Patents

Literature

161results about How to "Avoid slurry leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

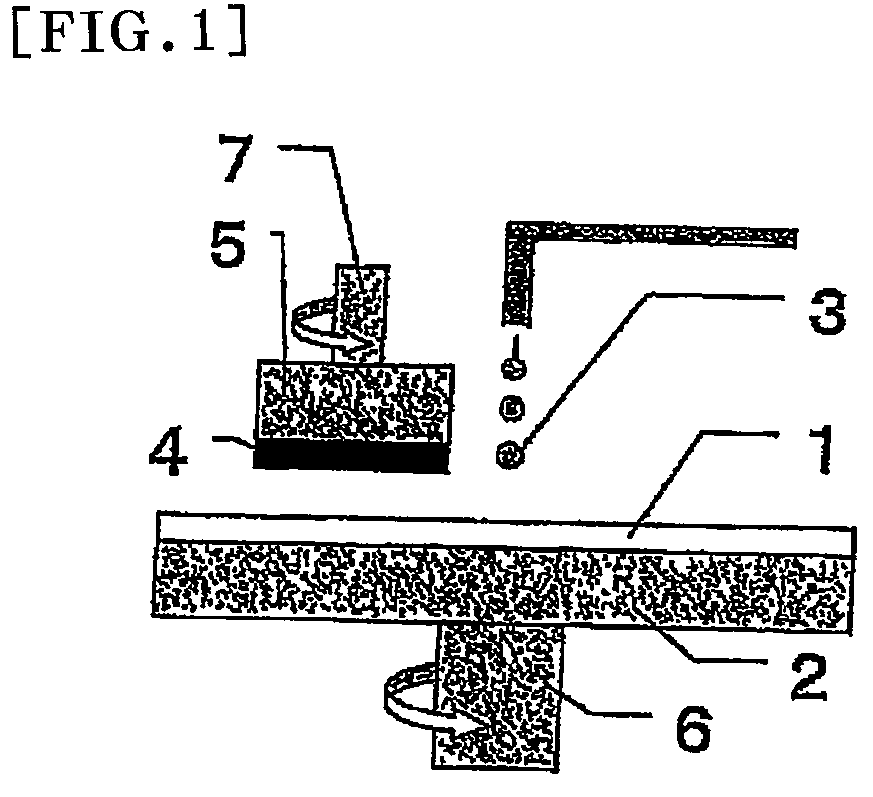

Method for manufacturing polishing pad

InactiveUS20090093202A1Improve productivityHigh thickness accuracyLamination ancillary operationsAbrasion apparatusProduction rateEngineering

A method for manufacturing a polishing pad, which may be laminated, with a small number of manufacturing steps, high productivity and no peeling between a polishing layer and a cushion layer includes preparing a cell-dispersed urethane composition by a mechanical foaming method; continuously discharging the cell-dispersed urethane composition onto a face material, while feeding the face material; laminating another face material on the cell-dispersed urethane composition; curing the cell-dispersed urethane composition, while controlling its thickness to be uniform, so that a polishing layer including a polyurethane foam is formed; cutting the polishing layer parallel to the face into two pieces so that two long polishing layers each including the polishing layer and the face material are simultaneously formed; and cutting the long polishing layers to produce the polishing pad.

Owner:TOYO TIRE & RUBBER CO LTD

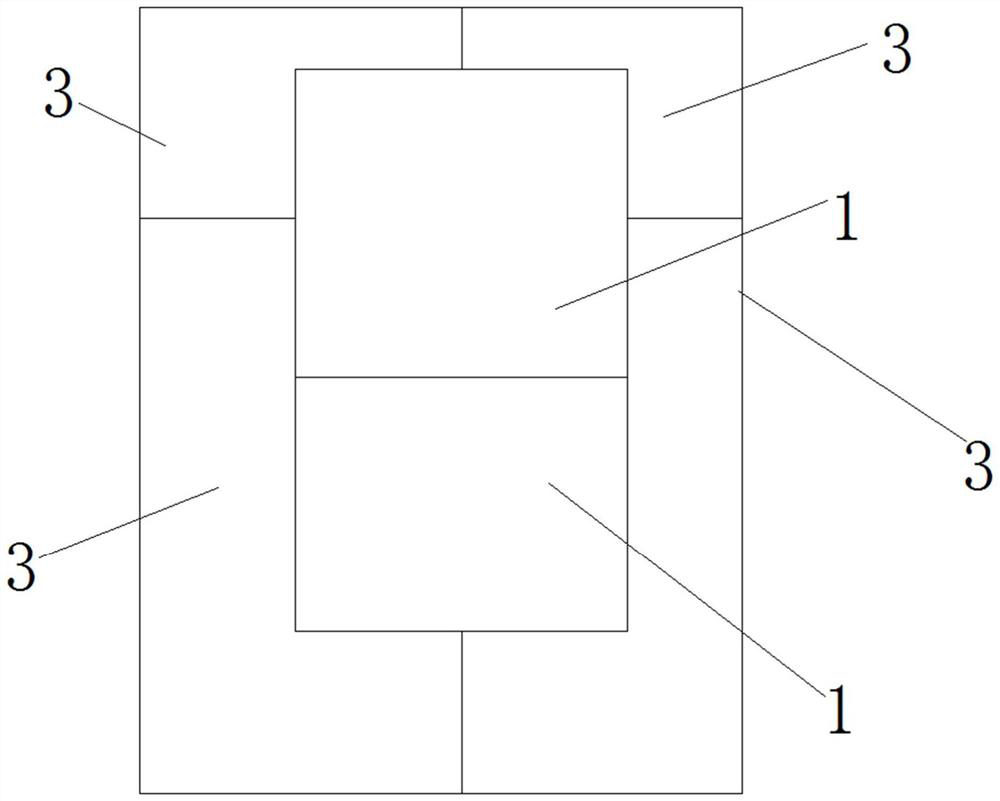

Improved concrete wall and column construction method

The invention discloses an improved concrete wall and column construction method. The method comprises the steps of pre-cleaning, basic steel bar binding, locating steel bar welding, angle steel mounting, limiting steel bar welding, formwork mounting, concrete pouring, mold removal cleaning and the like. The mode of carrying out synchronous mounting construction on roots of concrete walls and columns through angle steel and formworks is adopted, the construction progress is quick, the work load is small, the angle steel can be cyclically used many times, construction cost is saved, the situation of root rotting and slurry leaking can be avoided well, and the roots of the concrete walls and columns are formed attractively.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

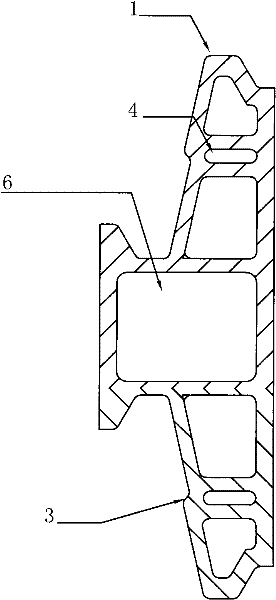

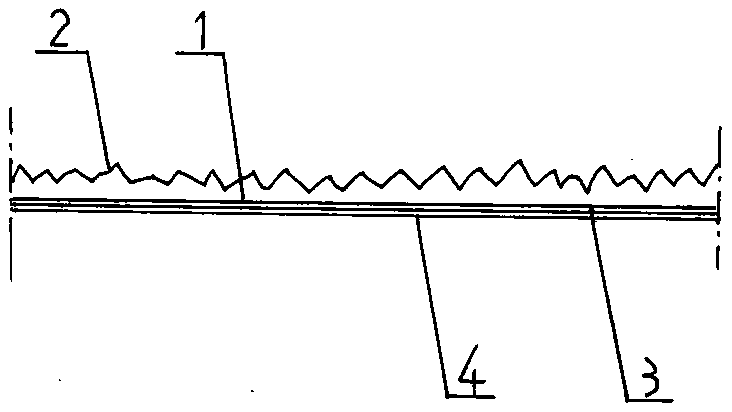

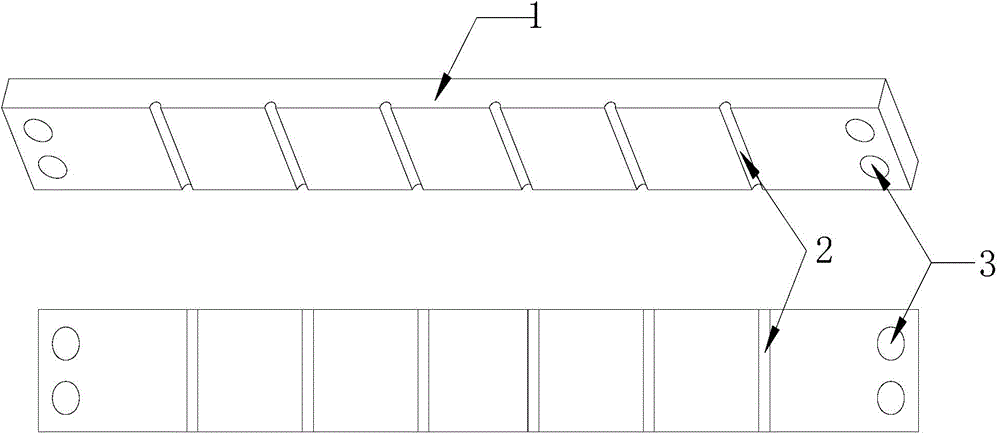

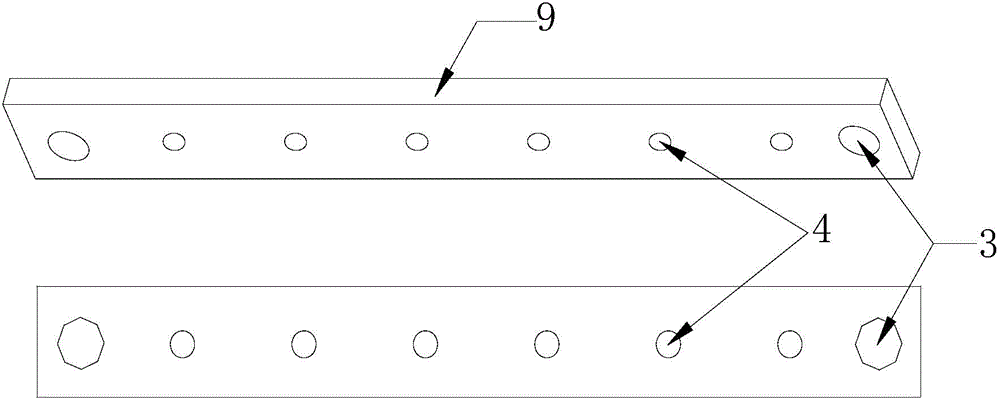

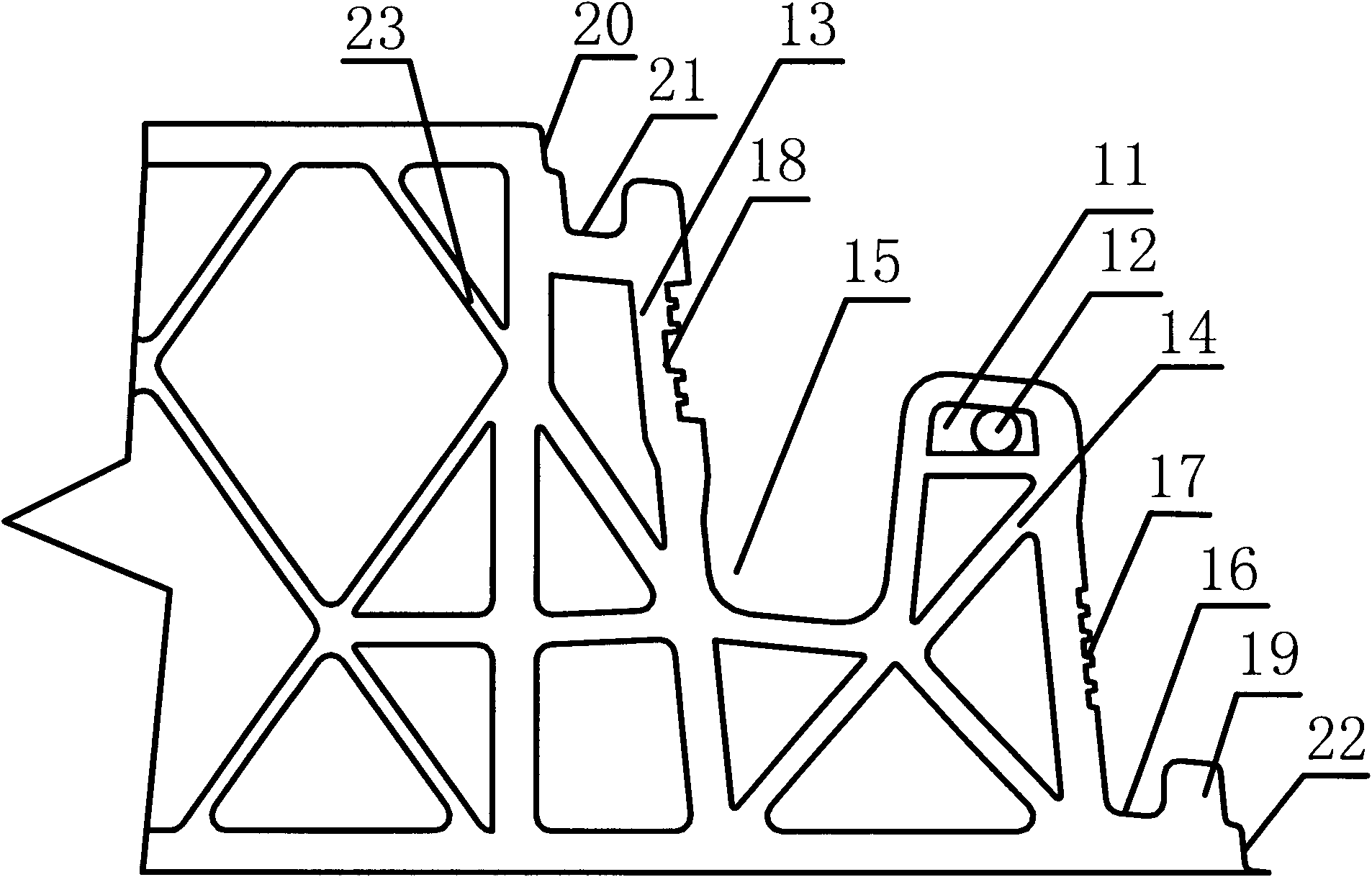

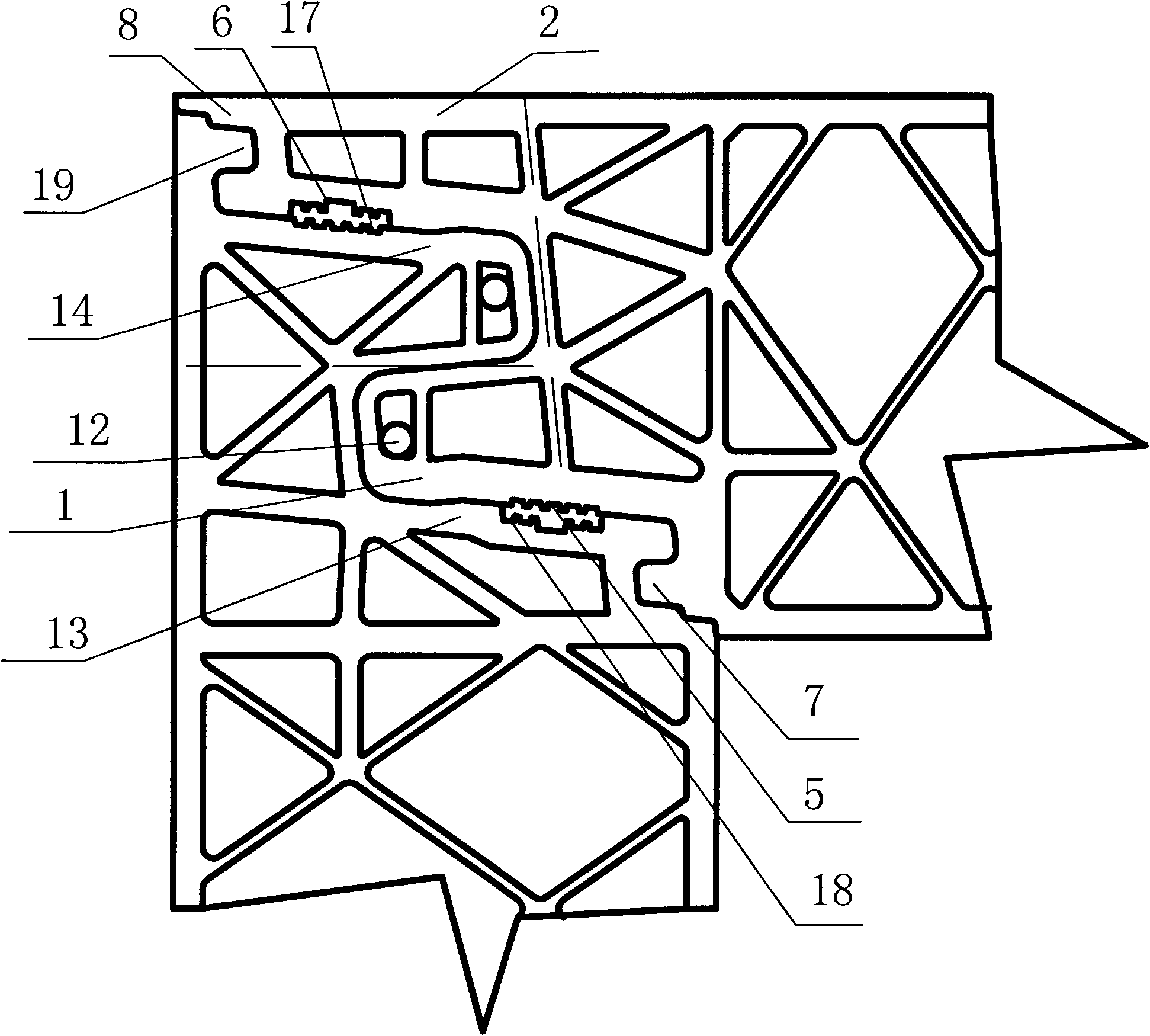

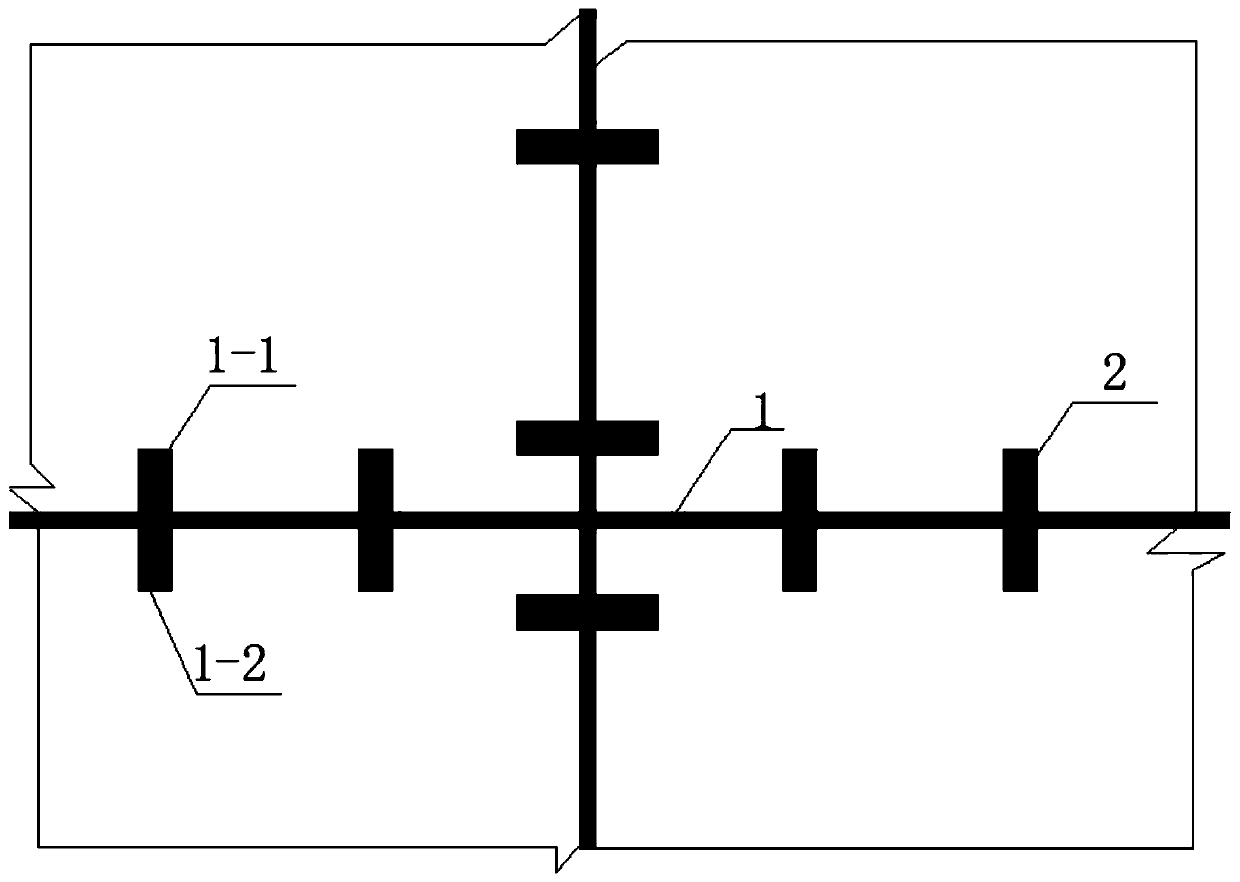

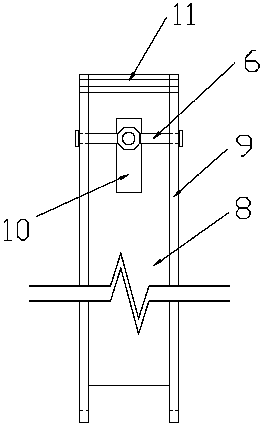

Precision building template system

ActiveCN102330493AImprove bindingAchieve matingAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSlurryEngineering

The invention discloses a spliceable precision building template system which is provided with two panels and reinforced ribs for connecting the two panels, wherein connecting heads (9) are formed on the splicing sides spliced with adjacent templates; seen from the cross section of the template, each connecting head (9) comprises a chuck (1) protruding towards the adjacent template, a clamping groove (2) and a connecting mechanism (4); the clamping groove (2) is inwards concaved relative to the protruding direction of the chuck (1); the connecting heads (9) of the adjacent templates are combined together by using the connecting mechanism (4); and the chuck (1) is suitably embedded into the clamping groove (2); and outer surfaces of the panels at two sides of the adjacent templates are positioned on the same plane at the same side. The building template with the structure can be freely spliced; after splicing, a joint is tight and favorable integrity is achieved; and after grouting, the probability of slurry leakage is low.

Owner:王亚运

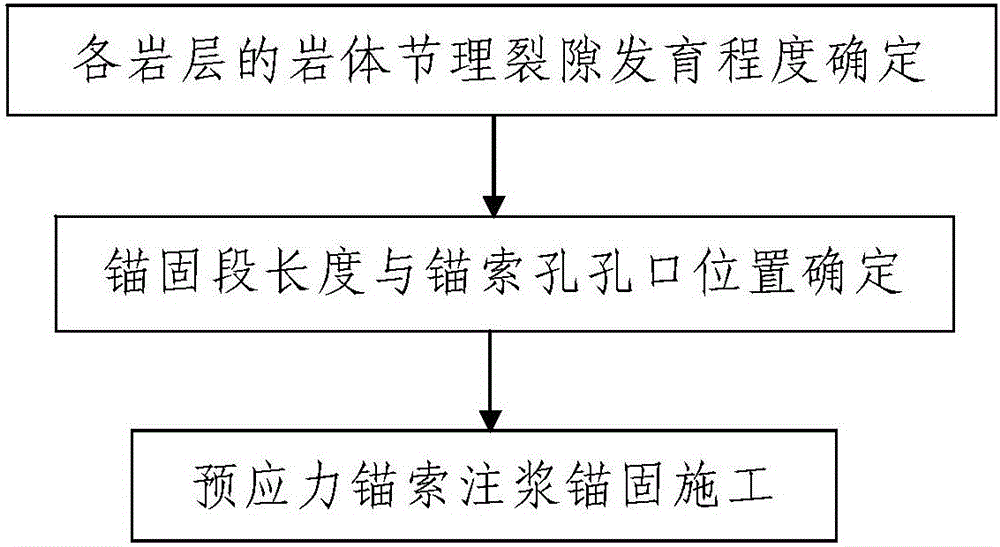

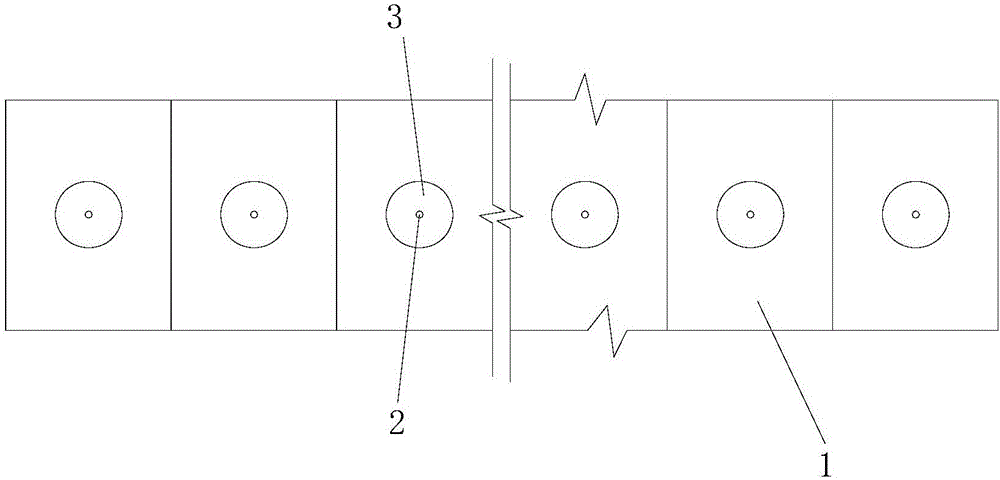

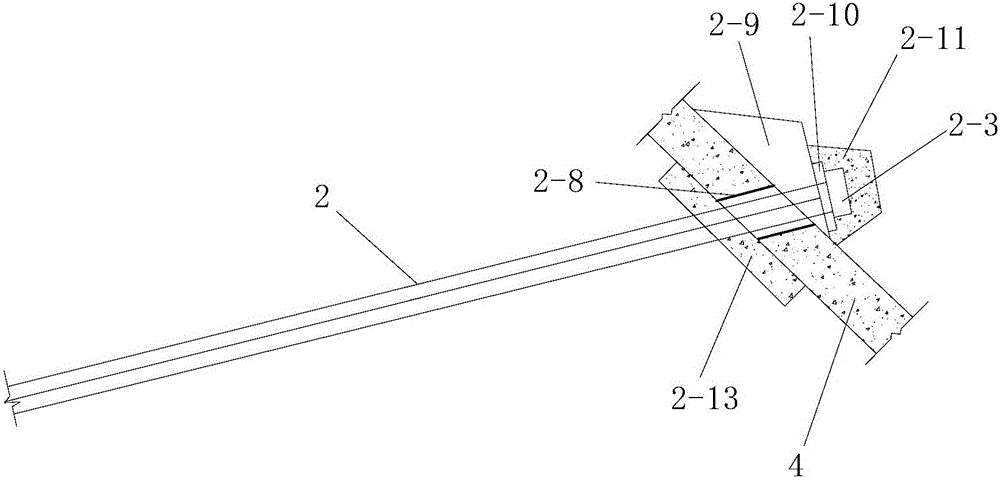

Fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method

ActiveCN106522243AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressHigh pressure

The invention discloses a fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method. Multiple prestressed anchor cables uniformly distributed on the same one plane are adopted to reinforce a slope to be reinforced; the method comprises the following steps: (1) the rock mass joint fissure development degree of each rock stratum is determined; (2) the lengths of anchoring sections and the hole port positions of anchor cable holes are determined; the prestressed anchor cables include anchor cable bodies, primary grouting pipes and secondary grouting pipes; anchoring tools are mounted at the back ends of the anchor cable bodies; and the anchor cable bodies include multiple steel strands; and (3) the prestressed anchor cables are grouted and anchored: when any one prestressed anchor cable is grouted and anchored, the construction includes the steps of drilling, placement of the anchor cables, normal-pressure grouting, high-pressure grouting, tensioning of the anchor cables and anchor sealing. The method is simple in steps, reasonable in design, convenient to construct, high in construction efficiency and excellent in use effect, and can conveniently and quickly finish the reinforcing process of the slope to be reinforced; and the adopted prestressed anchor cables are low in cost and higher in anchoring force, and can effectively reinforce the slope to be reinforced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

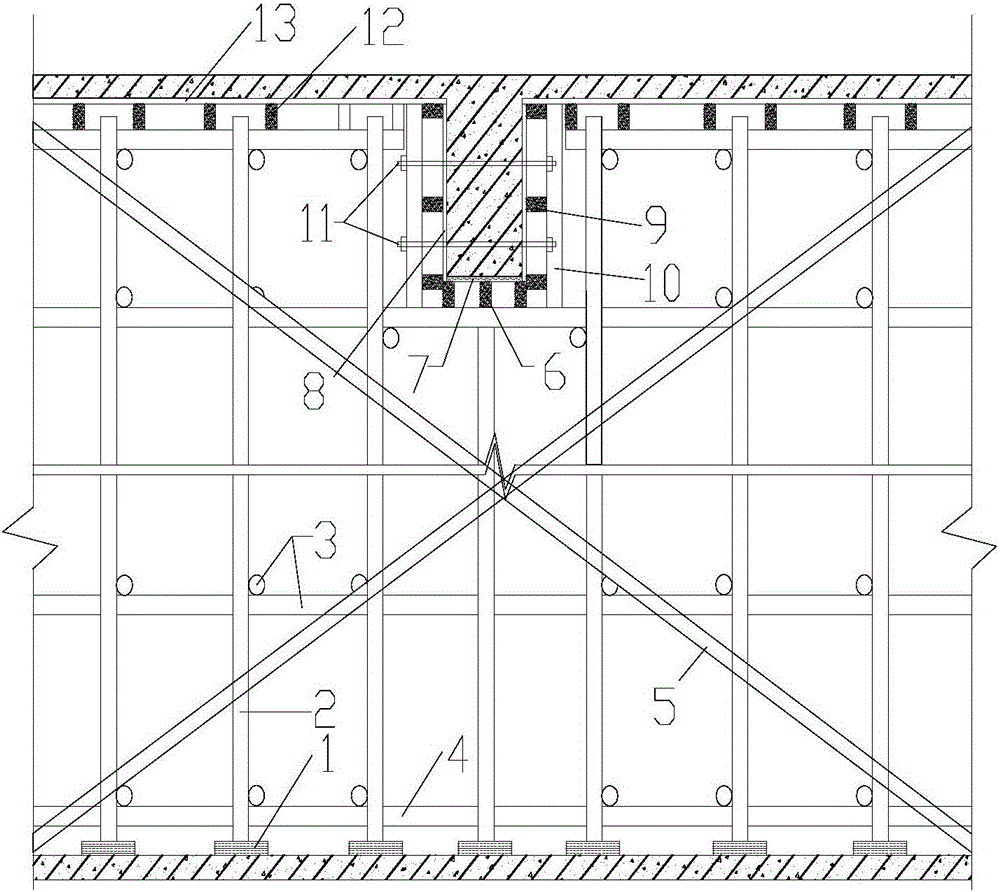

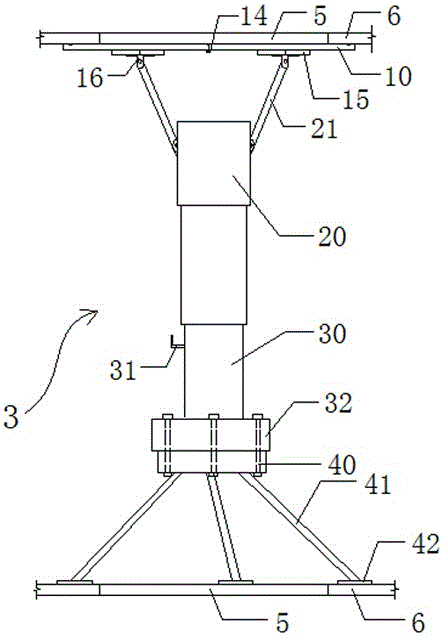

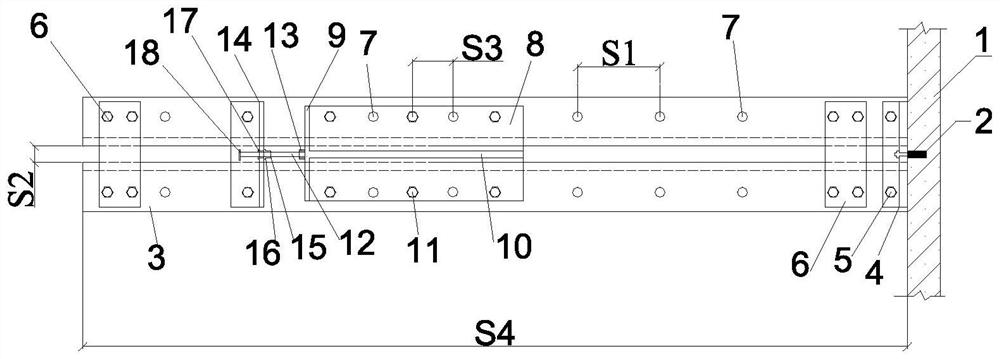

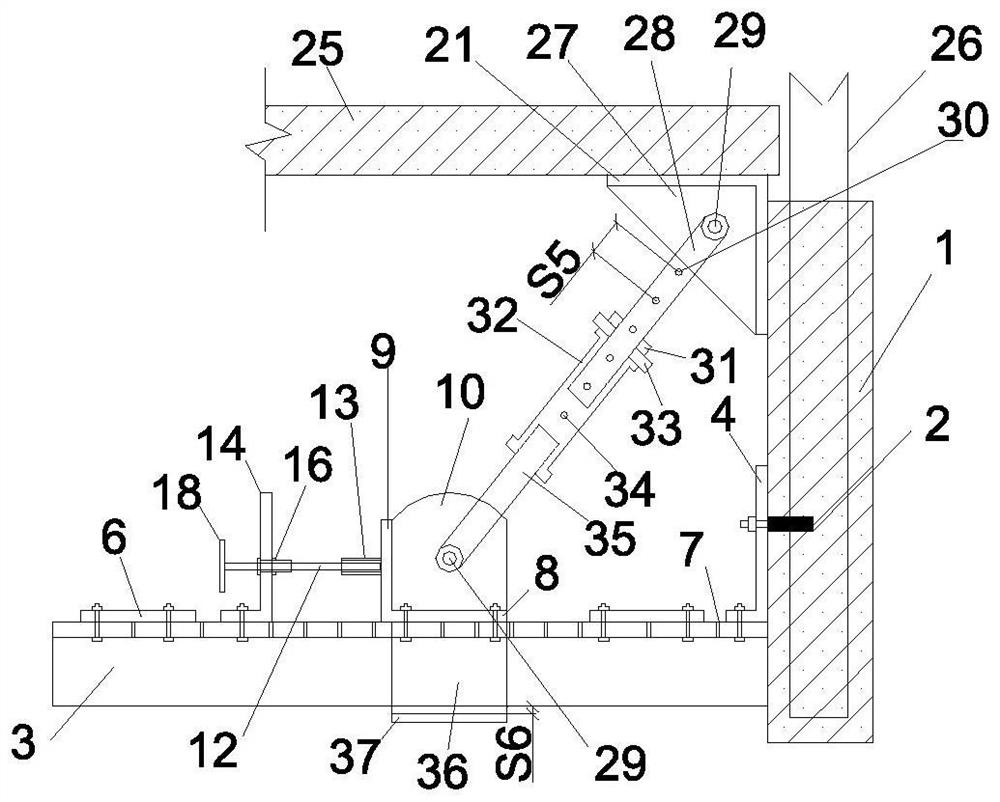

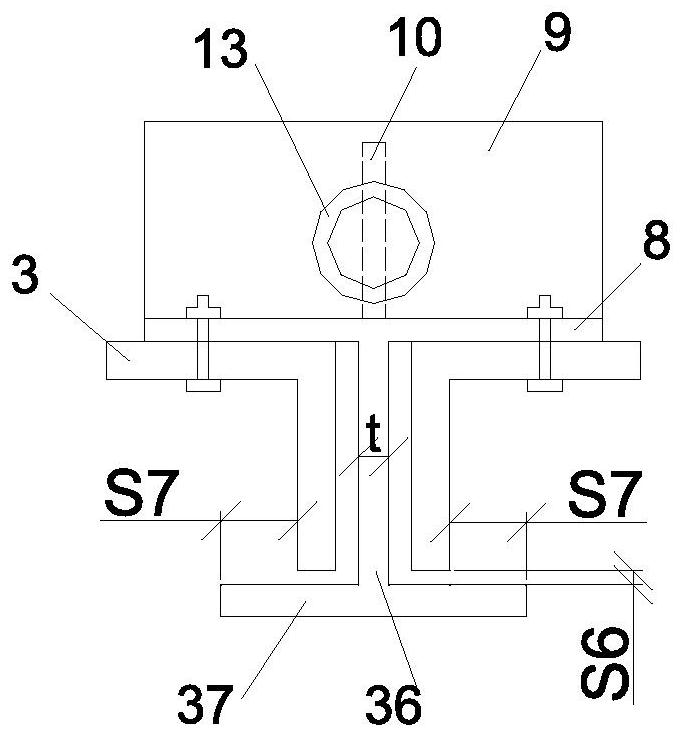

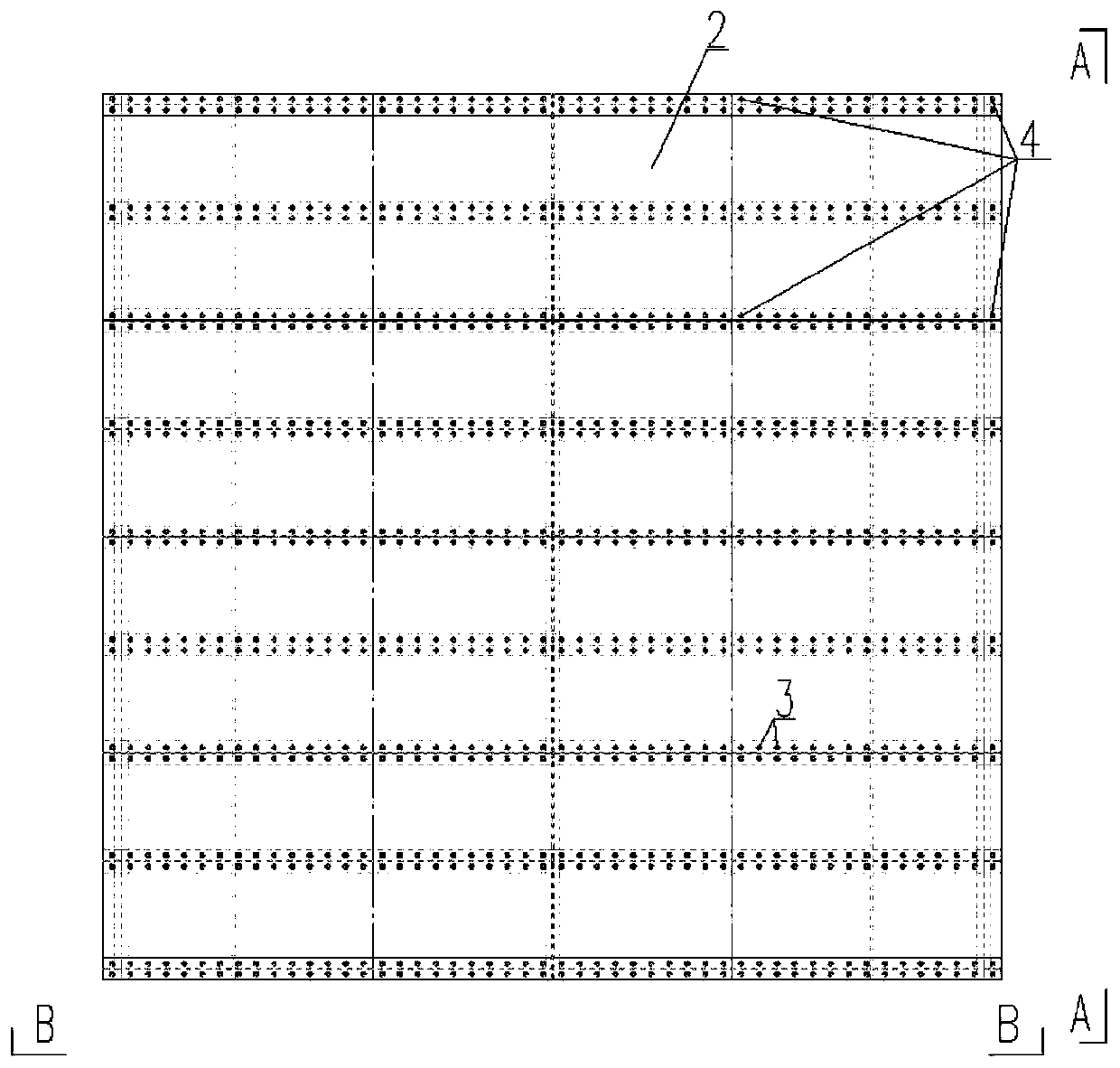

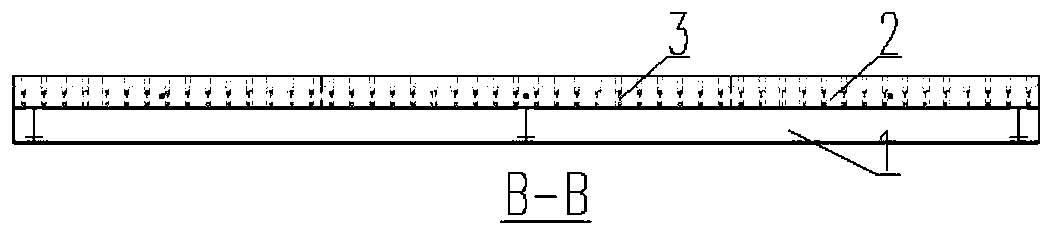

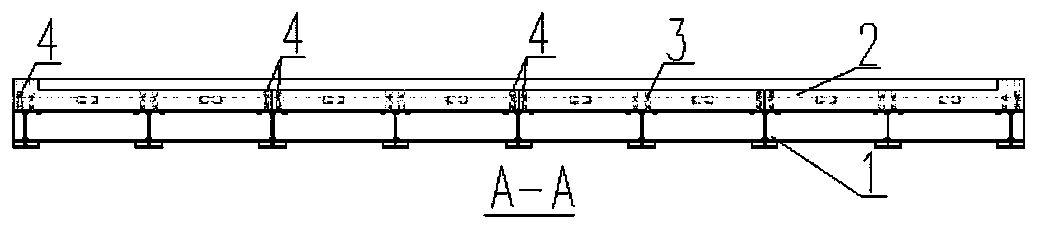

Adjustable large-area floor steel channel formwork system and construction method thereof

InactiveCN103498555AIncrease stiffnessAvoid lateral inward tippingForms/shuttering/falseworksSurface layerThreaded rod

The invention relates to an adjustable large-area floor steel channel formwork system and a construction method of the adjustable large-area floor steel channel formwork system. The system comprises a steel channel formwork, a supporting frame and a batten side mold, and a plurality of stiffening plates with vertical adjusting slot holes are welded in a groove of the steel channel formwork. The supporting frame is composed of vertical rods, horizontal rods and inclined rods, the upper portions of the vertical rods are connected with horizontal connecting parts which are parallel to the horizontal rods and extend into the groove of the formwork, threaded rods connected to the horizontal connecting parts penetrate through the vertical adjusting slot holes and are connected with the stiffening plates in an adjustable mode through nuts, and the top ends of the vertical rods are welded with transverse formwork stopping parts which are perpendicular to and tightly attached to the outer sides of the stiffening plates. The adjustable large-area floor groove steel formwork system further comprises a demolding threaded rod and a rotary hand shank. The construction method includes formwork installing and formwork removing. The adjustable large-area floor groove steel formwork system solves the technical problems that due to the fact that the formwork is not firmly supported and reinforced in an existing large-area floor formwork system, errors of elevation of concrete poured subsequently and flatness of a surface layer are large, formed large-area floor concrete is poor visually, and use functions are affected.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

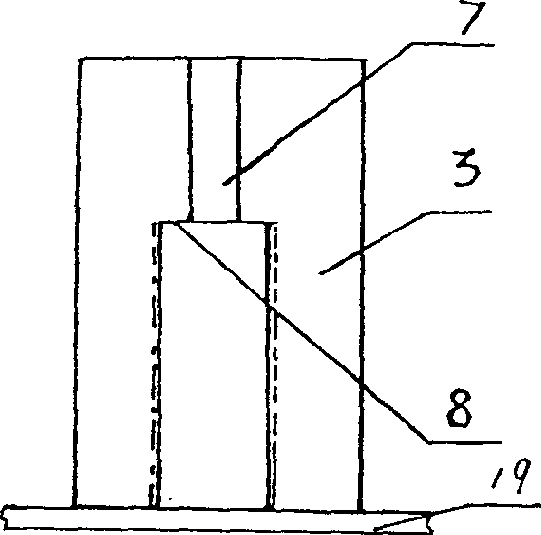

Masonry wall constructional column forming method

InactiveCN110644677AAchieve rotationReduce frictionStrutsForms/shuttering/falseworksArchitectural engineeringStructural engineering

Owner:CHINA METALLURGICAL CONSTR ENG GRP

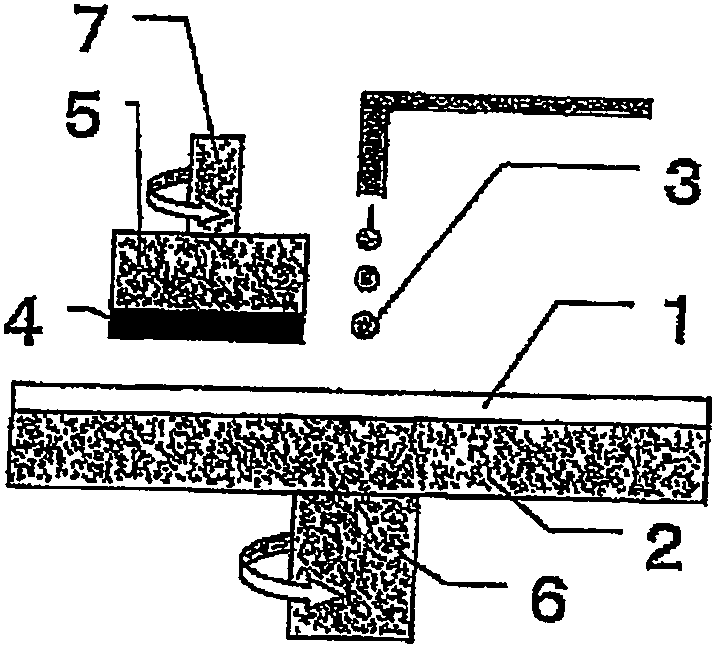

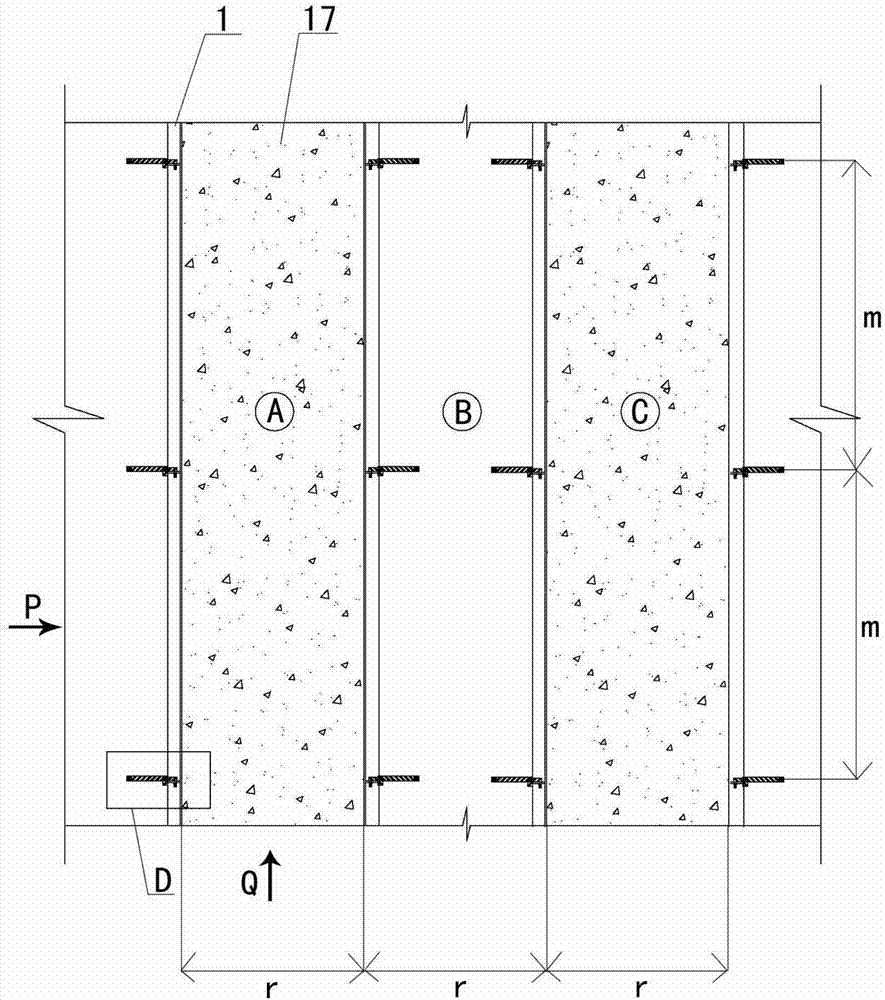

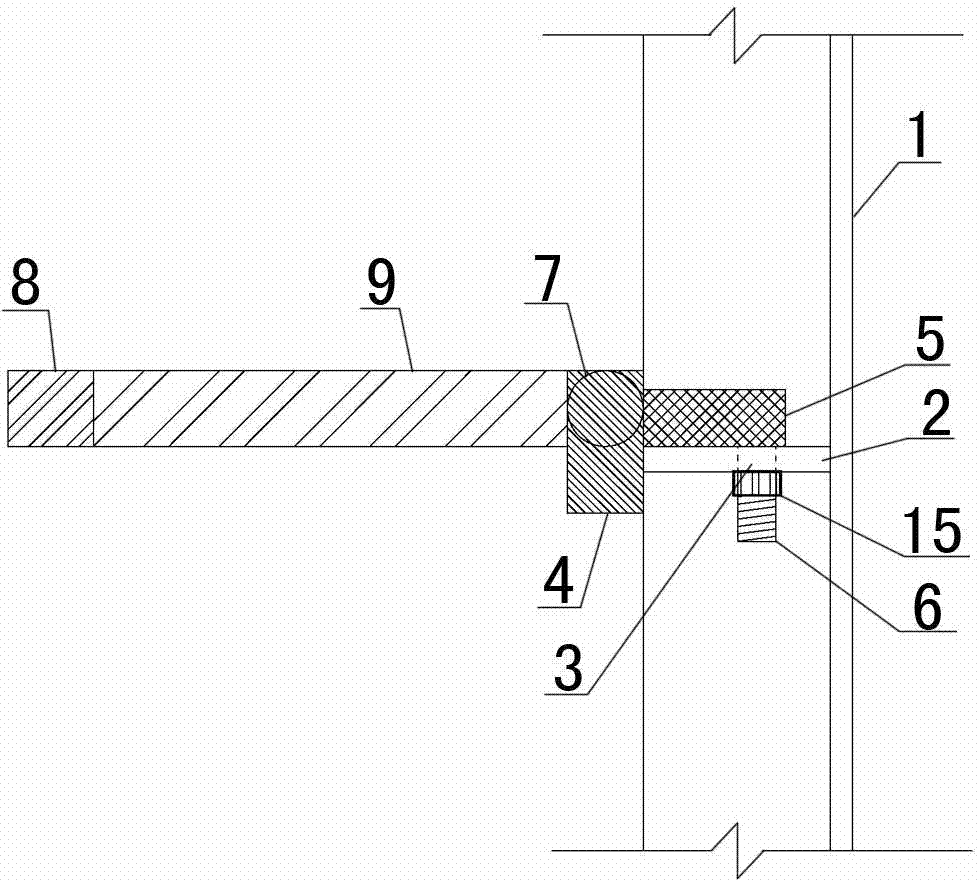

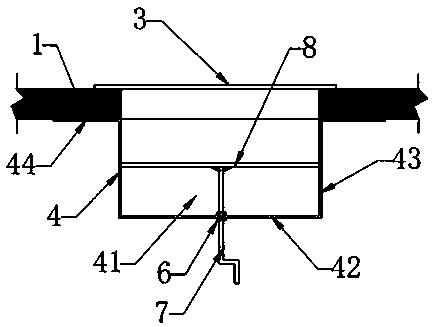

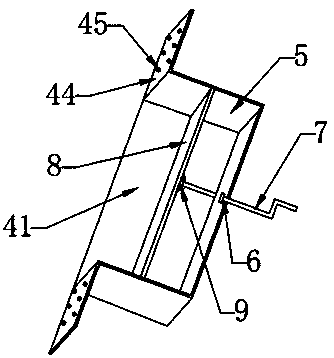

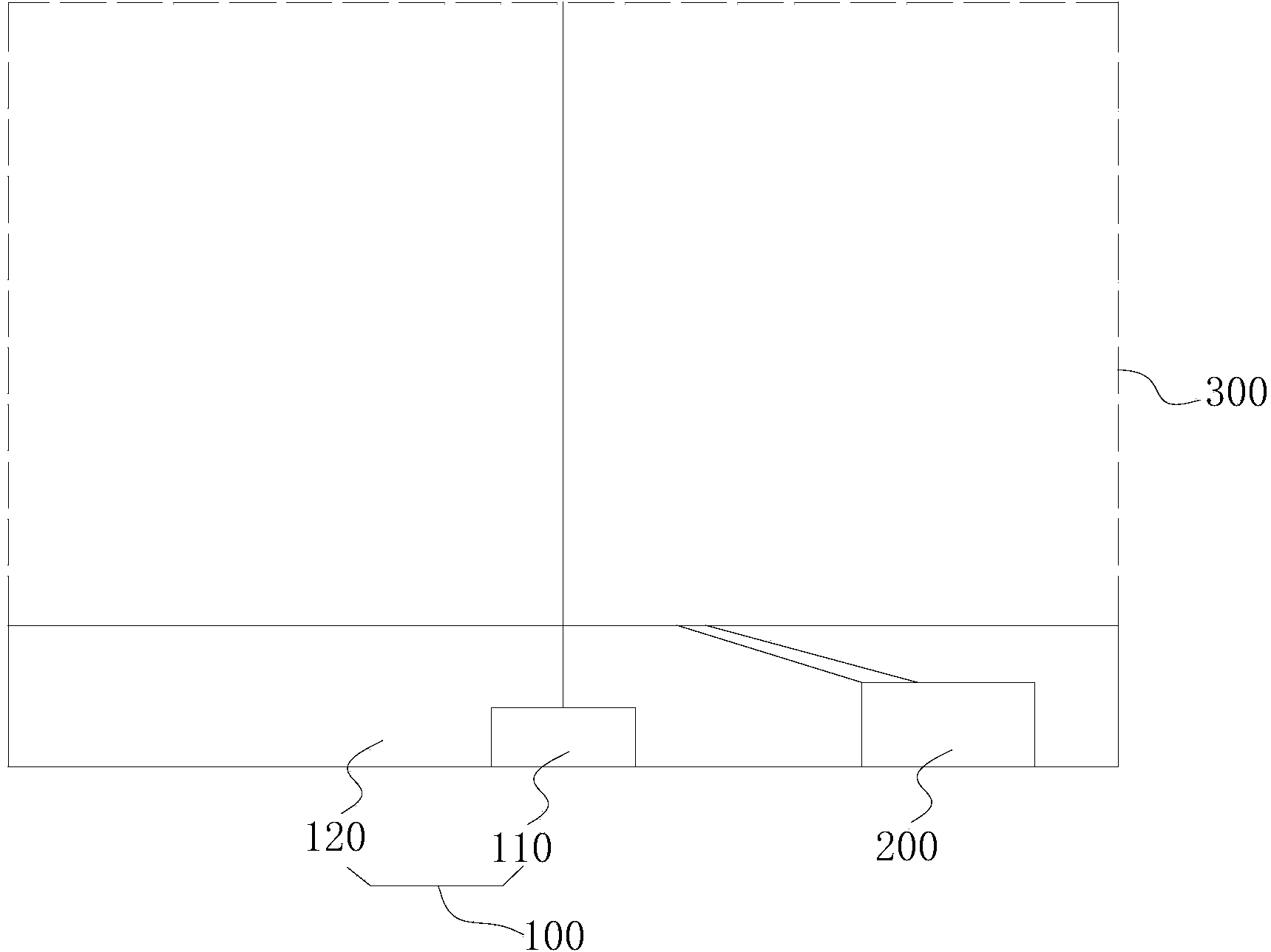

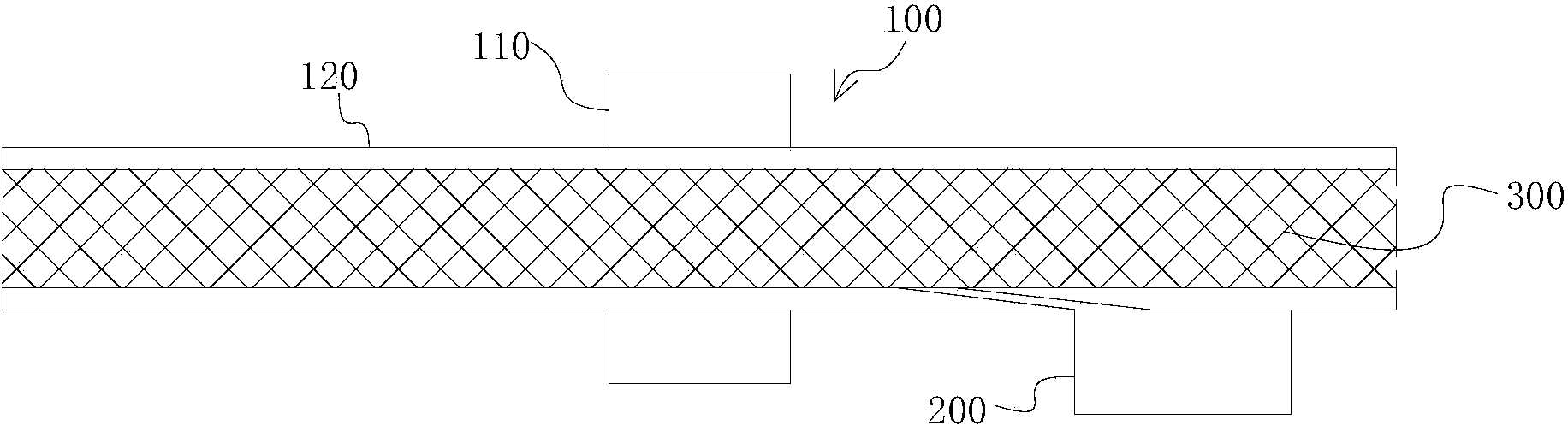

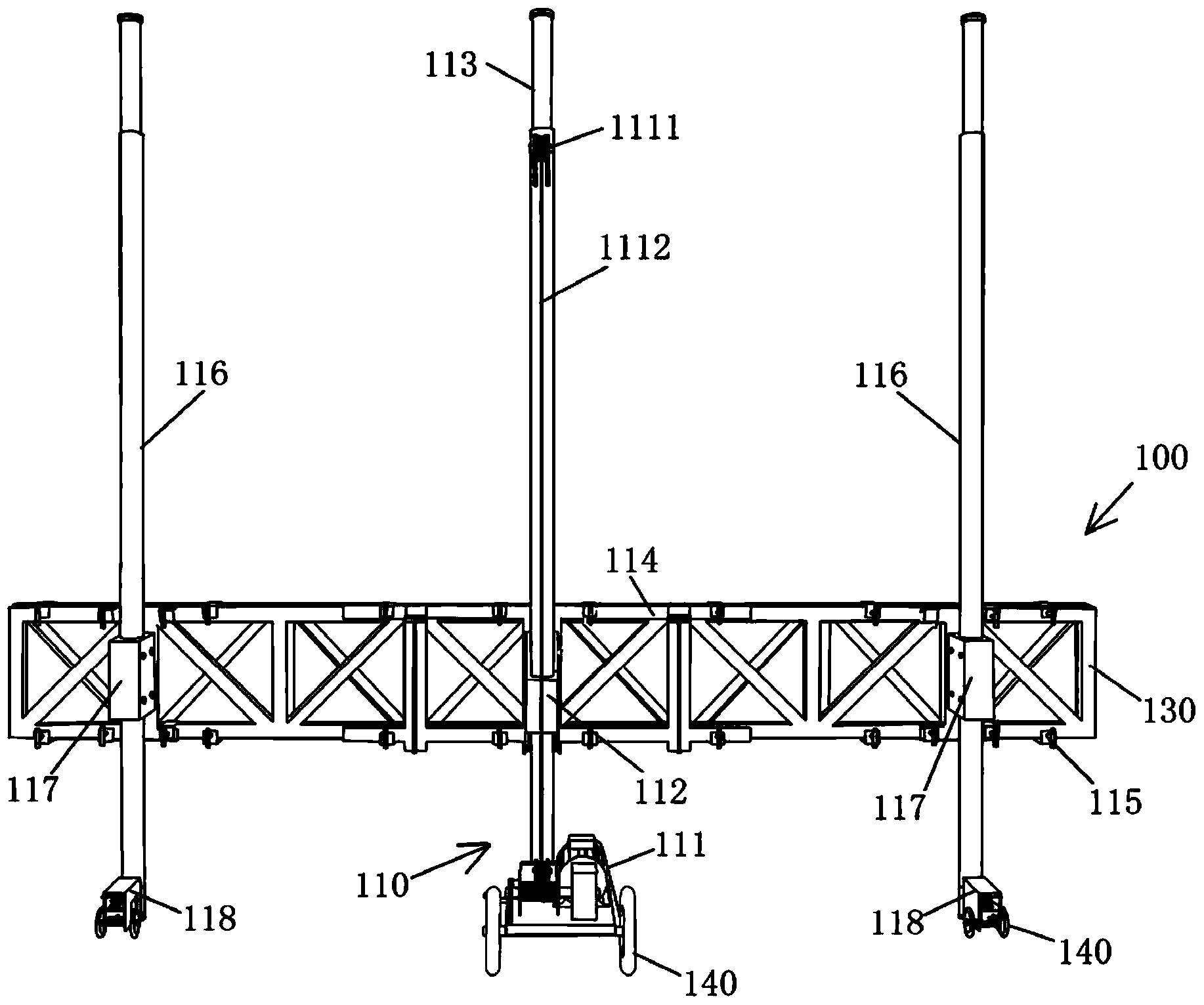

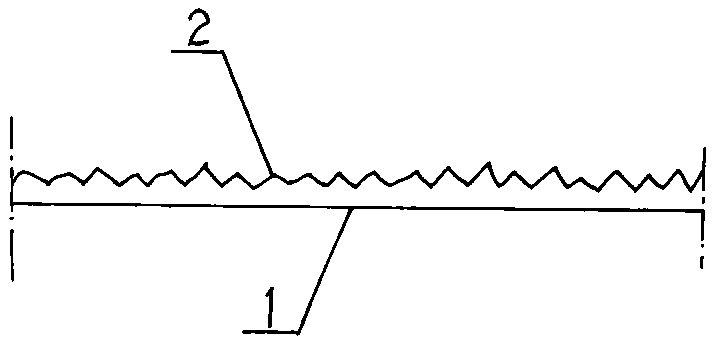

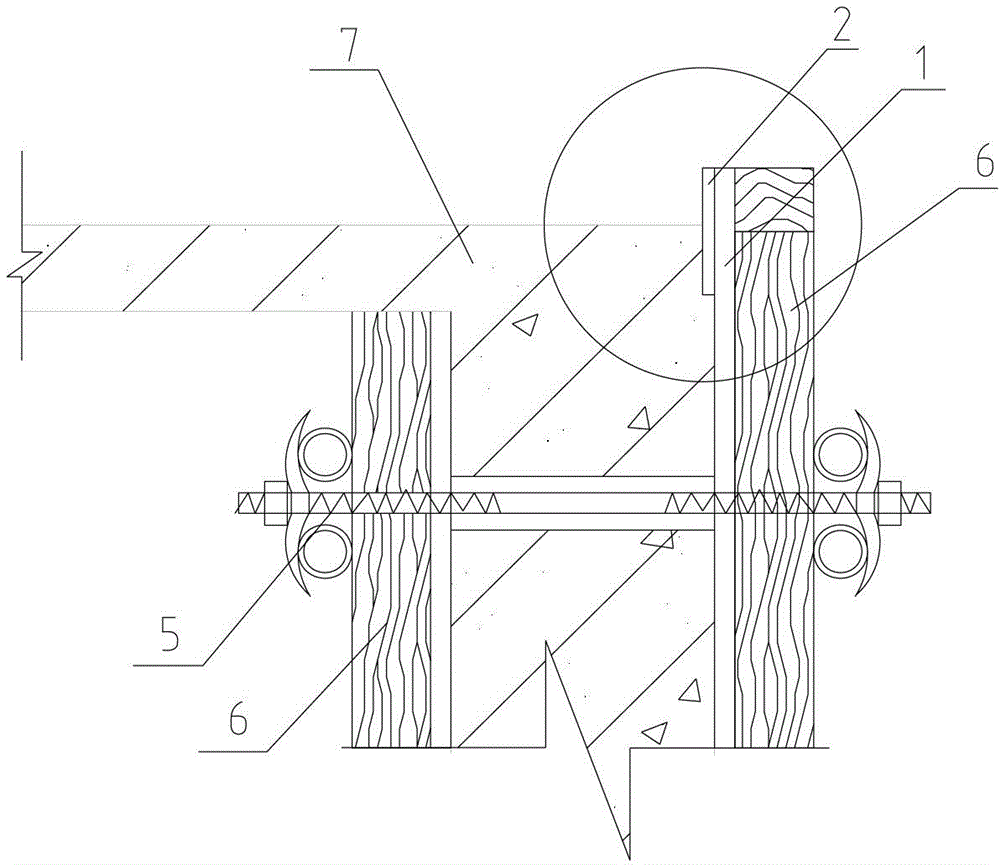

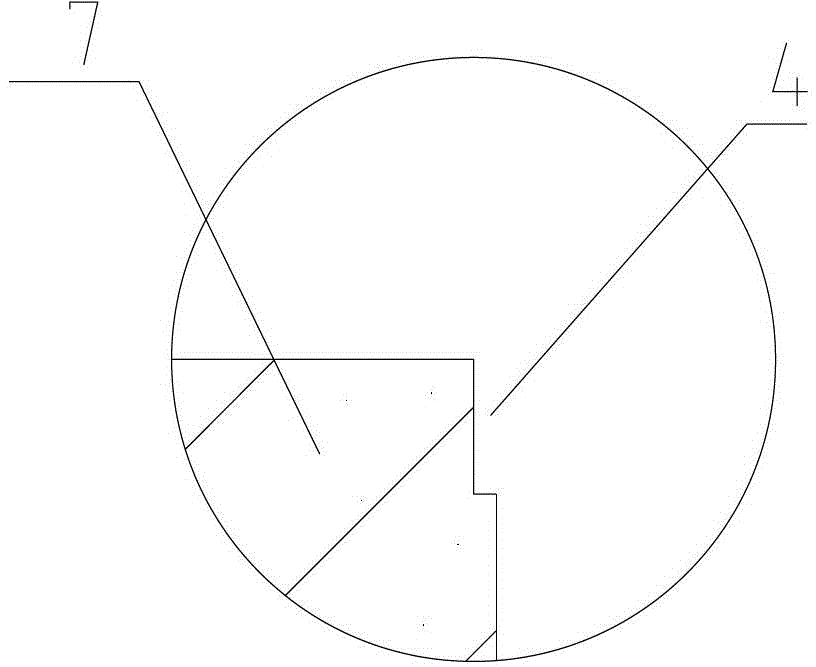

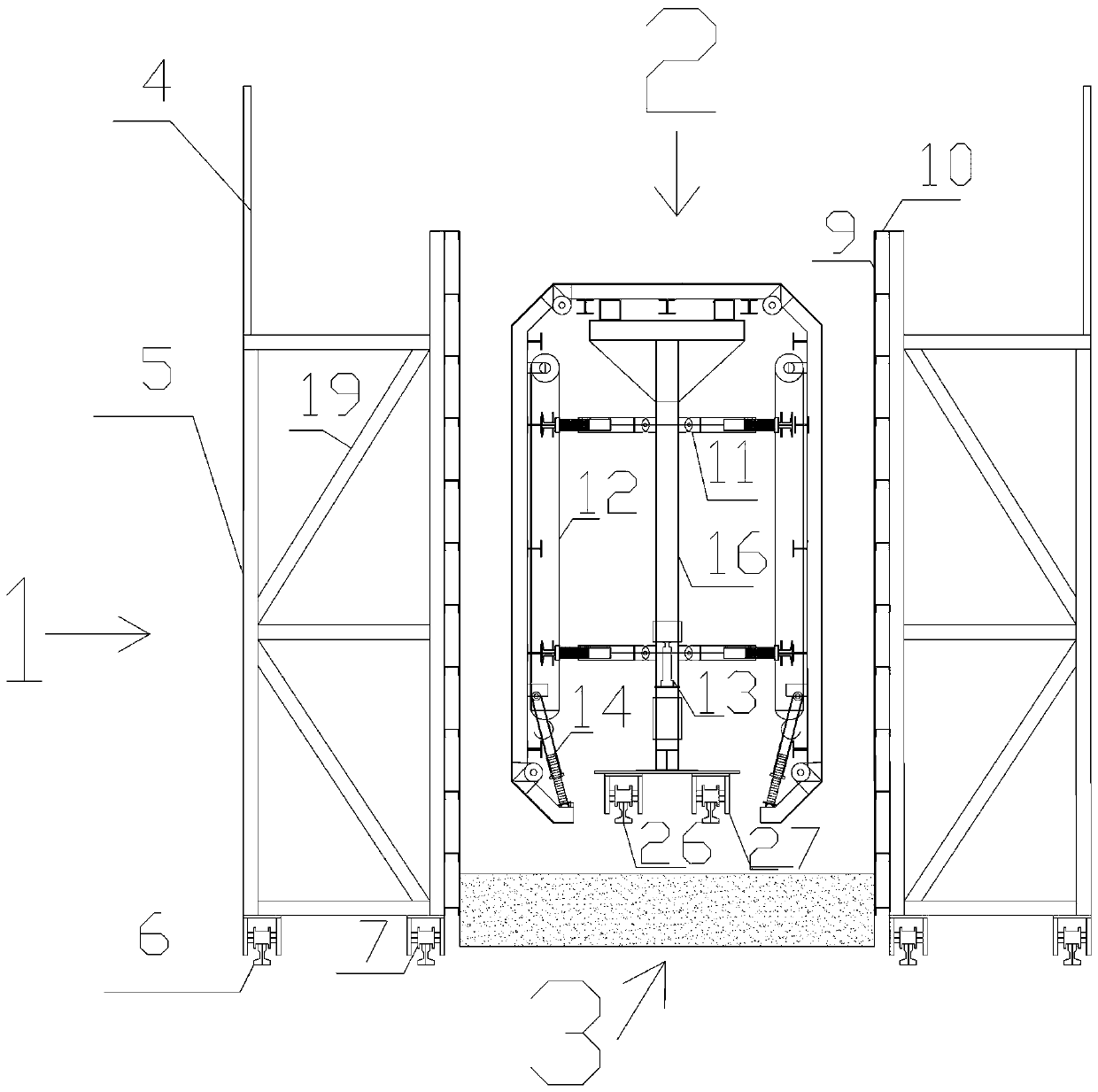

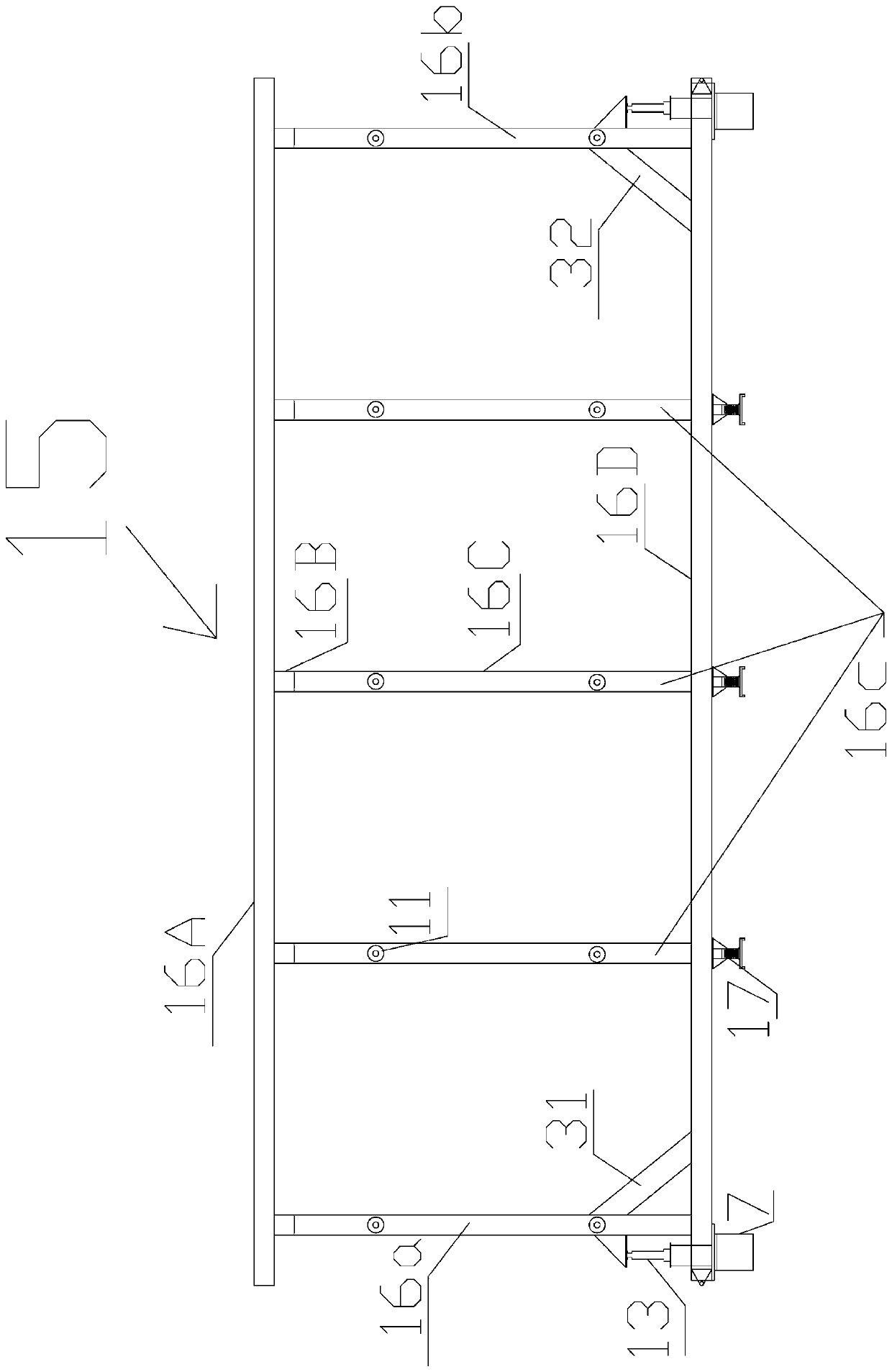

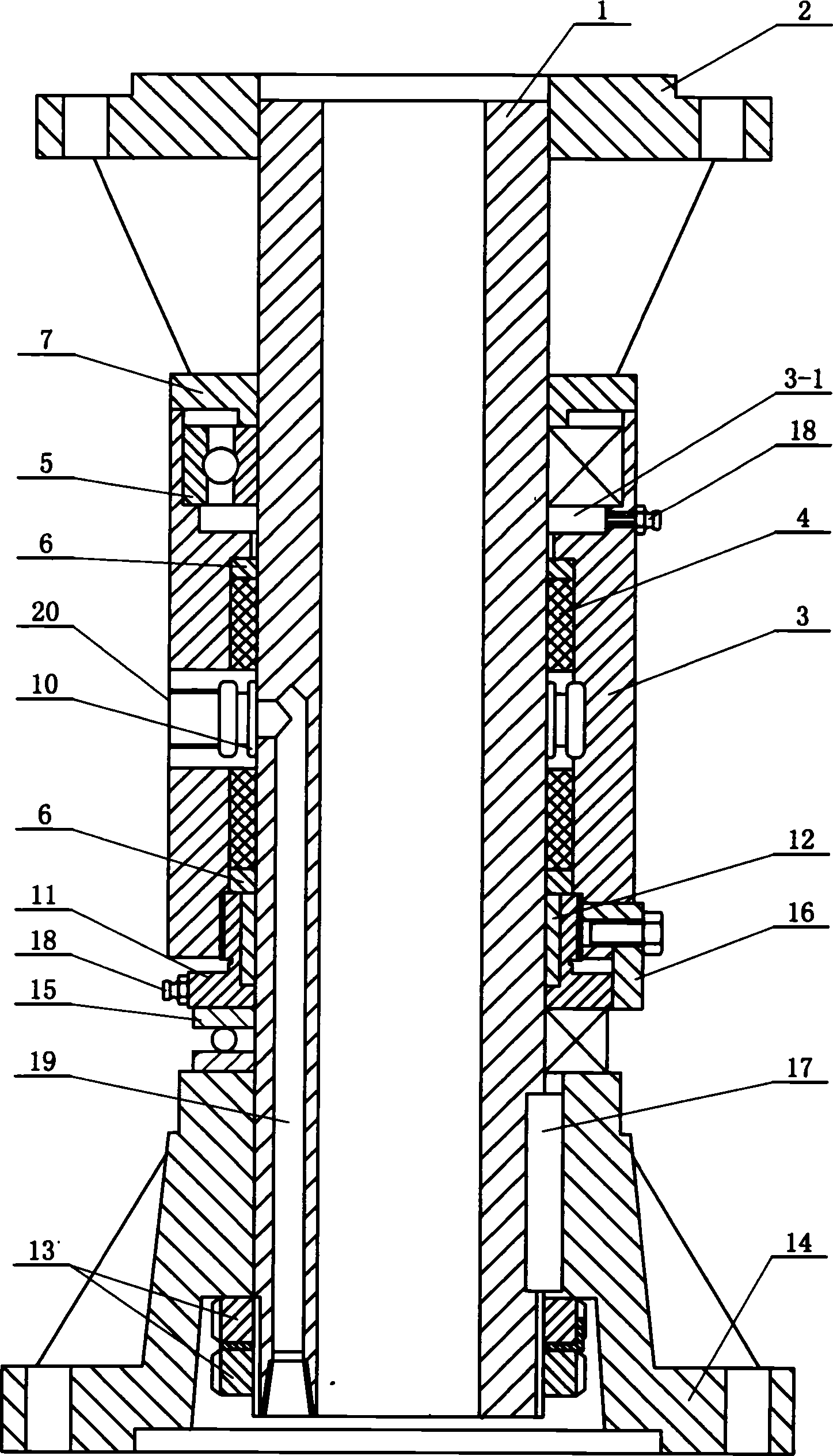

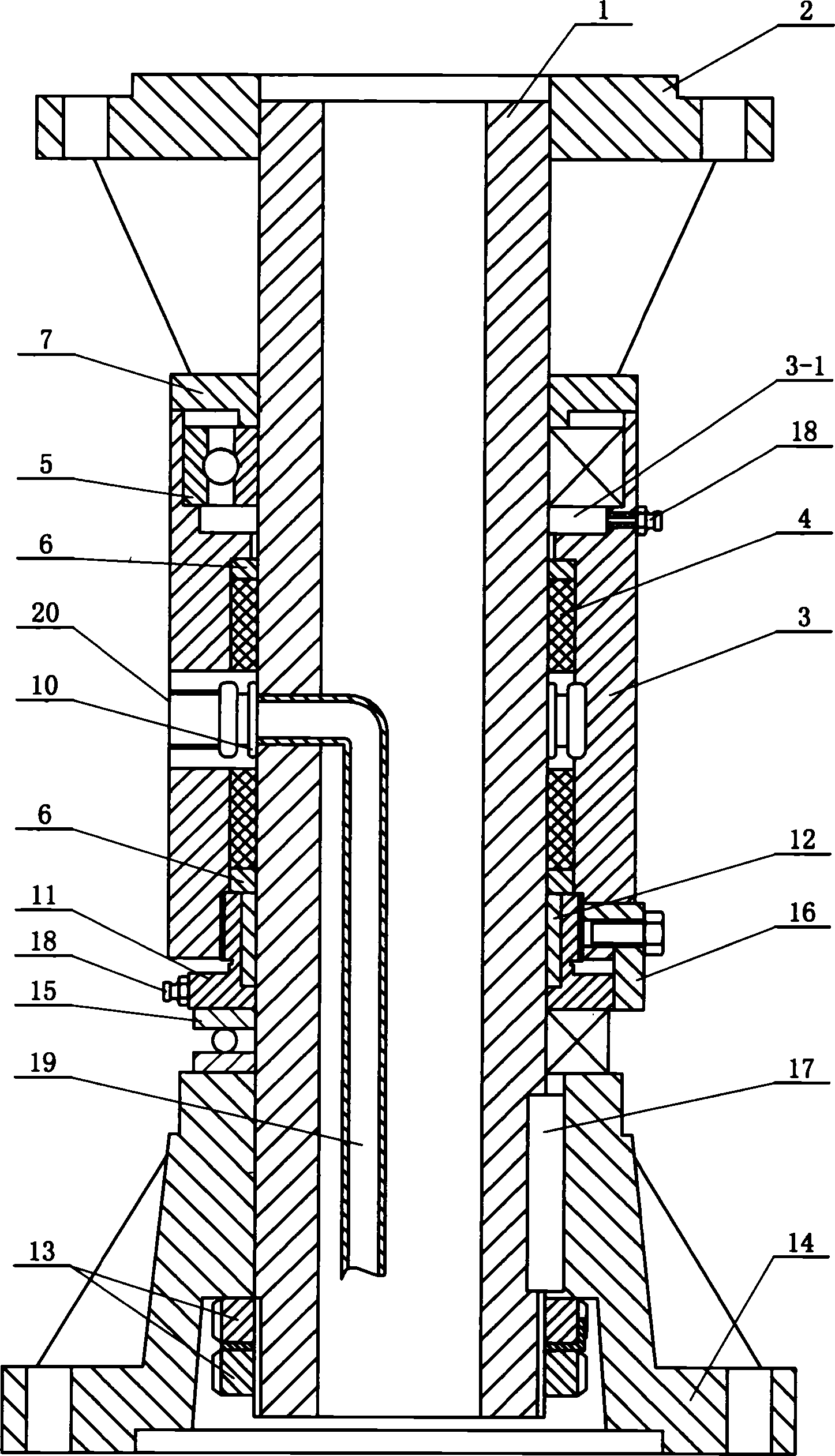

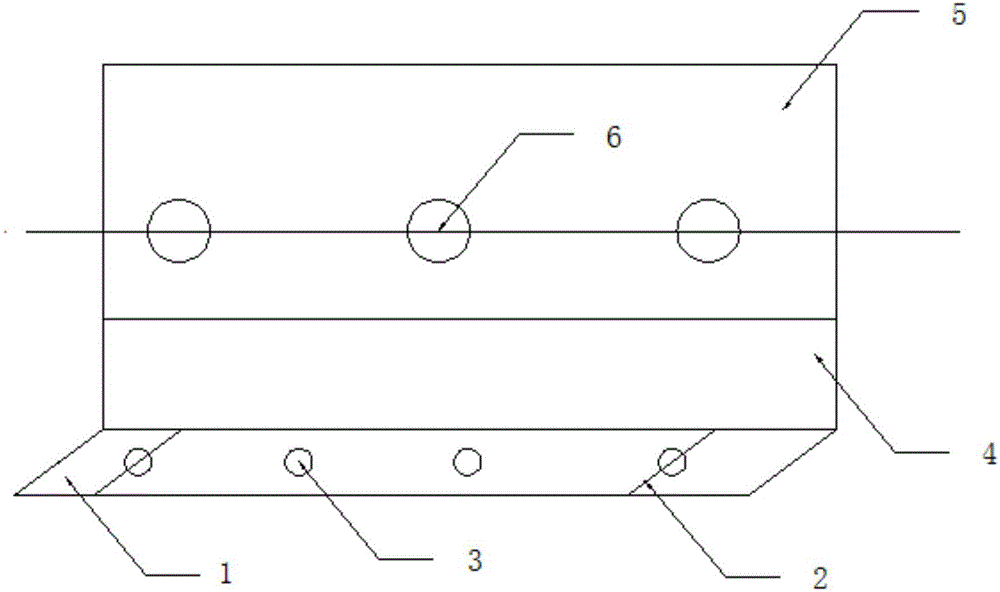

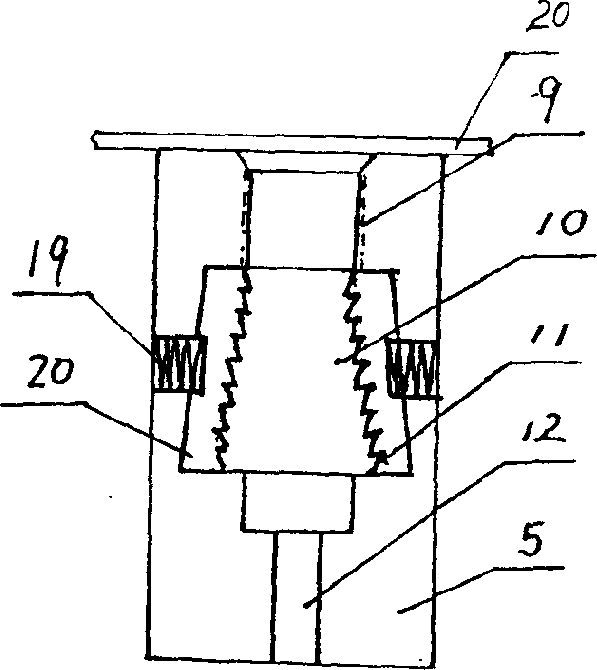

Walling method and walling device

ActiveCN103669872ARelieve pressureAvoid slurry leakageForms/shuttering/falseworksBuilding material handlingEngineeringWall material

The invention discloses a walling method and a walling device. The walling method includes the steps of respectively arranging formworks on the two sides of a wall to be poured, and installing supports outside the formworks, wherein the heights of the formworks are smaller than the height of the wall to be poured, and the widths of the formworks are equal to the width of the wall to be poured; pouring the position between the formworks on the two sides with a certain number of grout-type wall materials, then stopping pouring, after a certain period of time, lifting the formworks on the two sides to be at certain heights, pouring the position between the formworks on the two sides with a certain number of grout-type wall materials again, then stopping pouring, and repeating lifting and pouring till the whole wall is completely built; or pouring the position between the formworks on the two sides with the grout-type wall materials, and after a certain period of time, starting to continuously lift the formworks and synchronously and continuously pour the position between the formworks with the grout-type wall materials till the whole wall is completely built; after the whole wall is solidified, disassembling the formworks and the supports. The walling device comprises a formwork unit and a pouring unit. The walling method and the walling device are high in walling efficiency, good in quality and free of formwork-moving grout-leakage phenomena.

Owner:赵路航

Complex geological karst hole pile foundation construction process

PendingCN113445498AScientific and reasonable designAvoid instabilityBulkheads/pilesKarstStructural engineering

The invention discloses a complex geological karst hole pile foundation construction process. The complex geological karst hole pile foundation construction process comprises the steps that a concrete backfilling karst cave pile foundation construction method or a double-steel-casing all-casing follow-up pile foundation construction method is adopted to perform hole pile foundation construction; when the karst cave where the karst cave pile foundation is located is a small karst cave, hole pile foundation construction is carried out through a concrete backfilling karst cave pile foundation construction method; and when the karst cave where the karst cave pile foundation is located is a large karst cave or a communicating type bead string karst cave group, hole pile foundation construction is carried out through the double-steel-casing all-casing follow-up pile foundation construction method. The conditions of mud loss, wall protection instability and the like of a traditional construction method can be effectively avoided, the construction safety can be effectively guaranteed, the construction period is guaranteed, and meanwhile, the construction cost can be reduced.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Concrete joint drilling device and construction method thereof

The invention belongs to a concrete joint drilling device and a construction method thereof. The device comprises a base layer, one side surface of the base layer is a concave-convex surface, the concave-convex surface of the base layer is in contact with the cast concrete, one side surface of the substrate layer is a concave-convex surface, and the other side surface of the substrate layer is anadhesive surface; the adhesive surface is a glue surface layer located on the base layer and an anti-sticking layer located outside the glue surface layer; the substrate is made of rubber or a fiber material, the fiber material is a plant fiber material; the method is characterized in that during pouring, the concave-convex surface is tightly attached to the concrete to enable the concrete surfaceat the position to form an uneven scabbling surface. The device and method have the advantages of being simple in structure, reasonable in design, time-saving and labor-saving, high in construction speed and quality, low in construction cost and good in using effect.

Owner:CHINA CONSTR MUNICIPAL ENG +1

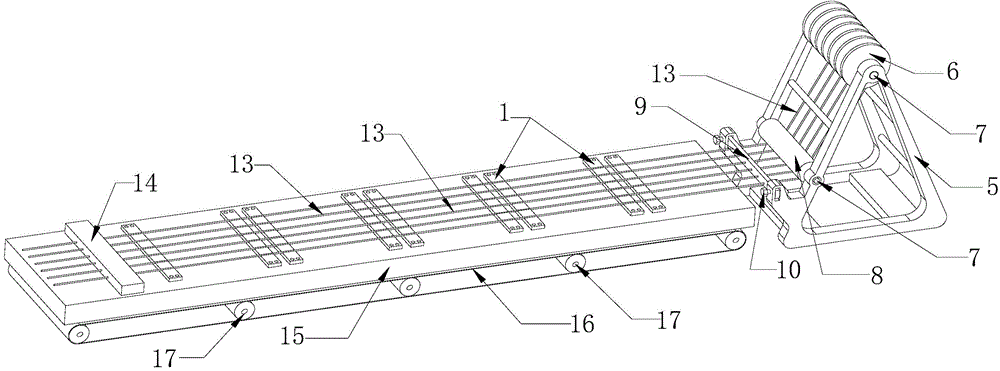

Engineering construction method and construction equipment for transparent concrete

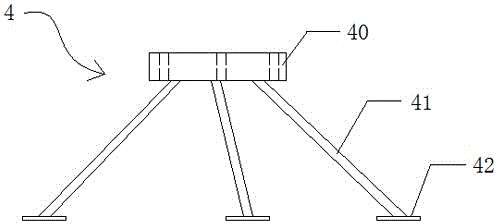

ActiveCN103603458AFast productionOptimize layoutCeramic shaping apparatusBuilding componentsArchitectural engineeringSlide plate

The invention discloses an engineering construction method and construction equipment for transparent concrete and belongs to the technical field of manufacturing of novel building materials. The engineering construction method is characterized by comprising the steps of manufacturing optical fiber arrangement units through transparent concrete optical fiber arrangement equipment disclosed by the invention, wherein the optical fiber arrangement units are fixedly stacked and mounted together according to a required form, namely a single sheet is stacked with another single sheet to obtain multiple sheets, and finally blocks are formed; and mounting a plurality of block structures in a detachable molding tank side by side, pouring concrete and performing maintenance and demolding to obtain the transparent concrete. The optical fiber arrangement equipment comprises a triangular fixed machine seat, wherein the upper part of the triangular fixed machine seat is connected with a wire storage disk through a rotating shaft; the left lower part of the triangular fixed machine seat is connected with a rotating wheel through the rotating shaft; a fiber guide plate is arranged on the left of the rotating wheel; a caterpillar track with a sliding plate is arranged on the left of the triangular fixed machine seat; aluminum alloy pressing strips for manufacturing the optical fiber arrangement units are fixed on the sliding plate. The engineering construction method and construction equipment have the characteristics of high optical fiber arrangement speed, convenience, uniformity, convenience in operation, simple technology and high efficiency; the transparent concrete in various forms can be manufactured according to a personal requirement; the engineering construction method and construction equipment are suitable for large-scale industrial production.

Owner:DALIAN UNIV OF TECH

Template used for casting floor beam and construction method of floor beam

InactiveCN106437146AReduce loadAvoid mold expansionForms/shuttering/falseworksFloor slabBuilding construction

The invention discloses a template used for casting a floor beam. The template comprises a beam bottom template, a beam side template, a beam end template and a floorslab bottom mold; the beam bottom template, the beam side template and the beam end template form an opening structure with the top opened and the periphery and the bottom closed; the floorslab bottom mold is arranged on the side of the top of the beam side template; the template also comprises a horizontal back ridge and a clamping piece; the horizontal back ridge is limited between the clamping piece and the side face of the beam side template. The invention also discloses a construction method of the floor beam. The template used for casting the floor beam and the construction method of the floor beam disclosed by the invention have the advantages that the floor beam has correct sectional dimension, no mold swelling, no mold explosion, no mud leakage and no deformation, the concrete construction quality is ensured, the construction is simple, the disassembly and the assembly are convenient, and the cost and the unnecessary repair can be effectively reduced and saved.

Owner:CHINA MCC17 GRP

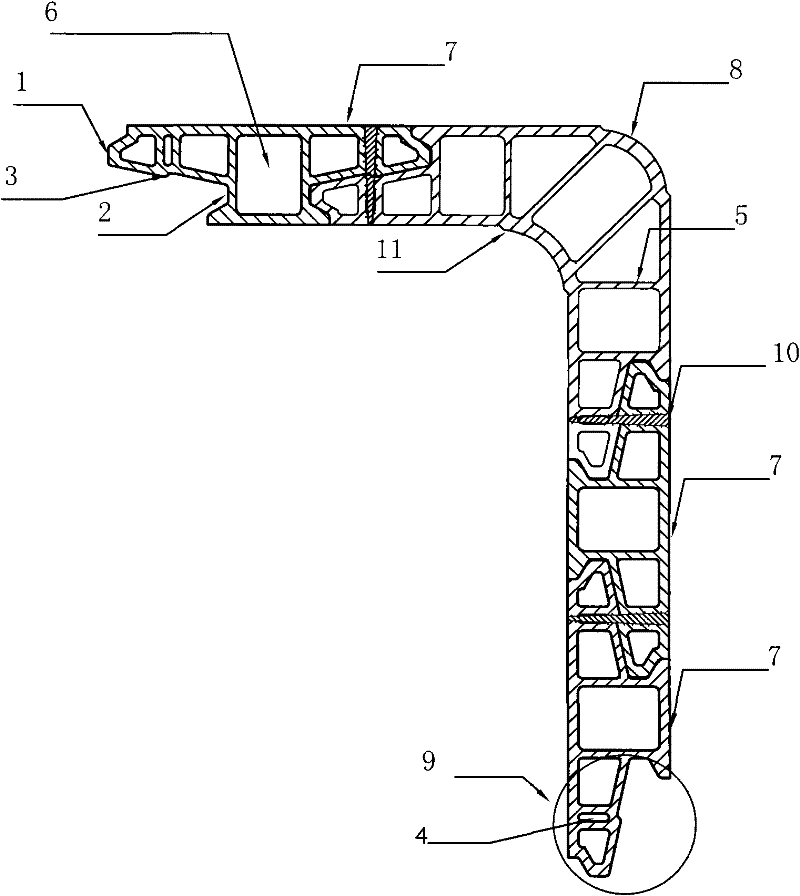

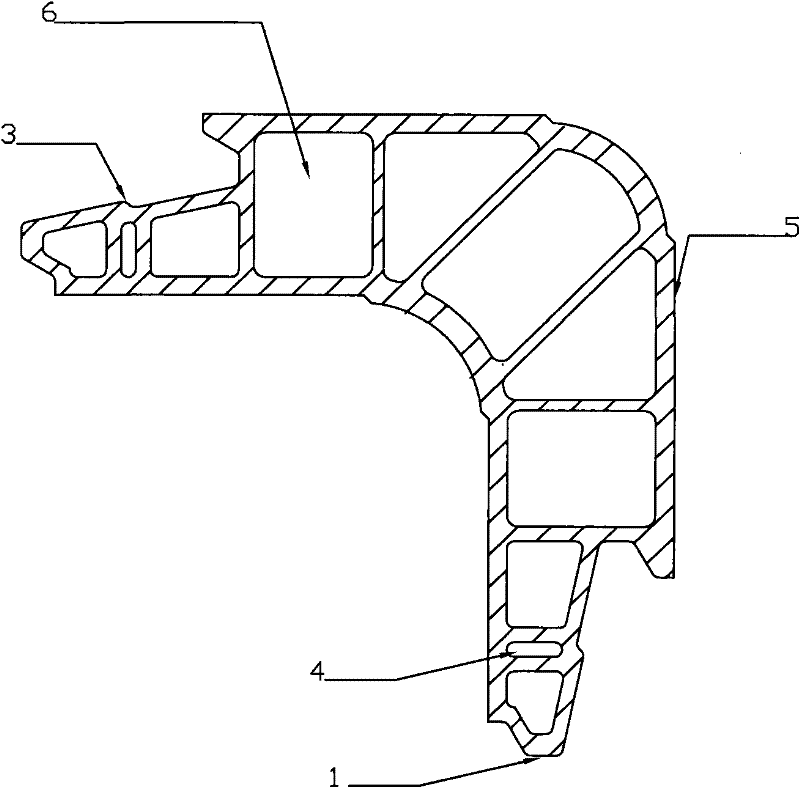

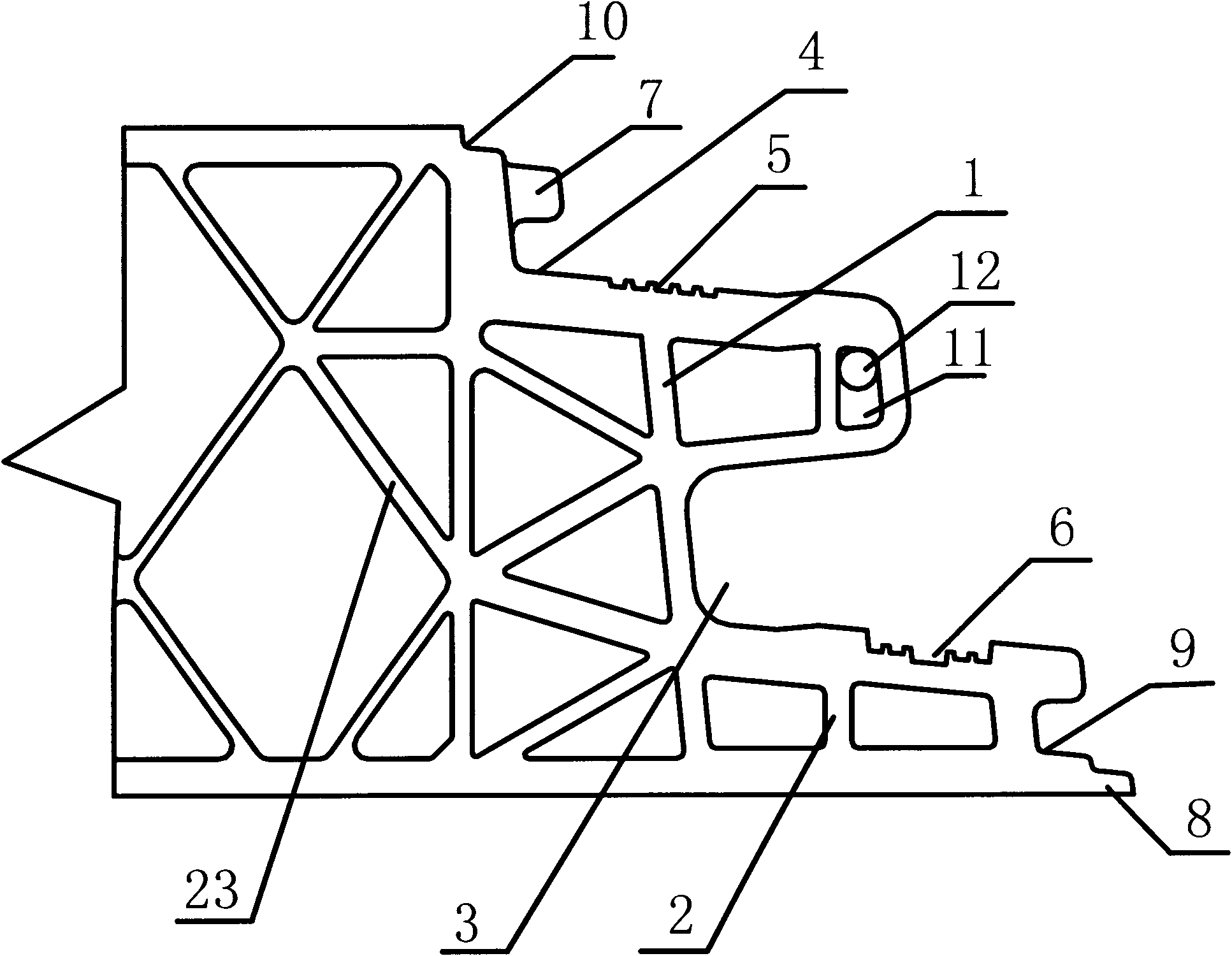

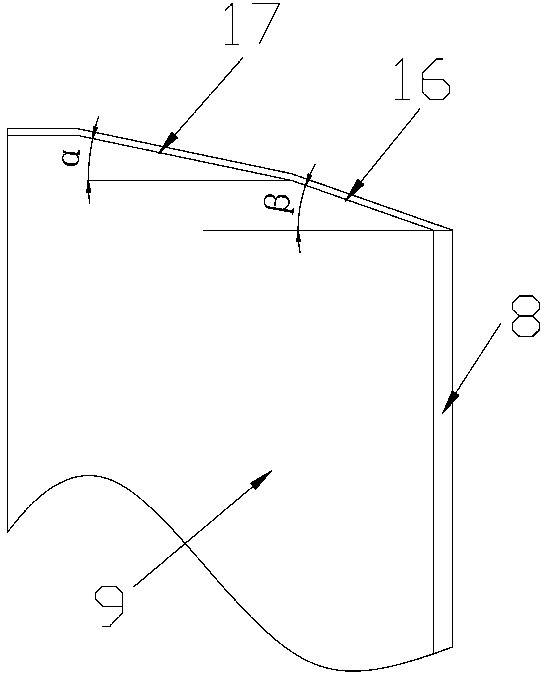

Plastic building template system

ActiveCN102061805AHigh strengthImprove bindingForming/stuttering elementsEngineeringSurface flatness

The invention relates to a plastic building template system. The system comprises first templates which are spliced together to form a plane template system, and second templates which are spliced with the first templates to form corners, wherein, plane connecting heads are formed on spliced edges of the first templates; the second templates form corner connecting heads on spliced edges between the second templates and the first templates; and the plane connecting heads are coupled with the corner connecting heads so that seams of the building template system have higher strength and better binding tightness and meanwhile external surfaces of panels at two sides of the neighboring templates are respectively limited on the same plane at the same side, thus the surface of the building template system close to a grouting side is flat, and the surface flatness of the building after cast molding is ensured.

Owner:王亚运

Separate splicing form board straight splicing joint plugging device and method

PendingCN111962866AImprove construction qualitySolve the slow construction speedAuxillary members of forms/shuttering/falseworksStructural engineeringSlurry

The invention discloses a separate splicing form board straight splicing joint plugging device and method. The method comprises the steps that a base plate provided with a lead screw and a tightly-pressing buckle plate are adopted for separate splicing form board straight splicing joint plugging operation; after splicing form boards and tightly-pressing blocks are mounted based on the base plate,firstly, the lead screw is sleeved with the tightly-pressing buckle plate, so that the tightly-pressing blocks are clamped and pressed, and pin bolts are driven into the tightly-pressing blocks; and then, on the basis of the principle that a nut is screwed onto the lead screw, the tightly-pressing blocks are fastened, and the splicing form boards are compacted. The base plate is located at a straight splicing joint, and it is guaranteed that no slurry leaks due to the height difference between the surfaces of the adjacent splicing form boards; by means of splicing joints formed between the adjacent splicing form boards and between the tightly-pressing blocks, on one hand, the splicing joints can cooperate with the nut to achieve the effects that the tightly-pressing blocks are supported firmly and the splicing form boards are compacted conveniently, and on the other hand, the effect that when the form boards are dismounted, the form boards are dismounted wholly and rapidly by virtue ofthe external force for drawing the lead screw can be achieved conveniently; and the tightly-pressing buckle plate is located between the tightly-pressing blocks and the nut when the two adjacent splicing form boards are spliced, on one hand, the effect that the tightly-pressing buckle plate is clamped and buckled is achieved, and on the other hand, the effect that the tightly-pressing buckle plate cooperates with the nut to replace a fastening gasket is achieved; and the separate splicing form board straight splicing joint plugging device is simple in structure and convenient to operate.

Owner:陕西有色建设有限公司

Flexible concrete rabbet connecting construction method

InactiveCN102943564AGuarantee the pouring qualityIncrease storage spaceAuxillary members of forms/shuttering/falseworksBuilding material handlingSlurryWood plank

A flexible concrete rabbet connecting construction method mainly comprises the following steps: attaching a fixing wooden slat to the inner side of the top of a moulding plate so as to reserve an L-shaped rabbet at a connecting position of a bottom concrete component; sticking and nailing a through elastic sealing strip at the bottom of the moulding plate; rightly pressing the elastic sealing strip into the L-shaped rabbet reserved in the bottom concrete component; and the like. According to the flexible concrete rabbet connecting construction method, in construction, the problems of dislocation, slurry leakage, unsmooth and straight connection and the like of the connecting position can be effectively avoided and the pouring quality of concrete at the connecting position is ensured; and after the construction, a beautiful, unsmooth and straight protruding strip is formed at the connecting position.

Owner:CHINA HUAYE GROUP +1

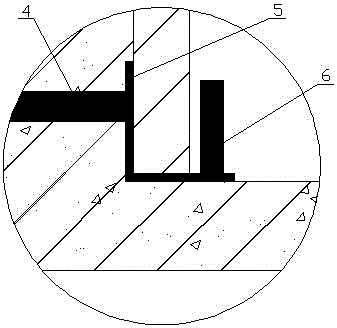

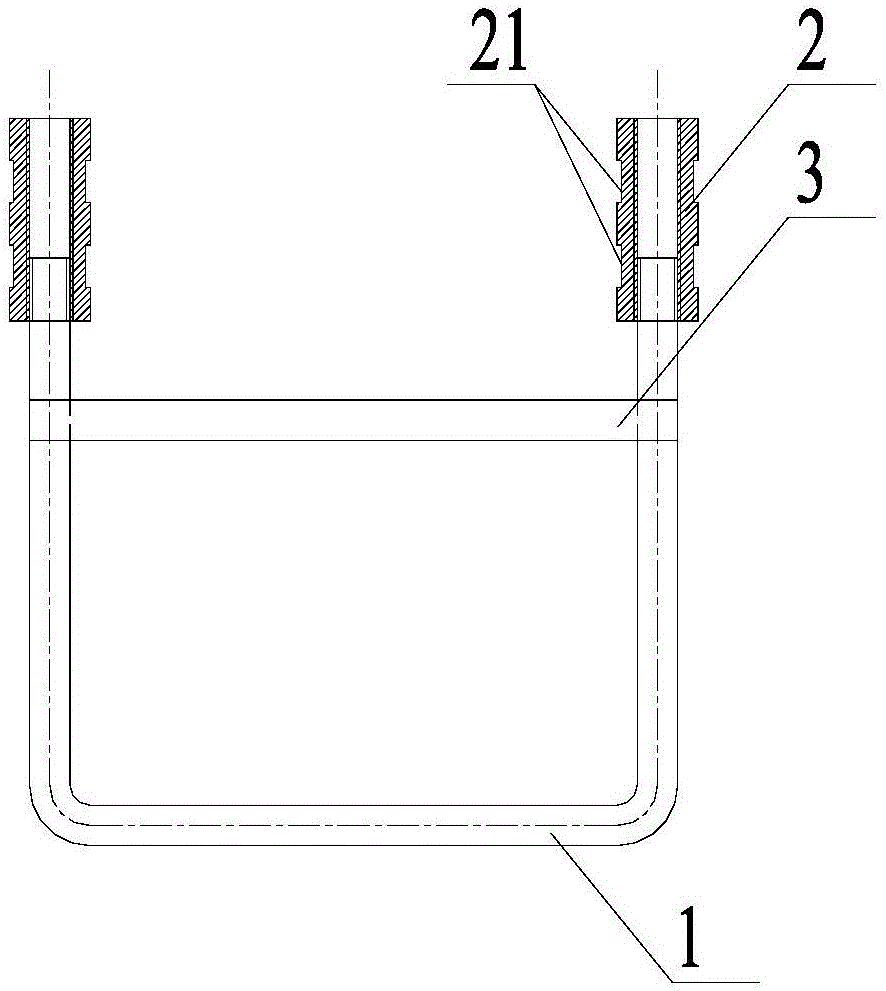

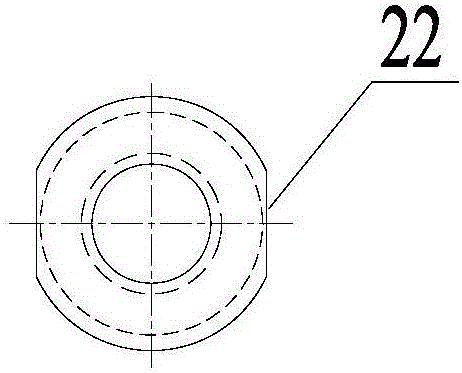

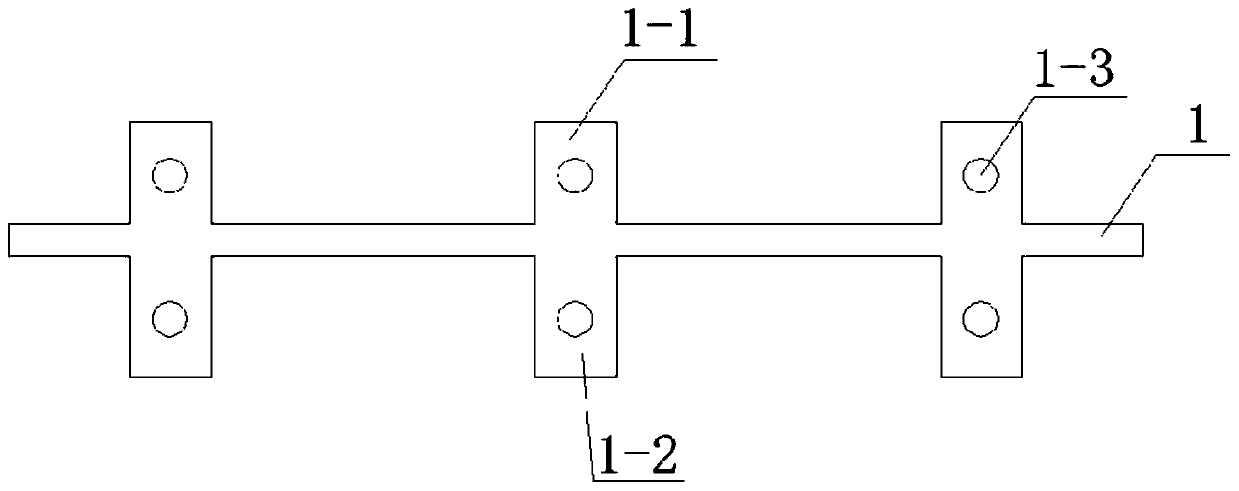

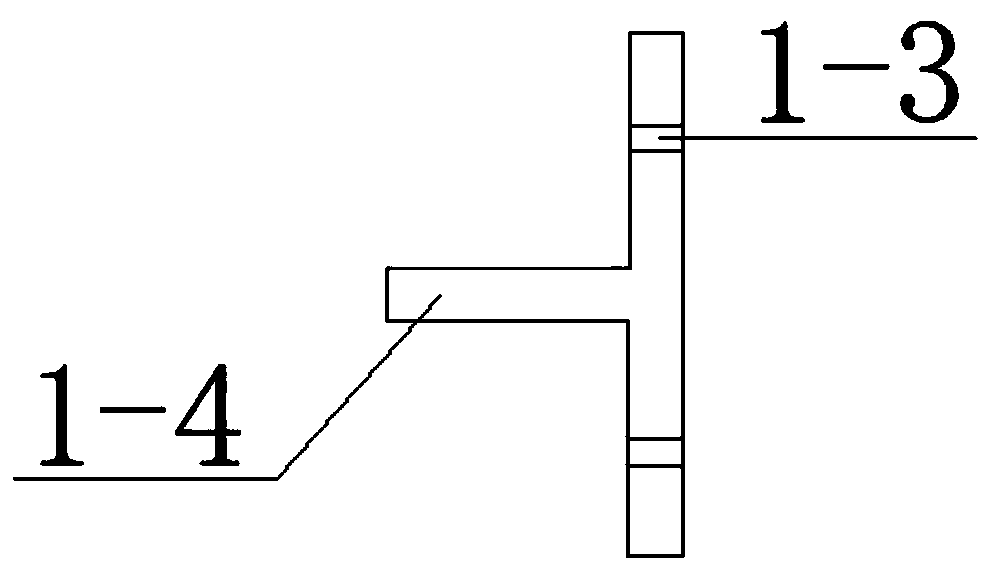

U-shaped building embedded part and construction method of anchoring component of U-shaped building embedded part

InactiveCN105888078AAvoid slurry leakageReduce the difficulty of demouldingBridge structural detailsBuilding constructionsSteel barSlurry

The invention discloses a U-shaped building embedded part and a construction method of an anchoring component applying the U-shaped building embedded part. The embedded part comprises a U-shaped bolt, two connecting sleeves and a reinforcing steel bar; the U-shaped bolt and the connecting sleeves are connected through threads, and the reinforcing steel bar and the U-shaped bolt are welded, so that the U-shaped bolt is prevented from being deformed in the carrying process. When embedding in pouring construction is conducted, the ends of the connecting sleeves abut against a whole formwork, holes do not need to be preformed in the whole formwork, the slurry leakage phenomenon cannot occur in the pouring process, and later formwork stripping is easy; in addition, accessory equipment is connected with the sleeves of the U-shaped embedded part through bolts, when the accessory equipment fails, the accessory equipment can be maintained and replaced by screwing down the connecting bolts, and therefore concrete structure ancillary facilities are greatly convenient to maintain and replace.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

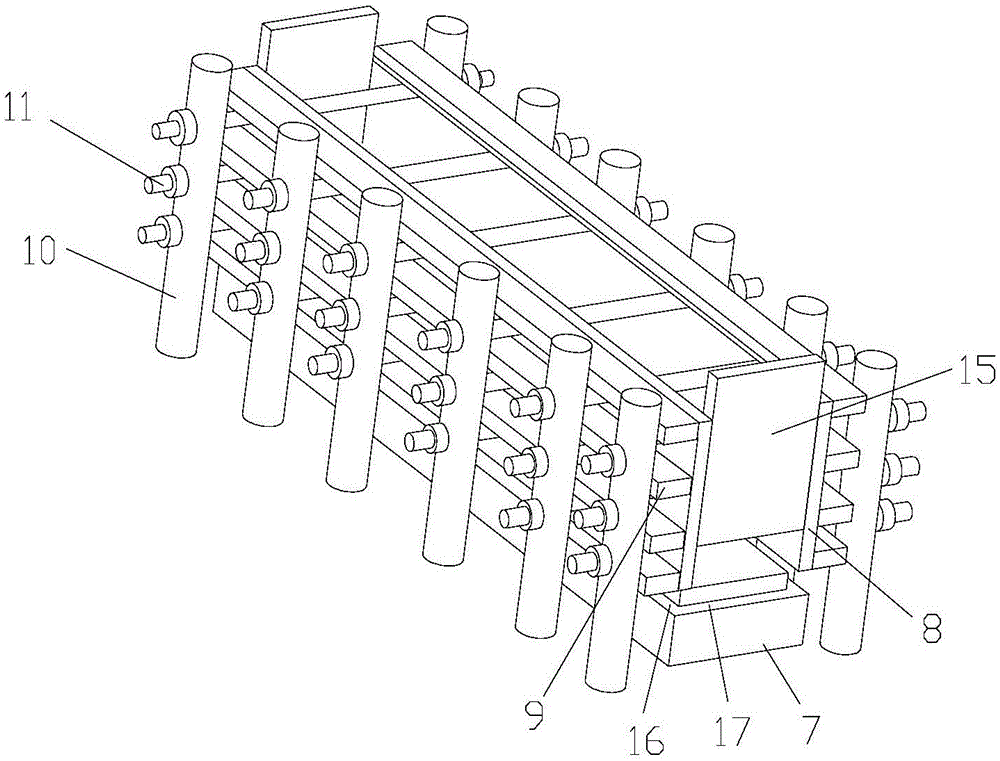

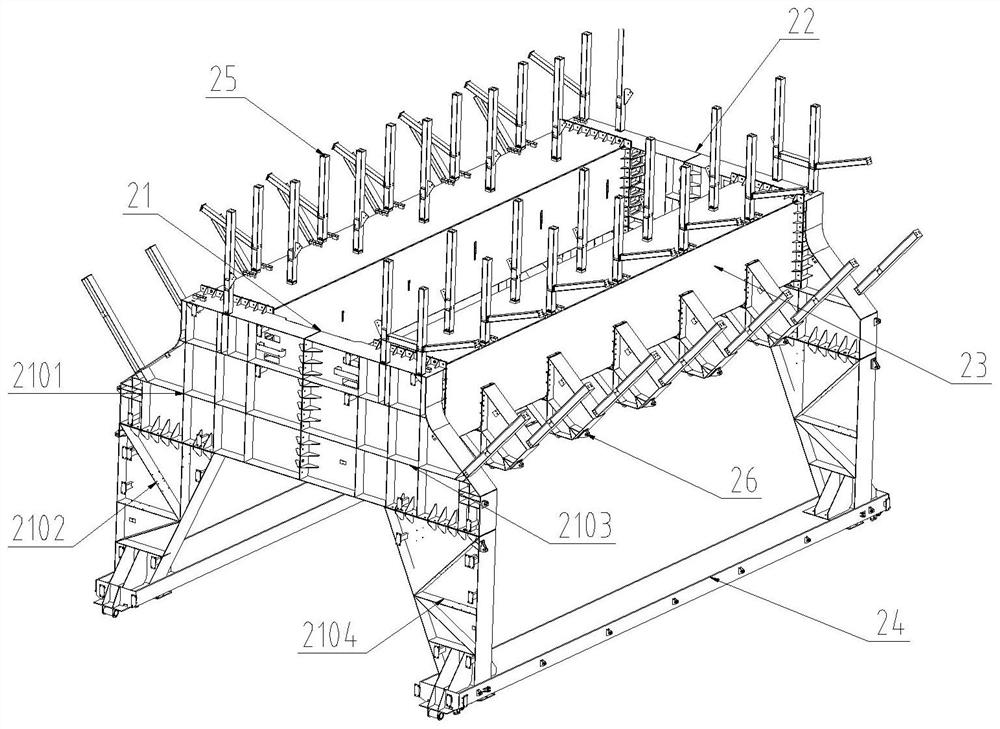

Prefabricated pipe gallery mechanical and hydraulic combined type overall installation and disassembly steel formwork and installation method

PendingCN109972655ASave materialSolve the difficult problem of installation and disassemblyArtificial islandsUnderwater structuresSupporting systemReinforced concrete

The invention discloses a prefabricated pipe gallery mechanical and hydraulic combined type overall installation and disassembly steel formwork and an installation method. An outer mold steel pulley matched with an outer mold steel track is installed under an outer support truss of an outer mold support system. An inner mold steel formwork of an inner mold support system includes a top mold, sidemolds and lower chamfering molds which are hinged as a whole; a first mechanical spiral expansion machine of an inner mold installation and disassembly system is connected with a vertical frame body and the side molds, a second mechanical spiral expansion machine is mounted on the vertical frame body, and a third mechanical spiral expansion machine is connected with the side molds and the lower chamfering molds; and the inner mold installation and disassembly system further includes chain blocks with one ends fixed to the side molds and the other ends used for hooking the lower chamfering molds during demolding. The installation and disassembly steel formwork can solve the technical problems that one-time overall pouring molding cannot be achieved, the formwork joint is not tight, the formwork installation dimensional accuracy is not high, the formwork is difficult to install and disassemble, the formwork is prone to deforming and large-scale machines need to be matched with the formwork installation when a standard prefabricated reinforced concrete box-type component bottom plate and a wall top plate use a chamfer steel mold and wood mold system and a normal steel formwork.

Owner:中铁二十二局集团第三工程有限公司 +1

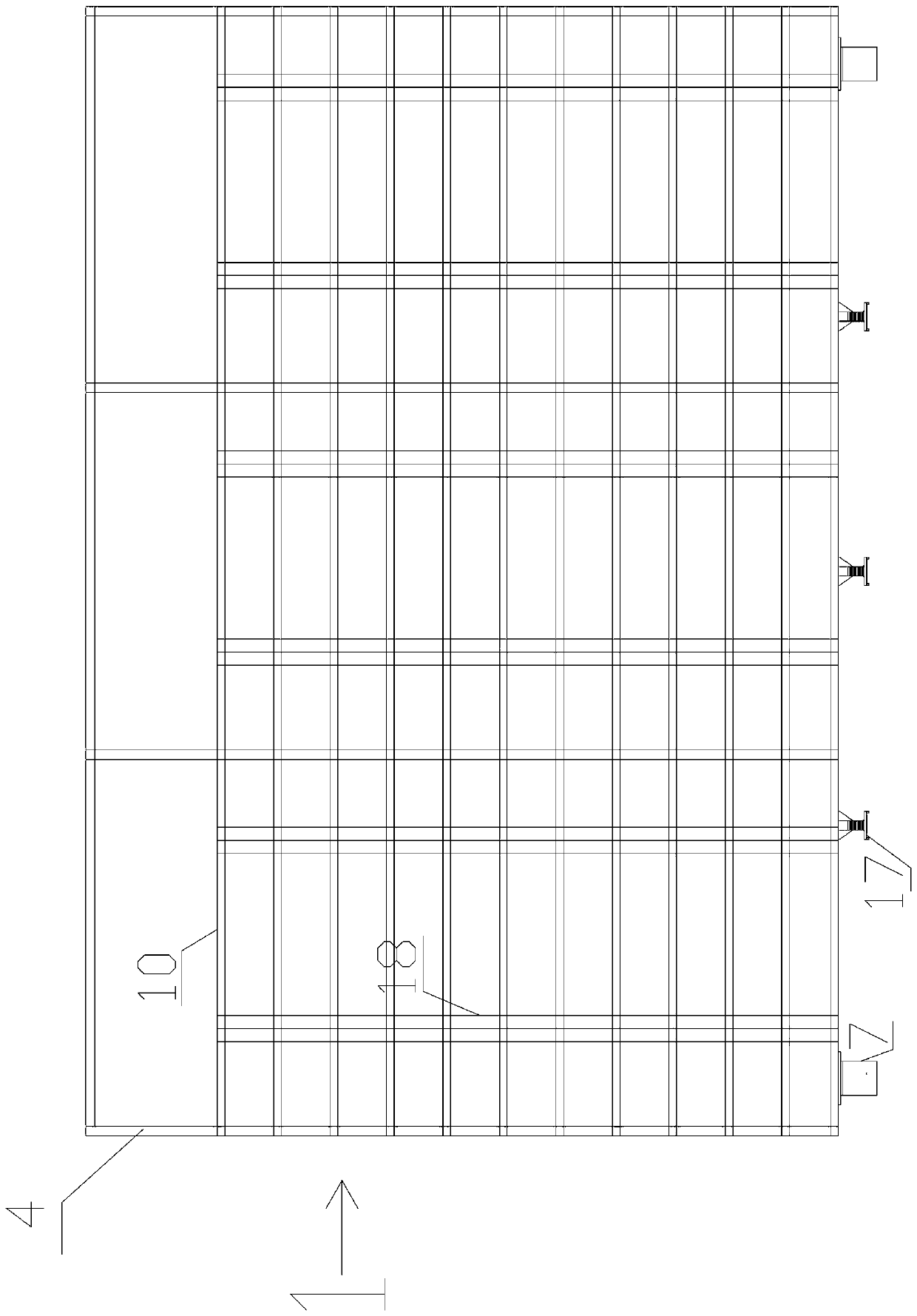

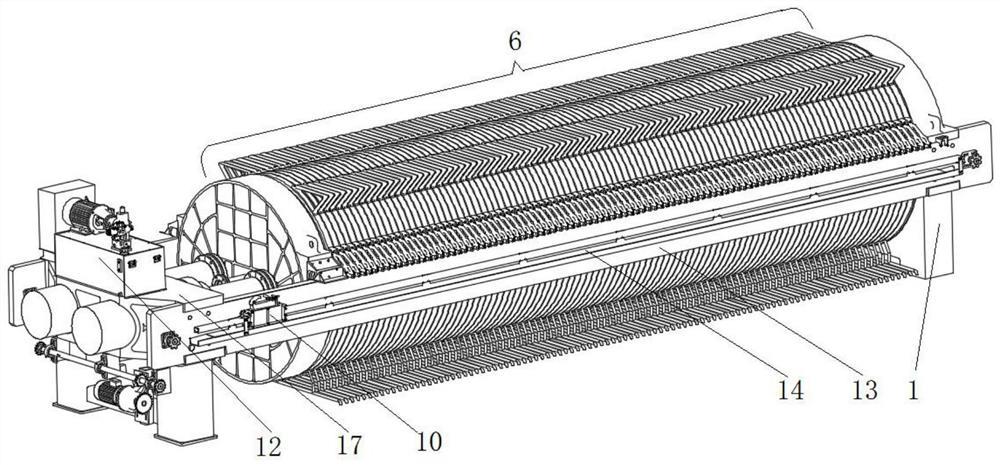

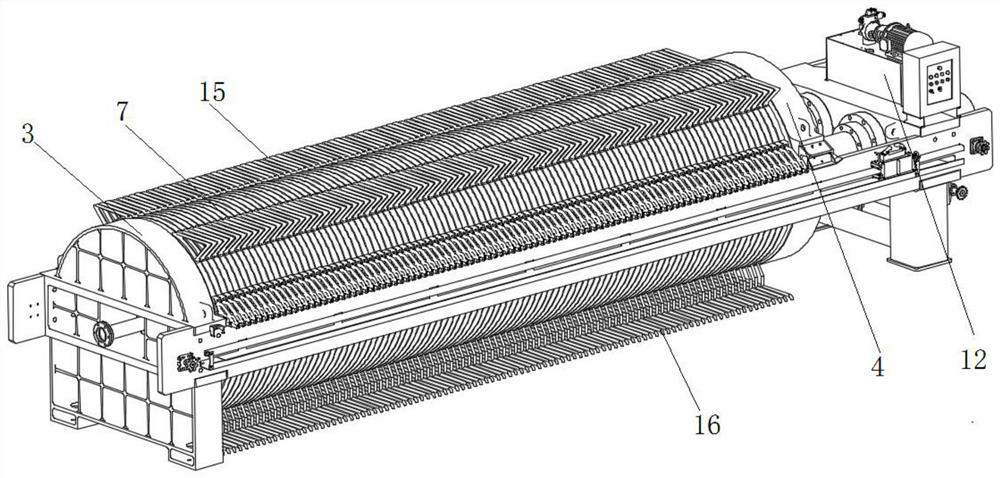

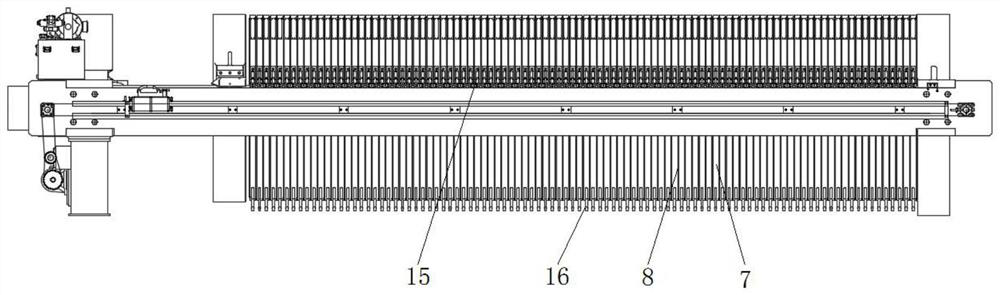

Large circular plate high-pressure automatic filter press

PendingCN112206555AIncrease productionGuaranteed tightnessFiltration separationAutomatic controlControl system

The invention discloses a large circular plate high-pressure automatic filter press, which relates to the field of environmental protection equipment and mainly comprises a rack part, a filtering part, a hydraulic system, an automatic plate pulling device and an electrical control system. The single-machine yield is increased by adopting large-area circular filter pressing plates, and meanwhile, the sealing surface is used for ensuring the sealing property of each filter chamber during filter pressing, so that the phenomenon of slurry leakage between the filter plates during high-pressure filter pressing is effectively avoided. Meanwhile, double oil cylinders are horizontally arranged side by side, so that the space is saved, and the filtering pressure can be effectively improved; a mode of simultaneously feeding slurry from two ends is also adopted, so that the filter pressing time is further shortened, and the filtering efficiency is improved. Besides, the automatic filter press provided by the invention is integrally designed and manufactured by machine, electricity and liquid, can realize automatic control of various processes such as filter plate pressing, filtering, squeezing, filter plate loosening, discharging and the like, and is high in practicability.

Owner:广东增盛机械科技有限公司

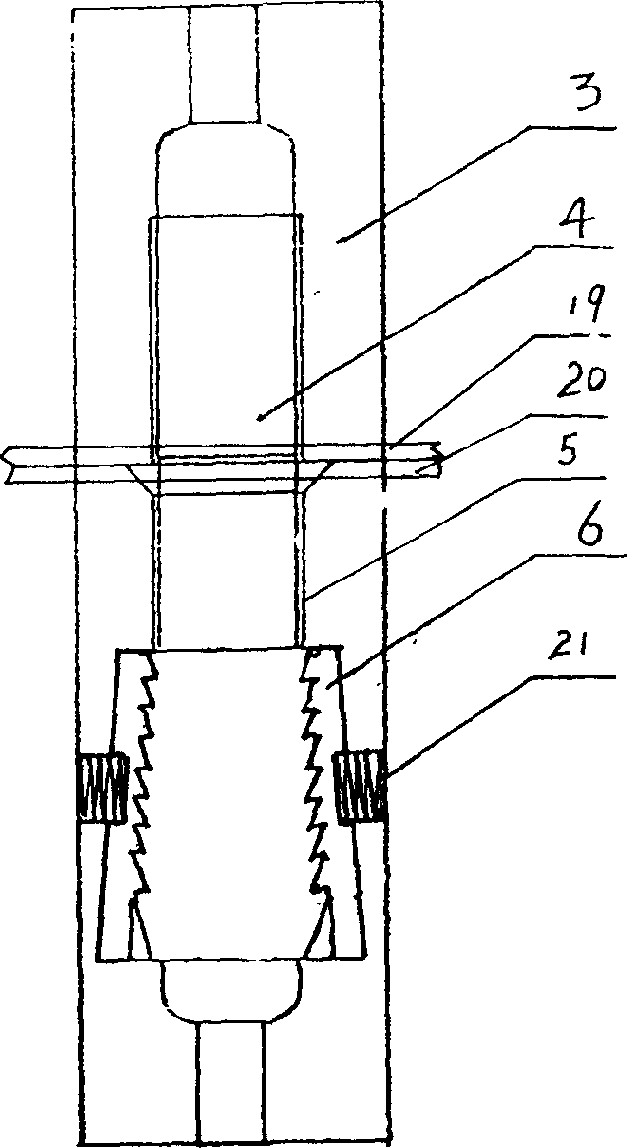

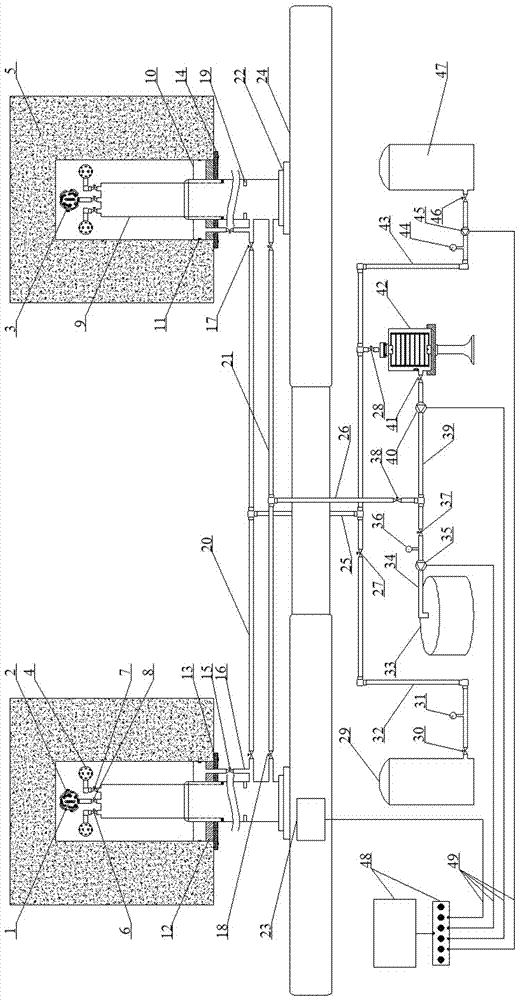

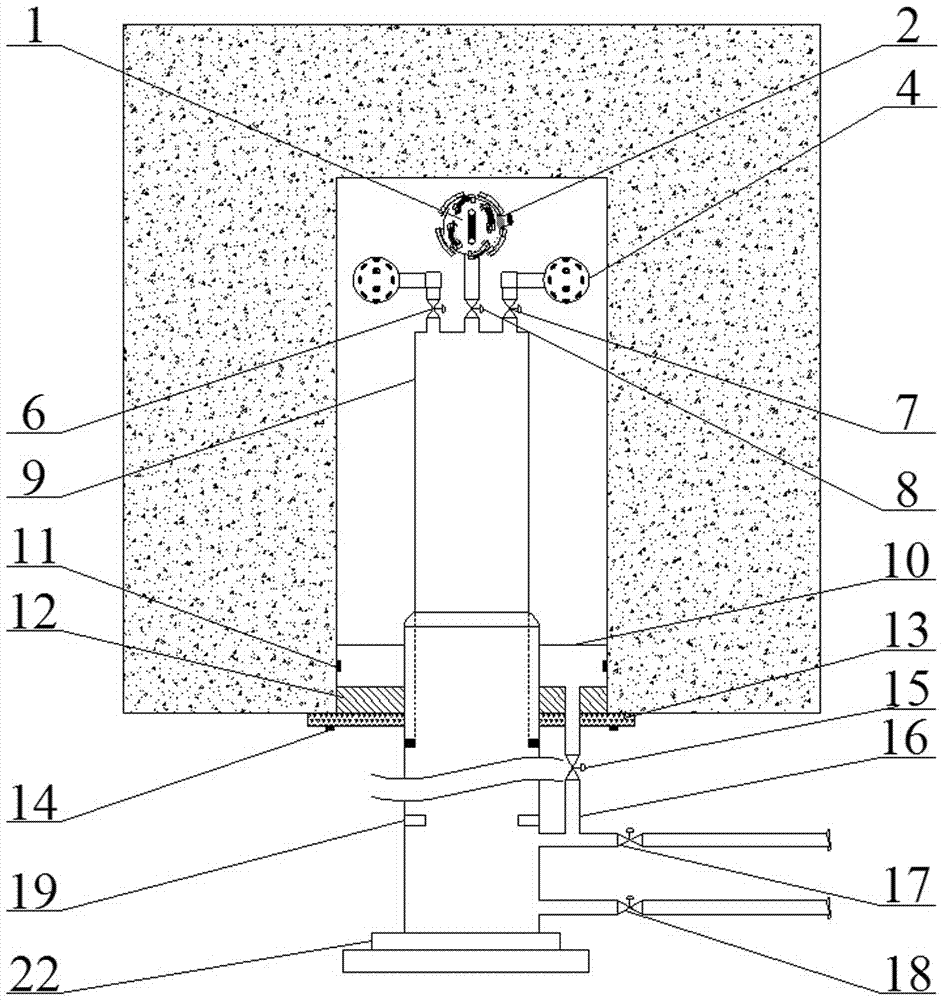

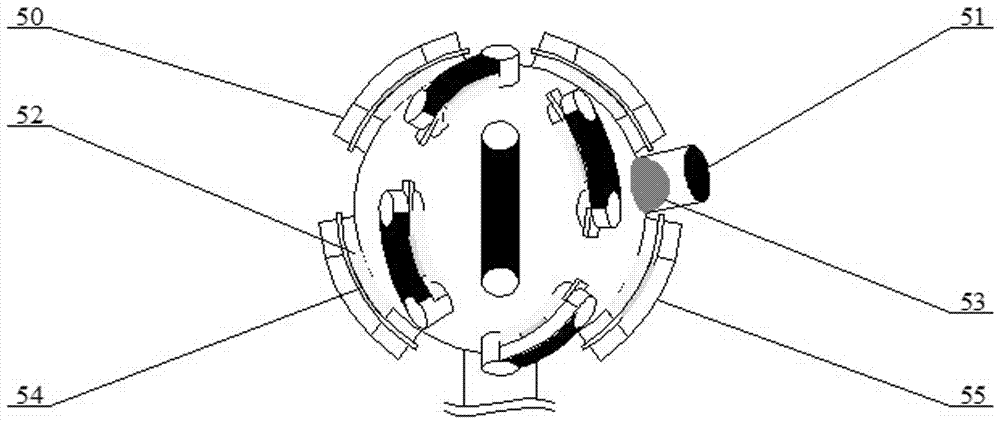

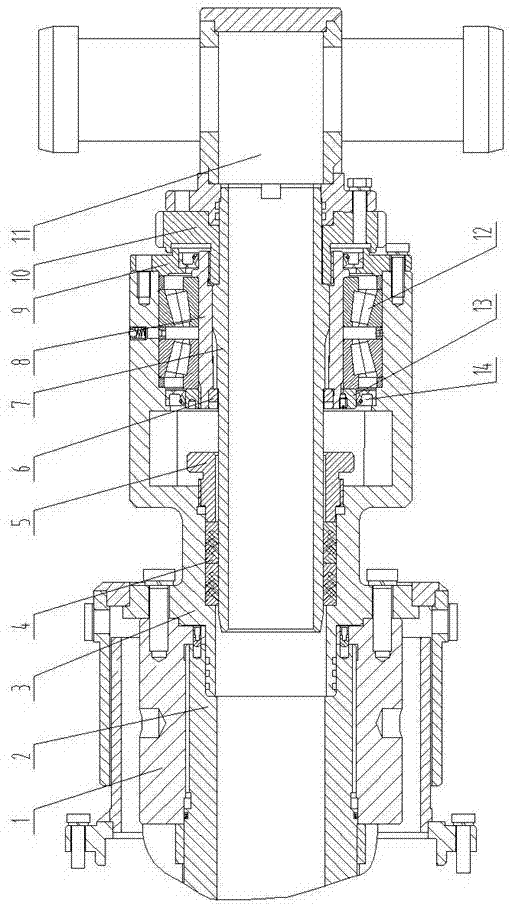

Rotating connection apparatus for borehole pump pouring concrete rotary guniting enlarging footing piling

InactiveCN1888325APrevent moving upImprove bearing capacityBulkheads/pilesThrust bearingCement slurry

The present invention relates to a building pile-forming equipment by pressure injecting concrete and pressure injecting cement slurry. Said invention is characterized by that said pile-forming equipment includes a min body pipe, its upper end and lower end are respectively fixedly mounted in upper connecting disk interior and lower connecting disk interior, on the main body pipe a case shell is mounted, on the case shell and main body pipe are set several slurry-feeding holes connected with slurry-conveying pipe. In the case shell a first bearing is mounted, the upper end of said first bearing is equipped with a baffle ring, a second bearing is mounted on the main body pipe of upper end of lower connecting disk, said second bearing adopts angular contact bearing.

Owner:刘润郊

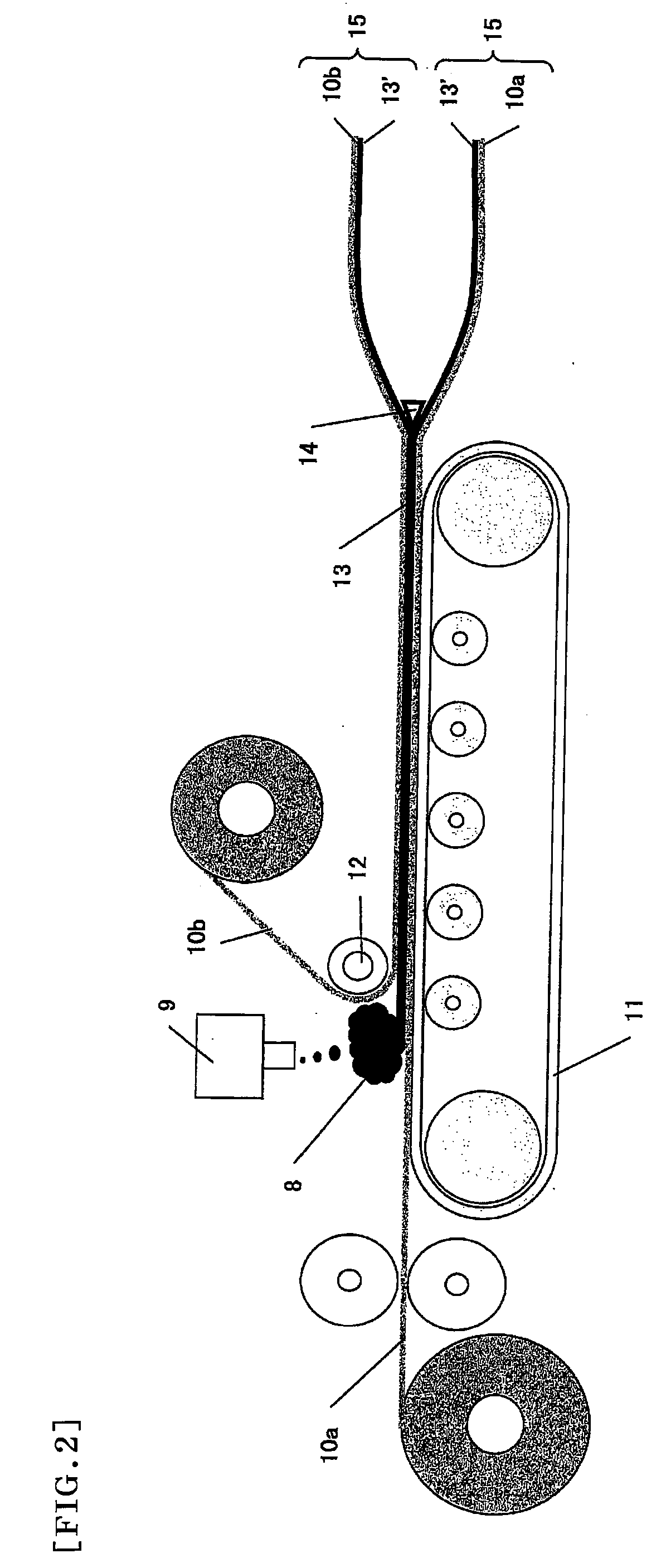

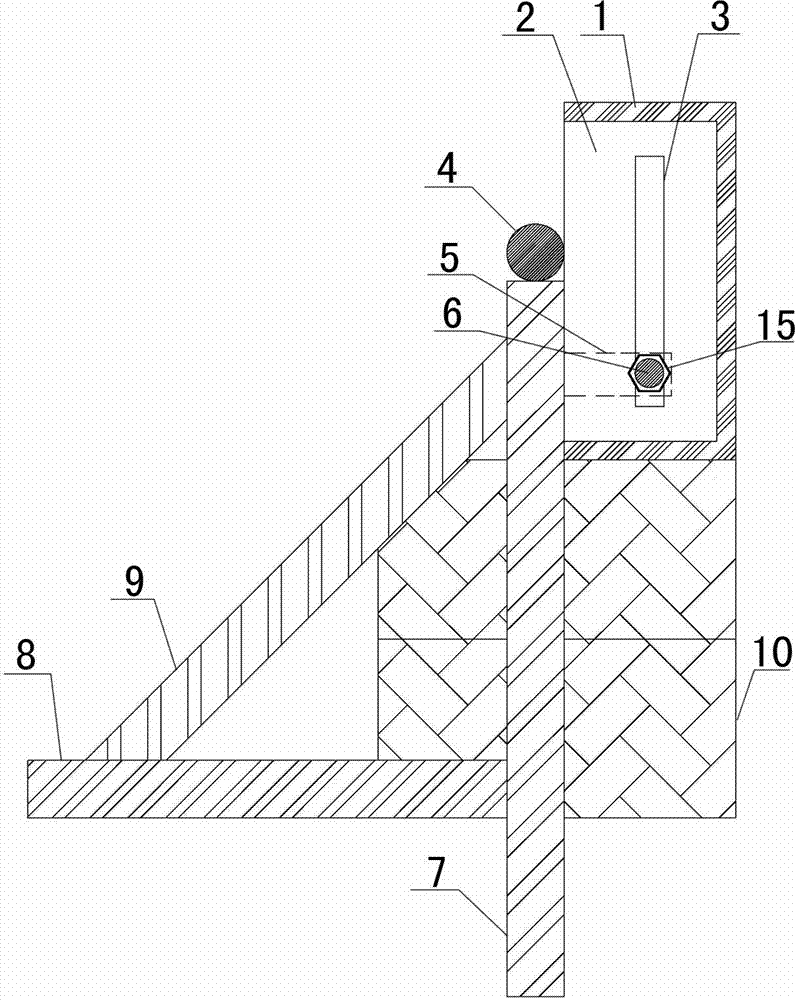

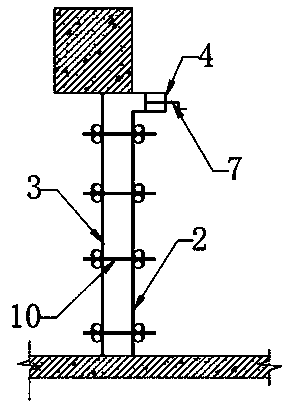

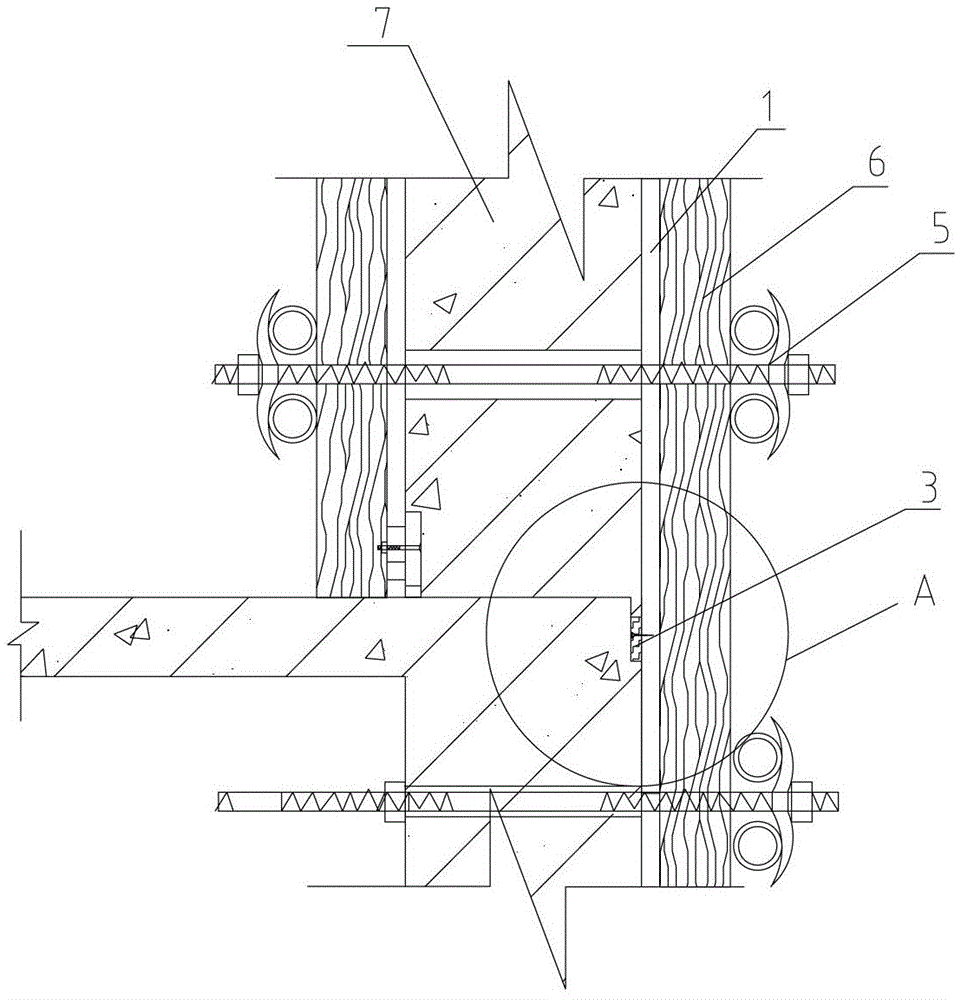

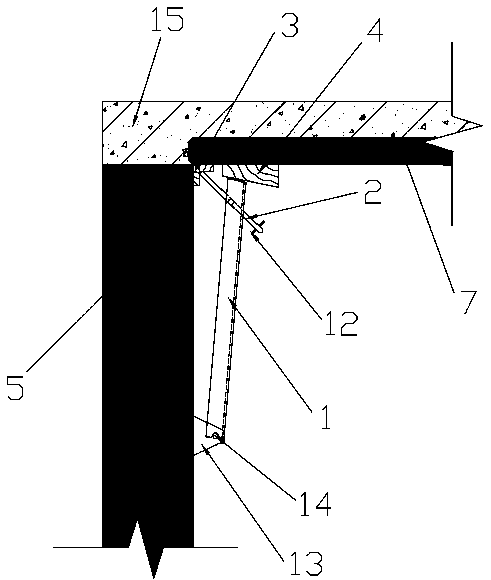

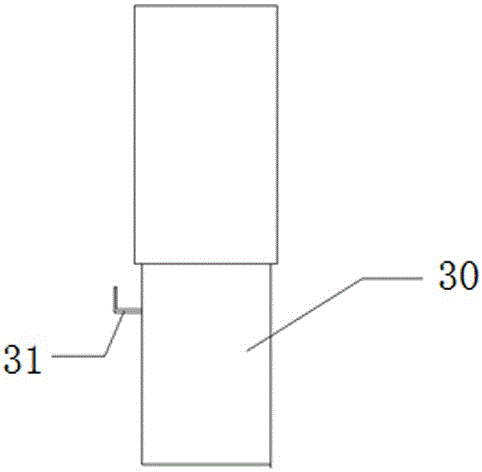

Shear wall formwork installation foot angle iron device

InactiveCN106284979AAvoid slurry leakagePut an end to rotten rootsForms/shuttering/falseworksControl linePlastic film

The invention discloses a shear wall formwork installation foot angle iron device, which comprises a base plane and an angle iron unit perpendicularly fixed on the base plane, a plurality of steel nails are arranged on the base plane, the steel nails close to the side edges of the base plane are arranged on control lines, both the steel nails and the angle iron unit are fixed on a rubber-plastic sheet foot, the rubber-plastic sheet foot is fixed at the foot of a shear wall, the angle iron unit is provided with screw holes, the control lines are arranged at the positions 200mm away from both sides of the base plane, the spacing between each two steel nails is equal to or less than 250mm, and the number of the steel nails is not less than 3. The invention relates to shear wall formwork installation construction in formwork construction, and in particular to the angle iron device which is 50 multiplied by 50 multiplied by 3mm, and when in use, the angle iron device can effectively prevent the common quality problems of shear walls, such as foot grout leakage, foot rotting and deformation and displacement phenomenon, improve the appearance of shaped concrete and reduce secondary repair.

Owner:CHINA MCC17 GRP

Eleastic expansion meshing body pile connecting end plate and prefab

InactiveCN1676774AAccurate distributionGuaranteed reliabilityBuilding constructionsBulkheads/pilesEngineeringRebar

The invention relates to tubular interface, the pre-make part, which is made of pre-make part's interface and the connection instruction between the pre-make parts as well as the facture of the pre-make part. It comprises end board, two or more inflation draw crew caps and the top draw screw cap which distribute circumferentially on the end board, and the screw part of inflation mesh screw connects convolutedly into the inflation draw crew cap. The mesh alveolus locates in the cavity of the top draw screw cap. The insert-style mesh alveolus locates in the inflation cavity of the top draw screw cap. There is a spring sets between the outside of the alveolus and the wall of the top draw screw cap. When they are face-to-face connected, the insert-style mesh alveolus locates in the inflation cavity of the top draw screw cap, the mesh tooth part of mesh screw inserted in the insert-style mesh alveolus of the insert-style top draw screw cap and meshes with the mesh teeth in the alveolus. The two ends of the pre-make part have end-stake with many inflation draw screw caps and the pre-make part with many top draw screw caps respectively. In the pre-make part, there are many items of the portrait reinforcing steel bar whose two ends clip to the steel cap of the inflation draw screw caps and the top draw screw cap respectively. The mesh screw is used to the face-to-face connection of two pre-make parts.

Owner:周兆弟

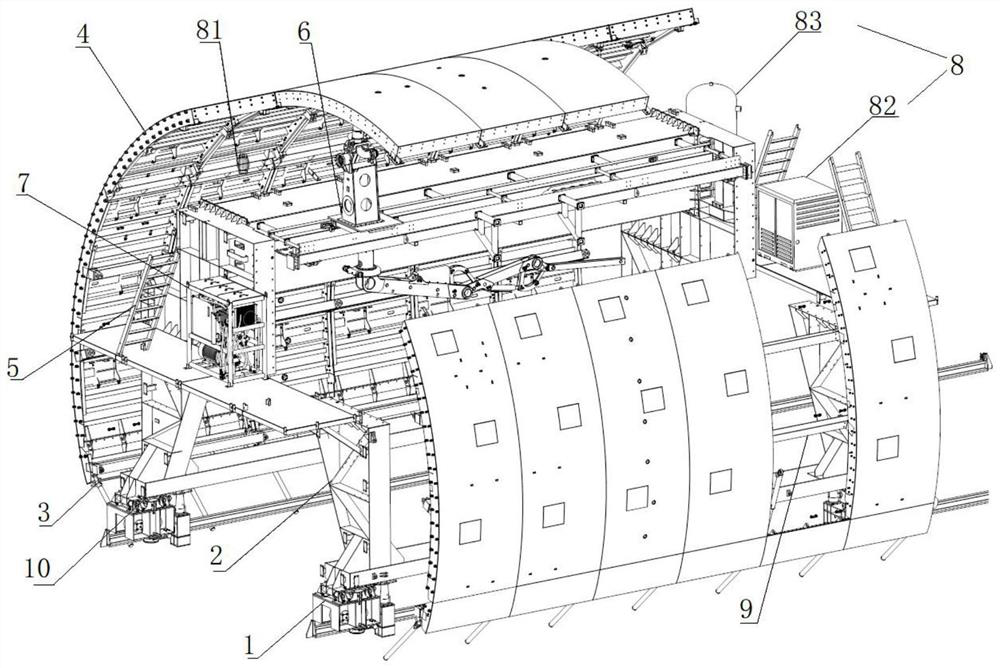

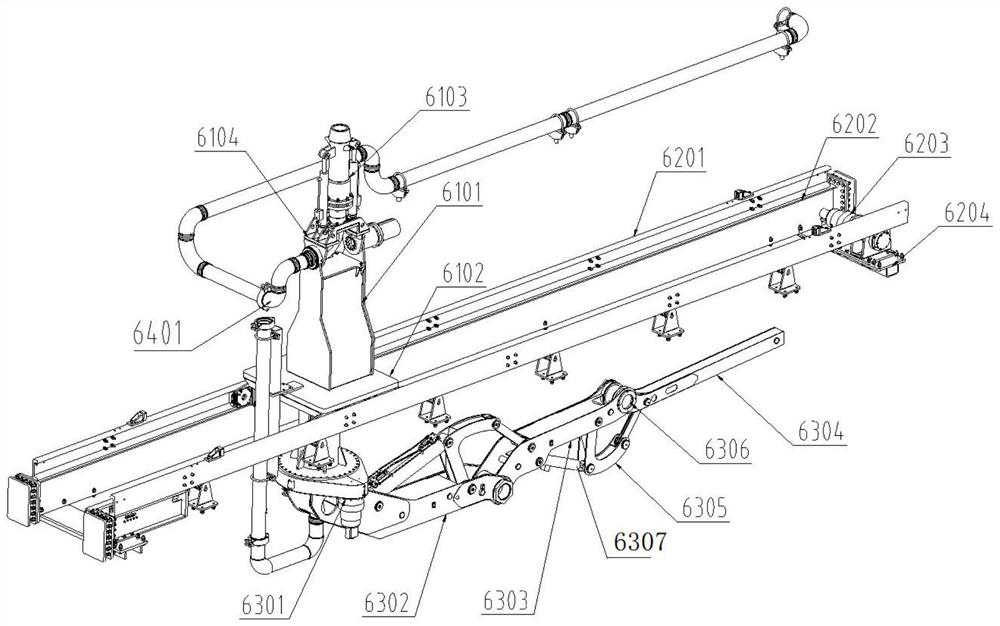

Pouring system and lining trolley

PendingCN112502745AGuarantee lining qualitySimple structureUnderground chambersTunnel liningPipeSupport plane

The invention provides a pouring system. The pouring system comprises an upper-layer pouring device, a lower-layer pouring device, a sliding assembly, a supporting frame and a grouting main pipe, thesupporting frame is arranged on the sliding assembly in a sliding mode, the upper-layer pouring device and the lower-layer pouring device are arranged on the upper side and the lower side of the supporting frame respectively, and the upper-layer pouring device and the lower-layer pouring device move along with the supporting frame; and the grouting main pipe selectively communicates with a grouting pipe of the upper-layer pouring device or a grouting pipe of the lower-layer pouring device, so that pouring operation of the upper-layer pouring device or the lower-layer pouring device is realized. The upper-layer pouring device is configured with arch crown pouring for pouring, the lower-layer pouring device is configured with arch wall pouring for pouring, and the lining quality is guaranteed through layer-by-layer windowing pouring. The invention further provides a lining trolley. Visual management of pouring operation of the lining trolley is achieved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

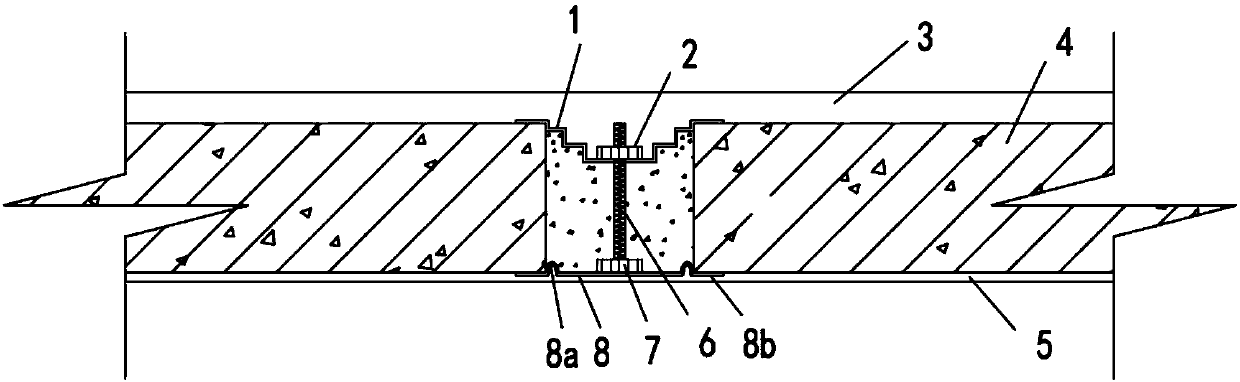

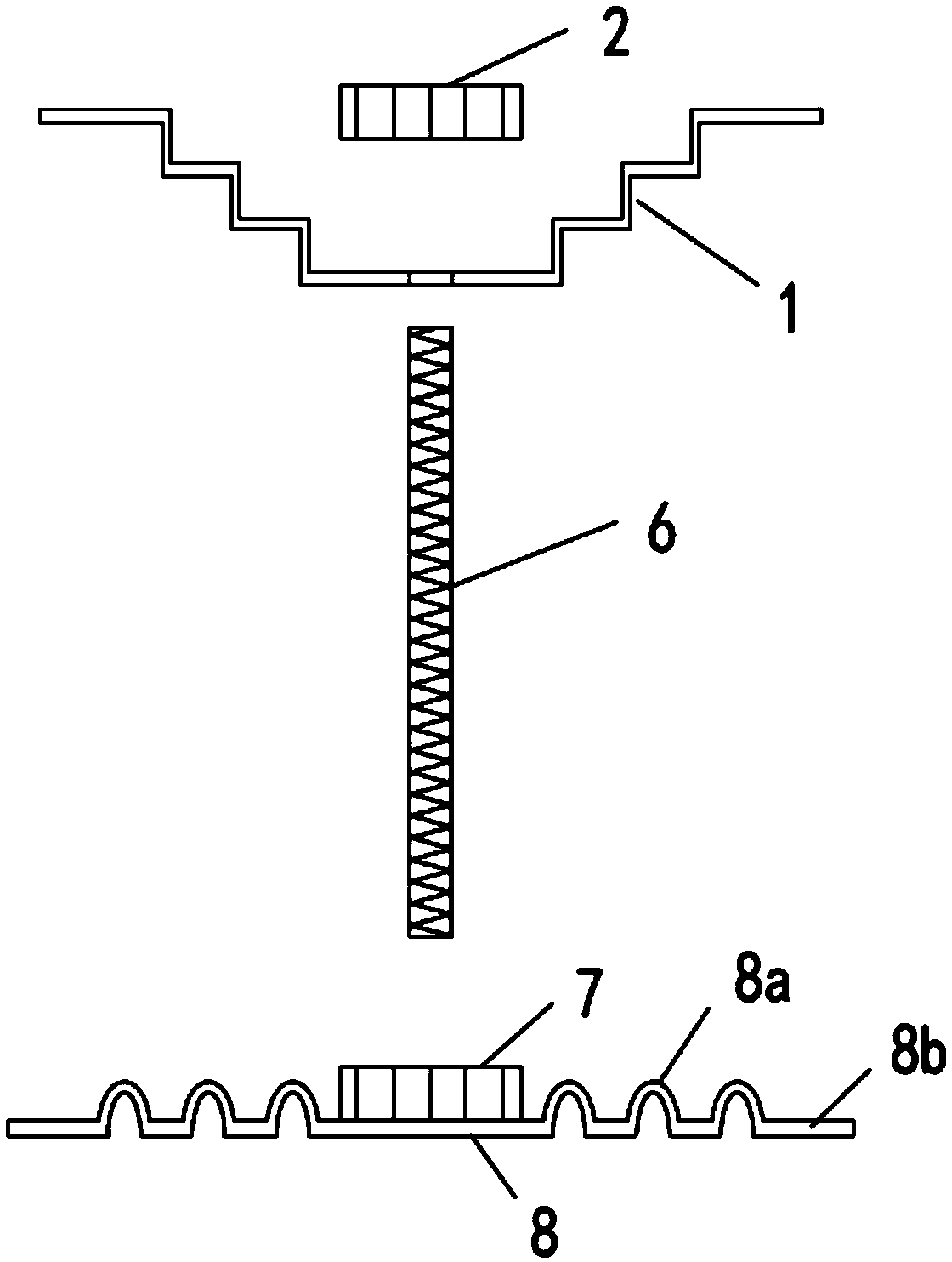

Manufacturing method and construction method of mud-leakage-prevention sealing device for wood formwork splicing seam

InactiveCN111206766AAvoid slurry leakageImprove molding qualityAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringFlange

The invention discloses a manufacturing method and a construction method of a mud-leakage-prevention sealing device for a wood formwork splicing seam, and belongs to the technical field of building construction. The manufacturing method and the construction method comprise the following steps that 1, a seam blocking plate is made of a steel plate with the thickness of 1.0mm, a web plate of the seam blocking plate is a full-length plate, and an upper flange plate and a lower flange plate are symmetrically arranged at an interval; 2, holes are formed in the upper flange plate and the lower flange plate correspondingly; and 3, in the formwork mounting process, the seam blocking plate is clamped into a gap between every two adjacent formworks, meanwhile, the formwork surfaces where the upper flange plate and the lower flange plate are located are screwed up by adopting self-tapping screws, so that the formwork surfaces are tightly attached to the inner sides of the upper flange plate and the lower flange plate, then a formwork reinforcing system is installed, and concrete is poured after acceptance. According to the manufacturing method and the construction method, operation is simpleand easy to carry out, the construction speed is high, material waste is reduced, and the green construction concept is met.

Owner:CHINA MCC17 GRP

Deicing grouting crack arrest system and method of tunnel surrounding rock in seasonal frozen region

PendingCN107956482AFast testHigh precisionUnderground chambersTunnel liningAutomatic controlDisplay device

The invention discloses a deicing grouting crack arrest system of a tunnel surrounding rock in seasonal frozen region and a deicing grouting crack arrest method. The deicing grouting crack arrest system comprises a deicing device, a hole sealing device, a grouting device and a control device, wherein the control device comprises a displayer and a circuit board; the deicing device comprises an airblasting powder sprayer, a flexible detecting steel pipe, a flexible steel pipe, a wireless sound wave emitter, a wireless sound wave receiver, and a wireless device controller; the hole sealing device comprises two hole sealing units in parallel, and every hole sealing unit comprises a blocking air sac located in a hole end of the tunnel surrounding rock drill hole; the blocking air sac is sleeved on the outer pipe of the flexible detecting steel pipe, and the outside of the hole end of the tunnel surrounding rock drill hole is provided with a blocking steel plate for fixing a second water filling pipe; the grouting device comprises an automatic stirring tank and a grout pumping automatic control pump. The system can avoid poor grouting and blocking effect of deep surrounding rock crack in the crack arrest process; the applicability and safety are stronger.

Owner:HARBIN INST OF TECH

Coal seam gas drilling rig power head tap device

A coal seam gas drilling rig power head tap device comprises a water joint and a power head floating core shaft; a positioning nut sleeves a water inlet end of the power head floating core shaft; the positioning nut is in threaded connection with the power head floating core shaft. The coal seam gas drilling rig power head tap device is characterized in that a sealing connection mechanism is arranged between the positioning nut and the water joint; the sealing connection mechanism comprises a centering supporting sleeve which is fixedly connected with the positioning nut; a core pipe which is fixedly connected with the water joint is arranged inside the centering supporting sleeve; an inner chamber of the core pipe is communicated with an inner chamber of the power head floating core shaft and the water joint to form a water inlet channel; a centering mechanism is arranged between the outer wall of a water inlet end of the core pipe and the inner wall of the centering supporting sleeve; a sealing device is arranged between the outer wall of a water outlet end of the core pipe and the inner wall of the centering supporting sleeve. According to the coal seam gas drilling rig power head tap device, the structure is compact, the work is stable, sealing parts are convenient to replace, the integral installation and detachment is simple, the requirements of the actual use of the existing coal seam gas drilling rig are met, and the guarantee is provided for the improvement and innovation of the traditional core drill.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

Edge-sealing device and method for concrete construction of assemble structure laminated lay thereof

An edge sealing device includes an edge-sealing template and a plurality of edge-sealing units, Edge-sealing unit comprise a brace, tighten the screw and wedge, the bottom end of the brace is used forsnapping on the prefabricated wall panel, The top of the strut is provided with a rotatable connecting rod, The centerline of the connecting rod is arranged in the horizontal direction, A screw screwis screwed to the connecting rod, the edge-sealing formwork is L-shaped, A surface perpendicular to each other on that outside of the edge seal formwork is respectively used for adhere to a prefabricated wall board and a laminated floor board, a screwing screw is used for supporting the edge seal formwork, the top end of the strut is also used as a simple inclined wedge mechanism formed by an inclined wedge and a wedge block, the inclined surface of the wedge block is used for self-locking clamping with the inclined wedge, and the upper surface of the wedge block is adhering to the lower surface of the laminated plate. The invention has the advantages of low cost, easy fabrication and convenient installation on the spot, and can effectively prevent the grout leakage phenomenon when the concrete of the post-pouring horizontal composite layer of the floor is poured, and is beneficial to the construction of the later decoration project.

Owner:南京市裕和建设有限公司

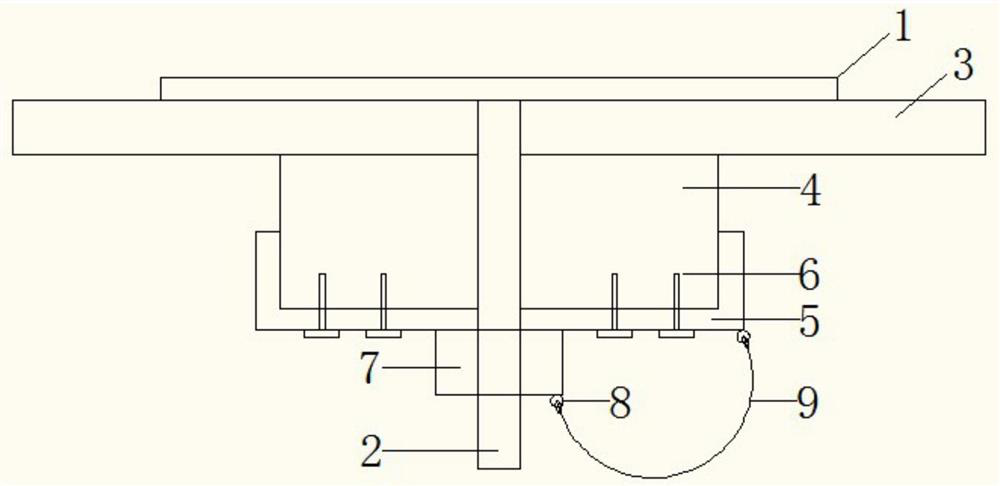

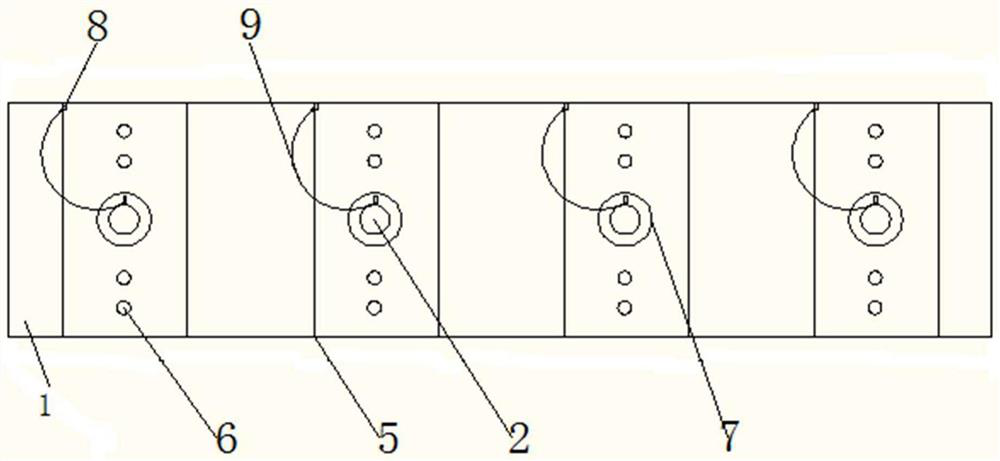

Construction reserved hole auxiliary pouring equipment and supporting device

InactiveCN106522543AThe overall structure is simpleEasy to useAuxillary members of forms/shuttering/falseworksShoresArchitectural engineeringBuilding construction

The invention relates to the technical field of building engineering construction, in particular to construction reserved hole auxiliary pouring equipment and a supporting device. The construction reserved hole auxiliary pouring equipment comprises a pouring mold plate and the pouring mold plate supporting device. The pouring mold plate supporting device comprises a telescopic jacking device. The jacking device is provided with a jacking pushing part matched with the pouring mold plate. A bottom supporting device is arranged below the jacking device. When the construction reserved hole auxiliary pouring equipment and the supporting device are used, the structure is simple, installation is convenient, and erecting is not needed.

Owner:HENAN UNIV OF SCI & TECH

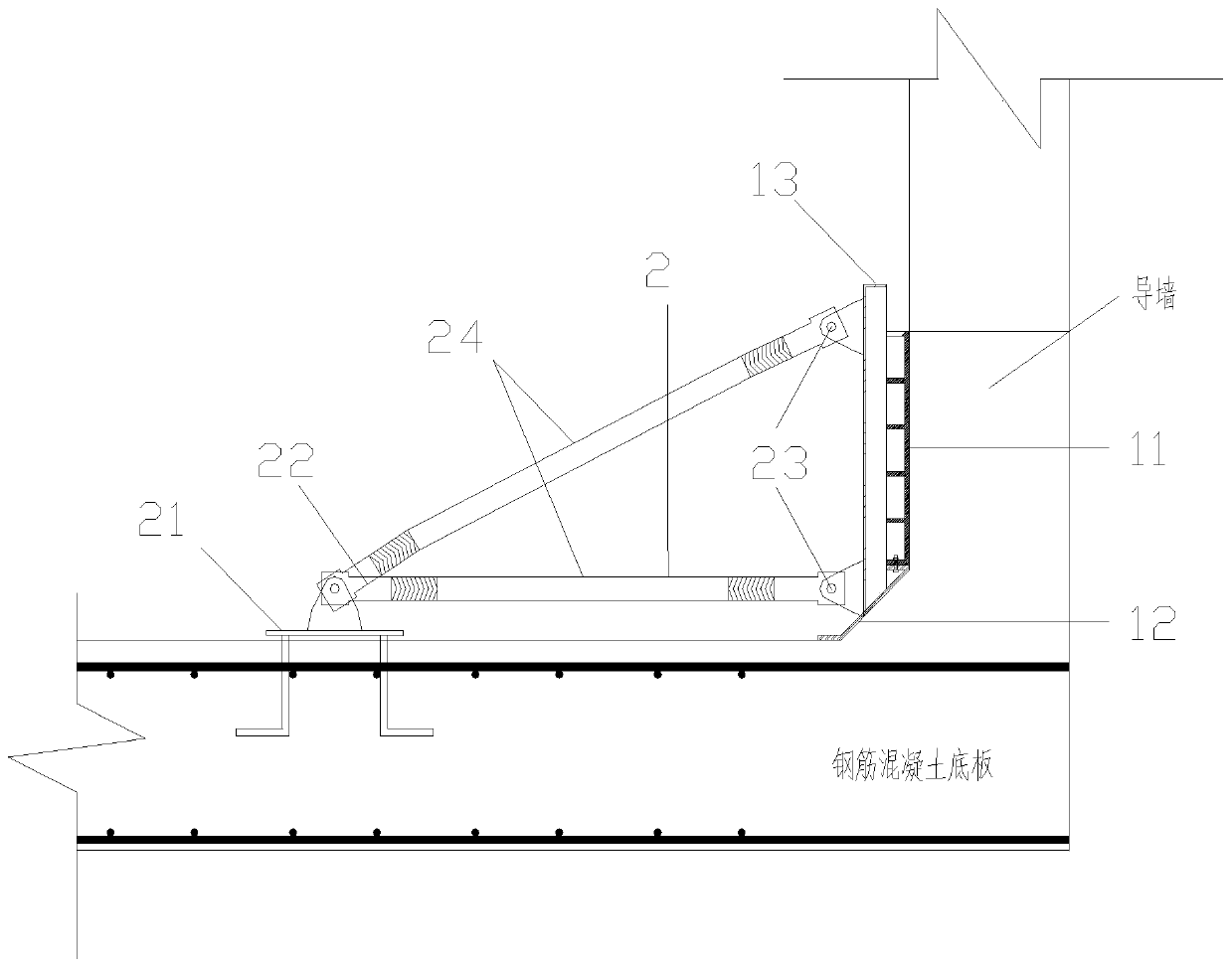

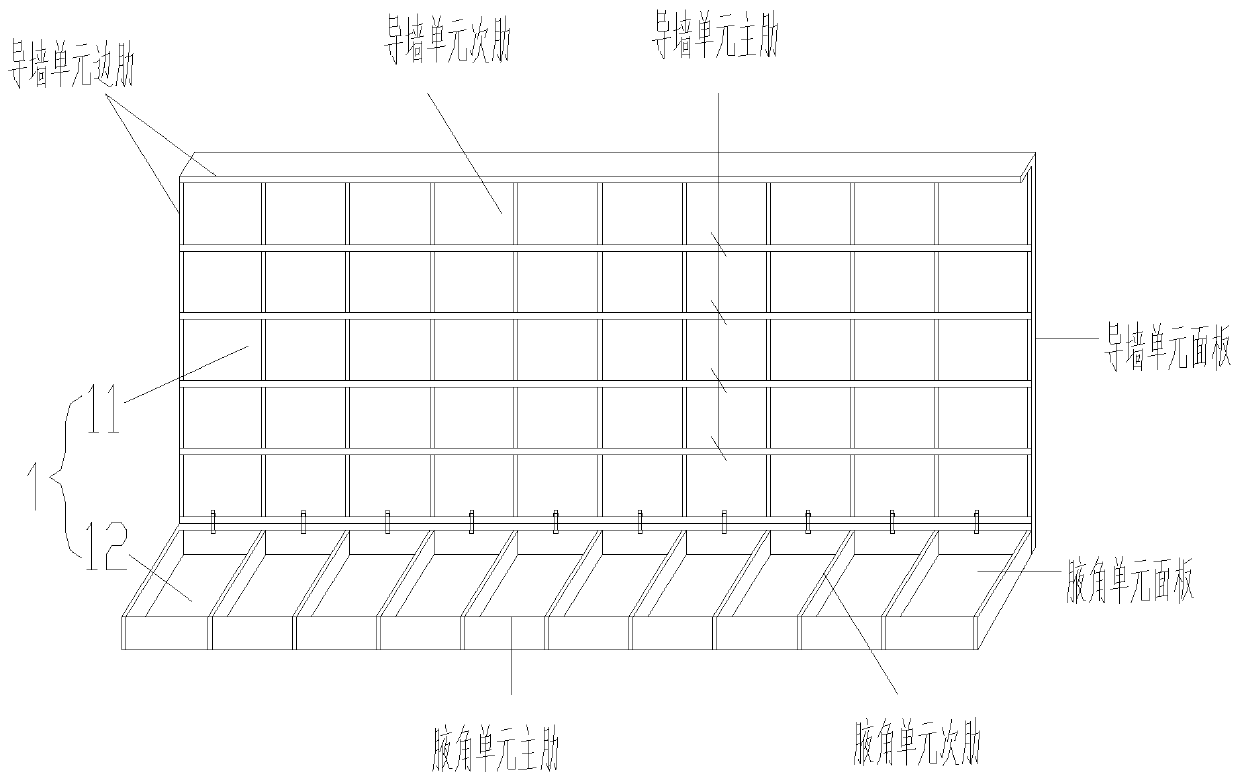

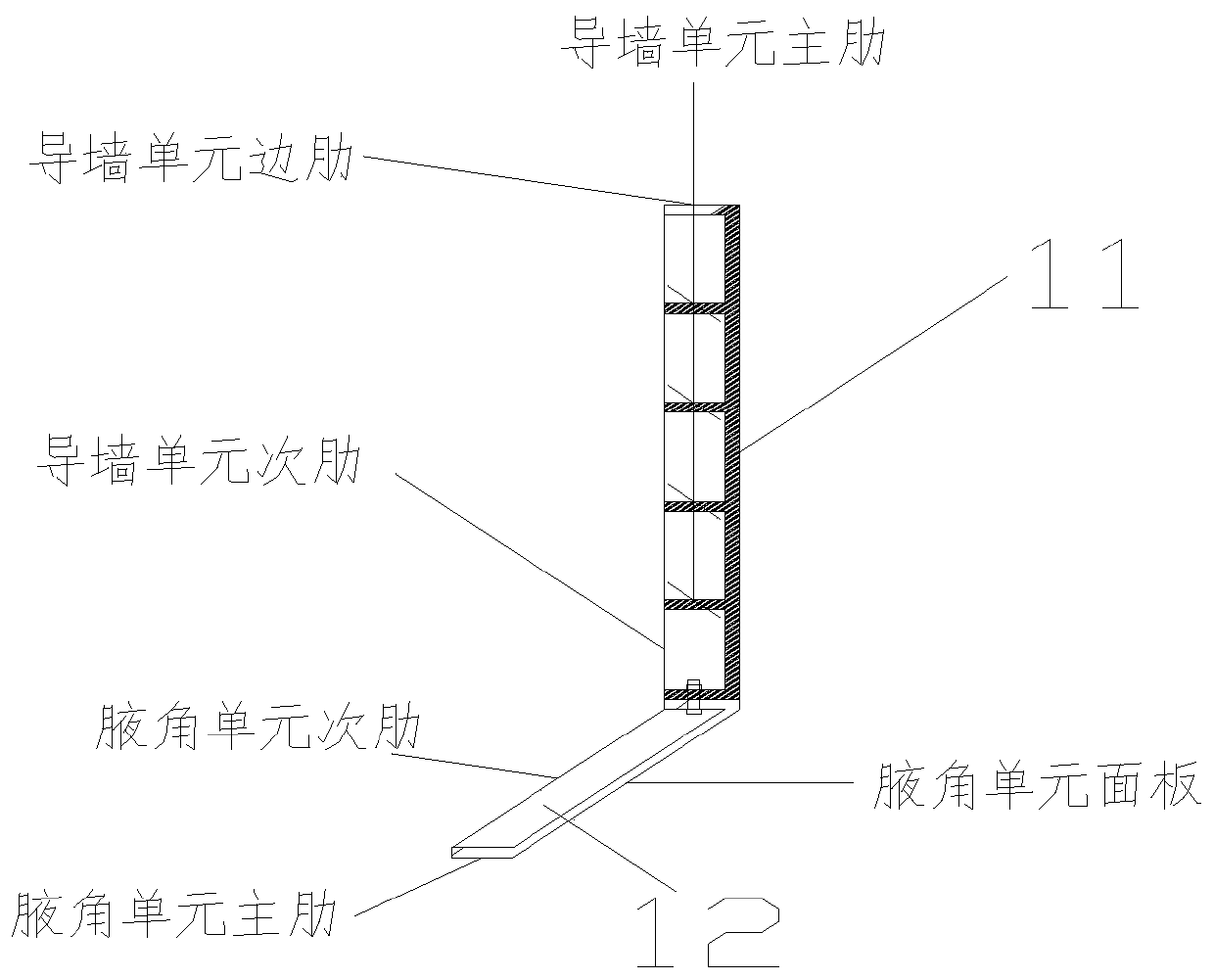

Underground finite space fertilizer-tank-free structure side wall large steel formwork system and construction method

InactiveCN110424455AGuaranteed verticality accuracyInhibit swellingArtificial islandsForms/shuttering/falseworksSupporting systemEngineering

The invention discloses an underground finite space fertilizer-tank-free structure side wall large steel formwork system and a construction method, and belongs to the technical field of underground engineering construction. A plurality of guide wall axillary angle formwork monomers are spliced to form a guide wall axillary angle formwork system and a supporting system, and a plurality of side wallformwork monomers are spliced to form a side wall formwork system. Guide wall units and axillary angle units are connected into a whole. Side wall units are connected into a whole through connectingbolt pairs, and then the guide wall axillary angle formwork system is fixed and supported through the supporting system. The perpendicularity of the guide wall axillary angle formwork system and the side wall formwork system is precisely controlled through the stretching length of adjustable-length supporting rods. The forming quality and waterproof effect of an urban underground comprehensive pipe gallery side wall cast-in-place concrete structure are guaranteed, the quality defect and later hidden water seepage danger of the wall cast-in-place concrete structure are eliminated, constructionis efficient, formworks can be reused, and resources are saved.

Owner:CHINA MCC17 GRP

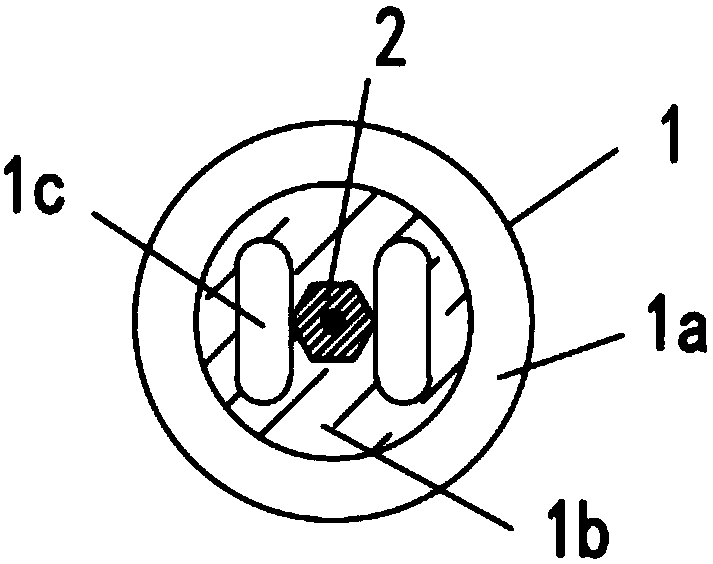

Blocking device suitable for small-area floorslab cave hole

PendingCN109577498APut an end to common quality problems that are prone to leakageQuick installationBuilding material handlingBuilding insulationsFloor slabEngineering

The invention discloses a blocking device suitable for a small-area floorslab cave hole. The device comprises an upper sealing plate, a lower sealing plate and a connectingfastening assembly connecting the upper sealing plate and the lower sealing plate; the upper sealing plate comprises a sinking type round upper sealing body in the middle and a ladder-shape upper hole sealing edge extending upward and outward along the edge of the top portion of the upper sealing body; the lower sealing plate is matched with the shape of the floorslab cave hole and comprises a lower sealing body and a lowerhole sealing side extending outward from the lower sealing body, and multi-level annular pressing grooves protruding upward are formed in the lower sealing body from inside to outside; theconnectingfastening assembly comprises a threaded rod, an upper nut and a lower nut. The device relates to blocking work offloorslab cave holes with the side length less than 200 mm or the diameter less than 200mm on the construction site, all kinds of horizontal cave holes of floorslab wire releasing cave holes, waste water supplying pipeline cave holes, rod piece dismantling waste cave holes and the like can be blocked, the device has the advantages that free combination is achieved, installing is quick, and the operation is simple and convenient, and it is avoided that after repairing by blocking conventional horizontal cave holes, the common quality problem of leakage is easily caused.

Owner:ZHONGTIAN CONSTR GROUP

Device for supporting angle formwork during secondary concrete pouring at intersection of precast beams and slabs and method of device

PendingCN111877755AAdjust the fitEasy to installAuxillary members of forms/shuttering/falseworksShoresReinforced concreteButt joint

The invention belongs to the technical field of formwork supporting in concrete engineering, and discloses a device for supporting an angle formwork during secondary concrete pouring at the intersection of precast beams and slabs and a method of the device. Angle steel connecting plates are connected with two pieces of angle steel through bolts correspondingly, and angle steel reserved holes are formed in the two pieces of angle steel correspondingly. L-shaped steel plates are fixed to the right ends of the two pieces of angle steel through bolts, and the L-shaped steel plates are fixed to thesides of a prefabricated reinforced concrete beam through expansion bolts. An inclined strut support is arranged on the angle steel connecting plates, and a support adjusting device is arranged at the left end of the inclined strut support; and the inclined strut support is connected with a diagonal brace system through a hinge connection hole, and the diagonal brace system is connected with a steel formwork system through a hinge connection hole. By arranging the support adjusting device and the diagonal brace system, the attaching degree of a steel formwork and the surfaces of the beam andthe slab can be adjusted; and under the action of an inclined strut, the angle formwork bears vertical jacking force and horizontal thrust, so that the steel formwork is tightly attached to the surfaces of the beam and the slab, seamless butt joint is achieved, the sealing performance is high, and meanwhile the slurry leakage phenomenon is eradicated completely.

Owner:怀化市城市建设投资有限公司 +2

Fastening joint of assembly type reinforced concrete combination bridge and manufacturing method of fastening joint

InactiveCN110093858AReduce construction costsThere will be no slurry leakageBridge structural detailsBridge erection/assemblyHigh strength concreteReinforced concrete

The invention discloses a fastening joint of an assembly type reinforced concrete combination bridge and a manufacturing method of the fastening joint. The fastening joint comprises a steel beam, a prefabricated concrete plate, shear-resistant pieces, fastening pieces and a bonding material. The prefabricated concrete plate comprises a concrete plate body, shear-resistant piece holes, fastener notches, pre-embedded fastener positioning plates, positioning plate long circular holes and sleeves. The positions, corresponding to the shear-resistant piece holes of the prefabricated concrete plate,of the shear-resistant pieces are welded to the steel beam. Long circular holes are formed in the steel beam corresponding to the four corners of the prefabricated concrete plate. The pre-embedded fastener positioning plates and sleeves are arranged in the four corners of the concrete plate body. The positioning plates are provided with long circular holes. The sleeves are welded between the two fastener positioning plates. After a bonding material layer is arranged around the shear-resistant pieces, the prefabricated concrete plate is placed at the corresponding position, and fasteners are used to penetrate through the prefabricated concrete plate and the steel beam to compact the bonding material. Finally, high-strength concrete is poured from the shear-resistant pieces and the fastenernotches. Thus, quick installation is achieved, the phenomenon of slurry leakage is avoided, materials are saved and labor cost is reduced.

Owner:ZHEJIANG INST OF COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com