An uncooled two-color infrared detector mems chip and its manufacturing method

A technology of an infrared detector and a manufacturing method, which is applied to electric radiation detectors, radiation pyrometry, manufacturing of microstructure devices, etc. or performance reduction, etc., to achieve the effect of extending the working temperature range, good image quality, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The principle and characteristics of an uncooled two-color infrared detector MEMS chip in the present invention will be described below in conjunction with the accompanying drawings. The given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

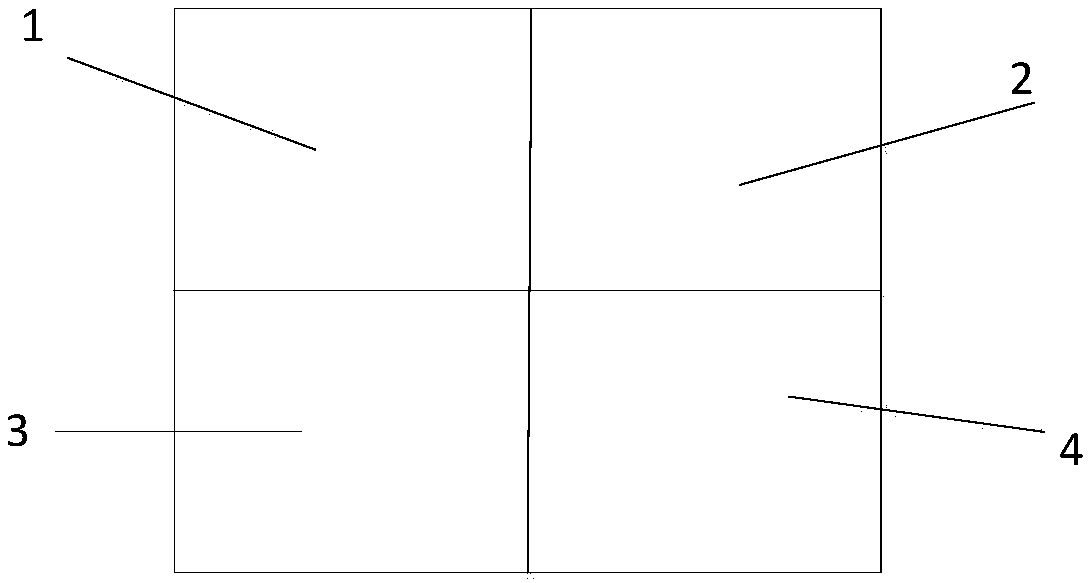

[0064] Such as figure 1 and Figure 15 Shown, a kind of uncooled two-color infrared detector MEMS chip comprises a substrate 5 with ASIC (Application Specific Integrated Circuit: Application Specific Integrated Circuit) and a detector with a micro-bridge support structure, said detector and said The ASIC circuit of the semiconductor substrate 5 is electrically connected, and the detector is divided into four areas arranged in a matrix, which are respectively the first area 1, the second area 2, the third area 3 and the fourth area 4;

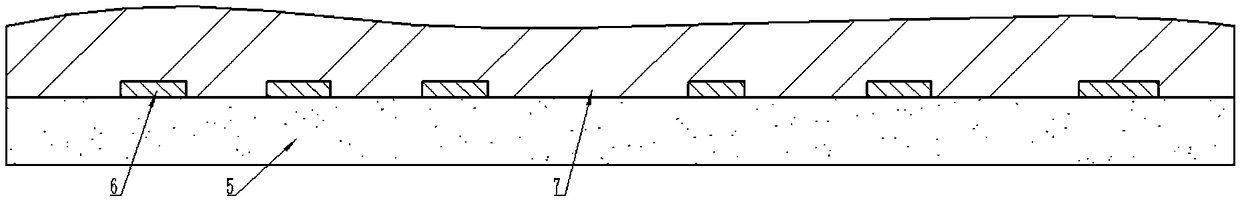

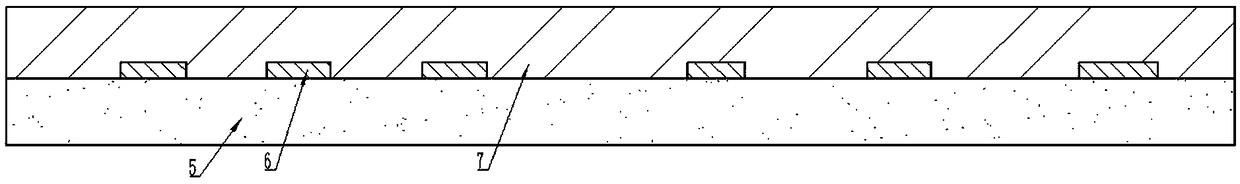

[0065] The detector includes a metal reflective layer 6 and an insulating medium layer 7 on the substrate, the metal reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com