Cable shearing mechanism for power construction

A technology of shearing mechanism and electric construction, which is applied in cable installation, cable installation device, equipment for cutting/disconnecting cables, etc. The effect of clamping mechanism failure, avoiding personal injury and preventing crush injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

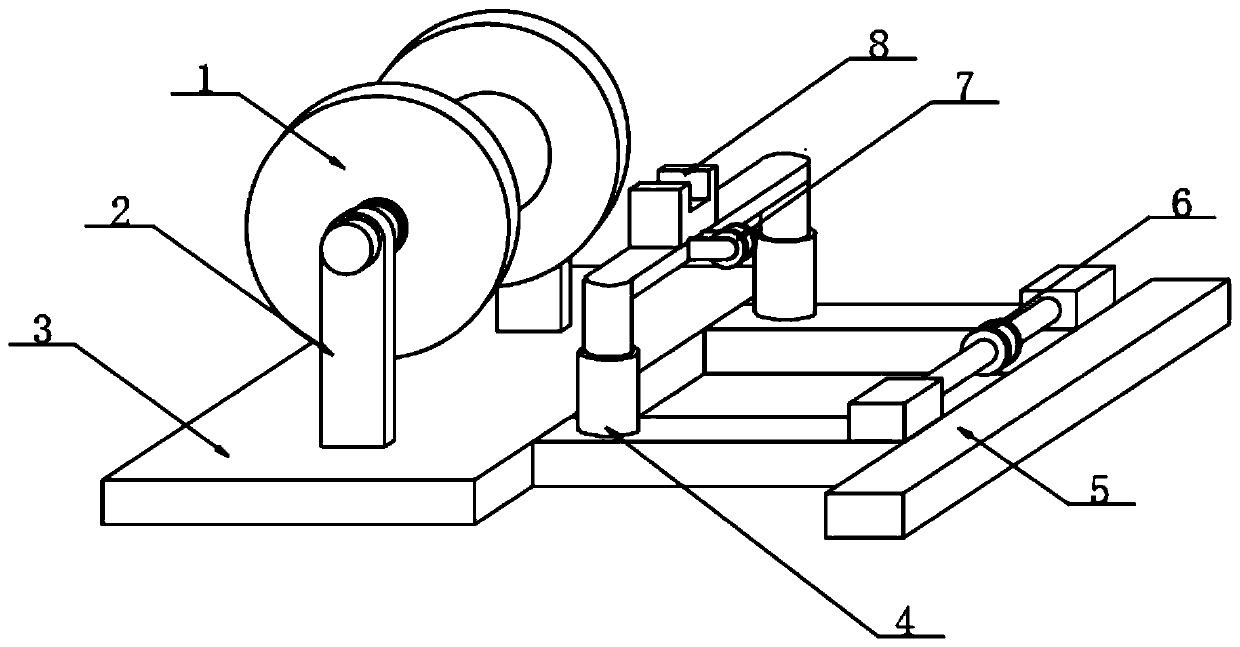

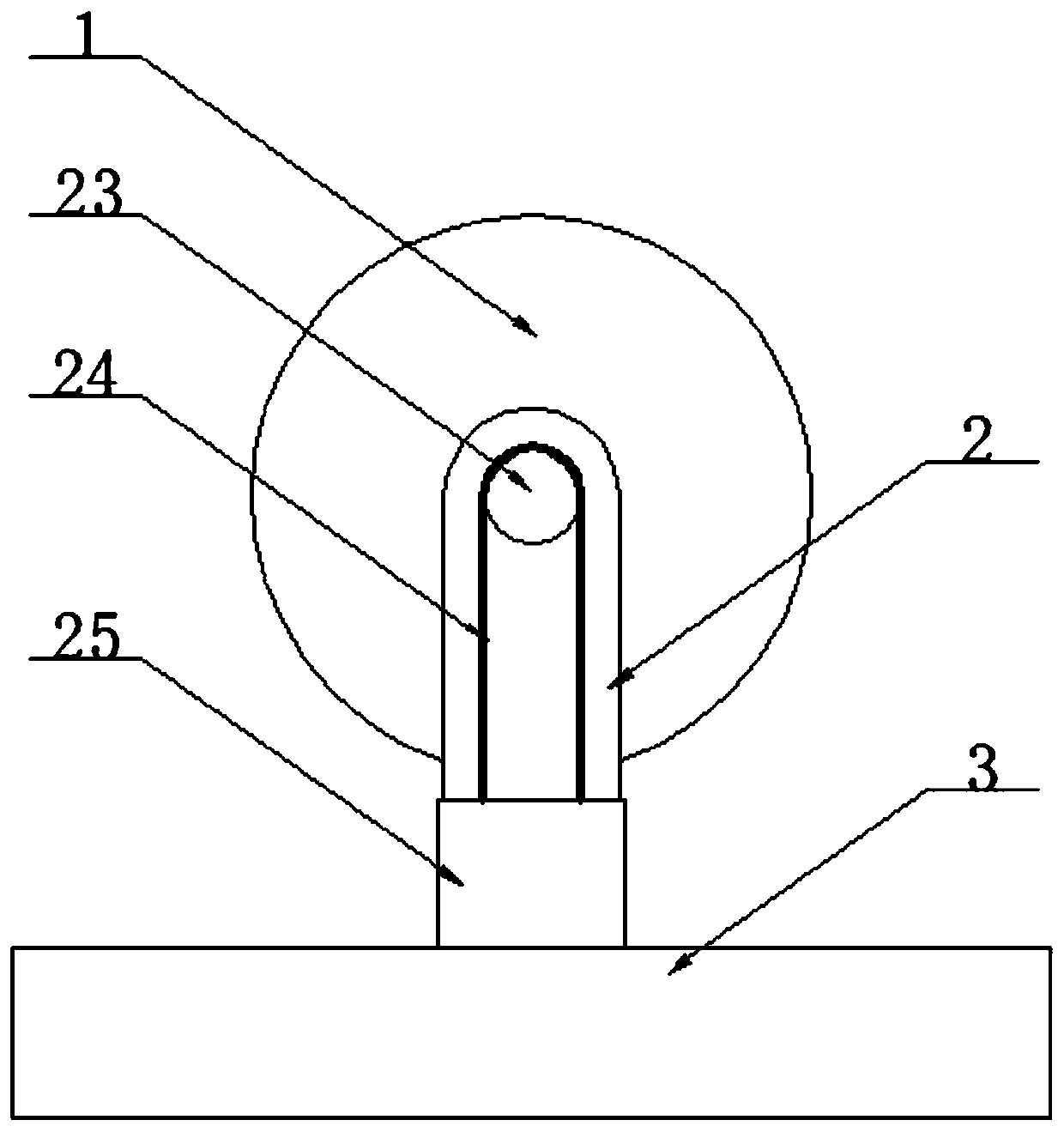

[0018] See Figure 1~3 In the embodiment of the present invention: a cable cutting mechanism for electric power construction, including a chassis 3, the top of the chassis 3 is provided with a bracket 2, and the bracket 2 is provided with a rotating shaft 23, and the rotating shaft 23 is sleeved with a winding Disk 1, one side of the chassis 3 is connected with a truss 5, and a telescopic rod 4 is installed on the end of the truss 5 close to the chassis 3, and a shear seat 8 is installed on the top of the telescopic rod 4, and the top of the telescopic rod 4 is located in the shear A pressing wheel 7 is installed at the bottom end of the seat 8 and a guide wheel 6 is installed at the other end of the top of the truss 5.

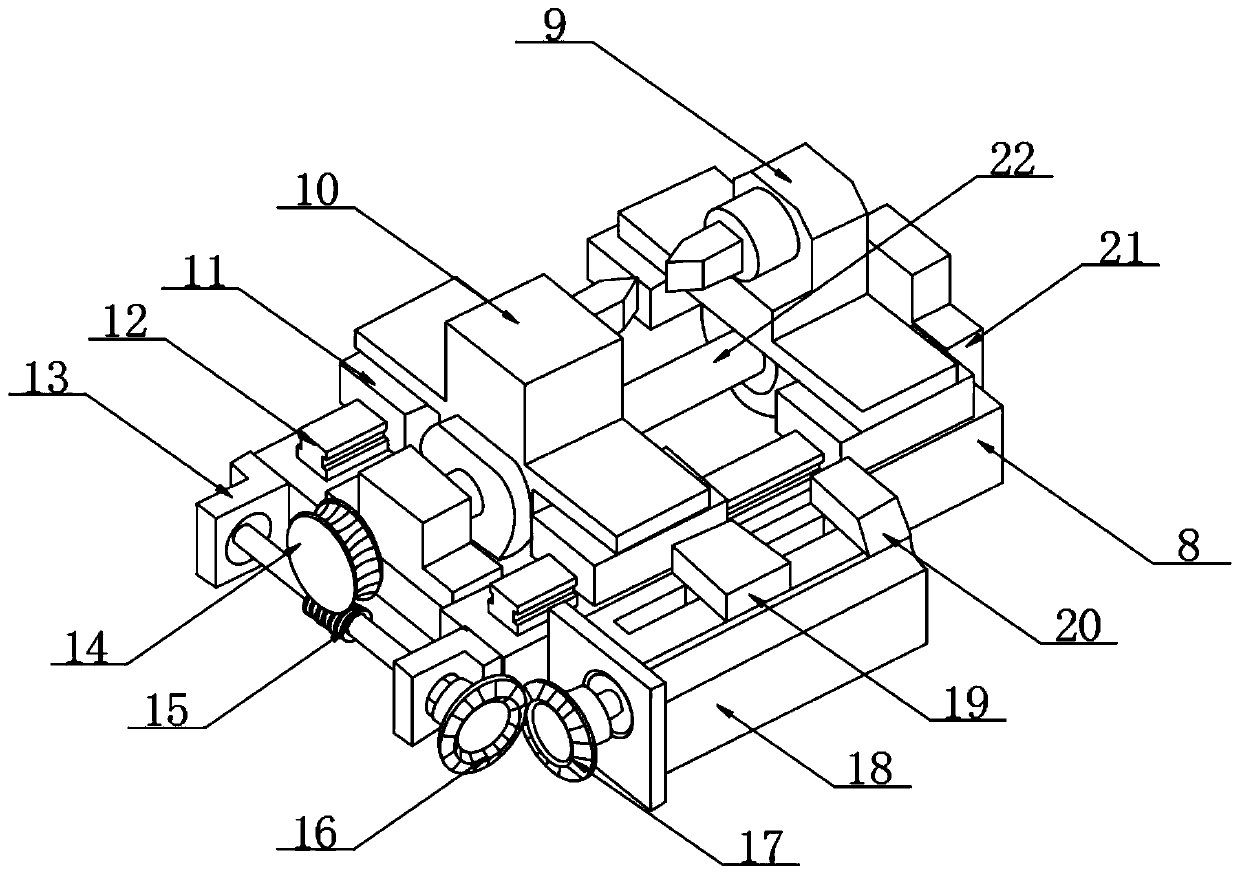

[0019] in figure 2 Among them, a fixing seat 18 is welded on one side of the shearing seat 8, and a second clamping block 20 is welded to the top end of the fixing seat 18, a second bevel gear 17 is installed at the front end of the fixing seat 18, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com