Needle drum of cigarette making machine suitable for adhesion of long filter tip and tipping paper

A technology for tipping paper and cigarette making machine, which is applied in the manufacture of cigarettes, tobacco, and other fields, can solve the problems of uneven bonding of tipping paper, rubbing wrinkles of tipping paper, unstable tipping filter tip, etc., and achieve stable The effect of stable adsorption, improved adsorption force and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

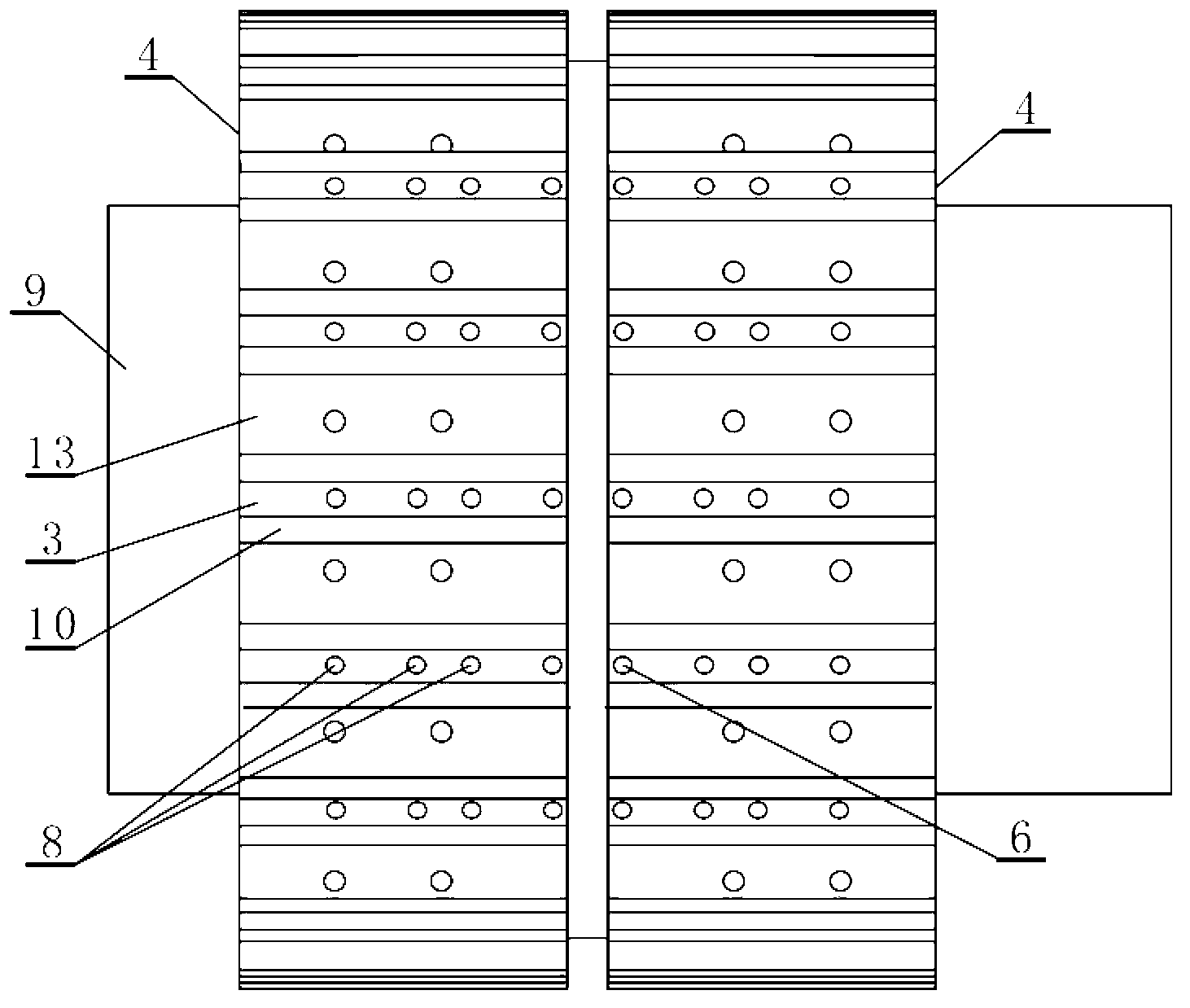

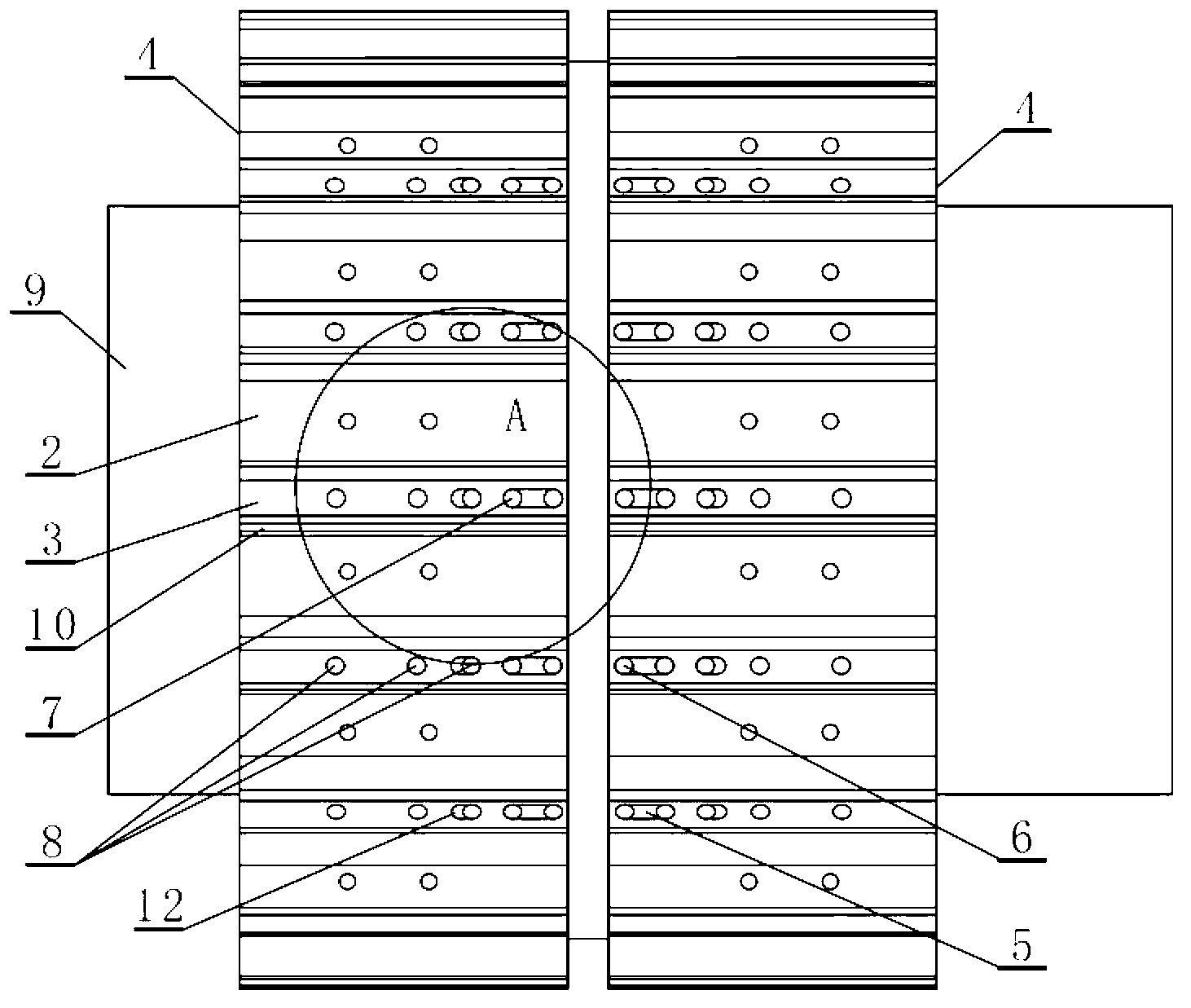

[0018] Such as image 3 , 5 As shown, a filter enhanced adsorption hole 7 is arranged between the filter adsorption hole 6 and the tobacco rod adsorption hole 8, and the distance between the filter tip adsorption hole 6 and the filter enhanced adsorption hole 7 is 9 mm.

[0019] Such as Figure 5 As shown, the filter suction hole 6 and the filter enhanced suction hole 7 are connected by a negative pressure suction groove 5 with a width of 4 mm, and the negative pressure suction groove 5 is 1 to 2 mm deep.

[0020] The diameter of the filter enhanced adsorption hole 7 is 4mm.

[0021] Such as Figure 5 As shown, the tobacco rod adsorption hole 8 near the filter tip adsorption hole 6 is provided with a negative pressure groove 12 with a width of 4 mm, and the negative pressure groove 12 extends toward the direction far from the filter tip adsorption hole 6 .

[0022] The negative pressure groove 12 is 6.5mm long and 1-2mm deep.

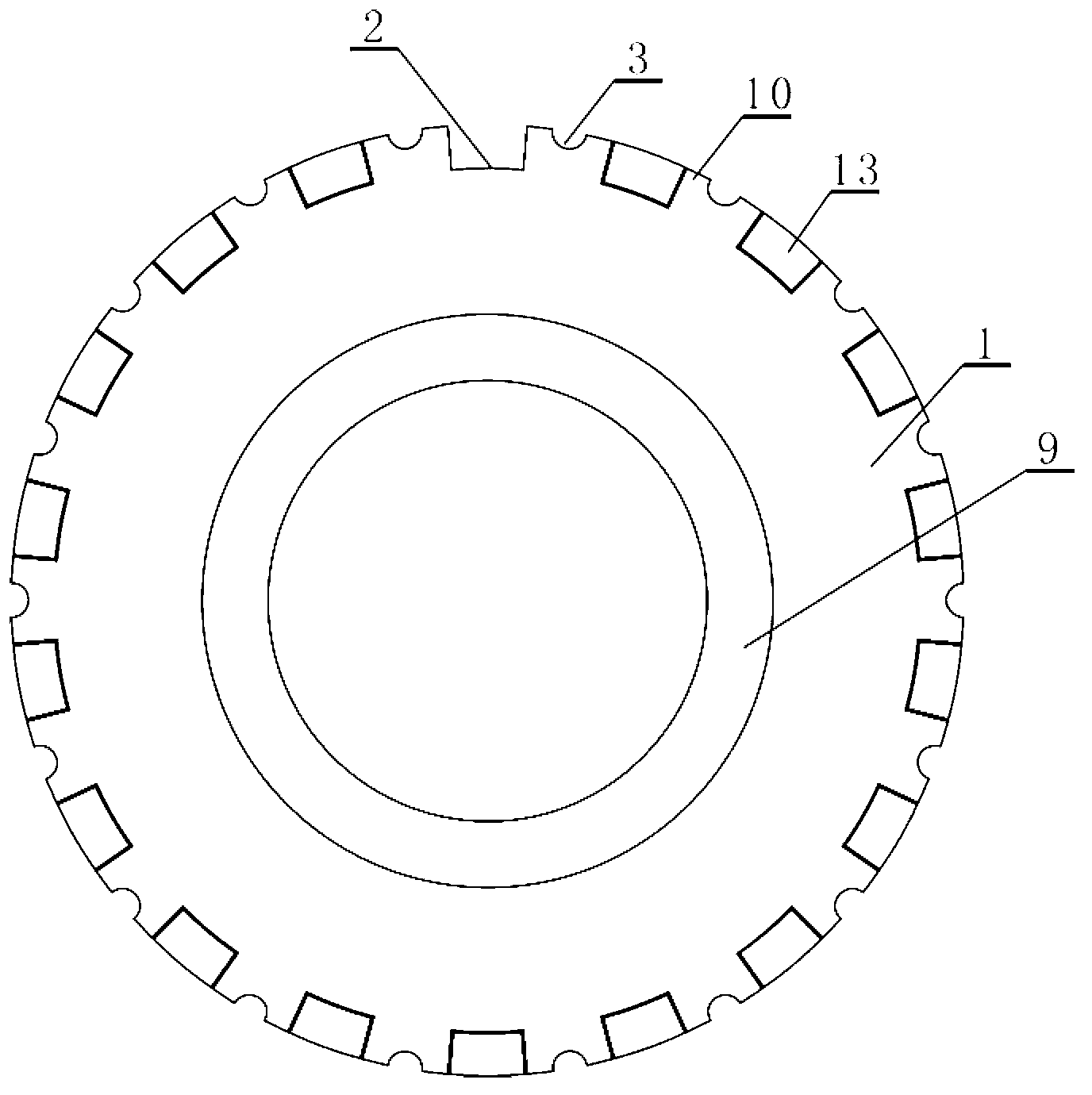

[0023] Such as Figure 4 , 6 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com