Shear wall formwork installation foot angle iron device

A shear wall and angle steel technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of large amount of repair, deformation and displacement, labor and material loss, etc., to achieve Eliminate slurry leakage, enhance the appearance of molding, and reduce the effect of secondary repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

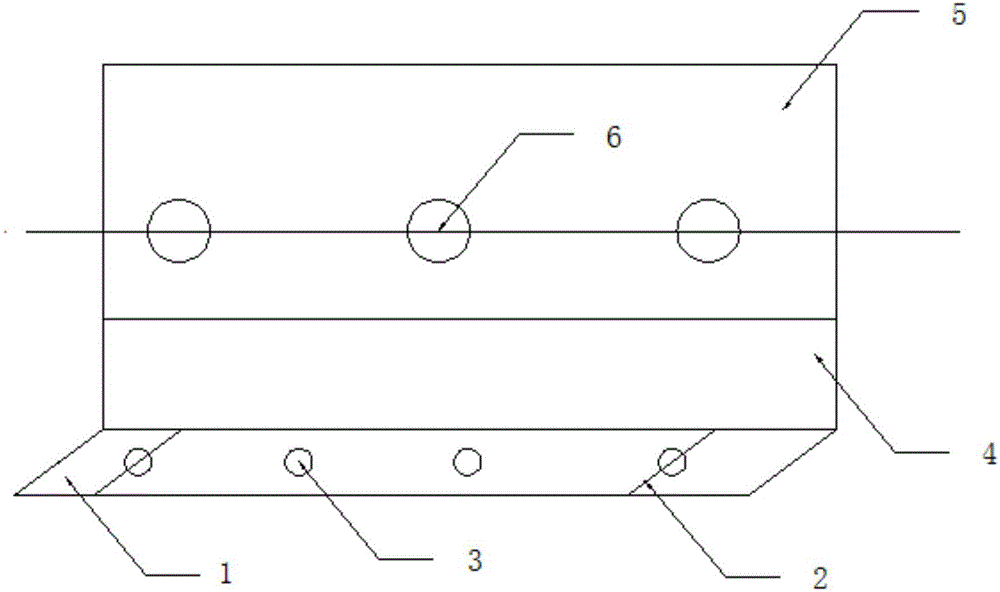

[0016] Such as figure 1 As shown, a shear wall formwork installation root angle steel device includes a base plane 1 and an angle steel device 5 fixed vertically on the base plane 1. A number of steel nails 3 are provided on the base plane 1, close to the side of the base plane 1. The steel nail 3 is arranged on the control line 2, and the steel nail 3 and the angle steel device 5 are both fixed on the rubber-plastic sheet foot 4.

[0017] Further, the rubber-plastic sheet footing 4 is fixed at the root of the shear wall, the angle steel device 5 is provided with a screw hole 6, the control line 2 is set at 200mm on both sides of the base plane 1, and the spacing between the steel nails 3 is within 250mm, And there are no less than 3 steel nails.

[0018] Specifically, the present invention mainly fixes the angle steel device with steel nails 3 before the template is installed to make it into a whole, which can not only ensure that the shear wall concrete does not leak slurry and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com