Superdeep well great displacement high performance boring tool protector for well

An extended-reach well, high-performance technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve problems such as failure to successfully complete the well, inability to run the casing string, large friction torque of the pipe string, etc. Safety and drilling capacity, enhanced lubrication, prevention of casing eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

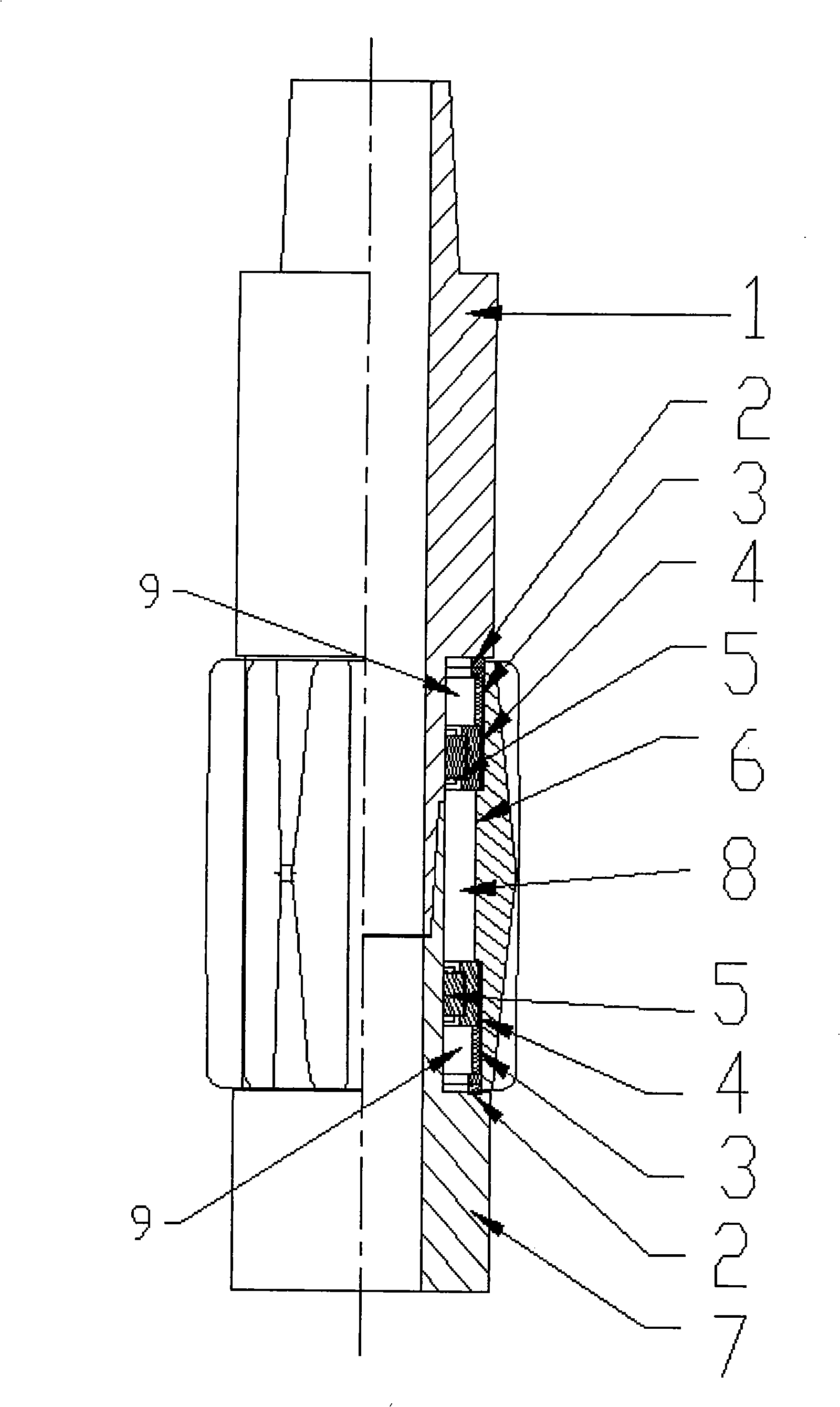

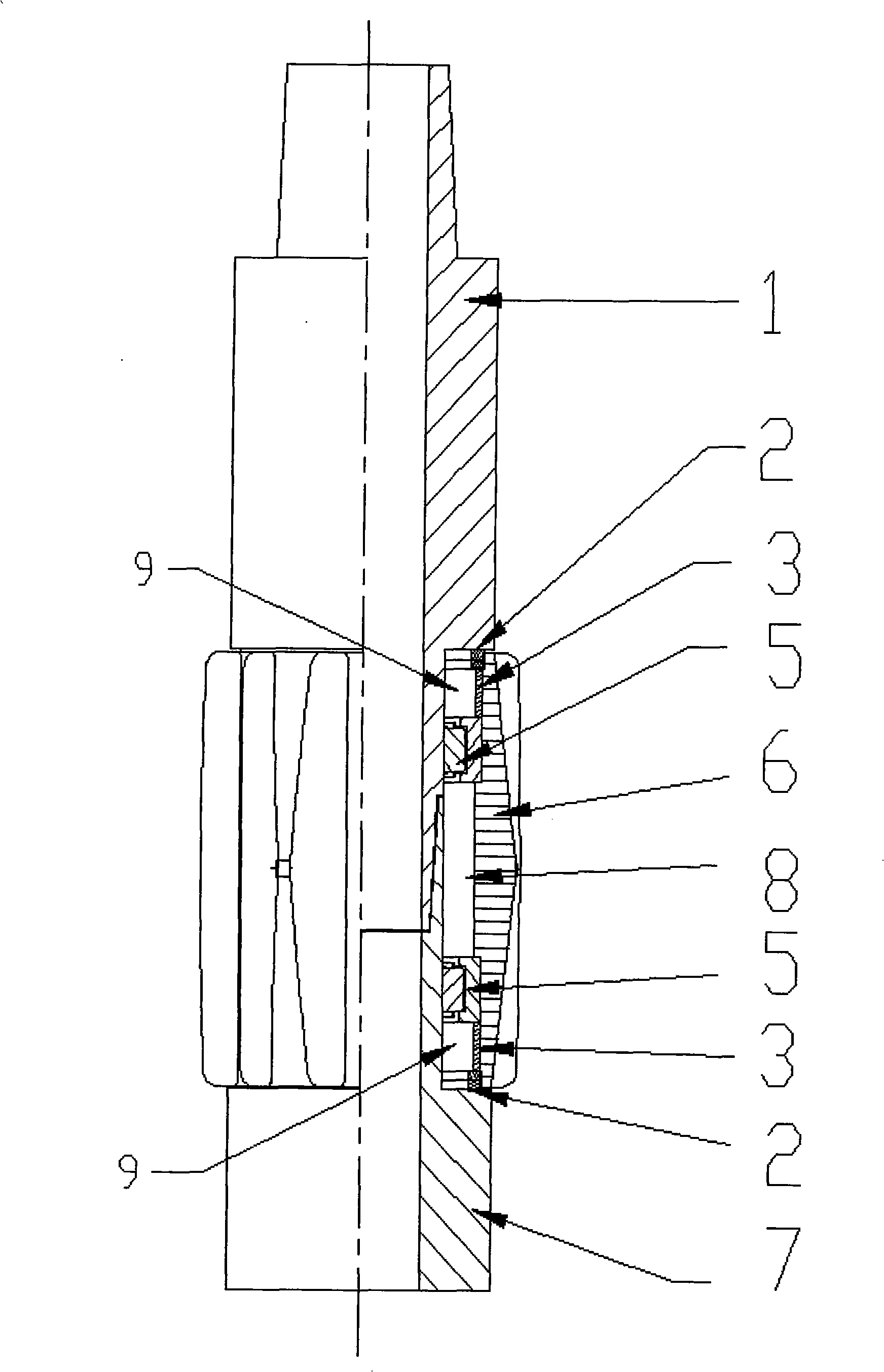

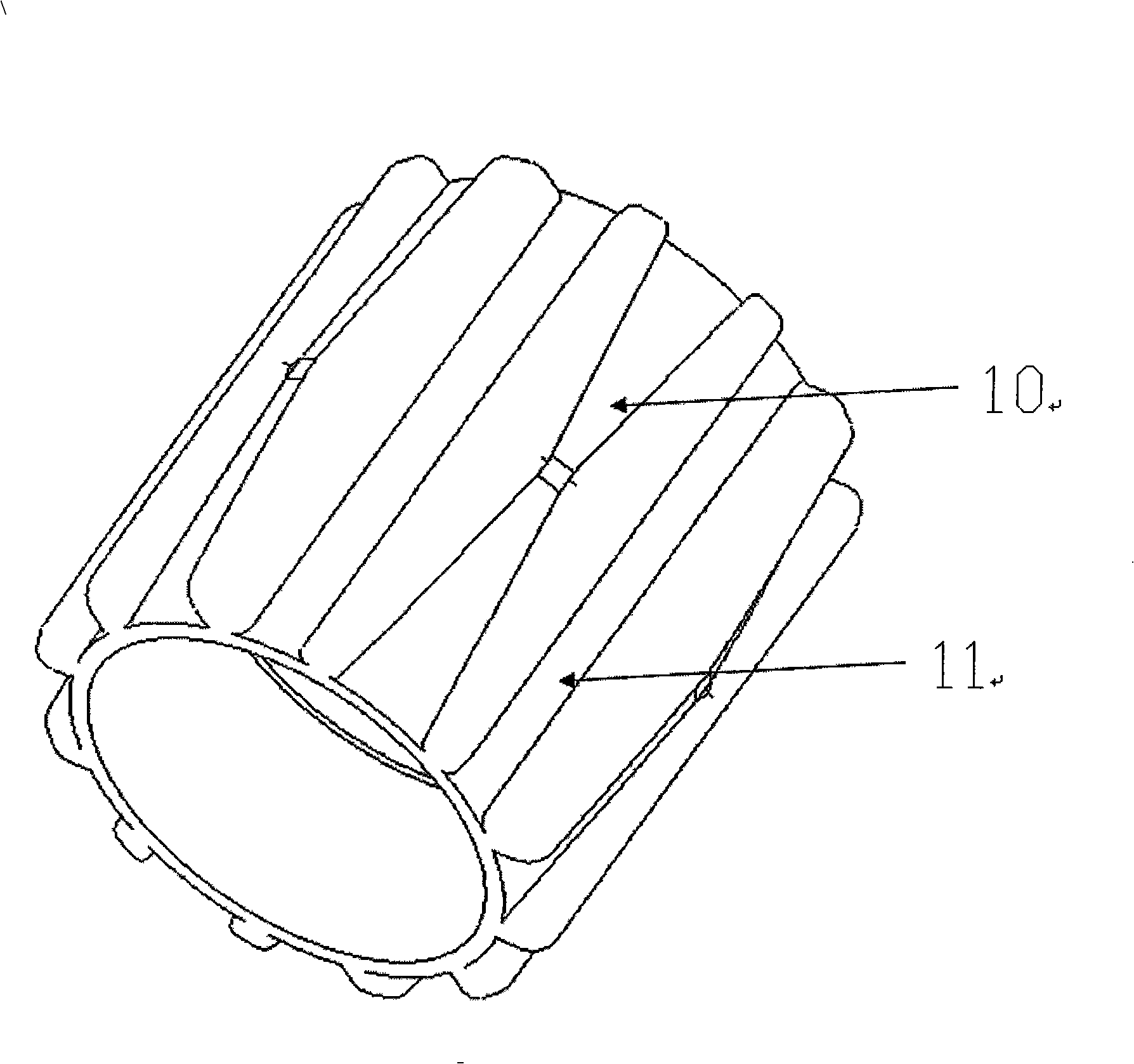

[0012] according to figure 1 , image 3 As shown, the coupling casing 6 is installed at the joints 1 and 7 of the centralizer body, and a pair of rolling bearings 5 are installed inside the coupling casing 6. The outer surface of the coupling casing 6 is provided with a medium flow channel 11 and a wedge-shaped pressure groove 10, and its inner surface Blow mold or assemble a layer of vibration-damping rubber sleeve 4 on the installation part of rolling bearing 5. The vibration-damping rubber sleeve has the function of damping and absorbing vibration, which can reduce the collision strength between the drilling tool and the well wall, and improve the structural safety and drilling capacity of the lower drilling tool ;The self-lubricating sealing ring group 2 is placed at the joint and the coupling shell, and each group is composed of 2~3 pairs of self-lubricating sealing graphite rings. The self-lubricating sealing ring group not only plays the role of lubrication and sealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com