Patents

Literature

485 results about "Pressure groove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

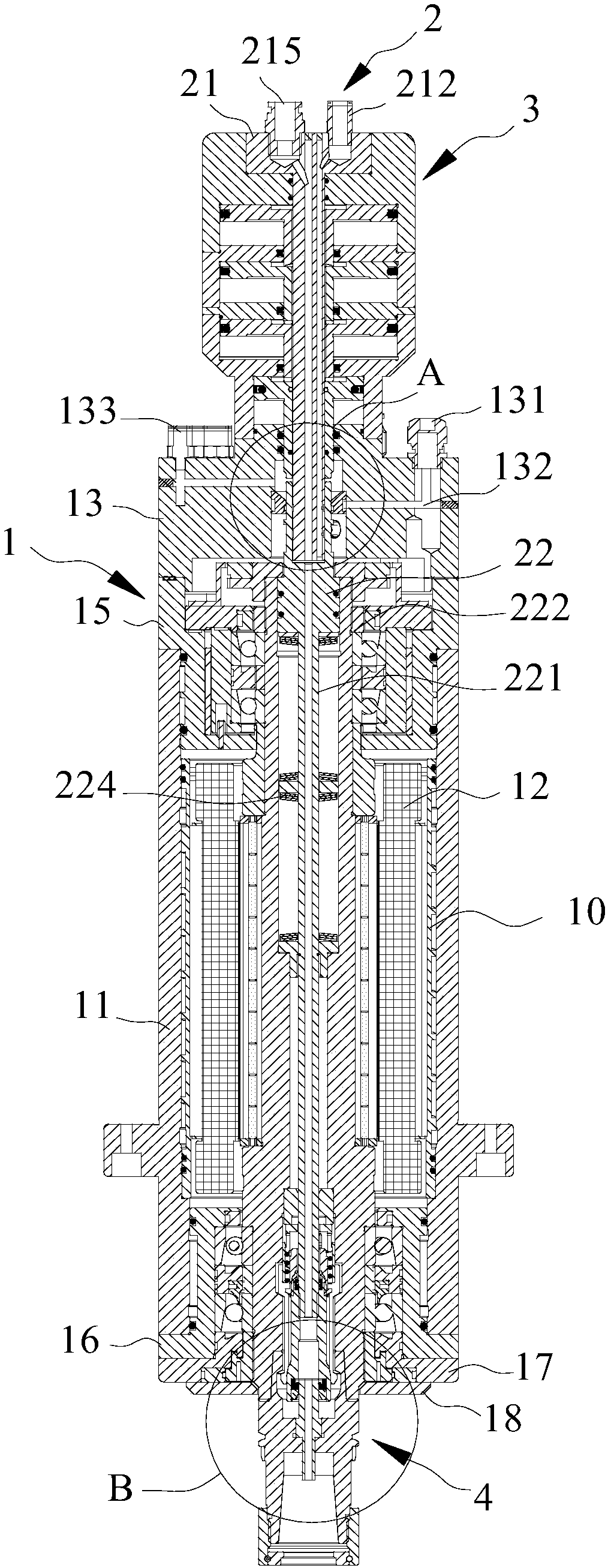

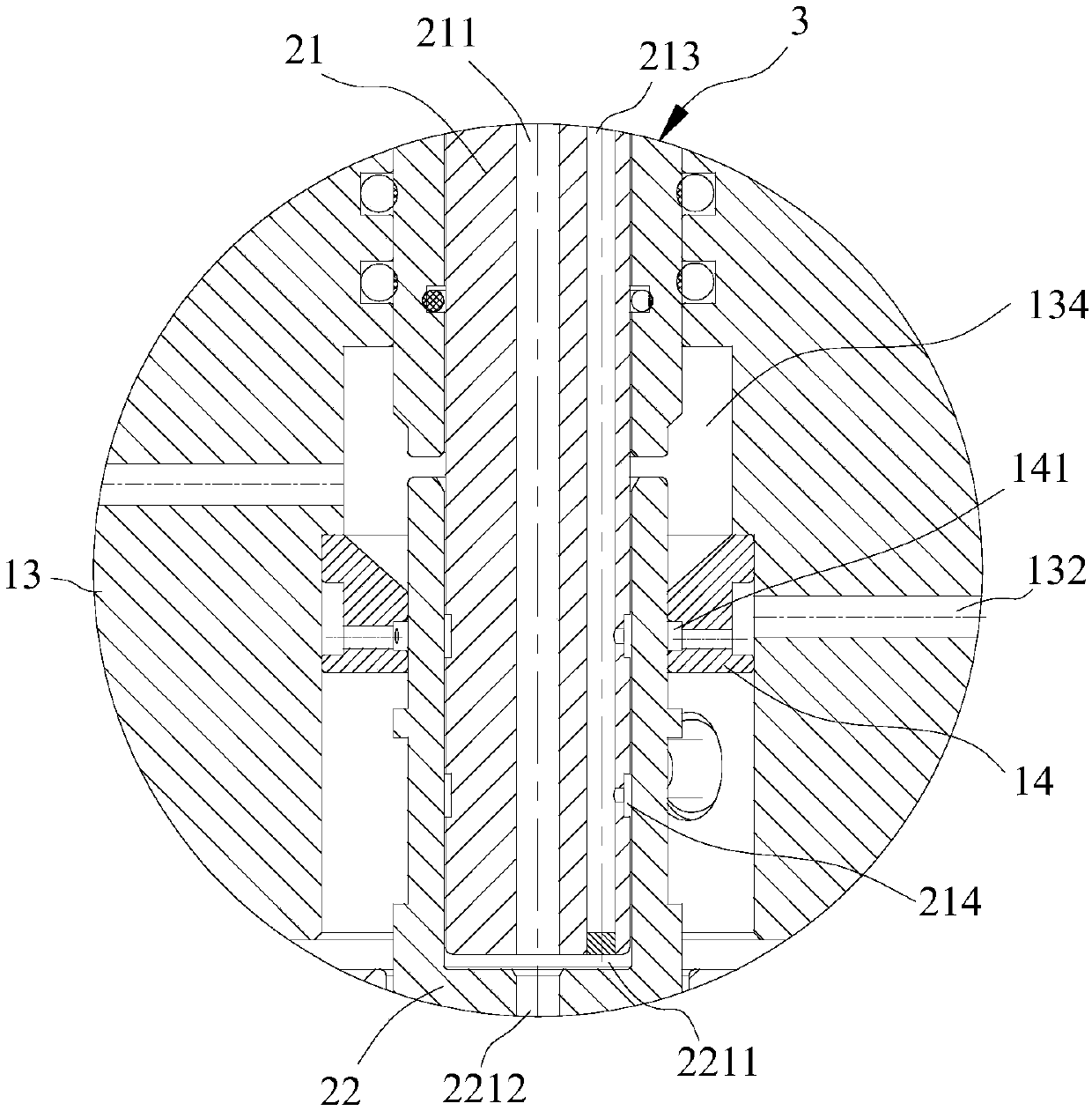

Circular stapler

InactiveUS20100084453A1Relieve pressureImprove performanceSuture equipmentsStapling toolsHand heldEngineering

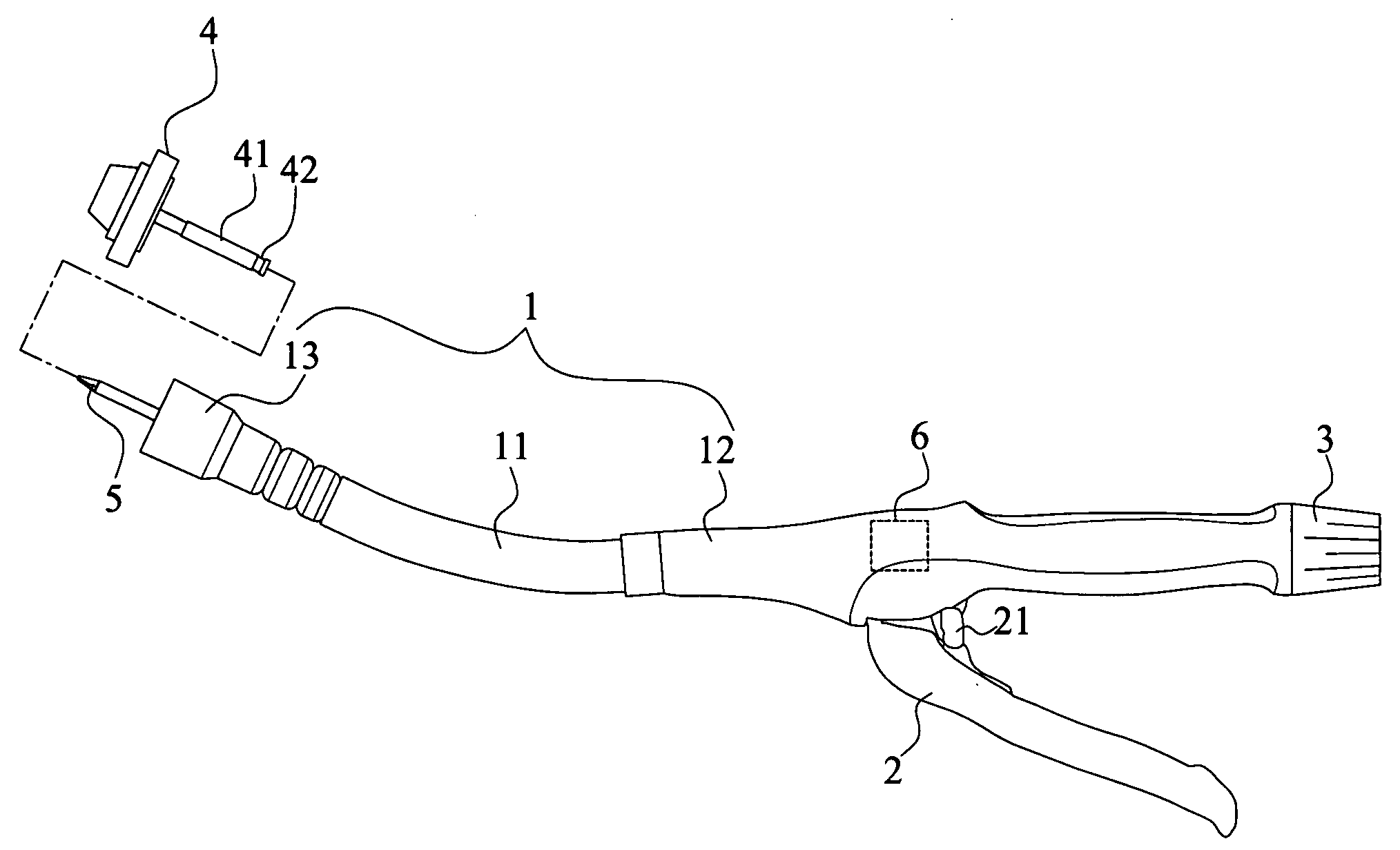

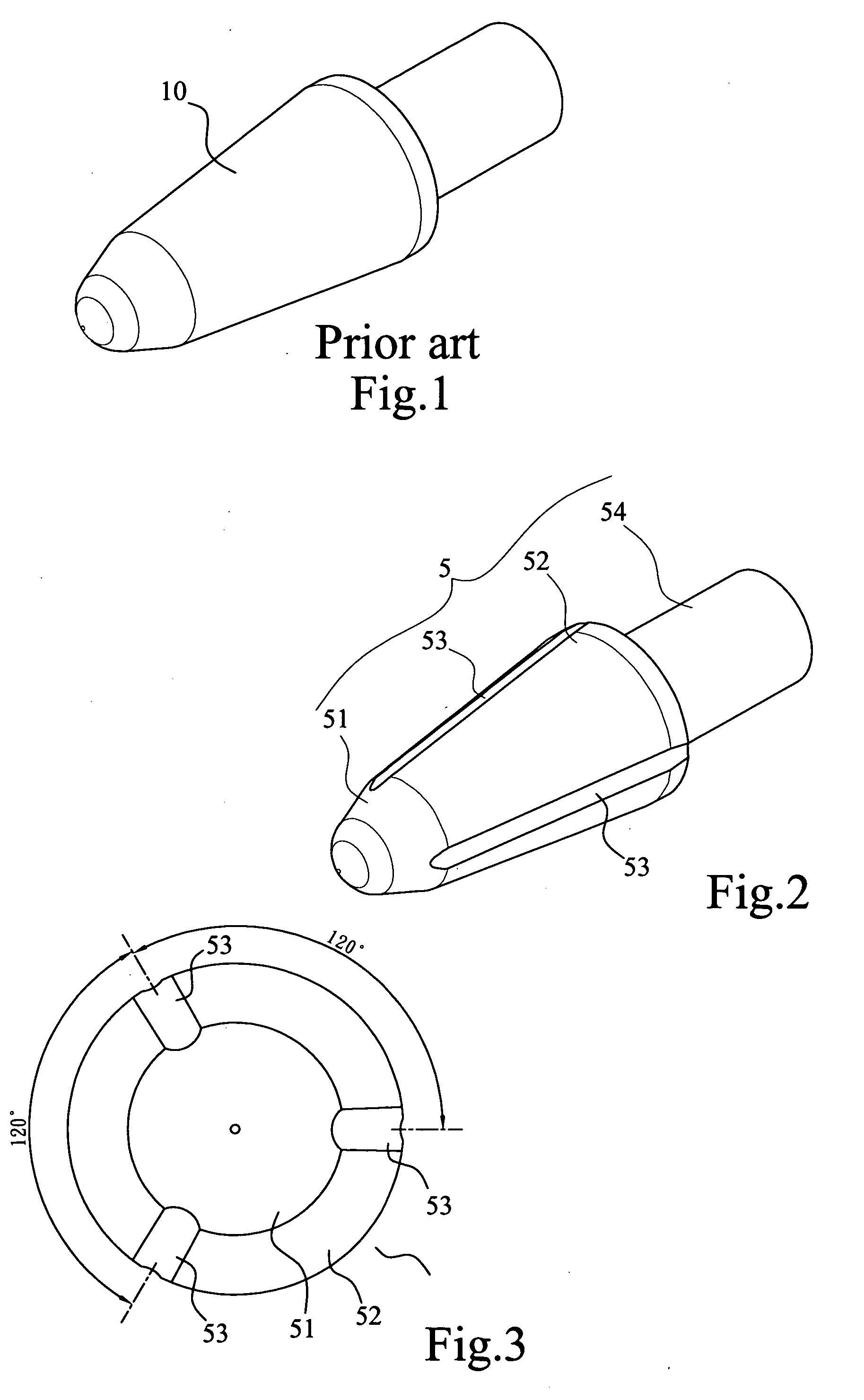

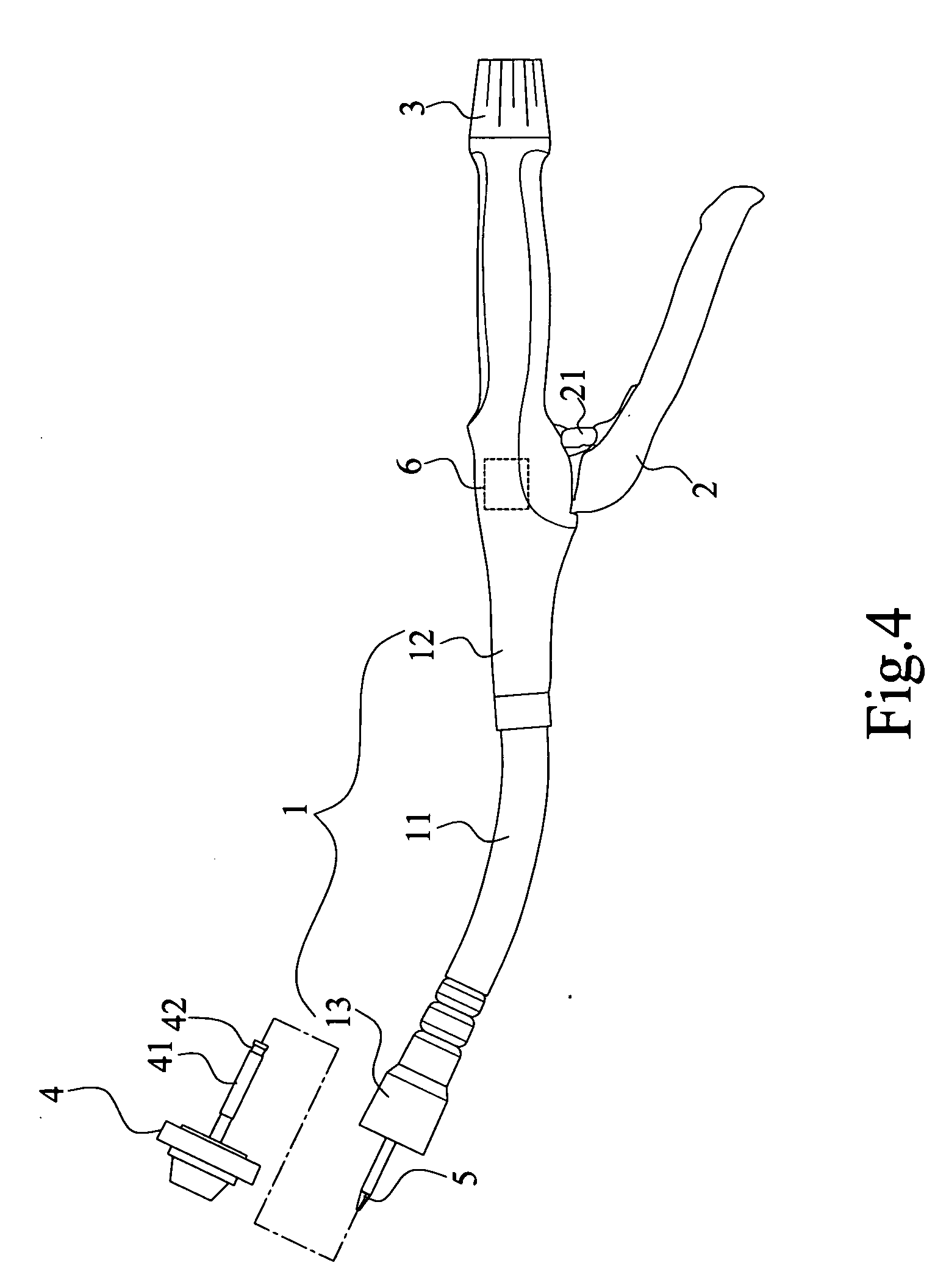

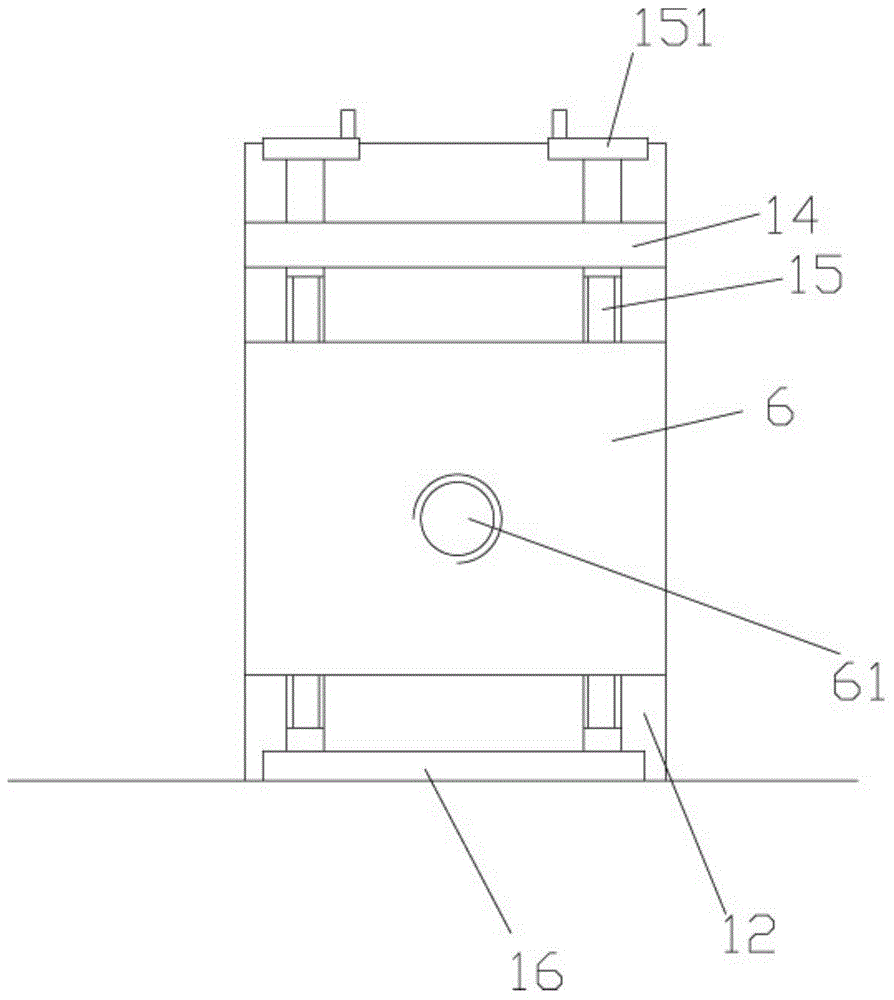

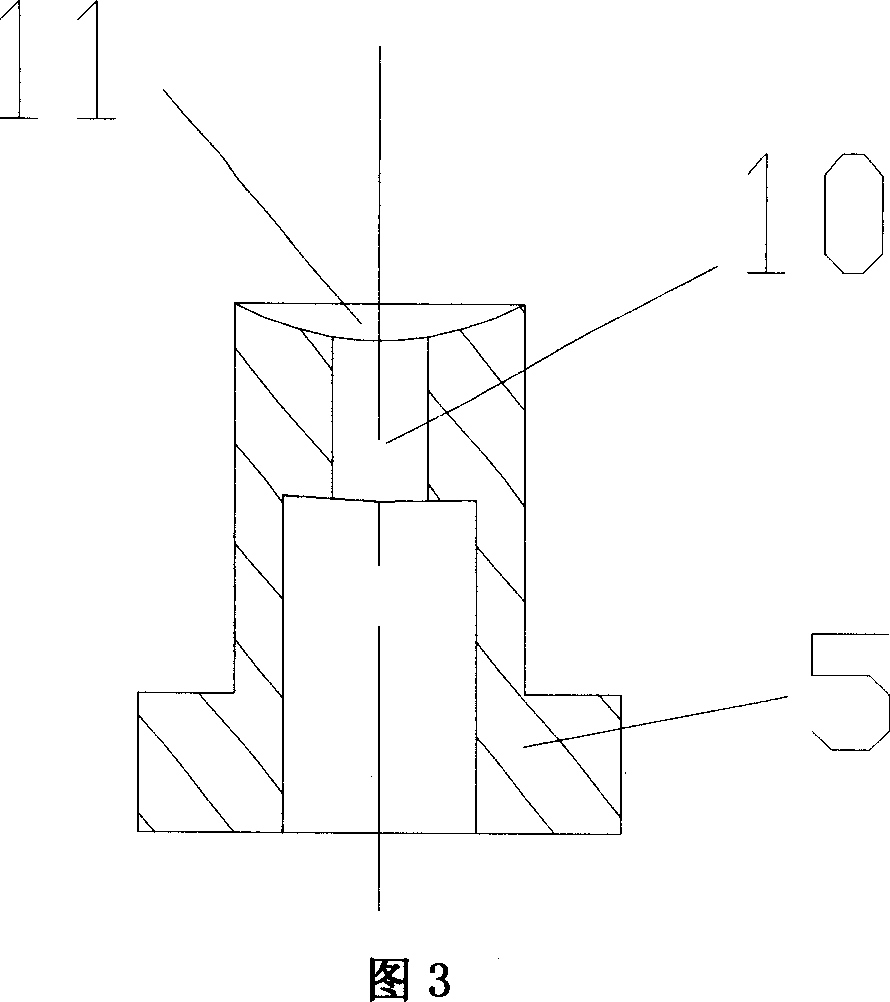

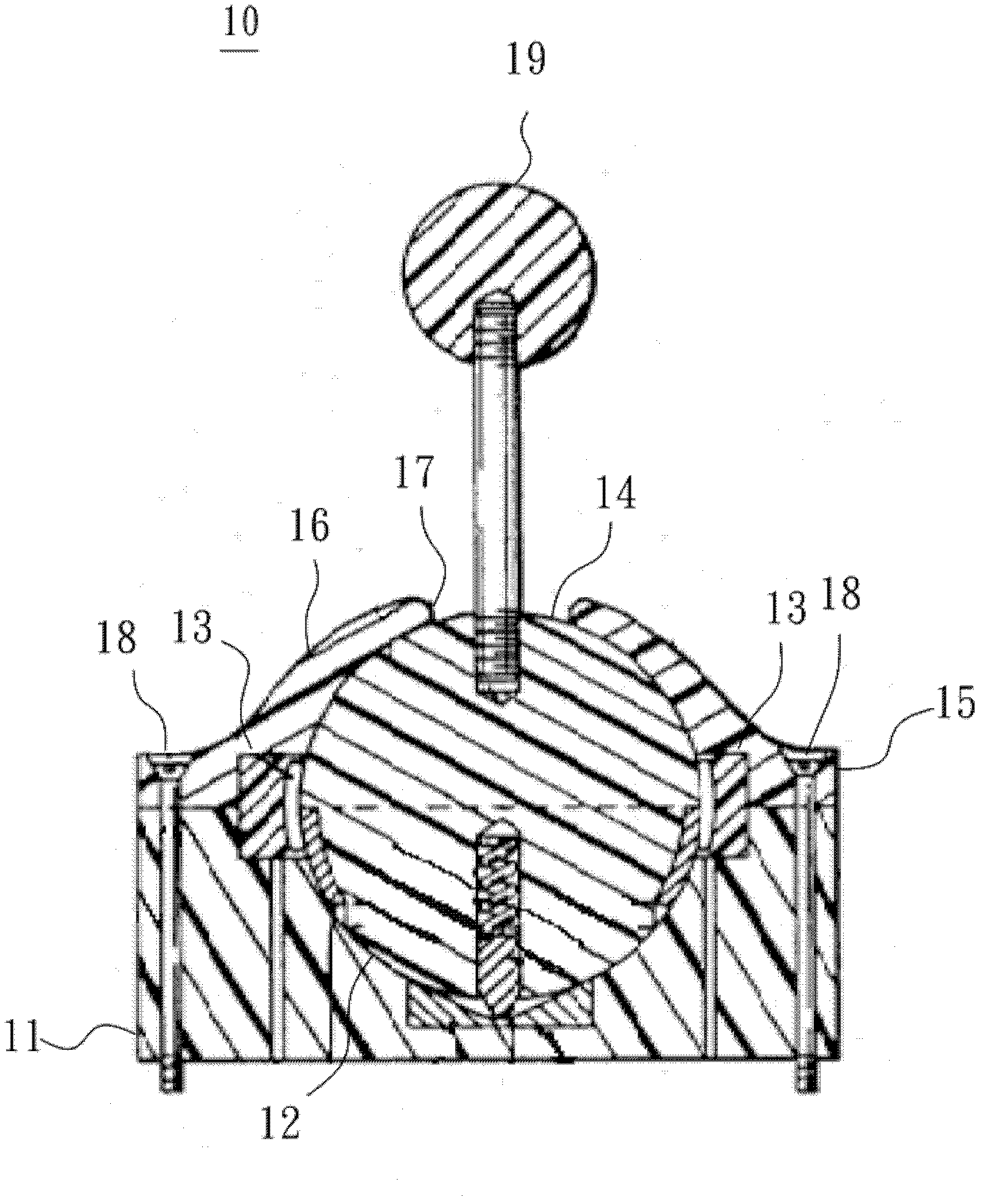

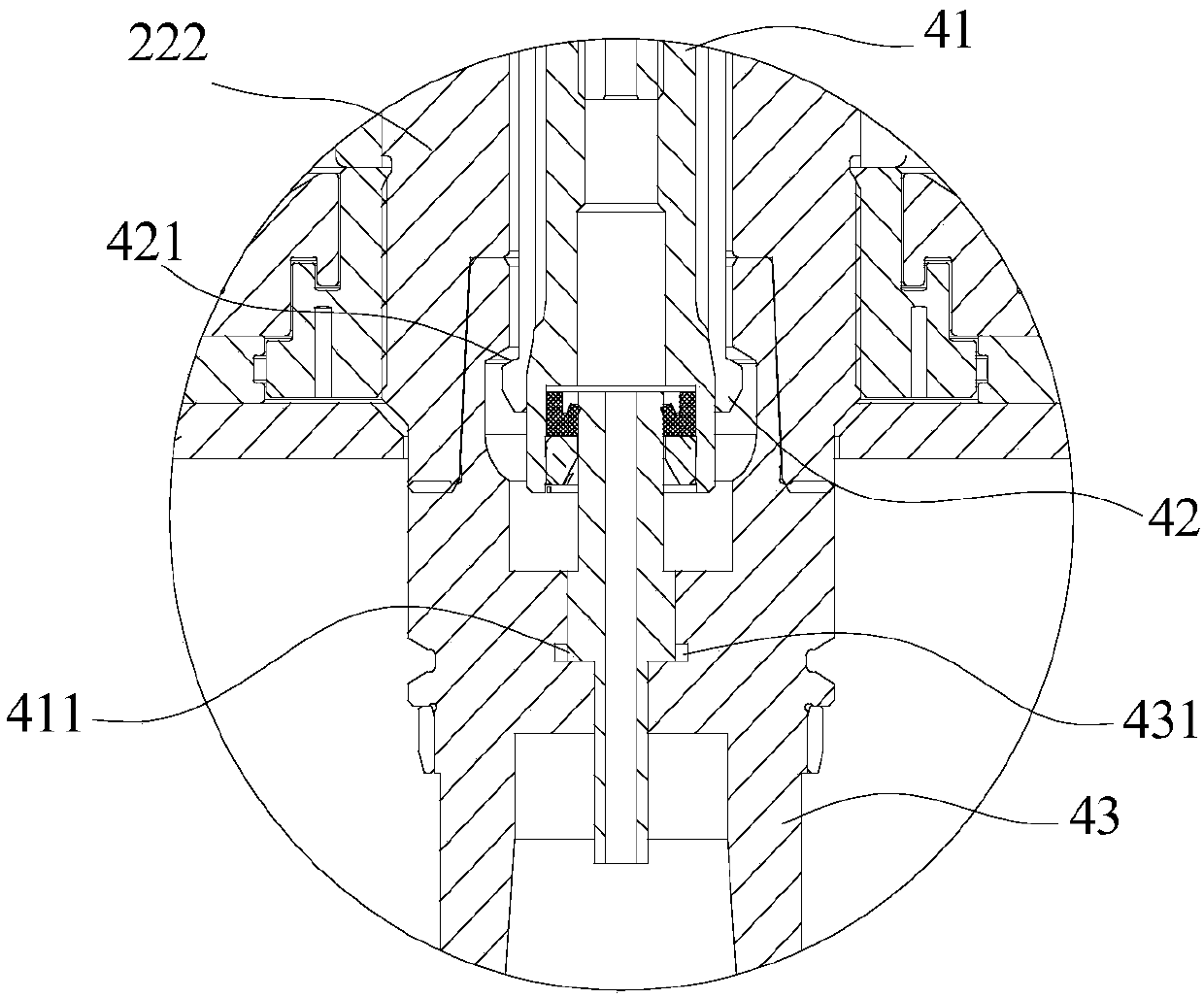

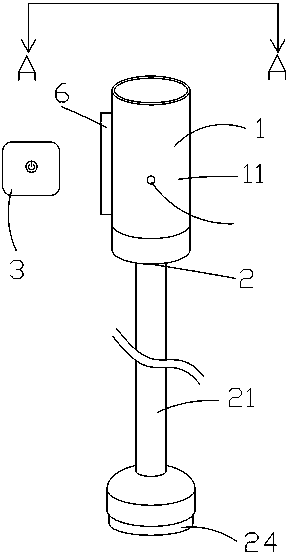

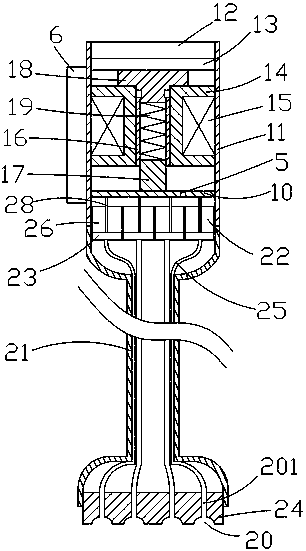

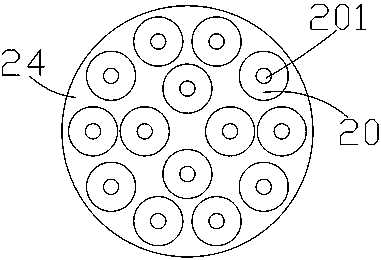

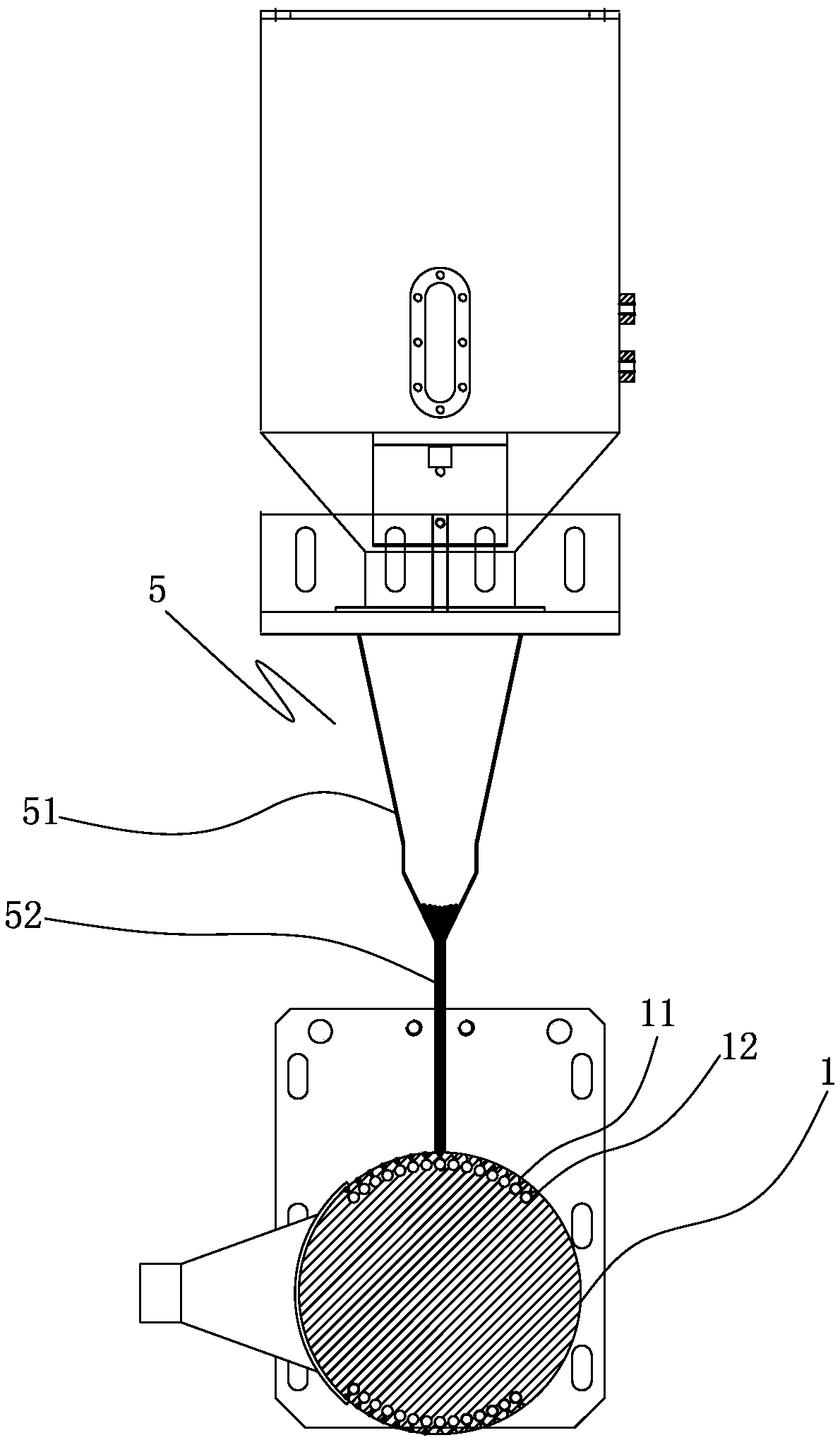

A circular stapler facilitate performing end to end anastomosis; further an occasional prompt with sound effect warning timely firing the stapler bolts. A circular stapler includes a bolting machine (1) consists of a shaft (11), an actuator (12), and a stapler (13); a hand-held handle (2); an adjusting knob (3); and an anvil (4), a hollow anvil shaft (41);characterized in that: a conic trocar (5) disposed to a most distal end of said bolting machine (1), a cambered surface of said conic trocar (5) formed with, at least, three relieve-pressure grooves (53) equal distant distributed are extended from an apex (51) to a bottom (52); an audio prompt (6) disposed inside said bolting machine (1), said audio prompt (6) includes a printed circuit board (PCB) (61), a buzzer (62) electrically connected to the PCB (61) controlled by a switch, and a battery (64) supplies power to the PCB (61).

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

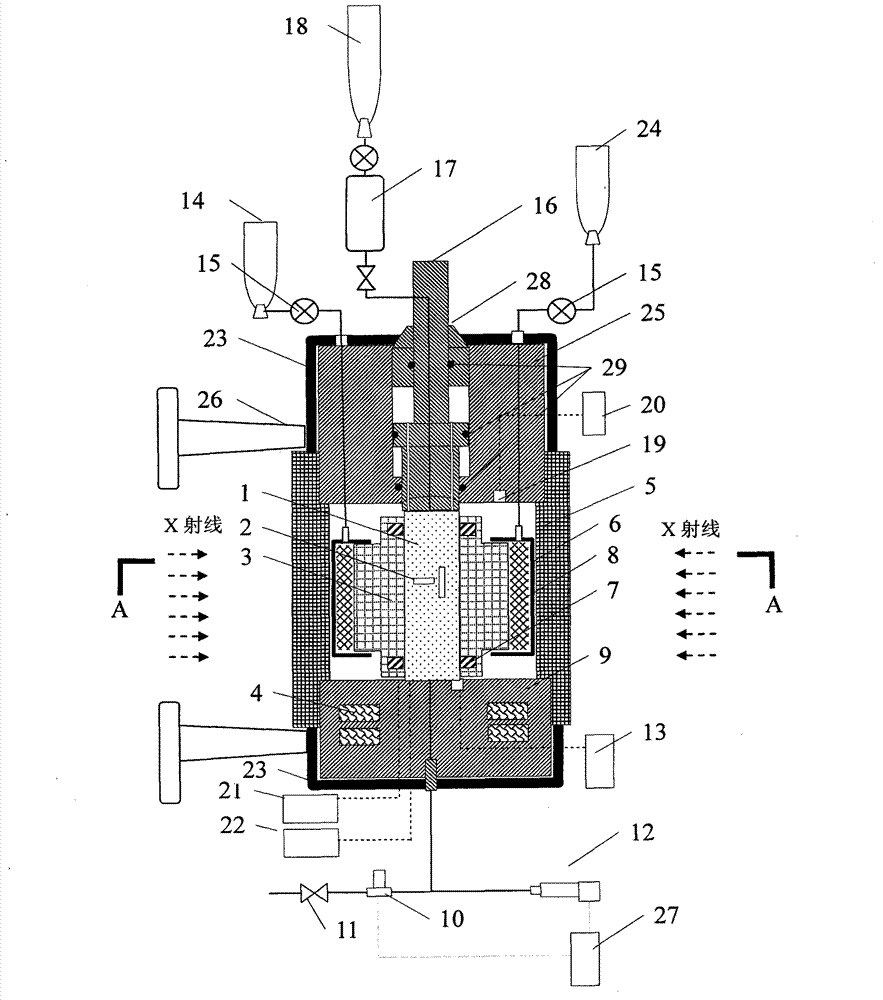

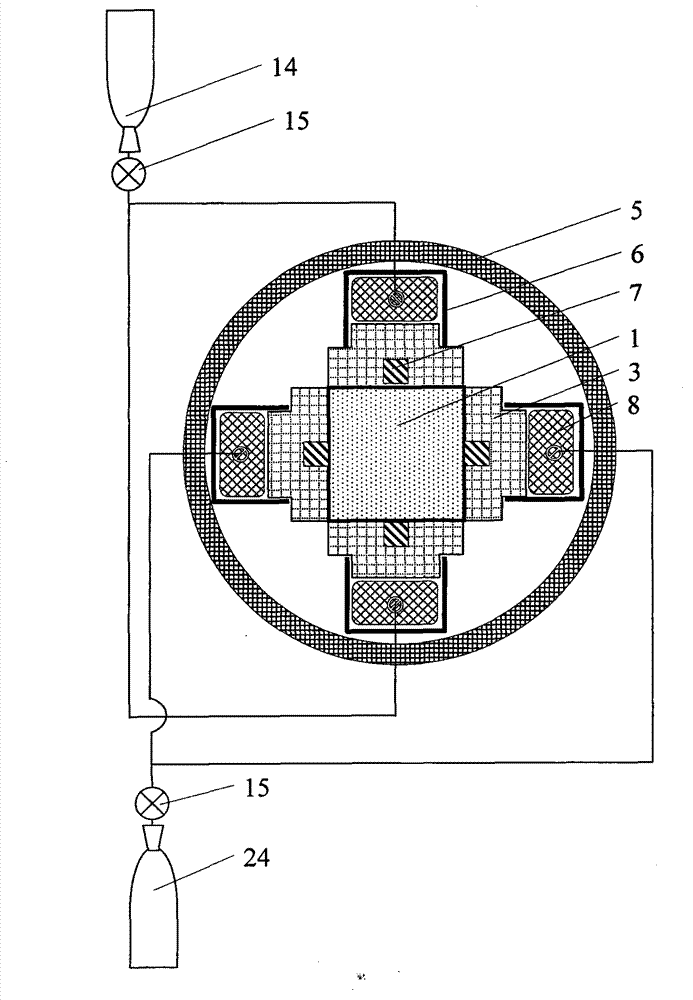

Device for testing coupling function of multi-physics field of core rock and use method of device

The invention discloses a device for testing a coupling function of a multi-physics field of core rock and a use method of the device. The device is a sealed barrel body which is composed of a top cover, a barrel body and a base disc; a column chamber and a temperature sensor are arranged in the device; a plunger is installed inside the column chamber; a pressure groove is arranged inside the barrel body; an airbag and a convex rubber piston are arranged inside the pressure groove; the airbag is connected with an external high pressure gas source; a gas pipeline for filling gas to the barrel body is arranged in the plunger; an acoustic emission sensor is installed inside the rubber piston; the acoustic emission sensor is connected with an external acoustic emission acquiring system; a gas discharge port is arranged on the base disc and is connected with a gas pressure difference transmitter, a gas mass flowmeter and a gas data acquirer; and electric heating wires are arranged inside the base disc. With the adoption of the device, not only the transformation and the acoustic emission activity of a coal test piece at different temperatures and stress states are recorded in real time, but also the absorption and desorption processes of coal-gas are carried out; and the visual microstructure characteristics of the coal test piece are quantified by using the CT (computed tomography) technology.

Owner:SHANDONG UNIV OF SCI & TECH

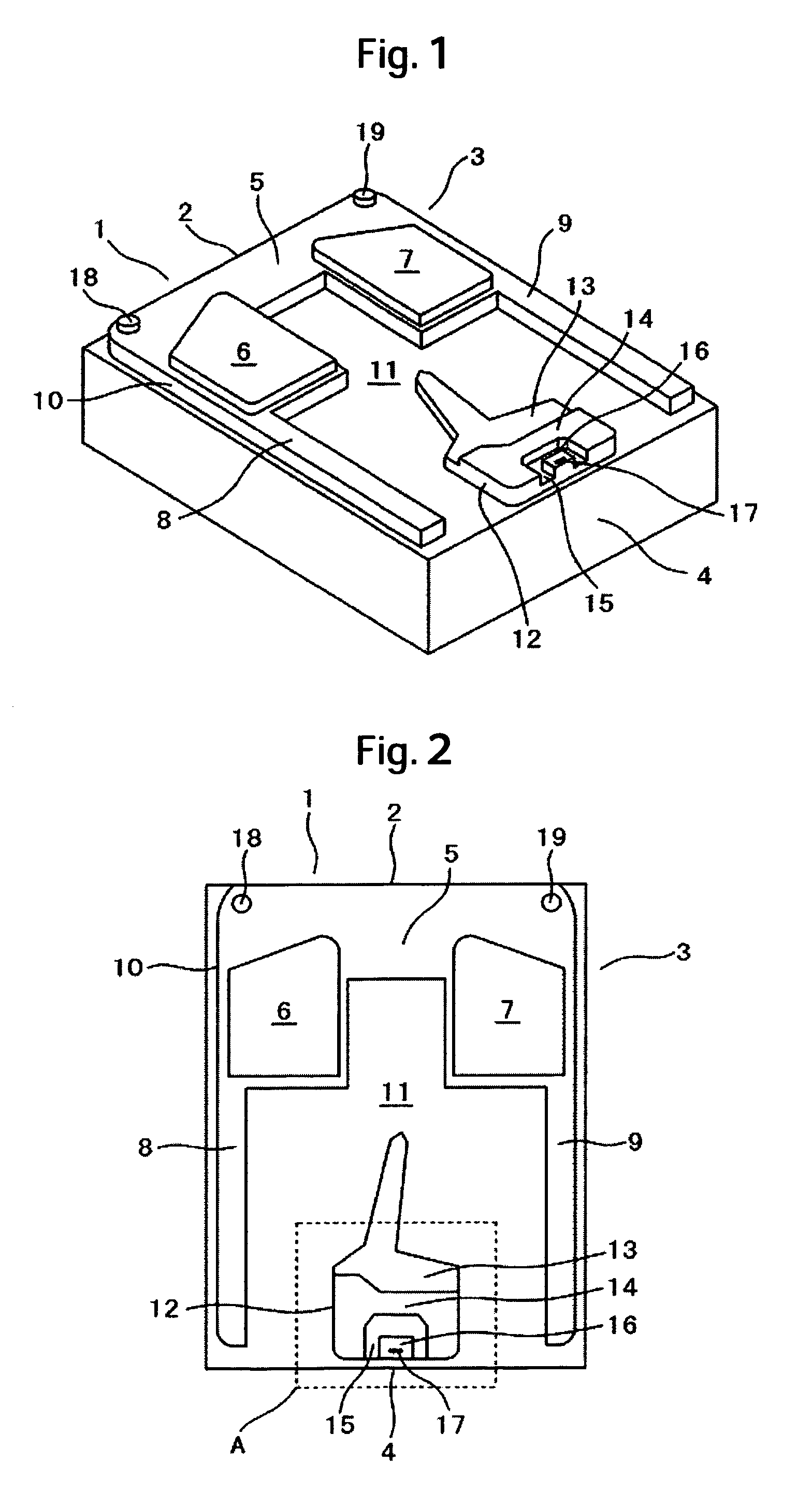

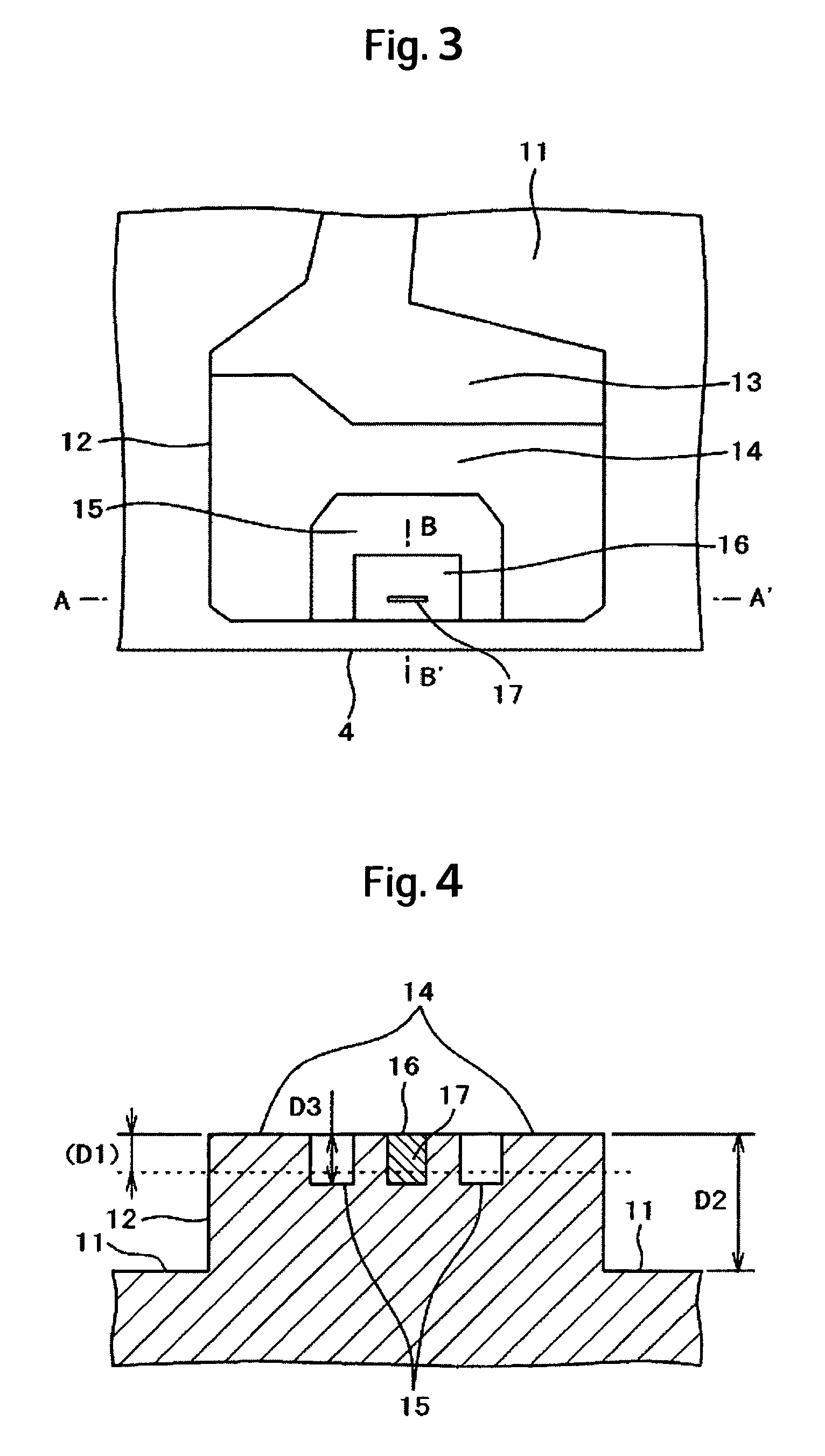

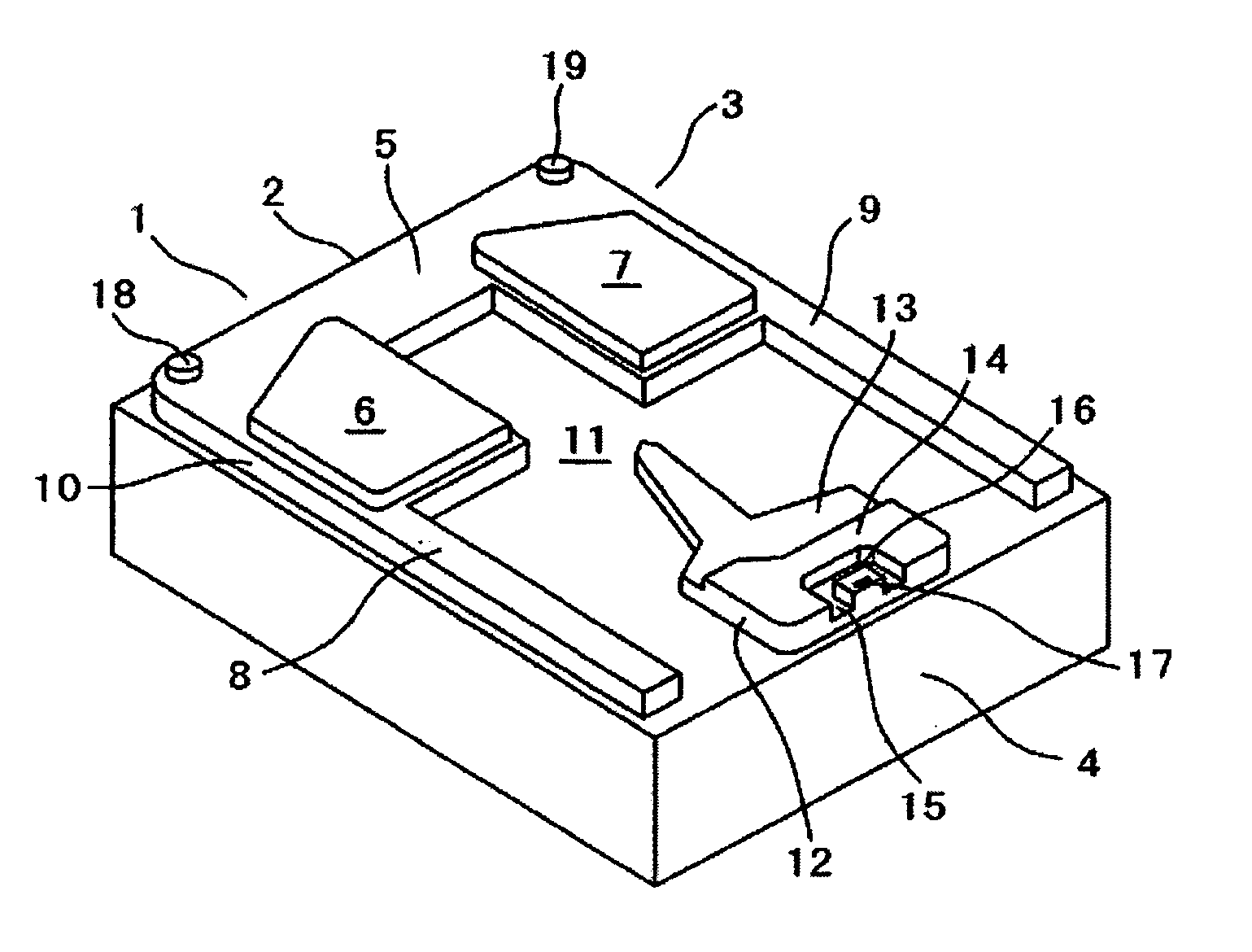

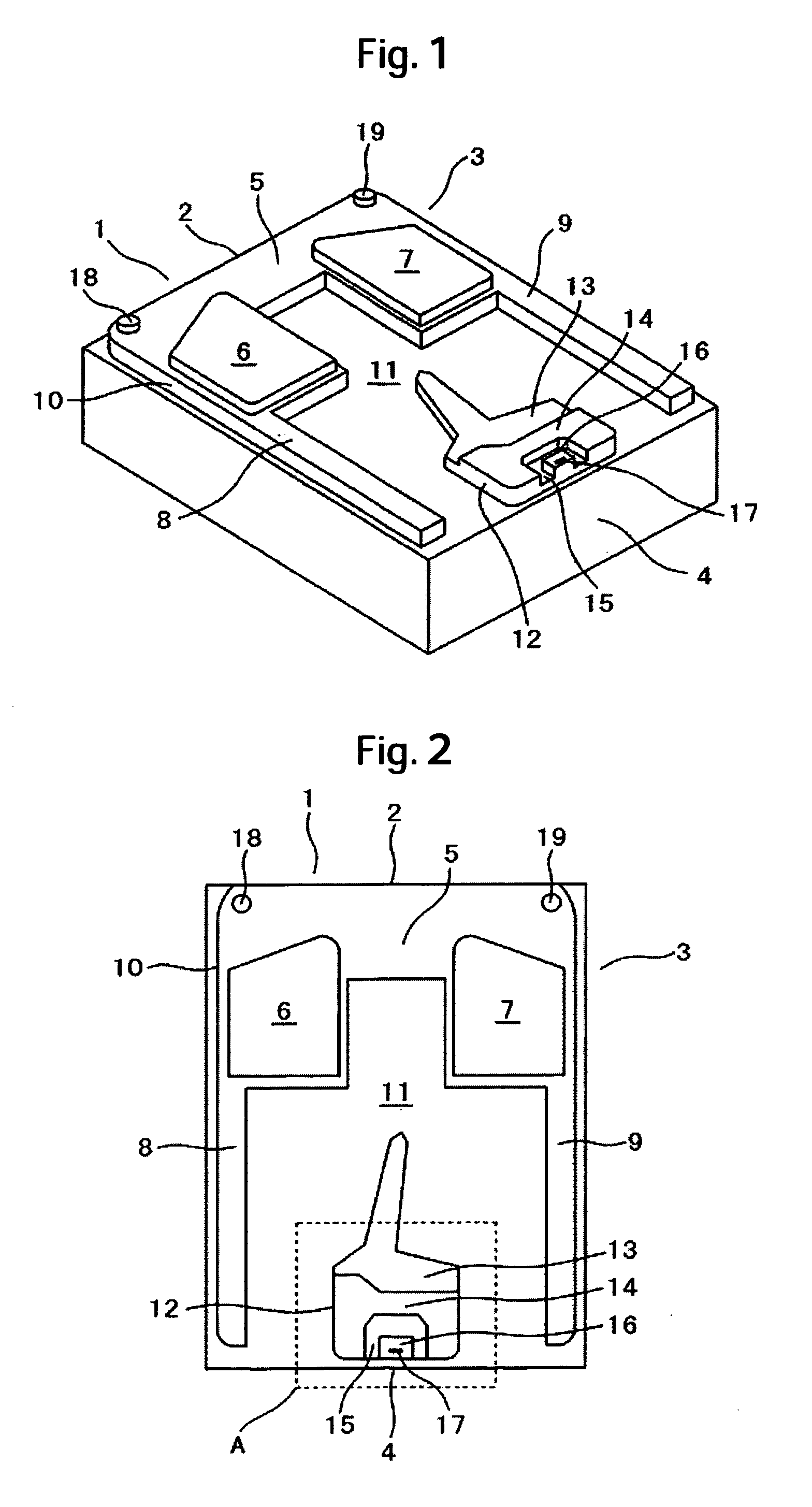

Magnetic head slider with trailing rail surface for flying height control

InactiveUS7679863B2Decrease offset ratio in flying heightFluid-dynamic spacing of headsRecord information storageLeading edgeControl power

Embodiments of the invention provide a slider structure able to lower a flying height compensation ratio caused by a projecting deformation of an air bearing surface of a slider by a flying height control mechanism and afford a change in flying height with a low control power. In one embodiment, a slider is provided with a leading edge, an air bearing surface, and a trailing edge. The air bearing surface includes a front pad, the front pad being made up of a front step bearing surface, leading rail surfaces, and side step bearing surfaces. The air bearing surface also includes a negative pressure groove surface surrounded by the front pad. The air bearing surface further includes a rear pad, the rear pad being made up of a rear step bearing surface formed at the same depth as the depth of the front step bearing surface and positioned on the trailing edge side, a trailing rail surface, an intermediate groove deeper than the trailing rail surface, and a trailing pad surface lying at the same height as the trailing rail surface. The front and both sides of the trailing pad surface are surrounded by the trailing rail surface.

Owner:WESTERN DIGITAL TECH INC

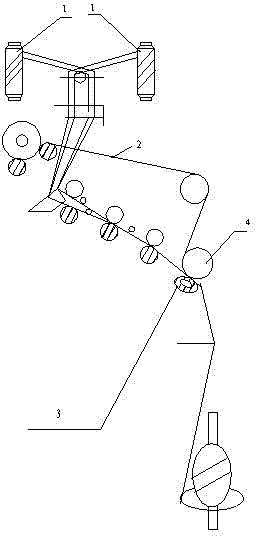

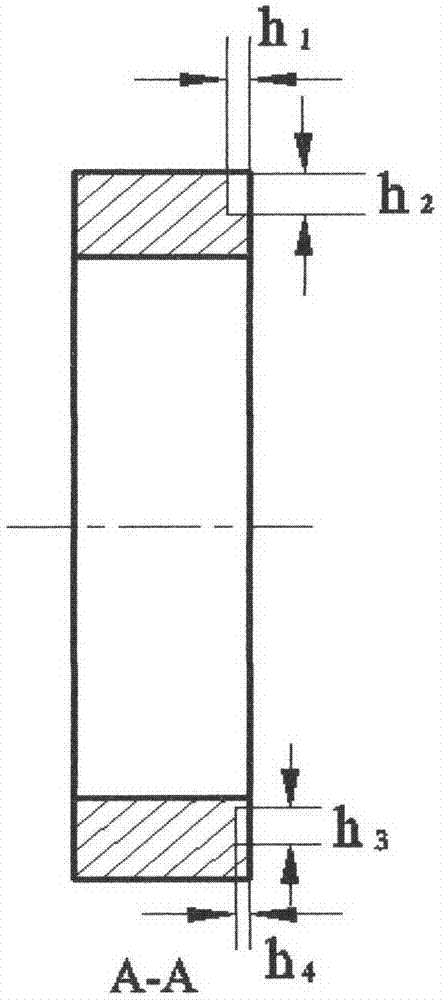

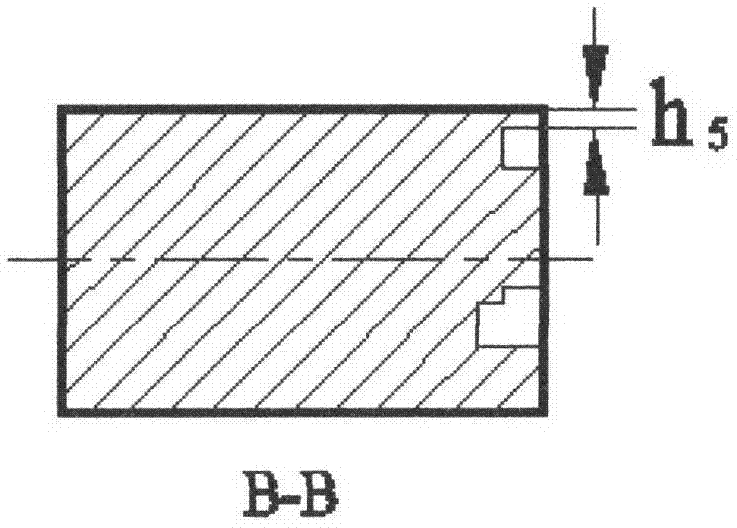

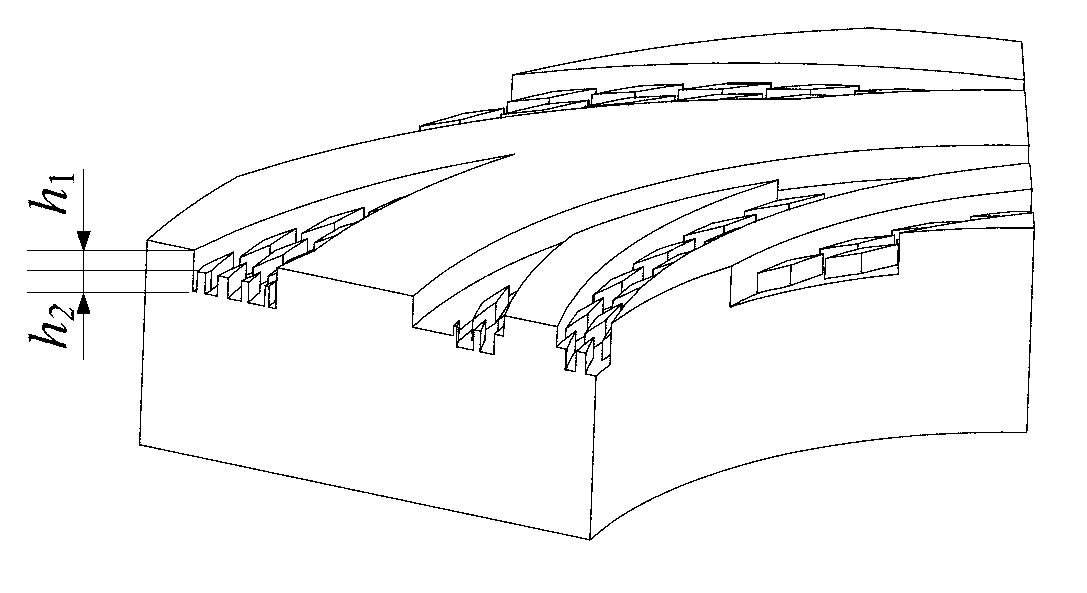

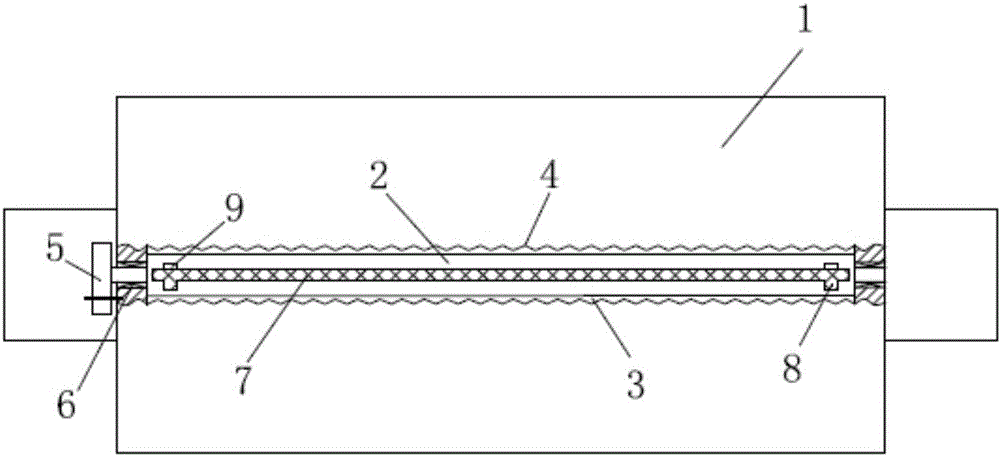

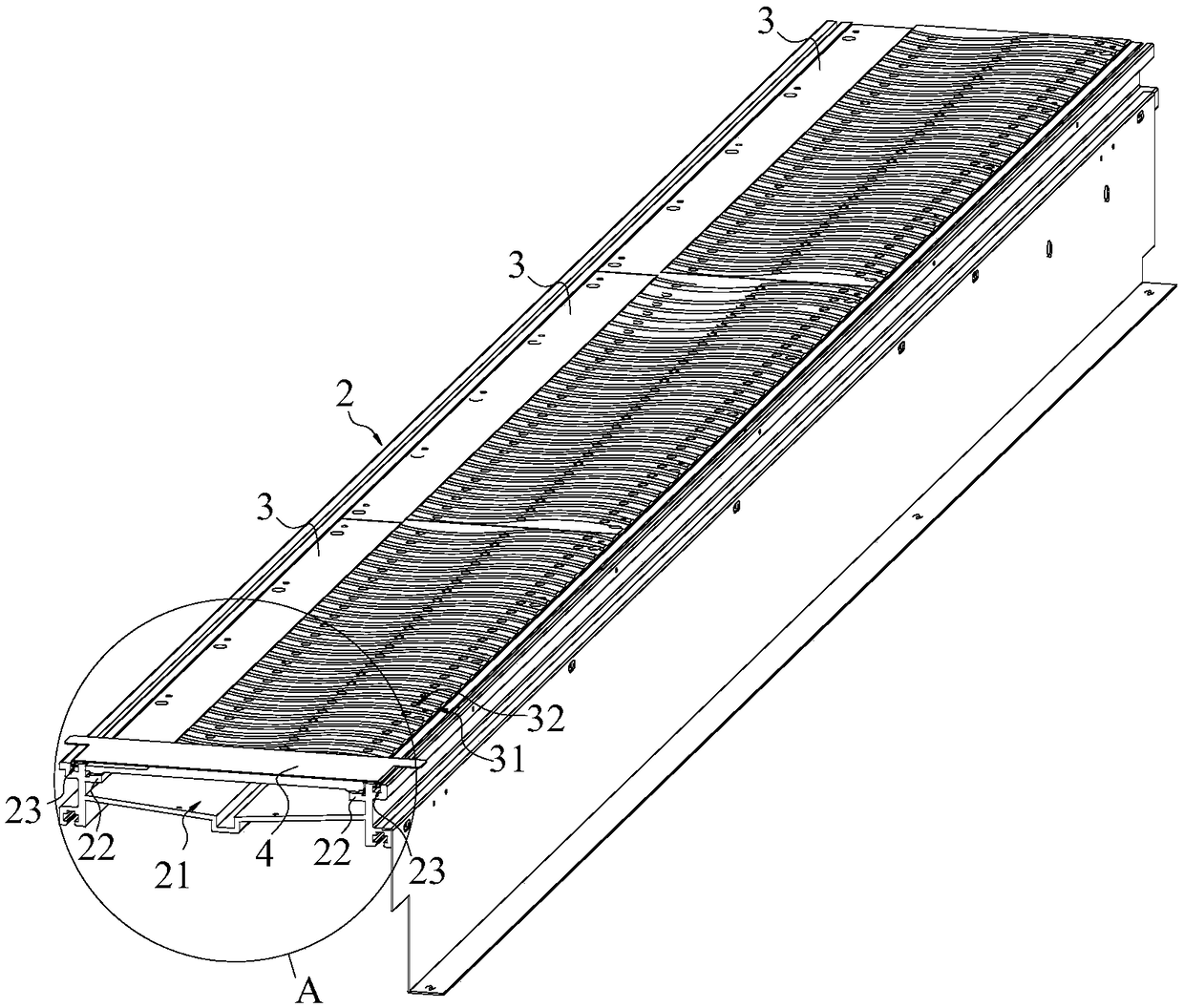

Production technology of siro compact spinning covering yarn

The invention relates to the production technology of a siro compact spinning covering yarn. A traditional compact spinning negative pressure pipe negative pressure groove is designed in an I-shaped straight groove mode, a cotton net is too narrow and the yarn-leakage phenomenon exists, meanwhile, the yarn hairiness is serious, evenness is poor, strength is low, fluctuation is large, and wool particles / neps are prone to being formed during a post processing process. The production technology of the siro compact spinning covering yarn enables the negative pressure pipe negative pressure groove to be designed into a V-shaped groove; meanwhile, the siro spinning technology is used, two coarse yarns are fed at the same time at one spindle position at a certain interval, the two coarse yarns are dragged respectively, an elastic filament is arranged between the two coarse filament, two fiber beams are formed in a negative pressure zone formed by the V-shaped groove after the two coarse yarns are dragged, the filament is guided to be arranged between the two fiber beams from the position behind a clustering front leather roller, and therefore the filament can be effectively wrapped, and a good covering yarn product can be manufactured.

Owner:重庆三峡技术纺织有限公司

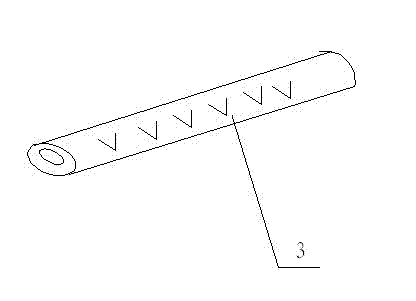

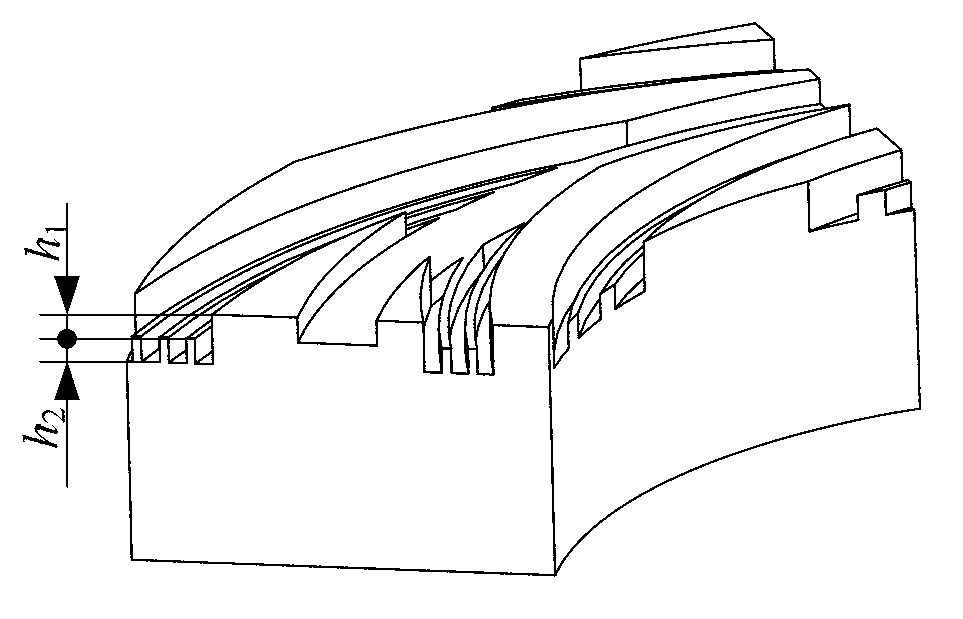

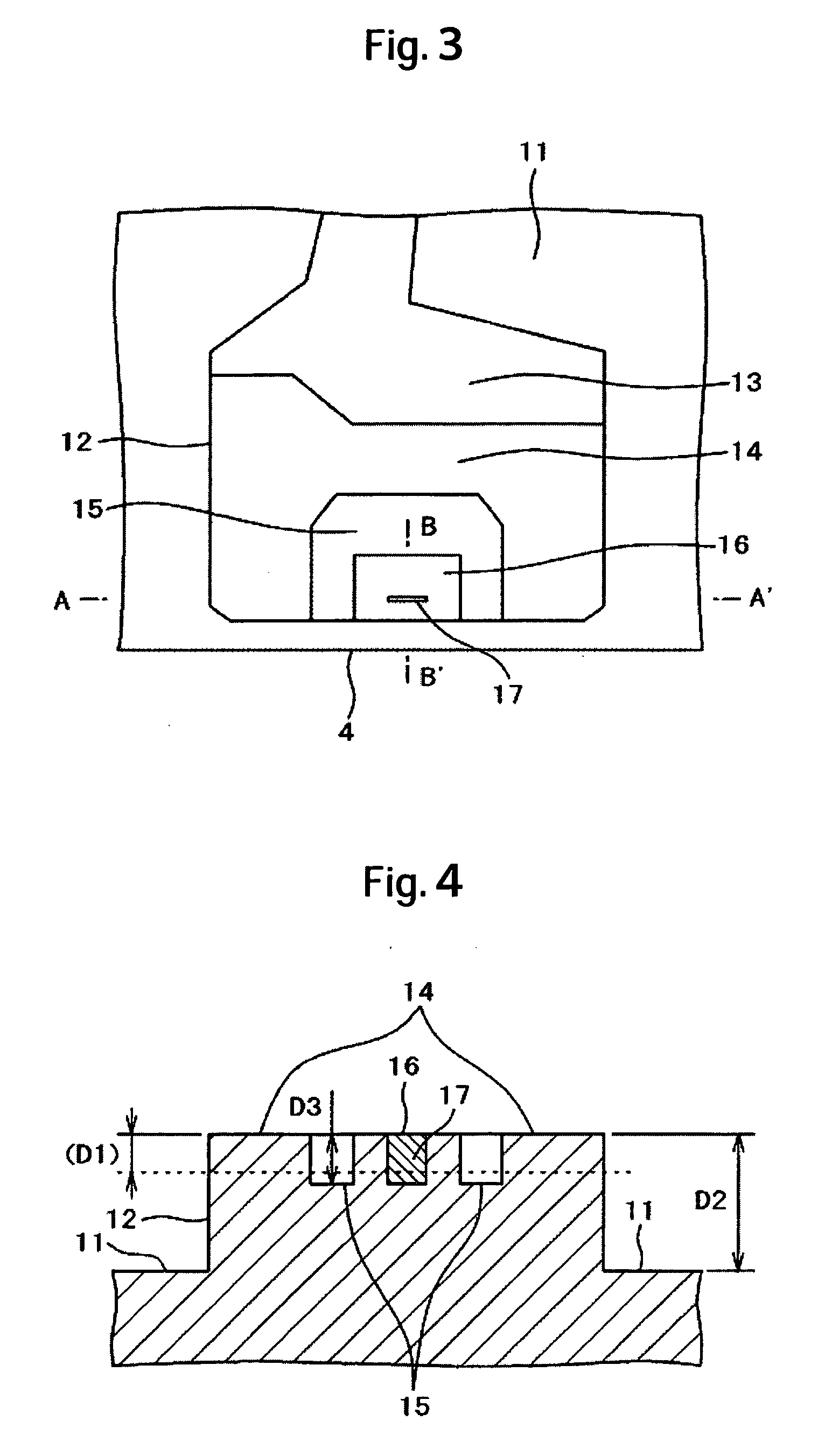

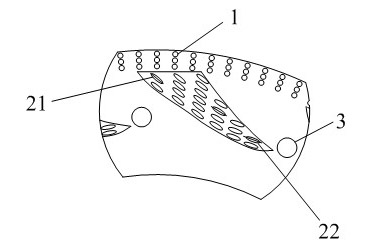

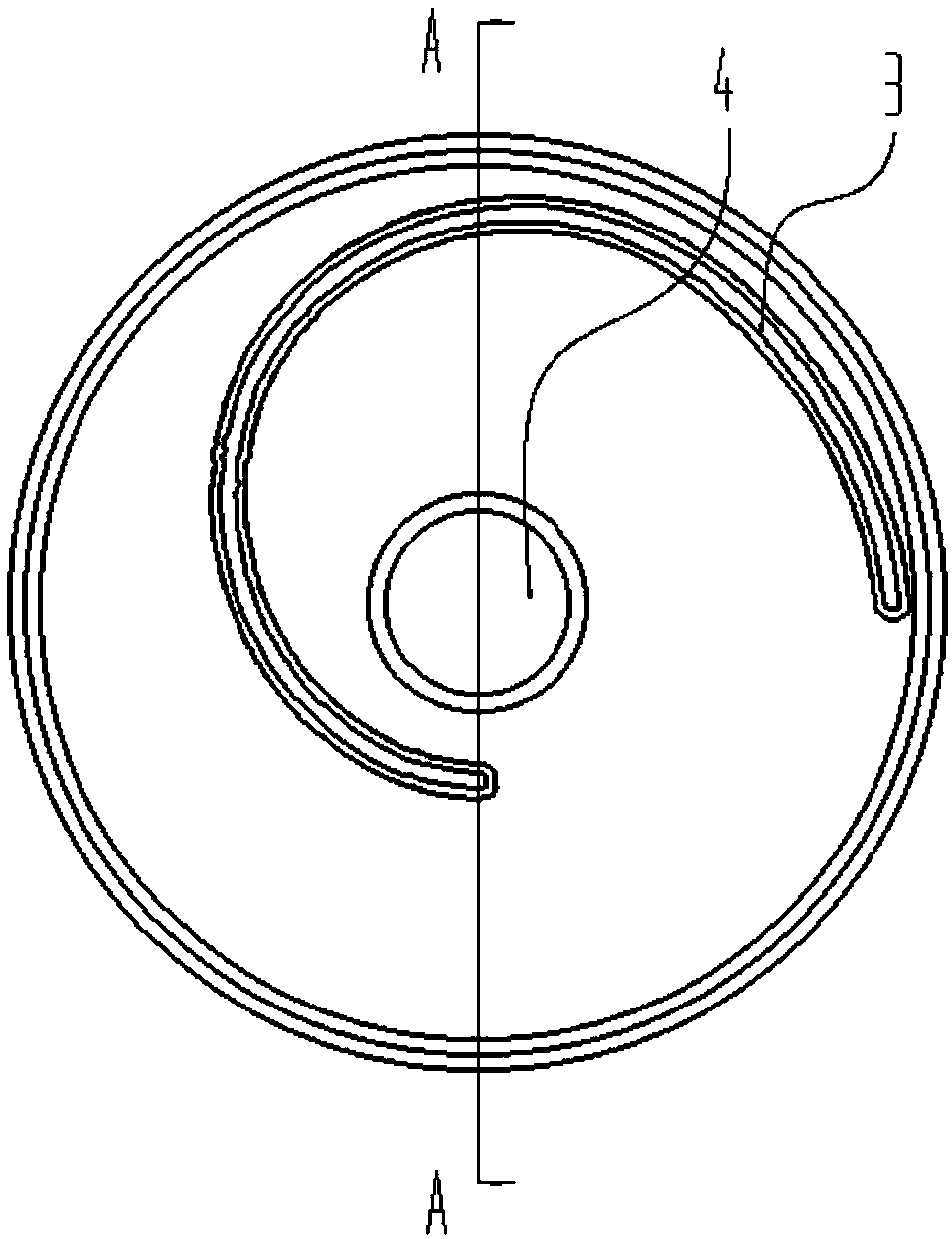

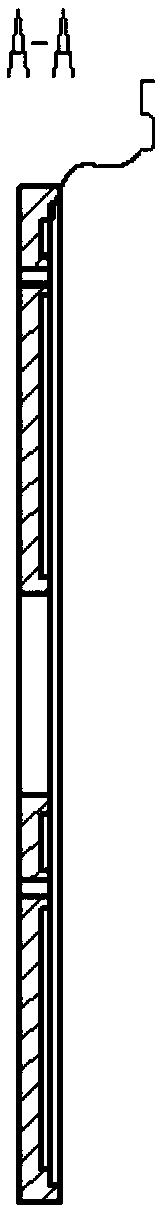

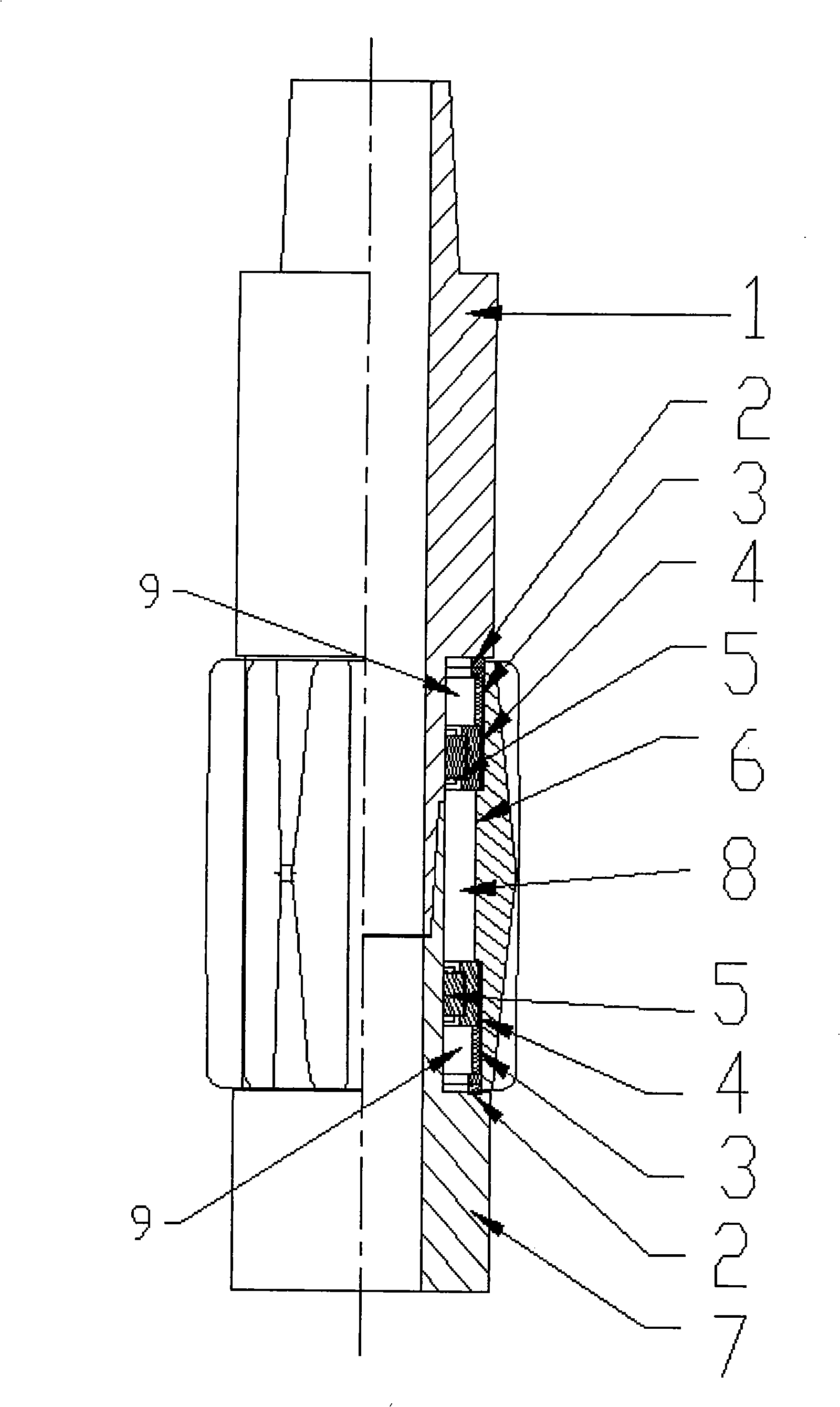

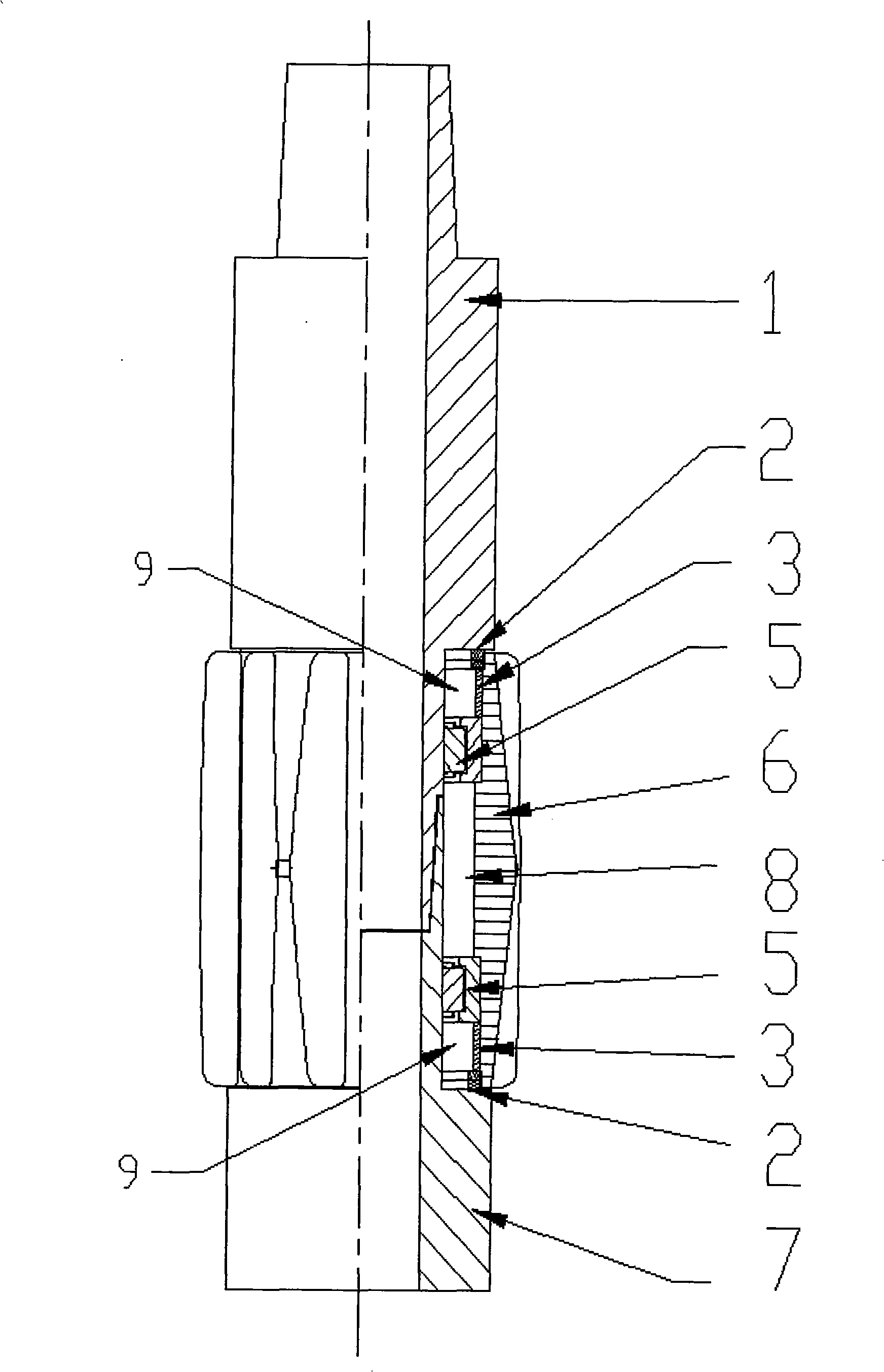

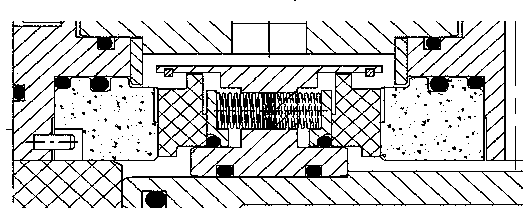

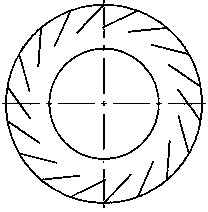

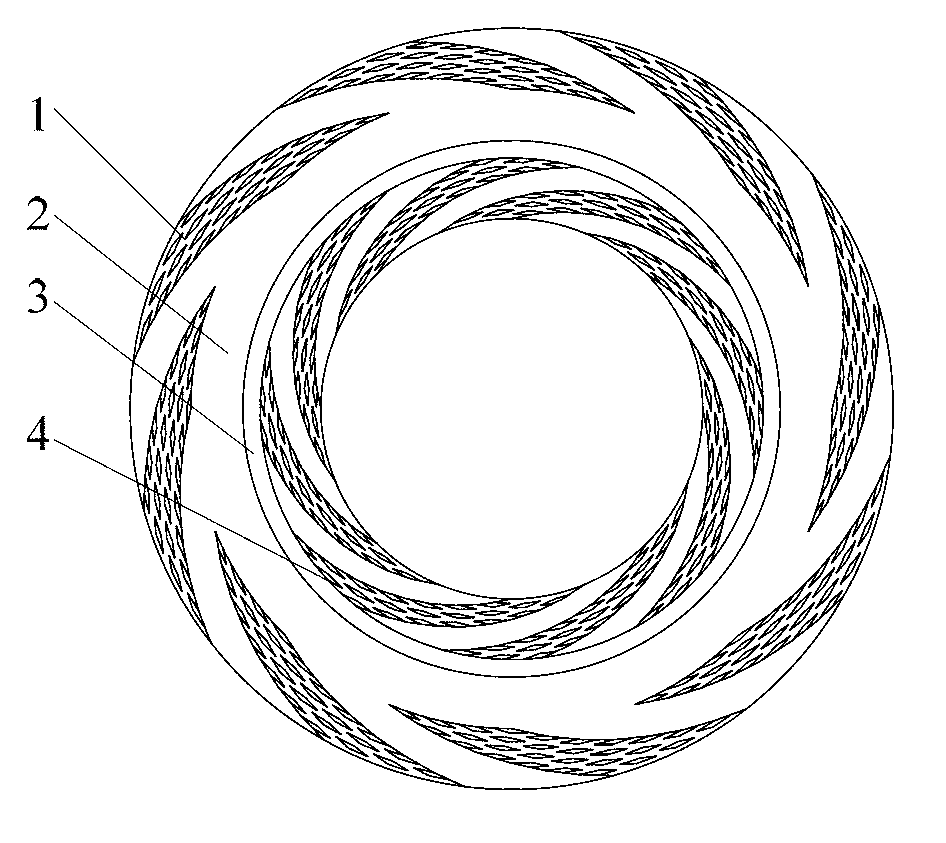

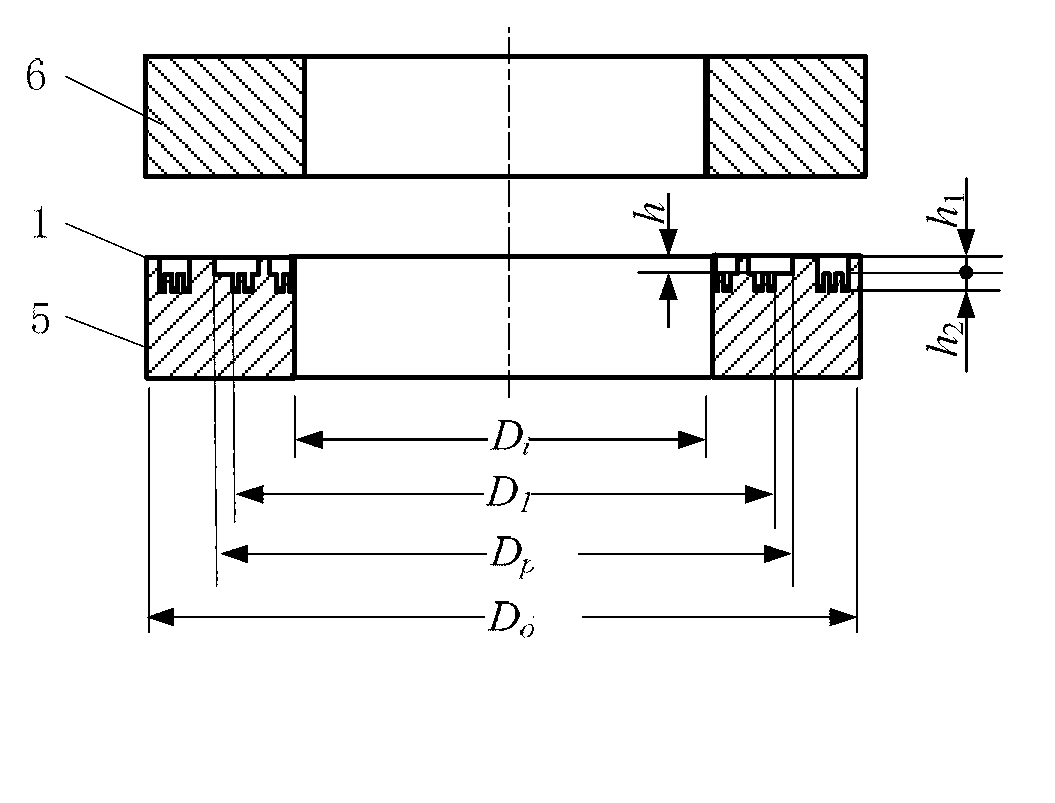

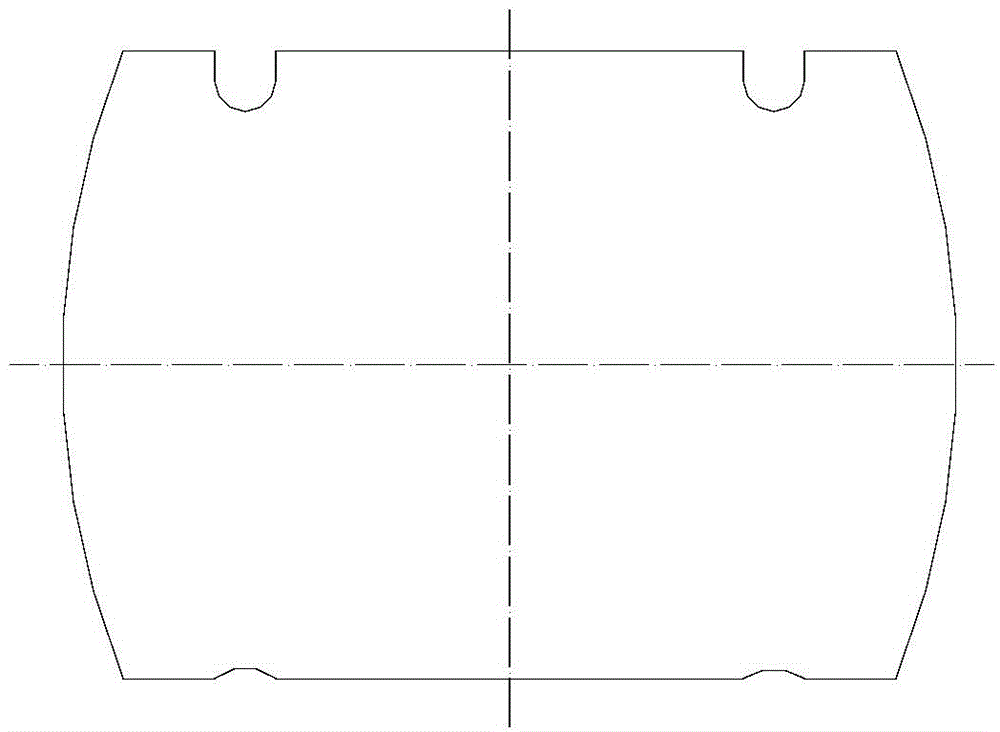

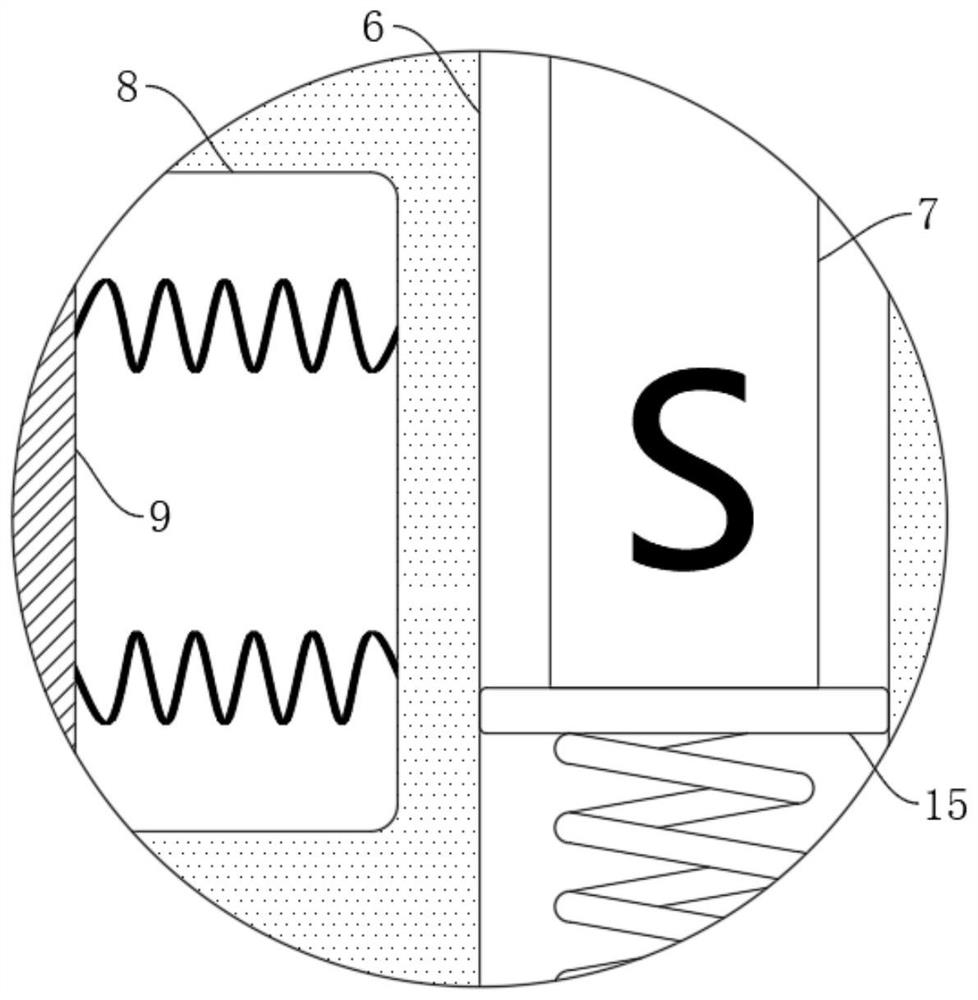

Combination fluid dynamic pressure groove mechanical seal ring capable of automatically discharging particles

InactiveCN103791097AReduce wearImprove the state of friction and lubricationEngine sealsSolid particleEngineering

The invention relates to a combination fluid dynamic pressure groove mechanical seal ring structure capable of automatically discharging particles. The combination fluid dynamic pressure groove mechanical seal ring structure is characterized in that on a sealing moving ring or a static ring, a circulation outer circle arc groove and a pumping groove which are symmetrically arranged about the rotation center are sequentially arranged from the high-pressure side and the low-pressure side. The outer circle arc groove is formed in the upper portion (high-pressure side) of the end face and the pumping groove is formed in the lower portion (low-pressure side) of the end face. The arc groove and the pumping groove are communicated at the contact place so as to ensure that the particles entering the pumping groove enter the arc groove by means of the pumping effect and return to a sealing cavity through medium circulation. Meanwhile, by means of the dynamic pressure effect and the pumping effect of the arc groove and the pumping groove, the bearing capacity and the low leakage amount of a liquid film are ensured. Thus, the good sealing capacity and the automatic particle discharging capacity of the combination fluid dynamic pressure groove mechanical seal can be achieved. The dynamic pressure groove is prevented from being blocked and abrasion of the sealing end face is relieved. The seal ring can be applied to working conditions including solid particle media.

Owner:JIANGSU UNIV

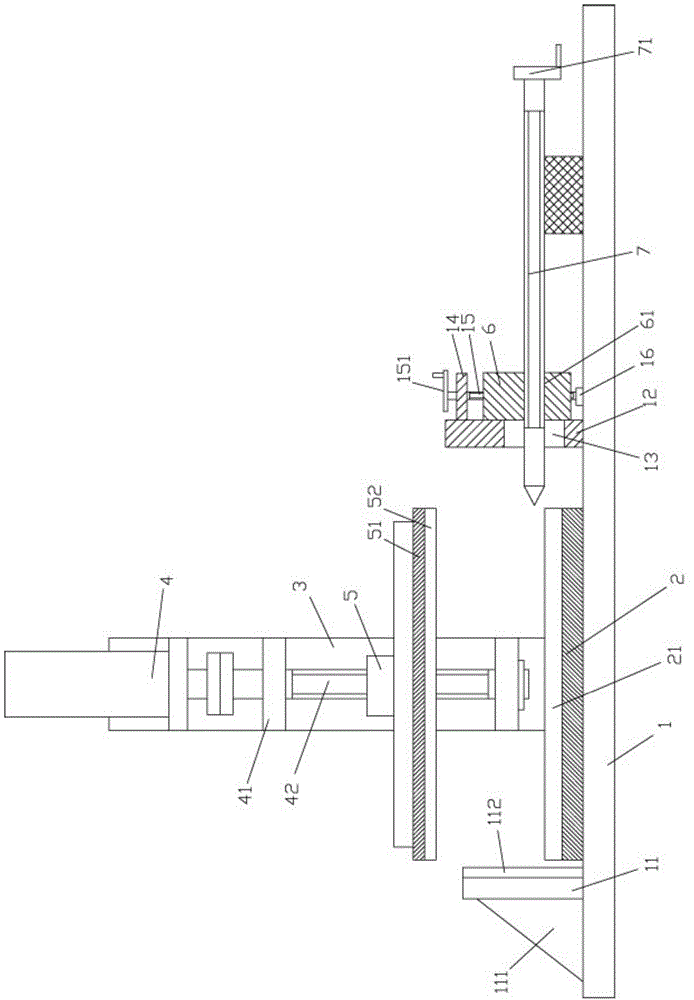

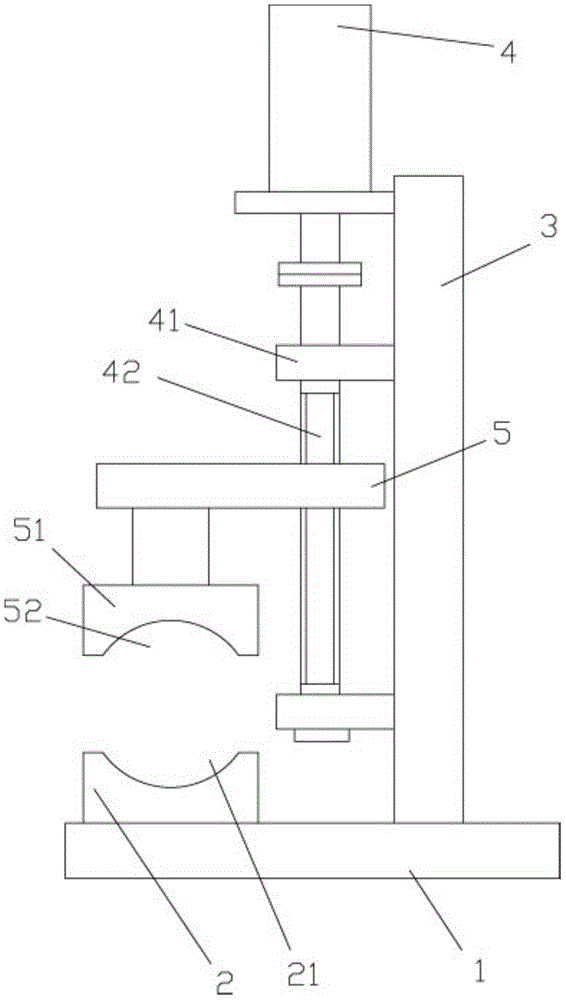

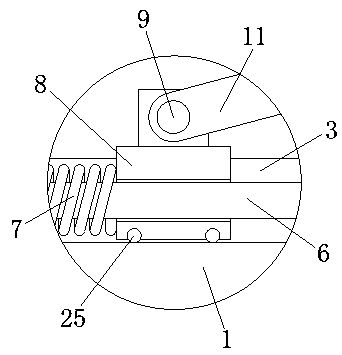

Construction corrector of hollow steel tubes

InactiveCN104307930AImprove repair rateLow costMetal-working feeding devicesPositioning devicesArchitectural engineeringPressure groove

The invention discloses a construction corrector of hollow steel tubes. The construction corrector comprises a bottom frame. A tube holder block is fixed on the bottom frame and provided with a holding groove inside. A support pillar is fixed on the bottom frame. A servo motor and two support blocks are fixed on the support pillar. An upper pressure block is fixed on a connecting block. The bottom of the upper pressure block is provided with a pressure groove. A retaining plate is fixed to one end of the bottom frame at one end of the tube holder block; a support plate is fixed to the other end of the bottom frame and is provided with a slotted through hole. An adjusting block is fixed on the support plate. The upper end of an adjusting screw is hinged to the adjusting block; the lower end of the adjusting screw is hinged to an end block fixed on the bottom frame. The middle of the adjusting screw is screwed to a middle moving block. The middle of the middle moving block is provided with a screw through hole. A correcting screw is screwed in the screw through hole. The construction corrector of the hollow steel tubes has the advantages that quick clamping of steel tubes is available, recesses in sidewalls of the hollow steel tubes can be corrected to allow reuse of the steel tubes, repair rate of the steel tubes is increased, and cost is lowered.

Owner:MESKA GRP CONSTR

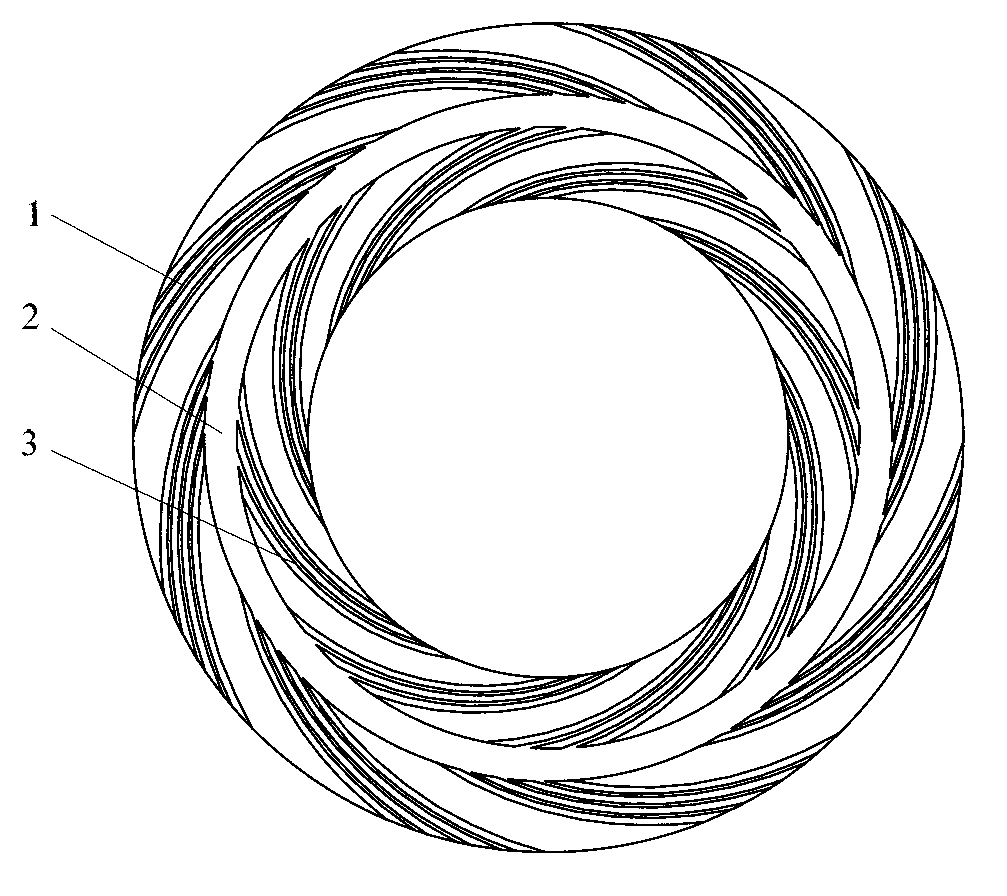

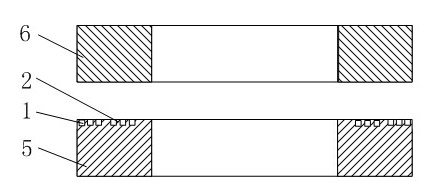

Microgroove double-layer composite groove deep end surface mechanical seal structure

ActiveCN103062411AEnhance the dynamic pressure effectImprove adsorption capacityEngine sealsEngineeringHigh pressure

The invention discloses a microgroove double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a microgroove double-layer composite groove deep dynamical pressure groove, a ring groove and a microgroove double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, the upper layer of the dynamical pressure groove is hollow, and a microgroove shape line on the lower layer of the dynamical pressure groove forms an upstream texture and is same to a dynamical pressure groove shape line on the upper layer; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, the upper layer of the pumping groove is hollow, and a microgroove shape line on the lower layer of the pumping groove forms a downstream texture and is same to a shape line on the upper layer of the pumping groove; the upstream texture and the downstream texture are connected through the ring groove; and the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove.

Owner:山东誉中新材料股份有限公司

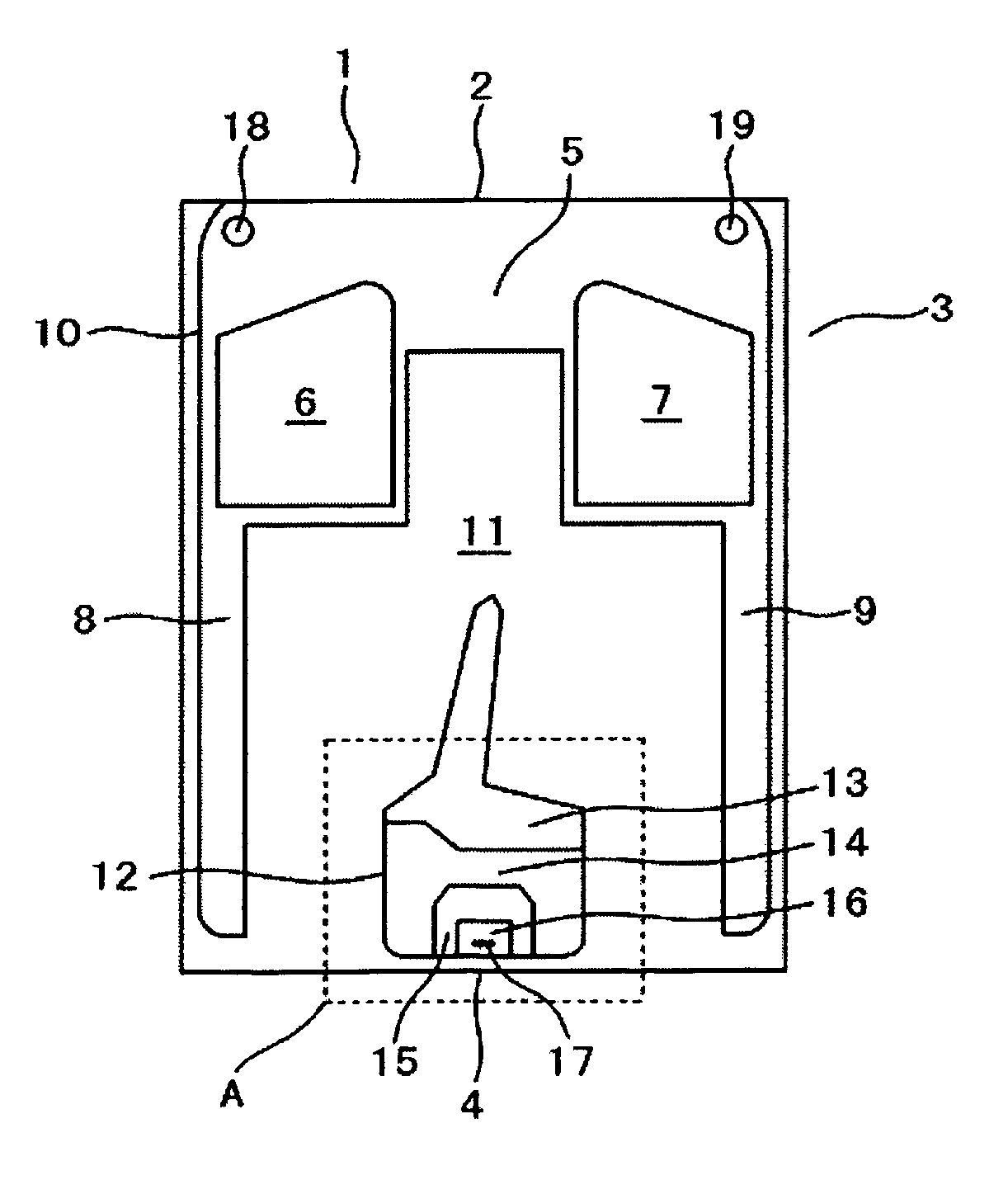

Magnetic head slider with flying height control

InactiveUS20070058296A1Decrease offset ratio in flying heightFluid-dynamic spacing of headsRecord information storageLeading edgeControl power

Embodiments of the invention provide a slider structure able to lower a flying height compensation ratio caused by a projecting deformation of an air bearing surface of a slider by a flying height control mechanism and afford a change in flying height with a low control power. In one embodiment, a slider is provided with a leading edge, an air bearing surface, and a trailing edge. The air bearing surface includes a front pad, the front pad being made up of a front step bearing surface, leading rail surfaces, and side step bearing surfaces. The air bearing surface also includes a negative pressure groove surface surrounded by the front pad. The air bearing surface further includes a rear pad, the rear pad being made up of a rear step bearing surface formed at the same depth as the depth of the front step bearing surface and positioned on the trailing edge side, a trailing rail surface, an intermediate groove deeper than the trailing rail surface, and a trailing pad surface lying at the same height as the trailing rail surface. The front and both sides of the trailing pad surface are surrounded by the trailing rail surface.

Owner:WESTERN DIGITAL TECH INC

Negative pressure groove end face mechanical seal structure

The invention relates to a negative pressure groove end face mechanical seal structure, comprising a mechanically sealed moving ring and a mechanically sealed static ring, one side of the end faces of the moving ring and the static ring is a high pressure side namely upstream, the other side of the end faces of the moving ring and the static ring is a low pressure side namely downstream, at leastone end face of the moving ring or the static ring is provided with negative pressure groove groups which are symmetrically distributed with the center of rotation, the upstream of each negative pressure groove group is provided with a micropore annular band, each negative pressure groove group is composed of micropore dynamic pressure grooves with spiral deformation and inclination and relief grooves, the micropore dynamic pressure grooves and the relief grooves are distributed at intervals, the relief grooves are close to the terminals of the dynamic pressure grooves, and the downstream of each negative pressure groove group is provided with an annular sealing dam with a smooth plane. The invention has the beneficial effects of enhancing antijamming capability of sealing in operation athigh speed, improving dynamic pressure opening capability of a high speed seal face under the low speed working condition, realizing non-contact stability of the seal face under the high speed working condition, reducing end face contact wear, prolonging service life and improving sealing reliability.

Owner:海宁市黄湾镇资产经营有限公司

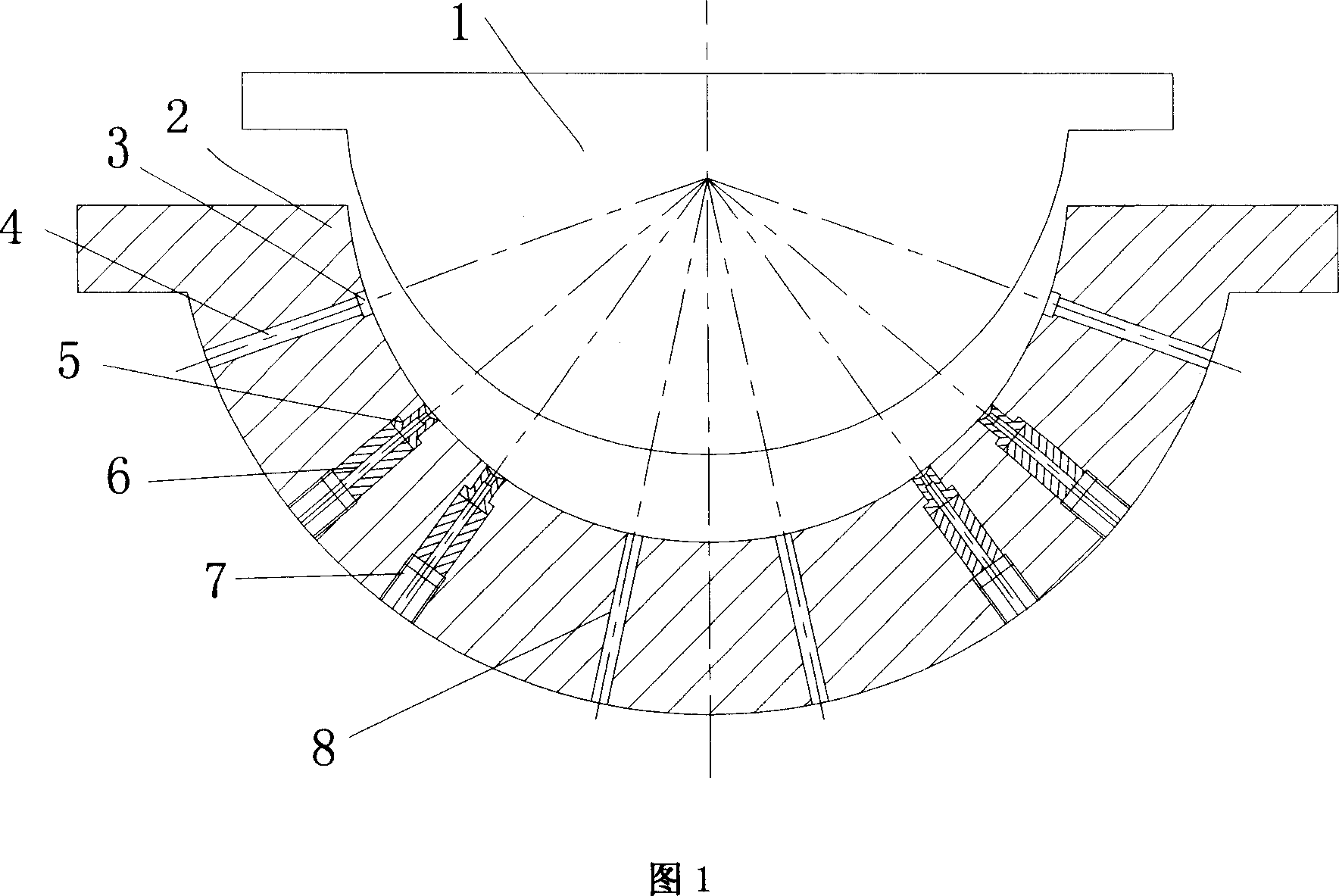

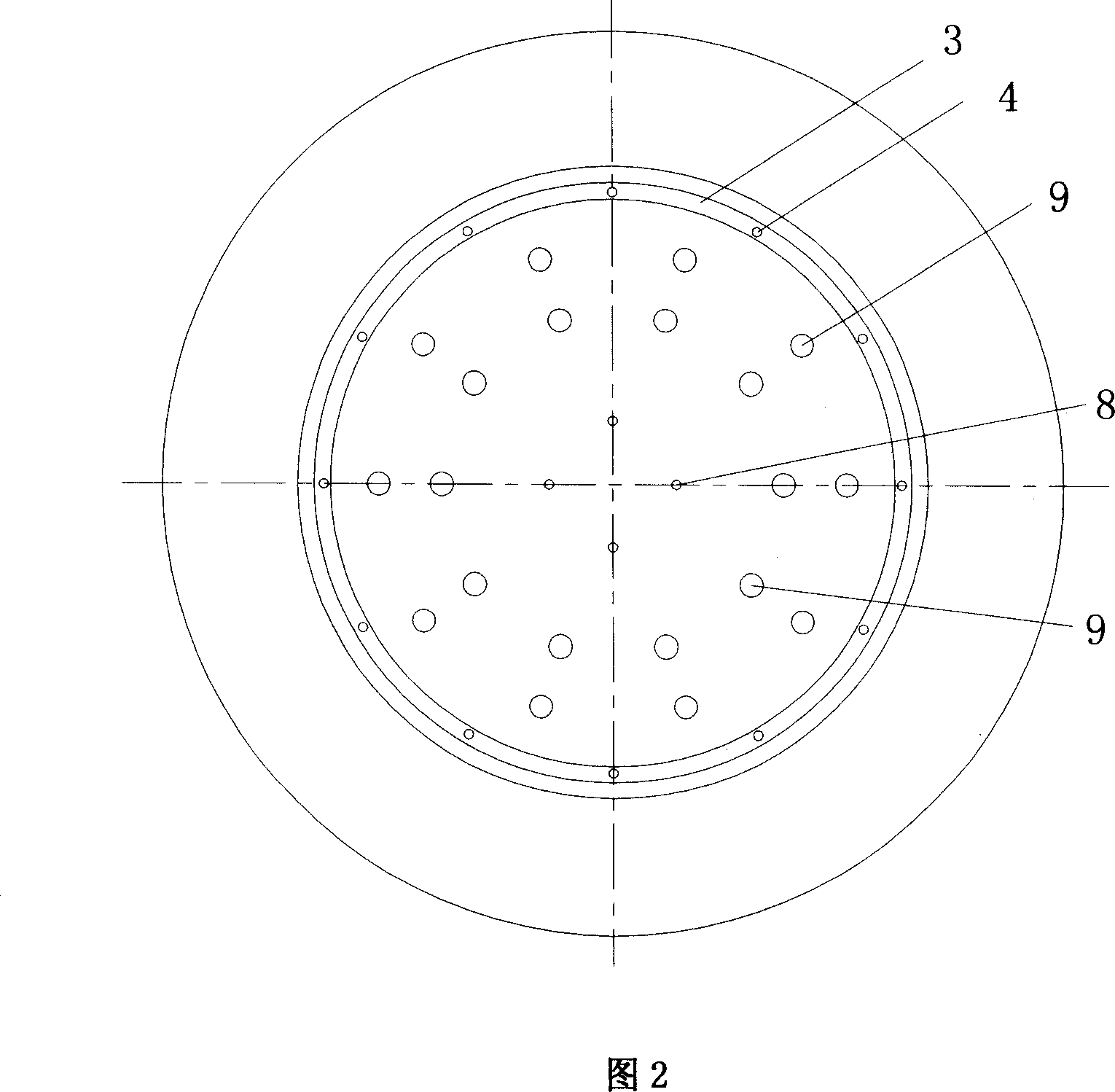

High pressure big angle-wrap porous section-variable closed type air-floating ball bearing

The present invention relates to a high pressure large wrap angle running-in type porous variable section closing air floating ball bearing which is composed of ball head, ball socket, air feed locker, position sleeve and fixing sleeve. The ball socket is disposed with single row or multiple rows of air intake channels, air discharge uniform pressure groove, air intake hole and air discharge hole. The air feed locker, the position sleeve and the fixing sleeve are assembled in the air intake channel, the air enters the bearing air film gap through the flow channel formed the air intake channel to supply support force which is balance with the outer load acted on the ball head. The air feed locker is composed of a curved surface gradually expanding mixing chamber or a cone surface gradually expanding mixing chamber and the air intake small holes. The beneficial effect of the invention is that: the bearing area is increased and the bearing force is greatly improved. The air feed locker can be disassembled conveniently, the pressure dive phenomenon at the transition place of the air intake channel and the air film will be improved under the working condition of high pressure and air film, the bearing force is far more than conventional air floating ball bearing. The bearing is adapted to ground air floating simulation equipments that need heavy load, precision heavy machine, measure device and large space structure.

Owner:DALIAN MARITIME UNIVERSITY

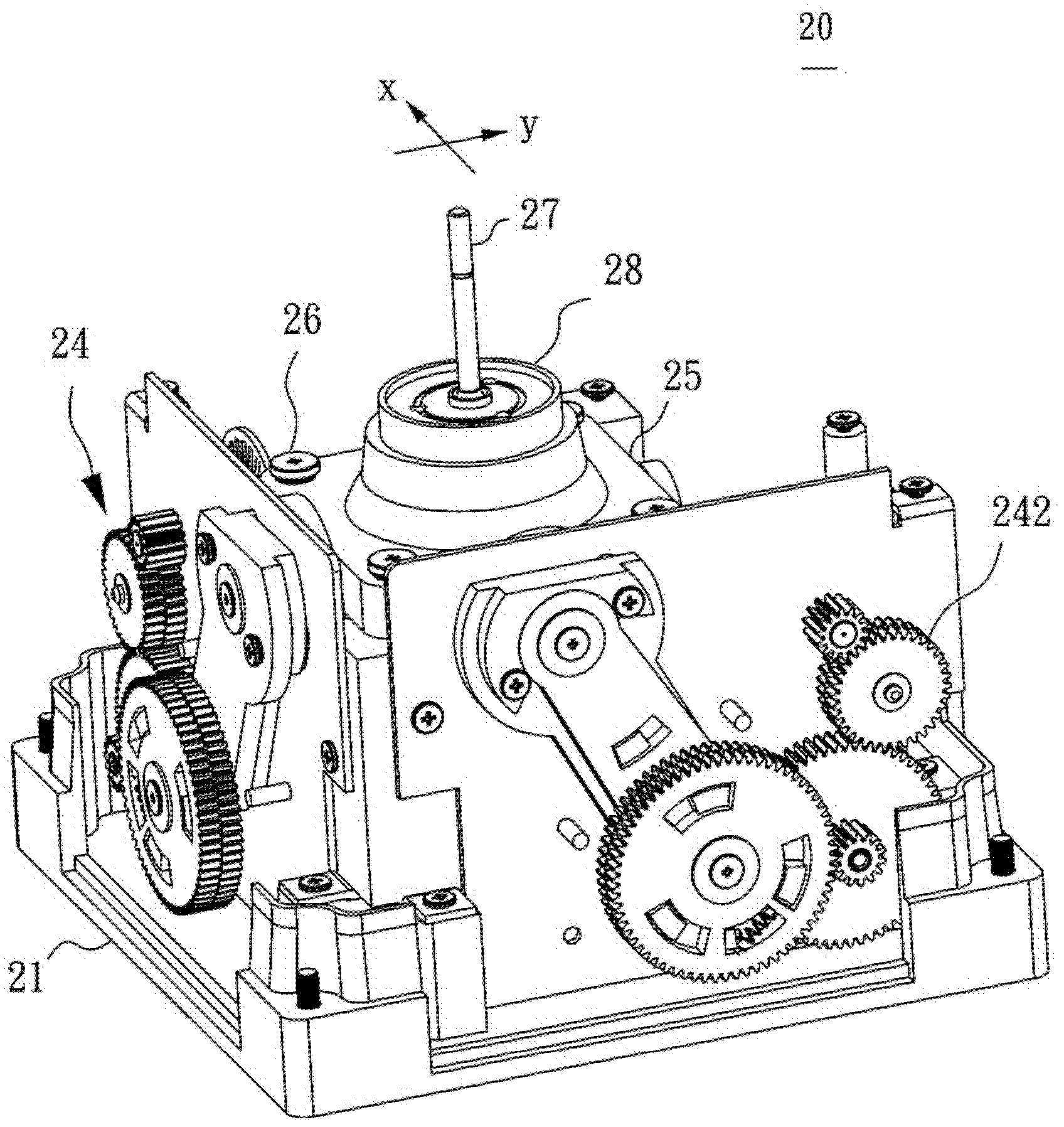

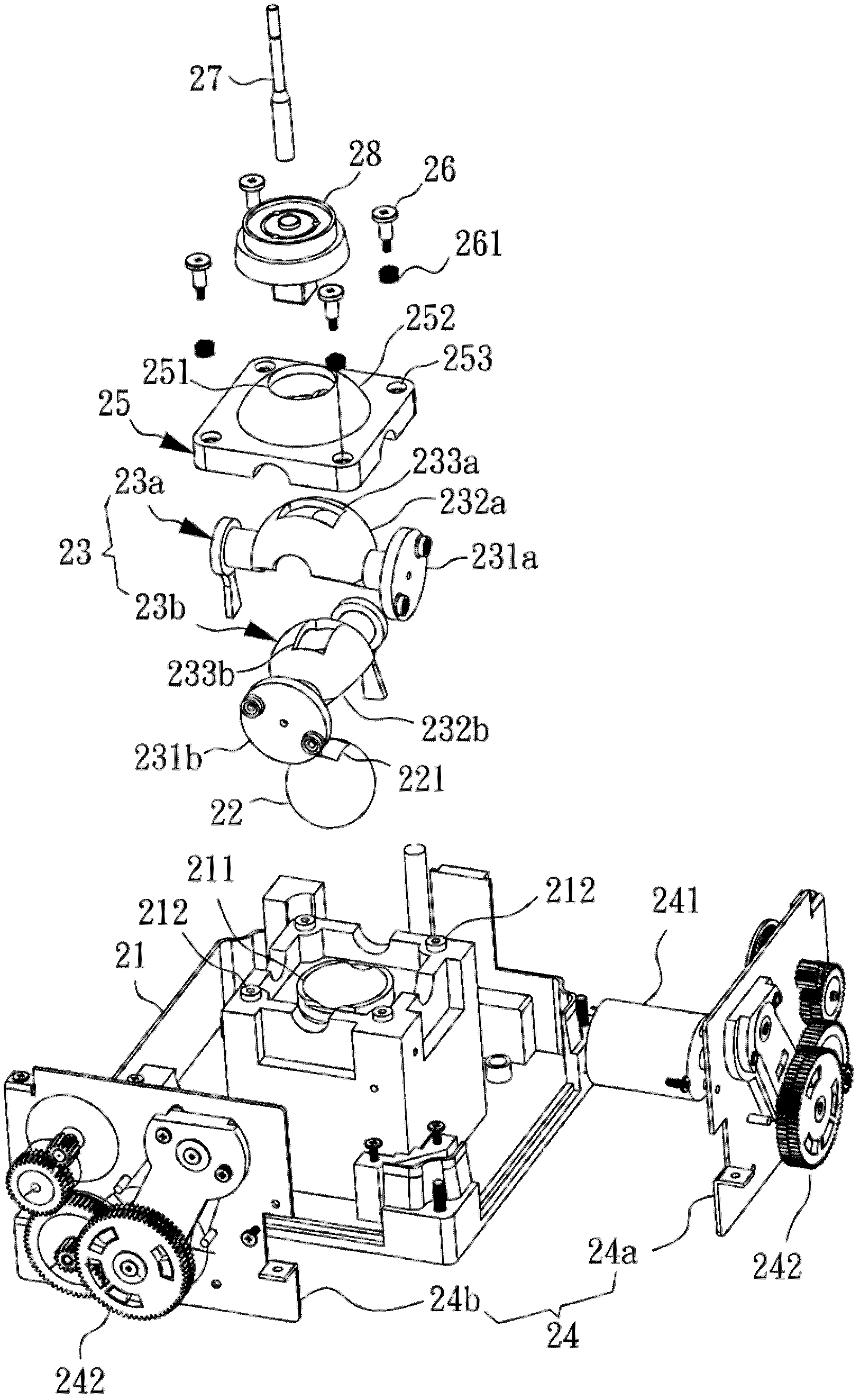

Force feedback device

InactiveCN103186163AManual control with multiple controlled membersLimiting/preventing/returning movement of partsMechanical engineeringPressure groove

The invention discloses a force feedback device which is characterized in that a plurality of assembling bolts are provided with springs in a sleeving manner, penetrate through top pressure groove holes around a top cap, and lock the top cap into a base. The springs are stayed in the step-shaped top pressure groove holes and extruded among bolt heads of the assembling bolts and the top cap, and absorption gaps are reserved among the bolt heads and the top cap due to the fact that the bolt body height of each assembling bolt is greater than the predetermined height of each top pressure groove hole, so that the operation of a rocker is smooth.

Owner:QUANTA STORAGE INC

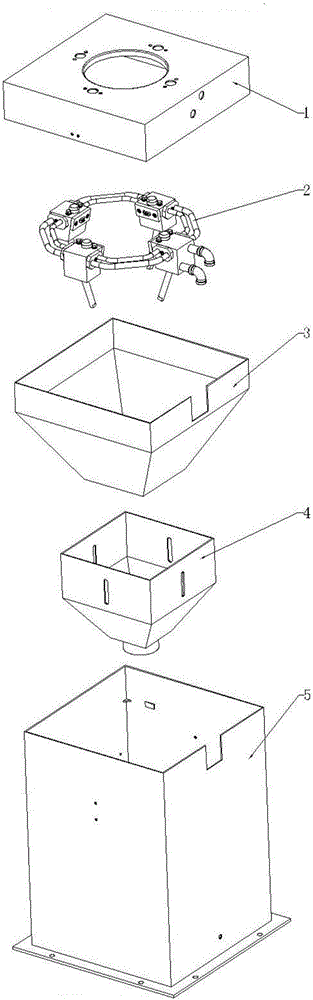

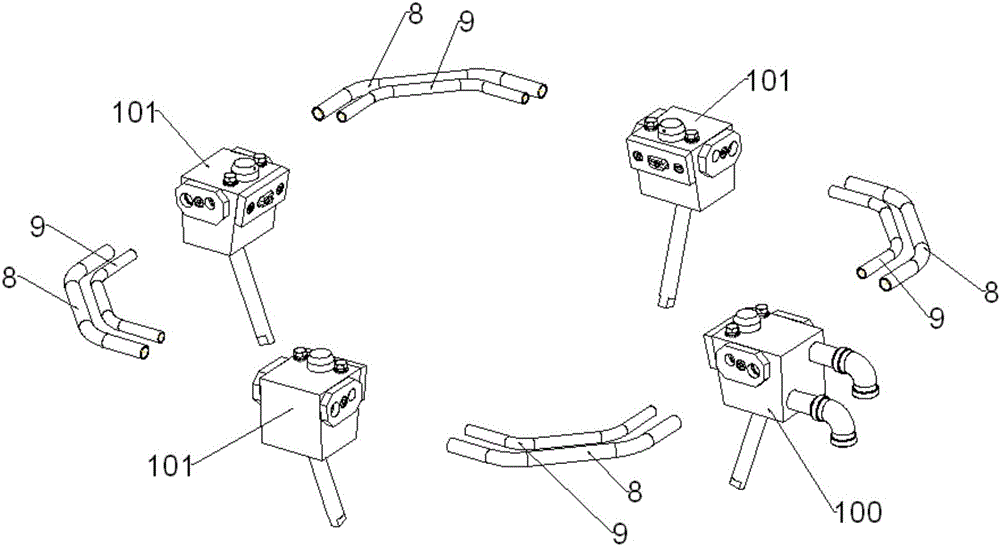

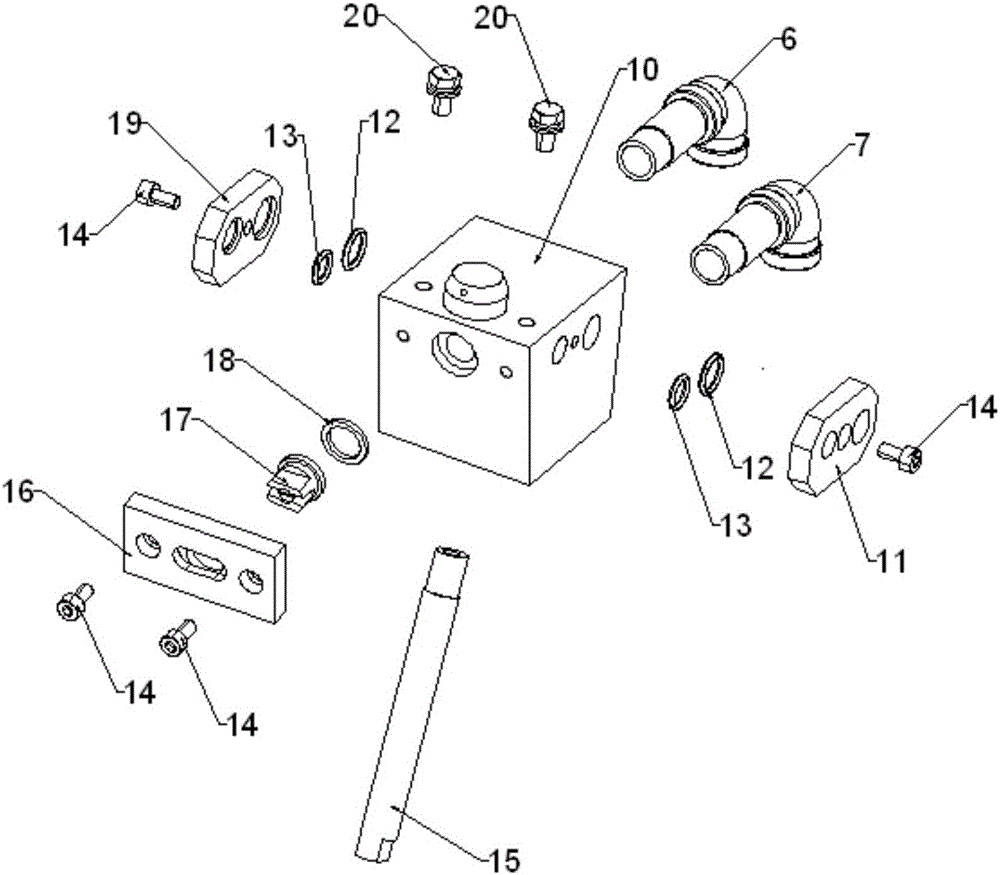

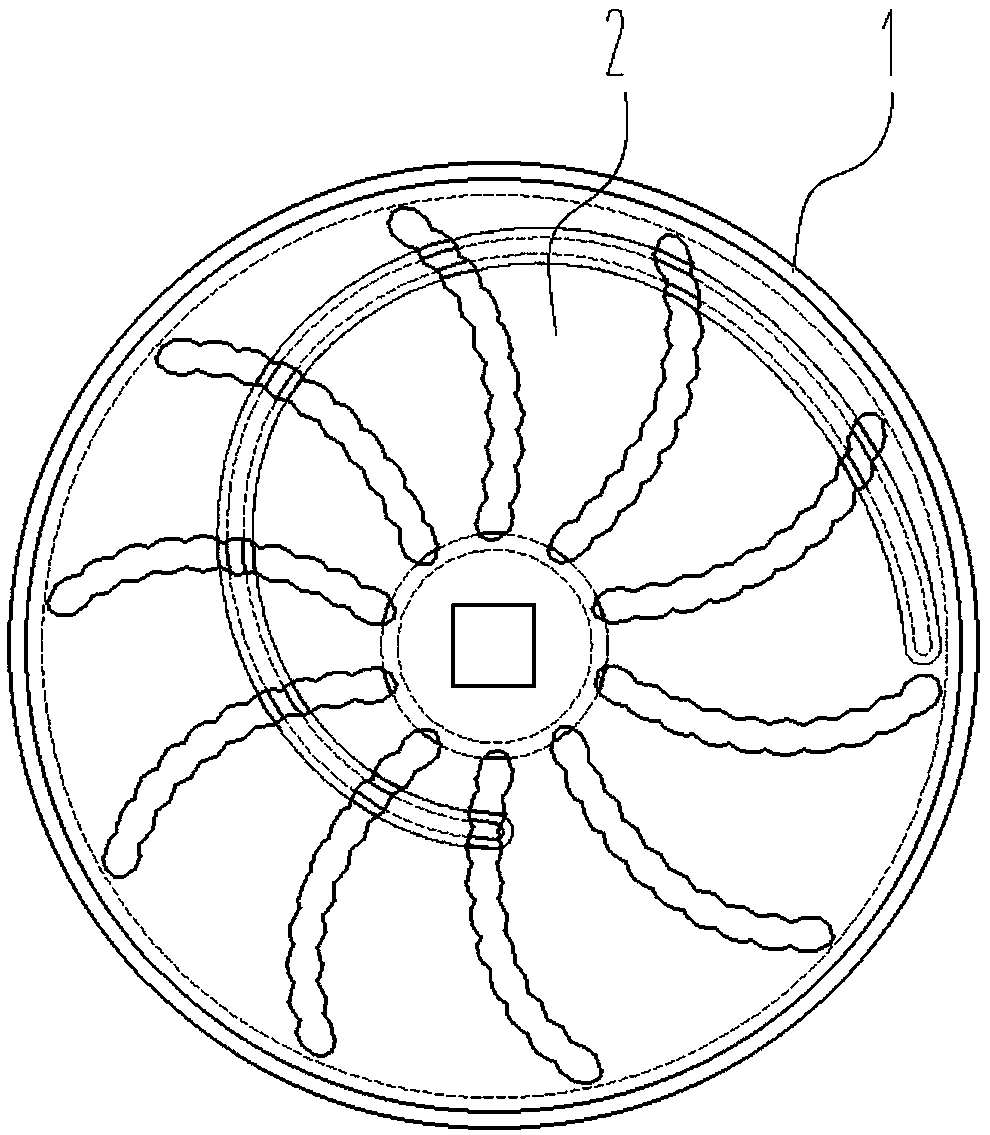

Full-automatic cleaning device of spraying tool

InactiveCN105127037AExtended service lifeNo maintenanceLiquid spraying plantsProduction rateWorking environment

The invention mainly aims at providing a full-automatic cleaning device of a spraying tool in the coaling industry. The full-automatic cleaning device is a necessarily-matched product during integration of a flexible intelligent coating robot unmanned system, and the production efficiency of the whole coating industry is greatly improved. According to the full-automatic cleaning device of the spraying tool, the device comprises five components including a cover, a spraying assembly, a negative pressure groove, a hopper and a supporting seat. The hopper is put into the supporting seat, and is fixed through a screw; the negative pressure groove is put on the upper portion of the supporting seat to be clamped by a check block; the cover and the spraying assembly are combined together through a fixed screw and put on the upper portion of the supporting seat for covering; and the cleaning device has the beneficial effects that the domestically-blank full-automatic cleaner device of the spraying tool is filled; the device is suitable for spraying tools such as a spraying tool and a static spin cup, and the adaptability is high; the spraying tool is mounted on a wrist of a robot and does not need to be dismounted, and in the cleaning process, full-automatic cleaning is carried out on the spraying tool; the device is efficient, energy-saving, environment-friendly and capable of greatly relieving the labor intensity of a worker, improving the working environment of a worker, improving productivity and ensuring the product; and meanwhile, the service life of the spraying tool is prolonged, VOC emissions are reduced, and the device is simple in structure, easy to mount, and free of maintenance.

Owner:SHENZHEN TAIDA ROBOT CO LTD

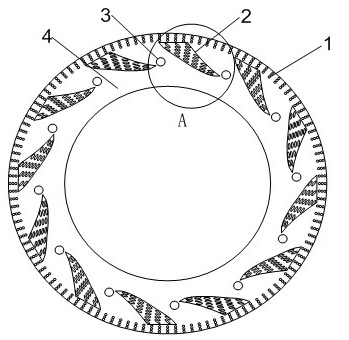

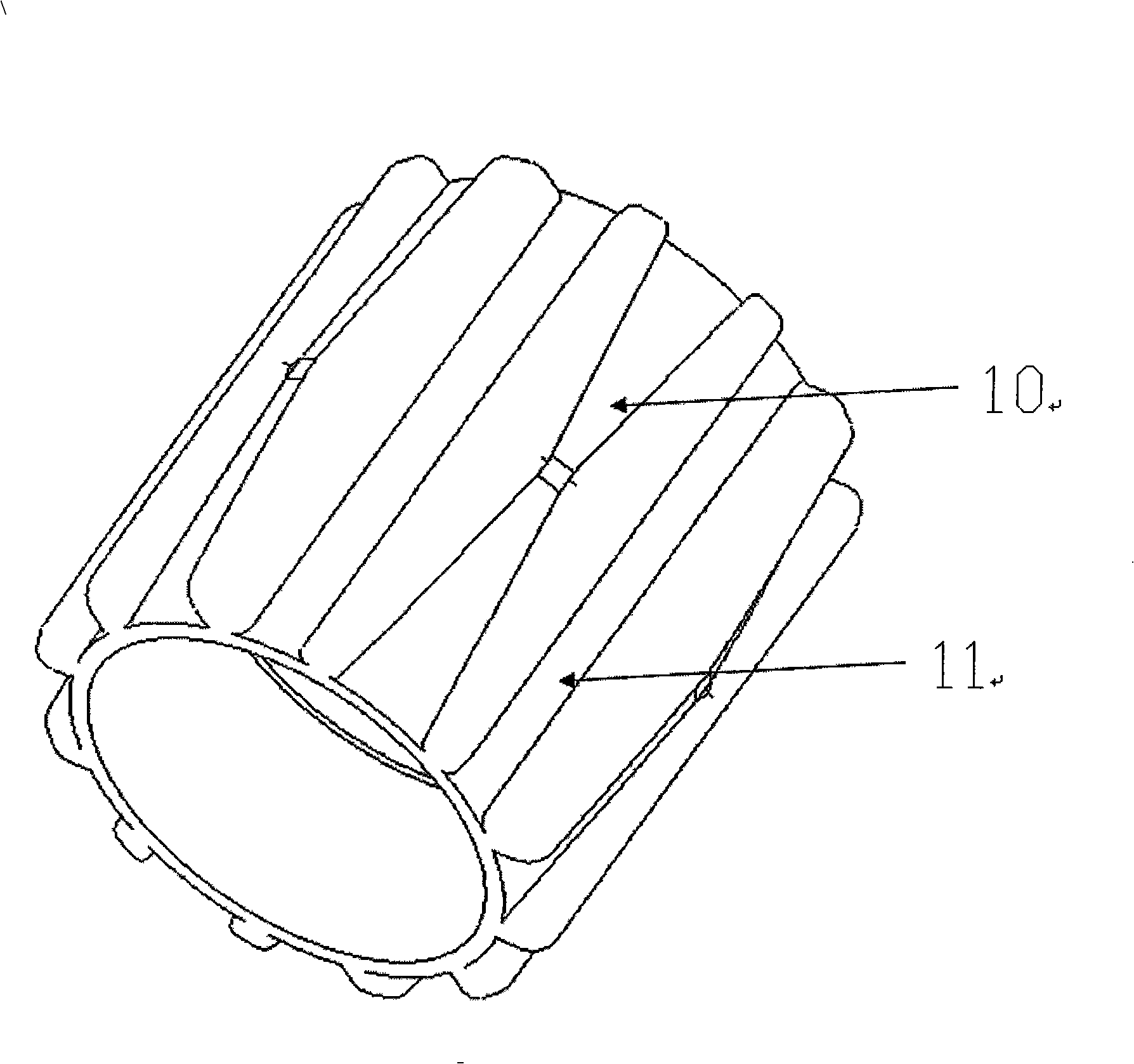

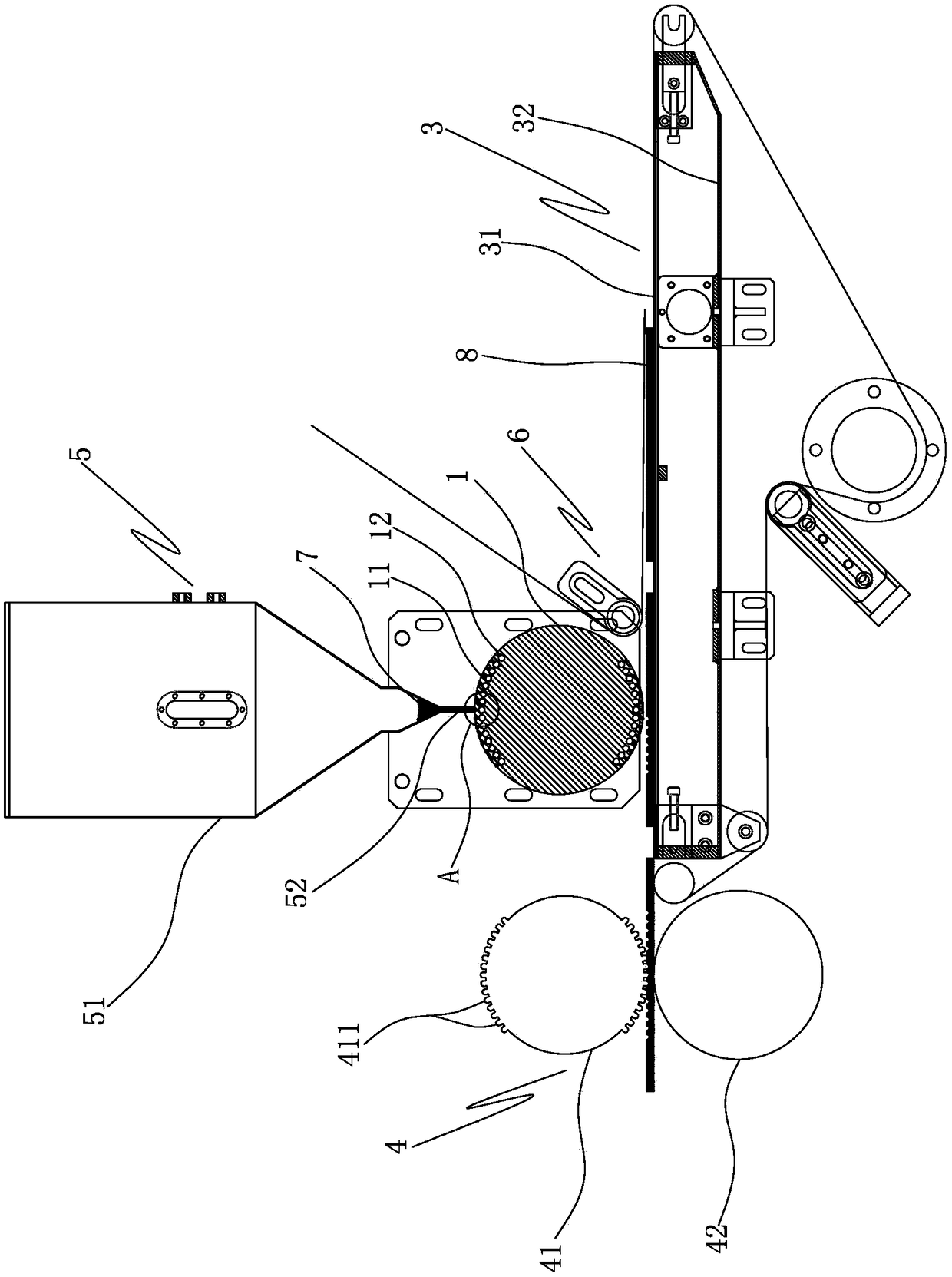

Collision theory based self-adaption flexible seed-clearing air-suction type planter plate

ActiveCN108650948ALow movement resistanceImprove adsorption capacitySingle grain seedersCollision theoryEngineering

The invention discloses a collision theory based self-adaption flexible seed-clearing air-suction type planter plate. The collision theory based self-adaption flexible seed-clearing air-suction type planter plate mainly comprises an involute fixation seed suction plate and a radially corrugated seed suction groove type seed suction plate. The curve of a negative pressure groove in the involute fixation seed suction plate adopts an involute curve whose polar coordinate is that R=[20(sin(t)-tcos(t))]mm, wherein t=(0-355 degrees]; the curve of a radial seed suction groove in the radially corrugated seed suction groove type seed suction plate is part of a cartesian leaf curve, the polar coordinate of the cartesian leaf curve is that R=[100tan(t)<2> / (1+tan(t)<3>)]mm, wherein t=(0-45 degrees], and an elliptic long axis with the long axis of 10mm and the short axis of 8 mm fits the distribution of the curve of a radial seed suction groove to form a corrugated seed suction groove. The radiallycorrugated seed suction groove type seed suction plate saves the additional installation of a seed clearing device, sucks and conveys the seeds and repeatedly collides to clear the seeds in the process of matched working with the involute fixation seed suction plate, the sowing speed is improved to maximally, the breaking of the seeds is reduced, and the planter plate is more simplified.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Superdeep well great displacement high performance boring tool protector for well

The invention relates to a high performance driller protector which is used for a mud medium ultra deep well and an ultra deep well extended reach well with strong vibration, high friction and high possibility of failure. The driller protector has the functions of lubricating strongly, centralizing, reducing friction and resistance, releasing the bushing camber wear, preventing a key slot from clamping and the driller and protecting a connector. The technical proposal is as follows: a coupling housing is arranged at a centralizer connector body, the outside surface is provided with a medium flow passage and a tapered pressure groove which are uniformly distributed on the coupling housing in a spaced way; the inner part is provided with a pair of rolling bearings directly interference arranged on the connector body; the rolling bearings and the sleeve as well as the self-lubricating obturating ring set are respectively arranged on the inner surface of the two ends of the coupling housing symmetrically; and a middle filling cavity of the two rolling bearings and a top filling cavity between the bearings and the connector body are filled with graphite. The driller protector has strong ability to decrease vibration and to release the abrasion of the drill pipe and the bushing, reduces the torque, increases the drilling ability, has a simple structure and low cost, and is used for drilling in an oil-gas field.

Owner:SOUTHWEST PETROLEUM UNIV

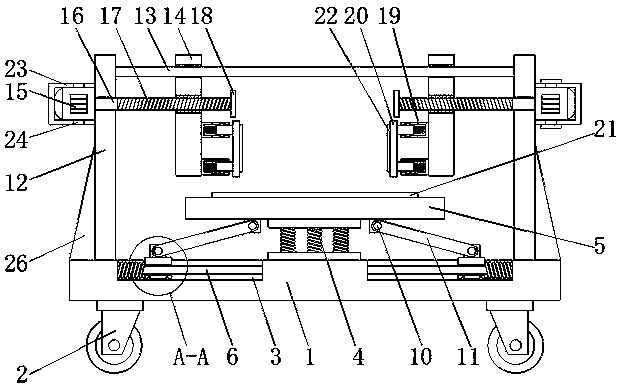

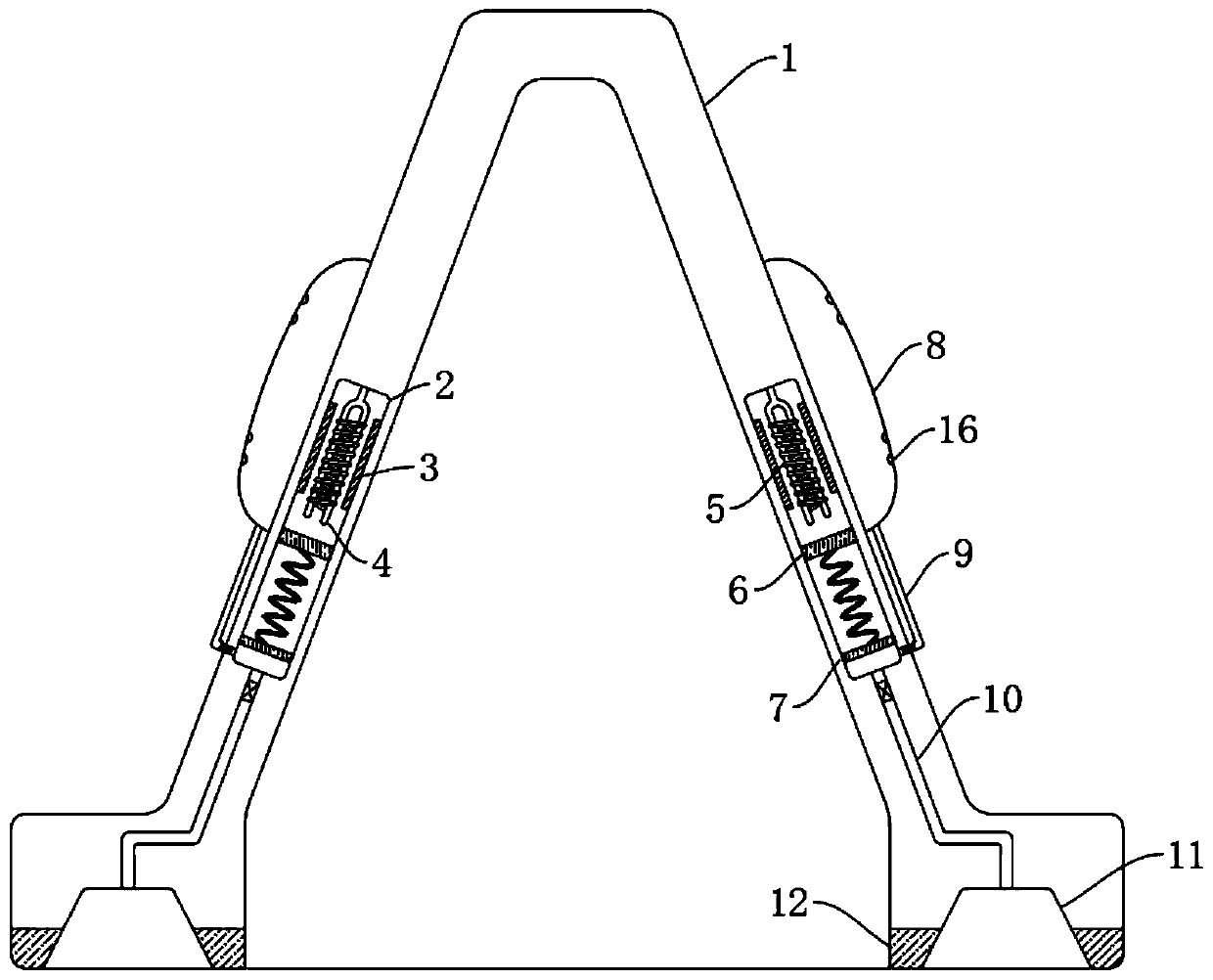

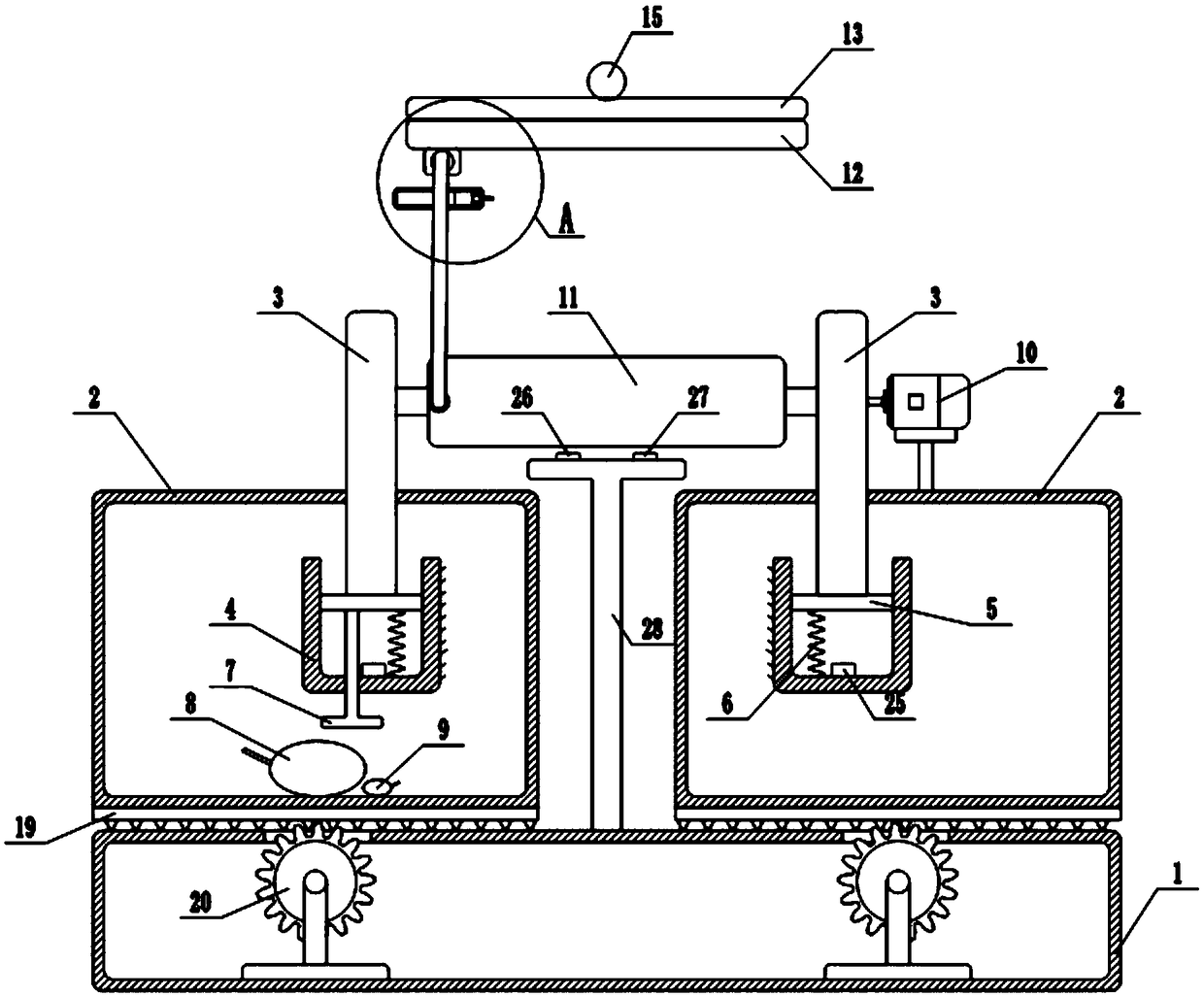

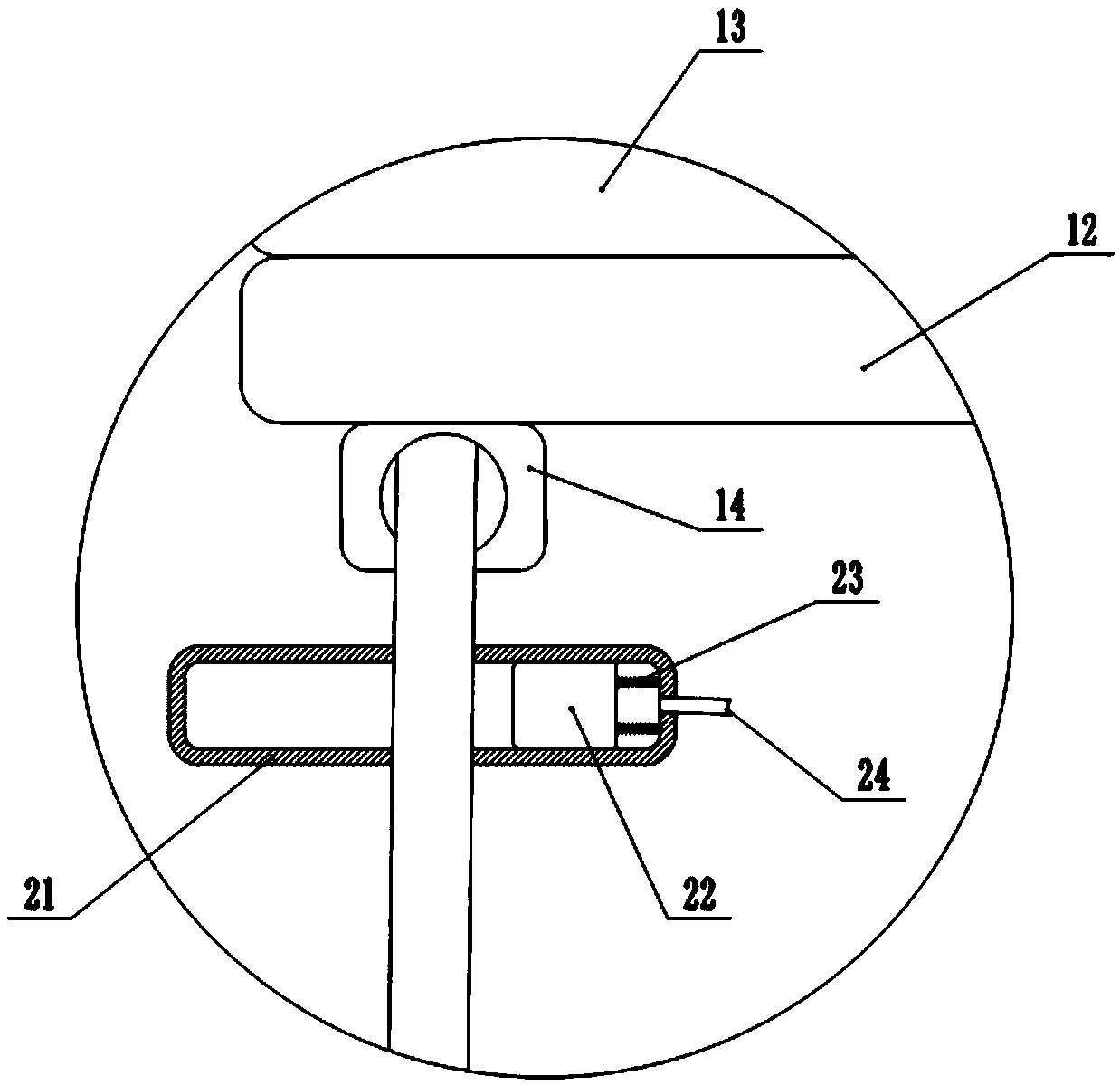

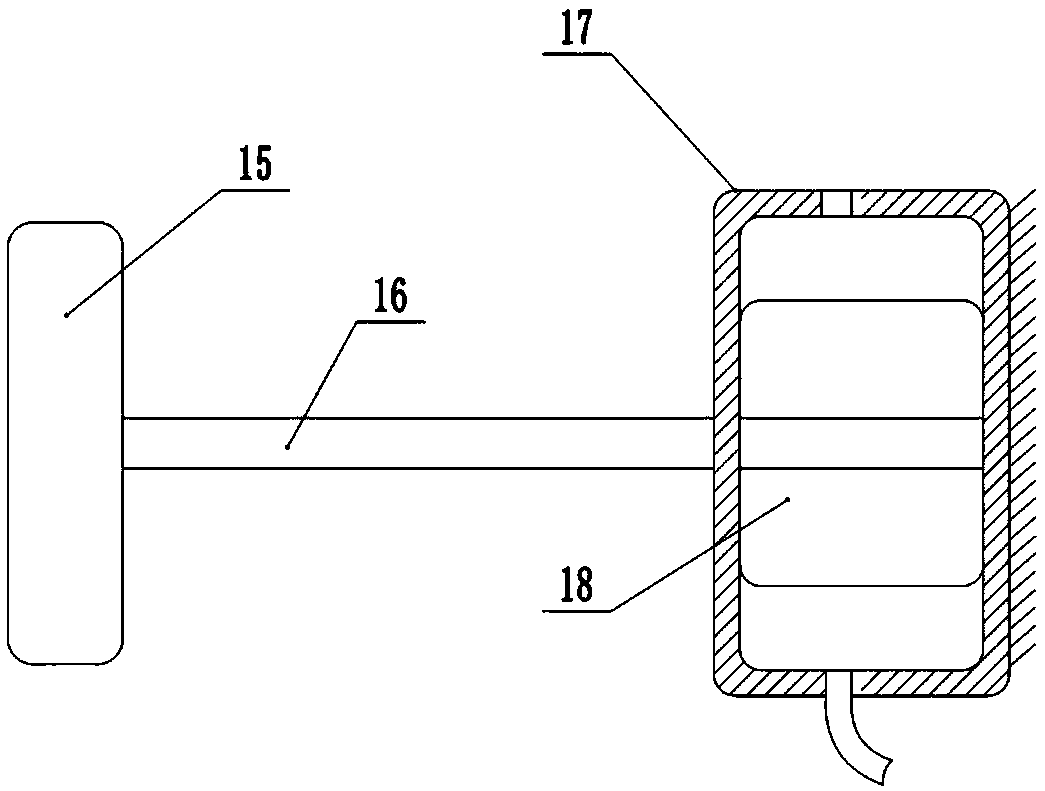

Transporting device of geothermal energy equipment

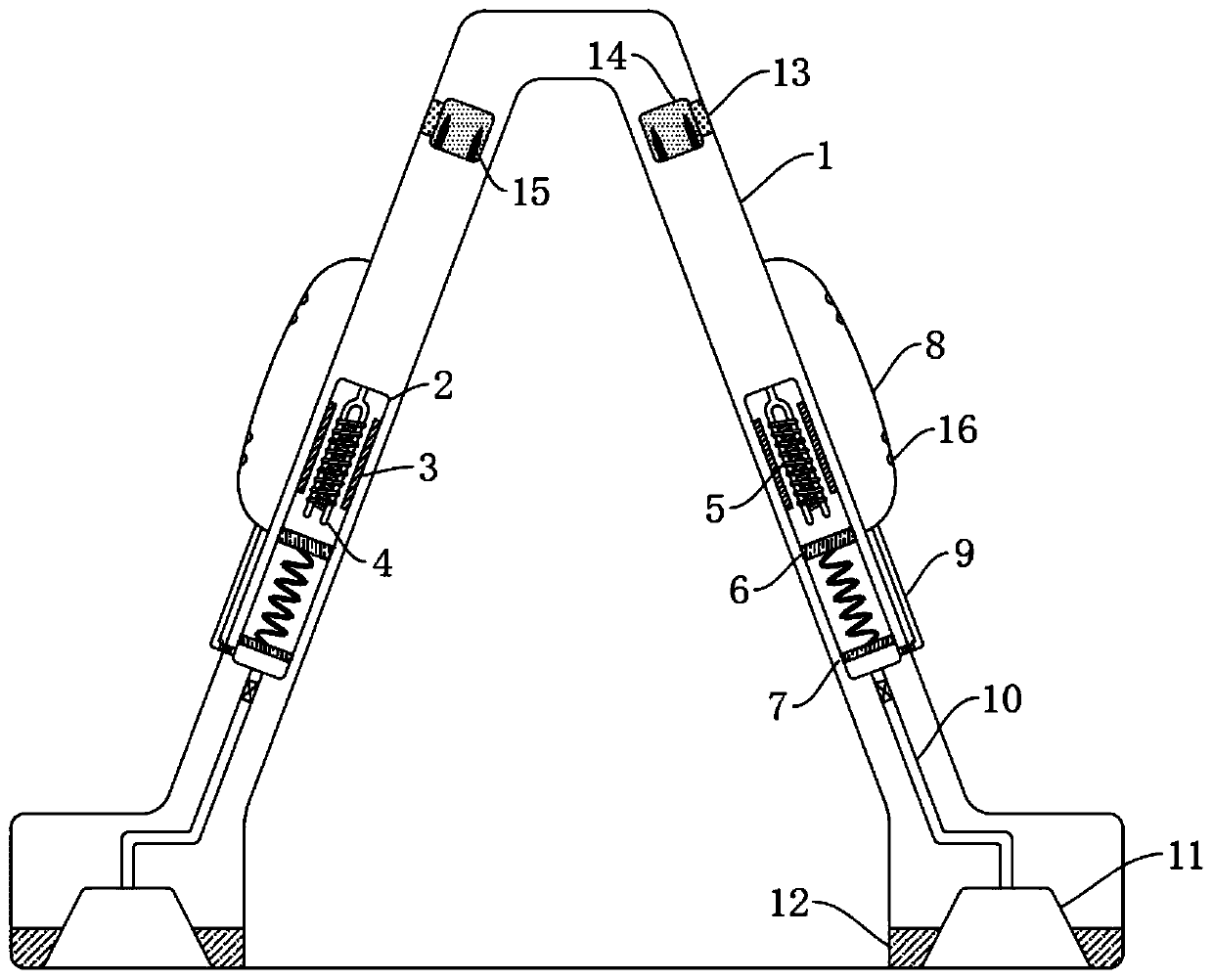

ActiveCN109160058ASolve the problem of not having shock absorption effectGuaranteed service lifePackaging vehiclesContainers for machinesEngineeringPressure groove

The invention discloses a transporting device of geothermal energy equipment, the device includes a bottom plate, the bottom of the bottom plate is fixedly provided with moving wheels, the top of thebottom plate is symmetrically provided with side pressure grooves, a spring support pad is fixedly connected at the top of the bottom plate and at a position between the two side pressure grooves, thetop of the spring support pad is provided with a placing plate, the left side of the inner wall of the side pressure groove is fixedly connected with a first limit lever, the right end of the first limit lever is fixedly connected with the right side of the inner wall of the side pressure groove, and the inner wall of the side pressure groove, away from the spring support pad, of the side pressure groove is fixedly connected with a first shock absorbing spring on. The transporting device of the geothermal energy equipment can clamp and fix the equipment of different sizes and protect the equipment from shock from the bottom and both sides, thereby effectively preventing the internal components of the equipment from being damaged due to the bumps in the transportation and transfer process,ensuring the service life of the geothermal energy equipment, reducing the maintenance cost and facilitating the use.

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

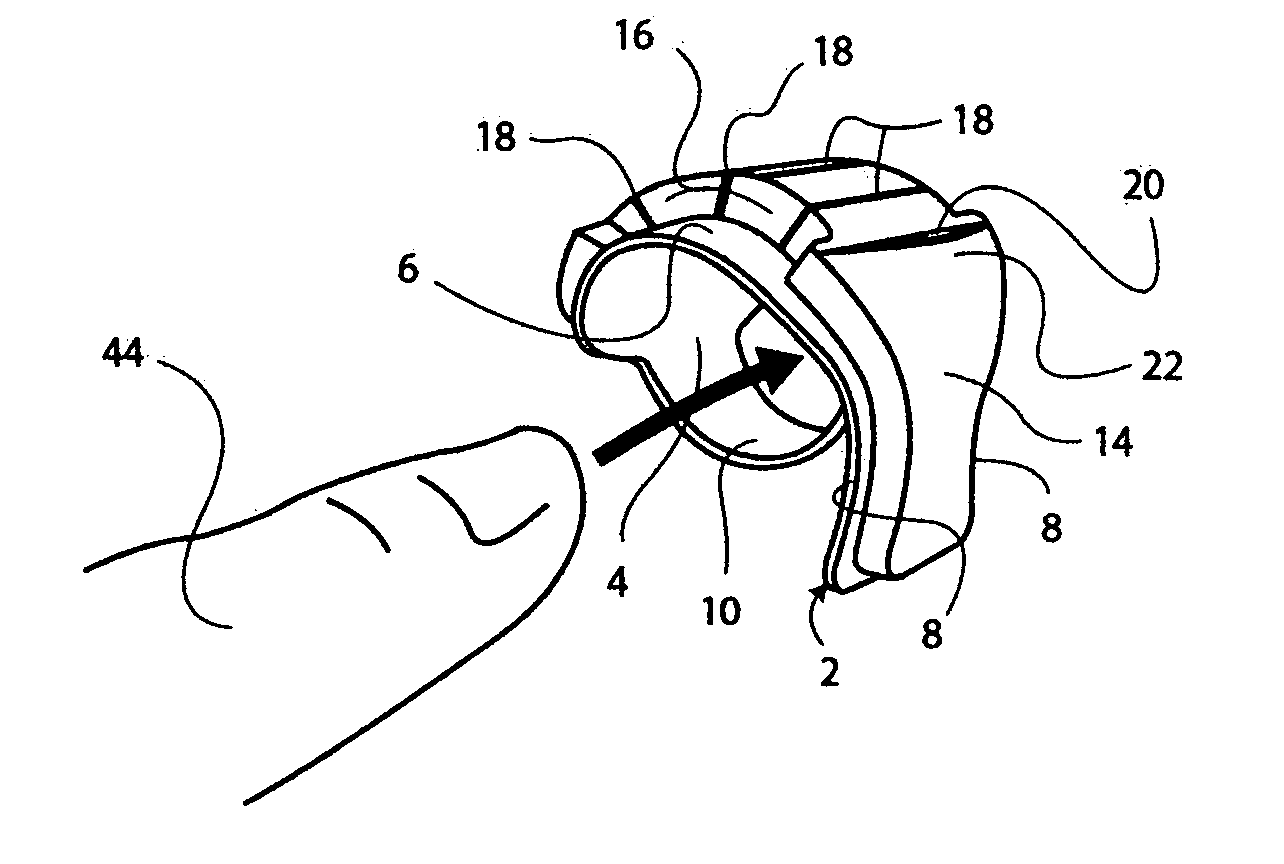

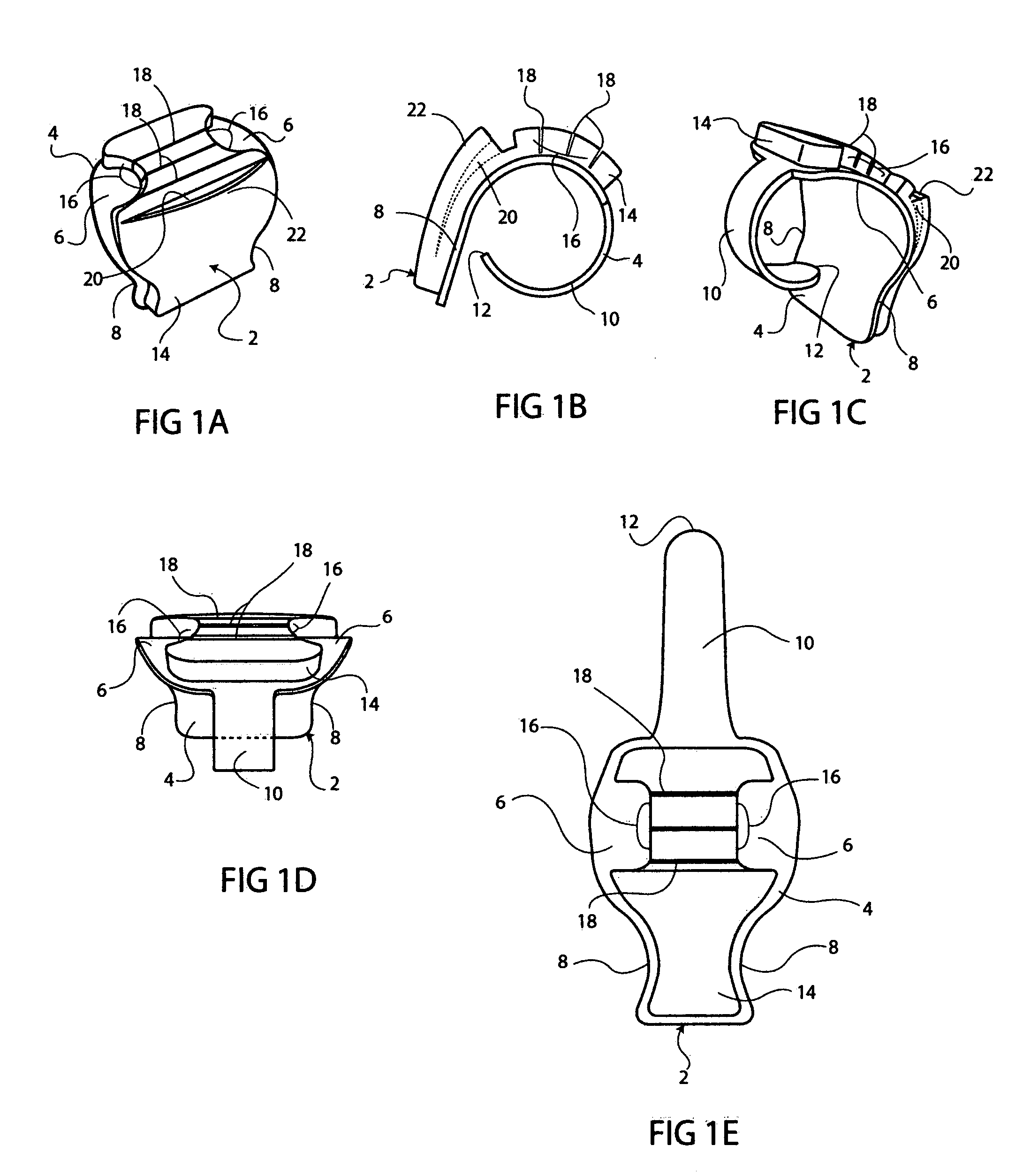

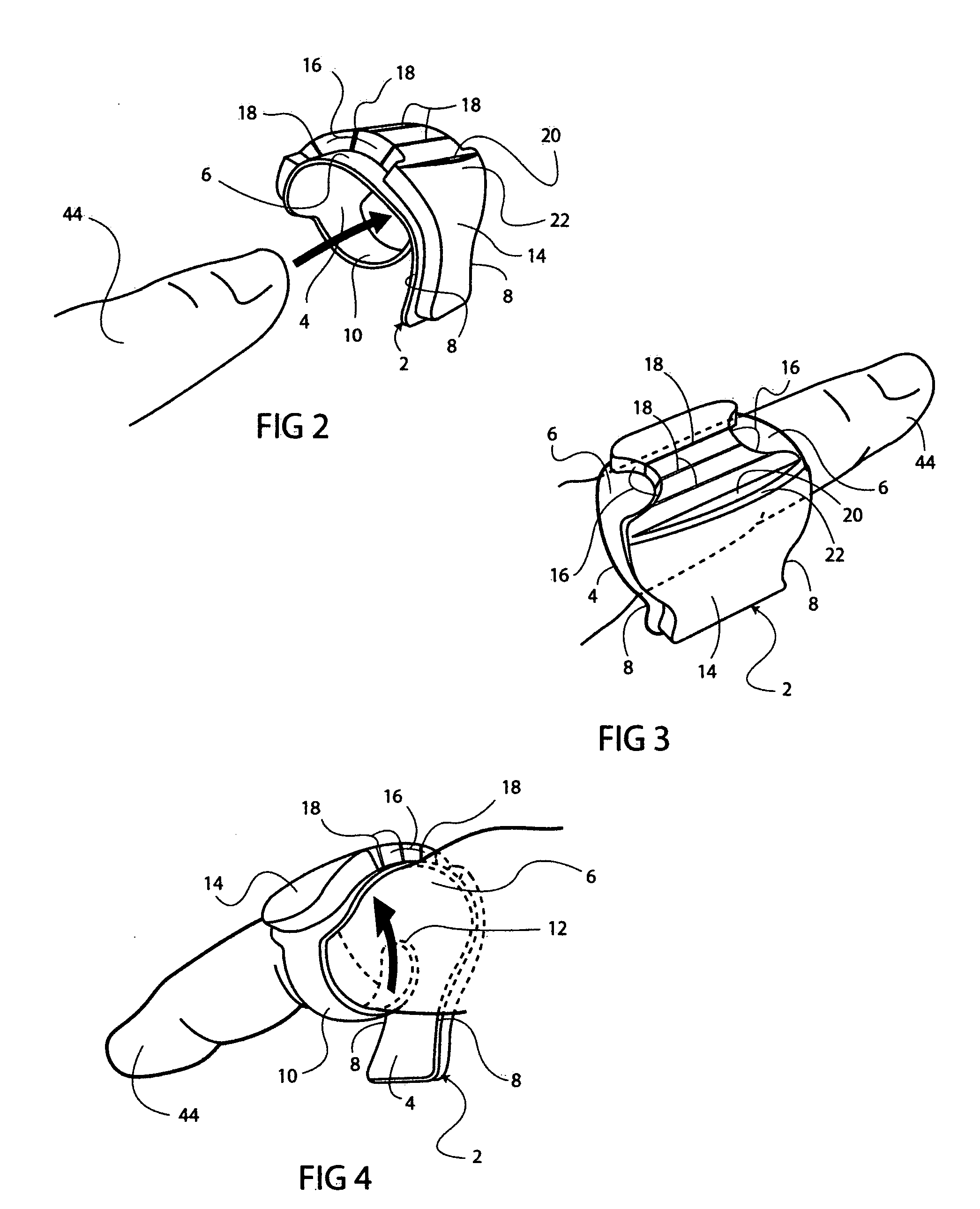

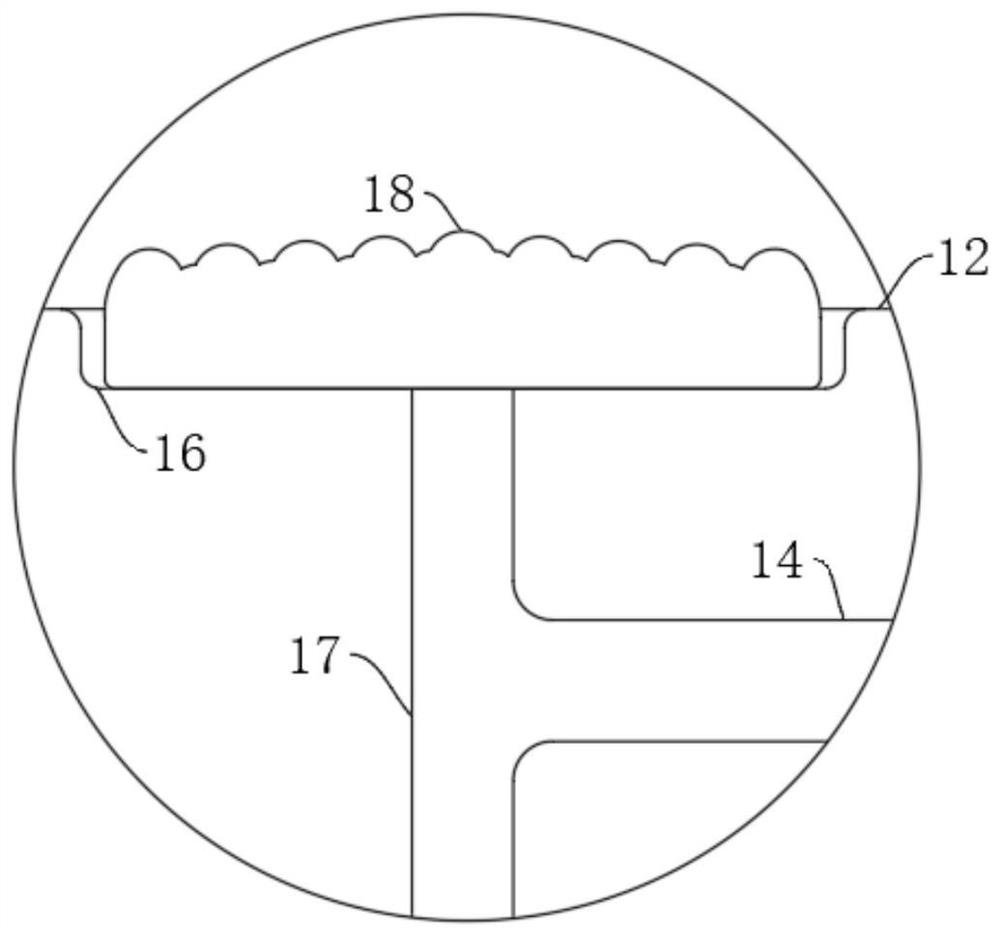

Disposable finger mounted instrument cleaner

InactiveUS20070283515A1Improve protectionMinimal disruptionTravelling sacksTravelling carriersEngineeringPressure groove

A disposable finger mounted instrument cleaner (2) of the type having a semi-circumferential protective body (4) with a swiping expanse (6) to generously occlude lateral and extensor aspects of a finger and a tapered gripping coil (10) to wrap around the flexor aspects of a finger. Attached to the swiping expanse is an adherent foam body (14) with a number of pressure sensitive grooves (18) and debris traps (16) so that an instrument can be inserted into the pressure grooves to deposit debris in the debris traps. In Addition, the foam body has a pocket (20) for thorough instrument immersion and for holding desired medicaments.

Owner:VISCOMI BRIAN D +2

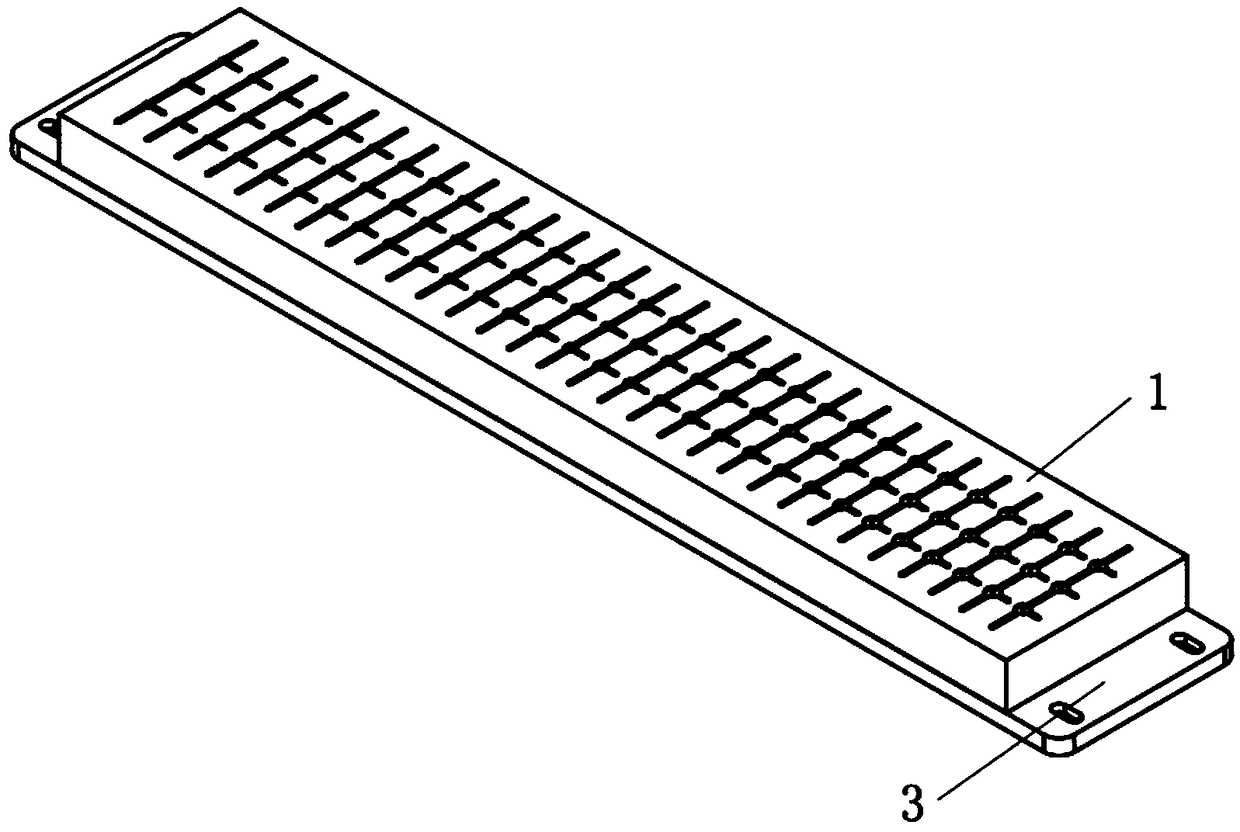

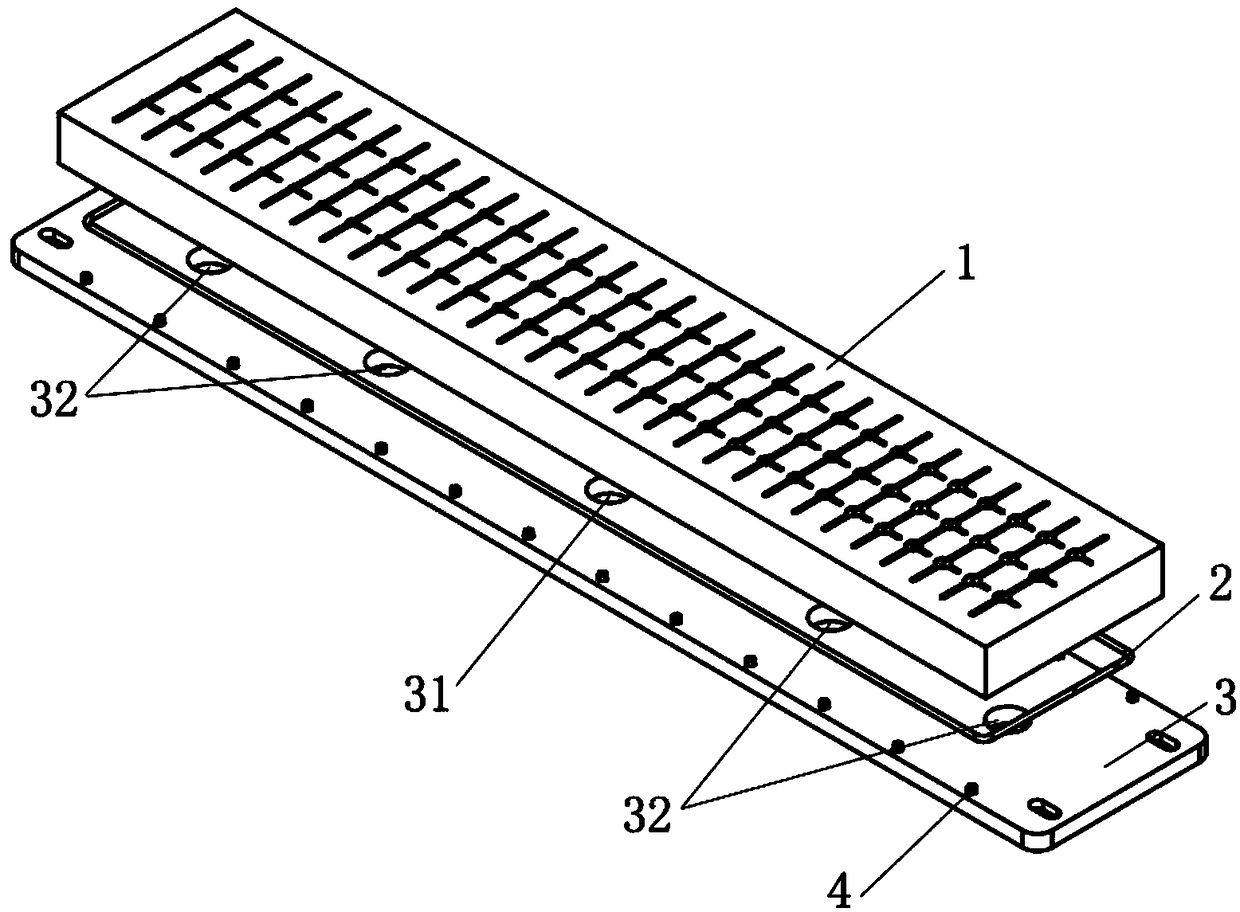

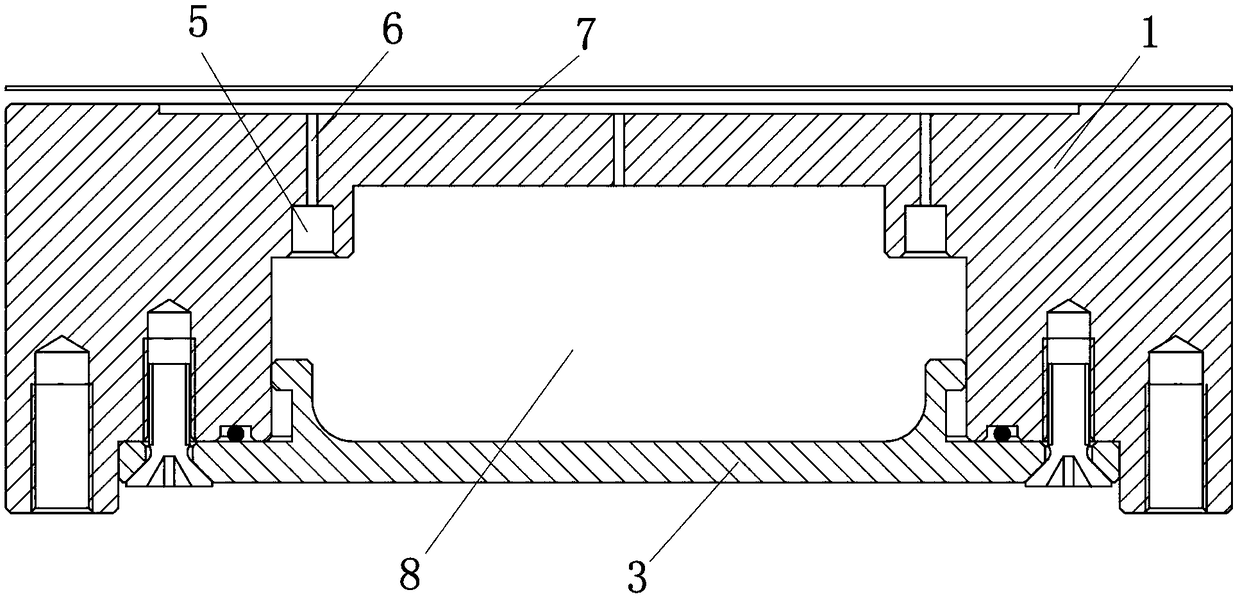

Noncontact air-floating platform

ActiveCN108861590ASimple structureReduce energy consumptionCharge manipulationConveyor partsEngineeringFloating platform

The invention belongs to the technical field of air-floating conveying and discloses a noncontact air-floating platform. The noncontact air-floating platform comprises an air-floating strip, a seal bottom plate and a seal ring. The lower end of the air-floating strip is provided with a cavity, the upper end face of the air-floating strip is provided with a plurality of uniform pressure grooves, each uniform pressure groove is internally provided with a plurality of pressure cavities, the bottom of each pressure cavity is communicated with one end of an orifice, the other end of each orifice iscommunicated with a buffer hole, and each buffer hole is communicated with the cavity. The upper end of the seal bottom plate is connected with the lower end of the air-floating strip, the cavity andthe upper end of the seal bottom plate form an air chamber, the upper end face of the seal bottom plate is provided with a plurality of air inlet holes, and one end of each air inlet hole is communicated with the air chamber. The seal ring is arranged between the air-floating strip and the seal bottom plate. The noncontact air-floating platform is simple in structure, environmentally friendly, clean and low in energy consumption, and air-floating support stability and anti-interference effects are improved.

Owner:通彩智能科技集团有限公司

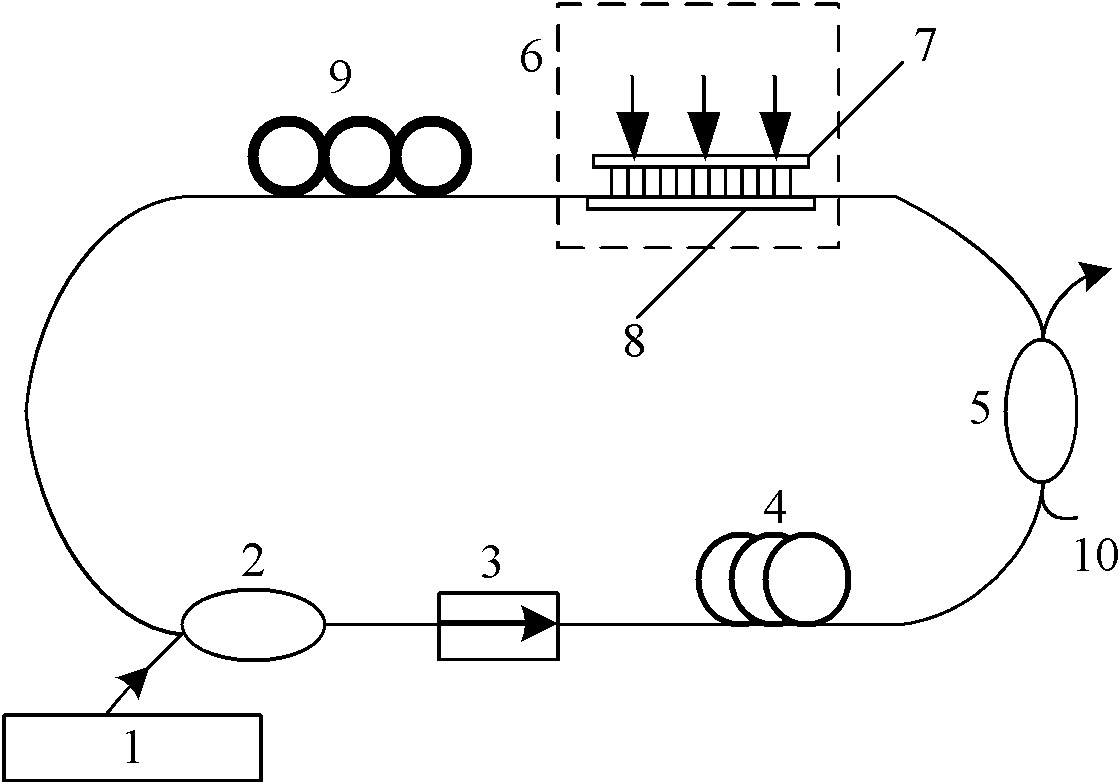

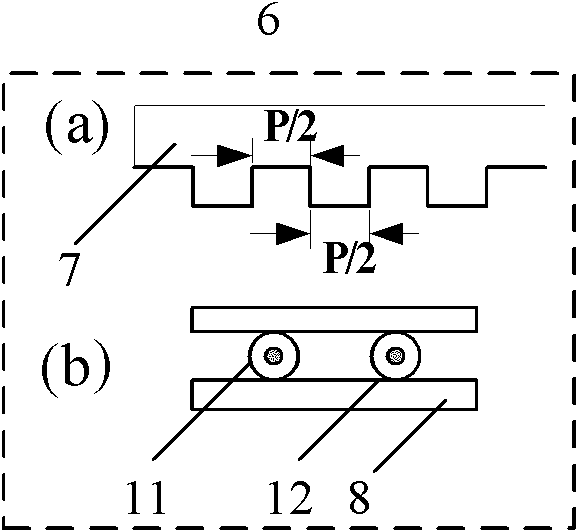

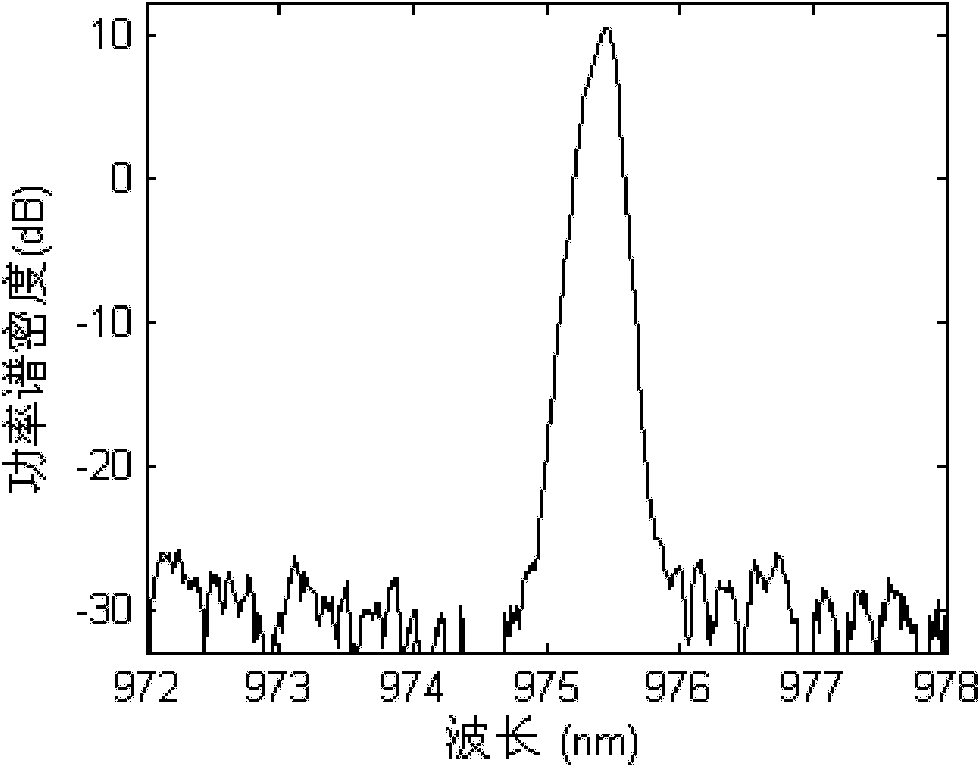

Fiber optical laser of L waveband with wavelength tunable

InactiveCN102157889AGood linear relationshipSimple structureActive medium materialActive medium shape and constructionGratingLong-period fiber grating

The invention relates to a fiber optical laser of an L waveband with tunable wavelength, which is characterized by wide tuning range, simple structure, narrow width of output laser ray and high stability and etc. The fiber optical laser of an L waveband with tunable wavelength comprises a light source and an annular laser chamber, wherein the light source is used for transmitting the light into the annular chamber; the light is partially output by a coupler, and the another part of the light is sent to an optical fiber grating filter with mechanical sensing growth cycle which is in transition connection with the interior of the annular chamber, wherein the optical fiber grating filter with mechanical sensing growth cycle comprises a pressure groove template of which the cycle is P; the pressure groove template is matched with a pair of smooth base plates; an optical fiber of an optical fiber grating with a growth cycle to be written and a balance optical fiber are arranged between the two smooth base plates; and the wavelength regulation of the optical fiber grating filter with mechanical sensing growth cycle is realized by changing the cycle of the pressure groove template with the cycle P under the under that the preset pressure is maintained. The fiber optical laser of an L waveband with tunable wavelength provided by the invention has the advantages that the inhibition band within the annular chamber can be regulated, the gain peak of the annular chamber is changed, and the laser with wavelength tunable is realized.

Owner:SHANDONG UNIV

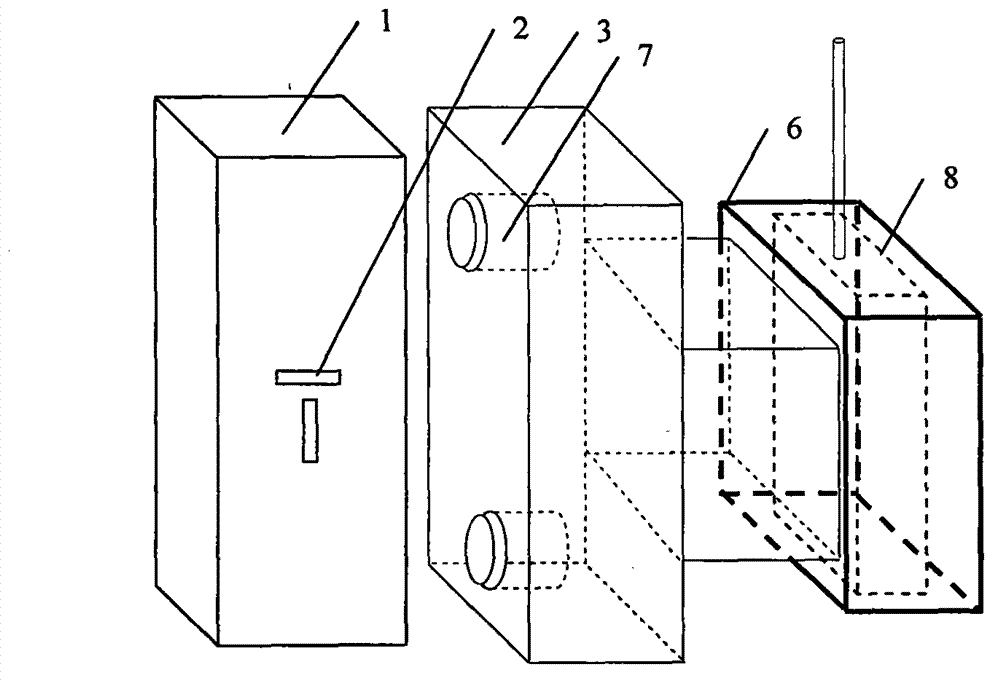

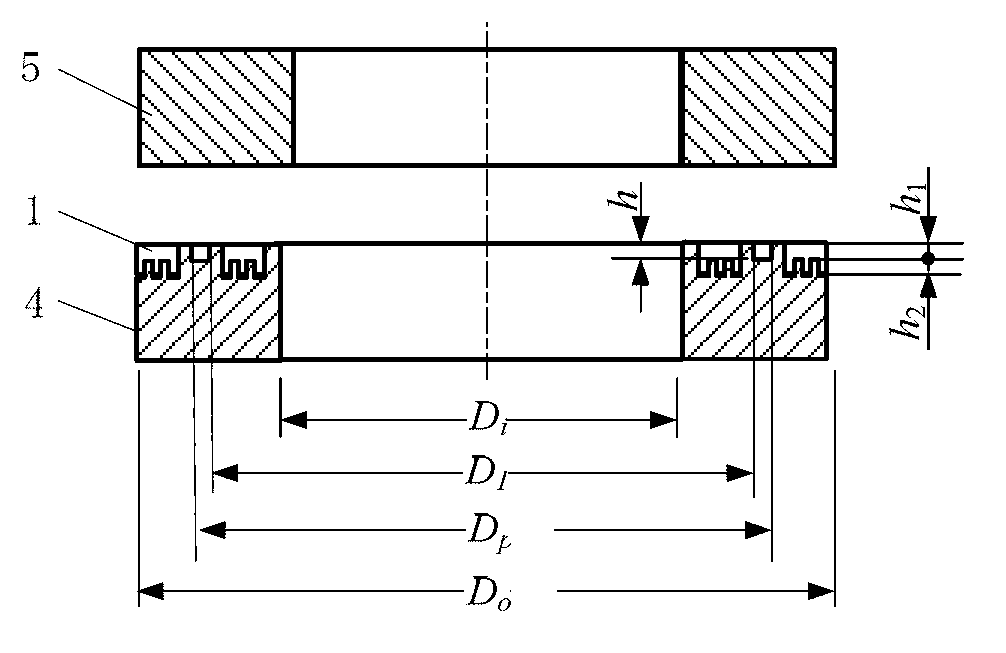

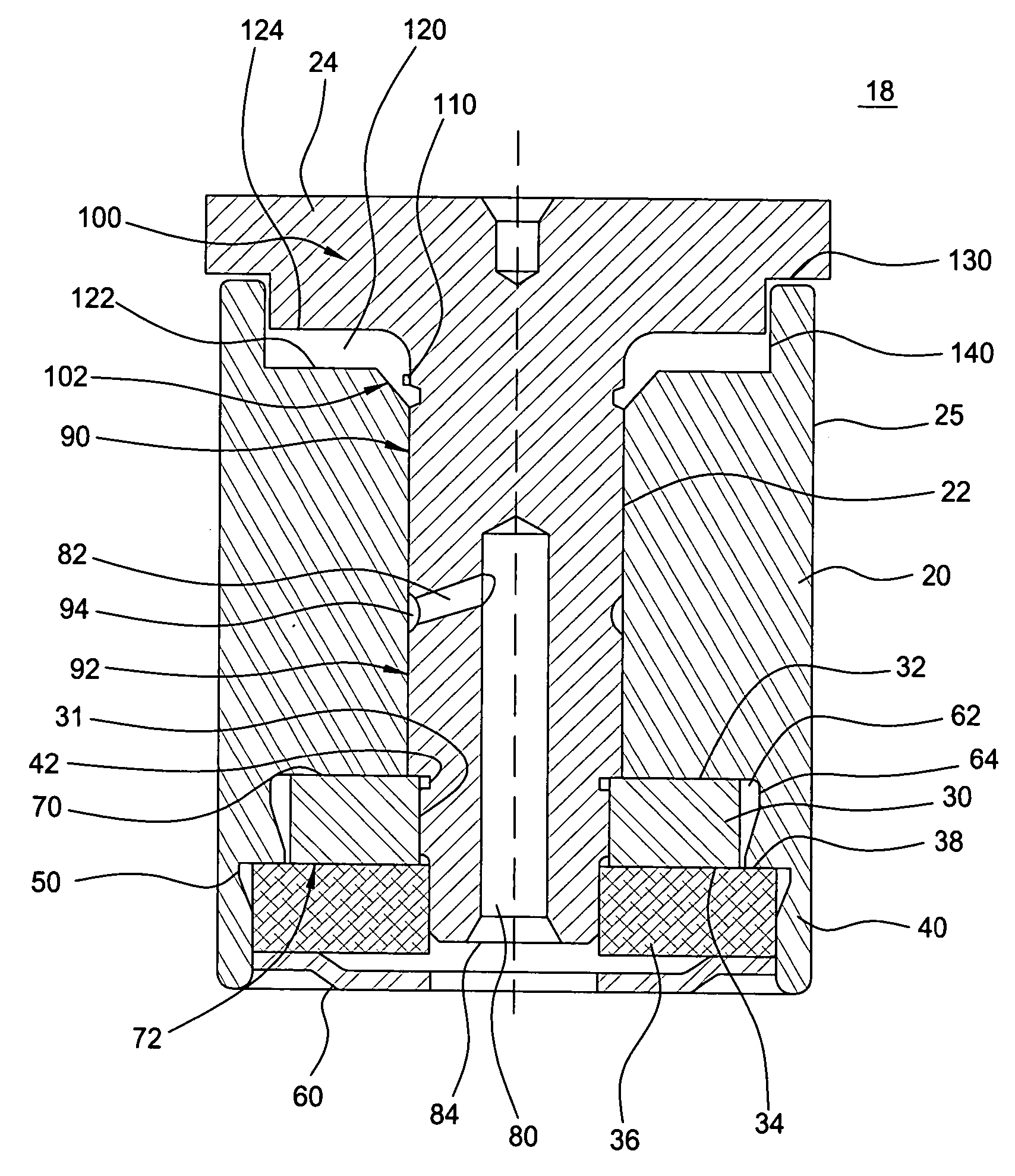

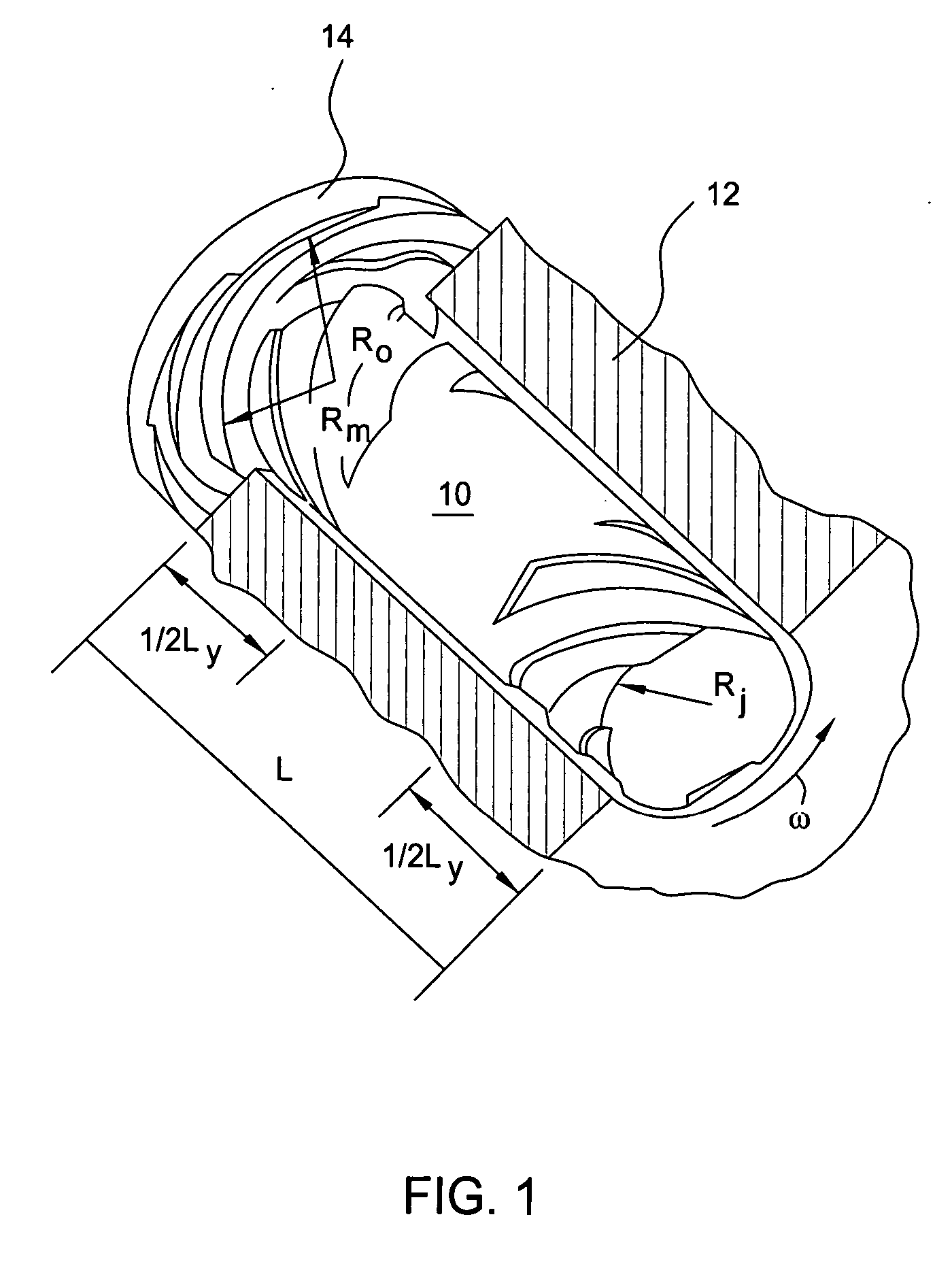

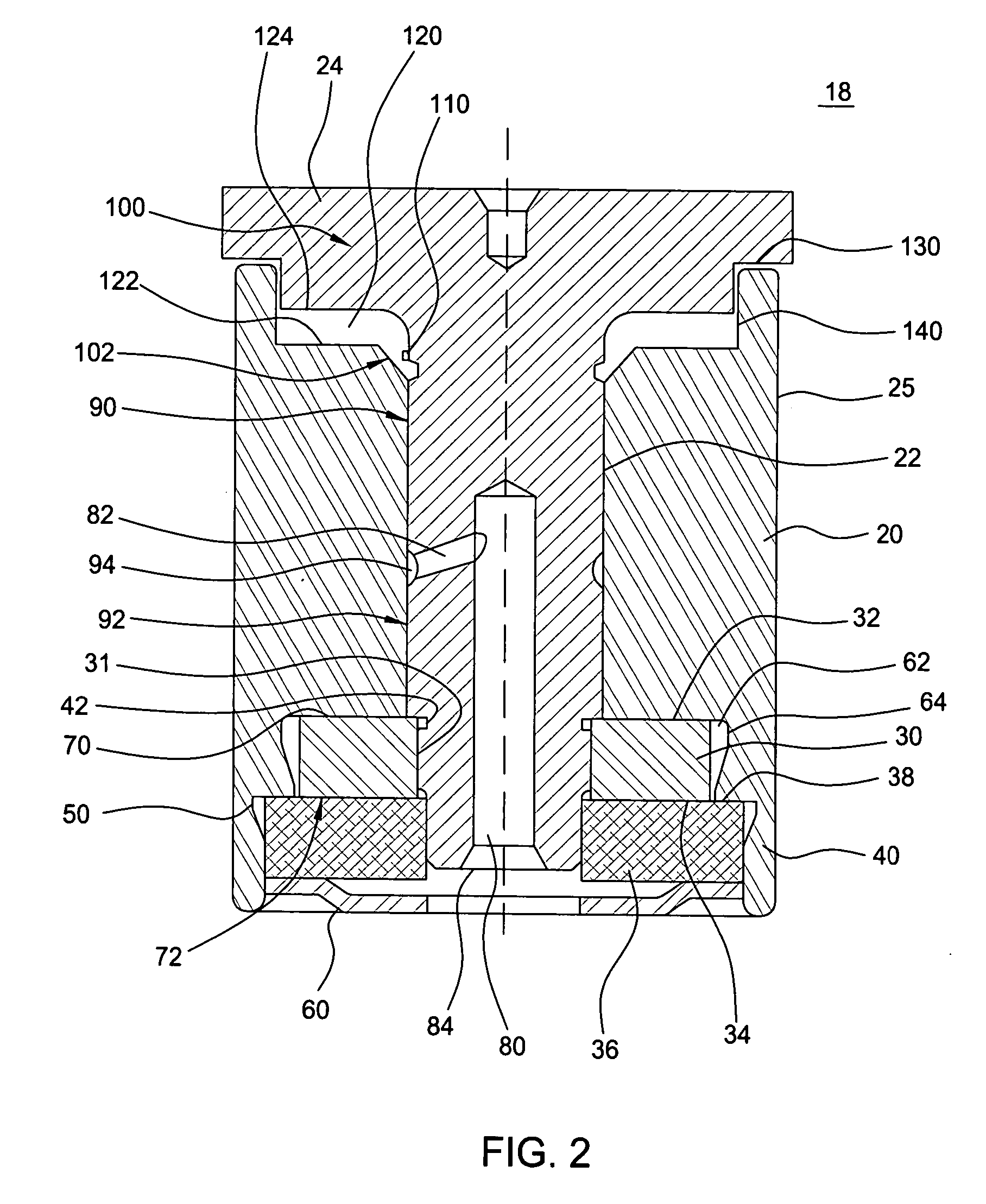

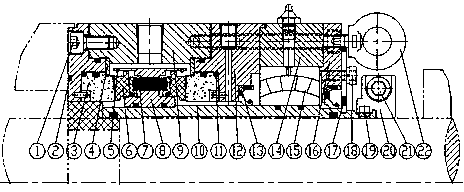

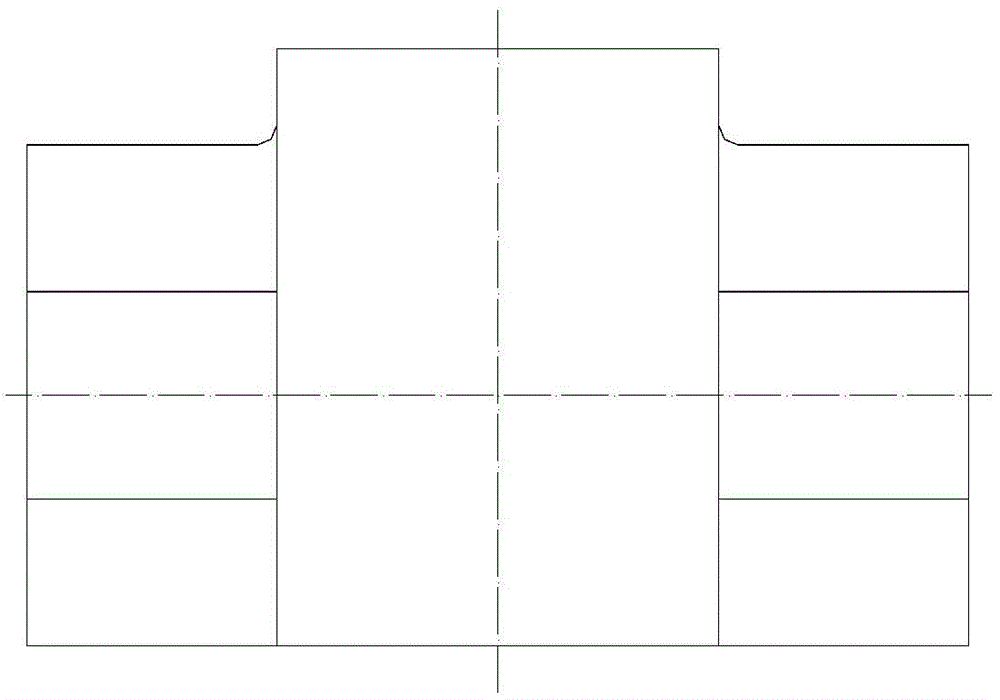

Single plate hydrodynamic bearing cartridge

InactiveUS20050100256A1Simple designHighly adaptable and scalableBearing componentsSliding contact bearingsThrust bearingSingle plate

A hydrodynamic bearing having a shaft relatively rotatable with respect to a surrounding sleeve and having a thrust plate on one end thereof rotating in a recess of the sleeve. The shaft is preferably interrupted by a equi-pressure groove accessing a central reservoir in the shaft and having journal bearings defined by herringbone patterns above and below the groove to stabilize and provide stiffness to the cartridge. The stiffness of the cartridge is further enhanced by a thrust plate carried at one end of the shaft and rotating in a recess of the sleeve and being used to define thrust bearings on either surface.

Owner:SEAGATE TECH LLC

Double mechanical sealing method and double mechanical sealing device for kettle gas films

The invention discloses a double mechanical sealing method and a double mechanical sealing device for kettle gas films, and belongs to the field of machine manufacture. The double mechanical sealing device mainly comprises a shaft sleeve, a moving-ring seat, a stationary ring, a stationary-ring press plate, a moving ring, a bearing, a stationary-ring seat, an auxiliary seal and the like. The double mechanical sealing method is characterized in that a back-to-back rotating double-end-face structure is adopted for sealing to realize non-contact operation, and a fluid dynamic-pressure groove is formed in the end face of the seal stationary ring; high-pressure isolating gas is injected between two sealing structures, and a spring is not affected by solid particles and impurities in media as not contacting with the media; the stationary ring which is supported by two O-shaped rings and is positioned by the press plate can bear back pressure; a cartridge structure is adopted. The double mechanical sealing method and the double mechanical sealing device have the advantages that an auxiliary system is simple in structure and can ensure technological media to be prevented from pollution, leakage and overflow of sealed media can be completely avoided, and no environmental pollution is caused; through the cartridge structure, accuracy, convenience and rapidness in overall mounting are realized, and demounting is facilitated. The device is applicable to various blenders, reactors, dryers, reaction kettles, polymerizers and the like in the fields of petroleum, chemical engineering, pharmacy, rubber, oil refining and the like.

Owner:DONGYING HISCIEN SEALING TECH

Micro-bulge double-layer composite groove deep end surface mechanical seal structure

The invention discloses a micro-bulge double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a micro-bulge double-layer composite groove deep dynamical pressure groove, a sealing dam, a ring groove and a micro-bulge double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the dynamical pressure groove; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the pumping groove; the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove; the sealing dam is an unprocessed smooth plane; and the ring groove is communicated with the pumping groove and arranged on the upstream of the pumping groove.

Owner:JINTUO PETROLEUM MACHINERY MANUFACTRING CO LTD

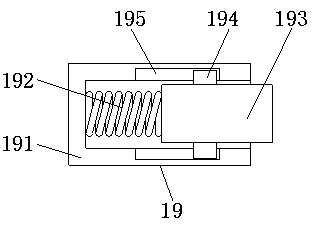

Motorized spindle

ActiveCN107695762AImprove running accuracyExtended service lifeDriving apparatusMaintainance and safety accessoriesWater circulationEngineering

The invention relates to a motorized spindle. The motorized spindle comprises a spindle system assembly, a shaft core assembly, a tool changing air cylinder assembly and a tool installing assembly; the tool changing air cylinder assembly is arranged at the upper portion of the spindle system assembly, and the tool installing assembly is arranged at the lower portion of the shaft core assembly; thespindle system assembly comprises a machine body assembly and a stator, the stator is arranged inside the machine body assembly, and the shaft core assembly penetrates the stator; the shaft core assembly comprises a center water outlet guide body and a core shaft which are sequentially connected, the middle portions of the center water outlet guide body and the core shaft are provided with channels used for cooling water circulation, a first pressure groove for high pressure gas is formed in the connecting position of the center water outlet guide body and the core shaft, and the spindle system assembly further comprises an upper bearing assembly and a lower bearing assembly; the upper bearing assembly, the machine body assembly and the lower bearing assembly are sequentially connected; and the upper bearing assembly and the lower bearing assembly are provided with oil spraying holes. According to the motorized spindle, the spindle running accuracy is improved, the spindle service life is prolonged, cooling water is effectively prevented from entering the interior of the spindle, and the spindle runs efficiently and stably.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

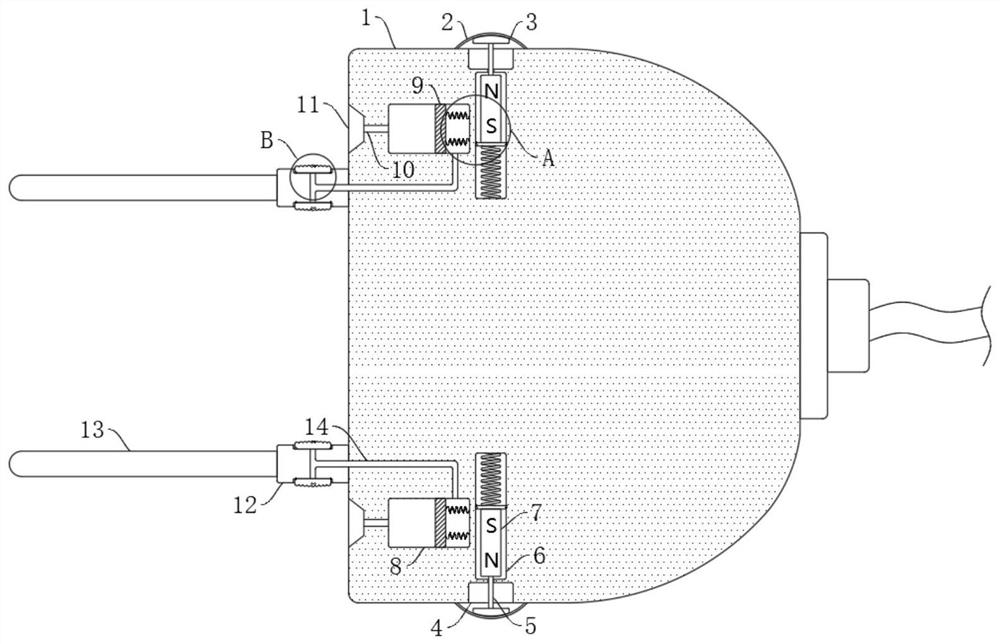

Human organ epidermis adsorber for surgical robot

The invention discloses a human organ epidermis adsorber for a surgical robot. The adsorber comprises a driving part, a gas transmission pipe communicated with the driving part and a suction head communicated with the gas transmission pipe, wherein the driving part comprises a cylinder body; a battery, a circuit board, a static iron core, an electromagnetic coil, a moving iron core and a spring are sequentially arranged in the cylinder body from top to bottom; the battery, the circuit board and the electromagnetic coil constitute an electric circuit; the circuit board is in signal connection with a controller; a piston cavity is formed by the electromagnetic coil and the bottom of the cylinder body; a piston is connected to the lower end part of the moving iron core and in sliding fit withthe inner wall of the piston cavity; a negative-pressure groove capable of covering the epidermis is formed in the suction head; the piston is propped against the bottom of the cylinder body under the elastic force of the spring; when the electromagnetic coil is energized, attraction force is generated to attract the moving iron core, the moving iron core drives the piston to compress the spring,and the piston moves up to enable the negative-pressure groove to form pressure far lower than the outside air pressure, so that the epidermis is adsorbed; the adsorber is suitable for adsorbing andfixing the epidermis at the operation site to prevent the epidermis from creeping during the operation of the operation robot.

Owner:徐州众杰电子科技有限公司

Valve body forging method

ActiveCN104439032ADense microstructureBeautiful appearanceValve arrangementsPressure grooveMaterials science

The invention relates to the field of valve body manufacturing, in particular to a valve body forging method. The valve body forging method saves materials and energy and reduces consumption on the condition of meeting the requirement of customers for product diversification. At first, blank forming is achieved by utilizing free forging for executing the following steps of A, selecting round steel with the weight being 1.15-1.25 times the weight of a finished valve body, riveting the two ends of the round steel, conducting indentation material separation, and forging the round steel into the preset size; B, enabling the two ends of the round steel to get off a table, forging eccentricity of the middle and the two ends, and forging the two ends into 260-degree octagons; C, then utilizing pressing blocks for making octagonal pressure grooves in the two ends into the preset size, and ensuring that flanges and grooves of a green body are within the design size range. Then, final forming is achieved by adopting semi-die forging for executing the following steps of a, forging the middle octagon of the green body in a vertical die buckling and pressing mode; b, after the middle octagon is formed, controlling the height of the flanges at the two ends through cushion blocks and forging the flanges to be rounded; c, finally, trimming the sizes of all parts of the forged piece into the designed sizes.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

High-stability roadblock

InactiveCN111364383AImprove stabilityNot easy to dumpTraffic signalsRoad signsSoft layerDriver/operator

The invention discloses a high-stability roadblock including a shell. Two stabilizing mechanisms are arranged in the shell; the stabilizing mechanism comprises a mounting cavity formed in the shell; the inner wall of the mounting cavity is fixedly connected with a tuning fork; a solenoid is fixedly wound on the side wall of the tuning fork; two permanent magnet plates are fixedly connected to theinner wall of the mounting cavity; an electromagnetic block is fixedly connected to the inner wall of the mounting cavity; the electromagnetic block is electrically connected with the solenoid; the lower wall of the electromagnetic block is elastically connected with a magnetic sliding plug through a tension spring; the lower wall of the shell is fixedly connected with a soft layer; the soft layerand the lower wall of the shell are jointly provided with a negative pressure groove; the lower wall of the mounting cavity is communicated with the negative pressure groove through an air suction channel; a first one-way valve is arranged in the air suction channel; an air outlet pipe is communicated with the side wall of the mounting cavity; and a second one-way valve is arranged in the air outlet pipe. According to the invention, the roadblock has good stability, is not easy to topple over, and can play a good role in prompting a driver.

Owner:吴庆荣

Fabric drum with keep plate provided with torsional spring

The invention discloses a fabric drum with a keep plate provided with a torsional spring. The keep plate and a pressure groove are pressed conveniently through the torsional spring hinged to the keep plate, the keep plate can automatically bounce, then a cloth leftover is conveniently prefixed to a reel, the reel is driven to rotate through a rotary handle arranged at one end of the reel, the cloth leftover is wound on the reel with an annular groove and squeezed with sawteeth on the lateral wall of a long groove, and therefore the contact area of the cloth leftover and the reel is increased, the cloth leftover is effectively pressed, prevented from slipping and locked by the rotary handle. The fabric drum of the structure is convenient to operate, fabric batching is stable and reliable, slipping is avoided, and time and labor are saved.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

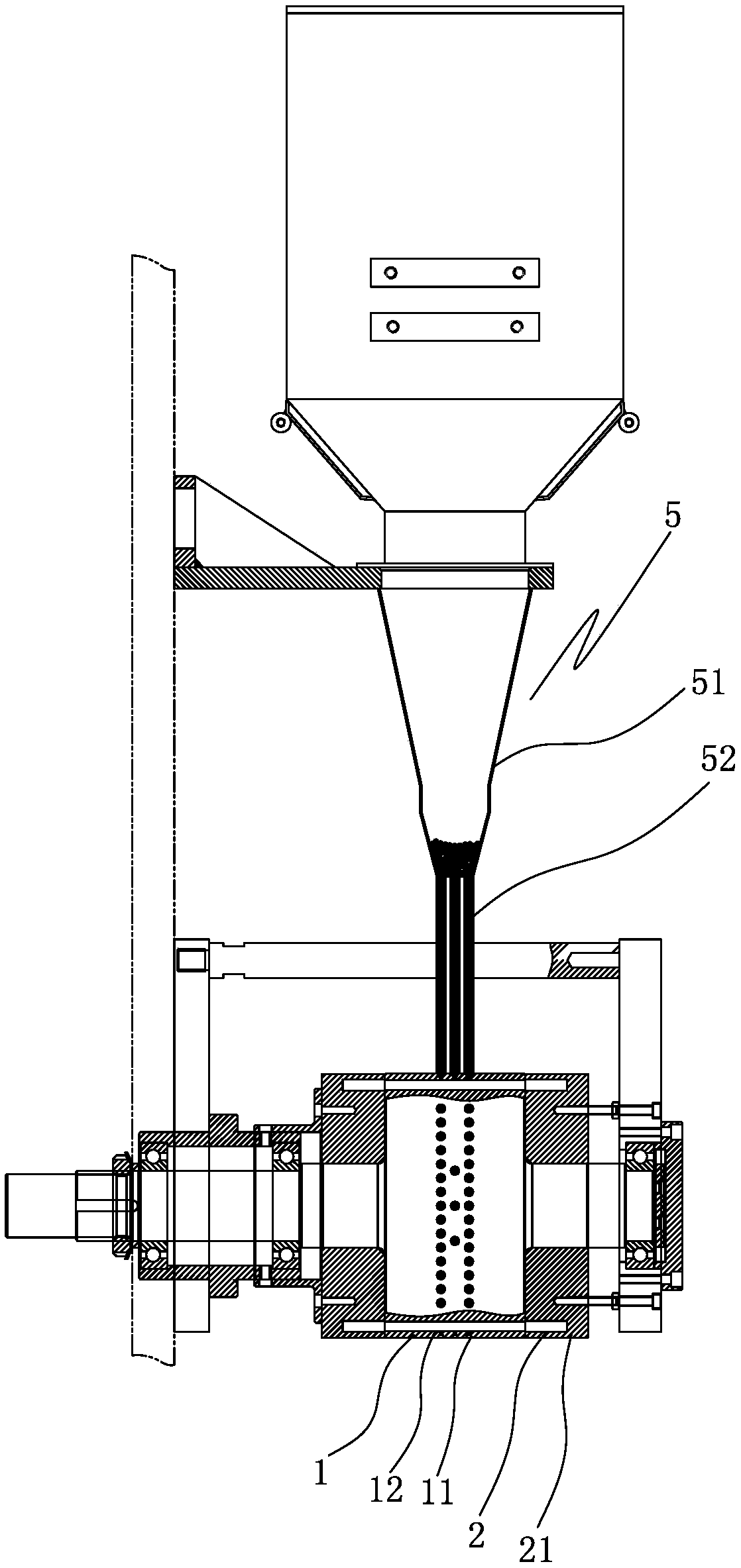

Production device and method of blasting bead sanitation product

PendingCN108938205AAutomate operationSimple structureAbsorbent padsBaby linensSurface layerMechanical engineering

Owner:JINJIANG HAINA MACHINERY

Anti-falling structure based on AI intelligent test server power plug

InactiveCN111834808APrevent looseningGuaranteed to workEngagement/disengagement of coupling partsStructural engineeringPressure groove

The invention discloses an anti-falling structure based on an AI intelligent test server power plug. The anti-falling structure comprises a shell; two inserting pieces are arranged on the side wall ofthe shell; two anti-falling mechanisms are arranged on the shell; the anti-falling mechanism comprises a fixing groove formed in the side wall of the shell. A containing cavity is formed in the shell. A placing plate is elastically connected to the bottom in the placing cavity through a pressure spring; the side wall of the placing plate is fixedly connected with a permanent magnet strip; the upper wall of the permanent magnet strip is fixedly connected with a connecting rod, the connecting rod extends into the fixing groove and is fixedly connected with a pressing plate, a control cavity isformed in the shell, the inner wall of the control cavity is elastically connected with a piston plate through a plurality of tension springs, the side wall of the shell is provided with a negative pressure groove, and the negative pressure groove communicates with the control cavity through a connecting channel. The plug can be prevented from loosening, normal work of the AI intelligent test server is ensured, and people can easily pull out the plug and insert the plug into a socket.

Owner:姜青青

Cable winding device

The invention relates to the technical field of cable winding, and discloses a cable winding device, comprising a machine frame, a shell is fixedly connected to the machine frame, two support blocks are slidably connected to the shell, two support columns pass through the two support blocks, a pressure groove is fixedly connected in the support block, a support plate is slidably connected in the pressure groove, and the lower end of the support column is fixedly connected with the support plate. One support plate is fixedly connected with a contact plate, and a first elastic air bag and a second elastic air bag are arranged in the support block; a first motor is arranged on any support block, the output end of the first motor is detachably connected with a reel, and the reel is rotatably arranged between two support columns; the machine frame is rotatably connected with a ring track, the upper surface of the ring track is fixedly connected with a chain, the lower surface of the ring track is rotatably connected with a guide block, the machine frame is rotatably connected with a sprocket, the sprocket is connected with a rotary shaft, one end of the rotary shaft is fixedly connectedwith an air box, and the air box communicates with the first elastic air bag; the machine frame is provided with a shearing assembly. The invention has the advantage of even winding of cables.

Owner:宁波隆锐机械制造有限公司

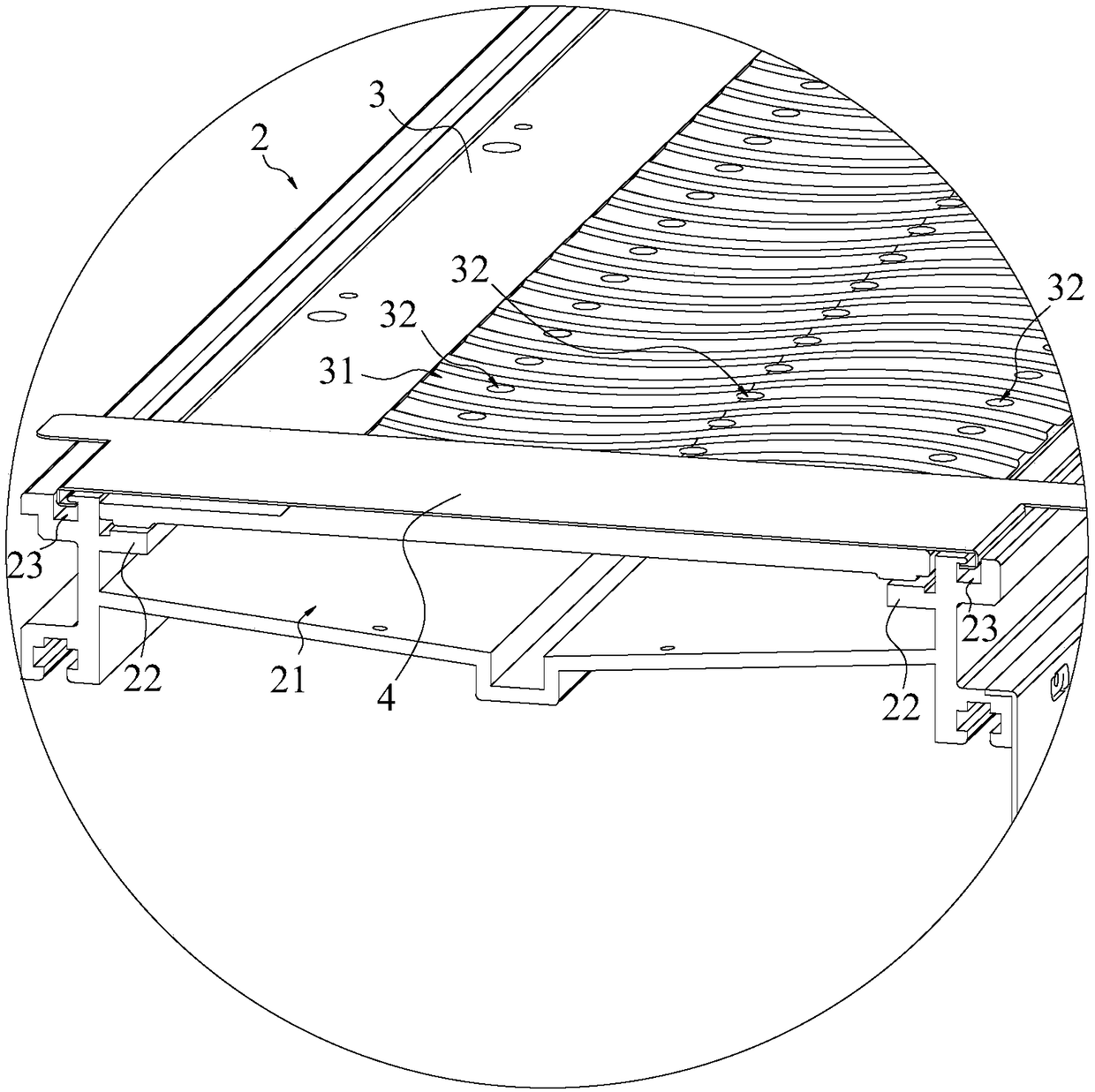

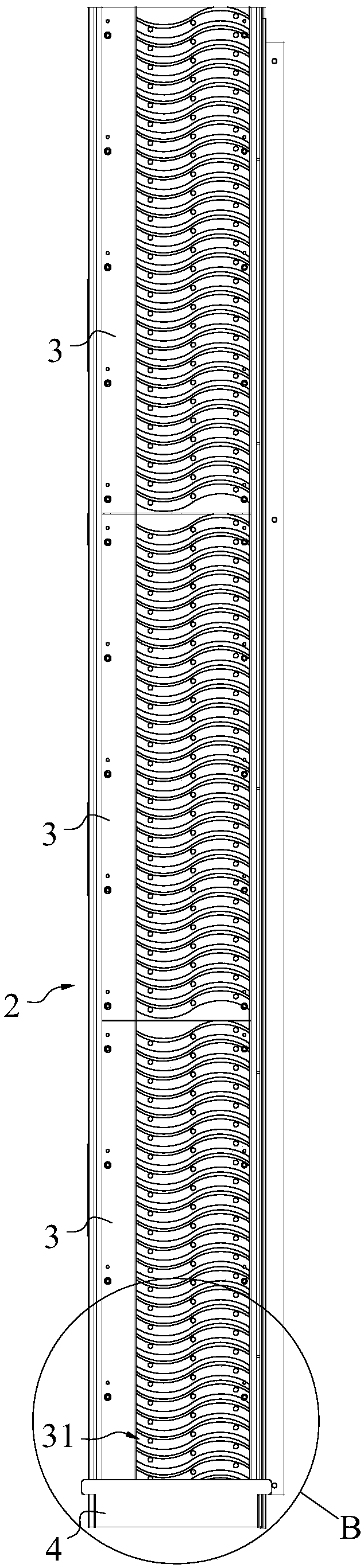

Digital printing and air sucking device and digital printing machine

PendingCN108638670ADifficult to raise sharesImprove drying efficiencyOther printing apparatusEngineeringDigital printing

The invention belongs to the technical field of printing equipment, and in particular, relates to a digital printing and air sucking device and a digital printing machine. The digital printing and airsucking device comprises a printing platform and an air sucking cover plate; the printing platform is provided with a negative-pressure groove; the air sucking cover plate covers the negative-pressure groove, and is provided with multiple air sucking runners arranged side by side; each air sucking runner extends in a moving direction of a medium in a wave or sawtooth form; and multiple air sucking holes arranged in each air sucking runner in the extension direction. The air sucking area of the air sucking holes is changed from a hole form to a whole air sucking runner, so that the air suckingarea of the air sucking holes is increased, and the medium can be dried more uniformly; the dried medium is more smooth and not easy to drape; meanwhile, the drying speed is accelerated; and gaps between the runners can level the medium, so that the areas, recessed into the air sucking runners, of the medium can be leveled by the gaps between the runners during drying and curing, and the medium can be cured more smoothly and is not easy to drape.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com