High solid content latent curing polyurethane acroleic acid hybrid emulsion

A polyurethane acrylic, high solid content technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of increasing the content of volatile organic compounds in emulsions, decreasing storage stability of emulsions, and inconvenient application and construction of wood coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

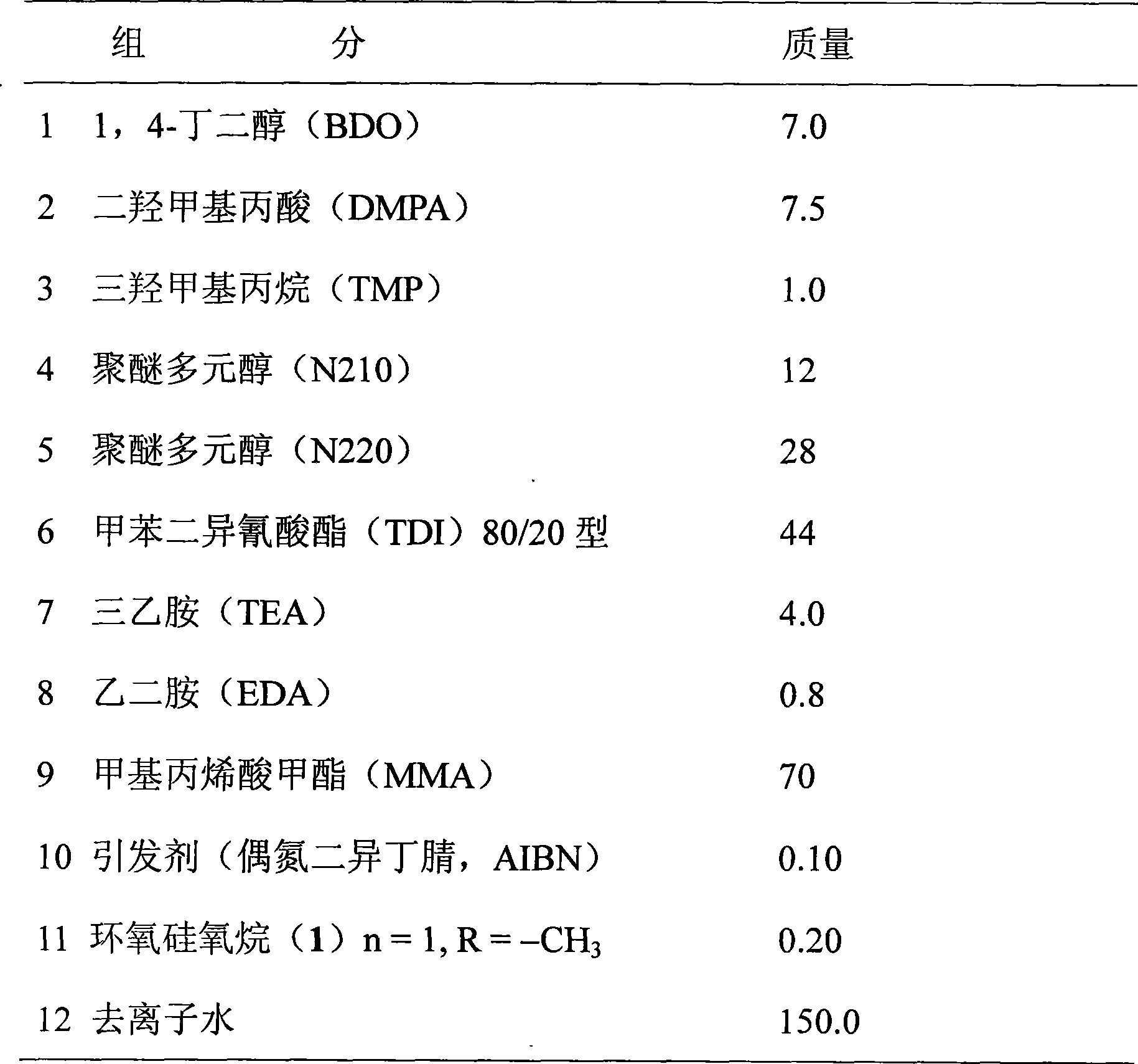

[0051] The latent curing polyurethane acrylic hybrid emulsion with high solid content is used, and its formulation components are listed in Table 2.

[0052] Table 2 High solid content latent curing polyurethane acrylic hybrid emulsion

[0053]

[0054] Under the protection of dry nitrogen, the dehydrated polyether glycol N210, N220, BDO and DMPA are added to a 1000ml four-necked flask equipped with a thermometer, a stirring device and a reflux condenser, a small amount of N-methylpyrrolidone is added, and the temperature is raised to Stirring was started at 60°C, and TDI was added dropwise when the reaction system became transparent, and the drop was completed in 1 hour. React at 70°C-80°C for 3-5 hours, and use n-butylamine titration method to determine the end point of the reaction. After reaching the end point, cool down to 40°C, add triethylamine to neutralize, add acetone to dilute, emulsify in normal temperature water, and use ethylenediamine to extend the chain to ...

Embodiment 2

[0057] Using the high-solid-content latent-curing polyurethane-acrylic hybrid emulsion prepared in Example 1, the wood coating formulation was prepared as shown in Table 3.

[0058] Table 3 Waterborne Wood Coating Formulation

[0059] serial number composition Mass percentage, % 1 PUA emulsion in example 1 88 2 Deionized water 8.1 3 Coalescing agent (dipropylene glycol butyl ether) 3.0

[0060] 4 Wetting agent (TEGO-245) 0.2 5 Defoamer (TEGO—805) 0.05 6 Leveling agent (BYK-330) 0.1 7 Thickener (RM2020) 0.15 8 pH adjuster (AMP-95) 0.20 9 antifungal agent 0.20 total 100

[0061] The preparation method is as follows: firstly add raw materials No. 2-9 into the stirring tank, disperse with a high-speed disperser for 10-30 minutes, then slowly add the PUA emulsion into the stirring tank, stir at a medium speed for 30-60 minutes, and use AMP-95 Adjust the pH value of the coating, and wh...

example 3

[0063] Polyester diol and aliphatic diisocyanate were used to prepare latently cured polyurethane-acrylic hybrid emulsion with high solid content. The raw materials used are listed in Table 4.

[0064] Table 4 High solid content latent curing polyurethane acrylic hybrid emulsion

[0065]

[0066]

[0067] Under the protection of dry nitrogen, the dehydrated polyether glycol N210, T1136, BDO and DMPA were added to a 1000ml four-necked flask equipped with a thermometer, a stirring device and a reflux condenser, a small amount of N-methylpyrrolidone was added, and the temperature was raised Stir at 60°C, start to add IPDI dropwise when the reaction system becomes transparent, finish dropping in 1 hour, then add catalyst, react at 70°C-80°C for 3-5 hours, use n-butylamine titration method to judge the reaction end point. After reaching the end point, cool down to 40°C, add triethylamine to neutralize, add acetone to dilute, emulsify in normal temperature water, and use ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com