Fastening joint of assembly type reinforced concrete combination bridge and manufacturing method of fastening joint

A combined bridge and prefabricated technology, applied in the field of steel structure bridges, can solve the problems such as the inability of bonding materials and steel beams to achieve compaction and leakage, and achieve the effects of saving labor costs, speeding up construction speed, and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

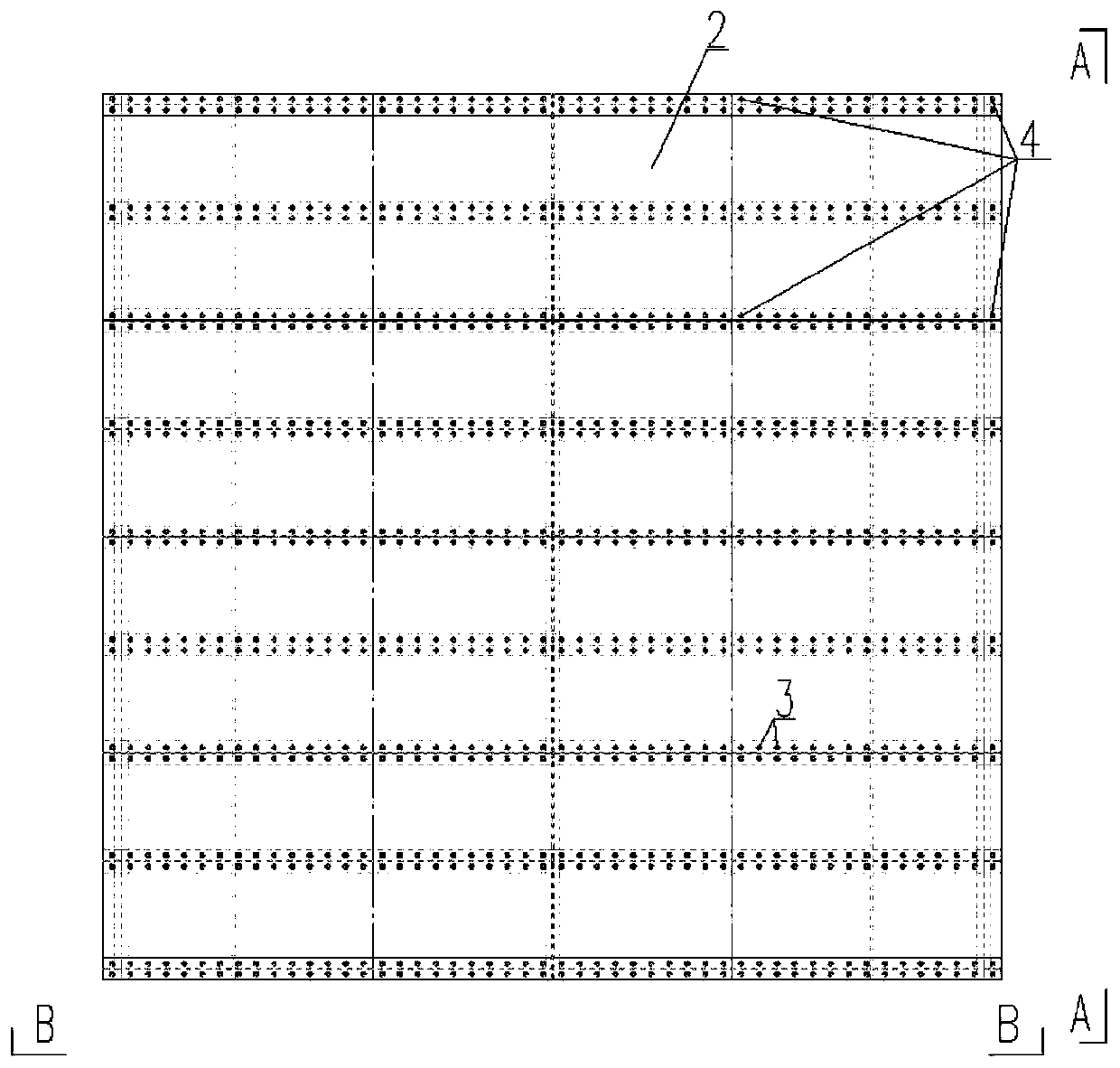

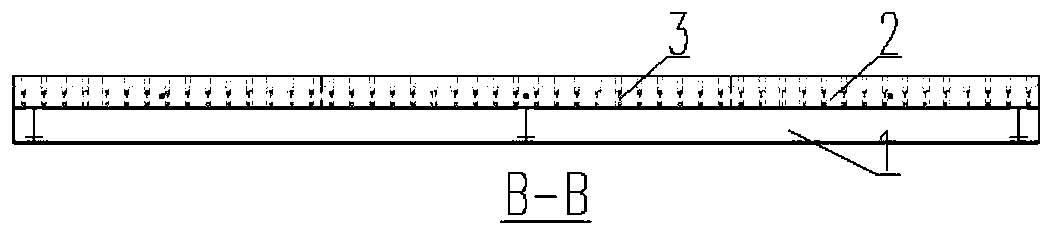

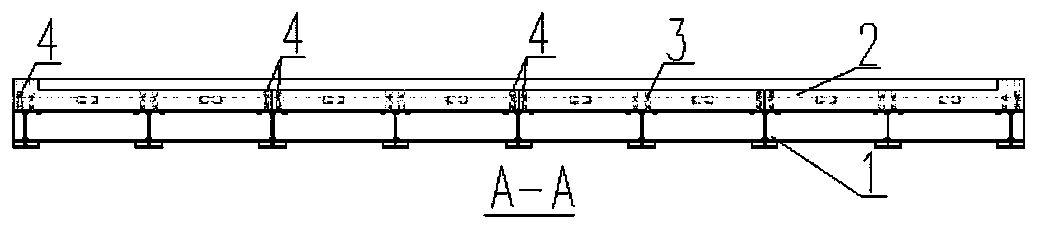

[0035] Example 1: As shown in Figures 1-7, the fastening nodes of a prefabricated steel-concrete composite bridge include: steel girder 1, precast concrete slab 2, shear member 3, fastener 4 and bonding material 5. Wherein the prefabricated concrete slab includes a concrete slab body 26, a shear member hole 21, a fastener notch 22, an embedded fastener positioning plate 23, a positioning plate oblong hole 24 and a sleeve 25; the fastener 4 includes a tight Firmware notches 22, nuts 41, hexagonal socket screws 42 and gaskets 43; the shear member 3 is welded on the steel beam 1 at the position corresponding to the shear member hole 21, and is welded on the steel beams corresponding to the four corners of the precast concrete slab Provide oblong holes 11 on the beam. When pouring concrete prefabricated slabs, pre-embed fastening positioning plates 23 and sleeves 25 at the four corners of the concrete slab body, open oblong holes 24 on the positioning plates 23, and weld the sleeve...

Embodiment 2

[0037] Embodiment 2: A method for manufacturing a fastening structure of a prefabricated steel-concrete composite bridge, comprising the following steps:

[0038] Step 1: Arrange the position and quantity of shear members on the steel beam according to the calculation results;

[0039] Step 2: Determine the size of the precast concrete slab according to the transportation conditions and on-site hoisting conditions;

[0040] Step 3: Determine the location of the fasteners according to the size of the precast concrete slab, and open long round holes at the corresponding positions on the steel beam to replace the shear members;

[0041] Step 4: Before pouring the precast concrete slab, pre-embed fastening positioning plates and sleeves at the four corners of the concrete slab body, open long round holes on the positioning plates, and weld the sleeves between the two fastener positioning plates. And reserve the notch for fasteners to meet the installation of fasteners;

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com