Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

A technology for collapsible loess and underground deep foundation pits. It is applied in infrastructure engineering, excavation, artificial islands, etc., and can solve problems such as difficult construction, complicated construction steps, and difficulty in guaranteeing the construction quality of deep foundation pits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

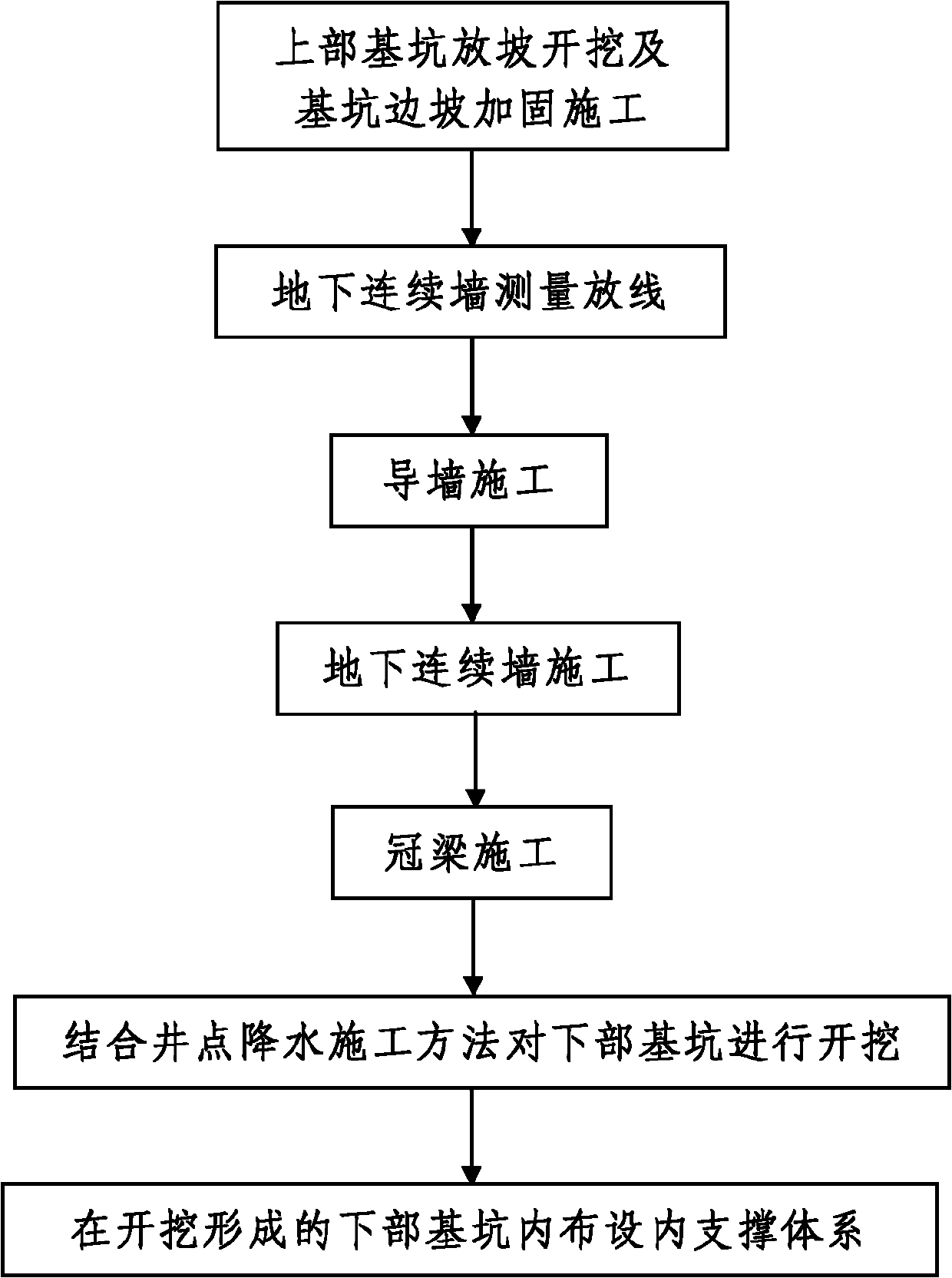

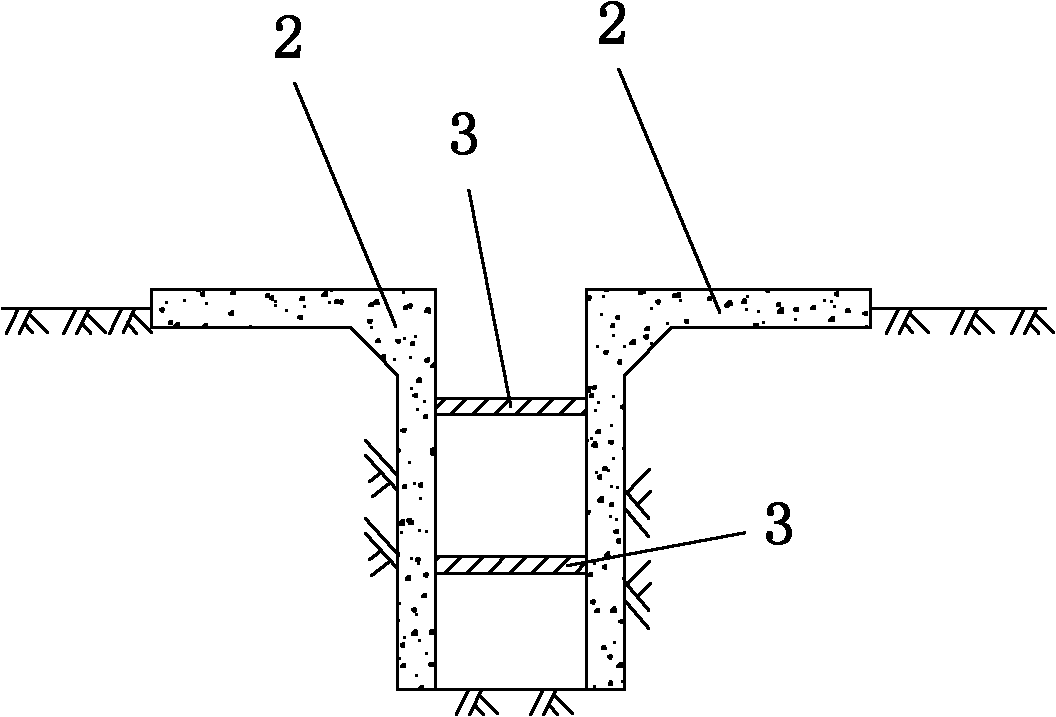

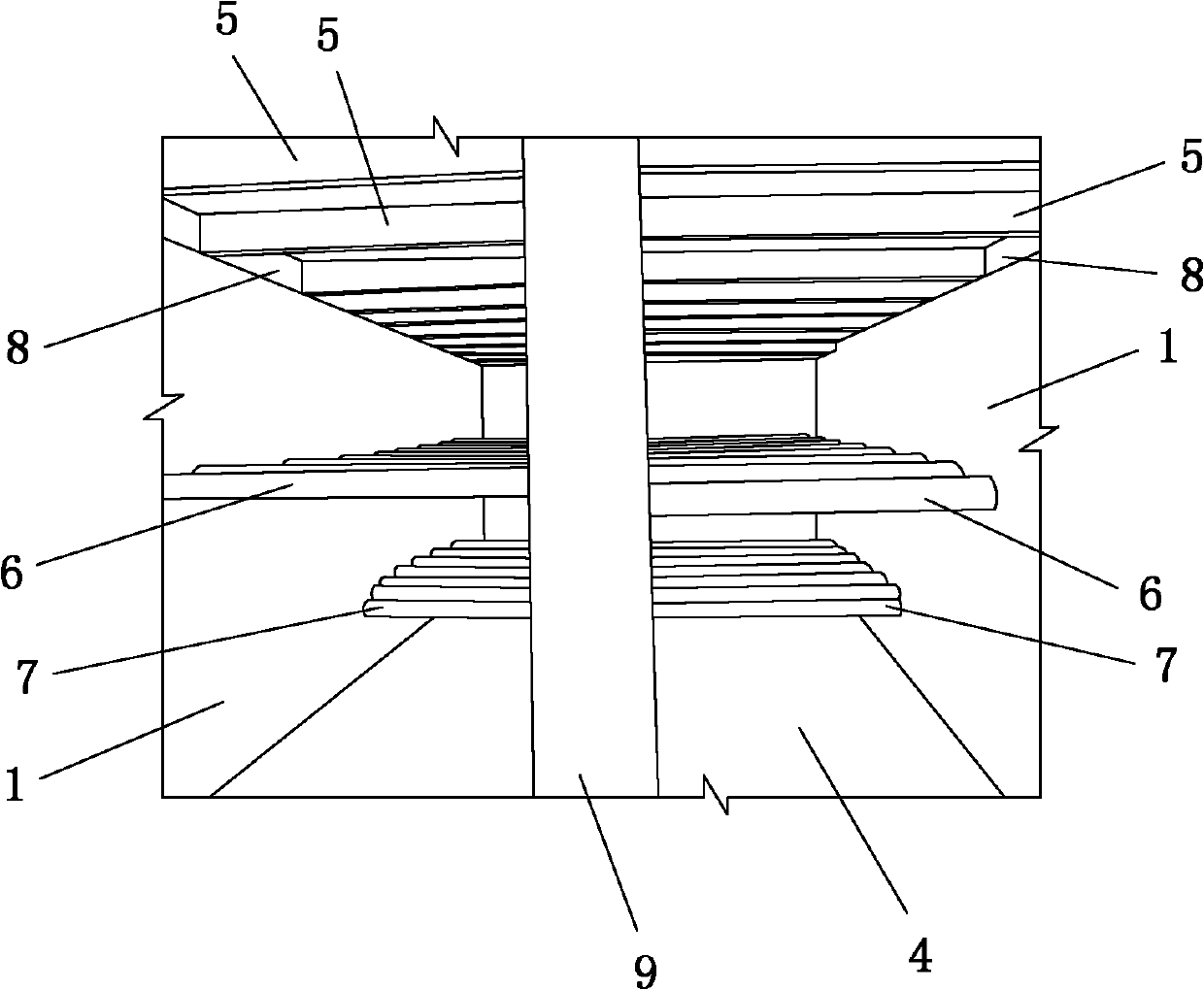

[0049] Such as figure 1 A construction method for the underground diaphragm wall of a deep foundation pit of a subway station in a collapsible loess area is shown. The buried depth of the floor of the constructed subway station is 17m to 28m and the thickness of the roof covering soil is 2m to 4m. The deep foundation of the constructed subway station is The pit is divided into an upper foundation pit and a lower foundation pit 4 from top to bottom. The enclosure structure of the lower foundation pit 4 is an underground diaphragm wall 1. The upper foundation pit is formed by slope excavation with a depth of 6m-10m. In the foundation pit, the top elevation of the underground diaphragm wall 1 is consistent with the top elevation of the upper foundation pit and its bottom elevation is 7m to 11m lower than the elevation of the constructed subway station floor. The construction method includes the following steps:

[0050] Step 1. Upper foundation pit slope excavation and foundation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com