Sand pump pulp inlet pipe connecting device and connecting method thereof

A technology for connecting devices and slurry inlet pipes, which is applied to parts, flange connections, pipes/pipe joints/pipe fittings of elastic fluid pumping devices, etc., which can solve the problems of inconvenient replacement, difficult installation of slurry inlet pipes, Affect environmental sanitation and other issues to achieve the effect of reducing the loss of useful metals, eliminating the phenomenon of slurry leakage, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

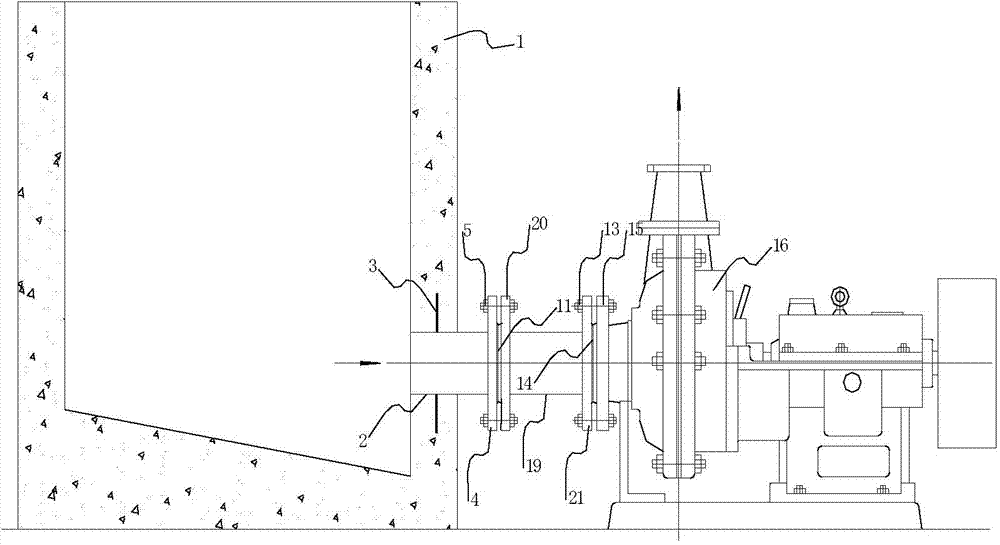

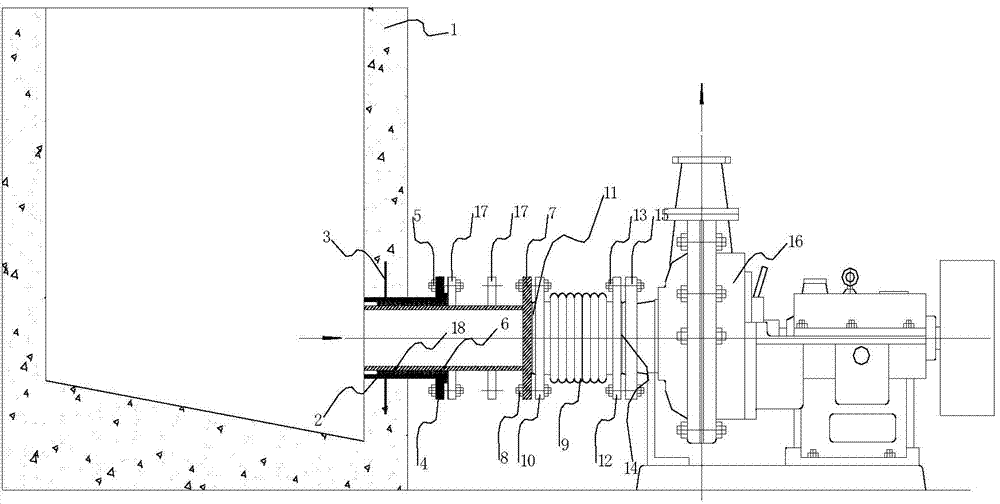

[0020] Example 1 like figure 2 As shown, a sand pump slurry inlet pipe connection device includes a fixed sleeve 2 pre-embedded in the wall at the outlet of the sand pump pool 1, and an anchor is welded on the outer pipe wall of the fixed sleeve 2 embedded in the wall. Rib 3, the end of the fixed sleeve 2 protruding from the wall is welded with a 1# flange 4: the movable sleeve 6 whose outer diameter is smaller than the inner diameter of the fixed sleeve 2 extends into the fixed sleeve 2, and the fixed sleeve 2 is connected to the fixed sleeve 2. The gap between the movable sleeves 6 is filled with sealing packing 18; the outer end of the movable sleeve 6 is welded with a 2# flange 7, and the middle part of the movable sleeve 6 is covered with a sliding fit and matched with the 1# flange 4 The movable flange 17, the movable flange 17 is tightened and connected with the 1# flange 4 through the 1# bolt 5, and the sealing packing 18 is pressed; the 3# flange 10 at the left end...

Embodiment 2

[0027] Example 2 like figure 2 As shown, the method for connecting the slurry inlet pipe of a sand pump with a sand pump inlet pipe connection device described in Embodiment 1 includes;

[0028] [1] Set the movable flange 17 on the movable sleeve 6, and then extend the small end of the movable sleeve 6 into the fixed sleeve 2;

[0029] [2] Add 2# rubber gasket 14 to the 4# flange plate 12 on the right end of the telescopic tube 9, connect it to the 5# flange plate 15 of the slurry inlet of the sand pump 16 through the 3# bolt 13, and connect the 4# flange plate 12 Match with 5# flange 15;

[0030] [3] The outer end of the movable sleeve 6 located outside the fixed sleeve 2 is welded with a 2# flange 7, and the 3# flange 10 at the left end of the telescopic tube 9 is added to the 1# rubber gasket 11, through the 2 #Bolt 8 is connected with the matching 2# flange 7;

[0031] [4] Insert the sealing packing 18 into the gap between the fixed sleeve and the movable sleeve to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com