Masonry wall constructional column forming method

A molding method and technology for constructing columns, which are applied to building structures, columns, piers and other directions, can solve the problems of wasting labor, wasting concrete, wasting concrete materials, etc., and achieve the effect of promoting labor saving and convenience, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

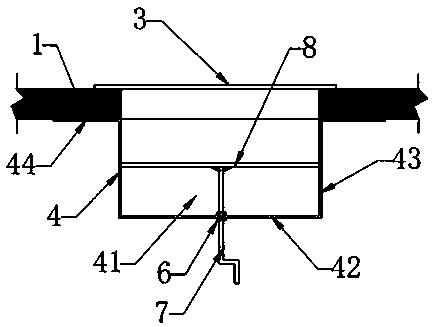

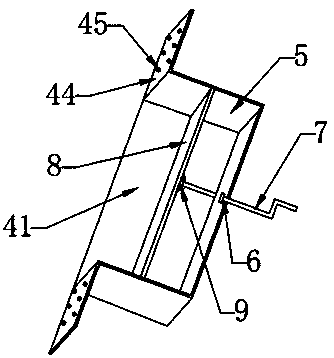

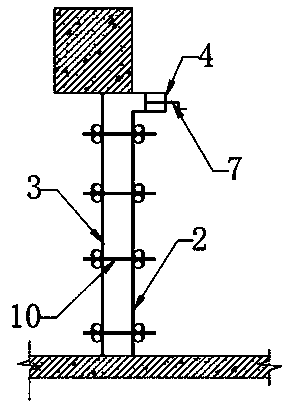

[0026]As shown in the figure, the method for forming a masonry wall structural column provided in this embodiment includes the following steps: S1, according to the design drawings of the masonry wall, build a brick wall 1 at the corresponding position, and reserve a structure at the corresponding position of the masonry wall Column forming gap; S2, according to the design drawing of the masonry wall, use CAD to draw the structural column formwork, and prefabricate the corresponding structural column formwork in the factory. The concrete push hopper with the upper end attached, the concrete push hopper includes a hopper 4 and a push plate 8 slidingly installed in the hopper 4, the hopper 4 consists of a bottom plate 41, a front panel 42 fixed on the bottom plate 41 and two The two side plates 43 are located on the left and right sides of the bottom plate 41, and together with the bottom plate 41 and the front panel 42, they form a rectangular shell with a material inlet 5 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com