Patents

Literature

43 results about "Casing wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

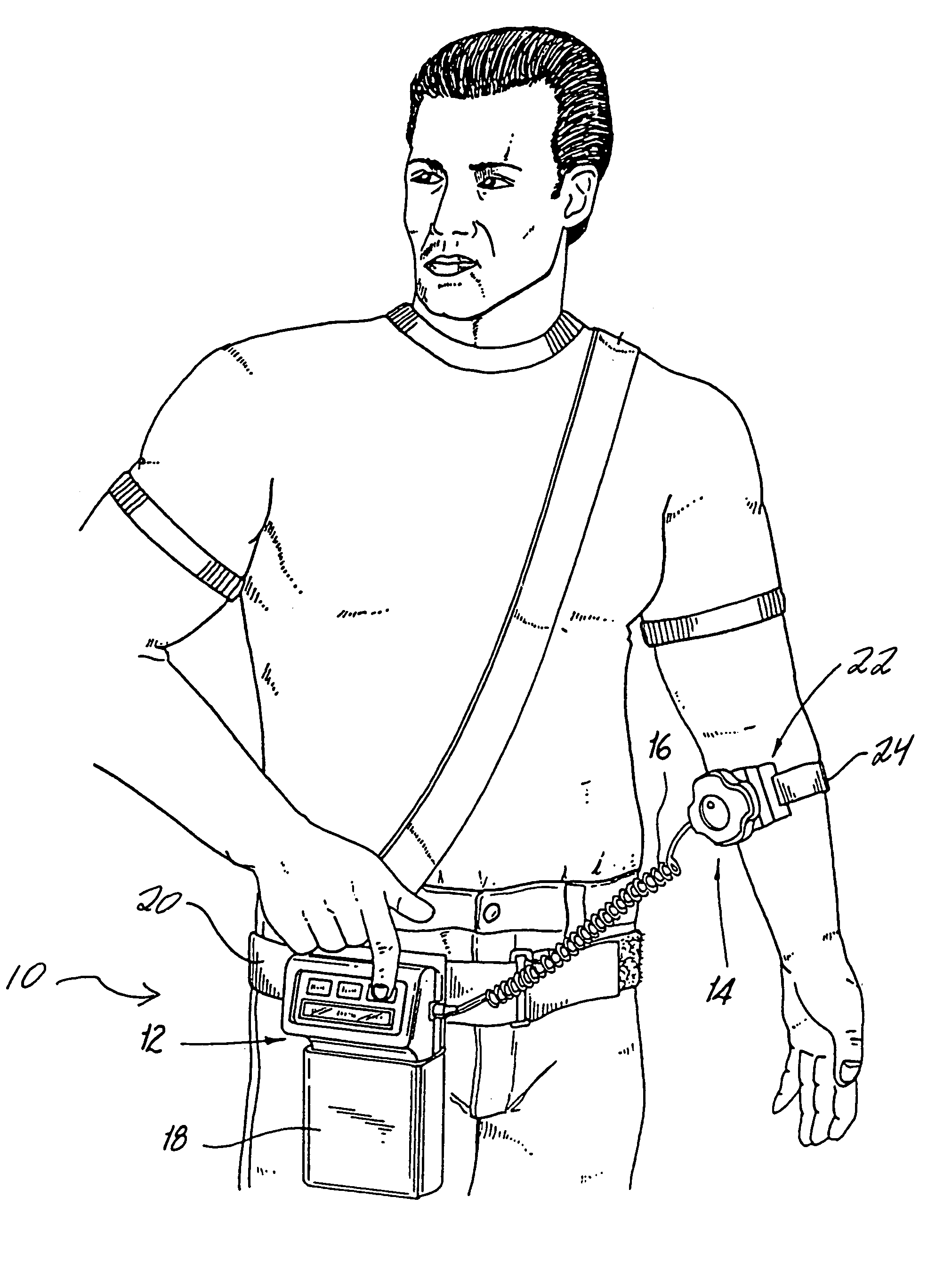

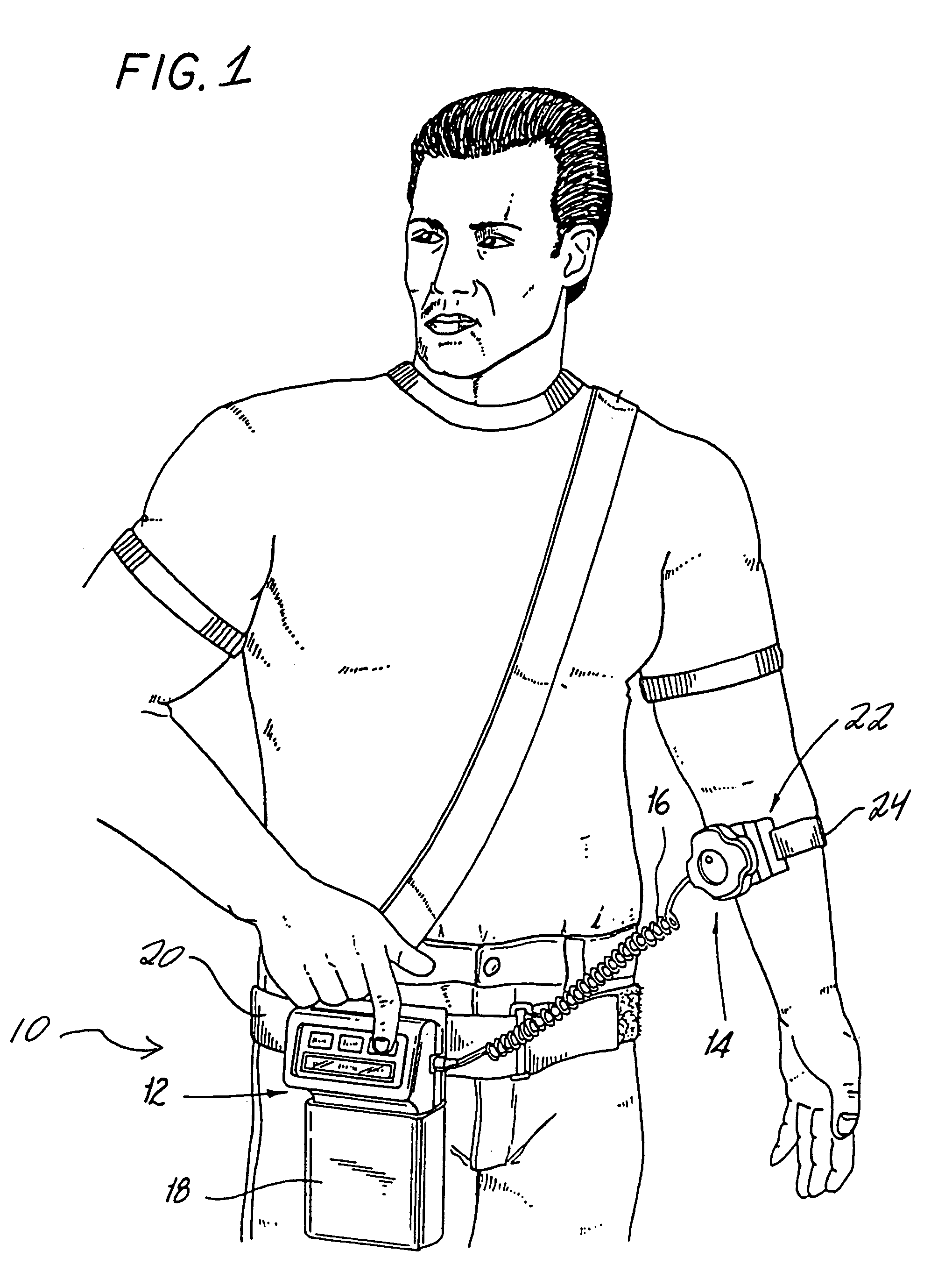

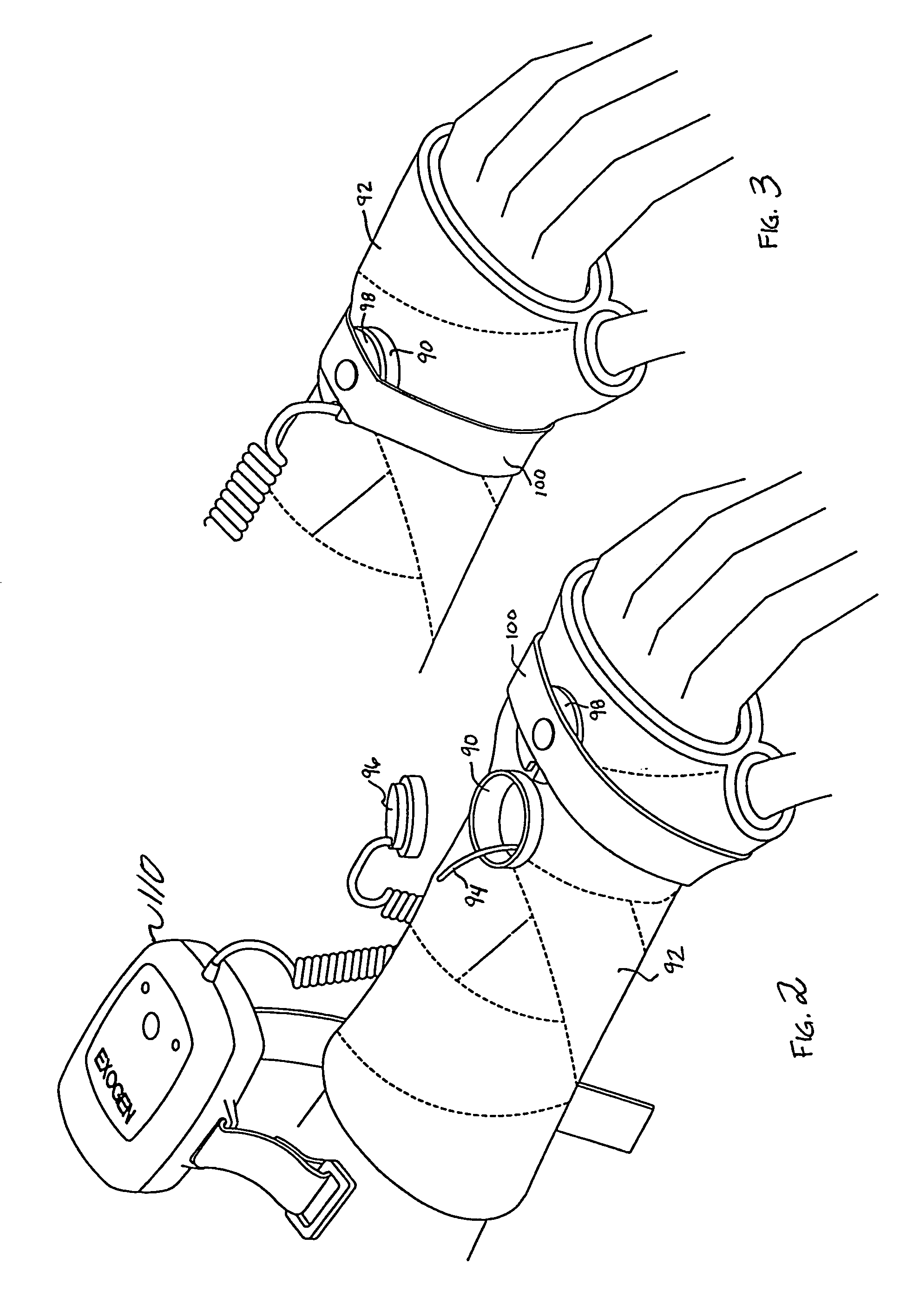

Apparatus and method for ultrasonically and electromagnetically treating tissue

InactiveUS7410469B1Increase stimulationGood cell permeabilityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMagnetic tension forceCasing wear

The invention relates to apparatus and method for ultrasonically and electromagnetically treating tissue to treat, for example, traumatized tissue or a bone injury. The apparatus includes at least one ultrasonic transducer assembly and at least one electromagnetic coil-assembly configured to cooperate with a placement module for placement in proximity to the treatment area. The apparatus also utilizes a portable main operating unit constructed to fit within a pouch or carrying case worn by the patient. In operation, at least one ultrasonic transducer and at least one electromagnetic coil are activated by transmitting control signals to the placement module from the main operating unit. The activation of the at least one ultrasonic transducer causes ultrasonic waves to be propagated toward the treatment area which are modulated by electrostatic and magnetic forces generated by the at least one electromagnetic coil. The activation of the at least one ultrasonic transducer and the at least one electromagnetic coil may be performed at the same time or at different times for varying periods.

Owner:EXOGEN

Hardfacing alloy, methods, and products

ActiveUS7361411B2Extended service lifeReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

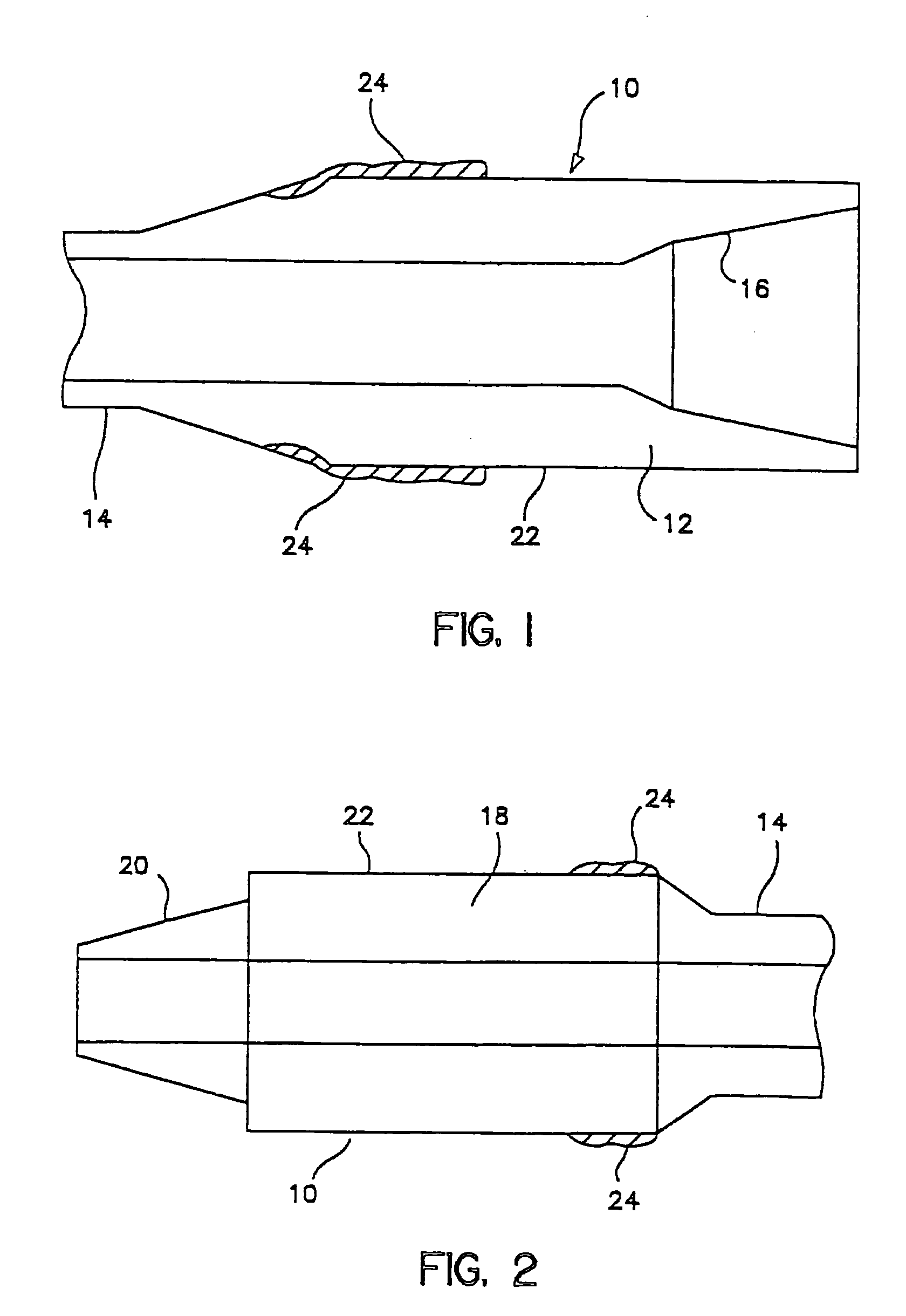

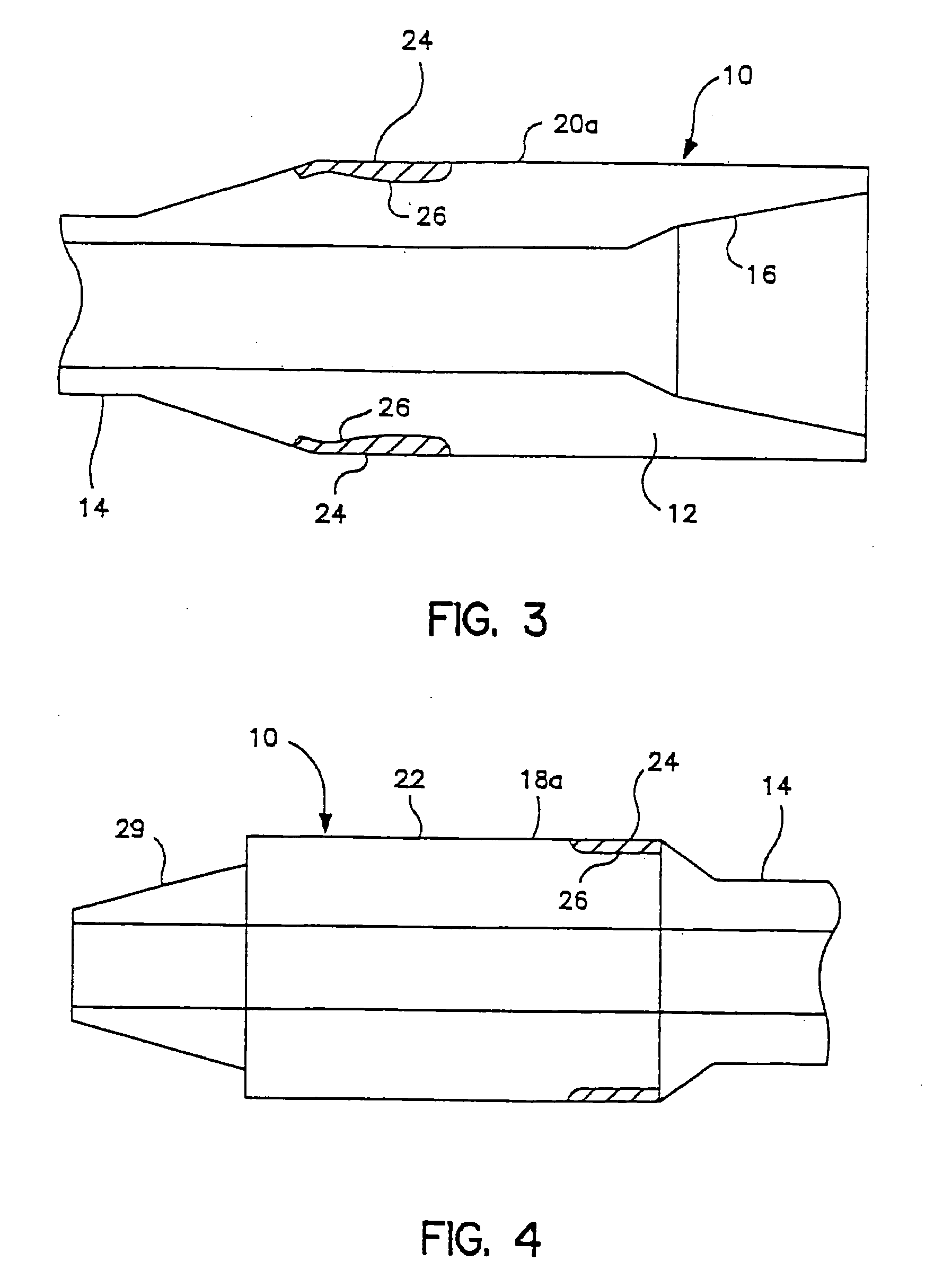

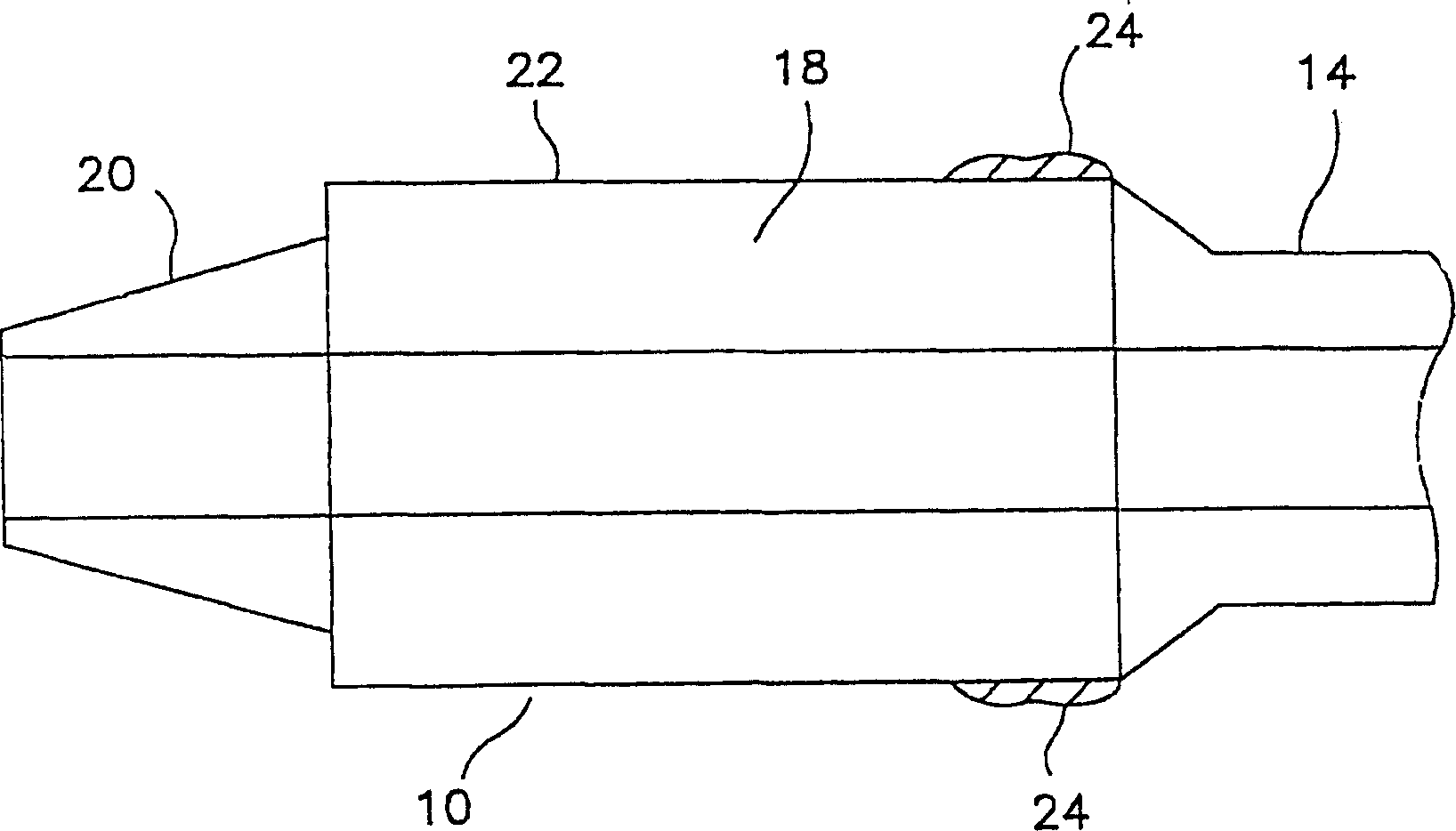

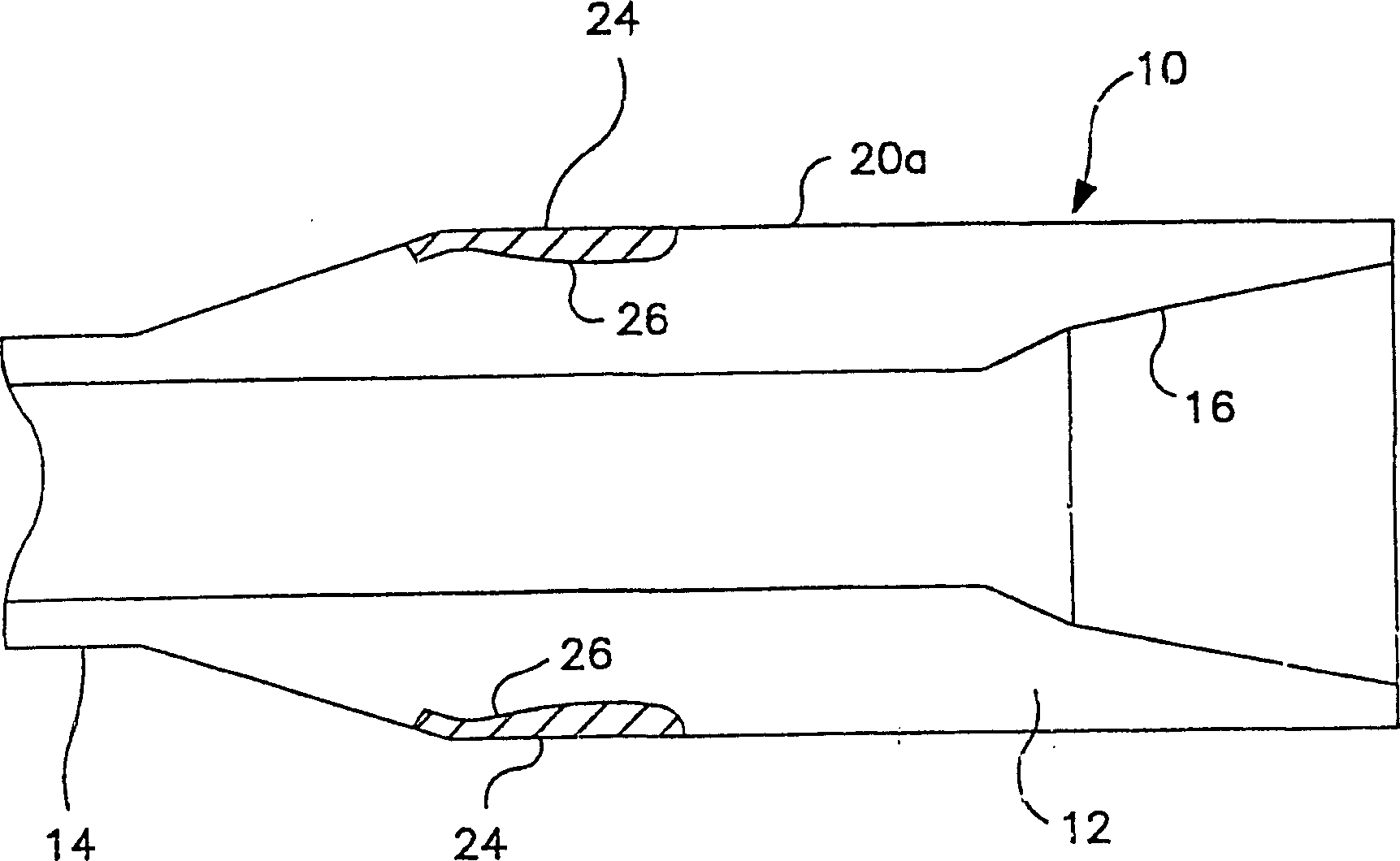

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD D B A ARNCO TECH TRUST +1

Hardfacing alloy, methods and products

InactiveUS7569286B2Increase resistanceReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD

Hardfacing alloy, methods and products

InactiveUS20080241584A1Increase resistanceReduce coefficient of frictionDrill bitsDrilling rodsCasing wearBoride

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD

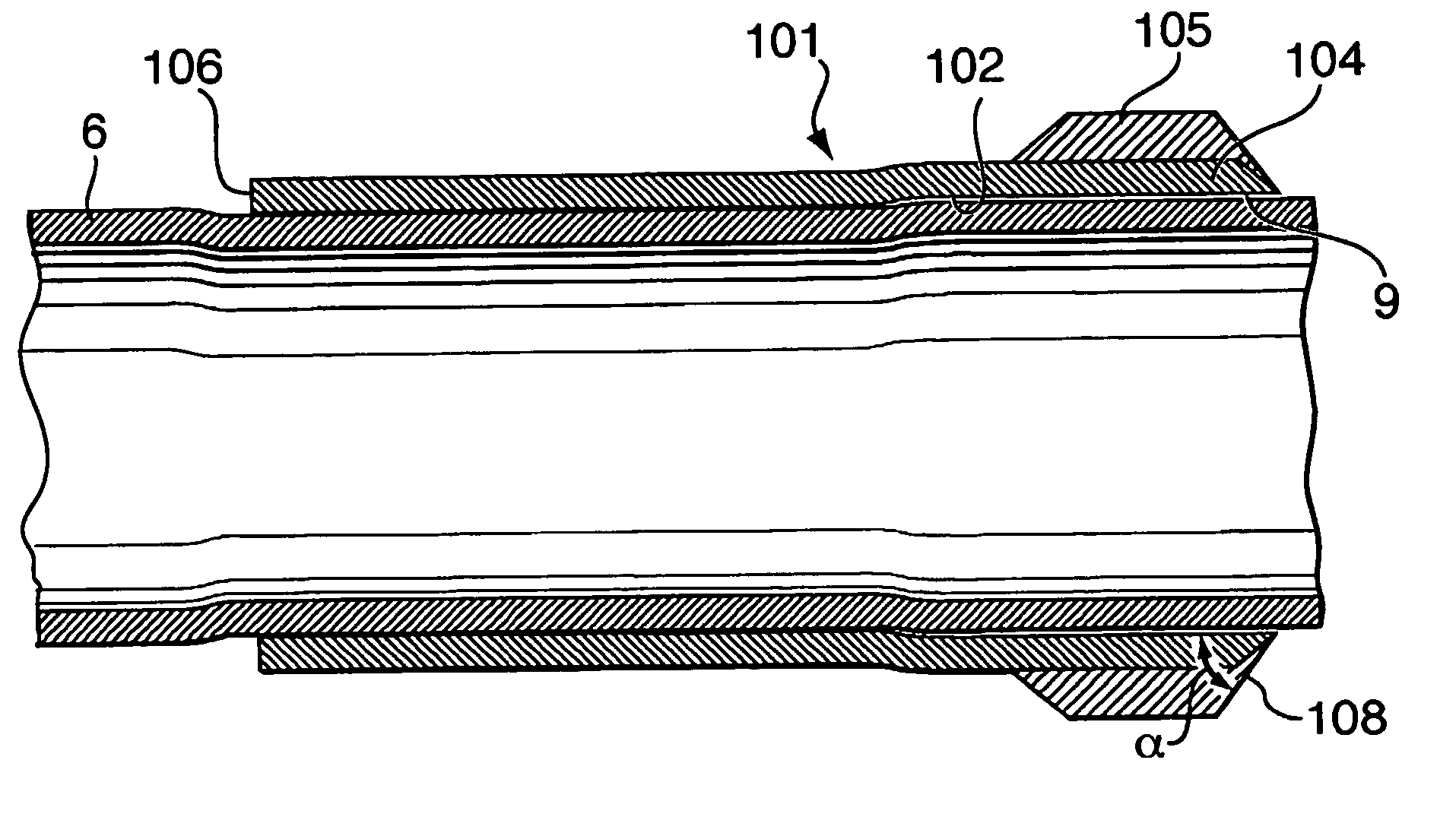

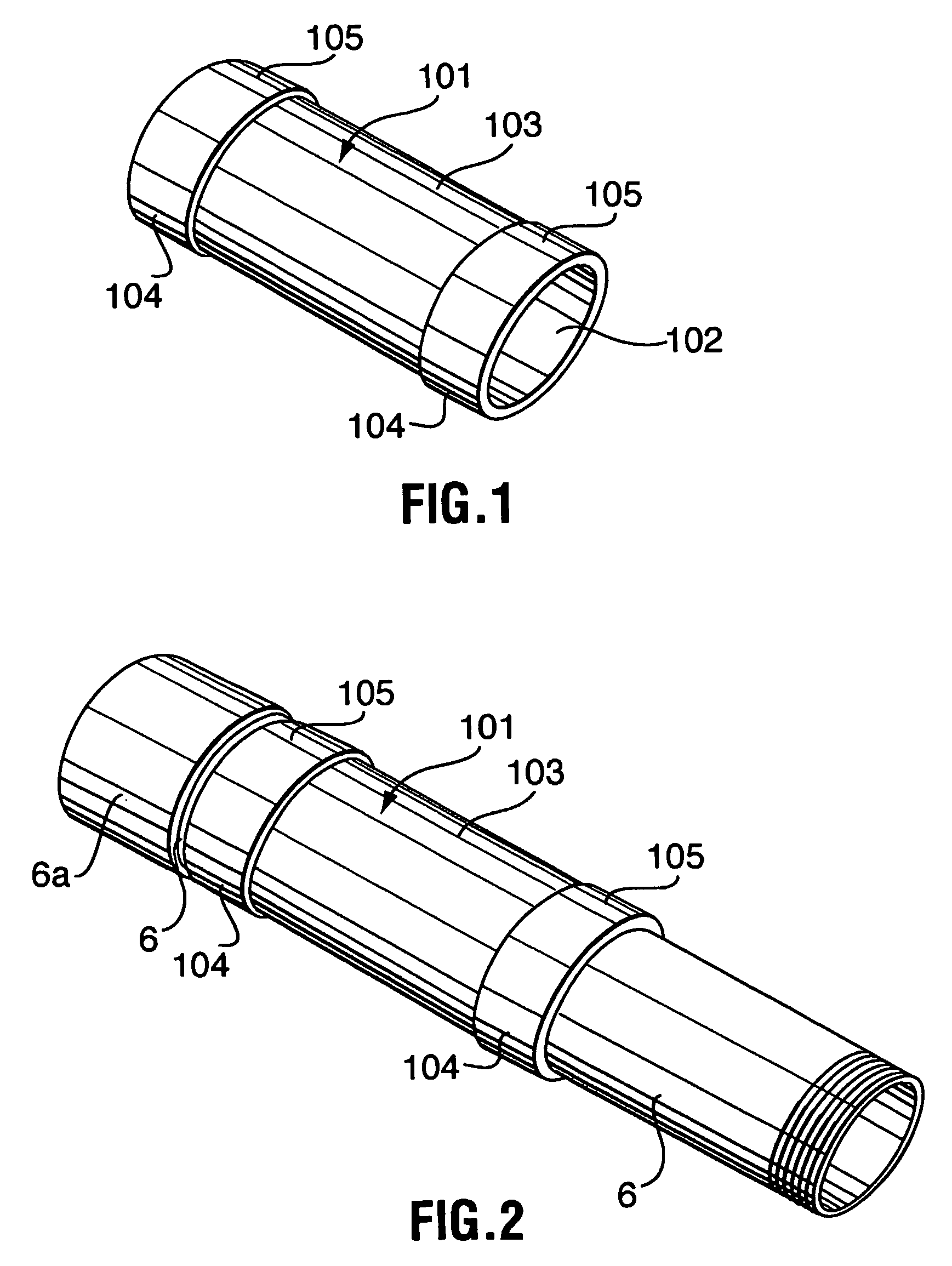

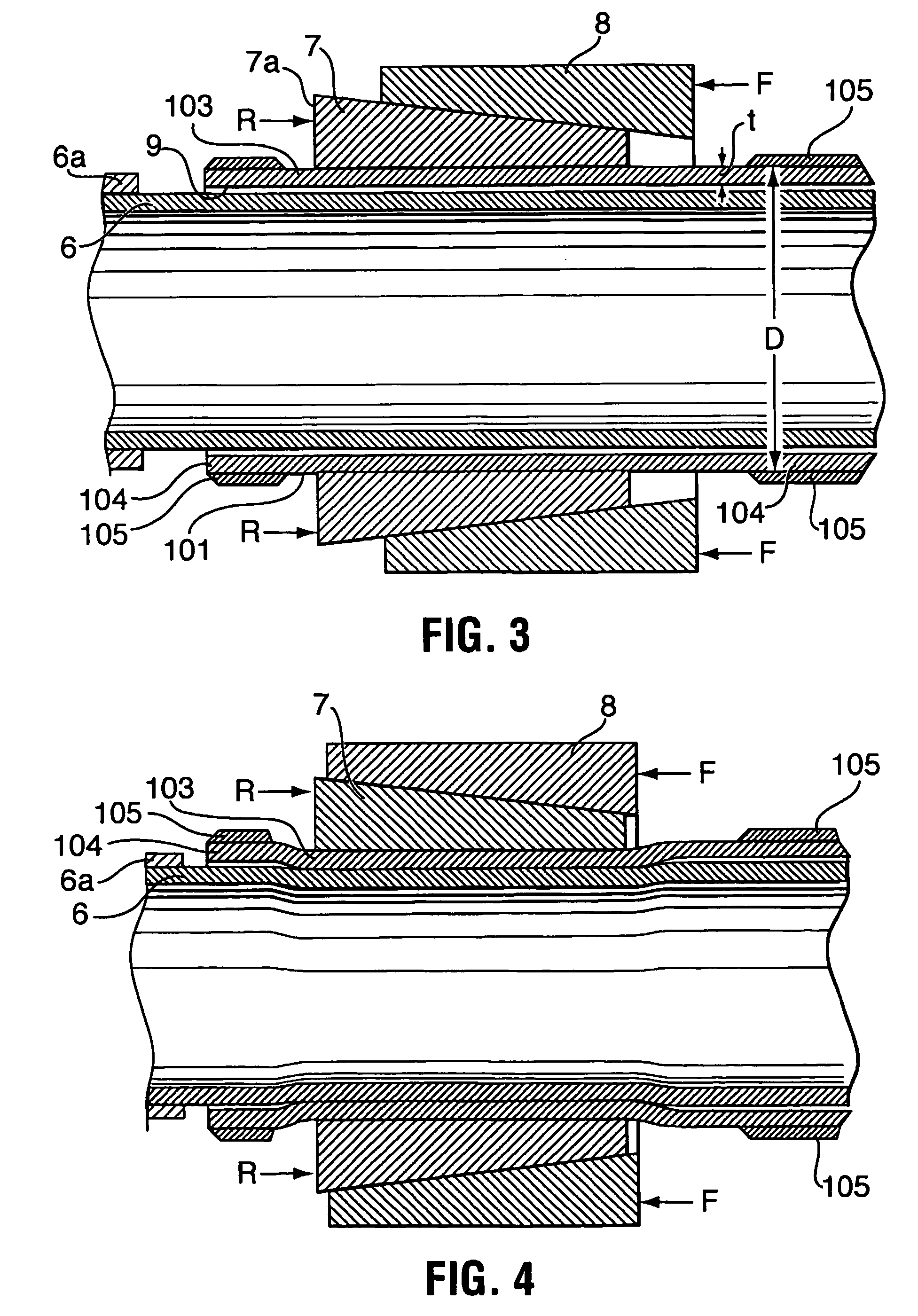

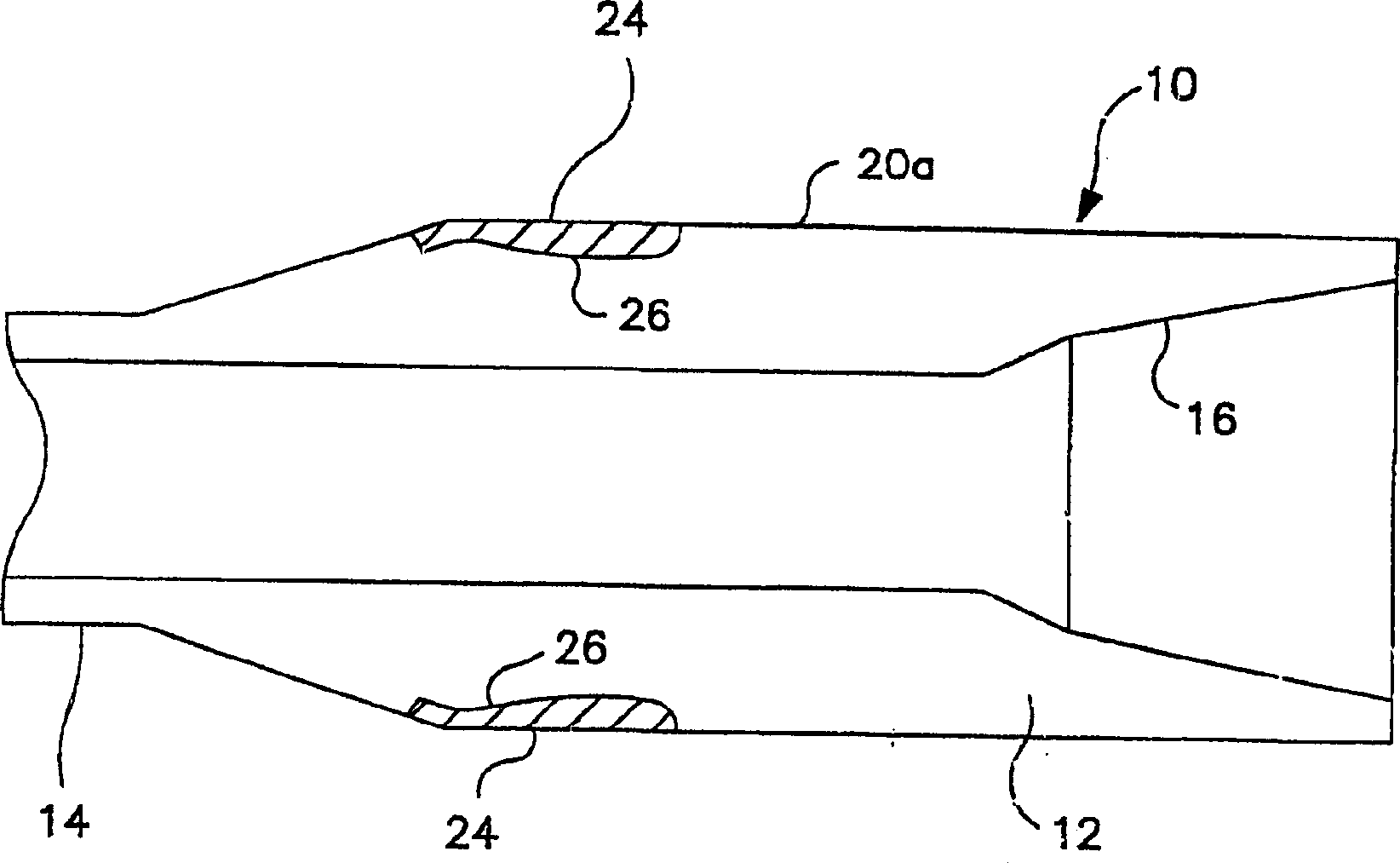

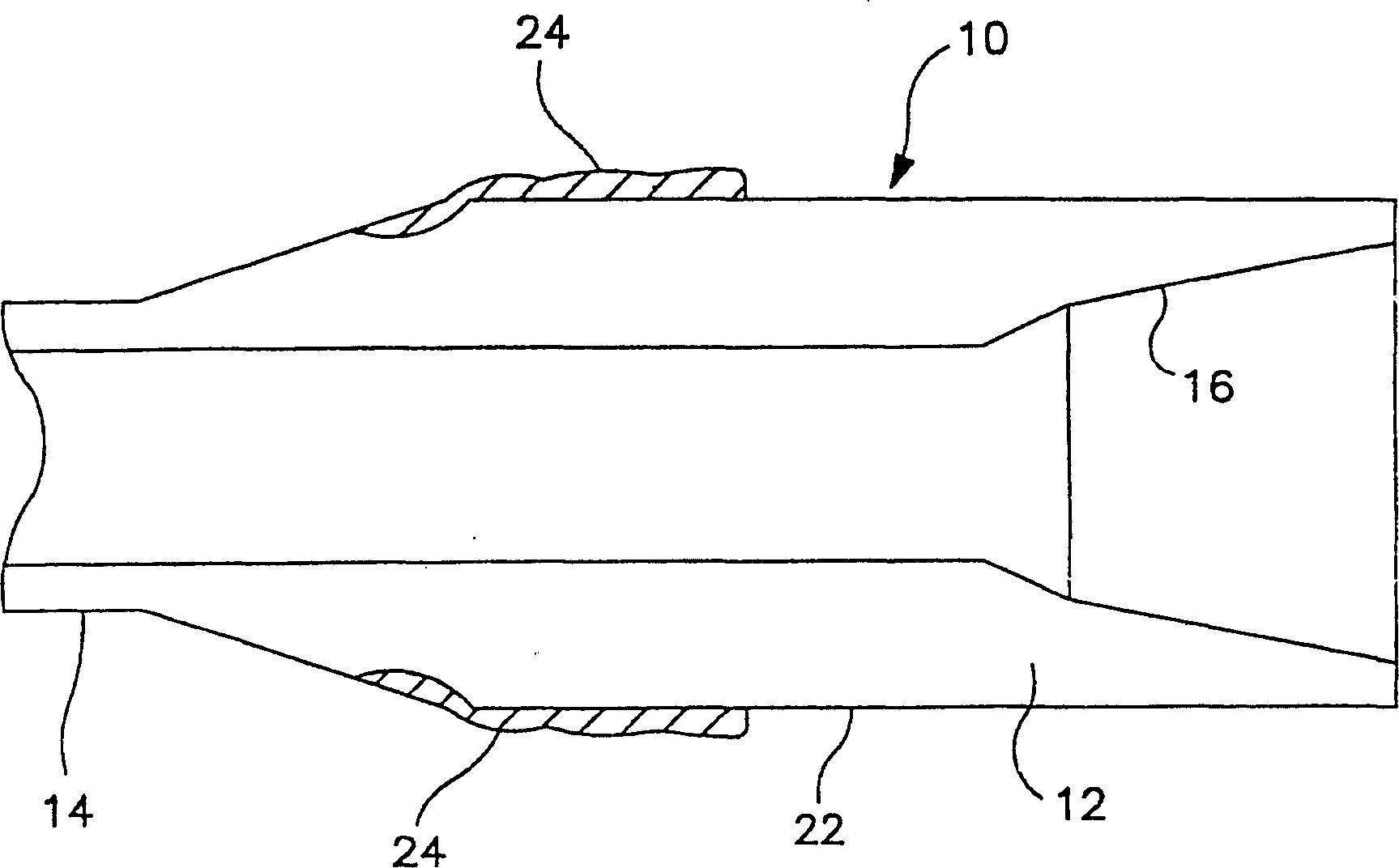

Casing wear band and method of attachment

InactiveUS7124825B2Increased frictional contactAugmenting frictional aspectDrilling rodsFluid removalCasing wearMechanical engineering

A crimpable wear band (105) tool has been invented for installation on casing (6), used in well bore drilling. A wear band (105) is provided having a cylindrical body which when coaxially placed over a pipe and substantially radially inwardly displaced at a plurality of points (i.e. crimped) about the circumference of a section of cylindrical body, attaches to the pipe to create a connection having structurally significant axial and torque load transfer capacity. When crimped according to the methods of the present invention, the load transfer capacity of the connection between the wear band (105) tool and the pipe (6) can be arranged to substantially prevent significant relative movement of the wear band tool on the pipe under loads that may be encountered when using one or more of the pipes as components of a tubular string used for drilling or running the casing in to complete a well bore.

Owner:NABORS DRILLING TECH USA INC

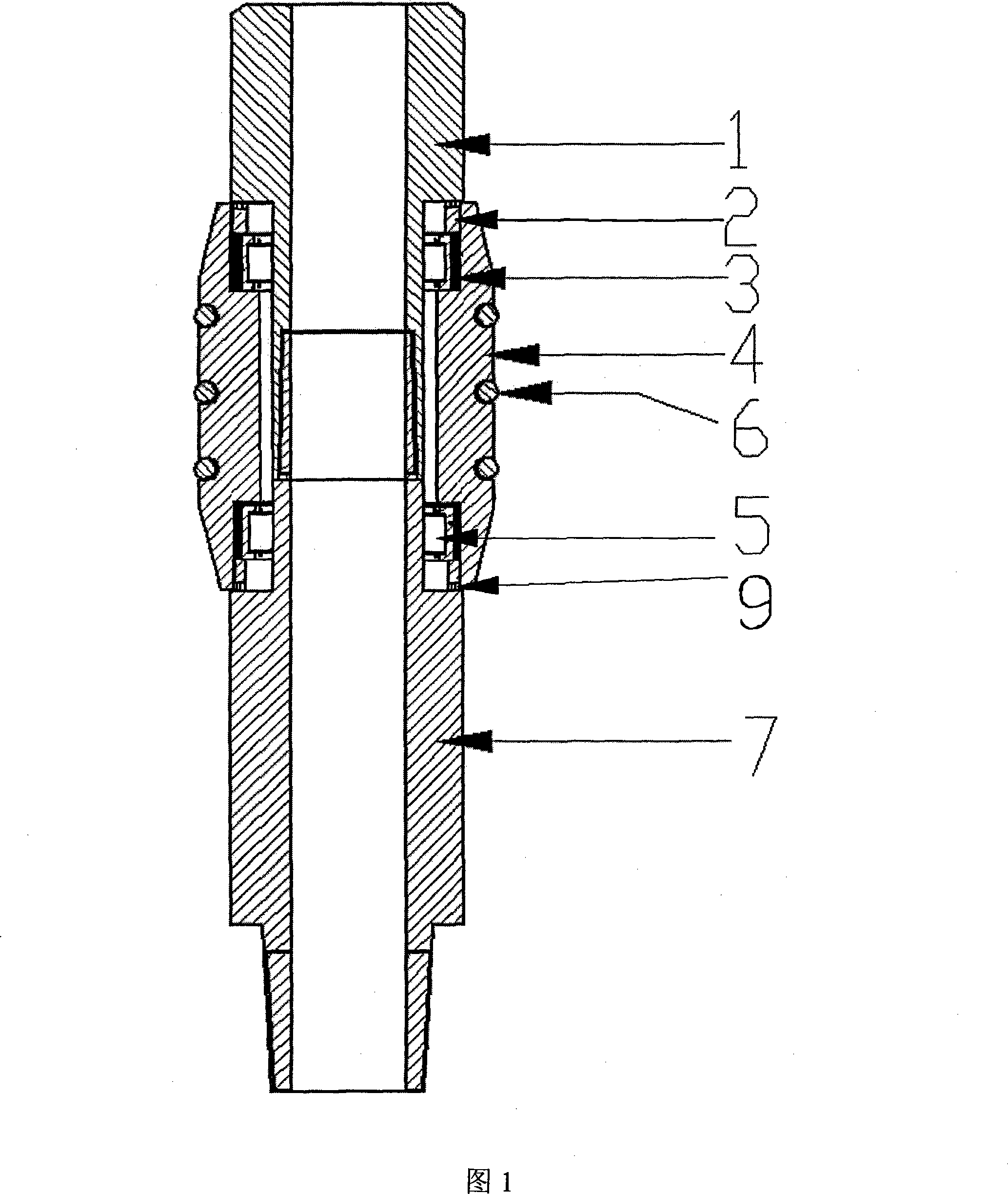

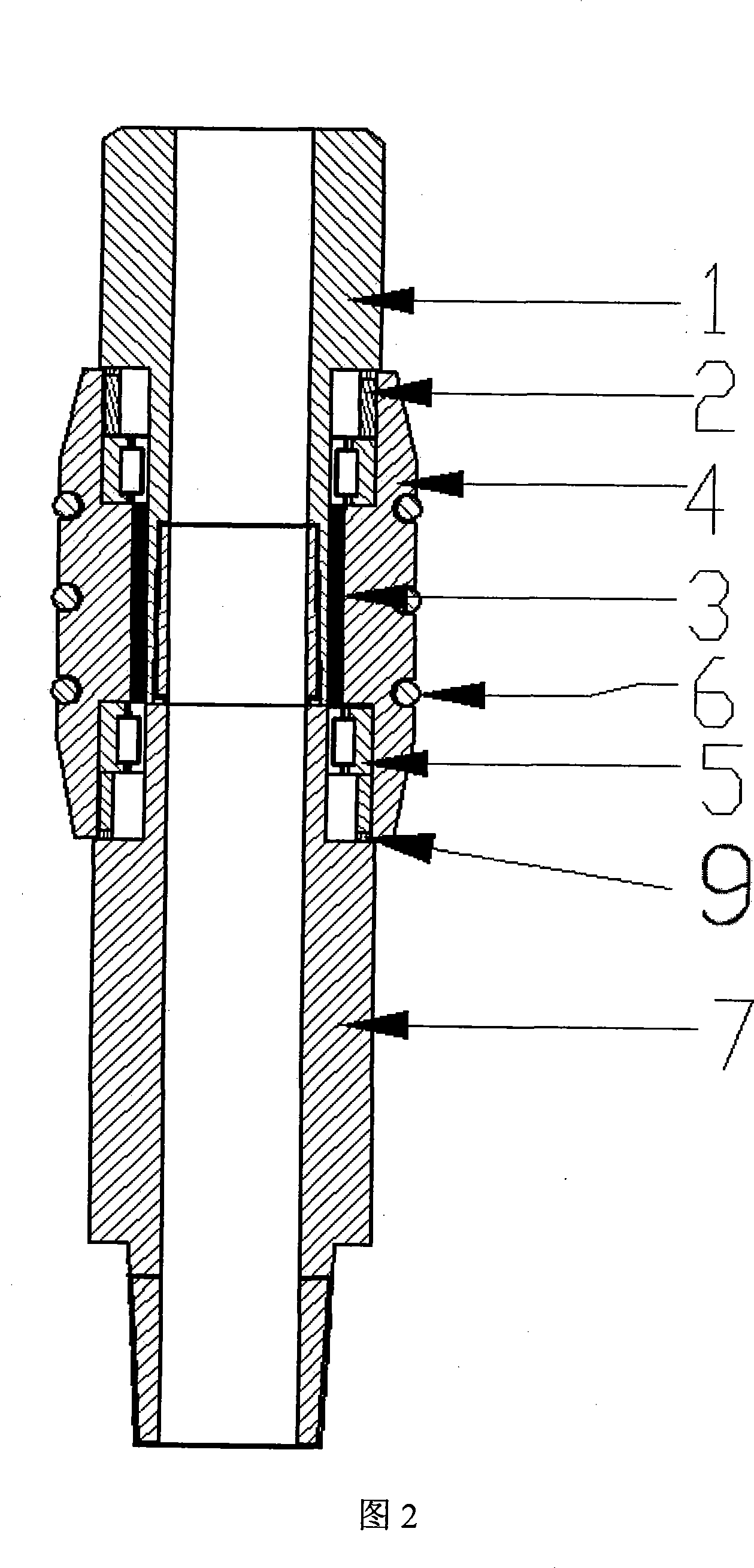

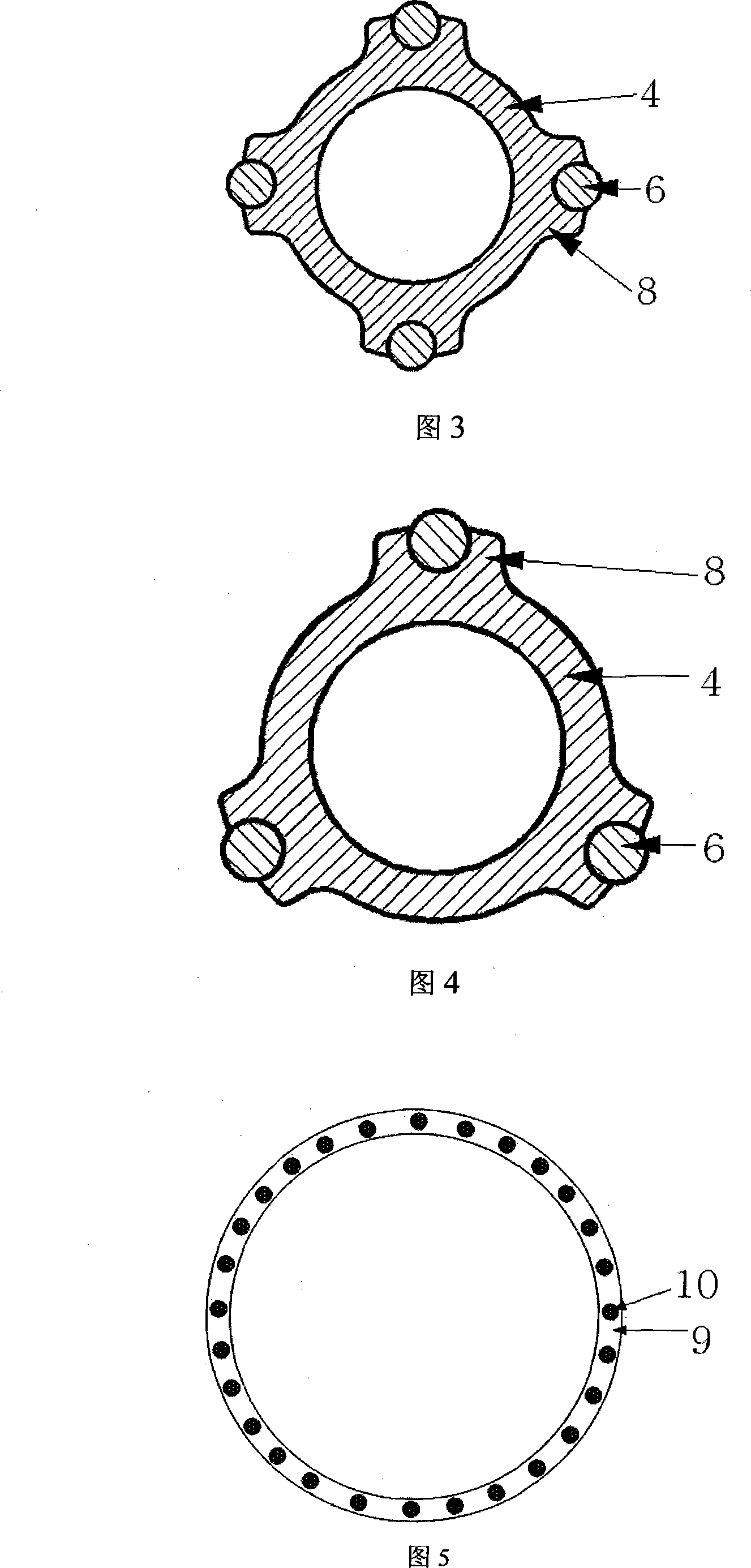

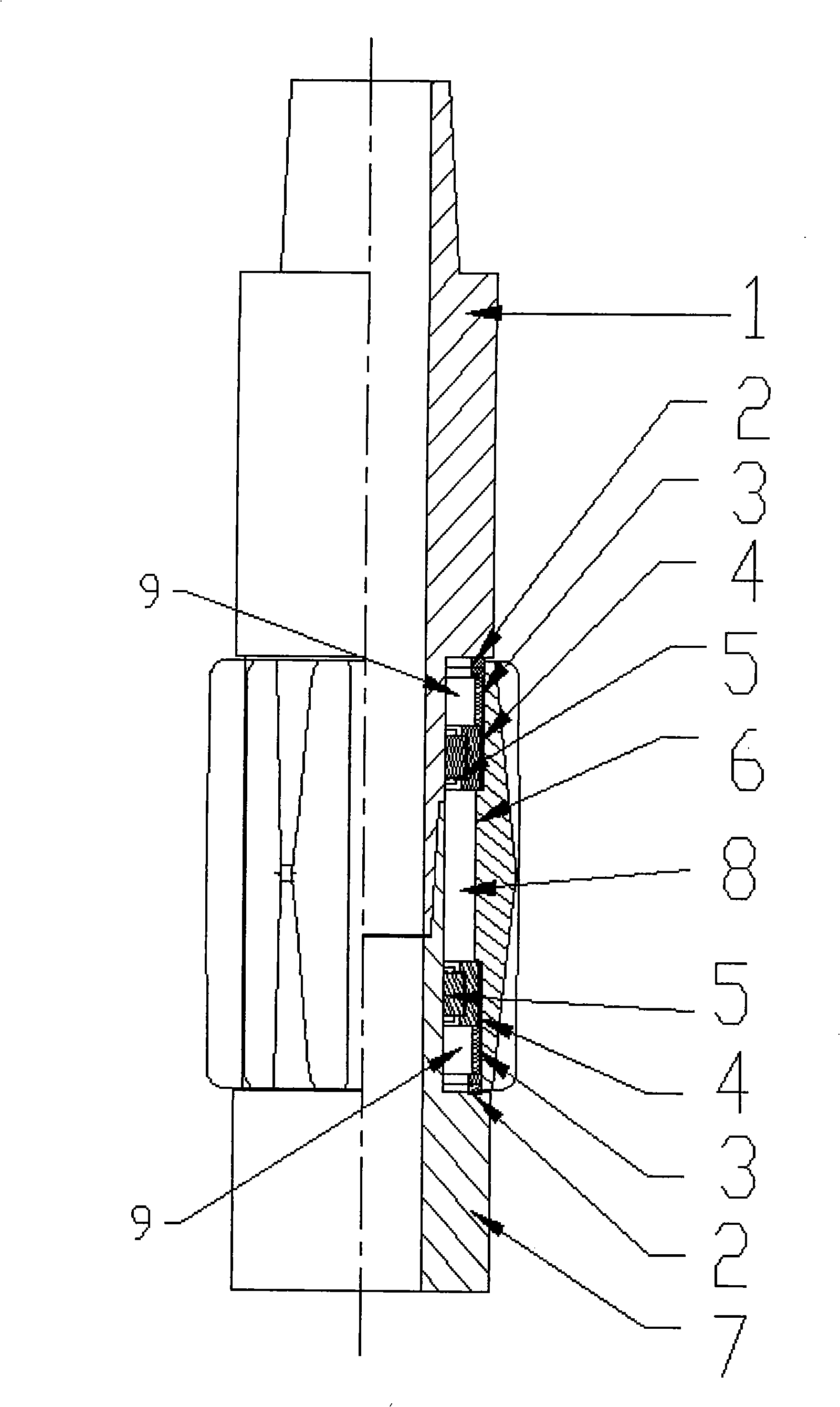

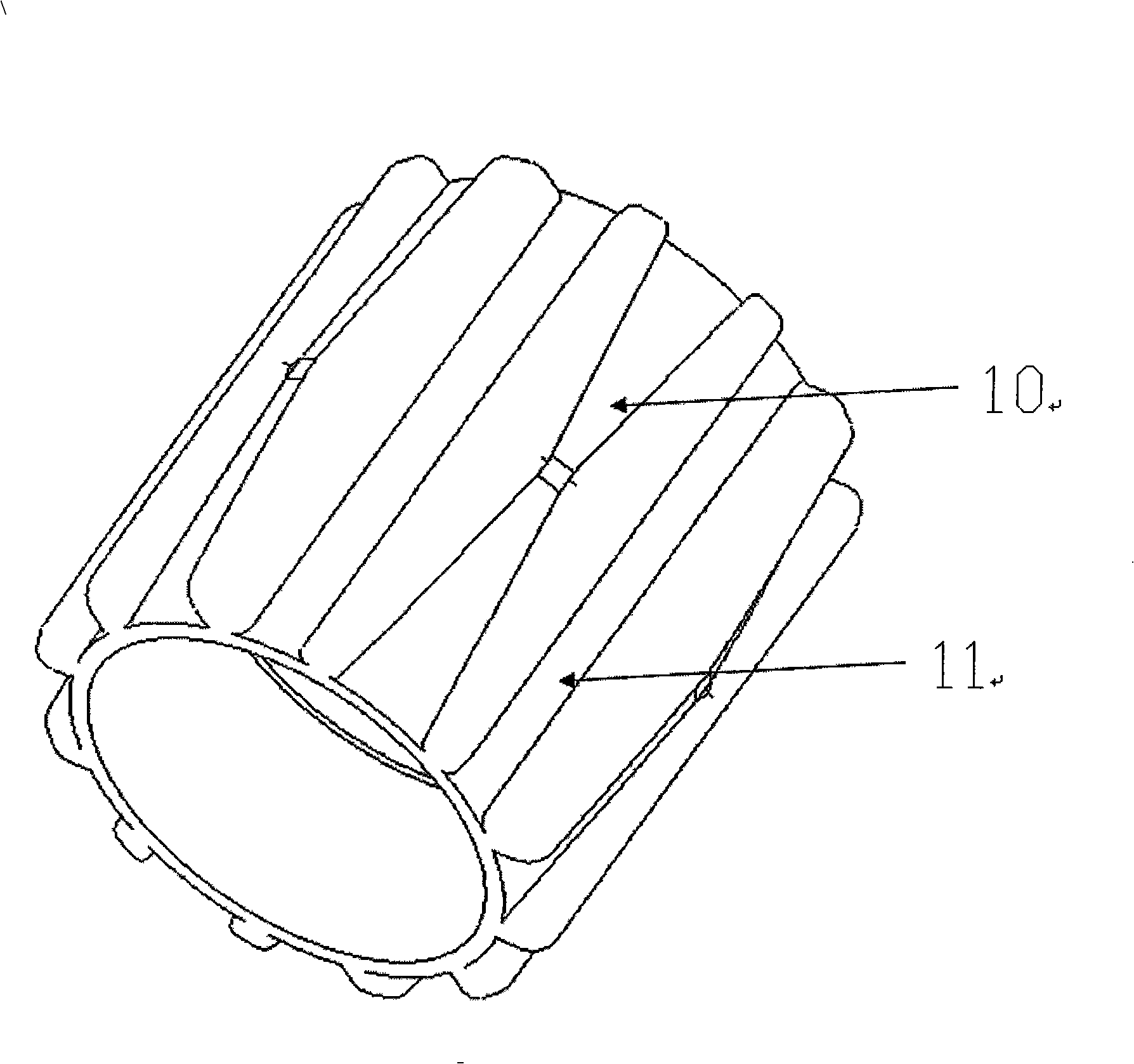

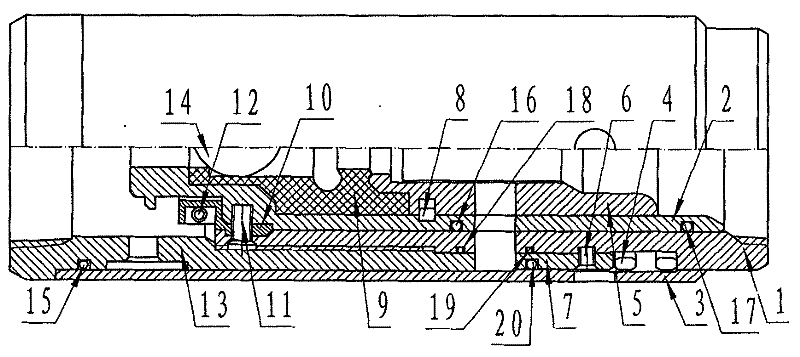

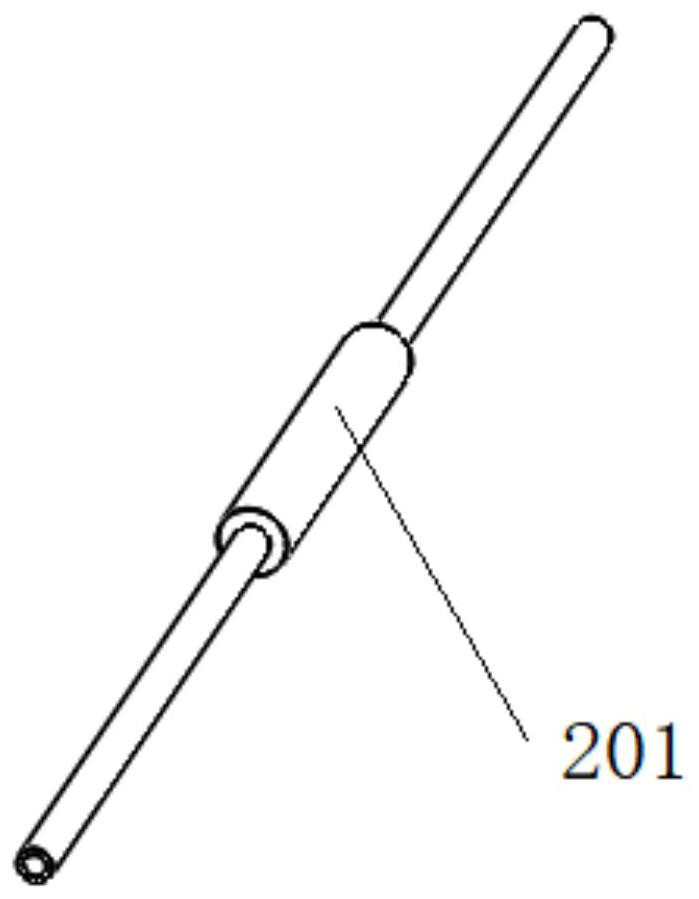

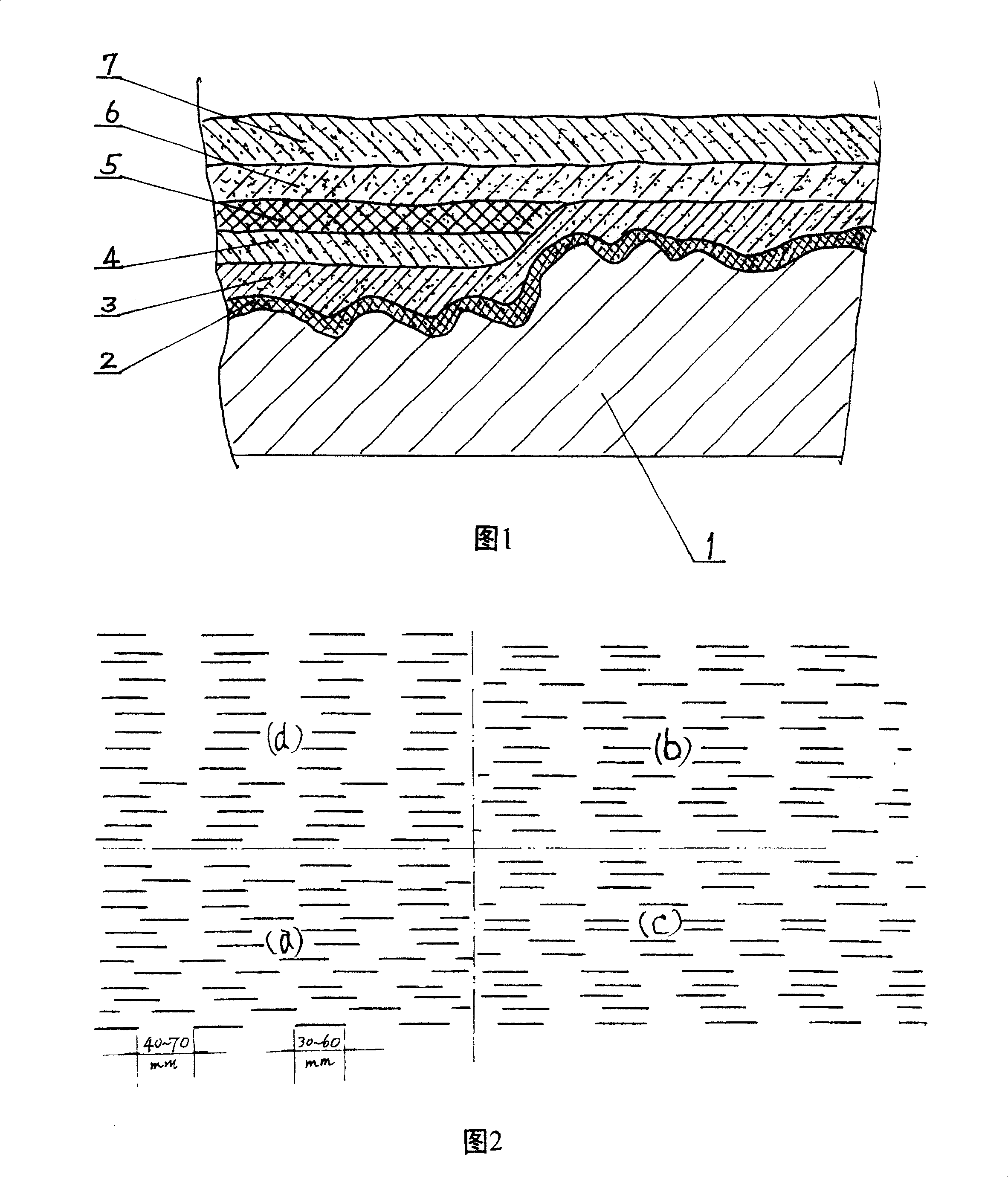

Reduction-resistant vibration-damping break-proof righting coupling for gas drilling

InactiveCN101220732AReduce wearReduced torque transfer lossesDrilling rodsDrilling casingsCasing wearRolling-element bearing

The invention provides an antidrag, vibration-damping, break-proof and strengthening coupling which is utilized in the oil-gas field which has a gas drilling which has strong vibration, high frictional resistance, erosion and is easy to be inoperative. The technical proposal is that: the upper and lower joints are coupled by threads and is positioned by a shaft shoulder; a radial rolling bearing is consist of an upper set and a lower set of cylindrical roller bearings without inner ring, wherein one set is arranged between the shell and the upper adapter, and the other set is arranged between the shell and the lower adapter and positioned by a sleeve; three posing belts are symmetrically distributed on the outer surface of the shell, and the two ends of the posing belt is plagiohedral and the posing belt is provided with a groove; an axial rolling bearing consists of three sets of drum-shaped rollers which are respectively arranged in the grooves of the posing belts on the outer surface of the shell and touch against the borehole wall or the sleeve; a shock-absorbing rubber sleeve is arranged between the upper and lower radial rolling bearings without inner ring and the shell and is positioned by a sleeve. This invention has good shock-absorbing performance, strong vibration-absorbing capacity and can relieve the abrasion of the drill stem / sleeve, reduce torque and increase drilling capacity; furthermore, the structure is simple and the cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

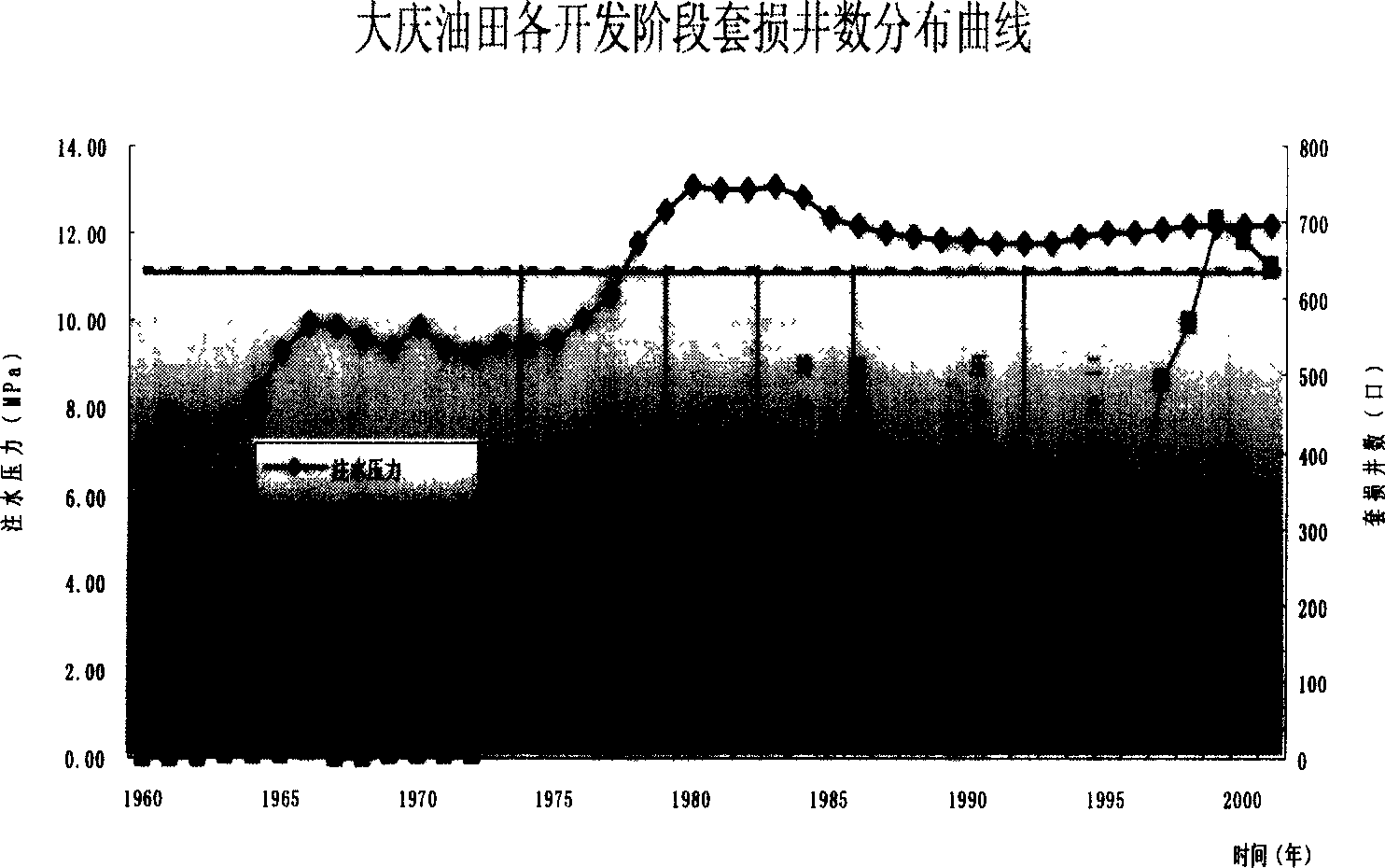

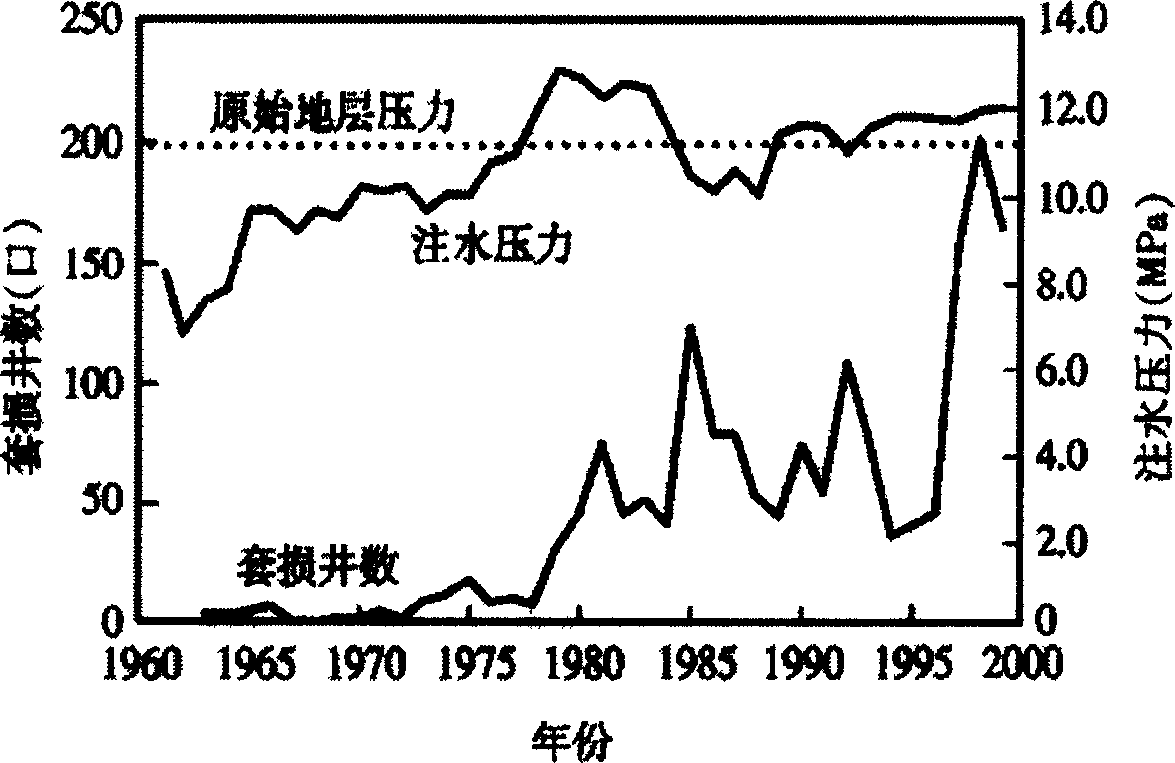

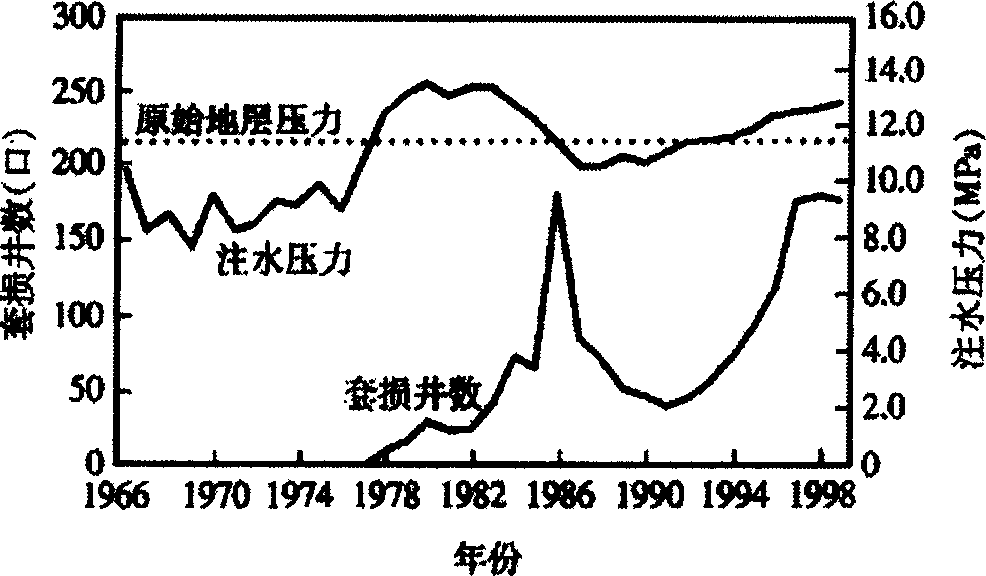

Method for preventing casing wear in oil field

The present invention discloses a method for preventing bushing damage; the method is mainly used for selecting and controlling reasonable water injection pressure; the water injection pressure is a water injection pressure which can obtain maximum liquid producing amount without threatening the safe stress of the bushing. And, the reasonable water injection pressure is lower than the bursting pressure of discharging hole top board under single layer exploitation condition; the reasonable water injection pressure is controlled adjacent to the original ground pressure under multiple layer combine exploitation condition; the cement job quality can be considered when determining the reasonable water injection pressure, the water injection pressure is original ground pressure at the area with good cement job quality and is lower the original ground pressure at the area with middle cement job quality. The technology scheme of the invention can effectively prevent the generation of bushing damage and has stronger practical instruct meaning and operability.

Owner:DAQING OILFIELD CO LTD

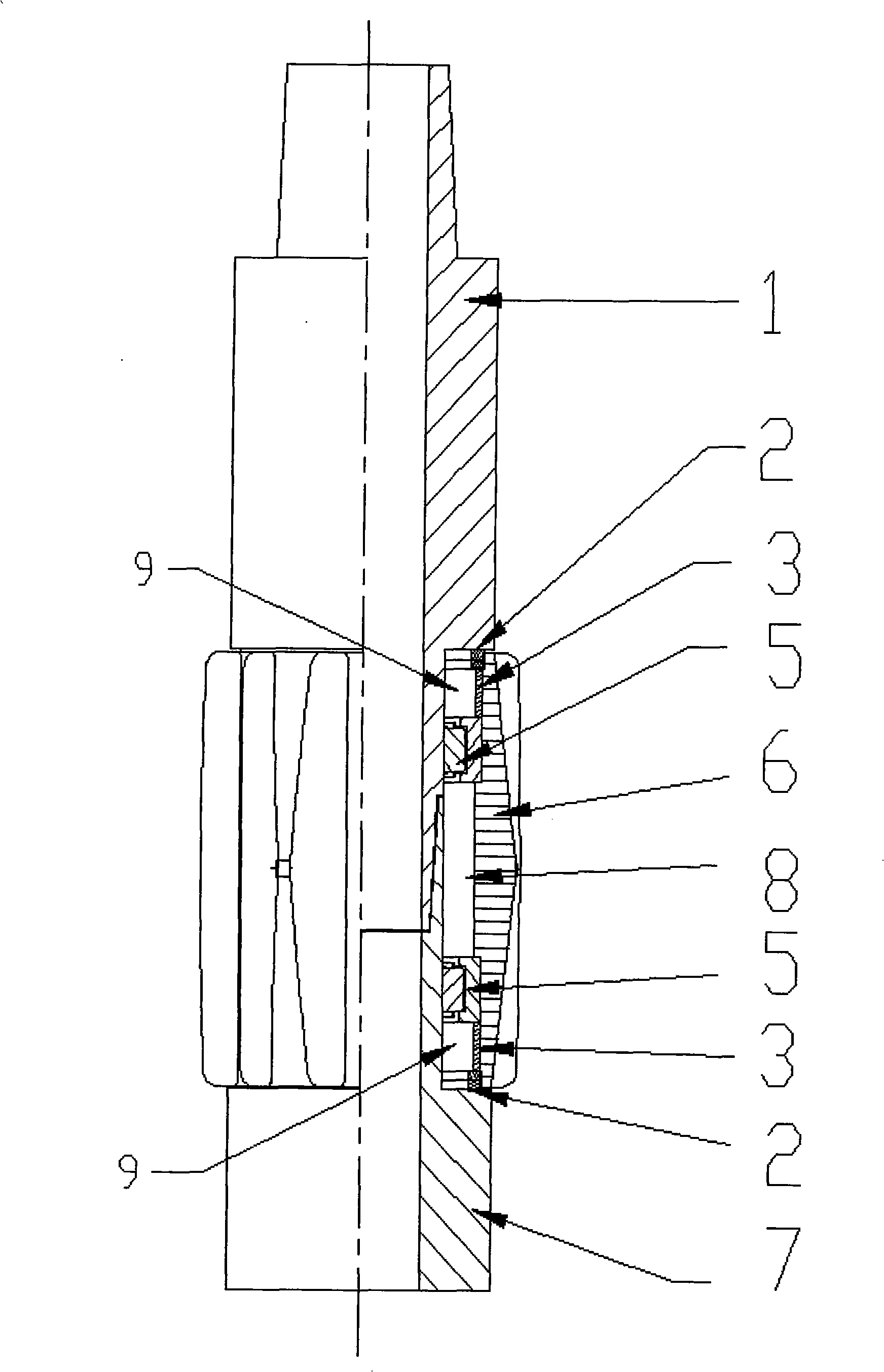

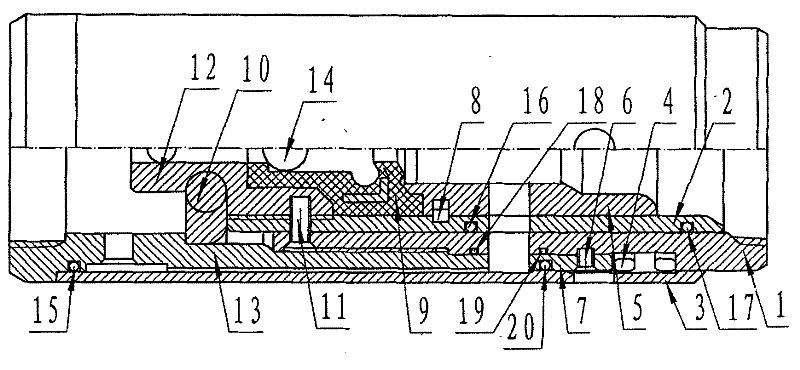

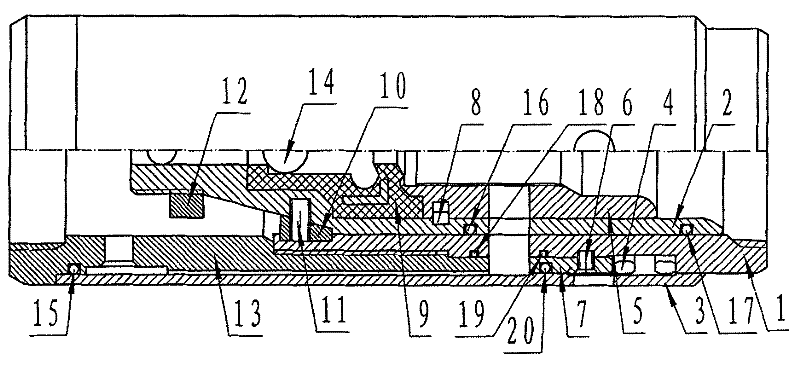

Superdeep well great displacement high performance boring tool protector for well

The invention relates to a high performance driller protector which is used for a mud medium ultra deep well and an ultra deep well extended reach well with strong vibration, high friction and high possibility of failure. The driller protector has the functions of lubricating strongly, centralizing, reducing friction and resistance, releasing the bushing camber wear, preventing a key slot from clamping and the driller and protecting a connector. The technical proposal is as follows: a coupling housing is arranged at a centralizer connector body, the outside surface is provided with a medium flow passage and a tapered pressure groove which are uniformly distributed on the coupling housing in a spaced way; the inner part is provided with a pair of rolling bearings directly interference arranged on the connector body; the rolling bearings and the sleeve as well as the self-lubricating obturating ring set are respectively arranged on the inner surface of the two ends of the coupling housing symmetrically; and a middle filling cavity of the two rolling bearings and a top filling cavity between the bearings and the connector body are filled with graphite. The driller protector has strong ability to decrease vibration and to release the abrasion of the drill pipe and the bushing, reduces the torque, increases the drilling ability, has a simple structure and low cost, and is used for drilling in an oil-gas field.

Owner:SOUTHWEST PETROLEUM UNIV

Circulating drilling-free blind plate cementing device

The invention relates to a circulating drilling-free blind plate cementing device for semi-stroke cementation and plug-free cementation of a horizontal well for oil drilling. In particular, the circulating drilling-free blind plate cementing device comprises a diverting short joint, a circulating short joint and a sealing rubber ring and is characterized in that the circulating short joint is arranged in the diverting short joint and is fixedly connected with the diverting short joint through a fixing bracket and a fixing shear pin; a seat sealing rubber cylinder is arranged in the circulating short joint and is fixedly connected with a fishing short joint; a seat sealing flange is arranged outside the seat sealing rubber cylinder; and a sealing protective cover is arranged outside the diverting short joint, a closing spring and a seat sealing slide sleeve are arranged in the sealing protective cover, and the lower end of the diverting short joint is linked with a casing packer hoop through a threaded buckle and is sealed by the sealing rubber ring. The casing wear, window opening and borehole rejection caused by drilling blockage during cementation can be avoided.

Owner:程显达

Hardbanding alloy

ActiveUS9540711B2Prolong lifeArc welding apparatusWelding/cutting media/materialsCasing wearCrack free

The present disclosure relates to an alloy, for hardbanding and / or hard overlay applications, which is abrasion resistant to the order of siliceous earth particles and weldable in crack free state on industrial products. The alloy is a carbon chrome based alloy comprising titanium and vanadium carbides and thus has an extremely low coefficient of friction, high abrasion resistance as welded without working. In tool joints and stabilizers, the alloy achieves an optimum balance between tool joint and stabilizer wear resistance and induced casing wear. The alloy is also self-shielded and therefore does not require external shielding gas.

Owner:FIFIELD ROBIN WILLIAM SINCLAIR

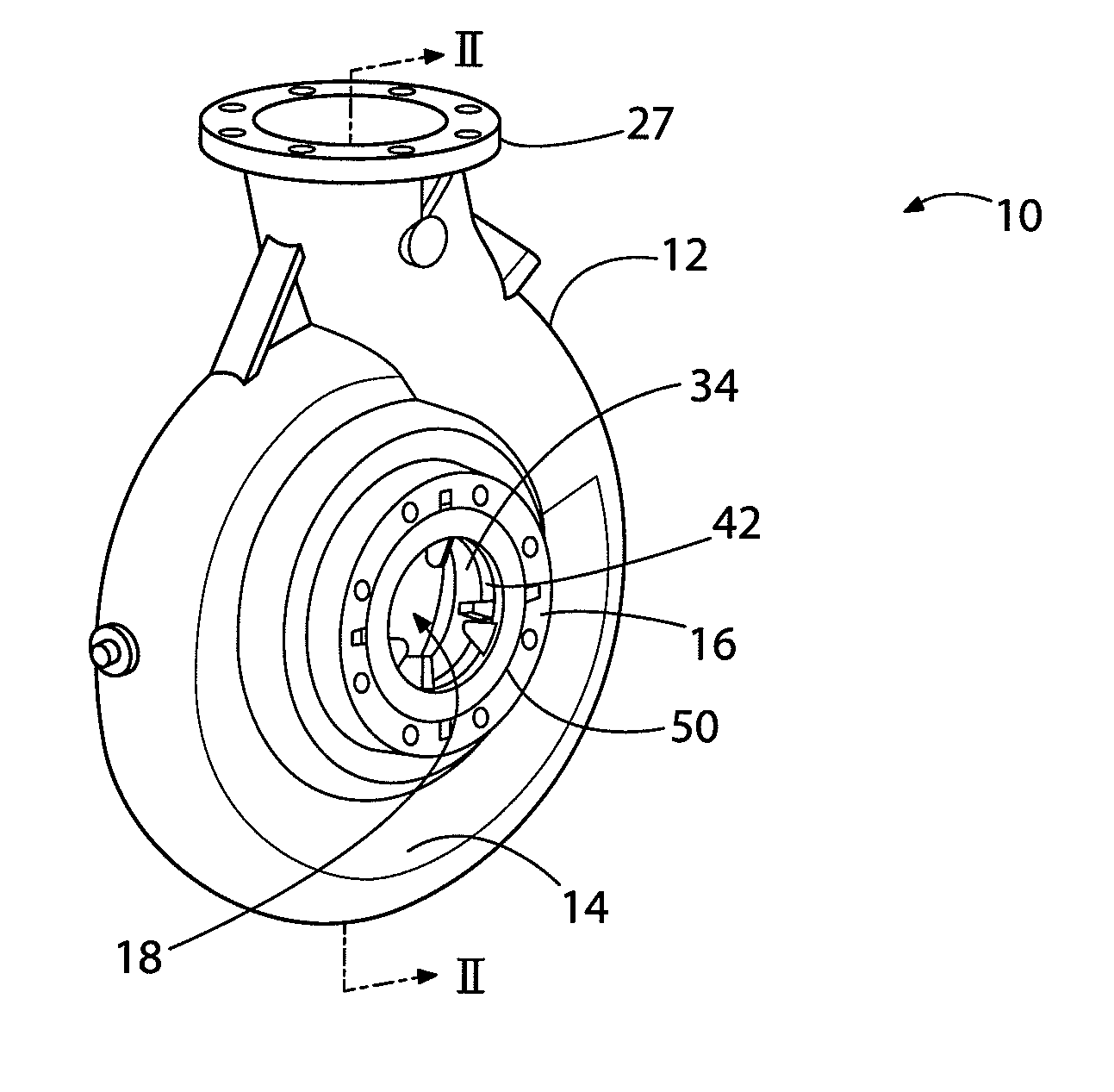

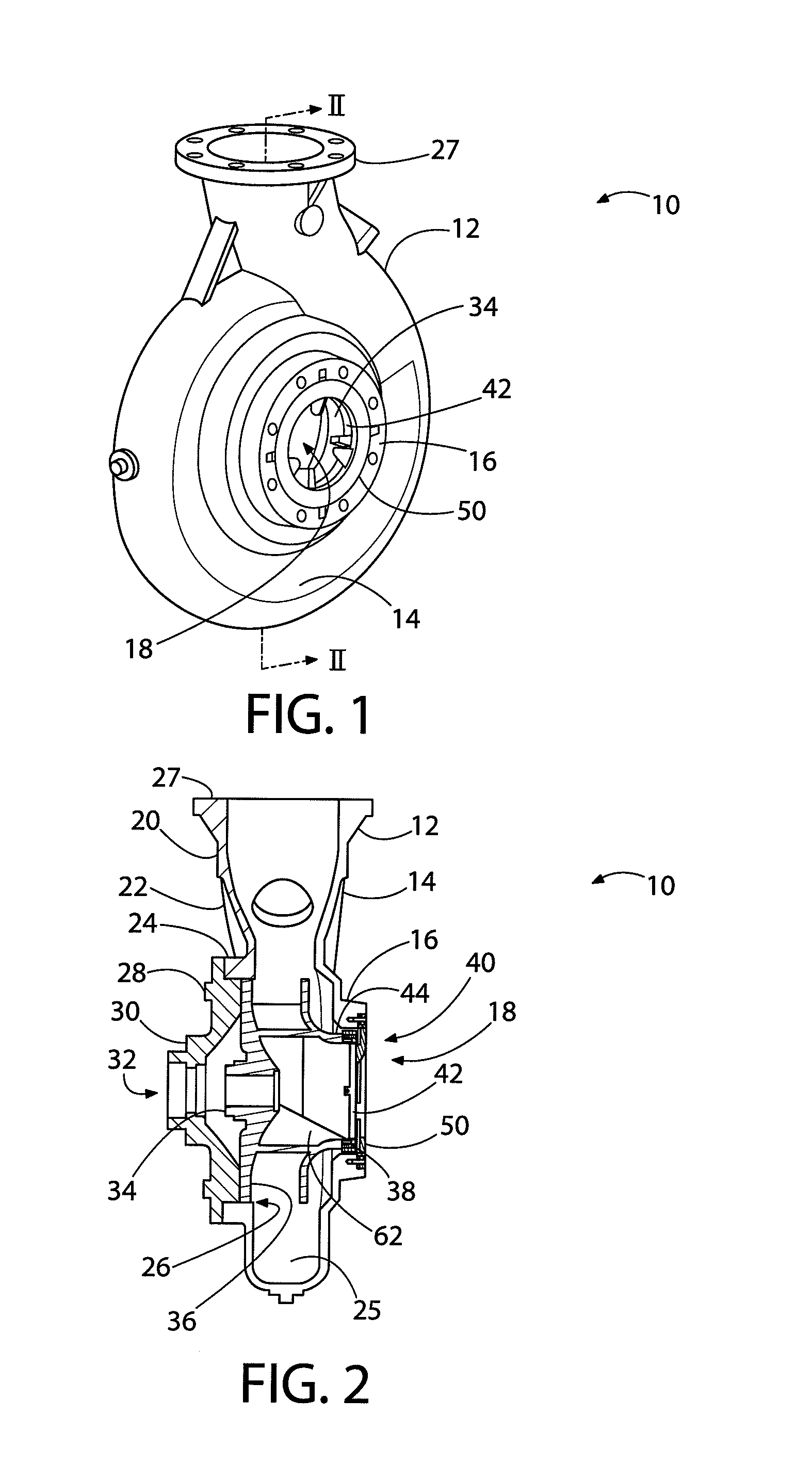

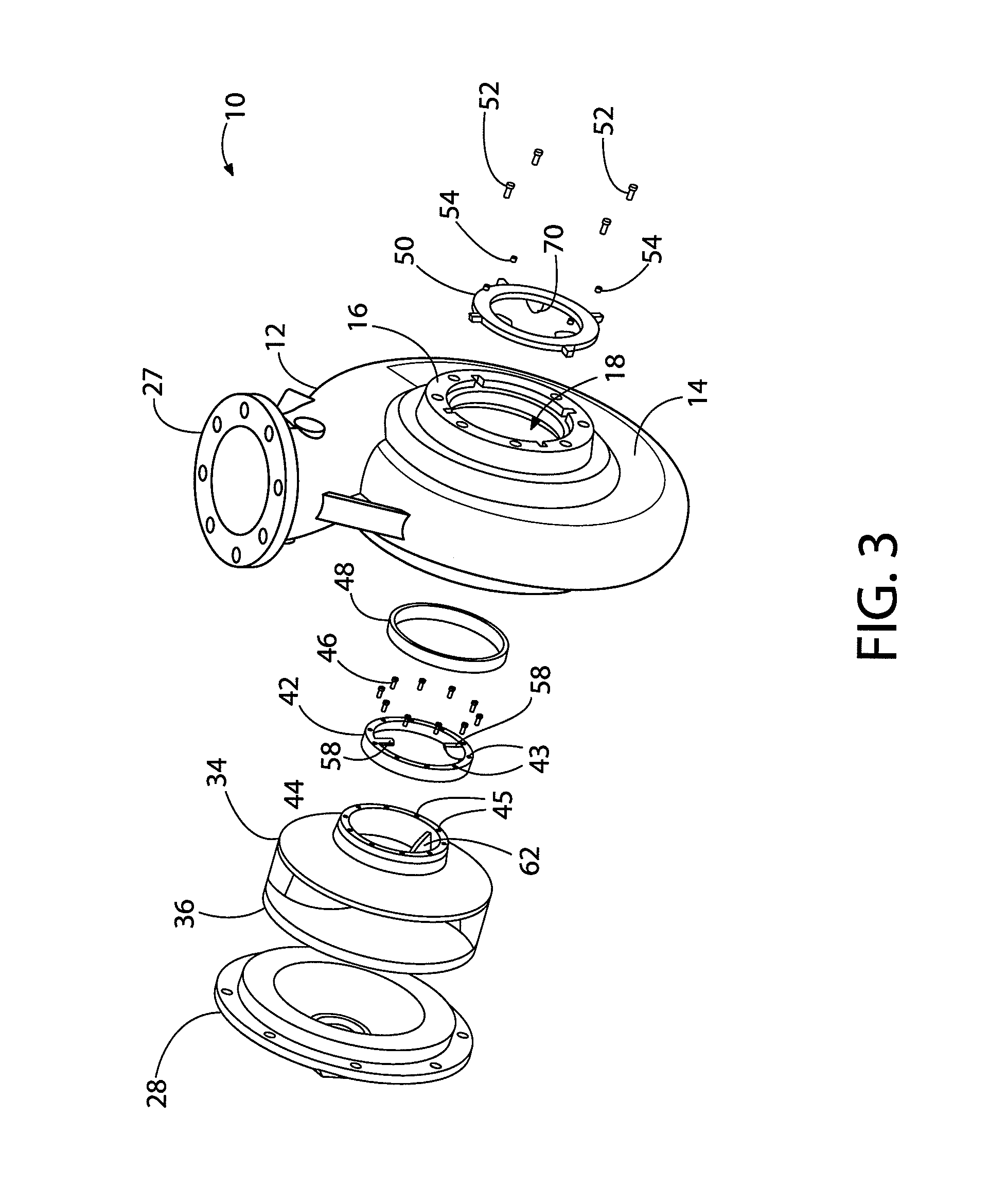

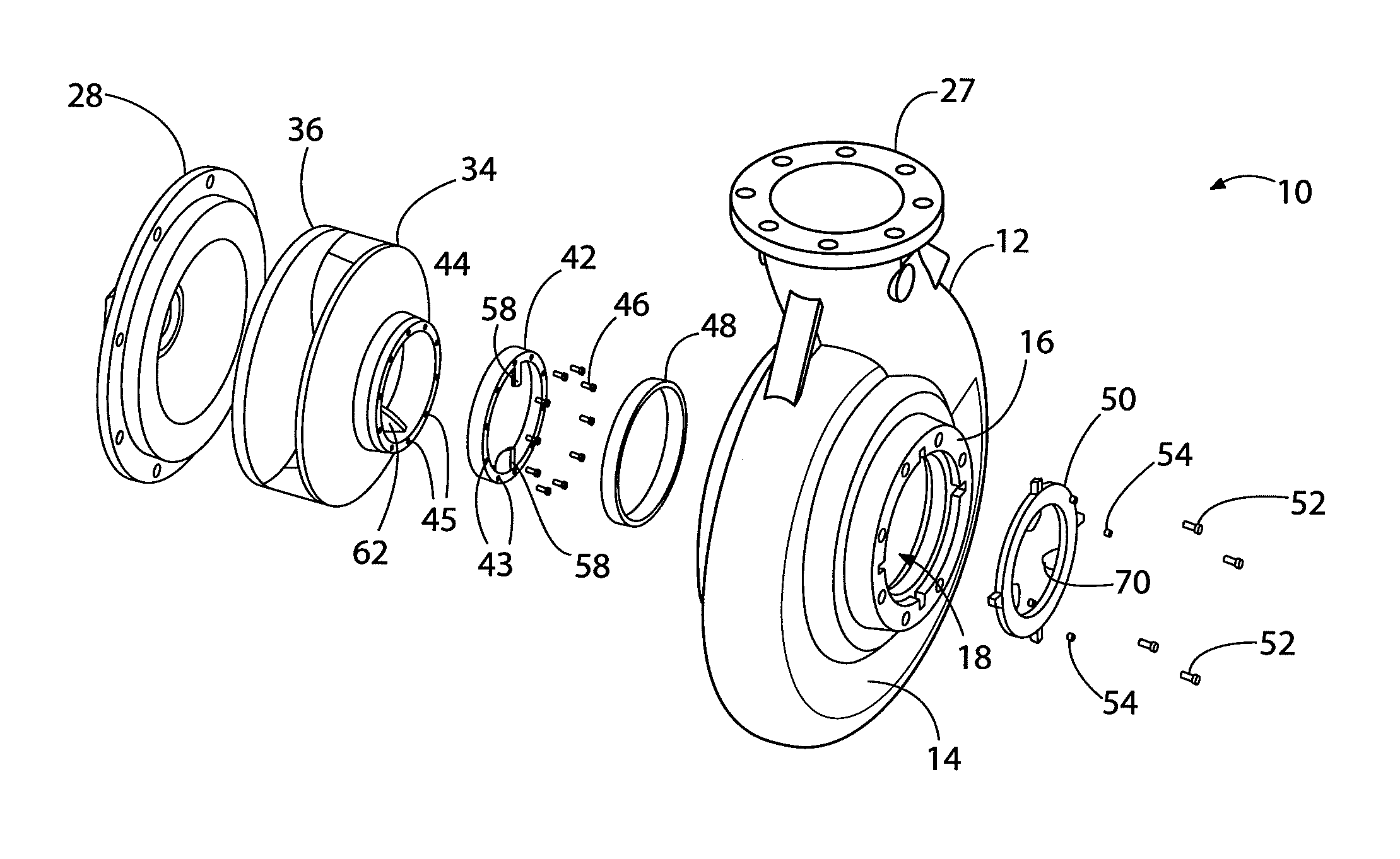

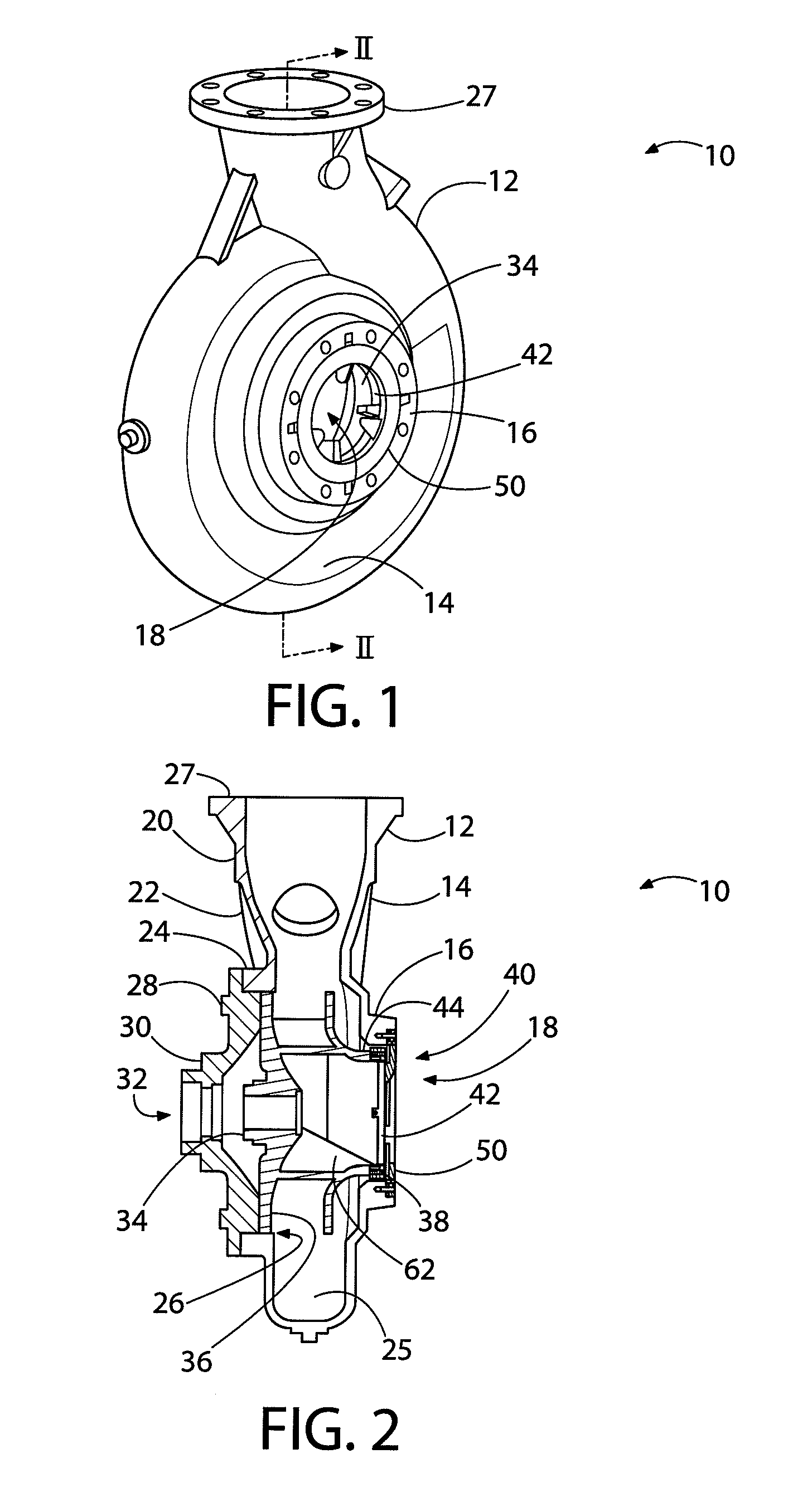

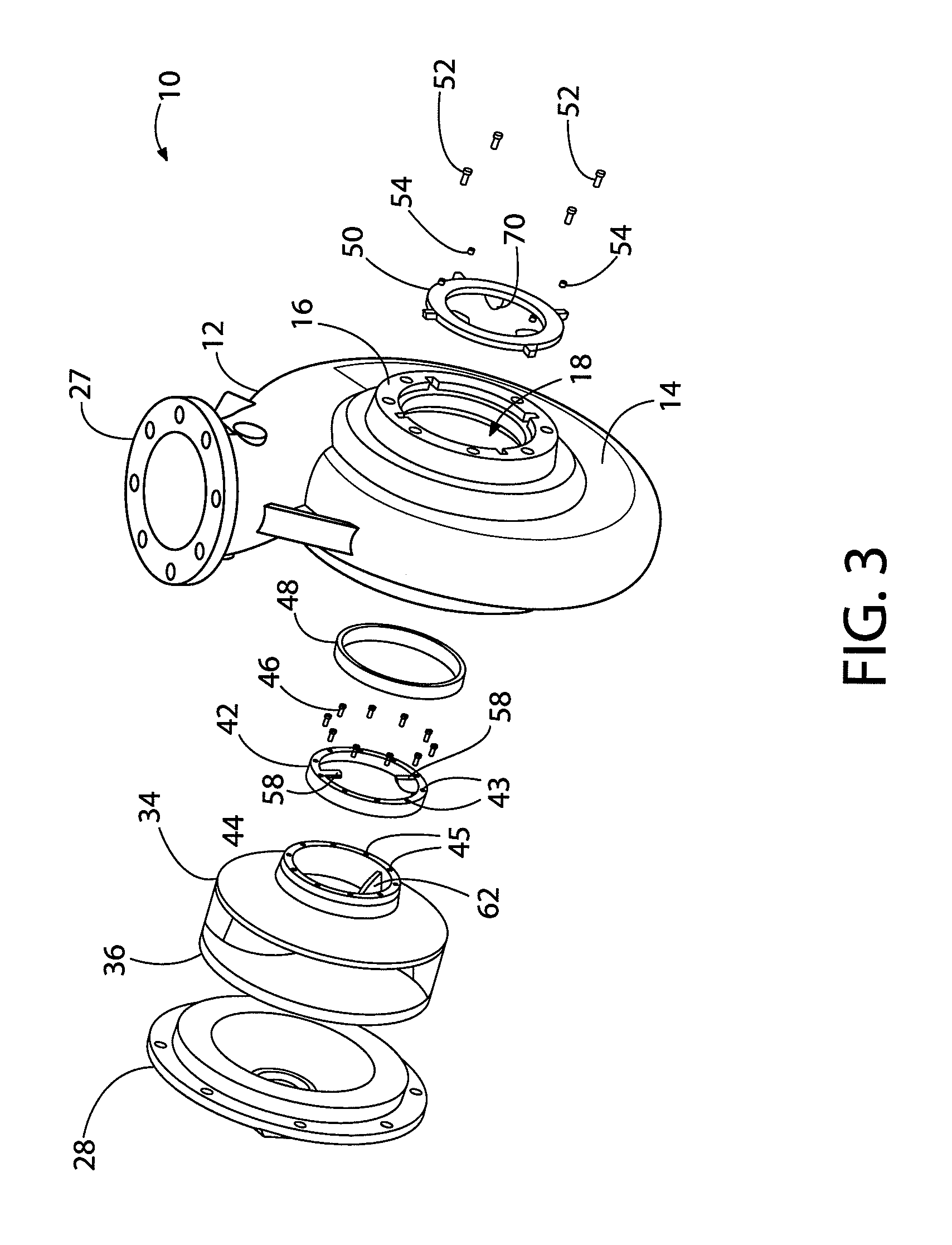

Cutter apparatus for centrifugal pump

A centrifugal pump with a cutter mechanism consisting of a toothed cutter rotor, integral with the impeller wear ring, affixed to the impeller and a toothed cutter stator affixed to the casing, separately from the casing wear ring. A cutter mechanism consisting of a stator and rotor set such that they may be installed on the centrifugal pump impeller and casing as original equipment or as a retrofit. A cutter mechanism such that when installed in a centrifugal pump they prevent stringy materials, garbage and other agglomerated soft wastewater solids from partially restricting or totally blocking the inlet to the pump impeller. A cutter mechanism such that when it prevents solids from restricting or blocking the impeller inlet, it does so without significant decrease of flow throughput or significant increase in absorbed hydraulic horsepower.

Owner:CORNELL PUMP CO LLC

Hardbanding alloy

ActiveUS20120196149A1Prolong lifeArc welding apparatusWelding/cutting media/materialsCasing wearCrack free

The present disclosure relates to an alloy, for hardbanding and / or hard overlay applications, which is abrasion resistant to the order of siliceous earth particles and weldable in crack free state on industrial products. The alloy is a carbon chrome based alloy comprising titanium and vanadium carbides and thus has an extremely low coefficient of friction, high abrasion resistance as welded without working. In tool joints and stabilizers, the alloy achieves an optimum balance between tool joint and stabilizer wear resistance and induced casing wear. The alloy is also self-shielded and therefore does not require external shielding gas.

Owner:FIFIELD ROBIN WILLIAM SINCLAIR

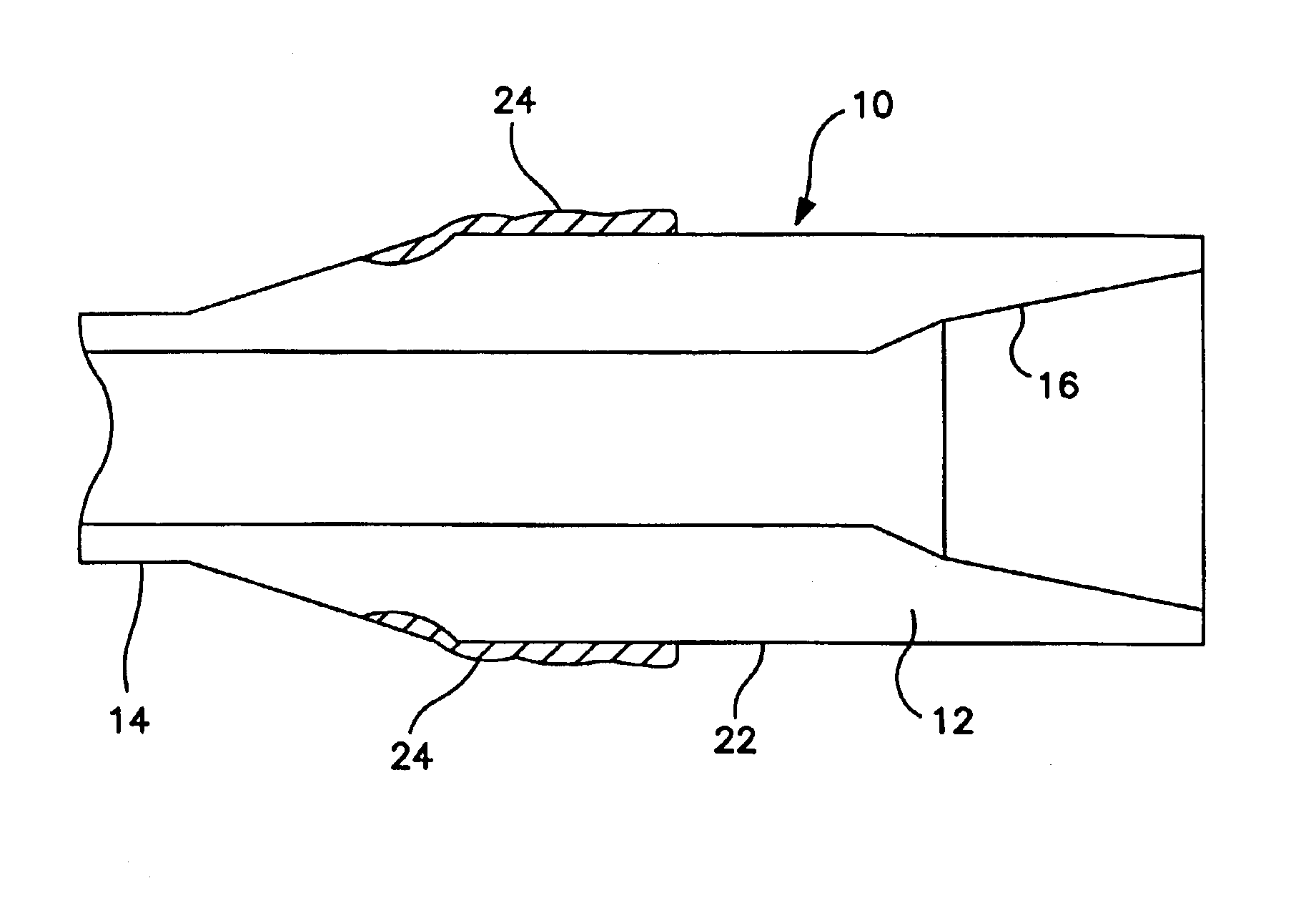

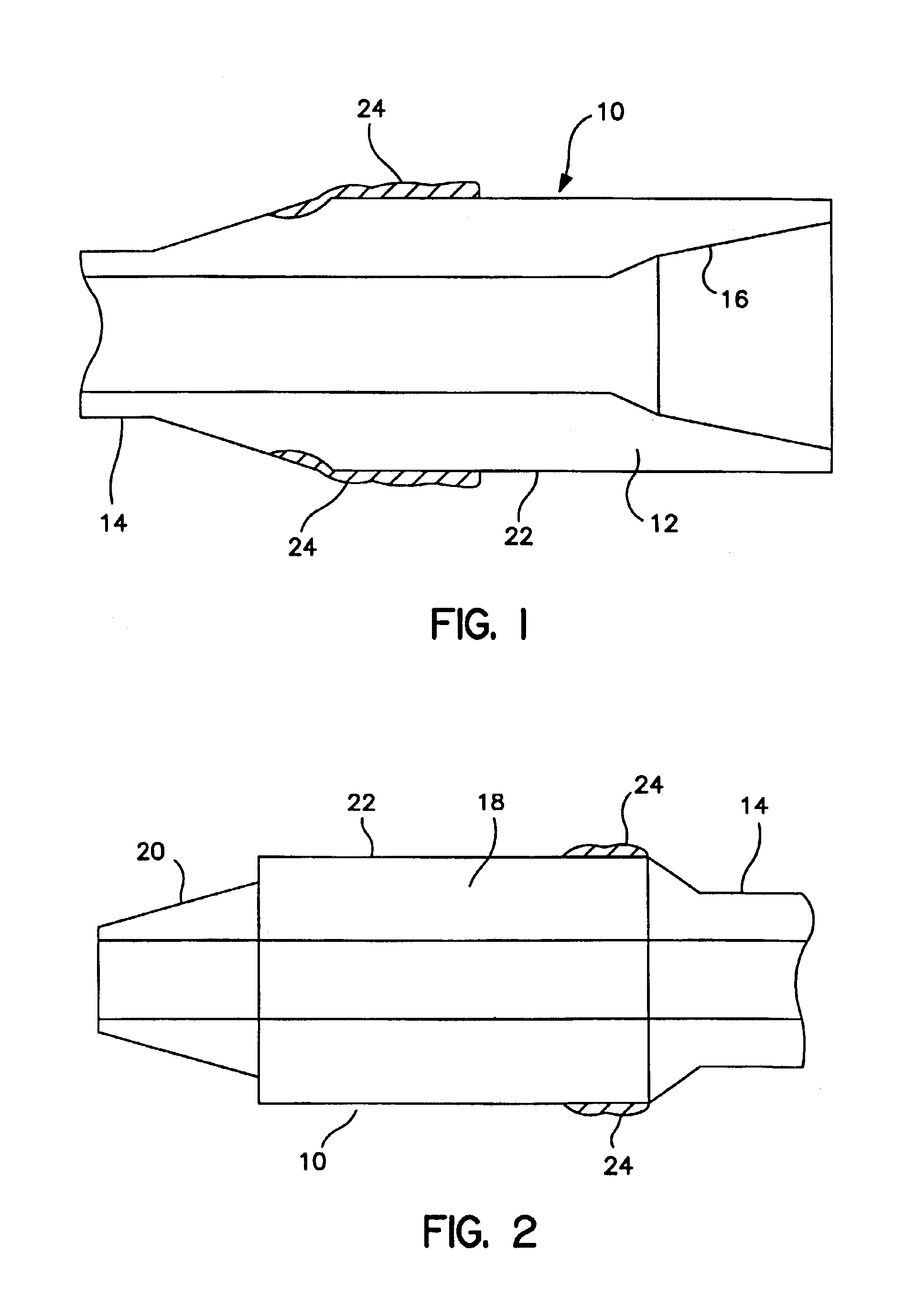

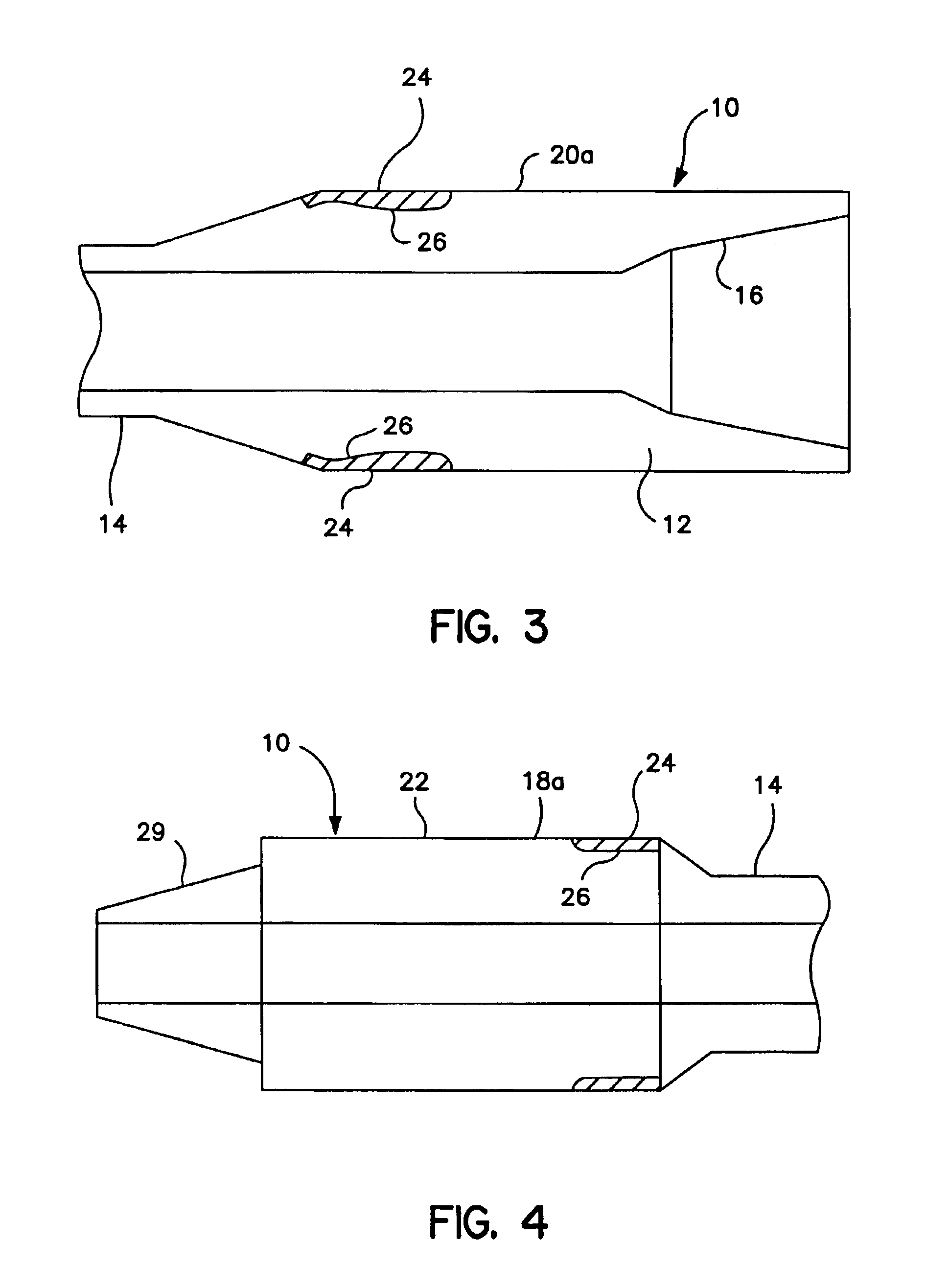

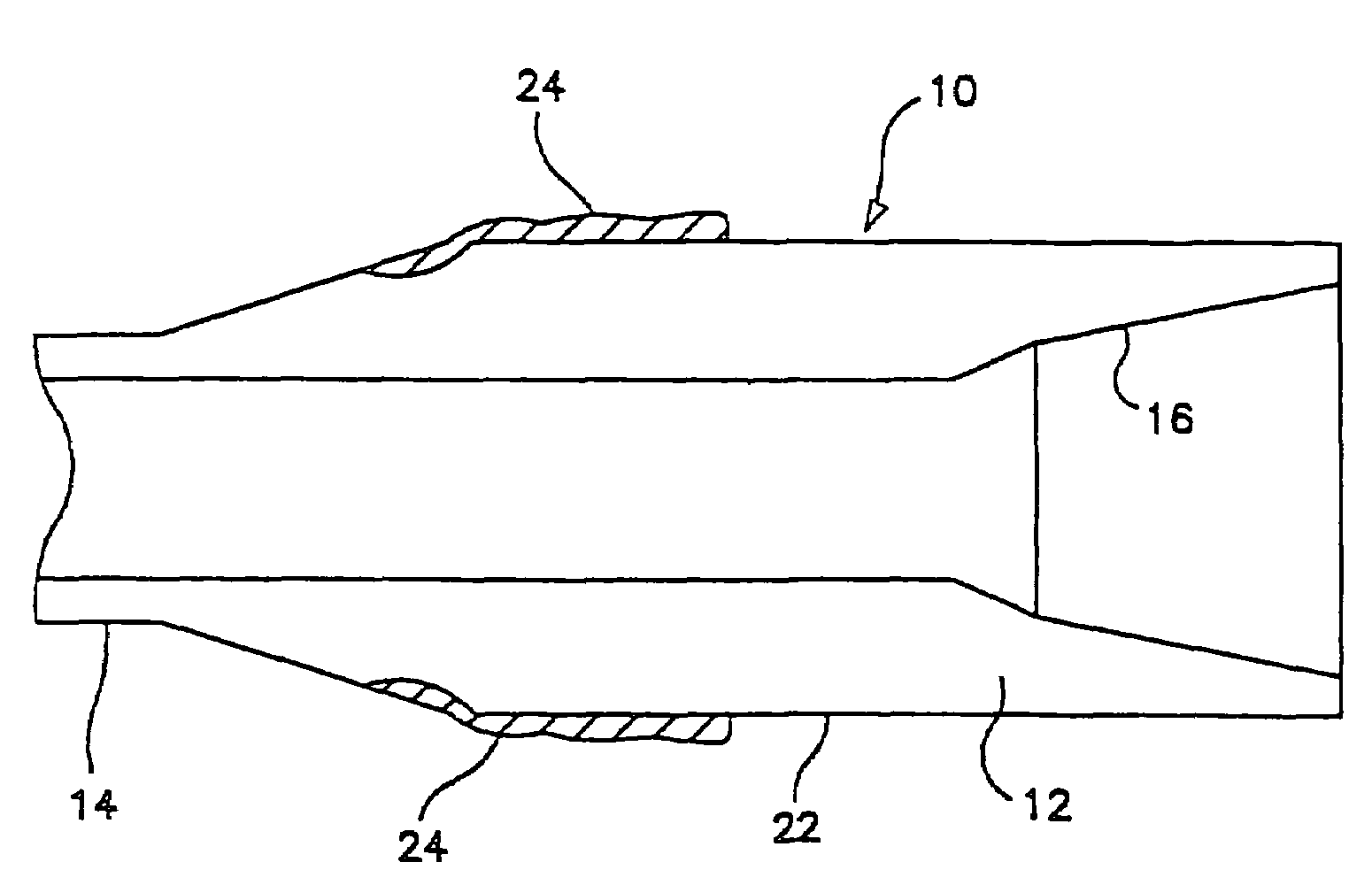

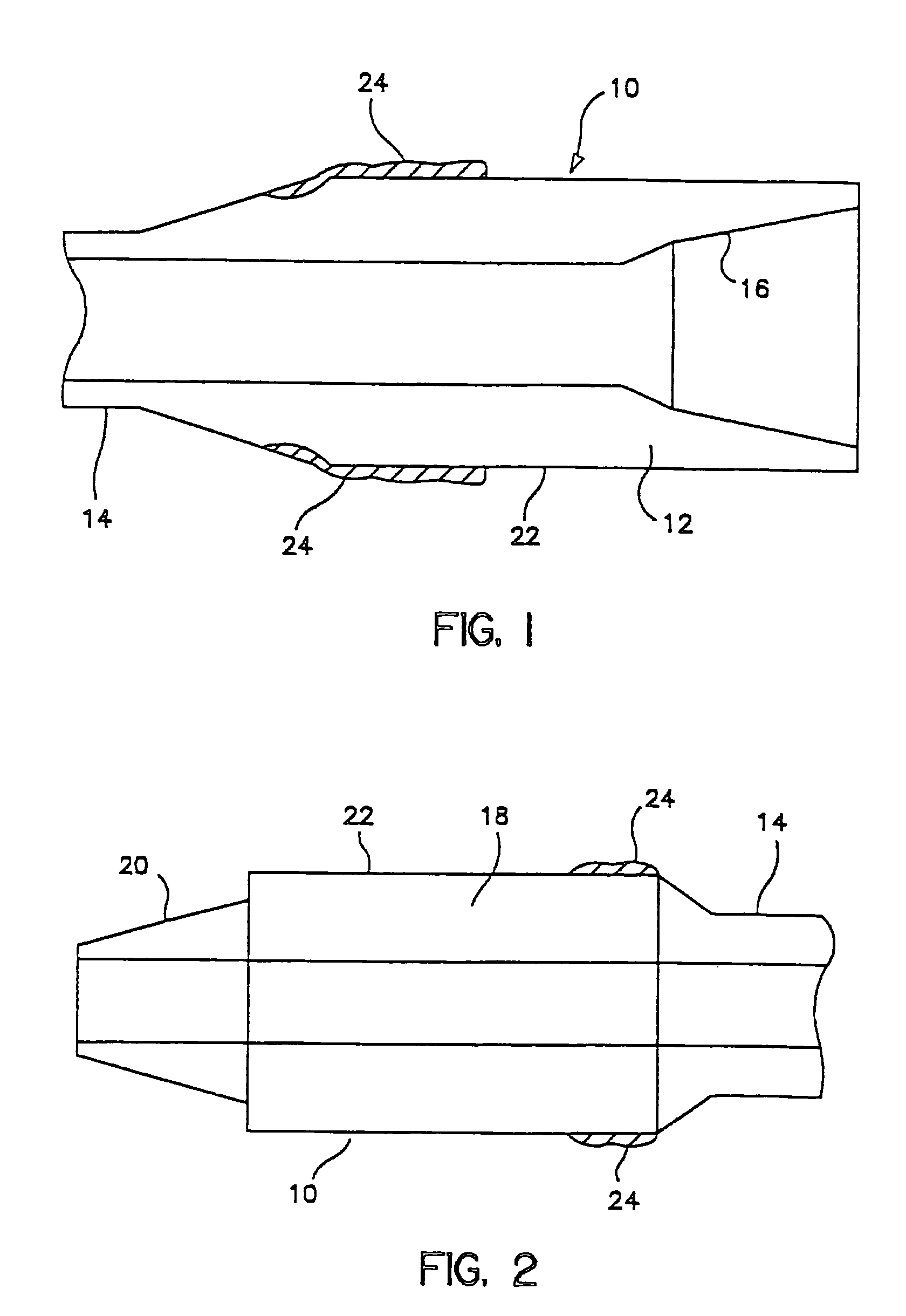

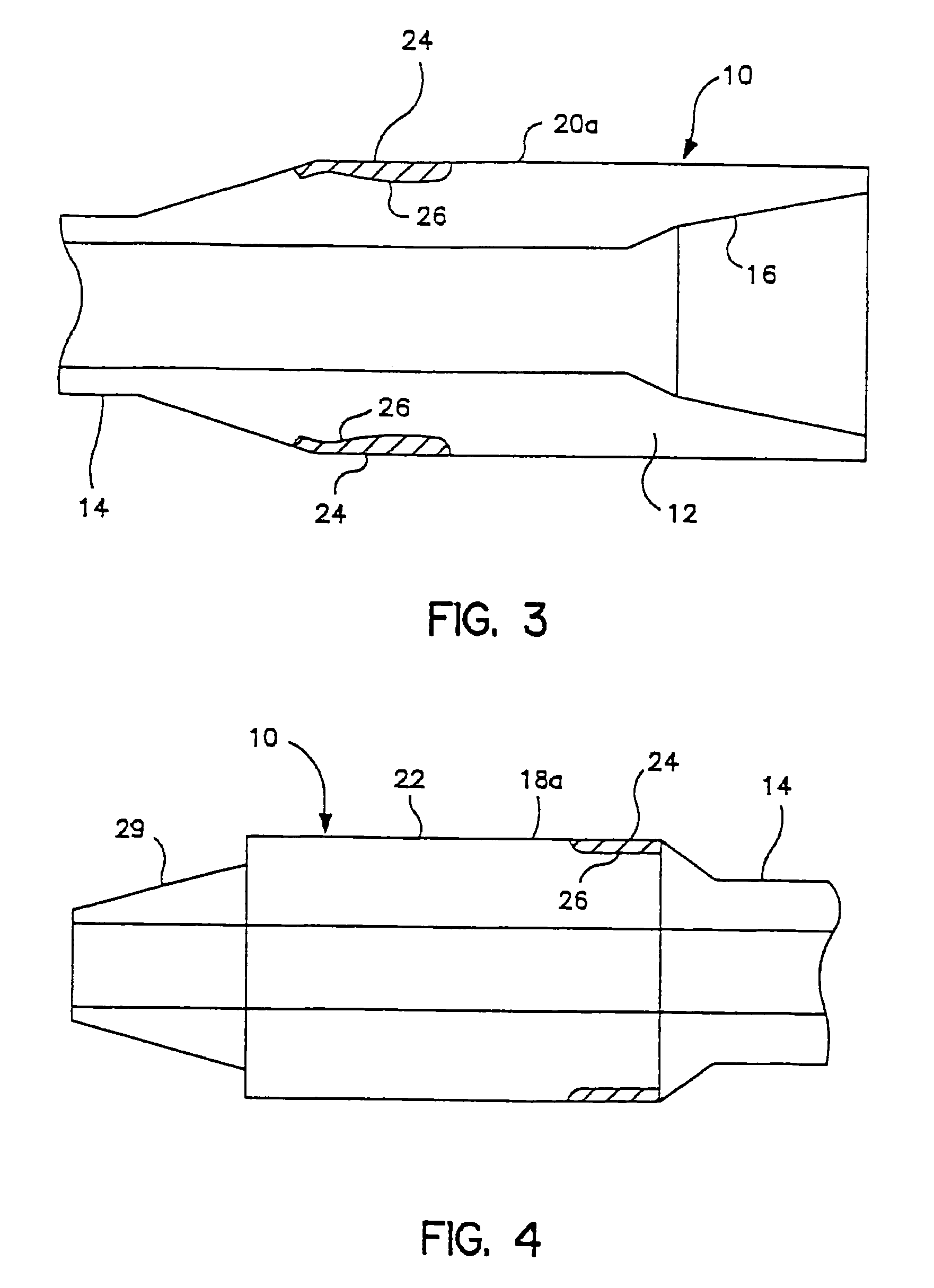

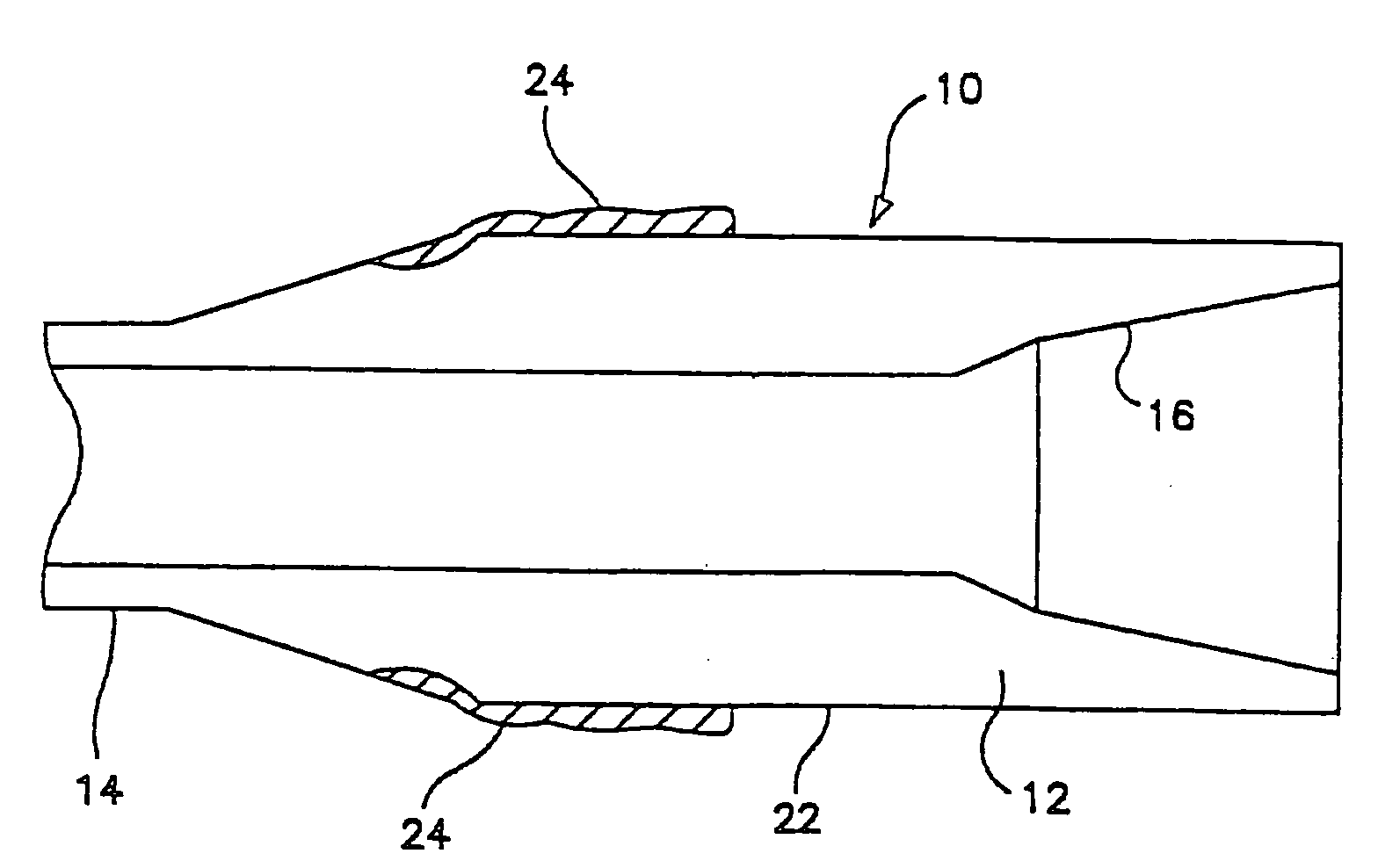

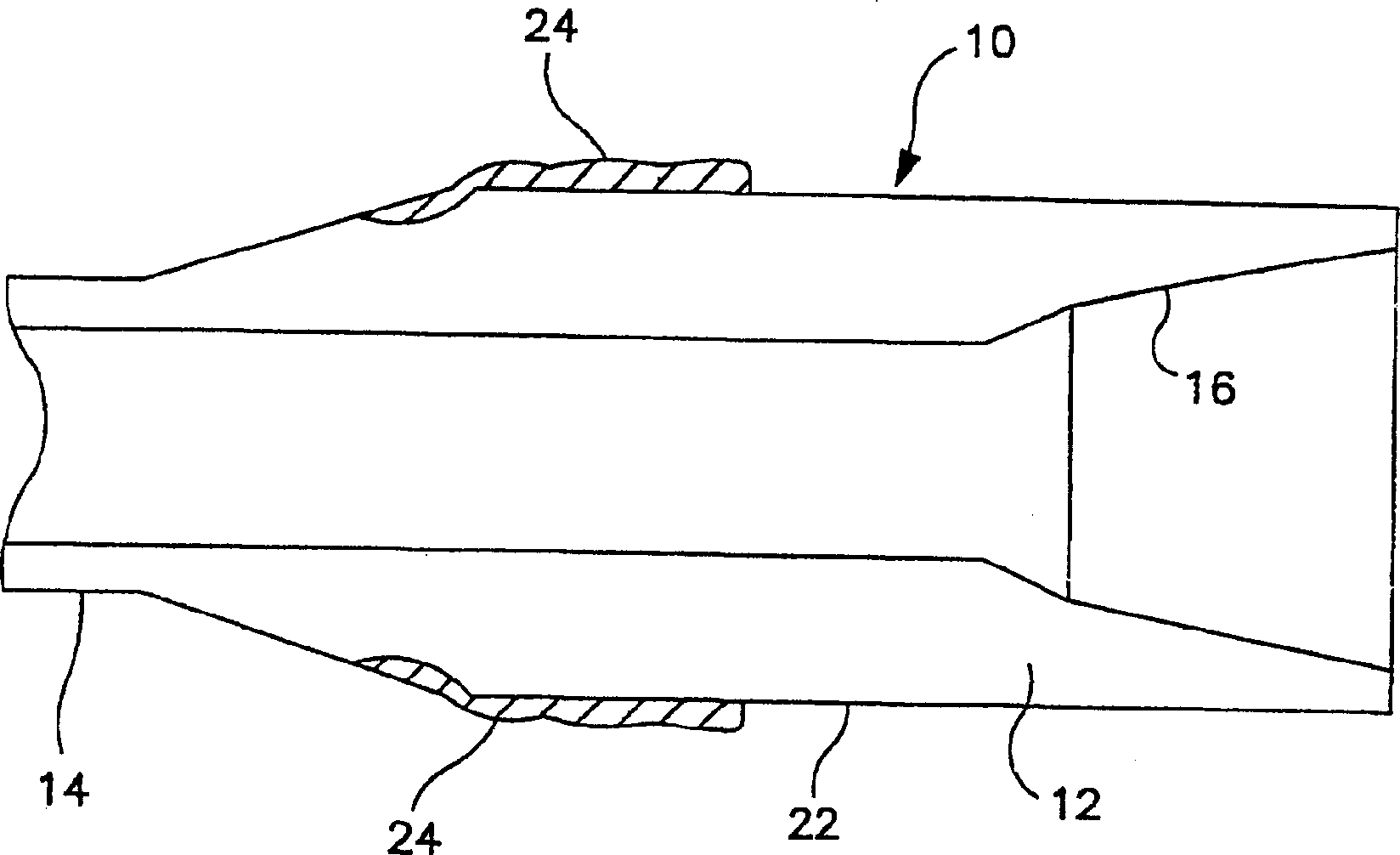

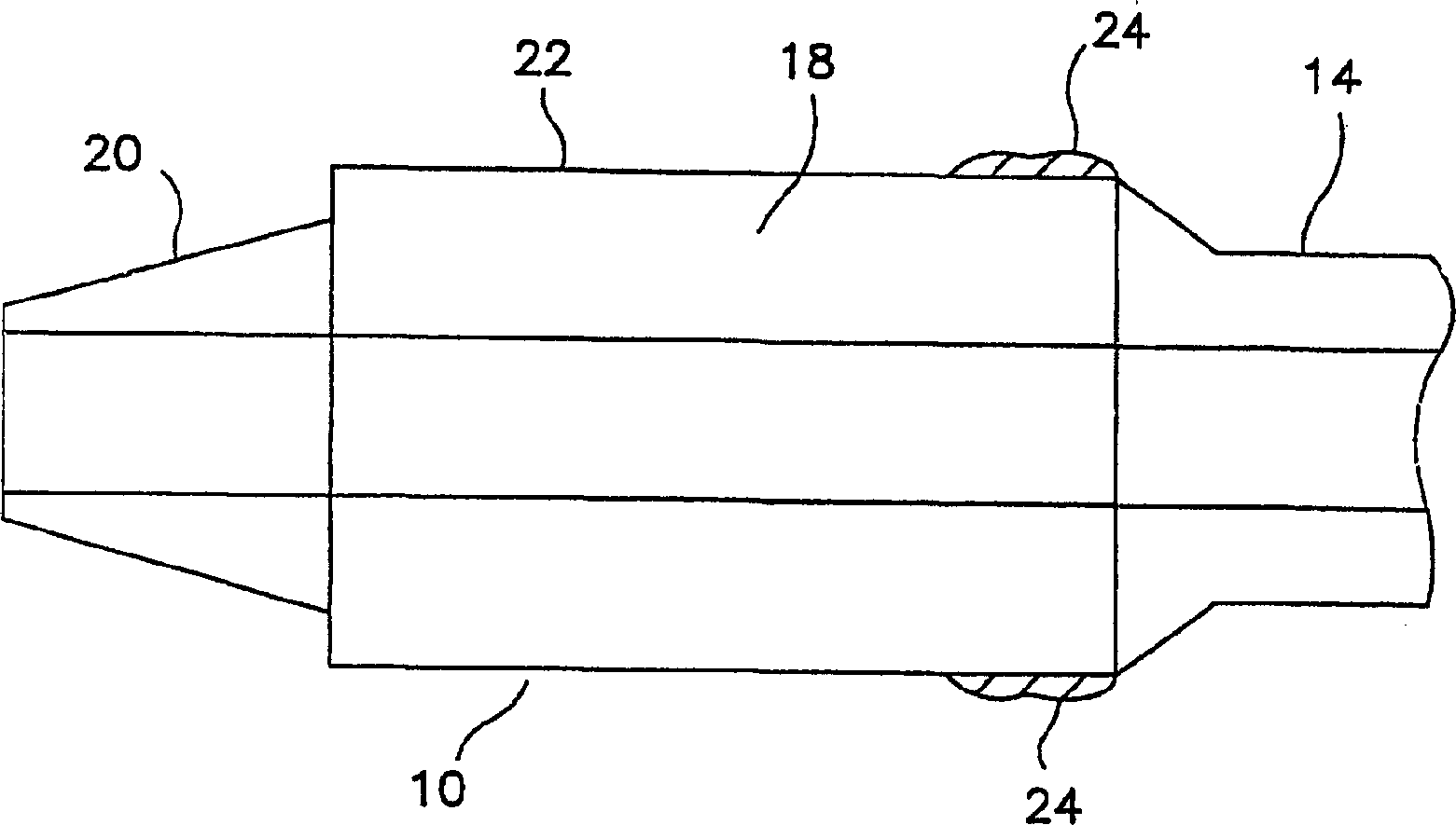

Hardfacing alloy. methods and products

Disclosed is a hardfacing material capable of withstanding abrasion by siliceous formation particles, etc., weldable to industrial products such as drill joints and stabilizers for oil and gas well drilling, and other industrial products without cracks alloy. The alloy for surface hardening has a low coefficient of friction and high wear resistance after welding without machining, and in the tool joint and stabilizer, the wear resistance of the tool joint and the stabilizer and the resulting casing are obtained Optimal balance between wear and tear. Other embodiments of the invention include welding a hardfacing alloy (24) to the outer cylindrical surface (22) of the casing and pin components of a tool joint and to welding Tool joints on stabilizing ribs of stabilizers and other industrial products; methods of manufacturing said hardfacing alloys; methods of applying said hardfacing alloys on surfaces, including preheating and post-welding treatment conditions, In order to resist wear and tear.

Owner:ATT TECH LTD

Hardfacing alloy. methods and products

Owner:ATT TECH LTD

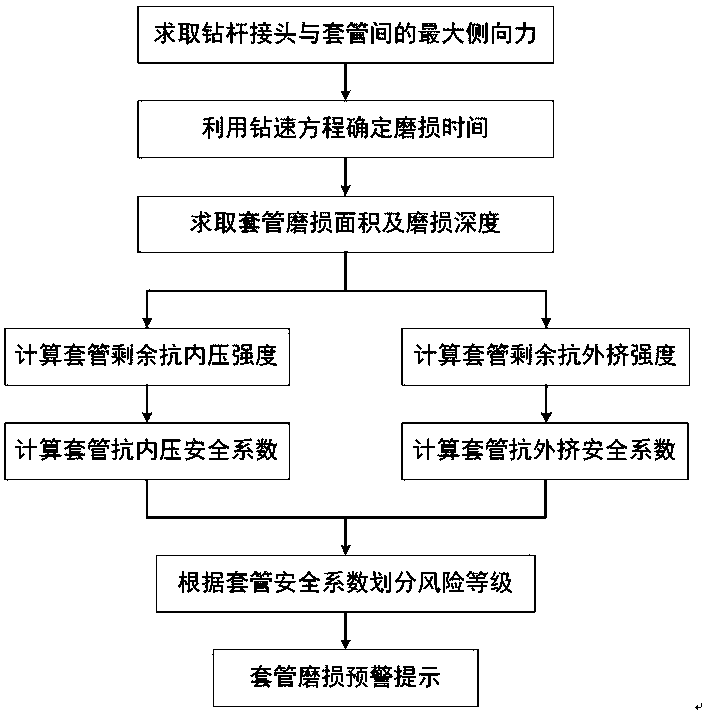

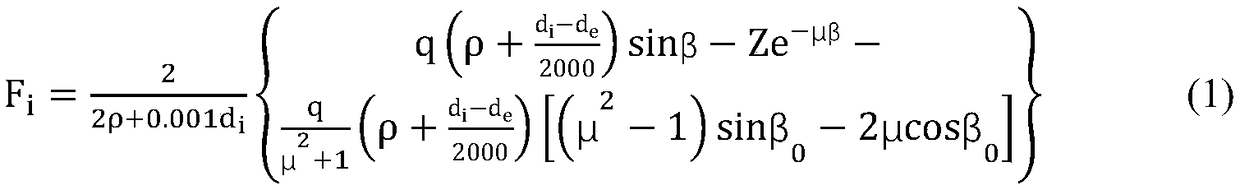

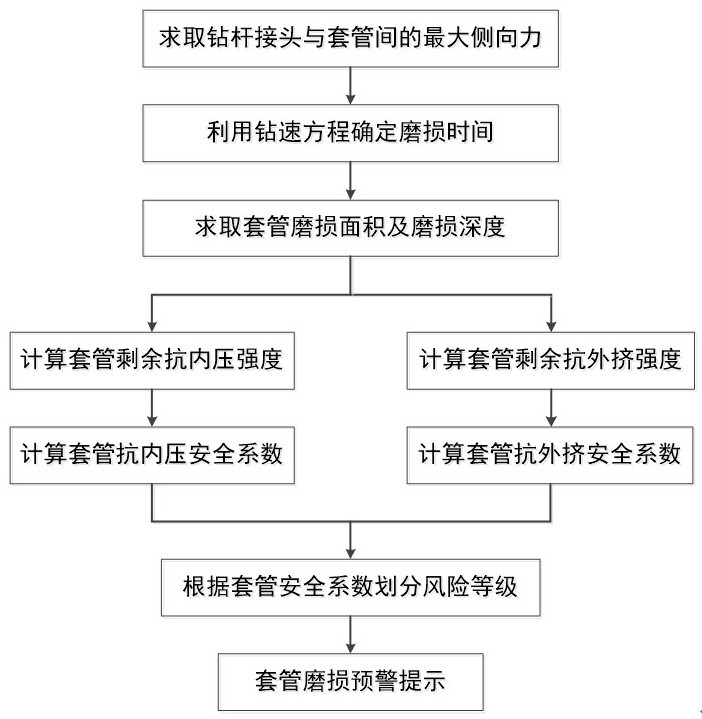

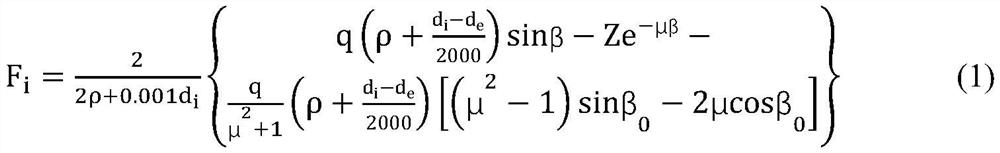

Real-time early warning method for casing abrasion risk

ActiveCN108104795AOvercoming the disadvantages of total wearService Reliability Early WarningEarth drilling toolsSurveyInternal pressureCasing wear

The invention belongs to the field of oil and gas well building safety and particularly relates to a real-time early warning method for the casing abrasion risk. The real-time early warning method ischaracterized in that firstly, the maximum lateral force between a drill rod joint and a casing is selected through calculation, the abrasion time is determined through the drilling rate equation, andthe abrasion area and depth of the casing are obtained; then the residual internal pressure strength and the residual collapsing strength of the casing are obtained, the residual internal pressure resistance safety factor and the residual collapsing resistance safety factor of the casing are calculated, and according to the obtained residual internal pressure resistance safety factor and residualcollapsing resistance safety factor of the casing, the risk grade is divided; and finally, according to the risk grade, the casing abrasion situation is determined, and real-time early warning is conducted. The real-time early warning method has the advantages that the abrasion depth of the casing at the maximum abrasion risk position can be calculated according to the well track, the abrasion quantities of the casings in current drilled and to-be-drilled wells can be pre-evaluated, and thus casing protection measures are advantageously taken in the later period.

Owner:SOUTHWEST PETROLEUM UNIV

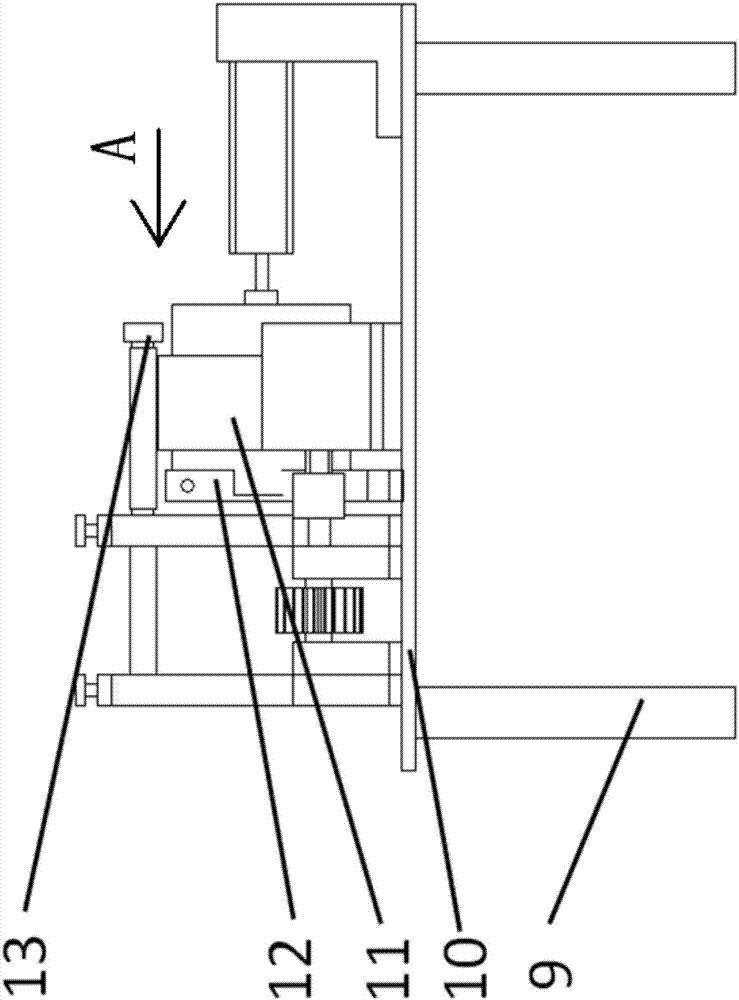

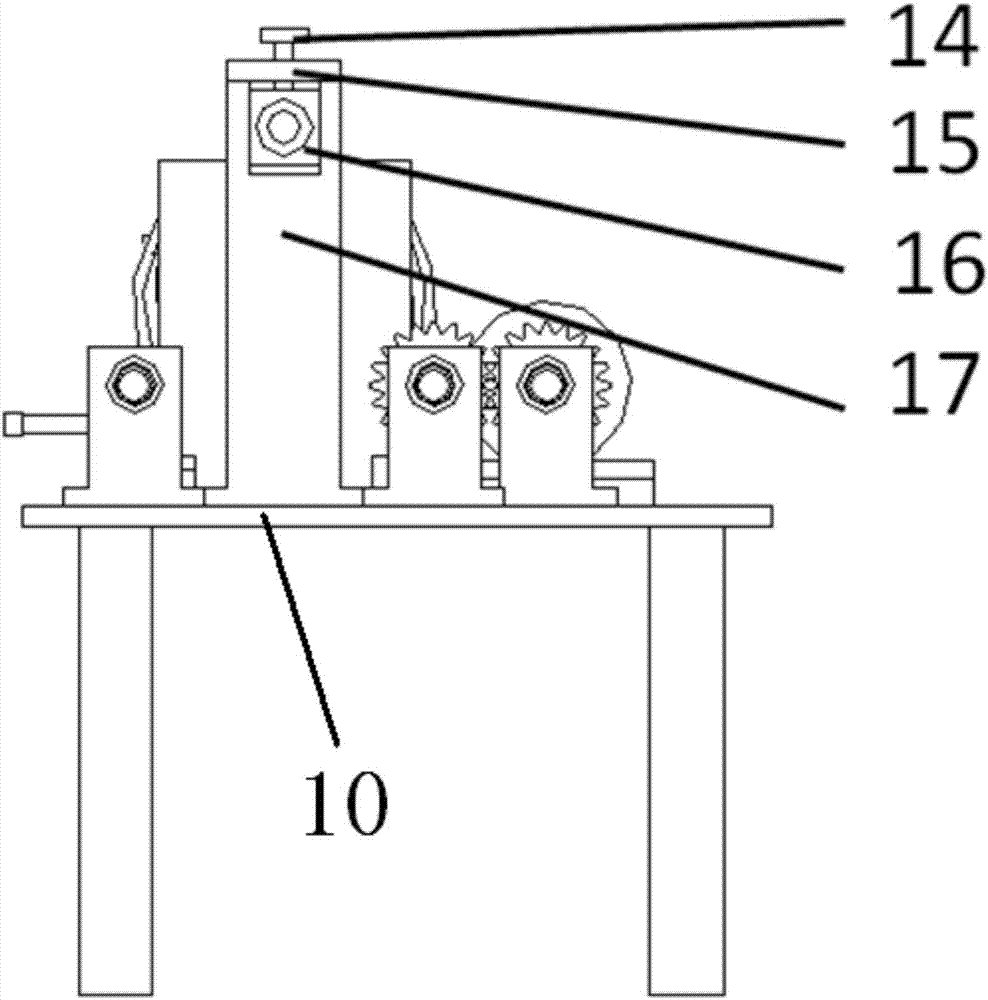

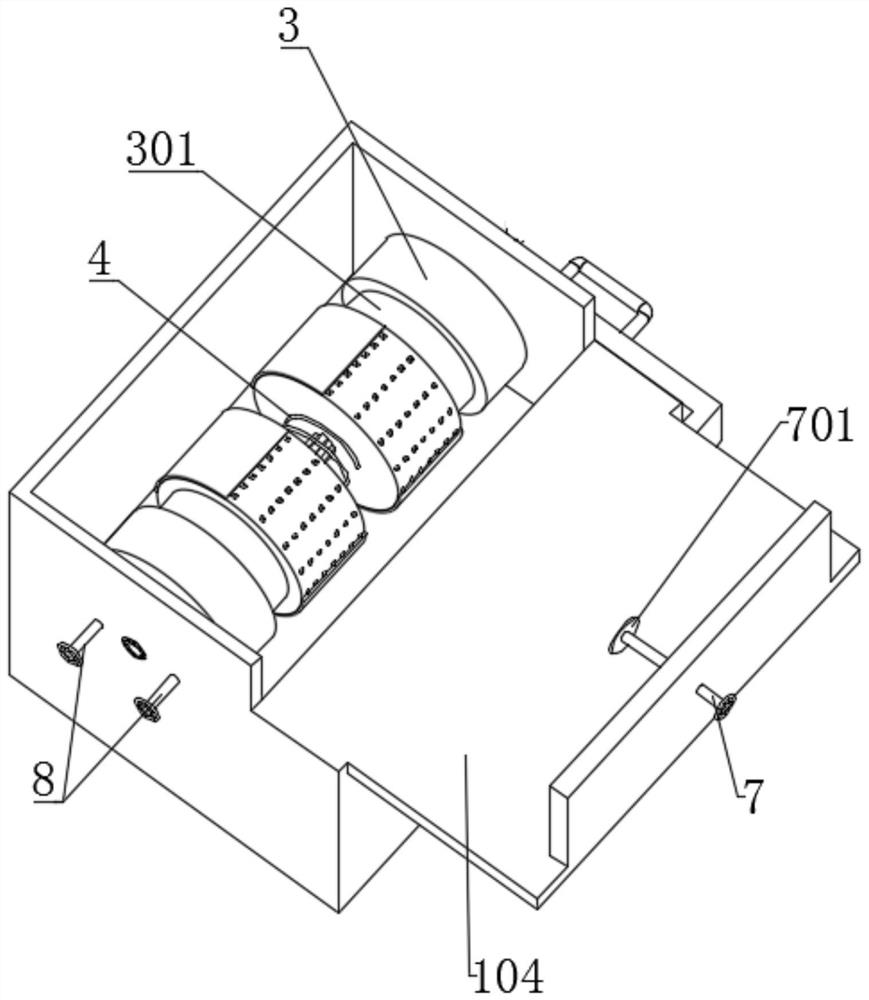

Oil-gas well casing wear test bed

InactiveCN107063911ACompact structureEasy to processInvestigating abrasion/wear resistanceCasing wearTest sample

The invention discloses an oil-gas well casing wear test bed. The test bed comprises a simulation casing rotation driving assembly and a simulation tension loading assembly. The oil-gas well casing wear test bed can simulate relative rotation of a casing and drill pipe system in oil-gas well drilling equipment. The test bed has the advantages that a drill pipe can be loaded more closely to the real working condition, the eccentric distance between a casing and the drill pipe is adjustable, and a test sample is convenient to install. A platform for researching the wear failure problem of the casing is provided.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

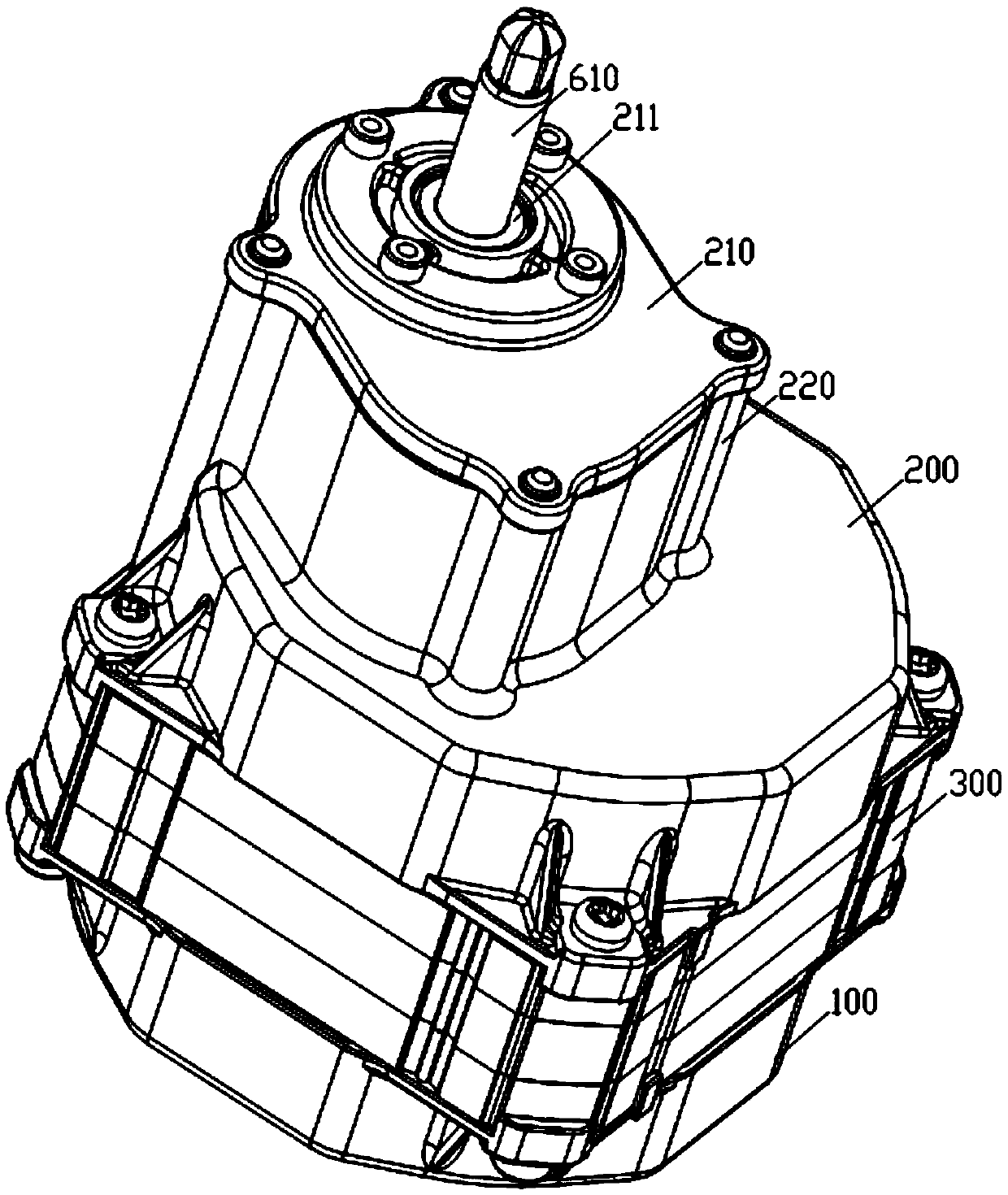

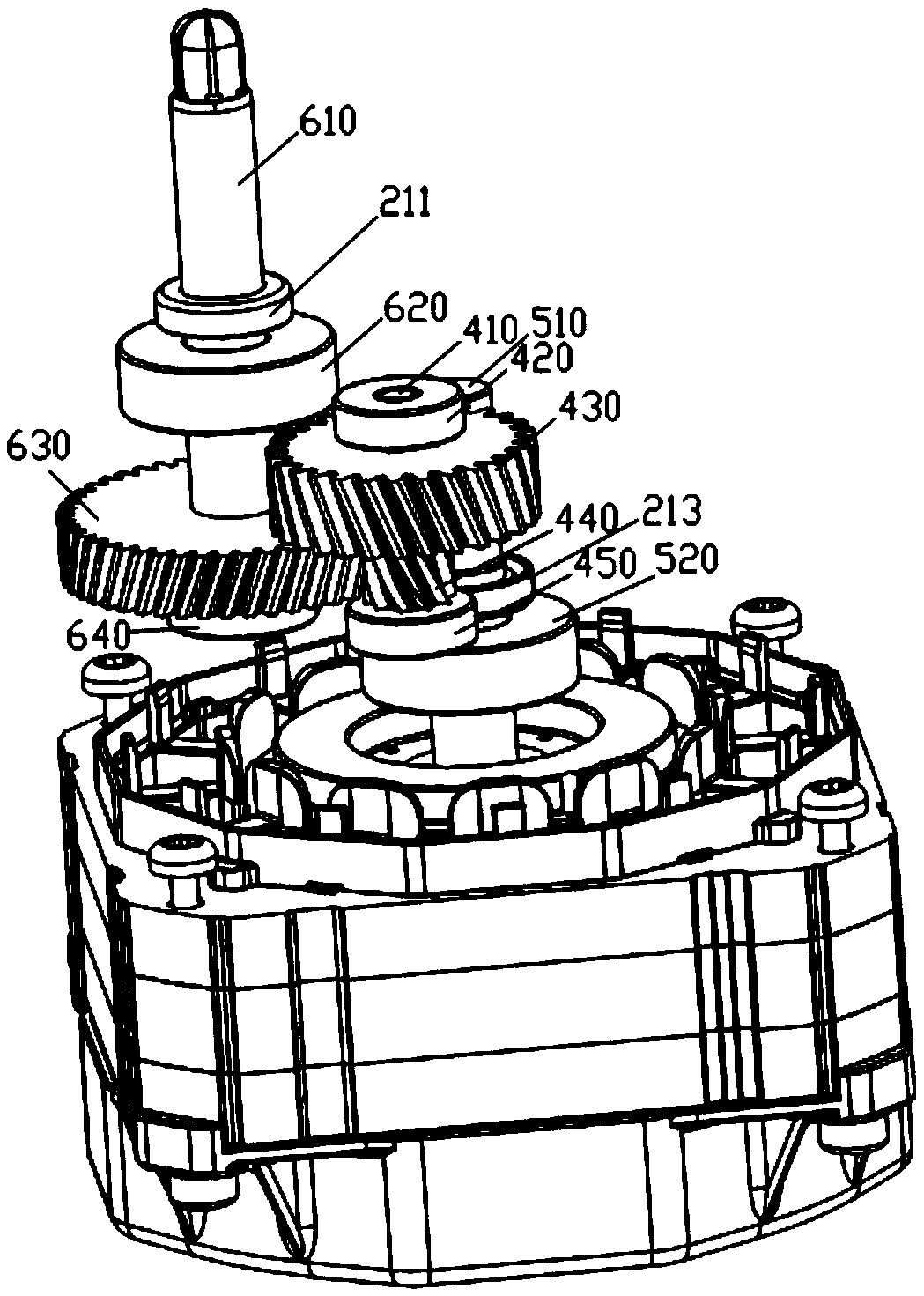

Low-speed motor with lubricating oil gear case structure

InactiveCN105591496AExtended service lifeImprove the lubrication effectGear lubrication/coolingMechanical energy handlingRubber ringCasing wear

The invention discloses a low-speed motor with a lubricating oil gear case structure. The lubricating oil gear case can be used on a plurality of food processing devices, and is particularly suitable for small household electrical products of juice extractor, noodle machine, mincer, etc. The low-speed motor comprises the components of a motor housing, a motor stator, a motor rotor and the gear case. The gear case is filled with liquid lubricating oil. The input end and the output end of the gear case are provided with oil sealing rubber rings for sealing the lubricating oil in the gear case and preventing overflow. Lubricating grease is replaced by the lubricating oil which is filled in the gear case, thereby improving lubrication effect of gears, further reducing wearing between the gears, and prolonging service life of the gear case. Furthermore the lubricating oil is sufficiently filled in the whole gear case, thereby effectively reducing noise caused by gear friction. The low-speed motor with the lubricating oil gear case structure according to the invention settles technical problems of gear case wearing and relatively large noise in application of an existing low-speed motor in the small household electrical appliances.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

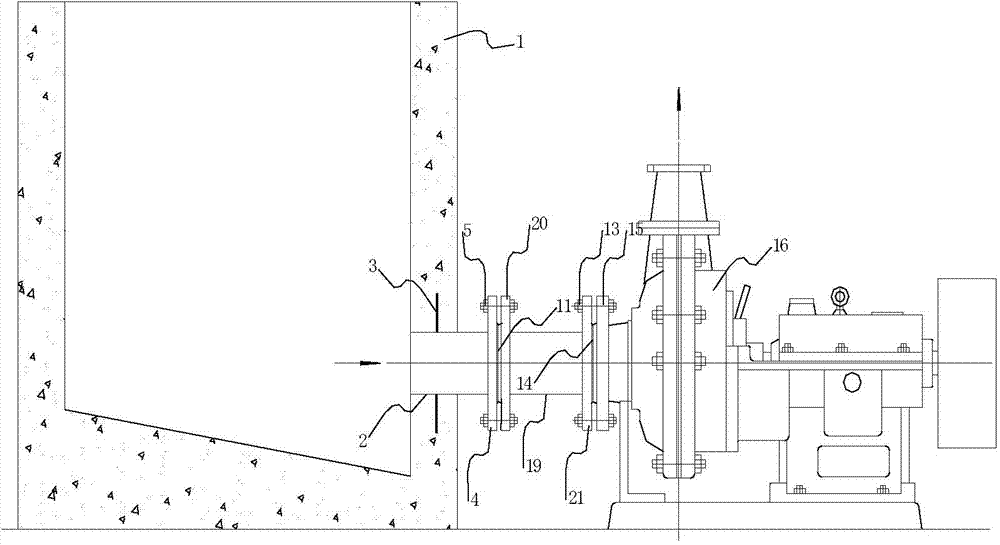

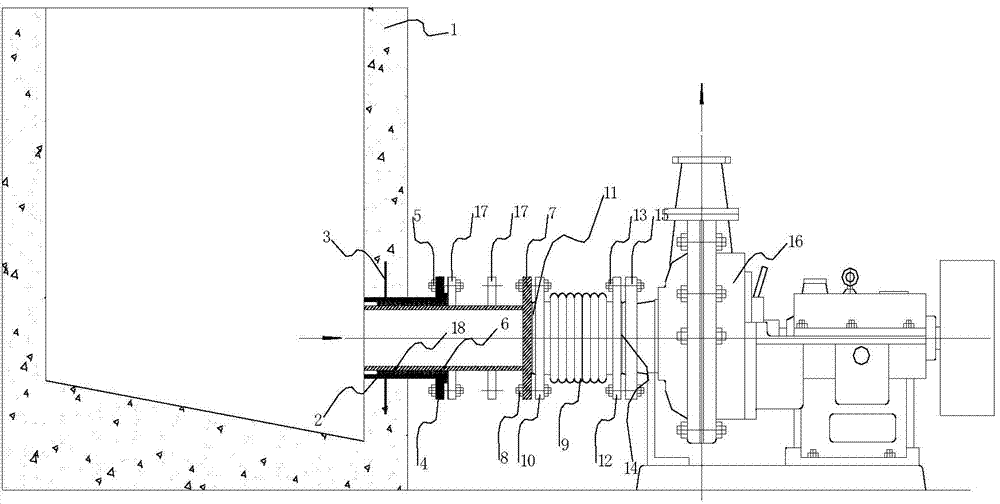

Sand pump pulp inlet pipe connecting device and connecting method thereof

InactiveCN104747839AReduce precisionReduced concentricity requirementsFlanged jointsPump componentsCasing wearStructural engineering

The invention relates to a sand pump pulp inlet pipe connecting device and a connecting method thereof. The segment, with an anchor bar welded, of a fixed casing pipe is buried in a wall of a sand pump pond, the segment, with a flange plate welded, of the casing pipe is exposed out of the wall of the sand pump pond. A movable casing pipe comprises a casing pipe body and a flange plate, the outer diameter of the movable casing pipe is smaller than the inner diameter of the fixed casing pipe, and one end of the movable casing pipe stretches into the fixed casing pipe. Flange plates are arranged at the two ends of a telescopic pipe with the flange plates, one end of the telescopic pipe is connected with the flange plate of the movable casing pipe, and the other end of the telescopic pipe is connected with a flange plate on an ore pulp inlet of the sand pump. Sealing padding is stuck into a gap between the fixed casing pipe and the movable casing pipe, the movable flange plate is connected with the flange plate of the fixed casing pipe after the gap is full, and the sealing padding is compressed. The requirement for the mounting precision of the sand pump can be reduced, the pre-buried fixed casing pipe is hardly abraded, the movable casing pipe is quite convenient to replace after being abraded, the phenomenon that due to vibration of the sand pump, pulp is leaked out of the connecting position is completely eradicated, and losses of useful metal are reduced.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

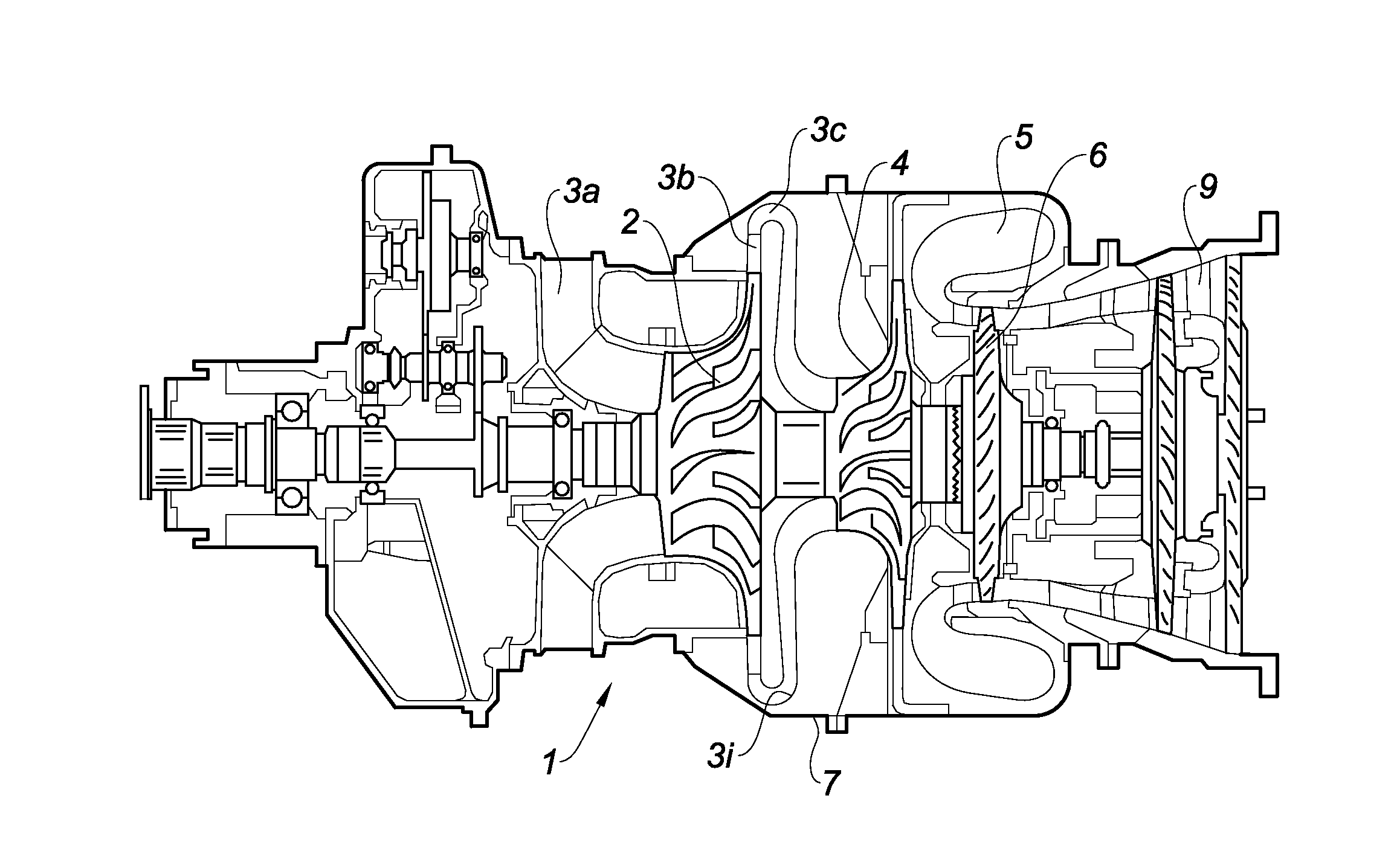

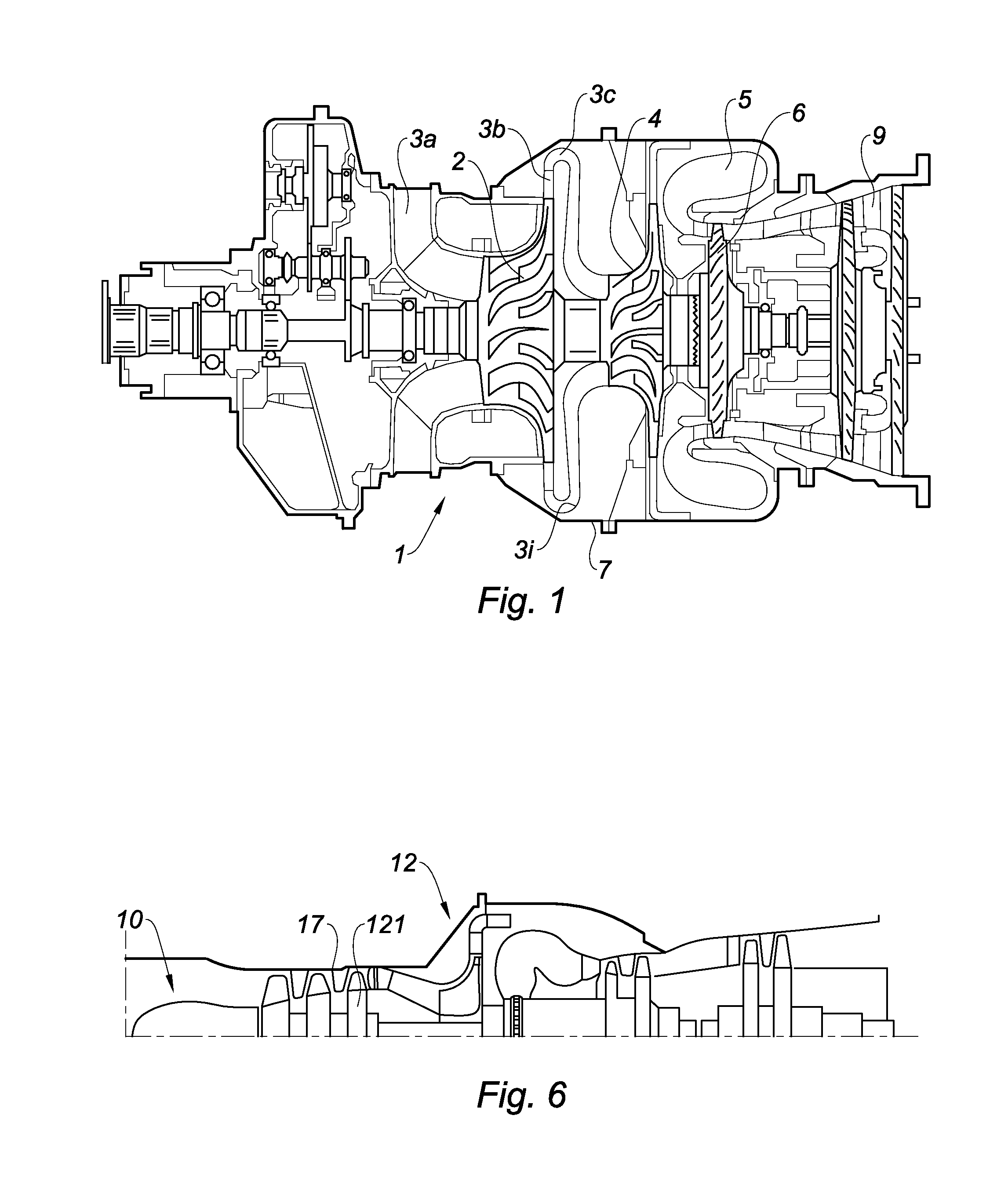

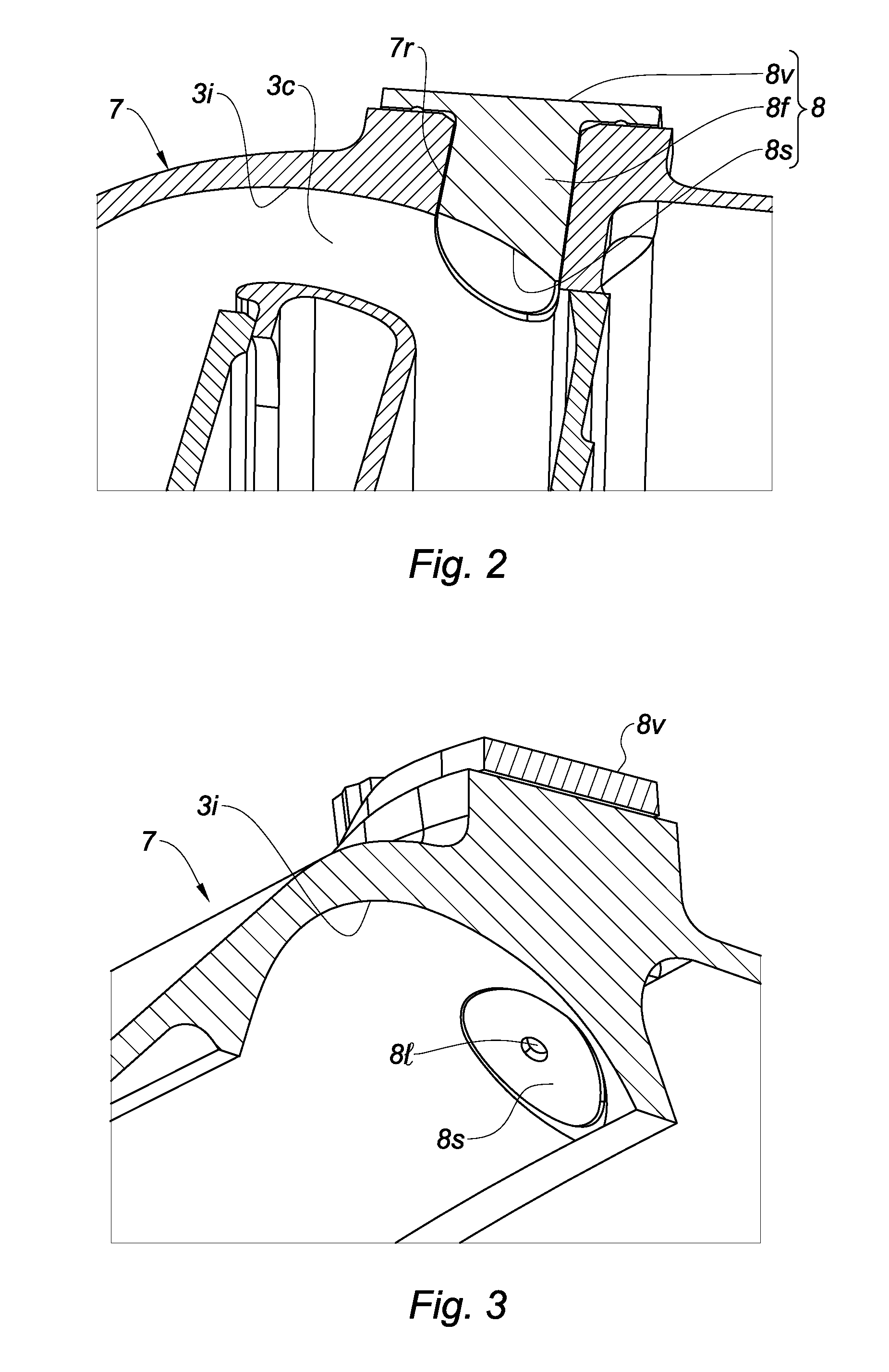

Turbomachine comprising a casing wear indicator

The present invention relates to a turbine engine comprising a casing (7) which has an inner wall (3i) forming a wall of an air duct (3) and at least one opening (7r) passing through the casing, leading into said duct (3) and forming a passage for an endoscope, the opening (7r) being closed during operation of the turbine engine by a stopper (8) which has an end-surface portion (8s) in the extension of the inner wall (3i), characterised in that an indicator of wear to the inner wall of the casing is associated with the stopper (8) or with the inner wall (3i) of the casing, in the proximity of the stopper (8).The means of the invention allows simple inspection, without a measurement apparatus being used.

Owner:SAFRAN HELICOPTER ENGINES

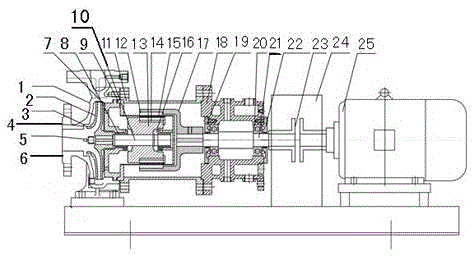

Novel high-temperature magnetic drive pump

InactiveCN105545759AReduce radial forceGuaranteed uptimeSpecific fluid pumpsPump componentsCasing wearImpeller

The invention relates to a novel high-temperature magnetic drive pump which comprises a motor, a pump body, a pump cover, an impeller, a bearing box and a pump inlet formed in the front end of the pump body. The novel high-temperature magnetic drive pump is characterized in that the end of an output shaft of the motor is connected with a transmission shaft through a coupling; the coupling is sleeved with a coupling guard; a casing wear ring is arranged on the pump body; the lower portion of an impeller shaft is sleeved with the impeller; an impeller nut for locking the impeller is arranged at the bottom of the impeller shaft; an impeller wear ring is arranged on the impeller; inner magnetic steel, outer magnetic steel and an isolation sleeve are fixed to the end of the impeller shaft; a magnetic sheet is arranged between the inner magnetic steel and the outer magnetic steel and provided with a locating sleeve and a sheath; a graphite shaft sleeve is arranged between the impeller shaft and the pump cover; the bearing box is arranged on the pump cover; and a water jacket is arranged outside the bearing box.

Owner:JIANGSU HANNA PUMP IND CO LTD

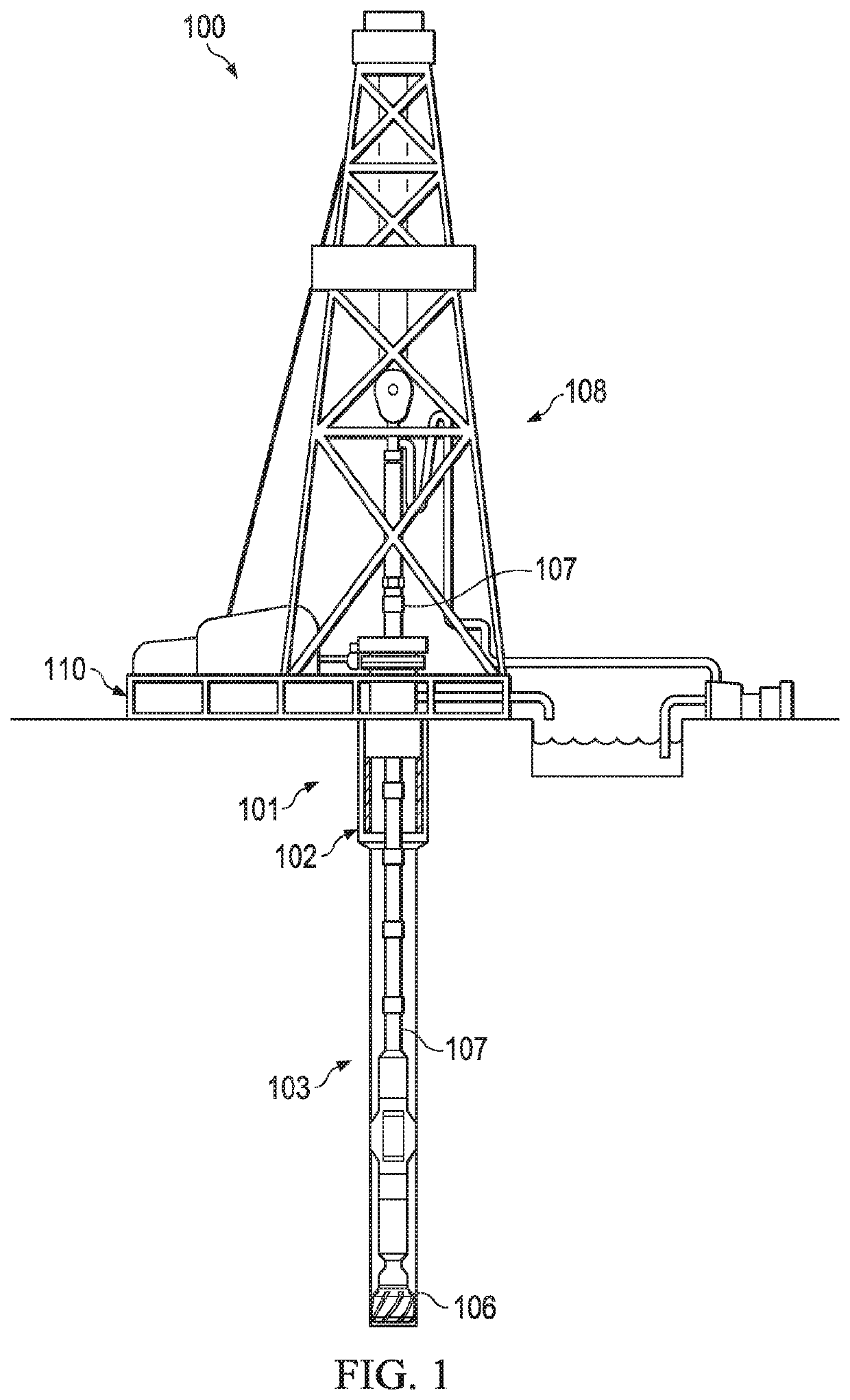

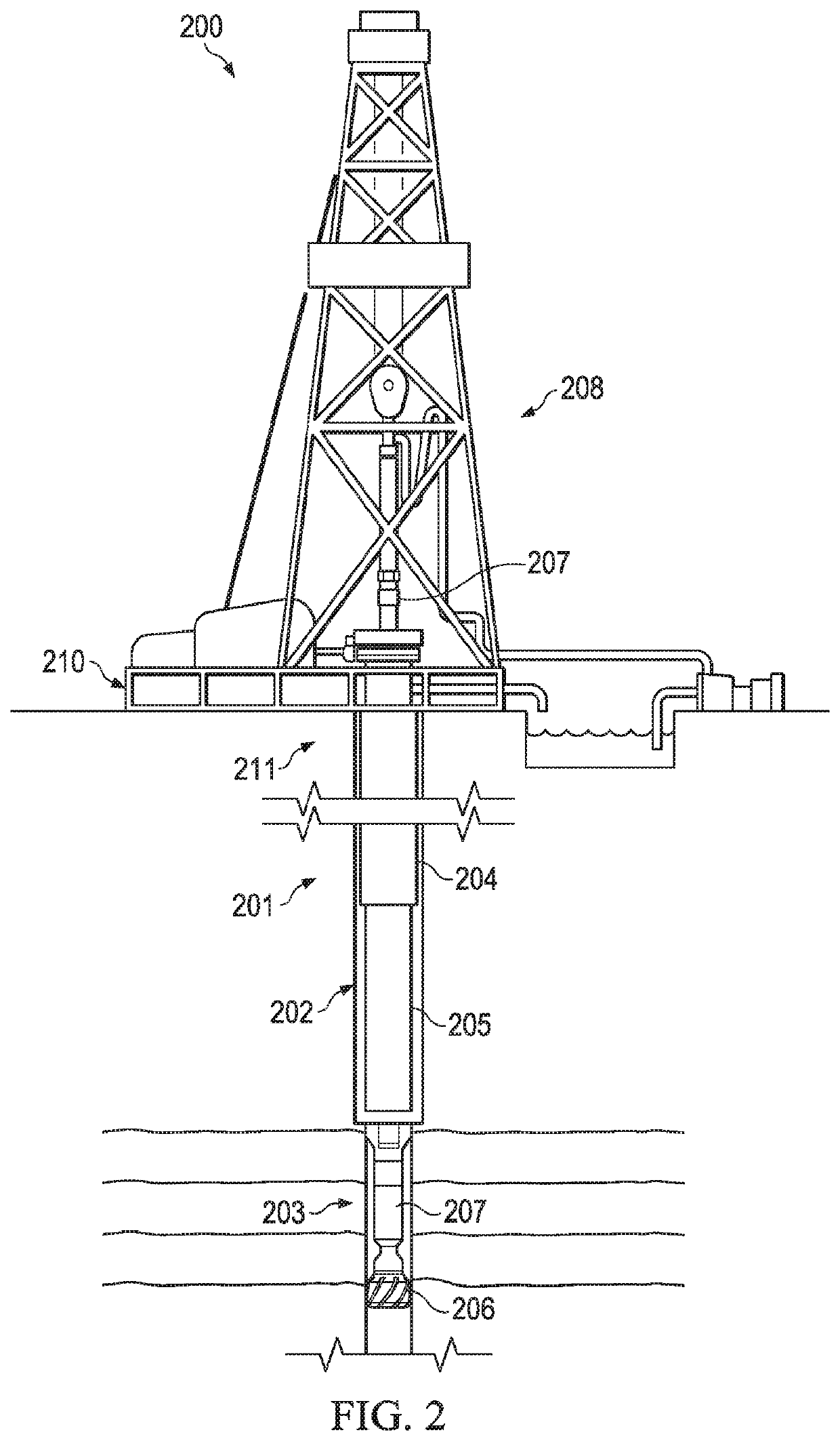

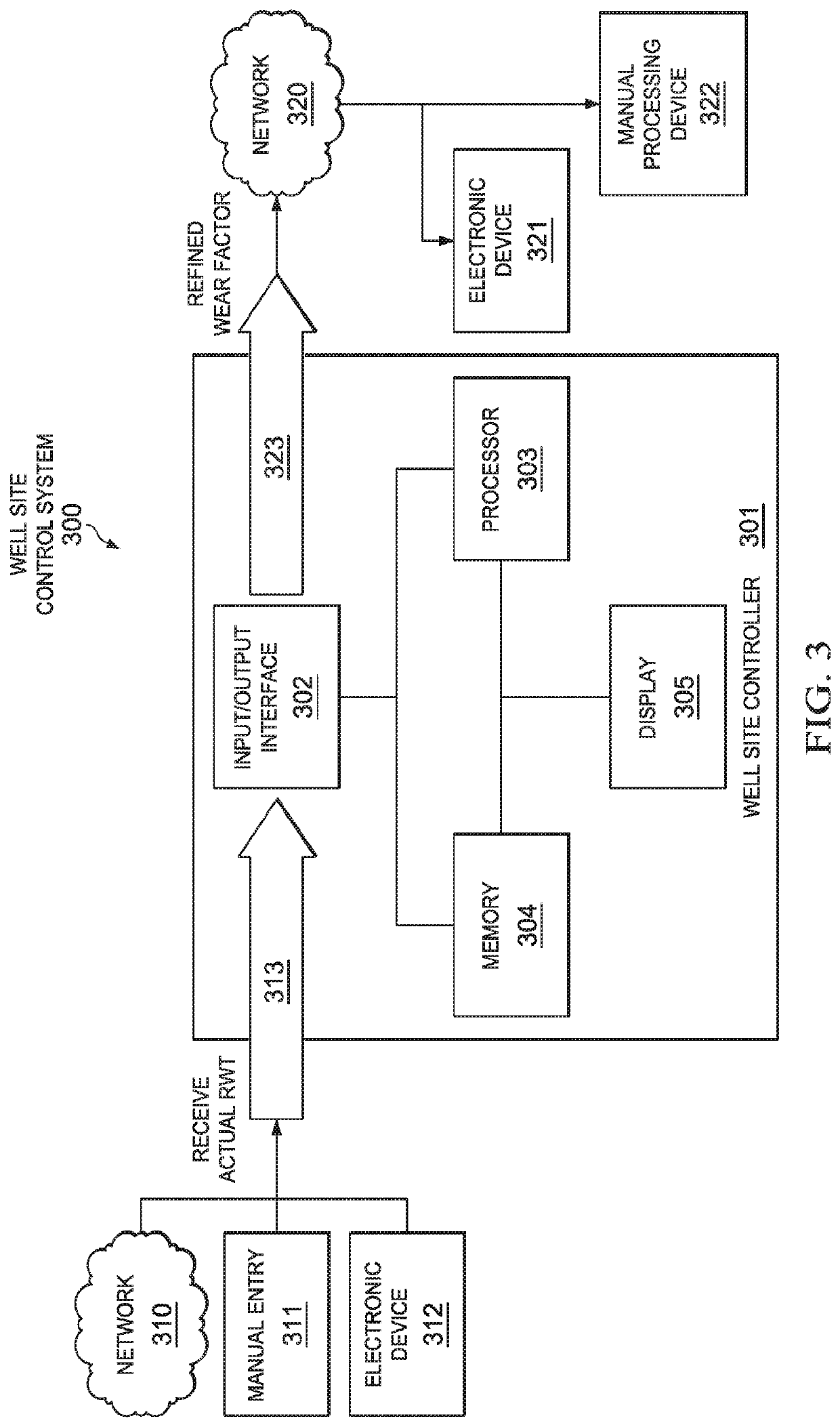

Method and apparatus to predict casing wear for well systems

A method for determining casing wear of casing in a wellbore, a computer program product for determining a back-calculated casing wear factor (CWF) value for casing in a wellbore, and a well site controller are provided herein. In one embodiment, the well site controller includes: (1) an interface configured to receive actual remaining wall thickness (RWT) values that correspond to a set of casing depth values of a wellbore and (2) a processor configured to determine a back-calculated casing wear factor (CWF) value for the wellbore based on a comparison between the actual RWT value and an estimated RWT value, for the set of casing depth values, where the estimated RWT value is calculated using an estimated CWF value as input.

Owner:LANDMARK GRAPHICS

Cutter apparatus for centrifugal pump

A centrifugal pump with a cutter mechanism consisting of a toothed cutter rotor, integral with the impeller wear ring, affixed to the impeller and a toothed cutter stator affixed to the casing, separately from the casing wear ring. A cutter mechanism consisting of a stator and rotor set such that they may be installed on the centrifugal pump impeller and casing as original equipment or as a retrofit. A cutter mechanism such that when installed in a centrifugal pump they prevent stringy materials, garbage and other agglomerated soft wastewater solids from partially restricting or totally blocking the inlet to the pump impeller. A cutter mechanism such that when it prevents solids from restricting or blocking the impeller inlet, it does so without significant decrease of flow throughput or significant increase in absorbed hydraulic horsepower.

Owner:CORNELL PUMP CO LLC

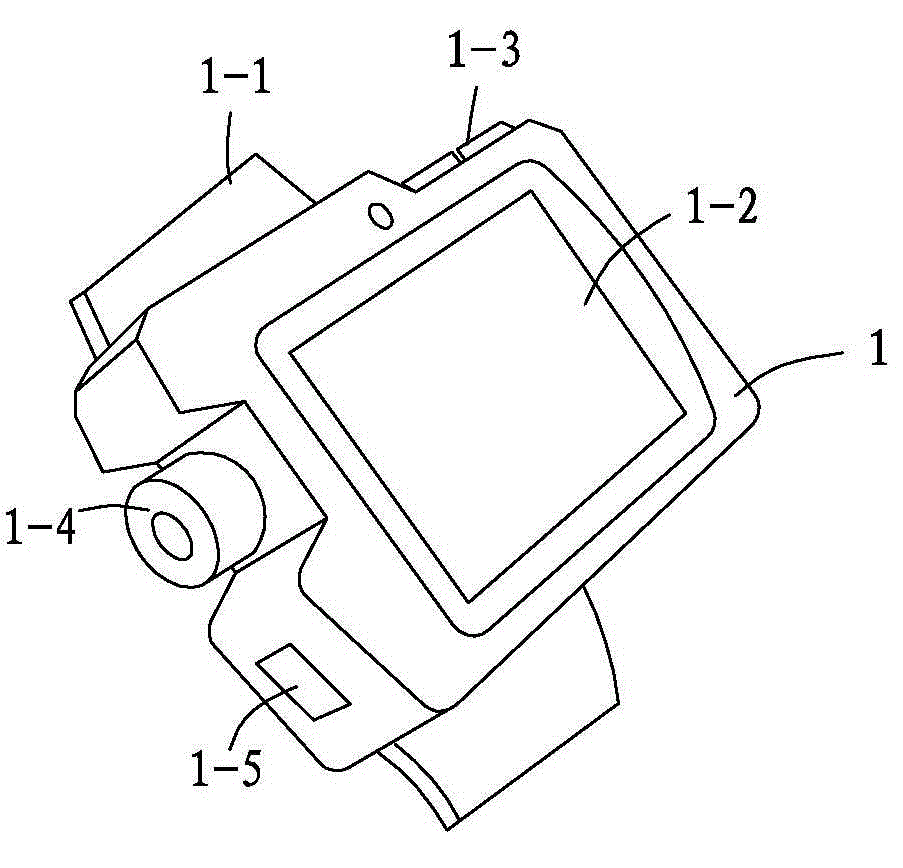

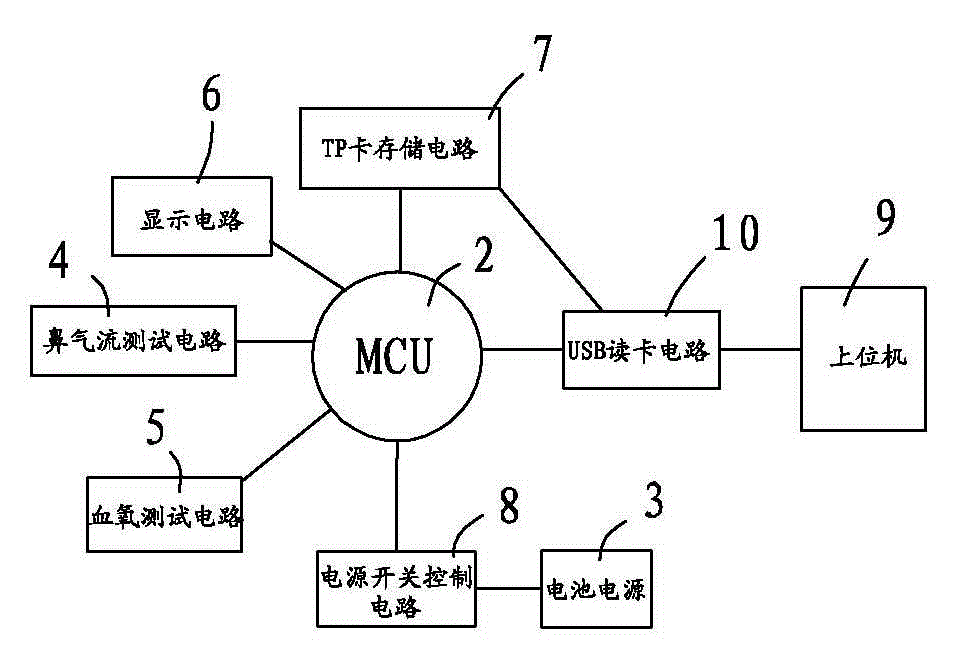

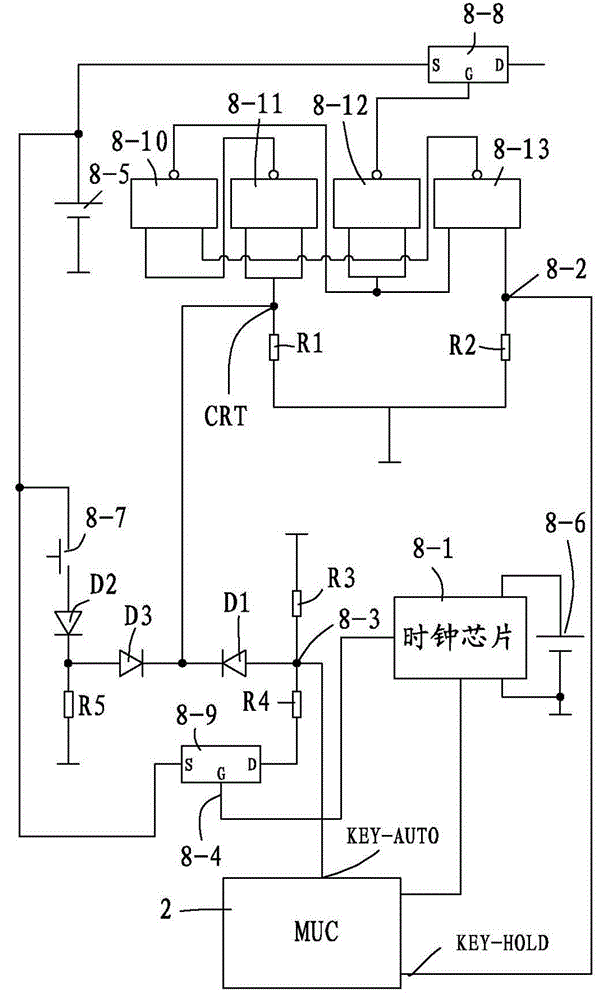

Sleep and breath preliminary screening instrument with timing power-on function and power-saving method

ActiveCN102940491AGuaranteed Cruise TimeEasy to compare and analyzeDiagnostic recording/measuringSensorsCasing wearPower flow

The invention relates to a sleep and breath preliminary screening instrument with a timing power-on function and a power-saving method. The instrument comprises a casing wearing on the wrist, a display and control buttons are arranged on the casing, a nose airflow signal input interface and a blood oxygen signal input interface are arranged on the side wall of the casing respectively, and a control analysis circuit is fixed in the casing. According to the instrument, the timing power-on is achieved under a state that the circuit is completely out of power, cruising time of a battery is guaranteed, the power-on can be identified automatically, the effectiveness of the power-on state can be determined, and ordered carrying out of manual power-on and timing power-on can be achieved. The instrument is in a power-saving mode during storage, the working current is smaller than 30mA, the instrument can perform data storage as long as 20 hours, and the screen is in a blank screen state during the power-saving mode, so that the visual trouble caused by bright screen of the instrument during sleep of a patient can be avoided.

Owner:CONTEC MEDICAL SYST

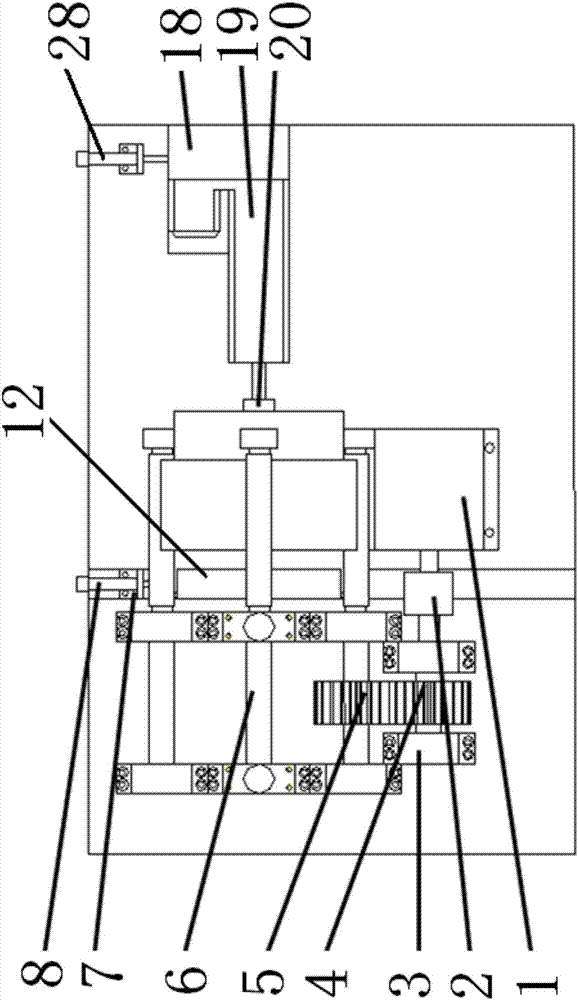

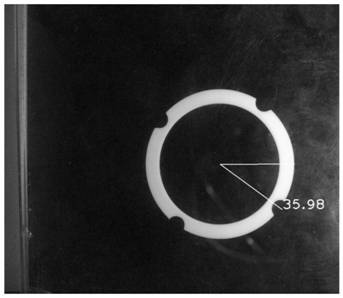

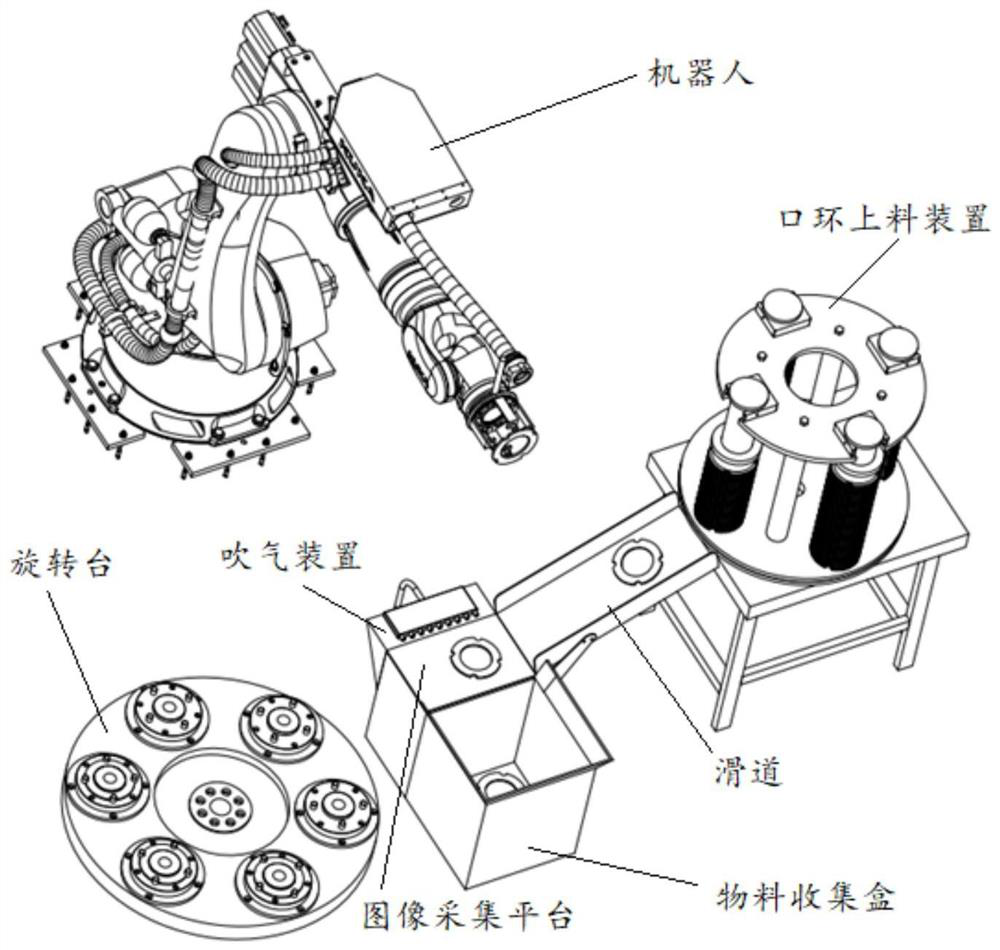

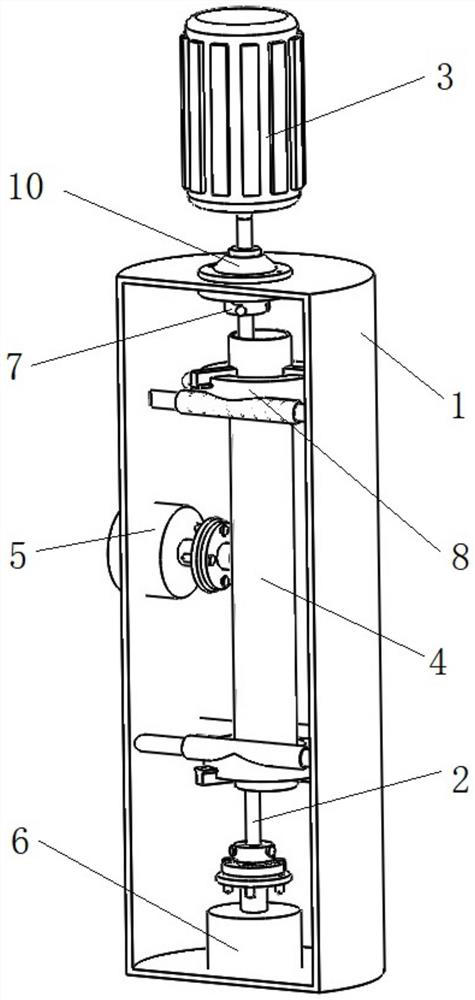

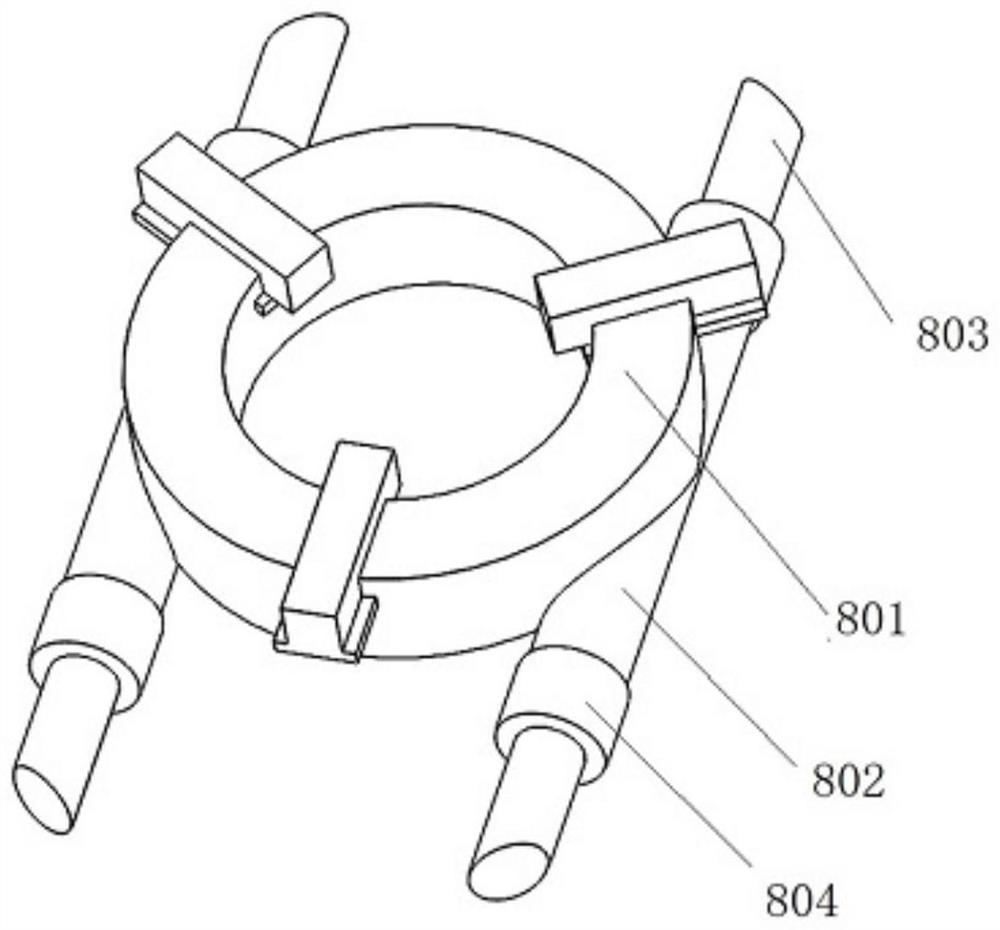

Casing wear ring automatic mounting device and method

ActiveCN112536584AEasy to installImplement automatic installationImage enhancementCharacter and pattern recognitionCasing wearElectric machinery

The invention discloses a casing wear ring automatic mounting device. The casing wear ring automatic mounting device comprises a wear ring feeding device, an industrial camera and a rotating table, wherein the wear ring feeding device is communicated with an image acquisition platform through a slideway, and is in communication connection with an electrical PLC server; the industrial camera is incommunication connection with an upper computer; a wear ring pose recognition device used for recognizing the casing wear ring pose is integrated on the upper computer; the rotating table is providedwith a circular rotating disc and a driving motor for controlling the circular rotating disc to rotate; a plurality of wear ring bases are uniformly arranged on the circular rotating disc; the drivingmotor controls the wear ring base to be assembled currently to rotate to a designated position; the driving motor is in communication connection with the electrical PLC server; and a robot client, the electrical PLC server and the upper computer are in communication connection. The pose data of a wear ring is obtained by identifying a wear ring image, the wear ring is adjusted to a placement teaching point pose according to the pose of the wear ring, and a convex point on the wear ring base is located in the concave arc of the wear ring when the wear ring is mounted on the wear ring base at the specified position, so that the wear ring is automatically and accurately mounted.

Owner:WUHU HIT ROBOT TECH RES INST

A self-stabilizing wear-resistant testing machine for trolley case

ActiveCN108871934BEasy to move back and forthThe test effect is accurateInvestigating abrasion/wear resistanceCasing wearElectric machinery

Owner:平湖叶阳箱包股份有限公司

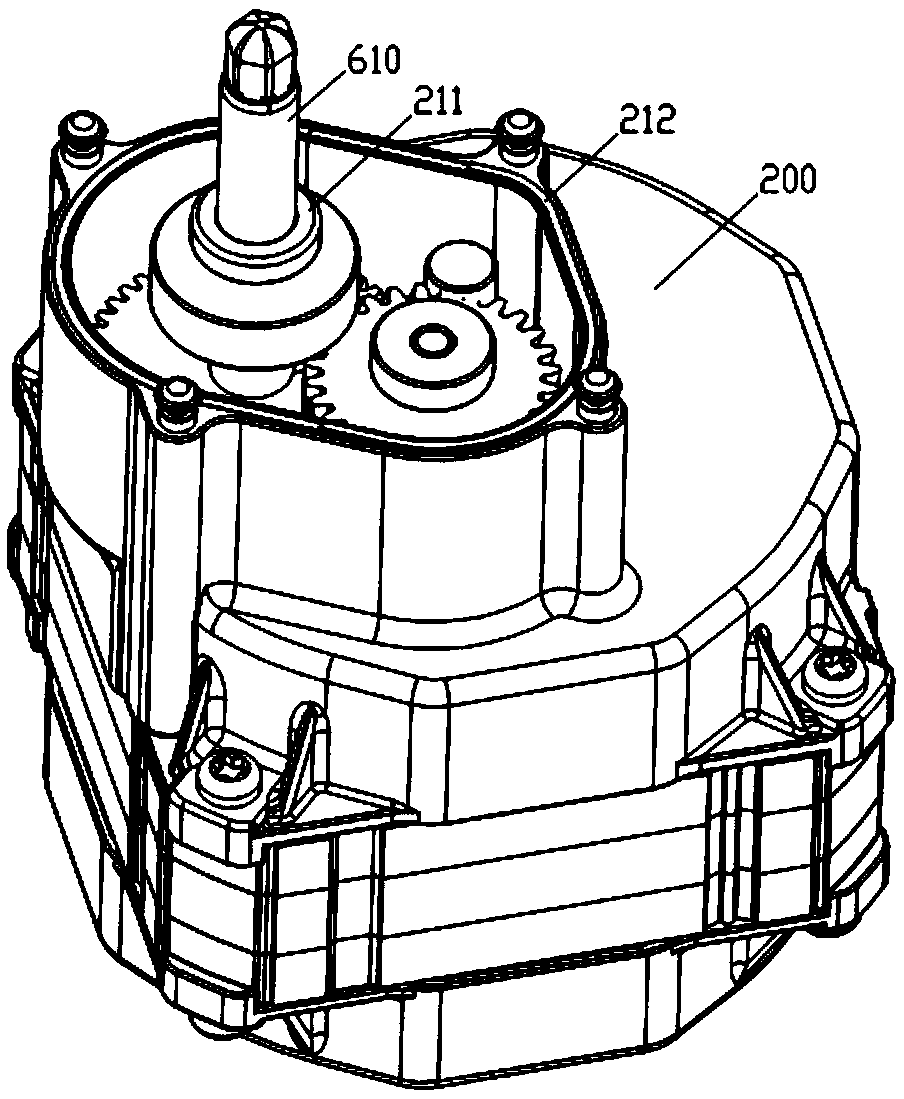

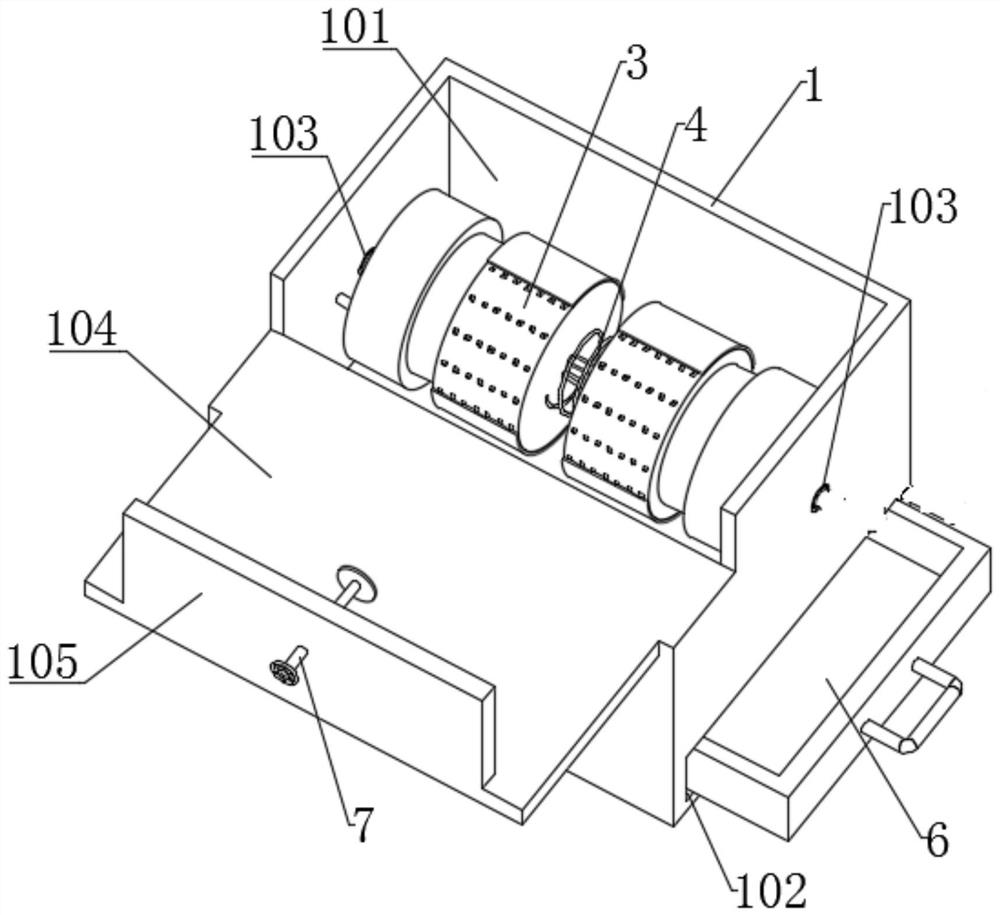

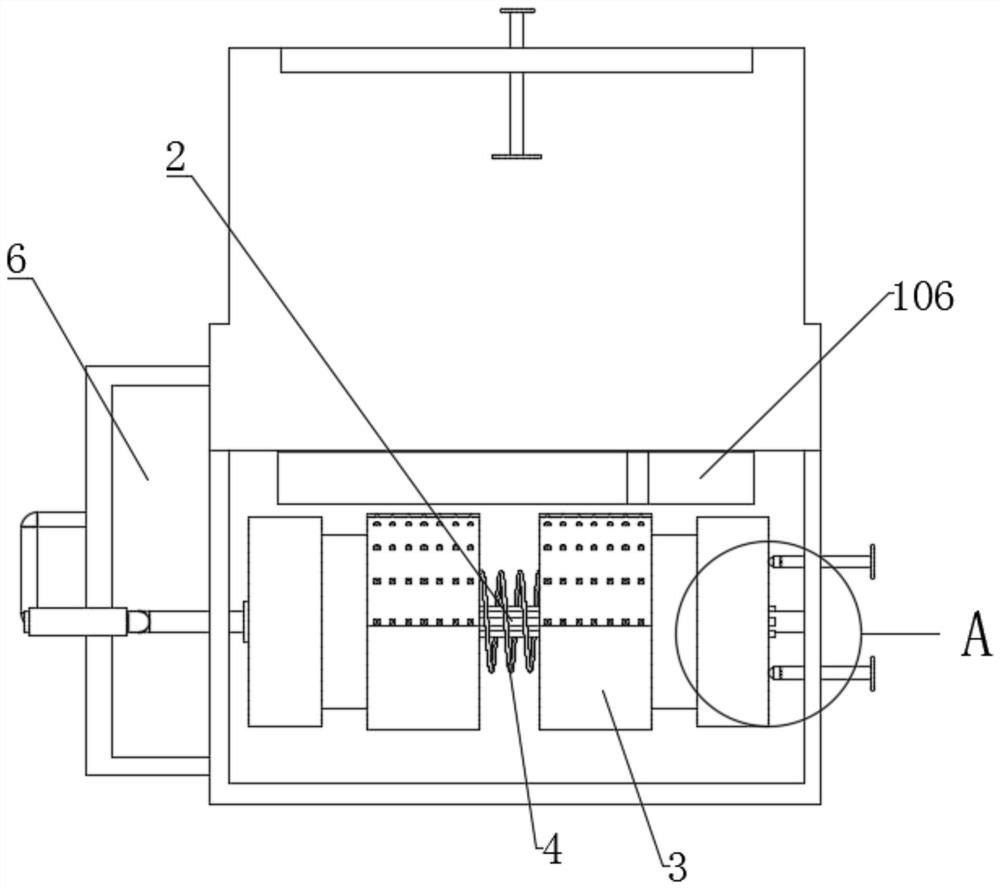

A device for measuring wear of drill pipe connection section and casing

ActiveCN112727439BImprove stabilityEnsure linear contactSurveyDrilling rodsCasing wearClassical mechanics

The invention discloses a device for measuring wear of a drill pipe and a casing, which comprises a bearing structure, a drill pipe, a rotating mechanism, a sleeve, and a horizontal force applying mechanism; the bearing structure is used to carry various parts of the device, and one end of the drill Through the sleeve, the rotating mechanism is used to drive the drill pipe to rotate; the two ends of the drill pipe are fixed on the bearing structure through the rotating parts; the sleeve is fixed on the bearing structure through the directional sliding mechanism, which defines the moving path, its sliding direction and The axis of the drill pipe is vertical; the telescopic end of the horizontal force-applying mechanism is in contact with the outer wall of the sleeve, and its telescopic direction is parallel to the sliding direction of the directional sliding mechanism, which is used to compress the sleeve and the drill pipe. The drill pipe of this device is relatively fixed, and the drill string moves and presses the drill pipe. The structure is relatively simple. At the same time, the drill string is guided to move by the directional sliding mechanism, which can ensure the linear contact between the drill pipe and the casing, and uniform force wear everywhere, and the casing The wear part is fixed, which can simulate the actual wear situation.

Owner:SOUTHWEST PETROLEUM UNIV

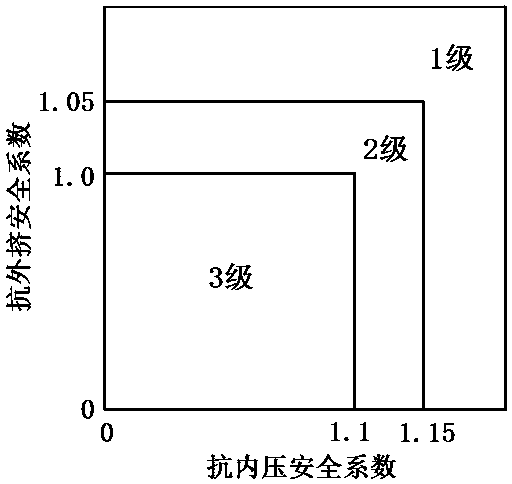

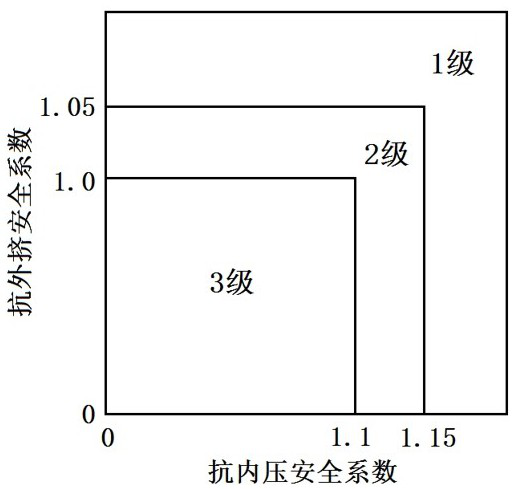

A real-time early warning method for casing wear risk

ActiveCN108104795BOvercoming the disadvantages of total wearService Reliability Early WarningEarth drilling toolsSurveyCasing wearRisk level

The invention belongs to the field of oil and gas well construction safety, and in particular relates to a real-time early warning method for casing wear risk. It is characterized in that: firstly, the maximum lateral force between the drill pipe joint and the casing is selected by calculation, and the wear time is determined by using the drilling speed equation, and the wear area and depth of the casing are obtained; then, the remaining internal pressure resistance strength of the casing is obtained and residual anti-collapse strength, calculate the remaining internal pressure safety factor and residual anti-extrusion safety factor of the casing, and divide the risk level according to the obtained casing residual internal pressure safety factor and residual anti-extrusion safety factor; finally determine the casing according to the risk level Pipe wear and real-time early warning. The advantage of the invention is that: the wear depth of the casing at the position with the greatest wear risk can be calculated according to the wellbore trajectory; the wear amount of the casing in the currently drilled and to-be-drilled wellbore can be pre-evaluated, which is convenient for later casing protection measure.

Owner:SOUTHWEST PETROLEUM UNIV

Method for restoring slurry pump casing used for river and sea dredger

The invention discloses a repair method for the inner pump casing of the high-chromium cast iron mud pump of imported dredgers and the inner pump casing of high-chromium cast iron mud pumps of domestic dredgers. First, the rust and burrs on the worn surface of the inner pump casing of the mud pump are removed, Some parts are angled as required. On the worn surface of the pump casing in the clean mud pump, use the short-arc welding process and the skip welding process to surfacing the mesh-shaped bottom layer, and knock the weld seam at the same time to eliminate stress, avoid cracks, and control the bottom layer surface. interlayer temperature above. UTP wear-resistant electrode and DC welding machine are used to weld the first wear-resistant layer, the second wear-resistant layer, the isolation layer, the third wear-resistant layer and the second wear-resistant layer on the bottom layer by short-arc welding process and skip welding process. Four wear-resistant layers to control the interlayer temperature of each layer. The inner pump casing of the repaired mud pump for dredgers does not deform and does not damage the substrate. The surfacing layer is wear-resistant and impact-resistant, saving costs by 70-90%, and the service life is increased by 3-5 times, which has promotional value.

Owner:李小鸽

A kind of high-hardness, wear-resistant and heat-resistant material for mobile phone shell

Owner:安徽酷米智能科技股份有限公司

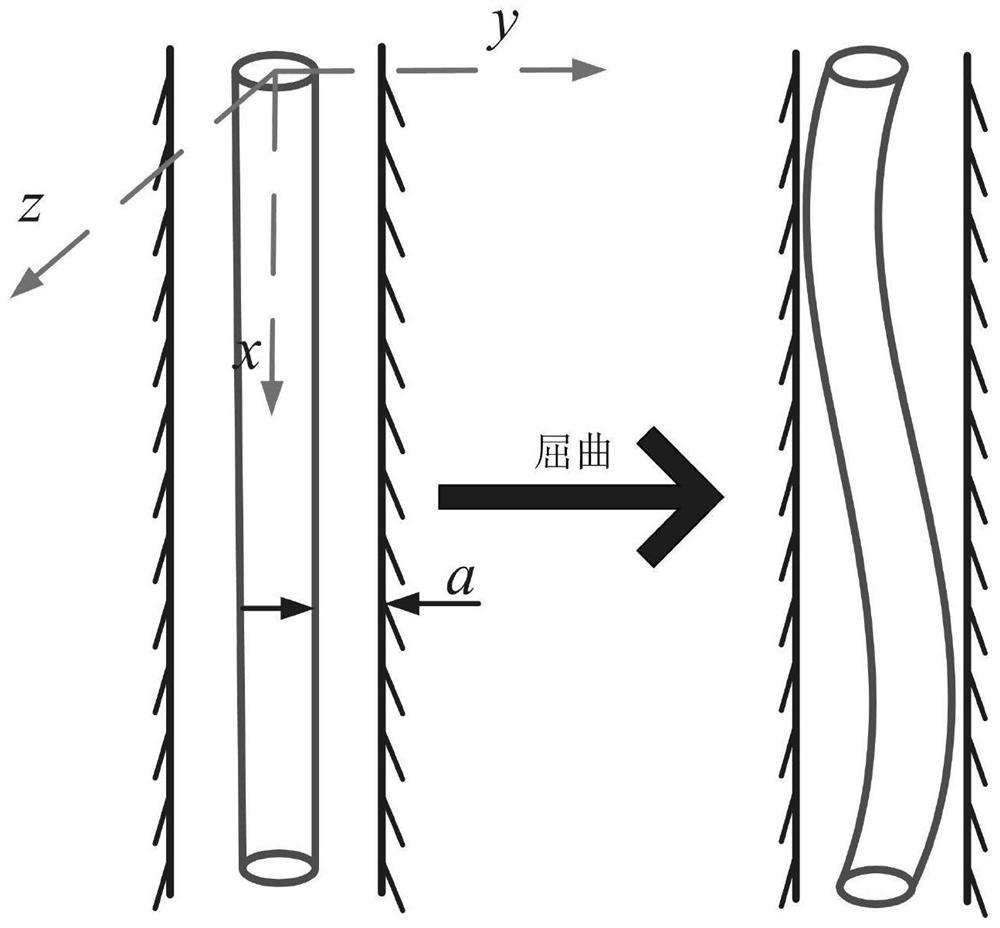

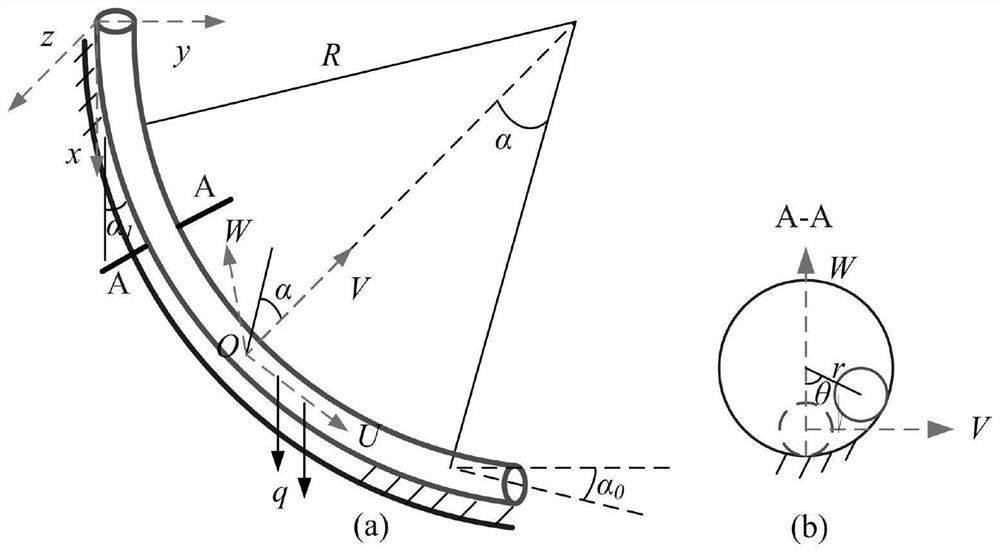

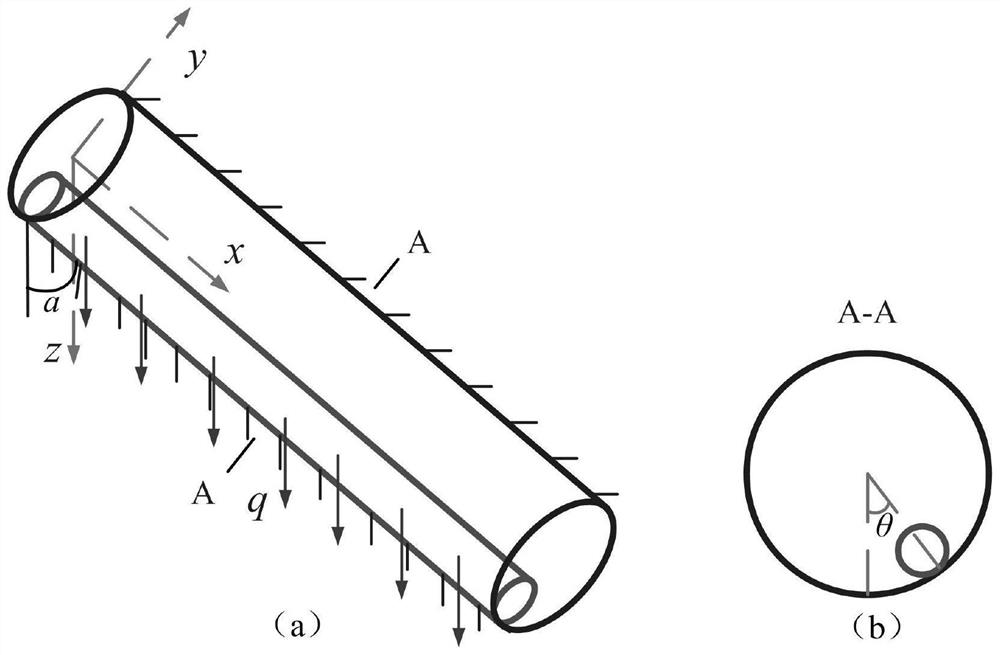

Frictional wear prediction method for high-temperature, high-pressure and high-yield tubing string casing

The invention discloses a frictional wear prediction method for a high-temperature, high-pressure and high-yield tubing string casing. The method comprises the steps of determining the total relative slippage displacement Lh of an oil casing of the tubing string casing according to a kinetic model of the tubing string casing; determining the contact force N of an oil pipe and the inner wall of the casing according to a high-temperature, high-pressure and high-yield gas well tubing string critical buckling load calculation model; carrying out an oil casing frictional wear unit test according to the field actual working condition material and the completion fluid to determine the sliding friction coefficient mu and the wear efficiency eta / Hb of the oil casing; and determining the wear volume and the wear area of the oil casing according to the total relative slippage displacement Lh of the oil casing, the contact force N of the oil pipe and the inner wall of the casing, the sliding friction coefficient mu and the wear efficiency eta / Hb. The invention provides a calculation method for buckling critical loads of tubing strings in different well sections and a calculation method for contact loads of oil casings, aiming at the problem of frictional wear failure of the oil casings caused by vibration of the tubing strings of the high-temperature, high-pressure and high-yield gas well; and the high-temperature, high-pressure and high-yield gas well tubing string frictional wear loss calculation model is established, the wear volume of the oil casing can be accurately calculated, and the wear depth is calculated accordingly.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com