Patents

Literature

132results about How to "Guaranteed synchronous motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

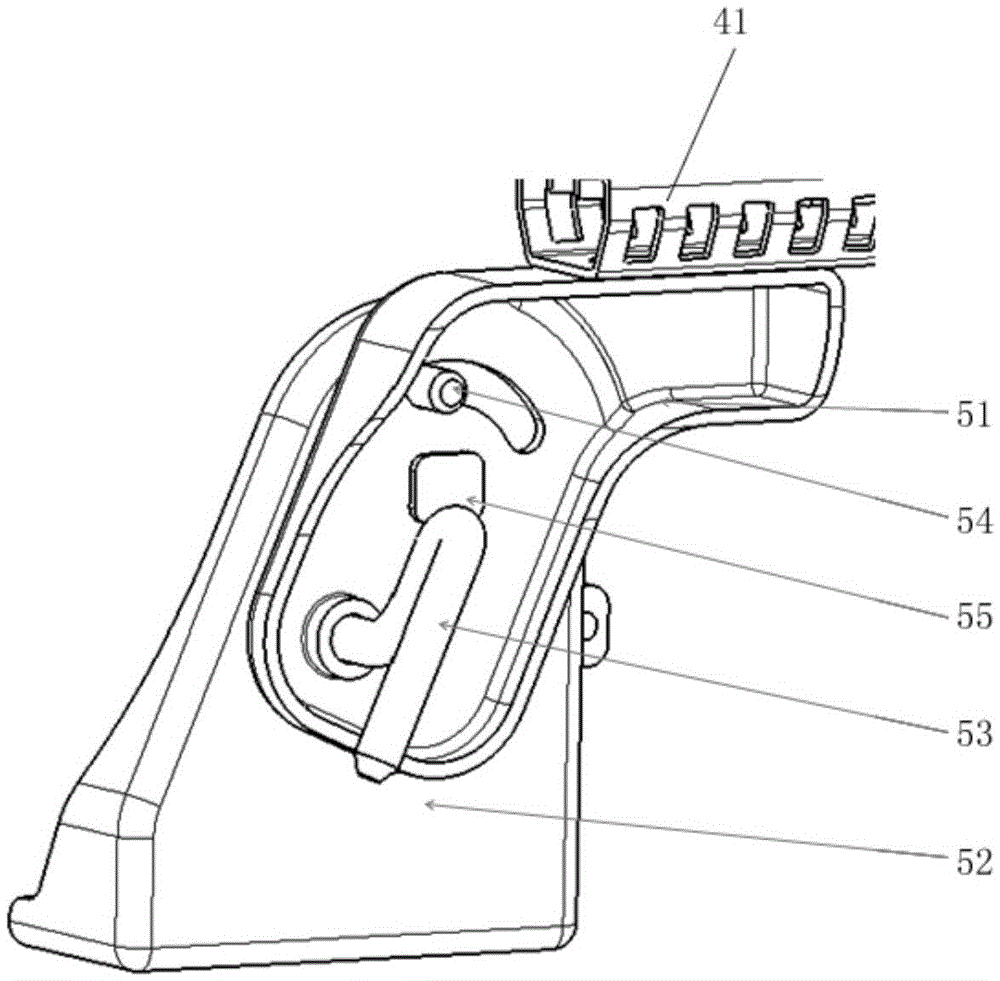

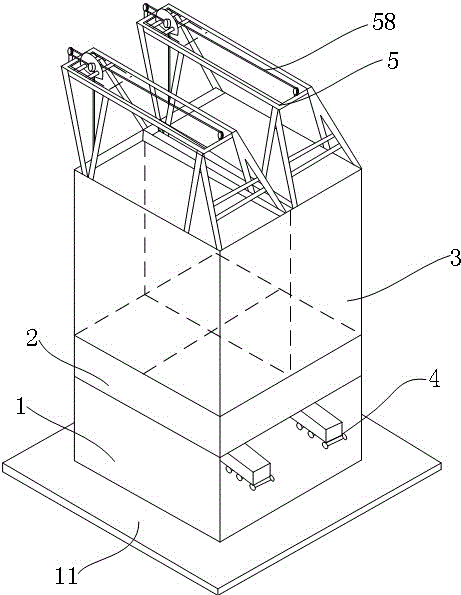

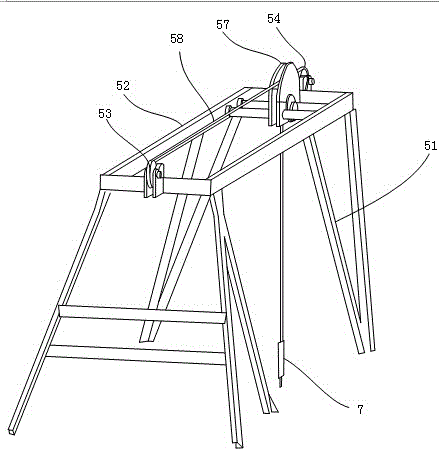

Positioning device of hanging device and use method of positioning device

The invention provides a positioning device of a hanging device and a use method of the positioning device. The positioning device comprises a supporting and fixing cross beam component (52), a hanging body (5) with hanging hook components (51) hooked to the supporting and fixing cross beam component (52), and a pushing-pressing type elastic fixing device assembly, wherein the pushing-pressing type elastic fixing device assembly comprises a shell component (9) with a left side wall (92) and a right side wall (91), two elastic pushing-pressing assemblies being capable of vertically sliding between the left side wall (92) and the right side wall (91) of the shell component (9), having outer elastomers (6) and inner bearing drive plate components (8) fixed on the inner sides of the outer elastomers, and being symmetric in structure, and an elastic pushing assembly capable of moving left and right under the adjustment of an adjusting screw rod (2) rotatably mounted on the left side wall (92) and the right side wall (91).

Owner:吴志远

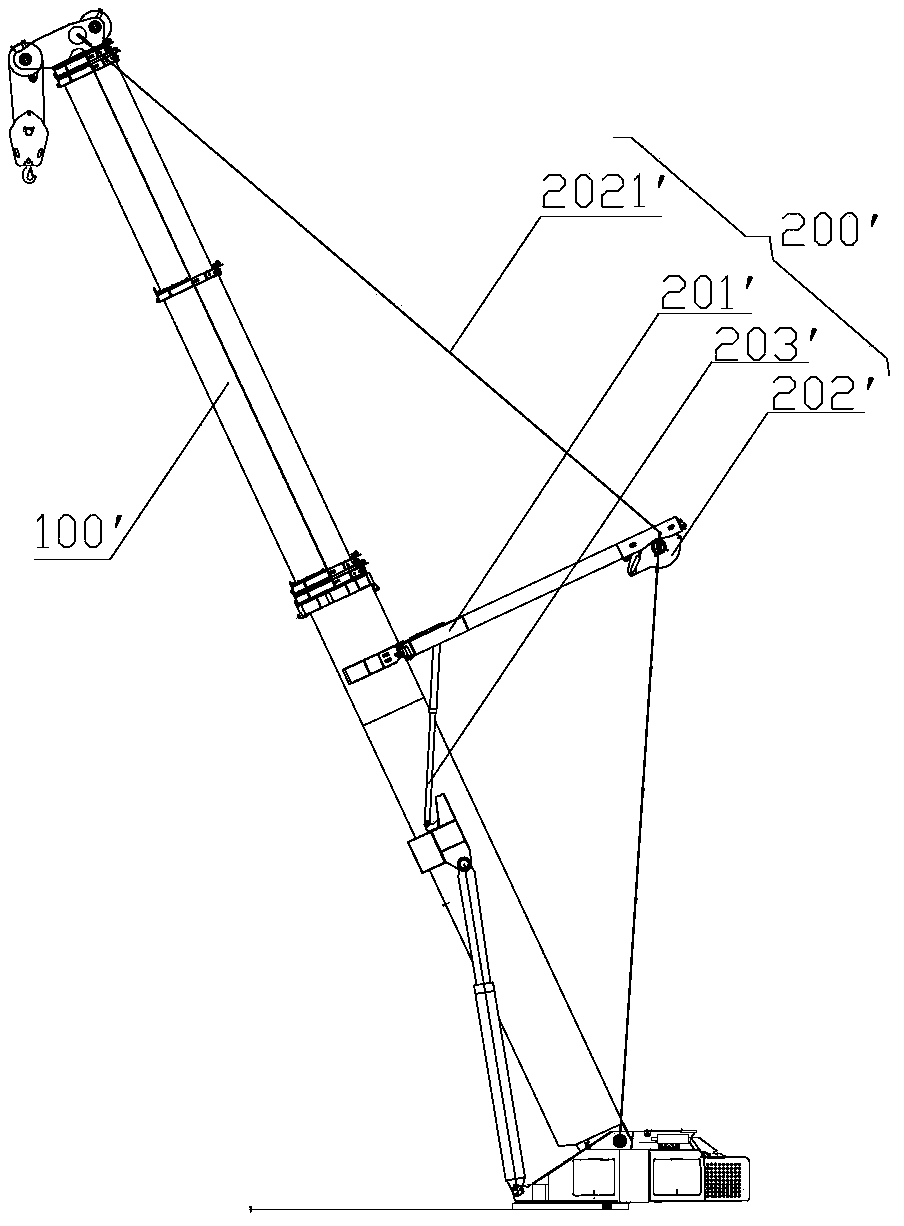

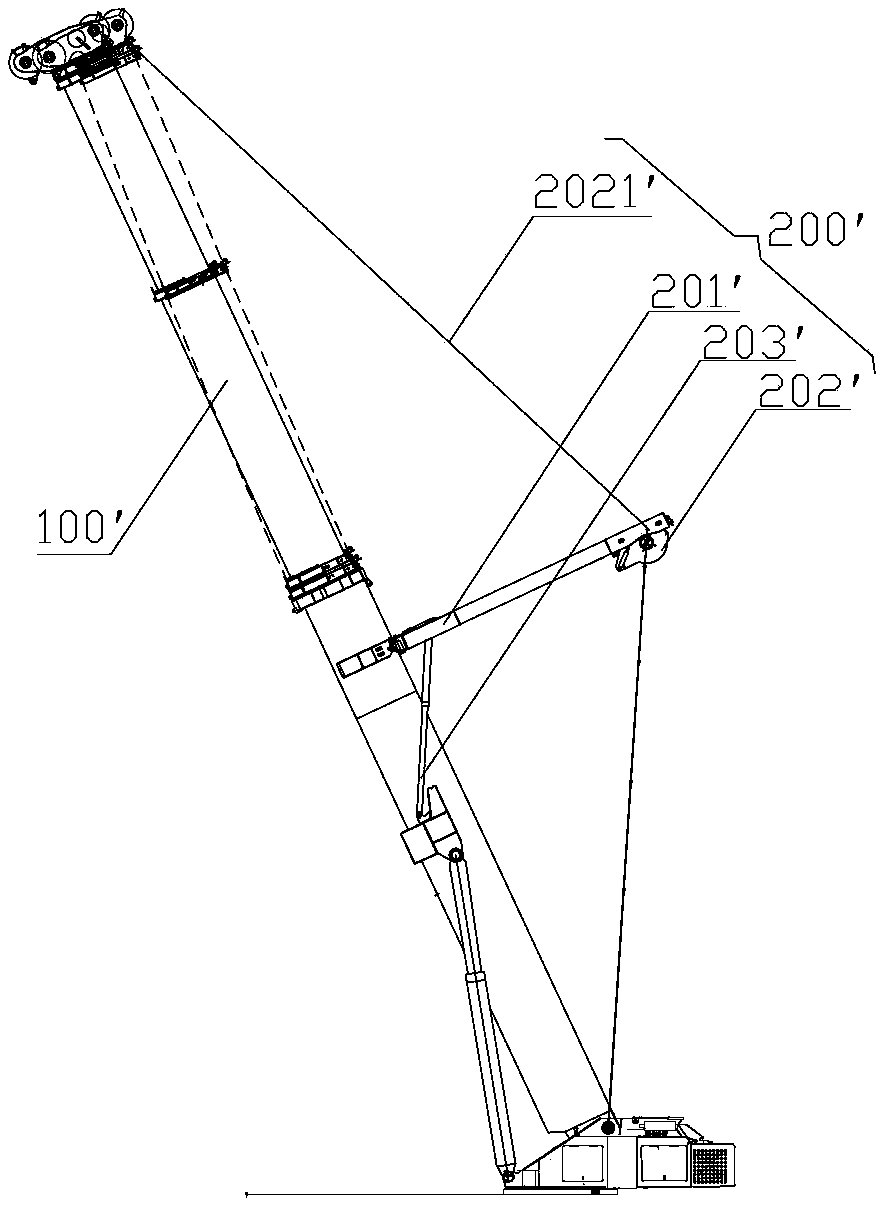

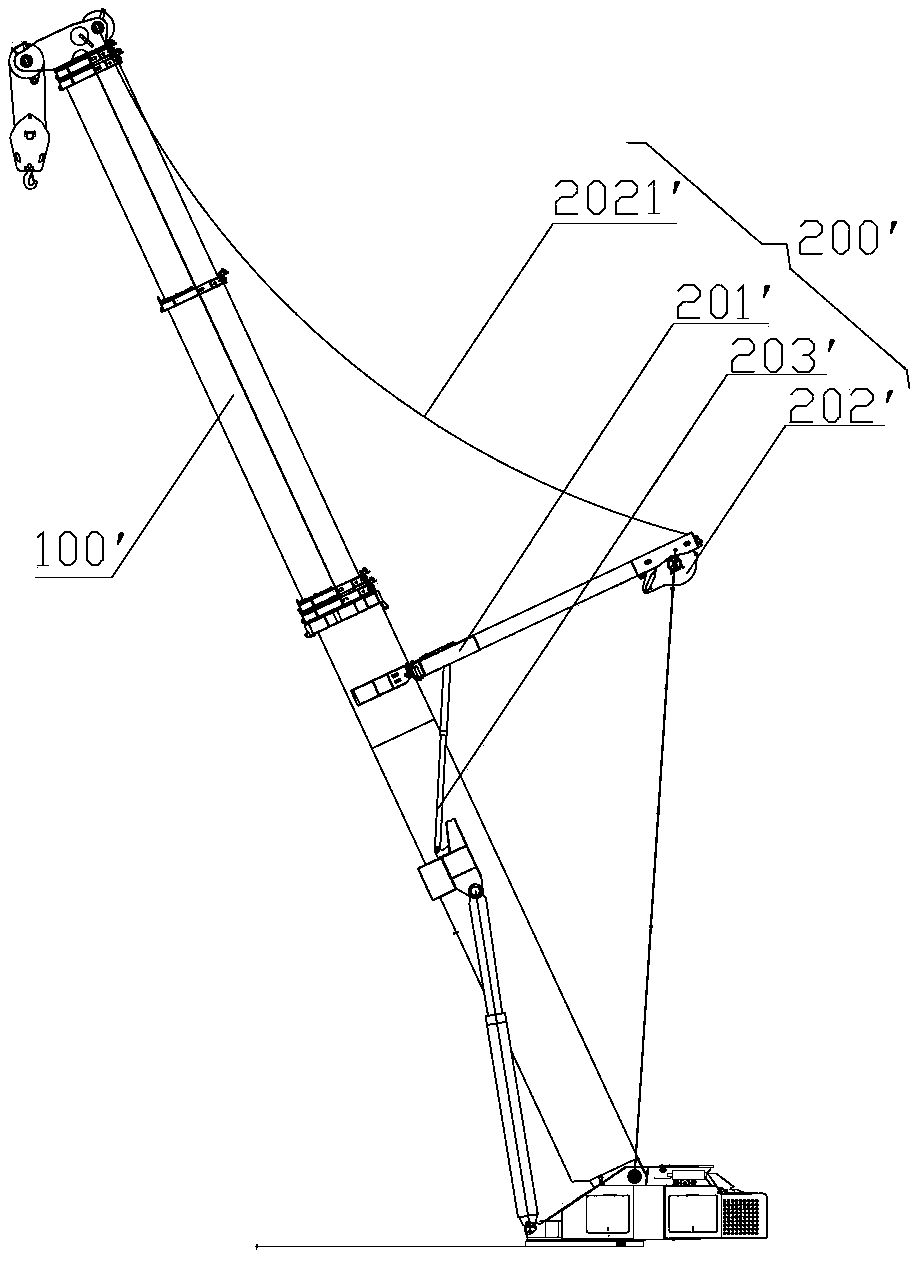

Super-lifting winch control method and system for crane

ActiveCN103395695AGuaranteed synchronous motionImprove safety and reliabilityWinding mechanismsLoad-engaging elementsControl systemOutput device

The invention discloses a super-lifting winch control system for a crane. The crane comprises a telescopic main arm, which is in connection with a super-lifting arm. The control system comprises: a detection device, which is in connection with the main arm and the super-lifting arm, and is used for detecting an included angle of the super-lifting arm and the main arm and acquiring the main arm length and the main arm telescopic speed; a controller, which is in connection with the detection device, and is used for acquiring a current value required by a proportional electromagnetic valve for controlling winch flow at the same time of winch contract and release and main arm stretching and contraction according to the included angle, the main arm length and the main arm telescopic speed, and sending an instruction of outputting the winch flow according to the required current value; and an output device, which is in connection with the controller and is used for receiving and outputting the instruction of the controller. The control system can make the steel wire rope contraction and release speed by winch adapt to stretching and contraction of the main arm, so that the steel wire rope and the main arm can achieve synchronous motion. The invention also discloses a super-lifting winch control method corresponding to the system, and the method can reach the same effect.

Owner:XUZHOU HEAVY MASCH CO LTD

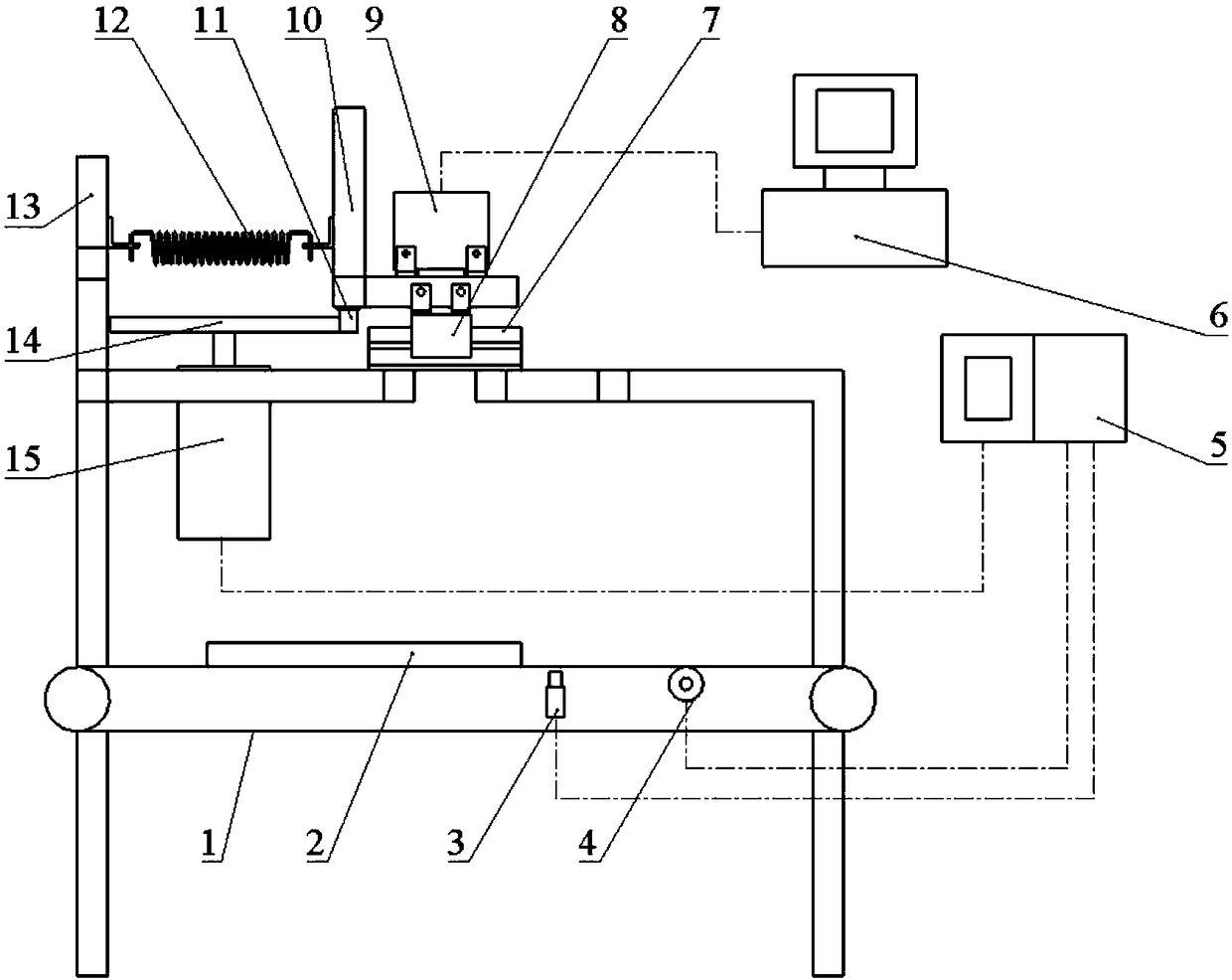

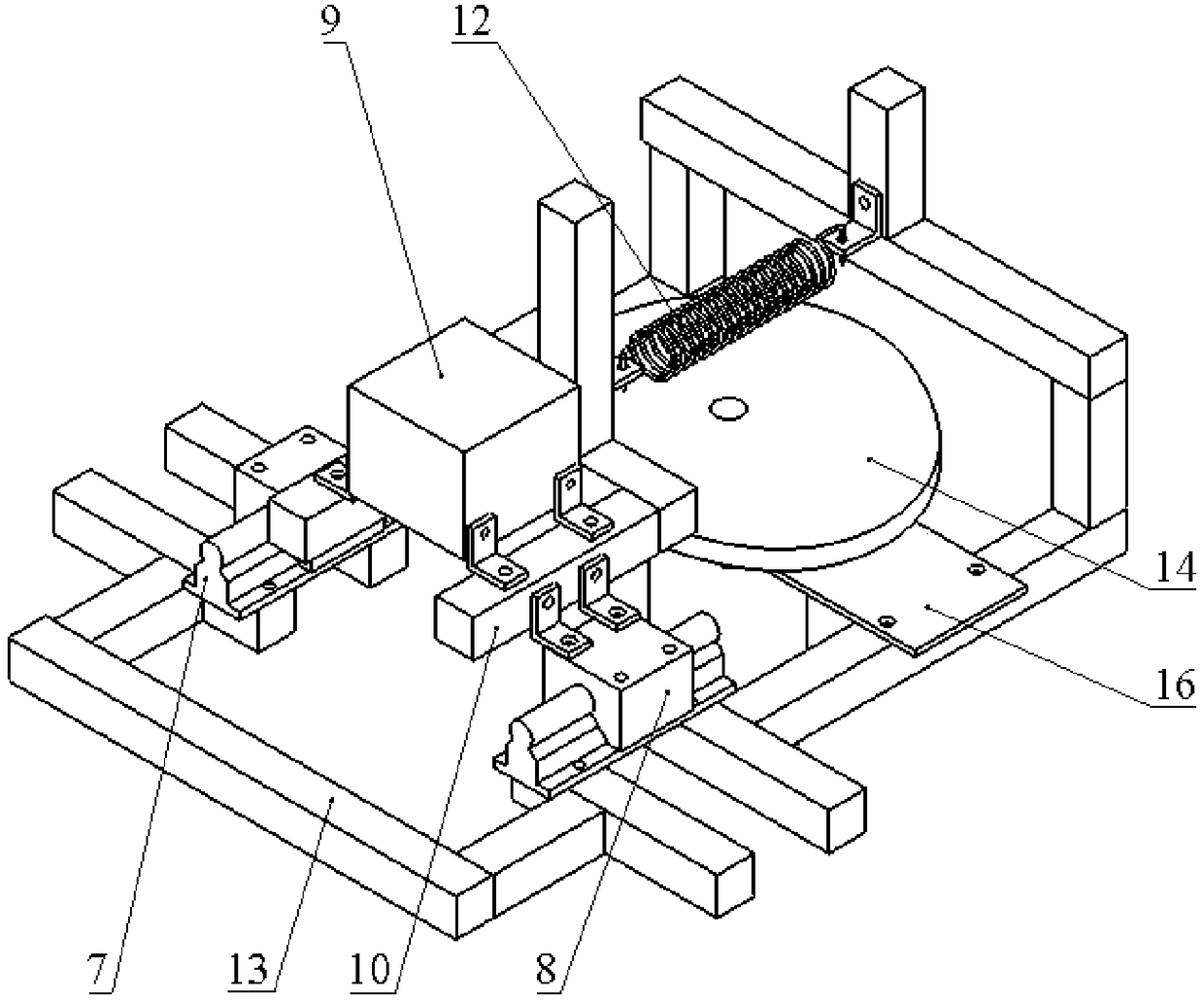

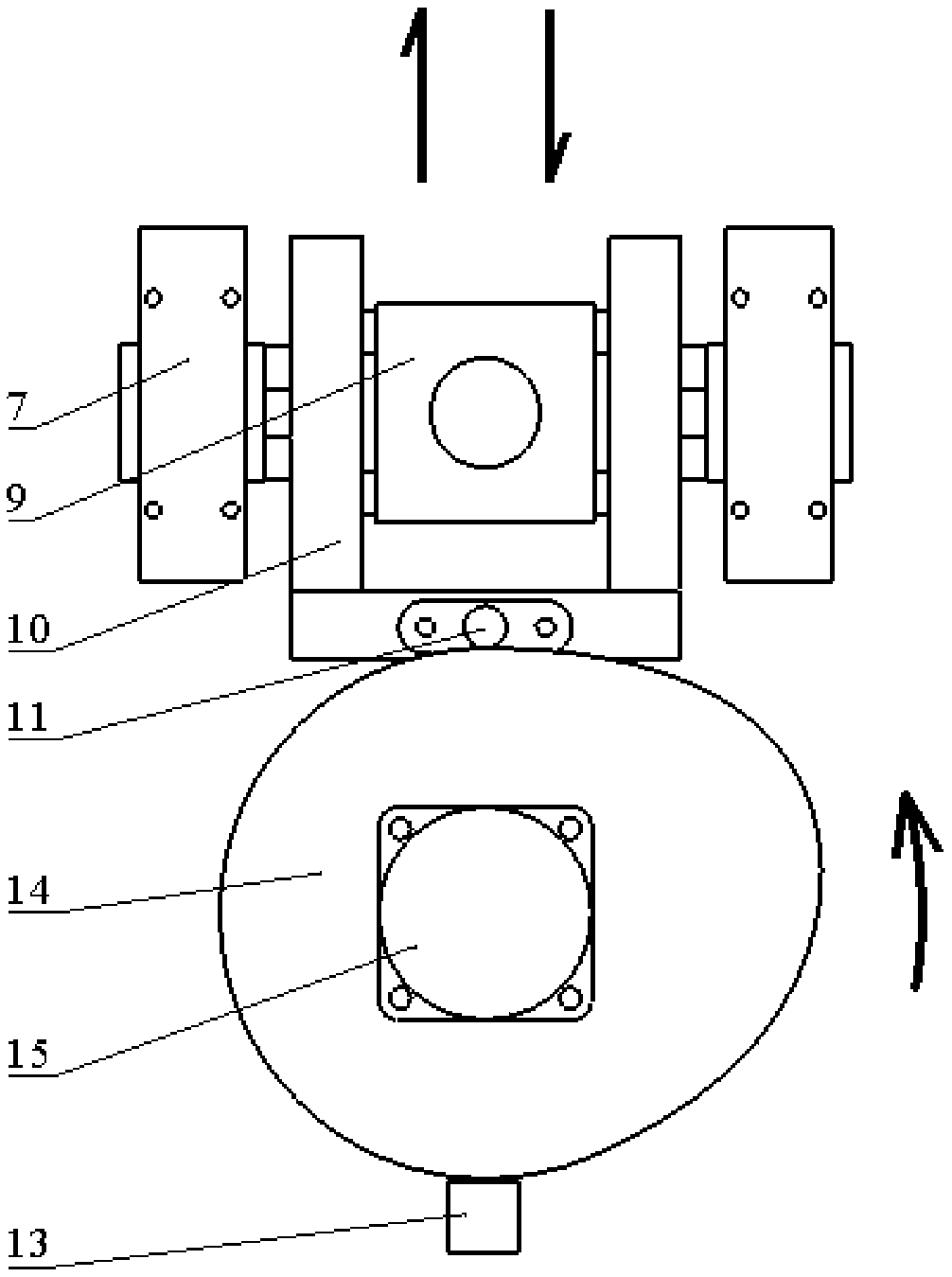

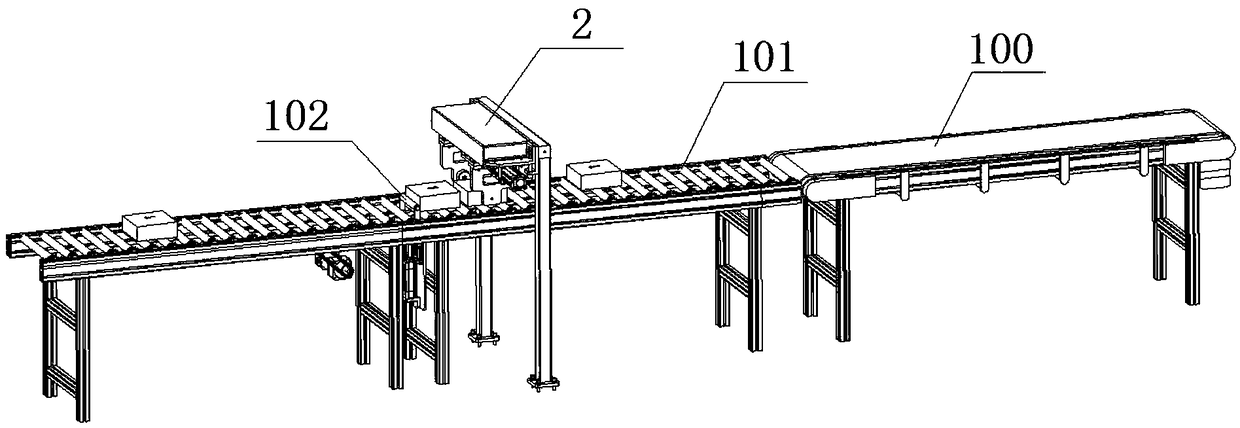

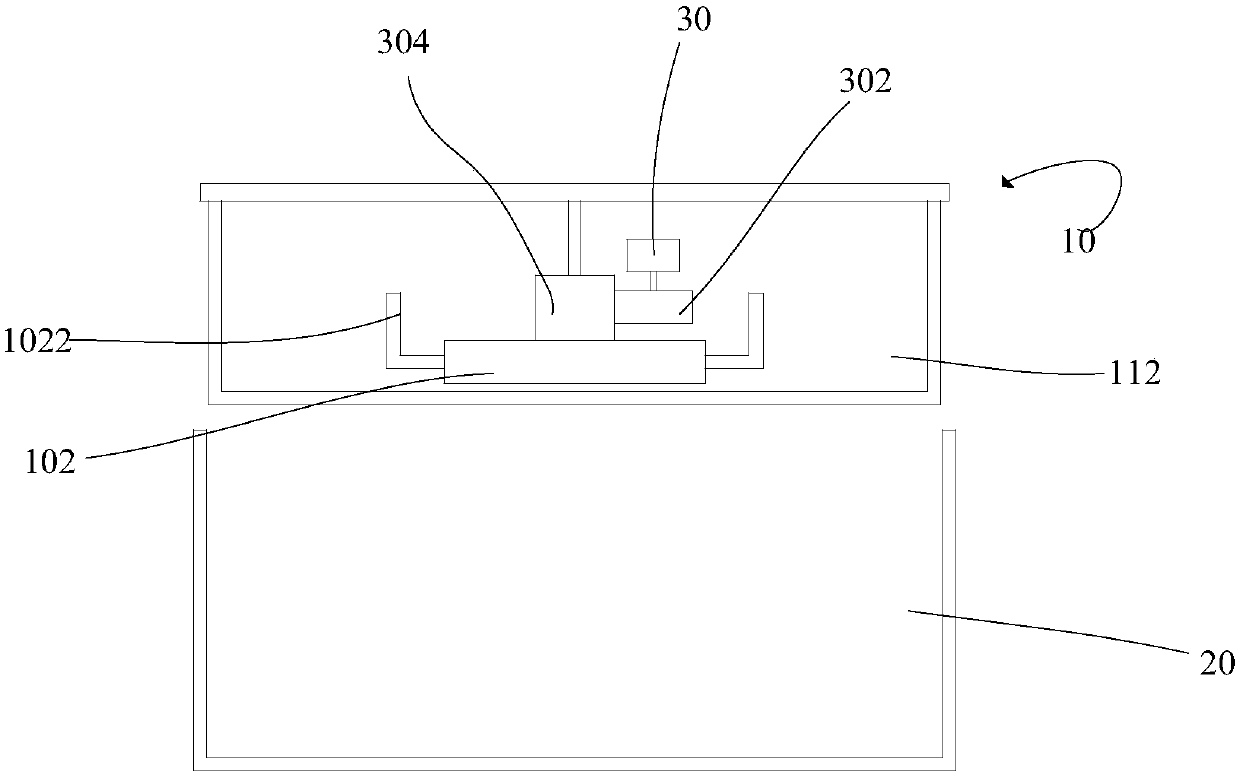

Artificial board surface defect online detection device based on synchronous principle

ActiveCN108341230ATo achieve the effect of reciprocating motionTo achieve the effect of "synchronization"ConveyorsMaterial analysis by optical meansMachine visionElectric machinery

The invention relates to an artificial board surface defect online detection device based on the synchronous principle and belongs to the technical field of wood detection devices. According to the artificial board surface defect online detection device based on the synchronous principle, an encoder obtains instantaneous speed of a to-be-detected artificial board on a to-be-detected artificial board conveyer belt and conveys the instantaneous speed to a controller, whether the to-be-detected artificial board enters a shooting area or not is judged through a trigger switch, the controller sendsinstructions to a motor according to a detection signal to drive driven pieces including a camera to move at the speed identical with that of the to-be-detected artificial board, in the movement process, the camera completes shooting of the to-be-detected artificial board, images are then transmitted to a computer, defect discrimination is conducted on the obtained images through a processing algorithm, and meanwhile the camera can automatically return to the original position under the action of the resilience of a spring and gets ready for next shooting. The artificial board surface defectonline detection device based on the synchronous principle eliminates image motion blur fundamentally, solves the problems that according to traditional blurred image deblurring, a processing algorithm is complicated, consumed time is long and achieves machine visual online detection of surface defects of the to-be-detected artificial board.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

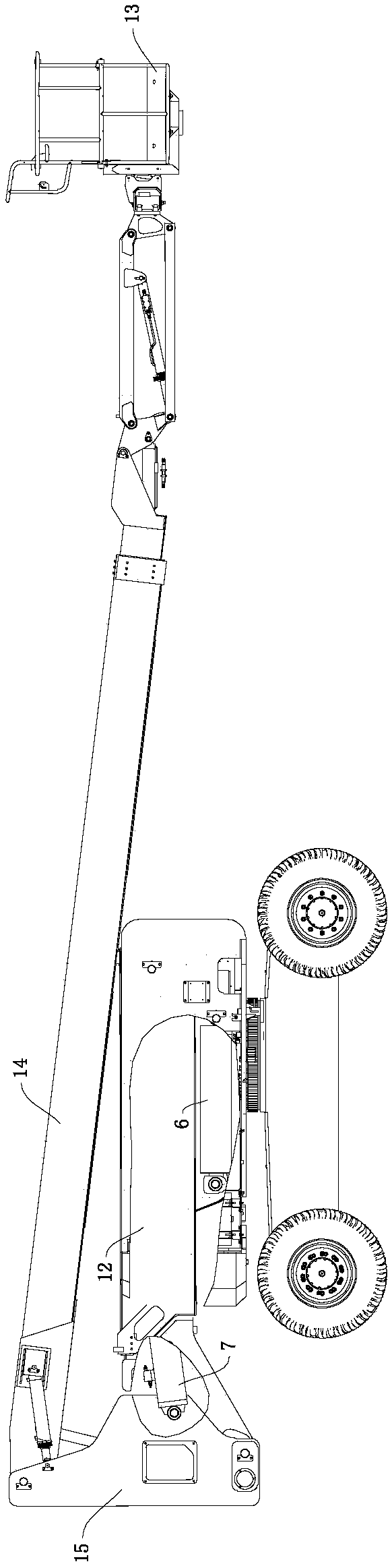

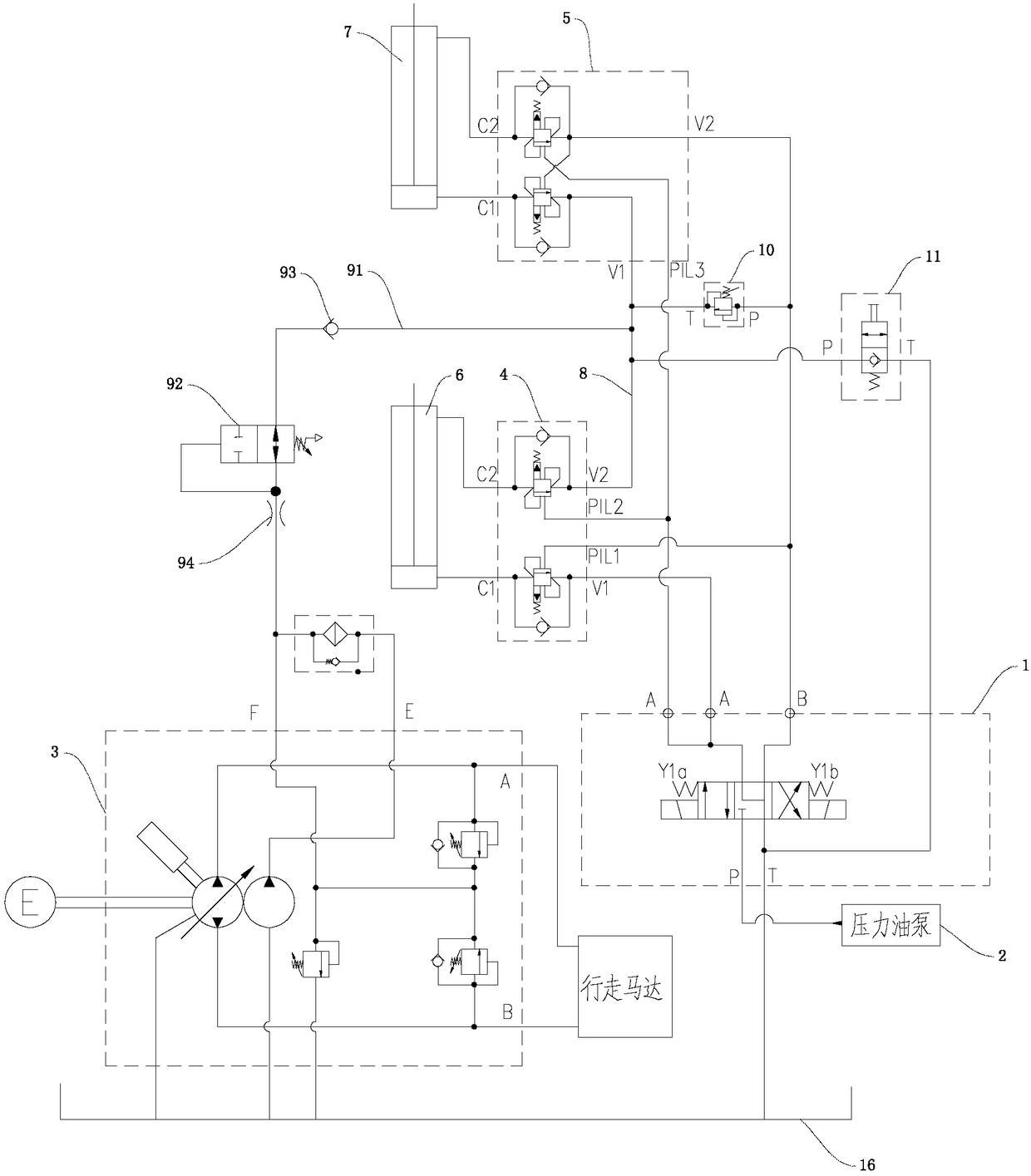

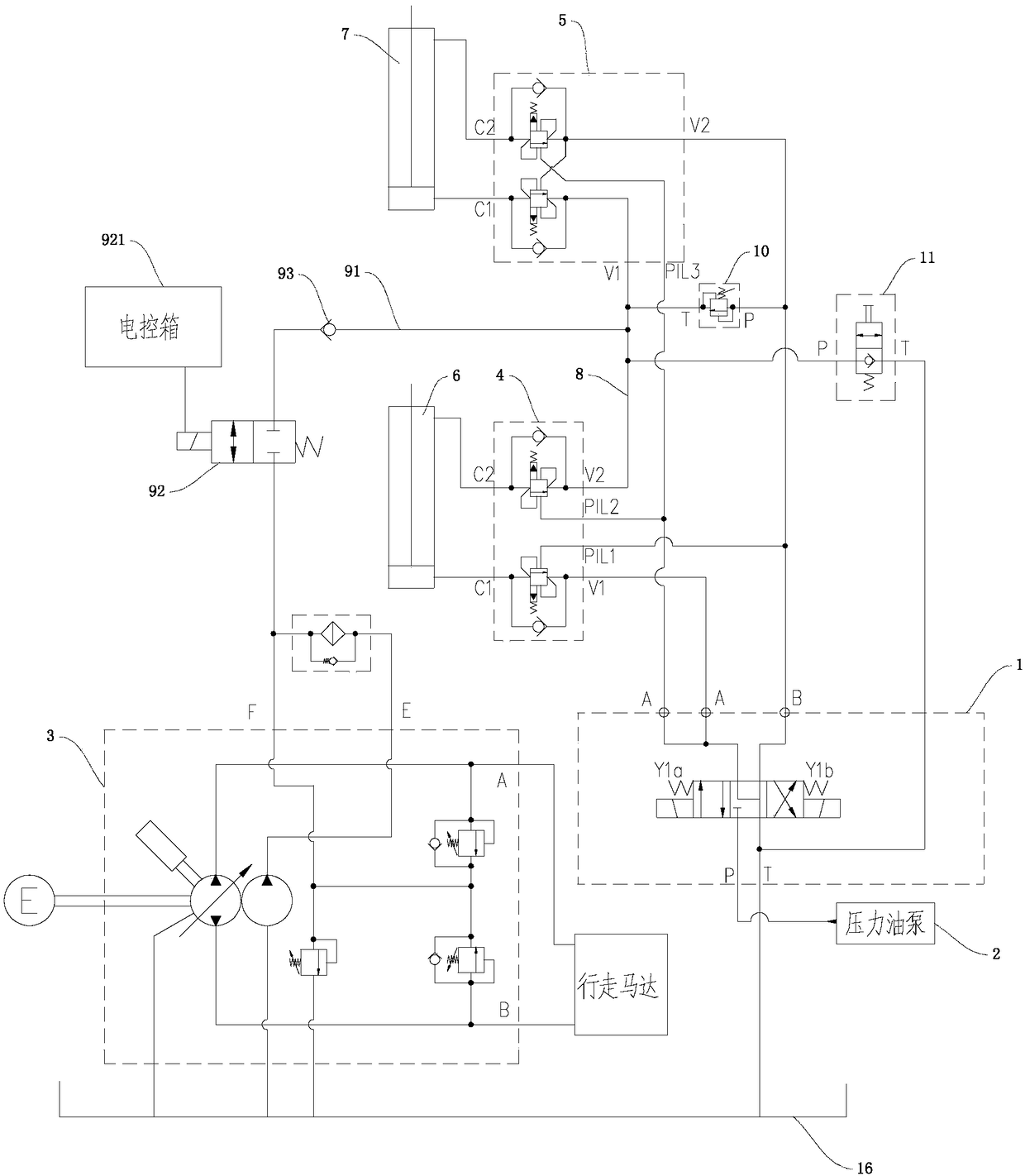

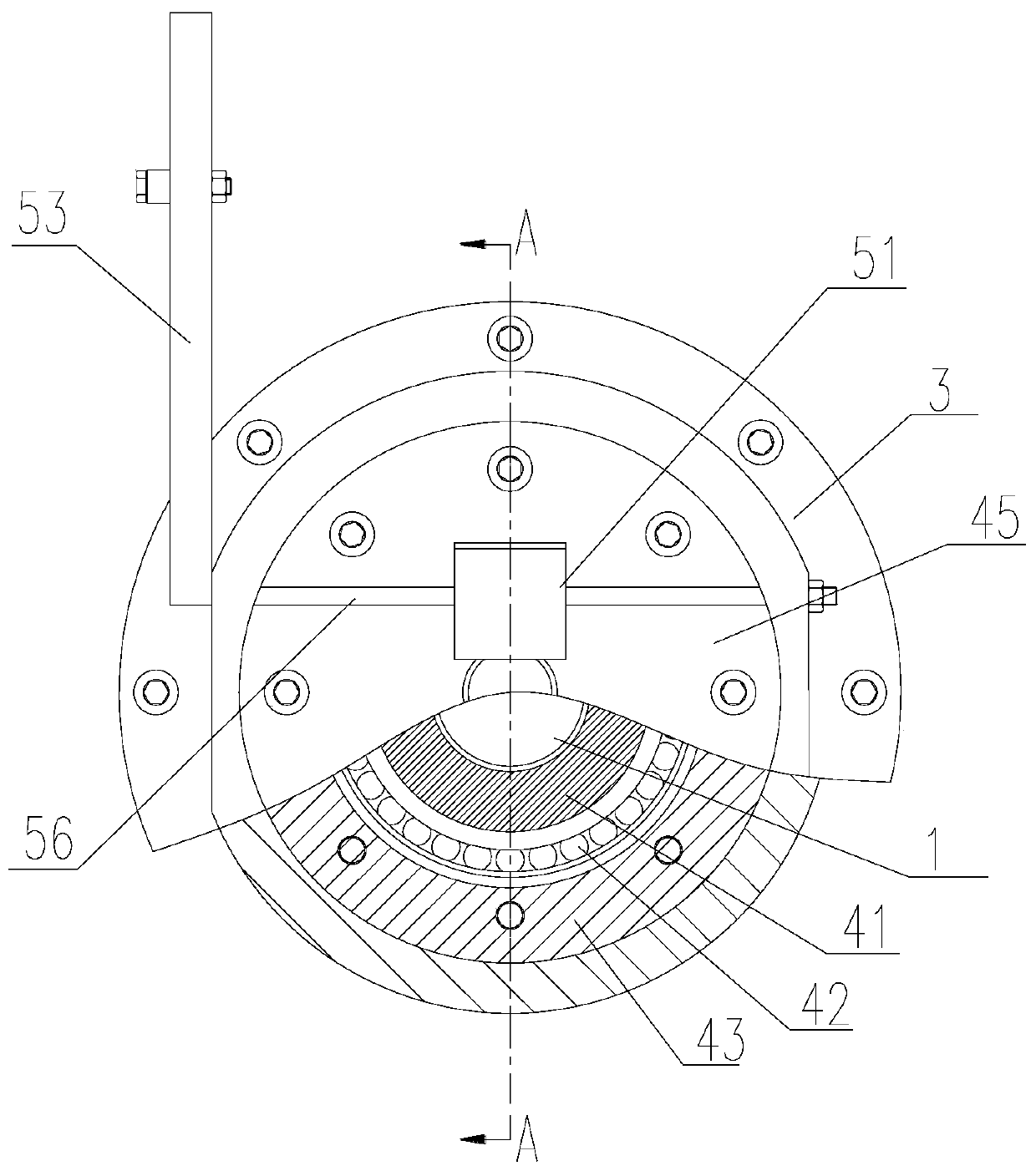

Crank-arm-type overhead working truck connector levelling hydraulic system

PendingCN108278229AGuaranteed synchronous motionServomotor componentsServomotorsTruckReversing valve

The invention discloses a crank-arm-type overhead working truck connector levelling hydraulic system which comprises a traveling oil pump, a hydraulic oil tank, a pressure oil pump, an electromagneticreversing valve, a connector levelling oil cylinder and a folding-arm amplitude-change oil cylinder. An oil inlet P, a working port A, a working port B and a return port T are formed in the electromagnetic reversing valve. The oil inlet P and the pressure oil pump communicate, and the return port T and the hydraulic oil tank communicate. A rod cavity of the folding-arm amplitude-change oil cylinder communicates with a rodless cavity of the connector levelling oil cylinder through a first connecting pipeline, and the working port A communicates with a rodless cavity of the folding-arm amplitude-change oil cylinder through a second connecting pipeline. A rod cavity of the connector levelling oil cylinder communicates with the working port B through a third connecting pipeline. An oil compensating loop is arranged on the first connecting pipeline, one end of the oil compensating loop communicates with the first connecting pipeline, and the other end of the oil compensating loop communicates with the traveling oil pump. Synchronous movement of the folding-arm amplitude-change oil cylinder and the connector levelling oil cylinder is effectively kept, and the crank-arm-type overhead working truck connector levelling hydraulic system is applied to the field of hydraulic control.

Owner:HUNAN SINOBOOM HEAVY IND

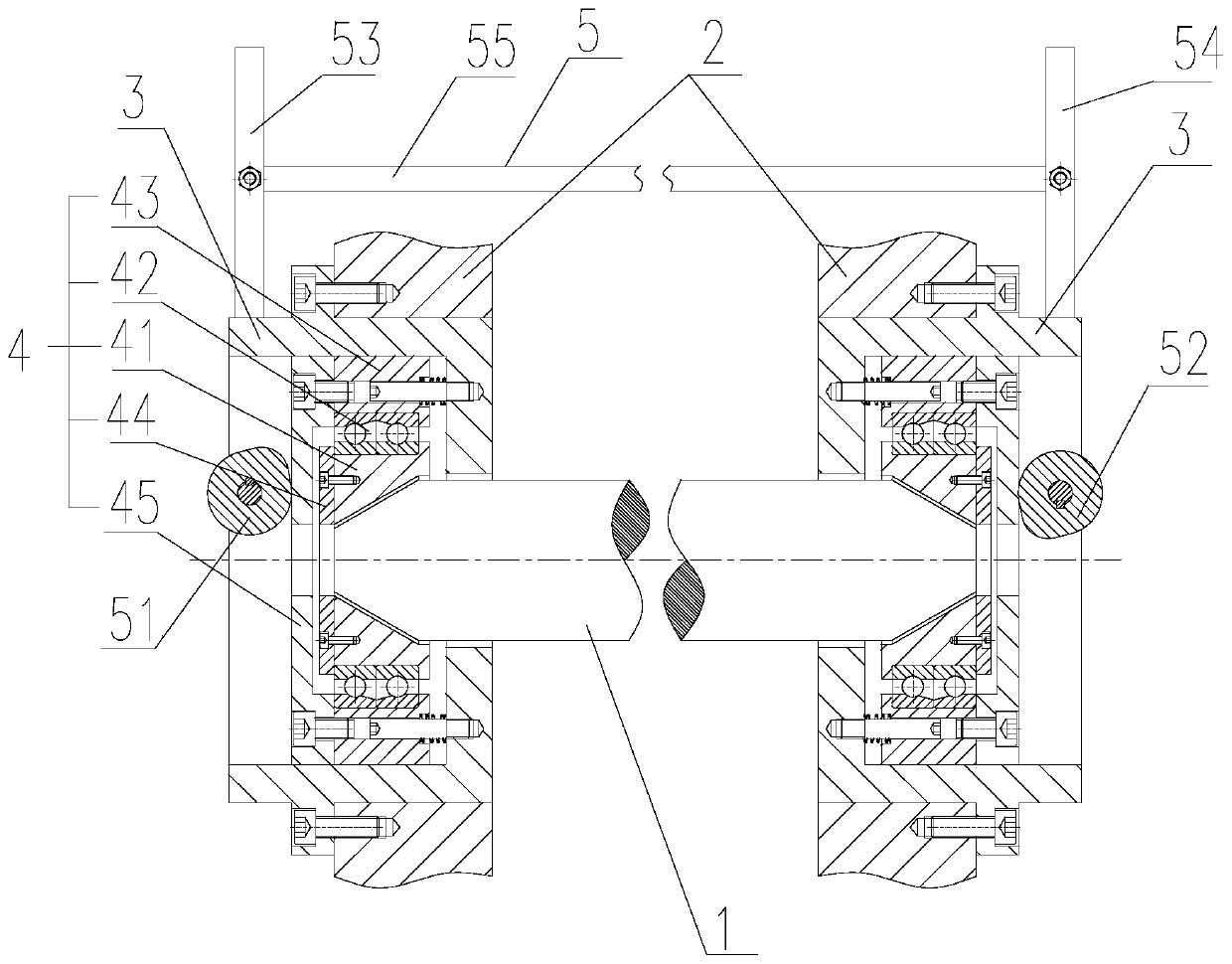

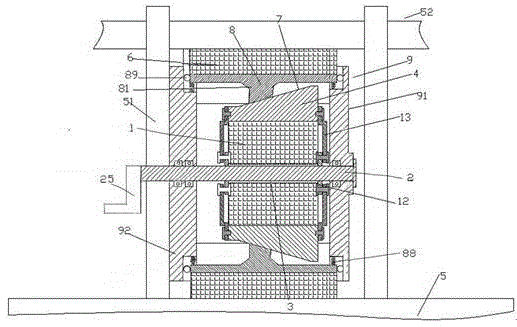

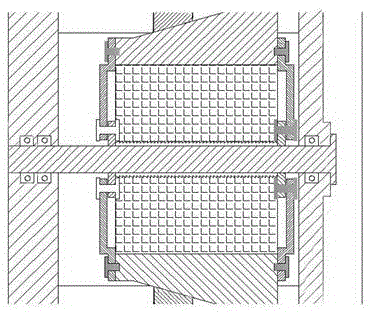

Manual type bearing protection device

The invention relates to a magnetic levitation bearing system, in particular to a manual type bearing protection device. The manual type bearing protection device comprises a rotor, two bearing seats,two groups of bearing protection assemblies and a manual driving assembly; two ends of the rotor are in a circular truncated cone shape; the two bearing seats are arranged at the two ends of the rotor, and the two ends of the rotor extend into the bearing seats; the two groups of the bearing protection assemblies are symmetrically and slidably arranged in the bearing seats, cone-shaped holes which are matched with the ends of the rotor are formed in the bearing protection assemblies; and the manual driving assembly drives the bearing protection assemblies to axially move close to each other until the bearing protection assemblies are in contact with the rotor. The manual type bearing protection device can temporarily support the rotor when a magnetic bearing system fails, can manually protect the rotor, prevents damage caused by falling of the high-speed rotor, and improves the security of the system.

Owner:JIANGSU UNIV OF TECH

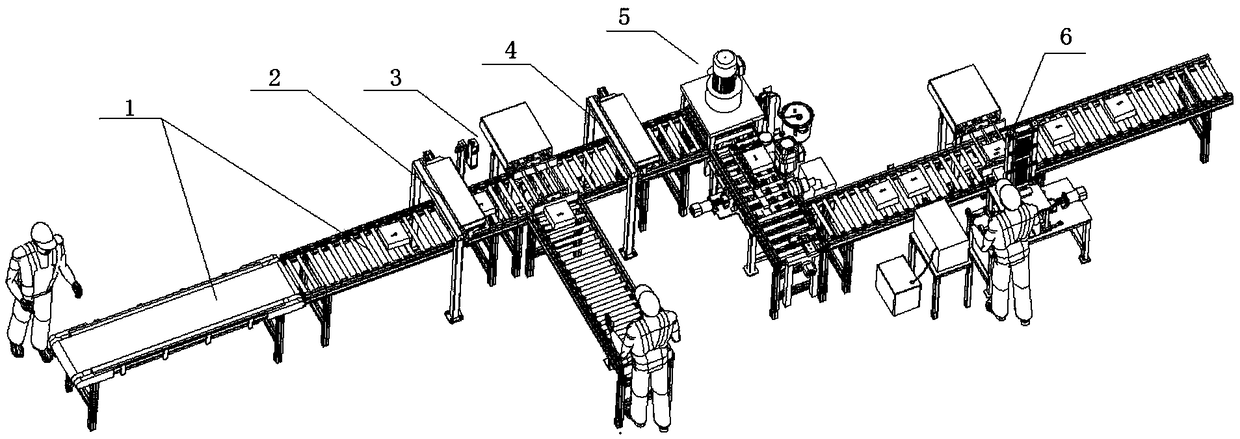

Automatic identifying and detecting operation line for refractory bricks

The invention discloses an automatic identifying and detecting operation line for refractory bricks. The automatic identifying and detecting operation line for the refractory bricks comprises a conveying unit, and the conveying unit is used for conveying the refractory bricks among a primary centering unit, a laser detection unit, a secondary centering unit, a marking and ink jetting unit and an automatic pasting unit in sequence. By means of the automatic identifying and detecting operation line for the refractory bricks, the detection and automatic identification work of the finished refractory bricks in different shapes and even having gradient is achieved, automation is achieved on the whole, and the problems about low operation efficiency, non-uniform identification, large detection errors and the like caused by manual completion of the subsequent operation of the finished refractory bricks in the prior art are solved.

Owner:BEIHUA UNIV

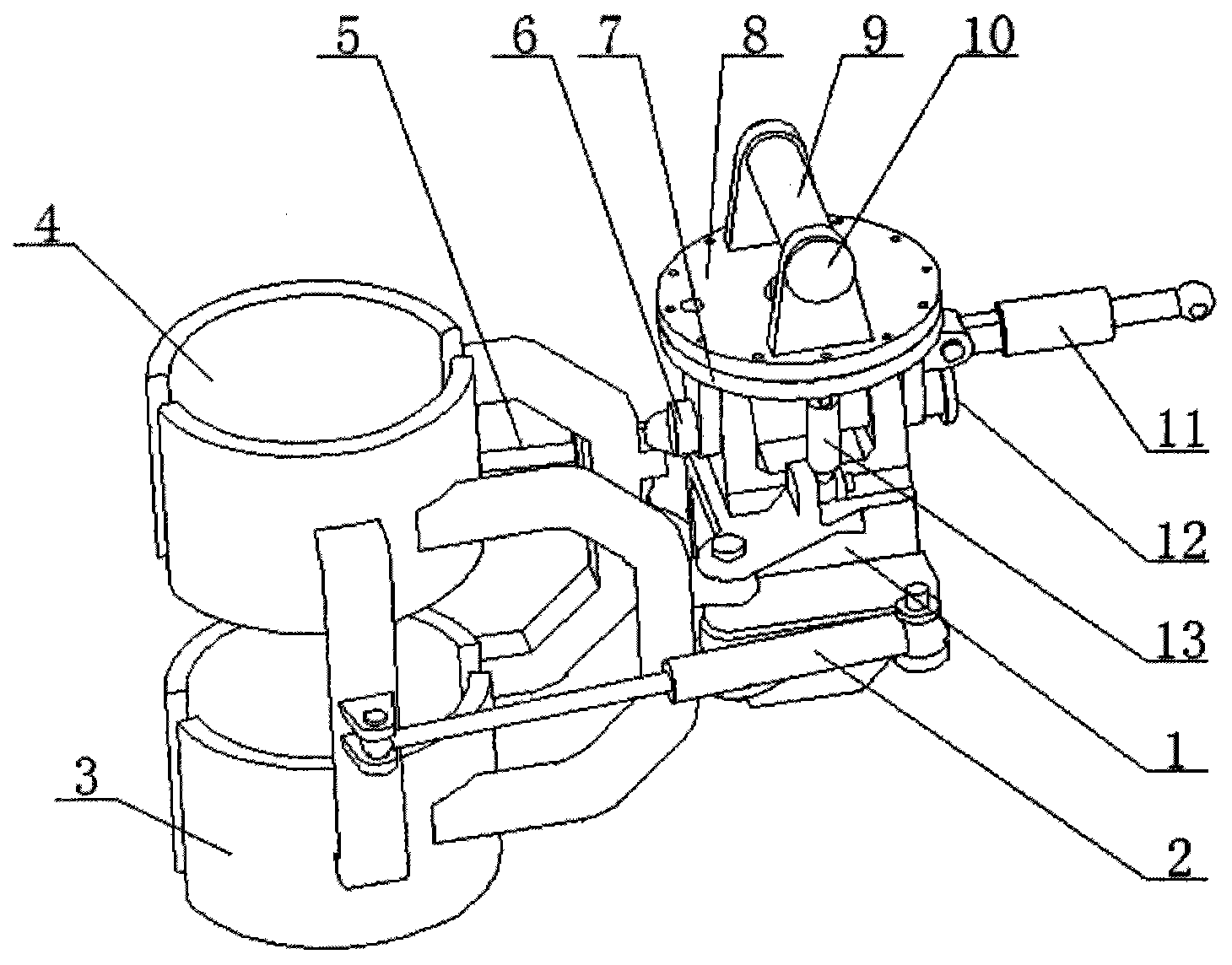

Hydraulic piling machine pile controller

InactiveCN103967012ASimple structureThe transmission structure is stable and reliableBulkheads/pilesHydraulic cylinderEngineering

The invention discloses a hydraulic piling machine pile controller which comprises a pile controller box body and a pile controller verticality adjusting mechanism connected with the pile controller box body. The pile controller box body comprises a control box body. A left swing arm hinge lug and a right swing arm hinge lug are arranged on the two sides of the control box body in a mirror-image mode. Clamping mechanisms are arranged on the left swing arm hinge lug and the right swing arm hinge lug. The pile controller verticality adjusting mechanism comprises a lower flange disc matched with the control box body in a rotating mode. The lower flange disc is connected with an upper flange disc through a periphery-arranged bolt. A longitudinal-shaft-surrounding verticality adjusting hydraulic cylinder is arranged on one side of the lower flange disc. One end of the longitudinal-shaft-surrounding verticality adjusting hydraulic cylinder is connected with a first longitudinal-shaft-surrounding verticality adjusting hydraulic cylinder hinge lug fixed at the bottom of the lower flange disc. The hydraulic piling machine pile controller is simple in structure, a left swing arm and a right swing arm are used for clamping and guiding a precast pile, the whole transmission structure stability and reliability are guaranteed, guiding performance is high, when a first pile is implanted, clamping locating is carried out through the pile controller, a guiding function is achieved during a precast pile implanting process, when a following pile is implanted, clamping of the ends of the two precast piles can be carried out through the pile controller, and coaxial connecting between the piles is carried out.

Owner:ZHONGBEI UNIV

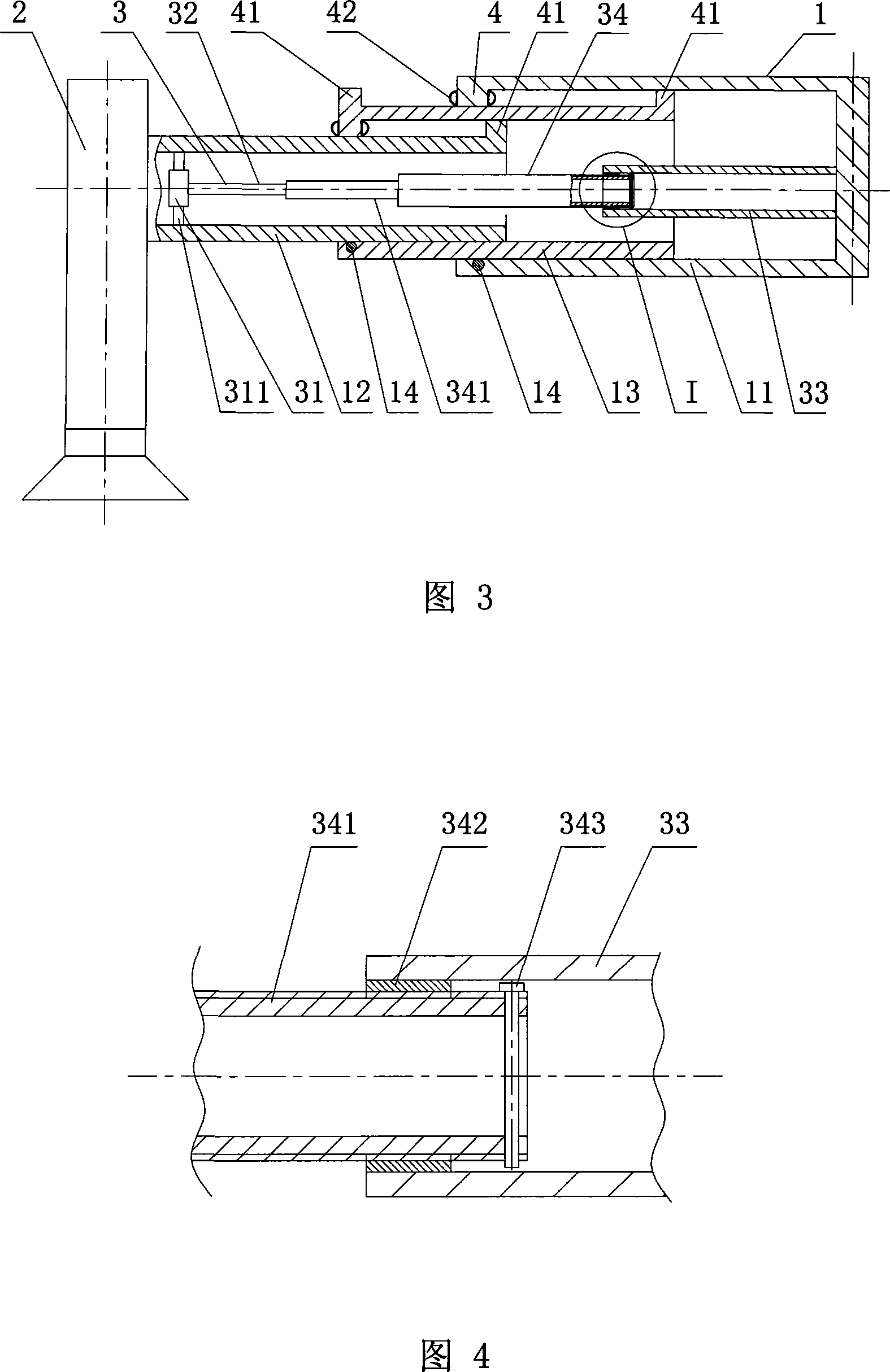

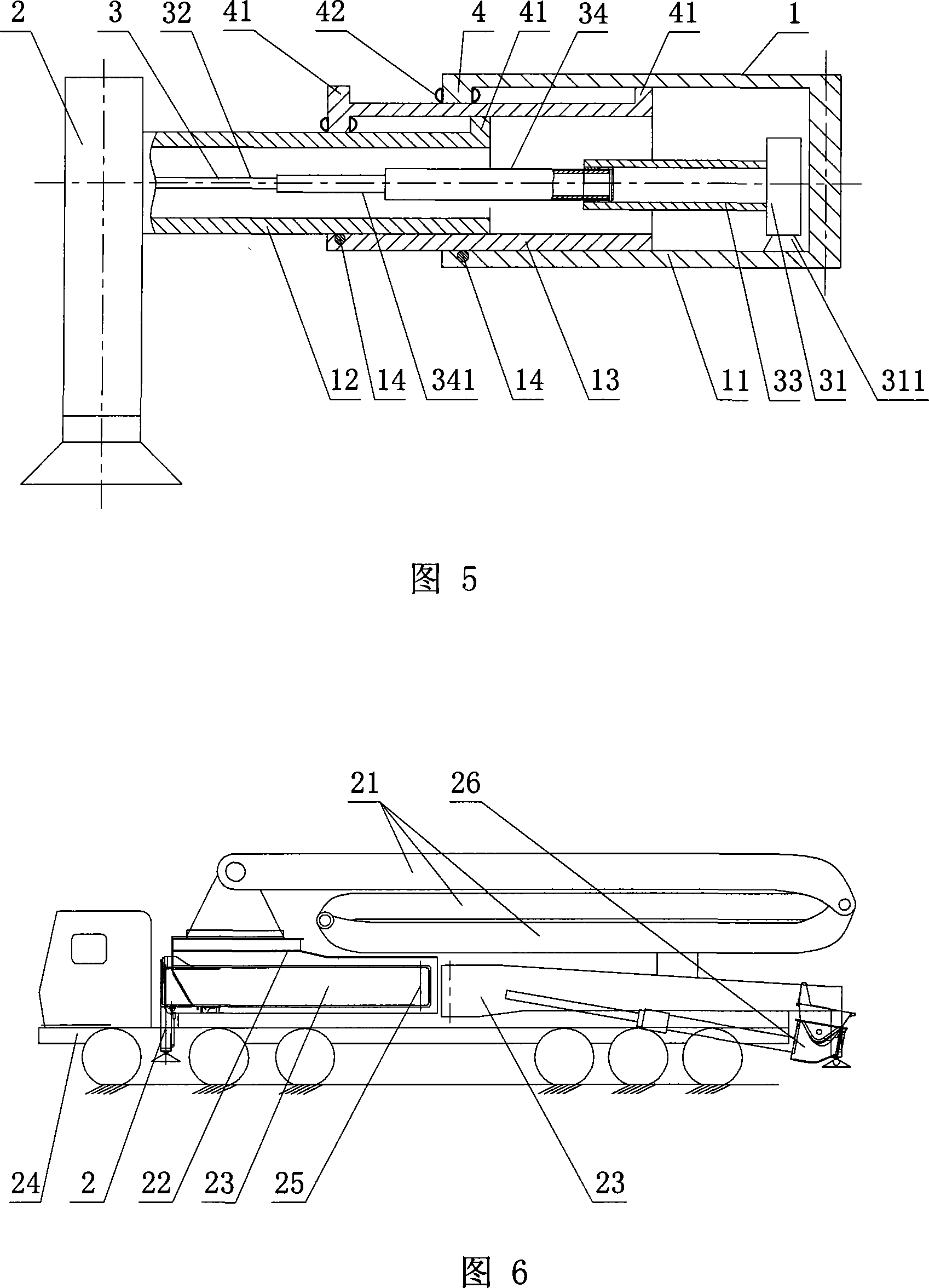

Telescopic component and support for engineering machinery and concrete pump vehicle with the support

InactiveCN101121399ASimple structureEasy to processVehicle fittings for liftingEngineeringScrew thread

A telescopic component used for construction machinery, a telescopic support leg and a concrete pump truck composed of the component. The telescopic assembly includes a telescopic sleeve assembly, and the sleeve assembly is equipped with a screw mechanism and a stop device. The screw mechanism includes a prime mover, a circular shaft and a hollow cylinder, and the circular shaft and the hollow cylinder are threaded, or between the circular shaft and the hollow cylinder Set the middle hollow shaft group, the middle hollow shaft group is composed of the middle hollow shaft with internal and external threads, the two ends of the middle hollow shaft group are respectively screwed with the round shaft and the hollow tube, the prime mover is connected with the end of the round shaft or the hollow tube connection, the prime mover is fixed at one end of the sleeve assembly, and the other end of the sleeve assembly is fixedly connected with the end of the screw mechanism where the prime mover is not installed. The telescopic part of the telescopic outrigger is composed of the telescopic assembly, and one end of the telescopic outrigger is provided with a supporting foot assembly, and the other end is connected with the bracket on the chassis of the construction machine. The telescopic outrigger is installed in the supporting part of the concrete pump truck. The invention has the advantages of simple structure, convenient manufacture and low cost.

Owner:SANY AUTOMOBILE MFG CO LTD

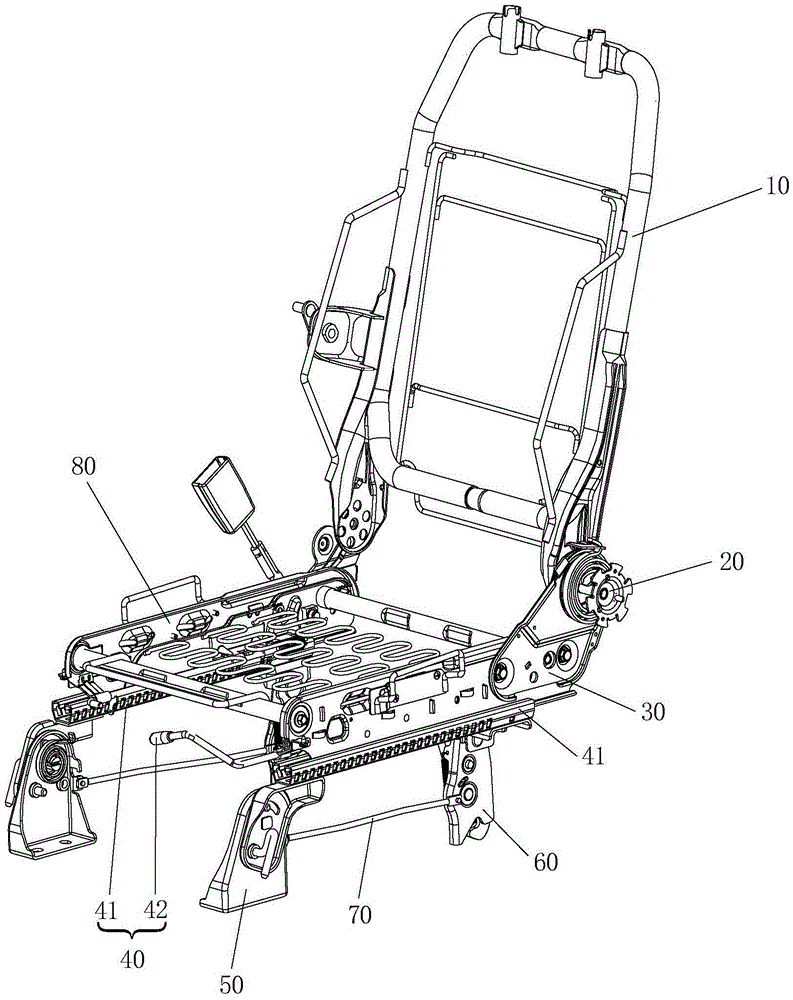

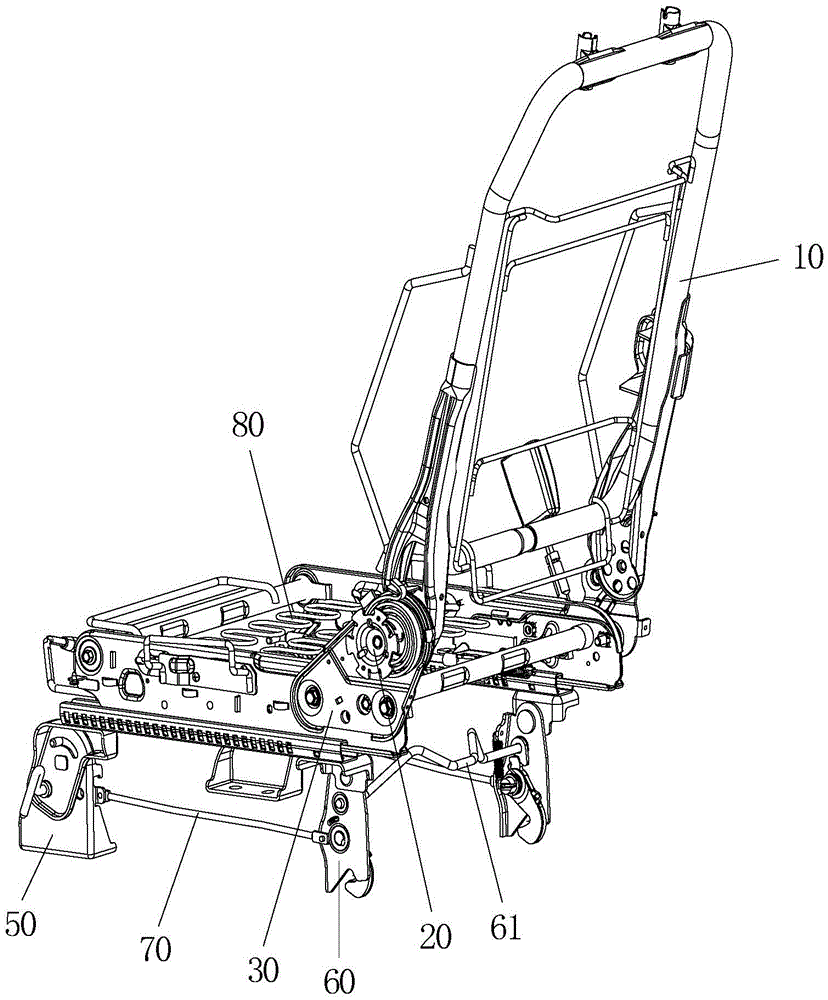

Multifunctional automobile middle-row seat frame

ActiveCN105539235ASmall operating forceSimple structural designSeat framesMovable seatsMechanical engineering

The invention relates to a multifunctional automobile middle-row seat frame. According to the technical scheme, the multifunctional automobile middle-row seat frame comprises a backrest frame body and a cushion frame body which are connected through an angle regulator, and a backrest unlocking device controls the backrest frame body to turn over; a sliding rail device, hinging devices and floor lock devices are arranged, the sliding rail device is composed of sliding rails and a sliding rail unlocking device, the sliding rails are installed at the lower end of the cushion frame body, the hinging devices are installed at the front ends of the sliding rails, the floor lock devices are arranged at the rear ends of the sliding rails, and the hinging deices and the floor lock devices are connected through connecting rods. The multifunctional automobile middle-row seat frame is reasonable in structural layout, easy to operate, slidable, foldable and capable of increasing the storage space of a passenger zone to the maximum.

Owner:SHENYANG ZHONGRUI MACHINERY CO LTD

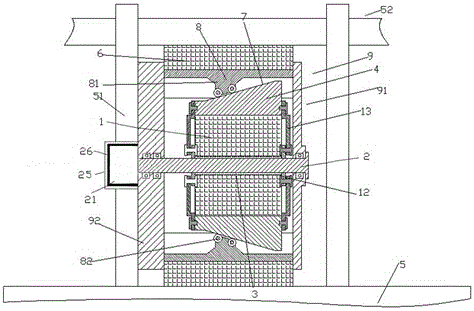

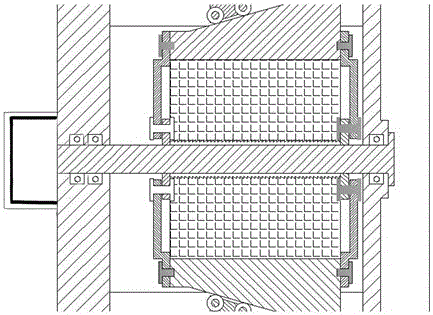

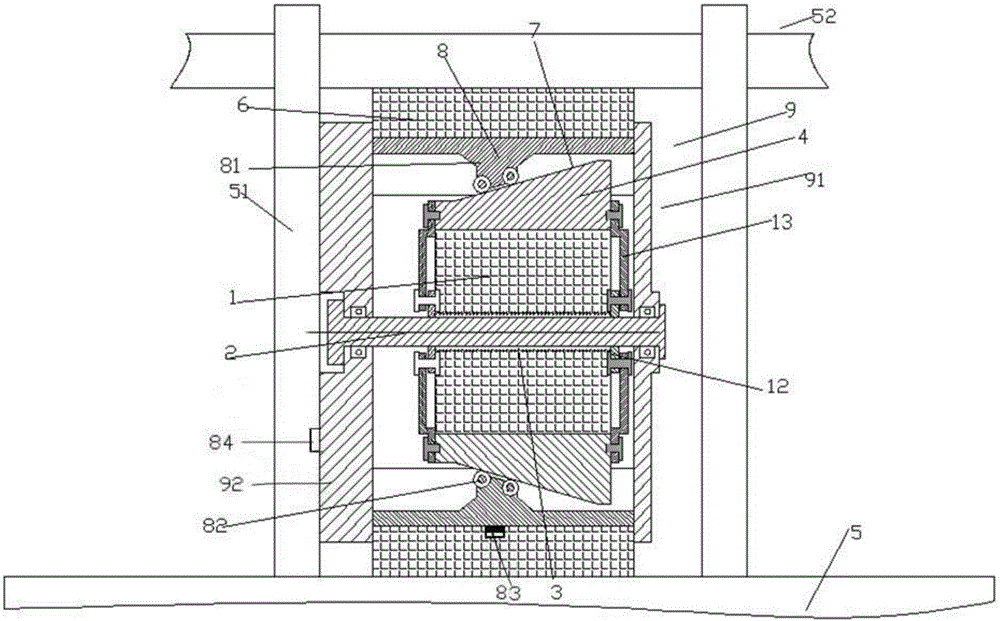

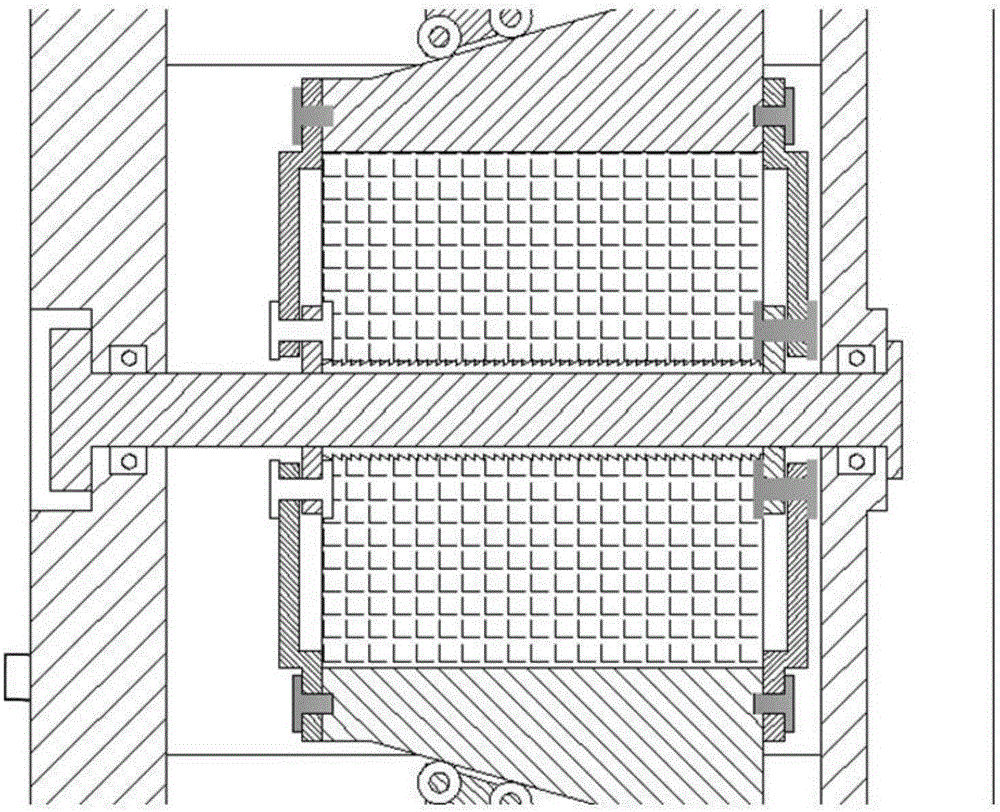

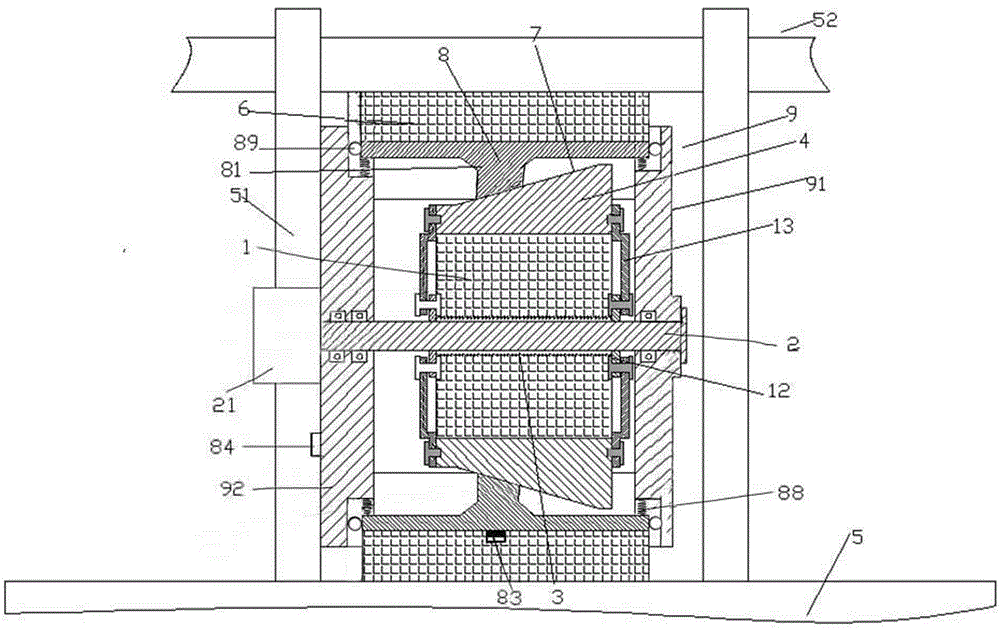

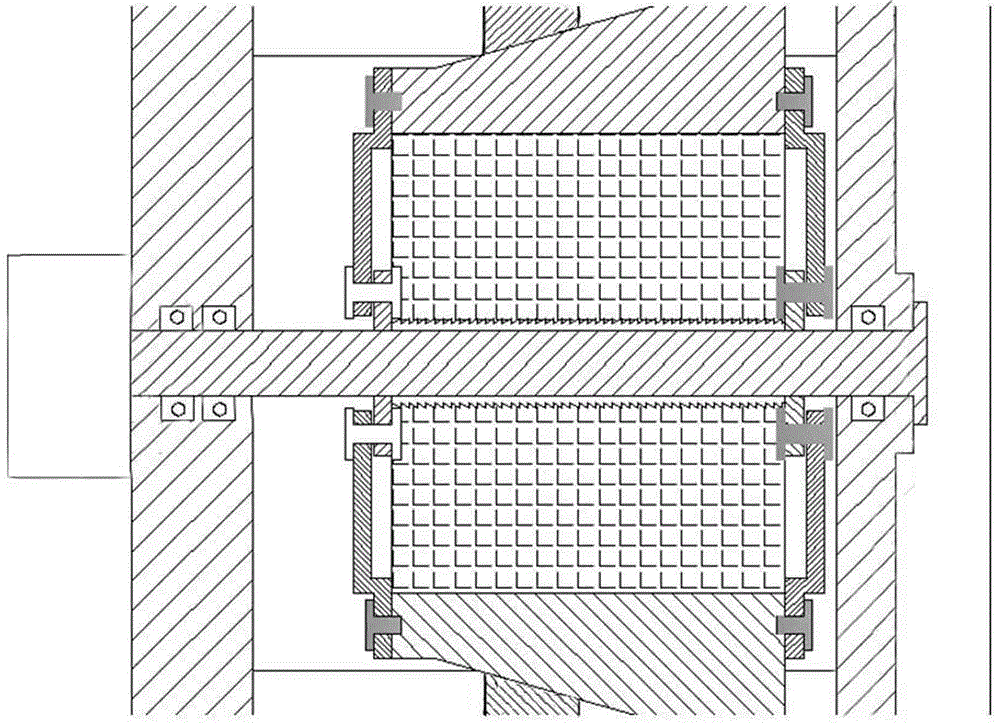

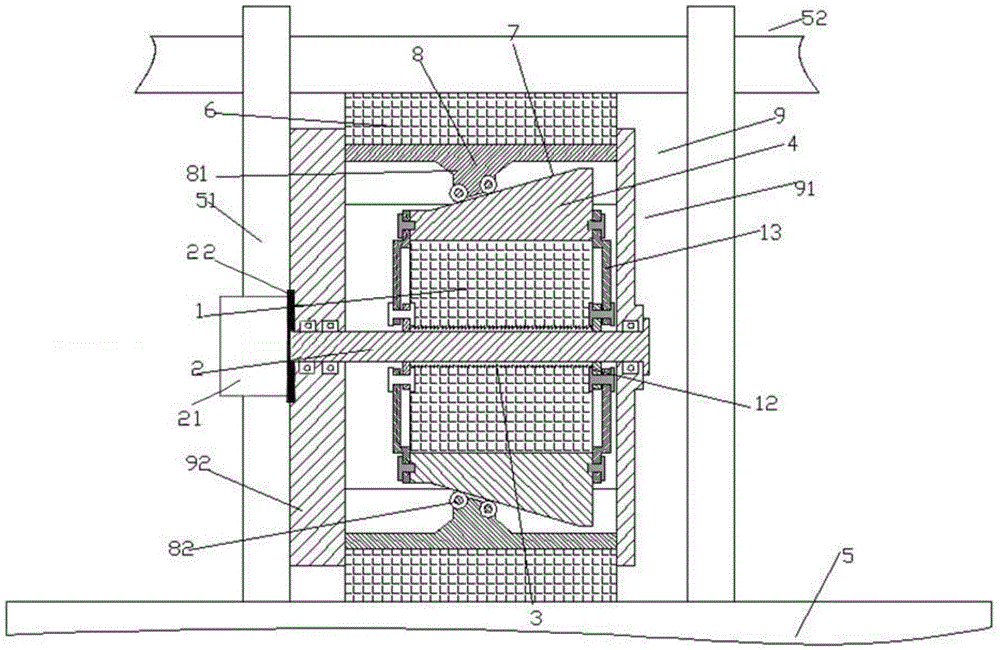

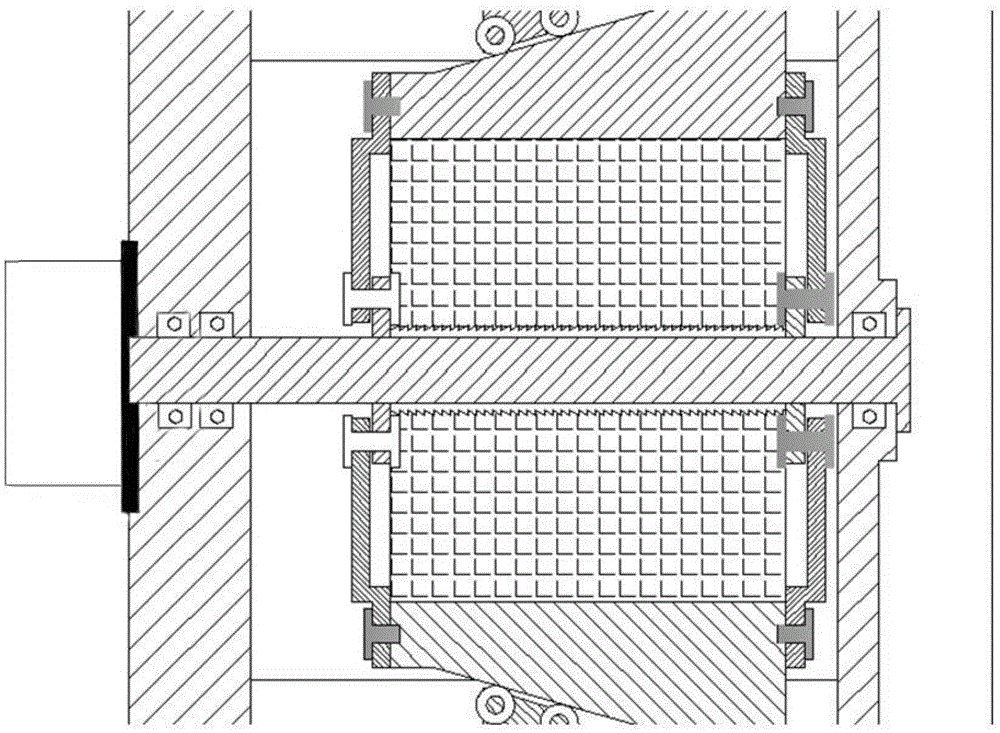

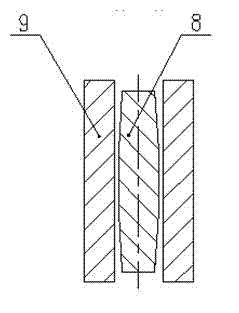

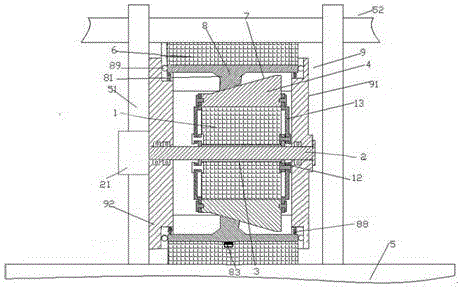

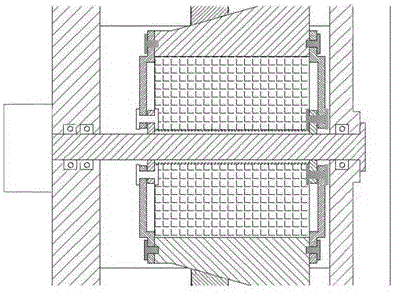

Fixing device for suspension type component and using method of fixing device

The invention relates to a fixing device for a suspension type component and a using method of the fixing device. The device comprises a supporting and fixing cross beam component (52), a suspension body (5) and an ejecting type elastic fixing device assembly, wherein the suspension body (5) is provided with suspension hook components (51) used for being hooked to the supporting and fixing cross beam component (52). The ejecting type elastic fixing device assembly comprises a shell component (9), two elastic ejecting assemblies symmetrical in structure and an elastic pushing assembly, wherein the shell component (9) comprises a left side wall (92) and a right side wall (91), the elastic ejecting assemblies can slide vertically between the left side wall (92) and the right side wall (91) and are provided with outer elastomers (6) and inner bearing transmission plate components (8) fixed to the inner sides of the outer elastomers, and the elastic pushing assembly can be adjusted by an adjusting screw (2) rotationally installed on the left side wall (92) and the right side wall (91) to move left and right.

Owner:李长娟

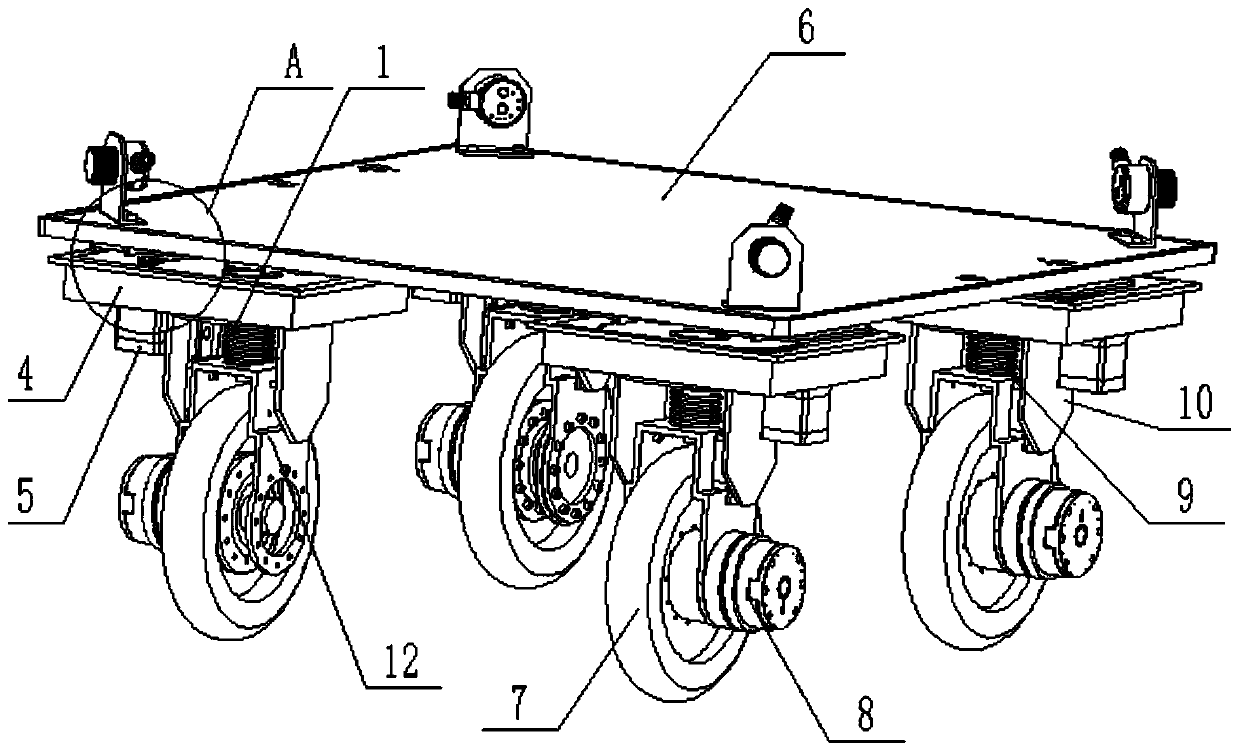

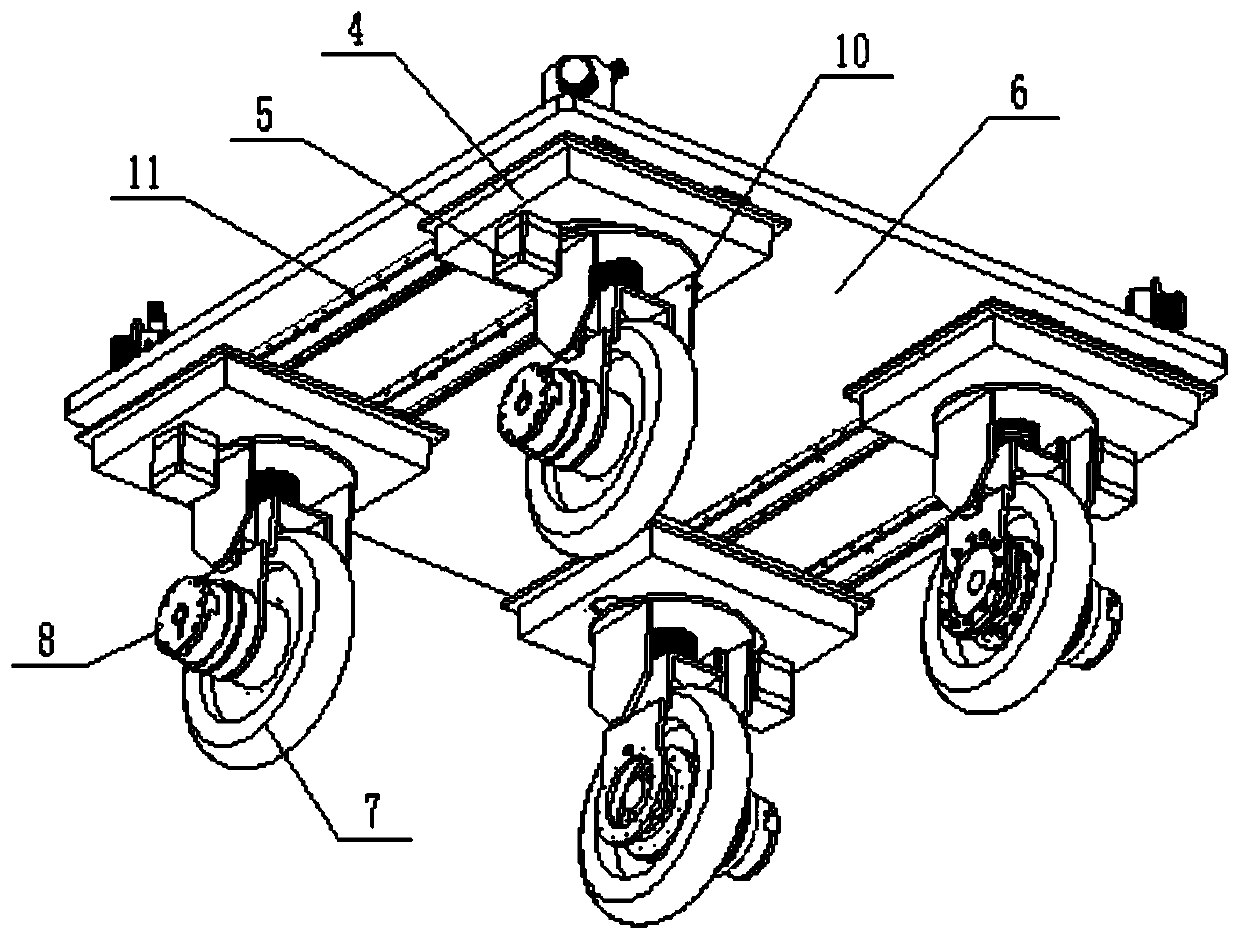

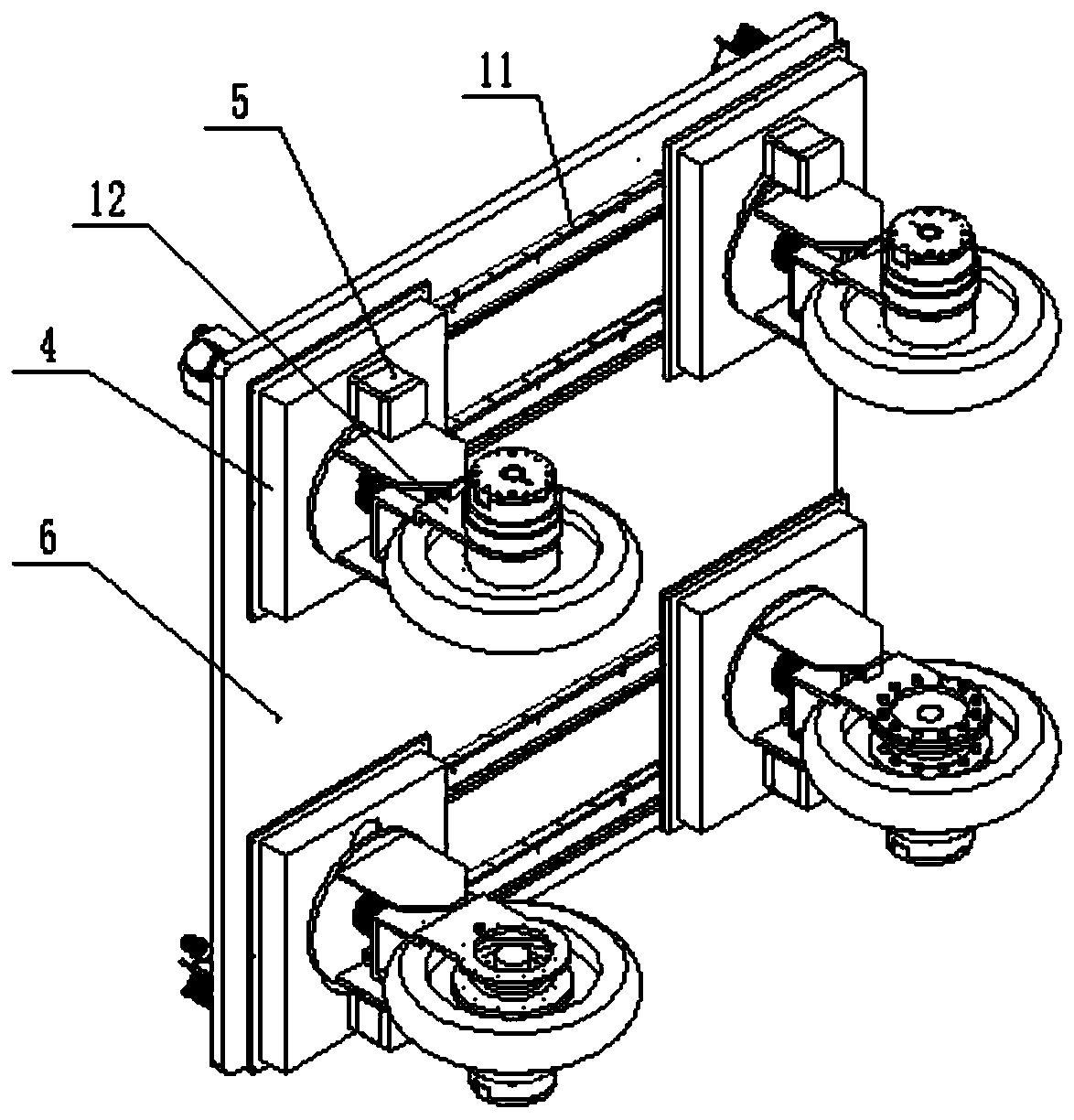

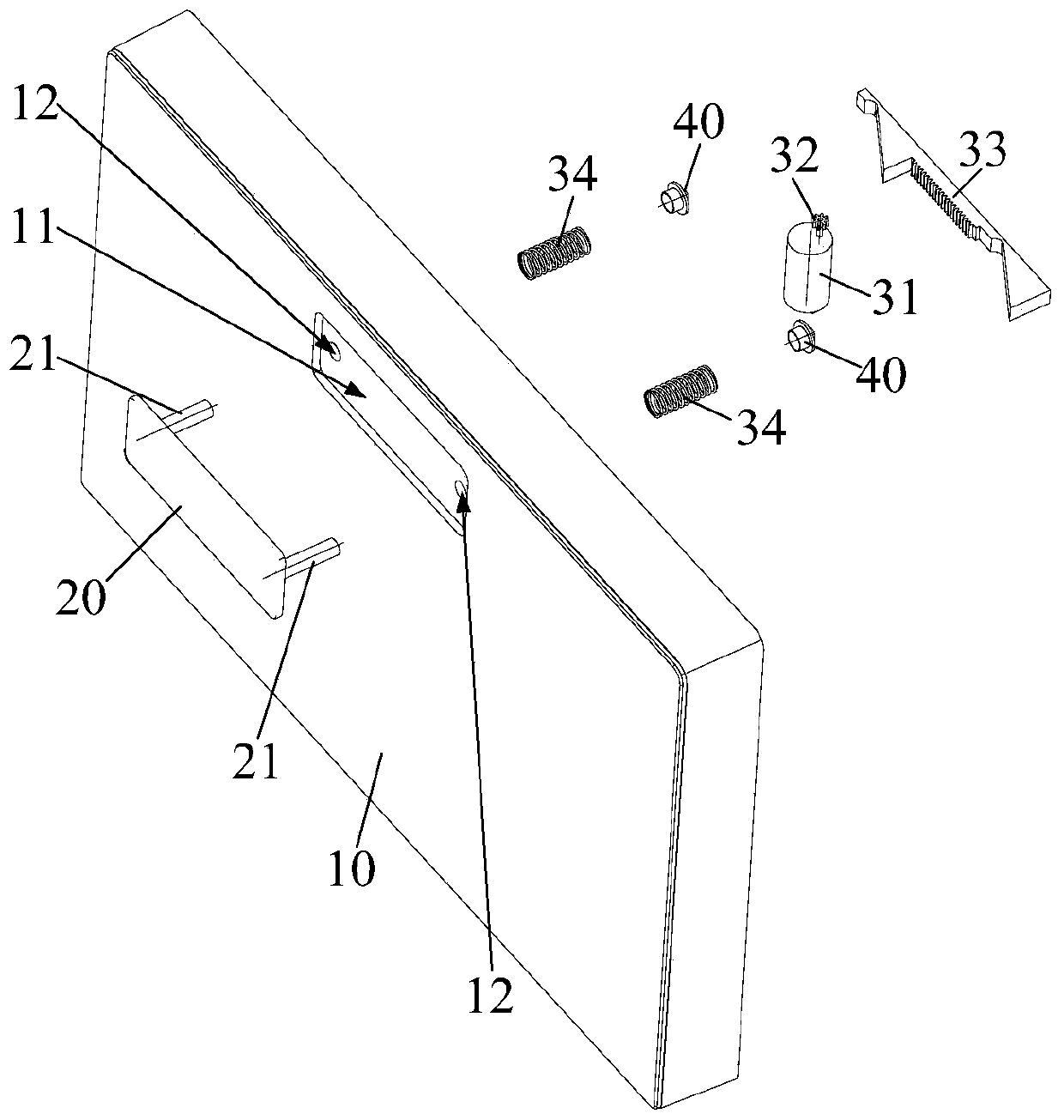

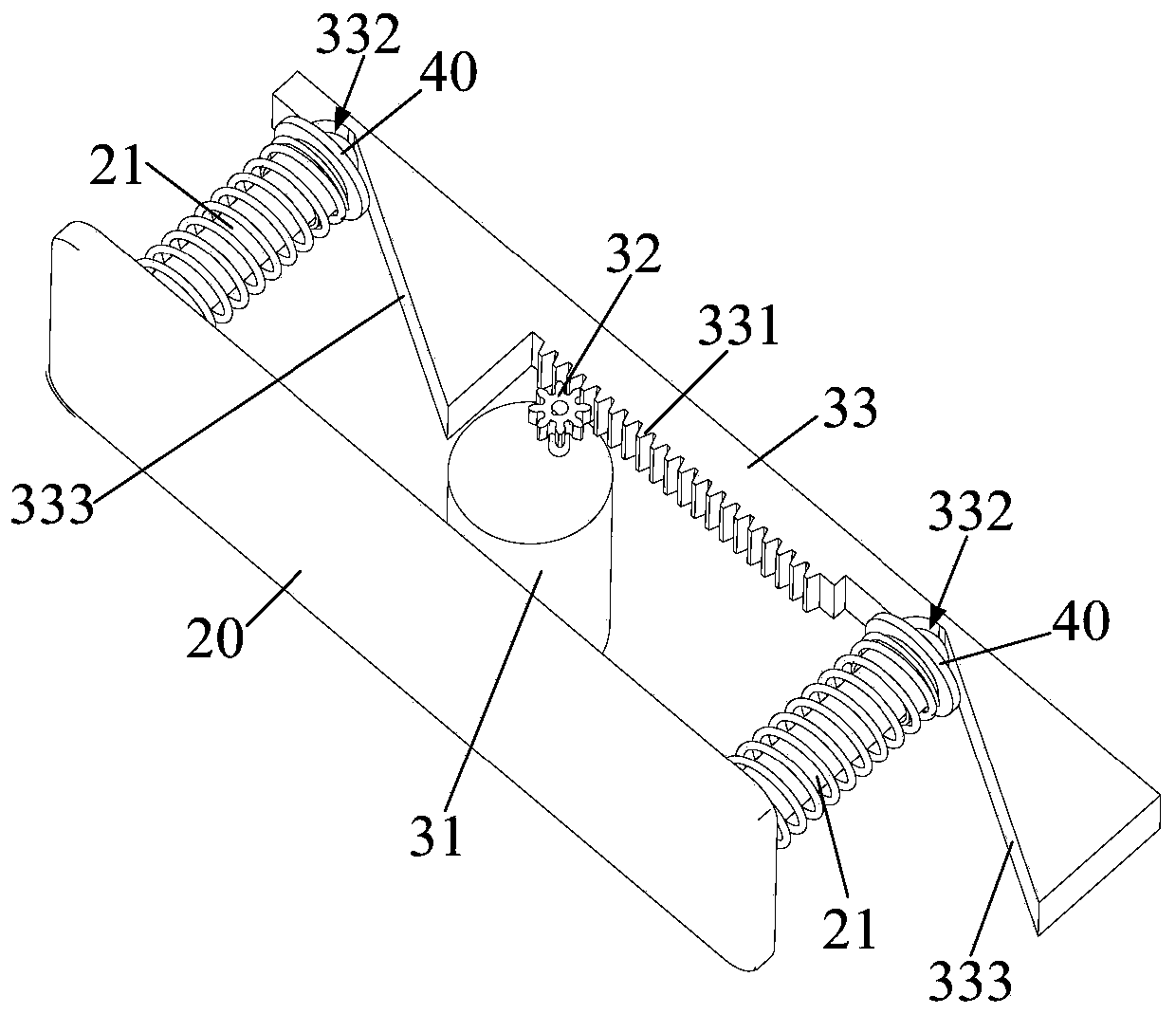

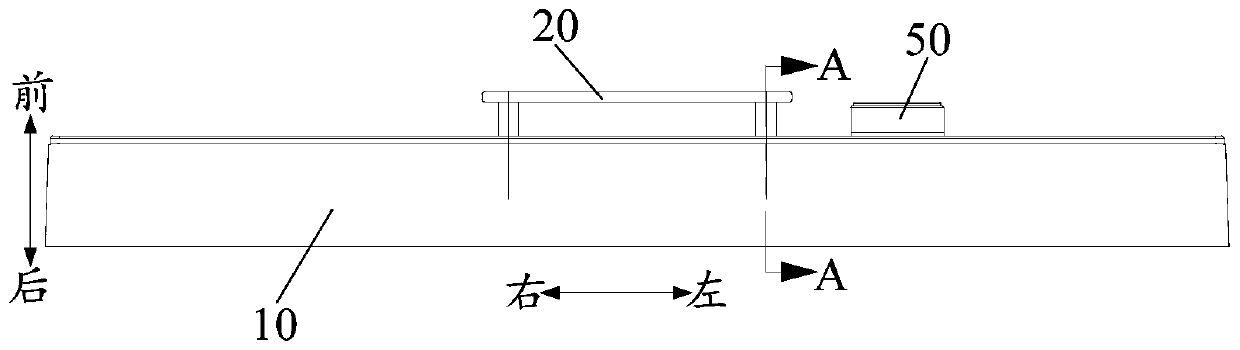

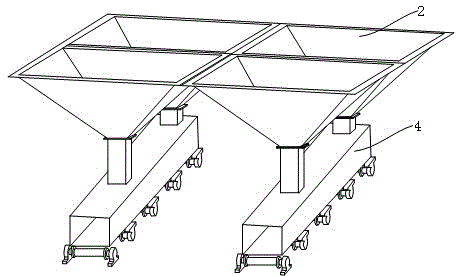

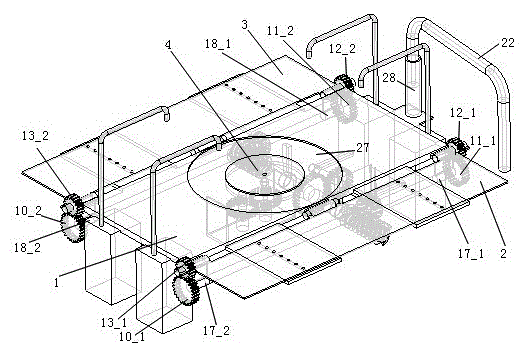

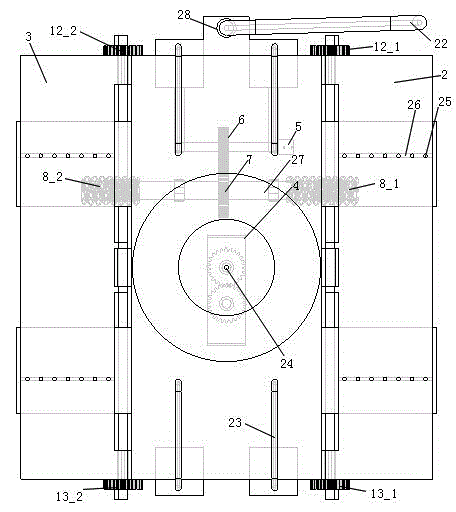

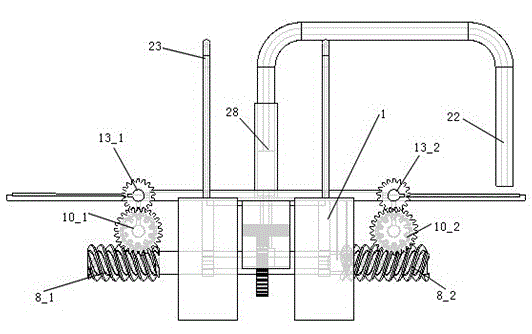

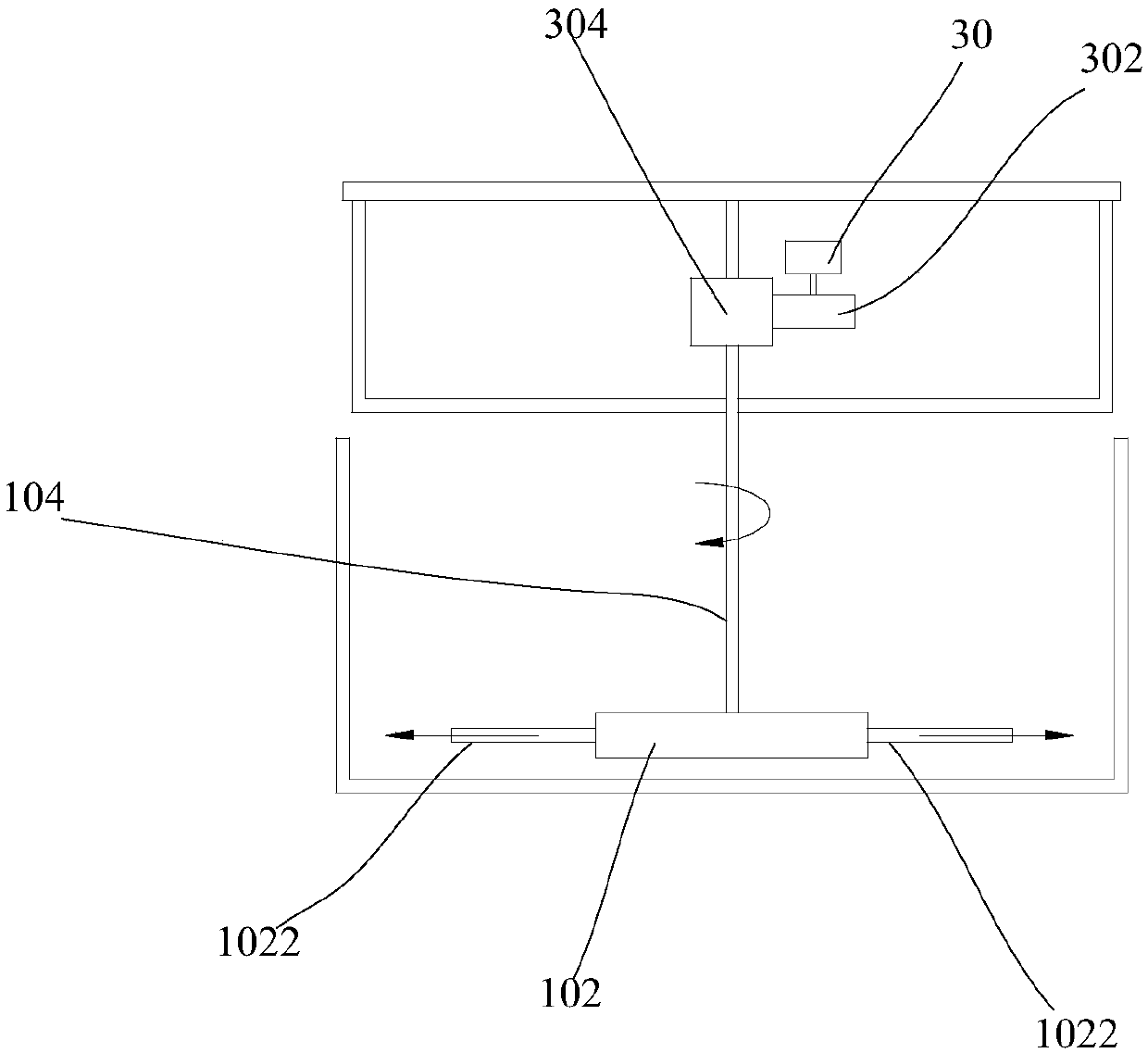

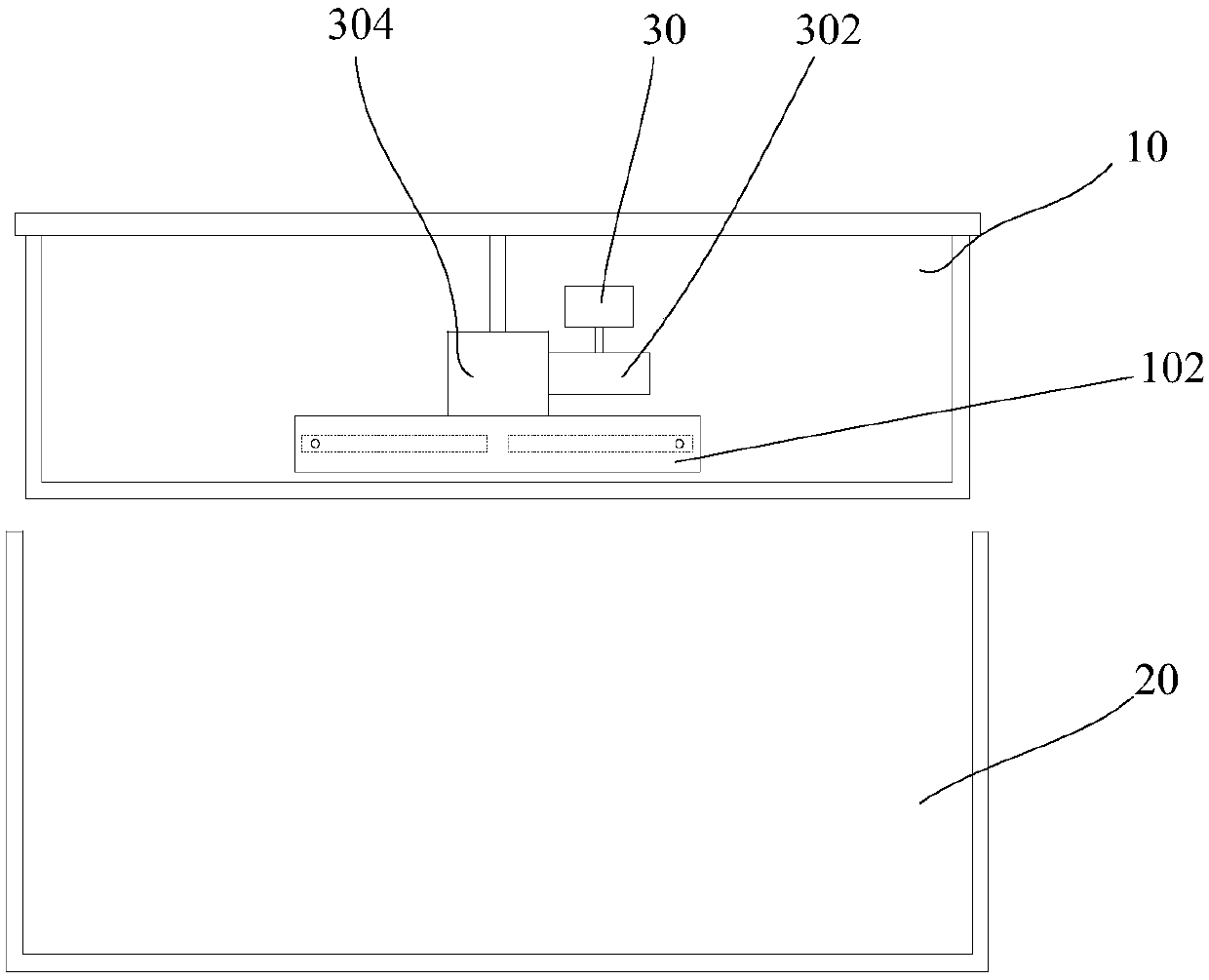

Wheel-span- adjustable carrying platform

InactiveCN111196309AExtended service lifeSmooth rotationMechanical steering gearsElectrical steeringEngineeringStructural engineering

The invention relates to a wheel-span-adjustable carrying platform. The wheel-span-adjustable carrying platform comprises a workbench; two parallel columns of walking wheel assemblies are installed onthe lower surface of the workbench; each walking wheel assembly can rotate along the vertical axis of the walking wheel assembly to complete the steering of the walking wheel assembly; a rotary driving piece is installed in each walking wheel assembly to drive walking wheels in the walking wheel assembly to rotate along the central axis of the walking wheel assembly; the walking wheel assembliesin are connected through fixing pieces; the walking wheel assemblies are in sliding connection with the lower surface of the workbench through guiding pieces; and the extending directions of the guiding pieces are perpendicular to the extending directions of the walking wheel assemblies. The two columns of walking wheel assemblies can synchronously slide along the guide pieces in the same direction or in the opposite directions, so that the wheel span of the two columns of walking wheel assemblies can be changed.

Owner:SHANDONG JIAOTONG UNIV

Household appliance and door assembly thereof

ActiveCN109723279AImprove user experienceReduce adverse effectsWing handlesEngineeringMechanical engineering

The invention provides a household appliance and a door assembly thereof. The door assembly comprises a door plate and a door handle, wherein a handle groove used for containing the door handle is formed in the door plate, the door handle is arranged at the handle groove, is matched with the shape of the handle groove and can move back and forth relative to the door plate so as to extend out of orretract into the handle groove. According to the door assembly, the handle groove is formed in the door plate, the door handle is movably arranged at the handle groove, the door handle can retract into the handle groove when not being used, so that the effect of hiding the door handle is achieved, the whole door board is smooth, attractive and elegant, and the attractiveness of the product is improved; meanwhile, the phenomenon that a user can be easily scratched due to the fact that the two ends of certain door handles are protruded in the prior art is also avoided, and the use experience ofthe user is improved; and when the door handle needs to be used, the door handle can extend out of the handle groove so as to protrude out of the surface of the door plate, it is guaranteed that theuser can hold the door handle by hand to carry out door opening, door closing and the like, so that the corresponding functions of the door handle is realized.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

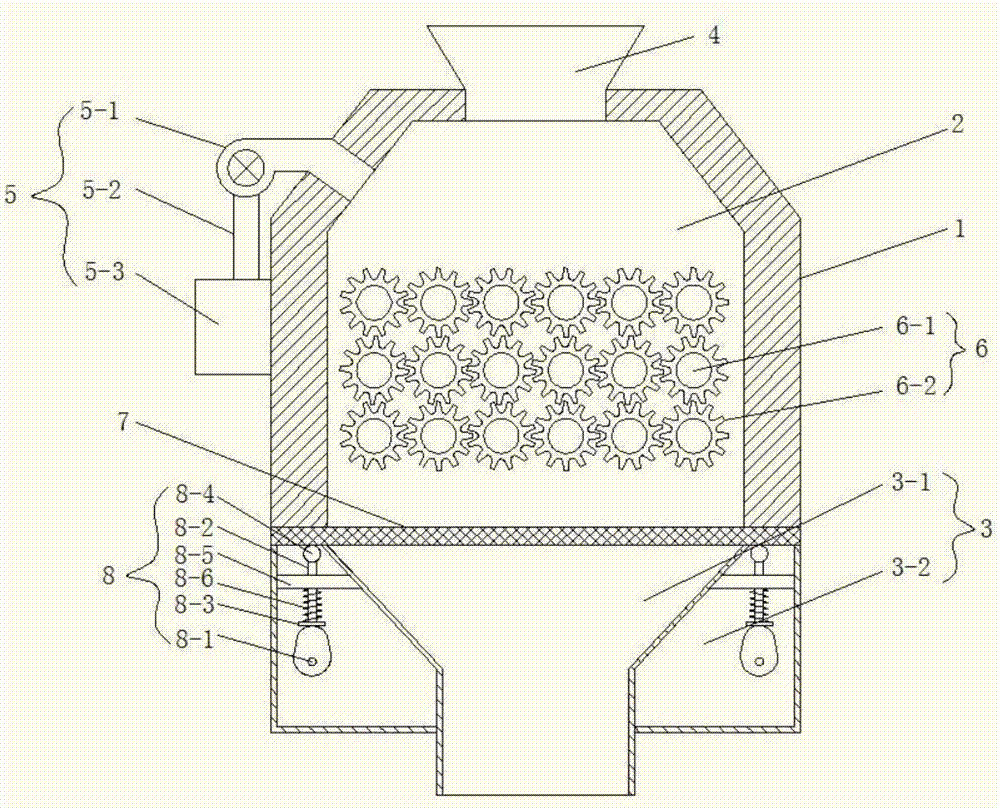

Anti-blocking molybdenum powder processing pulverizer

The invention discloses an anti-blocking molybdenum powder processing pulverizer, and relates to the technical field of pulverizers. The anti-blocking molybdenum powder processing pulverizer comprisesa machine shell; the machine shell is internally provided with a pulverizing chamber and a discharging chamber from top to bottom, a filter plate is arranged between the pulverizing chamber and the discharging chamber, and the pulverizing chamber is internally provided with a pulverizing mechanism; the discharging chamber comprises a funnel-shaped discharging cavity and vibrating cavities uniformly distributed on the two sides of the discharging cavity, and the two vibrating cavities are internally provided with same vibrating mechanisms; each vibrating mechanism comprises a cam and a cylindrical pushing rod arranged above the cam; the bottoms of the pushing rods are connected with stop blocks making contact with the cams, the tops of the pushing rods are connected with hammering balls used for striking the filter plate, and the diameter of each hammering ball is greater than that of each pushing rod; fixing plates are arranged on the pushing rods in a penetrating mode, and the fixingplates are located between the hammering balls and stop blocks and fixed in the vibrating cavities; and buffering springs which are wound around the pushing rods are arranged between the fixing plates and the stop blocks. The anti-blocking molybdenum powder processing pulverizer has the advantages of being simple in structure, convenient to operate and smooth in discharging of molybdenum powder.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Hung-type fixing device provided with LED indicator lamp and using method of fixing device

InactiveCN105845026AEnsure consistencyEnhanced push-pull performanceLighting elementsSemiconductor devices for light sourcesEngineeringLead Indicator

The invention discloses a hung-type fixing device provided with an LED indicator lamp and a using method of the fixing device. The device comprises a supporting fixed cross beam part (52), a hanging body (5) which is provided with hanging hook parts (51) hooked and hung on the supporting fixed cross beam part (52), and an ejecting-type elastic fixing device assembly, wherein the ejecting-type elastic fixing device assembly comprises a shell part (9) which is provided with a left sidewall (92) and a right sidewall (91), two elastic ejecting components and an elastic pushing component; the two elastic ejecting components are capable of sliding up and down between the left sidewall (92) and the right sidewall (91) of the shell part (9), the two elastic ejecting components are provided with outer-side elastic bodies (6) and inner-side bearing transmission plate parts (8) which are fixedly arranged on the inner sides of the outer-side elastic bodies and the two elastic ejecting components are mutually symmetrical in structure; and the elastic pushing component is capable of moving left and right when the elastic pushing component is regulated by a regulating screw rod (2) which is arranged on the left sidewall (92) and the right sidewall (91) in a rotatable mode.

Owner:陈园婷

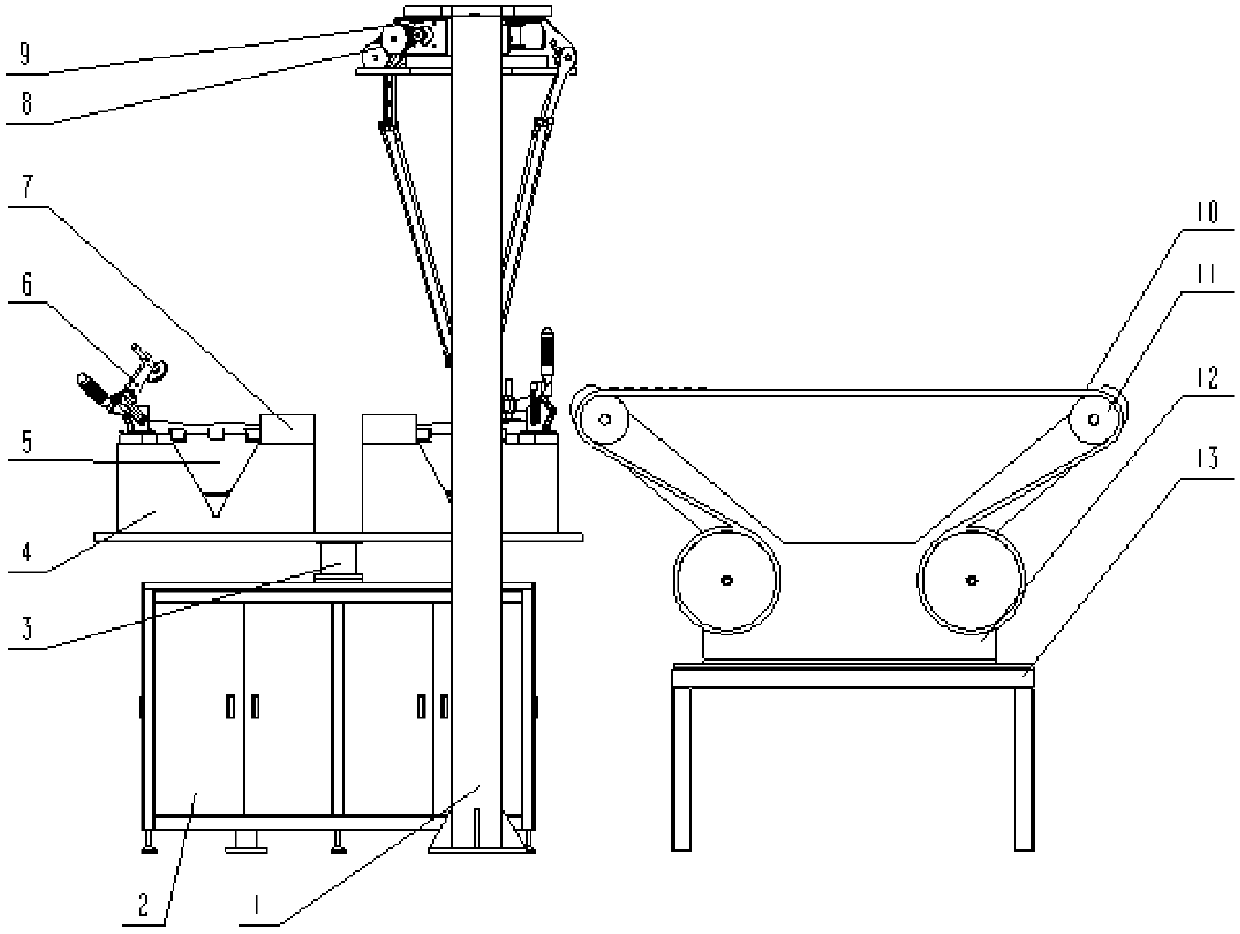

Automatic stamping equipment

PendingCN112338040AGuaranteed synchronous motionAvoid affecting punching qualityMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention discloses automatic stamping equipment. The automatic stamping equipment comprises a rack, a female die assembly, a stamping mechanism, a feeding mechanism and a driving assembly, wherein a workbench is arranged at the top of the rack; the female die assembly is arranged on the workbench, and a punched hole is formed in the female die assembly; the stamping mechanism is arranged on the rack; the feeding mechanism is arranged on the rack, and a raw material belt penetrates through the feeding mechanism and extends to the position between the female die assembly and the stamping mechanism; the driving assembly comprises a rotary power source, a feeding transmission wheel and a stamping transmission wheel; a feeding transmission wheel and a stamping transmission wheel are arranged on a power transmission shaft of the rotary power source at intervals; and the feeding transmission wheel is in transmission connection with the feeding mechanism, the stamping transmission wheel is in transmission connection with the stamping mechanism, and the driving assembly can drive the feeding mechanism to move forwards in a clearance mode and meanwhile drive the stamping mechanism to punch the raw material belt when the feeding mechanism is suspended. According to the automatic stamping equipment, the synchronism of feeding and stamping can be guaranteed, and then the product quality is improved.

Owner:红禾朗(重庆)工业制造有限公司

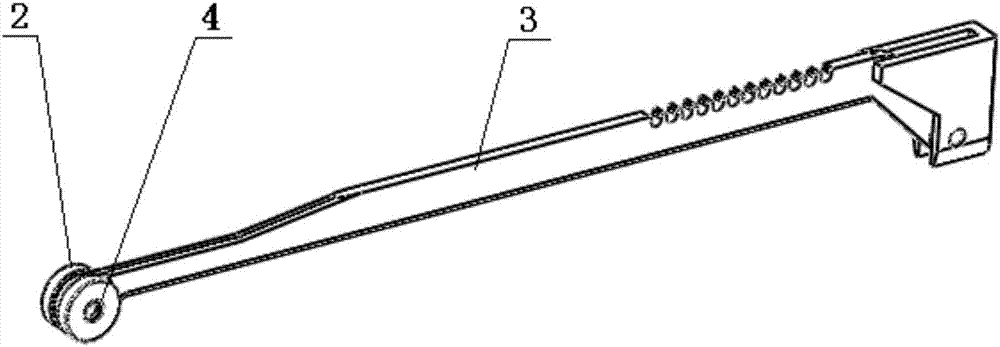

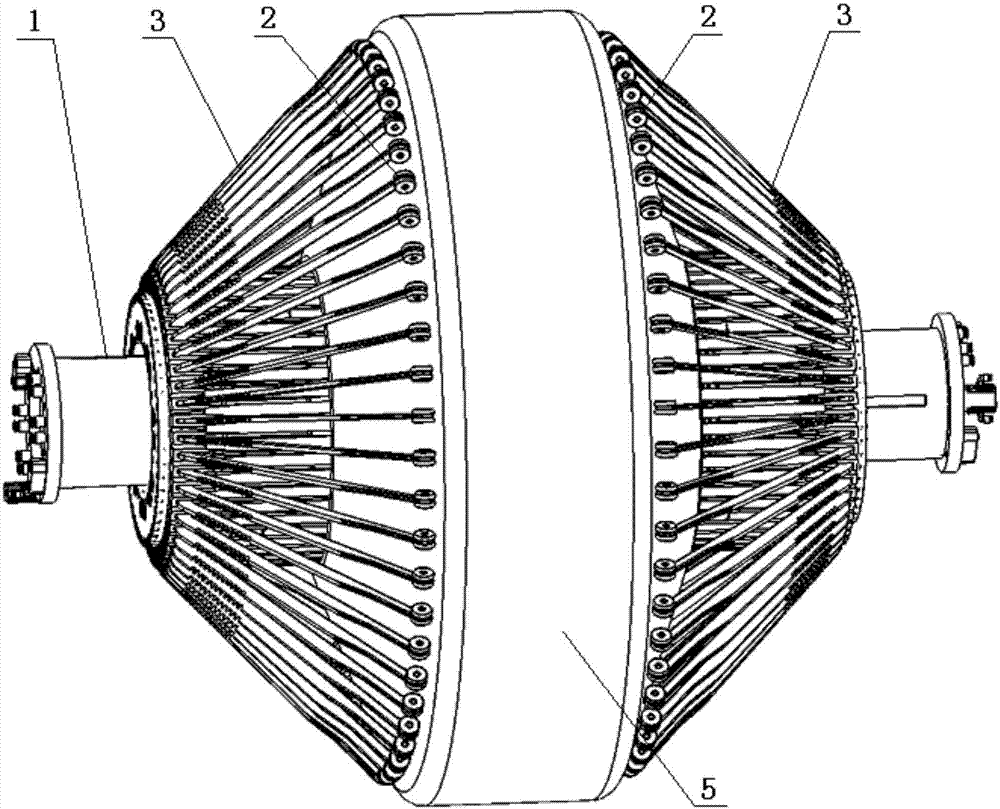

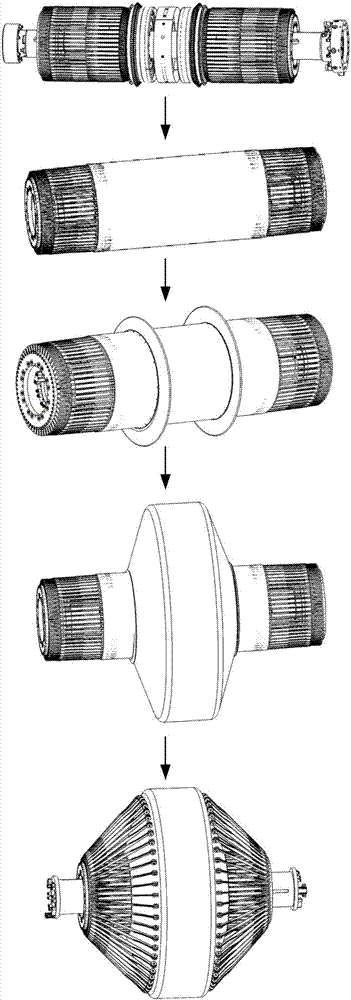

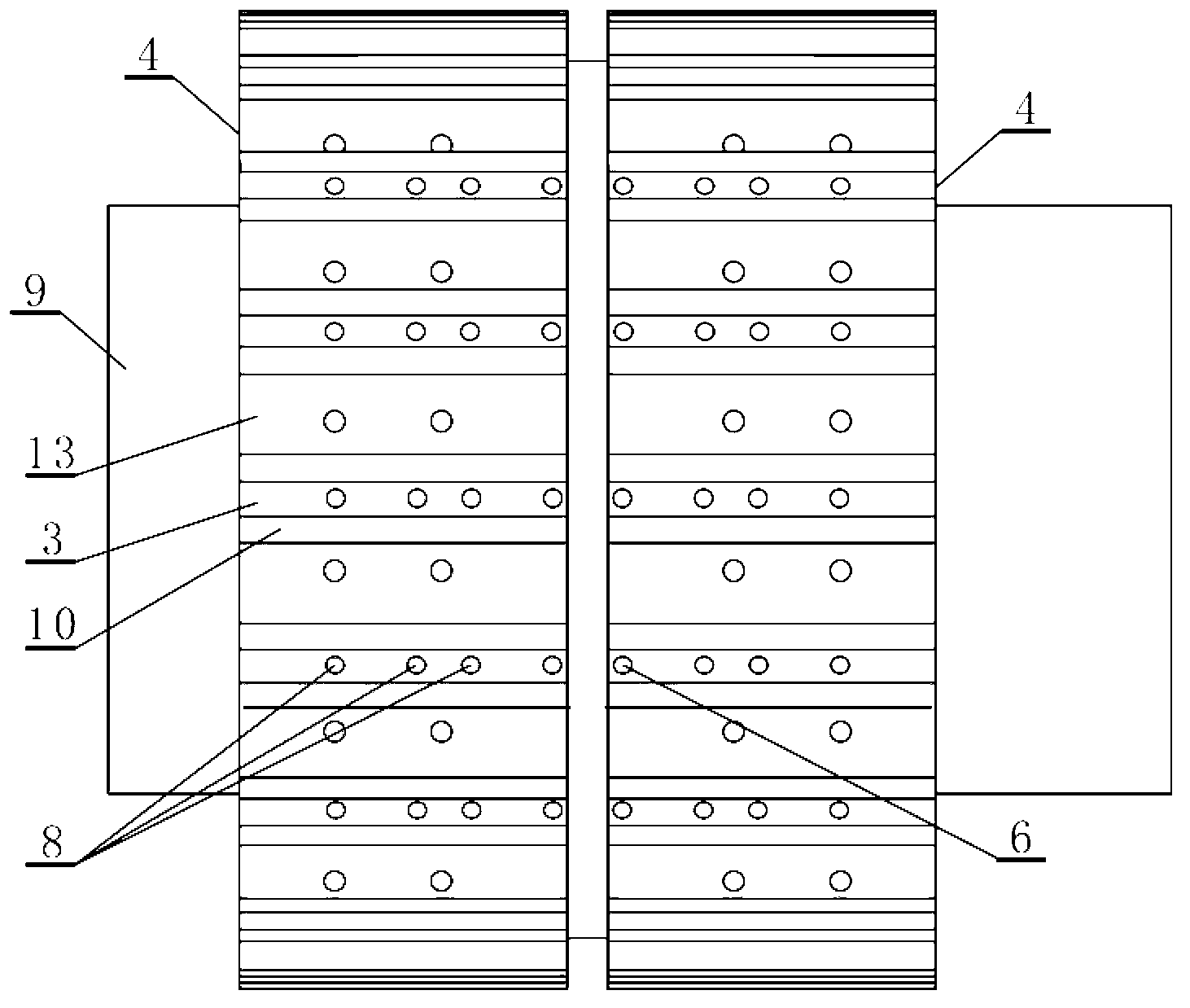

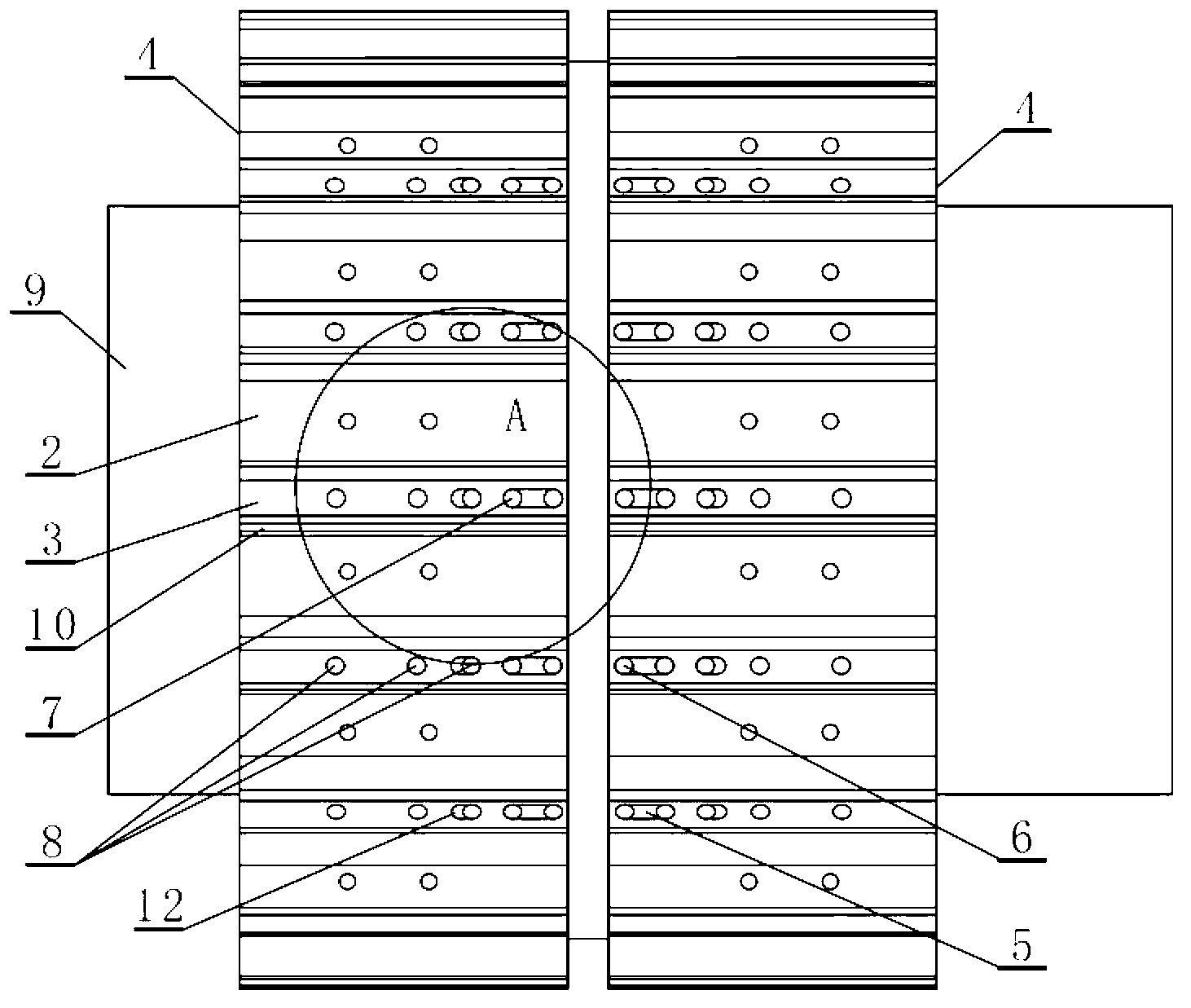

Mechanical assembly drum, anti-package equidistant control device and control method thereof

PendingCN107471705APressure value adjustmentSame pressure valueTyresEngineeringStructural engineering

The invention discloses a mechanical assembly drum, an anti-package equidistant control device and a control method thereof. The anti-package equidistant control device comprises the mechanical assembly drum which comprises anti-package rod devices arranged on two sides of a green tire and a driving device which controls the anti-package rod devices to operate; each of the anti-package rod devices comprises an anti-package rod (3) and a pressure sensor (4) for detecting stress of the anti-package rod (3). The mechanical assembly drum also comprises a comparing device for pressure values of the pressure sensors (4) on the anti-package rods on two sides. The comparing device is in communication connection to the driving device. The anti-package equidistant control device provided by the invention can adjust the pressure values of the anti-package rods effectively, so that the pressure values on two sides of the green tire tend to be same, so that synchronous movement of the anti-package rods on two sides is ensured, the stress on two sides of the green tire is same, and the quality of the green tire is improved.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG

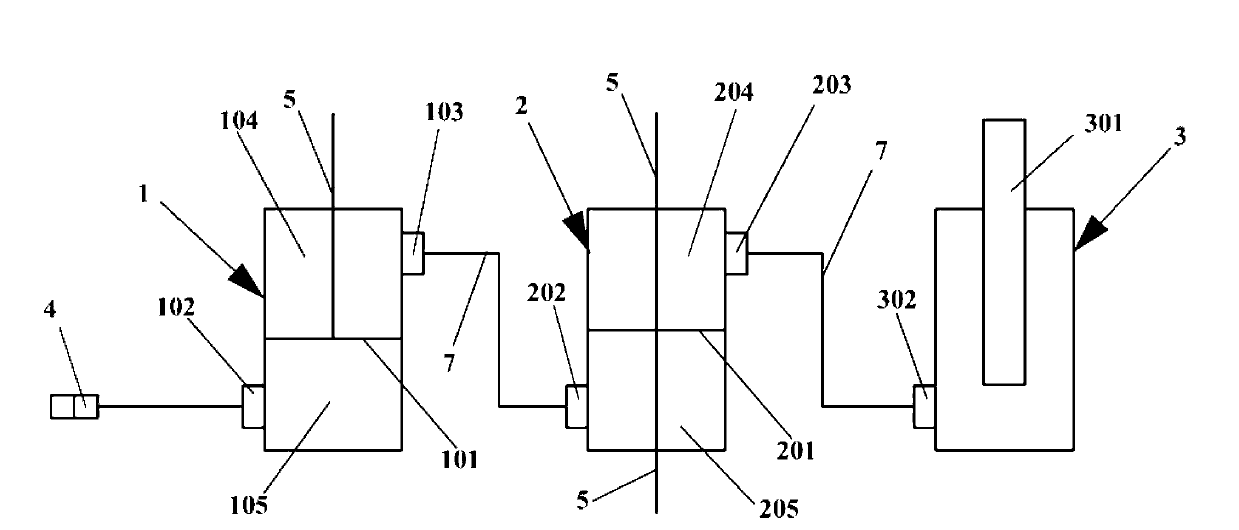

Detachable automatic sand adding sand tank, combined sand tank and realization method

ActiveCN103144867AIngenious designReasonable structureLarge containersLoading/unloadingEngineeringMotive power

The invention discloses a detachable automatic sand adding sand tank, which mainly solves the problems of inconvenient transportation, high labor cost and low efficiency of sand adding operation and the like of the existing sand tank. The detachable automatic sand adding sand tank comprises a sand tank body, an automatic sand feeding mechanism, a conveyer and a motive power system, the sand tank body is formed by combining a base, a sand leaking tank and a sand storage tank which are in sequential detachable connection from bottom to top, the automatic sand feeding mechanism is arranged at the upper end of the sand storage tank, the conveyer is arranged in the base, is communicated with the sand leaking tank and is used for transporting sand, the motive power system provides motive power for the automatic sand feeding mechanism and the conveyor, the base, the sand leaking tank and the sand storage tank are respectively in a detachable structure, and a utility knife which is near the automatic sand feeding mechanism and is used for gashing sand bags is also arranged in the sand storage tank. The invention also provides a combined sand tank formed by two detachable automatic sand adding sand tanks and a realization method of the detachable automatic sand adding sand tank. The detachable automatic sand adding sand tank, the combined sand tank and the realization method have the advantages that the transport efficiency is high, the cost is low, and in addition, the automation degree and the construction efficiency are respectively much greater than those of the prior art.

Owner:汤树林

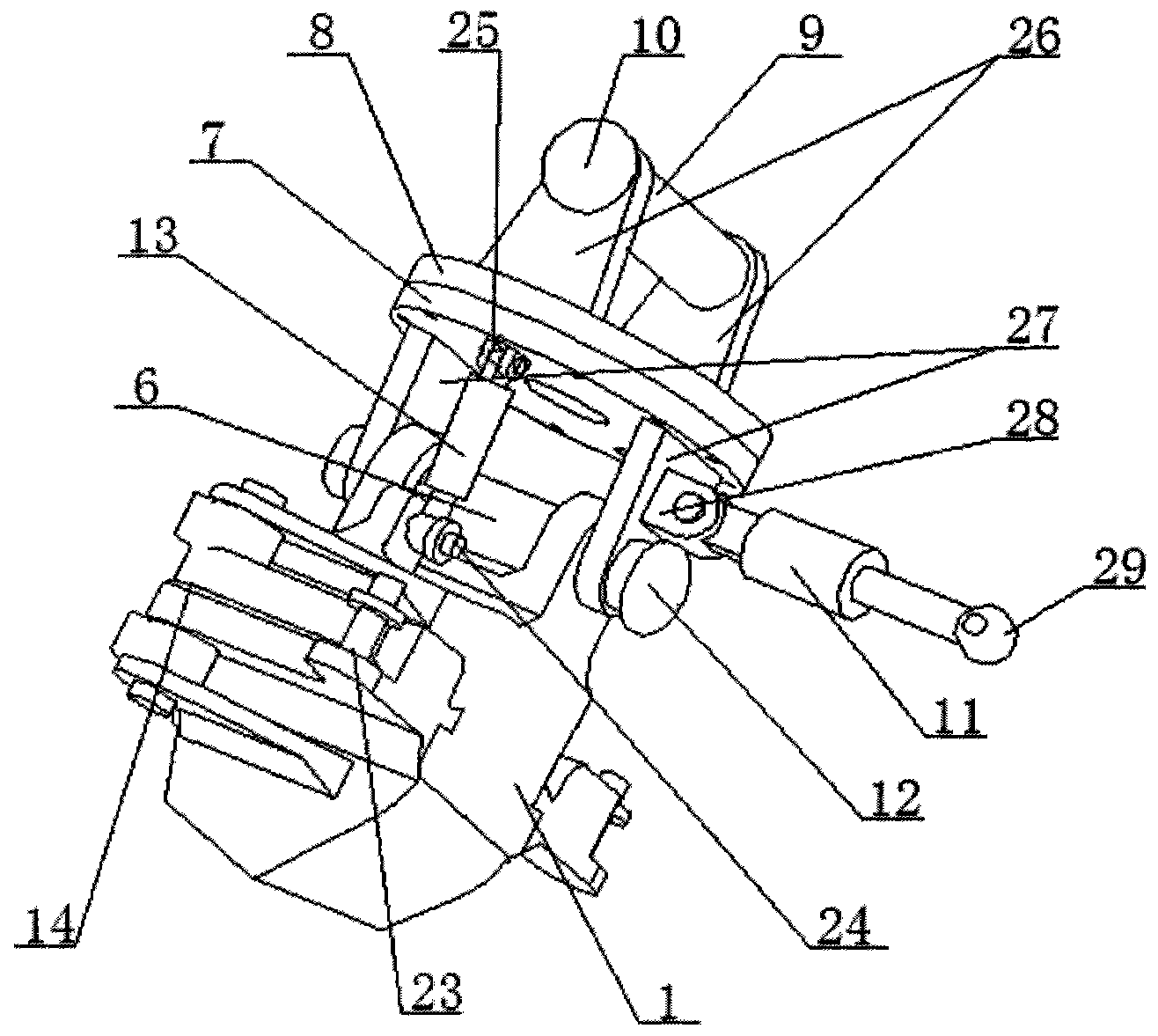

Oil cylinder group capable of realizing synchronous movement

InactiveCN102996563AGuaranteed synchronous motionSynchronous motion heightServomotorsHydraulic fluidPiston rod

The invention discloses an oil cylinder group capable of realizing synchronous movement. The oil cylinder group capable of realizing synchronous movement comprises a single piston rod oil cylinder, one or more double piston rod oil cylinders, a plunger oil cylinder and a reversing valve. The reversing valve, the single piston rod oil cylinder, the double piston rod oil cylinders and the plunger oil cylinder are sequentially connected. The single piston rod oil cylinder and the double piston rod oil cylinders are both provided with two main hydraulic fluid ports. A main hydraulic fluid port is arranged on a cylinder wall of the plunger oil cylinder. Compensating systems are arranged on the main hydraulic fluid ports of the single piston rod oil cylinder, the double piston rod oil cylinders and the plunger oil cylinder. The oil cylinder group capable of realizing synchronous movement provided by the invention has the advantages that a group of oil cylinders can move synchronously at a high degree, the cost of the oil cylinder system is low and the like.

Owner:HEFEI CHANGYUAN HYDRAULICS

Regular hexagon packing device for Pu'er tea cake

The invention relates to a regular hexagon packing device for Pu'er tea cake, and belongs to the technical field of agricultural processing. The regular hexagon packing device comprises a folding device, a pneumatic compression device, a folding plate transmission device, a rotating table transmission device and a labeling device, wherein the folding device comprises folding plates and a rotating table. When tissue paper and the tea cake are sent to an assigned position of a workbench, certain positions of the tissue paper and the tea cake are folded with the folding plates, then the rotating table drives the tea cake and the tissue paper to rotate synchronously to change folding positions, and the whole folding process is fulfilled in such manner. The regular hexagon packing device has the advantages that a regular hexagon folding process can be fulfilled effectively; the manual tea cake packing technology can be replaced; the packing efficiency of the tea cake is improved to a great extent; the labor cost of personnel is reduced; the whole mechanical device is simple in structure and convenient to operate.

Owner:KUNMING UNIV OF SCI & TECH

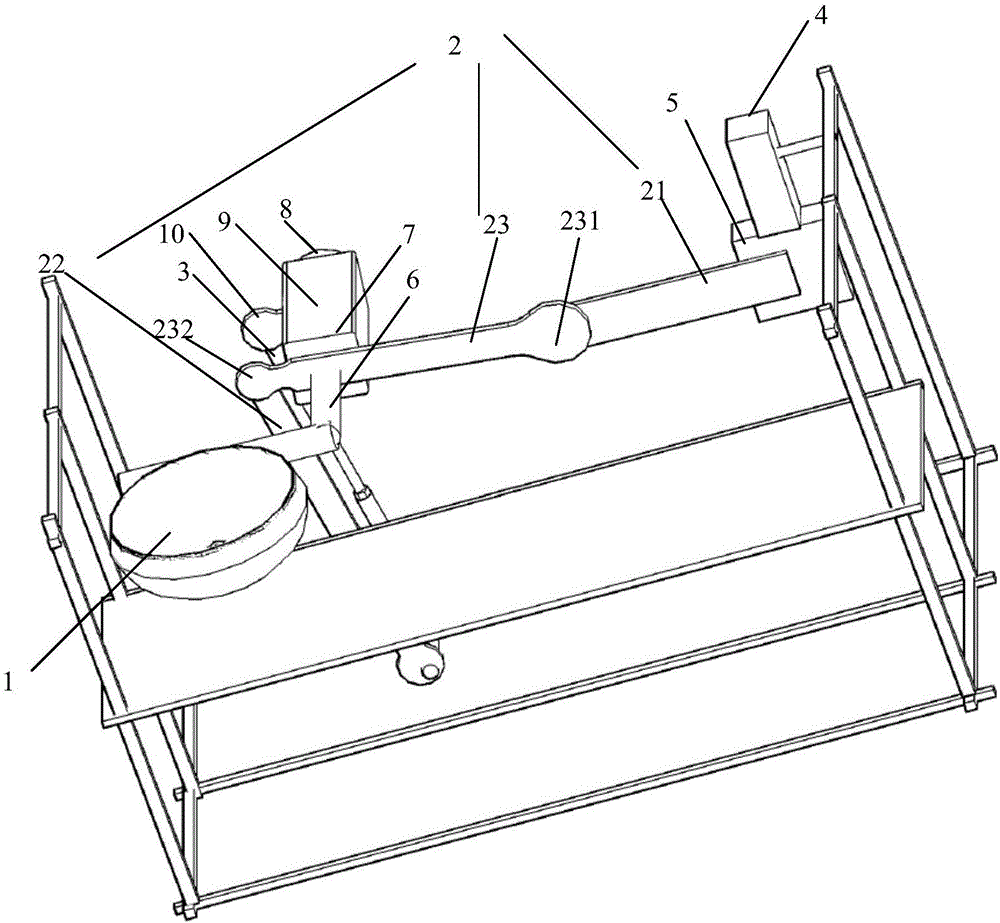

Stir-frying machine comprising pan tossing and turning mechanism and pan tossing and turning method

The invention provides a stir-frying machine comprising a pan tossing and turning mechanism and a pan tossing and turning method. The pan tossing and turning mechanism of the stir-frying machine comprises a stir-frying pan, a crank and rocker mechanism and a pull rod, wherein the crank and rocker mechanism comprises a crank, a rocker and a connecting rod for connecting the crank with the rocker, the crank is driven by a first motor, a rotating shaft is connected to the middle of the connecting rod, the first end of the connecting rod is connected to the crank, the second end of the connecting rod is connected to the upper end of the rocker, one end of the rotating shaft is fixedly connected to the stir-frying pan, and the other end of the rotating shaft is driven by a second motor; the upper end of the pull rod is movably connected to a shell of the second motor, the pull rod pulls the shell down, and the pull rod and the rocker move synchronously. According to the pan tossing and turning mechanism, the stir-frying pan moves stably during pan tossing and turning, parts of the stir-frying pan are reduced, and the failure rate is reduced.

Owner:马清沛

Intelligent fixing device for suspension type part and application method of intelligent fixing device

The invention relates to an intelligent fixing device for a suspension type part and an application method of the intelligent fixing device. The device comprises a bearing fixed crossbeam part (52), a suspension body (5) and a pushing-pressing type elastic fixing device component, wherein the suspension body (5) is provided with a suspension hook part (51) for hooking the bearing fixed crossbeam part (52), the pushing-pressing type elastic fixing device component comprises a shell component (9), two structurally-symmetrical elastic pushing-pressing components and an elastic pushing component, the shell part is provided with a left lateral wall (92) and a right lateral wall (91), the two elastic pushing-pressing components can slide up and down between the left lateral wall (92) and the right lateral wall (91) and are provided with outer elastomers (6) and inner bearing transmission plate parts (8) fixed on the inner sides of the outer elastomers, and the elastic pushing component can be adjusted by adjusting screws (2) rotatably mounted on the left lateral wall (92) and the right lateral wall (91) to move left and right.

Owner:XIAMEN DEME STATIONERY CO LTD

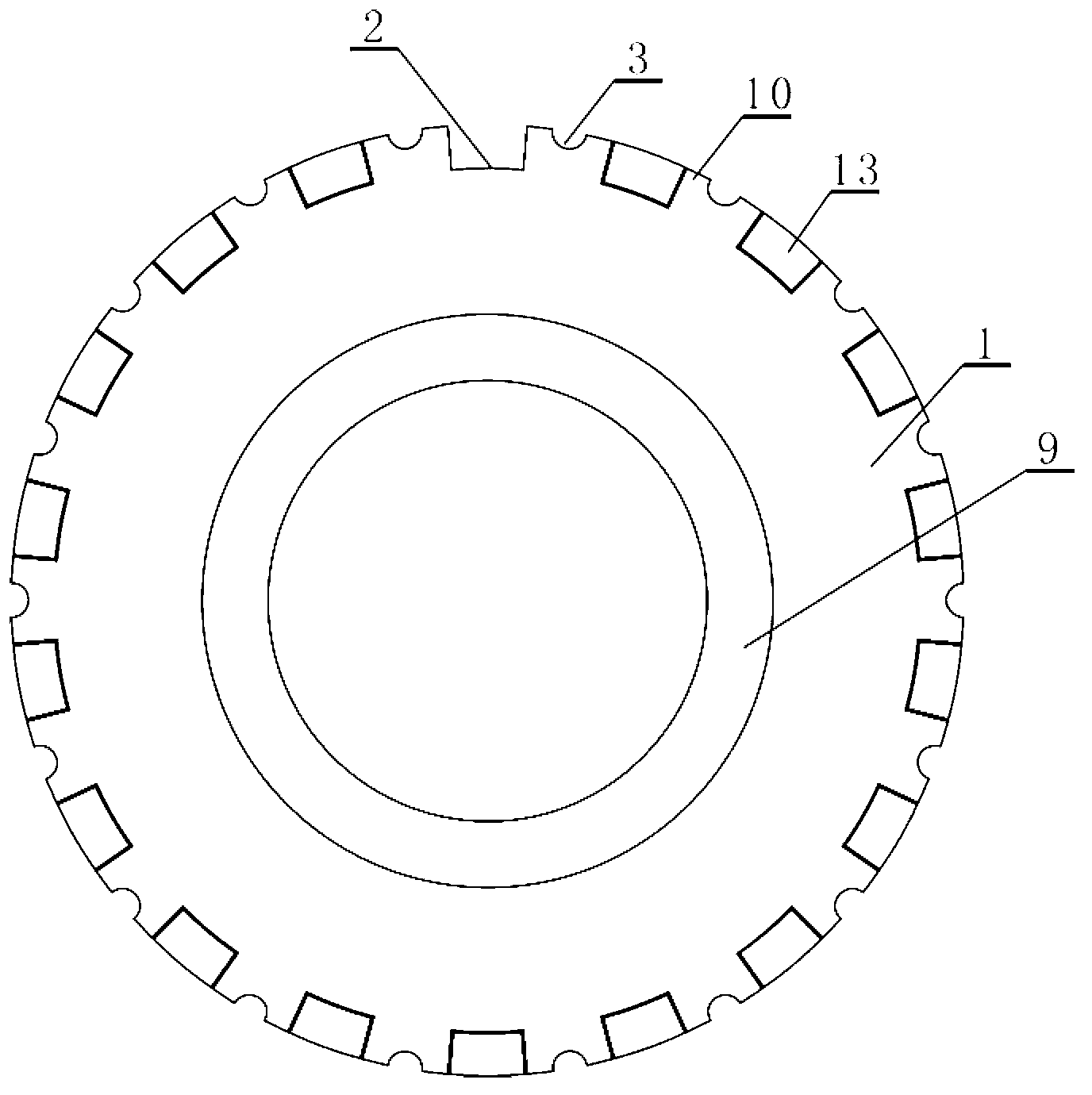

Needle drum of cigarette making machine suitable for adhesion of long filter tip and tipping paper

InactiveCN103181617AChange structureImprove the adsorption positionCigarette manufactureEngineeringUltimate tensile strength

The invention discloses a needle drum of a cigarette making machine suitable for adhesion of a long filter tip and tipping paper. The diameter of a drum body is 216mm; two cigarette adsorption areas with widths of 72.5mm are formed in the surface of the drum body, and the distance between the two cigarette adsorption areas is 9mm; needle strip grooves and cigarette-loading grooves are formed around the surface of the drum body at intervals; an included angle between each needle strip groove and each cigarette-loading groove is 10 degrees; an included angle between two adjacent needle strip grooves or cigarette-loading grooves is 20 degrees; one filter tip adsorption hole and three cigarette strip adsorption holes with the diameters of 4mm are sequentially formed in the cigarette-loading groove from a separation region to the outside, and distances from the filter tip adsorption hole to the three cigarette strip adsorption holes are 18mm, 30mm and 48mm in sequence; each needle strip groove has the upper width of 25mm, the lower width of 18mm and the depth of 10mm; the cigarette-loading grooves are semicircular and are 7.8mm in diameter; and the ridge width between the needle strip groove and the cigarette-loading groove is 3mm. By using the needle drum, the reliable adsorption of a cigarette strip and a filter tip and the stable conveying of the tipping paper are guaranteed, the tipping paper, the cigarette strip and the filter tip are accurately jointed and adhered, the product quality is guaranteed, the gum deposit of the needle drum is avoided at the same time, and the labor intensity of cleaning the needle drum is alleviated.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Cooking utensil

PendingCN109247841ASimple structureHigh degree of automationPressure-cookersWater flowCooking process

The invention provides a cooking utensil. The cooking utensil comprises an upper cover, an inner pot, a telescoping device and a conveying device, wherein the inner pot is positioned below the upper cover; the telescoping device is mounted on the upper cover, and can perform telescoping movement between the upper cover and the inner pot; and the conveying device is matched with the telescoping device, and comprises a conveying pipe communicating with the inner pot and a conveying part communicating with the conveying pipe and positioned below the telescoping device, and the conveying part canmove to the bottom of the inner pot under the driving of the telescoping device for conveying airflow to the inner pot and / or conveying air flow to the inner pot and / or discharging dirt in the inner pot. With the cooking utensil, the automatic water inlet and water drainage and / or automatic air inlet and air exhaust functions can be realized, so that the automation degree in automatically washingrice of the cooking utensil is greatly improved, and further, the use convenience of a user is improved; and meanwhile, the telescoping device can move upwards for realizing resetting after finishingthe work, and thus the follow-up cooking process or other work procedures can not be influenced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Electric fixing device for suspending device and use method of electric fixing device

InactiveCN105673637AEnsure consistencyEnhanced push-pull performanceFriction grip releasable fasteningsSignsMechanical engineeringEngineering

Owner:包宇青

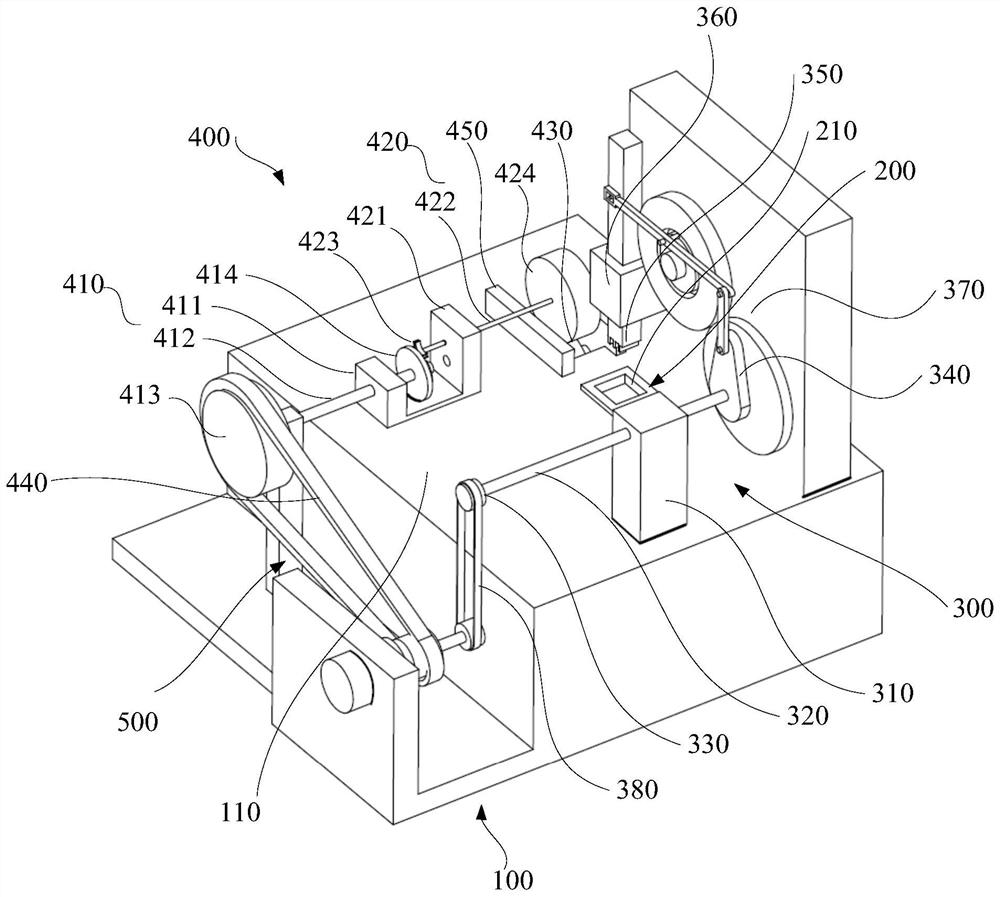

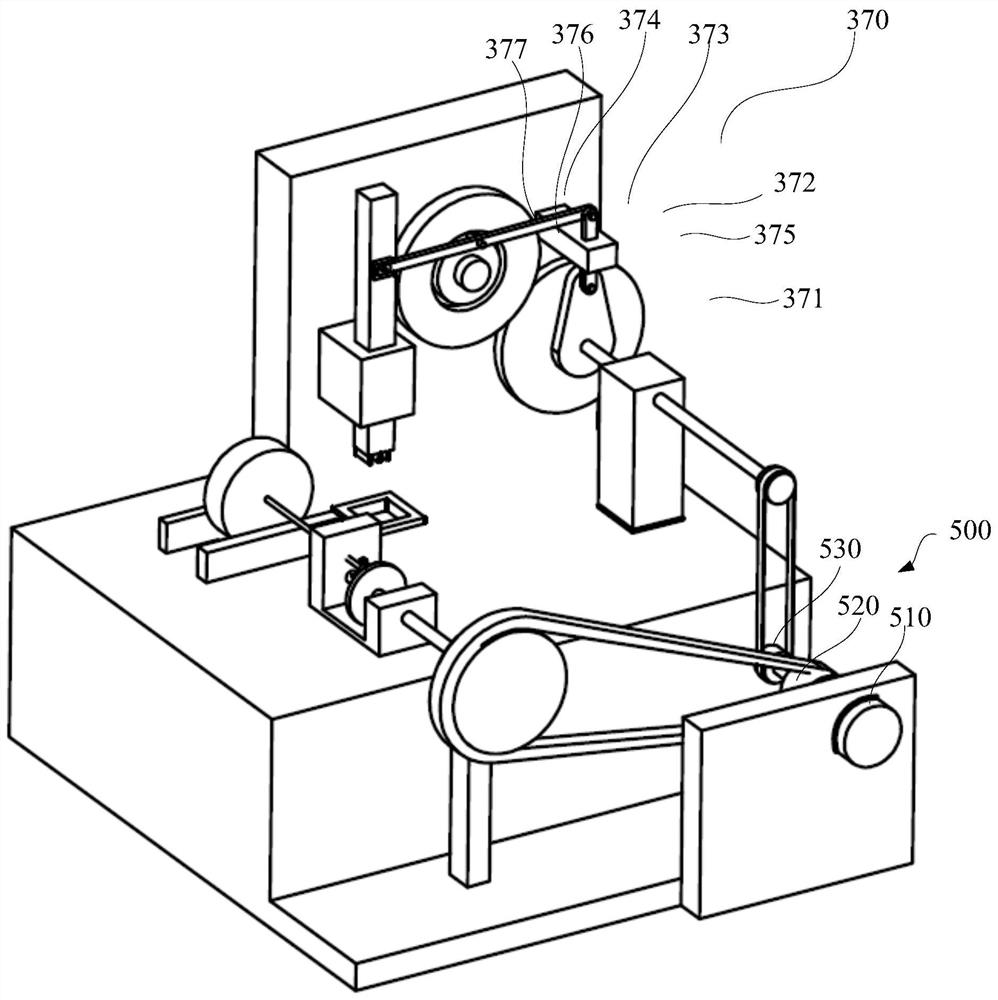

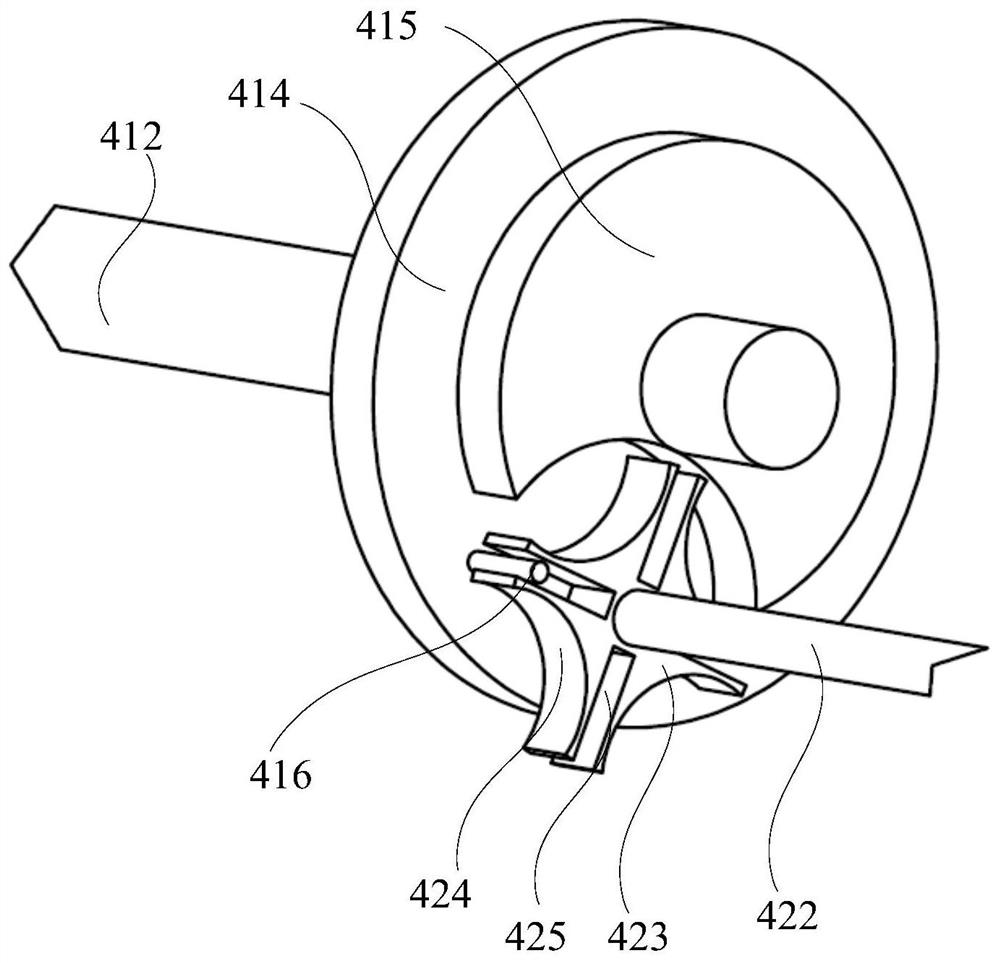

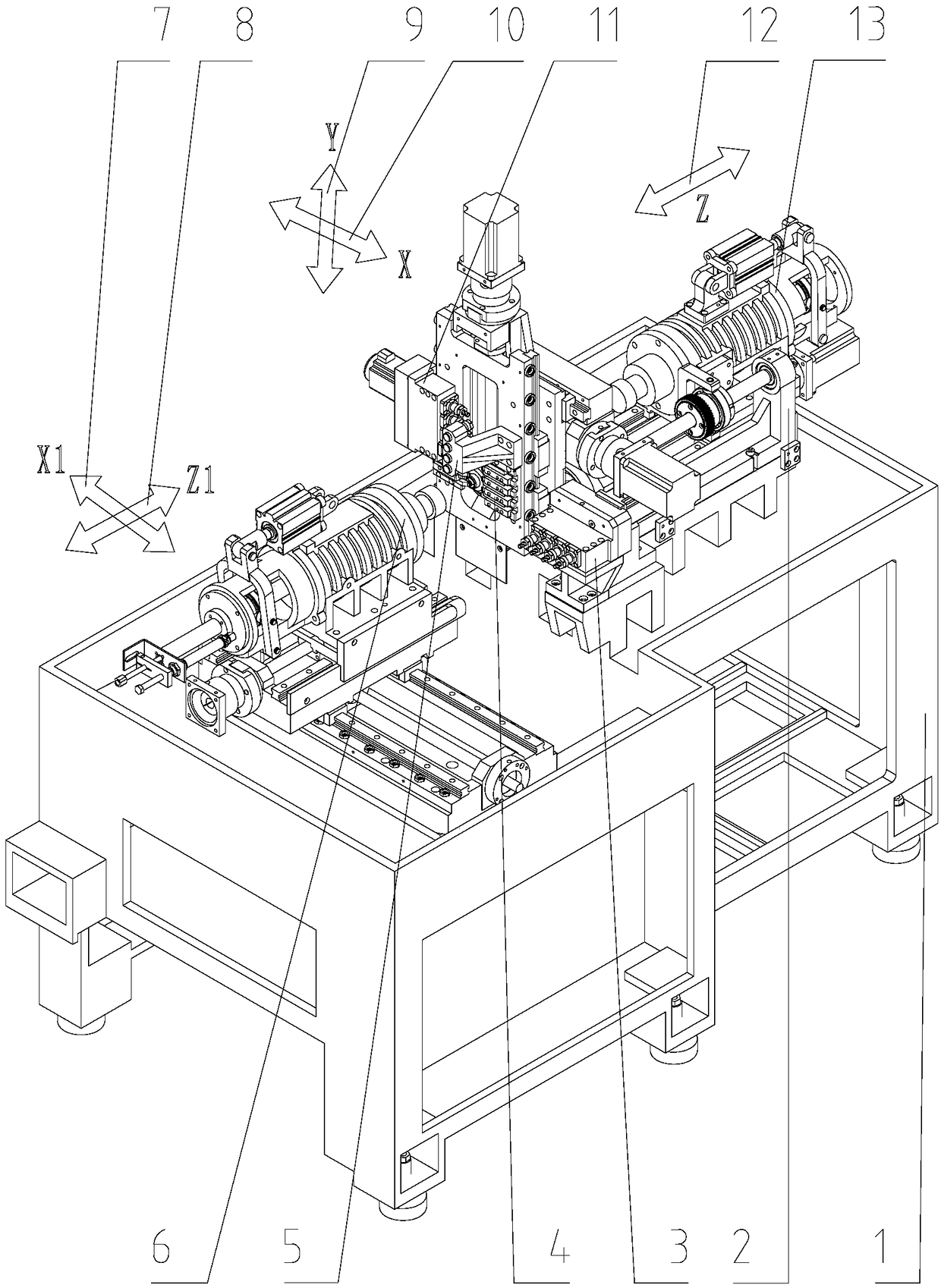

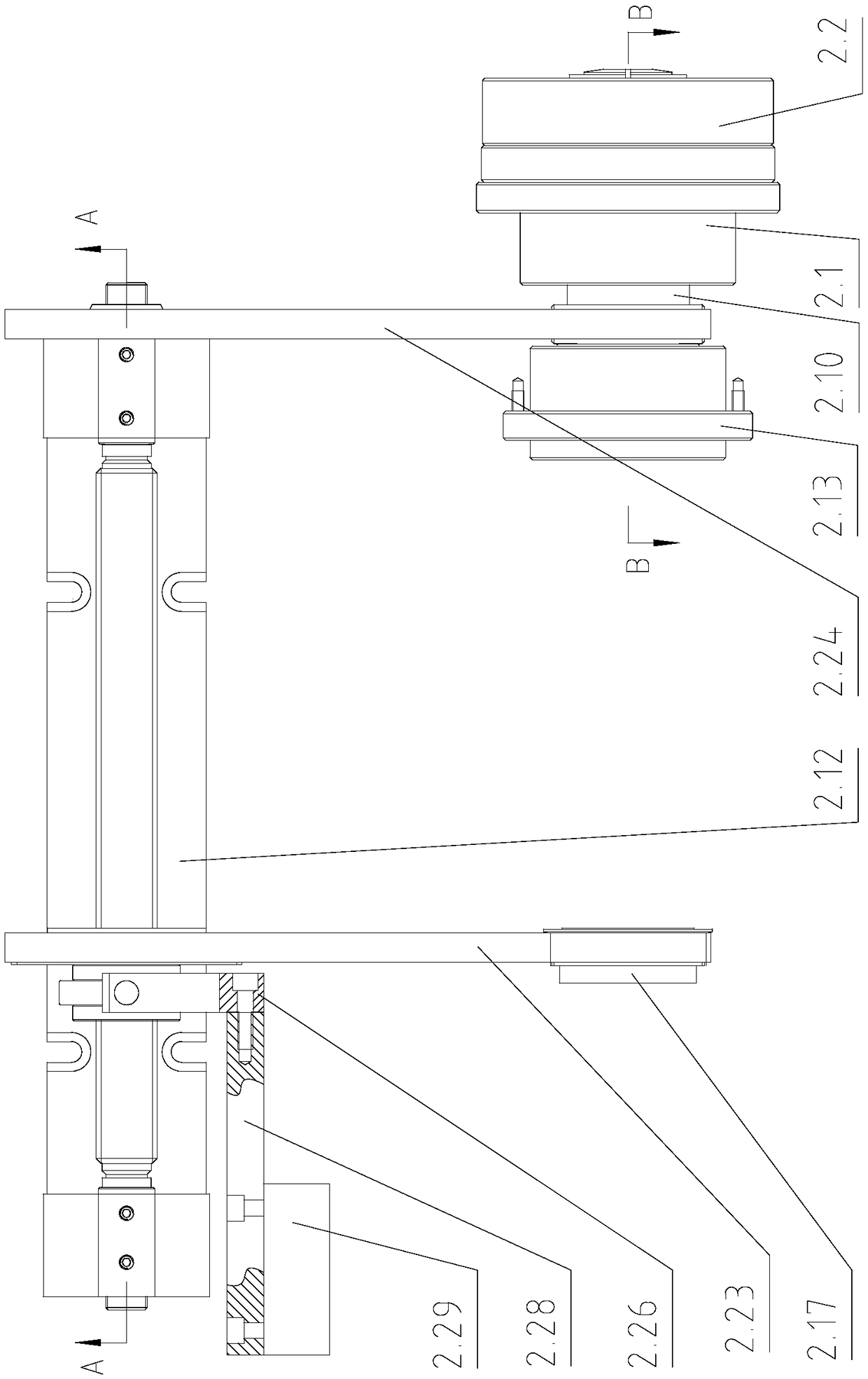

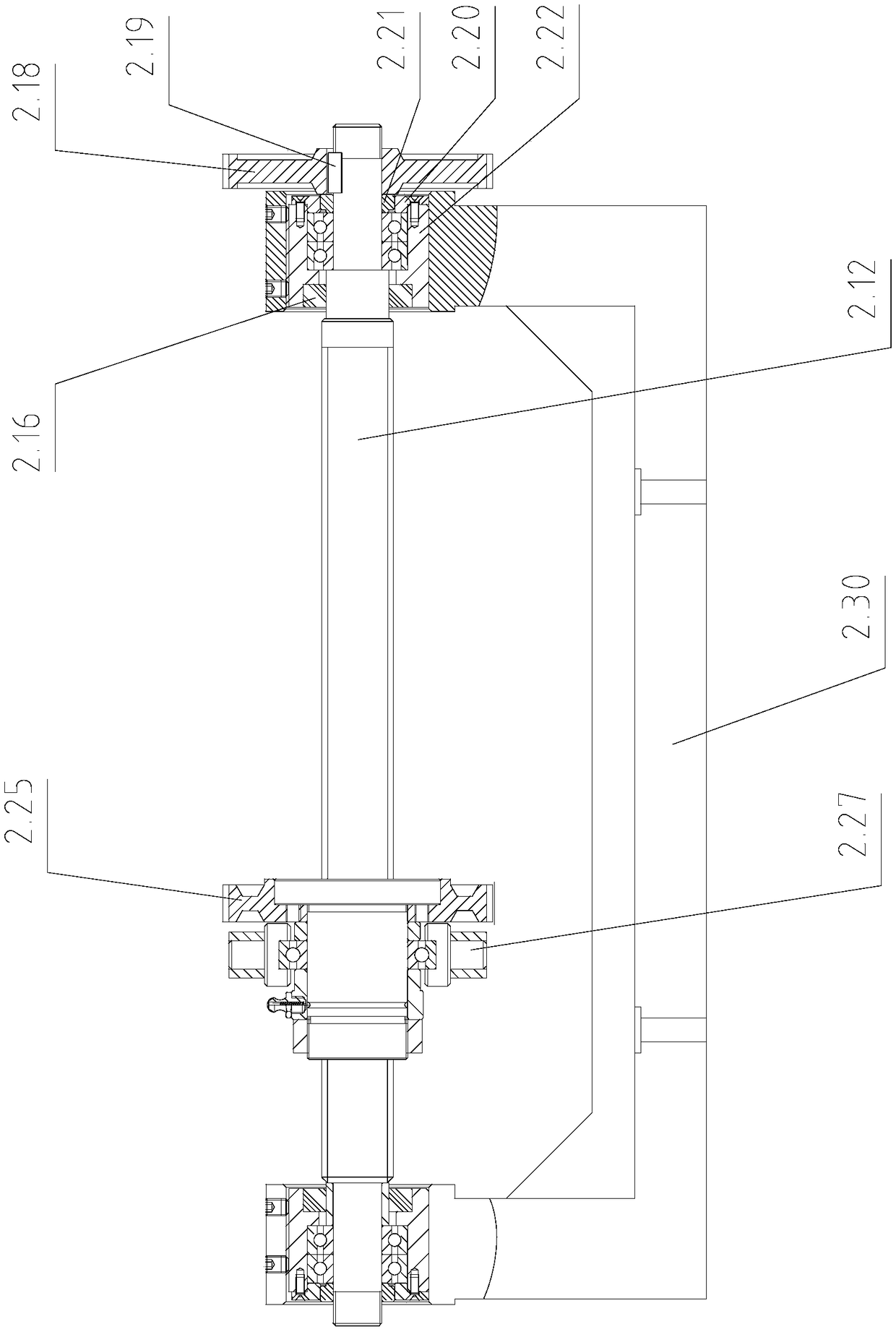

Longitudinal cutting turning and milling compound machine tool

PendingCN109128835AImprove versatilityEasy maintenance and operationOther manufacturing equipments/toolsFailure rateEngineering

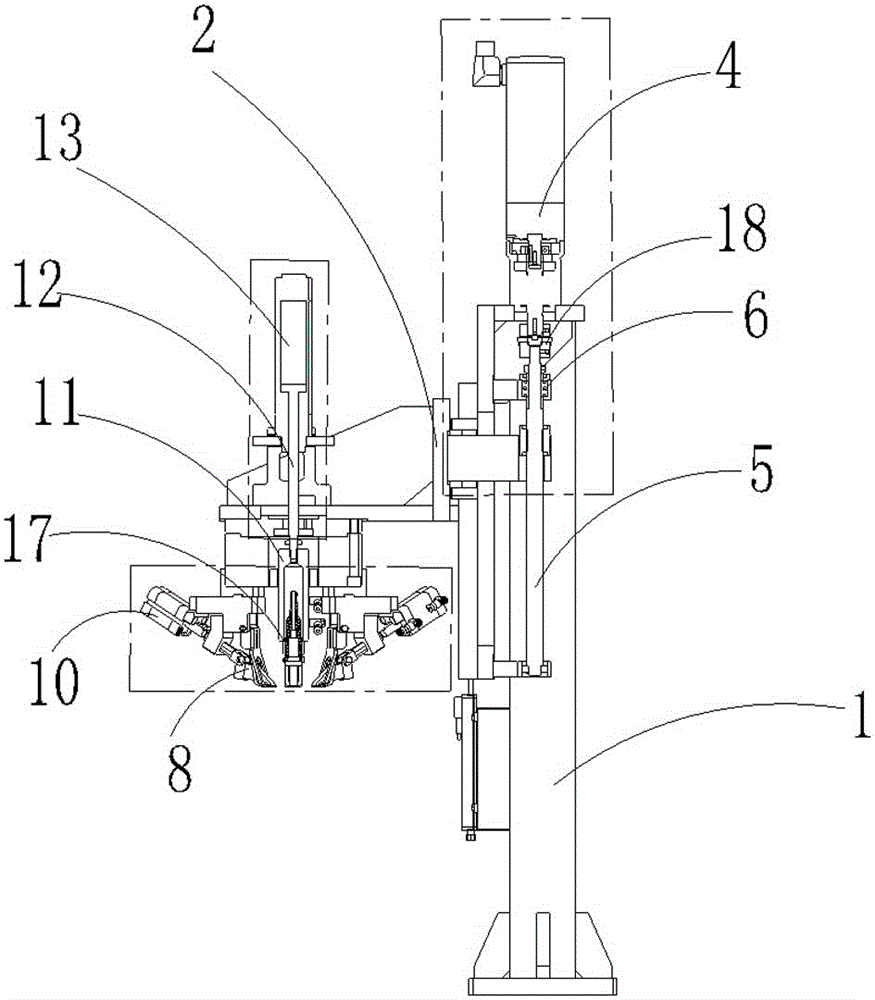

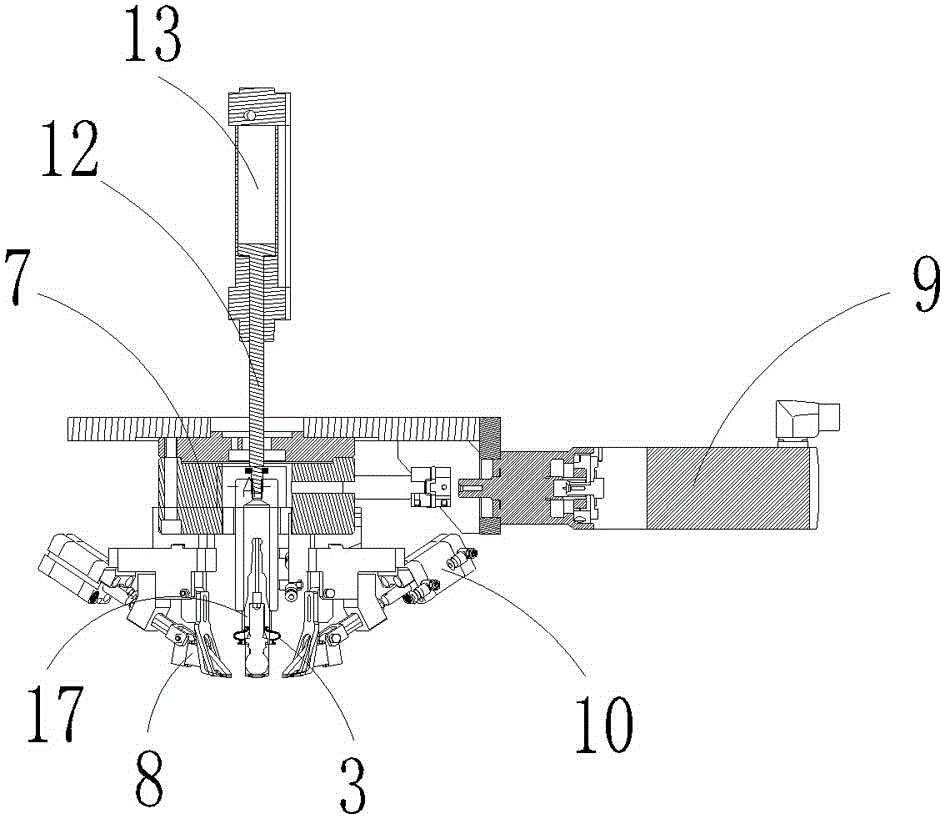

The invention provides a longitudinal cutting turning and milling compound machine tool, and solves the technical problems of weaker performances of function parts, base parts, standard parts, nonstandard parts, auxiliary fittings and electric fittings of domestic high-top machine tools and higher failure rate. The longitudinal cutting turning and milling compound machine tool comprises a stand, adriving system, a synchronous guide sleeve system, a cutter system and a transmission system; the driving system comprises a main shaft part and a secondary main shaft part; the synchronous guide sleeve system comprises a synchronous guide sleeve part and a transmission part; the cutter system comprises a side surface power milling part, an axial power milling part, a drilling cutter base part and a turning cutter part; and the transmission system comprises an X-axle feeding transmission part, a Y-axle feeding transmission part, an X1-axle feeding transmission part, a Z1-axle feeding transmission part and a Z-axle feeding transmission part. The longitudinal cutting turning and milling compound machine tool can be widely applied to machining of complicate precise parts.

Owner:WEIHAI BEST PRECISION MACHINERY

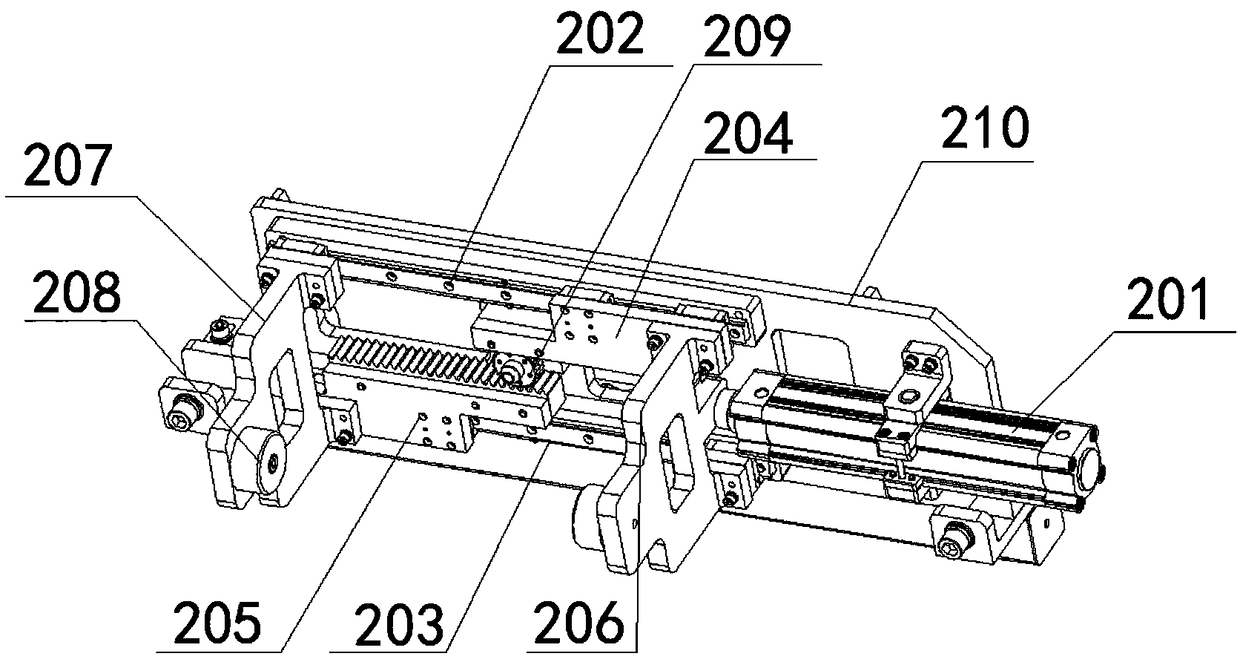

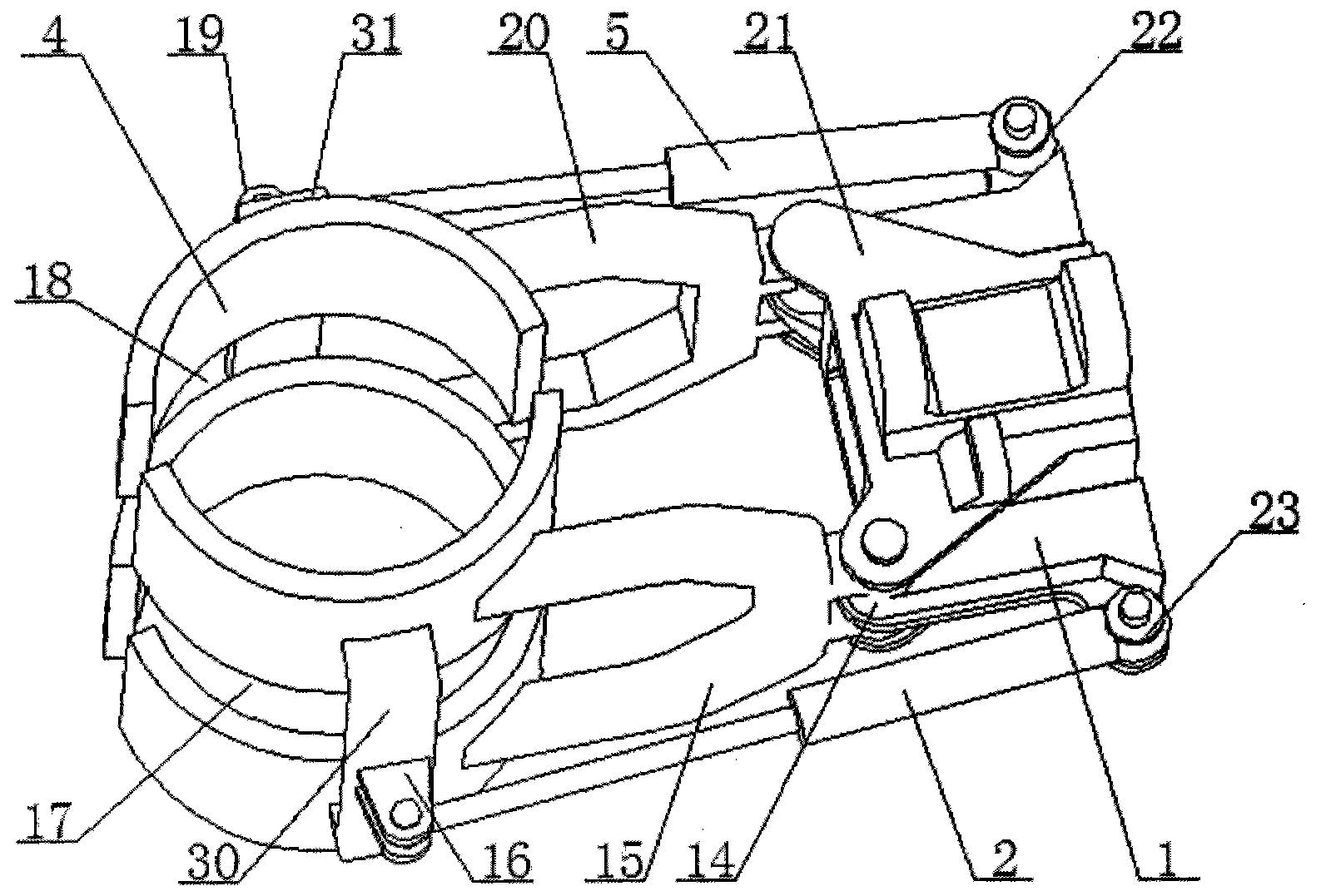

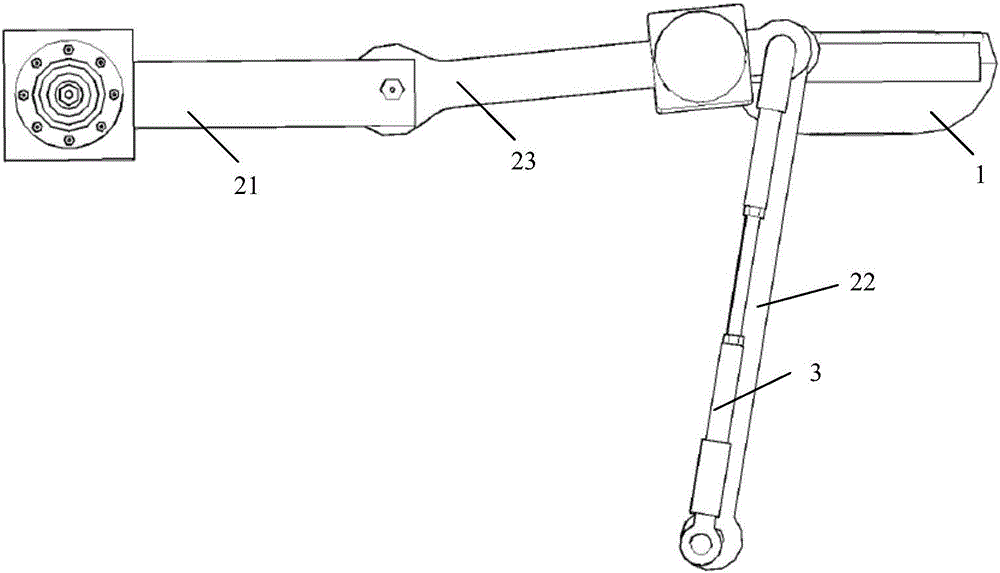

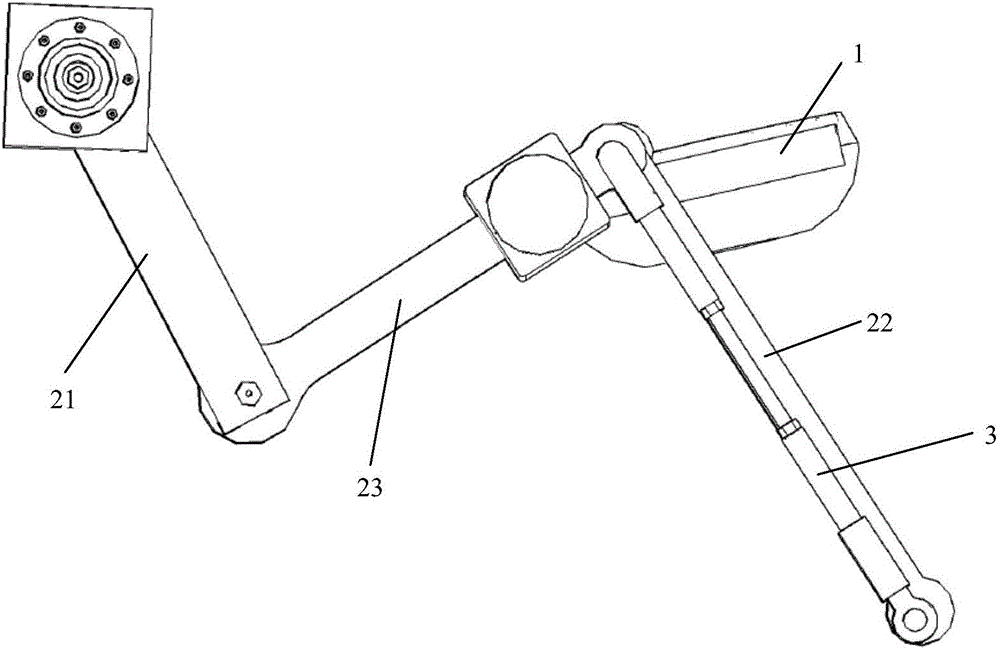

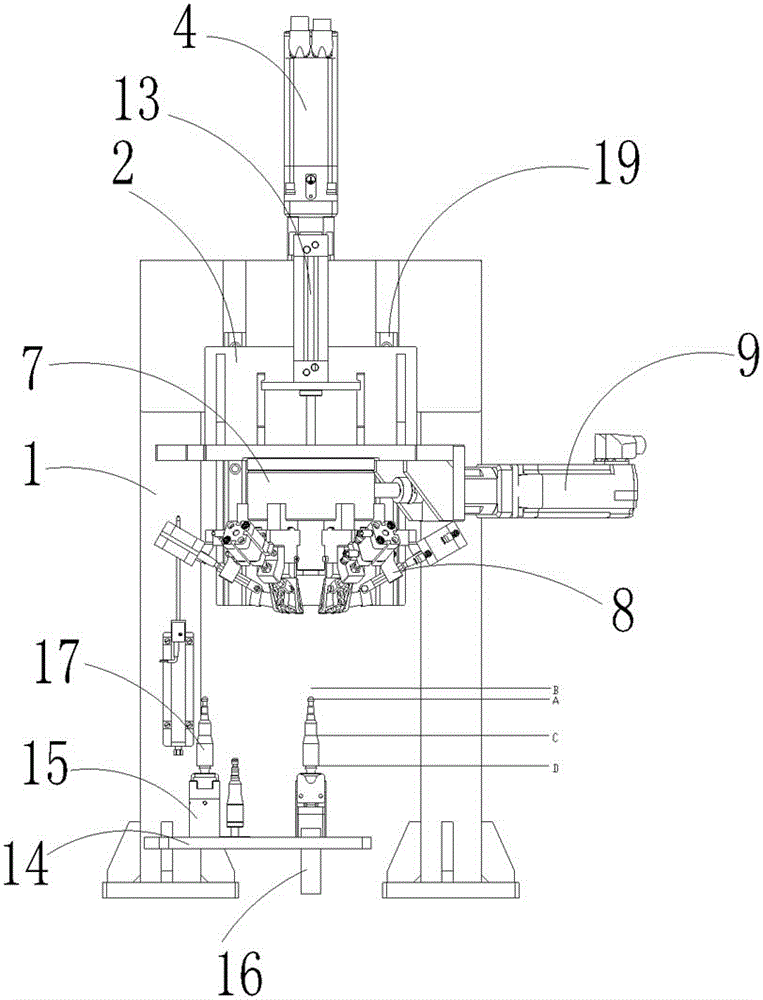

Assembling mechanism of automobile stabilizer bar dust cover and assembling method of assembling mechanism

ActiveCN105904192AGuaranteed synchronous motionCompact structureVehicle componentsMetal working apparatusEngineeringManipulator

The invention relates to an assembling mechanism of a dust cover, in particular to an assembling mechanism of an automobile stabilizer bar dust cover and an assembling method of the assembling mechanism. The assembling mechanism comprises a vertical frame, an installing plate and the dust cover. A lead screw-sliding block assembly is arranged in the vertical frame. The installing plate moves up and down along with the lead screw-sliding block assembly. A pressing assembly is arranged in the installing plate. The bottom end of the vertical frame is provided with a jacking, flowing and centering assembly. The dust cover moves up and down through the jacking, flowing and centering assembly. The dust cover and the pressing assembly are distributed up and down correspondingly. According to the assembling mechanism of the automobile stabilizer bar dust cover and the assembling method of the assembling mechanism, the structure is compact, centering of a six-claw manipulator is achieved through an auxiliary regulation tool in the regulation process, synchronous movement of six claws is guaranteed through a servo motor in a working state, and the good centering precision is maintained.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

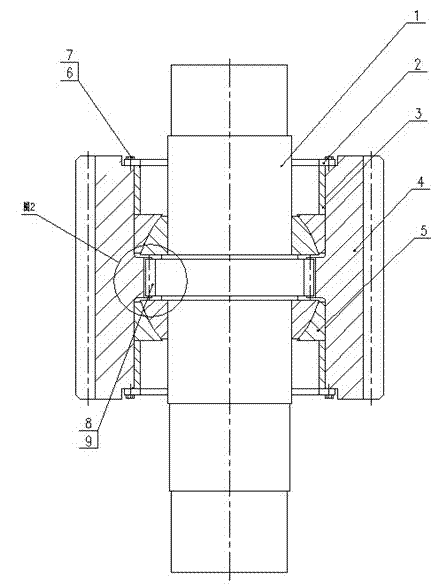

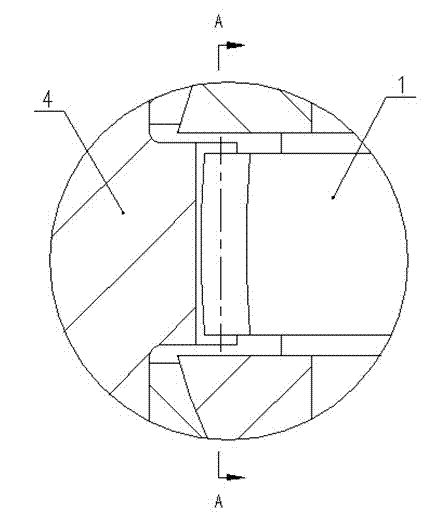

self-calibrating gear

InactiveCN102269225AGuaranteed SensitivityPrevent axial joltYielding couplingPortable liftingEngineeringSelf correction

The invention relates to a self-calibrating gear, including a gear, wherein: the shaft center of the gear is a shaft, a section of protruding external spline is arranged in the shaft, and a section of protruding internal spline is arranged in the gear assembly hole, the length of which is Corresponding to the external spline; the external spline is a convex arc along the axial direction, and its highest point is located at half of the external spline, and the axial arc of the internal spline is in line with the The convex arcs of the external splines match and mesh with each other; the front and rear ends of the external splines and internal splines are respectively provided with joint bearings, and an adjustment ring and a pressure plate are arranged between the joint bearing and the end face of the gear in turn, and the pressure plate passes through The bolt is fixed on the end face of the gear.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

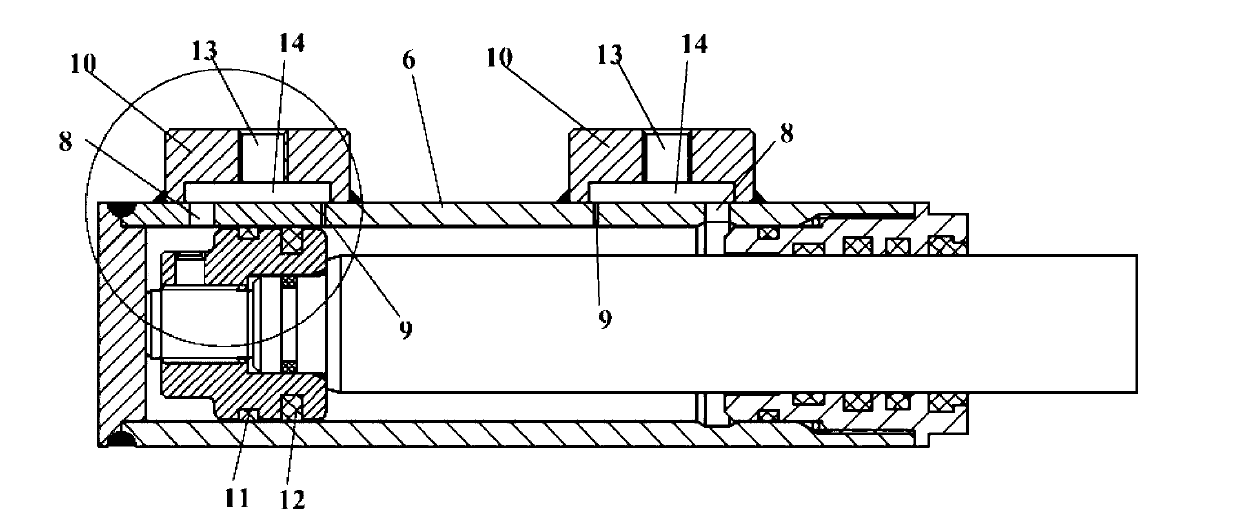

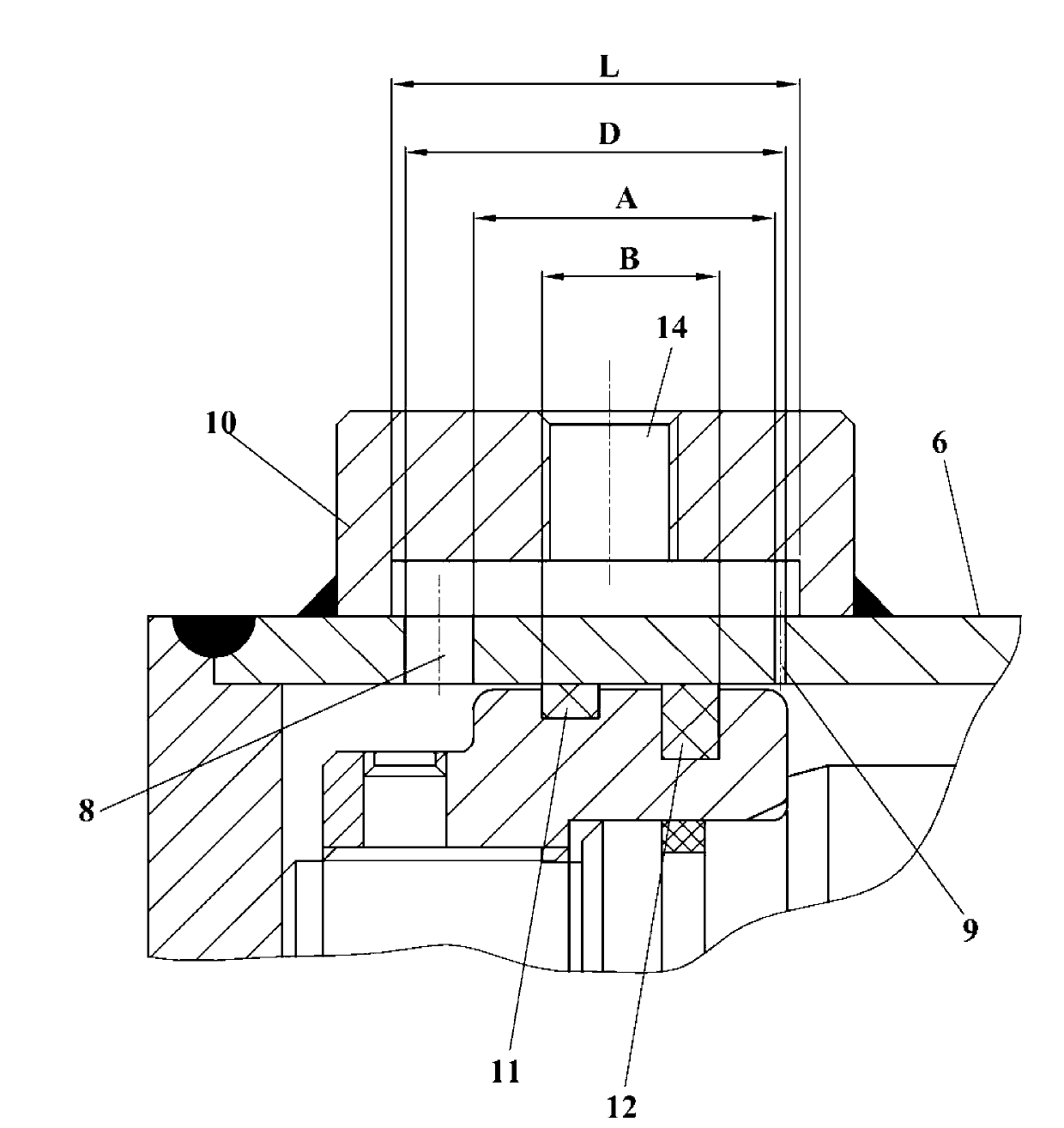

Intelligent fixing device for suspension device and application method thereof

InactiveCN105736529AGuaranteed synchronous motionStable structureFriction grip releasable fasteningsSignsElastomerEngineering

The invention discloses an intelligent fixing device for a suspension device and an application method thereof. The device comprises a support fixed cross beam part (52), a suspension body (5) with a suspension hook part (51) for hooking the support fixed cross beam part (52), and an ejecting elastic fixed device module; and the ejecting elastic fixed device module includes a shell part (9) with a left side wall (92) and a right side wall (91), two elastic ejecting modules capable of sliding up and down between the left side wall (92) and the right side wall (91) of the shell part (9) and having an outer side elastomer (6) and an inner side bearing transmission plate part (8) fixed on the inner side of the outer side elastomer and having symmetric structures, and an elastic pushing module capable of moving left and right through adjustment by adjusting screw rods (2) rotationally mounted on the left side wall (92) and the right side wall (91).

Owner:李长娟

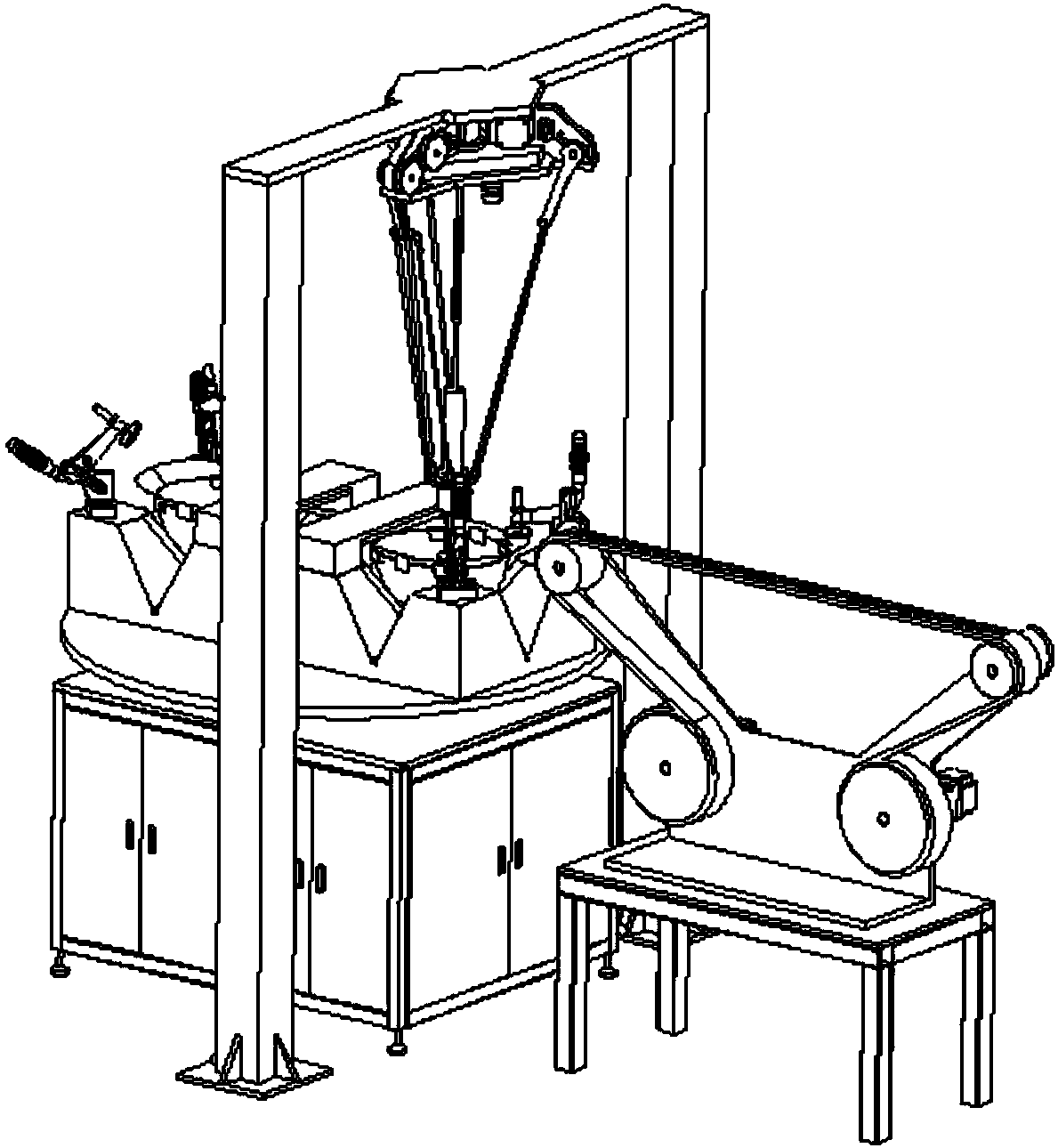

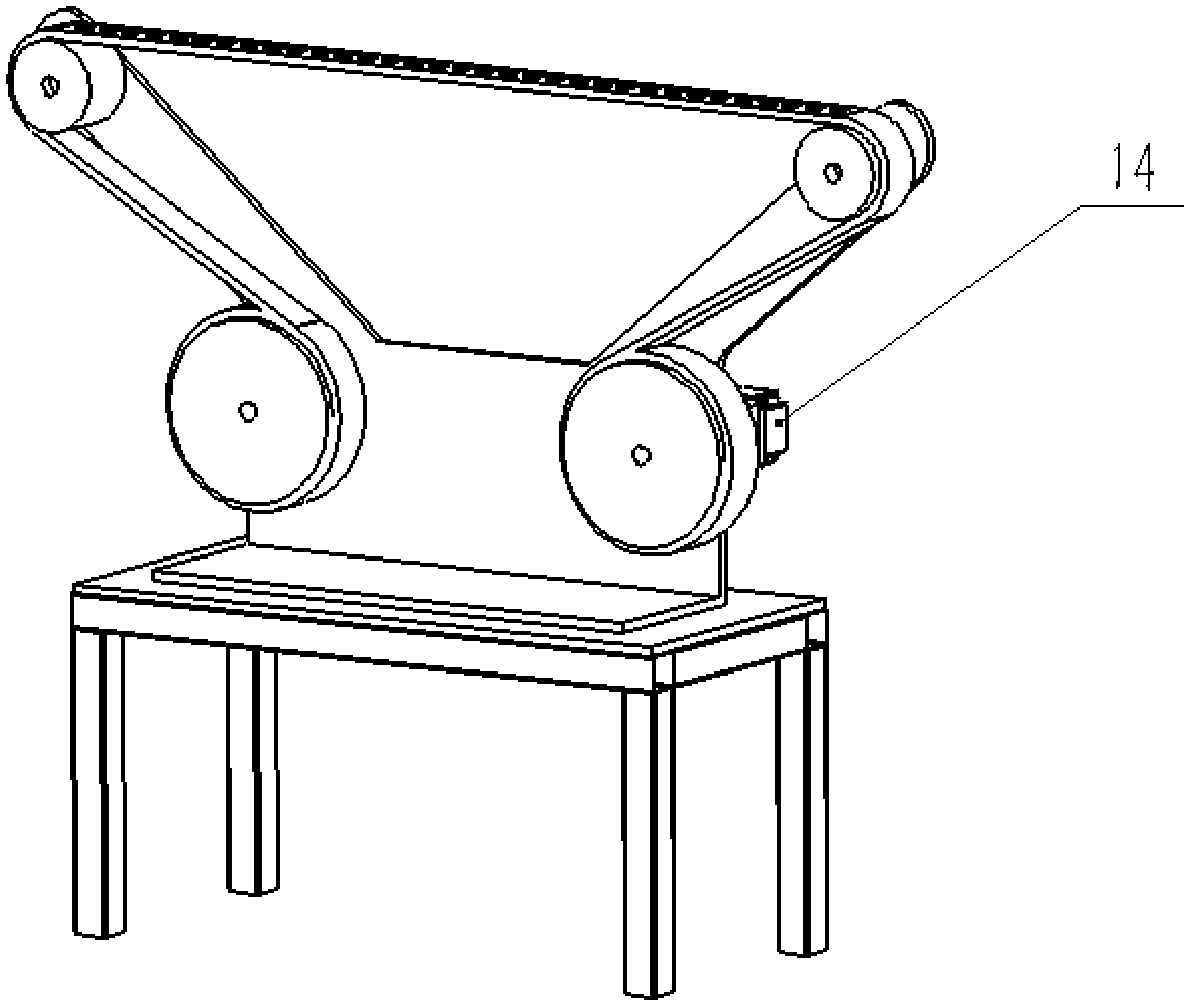

Automatic pasting apparatus for hook-and-loop fastener on safety helmet

InactiveCN107927985ASolve quality problemsResolve Product ConsistencyHatsSuction forceElectronic control system

The invention discloses an automatic sticking device for helmet magic stickers, which is composed of a feeding mechanism, a sticking workbench, a parallel robot and an electric control system; by controlling the motor and the parallel robot, the automatic feeding, picking, and Paste and press to realize the automatic production of hard hat Velcro paste. The indexing plate is located under the turntable and is driven by a motor to realize multi-angle conversion of multiple stations. The safety cap is positioned and clamped in the positioning fixture. The suction cup sucks the Velcro attached to the isolation belt, moves through the parallel robot, removes the Velcro, and moves to the designated position; the electronic control system ensures the synchronous movement of the Velcro belt and the robot, and controls the parallel robot to achieve precise positioning and automatic sticking; Control the air path to control the vacuum suction cup to provide adsorption force, so as to realize the simultaneous picking up while following the movement of the adhesive Velcro, so that it can be separated from the release paper. The pasting device is suitable for various products that are automatically pasted by Velcro, and has a simple structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

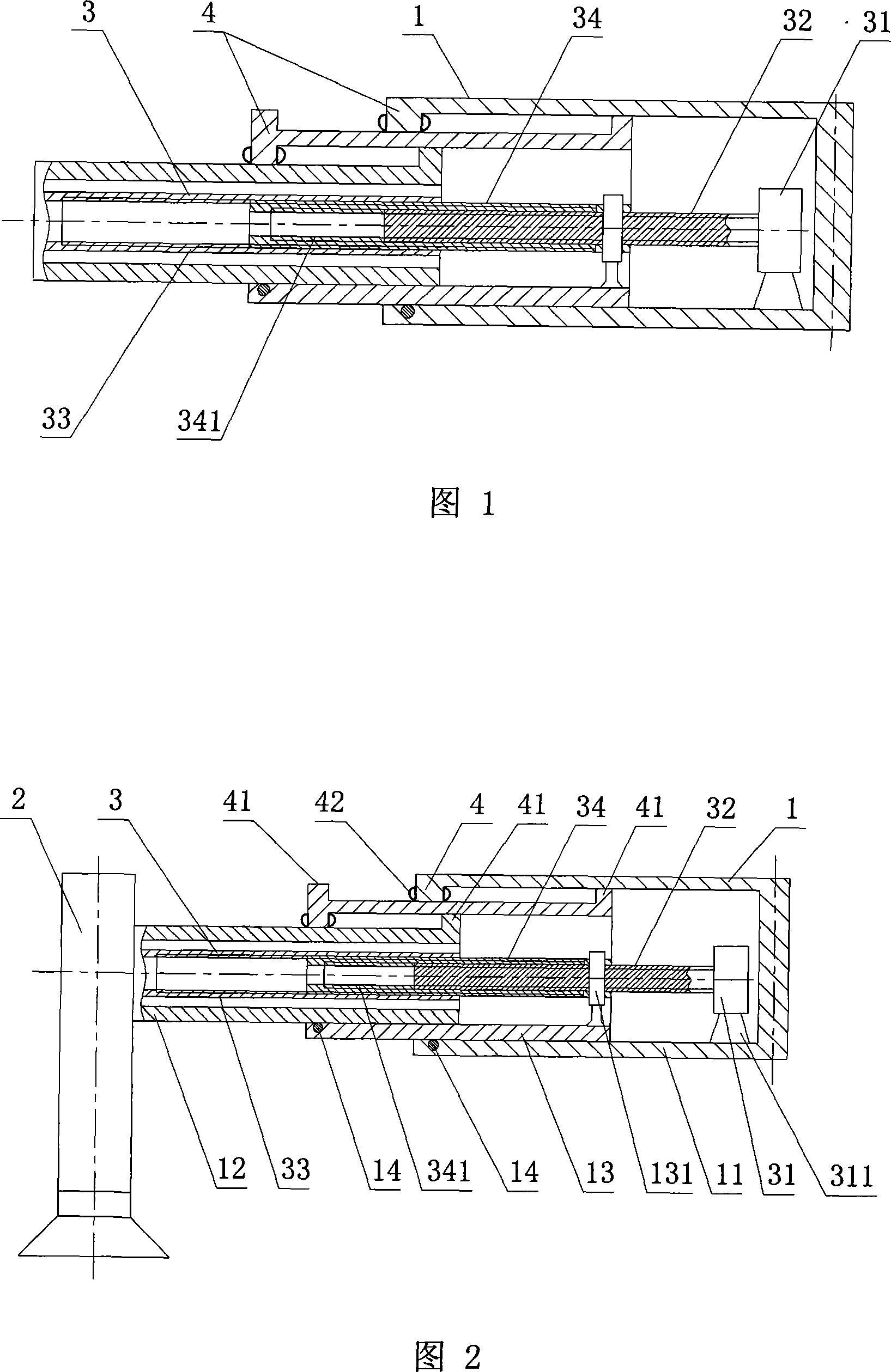

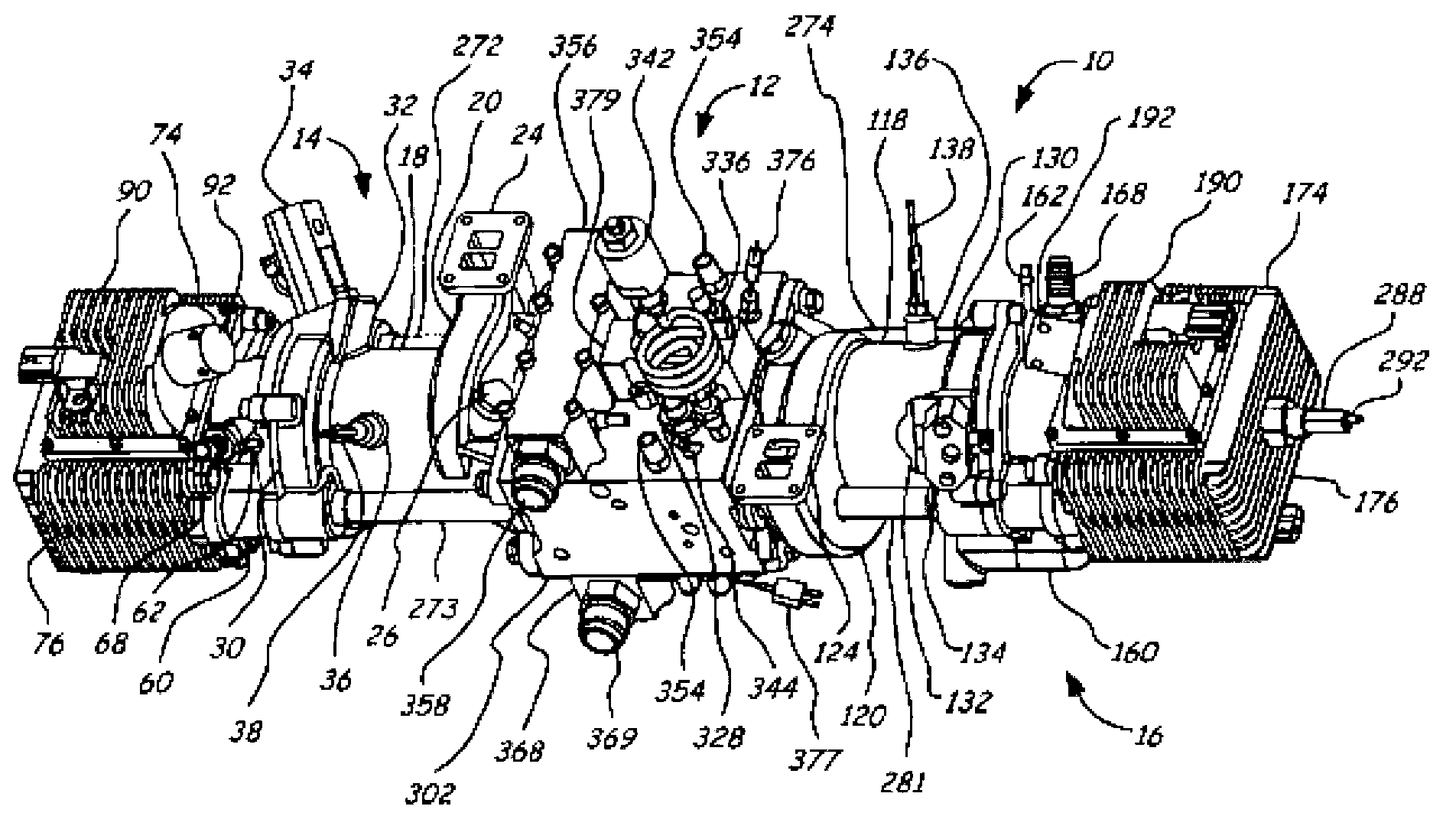

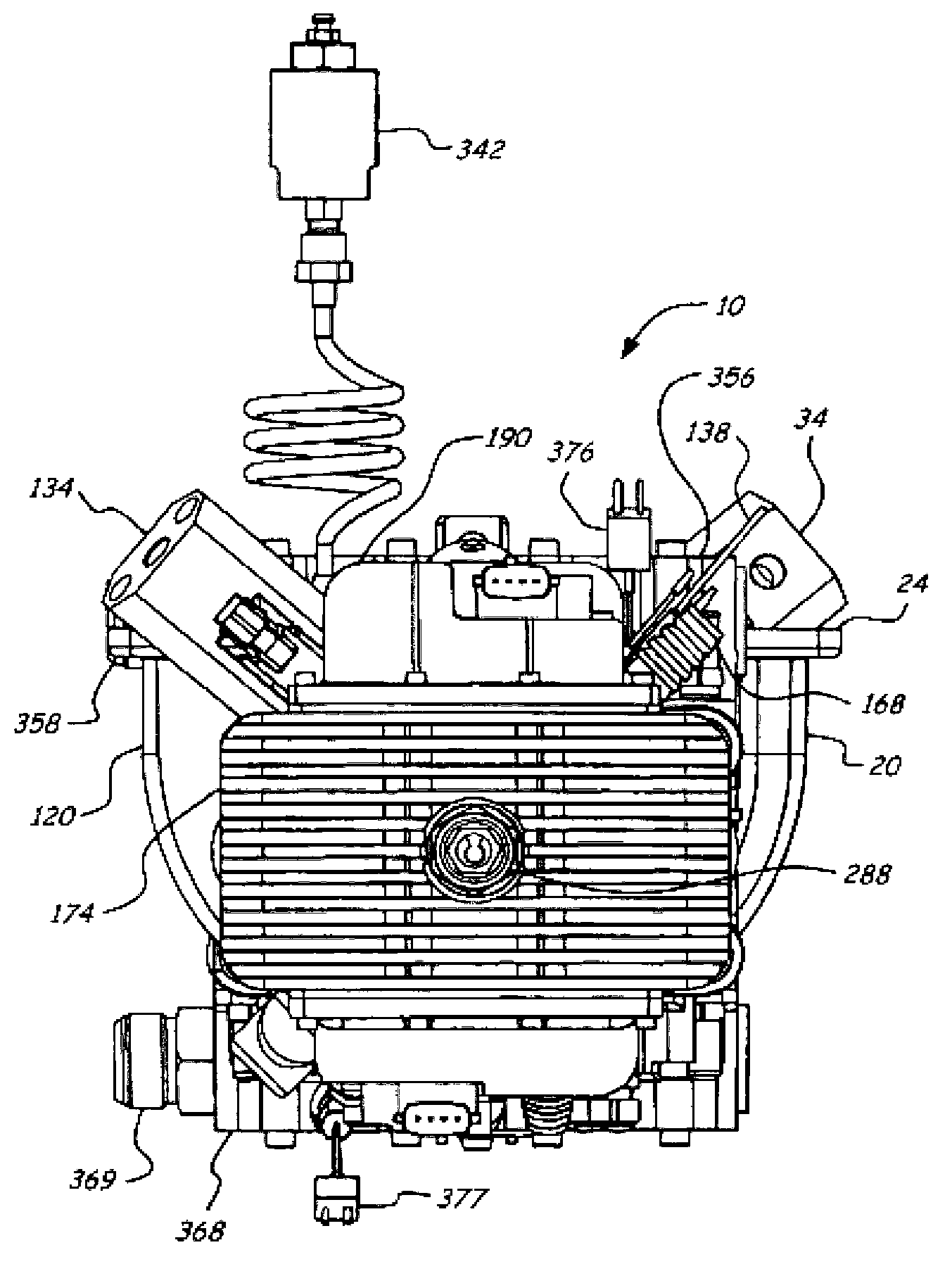

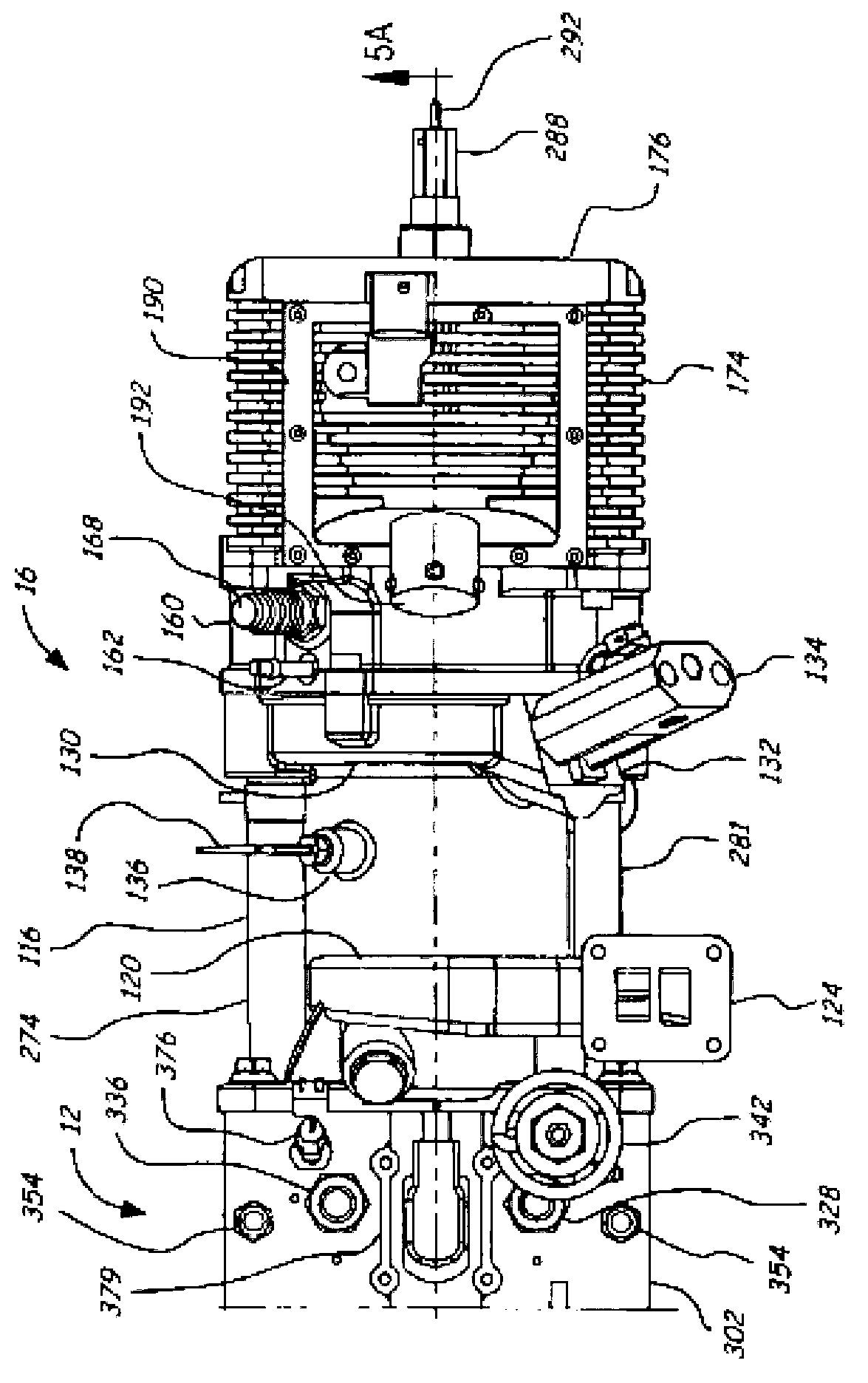

Free-piston engine

InactiveCN103075249ANormal movementSmooth motionPistonsFree piston enginesFree-piston engineCoupling

The invention relates to a free-piston engine, which comprises a hydraulic pump body assembly, a first air cylinder, a second air cylinder, a push rod hole, a first pull rod hole, a first crossed connection passage, a first inner piston, a second inner piston, a push rod, an inner plunger, a first outer piston, a second outer piston and a first outer plunger, wherein the first air cylinder and the second air cylinder are arranged on two sides of the hydraulic pump body assembly; the first crossed connection passage is arranged between the first push rod hole and the first pull rod hole; the first inner piston is arranged in the first air cylinder; the second inner piston is arranged in the second air cylinder; two ends of the push rod are respectively fixed on the first inner piston and the second inner piston; the inner plunger is installed between the push rod and the push rod hole, an inner pump chamber and an inner coupling pump chamber are respectively formed on two ends of the push rod hole, and an inner coupling pump chamber is communicated with the first crossed connection passage; the top end of the first outer piston is close to the first inner piston; the top end of the second outer piston faces towards the second inner piston; two ends of the first pull rod are arranged on the first outer piston and the second outer piston; and the first outer plunger is arranged between a first pull rod and the first pull rod hole, the first outer plunger forms a first outer pump chamber and a first outer coupling pump chamber with two ends of the first pull rod hole, and the first outer coupling pump chamber is communicated with the first crossed passage.

Owner:ANHUI ZHONGDING POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com