Edge-sealing device and method for concrete construction of assemble structure laminated lay thereof

A technology of edge banding device and laminated board, which is applied to the preparation of building components on site, building structure, formwork/formwork/work frame, etc. It can solve the problems of anti-leakage grout and unfavorable decoration construction, etc., and achieve convenient on-site installation, No environmental pollution, clean appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

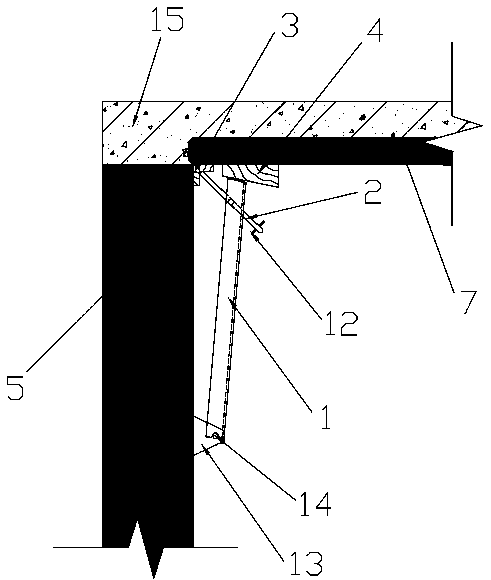

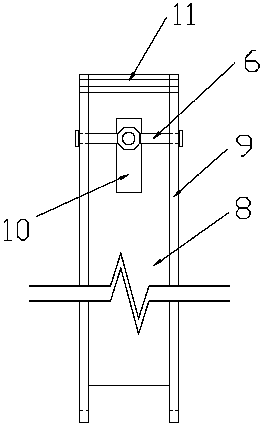

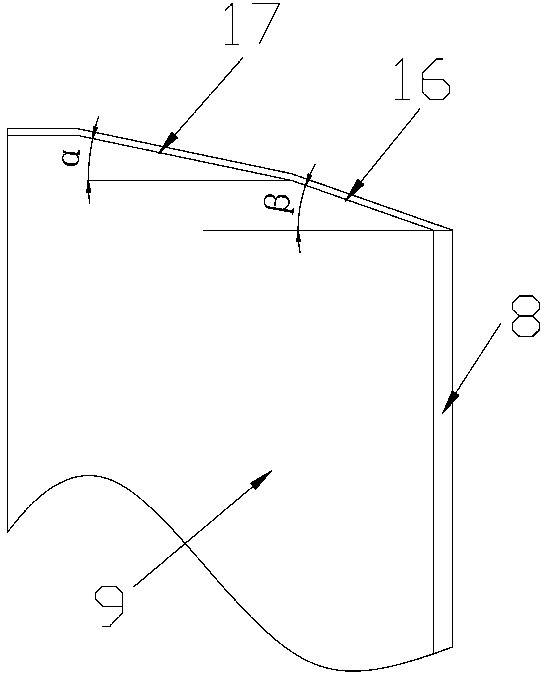

[0034] Such as Figure 1-Figure 2The edge banding device includes an edge banding template 3 and a plurality of edge banding units, and the edge banding unit includes a strut 1, a tightening screw 2 and a wedge 4, and the bottom end of the strut 1 is used for Fastened on the diagonal bracing connecting seat 13 on the prefabricated wall panel 5, the upper part of the strut 1 is rotatably provided with a connecting rod 6, the screw 2 is perpendicular to the connecting rod 6 and the two are screwed together , the tightening screw 2 passes through the connecting rod 6, the edge sealing template 3 described in this application is L-shaped, specifically includes a horizontal plate unit and a vertical plate unit, the length of the edge sealing template 3 is the same as The lengths of the prefabricated wall panels 5 are equal, and the vertical panel unit and the horizontal panel unit of the edge sealing formwork 3 are respectively used to contact the surface of the side of the prefabr...

Embodiment 2

[0041] This embodiment is a method for the construction of prefabricated structure laminated concrete, using the edge banding device described in Embodiment 1, including the following steps:

[0042] Step 1, step 1, prepare the edge banding device, hoist the prefabricated wall panel 5, complete the installation of the diagonal brace for temporary fixation, reserve the diagonal brace connecting seat 13 for installing the edge banding device, and set up the lower support of the laminated board (specifically, use Vertical steel pipe supports are used to support the laminated slab to prevent the laminated slab from falling), hoist the laminated slab 7 to a predetermined position, the edge of the laminated slab is supported by the prefabricated wall panels, and the rest is supported by steel pipes forming the lower support of the laminated slab , and then complete the reinforcement and side form construction of the horizontal laminated layer after the floor is poured; step 1 in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com