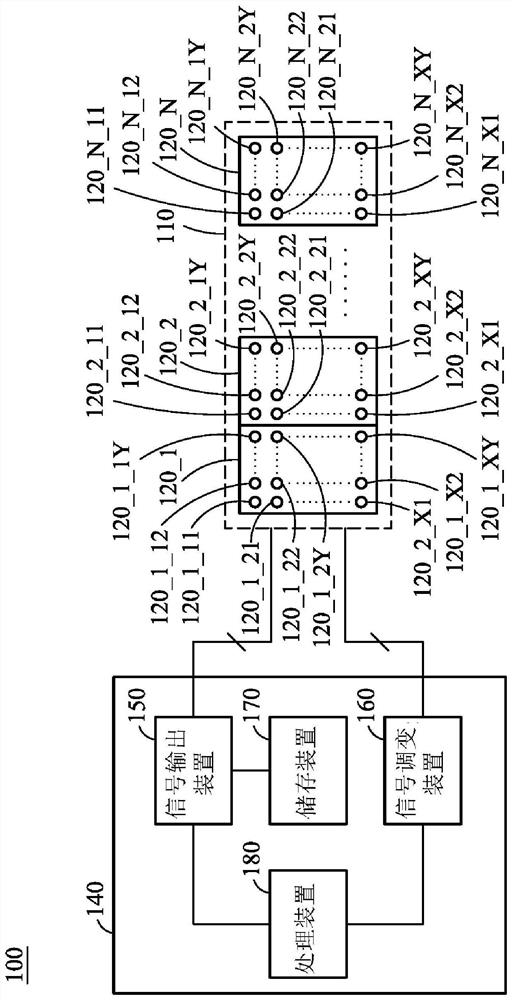

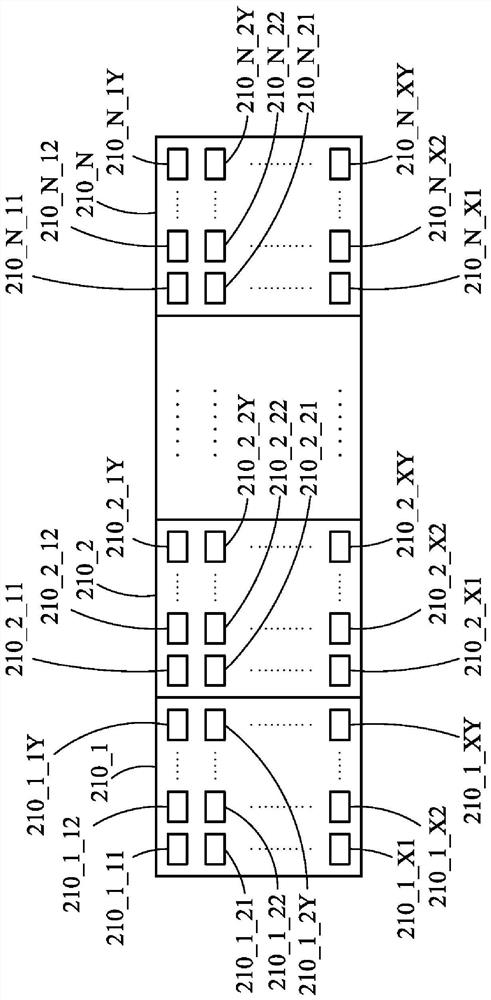

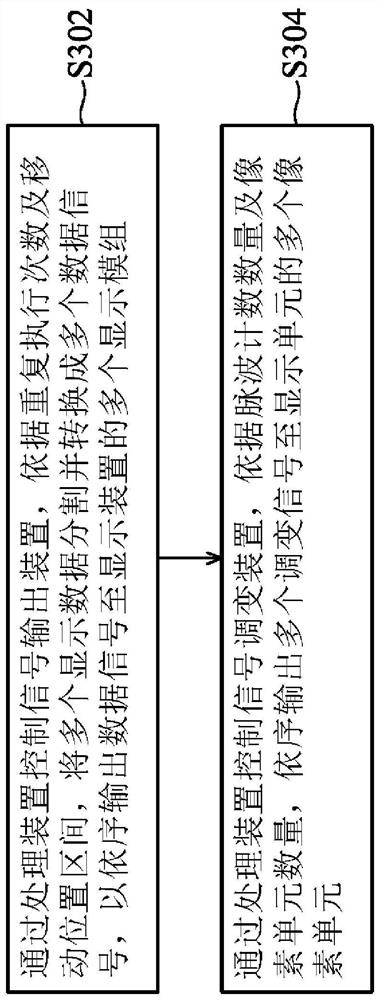

Control device, display device and operation method thereof

PendingCN112785968ANo time differenceReach transferStatic indicating devicesInput/output processes for data processingControl signalDisplay device

The invention provides a control device, a display device and an operation method thereof. The control device includes a signal-output device, a signal modulation device, a storage device, and a processing device. The signal-output device outputs a plurality of data signals. The signal modulation device outputs a plurality of modulation signals. The storage device is coupled to the signal-output device and stores a large amount of display data. The processing device is coupled to the signal-output device and the signal modulation device. The processing device controls the signal-output device so that the signal-output device divides the display data and transforms the display data into the data signals according to the repeat performing number and the moving position region, so as to sequentially output the data signals. The processing device controls the signal modulation device, so that the signal modulation device sequentially outputs the modulation signals according to the pulse wave counting number and the pixel unit number.

Owner:NUVOTON

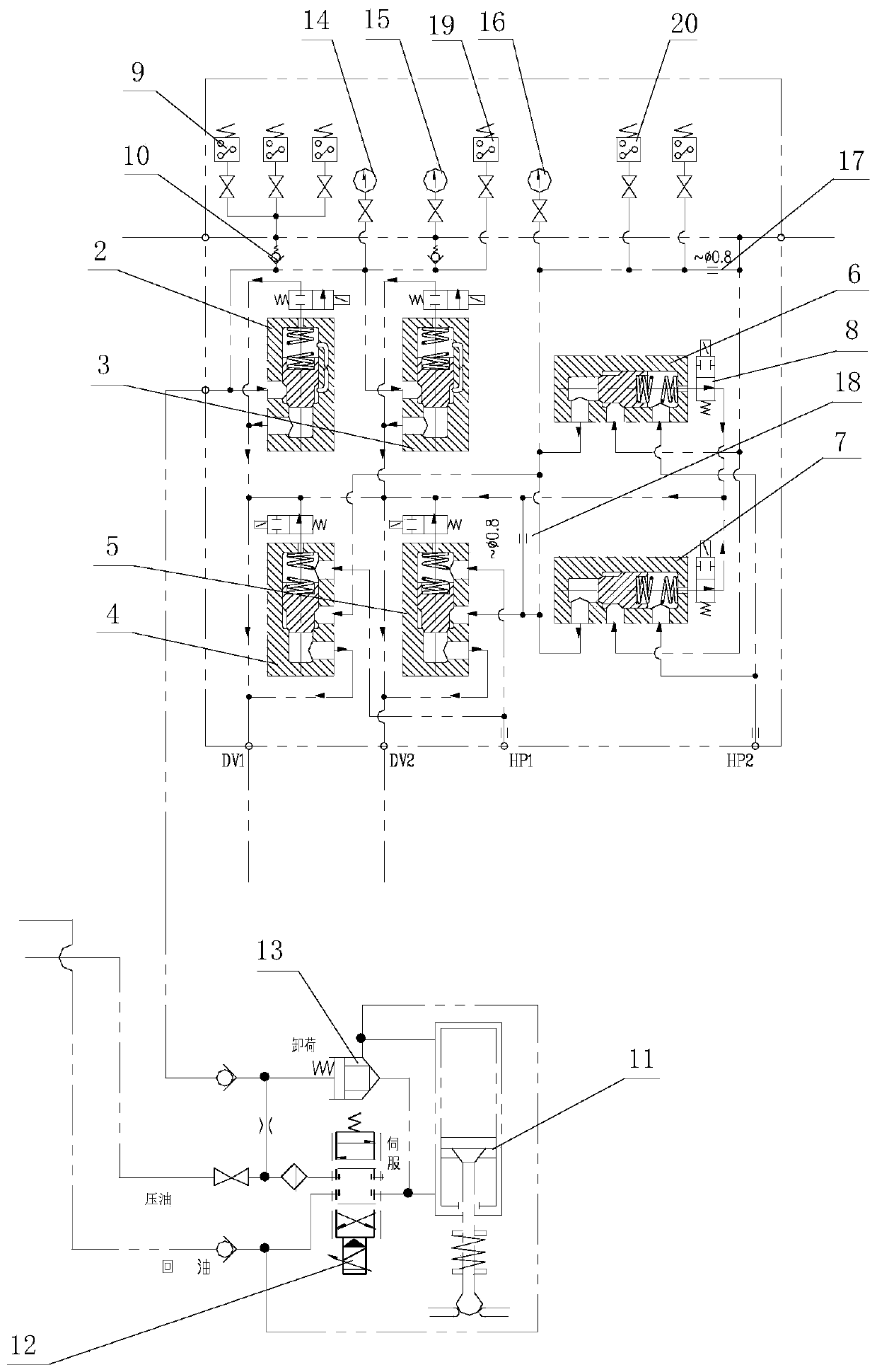

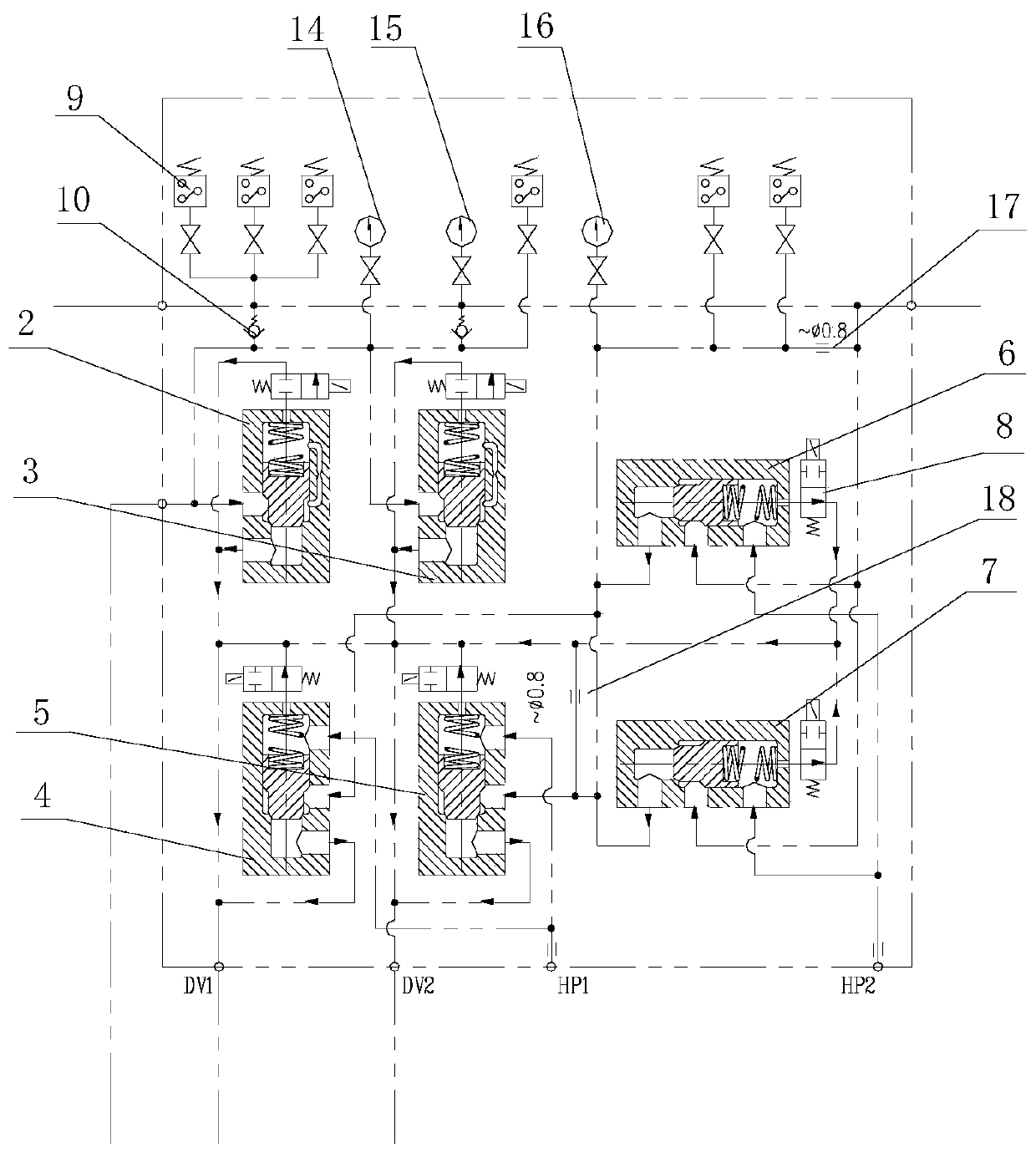

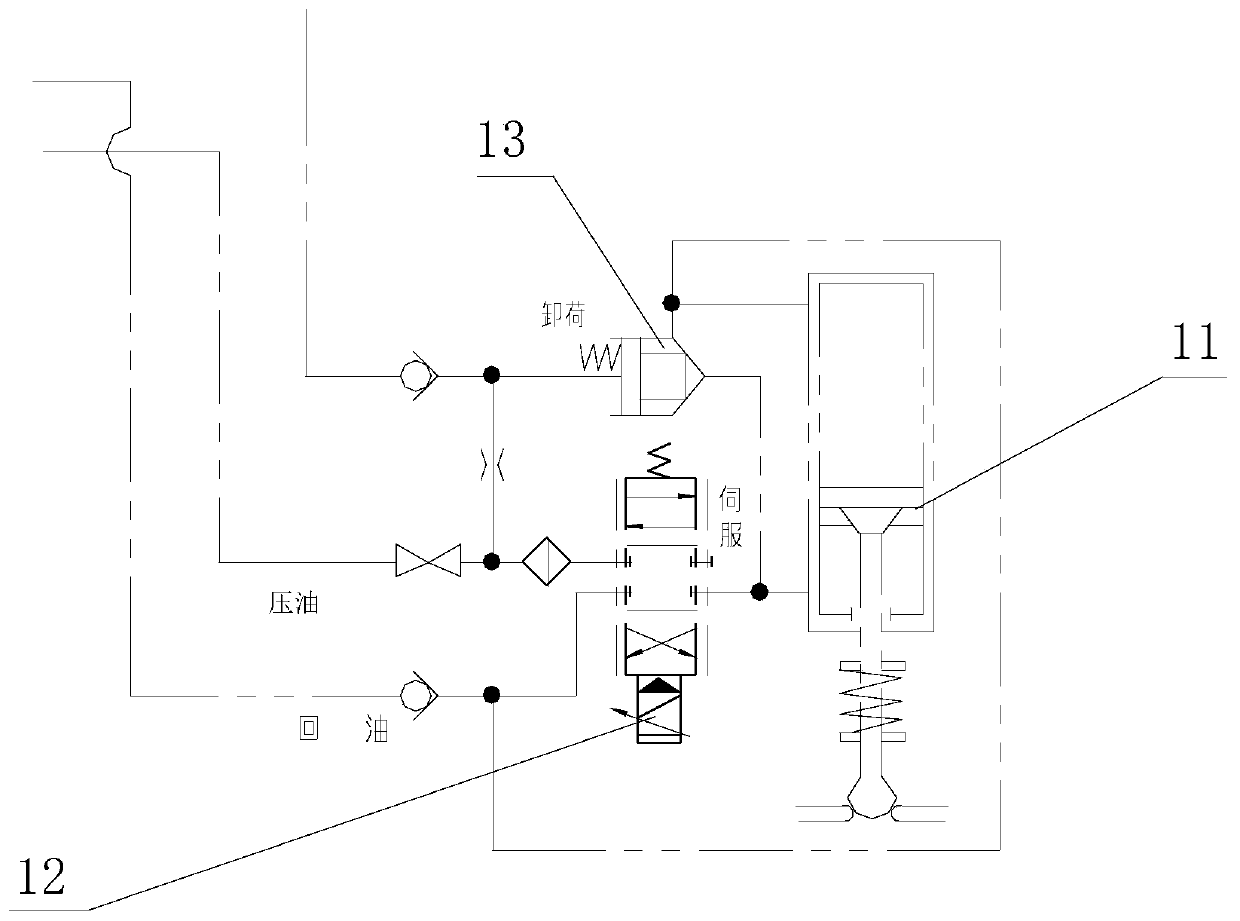

Valve hydraulic system

InactiveCN111594507AAvoid mistakesAvoid making mistakesFluid-pressure actuator safetyFluid-pressure actuator testingControl engineeringProcess engineering

The invention provides a valve hydraulic system. The valve hydraulic system comprises an electromagnetic main valve, a speed monitoring module, an overload protection module and a testing module, wherein the electromagnetic main valve is connected with an executing mechanism, an unloading valve is arranged on a bypass of the electromagnetic main valve, the unloading valve is used for unloading hydraulic oil in an emergency state, the electromagnetic main valve is independently connected with the speed monitoring module and the overload protection module, the speed monitoring module is connected with a speed protection switch, the overload protection module is connected with an overload protection switch, and the test module is connected with a test protection switch. According to the valvehydraulic system, when forging and pressing work is conducted, the high forging and pressing quality is achieved, the forging and pressing efficiency can be improved, and finally, accurate matching with a manipulator in time is achieved, so that errors of forged and pressed parts caused by the fact that the forged and pressed parts are not in place are avoided, and the quality is improved; and maintenance personnel can be guided to overhaul the designated position, the maintenance speed is increased, the downtime of forging and pressing equipment is shortened, and the productivity of the forging and pressing equipment is increased.

Owner:常州市瑾瑜精密科技有限公司

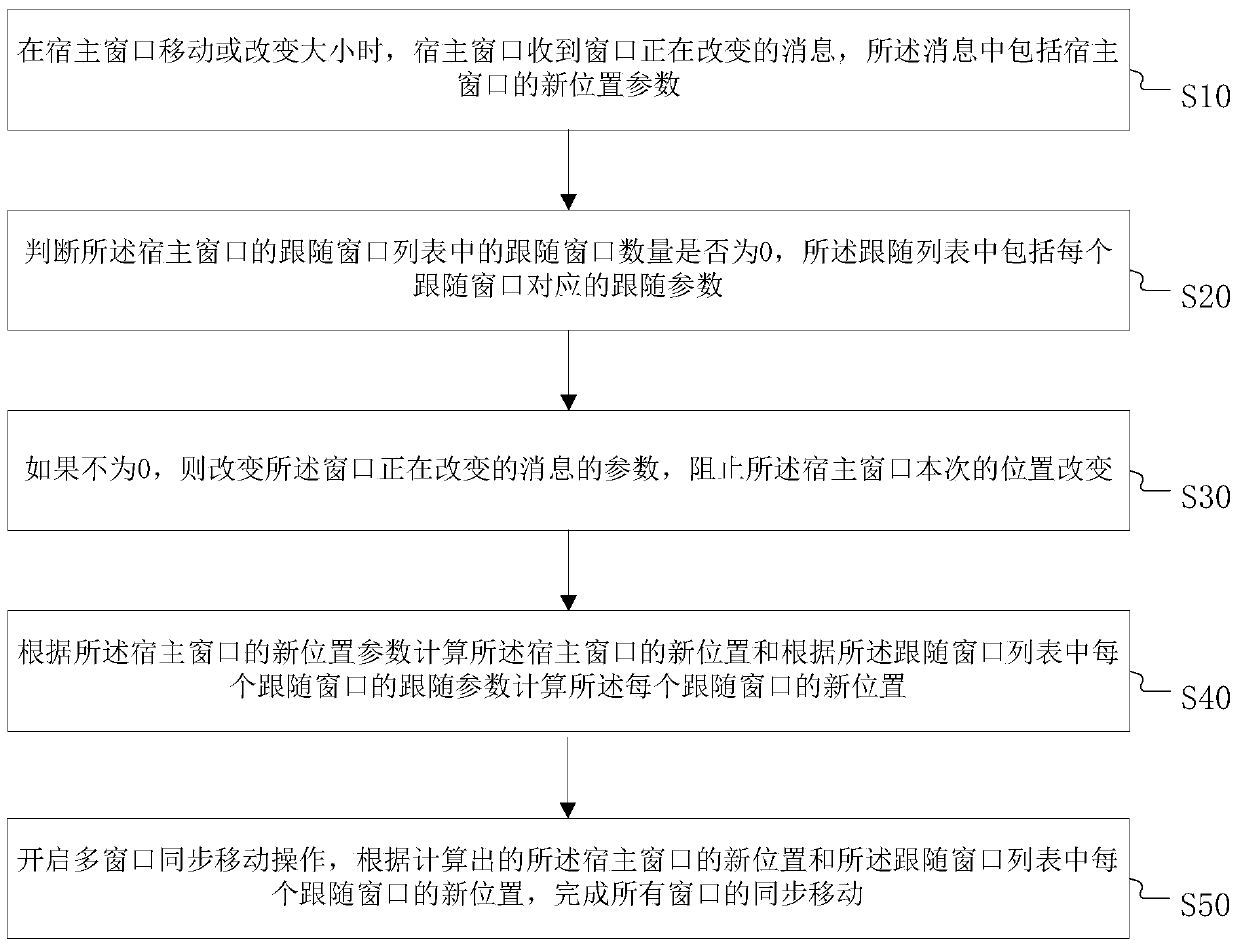

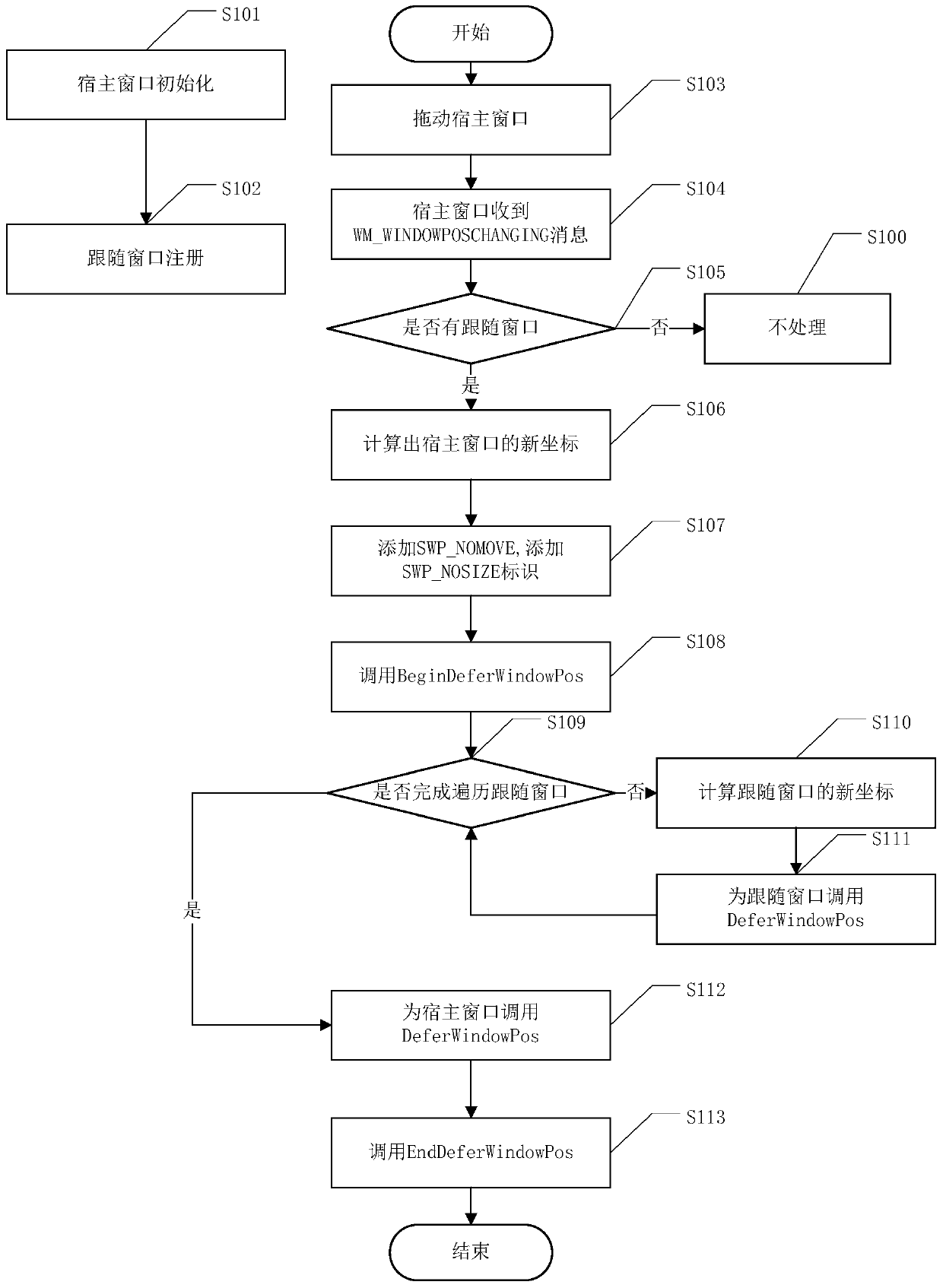

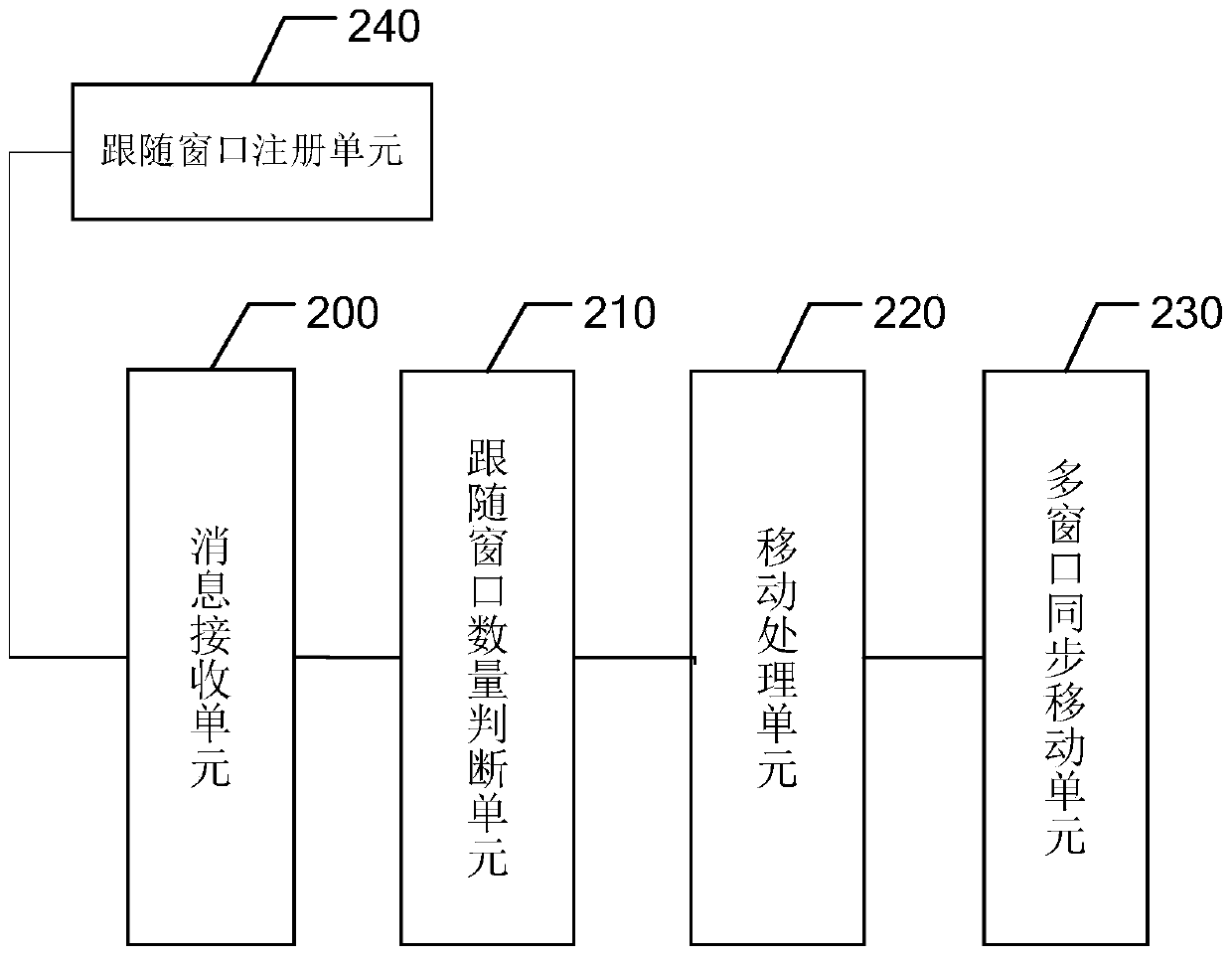

A method and device for realizing synchronous movement of multiple windows

ActiveCN106484212BSolve the problem of following out of syncNo time differenceInput/output processes for data processingComputer hardwareTime difference

The invention discloses a method and an apparatus for realizing synchronous movement of multiple windows. The method comprises the steps of receiving a message that a window is being changed by the host window when the host window moves or is changed in size, wherein the message comprises new position parameters of the host window; judging whether the number of following windows in a following window list of the host window is 0 or not, wherein the following list comprises following parameters corresponding to the following windows; if the number of the following windows is not 0, changing parameters of the message that the window is being changed, and preventing change of the current position of the host window; and enabling a multi-window synchronous movement operation, and finishing synchronous movement of all windows according to the calculated new position of the host window and new positions of the following windows in the following window list. According to the method and the apparatus, the problem of a time difference of movement among the windows in an existing multi-window movement scheme is solved, so that all the windows can be updated in position at the same time.

Owner:BEIJING FEINNO COMM TECH

Circulation filling system with automatic counting function

The invention discloses a cyclic material containing system with an automatic counting function. A conveying guide rail is arranged between an upper production line and a lower production line, a transmission guide rail is connected with the upper production line and the lower production, a guide nail is arranged on a connecting plate, a first air cylinder is arranged on guide plates, a first piston rod is fixed with the connecting plate, a support frame is arranged between the guide plates and the connecting plate, a first rotating pin is arranged between the support frame and the connecting plate, a second rotating pin is arranged between the guide plates and the support frame, a clamping system comprises mutually parallel support plates, the support plates are arranged between the guide plates, the guide plates are in contact with the support plates, the support plates are provided with through holes, a baffle plate is arranged in a groove, a second air cylinder is arranged on the support plates, and is connected with a control box, the control box is connected with the first air cylinder, and the transmission guide rail is connected with the guide plates. The cyclic material containing system has the advantages that the cyclic replacement on the box body is realized, the replacing efficiency is improved, the time difference does not occur in the replacing process, each box of workpieces can realize the automatic weighing counting, and the accurate number can be obtained.

Owner:SICHUAN RUITENG ELECTRONICS

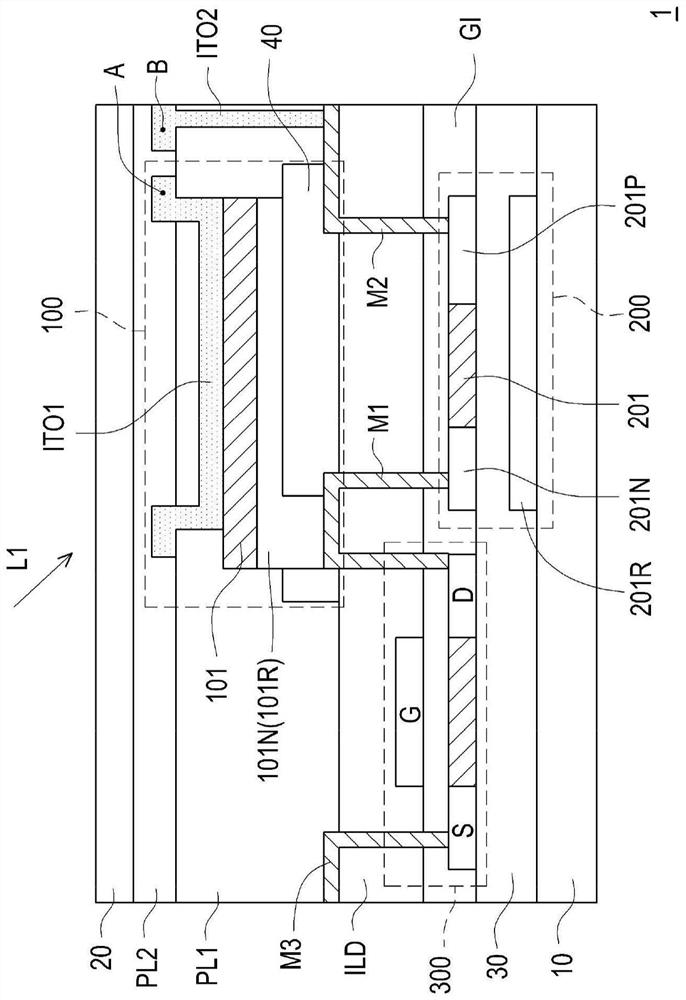

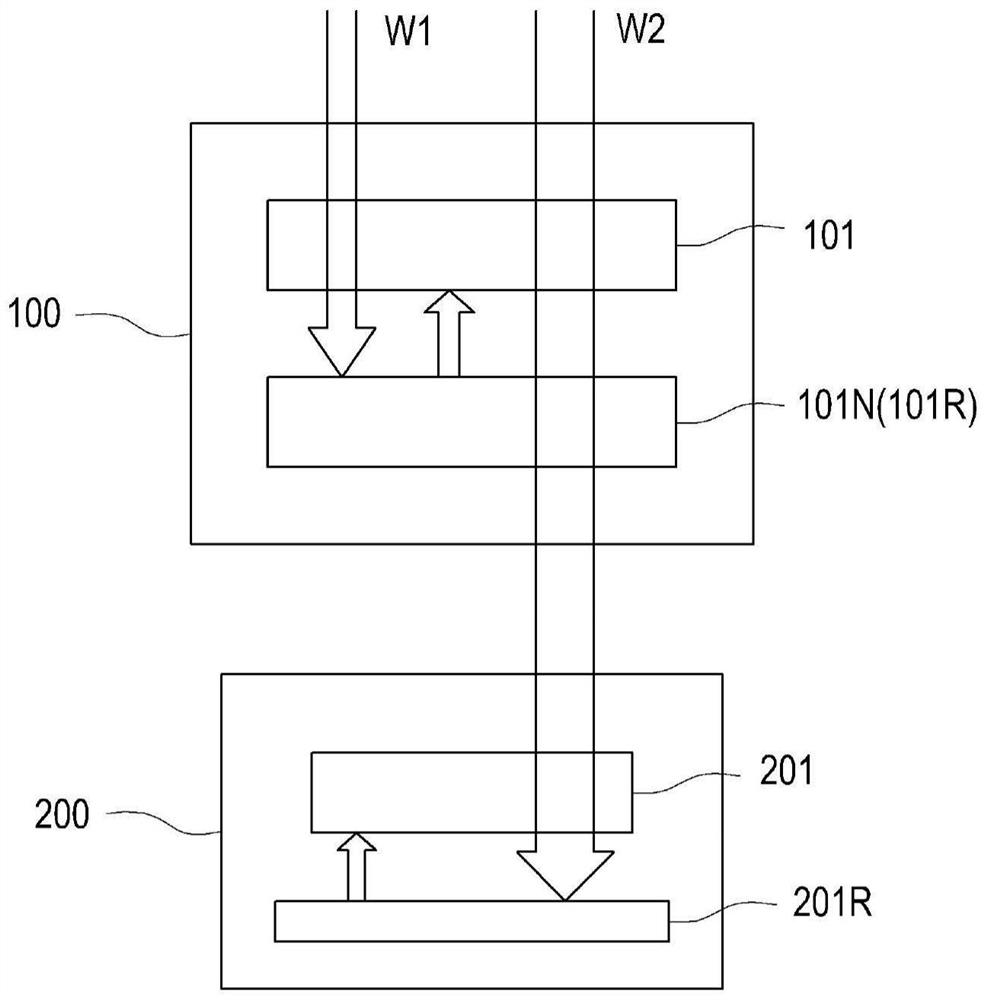

Light detection device

PendingCN114383722AReduce in quantityReduce pixel areaSpectrum investigationPhotometry electrical circuitsPhotodetectorActive layer

A light detection device includes a substrate, a first light detector, a second light detector, and a switching element. The first photodetector is disposed on the substrate and includes a first active layer. The second photodetector is disposed between the substrate and the first photodetector, and the second photodetector includes a second active layer. The switch element is arranged on the substrate. The horizontal projection of the second active layer on the substrate completely falls within the horizontal projection of the first active layer on the substrate, and the negative electrode of the first light detector and the negative electrode of the second light detector are electrically connected with the switch element through the first metal layer.

Owner:AU OPTRONICS CORP

Flat tire control protection method

InactiveCN103568740ANo time differenceOvercoming the Insufficiency of Explosion-proof MeasuresTyre measurementsFlat tireAutomotive engineering

The invention discloses a flat tire control protection method. The flat tire control protection method comprises a solid tire body, a supporting fixed base and a connecting piece, wherein the solid tire body is a circular tire body which is made of foam material and is arranged outside an automobile hub and inside an automobile outer tire; the supporting fixed base is arranged between the automobile hub and the solid tire body and is sleeved on the automobile hub, the width of the supporting fixed base and the width of the solid tire body are consistent, and the supporting fixed base is composed of left and right round tire bases through combination; each tire base is composed of two half-round fission tire bases through the combination, the appearance of the connecting piece is of a V shape, and the connecting piece is provided with three connecting holes, is fixed on the solid tire body by two of the connecting holes and is fixed on the supporting fixed base by the other connecting hole. The supporting fixed base provided by the invention has the advantage that the running security of an automobile is improved.

Owner:代刚

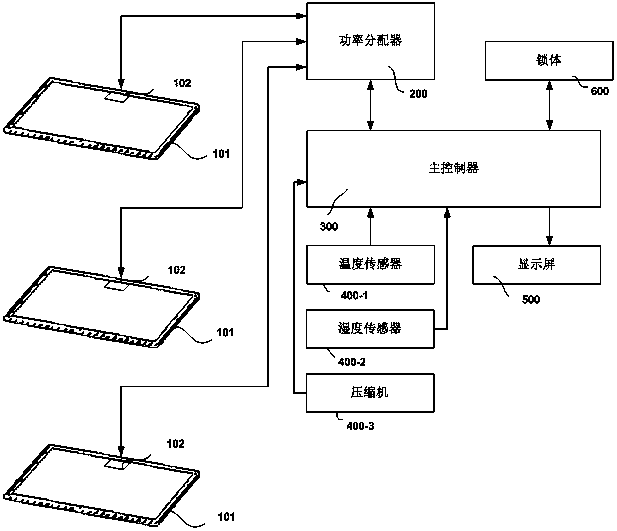

Intelligent refrigerator based on Internet of Things and refrigerator system

ActiveCN108204697ANo time differenceNo phase differenceLighting and heating apparatusDomestic refrigeratorsThe InternetEngineering

The invention discloses an intelligent refrigerator based on the Internet of Things. A refrigerating space is formed in the refrigerator; multiple supporting plates are arranged in the refrigerating space, and a complete reader antenna body is arranged on the edge of each supporting plate in a surrounding mode; the intelligent refrigerator further comprises a main controller and antenna controllers arranged on the reader antenna bodies in a matching mode, the main controller outputs set power to a power divider, and multiple output ports of the power divider output an average value of the setpower to the multiple antenna controllers in the same phase; and commodities placed on the supporting plates are each provided with a tag, the antenna controllers drive exciting magnetic fields formedby the reader antenna bodies to activate internal circuits of the tags, the multiple antenna controllers simultaneously receive identifies of the tags in the corresponding antenna magnetic field ranges and output the identifies from the tags to the main controller through the power divider in the same phase, and the main controller decodes the identifies. The invention further discloses a refrigerating system. The intelligent refrigerator has the good practicability.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

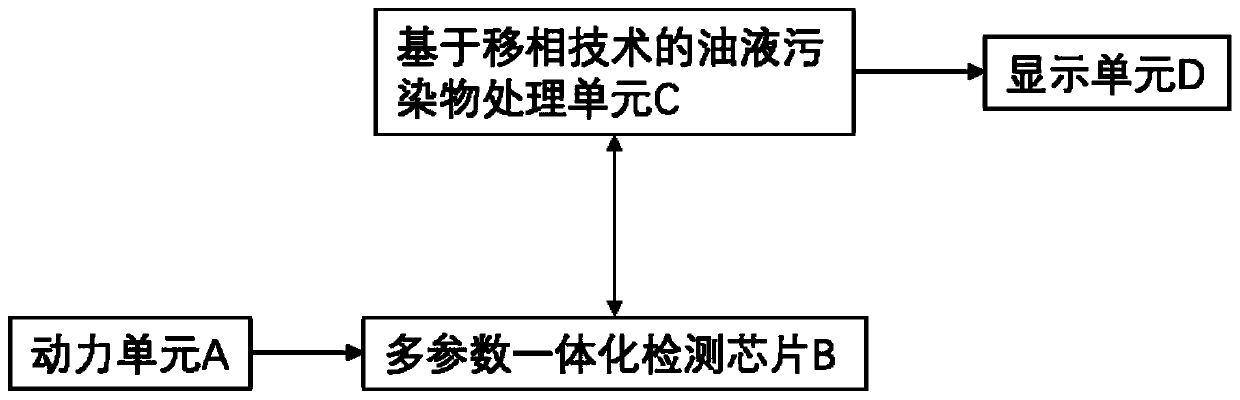

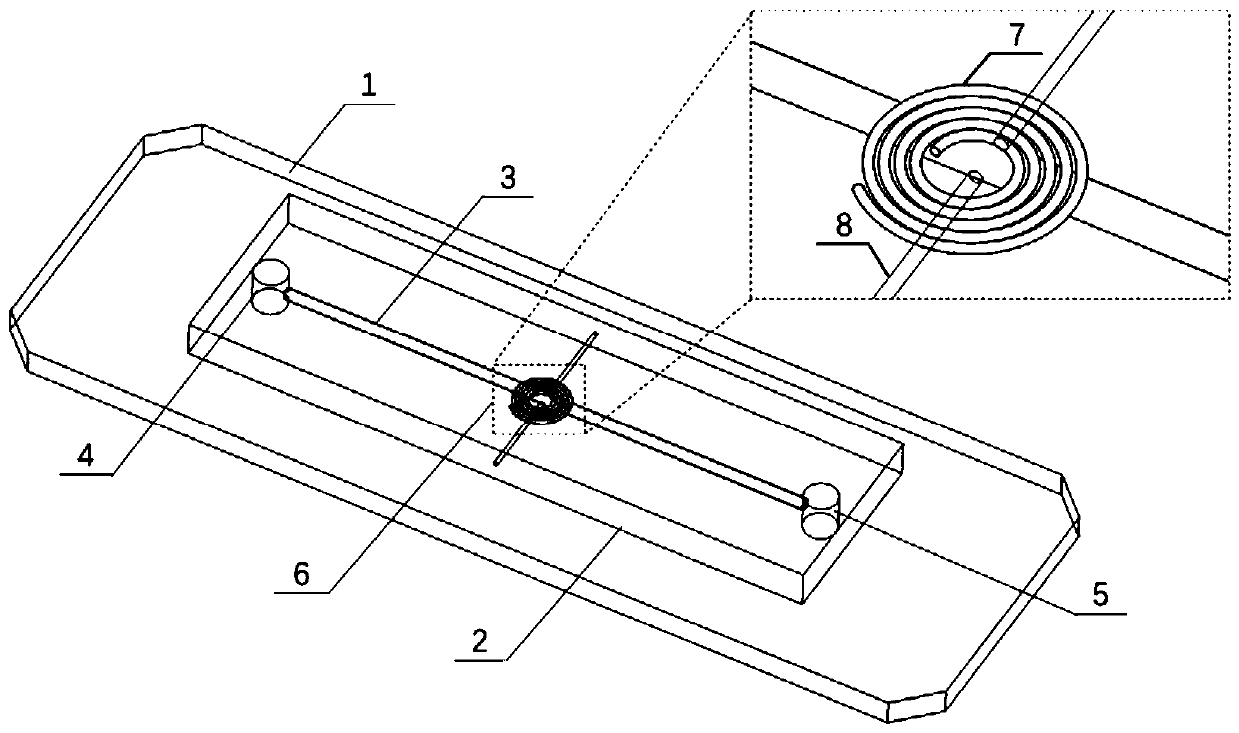

Oil pollutant multi-parameter integrated detecting device and method based on phase shifting technology

PendingCN110426426ARealize differentiated detectionEasy to detectMaterial capacitanceCapacitanceInductance

The invention relates to an oil pollutant multi-parameter integrated detecting device and method based on the phase shifting technology. In the prior art, unknown oil pollutants cannot be distinguished or detected, only one or two known oil pollutants can be distinguished and detected, and the actual detection and application requirements cannot be met. The inductance detection and capacitance detection can be conducted on each known oil pollutant at the same time, an inductance output curve corresponding to inductance output signals and a capacitance output curve corresponding to capacitanceoutput signals of each pollutant are obtained, and the known oil pollutants can be distinguished, detected and counted by comprehensively analyzing the inductance output curves and the capacitance output curves of the pollutants. An inductance detection object and a capacitance detection object are the same, and the inductance detection and capacitance detection can be conducted at the same time without time difference. The oil pollutant detection cost is reduced, the detecting device is simple, the detecting result is reliable, and the actual detection and application requirements are met.

Owner:DALIAN MARITIME UNIVERSITY

Welding head of electric spot welding machine

InactiveCN101244490AExtended service lifeReduce energy lossElectrode featuresWelding/cutting media/materialsPower flowEngineering

The invention discloses a welding head of electric spot welding machine. The welding head is a cylindrical metal bar with high melting point which is cleaved along the middle to form the leading parts of two electrodes. The bottom of the welding head has a reserved part heating element which is connected to form a heating element. The leading parts as well as the middle heating element form a current circuit. Because the material of the heating element is the same as the material of the leading parts and the cross-sectional area of the heating element is smaller than the cross-sectional area of the leading parts, the resistivity of the heating element is higher. When current flows along the heating element, high temperature due to the electric-thermal conversion accomplishes welding. A chamfer transition is arranged between the welding planar and the lateral face of the welding head. The area of the welding planar is near or equal to the area of the middle heating element. The heat energy is equably and intensively distributed on the hot side. The welding head has an advantage that: the welding head of spot welding has stable welding quality and long service life, and requires less maintenance.

Owner:吴云龙

System for replacing workpiece accommodating boxes in automatic cycle manner

The invention discloses a system for replacing workpiece accommodating boxes in an automatic cycle manner. Conveying guide rails are arranged between an upper production line and a lower production line, and are connected with the upper production line and the lower production line; guiding nails are arranged on connecting plates; the guiding plates are provided with cylinders I; piston rods I are fixed with the connecting plates; support frames are arranged between the guiding plates and the connecting plates; rotating pins I are arranged between the support frames and the connecting plates; rotating pins II are arranged between the support frames and the guiding plates; clamping systems include mutually parallel support plates; the support plates are arranged between the guiding plates; the guiding plates are in contact with the support plates; the support plates are provided with through holes; baffles are arranged in grooves; cylinders II are arranged on the support plates, and are connected with control boxes; the control boxes are connected with cylinders I; the conveying guide rails are connected with the guiding plates. Through the adoption of the system, boxes can be replaced in a cyclic manner, so that the replacing efficiency is improved, the labor intensity of operating staff is reduced, time difference during replacement is avoided, and workpieces can be completely collected.

Owner:SICHUAN RUITENG ELECTRONICS

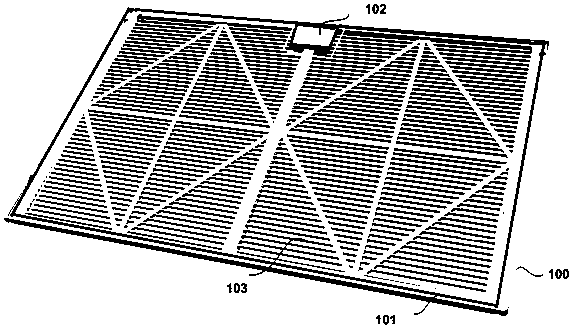

Display driving module with multi-path display output, mainboard, and method multi-path display output

InactiveCN100397471CNo time differenceCathode-ray tube indicatorsDigital videoDigital analog converter

It is a kind of display drive module and method that with multiple display output. It can solve the problem that single display drive module cannot drive multiple displays. The display drive module can process and convert multiple image signals that in image memory to multiple digital video signals and output them by image processing controller. The output of image processing controller connects to multiple analog-digital converter, which can convert the digital video signal to analog R, G, B signal and output them. The output of each analog-digital converter connects to display, and enables the displays to display the image data according to the received signal. So this single display drive module drives multiple displays and updates image of them simultaneously.

Owner:VIA TECH INC

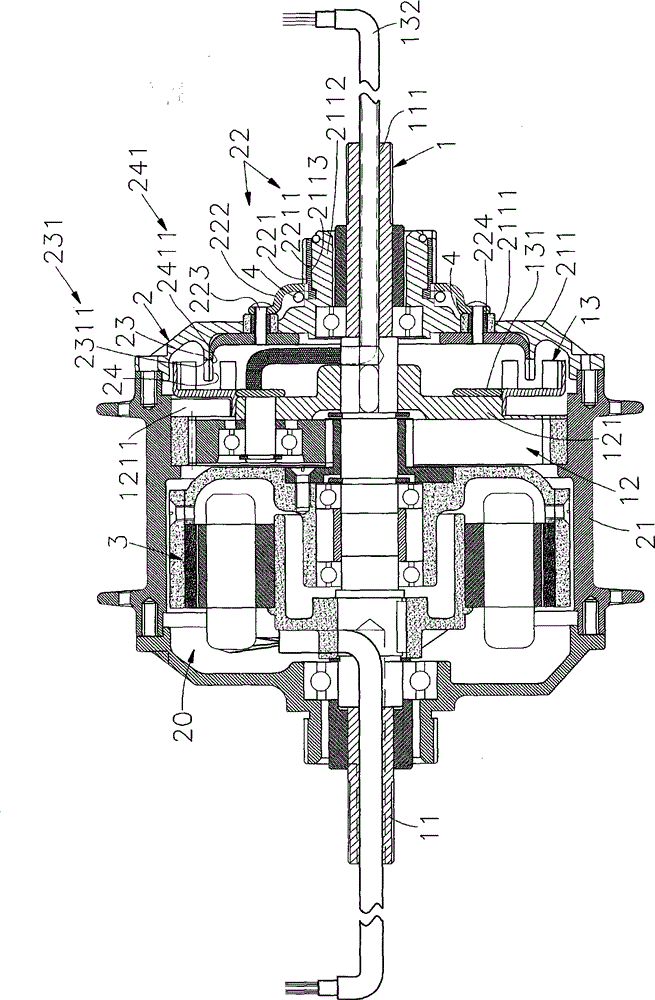

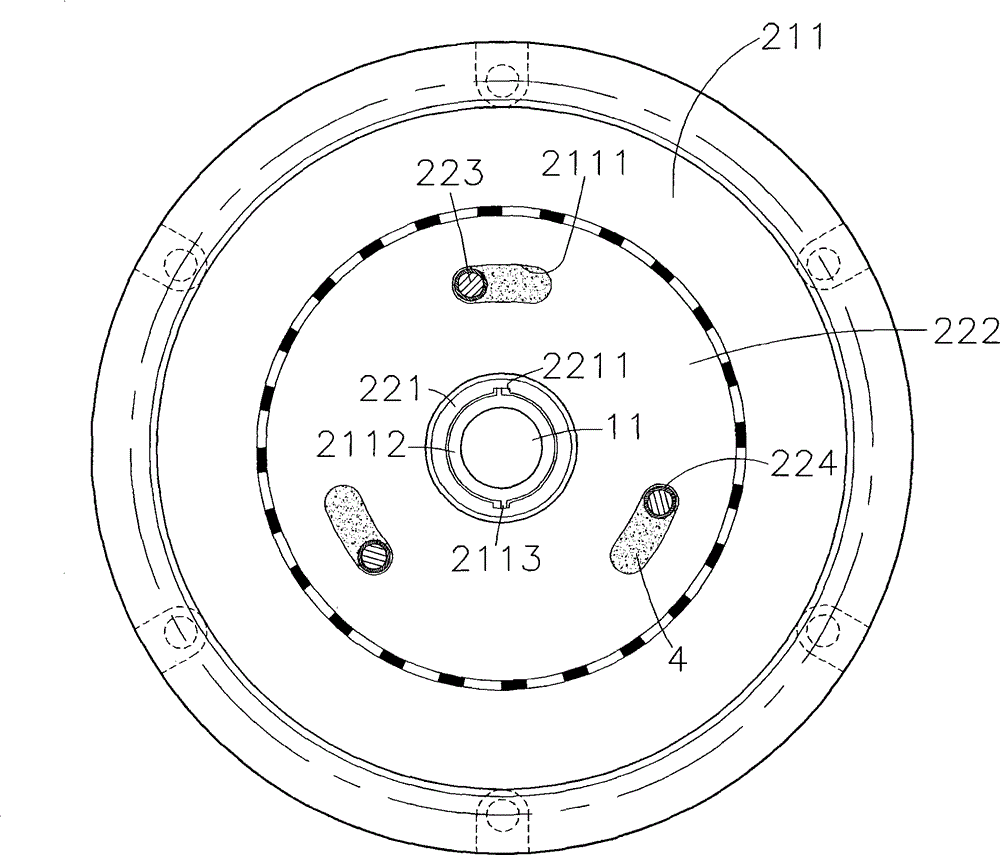

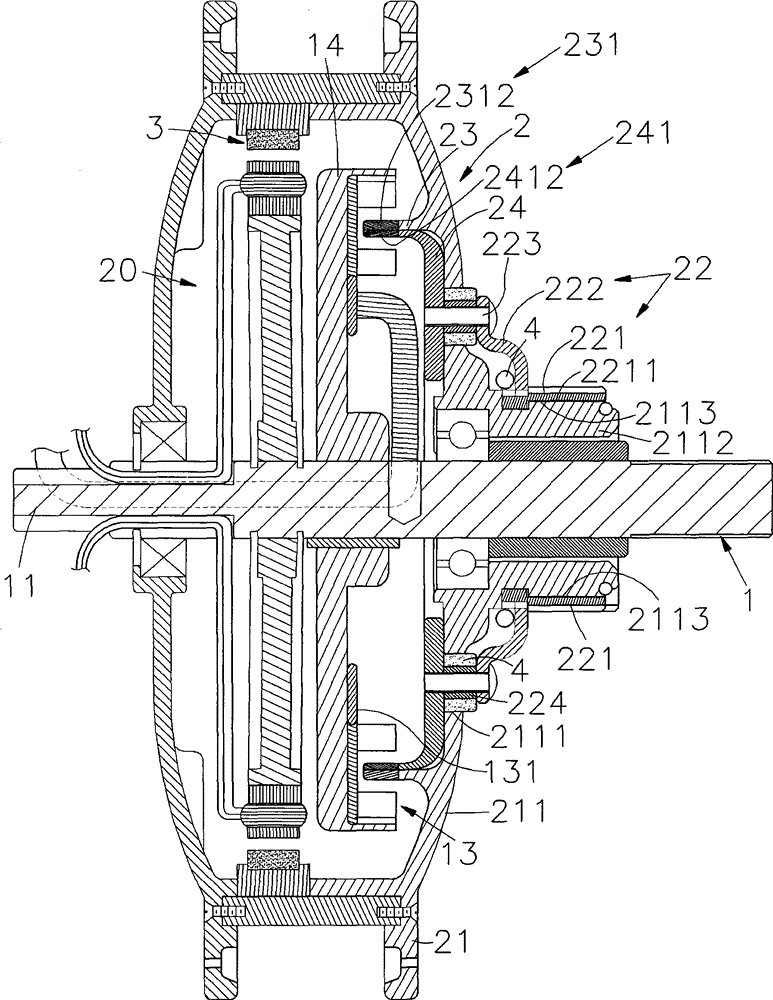

Torsion detecting rim motor

InactiveCN101989779BNo time differenceImprove handling easeWheelchairs/patient conveyanceMechanical energy handlingElastic componentEngineering

The invention relates to a torsion measuring device, in particular to a torsion detecting rim motor, which comprises a fixed device, a movable device, a power motor and an elastic component, wherein the fixed device is arranged on a vehicle and is provided with a sensor; the movable device is sleeved on the fixed device and is connected with a wheel through a stock; a linked module for receiving an external force is arranged on one side of the stock, and a driven rotary gate disc of a plurality of first detected area is arranged on the other side of the stock; the linked module is provided with a driving rotary grate disc which are superposed with the driven rotary grate disc; a plurality of second detected areas are formed on the driving rotary grate disc; the power motor is sleeved on the fixed device and accommodated in the stock of the movable device for driving the movable device to rotate; and the two ends of the elastic component bears the forces applied by the stock of the movable device and the linked module. In the invention, the change between the detected areas can be detected, the power motor, according to data size, can be started to provide corresponding auxiliary power, and time difference is eliminated and the operation simplicity is improved.

Owner:李宝玲

Monorail crane pneumatic turnout

ActiveCN113753096AImprove securityImprove reliabilityFluid-pressure devices for scotch-blocksControl engineeringMonorail

The invention discloses a monorail crane pneumatic turnout. A limiting assembly is arranged on a frame body, the limiting assembly comprises a support and a second air cylinder arranged on the frame body, the support is driven by the second air cylinder to move up and down, and a first pressing block and two limiting plug pins are fixedly connected to the support; when the swing way is in butt joint with the second fixed way or the third fixed way, the second air cylinder drives the first pressing block to downwards press the first car arrester so that the swing way can be conducted, meanwhile, the two limiting bolts synchronously stretch out downwards, and one limiting bolt makes contact with the upper portion of the inward side edge of the swing way so that the swing way can be prevented from swinging; and when the swing way needs to be reversed, the second air cylinder drives the support and the limiting plug pin to move upwards, so that the first car arrester is reset, and the swing way is made to swing. The whole process is not delayed, so that the response speed of components of the turnout is increased, and the safety and reliability of the structure are improved.

Owner:XIANGTAN HENGXIN IND

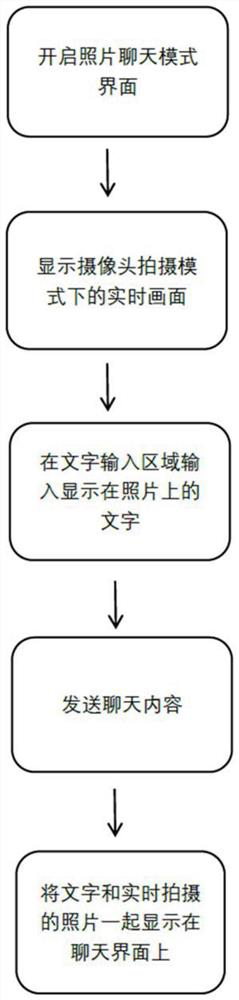

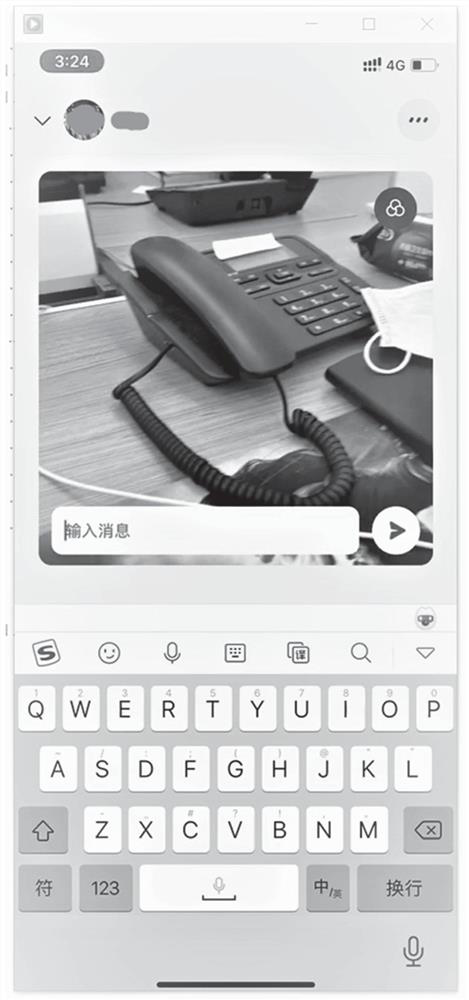

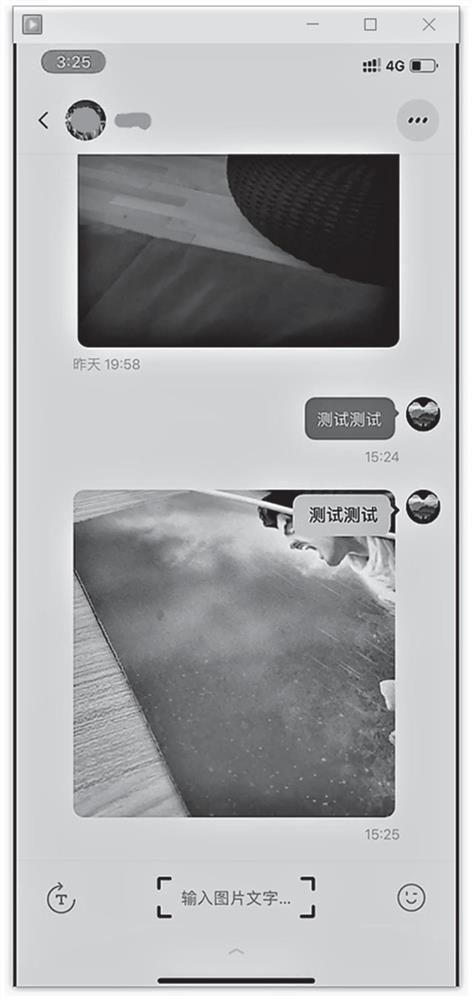

Photo chatting method and device and storage medium

PendingCN114443187AEasy to operateGood sharing effectExecution for user interfacesInformation transmissionComputer graphics (images)

The invention discloses a photo chatting method and device and a storage medium. The method comprises the following steps: opening a photo chatting mode interface; displaying a real-time picture in a camera shooting mode; inputting characters displayed on the photo in the character input area; sending the chat content; and displaying the characters and the pictures shot in real time on a chat interface together. According to the invention, through a mode of combining a real situation and characters, words wanting to say for a scene in front of eyes are vividly and accurately reproduced and sent out, so that emotion expression and reception are smoother and more direct, information transmission and reception are more accurate, and the form is more interesting; and compared with the traditional chat software, a better effect is achieved on social attributes.

Owner:北京陌陌信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com