Concrete joint drilling device and construction method thereof

A technology for concrete and joints, which is applied in the field of chiseling devices for concrete joints, which can solve the problems of difficult manual chiseling, damage to prefabricated beam and slab structures, and long time-consuming chiseling processes, and achieves simple structure, low construction cost, and easy construction. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

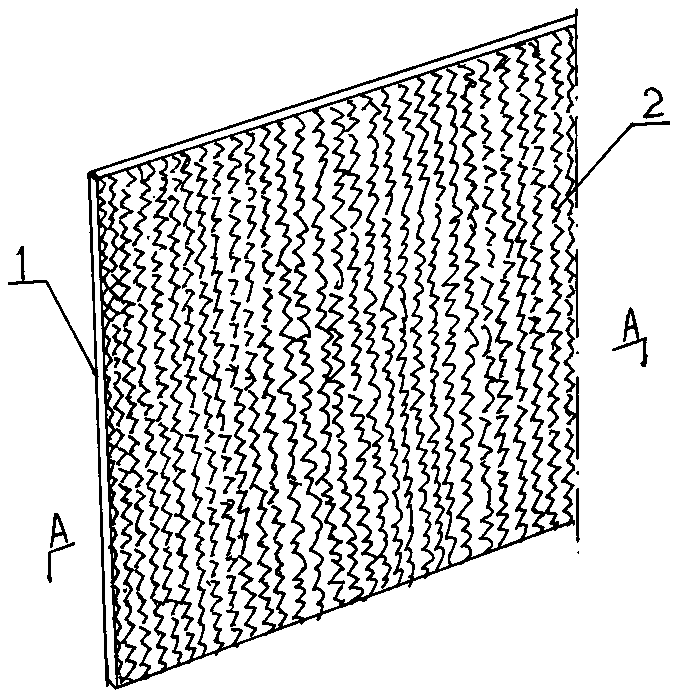

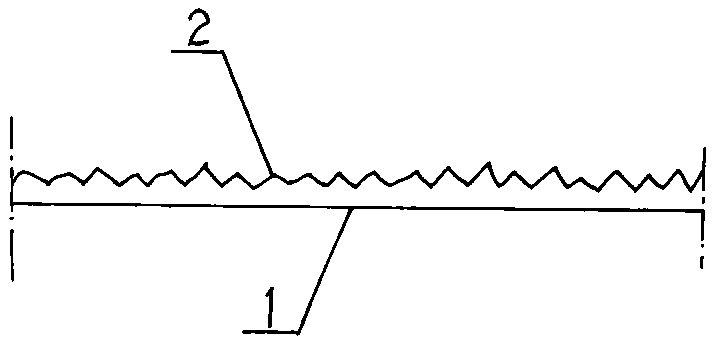

[0038] Embodiment 1: as Figure 1 to Figure 6 As shown, a prefabricated beam-slab concrete junction roughening device includes a base layer 1, one side of the base layer is a concave-convex surface 2; or one side of the base layer is a concave-convex surface, and the other side of the base layer is an adhesive surface; Or the base layer is the formwork 6, and the concave-convex surface is the concave-convex part provided on the template at the corresponding junction 7 of the prefabricated beam slab; the concave-convex surface of the base layer is the contact surface with the poured concrete.

[0039] The adhesive surface is the adhesive surface layer 3 on the base layer and the release layer 4 outside the adhesive surface layer. The release layer is a plastic film, or a release paper, or a silicon-coated protective paper. The base is made of plastic material, rubber or fiber material. The fiber material is plant fiber material. The outer surface of the concave-convex surfac...

Embodiment 2

[0055] Embodiment 2: as figure 1 , figure 2 and Figure 4 As shown, it is a one-time use of concrete joint chisel wool stickers. One side of the base layer 1 is a concave-convex surface 2 . The base is made of plastic material, such as PPC, PVC, etc., rubber, or fiber material. The rubber should have a certain hardness, and the base layer and the concave-convex surface are made of the same material, which is the concave-convex surface made on one side of the rubber sheet.

[0056] The fiber material is a plant fiber material, such as paper with a certain hardness, the base layer and the concave-convex surface are made of the same material, and the concave-convex surface is made on one side of the paper sheet. Can be sprayed with plastic material film layer 5 or other waterproof material at the outer side of the uneven surface of described base layer for waterproofing, as waterproof wax etc., its effect is to prevent cement mortar from sticking to uneven surface.

[0057]...

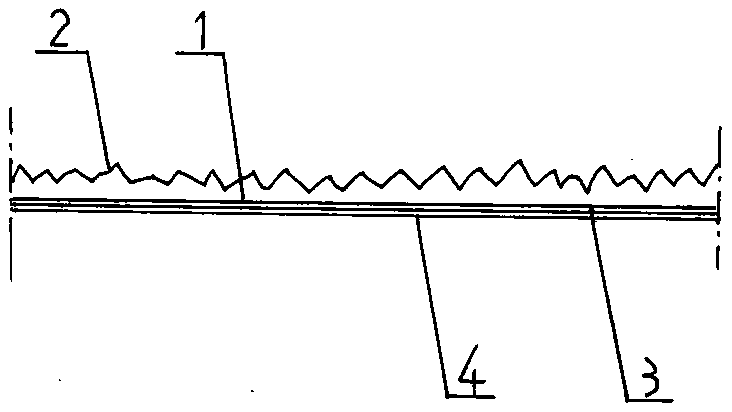

Embodiment 3

[0058] Embodiment 3: as image 3 and Figure 4 As shown, it is a one-time use of concrete joint chisel wool stickers. The difference from Example 2 is: for the convenience of bonding the present invention to the corresponding template, one side of the base layer is a concave-convex surface, and the other side of the base layer is an adhesive surface. The adhesive surface is an adhesive surface layer located on the base layer and a release layer located outside the adhesive surface layer. The release layer is a plastic film, or a release paper, or a silicon-coated protective paper.

[0059] For waterproofing, the outer side of the concave-convex surface of the base layer can be sprayed with a plastic material film layer 5, such as PPC, PVC, etc. or other waterproof materials, such as waterproof wax.

[0060] When in use, the anti-adhesive layer is first removed, the glue surface layer is bonded to the conventional formwork at the corresponding prefabricated beam-slab junctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| flow consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com