Separate splicing form board straight splicing joint plugging device and method

A technology for blocking device and splicing seam, which is applied to the connection of formwork/template/work frame, the preparation of building components on site, construction, etc., which can solve the difficulty of excavation and leveling of raised structures and the inability to seal the splicing seam. , decoration and other troublesome problems, to achieve the effect of improving construction quality and demolition speed, reducing construction cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

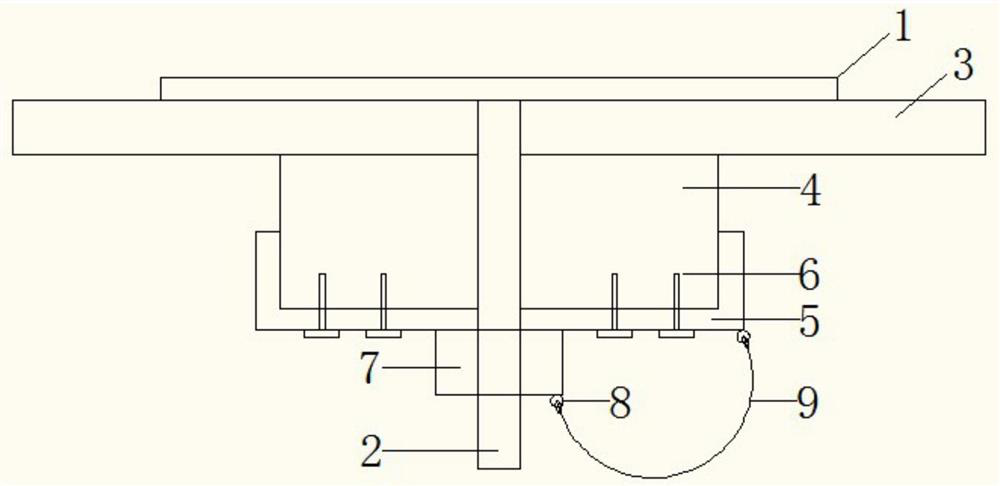

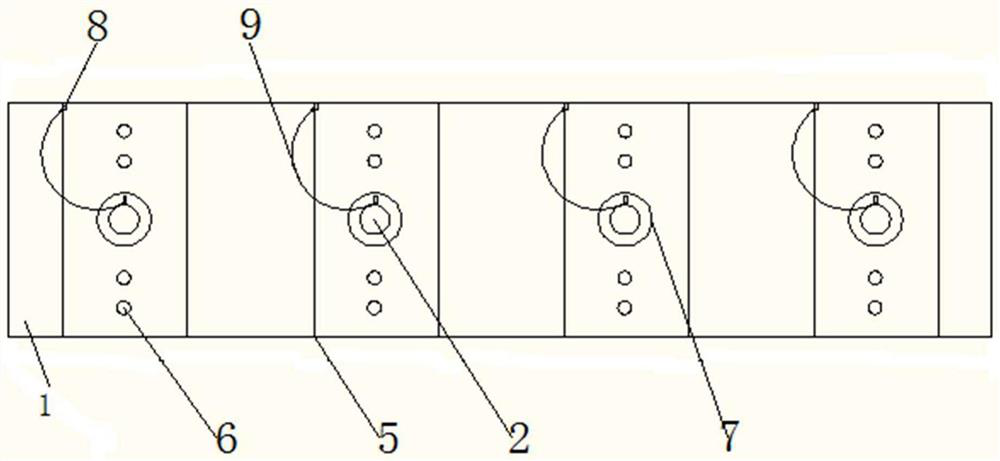

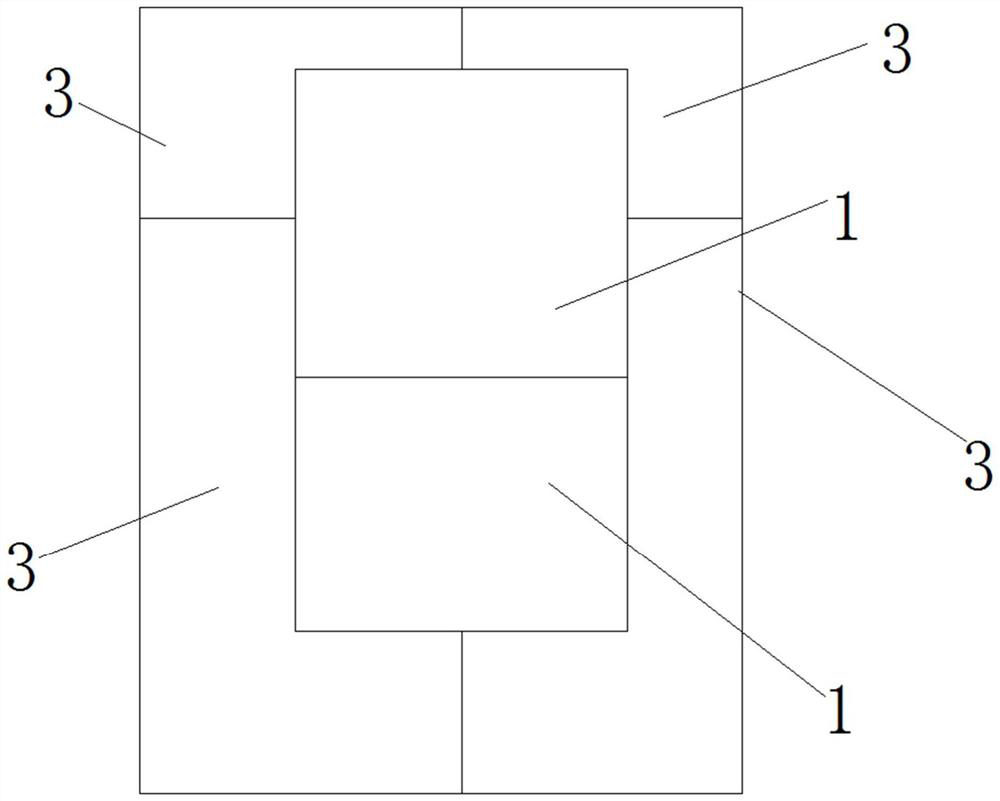

[0029] Such as figure 1 As shown, a flat splicing seam sealing device for loose formwork, including a base plate 1, a pressing block 4 and a pressing buckle plate 5, the base plate 1 is provided with a screw rod 2 perpendicular to the base plate 1, when splicing and pressing, The screw rod 2 on the bottom plate 1 is located between the gap between the two splicing templates 3, the width of the bottom plate 1 is not greater than the joint width of the two splicing templates 3, the splicing template 3 is located between the bottom plate 1 and the pressing block 4, the bottom plate 1 and the pressing block The tight block 4 is locked by the lock nut 7, and the compression buckle 5 is arranged between the lock nut 7 and the compression block 4, so as to ensure that the lock nut 7 can compact the compression blocks 4 on both sides. When splicing is required, the two splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com