Paving method of CRTS I type plate type ballastless track slab in severe cold region

A slab ballastless track and track slab technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of inability to meet special requirements in severe cold regions, large annual temperature difference, etc., and achieve the effect of improving laying accuracy and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

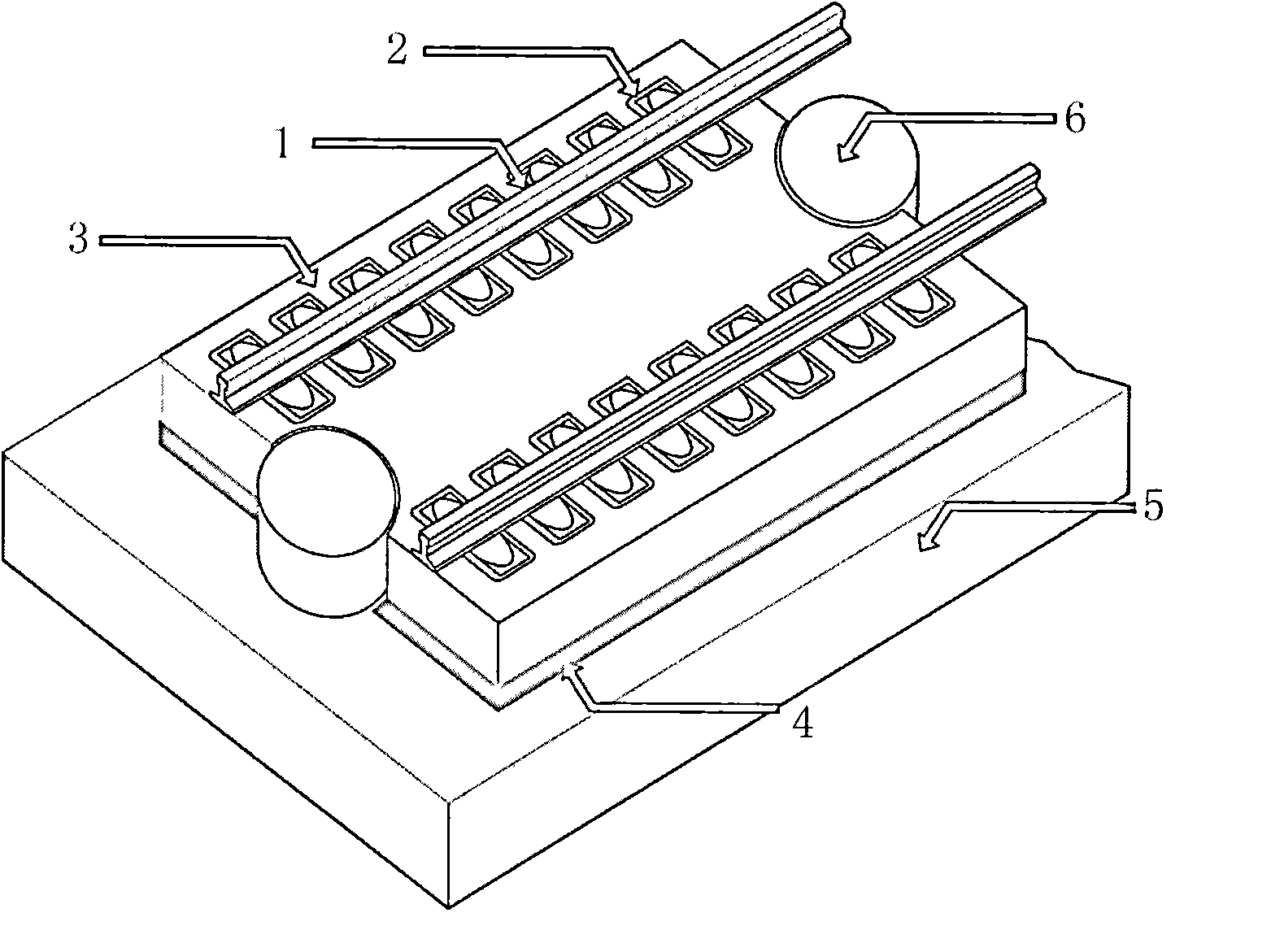

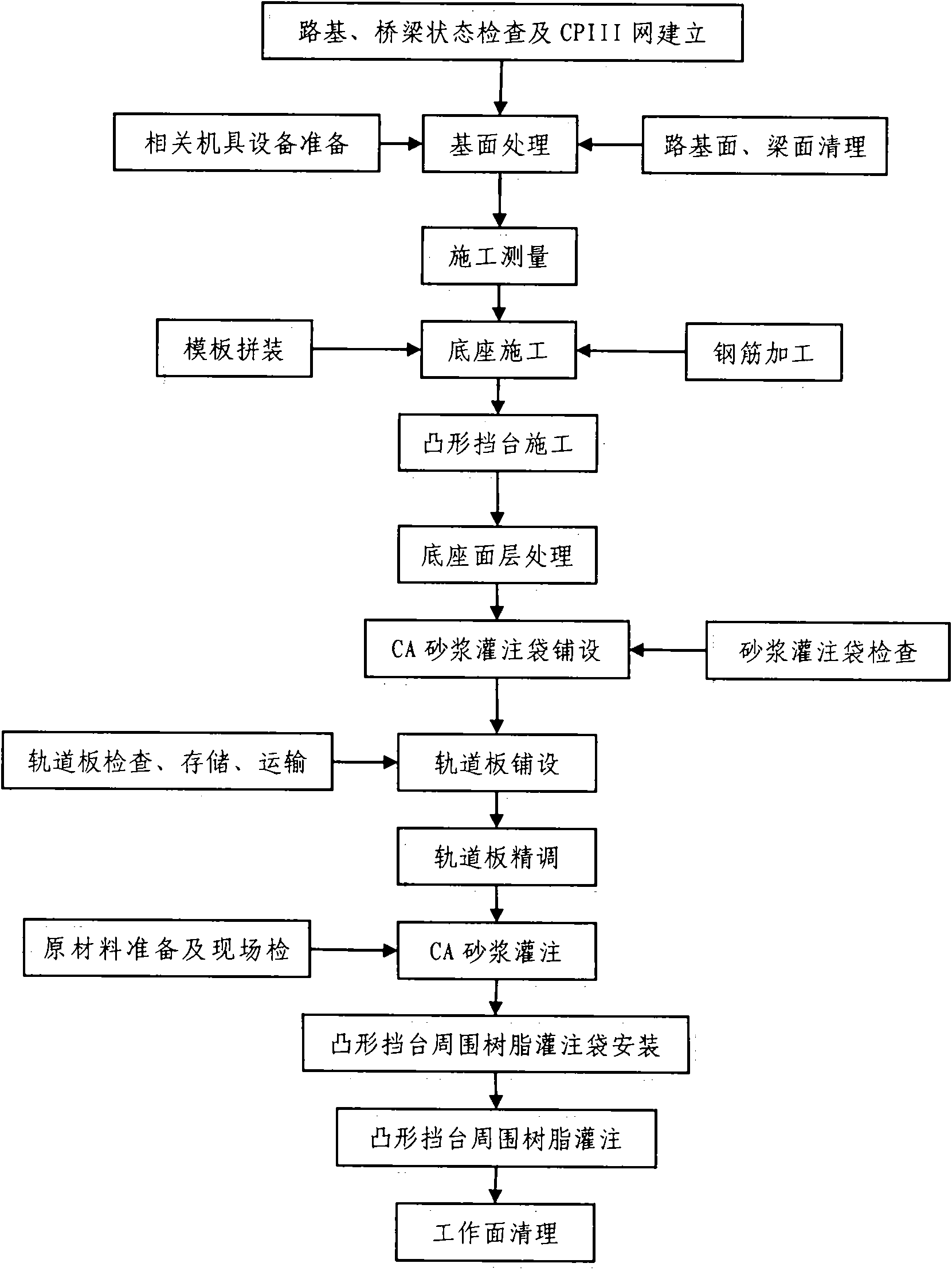

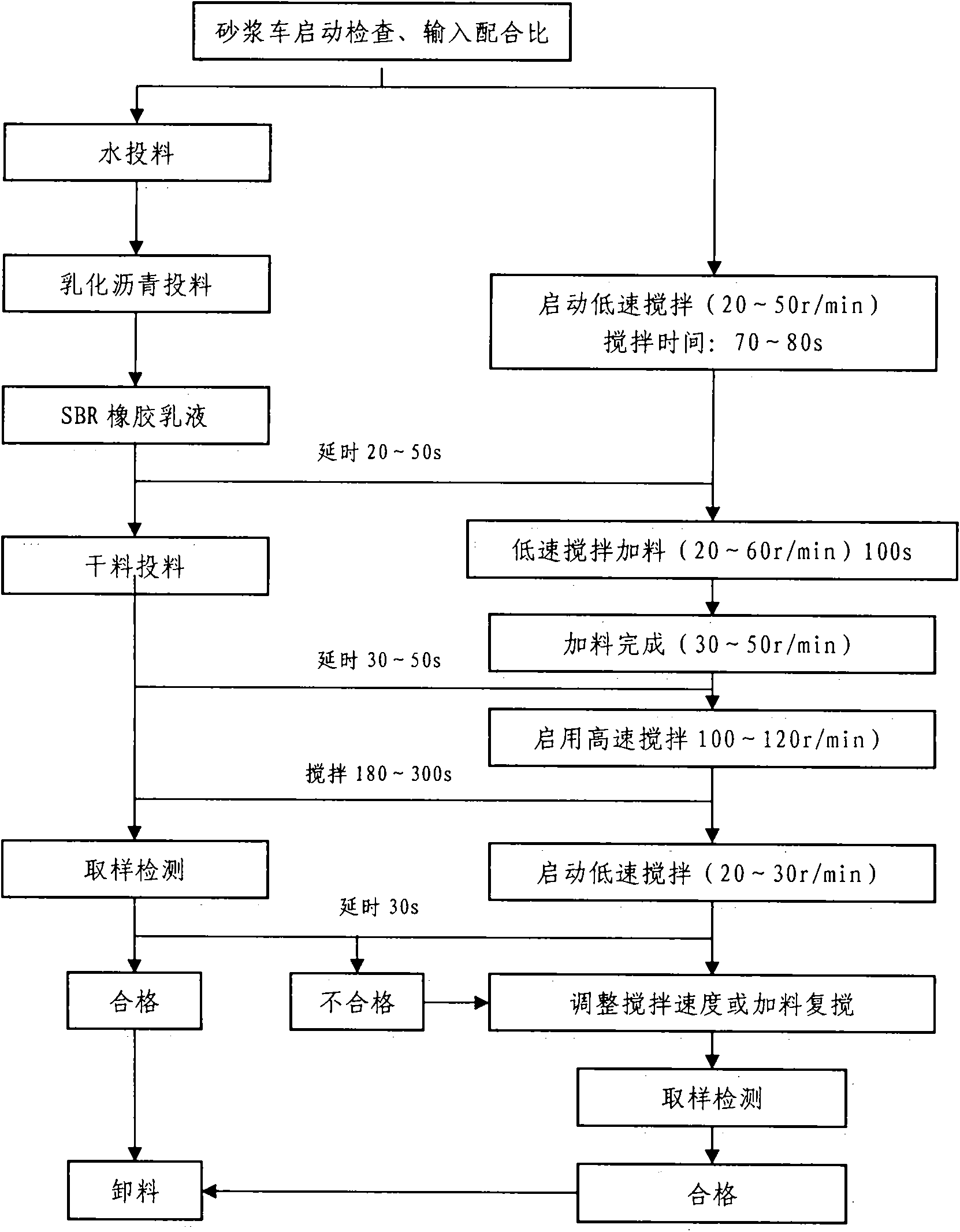

[0028] According to the characteristics of high accuracy requirements for track slab laying, complex process, and high requirements for CA mortar weather resistance, the present invention establishes a CPIII precision control network after the settlement evaluation of the subgrade and bridge substructure meets the design requirements, and then performs track slab base and For the construction of the convex block, after the fine adjustment of the track slab is completed, the mortar truck is used to mix the mortar on site, transfer it in a transfer tank, and pour the funnel into the process principle to ensure that the laying quality of the track slab meets the requirements.

[0029] The process flow and key points of operation are described in detail below.

[0030] 1. Construction process

[0031] (1), the overall construction sequence

[0032] The overall construction process is as figure 2 As shown, the following steps are sequentially included: subgrade and bridge status...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com