Micro LED color display device

A color display device, red technology, applied in the direction of semiconductor devices, static indicators, electric solid devices, etc., can solve the problem of large chromaticity differences, green color chromaticity uniformity needs to be improved, green color stability is not easy to control, etc. problem, to achieve the effect of easy specification control, easy control of stability, and improvement of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

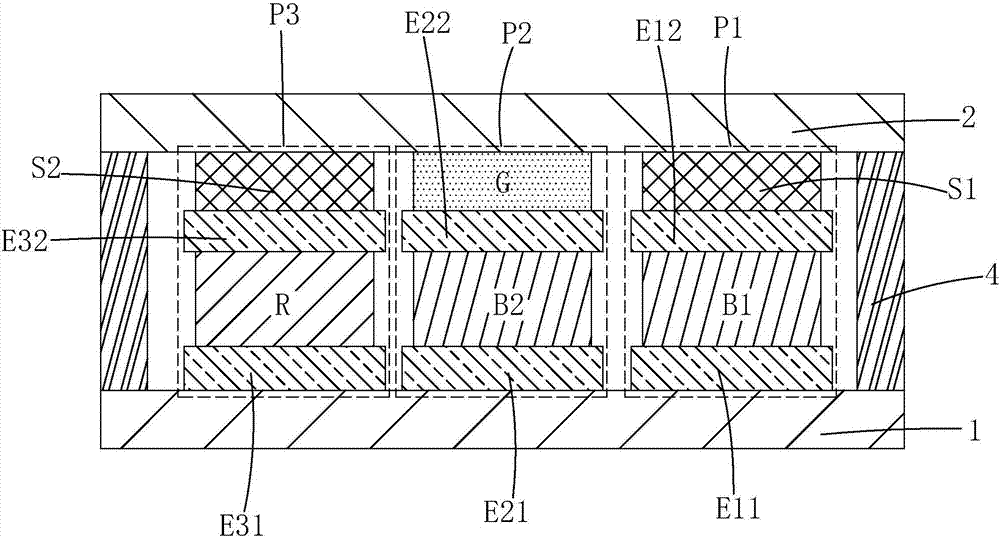

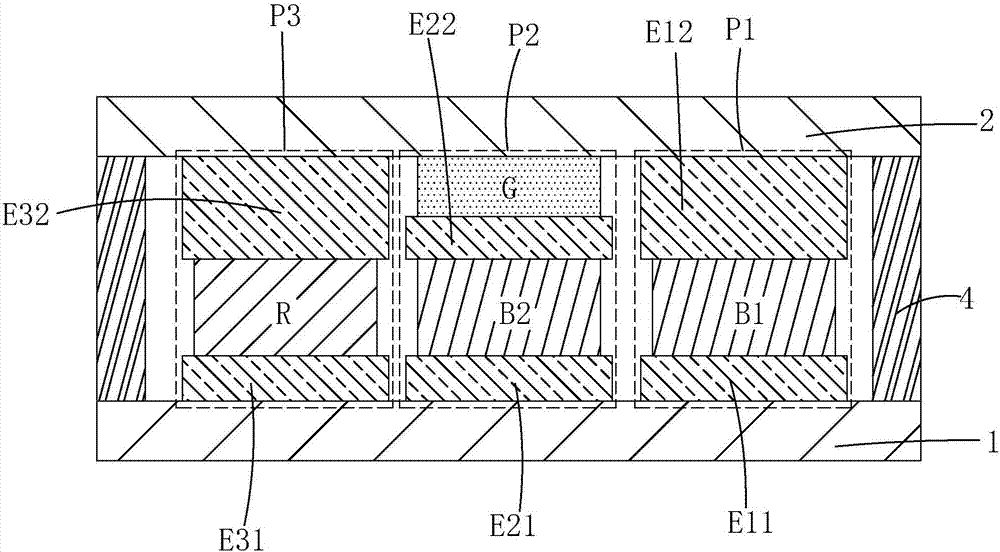

[0030] The invention provides a Micro LED color display device. figure 2 Shown is the first embodiment of the Micro LED color display device of the present invention, including a driving substrate 1, a packaging substrate 2 opposite to the driving substrate 1, and an array between the driving substrate 1 and the packaging substrate 2. A plurality of blue sub-pixels P1 , green sub-pixels P2 , and red sub-pixels P3 arranged in a formula, and a support 4 disposed between the driving substrate 1 and the packaging substrate 2 .

[0031] The blue sub-pixel P1 includes a first lower pixel electrode E11 disposed on the driving substrate 1, a first upper pixel electrode E12 disposed opposite to the first lower pixel electrode E11, and sandwiched between the first lower pixel electrode E11. The first blue LED B1 between the lower pixel electrode E11 and the first upper pixel electrode E12, and the first transparent spacer S1 arranged between the first upper pixel electrode E12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com