Underground finite space fertilizer-tank-free structure side wall large steel formwork system and construction method

A limited space, steel formwork technology, applied in underwater structures, infrastructure engineering, formwork/formwork/work frame, etc., can solve problems such as hidden dangers of water seepage to tie bolts, limited planning red line width, etc., to prevent swelling. model, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

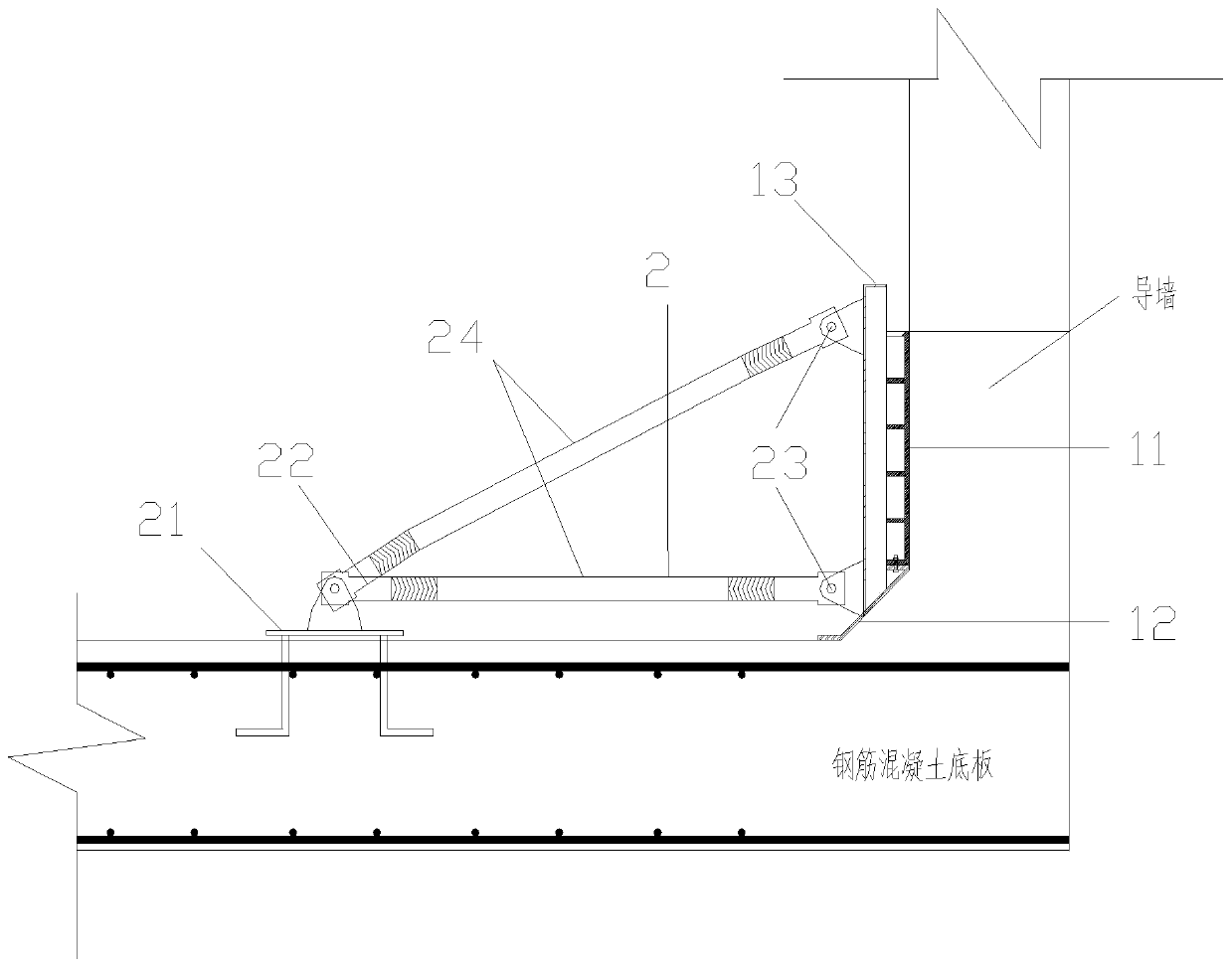

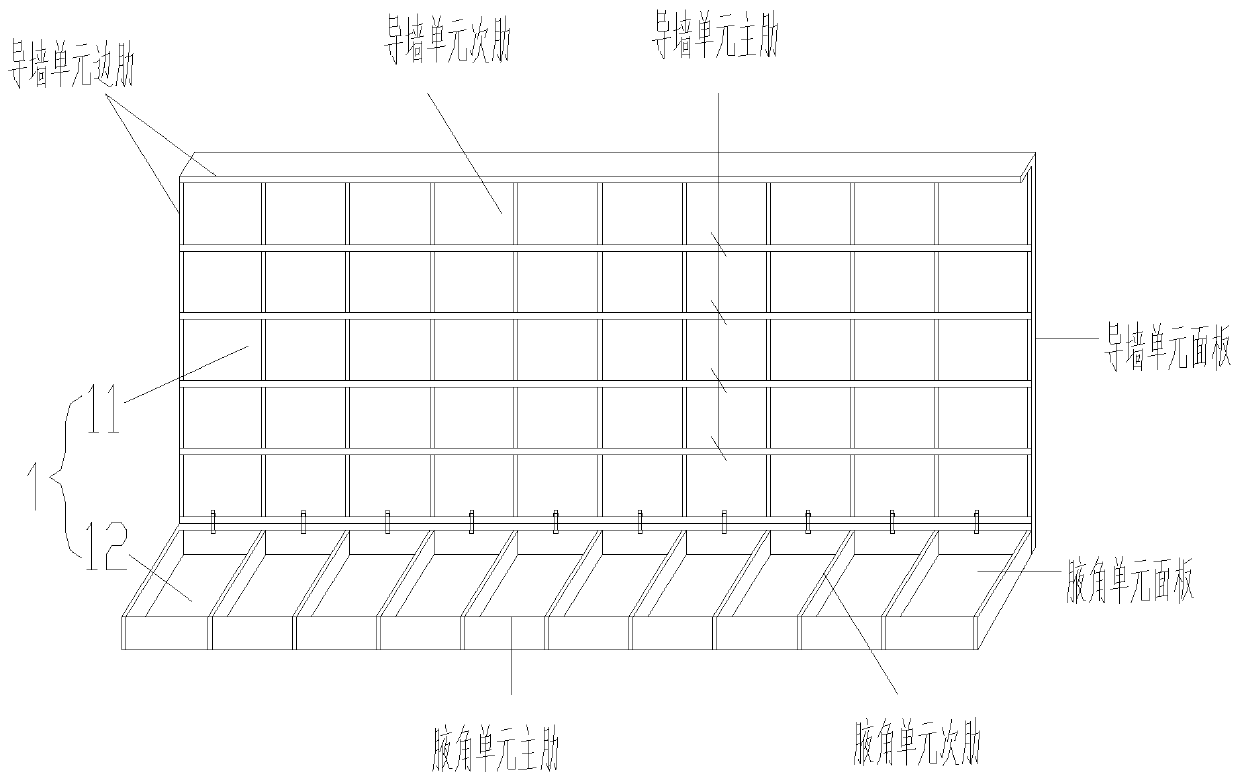

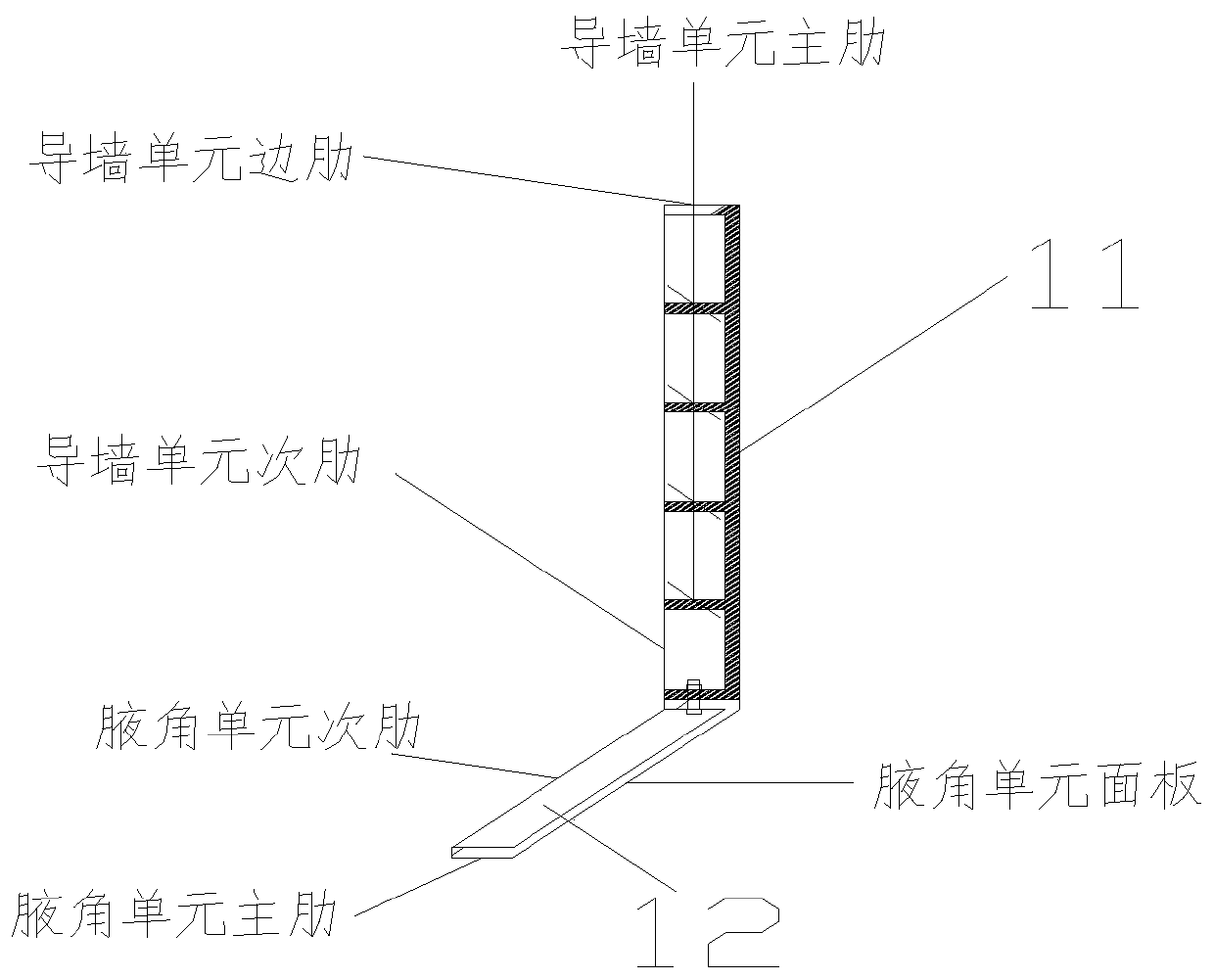

[0043] Such as Figure 1 to Figure 7 As shown, it includes formwork system for guide wall axillary corners, support system 2, and formwork system for side walls.

[0044] Guide wall corner formwork system includes several guide wall corner formwork units 1 spliced left and right by connecting bolt pairs. Guide wall corner formwork unit 1 includes guide wall unit 11, armpit unit 12 and back flute 13. The bottom of the unit 11 and the top of the corner unit 12 are fixedly connected to form the guide wall corner unit through the connecting bolt pair, and the back flute 13 is welded and fixedly connected to the back side of the corner unit of the guide wall (and the bottom of the back flute 13 is connected to the corner unit 12 slope welded connections).

[0045] The height of the guide wall unit 11 and the axillary corner unit 2 should be processed according to the design structural size, the connection between the various systems of the formwork should be safe and reliable, a...

Embodiment 2

[0052] Such as figure 1 , Figure 4 , Image 6 with Figure 7 As shown, the strength and stiffness of the large steel formwork system should be calculated according to the most unfavorable working conditions according to the characteristics of the material, structural form, and support method. The construction method of the large steel formwork system for the side wall of the structure without fertilizer tank in the limited underground space includes the following main steps:

[0053] A. Assembling the guide wall axillary corner components: assemble the single axillary corner unit 12 and the single guide wall unit 11 on the ground in advance, and assemble the guide wall axillary corner components into a guide wall axillary corner formwork system;

[0054] B. Installation of guide wall axillary corner formwork system: After the bottom plate reinforcement and side wall inserts are installed, according to the edge line and control line of the formwork to be installed on the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com