Compression roller device provided with buffering mechanisms

A technology of buffer mechanism and pressure roller device, which is applied in the field of pressure roller buffer devices, which can solve the problems that the wear of the buffer material cannot be effectively solved, the frame of the pressure roller is tilted and deformed, and there is no buffer installed, so as to avoid bad roll shape and reduce impact Powerful and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

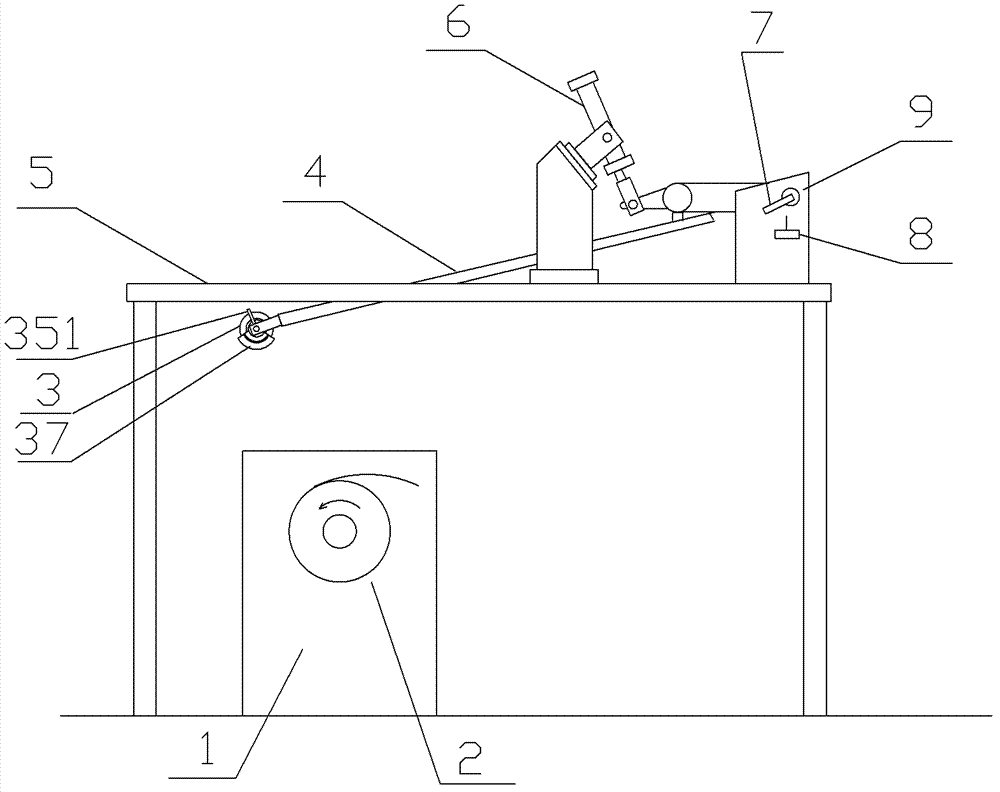

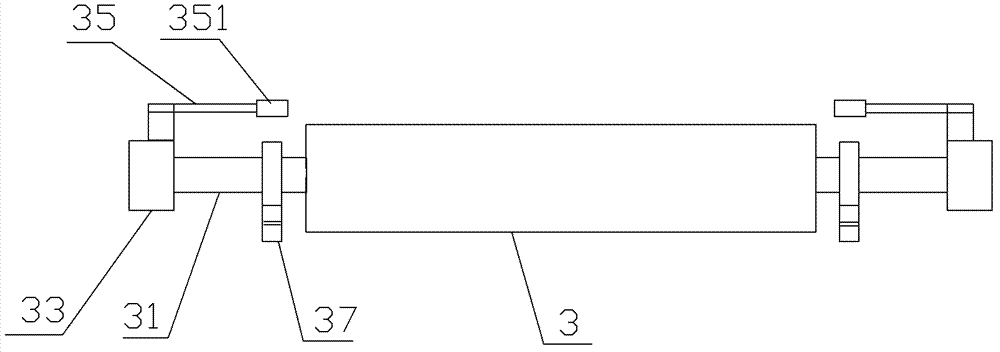

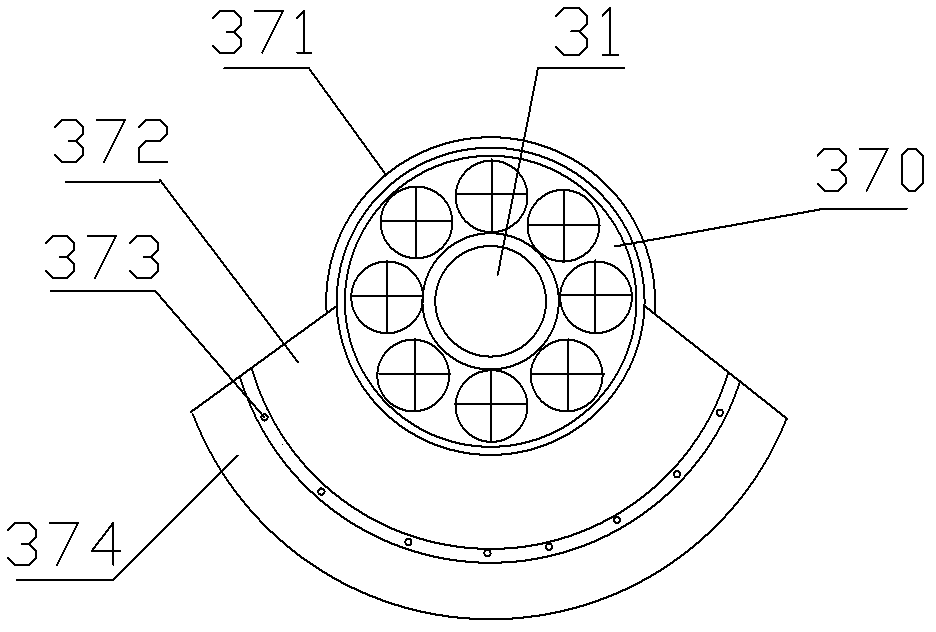

[0017] Such as figure 1 As shown in -4, this embodiment has a pressure roller device with a buffer mechanism, which consists of: a support platform 5, a pressure roller frame seat 9, a pressure roller frame 4, and a pressure roller shaft fixed by the pressure roller bearing seat 33 and the pressure roller frame 4 31. The improvement of the pressure roller 3 installed on the pressure roller shaft 31 is that it also includes a buffer mechanism 37 installed on the pressure roller shaft at both ends of the pressure roller. The buffer mechanism 37 includes: installed on the pressure roller shaft The rolling bearing 370 on 31, the outer circle of the rolling bearing 370 is provided with an elastic buffer body 374, and the elastic buffer body 374 has a cylindrical surface concentric with the pressure roller shaft 31 with an arc of 150° (generally between 90°-180°). The radius of the cylindrical surface is greater than the radius of the pressure roller 3 by 5 cm (generally 3-10 cm), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com